Page 1

Bul. 140U

K-Frame Circuit Breaker

Instruction Leaflet for Alarm Switch and Alarm /Auxiliary Switch Combination

a

DO NOT ATTEMPT TO INSTALL OR PERFORM MAIN

TENANCE ON EQUIPMENT WHILE IT

DEATH, SEVERE PERSONAL INJURY,

TIAL PROPERTY DAMAGE CAN RESULT FROM CON

TACT WITH ENERGIZED EQUIPMENT. ALWAYS

VERIFY THAT NO VOLTAGE

PROCEEDING WITH THE TASK, AND ALWAYS FOL

LOW GENERALLY ACCEPTED SAFETY PROCE

DURES.

ALLEN-BRADLEY

PLICATION OR MISINSTALLATION

UCTS.

The user is cautioned

warnings, and cautions relating to the safety of personnel

and equipment as well as all general and local health and

safety laws, codes, and procedures.

The recommendations and information contained herein

are based on Allen-Bradley experience and judgement,

but should not be considered to be all

ing every application or circumstance which may arise. If

any questions arise, contact Allen-Bradley for further

information or instructions.

1.

INTRODUCTION

WARNING

IS

ENERGIZED.

OR

SUBSTAN

IS

PRESENT BEFORE

IS

NOT LIABLE FOR THE MISAP

OF

ITS PROD

to

observe all recommendations,

-

inclusive or cover

-

-

-

-

-

-

-

-

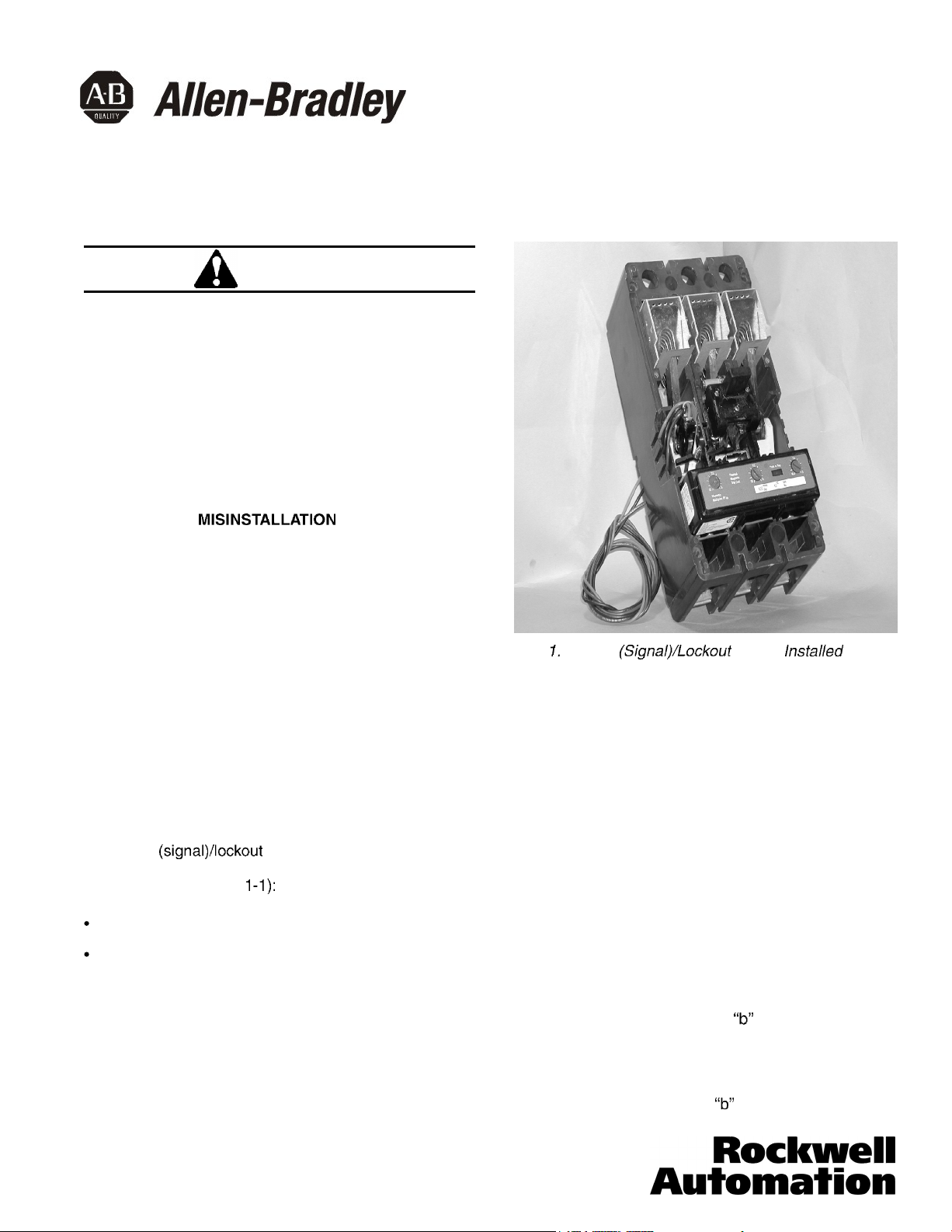

Fig.

I

-

1.

Alarm (Signal)/iockout

K-Frame Circuit Breaker

switch has a make (alarm) and a break (lockout) contact;

it is mounted so that the switch actuator arm is controlled

by the circuit breaker operating mechanism cradle. The

actuator arm extends past the operating mechanism cra

dle; therefore, only one plug-in module containing an

switch or switches can be used in a circuit breaker.

Switch

Installed in

-

ASL

General Information

The alarm (signal)/lockout switch

-

attached to a plug

combinations (see Fig.

One or two ASL switches

One auxiliary switch and one ASL switch

The plug

trip unit and occupies the accessory mounting cavity in

the circuit breaker frame.

The

ing when the circuit breaker trips; it consists of one or two

single

-

in module is mounted in slots in the top of the

ASL

switch provides remote signaling and interlock

-

pole, double-throw (SPDT) switches. Each SPDT

40752-035(1)

in module available in the following

1-1):

Effective 3/02

(ASL

switch) is

ON

or

When the circuit breaker is in the

cradle holds the make contact open and the break con

tact closed. When the circuit breaker is in the tripped

position, the make contact is closed and the break con

tact is open. Any type

matic trip, shunt trip, or undervoltage release) actuates

the

ASL

switch.

The auxiliary switch in the combination accessory indi

cates circuit breaker contacts status and is used for

remote signaling and system interlocking purposes. Each

SPDT switch has one “a” and one

module mounts in the accessory mounting cavity of the

circuit breaker

against the molded crossbar. When the molded crossbar

is in the contacts

SPDT switch is closed and the

so

of

trip operation (for example, auto

that the switch actuator arm rests

-

closed position, the “a” contact of each

“b” contact is open. When

OFF

“b” contact. The plug-in

position, the

-

-

-

-

Page 2

Page 2

the molded crossbar is in the tripped or contacts-open

‘(a”

position, the

closed.

Table 1-l lists electrical rating data for the ASL switch

and auxiliary switch.

Table l-1. Alarm

Auxiliary Switch Electrical Rating

Maximum Freq.

Voltage

P)

600

125

250

0

Endurance - 1000 electrical operations plus

5000 mechanical operations

0

Pigtail wire size -No. 18 AWG (0.82

0

Terminal block is listed for use with one or two

No. 18 to No. 14 AWG solid or stranded

copper wire. Torque is 7 lb-in (0.8 N.m)

@

Non-inductive load

contact is open and the “b” contact is

(Signal)/Lockout

Current

(A)

50/60

Hz

DC

DC

6

0.50

Switch and

Data@@@

Maximum Dielectric

Withstand

Voltage (V)

2500

0.250

mm2)

This Instruction Leaflet (IL) gives detailed procedures for

installing the ASL switch and ASL switch/auxiliary switch

combination (accessory combination.)

2. INSTALLATION

Note: The ASL

tion can be field-installed in K-Frame circuit

breakers.

Before attempting to install the ASL switch or acces-

sory combination, check that the catalog number is

correct and the rating of the accessory(s) satisfies

the job requirements.

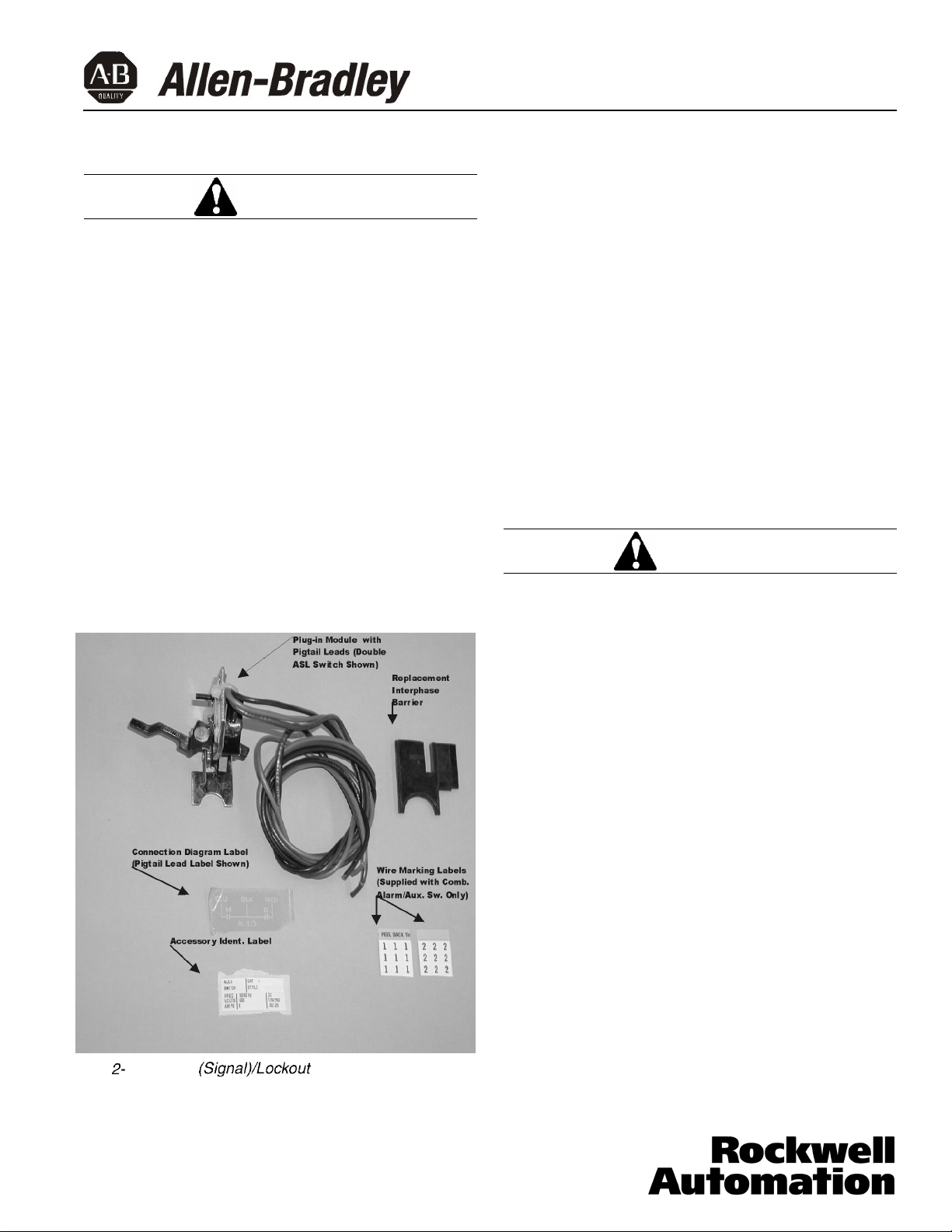

The ASL switch and accessory combination, as shown in

kit form in Fig. 2-1, can be installed in the right or left

accessory mounting cavity of a 2-,3-, or 4-pole circuit

breaker. An ASL switch or accessory combination must

be installed in the circuit breaker before the circuit

breaker is mounted in an electrical system. To install the

ASL switch or accessory combination, perform the following procedures:

Note: A circuit breaker that is mounted in an electrical system must be removed to install the accessory.

To ensure correct accessory installation, the circuit

breaker must be placed on a horizontal surface.

switch(es)

and accessory combina-

Depending on the model ordered, connections for the

ASL switch and auxiliary switch contacts are in one of

four forms. The standard wiring configuration is pigtail

leads exiting the rear of the base directly behind the

accessory. Optional configurations include a terminal

block mounted on the same side of the base as the

accessory, leads exiting the side of the base where the

accessory is mounted, and leads exiting the rear of the

base on the side opposite the accessory, The

long pigtail leads are color coded for identification; identi-

fication labels are provided for pigtail leads and terminal

block points. For allowable locations of all accessories,

refer to Product Selection Guide.

Note: No more than three pigtail leads can be routed

through the rear trough in the circuit breaker base.

When the walking beam interlock is used with the circuit breaker, the rear trough cannot be used for

accessory pigtail leads.

18-inch

40752-035(1) Effective 3/02

Page 3

Page 3

General Installation

a

BEFORE REMOVING A CIRCUIT BREAKER

INSTALLED IN AN ELECTRICAL SYSTEM, MAKE

SURE THE CIRCUIT BREAKER IS SWITCHED TO THE

OFF POSITION AND THERE IS NO VOLTAGE

PRESENT WHERE WORK IS TO BE PERFORMED.

SPECIAL ATTENTION SHOULD BE PAID TO

REVERSE FEED APPLICATIONS TO ENSURE NO

VOLTAGE IS PRESENT. THE VOLTAGES IN ENERGIZED EQUIPMENT CAN CAUSE DEATH OR SEVERE

PERSONAL INJURY.

Note: Steps 2-1 through 2-11 and 2-14 through 2-19

are for general installation and apply to the ASL

switch and the accessory combination. Step 2-12

covers installation of the ASL switch. Step 2-13 covers installation of the accessory combination.

For new circuit breaker installation, the trip unit must

be installed in the circuit breaker before attempting

to install an ASL switch or accessory combination.

WARNING

Note: Molded case switch trip units are not equipped

with a Push-to-Trip button. For molded case

switches, omit step 2-2.

2-2.

2-3.

2-4.

Note: To install accessory, circuit breaker must be in

tripped position.

2-5.

DO NOT RESET CIRCUIT BREAKER AFTER MOLDED

HANDLE IS REMOVED. CRADLE RESET PIN MAY

FLY OUT AND CAUSE INJURY IF MECHANISM IS

TRIPPED.

Press PUSH-TO-TRIP button to trip operating

mechanism.

Disconnect and remove circuit breaker from installation and terminal connections.

Remove cover screws and cover.

For high instantaneous trip-type molded case

switches, locate recessed hole in either

of the trip unit outer poles. (Fig 2-2). Push a

fine point implement in one hole to trip the molded

case switch.

a

WARNING

2-

1.

A/arm

(Signal)/Lockout

2-l. Switch circuit breaker to OFF position.

Switch Kit

2-7.

Remove handle-retaining screws and molded han-

dle from handle arm. (See Fig. 2-3.)

2-8.

Remove interphase barrier between center pole

and pole in which accessory is to be mounted.

(See Fig. 2-3.)

Install replacement interphase barrier supplied with

2-9.

kit in base. (See Fig. 2-3.)

Note: Before the next step, be sure that replacement

interphase barrier has been installed in correct

accessory cavity side, and that cradle reset pin has

not fallen out of retaining-slot in handle arm.

2-10. Put molded handle on handle arm, and install

retaining screws.

Note: For all combinations of accessories, leads

from inner accessory switch must go to the wiring

trough nearest line end of circuit breaker. For a double combination, leads from the outer accessory

switch must go to center trough.

40752-035(1) Effective 3/02

Page 4

Page 4

Fig. 2-2.

Recessed

Hole

Location in K-Frame Trip Unit

Note: For an accessory having rear or opposite-side

exiting pigtail leads, thread leads through trough in

side of base before attempting to insert mounting

bracket. Pigtail leads exiting in this manner should

be eased through trough as mounting bracket is

inserted into trip unit retaining slots.

Fig. 2-4. Accessory Wiring Options

2-11. Route wiring to meet installation requirements.

Rear Exiting Leads

Preferred

Side Exiting Leads

(See Fig. 2-4.)

Terminal Block

Opposite-Side

Exiting Leads

ASL

Switch

Module

Position Actuator Ar

Under Cradle

m

Fig. 2-3. Interphase Barrier Replacement

40752-035(1) Effective 3/02

Fig. 2-5. Alarm

(Signal)/Lockout

Actuator Arm

Switch Installation

Page 5

Page 5

a

PIGTAIL WIRES SHOULD BE FORMED AND ROUTED

TO CLEAR ALL MOVING PARTS WHEN ACCESSORY

IS PROPERLY INSTALLED. PIGTAIL LEADS COULD

BE DAMAGED IF IN CONTACT WITH MOVING

PARTS.

Alarm (Signal)/Lockout Switch Installation

2-12. Insert ASL switch as described in the following

steps:

a.

Put tip of actuator arm through slot in replacement interphase barrier and under cradle. (See

Fig. 2-5.)

b.

Turn ASL switch mounting bracket to line up

with slots in trip unit.

c.

Slide ASL switch mounting bracket into slots

until retaining clip snaps into trip unit. Make

sure ASL switch actuator arm is positioned as

shown in Fig. 2-6. For terminal block assemblies, slide terminal block into mounting slot on

side of base as plug-in module is being positioned.

d.

If required, complete routing of leads to oppo-

site-side through rear wiring trough.

CAUTION

Crrcult

Breaker -- ---Handle

Fig. 2-6.

ASL Switch

Mounting

Bracket

Arm (Must Be

Positioned Under,

And Operated

By the Cradle)

[Interphase Barrier Omitted for Clarity)

Alarm

(Signal)/Lockout

Location

Switch Actuator Arm

Accessory

Combination Module

-

Position ASL Switch

Actuator Arm Under

Cradle

r

Trip

Unit

to

ASL Switch

ASL Switch

e.

For double ASL switch with pigtail leads, attach

wire marking labels to bundle of three leads for

each switch. (Markers designated 1 and 2 are

provided.)

Accessory Combination Installation

2-l 3. Install accessory combination switch as described

in the following steps:

a.

Put tip of ASL switch actuator arm through slot

in replacement interphase barrier and under

cradle (Fig. 2-7). Make sure ASL switch operat-

ing arm is positioned as shown in Fig. 2-6.

b.

Turn accessory combination mounting bracket

to line up with slots in trip unit.

40752-035(1) Effective 3/02

I

Arm

Show D&ail)

six

Cradle

1

Fig. 2- 7. Accessory Combination Ins talla tion

Slot In Replacement

L

Interphase Barrier

Page 6

c.

Slide accessory combination mounting bracket

into slots until retaining clip snaps into trip unit.

Be sure that auxiliary switch operating arm is

between accessory operating projection on the

molded crossbar and arc extinguisher

(Fig. 2-8). For terminal block assemblies, slide

terminal block into mounting slot on side of

base as accessory combination is being posi-

tioned.

Trip Unit

r

Auxiliary Switch

Mounting Bracket

Page 6

General Installation

a

WHEN INSTALLING CIRCUIT BREAKER COVER,

MAKE SURE THAT ALL INTERNAL PARTS ARE IN

PLACE:

. SLIDING HANDLE BARRIERS ARE INSTALLED

SO THAT THE HANDLE OPENING IS ALIGNED

WITH THE HANDLE.

l PIGTAIL LEADS ARE CLEAR OF COVER.

CAUTION

Ctip

Auxiliary Switch

Operating Arm

Fig. 2-8.

d.

e.

-

Breaker

Handle

Accessory Operating g

Projection

Auxiliary Switch Operating Arm Location

If required, complete routing of leads to opposite-side through rear wiring trough.

For

ASUauxiliary

tion with pigtail leads, attach wire marking

labels to bundle of three leads for each switch.

(Markers designated A and B are provided.)

switch accessory combina-

WHEN REMOVED AND REINSTALLED,

FORMING SCREWS TRY TO REFORM THE THREADS

IN THE CIRCUIT BREAKER BASE. CARE SHOULD

BE TAKEN EVERY TIME A THREAD-FORMING

SCREW IS USED TO ENSURE THAT THE SCREW

STARTS IN THE ORIGINAL THREADS. DAMAGED

THREADS CAN RESULT IN IMPROPER CIRCUIT

BREAKER COVER RETENTION.

2-14. With circuit breaker handle in TRIPPED position

and accessory pigtail leads (if used) routed as

required, install circuit breaker cover. Secure with

pan-head screws followed by thread-forming

screws, as shown in Fig. 2-10.

2-15. Place accessory labels (supplied with kit) on circuit

breaker. (See Fig. 2-11.)

Note: Accessory labels show connection diagram for

ASL switch and/or auxiliary switch contacts. Pigtail

leads are color coded red, black, and blue.

that wire marking label is attached correctly to leads

and agrees with related leads at accessory.

2-16. Test ASL switch by connecting continuity tester or

ohmmeter across pigtail leads or terminal block

connections. Check continuity as follows:

THREAD-

Be

sure

40752-035(1) Effective 3/02

a.

Circuit breaker handle OFF - Check that

make contact(s) are open and break contact(s)

are closed.

Page 7

Pigtail Leads

ASL Switch

Blue

1

Make

(Alarm)

T

Page 7

Auxiliary Switch

Red

a

Fig. 2-

IO.

Cover Screw

lnstalla

tion Positions

Modification

r

Label

Leads Are Bundled and

Tagged “B”

Terminal Block

Blue

--CBreak +(Lockout)

Red

ASL Switch

Fig. 2- 12. Alarm

Switch Connection Diagram

b.

Circuit breaker handle ON - Check that make

contact(s) are open and break contact(s) are

closed.

C.

Press PUSH-TO-TRIP button - Check that

make contact(s) are closed and break contact(s) are open.

Lo

-

(Signat)lLockout

Leads Are Bundled and

Tagged “A”

Red

-

-b

+t

b

Blue

Auxiliary Switch

-

Switch - Auxiliary

Terminal Black

I

Terminal Block

Connection

Diaaram

(When Used)

Label

Pigtail Lead

Connection

Diagram

Label

(When Used)

Fig. 2- I I. Preferred Mounting Locations for Accessory

Nameplate Labels

40752-035(1) Effective 3/02

d.

If ASL switch fails test, make sure that module

is properly seated in trip unit slots. If problem

persists. contact Allen-Bradley.

2-17. Test auxiliary switch (when supplied). Connect con-

tinuity tester or ohmmeter across pigtail leads or

terminal block connections. Check continuity as fol-

lows:

a.

Circuit breaker handle OFF

-

“a” contact - open

“b” contact

b.

Circuit breaker handle ON

-

closed.

-

“a” contact - closed

“b” contact

-

open.

Page 8

c. Press PUSH-TO-TRIP button

-

‘la’’ contact - open

“b” contact - closed.

d. If auxiliary switch fails test, make sure that

module is properly seated in trip unit slots. If

problem persists, contact Allen-Bradley.

-

1 8. Install circuit breaker

2

-

19. Connect accessory leads

2

-

(See Fig. 2

Allen-Bradley assumes

12.)

no

as

required.

responsibility for malfunc

tioning accessories installed by the customer.

Page 8

-

40752-035(1)

Effective 3/02

Loading...

Loading...