Page 1

Q and M-Frame Circuit Breakers

Instruction Leaflet for Electronic RMS Trip Unit Installation and Operation

Table

of

Contents

Description Page

1

.O

General Information

Protection

1.1

UL Listed Devices

2.0

Installation

3.0

Preparation (All Trip Units)

3.1

4-Pole Trip Unit Installation

3.2

Ground Fault Trip Unit Installation

3.3

General

3.3.1

Installation

3.3.2

3-Pole (Non-Ground Fault) Trip Unit Installation

3.4

Final Installation Instructions (All Trip Units)

3.5

Principle of Operation

4.0

General

4.1

Overload Trip

4.2

Short Delay/lnstantaneous Trip

4.3

Ground Fault Protection

4.4

Protection Settings

5.0

General

5.1

Short Delay Pick-up Settings

5.2

Short Delay Time Settings

5.3

Instantaneous Pickup Setting

5.4

Ground Fault Pick-up Setting

5.5

Ground Fault Time Settings

5.6

Testing

6.0

Functional Field Testing

6.1

Performance Testing for Ground Fault Trip Units

6.2

6.2.1

Code Requirements

Standards Requirements

6.2.2

6.2.3

General Test Instructions

7.0

Rating Plug

References

8.0

Q-Frame Molded Case

8.1

Circuit Breakers

Internal Accessories

8.2

..............................................................

.............................................................

..................................................................

.............................................................

..................................................................

..................................................................

...................................................................

..........................................................

..........................................................

...............................................

..................................................

.....................................

.....................................

..........................

.....

...........

............................................

.........................................................

..............................

.........................................

.................................................

.................................

.....................................

................................

.................................

...................................

.........................................

-

....

...............................................

.......................................

.......................................

...................................................

............................................

12

12

12

12

Bul. 140U

PRESENT BEFORE PROCEEDING

AND ALWAYS FOLLOW GENERALLY ACCEPTED

SAFETY PROCEDURES.

1

ALLEN

1

MISAPPLICATION

2

PRODUCTS.

2

2

The user is cautioned to observe all recommendations,

2

warnings, and cautions relating to the safety of personnel

3

and equipment as well as all general and local health and

3

safety laws, codes, and procedures.

3

The recommendations and information contained herein

5

are based on Allen

6

but should not be considered to be all

6

ing every application or circumstance which may arise. If

7

any questions arise, contact Allen-Bradley for further

7

information or instructions.

7

7

7

7

7

7

7

7

8

8

8

8

8

9

9

Fig.

1

-BRADLEY

1

Electronic RMS Trip Unit

M Frame Circuit Breaker

.O

GENERAL INFORMATION

IS

NOT LIABLE FOR THE

OR MISINSTALLATION

-Bradley experience and judgement,

-

for

OF ITS

inclusive or cover

3-Pole Q-Frame &

-

A

A

DEATH, SEVERE PERSONAL INJURY,

SUBSTANTIAL PROPERTY DAMAGE CAN RESULT

FROM CONTACT WITH ENERGIZED EQUIPMENT. DO

NOT

AlTEMPTTO INSTALL

MAINTENANCE ON EQUIPMENT WHILE IT

ENERGIZED. ALWAYS VERIFY THAT NO VOLTAGE

40752-072(2) Effective

WARNING

OR

6/02

OR

PERFORM

IS

IS

1.1

Protection

The Electronic RMS, illustrated in Figure

tronic trip unit that incorporates a microprocessor-based

custom application specific integrated circuit design for

use with Q

Circuit Breakers.

The Electronic RMS Trip Unit

sensing for proper correlation with thermal characteristics of

conductors and equipment. Interchangeable rating plugs

-

Frame and M Frame Molded Case

provides true RMS current

1,

is an elec

-

Page 2

Page

2

are provided to establish the continuous current rating of

each circuit breaker.

The Electronic RMS Trip Unit is completely self

tained and when the circuit breaker is closed, requires no

external power to operate its protection systems. It

operates from current signal levels and control power

derived through current sensors integrally mounted in the

trip unit.

Electronic

applications only. For DC applications, a thermal

trip unit should be used.

The Electronic RMS Trip Unit is available in 4 different

types, (see Table 1

delay time function (adjusted by changing the rating plug),

and may be equipped with a maximum of two phase and

two ground (time

application requirements. The types of adjustments

available for each model include the following:

Adjustment

1)

Short Delay Pick-up

2) Short Delay Pick-up/Short DelayTime

3)

Short Delay Pick-Up/Ground Fault

Pick-up/Ground Fault Time

2.0 UL LISTED DEVICES

The Electronic RMS Trip Unit is listed in accordance

with Underwriters Laboratories, Inc. Standard UL489

and satisfies the applicable requirements of the

International Electrotechnical Commission (IEC)

recommendations for molded case circuit breakers.

Fig.

RMS Trip Units are suitable for 50/60

-

1). Each trip unit contains a fixed long

-

current) adjustments to meet specific

Retaining

Screw

KPlaces)\

-

2

-

\Trip Unit

Preliminary Alignment

Sensor

-

Tm

LS

LSI

LSG

Current

Sensor

L

of

Trip Unit and Current

-

-

Retaining

Screw

Secondary

Winding

Connector

con

-

Hz

AC

magnetic

3

.O

INSTAL LATlO N

3.1 Preparation

The installation procedure consists of inspecting and

installing the trip unit and rating plug. To install the trip

unit, perform the following steps.

Note: If required, internal accessory installation

should be done before the circuit breaker is mounted

and connected. Refer to individual accessory instruc

tion leaflets.

Make sure that the trip unit is suitable for the intended

installation by comparing nameplate data with any

existing equipment and system requirements. Inspect the

trip unit for completeness, and check for damage before

installing it in the circuit breaker frame.

Note:Trip unit center retaining screw is captive in the

trip unit conductor; the remaining retaining screws

are supplied with the frame.

Remove circuit breaker pan

To continue installation, proceed to the section applicable

to the trip unit being installed:

UnitTvpe Section

Trip

4

-

pole Type Trip Unit 3.2

3

-

pole Ground Fault Trip Unit

3

-

pole Non-Ground Fault Trip Unit

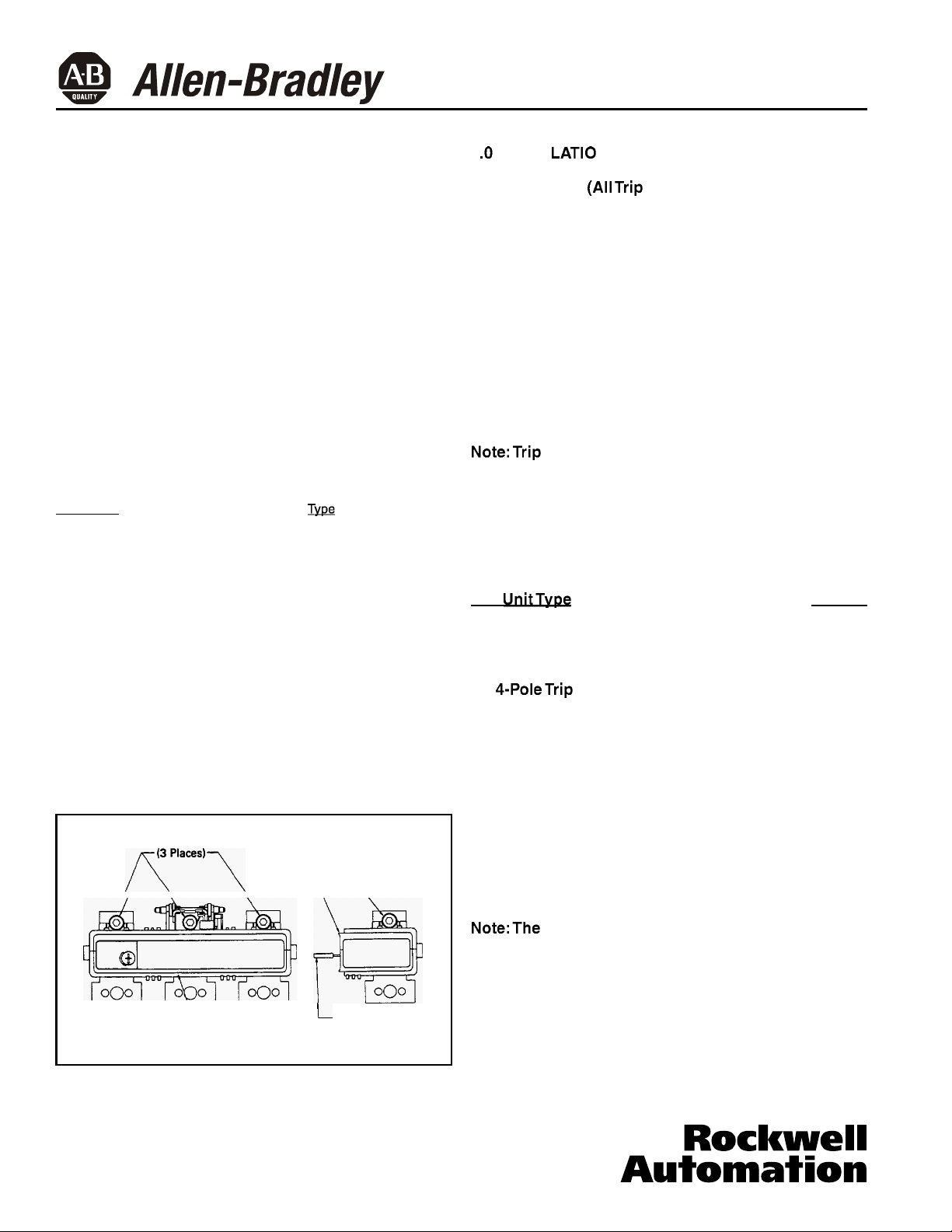

4-PoleTrip Unit Installation

3.2

Remove the three screws for the left

fourth pole contact bases (Fig. 3) from the hardware bag.

Place the trip unit and fourth pole current sensor side by

side on a flat surface. (See Fig. 2)

Remove the CAUTION tag from the current sensor

secondary winding leads.

Note: Secondary winding connector is not polarized.

Plug the current sensor secondary winding connector into

the receptacle in the side of the trip unit. Either polarity is

acceptable.

Note:The two trip unit outer retaining screws and

fourth pole sensor retaining screw may be placed in

the trip unit conductor holes at this time. If preferred,

the 5/16 inch hexagonal

position the screws when the trip unit is in the base.

Position trip unit and fourth pole current sensor in base.

Make sure latch bracket pin is properly seated in slots in

side plates (see Fig. 4). If necessary, push circuit breaker

handle towards the closed position to help seat trip unit.

(AllTrip Units)

-

head cover screws, and cover.

-

head wrench may be used to

3.3

3.4

-

and right-pole and

-

40752-072(2) Effective 6/02

Page 3

Page

3

-

Contact

Base

-

Load

Copper

Fig.

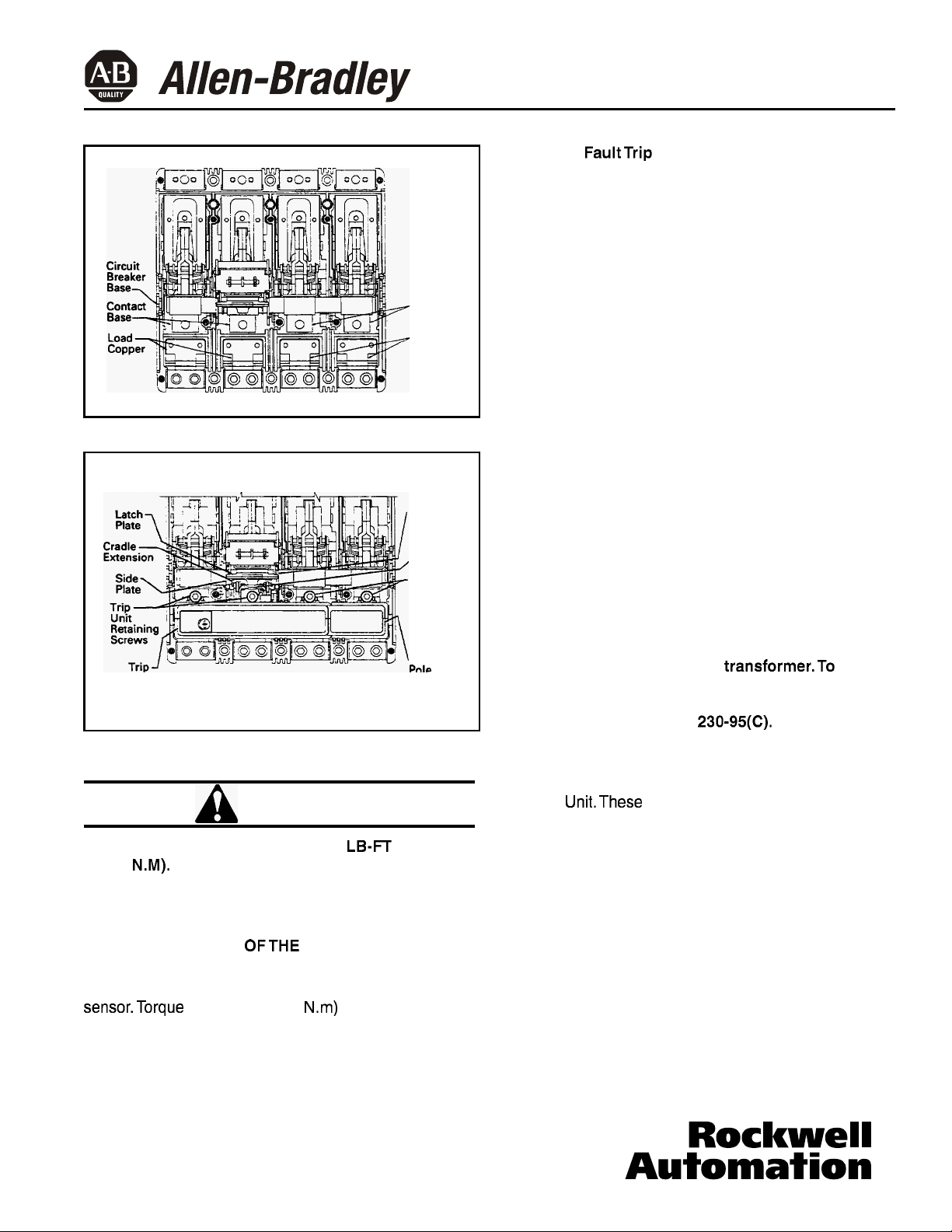

3

Contact Bases and Load Copper

LINE

END

Side

Plate

Trigger

Trip

Unit and

Current

Sensor

Retaining

Screws

Fourth

Pnh

. -.

-

Current

Sensor

Fig.

Unit

4

Trip Unit Installed in Circuit Breaker

a

END

LOAD

CAUTION

DO NOT EXCEED A TORQUE OF 12 LB-FT

(16.27 N.M). EXCESSIVE TORQUING WILL SHEAR

SCREWS.

FAILURE TO APPLY THE REQUIRED TORQUE

MAY

LEAD TO EXCESSIVE HEATING AND CAUSE

NUISANCE TRIPPING

OFTHE CIRCUIT BREAKER.

Screw in and tighten three trip unit retaining screws

(center first) and the screw for the fourth pole current

sensor.Torque to 12 Ib-ft (16.27 N.m) (see Fig. 4).

-

Finish installation of the 4

pole Trip Unit by following the

instructions in Section 3.5.

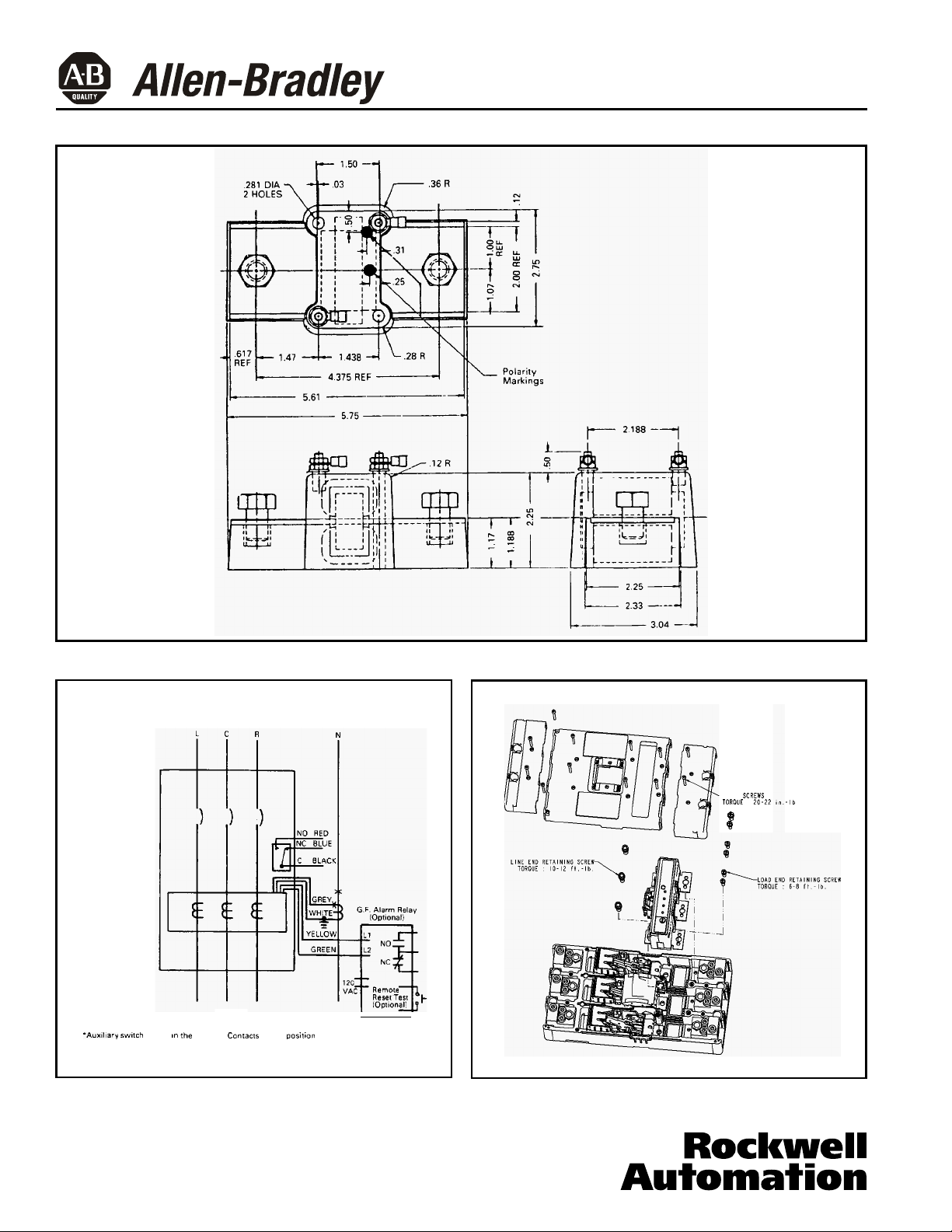

3.3 Ground

FaultTrip Unit Installation

3.3.1 General

Ground fault trip units are supplied from the factory with a

wire harness with pigtail lead connections for a neutral

current sensor (white and grey wires) and a ground fault

alarm relay (yellow and green wires). A neutral current

sensor is provided with each trip unit, and the ground fault

alarm relay is ordered and shipped separately if required.

If the alarm relay is not required, the green and yellow

leads should be cut off before the trip unit is installed in

the breaker.

Electroni

c RMS

Ground Fault Trip Units detect ground

fault currents through Residual Sensing. They are not

designed to use source ground or zero sequence ground

fault sensing methods. If the system neutral is grounded,

but no phase to neutral loads are used, the neutral current

sensor is not necessary. In that case, the white and grey

leads on the trip unit should be cut off before installation.

If the system neutral is grounded and phase to neutral

loads are used, then the neutral current sensor (see Fig.

5)

must be used. It should be connected to the breaker

according to the diagram in Fig. 6. It has the same turns

ratio as the phase current sensors in the trip unit.

Note: The polarity of the sensor connections is

critical. Always observe the polarity markings on the

installation drawings. The polarity markings are

identified as white dots on the

transformer.To insure

correct ground fault equipment performance, conduct

field tests to comply with National Electric Code

requirements under article

230-95(C). See Section 6.2

for testing instructions.

The optional “Internal Accessories” listed in Section 8.2

are available for installation in a Electronic RMS

Fault Trip

Unit.These items, if required, must be ordered

Ground

separately.

3.3.2 Installation

Plug the wire harness supplied for the neutral current

sensor and ground fault alarm relay (white, grey, yellow

and green wires) into the connector located in the right

pole of the trip unit. With the correct polarity the harness

should snap into place. Do not force the harness into the

connector with the wrong polarity.

Remove trip unit outer pole screws and red plastic

washers from the breaker frame. Discard red plastic

washers (fig. 7). For the M

-

frame, also remove the load

end trip unit mounting screws from the frame

(fig.

7a).

40752-072(2) Effective

6/02

Page 4

Page

4

Fig.

Fig.

5

.Aux~Iiary

6

switch

shown m the

"

Breaker

SOURCE

LOAD

Canlacis

Open''

pmilmn

Fig. 7a

M-Frame

Trip

Unit Installation

-

COVER

TORQUE

9

9

SCREWS

20-22

-1b

40752-072(2) Effective 6/02

Page 5

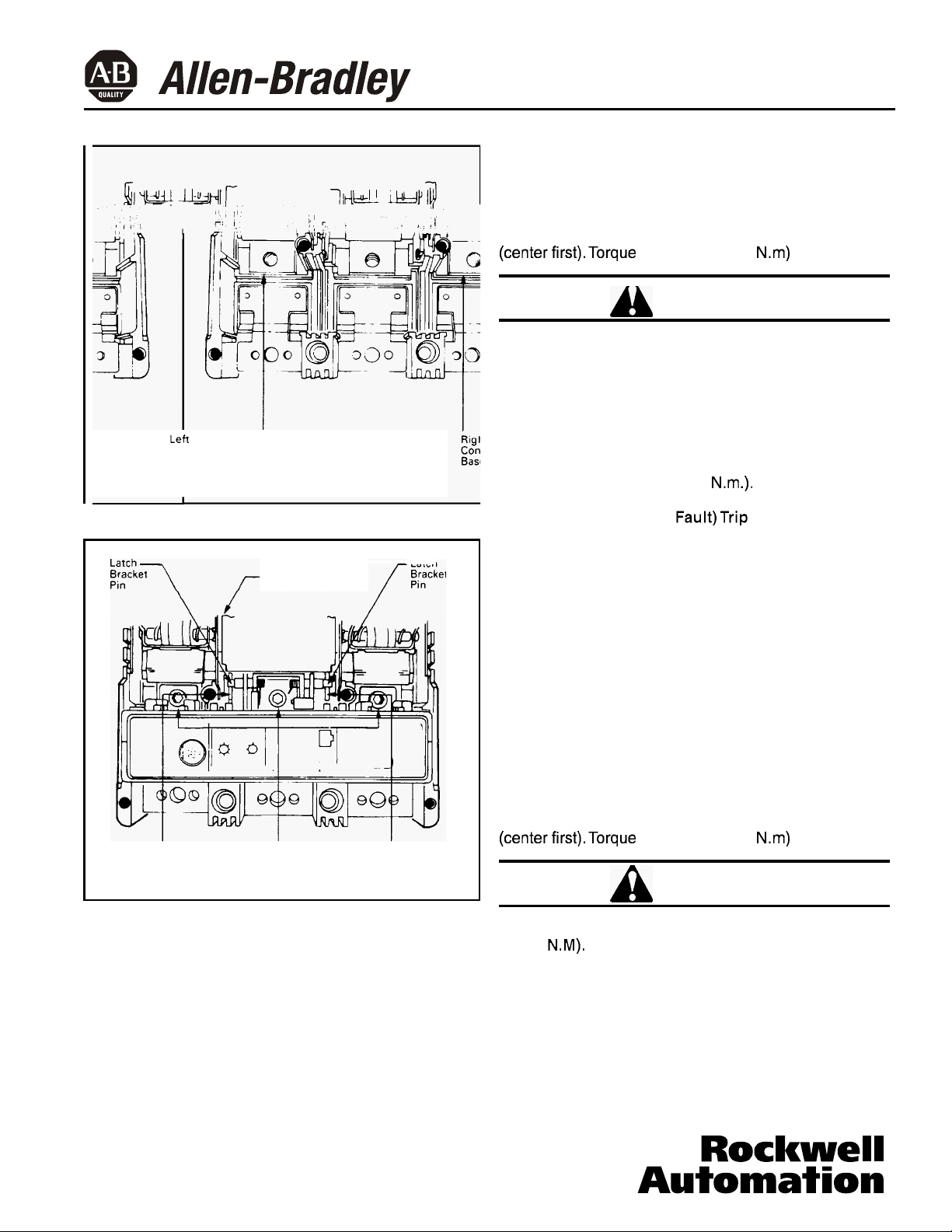

Lefl

Contact

Base

Right

Contact

Base

Page

Position trip unit in base. Make sure latch bracket pin is

properly seated in slots in side plates (see Fig. 8). If

necessary, move latch toward load end of circuit breaker

to seat trip unit.

Screw in and tighten three trip unit retaining screws

(centerfirst).Torque to 12 Ib-ft (16.27 N.m) (see Fig. 8).

A

A

DO NOT EXCEED A TORQUE OF 12 LB-FT

(16.27 n.m.) EXCESSIVE TORQUING WILL SHEAR

SCREWS.

FAILURE TO APPLY THE REQUIRED TORQUE MAY

LEADTO EXCESSIVE HEATING AND CAUSE

NUISANCE TRIPPING OF THE CIRCUIT BREAKER.

For an M-Frame, also screw in and torque the load end

screws to 6

-

8 Ib-ft. (8.14-10.85 N.m.).

CAUTION

5

Fig.

7

Left- and Right-Pole Contact Bases

Circuit Latch

Breaker

Handle

Side Trip Side

Plate Unit Plate

Fig.

8

Trip Unit Installed in Circuit Breaker

Note: The two

placed

preferred, the 5/16 inch hexagonal

be used

the base.

in

trip

unit

the trip

to

unit

position the screws when the

Retaining

Screws

outer retaining screws may be

conductor holes at

this

time. If

-

head wrench may

trip

unit

is

3.4 3-Pole (Non-Ground FauIt)Trip Unit Installation

Remove trip unit outer pole screws and red plastic

washers from the breaker frame. Discard red plastic

washers (fig. 7). For the M

end trip unit mounting screws from the frame

(fig.

7a).

NOTE: The two

be placed

If preferred, the 5/16 inch hexagonal

be used

the base.

Position trip unit in base. Make sure latch bracket pin is

properly seated in slots in side plates (see Fig. 8). If

necessary, move latch toward load end of circuit breaker

to seat trip unit.

Screw in and tighten three trip unit retaining screws

(centerfirst).Torque to 12 Ib-ft (16.27 N.m) (see Fig. 8).

in

the trip

to

position the screws when the

A

DO NOT EXCEED A TORQUE OF 12 LB

(16.27

SCREWS.

FAILURE TO APPLY THE REQUIRED TORQUE MAY

in

LEADTO EXCESSIVE HEATING AND CAUSE

N.M). EXCESSIVE TORQUING WILL SHEAR

NUISANCE TRIPPING OF THE CIRCUIT BREAKER.

-F

rame, also remove the load

trip

unit

outer retaining screws may

unit

conductor holes at

CAUTION

-

head wrench may

trip

-

FT

this

unit

time.

is

in

40752-072(2) Effective

6/02

Page 6

Page

6

For an M-Frame, also screw in and torque the load end

screws to 6

3.5

Final Installation Instructions (All Trip Units)

Install accessory(ies),

instruction leaflet listed in Section 8.2. Where accessories

are not required, install protective barriers supplied with

the trip unit in accessory retaining slots in left

hand poles of trip unit and in fourth pole current sensor

applicable.

Make sure interphase barriers and sliding handle barrier

are in place.

Install circuit breaker covers and pan

shown in Fig.

THE RATING PLUG MECHANICALLY INTERLOCKS

WITH THE TRIP UNIT. IF RATING PLUG

CORRECTLY INSTALLED, THE CIRCUIT BREAKER

CANNOT BE RESET

POSITION

-

8 Ib-ft. (8.14-10.85 N.m.)

if

required, using the appropriate

9.

a

CAUTION

OR

PLACED IN THE ON

-

and right

-

head screws as

IS

NOT

-

if

until the arrow points to ENGAGED. If an adjustable rating

plug is used, four continuous current settings are possible.

Set the switch marked A, B, C, D to the current rating

desired.

Note: The reverse procedure

rating plug. Turn the Push

remove

breaker to

button and gently pull. A small screwdriver placed

under the left edge of the rating plug will assist in

removal.

Reset circuit breaker by moving handle to the reset

position. Move handle to the

handle should remain at the

Press Push

tripping of the circuit breaker.

position.This action will cause the circuit

trip.Then grasp the lip of the Push-to-Trip

-to-

Trip button (in rating plug) to check manual

is

used to remove the

-to-

Trip button to the

ON

position. Circuit breaker

ON

position.

Torque 20-22 IN-LB

Fourth

9

Fig.

Note: Before attempting to install the rating plug, the

arrow

must be pointing toward the REMOVE

can be done with a small screwdriver.

Install rating plug. Position the rating plug as shown in Fig.

10. Insert the rating plug in the trip

plunger must align correctly with the matching receptacles

and slot in the trip unit. After the rating plug is pressed into

position, depress the Push

screwdriver and turn it clockwise one quarter of a turn

Cover Screw

in

the Push-to-Trip button portion of the plug

Installation Positions

position.This

unit.The pins and

-to-

Trip button with a small

Trip

Unit

Fig.

10

Installing Rating Plug

4.0

PRINCIPLE OF OPERATION

In open air at 40"C, an Q-Frame circuit breaker with an

Electronic RMS

up to 800 amperes without exceeding a 50°C rise at the

terminals. The calibration of the trip unit is insensitive to

ambient temperatures over a range of

However, the trip unit contains thermal temperature

protective circuitry that initiates a trip operation for self

protection if the internal ambient temperature at the

printed circuit board (PCB) reaches approximately 100°C.

This may occur for open air temperatures above 40°C

with circuit breaker currents near full load.

Trip Unit installed will carry continuously

-20"

to +55"C.

-

40752-072 (2) Effective

6/02

Page 7

Page

7

For ambient conditions above 40°C and where the

maximum ampere rating plug has been installed, derating

of the circuit breaker frame should be considered to avoid

exceeding a safe terminal temperature operating range.

Consult A

4.1 General

llen-Bradley for recommendations.

The Electronic RMS Trip Unit provides a tripping signal

to the flux transfer shunt trip when current and time delay

settings are exceeded. This is accomplished by employing

the Allen

-Bradley custom designed integrated circuit

SpreTMchip, which includes a microcomputer to perform

its numeric and logic functions.

In the Electronic RMS

Trip Unit, all required sensing and

tripping power to operate its protection function is derived

from the current sensors in the circuit breaker. The

secondary currents from these sensors provide the

correct input information for the protection functions, as

well as tripping power, whenever the circuit breaker is

carrying current. These current signals develop analog

voltages across the appropriate calibrating resistors.

The microcomputer, in cyclic fashion, repeatedly scans

the voltage values across each calibrating resistor and

enters these values into memory. These data are used to

calculate true RMS current values, which are then repeat

edly compared with the protection function settings and

other operating data stored in the memory. The software

program then determines whether to initiate protection

functions, including tripping the breaker through the flux

transfer shunt trip device in the circuit breaker.

4.2 Overload Trip:

In accordance with standards require

ments, the trip unit initiates a trip of the circuit breaker

within two hours for an overload of 135 percent, and will

trip in less time for higher overload currents.

A

“Thermal Memory” effect prevents the breaker from

being re

-

energized immediately after an overload.

A

“cooling off” period of up to 5 minutes is required, which

allows time for cabling to cool off.

4.3 Short Delay/lnstantaneous Trip:

conditions that exceed the short delay pick

For short circuit

-

up settings,

the trip unit initiates a trip after a delay prescribed by the

I2t ramp function for trip units with catalog number suffixes

LS, LSG.

A

flat response time delay action

is provided by trip units with catalog number suffixes LSI,

(I)

and LSIG unless the instantaneous

setting

is selected.

4.4 Ground Fault Protection:

fault pick

-

up and time delay settings shown in Table 1-2

When selected, ground

allow selective ground fault coordination with other circuit

protection devices.

5.0

PROTECTION SETTINGS

5.1 General

Prior to placing any circuit breaker in operation, each trip

unit protection setting must be set to the values specified

by the engineer responsible for the installation. The

available settings along with the effect of changing the

settings are illustrated in Figures 12

-

1 to 12-3.

The installed rating plug establishes the maximum

(I,)

continuous current rating

of the circuit breaker. Short

delay current settings are defined in multiples of ln.

One to four time and pick-up adjustment settings are

available depending on the particular trip unit purchased.

A

rotary switch is provided for each setting. The rotary

switch is adjusted using a small flatblade screwdriver

(Figure 11).

5.2 Short Delay Pick-up Setting

Seven settings are available that range from 2 to

shown in Figure 12

Electronic RMS

5.3 Short DelayTime Settings

-

1. This feature is included on all

Trip Units.

For catalog number LS and LSG the short time delay is an

-

ramp configuration with the actual time delay a

function of the trip current involved.

For catalog number LSI and LSIG the short time delay

is a flat response. Four settings (I,.1, .2, .3 second)

are available (see Figure 12-2). The "I" setting

-

gives a trip response with no intentional delay

(Instantaneous).

5.4 Instantaneous Pickup Setting

For catalog number LSI and LSIG Instantaneous Pickup

is achieved by setting Short Delay Time to "I"

(Instantaneous.) Short Delay Pickup (see paragraph 5.2)

then becomes Instanta

5.5

Ground Fault Pick-up Setting

Five settings ranging from 1 through

(see Figure 12

-

3) and correspond to the fixed ampere

neous Pickup.

5 (xlG)

are available

values listed on the trip unit nameplate and in Table 1.2.

Note: These ampere values are always the same no

matter what rating plug is installed in the circuit

breaker.

8

, .

(I,)

as

40752-072(2) Effective 6/02

Page 8

5.6 Ground FaultTime Settings

The ground fault time delay is a flat response with four

settings

I

setting gives a trip response with no intentional delay

(I,

.15, .3,

.5

second) available (Figure 12-3).The

(Instantaneous). This option is available on Catalog Nos.

LSG and LSIG.

Page

8

6.OTESTING

6.1 Functional Field Testing

A test receptacle is built into each trip unit to allow use of

the STK2 Test Kit. The Test Kit performs a test of the Long

Delay, Short Delay and Ground Fault functions.

Performance Testing for Ground Fault Trip Units

6.2

6.2.1 Code Requirements

The National Electrical Code under Article 230-95-C

requires that any ground

-

fault protection system be

performance tested when first installed. The test shall be

conducted in accordance with approved instructions

Fig.

I\

Remove-

11

Adjustment Switches and Test Points

Short

Delay Pickup

(Multiples

I

3@7

of

5

Rated

Current

I

I

\

LTest

Jacks

I

Ih

1

Ilh

W

E

+

1,)

5

Short Delay Pick-up

(Multiples

of

Rated

Cu

irrent)

Fig.

12-1

Short Delay Trip Current Adjustment and Curve

Details

40752-072(2) Effective

6/02

Current

Fig.

Current

12-2

Short Delay Trip Current and Short Delay Trip

Time Adjustment and Curve Details

Page 9

Page

9

300\(!&

I

’*+

I

L

t

L

Time

Ms

Current

Fig. 12-3 Ground Fault Trip Current, and Ground Fault Trip

Time Adjustments and Curve Details

provided with the equipment. A written record of this test

shall be made and shall be available to the authority

having inspection jurisdiction.

6.2.2 Standards Requirements

As

a follow-up to the basic performance requirements

stipulated by the

1053 requires that certain minimum instructions must

accompany each ground fault protection system. These

following statements plus a copy of the test record form

illustrated in Fig. 16 are shipped with each Elect

RMS

Trip Unit.

6.2.3 General Test Instructions

The interconnected system shall be evaluated in accor

dance with the equipment assembler’s detailed instruc

tions by qualified personnel.

The polarity of the neutral sensor connections (if used)

must agree with equipment assembler’s detailed instruc

tions to avoid improper operations following apparently

correct simulated test operations. Where a question

exists, consult the specifying engineer and/or equipment

assembler.

The grounding points of the system shall be verified to

determine that ground paths do not exist that would

bypass the sensors. The use of high

resistance bridges may be used.

N.E.C.

as stated above, UL Standard

ronic

-

voltage testers and

No.

-

-

-

8

.-

i

+

2x-Ex

2x-8x 2x.8~ 2x-Ex

See

Fig.

2-7

and

Continuation of Short Time

Instantaneous Portions of Curves

Fig.

Current

Rating Plug Setting (Amperes)

2-8

for

Fig. 13 Optional Adjustable Ampere Setting Rating

Plug Used in

THERE

BURN WHENEVER WORKING IN

ELECTRICAL EQUIPMENT. ALWAYSTURN OFF

POWER SUPPLYING BREAKER BEFORE

CONDUCTING TESTS.

Note: Since the Electronic RMS

their operating power from the phase currents, and

not from the neutral current, passing current through

the neutral sensor only will not properly test the

ground fault feature.

Using a low voltage (0-24 volt), high current,

apply a test current of 125% of the Electronic RMS

Ground

of the circuit breaker, as shown in Fig. 14

cause the breaker to trip in less than 1 second, and

alarm indicator is supplied, it should operate. Reset the

breaker and the alarm indicator. Repeat the test on the

other two phases.

IS

A HAZARD OF ELECTRICAL SHOCK

FaultTrip Unit pick-up setting through one phase

Electronic RMS

a

WARNING

Trip Unit

OR

OR

AROUND

Trip Units derive

AC

source,

-

1 .This should

if

an

40752-072(2) Effective

6/02

Page 10

69

Source

1

Load Current-Lim

Resisto!

(if required1

voltage

i

iring

Source

Load

Nl

Current Limiting

Resistor

(if

required)

Page

10

Fig. 14-1 Connections for Ground Fault

Voltage

Source

Current

Limiting

Resistor

(if

required)

Trip

Test

Fig. 14-2 Connections for Ground Fault No-Trip Test, with

a Four

-

Wire System

Fig. 15 Typical Rating Plug

Fig. 14-3 Connections for Ground Fault No-Trip Test, with

a Three

40752-072(2) Effective

-

Wire System

6/02

Page 11

Page

11

GROUND FAULT

Ground Fault Test Record should be Retained

Installation in order to be available

Test Date

Circuit

Breaker

Number

to

TEST

RECORD FORM

by

the Authority having Jurisdiction.

Those in Charge

Results

of

the Building's Electrical

Tested By:

Fig.

16

Typical Performance Test Record Form

40752-072(2) Effective

6/02

Page 12

Page

12

If the system is a 4-wire system with a neutral current

sensor, apply the same current as described above

through one phase of the breaker, returning through the

neutral sensor, as shown in Fig.

not trip, and the alarm indicator,

operate. Repeat the test on the other two phases.

If the system is a 3

sensor, apply the same current as described above

through any two phases of the breaker, with the connec

tions exactly as shown in Fig. 14-3. The breaker should

not trip, and the alarm indicator,

operate. Repeat the test using the other two combinations

of breaker phases.

FIELDTESTING SHOULD BE USED FOR

FUNCTIONALTESTING AND NOT FIELD

CALIBRATION OF THE ELECTRONIC RMS GROUND

FAULTTRIP UNIT.

ANY TEMPORARY CONNECTION MADE

PURPOSE OF CONDUCTING TESTS SHOULD BE

RESTOREDTO PROPER OPERATING CONDITIONS

BEFORE

The results of the test are to be recorded on the test form

provided with the equipment.

7.0

The rating plug, as illustrated in Figure 15, is used to

establish the continuous ampere rating of the related

circuit breaker.

RETURNINGTHE BREAKERTO SERVICE.

RATING PLUG

-

wire system with no neutral current

a

CAUTION

14-2.The breaker should

if

supplied, should not

-

if

supplied, should not

FORTHE

For adjustable rating plugs (Table 1

current carrying conductors used with the breaker must

be sized to correspond with the maximum setting of the

rating plug, in accordance with National Electric Code

requirements.

The Long Delay protection function of the trip unit is set at

the rating plug value

neous protection functions are set as a multiple of In.The

Ground Fault protection function is independent of

Different rating plugs are available (Table 1-2) to match

the desired current rating and type of circuit breaker into

which the trip unit is to be installed.

Complete catalog descriptions of all available rating plugs

are given in the applicable circuit breaker supplementary

instruction leaflets (see Section

8.0 REFERENCES

8.1 Q

-

Frame Molded Case Circuit Breakers

40752-078

Contact AB

8.2 Internal Accessories:

accessories, which mount on the trip unit, are available for

use. The number of the instruction leaflet covering the

installation of each accessory is shown.

.

Alarm (Signal)/Lockout (ASL) Switch

.

Auxiliary Switch

.

ShuntTrip

Undervoltage Release Mechanism (Handle

Reset

.................................................... 40752-075

........................................................... 40752-070

((,).The Short Delay and Instanta

Frame Instruction Leaflet

Typical Time

curves for L Frame Breakers

The following types of internal

........................................... 40752-074

-2), the primary

8.0).

-

Current Characteristic

...........40752-076

-

In.

40752-072(2) Effective 6/02

Page 13

Trip Unit Functions

Long Delay Fixed Ampere

Rating¬ with

Fixed Long Delay

Table 1-1. Electronic RMS Trip Units

3 Pole

Electronic RMS Trip Unit type Catalog Numbers

LS LSI LSG LSIG

l

l

Page 13

l

l

Adjustable ampere

Setting with fixed

Long Delay

Short Delay Adjustable Short

Delay Pick-up with

Short Delay Time

2

l

t Ramp

Adjustable Short

Delay Time® with

Adjustable Short

Delay Pick-up, or

Adjustable

Instantaneous

Pick-up®

Instant Fixed

Instantaneous

(Override)¯

Ground Adjustable Ground

Fault Fault Pick-up with

Adjustable Ground

Fault Time

Fourth 100% rating for

Pole fourth pole

Protection

60% rating for

fourth pole

l

l

l

l

l

l

l

l

l

l

ll ll

ll

Fourth pole

unprotected

¬ Fixed rating plugs available, see Table 1-2

Optional four-setting adjustable rating plugs available, see Table 1-2

® Using trip unit with adjustable short delay time (LSI, LSIG), instantaneous pick-up is achieved when the lowest time delay setting

(1) is selected.

¯ A non-adjustable override setting is set at the frame withstand rating.

40752-072(2) Effective 6/02

Page 14

Page

14

Table 1-2. Electronic RMS Trip Unit

Trio Function

Ampere Rating

Fixed at 100%

Adjustable Long

-

Delay Pick

Short Delay Pick-up

(Adjustable)

Short

(Fixed)

Short

(Adlustable)

Instantaneous

Pick-upO

Ground Fault

Ground Fault Time

0

O

up

DelayTime

DelayTime

-

up

Pick

(Adjustable)

Delay

Not UL Listed

Occurs with short delay time adjustment set at

Function and Rating Settings

RatinalSettina Descriotion

Fixed rating plugs available

Trip Unit Fixed Rating Plugs

Amoere Ratina

600A

630A

800A

Trip Unit

Ampere Rating

600A

630A

800A

In

(I,)

IZt ramp configuration

Flat response with time delay settings at

100 ms

Trip Unit

Ampere Rating

600A

800A

Settinas at instantaneous

300A, 350A, 400A, 500A, 600A

300A, 315AO, 350A, 400A, 500A, 600A, 630AO

400A. 500A. 600A. 700A. 800A

Adjustable Rating Plugs

300A-400A-500A-600A

31 5A-400A-500A-630A

400A-500A-630A-800A

multiples

of

with marks at 2-3-4-5-6-7-8x

installed rating plug amperes

200

ms and 300 ms

Settings

120A, 240A, 360A, 480A, and 600A

160A, 320A, 480A, 640A, and 800A

(1).

I

(I,)

(IJO

fI I or 400A-500A-600A-800A

150ms. 300ms. and 500ms

(I,)

(I-!

(I,)

fI

I

40752-072(2) Effective 6/02

Printed in U.S.A./TQC

Loading...

Loading...