Page 1

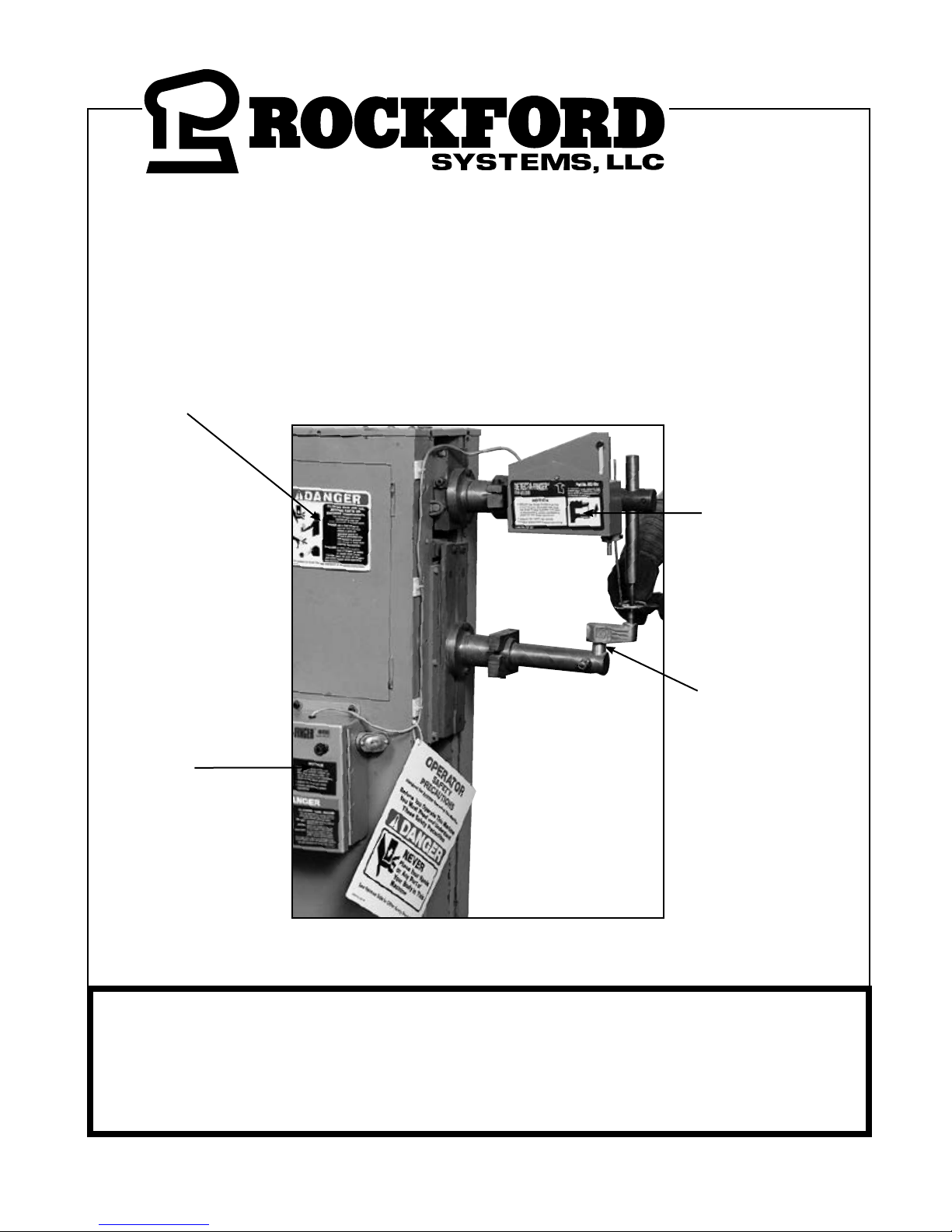

INSTALLATION MANUAL FOR

DETECT-A-FINGER

®

DROP PROBE DEVICE

FOR RESISTANCE-TYPE SPOT WELDERS

Danger Sign

Sensing Probe

Assembly

Sensing Probe

Control Box

IMPORTANT: PLEASE REVIEW THIS ENTIRE

PUBLICATION BEFORE INSTALLING,

OPERATING OR MAINTAINING THIS DEVICE.

5795 Logistics Parkway • Rockford Systems, LLC, Illinois 61109-2695 • Toll-Free 1-800-922-7533 • Phone 815-874-7891

Fax 815-874-6144 • Web Site www.rockfordsystems.com • E-Mail sales@rockfordsystems.com

Instruction Manual No. KSL-022

Page 2

SECTION 1—IN GENERAL

Detect-A-Finger® Drop Probe Device-Welder

SECTION 1 - IN GENERAL .............................................. 2 - 8

SECTION 2 - INSTALLATION OF COMPONENTS ........ 9 - 16

Control Box ........................................................................ 9

Sensing Probe ............................................................ 10-11

Other Components That May Be Required ................ 12-15

Installation Considerations ............................................... 16

SECTION 3 - OPERATING PROCEDURES &

TROUBLESHOOTING ......................................................... 17-18

SECTION 4 - REPLACEMENT PARTS ............................... 19

SECTION 5 - ORDER FORM & RMA FORM ...................... 20

Safety Precautions

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

This safety alert symbol identies important safety messages in

this manual. When you see this symbol, be alert to the possibility of

personal injury, and carefully read the message that follows.

CAUTION

Efcient and safe machine operation depends on the development, implementation and enforcement of a safety

program. This program requires, among other things, the proper selection of point-of-operation guards and safety

devices for each particular job or operation, a thorough safety training program for all machine personnel, that includes

instruction on the proper operation of the machine, the point-of-operation guards and safety devices on the machine,

and a regularly scheduled inspection and maintenance program.

Rules and procedures covering each aspect of your safety program should be developed and published both in an

operator’s safety manual, as well as in prominent places throughout the plant and on each machine. Some rules or

instructions which must be conveyed to your personnel and incorporated into your program include:

CAUTION used without the safety alert symbol indicates a potentially

hazardous situation which, if not avoided, may result in property damage.

Never place your hands or any part of your body in this machine.

Never operate this machine without proper eye, face and body protection.

Never operate this machine unless you are fully trained, instructed, and have read the

instruction manual.

Never operate this machine if it is not working properly – stop operating and advise

your supervisor immediately.

Never use a foot switch to operate this machine unless a point-of-operation guard or

device is provided and properly maintained.

Never operate this machine unless two-hand trip, two-hand control or presence sensing

device is installed at the proper safety distance. Consult your supervisor should you

have any questions regarding the proper safety distance.

Never tamper with, rewire or bypass any control or component on this machine.

A company’s safety program must involve everyone in the company, from top management to operators, since only as a group can

any operational problems be identied and resolved. It is everyone’s responsibility to implement and communicate the information

and material contained in catalogs and instruction manuals to all persons involved in machine operation. If a language barrier or

insufcient education would prevent a person from reading and understanding various literature available, it should be translated,

read or interpreted to the person, with assurance that it is understood.

FOR MAINTENANCE AND INSPECTION ALWAYS REFER TO THE OEM’s (ORIGINAL

MACHINE MANUFACTURER’S) MAINTENANCE MANUAL OR OWNER’S MANUAL. If you do

not have an owner’s manual, please contact the original equipment manufacturer.

© 2018 Rockford Systems, LLC. All rights reserved. Not to be reproduced in whole or in part without written permission. Litho in U.S.A.

2 Call 1-800-922-7533

Rockford Systems, LLC

Page 3

SECTION 1—IN GENERAL

Detect-A-Finger® Drop Probe Device-Welder

Safety References

OSH ACT AND FEDERAL REGULATIONS

Since the enclosed equipment can never overcome

a mechanical deciency, defect or malfunction in the

machine itself, OSHA (Occupational Safety and Health

Administration) has established certain safety regulations

that the employers (users) must comply with so that the

machines used in their plants, factories or facilities are

thoroughly inspected and are in rst-class operating

condition before any of the enclosed equipment is

installed.

1. U.S. Government—An Act—Public Law 91-596, 91st

Congress, S. 2193, December 29, 1970:

Duties

SEC. 5. (a) Each employer—

(1) SHALL FURNISH TO EACH OF HIS

EMPLOYEES EMPLOYzMENT AND A PLACE

OF EMPLOYMENT WHICH ARE FREE FROM

RECOGNIZED HAZARDS THAT ARE CAUSING

OR ARE LIKELY TO CAUSE DEATH OR SERIOUS

PHYSICAL HARM TO HIS EMPLOYEES;

(2) shall comply with occupational safety and

health standards promulgated under this Act.

(b) Each employee shall comply with occupational

safety and health standards and all rules, regulations,

and orders issued pursuant to this Act which are

applicable to his own actions and conduct.

2. OSHA 29 CFR Sections that an employer (user)

must comply with include:

1910.211 Denitions.

1910.212 General requirements for all machines.

1910.217 Mechanical power presses.

1910.219 Mechanical power-transmission apparatus.

3. OSHA 29 CFR 1910.147 The control of hazardous

energy (lockout/tagout).

4. OSHA Publication

“General Industry Safety and Health Regulations Part

1910,” Code of Federal Regulations, Subpart O

This publication can be obtained by contacting:

U.S. GOVERNMENT PRINTING OFFICE

P.O. BOX 979050

St. Louis, MO 63197-9000

(202) 512-1800

ANSI SAFETY STANDARDS FOR MACHINES

The most complete safety standards for machine tools

are published in the ANSI (American National Standards

Institute) B11 series. The following is a list of each ANSI

B11 Standard available at the printing of this publication.

B11–2008 General Safety Requirements

B11.1 Mechanical Power Presses

B11.2 Hydraulic Power Presses

B11.3 Power Press Brakes

B11.4 Shears

B11.5 Iron Workers

B11.6 Lathes

B11.7 Cold Headers and Cold Formers

B11.8 Drilling, Milling, and Boring Machines

B11.9 Grinding Machines

B11.10 Metal Sawing Machines

B11.11 Gear and Spline Cutting Machines

B11.12 Roll Forming and Roll Bending Machines

B11.13 Automatic Screw/Bar and Chucking Machines

B11.14 Withdrawn (Now see ANSI B11.18)

B11.15 Pipe, Tube and Shape Bending Machines

B11.16 Metal Powder Compacting Presses

B11.17 Horizontal Hydraulic Extrusion Presses

B11.18 Coil Processing Systems

B11.19 Performance Criteria for Safeguarding

B11.20 Integrated Manufacturing Systems

B11.21 Lasers

B11.22 CNC Turning Machines

B11.23 Machining Centers

B11.24 Transfer Machines

B11.TR1 Ergonomic Guidelines

B11.TR2 Mist Control Considerations

B11.TR3 Risk Assessment

B11.TR4 Programmable Electronic Systems (PES/PLC)

B11.TR5 Sound Level Measurement Guidelines

B11.TR7 Risk Assessment

R15.06 Robotic Safeguarding

B15.1 Mechanical Power Transmission Apparatus

B56.5 Guided Industrial Vehicles and Automated

Function of Manned Industrial Vehicles

B65.1 Printing Press Systems

B65.2 Binding and Finishing Systems

B65.5 Stand-Alone Patten Presses

B151.1 Horizontal (Plastic) Injection Molding Machines

B152.1 Hydraulic Die Casting Presses

B154.1 Rivet Setting Machines

B155.1 Packaging Machinery

01.1 Woodworking Machinery

These standards can be purchased by contacting:

ANSI—American National Standards Institute

25 West 43rd Street

New York, New York 10036

Phone: (212) 642-4900

www.ansi.org

(Continued on next page.)

Rockford Systems, LLC

Call 1-800-922-7533

3

Page 4

SECTION 1—IN GENERAL

Detect-A-Finger® Drop Probe Device-Welder

NATIONAL SAFETY COUNCIL SAFETY MANUALS

Other good references for safety on machine tools are

the National Safety Council’s Safety Manuals. These

manuals are written by various committees including

the Power Press, Forging and Fabricating Executive

Committee. Copies of the following publications are

available from their library:

• Power Press Safety Manual - 5th Edition

• Safeguarding Concepts Illustrated - 7th Edition

• Forging Safety Manual

These manuals can be obtained by contacting:

National Safety Council

1121 Spring Lake Drive

Itasca, IL 60143-3201

1-800-621-7615

www.nsc.org

OTHER SAFETY SOURCES

National Institute of Occupational Safety and

Health (NIOSH)

4676 Columbia Parkway

Cincinnati, OH 45226

Toll-Free: 1-800-35-NIOSH (1-800-356-4674)

Phone: (513) 533-8328

www.cdc.gov/niosh

OTHER SAFETY SOURCES (continued)

Robotic Industries Association (RIA)

900 Victors Way, Suite 140

P.O. Box 3724

Ann Arbor, MI 48106

Phone: (734) 994-6088

www.roboticsonline.com

NEMA (National Electrical Manufacturers

Association)

1300 North 17th Street, Suite 1847

Rosslyn, VA 22209

Phone: (703) 841-3200

www.nema.org

NFPA (National Fire Protection Association)

1 Batterymarch Park

Quincy, MA 02269-9101

Phone: (617) 770-3000

www.nfpa.org

For additional safety information and assistance in

devising, implementing or revising your safety program,

please contact the machine manufacturer, your state and

local safety councils, insurance carriers, national trade

associations and your state’s occupational safety and

health administration.

Warranty, Disclaimer and Limitation of Liability

Rockford Systems, LLC warrants that this product will be free from defects in material and workmanship for a period of 12 months from

the date of shipment thereof. ROCKFORD SYSTEMS LLC’S OBLIGATION UNDER THIS WARRANTY IS EXPRESSLY AND EXCLUSIVELY

LIMITED to repairing or replacing such products which are returned to it within the warranty period with shipping charges prepaid and

which will be disclosed as defective upon examination by Rockford Systems, LLC. This warranty will not apply to any product which will

have been subject to misuse, negligence, accident, restriction and use not in accordance with Rockford Systems, LLC’s instructions or

which will have been altered or repaired by persons other than the authorized agent or employees of Rockford Systems, LLC. Rockford

Systems, LLC’s warranties as to any component part is expressly limited to that of the manufacturer of the component part.

DISCLAIMER

The foregoing Warranty is made in lieu of all other warranties, expressed

or implied, and of all other liabilities and obligations on the part of

Rockford Systems, LLC, including any liability for negligence, strict liability,

or otherwise, and any implied warranty of merchantability or tness for a

particular purpose is expressly disclaimed.

4 Call 1-800-922-7533

WARRANTY

LIMITATION OF LIABILITY

Under no circumstances, including any claim of negligence, strict liability,

or otherwise, shall Rockford Systems, LLC be liable for any incidental or

consequential damages, or any loss or damage resulting from a defect in

the product of Rockford Systems, LLC.

Rockford Systems, LLC

Page 5

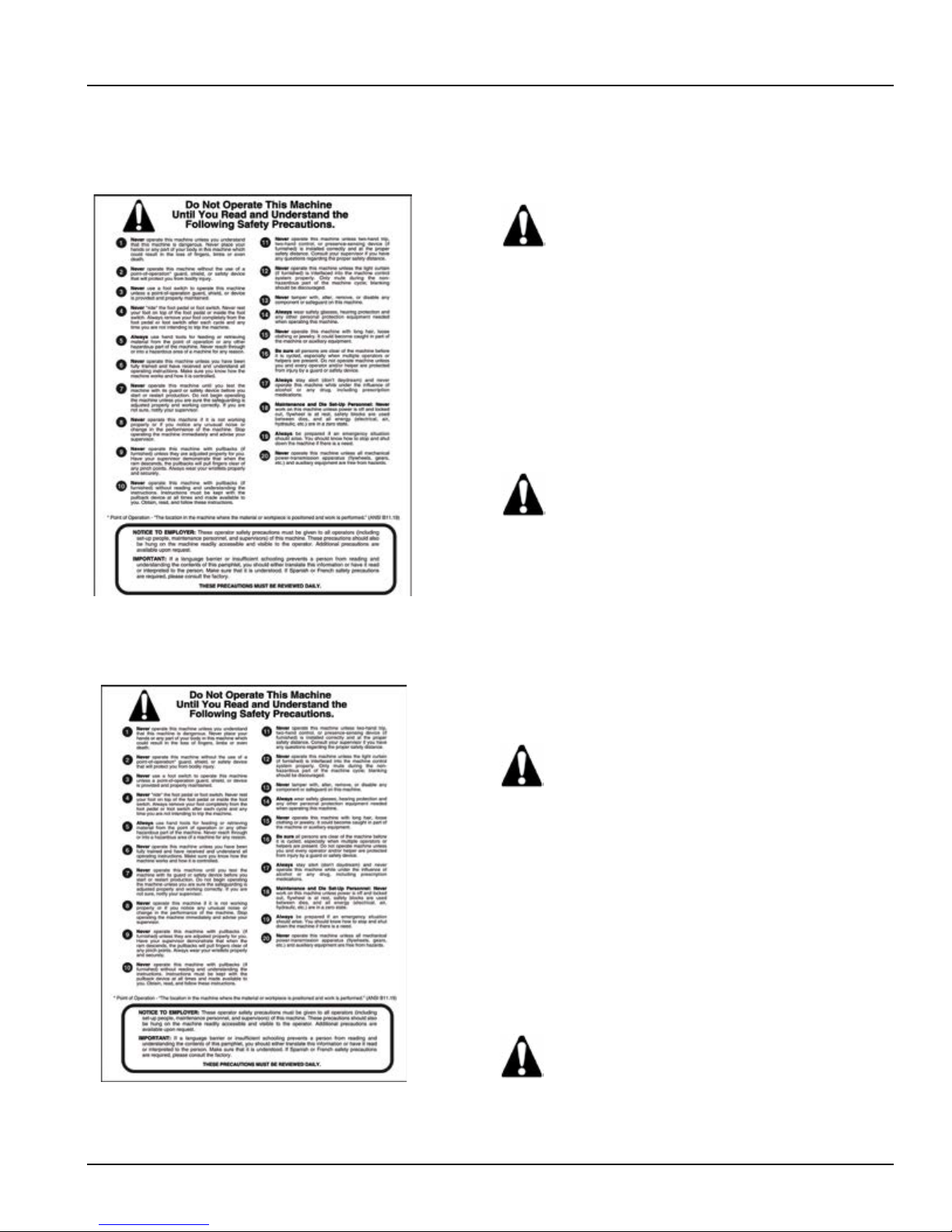

Operator Safety Precautions Sign

Front

SECTION 1—IN GENERAL

Detect-A-Finger® Drop Probe Device-Welder

Accompanying this equipment is an

81⁄2” x 11” operator safety precautions

sign, Part No. KSC-000, for anyone

operating the machine where this

equipment will be installed. These

precautions are to be given to all

operators, including setup people,

maintenance personnel and

supervisors.

This sign should also be attached

to the machine, readily accessible

and visible to the operator. (A hole

in the corner of this precautions

sign is provided for attaching

purposes.) Additional copies of these

precautions are available. Please

call, write, fax, or use the order form

found on a later page in this manual.

Back

Rockford Systems, LLC

Call 1-800-922-7533

When a language barrier or

insufcient education prevents a

person from reading or understanding

the contents of this operator safety

precautions sign, you should either

translate this information or have it

read or interpreted to the person. Make

sure that the person understands the

information. To order this sign in

Spanish, use Part No. KSC-000S; in

French, use Part No. KSC-000F.

These precautions must be reviewed

daily.

5

Page 6

SECTION 1—IN GENERAL

Detect-A-Finger® Drop Probe Device-Welder

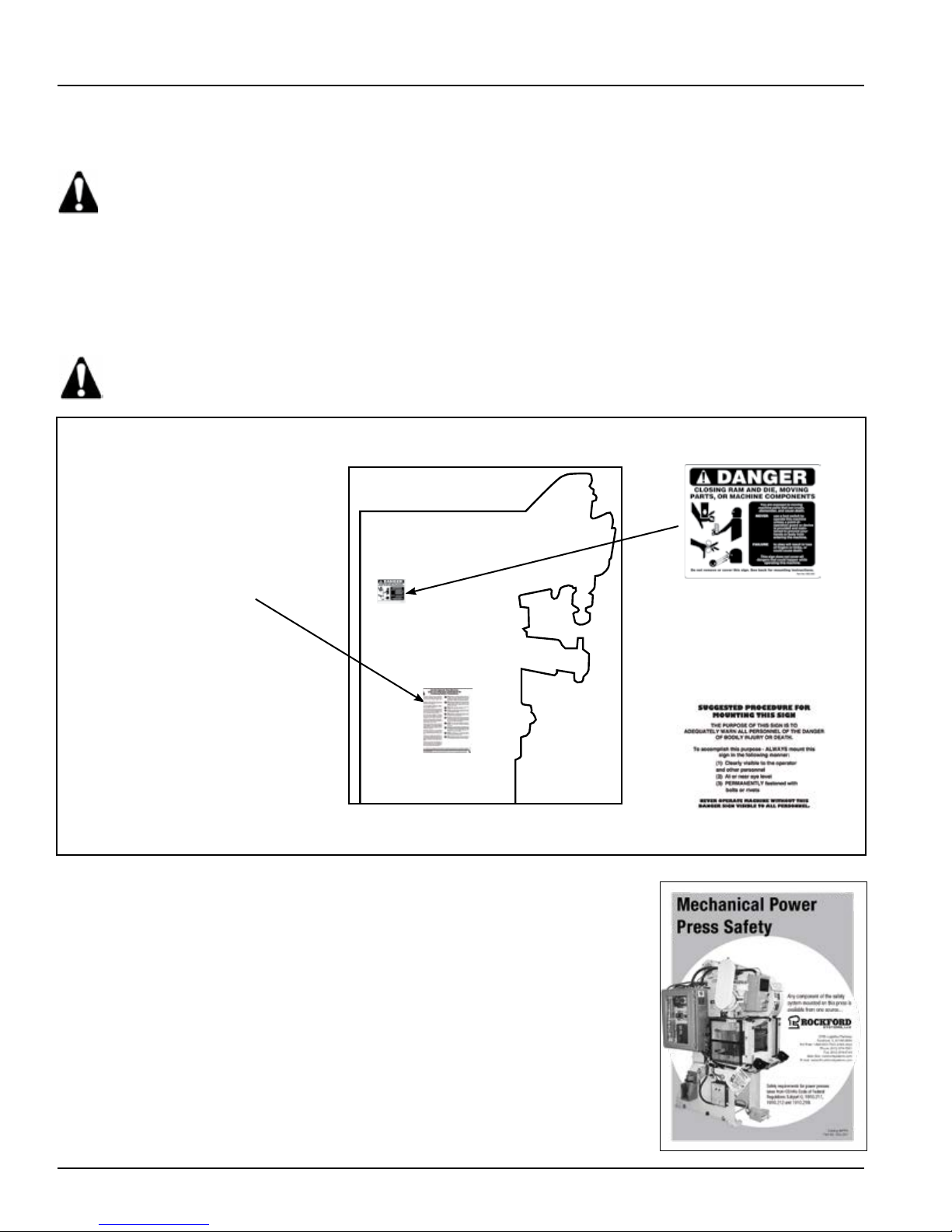

Danger Sign(s) to be Mounted on Machine

Accompanying this equipment is a 5” x 6” polyethylene danger sign, Part No. KSC-055. This sign MUST

BE PERMANENTLY MOUNTED IN A PROMINENT LOCATION on the machine where this equipment is

installed. This sign must be in a LOCATION THAT IS EASILY VISIBLE to the operator, setup person,

or other personnel who work on or around this machine. ALWAYS mount this sign with bolts or rivets

when installing the enclosed equipment.

If any danger sign becomes destroyed or unreadable, the sign must be replaced immediately. Contact factory for

replacement danger sign(s).

Never operate this machine unless the danger sign(s) is in place.

Part No. KSC-000 Operator

Safety Precations Sign

“M

echanical Power Press Safety

A copy of Booklet No. MPPS (Mechanical Power Press Safety) is available

upon request. This booklet is copied verbatim from the CFR (Code of Federal

Regulations) and contains all relevant sections of the OSHA standards concerning

power presses with which an employer (user) must comply. The enclosed

equipment must be installed, used and maintained to meet these standards.

Specically, any time a foot switch is used, a suitable point-of-operation

safeguard or device must be used to prevent bodily injury. In addition, every

press must be provided with a point-of-operation safeguard! Please review

this booklet before installing the enclosed equipment. If you are unfamiliar with

these detailed safety regulations, which include regulations on safeguarding

the point of operation properly, you may want to attend our regularly scheduled

machine safeguarding seminars. To obtain detailed information about these

training seminars, please call, fax, write, or check our Web site. Our telephone,

fax number, Web site, and mailing address are on the front cover of this manual.

” B

ooklet

Front Side

Part No. KSC-055 Danger Sign

(Foot) - Standard

Part No. KSC-055S - Spanish

Part No. KSC-055F - French

Reverse Side

6 Call 1-800-922-7533

Rockford Systems, LLC

Page 7

SECTION 1—IN GENERAL

Detect-A-Finger® Drop Probe Device-Welder

General Overview

The purpose of the Detect-A-Finger® Drop Probe Device is to effectively reduce accidents on applications where the

operator’s ngers may enter the point of operation. The components of this system are a sensing probe shaped to t

over or around the workpiece, a drop-probe assembly, and a control box. When the operator initiates a weld cycle,

the sensing probe is released and drops by gravity over or around the workpiece. If the operator’s ngers are still in

the danger area, the sensing probe cannot reach its preset down position and the welder is prevented from cycling.

Conversely, if no obstruction prevents the sensing probe from dropping, then as soon as it reaches its preset down

position, the control unit will allow the welder to cycle.

The control unit is ruggedly built to assure continued successful operation under adverse operating conditions usually

found around this type of machinery. For additional safety, the control relay in the control unit (when properly wired into

the machine system) will prevent cycling of the machine accidentally or intentionally. This can be conrmed by moving

the sensing probe manually without actuating the operating means.

Components in the System

• Control box

• Drop-probe assembly

• Sensing probe (2)—to be formed by user

• Sensing probe clamp

• Danger signs

Additional components that may be required

• Disconnect switch

• Transformer

• Lockout valve

• Foot switch

For mechanically operated welders:

• Air cylinder assembly

• Solenoid air valve

• Air lter-regulator-guage and lubricator assembly

Specications

®

Detect-a-Finger

CONTROL BOX

Input voltage ......................................................................................................................... 115 + 15% VAC, 50/60Hz

Operating current ................................................................................................................................. 0.6 Amps typical

Weight .......................................................................................................................................................approx. 8.5 lb

SENSING PROBE ASSEMBLY

Input voltage ........................................................................................................................... 24 + 15% VAC, 50/60Hz

(supplied from control box)

Operating current ................................................................................................................................. 3.0 Amps typical

Duty cycle ...................................................................................................25% (10-second max. continuous on-time)

Stroke .................................................................................................................................. 1.63 (15⁄8) inches maximum

Mechanical life ................................................................................................. Rotary solenoid–100 million operations

Weight .......................................................................................................................................................approx. 3.5 lb

Assembly—RKC-500

SENSING PROBE (UNFORMED)

Wire size ............................................................................................................................... .156 dia. x 18 inches long

Material ...................................................................................................................................Aluminum rod (standard)

Total weight ................................................................................................................... approx.0.5 lb (probe and clamp)

Rockford Systems, LLC

Call 1-800-922-7533

7

Page 8

SECTION 2—INSTALLATION OF COMPONENTS

Detect-A-Finger® Drop Probe Device-Welder

Preliminary Steps Before Installation

Before proceeding with the installation of the enclosed equipment, you should undertake the following preliminary

steps.

1. Read and make sure you understand this entire installation manual.

2. Refer to the front cover, other line drawings and photos, then make a sketch of your installation to plan the location

of the enclosed equipment on the machine.

3. Please make sure the machine is in rst-class condition. Before starting any installation, it is essential that

the machine is thoroughly inspected. Be sure all mechanical components and all collateral equipment are in rstclass operating condition. Your inspection should be done according to the machine manufacturer’s installation

and maintenance instruction manual. If you have any doubts or questions concerning the condition of the machine,

contact the machine manufacturer for assistance. Repair or replace all parts not operating properly before

proceeding.

Inspection and maintenance programs must be established and implemented to keep machines in

rst-class condition. Safety programs must include thorough inspections of each machine on a weekly

basis and records kept of these inspections. Any part of the machine that is worn, damaged or is not

operating properly must be replaced immediately or repaired before the machine is used.

4. Verify that the machine is in rst-class condition and operating properly; shut off all power to the machine. Padlock

all electrical and pneumatic energy in the off position and do not actuate the machine again until the installation of

all package components has been completed. Lockout/tagout energy isolation procedures must always be practiced

and enforced.

The operator must be protected from all hazards. All applicable sections of OSHA Section 1910.212

must be complied with on all machines where this equipment is installed.

The Detect-A-Finger® controls are applicable on most types of resistance welders. The function of the

Detect-A-Finger® device, when properly installed, adjusted and maintained, is to keep the operator from

inadvertently cycling the machine with ngers in the point of operation. This control only provides

an interface between the foot switch and the welder controller which will not allow stroke initiation

unless the area being probed is cleared of all obstructions. To accomplish this protection, the DetectA-Finger® must be properly installed on the machine and the device must be properly maintained and

adjusted by the user. A properly designed sensing probe must be used and additional sensing probe

safeguarding must be provided where applicable. This device does not protect the operator if ngers

are placed above the sensing probe.

Before starting any installation work, it is imperative the welder be inspected to exhibit proper operation.

Run the welder in a normal operating sequence to determine proper operation. Do not install the Detect-AFinger® on a welder that does not function properly. When the welder is operating satisfactorily, shut off

the power with the disconnect switch and do not operate the welder again until installation is complete.

Use of a lockout device and padlock on the disconnect handle must be used during this period.

The maintenance and inspection section in this manual cannot be all-inclusive for maintaining welders.

Always refer to the original welder manufacturer’s maintenance manuals or owner’s manual. If you do not

have an owner’s manual, please contact the welder manufacturer.

NOTE: The Detect-A-Finger® does not change the operation of the machine. This interface only interrupts the

foot switch signal. If this welder is capable of continuous operation while the foot switch is held, then

an interface will be required to have the sensing probe drop before each cycle of the welder.

8 Call 1-800-922-7533

Rockford Systems, LLC

Page 9

SECTION 2—INSTALLATION OF COMPONENTS

Detect-A-Finger® Drop Probe Device-Welder

Control Box

The RKC-500 series Detect-A-Finger® system control box is housed in a NEMA enclosure (approximately 61⁄4” wide

by 91⁄2” high by 41⁄2” deep) and consists of a through-the-door fuse holder, relay, terminal strips, transformer, and PC

board assembly. Mount the control box in a convenient location—the area around the control box should be kept clear

and be easily accessible for wiring and maintenance.

All electrical power to the machine must be off before mounting, wiring, or servicing the control box.

Fuse and Fuse

Holder

Terminal Strips

Relay

Transformer

PC Board Assembly

Rockford Systems, LLC

Call 1-800-922-7533

9

Page 10

SECTION 2—INSTALLATION OF COMPONENTS

Detect-A-Finger® Drop Probe Device-Welder

Sensing Probe Assembly

The drop rod is allowed to drop by gravity when the rotary solenoid is energized. The action arm return spring returns

this assembly when the power is removed. The DC voltage for the rotary solenoid is obtained from a full-wave bridge

rectier. The drop rod is guided in nylon bearings for long life and smooth operation. The limit switch actuates the

control relay in the control box at the end of the drop rod stroke.

Mount the sensing probe assembly as far forward as possible to allow for adjustments and electrode maintenance,

and to provide for minimum angle of the sensing probe. This position will also contribute to a long mechanical life of

the device since it minimizes the side loading on the drop rod bearings.

Rotary

Solenoid

Return

Spring

Drop

Rod

Drop

Rod

Arm

Limit

Switch

Bridge

Rectier

10 Call 1-800-922-7533

Rockford Systems, LLC

Page 11

SECTION 2—INSTALLATION OF COMPONENTS

Detect-A-Finger® Drop Probe Device-Welder

Sensing Probe

Two 18-inch pieces of 5⁄32 (.156) inch diameter aluminum rods are furnished with each Detect-A-Finger®. Other

materials or custom made congurations may also be used. The only restriction is the total weight of the probe

assembly (including the clamp). The action-arm return spring is capable of returning 0.5 pounds maximum. The user

must determine and form the best shape to accommodate the particular part being run. This device must be designed,

constructed and arranged to create a protected area, and to prevent engagement of the machine. In pneumatic and

hydraulic-powered machines, this device must prevent energizing of the control valve when an operator’s nger or other

part of the body is within the hazardous area.

The bottom of the drop rod, in its full down position, should barely clear the workpiece. This location allows for nal

positioning. If special mounting brackets are fabricated, they must be able to support the sensing probe assembly and

withstand any shock and vibration that may be encountered during machine operation. Be sure to insulate any and all

special brackets from the electrodes.

Examples of how the drop-probe rods can be fabricated

TYPICAL APPLICATIONS

PRESS-TYPE RESISTANCE WELDER ROCKER-ARM-TYPE RESISTANCE WELDER

Detect-A-Finger® Sensing-

Probe Assembly

Detect-A-Finger®

Control Box

Foot Switch

To Welder

Controller

To

Power

115 V AC

Detect-A-Finger®

Sensing Probe

Assembly

Sensing Probe

Detect-A-Finger®

Control Box

Foot Switch

Transformer

(if required)

To Welder

Controller

Main

Power

Disconnect

Switch

Sensing

Probe

Rockford Systems, LLC

Call 1-800-922-7533

11

Page 12

SECTION 2—INSTALLATION OF COMPONENTS

Detect-A-Finger® Drop Probe Device-Welder

Other Components That May Be Required

Main Power Disconnect Switch

A main power disconnect switch may have been supplied in the package shipment. This switch is designed to

disconnect the primary voltage to the machine and lock it out. Refer to the enclosed wiring schematics for proper wiring

of this switch.

OSHA regulation 1910.217 (b)(8), ANSI standards B11.1 and B11.3 require that:

A main power disconnect switch capable of being locked in the off position shall be provided with every control system.

If the machine already has a main power disconnect switch, it must be checked for the locking off and lockout feature.

Some switches use construction which can be easily altered mechanically to comply with this requirement. If this is

not possible, or an electrical disconnect switch is not provided, then you must obtain and install a proper disconnect

switch. Please contact Rockford Systems, LLC if a disconnect switch is needed.

Transformer—Part No. RSF-021

An enclosed transformer—Part No. RSF-021—may have been supplied with this shipment. This enclosed transformer

is a 100-VA, 230/460-V primary and a 115-V fused secondary unit. The fuse is 1 A, 230 V and it is accessible from the

outside of the transformer housing.

Air lockout valve

(If furnished—See enclosed manual KSL-098)

An air lockout valve is usually attached to the inlet end of a lter-regulator-lubricator assembly.

This three-way valve is operated with the manual movement of a slide that opens and closes the

valve. The valve can only be locked out when the slide is in the closed position. Downstream air

is automatically exhausted when the valve is locked out.

Air Lockout Valve

Foot Switch (If furnished—See enclosed manual KSL-001)

To meet OSHA and ANSI safety requirements, a foot switch must be protected

from unintentional operation. This foot switch pedal is protected on the top and

both sides by the cast cover and the front is protected by the hinged ap. Always

follow the wiring schematics for proper wiring connection and be sure to maintain

the foot switch in rst-class condition.

It is the responsibility of the employer (user) to always provide an

appropriate guard and/or device to prevent bodily injury whenever a

foot switch is used to initiate a machine cycle.

The guard and/or device must be properly installed, used, and

Foot Switch

Part No. CTD-011

maintained. The safeguard must prevent personnel from receiving

bodily injuries.

12 Call 1-800-922-7533

Rockford Systems, LLC

Page 13

SECTION 2—INSTALLATION OF COMPONENTS

Detect-A-Finger® Drop Probe Device-Welder

Other Components That May Be Required For Mechanically

Operated Welders

Most welders are controlled electrically, pneumatically or mechanically; if not, other components may be required.

Review this section for typical applications of the Detect-A-Finger®. Accessory equipment and components, such as

solenoid air valves or air cylinders are available from Rockford Systems for your convenience. If you require assistance

on the application of such components, please contact the factory.

Mechanical to Electro-Pneumatic Conversion—Convert from mechanical operation by removing the treadle and

replacing it with an air cylinder. The cylinder bore and stroke (push or pull type) can be determined from actual

machine measurements and the location of attachment to the welder linkage. The air cylinder is controlled by a 3-way

normally closed 120 VAC solenoid air valve. Adjustable ow control valves may be employed to smooth the welder

arm movement and a lter-regulator-lubricator and pressure gauge assembly is also required. The Detect-A-Finger®

controls the solenoid air valve.

RCL Series Air Cylinders (If furnished—See enclosed manual KSL-096)

One of the following pull-type air cylinders may be adequate to operate the welder:

Single-acting spring-return air cylinders are usually supplied with a swivel-clevis mount as standard. Other special

cylinders, such as clevis mount, ange mount (either end) or foot mount are also available. They can be push-type

(spring inside cylinder), or pull-type (spring on cylinder rod, as illustrated above). The main consideration must be that

the cylinder is a single-acting spring-return type (not double acting) to meet best safety practices. When mounting

the cylinder, be sure it is secured in such a manner that it will not vibrate loose, bind or rub on some other part of the

machine.

RCL-001 RCL-002 RCL-003

Machine Size

(Tons)

Size

(Bore x Stroke)

Pull Force

(@ 75 PSI)

NPT Port

Size

¼ to 7

¼” ¼” ¼”

8 to 35

1

/8” x 1”

1½

” x 1”

1

50 lb 100 lb 200 lb

2

36 to 70

” x 2”

Pull-Type Air Cylinder

zThe assembly consists of the cylinder, two mounting feet, mounting pin, drive yoke, drive pin, and yoke lock nut. This

assembly is illustrated at the bottom of page 14. Locate this assembly on the machine so that the feet can be mounted

to a convenient surface. The yoke should be attached to the welder linkage, and the air inlet should be oriented toward

the air solenoid valve location.

The air cylinder should be mounted in the most logical position to operate the welder linkage most efciently. The

main requirement in locating the cylinder assembly, is that the piston rod will have a straight, in-line pull (or

push) when attached to the operating linkage. When applying an air cylinder to the machine, make sure that

the cylinder rod, yoke or any moving parts will not bind after installation. Adjust so that the air cylinder bottoms

at the end of each stroke. The air cylinder will operate in any position. The operating linkage may be connected to

the air cylinder by any convenient means. Be sure the rod stroke is not too long because it could cause jackkning of

the cylinder. If this is a concern shorter stroke cylinders are available. Too much air pressure may damage the operating

linkage. Please consider these points when installing any air cylinder.

Make certain that the drive yoke and lock nut are located approximately halfway down on the threaded portion of the

piston rod in order to provide for either up or down adjustment when necessary. Attach one end of the exible rubber

hose in the threaded cylinder inlet port and tighten rmly.

Note: Threaded air joints do not generally require sealant; however, “Teon” tape may be used to prevent leakage.

Rockford Systems, LLC

Call 1-800-922-7533

13

Page 14

SECTION 2—INSTALLATION OF COMPONENTS

Detect-A-Finger® Drop Probe Device-Welder

Other Components That May Be Required For Mechanically

Operated Welders (continued)

Solenoid AiR Valve Assembly (If furnished—See enclosed manual KSL-151)

The solenoid air valve is a three-way, normally closed, quick exhaust type. This

assembly consists of the electric air solenoid valve, steel mounting bracket, and

exible hose. Assemble the mounting bracket to the base of the valve and orient

this assembly so that the air outlet port (marked “1” on the valve body) points

toward the air cylinder and is within reach of the exible hose. Next attach this

hose to the No. 1 port of the solenoid valve and mount the valve assembly on the

machine allowing sufcient exibility to accommodate cylinder movement. (See

Solenoid Air

Valve Assembly

Part No. RCD-006

Mount the solenoid valve assembly in a vertical position. The electrical conduit tting can be easily adjusted to face in

any horizontal direction by loosening the hex nut at the top and turning the enclosure. Retighten this nut after locating

the tting. Saddle-clamp type terminals are provided on the solenoid for wiring.

diagram below.) It is extremely important to use the rubber hose provided for

the connection between the solenoid valve and the air cylinder. It provides

the necessary exibility, size and length for proper exhaust of cylinder air,

all of which are required for successful machine operation.

Exhaust air mufer must be kept clean at all times. Never operate machine unless mufer is clean.

Yoke Pin

Drive Yoke

Yoke Nut

Cylinder Return

Spring

Provide loose

ring guide in

either of these

areas if

necessary to

limit cylinder

side-to-side

motion

Air

Cylinder

Cylinder

Inlet Port

Flexible Hose

Air Cylinder and Solenoid

Air Valve Connection

Solenoid

Air Valve

2

1

Electric

Conduit

Fitting

Air Inlet Port

Mounting

Feet

14 Call 1-800-922-7533

Air Outlet

Port

Solenoid Mounting

Bracket

Rockford Systems, LLC

Page 15

SECTION 2—INSTALLATION OF COMPONENTS

Detect-A-Finger® Drop Probe Device-Welder

Other Components That May Be Required For Mechanically

Operated Welders (continued)

Filter-regulator-lubricator (frl) assembly (If furnished—See enclosed

manual KSL-208)

The lter cleans air that goes to the solenoid air valve (and air cylinder, if furnished). The regulator and gauge are used

to adjust air pressure. The lubricator keeps the solenoid air valve or the air cylinder (if required) properly lubricated.

The lter-regulator unit with one threaded pipe plug, lubricator, gauge, mounting bracket, and a connector or nipple

are shipped together.

Filter-Regulator

Combination

Filter-Regulator-

Lubricator Assembly

Part No. RCL-043

The air lter must be kept clean at all times. Never operate the machine unless the air lter is clean.

The lubricator must not be lled while under pressure.

Lubricator

Unpack the lter-regulator unit and install the connector between the lter-regulatorlubricator (see arrow for air ow direction). Tighten this assembly and position the two

units with both bowls in alignment. Be sure to check air ow direction and the location

of the valve to avoid excessive piping.

Choose an appropriate location on the machine for mounting this assembly. If possible,

it should be accessible from oor level.

Install the pressure gauge in the threaded port opposite the mounting surface and plug

the unused port. Attach the mounting bracket to the machine and then mount the FRL

assembly using the lock nut supplied.

The length of the air line run is not critical; however, the port and pipe sizes should be

maintained.

Fill the lubricator with a good quality lubricant (see OEM’s specications) to the level

indicated by the maximum ll line on the transparent reservoir. Do not overll. When

the machine is cycled, the lubricator drip rate may be adjusted according to the

instruction manual. Please check the machine owner’s manual for proper specications

for oil, if required. Some clutch and brake assemblies do not require lubrication.

Regulate the air pressure high enough to develop sufcient pull (or push) to operate the welder mechanically.

Never apply more than 145 PSI.

Bring shop air supply to the welder. Connect the air supply at the threaded opening, indicated as In by the

direction arrow on the lter-regulator. Maintain minimum 1⁄4” pipe size.

Important—Blow air line clear of all dirt, scale, etc., before connecting lter. Drain water out of

lter bowl when lled. If bowl lls with water in a short period of time, install a larger lter in

your main air supply line leading to the welder.

It is recommended that a manual shut-off valve be installed in the main line ahead of the

lter-regulator-lubricator assembly and close to the welder for convenience and lockout.

Rockford Systems, LLC

Call 1-800-922-7533

15

Page 16

SECTION 2—INSTALLATION OF COMPONENTS

Detect-A-Finger® Drop Probe Device-Welder

Other Installation ConsiderationS

PIPING

1. An air lockout valve must be installed in the air line usually just before the lter-regulator-lubricator assembly to meet

OSHA 29 CFR 1910.147 Lockout/tagout requirements. However, a separate lockout valve could be furnished for each

air system on the machine such as counterbalance, clutch/brake, air cylinder, and blow-off.

2. From the lockout valve, connect at the In threaded opening of the lter-regulator. Try to maintain an appropriate pipe

size throughout for proper air ow. Connect the piping to the ports using teon tape on the male threads only. Do not

allow tape to enter the interior of the lter-regulator-lubricator, valve, or air cylinder. Before applying air pressure, make

sure the lter and regulator bowls are at least hand tight.

3. Most approved pipe or hose can be used on the welder. Make sure the size is consistent throughout the system in

order to avoid restriction. Keep air runs as short as possible.

4. See enclosed lter-regulator-lubricator (FRL) assembly Manual No. KSL-208 for additional details.

All air components require clean air. Blow all lines clean of water, dirt, scale, etc., before making nal

connection. Drain water from lter bowl regularly. Should this bowl rell in a short period of time, it

CAUTION

WIRING

National Electrical Code and NFPA 79 practices are usually followed for wiring the system, which includes color-coding

and the use of numbered wire markers on both ends of every wire. The size of wire depends on local ordinance—number

14 stranded copper wire with an approved insulation is recommended.

may indicate the need for a larger lter in the main air supply line or an air line dryer system. The

air lter must be kept clean at all times. Never operate the machine unless the air lter is clean and

water is drained.

DO NOT USE SOLID WIRE.

1. Install and wire the main disconnect switch (unless one already exists) using black wire. Follow wiring instructions

shown on the electrical schematics. Make certain this switch is capable of being locked in the off position only.

Complete wiring diagrams are provided for connecting all controls and components properly. The foot switch should

be installed so it is readily available to the machine operator.

2. Bring 120 V AC 3-wire service to the Detect-A-Finger® control box. Ground should be connected to the green ground

screw. Connect the hot side of 120 V AC to terminal 1. Connect the common to terminal 2. If 120 V AC is not available

on the welder, then a transformer must be incorporated to step down the line voltage. This transformer must be rated

in accordance with load requirements.

3. Connect the foot switch as follows:

Single stage—NO contact to terminals 3 and 4

Two stage—NO contact of 1st stage to terminals 3 and 4

NO contact (NC held open) of 2nd stage to terminals 7 and 8

Connect a green wire from the ground terminal in the foot switch to the green ground screw in the Detect-A-Finger®

control box.

4. Connect the welder controller—terminal 5 to FS-1 and terminal 6 to FS-2. If two stage, connect terminal 8 to FS-3 and

terminal 9 to FS-4.

5. Connect the sensing probe assembly—connect the 5-conductor cable provided between the color-coded terminals

shown on the wiring diagram. W White, R Red, B Black, BR Brown, G Green Ground Wire

Note: The drop rod when activated will drop and then, if probe area is clear, the welder will cycle and the drop rod

will return immediately without releasing the foot switch. If the drop rod needs to stay down until the foot

switch is released, a jumper may be placed between the R and BR terminals.

16 Call 1-800-922-7533

Rockford Systems, LLC

Page 17

SECTION 3—OPERATING PROCEDURES & TROUBLESHOOTING

Detect-A-Finger® Drop Probe Device-Welder

Operating Procedure

1. Apply power. If the power does not come on, check that the main disconnect switch is on, fuse is connected, and check

for proper wiring.

2. Measure the incoming voltage at terminals 1 and 2. It should be 115 V AC ± 15%. Shut off power for the next step.

3. The sensing probe should be in position over the workpiece and formed to protect the required area. Move the drop rod

manually to the point where the limit switch (in the control box) is actuated and locate the sensing probe to be no more

than 1⁄4 inch above the workpiece. Check this adjustment periodically and before every setup.

4. Reapply power—the welder should be ready to cycle. Depress the foot switch. The Detect-A-Finger® rotary solenoid

should energize, permitting the drop rod to drop until the limit switch is actuated. The limit switch now energizes the

control relay and the relay contacts close, energizing the welder controller or operating device (solenoid). The welder

electrodes should close thus permitting the parts to be welded.

Troubleshooting

Voltage Measurement Troubleshooting

SYMPTOM TEST POINTS READING PROBLEM

0

60 V AC

230 V AC

115 V AC

0

115 VAC

0

24 V AC

0

24 V AC

0

24 V AC

0

24 VAC

Carefully check continuity with test light or ohmmeter when the foot switch is

depressed. The relay contact should close. If not, replace relay. If the relay

contact closes properly, the problem is with the welder operating device or

wiring is defective. Check continuity with an ohmmeter. Reconnect FS1 and 2.

Carefully check continuity with test light or ohmmeter when the foot switch is

depressed. The relay contact (Terminals 7-9) should close. The foot switch

contact (Terminals 7-8) should close. If not, replace the defective component.

If these contacts (Terminals 8-9) close properly, the problem is with the welder

controller. Reconnect FS3 and 4.

No primary power.

Transformer wired for 460 V AC, 230 applied.

Transformer wired for 230 V AC, 460 applied.

Proper voltage applied, continue.

Fuse blown, replace.

Defective lamp, replace.

Transformer defective, replace.

Proper voltage, continue.

Foot switch defective or improperly connected,

locate problem and correct.

Proper voltage, continue.

Relay contact (N.C.) defective, replace relay.

Proper voltage—bridge rectier or rotary solenoid

defective. See resistance measurement section.

Limit switch not being actuated or limit switch

defective. Replace limit switch.

Proper voltage—relay coil open.

“Power On” Indicator

Will Not Light

“Power On”

Indicator is Lit,

Rotary Solenoid

Will Not Energize

No Power

Rotary Solenoid

Will Not Energize

“Power On”

Rotary Solenoid

Energizes, Welder

Will Not Cycle

“Power On”

Rotary Solenoid

Energizes, Welder

1st Stage (Squeeze)

Operates, 2nd Stage

(Weld) Will Not Function

Terminal 1-2

Terminal 2 to wire common

with fuse and light to door

Terminal 3-W

Terminal 4-W with

foot switch depressed

Terminal BR-W with

foot switch depressed and

sensing probe held up

Terminal R-W

with foot switch

depressed

Disconnect FS1 and 2 from Terminals 5 and 6.

Terminals 5-6

(Single stage)

Disconnect FS3 and 4 from Terminals 8 and 9.

Terminals 7-9

and 7-8 (2nd stage)

Rockford Systems, LLC

Call 1-800-922-7533

17

Page 18

SECTION 3—OPERATING PROCEDURES & TROUBLESHOOTING

Detect-A-Finger® Drop Probe Device-Welder

Troubleshooting

Resistant Measurement Troubleshooting

TERMINAL

From To

a b

b a

a c

c a

d b

b d

d c

c d

RESISTANCE

OHMS

700

∞

700

∞

∞

700

∞

700

(a)

(b)

(c)

(d)

(-DC)

AC

AC

(+DC)

Power off with components not connected.

Bridge Rectier, Terminal Identication

Readings may vary slightly from meter to meter. However, the

trend established between innity (∞ ) and the lower readings

must remain consistent throughout the test. Any unusual reading

means the bridge rectier is defective and must be replaced.

Transformer: Primary - 20 Ohms approx.

Secondary - 2 Ohms approx.

Rotary Solenoid - Resistance 7.72 Ohms.

AC solenoid air valves of the type usually supplied by Rockford

Systems, LLC have approximately

100 Ohms DC resistance.

18 Call 1-800-922-7533

Rockford Systems, LLC

Page 19

SECTION 4—REPLACEMENT PARTS

Detect-A-Finger® Drop Probe Device-Welder

Replacement Parts

REPLACEMENT PARTS FOR CONTROL BOX RKC-501

Part No. Description

RFT-017 Relay

RSC-327 Transformer

RTY-003 Fuse 1 Amp

FTL-020 PC Board

REPLACEMENT PARTS FOR SENSING PROBE ASSEMBLY RKC-502

Part No. Description

CMF-108 Rotary Solenoid

FKC-101 Spring

CMC-020 Limit Switch

FTL-020 PC Board

REPLACEMENT KITS

Part No. Description

FCT-042 Hardware Mounting Kit

FCT-044 Drop Rod Assembly Repair Kit

FCT-041 Sensing Probe and Clamp

Rockford Systems, LLC

Call 1-800-922-7533

19

Page 20

SECTION 5—ORDER FORM FOR SIGNS & LITERATURE—RMA FORM

Detect-A-Finger® Drop Probe Device-Welder

ORDER FORM FOR SIGNS AND LITERATURE

This instruction manual references signs and literature available for your machines. This order form is for your

convenience to order additional signs and/or literature as needed. (This order form is part of your installation

manual so please make a copy of it when ordering.)

Company

Address

City State Zip

Phone Fax

Name Purchase Order No. Date

Part No. Description Quantity Required

KSL-022 Instruction Manual—Detect-A-Finger® For Welder

KSC-000 Operator Safety Precautions Sign—Metalforming (English)

KSC-000S Operator Safety Precautions Sign—Metalforming (Spanish)

KSC-000F Operator Safety Precautions Sign—Metalforming (French)

KSC-055 Danger Sign (Closing Ram and Die) 5” x 6” (English)

KSC-055S Danger Sign (Closing Ram and Die) 5” x 6” (Spanish)

KSC-055F Danger Sign (Closing Ram and Die) 5” x 6” (French)

KSL-051 Mechanical Power Press Safety Booklet

For prices and delivery, please use address, phone or fax number listed on the front cover of this manual.

Your Signature Date

RETURN MATERIALS AUTHORIZATION REQUEST FORM

To return material for any reason contact the sales department in our organization at 1-800-922-7533 for an

RMA Number. All return materials shipments must be prepaid. Complete this form and send with material to

5795 Logistics Parkway, Rockford, IL 61109. Make sure the RMA Number is plainly identied on the outside of

the shipping container.

Company

Address

City State Zip

Phone Fax

Contact Name Representative

Items Authorized To Return on RMA No. Original Invoice No. Date

Part No. Serial No. Description

Service Requested: Full Credit 25% Restocking Repair & Return Warranty Replacement

Reason for return (describe in detail):

Return Materials Authorized By Date

KSL-022/RSI/1018

Loading...

Loading...