Page 1

Capacitor Bank

Controller

1413-CAP

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

) describes some important

differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of

uses for solid state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this

equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware

of safety considerations.

WARNING

Identifies information about practices or circumstances that can cause

an explosion in a hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

IMPORTANT

ATTENTION

Identifies information that is critical for successful application and

understanding of the product.

Identifies information about practices or circumstances that can lead

to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize

the consequence

SHOCK HAZARD

Labels may be located on or inside the equipment, for example, a drive

or motor, to alert people that dangerous voltage may be present.

BURN HAZARD

Labels may be located on or inside the equipment, for example, a drive

or motor, to alert people that surfaces may be dangerous

temperatures.

Allen-Bradley, Rockwell Automation, ControlLogix, Powermonitor 3000, MicroLogix, PanelView 550, PanelBuilder32, and RSLinx

are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Preface

General Information

Installation

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . 3

Additional Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Description of the Capacitor Bank Controller . . . . . . . . . . . . . 5

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 2

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Optional Additional Powermonitor Meters . . . . . . . . . . . . 8

System Architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Base System with Serial Options. . . . . . . . . . . . . . . . . . . . 9

Base System with Ethernet Options. . . . . . . . . . . . . . . . . 10

Assemble, Mount, and Connect Your Controller . . . . . . . . . . 11

MicroLogix 1500 Controller (All Configurations) . . . . . . . 11

AIC + Interface Converter (All Configurations) . . . . . . . . 14

Powermonitor Meter (All Configurations) . . . . . . . . . . . . 14

PanelView 550 Serial Terminal (Serial HMI options) . . . . 16

PanelView 550 Ethernet Terminal (Ethernet HMI Option) 18

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Communications Configuration . . . . . . . . . . . . . . . . . . . . . . 20

Base Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Serial HMI Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Ethernet HMI Option . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Additional Powermonitor Meters Option . . . . . . . . . . . . . 22

Powermonitor Meter Configuration . . . . . . . . . . . . . . . . . . . 23

Parameter Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . 24

Set Parameters with the Powermonitor Display Module . . 24

Controller Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Use the DAT for Configuration . . . . . . . . . . . . . . . . . . . . 31

Configuration with the PanelView 550 Terminal

(Optional HMI Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter 3

Operation

1 Publication 1413-UM001C-EN-P - May 2006

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

CTPT Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Operator Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Data Access Terminal (DAT) . . . . . . . . . . . . . . . . . . . . . 40

Optional PanelView 550 HMI . . . . . . . . . . . . . . . . . . . . . 42

Page 4

2 Table of Contents

SCADA Interface

Add Special Functionality

Catalog Number Explanation

Chapter 4

Power-circuit Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chapter 5

PFMGR4 Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Power Factor Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Step Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Step Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

User Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Appendix A

Base Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

With Serial Powermonitor 1413-CAP-MS A . . . . . . . . . . . 61

With Ethernet Powermonitor 1413-CAP-ME A . . . . . . . . . 62

Additional HMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Serial Base Unit with Serial HMI 1413-CAP-MS-PS A . . . . 62

Serial Base Unit with Ethernet HMI 1413-CAP-MS-PE A . . 62

Ethernet Base Unit with Ethernet HMI 1413-CAP-ME-PE A 62

Glossary

Index

Publication 1413-UM001C-EN-P - May 2006

Page 5

Preface

Read this to familiarize yourself with the rest of the manual. It

provides information concerning:

• who should use this manual.

• where to go for more information.

Who Should Use This Manual

Additional Resources

Use this manual if you are responsible for designing, installing,

programming, or troubleshooting the Capacitor Bank Controller

system.

You should have a basic understanding of electrical circuitry and

familiarity with relay logic. If you do not, obtain the proper training

before using this product.

Please refer to the following publications for additional information on

how to assemble, install, connect, operate and maintain your

capacitor bank controller.

Additional Resources

For This Information Refer to Publication

MicroLogix 1500 Technical Data 1764-TD001

MicroLogix 1500 User Manual 1764-UM001

Powermonitor 3000 Installation Manual 1404-IN007

Powermonitor 3000 User Manual 1404-UM001

Powermonitor 3000 Display Module

Installation Manual

PanelView 550 Installation Guide 2711-IN009

PanelView Standard Operator Terminals

User Manual

3 Publication 1413-UM001C-EN-P - May 2006

1404-IN005

2711-UM014

Page 6

4 Preface

Publication 1413-UM001C-EN-P - May 2006

Page 7

General Information

Chapter

1

Introduction

Description of the Capacitor Bank Controller

The capacitor bank controller is a replacement for standard,

fixed-function capacitor controllers currently on the market. The

controller consists of standard, off-the-shelf, Allen-Bradley hardware

with the application ladder code necessary to perform power factor

correction. The controller is designed to provide the same base

functionality as a fixed-function capacitor bank controller. Also, you

may add additional code to the controller to fit its functionality to

special circumstances.

The capacitor bank controller is a pre-engineered control system

containing a MicroLogix 1500 controller, a standard data access

terminal (DAT), one or more Powermonitor 3000 modules, and an

optional additional human-machine interface (HMI). Pre-engineered

ladder logic code in the controller gathers real and reactive power

data from up to four power feeds (utility feeds and/or generators).

The logic operates on the data in standard engineering units of kVAR

and kW and acts to minimize imported and exported reactive power

by switching up to 10 steps of capacitance. This strategy controls

power factor while reducing the likelihood of voltage surge caused by

excessive kVAR export.

Functions

• Auto configure

• Manual configure

• Discharge timer on each step

• Selectable operating modes

– Manual operation

– Linear, last-in, first-out

– Balanced, level-out usage of capacitor steps

– Optimal, finds best match of capacitor step to system kVAR

needs

– Special, customer-defined

– %THD, Linear mode with a voltage %THD setpoint

5 Publication 1413-UM001C-EN-P - May 2006

Page 8

6 General Information

• Alarms

– Bad step, indicates blown fuse, capacitor failure

– Target power factor not achieved

– High / Low voltage

– %THD High

– Current unbalance

– Metering

• Powermonitor data concentrated into the MicroLogix 1500

controller

• Phase current, line voltage, frequency, real and reactive power,

power factor and THD

Options

• Up to three additional Powermonitor meters to aggregate up to

four total feeds

• PanelView 550 keypad HMI terminal with serial or Ethernet

communications

• Ethernet Powermonitor meters to produce power and energy

data via your local area network

Publication 1413-UM001C-EN-P - May 2006

Page 9

Chapter

Installation

The capacitor bank controller system is supplied as a number of

components that you assemble, install, and connect in a suitable

enclosure.

2

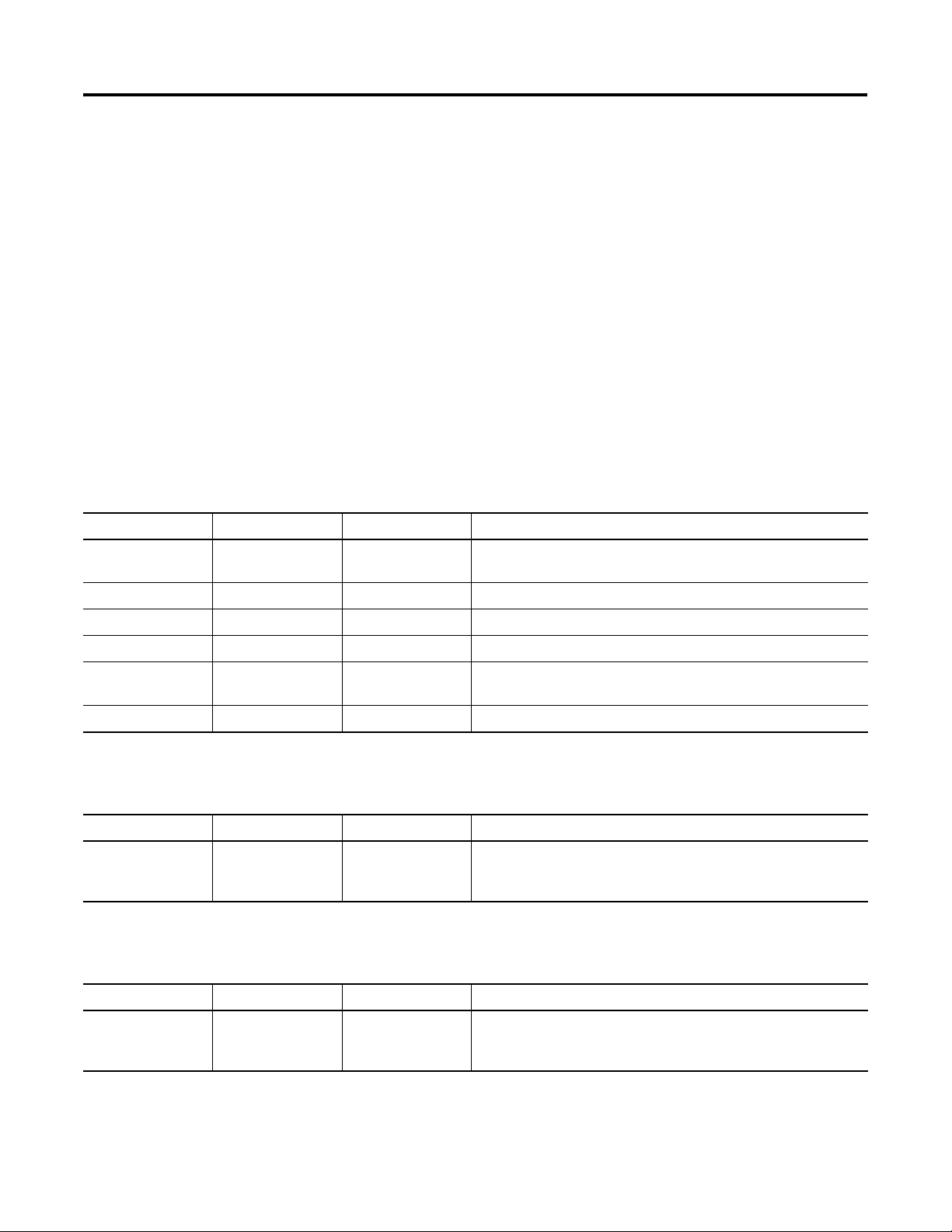

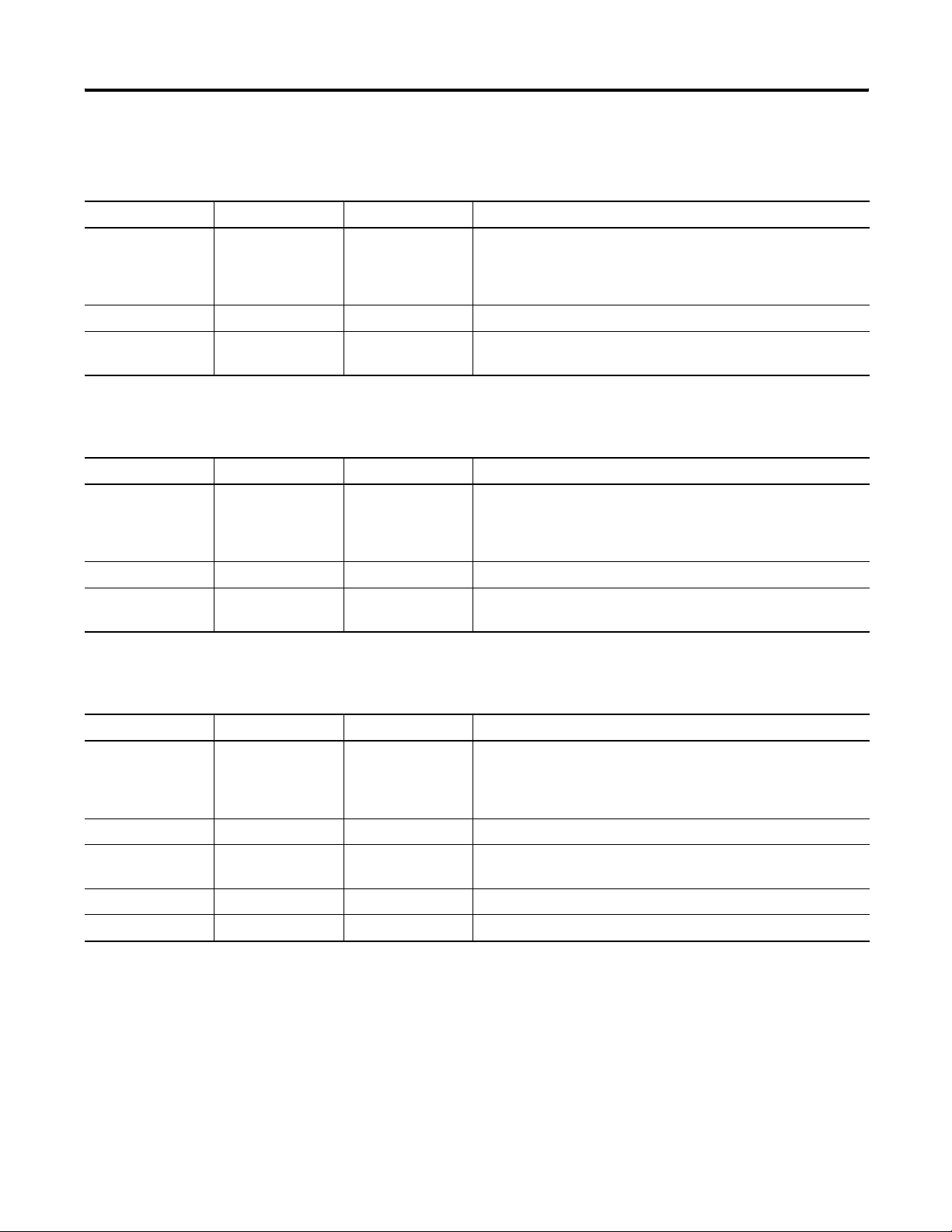

System Components

All Configurations

Key Quantity Part Number Description

1 1 1764-24BWA MicroLogix 1500 base unit with: 120/240V ac control power,

2 1 1764-LRP MicroLogix 1500 enhanced processor

3 1 1764-DAT MicroLogix 1500 data access tool

4 1 1761-NET-AIC Advanced interface converter (used for PM comms)

5 1 1761-CBL-AC00 MicroLogix controller to AIC+ cable, 9-pin D-shell to 9-pin D-shell,

6 1 1404-DM Powermonitor 3000 display unit with 3 m (9.84 ft) cable

Base Unit with Serial Meter 1413-CAP-MSA

Key Quantity Part Number Description

7 1 1413-M5000 A Powermonitor 3000-M5 meter with RS-485 communications port

The key number in the component lists are referenced in the

illustrations that follow.

(12) 24V dc inputs, and (12) relay outputs

45

cm (17.1 in.) long

including programmed MicroLogix 1500 8 k memory module with

real-time clock (1764-MM1RTC)

Base Unit with Ethernet Meter 1413-CAP-MEA

Key Quantity Part Number Description

7 1 1413-M5ENT A Powermonitor 3000-M5 meter with Ethernet communications port

including programmed MicroLogix 1500 8 k memory module with

real-time clock (1764-MM1RTC)

7 Publication 1413-UM001C-EN-P - May 2006

Page 10

8 Installation

Optional Serial HMI, Serial Meter 1413-CAP-MS-PSA

Key Quantity Part Number Description

7 1 1413-M5000NM A Powermonitor 3000-M5 meter with RS-485 communications port

including programmed memory module with real-time clock

(1764-MM1RTC) and programmed 2 MB flash memory card

(2711-NM13)

8 1 2711-NC21 PanelView terminal to MicroLogix communication cable

9 1 2711-K5A16 PanelView 550 operator terminal with RS-232 DF1 serial

communications

Optional Serial HMI, Ethernet Meter 1413-CAP-ME-PSA

Key Quantity Part Number Description

7 1 1413-M5ENTNM A Powermonitor 3000-M5 meter with RS-485 and Ethernet

communications ports including programmed memory module with

real-time clock (1764-MM1RTC) and programmed 2 MB flash

memory card (2711-NM13)

8 1 2711-NC21 PanelView terminal to MicroLogix controller communication cable

9 1 2711-K5A16 PanelView 550 operator terminal with RS-232 DF1 serial

communications

Optional Ethernet HMI 1413-CAP-ME-PEA

Key Quantity Part Number Description

7 1 1413-M5ENTNM A Powermonitor 3000-M5 meter with RS-485 and Ethernet

communications ports including programmed memory module with

real-time clock (1764-MM1RTC) and programmed 2 MB flash

memory card (2711-NM13)

10 1 1761-NET-ENIW MicroLogix Ethernet interface module with Web interface

11 1 1761-CBL-AM00 MicroLogix controller to AIC+ cable, 8-pin DIN to 8-Pin DIN, 45 cm

(17.1 in.) long

12 1 3.05 m (10 ft) CAT5 Ethernet crossover cable

13 1 2711-K5A20 PanelView 550 operator terminal with Ethernet/IP communications

Optional Additional Powermonitor Meters

Publication 1413-UM001C-EN-P - May 2006

The controller is designed to operate with up to three additional

Powermonitor meters. Additional Powermonitor meters must be

ordered separately. Please contact your local Allen-Bradley distributor

for information.

Page 11

Installation 9

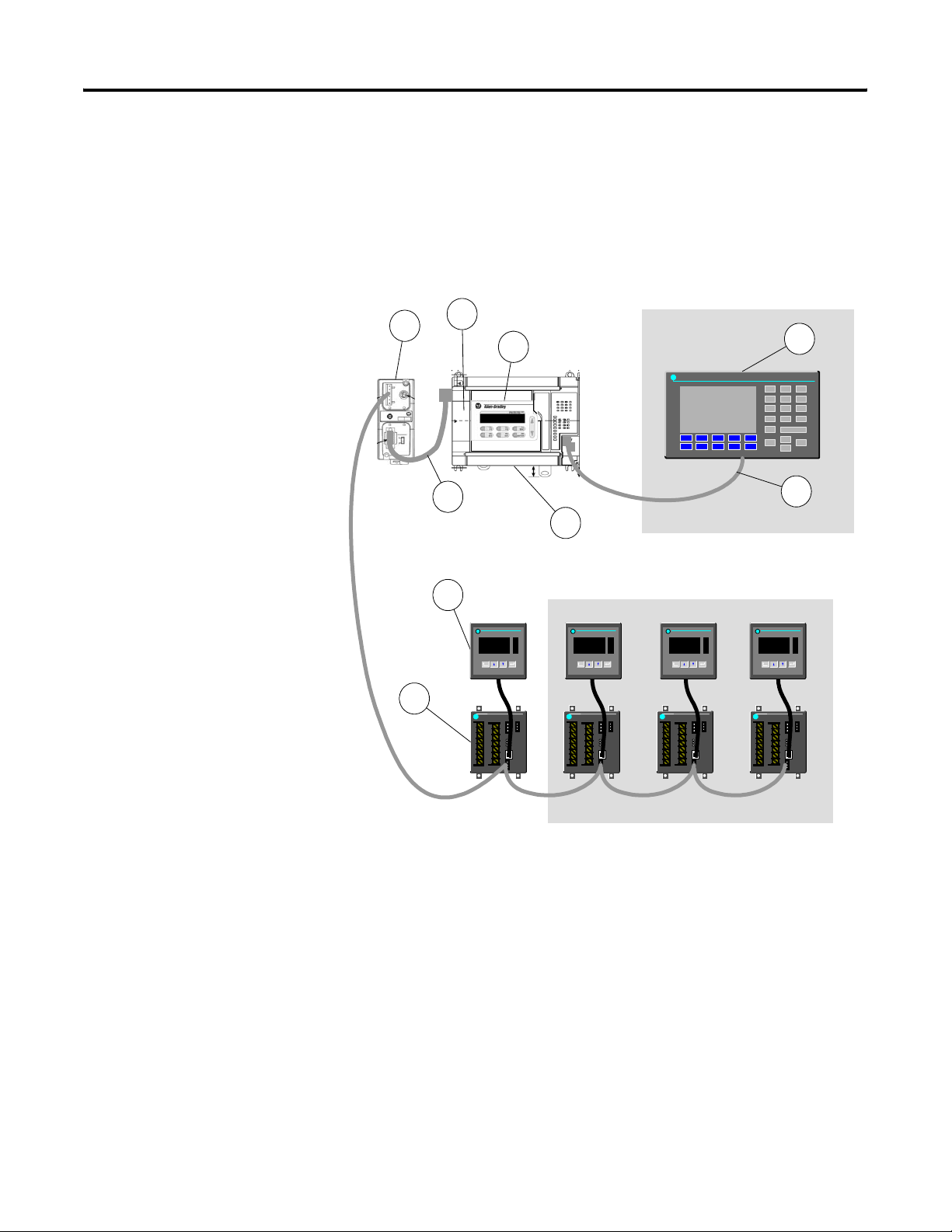

System Architecture

This section illustrates the base system with the serial and Ethernet

options.

Base System with Serial Options

4

2

F10

7 8 9

4 5 6

1 2 3

. 0 -

<--

^

< >

v

9

PanelView 550

<-------'

8

3

Allen-Bra dle y

F1F6F2F7F3F8F4F9F5

5

1

Optional Serial HMI

6

25.04M

WATT

Powermonitor 3000Allen-Bradley

L1

25.04M

WATT

Powermonitor 3000Allen-Bradley

L1

25.04M

WATT

Powermonitor 3000Allen-Bradley

L1

25.04M

WATT

Powermonitor 3000Allen-Bradley

L1

7

Allen-Bradley Powermonitor 3000Allen-Bradley P owermonitor 3000Allen-Bradley Powermonitor 3000Allen-Bradley Powermonitor 3000

Optional Additional Powermonitor Meters

Publication 1413-UM001C-EN-P - May 2006

Page 12

10 Installation

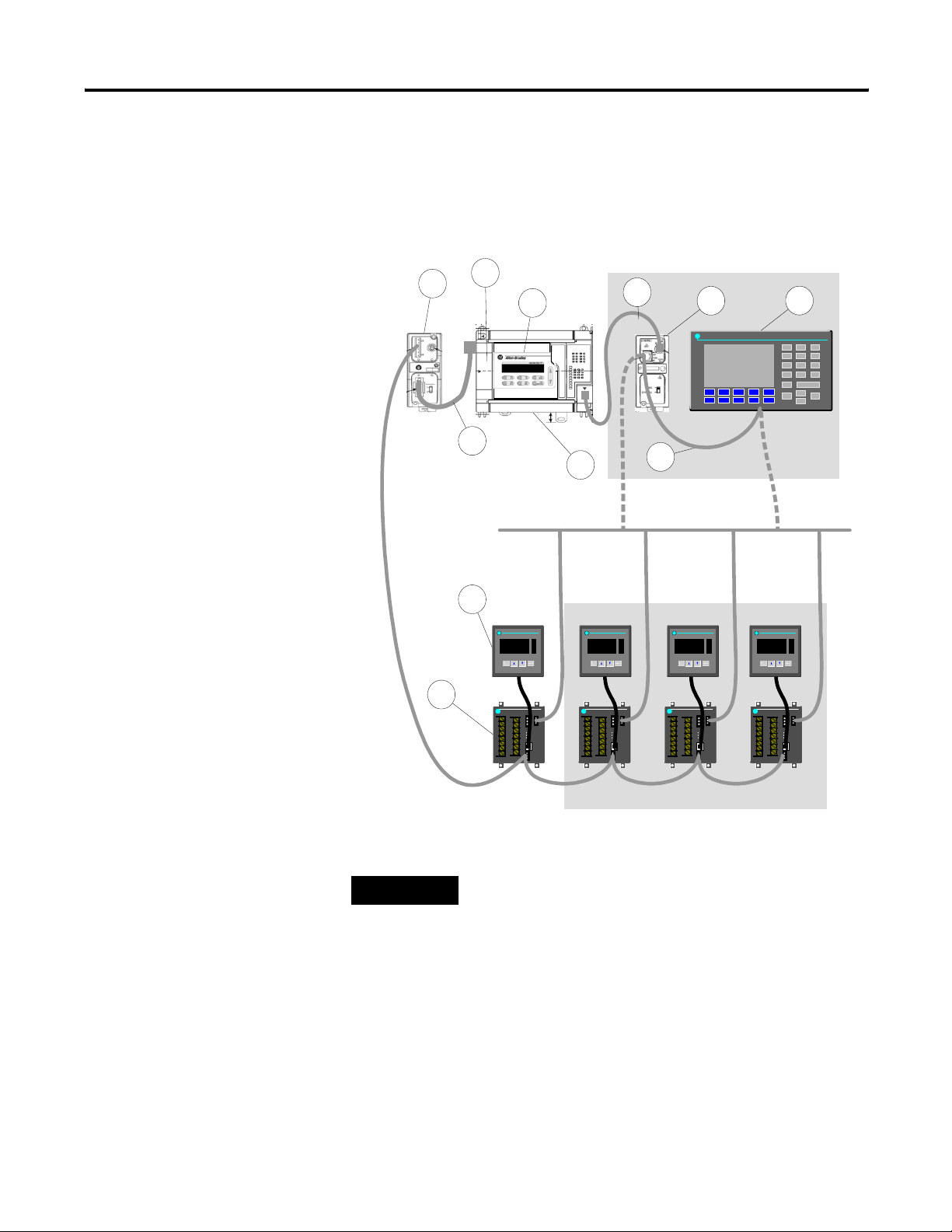

Base System with Ethernet Options

4

2

3

11

10

13

F10

7 8 9

4 5 6

1 2 3

. 0 -

<--

^

< >

v

PanelView 550

<-------'

Allen-Bradley

F1F6F2F7F3F8F4F9F5

5

1

12

Optional Ethernet HMI

Ethernet Local Area Network by Customer

6

25.04M

WATT

Powermonitor 3000Allen-Bradley

L1

25.04M

WATT

Powermonitor 3000Allen-Bradley

L1

25.04M

WATT

Powermonitor 3000Allen-Bradley

L1

25.04M

WATT

Powermonitor 3000Alle n-Bradley

L1

7

Allen-Bradley Po wermonit or 3000Allen-Bradley Powermonitor 3000Allen-Bradley Powermonitor 3000Allen-Bradley Powermonitor 3000

Publication 1413-UM001C-EN-P - May 2006

Optional Additional Powermonitor Meters

TIP

Ethernet crossover cable (12) is used if there is no connection to

a local area network.

Page 13

Installation 11

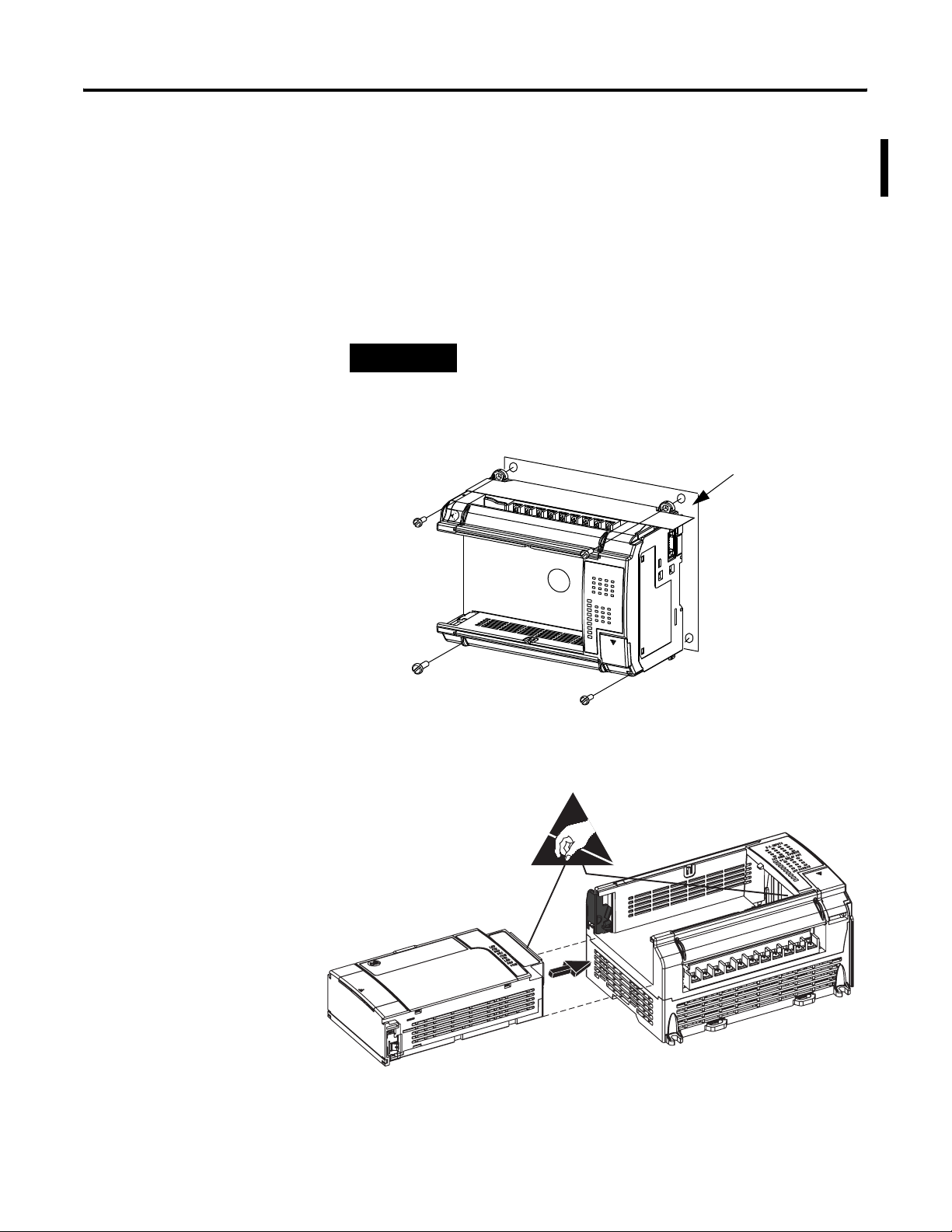

Assemble, Mount, and Connect Your Controller

This section describes how to mount the MicroLogix 1500 controller

and connect it to an AIC+ interface and PanelView module for use

with the capacitor bank controller.

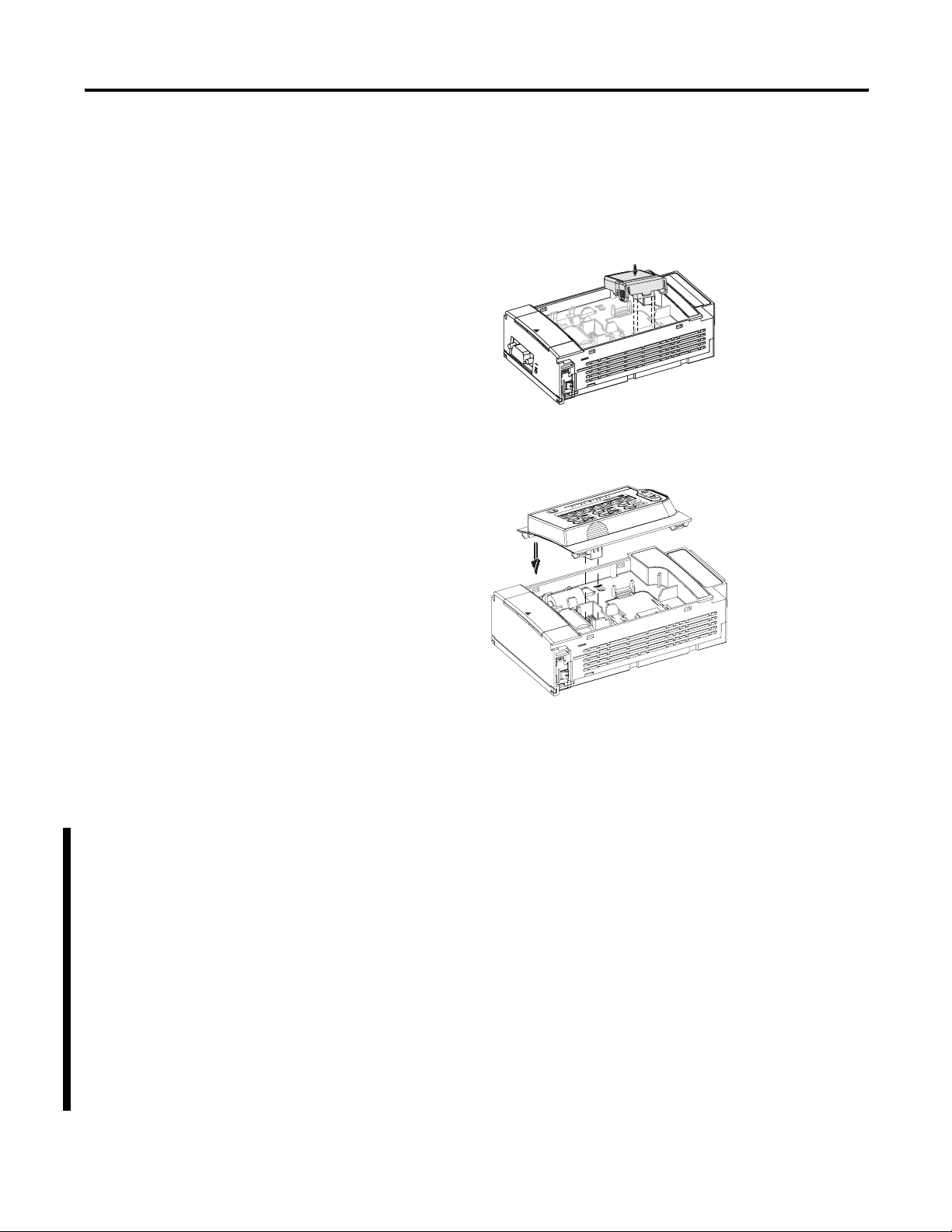

MicroLogix 1500 Controller (All Configurations)

TIP

1. Mount the MicroLogix 1500 base unit (1).

Please refer to Publication 1746-UM001, Chapter 2, for

information on performing these tasks.

Mounting Template

2. Install the MicroLogix 1500 processor module (2).

Publication 1413-UM001C-EN-P - May 2006

Page 14

12 Installation

3. Install the MicroLogix memory module (7a).

This module may be found packaged with the Powermonitor

meter (7).

4. Install the data access terminal (3).

Publication 1413-UM001C-EN-P - May 2006

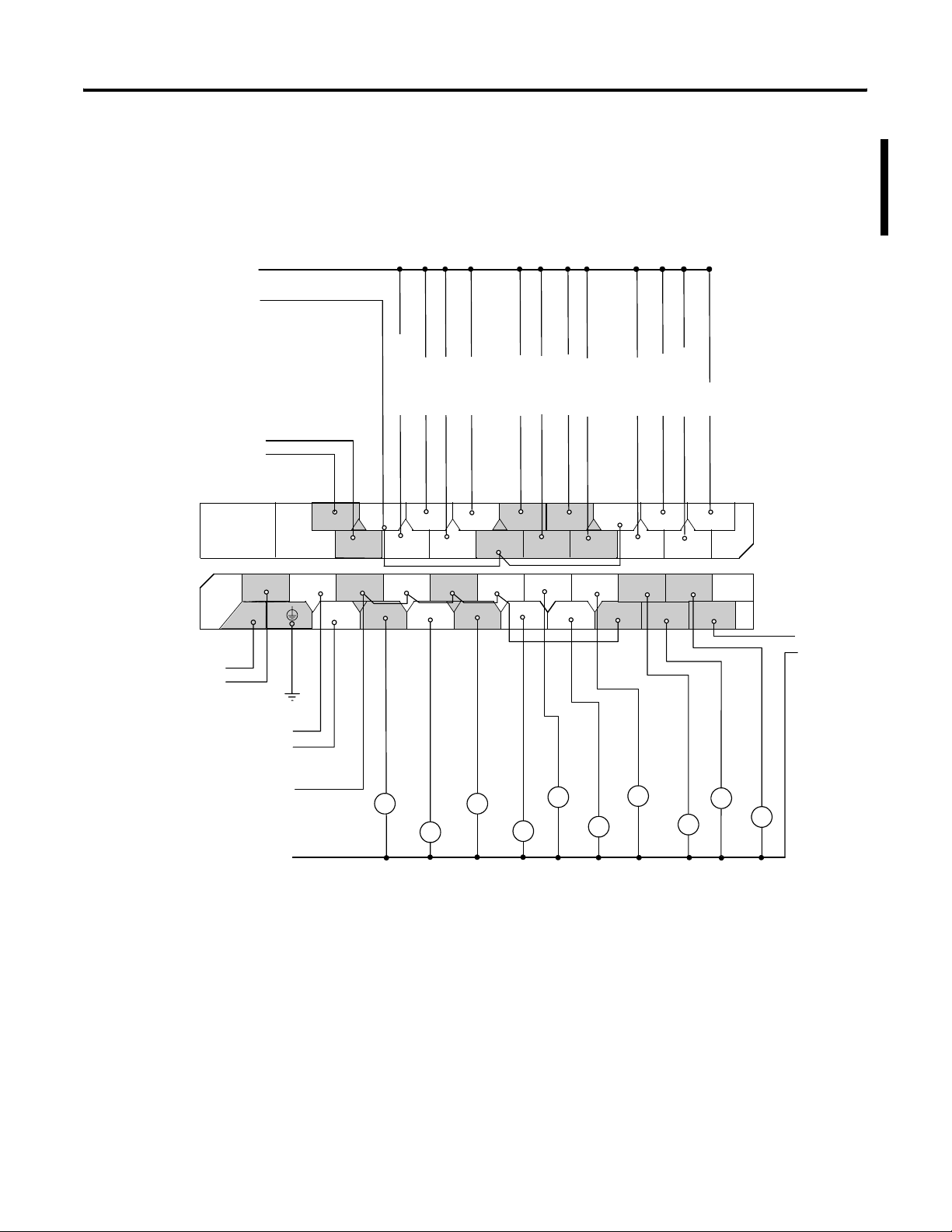

5. Connect the MicroLogix 1500 controller to 120V ac control

power, earth ground, capacitor step contactors (or interposing

relays as required), and an alarm circuit as shown in the wiring

diagram.

Wire the Controller

Fault-protection relays can be used to immediately discharge all or

specific capacitor steps during a fault occurrence. Input 0 is wired to a

normally closed fault-protection relay and discharges all capacitor

steps during a fault occurrence (low-state condition). Inputs 1… 10

are wired to normally closed fault-protection relays, and discharges its

respective capacitor step during a fault occurrence (low-state

condition). If fault protection is not being used for a specific capacitor

step, then that respective input is wired closed using the controller

supplied 24V dc power.

A normally-open momentary pushbutton is wired to Input 11. This

pushbutton is used to reset the controller after a fault occurrence.

Page 15

Fault Relay Power

Installation 13

Output 0 is used as an alarm relay and is wired normally open to an

external alarm indicator. Output 1…10 is wired to normally-open

contactors for each respective capacitor step.

Controller Wiring Diagram

Capacitor Step Contractors or Interposing Relays

Inputs

1764-24BWA

Outputs

24V dc

to AIC+

85-265

VAC

L1

120V ac

Control

Power

Isolated Alarm Output

DC

POWER

OUT

L2

VDC 0

Ground

Capacitor Step

Control Power

VAC

COM

VDC 1

VAC

Master Fault Relay

Group 0

DC

COM 0

I / 0

VAC

VDC 2

O / 1O / 0 O / 2

Group 1

1

Fault Relay 2

Fault Relay 1

I / 1

I / 2

VAC

VDC 3

Group 2

2

Fault Relay 3

I / 3

DC

COM 1

VAC

VDC 4

O / 3

Group 3

3

Fault Relay 4

I / 4

I / 5

O / 5

O / 4

Group 4

4

Fault Relay 6

Fault Relay 5

Fault Relay 7

Group 1

I / 6

O / 6 O / 9

Group 2

DC

COM 2

I / 7

O / 7 O / 8

VAC

VDC 5

Group 5

5

6

Fault Relay 8

I / 9

I / 8

7

Fault Relay 9

Fault Relay 10

I / 11

I / 10

O / 10

O / 11

8

Reset

24BWA

24BWA

Spare Output

9

10

Capacitor Step Contractors or Interposing Relays

Publication 1413-UM001C-EN-P - May 2006

Page 16

14 Installation

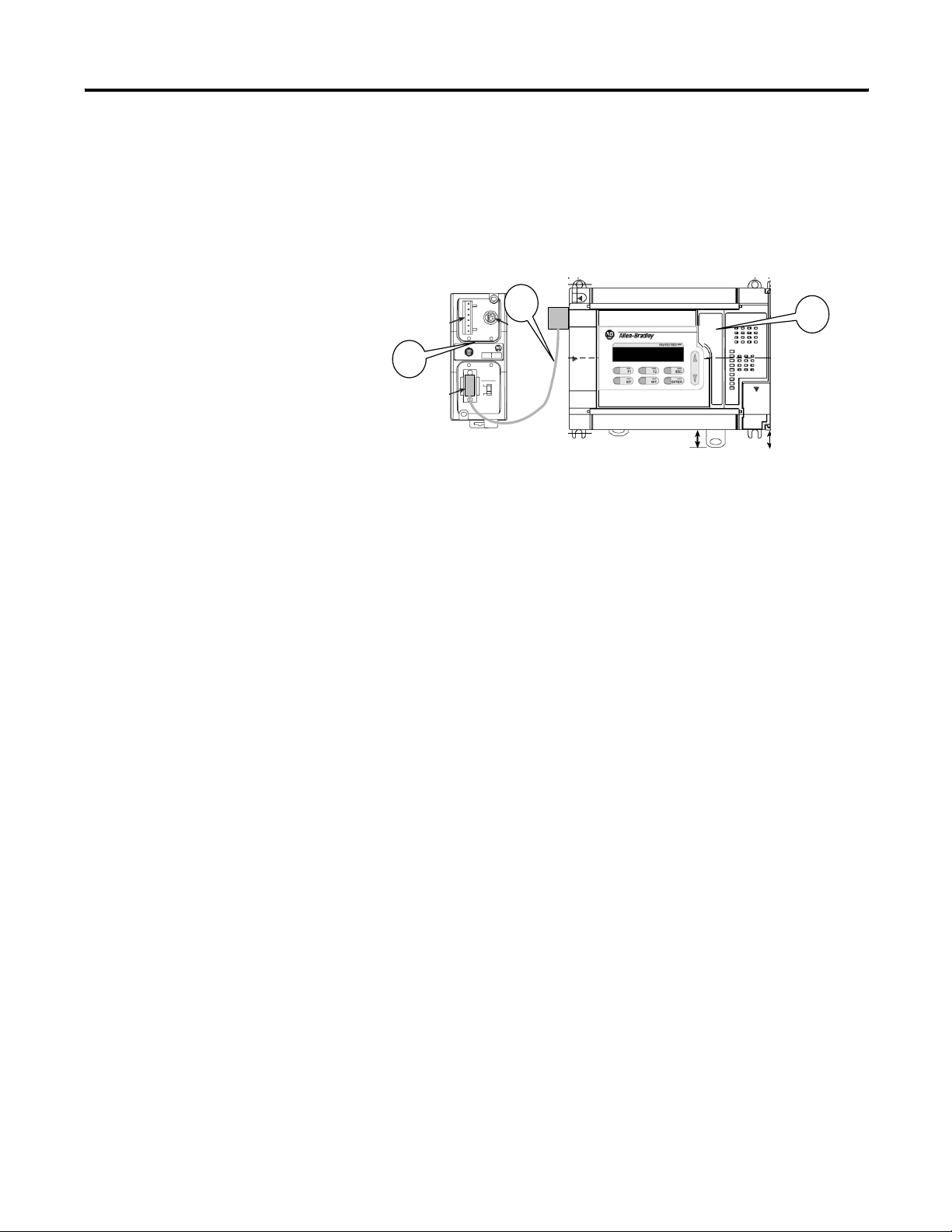

AIC + Interface Converter (All Configurations)

1. Mount the AIC+ communications converter (4) within 45 cm

(18 in.) of the left edge of the MicroLogix 1500 controller.

5

4

1

2. Connect the DB9 to DB9 cable (5) between Port 1 of the AIC+

(4) and Channel 1 of the MicroLogix 1500 controller (1).

3. Connect a source of 24V dc to the control power terminals on

the bottom of the AIC+.

The 24V dc power may be obtained from the DC Power Out

terminals on the MicroLogix 1500 controller.

4. Verify that the DC Source switch is in the External position and

that the Baud Rate selector is set to ‘Auto’.

Publication 1413-UM001C-EN-P - May 2006

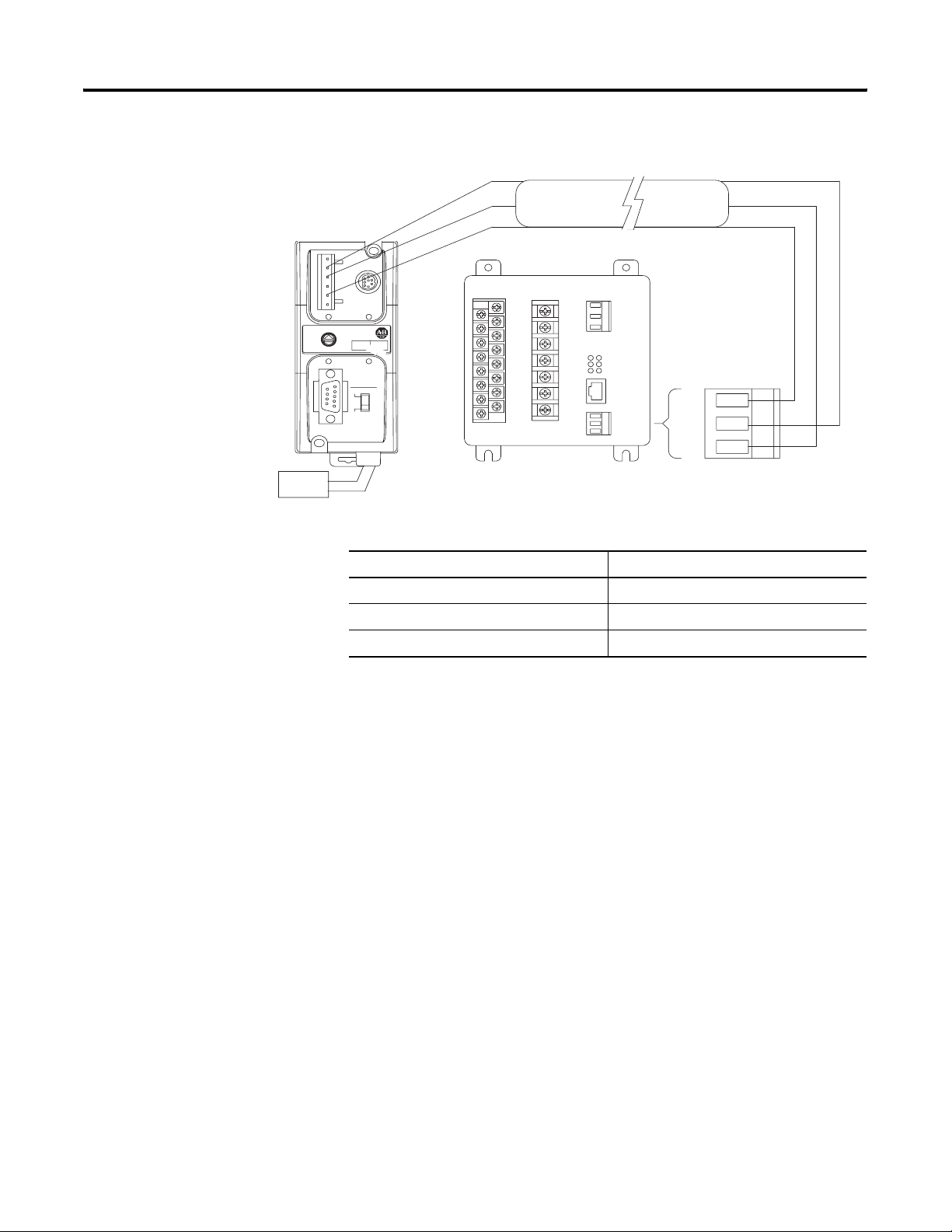

Powermonitor Meter (All Configurations)

1. Mount the Powermonitor meter (7) within 1200 m (4000 ft) of

the AIC+ communications converter (4).

2. Use a 2-conductor shielded cable, that you provide, to connect

the AIC+ RS-485 port to the Powermonitor RS-485 port.

Page 17

Installation 15

AIC+

24 V Power

Supply

Blue

CLR

SHLD

Powermonitor 3000 Device

SHLD

RS-485

Red

Black

_

+

AIC+ Powermonitor 3000 Meter

A -

B +

SHLD SHLD

Blue

CLR

SHLD

3. Connect any additional, optional Powermonitor meters RS-485

ports in a daisy-chain fashion, + to +, - to -, Shld to Shld.

In certain cases, terminating resistors may improve

communications robustness.

Refer to publication 1404-IN007 for more information.

4. Connect the Powermonitor meter to the power circuit, control

power, and earth ground.

See the instructions found in publication 1404-IN007.

Publication 1413-UM001C-EN-P - May 2006

Page 18

16 Installation

PanelView 550 Serial Terminal (Serial HMI options)

1. Mount the PanelView 550 HMI terminal in a suitable cutout

within 5 m (16 ft) of the MicroLogix controller.

Refer to publication 2711-IN009 for detailed installation

instructions.

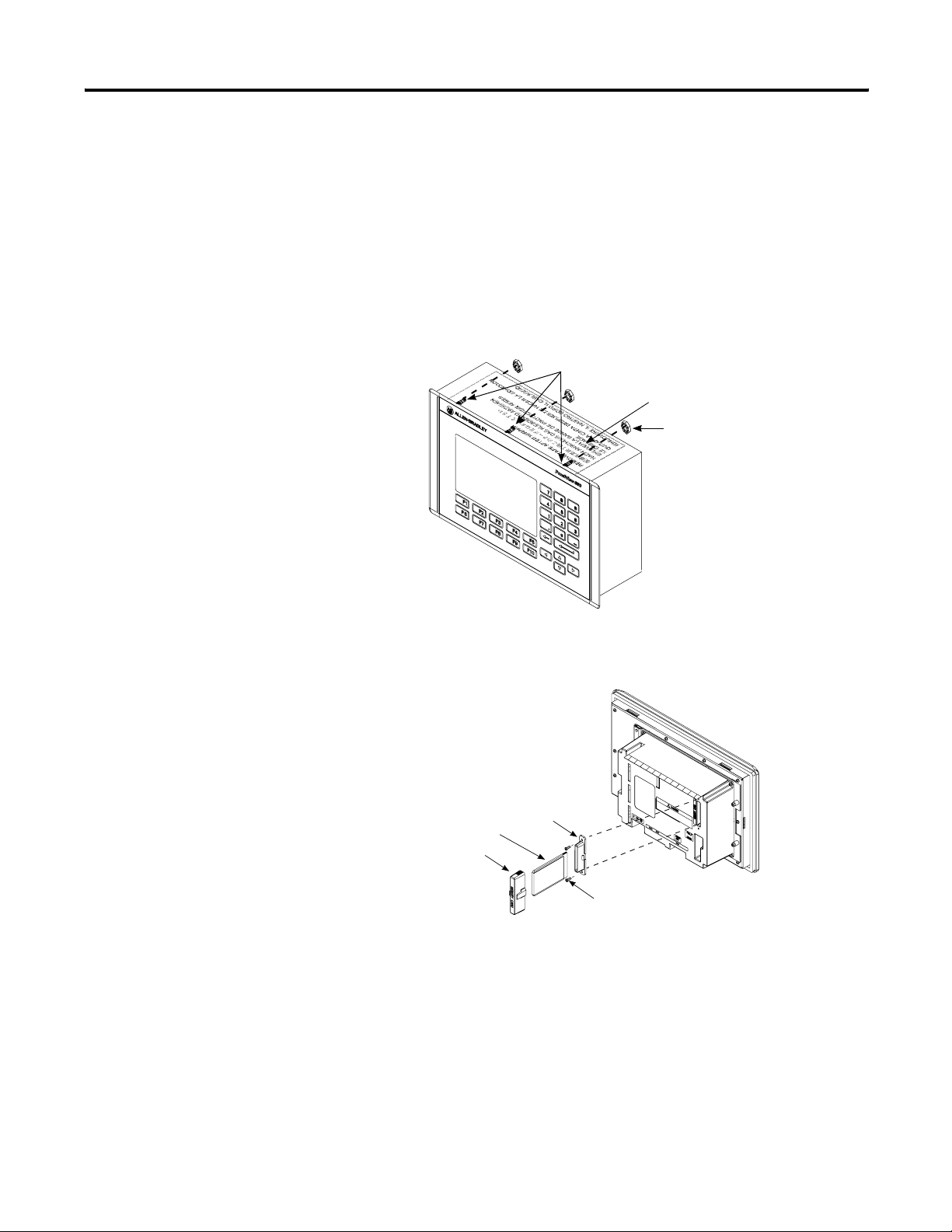

Mounting Studs

(3 Top / 3 Bottom)

Protective Installation Label

Self-locking Nuts

(6 used, 8 provided)

2. Install the memory card and retainer.

Memory Card

Retainer

Retainer Base

Base Mounting Screws

Publication 1413-UM001C-EN-P - May 2006

Page 19

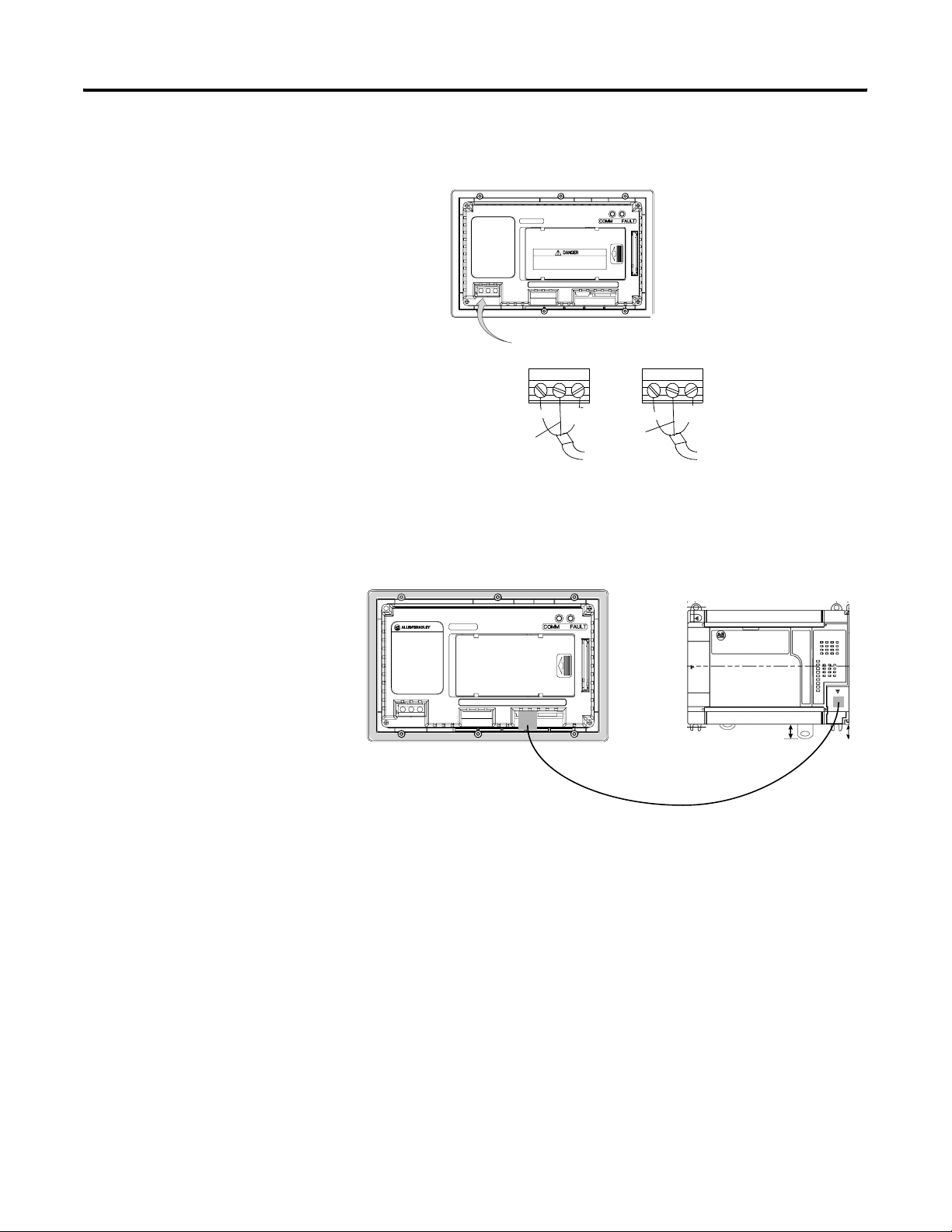

3. Connect 120V ac control power and earth ground.

Installation 17

Power Terminal Block (fixed)

120/240V ac, 3 Wire,

U.S. Color Code

L1

L2

GND GND

Green

Black (Line)

White

(Neutral)

Green

(Earth Ground)

(Earth Ground )

To P ower Sou rc e

120/240V ac,

3 Wire, European

Harmonized Color Code

L1

L2

Brown (Line)

Blue

(Neutral)

Green/Yellow

(Protective Earth)

To Power Source

4. Connect the communications cable between the MicroLogix

1500 controller Channel 0 and the PanelView 550 terminal serial

port.

Printer Port

Comm Port

2711-NC21

Publication 1413-UM001C-EN-P - May 2006

Page 20

18 Installation

PanelView 550 Ethernet Terminal (Ethernet HMI Option)

1. Mount the PanelView 550 HMI terminal in a suitable cutout

within 100 m (328 ft) of the MicroLogix controller.

Refer to publication 2711-IN009 for detailed installation

instructions.

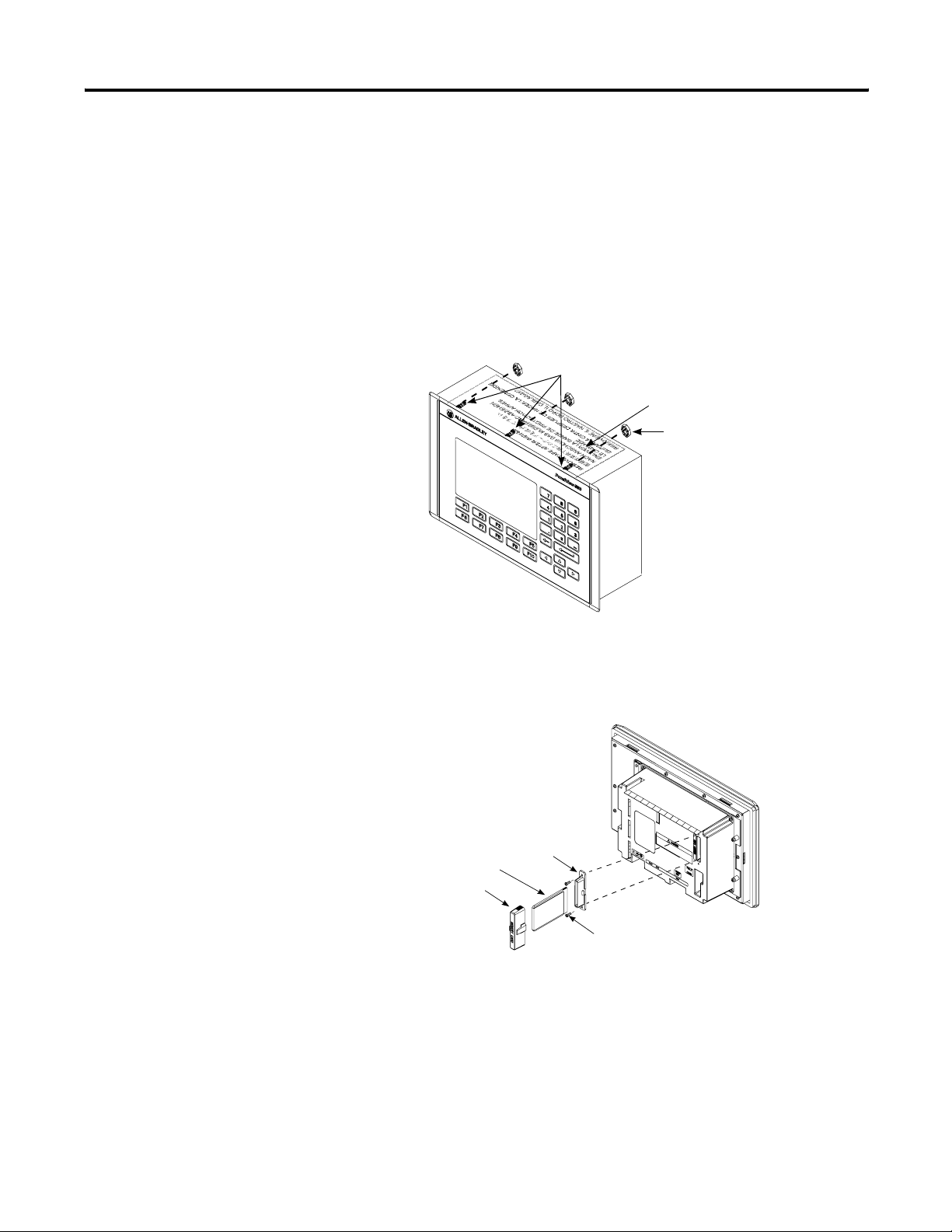

Mounting Studs

(3 Top / 3 Bottom)

Protective Installation Label

Self-locking Nuts

(6 used, 8 provided)

2. Install the memory card (7b, packed with the Powermonitor

meter) and retainer.

Memory Card

Retainer

Retainer Base

Base Mounting Screws

Publication 1413-UM001C-EN-P - May 2006

Page 21

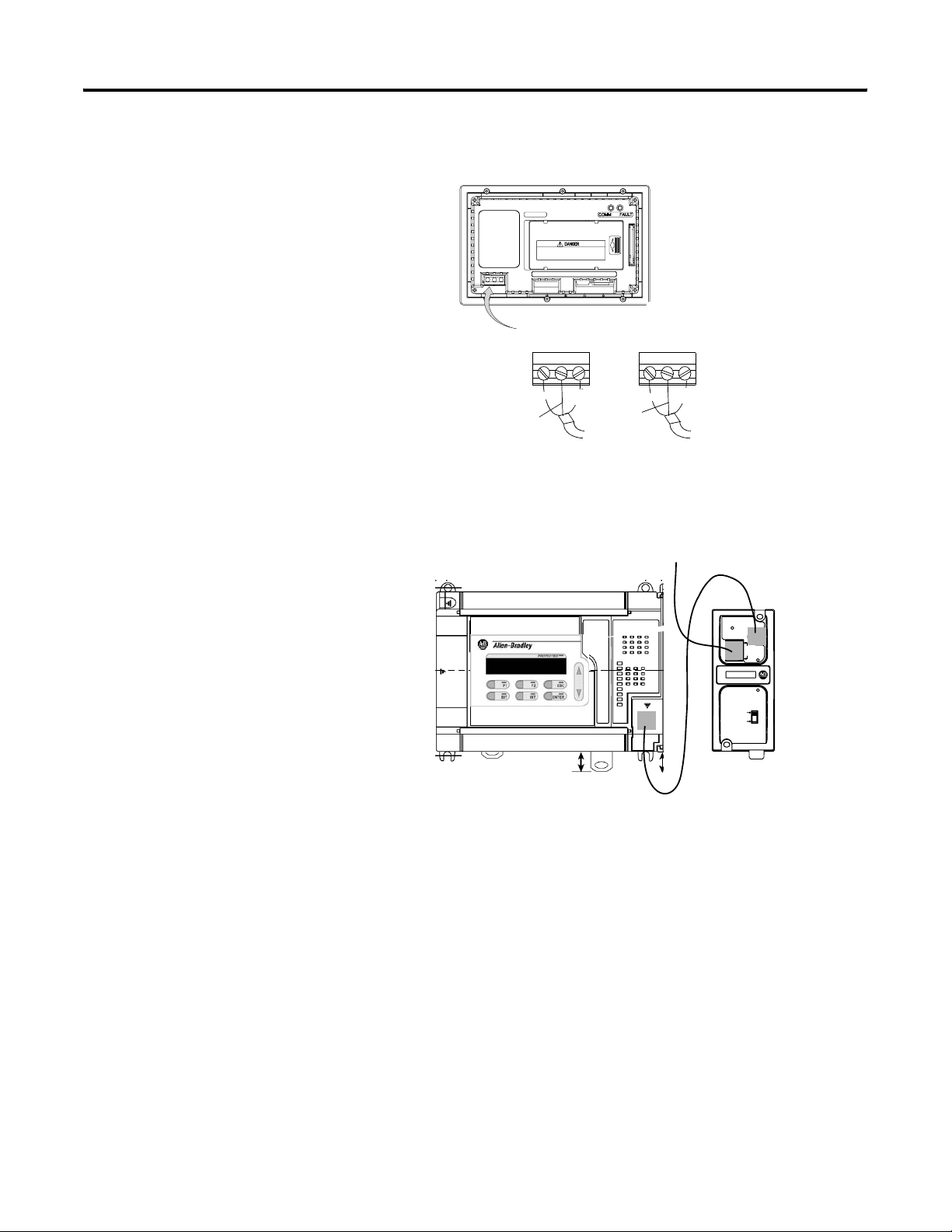

3. Connect 120V ac control power and earth ground.

Installation 19

Power Terminal Block (fixed)

120/240V ac, 3 Wire,

U.S. Color Code

L1

L2

GND GND

Green

Black (Line)

White

(Neutral)

Green

(Earth Ground)

(Earth Ground )

To P owe r S our ce

120/240V ac,

3 Wire, European

Harmonized Color Code

L1

L2

Brown (Line)

Blue

(Neutral)

Green/Yellow

(Protective Earth)

To Power Source

4. Install the Ethernet interface module (9) within 45 cm (18 in.) of

the Channel 0 connector on the MicroLogix 1500 controller (1).

To Ethernet LAN

ETHERNET

RS232

FAULT

NET

TX/RX

TX/RX

IP

PWR

CABLE

EXTERNAL

5. Verify that the DC Source switch on the Ethernet interface

module is in the Cable position.

6. Connect the cable (11) between Channel 0 of the MicroLogix

1500 controller and the Ethernet interface module.

7. Connect the PanelView 550 terminal to the Ethernet interface

module using the Ethernet crossover cable (12) if the system will

not be connected to a local area network.

8. Connect both the PanelView 550 terminal and the Ethernet

interface module to the Ethernet local area network via a

suitable hub or switch using user-provided CAT5 Ethernet cables

if the system will be connected to a local area network.

Publication 1413-UM001C-EN-P - May 2006

Page 22

20 Installation

Configuration

The capacitor bank controller base unit has been set up to require

minimal out-of-box configuration.

The base system has default communications settings. Certain

circumstances and options require additional configuration of

communications, which may include the use of programming software

not included with the controller.

You are required to configure the Powermonitor meters to coordinate

them to the power circuit in the base unit and all options.

Configuration of the Powermonitor meter is performed using the

display module.

The controller requires configuration to coordinate it to the number

and size of steps that exist in the capacitor bank being controlled, as

well as the desired operating mode and other selections. Use the data

access terminal (DAT) or the optional PanelView 550 operator

terminal to configure the controller.

ATTENTION

Do not operate the capacitor bank controller without first

configuring it to suit the controlled capacitor bank and system

options. Unpredictable operation, including undesirable power

system effects, may result.

Communications Configuration

Publication 1413-UM001C-EN-P - May 2006

The following sections provide information on configuring

communications for the components.

Base Unit

Communications settings are factory configured. The MicroLogix 1500

controller settings are contained in the EEPROM memory module.

Powermonitor meter settings are stored in onboard non-volatile

memory (NVRAM). Configuration settings are listed below.

Page 23

Communications Settings

Installation 21

Device / Parameter MicroLogix 1500 Controller

(1)

Chan 0

MicroLogix 1500 Controller

Chan 1

Protocol DF1 Full Duplex DF1 Half-duplex Master

Baud 19,200

19,200

(1)

Source ID / Node Address 1 0 101

Parity / Stop Bits None / 1

Handshaking None

Error Checking CRC

(1)

Default or out-of-box settings.

None / 1

None

CRC

(1)

(1)

(1)

Serial HMI Option

Communications settings for the PanelView 550 are factory configured

and stored on the flash memory card.

Powermonitor Meter 1

DF1 Half-duplex Slave

(1)

19,200

None / 1

None

CRC

(1)

(1)

(1)

(1)

PanelView 550 Configuration Settings

Device / Parameter PanelView 550 Operator Terminal

Protocol DF1 Full Duplex

Baud 19,200

Source ID / Node Address 2

Parity / Stop Bits None / 1

Handshaking None

Error Checking CRC

Ethernet HMI Option

This option allows the PanelView 550 terminal to connect to your

Ethernet network. It obtains data from the MicroLogix 1500 controller

through an Ethernet interface module and your local area network.

The MicroLogix 1500 controller obtains data from the Powermonitor

meters through its Channel 1 serial port, in the identical way as the

base unit and serial HMI options.

Default communications settings are factory configured.

Publication 1413-UM001C-EN-P - May 2006

Page 24

22 Installation

PanelView 550 Ethernet Configuration Settings

Device / Parameter MicroLogix 1500 Controller

via NET-ENI

IP Address 192.168.0.100 192.168.0.105 192.168.0.101

Subnet Mask 255.255.255.0 255.255.255.0 255.255.255.0

Default Gateway 192.168.0.1 192.168.0.1 192.168.0.1

PanelView 550 Operator

Te rm in al

Powermonitor Meter 1

To change from the default Ethernet addresses, additional software is

required.

The ENI Utility is a free download used to configure the Ethernet

interface module.

The ENI Utility can be found at:

http://www.ab.com/micrologix. Follow the links to Get Software and

EtherNet/IP and DeviceNet Interface Configuration Utilities.

For information on using the ENI utility, please refer to Rockwell

Automation Knowledgebase article A19540 - Quick Start -- Getting

started with using the ENI Utility.

You need to supply 24V dc power to the Ethernet Interface while

using the ENI utility since the cable to the MicroLogix 1500 controller

is disconnected. After reconfiguring the Ethernet address, cycle power

to the Ethernet interface module.

Publication 1413-UM001C-EN-P - May 2006

Changing from the default addresses in the Powermonitor meters must

be done using the Powermonitor display module.

Refer to Powermonitor Meter Configuration on page 23.

Changing the PanelView 550 communications settings requires the use

of PanelBuilder32 software, which is purchased from your local

Allen-Bradley representative or distributor.

Additional Powermonitor Meters Option

The capacitor bank controller base system and HMI options provide

for the addition of up to three more Powermonitor meters. The

MicroLogix 1500 controller logic is designed to communicate with

Powermonitor meters that have the following communications

settings. If Ethernet Powermonitor meters are added to the system,

their Ethernet addressing should be configured per your networking

requirements.

Page 25

Installation 23

Powermonitor Ethernet Communication Settings

Device / Parameter Powermonitor Meter 2 Powermonitor Meter 3 Powermonitor Meter 4

Node Address 102 103 104

IP Address

(1)

192.168.0.UnitID 192.168.0.UnitID 192.168.0.UnitID

Subnet Mask 255.255.255.0 255.255.255.0 255.255.255.0

Default Gateway 192.168.0.1 192.168.0.1 192.168.0.1

(1)

The Unit ID is listed on the Powermonitor nameplate.

Powermonitor meter communications settings are changed using the

Powermonitor display module.

Please refer to Powermonitor Meter Configuration Parameters table.

Powermonitor Meter

The table below lists the configuration parameters that must be set up

for correct operation of the capacitor bank controller.

Configuration

For additional information regarding Powermonitor meter

configuration, please refer to the Powermonitor 3000 User Manual,

publication 1404-UM001.

Powermonitor Meter Configuration Parameters

Parameter PM 1

Wiring mode

PT (VT) primary voltage

PT (VT) secondary voltage

CT primary current

I4 primary current

RS-485 node number

IP address

Subnet mask

Default gateway address

(1)

Wiring mode must be Wye when using NEU or Retro CTPT mode.

(2)

Applies only to Ethernet Powermonitor meter options.

(3)

Default factory setting for base unit.

(4)

Optional additional Powermonitor meters.

(1)

(3)

101

(2)

(2)

(2)

192.168.0.101

255.255.255.0

192.168.0.1

PM 2

(4)

PM 3

(4)

PM 4

102 103 104

(4)

Publication 1413-UM001C-EN-P - May 2006

Page 26

24 Installation

Parameter Descriptions

• Wiring mode – selected to match the physical connections to

the power system

– Delta 3 CT

– Delta 2 CT

– Direct delta 3 CT

– Direct delta 2 CT

– Open delta 3 CT

– Open delta 2 CT

– Wye (default)

– Single phase

• PT (VT) primary voltage – reflects the voltage rating on the

high side of the potential/voltage transformers. Range

1…10,000,000 V, default 480

• PT (VT) secondary voltage – reflects the voltage rating on the

low side of the potential/voltage transformers. Range 1…600 V,

default 480

• CT primary current – reflects the current rating on the high

side of the phase current transformers. Range 1…10,000,000 A,

default 5. The CT secondary current is also adjustable but the

default value of 5 A is standard

• I4 primary current – reflects the current rating on the high

side of the neutral current transformer. Range and defaults are

the same as CT primary current setting

• RS-485 node number – sets the communications address on

the RS-485 network to the MicroLogix 1500 controller.

Factory-set at 101 for PM 1, must be user configured for optional

PMs 2 …4. Range 1…247, default is the Unit ID

• IP address, subnet mask, default gateway – Ethernet port

settings required for communications with the user’s local area

network

Publication 1413-UM001C-EN-P - May 2006

Set Parameters with the Powermonitor Display Module

The Basic Configuration table contains the configuration parameters

needed for initial setup of the Powermonitor meter in the base system.

The table and diagram below describe the basic functionality of the

Powermonitor display module.

Page 27

Display Module Key Function

Escape Key Up Arrow Key Down Arrow Key Enter Key

Display mode Returns to parent menu Steps back to the

previous

parameter/menu in the

list

POWERMONITOR 3000

L1

L2

L3

N

Steps forward to the next

parameter/menu in the

list

Installation 25

Steps into a sub-menu or

sets as default screen

Program mode Returns to parent menu Steps back to the

previous

parameter/menu in the

list

Edit mode Cancels changes to the

parameter, restores the

existing value, and

returns to Program mode

Increments the

parameter/menu value

The following flow chart shows the menu structure of the

Powermonitor meter parameters to be configured for the base unit

and various options. Use the Enter and Escape keys to move between

levels and the arrow keys to select options within a level. Once the

parameter you wish to configure is selected, press the Enter key to

edit the parameter. In Edit mode, the parameter’s displayed value will

blink. Use the arrow keys to change the value of the displayed

parameter. Press the Enter key to save the displayed value in the

Powermonitor meter. The display momentarily displays the previous

value then the new value.

In the chart, the configuration items for the capacitor bank controller

are highlighted with a grey background.

Steps forward to the next

parameter/menu in the

list

Decrements the

parameter value

Steps into a sub-menu,

selects the parameter to

be modified or changes to

Edit mode

Saves the parameter

change to Master

Module and returns to

Program mode

Publication 1413-UM001C-EN-P - May 2006

Page 28

26 Installation

Menu Flowchart

Level 1

Level 2

Level 3

Display

Program

Password?

Basic

Advanced

Native Comm.

Optional Comm.

...

Wiring Mode

PT Primary

PT Secondary

CT Primary

1

Not Used For Cap Bank

Controller Setup

2

3

Protocol

Delay

Baud

Address

IP Address

Subnet mask

Default Gateway

CT Secondary

I4 Primary

I4 Secondary

...

Controller Configuration

...

Notes:

1. Base Unit And All Options

2. Additional Power Monitor Options

3. Ethernet Options

You may view and edit the first 48 of the CAP Bank Controller

parameters using the data access terminal (DAT). The optional

PanelView 550 terminal in either of the HMI options provides

configuration screens for viewing and editing the parameters, as

indicated in the Control and Status Parameter table (Screens: 1 =

Configuration, X1 = Extended Configuration 1, X2 = Extended

Configuration 2). The range of each integer parameter is 0

unless otherwise specified. The parameters are stored in contiguous

locations in a data file (N7:0 … 47) in the controller.

… 32,768

Publication 1413-UM001C-EN-P - May 2006

Page 29

Control and Status Parameters

Installation 27

Address Parameter Unit Description Range Default DAT

INT

N7:0 Capacitor

Step 1 -

kVAR Measured and averaged capacitor size for each

step

- 0 Configuration

Measured

Size

N7:1 Capacitor

kVAR - 1 Configuration

Step 2 Measured

Size

N7:2 Capacitor

kVAR - 2 Configuration

Step 3 Measured

Size

N7:3 Capacitor

kVAR - 3 Configuration

Step 4 Measured

Size

N7:4 Capacitor

kVAR - 4 Configuration

Step 5 Measured

Size

N7:5 Capacitor

kVAR - 5 Configuration

Step 6 Measured

Size

N7:6 Capacitor

kVAR - 6 Configuration

Step 7 Measured

Size

PanelView

Screen

N7:7 Capacitor

Step 8 Measured

Size

N7:8 Capacitor

Step 9 Measured

Size

N7:9 Capacitor

Step 10 Measured

Size

kVAR - 7 Configuration

kVAR - 8 Configuration

kVAR - 9 Configuration

Publication 1413-UM001C-EN-P - May 2006

Page 30

28 Installation

Control and Status Parameters

Address Parameter Unit Description Range Default DAT

INT

N7:10 Capacitor

kVAR Nameplate capacitor size for each step 50 10 Configuration

Step 1 Effective

Size

N7:11 Capacitor

kVAR 50 11 Configuration

Step 2 Effective

Size

N7:12 Capacitor

kVAR 50 12 Configuration

Step 3 Effective

Size

N7:13 Capacitor

kVAR 50 13 Configuration

Step 4 Effective

Size

N7:14 Capacitor

kVAR 50 14 Configuration

Step 5 Effective

Size

N7:15 Capacitor

kVAR 50 15 Configuration

Step 6 Effective

Size

N7:16 Capacitor

kVAR 50 16 Configuration

Step 7 Effective

Size

PanelView

Screen

N7:17 Capacitor

kVAR 50 17 Configuration

Step 8 Effective

Size

N7:18 Capacitor

kVAR 50 18 Configuration

Step 9 Effective

Size

N7:19 Capacitor

kVAR 50 19 Configuration

Step 10 Effective

Size

N7:30 Capacitor

Discharge

seco

nds

Time

N7:31 Nominal

volts The nominal bus voltage of the system 480 31 Ext

Voltage

Publication 1413-UM001C-EN-P - May 2006

The amount of time after a capacitor step is

turned off, before a capacitor step is considered

fully discharged

60 30 Configuration

Configuration

1

Page 31

Control and Status Parameters

Installation 29

Address Parameter Unit Description Range Default DAT

INT

N7:32 Voltage

Threshold -

% The voltage percentage from nominal, that will

determine high and low limits for alarming

1 - 10 5 32 Ext

High & Low

N7:33 %THD

Voltage

% The %THD at which the controller acts to reduce

voltage % THD

0 - 100 3 33 Ext

Setpoint

N7:34 Lead

Deadband

kVAR The leading kVAR limit allowed for the system,

before the controller acts to correct lead, typically

20 34 Configuration

33% of smallest capacitor step

N7:35 Lag

Deadband

kVAR The lagging kVAR limit allowed for the system,

before the controller acts to correct lag, typically

35 35 Configuration

66% of largest capacitor step

N7:36 Step

Tolerance

% The kVAR percentage of effective, that will

determine low limits for each capacitor step

0 - 10 5 36 Ext

Low Limit

N7:37 Power

Factor

Out-of-Rang

seco

The amount of time the system kVAR must be out

nds

of the range of the lead or lag deadband, before

the controller acts to correct

60 37 Ext

e Time

N7:38 %THD

Alarm Time

seco

The amount of time after all capacitor steps are

nds

actuated, and %THD is still above the setpoint

38 Ext

limit, before setting the %THD High Alarm

PanelView

Screen

Configuration

1

Configuration

1

Configuration

2

Configuration

1

Configuration

1

N7:39 Step

Tolerance

Time

N7:40 Voltage

High

In-Range

Time

N7:41 Voltage Low

In-Range

Time

N7:42 Voltage

In-Range

Time

seco

The amount of time after a capacitor step is

nds

actuated, before taking a sample reading of the

system kVAR difference, to determine if the

capacitor step is above the step tolerance low

limit

seco

The amount of time the bus voltage must be

nds

below the high limit before resetting the Voltage

High Alarm

seco

The amount of time the bus voltage must be above

nds

the low limit before resetting the Voltage Low

Alarm

seco

The amount of time after the Voltage High and

nds

Voltage Low alarms have been reset, before

signifying that the voltage is in an acceptable

range.

39 Ext

Configuration

2

40 Ext

Configuration

1

41 Ext

Configuration

1

42 Ext

Configuration

1

Publication 1413-UM001C-EN-P - May 2006

Page 32

30 Installation

Control and Status Parameters

Address Parameter Unit Description Range Default DAT

INT

N7:43 Control

(1)

Word

This is the control word for the capacitor bank

controller. The first three (3) bits of the control

43 Ext

word is used to set the CTPT Mode. Bit 4 is used

to initiate a restore of factory defaults. This

should be treated as a momentary state. Bit 5 is

used to initiate the step size buffer. This bit should

also be treated as a momentary state. Bit 6 is

used for disabling step tolerance. The BCD value

for each bit is available for easy setup.

Examples

- CTPT Mode 2 and Disable Step Tolerance = 68

- CTPT Mode 0 and Restore Factory Defaults = 17

to initiate a restore, then 1.

- CTPT Mode 1 and Initiate Step Buffer = 34 to

initiate step buffer, then 2

N7:44 Unbalance

Alarm Time

N7:45 Number of

Powermonit

seco

The amount of time before alarming and resetting

nds

the Unbalance Alarm flag

The number of Powermonitor meters to include in

the aggregate kW and kVAR calculations

44 Ext

45 Configuration

or meters

PanelView

Screen

Configuration

2

Configuration

1

N7:46 Number of

Capacitor

Steps

N7:47 Operating

Mode

N7:59 Number of

Samples

(1)

Please see the Control Word table.

The number of capacitor steps to be controlled 46 Configuration

The operating mode:

47 Configuration

0 - Manual

1 - Linear

2 - Balanced

3 - Best Fit

4 - User Defined

5 - % Voltage THD

The number of kVAR samples to average together

when auto-configuring capacitor step sizes.

1 - 10 5 - Ext

Configuration

1

Control Word

Bit Parameter BCD Value

0 CTPT Mode 0 - Normal 1

1 CTPT Mode 1 - Neutral 2

2 CTPT Mode 2 - Retro 4

3 8

Publication 1413-UM001C-EN-P - May 2006

Page 33

Installation 31

Control Word

Bit Parameter BCD Value

4 Restore Factory Defaults 16

5 Initialize Step Buffer 32

6 Disable Step Tolerance; 0 = False, 1 = True 64

7 Enable Input Mode; 0 = False, 1 = True 128

Use the DAT for Configuration

The data access terminal (DAT) provides a basic configuration

interface for the capacitor bank controller. In Integer mode, the DAT

provides read/write access to the configuration parameters listed in

the Control and Status Parameters table. You may also use the DAT in

Bit mode to automatically detect and configure the capacitor-bank

step sizes.

The DAT enters the Bit mode automatically after applying power. Bit

mode can also be selected by pressing the BIT key. If Bit mode was

already active, the DAT displays the last bit element monitored. If

Integer mode was active, the DAT displays the first bit element, after a

brief delay during which a working message appears.

To select Integer mode, press the INT key. If Integer mode was

already active, the DAT displays the last integer element monitored. If

Bit mode had been active, the DAT displays the first integer element

after a brief delay during which a working message appears.

Auto-configure Capacitor Step Sizes

Use the DAT to automatically configure the step sizes.

1. Select Bit mode.

2. Scroll to and select bit 40.

3. Press the Enter key to edit the bit.

4. Use the up/down key to change the value of the bit to 1.

TIP

If the data is protected or undefined, pressing the

up/down key scrolls to the next data element.

5. Press the Enter key to store the new value.

Esc or INT/Bit keys discard the new value.

Publication 1413-UM001C-EN-P - May 2006

Page 34

32 Installation

The auto-configure process begins. During this process, the controller

energizes each capacitor-bank step for a short time, measures the

steps kVARs and records the value. This process repeats several times

and the results of each trial are averaged. When the process is

complete, the averaged values are copied to the Effinal_StepSize_Sn

parameters and the Auto_Detect_Cap_Size flag is reset.

You must manually configure any parameters that need to change

from the default values listed in the table.

Input Interlock Mode

The Input Interlock mode allows fault protection for each capacitor

step through the use of fault-protection relays. Wire normally closed

fault-protection relays to each input from 0…10 of the controller. Wire

a normally-open momentary pushbutton to Input 11. This pushbutton

serves as a reset button.

During a fault occurrence, the controller discharges and locks-out the

respective capacitor step associated with the fault relay that tripped.

The fault-protection relay wired to Input 0 discharges and locks-out all

capacitor steps. The remaining fault-protection relays discharge and

lock-out their respective capacitor step (that is, Input 1 discharges and

locks-out capacitor step 1).

In order to place a capacitor step back into the sequence, a fault must

not be present for that step, and a reset must be initiated by pushing

the Reset pushbutton.

Manually Set Configuration Parameters

Use the DAT to manually change the controller configuration

parameters.

1. Select Integer mode.

2. Scroll to and select the desired configuration parameter.

Refer to the Control and Status Parameters table on page 27.

3. Press the Enter key to edit the parameter.

4. Use the up/down keys to change the value of the parameter.

TIP

If the data is protected or undefined, pressing the

up/down key scrolls to the next data element.

Publication 1413-UM001C-EN-P - May 2006

Page 35

Installation 33

5. Press the Enter key to store the new value.

Esc or INT/Bit keys will discard the new value.

6. Repeat steps 2…5 as needed.

Configuration with the PanelView 550 Terminal (Optional HMI

Only)

The optional PanelView 550 terminal provides you with a more

user-friendly interface to the capacitor bank controller. Use the

function keys to navigate through the screens and enter data as

needed using the keypad.

A-B

Allen-Bradley

F1

F6

F2

F7

F3

F8

F4

F9

7 8 9

4 5 6

1 2 3

. 0 -

<--

F5

< >

F10

PanelView 550

<-------'

^

v

Configure the capacitor bank controller using the optional PanelView

terminal.

1. Press the F2 key to view the Menu from the Overview screen.

Publication 1413-UM001C-EN-P - May 2006

Page 36

34 Installation

2. Press F10 to view the Configuration screen from the Menu.

The controller tags available on the Configuration screen are shown

below in their relative location on the screen.

Num_Steps StepsActive Eff_StepSize_S1 Eff_StepSize_S6

Eff_StepSize_S2 Eff_StepSize_S7

Num_PMs DischgTimerPreset Eff_StepSize_S3 Eff_StepSize_S8

Eff_StepSize_S4 Eff_StepSize_S9

kVAR_Lead_DB kVAR_Lag_DB Eff_StepSize_S5 Eff_StepSize_S10

Mode Auto_Detect_Cap_Size

Initialize_Step_Buffer

3. Press the Direction keys to move the cursor over the desired

field and press the Enter key.

4. Enter the desired value using the keypad and press Enter to

store the new value.

Pressing the Backspace key cancels a change.

Publication 1413-UM001C-EN-P - May 2006

Page 37

Installation 35

5. Press F6 to navigate to the Auto Configure Effective kVAR

process.

TIP

The number of measurements to average for each step is

entered on the Extended Configuration Screen #2 (F10).

6. Press F6 to initiate the auto-configuration process.

7. When done, press F10 to return to the Configuration screen.

8. Select the desired operating mode by entering the number or by

selecting the description in the list box.

The new value is displayed in both formats.

9. To select the mode, move the curser over the list box and press

Enter.

10. Press the Direction keys to scroll through the selections.

11. Press Enter again to select the displayed mode.

F1 returns to the Overview screen.

Publication 1413-UM001C-EN-P - May 2006

Page 38

36 Installation

F10 navigates to the first Extended Configuration screen. This

screen operates in the same way as the initial configuration

screen.

The controller tags available on the Configuration screen are shown

below in their relative location on the screen.

NominalVoltage Nominal_Voltage_Scale Bus_Volts PF_inRange_Timer_Preset

VoltageRange InRangeTimerPreset Unbalanced_Limit

HighLimit HighLimitTimerPreset %THD_V_SetPoint Net_Current

LowLimit LowLimitTimerPreset %THD_Timer_Preset Unbalance_Timer_Preset

12. Press F10 to navigate to the Extended Configuration 2 screen

from the Extended Configuration 1 screen.

The controller tags available on the Configuration screen are shown

below in their relative location on the screen.

Publication 1413-UM001C-EN-P - May 2006

Number of Samples CTPT Mode Powermonitor Heartbeat

Step Tolerance Low Limit Input Mode Disable/Enable

Step Tolerance Time Restore Defaults

Powermonitor Password Kvar Tolerance Disable/Enable

Page 39

Operation

Chapter

3

Introduction

The capacitor bank controller gathers real- and reactive-power data

using one or more Powermonitor meters. The processor manipulates

data in engineering units of kVAR and kW. The unit does not directly

control power factor, but rather works to actively minimize imported

and exported kVAR. The net result of this philosophy indirectly

controls power factor and minimizes voltage excursions associated

with excessive kVAR export.

The capacitor bank controller can accommodate up to four different

utility feeds and/or generators. Each feed requires an individual

Powermonitor meter. The unit sums the kW and kVAR readings from

each of the Powermonitor meters to arrive at an aggregate kVAR so

that a single capacitor bank could be used to compensate several

feeds simultaneously.

The traditional C/k ratio is not required for the capacitor bank

controller since we are working in engineering units within the

processor.

Aggregate Power Factor is calculated and displayed using the

following formula:

KW

PF

Aggregate

------------------------------------------------------------------------------=

KW

2

Aggregate

Aggregate

KVAR

+

2

Aggregate

The Powermonitor meter data is gathered with RS-485 ports using the

DF-1 half-duplex protocol at a data rate of 19.2 Kbps.

Operating Modes

37 Publication 1413-UM001C-EN-P - May 2006

Each capacitor step can be individually selected to on, off, or auto

status. The capacitor discharge-timer interlock is in effect in Manual

mode to prevent capacitor bank damage. In Auto mode, a step is

available to any of the automatic sequences described below. In the

On or Off mode, a step is unavailable to any automatic operating

mode.

• Manual (mode = 0) – This mode disables all automatic

operating modes.

Manual mode is the default configuration. All capacitor steps

have a default configuration of auto.

Page 40

38 Operation

• Linear (mode = 1) – This mode of operation switches the

capacitor steps on and off in first-in, last-out (FILO) order. That

is, the first step on is the last step turned off. This is most useful

when all the capacitor steps are of similar sized.

• Balanced (mode = 2) – This mode counts the number of

opening operations on each capacitor step and switch-capacitor

steps to balance the number of opening operations equally

across all of the employed capacitor steps. This mode is also

most useful when all of the steps are of similar size.

• Best Fit (mode = 3) – This mode selects capacitor steps to be

switched on and off to most closely achieve the target power

factor and kVAR needs of the system. When the system’s kVAR

needs increase, the available step or steps with the closest

(aggregated) kVAR rating is added. On decreasing kVAR

demand, steps are switched off in similar fashion.

• Special (mode = 4) – This mode is reserved for

customer-defined switching sequences not described above

including voltage, current, and time of day type functions.

Special-switching mode might include switching on parameters

such as PF, current, voltage, time of day, weekends / weekdays,

or seasonal adjustments.

CTPT Modes

Refer to Add Special Functionality on page 51.

• %THD (mode = 5) – This mode selects capacitor steps to be

added in a linear fashion (for example, step 1, step 2) until the

%THD_V is below the setpoint for a user-configurable time

delay (default 60 seconds). The system will start to remove

capacitor steps when the %THD_V is 1% below the setpoint for

the user-configurable delay.

The CTPT mode configures the capacitor bank controller to be

connected to current transformers (CTs) and potential transformers

(PTs) in one of three ways:

• 0 = Normal mode - CTs and PTs are installed in a typical

three-phase configuration. The controller uses the real- and

reactive-power data produced by the power monitor(s) without

further processing.

• 1 = NEU mode - One CT wired on the A phase and one PT

wired from phase A to neutral are installed on a three-phase

circuit. The power monitors must be set up in Wye-wiring mode.

The controller multiplies the real- and reactive-power data

produced by the power monitors by 3.

Publication 1413-UM001C-EN-P - May 2006

Page 41

Operation 39

• 2 = Retro mode - One CT wired on the A phase and one PT

wired from phases B to C are installed on a three-phase circuit.

The power monitors must be set up in Wye-wiring mode. The

controller swaps the values of the real- and reactive-power data

produced by the power monitors and multiplies them by .

This mode is particularly useful in retrofit applications.

3

Alarms

• Bad Step - This alarm indicates a blown fuse and/or loss of

capacitor condition. The controller measures actual VAR output

from a capacitor step, averages, and compares this value with

the original effective capacitor value. When actual VAR is more

than the user-configurable StepKvarTolerance (default 5%)

below the effective step size for a user-configurable delay

(default 30 seconds), the alarm is activated. The alarm is reset

when actual VAR output is greater than or equal to the setpoint

for the same delay. The step will be latched as tripped/offline if

the VAR output falls below 90% of nominal.

• Target power factor not achieved - If actual power is less than

setpoint for a user-adjustable number of seconds, then set the

alarm flag.

• High and Low Voltage - If BusVolts is outside either limit, this

alarm is activated immediately. After the voltage returns to the

proper range for a configurable amount of time, this alarm is

reset.

• %THD_V above setpoint - If all available steps are added and

%THD_V remains above the setpoint longer than the

configurable time delay, an alarm will be generated and the

system alarm contact closes. The alarm is reset when the

%THD_V falls below setpoint for the same period of time.

• Unbalance - This alarm is set when the average neutral current

exceeds a preset maximum for a configurable period of time. It

is reset using the same timer.

Operator Interface

The capacitor bank controller offers three types of operator interface.

• Data access terminal (DAT) – A simplistic operator terminal

physically attached to the controller that provides read/write

access to configuration and operating data. The DAT is provided

with the base unit and all optional configurations.

• Serial PanelView 550 – A comparatively robust operator

interface terminal that provides selectable configuration and

operating screens and a keypad for navigation and data entry.

Communications with the controller is through a serial

point-to-point connection. The serial PanelView is offered in the

Serial HMI option only.

Publication 1413-UM001C-EN-P - May 2006

Page 42

40 Operation

• Ethernet PanelView 550 – A similar HMI to the serial

PanelView but using Ethernet communications, offered with the

Ethernet HMI option only.

Data Access Terminal (DAT)

The data access terminal (DAT) provides access to 48 integer and 48

binary data registers.

The Binary (bit) Elements and Integer (Word) Elements tables define

how these register assignments are made.

See Control and Status Parameters on page 27 for the Integer (Word)

Elements.

Binary (bit) Elements

Address Parameter Value DAT BIT PanelView Screen

B3:0 Capacitor Step 1 - Status 0 = Off, 1 = On 0 Bank Status

B3:1 Capacitor Step 2 - Status 1

B3:2 Capacitor Step 3 - Status 2

B3:3 Capacitor Step 4 - Status 3

B3:4 Capacitor Step 5 - Status 4

B3:5 Capacitor Step 6 - Status 5

B3:6 Capacitor Step 7 - Status 6

B3:7 Capacitor Step 8 - Status 7

B3:8 Capacitor Step 9 - Status 8

B3:9 Capacitor Step 10 - Status 9

B3:10 Capacitor Step 1 - Alarm 0 = No Alarm, 1 = In

B3:11 Capacitor Step 2 - Alarm 11

B3:12 Capacitor Step 3 - Alarm 12

B3:13 Capacitor Step 4 - Alarm 13

B3:14 Capacitor Step 5 - Alarm 14

Alarm

10

B3:15 Capacitor Step 6 - Alarm 15

B3:16 Capacitor Step 7 - Alarm 16

B3:17 Capacitor Step 8 - Alarm 17

B3:18 Capacitor Step 9 - Alarm 18

B3:19 Capacitor Step 10 - Alarm 19

Publication 1413-UM001C-EN-P - May 2006

Page 43

Operation 41

Binary (bit) Elements

Address Parameter Value DAT BIT PanelView Screen

B3:20 Capacitor Step 1 - Mode 0 = Manual, 1 = Auto 20 Step Control

B3:21 Capacitor Step 2 - Mode 21

B3:22 Capacitor Step 3 - Mode 22

B3:23 Capacitor Step 4 - Mode 23

B3:24 Capacitor Step 5 - Mode 0 = Manual, 1 = Auto 24 Step Control

B3:25 Capacitor Step 6 - Mode 25

B3:26 Capacitor Step 7 - Mode 26

B3:27 Capacitor Step 8 - Mode 27

B3:28 Capacitor Step 9 - Mode 28

B3:29 Capacitor Step 10 - Mode 29

B3:30 Capacitor Step 1 - Manual Command 0 = Command Off, 1 =

B3:31 Capacitor Step 2 - Manual Command 31

B3:32 Capacitor Step 3 - Manual Command 32

B3:33 Capacitor Step 4 - Manual Command 33

Command On

30

B3:34 Capacitor Step 5 - Manual Command 34

B3:35 Capacitor Step 6 - Manual Command 35

B3:36 Capacitor Step 7 - Manual Command 36

B3:37 Capacitor Step 8 - Manual Command 37

B3:38 Capacitor Step 9 - Manual Command 38

B3:39 Capacitor Step 10 - Manual Command 39

B3:40 Auto Configure Capacitor Step Sizes Set to 1 to initiate 40 Configuration

B3:41 System Alarm 0 = No Alarm, 1 = In

B3:42 Bad Step Alarm 42

B3:43 Power Factor Not Achieved Alarm 43

B3:44 Voltage Alarm 44

B3:45 % Voltage THD High Alarm 45

B3:46 Current Unbalance Alarm 46

EXAMPLE

Alarm

Step 4, Alarm status, is found at bit address 13.

41 Alarm Summary

Publication 1413-UM001C-EN-P - May 2006

Page 44

42 Operation

Use the DAT

PROTECTED

01 OFF - 0

F1

BIT

F2

INT

ESC

ENTER

The data access terminal (DAT) enters the Bit mode automatically after

you apply power. Bit mode can also be selected by pressing the BIT

key. If Bit mode was already active, the DAT displays the last bit

element monitored. If Integer mode was active, the DAT displays the

first bit element, after a brief delay during which a working message

appears.

Press the INT key to select Integer mode. If Integer mode was already

active, the DAT displays the last integer element monitored. If Bit

mode had been active, the DAT displays the first integer element after

a brief delay during which a working message appears.

To view controller data, select the desired mode (Bit or Integer). Use

the up/down keys to scroll to the word or bit address. The address

and value of the selected parameter is displayed. If the parameter is

read-only, the protected indicator will light.

The DAT checks for controller faults every 10 seconds. When the DAT

detects a controller fault, the display shows FL in the element number

field and the value of the controller’s major fault word (S2:6) is

displayed in the value field.

Publication 1413-UM001C-EN-P - May 2006

Please refer to the section on configuration for information on using

the DAT to edit configuration parameters.

Optional PanelView 550 HMI

The optional PanelView HMI provides you with a more robust user

interface. The following screens are provided.

• Overview Summary

Page 45

• Navigation / Menu

• Bank Status

• Extended Status

• Step Control

• Power Factor Summary

• Powermonitoring Data x4

• Alarm Summary

• System Configuration

Operation 43

Numeric

Keypad

Enter Key

Function

Keys

Screen Navigation Tree

Step Status

F3

Extended

Status

F3

Step Control

F3

Power Factor

Summary

F4

Overview

Summary

F1

Navigation/

Menu

F2

PM3K #1 Data

F5

PM3K #2 Data

F5

PM3K #3 Data

F5

Alarm

Summary

F9

Navigation

Keys

Configuration

F10

Extended

Configuration

F10

Extended

Configuration 2

F10

PM3K #4 Data

F5

Publication 1413-UM001C-EN-P - May 2006

Page 46

44 Operation

Overview Summary Screen

This is the home screen and displays after you apply power. Press the

F1 function key to navigate to the Menu screen.

Navigation / Menu Screen

F1 Overview

F3 Step Status

F4 PF Summary

Bank Status Screen

Navigation/Menu

F5 PM3K Data

F9 Alarm Summary

F10 Configuration

Publication 1413-UM001C-EN-P - May 2006

Page 47

Operation 45

The status for the steps is listed in vertical columns from 1…10. There

are no configurations on this screen. It displays status data only.

Mode: A = Automatic, which means the step is controlled based on

the operation mode selected. M = Manual, which means you can force

the step on or off via the keypad.

Step Status: 1 = On, 0 = Off.

Discharge Status: ‘-’ = Not Discharging, D = Discharging.

Alarm: ‘-’ = No Alarm, ‘*’ = In Alarm.

You can press the F3 function key to navigate to the Extended Status

Screen.

Press the F1 function key to return to the Overview Summary Screen.

Extended Status Screen

Press the F6 function key to reset the step counters.

There are no other user-configurable fields on this screen. Press the F1

function key to return to the Overview Summary Screen.

Publication 1413-UM001C-EN-P - May 2006

Page 48

46 Operation

Step Control Screen

The steps are listed in vertical columns from 1…10.

The first row within the AUTO row commands whether to allow

manual or automatic control of each individual step. Use the arrow

keys to navigate to each individual command. The second row within

the AUTO row, gives the status of each individual step. A = Automatic,

M = Manual.

The first row within the MANL row commands the step to be turned

on. 0 = Off, 1 = On. The step must be in Manual mode to allow for

manual command of that particular step. The second row within the

MANL row gives the state status of each individual step, ON or OFF.

The STAT row gives the final status of each individual step.

Power Factor Summary Screen

Publication 1413-UM001C-EN-P - May 2006

There are no user-configurable fields on this screen. Press the F1

function key to return to the Overview Summary Screen.

Page 49

Operation 47

Alarm Summary Screen

Alarms are listed in the center of the screen. Alarms can be cleared

and acknowledged by moving the curser over the appropriate field

and pressing the Enter key. Use the up / down keys to change the

state and the Enter key to record or save the change. Press the

Backspace key to cancel the change.

Press the F1 function key to return to the Overview Summary Screen.

Publication 1413-UM001C-EN-P - May 2006

Page 50

48 Operation

Powermonitor Meter Screen

There are four instances of this screen, one for each of the

Powermonitor meters.

There are no user-configurable fields on this screen. Press the F5

function key to cycle to the next Powermonitor Data Screen. Press the

F1 function key to return to the Overview Summary Screen.

Publication 1413-UM001C-EN-P - May 2006

Page 51

SCADA Interface

Chapter

4

Power-circuit Parameters

The capacitor bank controller reads power-circuit parameters from the

Powermonitor meters and makes that data available in its data table

for use by other applications such as SCADA or HMI systems.

The following table lists the Powermonitor meter data available in the

controller. The symbol x indicates the Powermonitor meter number.

Addresses related to Powermonitor meter no. 1 begin with F11:0,

addresses related to Powermonitor meter no. 2 begin with F12:0.

Available Powermonitor Meter Data

Address Parameter

F1x:0 L1 Current

F1x:1 L2 Current

F1x:2 L3 Current

F1x:3 L1-L2 Voltage

F1x:4 L2-L3 Voltage

F1x:5 L3-L1 Voltage

F1x:6 Frequency

F1x:7 L1 Real Power

F1x:8 L2 Real Power

F1x:9 L3 Real Power

F1x:10 Total Real Power

F1x:11 L1 Reactive Power

F1x:12 L2 Reactive Power

F1x:13 L3 Reactive Power

F1x:14 Total Reactive Power

F1x:15 L1 Power Factor

F1x:16 L2 Power Factor

F1x:17 L3 Power Factor

F1x:18 Total Power Factor

F1x:19 Measured Total %THD Voltage

Additional data is available in systems with the Ethernet

Powermonitor meter option.

49 Publication 1413-UM001C-EN-P - May 2006

Page 52

50 SCADA Interface

In these systems, all Powermonitor meter data may be accessed using

the Ethernet communications port integral to the Powermonitor meter.

Please refer to the Powermonitor 3000 User Manual, publication

1404-UM001, for further information.

Publication 1413-UM001C-EN-P - May 2006

Page 53

Chapter

5

Add Special Functionality

For added functionality, custom ladder-logic programming and

hardware integration are permitted, however, strict guidelines must be

followed to comply with warranty contracts.

• Altering of existing ladder-logic code is prohibited and will void

all warranty contracts.

• Additional functionality can only be implemented by adding

additional ladder logic code to subroutine PFMGR4.

• Additional subroutines may be written, but must be called

through PFMGR4.

PFMGR4 Logic

The following sections provide details of PFMGR4 ladder-logic

programming.

Overview

There are three basic sections to PFMGR4:

• Power factor alarm

The power-factor alarming section specifies whether your

system KVAR is within its specified range and how long to wait

before alarming when it is out of range.

• Step control

The step control section specifies when to actuate or trip a step.

• Step routine

The step routine section specifies what step should be actuated

or tripped.

51 Publication 1413-UM001C-EN-P - May 2006

Page 54

52 Add Special Functionality

Power Factor Alarm

The ladder logic code for this section has already been written. The

following is an explanation of the ladder logic code for lines one

through four.

If BUS_NET_KVAR (F8:2) falls outside of the limits defined by

KVAR_Lag_DB (N7:35) and PFMGR4_LEAD_DB_NEG (N94:0), then

the timer PF_INRANGE__TIMER_4 (T93:0) will be started. The default

time for this timer is 60 seconds. When this timer is done timing, it will

latch KVAR_NOT_ACHEIVED (B56:2) and reset the timer.

If BUS_NET_KVAR (F8:2) is within the limits defined by

KVAR_Lag_DB (N7:35) and PFMGR4_LEAD_DB_NEG (N94:0), then

reset PF_INRANGE__TIMER_4 (T93:0) and unlatch

KVAR_NOT_ACHEIVED (B56:2).

The above process sets the flag, KVAR_NOT_ACHEIVED (B56:2),

which indicates when the system KVAR is out of your specified limits.

This flag is used for HMI alarming.

Step Control

The step control consists of three parts. Part 1 specifies under what

conditions to tell the system that a step is waiting to be actuated or

tripped. Part 2 specifies under what conditions to tell the system that a

step should be actuated. Part 3 specifies under what conditions to tell

the system that a step should be tripped.

The following ladder logic examples are recommended formats for

your custom coding.

Part 1

If PF_INRANGE__TIMER_4 (T93:0) is done timing

• If PF_LEADING (B3:6/6) is high, and under any user-defined

conditions, latch KVAR_LAG_WAIT_2_ADD (B56:0/8).

• If PF_LAGGING (B3:6/7) is high, and under any other

user-defined conditions, latch KVAR_LEAD_WAIT_2_TRIP

(B56:0/7).

Part 1 should be implemented at line three in parallel with the outputs

of that rung.

Publication 1413-UM001C-EN-P - May 2006

See Part 1 Example.

Page 55

Part 1 Example

Add Special Functionality 53

Part 2

If KVAR_LAG_WAIT_2_ADD (B56:0/8) is high and

TOTALSTEP_AVAL_AUTO (N70:31) is greater than 0, then output

energize KVAR_LAG_ADD_STEP (B56:0/4) and unlatch

KVAR_LAG_WAIT_2_ADD (B56:0/8). This will actuate the required

step defined by the step routine.

See Part 2 Example.

Publication 1413-UM001C-EN-P - May 2006

Page 56

54 Add Special Functionality

Part 2 Example

Part 3

If KVAR_LEAD_WAIT_2_TRIP (B56:0/7) is high and STEPS_REQUIRED

(N7:58) is greater than 0, then Output Energize

KVAR_LAG_TRIP_STEP (B56:0/3) and unlatch

KVAR_LAG_WAIT_2_ADD (B56:0/7). This will trip the required step

defined by the step routine.

See Part 3 Example.

Part 3 Example

Step Routine

This section defines what step to use or trip. The outputs for the Step

Routine are USE_STEP_NUM (N58:1) and TRIP_STEP_NUM (N58:0).

When a step is controlled to be used, the step equal to the value in

USE_STEP_NUM (N58:1) will be actuated. When a step is controlled to

be tripped, the step equal to the value in TRIP_STEP_NUM (N58:1)

will be tripped.

Publication 1413-UM001C-EN-P - May 2006

Page 57

Add Special Functionality 55

User Variables

This chart displays a list of data points and their access rights for use

in your custom code.

User-defined Variables

Symbol Datapoint Description Datatype Units Access

Privilege

System Status

PF_leading B3/.102 This flag indicates the power factor is leading. Bit Read

PF_lagging B3/.103 This flag indicates the power factor is lagging. Bit Read

Bus_Net_PF F8:00 This register holds the total power factor on the monitored

bus.

Bus_Net_KW F8:01 This register holds the total real power on the monitored

bus.

Bus_Net_KVAR F8:02 This register holds the total reactive power on the

monitored bus.

Bus_Volts F8:15 This register holds the three-phase average line-to-line

voltage as measured by the first Powermonitor meter.

Net_Current F8:16 This register holds the net current obtained from the

Powermonitor meter.

%THD_V F8:17 This register holds the % total harmonic-distortion voltage

as measured by the first Powermonitor meter.

KVAR_Lead_DB N7:34 Leading kVAR dead-band limit, typically 33% of smallest

step.

KVAR_Lag_DB N7:35 Lagging kVAR dead-band limit, typically 66% of largest

step.

PF_inRange_ Timer_4 T93:0 Time to wait for PF to come into acceptable range, before

alarming.

Step Status

Open_1 B3/00 This flag indicates that Contactor #1 has been activated. (0

= Open, 1 = Active)

Float Read

Float W Read

Float kVAR Read

Float V Read

Float A Read

Float Read

Int Read

Int Read

Timer Read

Bit Read

Open_2 B3/01 This flag indicates that Contactor #2 has been activated. (0

= Open, 1 = Active)

Open_3 B3/02 This flag indicates that Contactor #3 has been activated. (0

= Open, 1 = Active)

Open_4 B3/03 This flag indicates that Contactor #4 has been activated. (0

= Open, 1 = Active)

Open_5 B3/04 This flag indicates that Contactor #5 has been activated. (0

= Open, 1 = Active)

Open_6 B3/05 This flag indicates that Contactor #6 has been activated. (0

= Open, 1 = Active)

Open_7 B3/06 This flag indicates that Contactor #7 has been activated. (0

= Open, 1 = Active)

Bit Read

Bit Read

Bit Read

Bit Read

Bit Read