Page 1

40752-090(1) Effective 5/02

N-Frame Circuit Breakers

Instruction Leaflet for Drilling and Assembling Flex-Cable Handle Mechanism

DO NOT ATTEMPT TO INSTALL OR PERFORM

MAINTENANCE ON EQUIPMENT WHILE IT IS ENERGIZED. SEVERE PERSONAL INJURY, DEATH, OR

SUBSTANTIAL PROPERTY DAMAGE CAN RESULT

FROM CONTACT WITH ENERGIZED EQUIPMENT.

ALWAYS VERIFY THAT NO VOLTAGE IS PRESENT

BEFORE PROCEEDING WITH THE TASK, AND

ALWAYS FOLLOW GENERALLY ACCEPTED

SAFETY PROCEDURES.

ALLEN-BRADLEY IS NOT LIABLE FOR THE

MISAPPLICATION OR MISINSTALLATION OF ITS

PRODUCTS.

The user is cautioned to observe all recommendations,

warnings and cautions relating to the safety of personnel and equipment as well as all general local health

and safety laws, codes and procedures.

The recommendations and information contained herein

are based on Allen-Bradley experience and judg-

ment, but should not be considered to be all-inclusive or

covering every application or circumstance which may

arise. If any questions arise, contact Allen-Bradley for

further information or instructions.

!

WARNING

GENERAL INFORMATION

The Shaft Handle M

echanism provides a means of externally operating the circuit breaker and can be applied to

enclosures of varying heights and depths. The handle

can be used with NEMA 1, 3R, and 12 enclosure applications, plus NEMA 4 and 4x applications, depending on

the accessory components selected. An operating handle, flexible shaft, and mechanism are required for standard applcation. Three lengths of shafts are available for

use with the range of depths of various enclosures (4’, 5’,

and 6’). When selecting the length of the Flexible Shaft,

ensure Minimum Bending Radius of 5 inches is maintained to operate properly.

WHEN INSTALLING A NEW HANDLE MECHANISM,

OR A NEW CIRCUIT BREAKER AND HANDLE

MECHANISM IN AN EXISTING ELECTRICAL SYSTEM, MAKE SURE THERE IS NO VOLTAGE PRESENT WHERE WORK IS TO BE PERFORMED. SPECIAL ATTENTION SHOULD BE PAID TO REVERSE

FEED APPLICATIONS TO ENSURE NO VOLTAGE IS

PRESENT. THE VOLTAGE IN ENERGIZED EQUIPMENT CAN CAUSE DEATH OR SEVERE PERSONAL

INJURY.

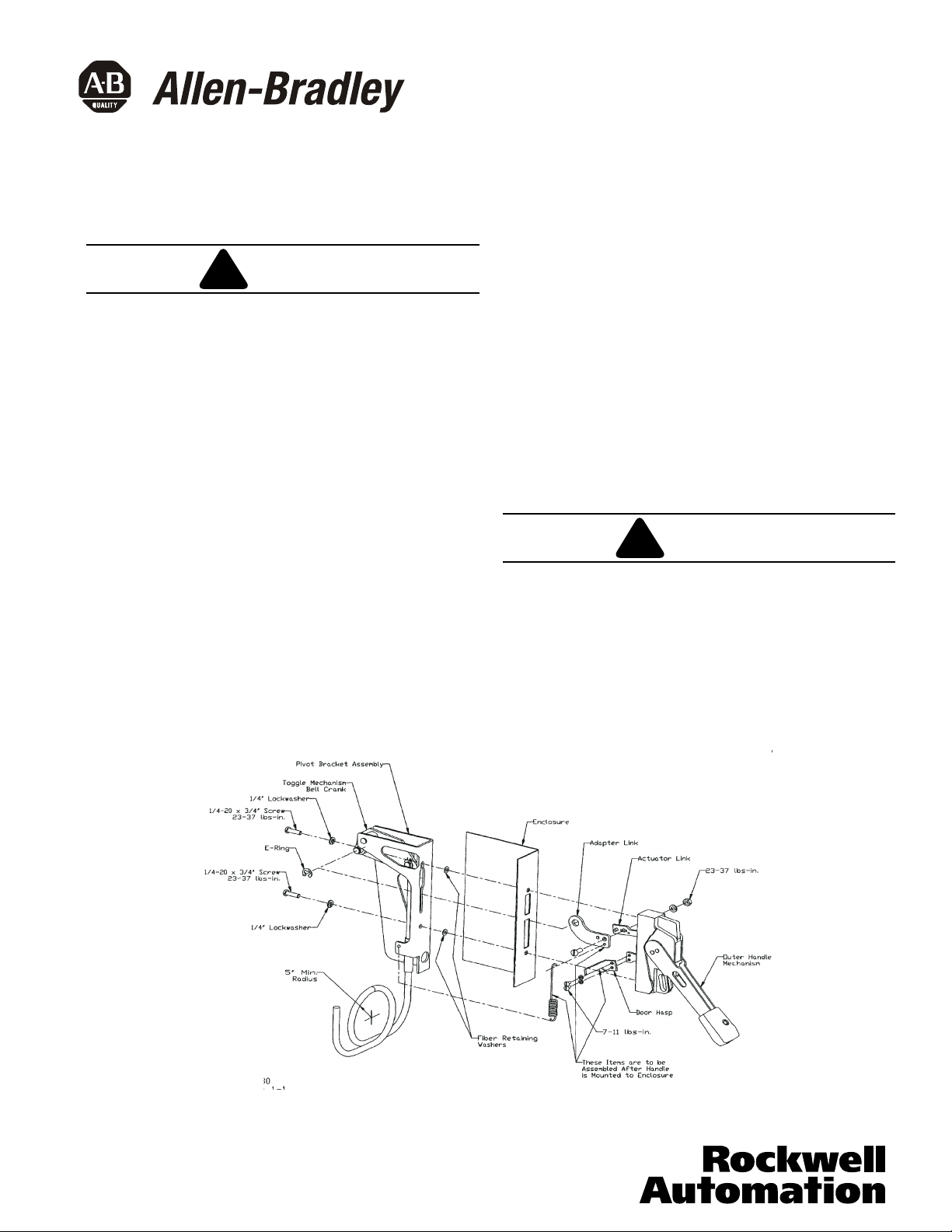

Figure 1-1 Pivot Bracket and Outer Handle Mechanism Assembly

!

WARNING

Bul. 140U

Page 2

Page 2

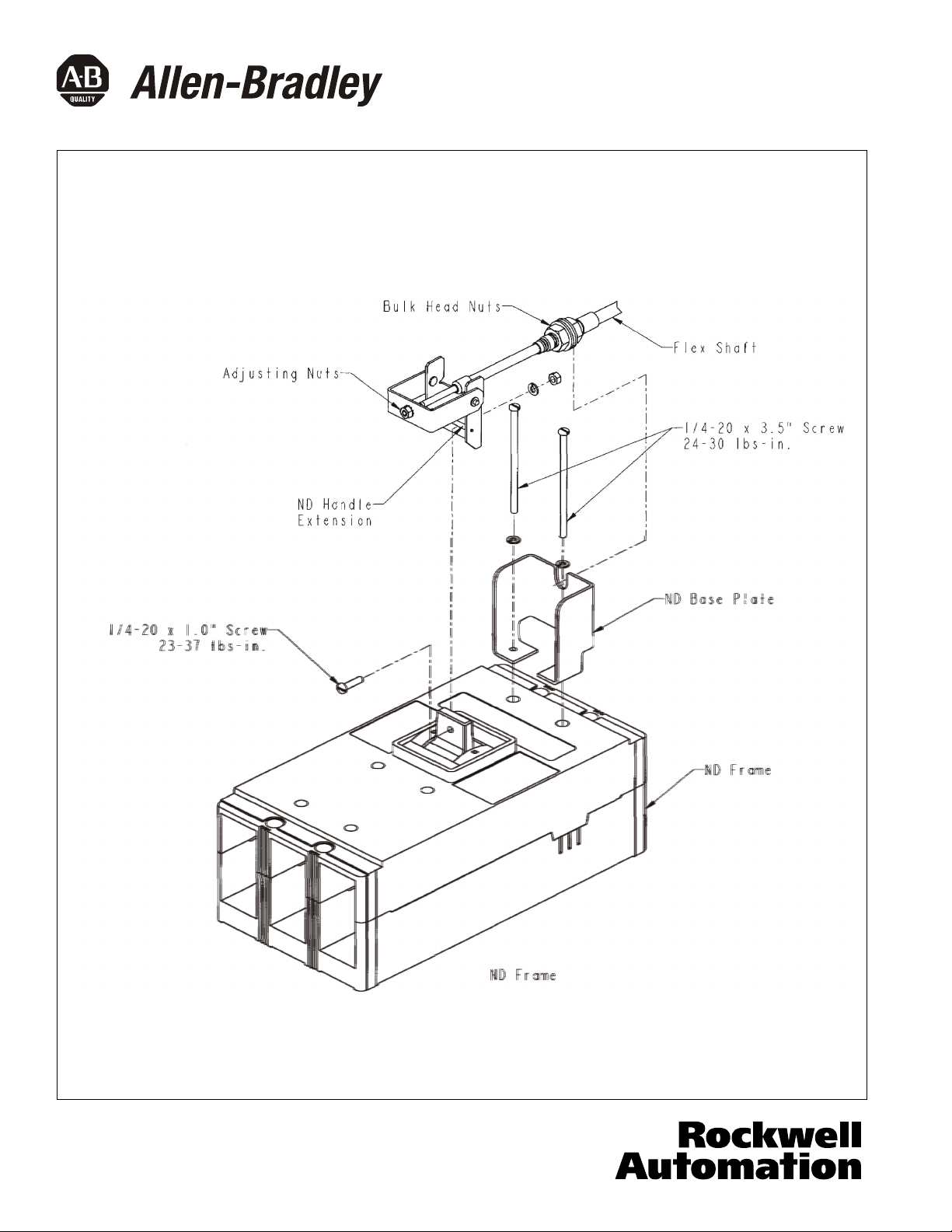

Figure 1-2 Mechanism Assembly

40752-090(1) Effective 5/02

Page 3

INSTALLATION

1.Remove the two 1/4-20 x 3/4" screws and

lockwashers from the outer handle mechanism.

kit. Place each screw and lockwasher though

the pivot bracket assembly Thread the fiber

retaining washers enclosed with the flex parts kit

onto the 1/4-20 x 3/4" screws. See Figure 1-1.

2.Install mechanism handle to enclosure by

placing the outer handle mechanism with gasket

over the enclosure cutout. Insert the mounting

screws from the pivot bracket assembly into

the outer handle mechanism.

3.Attach the adapter link to the handle actuator

Link and secure with 1/4-20 screw, lockwasher

and nut, Provided. See Fig 1-3.

6. Mount breakers Line end to enclosure using the

mounting hardware provided in the hardware kit.

the load end of the breaker per the following:

ND: Attach the load end of the bracket to the enclosure using hardware from the kit. Attach the base plate

to the circuit breaker using the ¼-20 x 3.5" screws and

¼" lockwashers enclosed in the parts kit at the load end

screws located between the trip unit and the two load

end mounting holes.

See fig 1-2 for illustration.

8. Place the outer handle mechanism in the full ON

position and the circuit breaker in the ON position.

Handle to the ON position. Place the handle extension

assembly onto the breaker handle and secure as

Shown on fig 1-2.

9. Locate bulk head nuts of the flexible shaft over the

groove of the base plate and tighten.

Page 3

10. Actuate the outer handle positions (ON,OFF,

RESET). If minor adjustments are necessary,

refer to the following adjustment checklist and

Figure 1-2.

Install door hardware (supplied); refer to

Adjustment Checklist

Situation:

tripped.

Adjustment:

Loosen the ¼-28 adjusting nut that is closest to the black

cap and turn towards the cap approximately 1.5-2 turns.

to the handle extension and inner adjusting nut.

Re-check for the ON, OFF, and RESET position. If not

successful, repeat procedure. If still not successful, and

the bulk head nuts, and shift the cable towards the load

end of the breaker. Re-tighten the bulk head nuts.

successful , repeat the beginning steps.

Situation:

Breaker resets after tripping, but does not turn ON.

referenced on Figure 1-3.

Adjustment:

Loosen the ¼-28 adjusting nut that is located on the end

approximately 1.5-2 turns. Re-tighten the adjusting nut

that is closest to the black cap to the handle extension

and RESET position. If not successful, and the adjusting

loosen the bulk head nuts, and shift the cable towards the

line end of the breaker. Re-tighten the bulk head nuts.

Re-check for the ON, OFF and RESET position. If not

successful, repeat the beginning steps.

If any other adjustment problems should arise, contact

your local Allen-Bradley representative.

4. Attach the E-Ring that attaches the adaptor

link to the toggle mechanism. See Fig 1-1.

5. Drill and tap the mounting holes for the circuit

breaker. See breaker frame instruction leaflet for

the drilling pattern.

NOTICE

Be certain that there is a 5 inch minimum

clearance between the load end of the breaker

and wall of the enclosure for the flex shaft.

reference figure 1-4.

Breaker turns ON and OFF, but will not RESET when

Re-tighten the adjusting nut that is on the end of the shaft

the adjusting nut is bottomed out onto the shaft, loosen

Re-check for the ON, OFF and RESET position. If not

7. Attach the base plate and mounting hardware to

of the breaker after removing the (2) load end cover

You must Release the Door Interlock to move the

of the shaft and turn towards the end of the shaft

and the outer adjusting nut. Re-check for the ON, OFF

nut on the end of the shaft is two threads from the end,

40752-090(1) Effective 5/02

Page 4

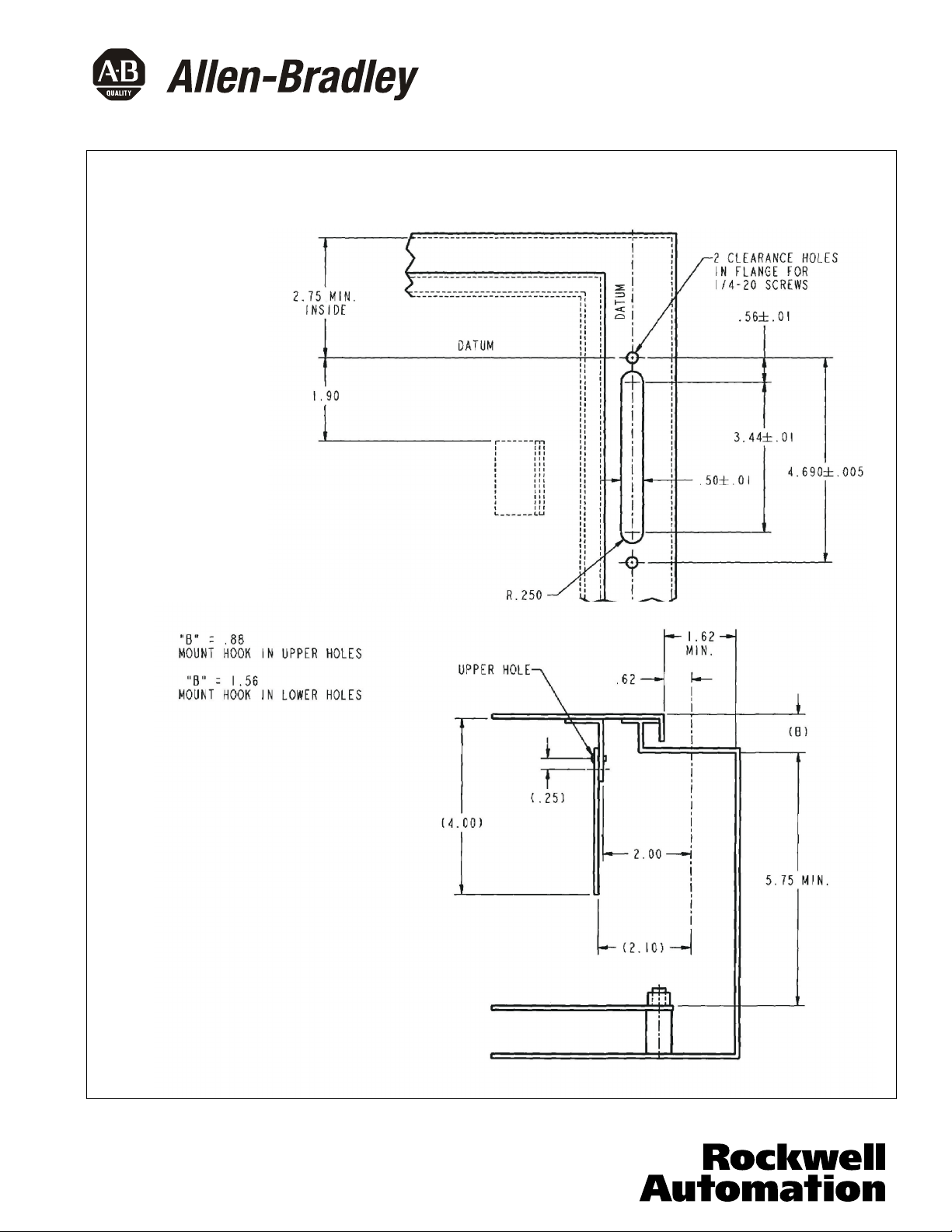

Figure 1-3 Flange Drilling Plan For Handle and Interlock Blade Mounting Dimensions

AMT-Vari-Depth Handle Mechanisms (Dimensions in Inches)

Outline and Drilling Plans

For Enclosure Door Interlock Assembly

Page 4

40752-090(1) Effective 5/02

Printed in U.S.A./TQC

Loading...

Loading...