Rockford Fosgate 250 2-Channel, 250, 360 2-Channel, 400 4-Channel, 500 2-Channel User Manual

...Page 1

Installation

and

Operation

Power 250 2-Channel

Power 360 2-Channel

Power 400 4-Channel

Power 500 2-Channel

Power 600 5-Channel

Power 800 2-Channel

Power 800 4-Channel

Power 1000 2-Channel

Páginas de Referencia para la Instalación

Schéma d’Installation

Installations Beiblatt

Istruzioni di Installation

Power Amplifier

Page 2

Sections marked

TROUBLESHOOTING

include recommendations for

curing installation problems

Sections marked

INSTALLATION

include “slam dunk”

wiring connections

GETTING STARTED

Welcome to Rockford Fosgate! This manual is designed to provide

information for the owner, salesperson and installer. For those of you

who want quick information on how to install this product, please turn

to the Installation Section of this manual or refer to the icons listed

below. Other information can be located by using the Table of

Contents. We, at Rockford Fosgate, have worked very hard to make

sure all the information in this manual is current. But, as we are constantly finding new ways to improve our product, this information is

subject to change without notice.

TROUBLE

S

H

O

O

T

I

N

G

Visit our website for the latest information on all Rockford products.

If, after reading your manual, you still have questions regarding this product, we recommend that you see your Rockford Fosgate dealer. If you need further assistance,

you can call us direct at 1-800-669-9899. Be sure to have your serial number, model

number and date of purchase available when you call.

The serial number can be found on the outside of the box. Please record it in the

space provided below as your permanent record. This will serve as verification of

your factory warranty and may become useful in recovering your amplifier if it is

ever stolen.

Serial Number: __________________________________

Model Number: __________________________________

I

N

S

T

+ -

+ -

A

L

L

A

T

I

O

N

Page 3

Dear Customer,

Congratulations on your purchase of the world's finest brand of car audio

amplifiers. At Rockford Fosgate we are fanatics about musical reproduction

at its best, and we are pleased you chose our product. Through years of

engineering expertise, hand craftsmanship and critical testing procedures,

we have created a wide range of products that reproduce music with all the

clarity and richness you deserve.

For maximum performance we recommend you have your new Rockford

Fosgate product installed by an Authorized Rockford Fosgate Dealer , as we

provide specialized training through Rockford Technical Training Institute

(RTTI).

Please read your warranty and retain your receipt and original carton for

possible future use.

Great product and competent installations are only a piece of the puzzle

when it comes to your system. Make sure that your installer is using 100%

authentic installation accessories from Connecting Punch in your installation. Connecting Punch has everything from RCA cables and speaker wire

to Power line and battery connectors. Insist on it! After all, your new system

deserves nothing but the best.

To add the finishing touch to your new Rockford Fosgate image order your

Rockford wearables, which include everything from T-shirts and jackets to

hats and sunglasses.

To get a free brochure on Rockford Fosgate products and Rockford accessories, in the U.S. call 480-967-3565 or FAX 480-967-8132. For all other

countries, call +001-480-967-3565 or FAX +001-480-967-8132.

PRACTICE SAFE SOUND™

CONTINUOUS EXPOSURE TO SOUND PRESSURE LEVELS OVER 100dB

MAY CAUSE PERMANENT HEARING LOSS. HIGH POWERED AUTOSOUND

SYSTEMS MAY PRODUCE SOUND PRESSURE LEVELS WELL OVER 130dB.

USE COMMON SENSE AND PRACTICE SAFE SOUND.

Page 4

Specifications

POWER 250 POWER 360 POWER 400 POWER 500 POWER 600.5 POWER 800 POWER 800 POWER 1000

2-channel 2-channel 4-channel 2-channel 5-channel 2-channel 4-channel 2-channel

Dynamic Power Rating

(IHF-202 Standard) - Measured at 14.4 Volts

Front/Rear + Subwoofer

Bridged into a 4Ω Load 3

20 Watts x 1 481 Watts x 1 232 Watts x 2 710 Watts x 1 232 Watts x 2 + — 960 Watts x 1 525 Watts x 2 1460 Watts x 1

Per channel into a 2Ω Load

160 Watts x 2 242 Watts x 2 127 Watts x 4 330 Watts x 2 120 Watts x 4 + 240 Watts x 1 480 Watts x 2 270 Watts x 4 730 Watts x 2

Per channel into a 4Ω Load

100 Watts x 2 154 Watts x 2 84 Watts x 4 210 Watts x 2 75 Watts x 4 + 115 Watts x 1 240 Watts x 2 150 Watts x 4 450 Watts x 2

Continuous Power Rating

(Competition Standard)

Measured at 13.8 Battery Volts

RMS continuous power / channel,

62.5 Watts x 2 90 Watts x 2 50 Watts x 4 125 Watts x 2 50 Watts x 4 + 100 Watts x 1 200 Watts x 2 100 Watts x 4 250 Watts x 2

both channels driven into a 4Ω

load from 20Hz to 20kHz with

<

0.05% Total Harmonic Distortion (THD)

RMS continuous power / channel,

125 Watts x 2 180 Watts x 2 100 Watts x 4 250 Watts x 2 100 Watts x 4 + 200 Watts x 1 400 Watts x 2 200 Watts x 4 500 Watts x 2

both channels driven into a 2Ω

load from 20Hz to 20kHz, with

<

0.1% Total Harmonic Distortion (THD)

RMS continuous power bridged

250 Watts x 1 360 Watts x 1 200 Watts x 2 500 Watts x 1 200 Watts x 2 + — 800 Watts x 1 400 Watts x 2 1000 Watts x 1

into a 4Ω load from 20Hz to

20kHz, with

<0.1% Total Harmonic

Distortion (THD)

Signal-to-Noise Ratio (A-weighted) >100dB >100dB >100dB >100dB >100dB >100dB >100dB >100dB

Crossover Slope (Butterworth) 24dB/octave 24dB/octave 24dB/octave 24dB/octave 24dB/octave 24dB/octave 24dB/octave 24dB/octave

Crossover Frequency

50Hz – 210Hz 50Hz – 210Hz 50Hz – 210Hz 50Hz – 210Hz 50Hz – 210Hz 50Hz – 210Hz 50Hz – 210Hz 50Hz – 210Hz

Specifications are subject to change without notice.

Page 5

POWER 250 POWER 360 POWER 400 POWER 500 POWER 600.5 POWER 800 POWER 800 POWER 1000

2-channel 2-channel 4-channel 2-channel 5-channel 2-channel 4-channel 2-channel

Dimensions (end caps installed)

2.4" (6.1cm) H 2.4" (6.1cm) H 2.4" (6.1cm) H 2.4" (6.1cm) H 2.4" (6.1cm) H 2.4" (6.1cm) H 2.4" (6.1cm) H 2.4" (6.1cm) H

9.9" (25.06cm) W 9.9" (25.06cm) W 9.9" (25.06cm) W 9.9" (25.06cm) W 9.9" (25.06cm) W 9.9" (25.06cm) W 9.9" (25.06cm) W 9.9" (25.06cm) W

11.4" (28.88cm) L 12.4" (31.42cm) L 13.4" (33.96cm) L 13.4" (33.96cm) L 18.4" (46.74cm) L 18.4" (46.74cm) L 18.4" (46.74cm) L 18.4" (46.74cm) L

Heatsink Type (internal use only) #2 #3 #4 #4 #4 #6 #6 #6

Frequency Response (±0.5dB) 20Hz - 20kHz 20Hz - 20kHz 20Hz - 20kHz 20Hz - 20kHz 20Hz - 20kHz 20Hz - 20kHz 20Hz - 20kHz 20Hz - 20kHz

Bandwidth (±3dB) 20Hz - 200kHz 20Hz - 200kHz 20Hz - 200kHz 20Hz - 200kHz 20Hz - 200kHz 20Hz - 200kHz 20Hz - 200kHz 20Hz - 200kHz

Damping Factor @ 4Ω >200 >200 >200 >200 >200 >200 >200 >200

(at output connector)

Slew Rate

30 Volts/ ms 30 Volts/ ms 30 Volts/ ms 30 Volts/ ms 30 Volts/ ms 30 Volts/ ms 30 Volts/ ms 30 Volts/ ms

IM Distortion (IHF) <0.05% <0.05% <0.05% <0.05% <0.05% <0.05% <0.05% <0.05%

Source Unit Compatibility

17V max. (RCA) 17V max. (RCA) 17V max. (RCA) 17V max. (RCA) 17V max. (RCA) 17V max. (RCA) 17V max. (RCA) 17V max. (RCA)

(+15dB gain overlap)

Input Sensitivity (+0dB gain overlap) 250mV~4V (RCA) 250mV~4V (RCA) 250mV~4V (RCA) 250mV~4V (RCA) 250mV~4V (RCA) 250mV~4V (RCA) 250mV~4V (RCA) 250mV~4V (RCA)

Protection NOMAD - Internal analog-computer output protection circuitry limits power in case of overload. Thermal switch shuts down the amplifier in case of overheating.

Battery Fuse Rating 30A 40A 50A 50A 50A 60A* 60A* 2-50A or 1-100A*

(External to Amplifier)

Fuse Type

ATC ATC AGU AGU AGU AGU AGU 2-AGU OR 1- ANL

Equalization (45Hz Punch Bass) Variable Variable Rear Variable Variable Variable Variable Rear Variable Variable

(0 to +18dB) (0 to +18dB) (0 to +18dB) (0 to +18dB) (0 to +18dB) (0 to +18dB) (0 to +18dB) (0 to +18dB)

Input Impedance 20k ohms 20k ohms 20k ohms 20k ohms 20k ohms 20k ohms 20k ohms 20k ohms

* recommended fuse not supplied with amplifier

Specifications are subject to change without notice.

Specifications

Page 6

Table of Contents

Specifications.............................................................................................. i

Introduction ................................................................................................1

Power Amplifier Accessory Pack....................................................................1

Feature Chart ..............................................................................................2

Design Features ..........................................................................................3

Installation Considerations ............................................................................8

Mounting Location ......................................................................................9

Battery and Charging ................................................................................10

Wiring the System......................................................................................10

Using Passive Crossovers............................................................................12

Table of Component Values ........................................................................13

Installation................................................................................................14

Operation..................................................................................................23

System Diagrams ......................................................................................26

Troubleshooting ........................................................................................30

Dynamic Power Measurements....................................................................32

Warranty Information ................................................................................34

International Information ............................................................................35

Page 7

– 1 –

Introduction

Rockford engineers designed the Power series amplifiers to withstand the

rugged automotive environment while delivering superior sound quality in

a flexible, reliable, and efficient package. TRANS•ana is a low voltage circuit in the preamp stage lets the music sound crystal clear and very real,

even when played at high volume levels. This is matched with TOPAZ, a

unique grounding circuit used to eliminate noise problems associated with

car audio systems and their installation. Flexibility is accomplished with the

use of a built-in variable crossover. The use of a protection circuit called

NOMAD, along with MOSFET and DSM (Discrete Surface Mount) technologies improve amplifier efficiency. The result of these components give the

Power amplifier awesome sound quality in a “Bullet Proof” package.

Explanations of these technologies, most of which are exclusively designed

and patented by Rockford, are described in the Technical Design Features.

Power Amplifier Accessory Pack

The accessory pack shipped with the Power amplifiers includes the mounting hardware necessary to secure the amp to the vehicle.

Installation & Operation Manual

Punch Verification Certificate

(4) Amplifier mounting screws (#8 x 3/4" Phillips)

(4) Speaker/Power connector set screws (3/32" Allen)

(4) Endbell mounting screws (9/64" Allen)

(1) Allen wrench (3/32")

(1) Allen wrench (9/64")

(1) Inline fuseholder (Power 250, Power 360 & Power 400 amps)

(1) AGU 30 amp fuse (Power 250 2-channel amp)

(1) AGU 40 amp fuse (Power 360 2-channel amp)

(1) AGU 50 amp fuse (Power 400 4-channel & Power 600 5-channel amps)

(1) Remote Punch Bass (replacement part #WP-2429)

(1) 15' Remote Punch Bass cable (replacement part #CC-2421)

(2) Remote Punch Bass bracket screws (4 x 7/16" Phillips)

NOTE: Refer to the specifications section for recommended fuse sizes on

the Power 800 2-channel, Power 800 4-channel & Power 1000 2-channel

amps.

Page 8

– 2 –

POWER AMPLIFIER MODEL Power Power Power Power Power Power Power Power

250 360 400 500 600 800 800 1000

# of CHANNELS 224 25242

Stable Into: (stereo/mono) 2Ω/4Ω 2Ω/4Ω 2Ω/4Ω 2Ω/4Ω 2Ω/4Ω 2Ω/4Ω 2Ω/4Ω 2Ω/4Ω

CIRCUITRY

1

TRANS•

ana – circuit topology x x x x x x x –

TRANS•

nova – patented circuit topology

2

––– ––––x

DIAMOND – patented MOSFET driver stage

3

––– ––––x

Class-G – high efficiency topology ––– –––––

MEHSA – heat dissipating technology x x x x xxxx

TOPAZ – patented noise eliminating circuitry

4

xxx xxxxx

DSM – discrete surface mount x x x x xxxx

MOSFETs – power supply & output devices x x x x xxxx

NOMAD – protection circuit x x x x xxxx

FEATURES

Die Cast Heatsink x x x x xxxx

Hi-Level Inputs – for factory radios ––– –––––

RCA Inputs – for aftermarket radios x x x x xxxx

Input Switches – eliminates “Y” adaptors ––x –––x –

Pass-Thru – feeds signal to aux. amp x x x x xxxx

Pwr/Spk Screw Terminals ––– –––––

Pwr/Spk Block Terminals x x x x xxxx

4 Gauge PWR/GND x x x x xxxx

Variable Punch Bass (0dB ~+18dB @ 45Hz) Remote Remote Remote Rear Remote Remote Remote Remote Remote

Rear Rear

Variable Xover (50Hz ~ 210Hz) HP/FULL/LP

5

HP/FULL/LP5HP/FULL/LP5HP/FULL/LP5HP/FULL/LP5HP/FULL/LP5HP/FULL/LP5HP/FULL/ LP

5

Crossover Slope (Butterworth) 24dB 24dB 24dB 24dB 24dB 24dB 24dB 24dB

Phase Warp ––– ––––x

1

Additional information on features, specifications and system designs can be found at: www.rockfordfosgate.com 2Trans•nova is patented under "U.S. Patent No. 4,467,288"

3

DIAMOND is patented under "U.S. Patent No. 5,673,000"

4

TOPAZ is patented under "U.S. Patent No. 5,751,823"

5

HP = 24dB/octave High-Pass / LP = 24dB/octave Low-Pass / FULL = Full Range

Power Amplifier Feature Chart

Page 9

– 3 –

Design Features

1. Cast Aluminum Heatsink – The cast aluminum heatsink of the Power amplifier

dissipates heat generated by the amplifier's circuitry. The inherent advantage of

casting provides a 30% improvement of cooling over conventional extrusion

heatsink designs.

2. Speaker/Power Terminals – The heavy duty, gold-plated terminal block connectors (+ and –) will accept 4 gauge cable and are immune to corrosion that

can cause signal degradation.

3. REM Terminal – This spade terminal is used to remotely turn on and turn off the

amplifier when +12V DC is applied.

4. Signal Input Switch (Power 400, Power 800 4-channel & 600 5–channel

amplifiers)

– This switch allows the amplifier to be driven with either 2 or 4

pairs of inputs.

5. RCA Input Jacks – The industry standard RCA jacks provide an easy connection

for signal level input. They are gold-plated to resist the signal degradation

caused by corrosion.

6. RCA Pass-Thru Jacks – The Pass-Thru provides a convenient source for daisychaining an additional amplifier without running an extra set of RCA cables

from the front of the vehicle to the rear amplifier location.

7. Gain Control – The input gain control is preset to match the output of most

source units. It can be adjusted to match output levels from a variety of source

units.

8. Remote Punch Bass – The Punch Bass helps correct for acoustical deficiencies

in the listening environment by helping reproduce full range sound without

adding excessive boost. The Punch Bass control is a narrow band adjustment

centered at 45Hz variable from 0dB to +18dB. Connection is made with a

cable using RJ-45 and can be installed under the dash for remote control access.

9. Internal Crossover – The internal crossover is a 24dB/octave Butterworth filter

selectable for High-Pass (HP), Full Range (FULL), or Low-Pass (LP) operation

variable from 50Hz to 210Hz.

10. LED Power Indicator – The LED illuminates when the unit is turned on.

11. Phase Warp (Power 1000 2-channel amplifier) – The phase warp is a variable

control used to adjust the phase of the output signal relative to the phase of the

input signal. The phase warp is most noticable when the system is playing a

sine wave (test tone). When used with the proper test equipment, this feature

can increase the relative SPL in a system.

Page 10

– 4 –

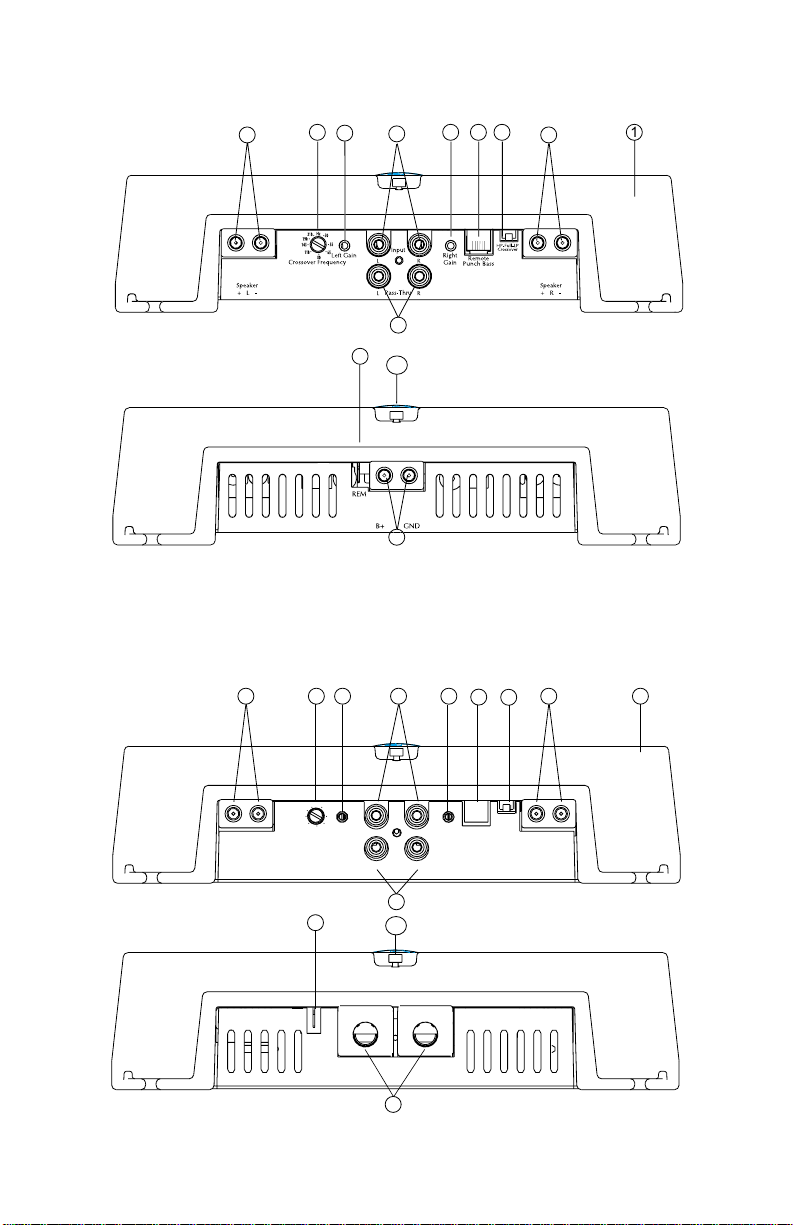

Power 250

2-channel

0

Power 360

2-channel

Speaker

+ L -

Crossover Frequency

Left Gain

Input

Pass-Thru

LR

LR

Right

Gain

Remote

Punch Bass

HP-Full-LP

Crossover

Speaker

+ R -

65

80

55

50

110

210

Hz

145

190

REM

B+ GND

2

10

5

2

9

8

77

9

2

6

1

3

1

Page 11

– 5 –

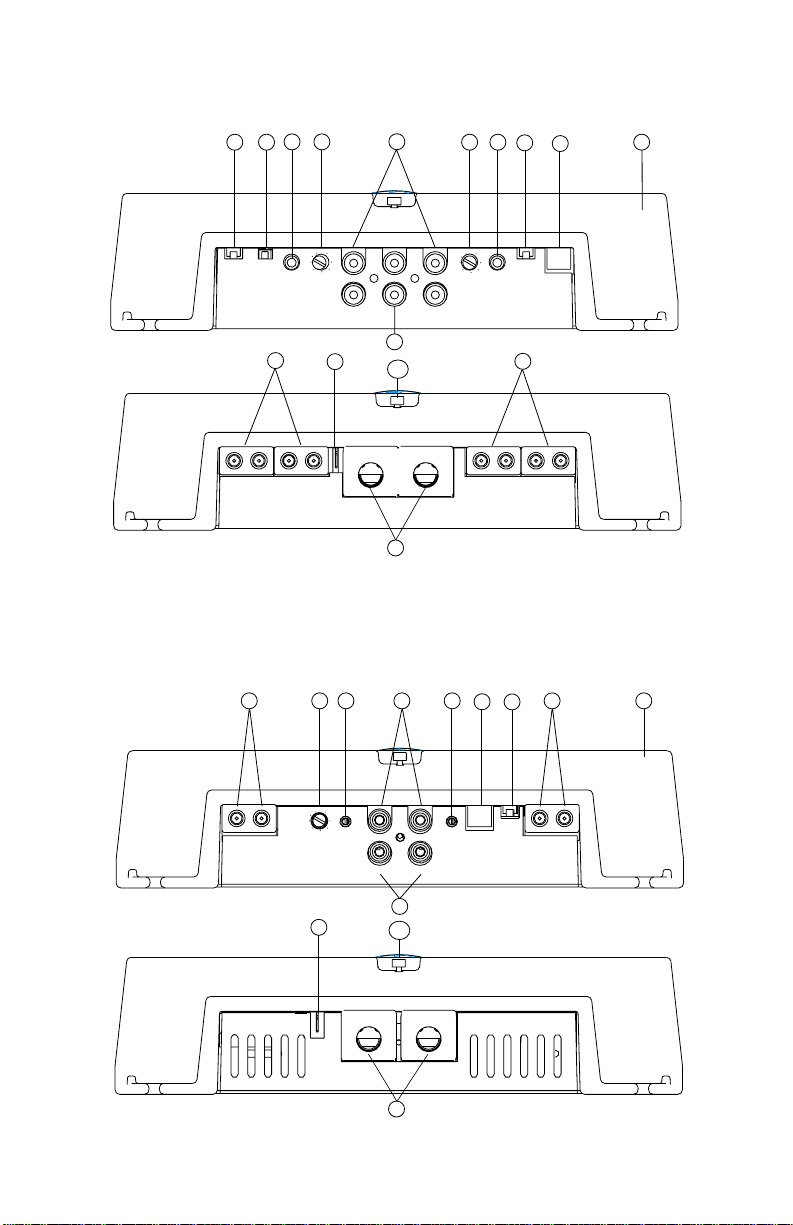

Power 400

4-channel

Front

Crossover

HP-Full-LP

4/2

Input

Front

Gain

Front

Crossover

Frequency

65

80

55

50

110

210

Hz

145

190

Front Pass-Thru Rear

RR

LL

Rear

Crossover

Frequency

65

80

55

50

110

210

Hz

145

190

Rear

Gain

Rear

Crossover

HP-Full-LP

Rear

Remote

Punch

Bass

LR+ LR- RR+ RR- B+ GND LF- LF+ RF+RF-

REM

LED

10

2

2

6

4

5

7

1

2

9

8

7

9

3

9

9

Power 500

2-channel

Speaker

+ L -

Crossover Frequency

Left Gain

Input

Pass-Thru

LR

LR

Right

Gain

Remote

Punch Bass

HP-Full-LP

Crossover

Speaker

+ R -

65

80

55

50

110

210

Hz

145

190

REM

B+ GND

2

10

5

2

9

8

77

9

2

6

1

3

Page 12

– 6 –

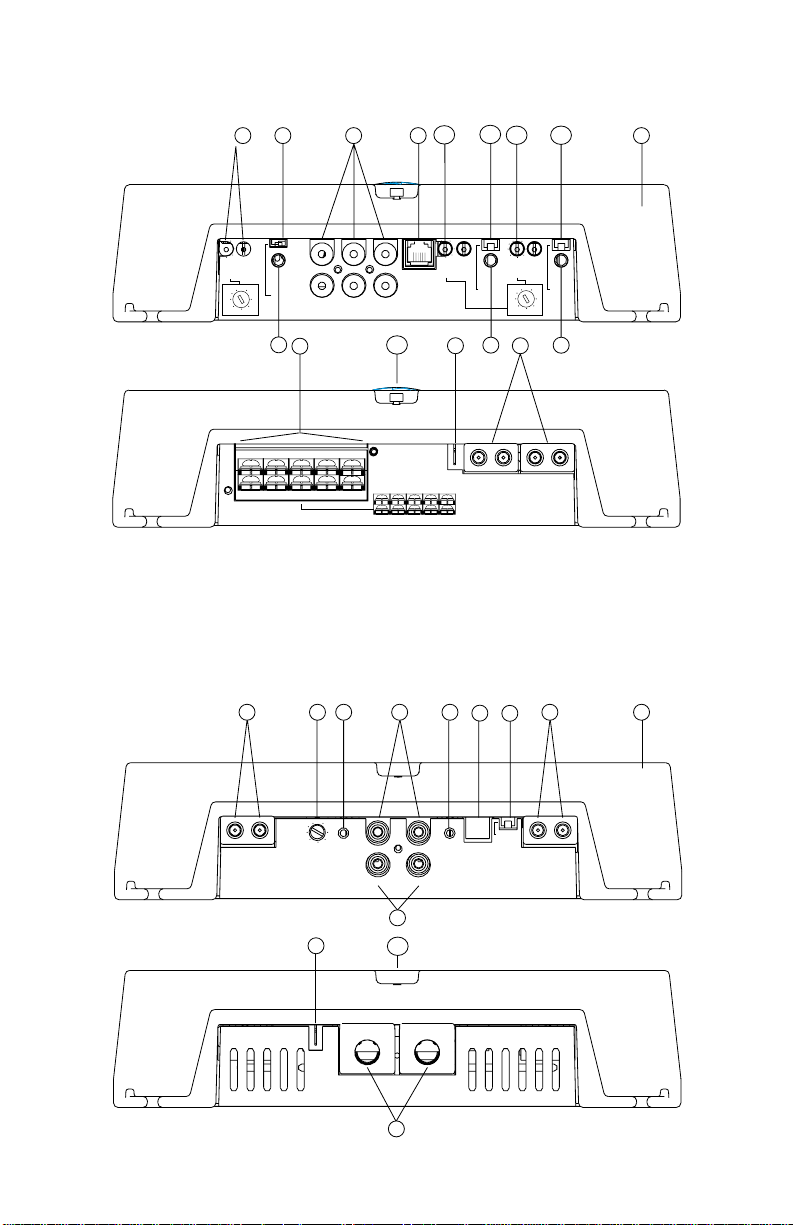

Power 800

2-channel

Speaker

+ L -

Crossover Frequency

Left Gain

Input

Pass-Thru

LR

LR

Right

Gain

Remote

Punch Bass

HP-Full-LP

Crossover

Speaker

+ R -

65

80

55

50

110

210

Hz

145

190

REM

B+ GND

5

2

9

8

77

9

2

6

1

10

3

2

Power 600

5-channel

Remote

Punch Bass

9

549 8

9

10

9

1

Sub LP

Crossover

Frequency

210

190

145

110

Sub

Punch

Sub

Bass

Gain

Hz

50

6/4/2

Input

55

65

80

7

2

RR+

LR-

RF- LF+ Sub-

LR+

RF+ LF- Sub+

RR-

RLR

L

Sub Rear Front

RR+

RR-

10

LR-

LR+

RF- LF+ Sub-

RF+ LF- Sub+

Rear

Crossover

Frequency

Rear

Front

Rear

Gain

HP-Full-LP

Rear

Crossover

7

B+

Crossover

Frequency

210

190

145

110

23

Front

Punch

Front

Bass

Gain

Hz

50

HP-Full-LP

Front

55

Crossover

65

80

7

GND

Punch

Bass

REM

Page 13

– 7 –

Power 800

4-channel

1

2

6

Front

Crossover

HP-Full-LP

4/2

Input

Front

Gain

Front

Crossover

Frequency

65

80

55

50

110

210

Hz

145

190

Front Pass-Thru Rear

RR

LL

Rear

Crossover

Frequency

65

80

55

50

110

210

Hz

145

190

Rear

Gain

Rear

Crossover

HP-Full-LP

Rear

Remote

Punch

Bass

7

7

LR+ LR- RR+ RR- B+ GND LF- LF+ RF+RF-

REM

10

899 4

5

9 9

3

2 2

2

1

2

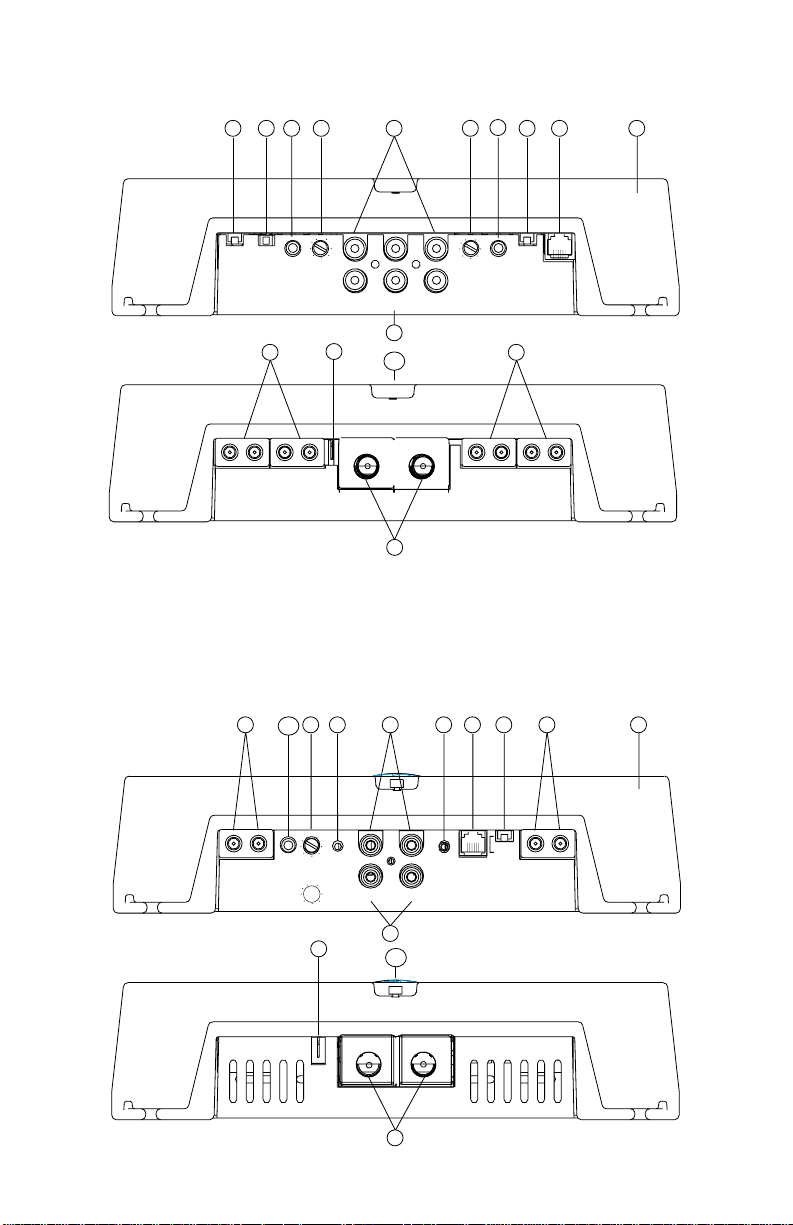

65

80

55

50

110

210

Hz

145

190

8 99

5

7

2

7

3

6

10

11

B+ GND

REM

HP–Full–LP

Crossover

Input

Pass-Thru

LR

LR

Crossover

Frequency

Speaker

+ L -

Speaker

+ R -

Right

Gain

Left

Gain

Remote

Punch Bass

Phase

Warp

Power 1000

2-channel

Page 14

– 8 –

Installation Considerations

This is a list of tools you will need for installing the Power amplifier:

• Voltmeter • Wire strippers

• Electric hand drill w/assorted bits • Battery post wrench

• 17' (5 m) Red Power Wire • Wire cutters

• 12' (4 m) Remote Turn-On Wire • Assorted connectors

• 1.5' (45 cm) Black Grounding Wire • Wire crimpers

This section focuses on some of the vehicle considerations for installing

your new Power amplifier. Checking your battery and present sound system, as well as pre-planning your system layout and best wiring routes, will

save installation time. When deciding how to lay out your new system, be

sure that each component will be easily accessible for making adjustments.

Before beginning any installation, be sure to follow these simple rules:

1. Be sure to carefully read and understand the instructions before

attempting to install the amplifier.

2.

For safety, disconnect the negative lead from the battery prior to beginning the installation.

3. For easier assembly, we suggest you run all wires prior to mounting

your amplifier in place.

4. Route all of the RCA cables close together and away from any high

current wires.

5. Use high quality connectors for a reliable installation and to minimize

signal or power loss.

6.

Think before you drill! Be careful not to cut or drill into gas tanks, fuel

lines, brake or hydraulic lines, vacuum lines or electrical wiring when

working on any vehicle.

7. Never run wires underneath the vehicle. Running the wires inside the

vehicle provides the best protection.

8. Avoid running wires over or through sharp edges. Use rubber or plastic grommets to protect any wires routed through metal, especially the

firewall.

9.

ALWAYS protect the battery and electrical system from damage with

proper fusing. Install a fuseholder and appropriate fuse on the +12V

power wire within 18” (45 cm) of the battery terminal.

10. When grounding to the chassis of the vehicle, scrape all paint from the

metal to ensure a good, clean ground connection. Grounding connections should be as short as possible and always be connected to metal

that is welded to the main body, or chassis, of the vehicle.

Page 15

– 9 –

Mounting Location

The mounting location and position of your amplifier will have a great effect

on its ability to dissipate the heat generated during normal operation. The

design of our cast aluminum heatsink serves to easily dissipate the heat generated over a wide range of operating conditions. However , to maximize the

performance of your amplifier, care should be taken to ensure adequate

ventilation.

Trunk Mounting

Mounting the amplifier vertically on a surface with the fin grooves running

up and down will provide the best cooling of the amplifier.

Mounting the amplifier on the floor of the trunk will work but provides less

cooling capability than vertical mounting.

Mounting the amplifier upside down to the rear deck of the trunk will not

provide proper cooling and will severely affect the performance of the

amplifier and is strongly

not recommended.

Passenger Compartment Mounting

Mounting the amplifier in the passenger compartment will work as long as

you provide a sufficient amount of air for the amplifier to cool itself. If you

are going to mount the amplifier under the seat of the vehicle, you must

have at least 1" (2.54cm) of air gap around the amplifier's heatsink.

Mounting the amplifier with less than 1" (2.54cm) of air gap around the

amplifier's heatsink in the passenger compartment will not provide proper

cooling and will severely affect the performance of the amplifier and is

strongly

not recommended.

Engine Compartment Mounting

Rockford Fosgate amplifiers should never be mounted in the engine compartment. Not only will this void your warranty but could create an embarrassing situation caused by the ridicule from your friends.

Page 16

– 10 –

Battery and Charging

Amplifiers will put an increased load on the vehicle's battery and charging

system. We recommend checking your alternator and battery condition to

ensure that the electrical system has enough capacity to handle the

increased load of your stereo system. Stock electrical systems which are in

good condition should be able to handle the extra load of any Rockford

amplifier without problems, although battery and alternator life can be

reduced slightly. To maximize the performance of your Rockford Fosgate

amplifier, we suggest the use of a heavy duty battery and an energy storage

capacitor.

Wiring the System

CAUTION: Avoid running power wires near the low level input cables, antenna,

power leads, sensitive equipment or harnesses. The power wires carry sub-

stantial current and could induce noise into the audio system.

1. Plan the wire routing. Take care when running signal level RCA cables

to keep them close together but isolated from the amplifier's power

cables and any high power auto accessories, especially electric motors.

This is done to prevent coupling the noise from radiated electrical fields

into the audio signal. When feeding the wires through the firewall or

any metal barrier, protect them with plastic or rubber grommets to prevent short circuits. Leave the wires long at this point to adjust for a precise fit at a later time.

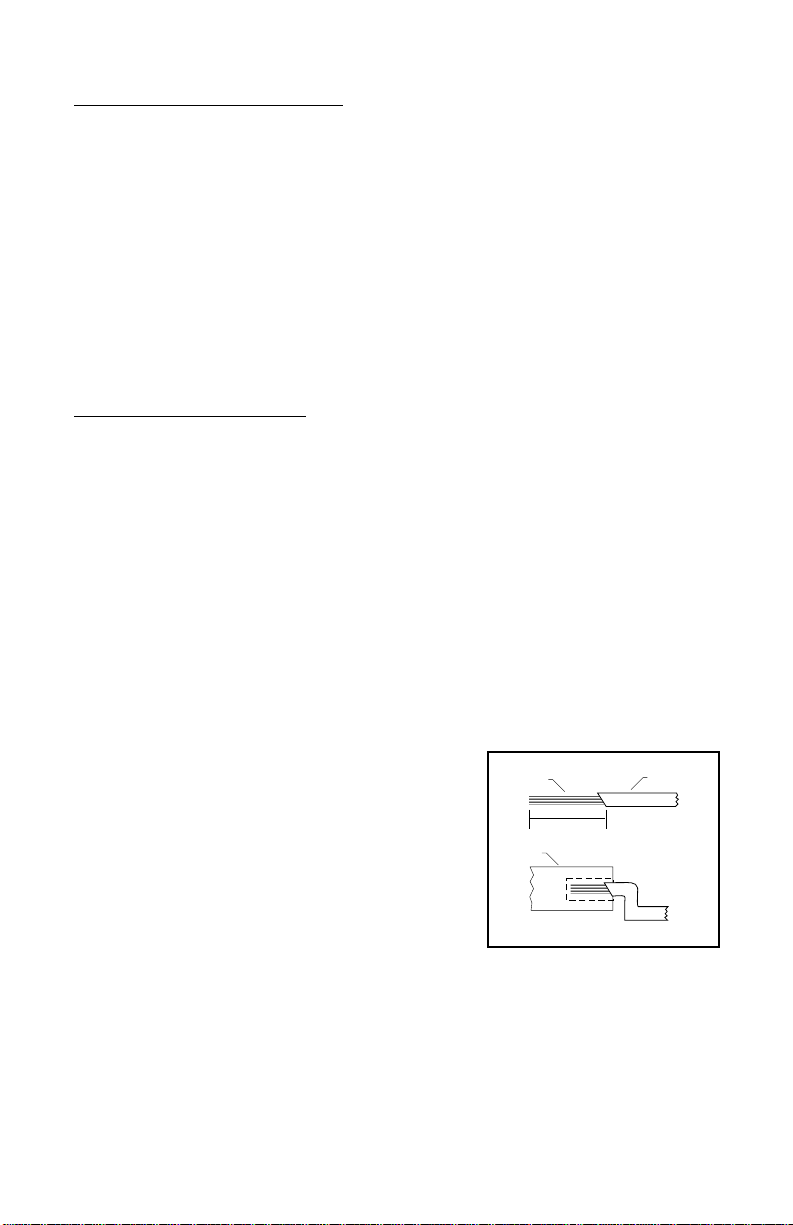

2. Prepare the

Power cable for attachment

to the amplifier by stripping 5/8" of insulation from the end of the wire. The use

of 8 gauge power cable can interfere

with the installation of the end caps.

Proper wire dress can prevent this from

occurring. To prevent the wire from fraying, strip the insulation at a 45° angle.

Insert the bared wire into the B+ terminal

with the long side of the insulation on the top. Bend the cable down at

a 90° angle. Tighten the set screw to secure the cable in place.

3. Strip 3/8" from the battery end of the power cable and crimp a large ring

terminal to the cable. Use the ring terminal to connect to the battery

positive terminal.

Do not install the fuse at this time.

STRIP WIRE

AMP

INSULATION

>

5/8"

>

>

><

Page 17

– 11 –

4. Prepare a length of cable to be used for the ground connection. Strip

5/8" of insulation from the end of the cable as described above and

connect to the appropriate terminal of the amplifier. Prepare the chassis ground by scraping any paint from the metal surface and thoroughly clean the area of all dirt and grease. Strip the other end of the wire

and attach a ring connector . Fasten the cable to the chassis using a nonanodized screw and a star washer.

5. Prepare the REM turn-on wire for connection to the amplifier by stripping 1/4" of insulation from the wire end and crimping an insulated

spade connector in place. Slide the connector over the REM terminal

on the amplifier. Connect the other end of the REM wire to a switched

12 volt positive source. The switched signal is usually taken from the

source unit's auto antenna or the accessory lead. If the source unit does

not have these outputs available, the recommended solution is to wire

a mechanical switch in line with a 12 volt source to activate the amplifier.

6. Securely mount the amplifier (with supplied screws) to the vehicle or

amp rack. Be careful not to mount the amplifier on cardboard or plastic panels. Doing so may enable the screws to pull out from the panel

due to road vibrations or sudden vehicle stops.

7. Determine the number of inputs needed to drive the amplifier and

move the input switch to the desired setting (Power 400 & Power 800

4-channel amplifiers only.).

8. Connect the source signal to the amplifier by plugging the RCA cables

into the input jack(s) at the amplifier.

9. Connect the speakers. Strip the speaker wires 5/8" and insert into the

appropriate terminal on the amplifier. Insert the bared wire into the

speaker terminal and tighten the set screw to secure into place. Be sure

to maintain proper speaker polarity.

DO NOT chassis ground any of

the speaker leads as unstable operation may result.

10. Perform a final check of the completed system wiring to ensure that all

connections are accurate. Check all power and ground connections for

frayed wires and loose connections which could cause problems from

road vibrations.

Page 18

– 12 –

Using Passive Crossovers

A passive crossover is a circuit that uses capacitors and/or coils

and is placed on speaker leads between the amplifier and speaker. The crossover delegates a specific range of frequencies to the speaker

for optimum driver performance. A crossover network can perform one of

three functions: High-Pass (capacitors), Low-Pass (inductors or coils) and

Bandpass (combination of capacitor and coil).

The most commonly used passive crossover networks are 6dB/octave systems. These are easy to construct and require one component per filter.

Placing this filter in series with the circuit will reduce power to the speaker by 6dB/octave above or below the crossover point depending on

whether it is a high-pass or low-pass filter. More complex systems such as

12dB/octave or 18dB/octave can cause impedance problems if not professionally designed.

Passive crossovers are directly dependent upon the speaker's impedance

and component value for accuracy. When passive crossover components

are used in multiple speaker systems, the crossover's effect on the overall

impedance should be taken into consideration along with the speaker's

impedance when determining amplifier loads. CAUTION: The Power

amplifiers are not recommended for impedance loads below 2Ω stereo

and 4Ω bridged (mono) loads.

+ -

+ -

I

N

S

T

A

L

L

A

T

I

O

N

Page 19

– 13 –

Table of Crossover Component Values

6dB/Octave Low-Pass

6dB/Octave High-Pass

Freq.

Hertz

Speaker Impedance

80 4.1mH 1000µF 8.2mH 500µF 16mH 250µF

100 3.1mH 800

µF 6.2mH 400µF 12mH 200µF

130 2.4mH 600

µF 4.7mH 300µF 10mH 150µF

200 1.6mH 400

µF 3.3mH 200µF 6.8mH 100µF

260 1.2mH 300

µF 2.4mH 150µF 4.7mH 75µF

400 .8mH 200

µF 1.6mH 100µF 3.3mH 50µF

600 .5mH 136

µF 1.0mH 68µF 2.0mH 33µF

800 .41mH 100

µF .82mH 50µF 1.6mH 26µF

1000 .31mH 78

µF .62mH 39µF 1.2mH 20µF

1200 .25mH 66µF .51mH 33µF 1.0mH 16µF

1800 .16mH 44

µF .33mH 22µF .68mH 10µF

4000 .08mH 20

µF .16mH 10µF .33mH 5µF

6000 51

µH14µF .10mH 6.8µF .20mH 3.3µF

9000 34µH 9.5µF68µH 4.7µF .15mH 2.2µF

12000 25

µH 6.6µF51µH 3.3µF 100µH 1.6µF

2 OHMS

8 OHMS

4 OHMS

L

C L

C

L C

L

C

L = Low-Pass (Inductor)

C = High-Pass (Capacitor)

For more information, see your Authorized Rockford Fosgate Dealer.

Page 20

Installation

Power 250 2-channel Power 500 2-channel

Power 360 2-channel Power 800 2-channel

– 14 –

• RCA Inputs connect to both left and right channels

• Gain for left and right channels are set equally to balance the subwoofer

•

Speaker Impedance should be 4Ω minimum

•

Variable Crossover can be set to High-Pass (HP), Low-Pass (LP) or

Full Range (FULL)

Power 250 Power 360 Power 500 Power 800

2-channel 2-channel 2-channel 2-channel

Power Connections

Bridged/Mono Mode

Power 250 Power 360 Power 500 Power 800

2-channel 2-channel 2-channel 2-channel

+ -

+ -

I

N

S

T

A

L

L

A

T

I

O

N

*Keep grounds as short as possible

LED

REM

B+ GND

Connect to remote

turn-on lead of

source unit

Less than 18"

Crossover Frequency

Speaker

+ L -

+ -

Connect to B+ of battery

with appropriate fuse

RCA Input

Hz

210

50

190

55

145

110

80

65

Left Gain

Input

LR

Pass-Thru

LR

Right

Gain

Remote

Punch Bass

HP-Full-LP

Crossover

Connect to chassis

ground of vehicle*

Speaker

+ R -

+ -

4Ω min.

Page 21

– 15 –

• RCA Inputs connect to both left and right channels

• Gain for left and right channels operate independently

•

Speaker Impedance for each channel should be 2Ω minimum

• Variable Crossover can be set to High-Pass (HP), Low-Pass (LP) or

Full Range (FULL)

+ -

• RCA Inputs connect to both left and right channels

• Gain for left and right channels are set equally to balance the subwoofer

•

Speaker Impedance for each stereo channel should be 2Ω minimum

• Speaker Impedance for bridged/mono channel should be 4Ω minimum

• Variable Crossover must be set for Full Range (FULL)

•

Passive Crossovers must be used for proper stereo/mono operation

3-Channel Mode

2-Channel Mode

Power 250 Power 360 Power 500 Power 800

2-channel 2-channel 2-channel 2-channel

Power 250 Power 360 Power 500 Power 800

2-channel 2-channel 2-channel 2-channel

+ -

I

N

S

T

A

L

L

A

T

I

O

N

RCA Input

Hz

210

50

190

55

Speaker

+ L -

145

110

80

Crossover Frequency

–

+

65

Left Gain

2Ω min.

Input

LR

Pass-Thru

LR

Right

Gain

2Ω min.

Remote

Punch Bass

HP-Full-LP

Crossover

Speaker

+ R -

–

+

RCA Input

Hz

210

50

190

55

Speaker

+ L -

145

110

80

Crossover Frequency

–

+

65

Left Gain

LR

LR

2Ω min.

+ -

Input

Pass-Thru

2Ω min.

4Ω min.

HP-Full-LP

Crossover

Right

Remote

Gain

Punch Bass

Speaker

+ R -

–

+

Page 22

– 16 –

Installation

Power 400 4-channel

Power 800 4-channel

Power 400 Power 800

4 -channel 4 -channel

Power Connections

+ -

+ -

I

N

S

T

A

L

L

A

T

I

O

N

*Keep grounds as short as possible

Connect to remote

turn-on lead of

source unit

LED

REM

Less than 18"

B+ GND

+ -

Connect to B+ of battery

with appropriate fuse

Connect to chassis

ground of vehicle*

Page 23

– 17 –

+ -

• RCA Inputs are connected to front inputs

•

4-2 Input Switch is set to 2-channel input mode

•

Gain for front and rear channels must be set identical

•

Speaker Impedance for each bridged channel should be no less than 4Ω

•

Variable Crossovers for front and rear channels must be set to identical

frequency (i.e. both set to 60Hz) and operating mode (i.e. both set to LP)

Power 400 Power 800

4 -channel 4 -channel

2-Channel Mode

+ -

I

N

S

T

A

L

L

A

T

I

O

N

RCA Input

4-2

Input

Hz

210

50

190

55

145

Front

4/2

Crossover

Input

Front

HP-Full-LP

Gain

LR+ LR- RR+ RR- B+ GND LF- LF+ RF+RF-

110

Front

Crossover

Frequency

65

80

REM

RR

LL

Front Pass-Thru Rear

+ -

4Ω min.

Bridged

Left

190

145

110

Crossover

Frequency

LED

Hz

210

50

55

65

80

Rear

Rear

Gain

4Ω min.

Bridged

Rear

Crossover

HP-Full-LP

Right

Rear

Remote

Punch

Bass

+ -

Page 24

– 18 –

+ -

• RCA Inputs are connected to front -or- front/rear inputs

•

4-2 Input Switch is set to 2-channel -or- 4-channel input mode

•

Gain for front and rear channels operate independently

•

Speaker Impedance for each front stereo channel should be no less than 2Ω

•

Speaker Impedance for rear bridged/mono channel should be no less than 4Ω

•

Variable Crossovers for front & rear are variable from 50Hz~210Hz and can be

set to HP (High-Pass), LP (Low-Pass) or FULL (Full Range)

* Reverse polarity on subwoofer if front channel is set to HP (High-Pass) and

rear channel is set to LP (Low-Pass)

Power 400 Power 800

4-channel 4-channel

3-Channel Mode

+ -

I

N

S

T

A

L

L

A

T

I

O

N

-or-

4-2

4-2

Input

Input

Front

4/2

Crossover

Input

Front

HP-Full-LP

Gain

LR+ LR- RR+ RR- B+ GND LF- LF+ RF+RF-

*

4Ω min.

Bridged

2-channel

Input

Hz

210

50

190

55

145

110

65

80

Front

Crossover

Frequency

Front Pass-Thru Rear

REM

+ -

4-channel

Input

RR

LL

Hz

210

50

190

55

145

Rear

110

65

Crossover

80

Rear

Rear

HP-Full-LP

Rear

Gain

+ -

2Ω min.

Remote

Punch

Bass

+ -

Crossover

Frequency

2Ω min.

Page 25

– 19 –

• RCA Inputs are connected to front & rear inputs

•

4-2 Input Switch is set to 4-channel input mode

•

Gain for front and rear channels operate independently

•

Speaker Impedance for all stereo channels should be no less than 2Ω

•

Variable Crossovers for front & rear are variable from 50Hz~210Hz and

can be set to HP (High-Pass), LP (Low-Pass) or FULL (Full Range)

+ -

Power 400 Power 800

4-channel 4-channel

4-Channel Mode

+ -

I

N

S

T

A

L

L

A

T

I

O

N

4-channel

Hz

50

55

65

80

Front

Front Pass-Thru Rear

REM

Input

RR

LL

4-2

Input

210

190

4/2

Input

145

110

Front

Gain

Crossover

Frequency

+ -

2Ω min.

Front

Crossover

HP-Full-LP

LR+ LR- RR+ RR- B+ GND LF- LF+ RF+RF-

+ -

2Ω min.

Hz

210

50

190

55

145

Rear

110

65

Crossover

80

Rear

Rear

HP-Full-LP

Rear

Gain

+ -

2Ω min.

Remote

Punch

Bass

+ -

Crossover

Frequency

2Ω min.

Page 26

– 20 –

• RCA Inputs are connected to front & rear inputs

•

6-4-2 Input Switch is set to 6-channel input mode

•

Gain for front and rear channels operate independently

•

Speaker Impedance for all stereo channels should be no less than 2Ω

•

Variable Crossovers for front & rear are variable from 50Hz~210Hz and

can be set to HP (High-Pass), LP (Low-Pass) or FULL (Full Range)

+ -

Power 600

5-channel

5-Channel Mode

+ -

I

N

S

T

A

L

L

A

T

I

O

N

6-channel input

6/4/2

Input

+ - + -

2Ω min.2Ω min.

Sub LP

Sub

Crossover

Punch

Sub

Frequency

Bass

Gain

Hz

210

50

6/4/2

190

Input

55

145

110

65

80

RR+

LR-

RF- LF+ Sub-

LR+

RF+ LF- Sub+

RR-

+ - + -

RR

L

Sub Rear Front

2Ω min.2Ω min.

Rear

Crossover

Remote

Frequency

Punch Bass

RR+

LR-

RF- LF+ Sub-

LR+

RF+ LF- Sub+

RR-

REM

Rear

Punch

Bass

+ -

Rear

Gain

HP-Full-LP

Rear

Crossover

B+

Front

Crossover

Frequency

210

190

145

110

Front

Punch

Front

Bass

Gain

Hz

50

HP-Full-LP

Front

55

Crossover

65

80

GND

2Ω min.

Page 27

– 21 –

Installation

Power 1000 2-channel

• RCA Inputs connect to both left and right channels

• Gain for left and right channels are set equally to balance the subwoofer

• Speaker Impedance should be 4Ω minimum

•

Variable Crossover can be set to High-Pass (HP), Low-Pass (LP) or

Full Range (FULL)

Power 1000

2 -channel

Power 1000

2 -channel

Bridged/Mono Mode

Power Connections

+ -

+ -

I

N

S

T

A

L

L

A

T

I

O

N

*Keep grounds as short as possible

Connect to remote

turn-on lead of

source unit

REM

Less than 18"

B+ GND

+ -

Connect to B+ of battery

with appropriate fuse

RCA Input

Connect to chassis

ground of vehicle*

+ -

4Ω min.

Page 28

– 22 –

• RCA Inputs connect to both left and right channels

• Gain for left and right channels operate independently

• Speaker Impedance for each channel should be 2Ω minimum

• Variable Crossover can be set to High-Pass (HP), Low-Pass (LP) or

Full Range (FULL)

• RCA Inputs connect to both left and right channels

• Gain for left and right channels are set equally to balance the subwoofer

• Speaker Impedance for each stereo channel should be 2Ω minimum

• Speaker Impedance for bridged/mono channel should be 4Ω minimum

•

Variable Crossover must be set for Full Range (FULL)

• Passive Crossovers must be used for proper stereo/mono operation

+ -

Power 1000

2 -channel

Power 1000

2 -channel

2-Channel Mode

3-Channel Mode

+ -

I

N

S

T

A

L

L

A

T

I

O

N

RCA Input

Speaker

+ L -

–

2Ω min.

+

2Ω min.

RCA Input

Speaker

+ R -

–

+

Speaker

+ L -

–

2Ω min.

+

2Ω min.

+ -

4Ω min.

Speaker

+ R -

–

+

Page 29

– 23 –

Operation

• HP Operation enables frequencies above the cut-off point to pass to the speaker

• FULL Operation enables all frequencies to pass to the speaker

•

LP Operation enables frequencies below the cut-off point to pass to the speaker

All Models

Crossover Operation

+ -

+ -

I

N

S

T

A

L

L

A

T

I

O

N

Page 30

– 24 –

• Carefully increase potentiometer to add Punch to your bass frequencies

• Exercise caution when increasing Punch Bass. Maximum boost can cause

potential woofer damage caused by overexcursion

• Pass-Thru feeds signal to secondary amplifier

•

Signal from Pass-Thru remains stereo

Note1: If using High Level Inputs causes engine whine in an amplifier connected

to the Pass-Thru, the Pass-Thru amplifier should have its RCA input

shield connected to the radio chassis ground. Refer to the

Troubleshooting section of this manual for more information.

See Note

1

All Models

+ -

All Models

Remote Punch Bass

Pass-Thru

+ -

I

N

S

T

A

L

L

A

T

I

O

N

Right

Gain

Remote

Punch Bass

HP-Full-LP

Crossover

Speaker

+ R -

33Hz 45Hz

-0 +18

Minimum

Flat

Speaker

+ L -

67.5Hz

210

190

145

110

Crossover Frequency

+18

+12

+6

+3

0dB

33Hz 45Hz

Hz

80

-0 +18

Maximum

Boost

50

55

65

Left Gain

67.5Hz

Input

LR

Pass-Thru

LR

Install Punch Bass in a

convenient location

under vehicle’s dash

Speaker

+ L -

Hz

210

190

145

110

80

Crossover Frequency

50

55

65

Left Gain

Input

Input

LR

Pass-Thru

LR

Right

Gain

Punch Bass

HP-Full-LP

Crossover

Remote

Speaker

+ R -

Left

amplifier if needed.

Connect Pass-Thru to

input of secondary

Right

Page 31

– 25 –

The Phase Warp is a variable control used to adjust the phase of the output signal relative to the phase of the input signal. This "phase alignment"

is most noticable when used with an array of woofers whose vertical or

horizontal planes are staggered (not eminating from the same point.)

Adjusting the Phase Warp can electrically realign the signal fed to each

woofer as if all woofers were aligned on a common ZDP. In SPL systems,

a desired ZDP (Zero Delay Plane) is the point source where all speaker's

voice coils are aligned on the same imaginary plane, thus allowing the

signals to arrive at the microphone at the same time.

The phase warp is most noticable when the system is playing a sine wave

(test tone), not music. When used with the proper test equipment, this

feature can increase the relative SPL in a system.

If the Phase Warp is not used (like with a competitive SPL vehicle,) each

amplifier's Phase Warp should be set to (0˚) or (-).

+ -

• - Phase Warp enables the sine wave to remain unchanged

• ~ Phase Warp delays the sine wave in order to "adjust phase"

• Amount of Phase Warp depends upon frequency being played

Power 1000

2-channel

Phase Warp

+ -

I

N

S

T

A

L

L

A

T

I

O

N

All waveforms are ”phase aligned” at

the targeted microphone position

-

~

Phase

Warp

-

~

Phase

Warp

-

~

Phase

Warp

Page 32

– 26 –

System Diagrams

400 Watt 3-Way System

Punch Woofers

+ –

8Ω

+ –

8Ω

BAND

PUSH

SEL

VOL

MENU

COMPACT DISC PLAYER WITH DIGITAL TUNER

ST RPT RDMLOUDLOCAL

DISP AS/PS

TRACK

SEEK

RDM DISC

RPT

SCAN

123456

Front

+

–

+

–

CD CHANGER CONTROL

LOUDMODE

Rear

+

–

80Hz - 20kHz

24dB/octave HP

TUNE

MUTE

Power

4-Channel

Amplifier

–

+

Fanatic

Component

System

–

+

–

+

20Hz - 80Hz

24dB/octave LP

Page 33

– 27 –

650 Watt 4-Way System

Punch

Midbass

80Hz - 275Hz

12dB/octave LP

12dB/octave HP

Punch Woofers

8Ω

BAND

PUSH

COMPACT DISC PLAYER WITH DIGITAL TUNER

SEL

VOL

MENU

ST RPT RDMLOUDLOCAL

DISP AS/PS

RDM DISC

TRACK

RPT

SCAN

123456

SEEK

Front

+

+

–

–

4Ω

4Ω

+

8Ω

–

MUTE

CD CHANGER CONTROL

LOUDMODE

TUNE

Rear

+

–

+

–

Pass-Thru

Power

4-Channel

Amplifier

+

–

275Hz - 20kHz

24dB/octave HP

Fanatic

Component

System

–

+

–

+

–

+

+

–

Power

2-Channel

Amplifier

20Hz - 80Hz

24dB/octave LP

Page 34

– 28 –

BAND

1050 Watt 4-Way System

PUSH

COMPACT DISC PLAYER WITH DIGITAL TUNER

SEL

VOL

ST RPT RDMLOUDLOCAL

DISP AS/PS

RDM DISC

TRACK

RPT

SCAN

123456

SEEK

MENU

Front

Pass-Thru

Power

4-Channel

Amplifier

+

Punch

Midbass

80Hz - 275Hz

12dB/octave LP

12dB/octave HP

Punch Woofers

+

Fanatic

–

–

4Ω4Ω

+

–

+

–

+

–

275Hz - 20kHz

24dB/octave HP

Component

System

–

+

–

+

–

+

CD CHANGER CONTROL

LOUDMODE

TUNE

Rear

Punch

Midbass

80Hz - 275Hz

12dB/octave LP

12dB/octave HP

MUTE

4Ω 4Ω

Power

4-Channel

Amplifier

+

+

Fanatic

–

–

+

–

+

–

+

–

275Hz - 20kHz

24dB/octave HP

Component

System

–

+

–

+

–

+

20Hz-80Hz

24dB/octave LP

8Ω

RFA-812

+

+

8Ω

–

–

Power

2-Channel

Amplifier

Page 35

– 29 –

BAND

1300 Watt 4-Way System

PUSH

COMPACT DISC PLAYER WITH DIGITAL TUNER

SEL

VOL

ST RPT RDMLOUDLOCAL

DISP AS/PS

RDM DISC

TRACK

RPT

SCAN

123456

SEEK

Front

MENU

Pass-Thru

Power

4-Channel

Amplifier

+

+

Punch

Midbass

80Hz - 275Hz

12dB/octave LP

12dB/octave HP

Punch Woofers

8Ω

–

4Ω 4Ω

+

8Ω

–

–

+

–

+

–

+

–

275Hz - 20kHz

24dB/octave HP

+

–

Fanatic

Component

System

–

+

–

+

–

+

CD CHANGER CONTROL

Rear

Punch

Midbass

12dB/octave HP

MUTE

LOUDMODE

TUNE

+

–

4Ω 4Ω

80Hz - 275Hz

12dB/octave LP

Punch Woofers

Pass-Thru

Power

4-Channel

Amplifier

+

–

+

–

+

–

+

–

275Hz - 20kHz

24dB/octave HP

+

+

Fanatic

Component

System

–

+

–

+

–

+

8Ω8Ω

–

–

20Hz-80Hz

24dB/octave LP

Power

2-Channel

Amplifier

20Hz-80Hz

24dB/octave LP

Power

2-Channel

Amplifier

Page 36

– 30 –

Installation Troubleshooting

If you are having problems after installation follow the

Troubleshooting procedures below.

Procedure 1: Check Amplifier for proper connections.

Verify that POWER light is on. If POWER light is on skip to Step 2, if not

continue.

1. Check in-line fuse on battery positive cable. Replace if necessary.

2. Verify that Ground connection is connected to clean metal of the vehicle’s chassis. Repair/replace if necessary.

3. Verify there is 10.5 - 15.5 Volts of current present at the positive battery

and remote turn-on cable. Verify quality connections for both cables at

amplifier, stereo, and battery/fuseholder. Repair/replace if necessary.

Procedure 2: Check Amplifier for audio output.

1. Connect a single 4 or 8 ohm test speaker directly to each output channel amplifier. Verify speakers in car are good and wiring between

amplifier and speakers, including connectors are good. Repair/replace

if necessary.

2. Verify good RCA/high-level input connections at stereo and amplifier.

Check entire length of cables for kinks, splices, etc. Test RCA/high-level

inputs for AC current with stereo on. Repair/replace if necessary.

3. Disconnect RCA/high-level input from amplifier. Connect RCA/highlevel input from test stereo directly to amplifier input.

Procedure 3: Check Amplifier if you experience Turn-on Pop.

1. Disconnect input signal to amplifier and turn amplifier on and off.

2. If the noise is eliminated, connect the REM lead of amplifier to source

unit with a delay turn-on module.

OR

1. Use a different 12 Volt source for REM lead of amplifier (i.e. battery

direct).

2. If the noise is eliminated, use a relay to isolate the amplifier from noisy

turn-on output.

TROUBLE

S

H

O

O

T

I

N

G

Page 37

– 31 –

Installation Troubleshooting

Procedure 4: Check Amplifier if you experience excess Engine

Noise.

1. Route all signal carrying wires (RCA, Speaker cables) away from power

and ground wires.

OR

2. Bypass any and all electrical components between the stereo and the

amplifier(s). Connect stereo directly to input of amplifier. If noise goes

away the unit being bypassed is the cause of the noise.

OR

3. Remove existing ground wires for all electrical components. Reground

wires to different locations. Verify that grounding location is clean,

shiny metal free of paint, rust etc.

OR

4. Add secondary ground cable from negative battery terminal to the

chassis metal or engine block of vehicle.

OR

5. Have alternator and battery load tested by your mechanic. Verify good

working order of vehicle electrical system including distributor, spark

plugs, spark plug wires, voltage regulator etc.

TROUBLE

S

H

O

O

T

I

N

G

Page 38

– 32 –

Dynamic Power Measurements

About the Dynamic Power Measurements

The Audio Graph PowerCube is a test instrument used to measure the output of an

amplifier in accordance with IHF-202 industry standards. The IHF-202 standard is a

dynamic power measurement and was developed as a means of measuring power

in a manner that best represents the Real World operation of an amplifier. Many

manufacturers, including Rockford Fosgate, at times will measure amplifier power

into a fixed resistor (4 ohm, 2 ohm). While this method is useful in some types of

evaluation and testing, it is not representative of an amplifier that is connected to a

speaker and playing music.

Music

Music is dynamic; the sound waves are complex and constantly changing. In order

to simulate this, the IHF-202 standard calls for the input signal to the amplifier to be

a 1kHz bursted tone. This signal is input (on for 20 milliseconds) and reduced 20dB

for 480 milliseconds. The signal is gradually increased in level until the amplifier's

output exceeds 1% Total Harmonic Distortion (THD). At 1% distortion becomes

audible, therefore, any power produced above that level is considered unusable.

Many manufacturers represent their amplifiers' output power in excess of 10% distortion. They use many names for this measurement, such as Total Maximum Power

or Maximum Output Power. This is not indicative of the actual usable output power.

Listening to Loudspeakers - Not Resistors

A loudspeaker is not a resistor. A resistor's value (resistance measured in ohms) is

fixed. A loudspeaker's impedance is dynamic. It is constantly changing in value,

dependent upon the frequency of the input signal. Therefore, measuring power with

the amplifier loaded into a 4 ohm resistor is not the same as measuring power with

the amplifier connected to a 4 ohm speaker. Most people do not listen to music

through a resistor.

A4 ohm speaker may experience a drop in impedance 4-6 times lower than its nominal (printed) impedance. A speaker will also create phase shifts in the signal that is

passed through it. These phase shifts happen because a speaker is an inductor (voice

coil) and a capacitor (compliance of the surround/spider), as well as a resistor (voice

coil wire).

To simulate a speaker the Audio Graph PowerCube measures output power into 20

different loads. It tests at 8 ohms, 4 ohms, 2 ohms and 1 ohm. Each of these impedances is also tested at –60°, –30°, 0°, +30° and +60° phase angles. These different

impedances and phase angles represent the shifts in impedance and phase that can

occur in a typical loudspeaker.

Page 39

– 33 –

Information Cubed

The data acquired in the testing procedure is then graphed in the form of a

3-dimensional cube, hence the name PowerCube.

The Phase Angle is expressed on the horizontal axis, the Output Voltage is

presented on the vertical axis and the Impedance is displayed on the Z axis.

Output Power, in watts, is listed on the left hand side for each impedance

at each phase angle.

What is an Amplifier?

An amplifier by definition is a voltage generating device, recreating the signal which is input to it identically but with increased volume. It will be connected to a reactive load (the speaker). The impedance of this load and

phase of the signal passing through the load will vary, dependent upon the

frequency of the input signal (music).

Therefore, a perfect amplifier will be able to maintain the same output voltage regardless of load characteristics and will not alter the signal it is reproducing. Aperfect amplifier when measured by the Audio Graph PowerCube

would present data that forms a perfect cube. Unfortunately, amplifiers are

not perfect. The laws of physics generally prevent it. A great amplifier is

about the best one can hope to attain.

As you can see by the PowerCube and as you will experience by listening,

your Punch amplifier is a GREAT AMPLIFIER!

• Example of a Punch Amplifier PowerCube

Audio Graph – The PowerCube™

MODEL BEING

TESTED

Amplifier:

PUNCH 200.2 14.4V x 2

Serial No:

Owner :

ROCKFORD CORPORATION

85 W

8Ω –60°

*

84 W

–30°

84 W

0°

84 W

30°

86 W

60°

162 W

4Ω –60°

*

157 W

–30°

156 W

0°

157 W

30°

162 W

60°

273 W

2Ω –60°

*

IMPEDANCE

–30°

30°

60°

1Ω –60°

*

–30°

30°

60°

258 W

251 W

0°

256 W

271 W

390 W

356 W

346 W

0°

352 W

390 W

VOLTAGE FROM

BATTERY

POWER

IN

WATTS

{

–60° (Cap)

MONO = BRIDGED MONO

0°

{

PHASE ANGLES

x2 = STEREO

Rated Power : 100 W @ 4 Ohms

2Ω

1Ω

(Ind) +60°

{

Impedance

50V

30V

10V

OUTPUT VOLTAGE

8Ω

4Ω

Page 40

– 34 –

Limited Warranty Information

Rockford Corporation offers a limited warranty on Rockford Fosgate products on the

following terms:

•

Length of Warranty

3 years on electronics-90 days on electronic B-stock (receipt required)

1 years on source units

1 year on speakers-90 days on speaker B-stock (receipt required)

•

What is Covered

This warranty applies only to Rockford Fosgate products sold to consumers by

Authorized Rockford Fosgate Dealers in the United States of America or its possessions. Product purchased by consumers from an Authorized Rockford Fosgate

Dealer in another country are covered only by that country’s Distributor and not

by Rockford Corporation.

•

Who is Covered

This warranty covers only the original purchaser of Rockford product purchased

from an Authorized Rockford Fosgate Dealer in the United States. In order to

receive service, the purchaser must provide Rockford with a copy of the receipt

stating the customer name, dealer name, product purchased and date of purchase.

•

Products found to be defective during the warranty period will be repaired or

replaced (with a product deemed to be equivalent) at Rockford's discretion.

•

What is Not Covered

1. Damage caused by accident, abuse, improper operations, water, theft

2. Any cost or expense related to the removal or reinstallation of product

3. Service performed by anyone other than Rockford or an Authorized Rockford

Fosgate Service Center

4. Any product which has had the serial number defaced, altered, or removed

5. Subsequent damage to other components

6. Any product purchased outside the U.S.

7. Any product not purchased from an Authorized Rockford Fosgate Dealer

•

Limit on Implied Warranties

Any implied warranties including warranties of fitness for use and merchantability are limited in duration to the period of the express warranty set forth above.

Some states do not allow limitations on the length of an implied warranty, so this

limitation may not apply. No person is authorized to assume for Rockford

Fosgate any other liability in connection with the sale of the product.

•

How to Obtain Service

Please call 1-800-669-9899 for Rockford Customer Service. You must obtain an

RA# (Return Authorization number) to return any product to Rockford Fosgate.

You are responsible for shipment of product to Rockford.

Ship to:

Electronics

Rockford Corporation

Warranty Repair Department

2055 E. 5th Street

Tempe, AZ 85281

RA#:_________________

Ship to:

Speakers

Rockford Acoustic Design

(Receiving-speakers)

609 Myrtle N.W.

Grand Rapids, MI 49504

RA#:_________________

Page 41

– 35 –

ESPAÑOL

International Information

LEA DETENIDAMENTE LAS SIGUIENTES INSTRUCCIONES DE INSTALACION DEL

PRODUCTO. EVITARA POSIBLES DAÑOS A VD., AL VEHICULO O AL PRODUCTO.

Introduccion

Los ingenieros de Rockford han diseñado los amplificadores Power para

ofrecer en el dificil entorno de un automóvil una calidad de sonido superior en un producto flexible, fiable y eficiente. Trans•ana es un circuito de

baja tensión en la etapa de preamplificación de los amplificadores Power

que permite que la musica suene limpia y cristalina y muy real, incluso a

altos niveles de audicion. Esto se complementa con el TOPAZ, un circuito

exclusivo de masa utilizado para eliminar los ruidos asociados con las instalaciones de car-audio. La flexibilidad esta garantizada con el uso de la

XCard incorporada. La fiabilidad se refuerza con el uso de un circuito de

proteccion llamado NOMAD, mientras que los MOSFET y la tecnologia

DSM (montaje discreto en superficie) aumentan la eficiencia del amplificador. La combinacion de todos estos componentes dan al amplificador

Power una impresionante calidad de sonido en un chasis discreto. Mas adelante encontrará mas explicaciones de todas estas tecnologías, la mayoria

de ellas usados en exclusiva y patentadas por Rockford.

Montaje en el Malatero

Monte el amplificador verticalmente con las lineas del radiador orientadas

de arriba hacia abajo. De esta manera conseguira la mejor ventilacion.

Montaje en el Compartimento de Pasajeros

El montaje en el compartimento de pasajeros sera eficiente en funcion de la

ventilacion que tenga el amplificador. Si va a instalar el amplificador bajo

un asiento deberá dejar al menos 2.5cm libres sobre la carcasa del amplificador.

Instalacion

Por seguridad, desconecte el terminal negativo de la bateria antes de

comenzar la instalacion.

Terminal B+

El cable B+ debe ir provisto de un fusible a una distancia no mayor de 45cm

de la bateria. Prepare el cable e instale el portafusibles en el compartimento del motor. Las conexiones han de ser impermeables.

Page 42

– 36 –

Terminal GND

Prepare un trozo de cable para usarlo como toma de masa. Prepare un

punto de masa en el chasis rascando y eliminando la pintura de la supericie

de metal y limpielo de toda suciedad asegure el cable al chasis con un

tornillo.

Terminal REM

Conecte el cable REM a un punto de +12V con mutable. La señal se suele

coger de la salida auto antena del radio cassette si este no tiene salida

remote.

Power 250 Power 360

2-canales 2-canales

Power 500

2-canales

Power 800 Power 1000

2-canales 2-canales

ESPAÑOL

Funcionamiento Estereo/Mono

Hz

210

50

190

55

145

110

65

Left Gain

80

Crossover Frequency

Speaker

+ L -

–

+

RCA Input

LR

LR

2Ω min.

+ -

HP-Full-LP

Input

Pass-Thru

2Ω min.

4Ω min.

Crossover

Right

Remote

Gain

Punch Bass

Speaker

+ R -

–

+

Page 43

– 37 –

Power 400 Power 800

4-canales 4-canales

ESPAÑOL

Funcionamiento Estereo

4-2

Input

Front

4/2

Crossover

Input

HP-Full-LP

LR+ LR- RR+ RR- B+ GND LF- LF+ RF+RF-

+ -

2Ω min.

Hz

210

190

145

110

Front

Front

Gain

Crossover

Frequency

+ -

2Ω min.

4-channel

50

55

65

80

Front Pass-Thru Rear

REM

Input

RR

LL

Hz

210

50

190

55

145

Rear

110

65

Crossover

80

Rear

Rear

HP-Full-LP

Rear

Gain

+ -

2Ω min.

Remote

Punch

Bass

+ -

Crossover

Frequency

2Ω min.

Page 44

– 38 –

ATTENTION: Veuillez lire les instructions suivantes pour l'installation de cet

amplificateur. Ne pas les suivre pourrait causer des blessures ou endommager

le véhicule.

Introduction

Les ingénieurs de Rockford Fosgate ont conçu l'amplificateur Power pour

supporter l'environnement rude de l'automobile en délivrant une qualité de

son supérieure dans un ensemble efficace, fiable et flexible.

Trans•ana/Trans•nova est un circuit de bas voltage dans l'étage de préamplification de tous les amplificateurs Punch qui reproduit un son musical

clair comme du cristal et très réel, même à très haut volume. Ceci est

accompagné du TOPAZ, un circuit unique employé pour éliminer les problèmes de bruits parasites associés aux systémes audiomobile et leur installation.

La fiabilité est garantie grâce au circuit de protection NOMAD, la technologie MOSFET et DSM (Composants Montés en Surface) améliorent l'efficacité de l'amplificateur.

L'ensemble de ces atouts donne à l'amplificateur Power une qualité de son

inégalable sous une carrosserie “pare-balles.”

Montage

Montage dans le coffre

Monter l'amplificateur verticalement avec les rainures de haut en bas ce qui

lui permet de refroidir plus facilement.

Montage dans l'habitacle

Monter l'amplificateur dans l'habitacle ne pose aucun problème, du

moment qu'il y ait assez d'air pour le refroidir. Si vous montez l'ampli en

dessous du siège, prévoyez 2.5 cm d'air autour du radiateur.

Installation

Pour votre sécurité, déconnectez la borne négative de la batterie du

véhicule avant de commencer l'installation.

Terminal B+

Il est impératif qu'il y ait un fusible sur le câble pour la connexion à la

masse. Préparez le châssis en grattant la peinture de la surface métallique et

nettoyez la saleté et l'huile. Attachez le câble au châssis avec une vis.

FRANÇAIS

Page 45

– 39 –

Power 250 Power 360

2-canales 2-canales

Power 500

2-canales

Power 800 Power 1000

2-canales 2-canales

FRANÇAIS

Terminal GND

Préparez une longueur de câble pour la connexion à la masse. Préparez le

châssis en grattant la peinture de la surface métallique et nettoyez la saleté

et l'huile. Attachez le câble au châssis avec une vis.

Terminal REM

Connectez le fil REM à une commande 12 volts positive de la source. La

commande 12 volts est habituellement prise sur la sortie antenne électrique

de la source ou la commande accessoire. Si la source ne dispose pas de ces

sorties, nous vous recommandons d'installer un interrupteur qui fournira un

positif 12 volts au REM de l'amplificateur.

Opération stéréo/mono

Speaker

+ L -

Hz

210

50

190

55

145

110

65

Left Gain

80

Crossover Frequency

–

+

RCA Input

LR

LR

2Ω min.

+ -

Input

Pass-Thru

4Ω min.

HP-Full-LP

Crossover

Right

Remote

Gain

Punch Bass

Speaker

+ R -

–

2Ω min.

+

Page 46

– 40 –

Power 400 Power 800

4-canales 4-canales

FRANÇAIS

Opération stéréo

4-channel

Hz

210

50

55

65

80

Front

Front Pass-Thru Rear

REM

Input

RR

LL

Hz

210

190

145

110

80

Rear

Crossover

Frequency

2Ω min.

50

55

65

4-2

Input

190

4/2

Input

145

110

Front

Gain

Crossover

Frequency

+ -

2Ω min.

Front

Crossover

HP-Full-LP

LR+ LR- RR+ RR- B+ GND LF- LF+ RF+RF-

+ -

2Ω min.

Rear

Crossover

Rear

Rear

HP-Full-LP

Gain

Remote

Punch

Bass

+ -

+ -

2Ω min.

Page 47

– 41 –

BITTE LESEN SIE DIESE GEBRAUCHSANLEITUNG ZUERST SORGFÄLTIG DURCH.

DAS KANN SIE VOR DEM FALSCHEN EINSATZ, AUSFALLEN ODER SOGAR

BESCHÄDIGUNG DES PRODUKTES ODER IHRES FAHRZEUGES SCHÜTZEN.

Einleitung

Rockford Ingenieure haben die Power Verstärker entwickelt. Mit höchstem

Technologie-Standart, hervorragender Klangqualität, einfacher

Handhabung und bester Servicefreundlichkeit Trans•ana/Trans•nova ist

eine Nieder-Volt Schaltung im Vorverstärkerteil aller Pünch Verstärker die

für kristallklaren Klang auch bei sehr hohen Lautstärken sorgt. TOPAZ, eine

einzigartige Erdungsschaltung verhindert und unterdrückt Einstreuungen

und Störungen die nur allzu oft Car Audio Systeme beeinträchtigen.

Flexibilität durch die Vielfalt der Aktivweiche mit ihren Lebensdauer durch

die Schutzschaltung NOMAD und der Einsatz von MOSFET Transistoren

und DSM (Discrete Surface Mount), machen diese Verstärker so effizient.

Das Ergebnis all dieser Komponenten machen Power-Verstärker so einzigartig und in ihrer Klangqualität nahezu unschlagbar.

Einbauort

Im Fahrzeugkofferraum

Der vertikale Einbau der Endstufen, das bedeutet, dab die Kühlrippen von

oben nach unten verlaufen, gibt dem Verstärker die beste Kühlung.

Auf der Beifahrerseite

Sollte der Verstärker auf der Beifahrerseite montiert werden, so ist es sehr

wichtig, für eine ausreichende Kühlung zu sorgen. Sollte der Verstärker z.B.

unter dem Beifahrersitz montiert werden, sollte dem Kühlkörper mindestens

ein Luftspalt von 2.5 cm bleiben, um so für eine ausreichende Kühlung zu

sorgen.

Einbau

Zur Sicherheit klemmen Sie den Negativ-Pol der Batterie während des

gesamten Einbaues ab.

B+ Anschlub

Die Plus-Leitung MUb ca. 45 cm nach dem Plus-Pol der Batterie

abgesichert sein. Preparieren Si die Kabellängen und montieren Sie den

Sicherungshalter im Motorraum. ALLE Verbindungen müssen wasserdicht

sein.

DEUTSCH

Page 48

– 42 –

DEUTSCH

Power 250 Power 360

2-canales 2-canales

Power 500

2-canales

Power 800 Power 1000

2-canales 2-canales

GND Anschlub

Preparieren Sie Ihr Kabel für die Negativ Leitung (Erdung). Preparieren Sie

die Anschlubstelle des Erdungskabels, indem Sie das Metall gründlich reinigen und vom Lack befreien. Befestigen Sie nun die Erdung an dieser Stelle

mit einer Schraube.

REM Anschlub

Verbinden Sie das Ein-und Ausschaltungskontroll-Kabel mit Ihrem Radio

(12 Volt positiv). Normalerweise verwenden Sie hierfür die Ant.-Remote

Ihres Radios oder ein eigens dafür vorgesehenes Kabel (Amp-Remote).

Sollte Ihr Radio diesen Anschlub nicht besitzen, so verwenden Sie eine 12

Volt Spannung, die Sie durch einen Schalter ein- und ausschalten können.

Stereo/Mono Operation

Speaker

+ L -

Hz

210

50

190

55

145

110

65

80

Crossover Frequency

–

+

Left Gain

2Ω min.

RCA Input

Input

LR

Pass-Thru

LR

2Ω min.

+ -

4Ω min.

HP-Full-LP

Crossover

Right

Remote

Gain

Punch Bass

Speaker

+ R -

–

+

Page 49

– 43 –

Power 400 Power 800

4-canales 4-canales

DEUTSCH

Stereo Operation

+ -

4-channel

Hz

50

55

65

80

Front

Front Pass-Thru Rear

REM

Input

RR

LL

Hz

210

190

145

110

80

Rear

Crossover

Frequency

2Ω min.

50

55

65

Rear

Gain

4-2

Input

210

190

4/2

Input

145

110

Front

Gain

Crossover

Frequency

+ -

2Ω min.

Front

Crossover

HP-Full-LP

LR+ LR- RR+ RR- B+ GND LF- LF+ RF+RF-

2Ω min.

Rear

Crossover

Rear

HP-Full-LP

Remote

Punch

Bass

+ -

+ -

2Ω min.

Page 50

– 44 –

ATTENZIONE: SI PREGA DI LEGGERE LE SEGUENTI ISTRUZIONI PER L'INSTALLAZIONE DI QUESTO PRODOTTO. IL NON SEGUIRLE POTREBBE RISULTARE SERIAMENTE DANNOSO PER LA PERSONA O PER IL VEICOLO.

Introduzione

Gli ingenieri Rockford hanno progettato la serie di amplificatori Power per

resistere all'ostico ambiente automobilistico mentre suonano con una musicalitá superiore, offrendo un insieme versatile, affidabile ed efficiente.

Trans•ana/Trans•nova é un circuito a bassa tensione dello stadio preamplificatore del Punch che permette al suono di essere cristallino e reale anche