Page 1

Installation Instructions

Air Flow Switch

Catalog Number(s) 1414-CPN10APWAB,

1414-CPN10APQAB, 1414-CPM10APWAB

About Air Flow Switch (AFS)

The AFS is a general purpose airflow proving switch designed for HVAC and energy

management applications. It may be used to sense positive, negative or differential

air pressure.

The plated housing contains a diaphragm, a calibration spring and a snap-acting

SPDT (NC) switch.

The sample connections located on each side of the diaphragm accept a .25” OD

tubing via the integral compression and nut.

An enclosure cover guards against accidental contact with the live switch terminal

screws and the set point adjusting screw. The enclosure cover will accept a .5”

conduit connection. The AFS (1414-CPM10APWAB) has a reset button located on

the top surface of the enclosure cover.

Publication 1414-IN003A-EN-P - October 2005

Page 2

2 Air Flow Switch

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication

SGI-1.1 available from your local Rockwell Automation sales office or online at

http://www.literature.rockwellautomation.com) describes some important differences between solid state

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you identify a hazard,

avoid a hazard and recognize the consequences.

Labels may be located on or inside the equipment (e.g., drive or motor) to alert people

that dangerous voltage may be present.

Labels may be located on or inside the equipment (e.g., drive or motor) to alert people

that surfaces may be dangerous temperatures.

Publication 1414-IN003A-EN-P - October 2005

Page 3

Air Flow Switch 3

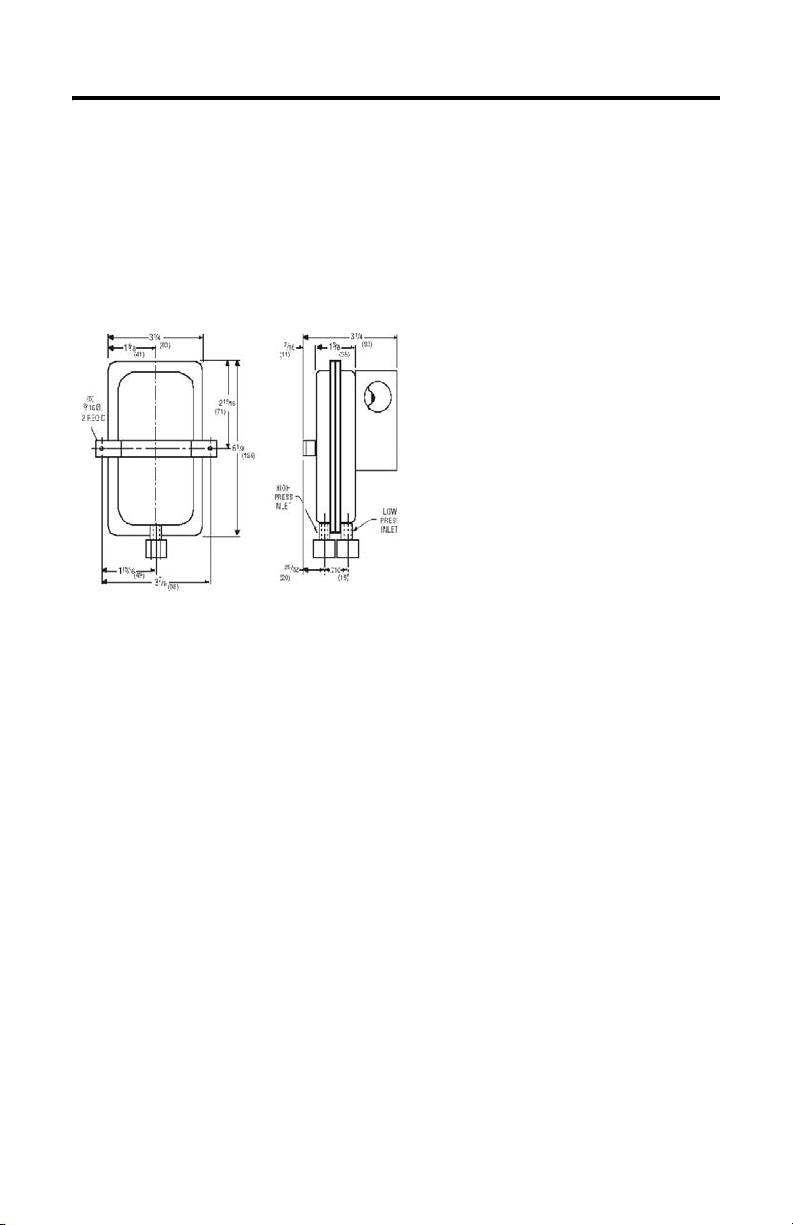

Install Air Flow Switch

Select a mounting location which is free from vibration. The AFS pressure switch

MUST be mounted with the diaphragm in any vertical plane in order to obtain the

lowest specified operating set point. Avoid mounting with the sample line

connections in the “UP” position. Surface mount via the two 3/16” diameter holes in

the integral mounting bracket. The mounting holes are 3 7/8” apart.

Figure 1 Dimensions

Air Sampling Connection

The AFS is designed to accept sample lines of .25” OD tubing by means of ferrule

and nut compression connections. Locate the sampling probe a minimum of 1.5

duct diameters down stream from the air source. Install the sampling probe as close

to the air stream as possible. The low pressure side is designated by the stamped

‘LOW’ on the housing of the diaphragm.

• Positive Pressure Only: Connect the sample line to the LOW side and the

HIGH side remains open to atmosphere.

• Negative Pressure Only: Connect the sample line to the HIGH side and the

LOW side remains open to atmosphere.

• Two Negative Samples: Connect the higher negative sample to the HIGH

side and the lower negative sample to the LOW side.

• Two Positive Samples: Connect the higher positive sample to the LOW side

and the lower positive sample to the HIGH side.

• One Positive and One Negative Sample: Connect the positive sample to the

LOW side and connect the negative sample to the HIGH side.

Publication 1414-IN003A-EN-P - October 2005

Page 4

4 Air Flow Switch

Figure 2 Alarm or Control

To prove excessive airflow or pressure

NO

C

NC

To prove insufficient airflow or pressure

NO

C

NC

Alarm

Con tr ol

Con tr ol

Alarm

Field Adjustment

From lowest operating point several turns of the adjusting screw are necessary to

engage the calibration spring. No change in set point will occur until the spring is

engaged. For higher set points continue turning screw in a clockwise direction. It

may be useful to connect a manometer in parallel with the switch when adjusting,

as the final operating point can be noted for future reference. Please see

specifications for actual ranges and set point information.

Specifications

Air Flow Switch Specifications

Specification 1414-CPN10APWAB 1414-CPN10APQAB 1414-CPM10APWAB

Sample Media Air Air Air

Mounting Position Diaphragm in any vertical

plane

Field Adjustable

Range

Switch Differential Progressive, increasing

Maximum Pressure .5” (0.03 bar) .5” (0.03 bar) .5” (0.03 bar)

Operating

Temperature Range

.05, ±.02” w.c. to 12” w.c. .05, ±.02” w.c. to 2” w.c. .40, ±.06” w.c. to 12” w.c

from approximately .02±

.01” w.c. at minimum set

point, to approximately .8”

w.c. at maximum set point.

-40°C … 82.2°C

(-40°F…180°F)

Publication 1414-IN003A-EN-P - October 2005

Diaphragm in any

vertical plane

Progressive, increasing

from 0.02± 0.01” w.c. at

minimum set point to

approximately 0.1” w.c.

at maximum set point.

-40°C … 82.2°C

(-40°F…180°F)

Diaphragm in any

vertical plane

Progressive, increasing

from approximately .06±

.01” w.c. at minimum set

point, to approximately

.8”w.c. at maximum set

point.

-40°C … 82.2°C

(-40°F…180°F)

Page 5

Air Flow Switch 5

Air Flow Switch Specifications

Specification 1414-CPN10APWAB 1414-CPN10APQAB 1414-CPM10APWAB

Life 100,000 cycles/min. at 5psi

Electrical Rating 300 va pilot duty at

Contact Arrangement SPDT SPDT SPDT

Electrical Connections Screw top terminals with

Sample Line

Connections

Automatic/Manual

Reset

max pressure each cycle

and at max electrical load.

115…277vac, 10 amp,

non-inductive, 277 vac,

60Hz.

cup washers

Ferrule and nut

compression type

connectors that accept .25”

OD rigid tubing.

Automatic Automatic Manual

100,000 cycles/min. at

5psi max pressure each

cycle and at max

electrical load.

300 va pilot duty at

115…277vac, 10 amp,

non-inductive, 277 vac,

60Hz.

Screw top term inals with

cup washers

Ferrule and nut

compression type

connectors that accept

.25” OD rigid tubing.

600 cycles/min. at 5psi

max pressure each cycle

and at max electrical

load.

300 va pilot duty at

115…277vac, 10 amp,

non-inductive, 277 vac,

60Hz.

Screw top terminals with

cup washers

Ferrule and nut

compression type

connectors that accept

.25” OD rigid tubing.

Publication 1414-IN003A-EN-P - October 2005

Page 6

6 Air Flow Switch

Publication 1414-IN003A-EN-P - October 2005

Page 7

Air Flow Switch 7

Publication 1414-IN003A-EN-P - October 2005

Page 8

All other trademarks are the property of their respective holders, and are hereby acknowledged.

Publication 1414-IN003A-EN-P - October 2005 PN 40055-233-01(1)

Supersedes Publication XXXX-X.X.X - Month Year Copyright © 2005 Rockwell Automation, Inc. A ll rights reserved. Printed in t he U.S.A.

Loading...

Loading...