Rockford OEQ2 Owner's Manual

HIGH

PERFORMANCE

PARAMETRIC

EQUALIZER

INSTALLATION

& O PERATION

®®

Dear Customer,

Congratulations on your purchase of the world's finest brand of car audio signal

processors. At Rockford Fosgate we are committed to musical reproduction at its best,

and we are pleased you chose our product. Through years of engineering expertise, hand

craftsmanship and critical testing procedures, we have created a wide range of products

that reproduce music with all the clarity and richness you deserve.

For maximum performance we recommend you have your new Rockford Fosgate

product installed by an Authorized Rockford Fosgate Dealer, as we provide specialized

training through Rockford Technical Training Institute (RTTI). Please read your

warranty and retain your receipt and original carton for possible future use.

To add the finishing touch to your new Rockford Fosgate image order your Rockford

accessories, which include everything from T-shirts and jackets to hats and sunglasses.

To get a free brochure on Rockford Fosgate products and Rockford accessories, in the

U.S. call 602-967-3565 or FAX 602-967-8132. For all other countries, call +001-602967-3565 or FAX +001-602-967-8132.

PRACTICE SAFE SOUND™

CONTINUOUS EXPOSURE TO SOUND PRESSURE LEVELS OVER

100dB MAY CAUSE PERMANENT HEARING LOSS. HIGH POWERED AUTO SOUND SYSTEMS MAY PRODUCE SOUND PRESSURE LEVELS WELL OVER 130dB. USE COMMON SENSE AND

PRACTICE SAFE SOUND.

If, after reading your manual, you still have questions regarding this product,

we recommend that you see your Rockford Fosgate dealer. If you need further

assistance, you can call us direct at 1-800-795-2385. Be sure to have your serial

number, model number and date of purchase available when you call.

The serial number can be found on the outside of the box. Please record it in

the space provided below as your permanent record. This will serve as

verification of your factory warranty and may become useful in recovering your

equipment if it is ever stolen.

Serial Number: ____________________

Model Number:____________________

TABLE OF CONTENTS

Introduction ............................................................................................1

Accessory Pack .......................................................................................1

Technical Design Features ......................................................................2

Design Features.......................................................................................3

Installation Considerations ......................................................................5

Mounting Location..................................................................................6

Wiring the System ...................................................................................6

OEQ2 Installation....................................................................................8

OEQ2 Operation ...................................................................................13

System Diagrams...................................................................................16

Rockford Fosgate Accessories................................................................20

Troubleshooting ....................................................................................21

Specifications........................................................................................24

Warranty Information............................................................................25

International Information.......................................................................26

GETTING STARTED

Welcome to Rockford Fosgate! This manual is designed to provide

information for the owner, salesperson and installer. For those of you who

want quick information on how to install this product, please turn to the

Installation Section of this manual or refer to the icons listed below. Other

information can be located by using the Table of Contents. We, at

Rockford Fosgate, have worked very hard to make sure all the information

in this manual is current. But, as we are constantly finding new ways to

improve our product, this information is subject to change without notice.

I

a

O

p

d

e

v

r

a

a

n

t

c

i

e

o

d

n

Sections marked

ADVANCED OPERATION

include in-depth

technical information

® ®

N

S

T

A

L

L

A

T

I

O

N

Sections marked

INSTALLATION

include “slam dunk”

wiring connections

TROUBLE-

S

H

O

O

T

I

N

G

Sections marked

TROUBLESHOOTING

include recommendations

for curing

installation problems

INTRODUCTION

The OEQ2 is an octave equalizer used to help compensate for

acoustical inaccuracies common in the automobile environment.

The OEQ2 is a stereo equalizer with ten bands of frequency adjustment spaced at octave intervals. Each band can accommodate up to

12dB of boost or cut to overcome dips and peaks in the response

curve. Frequency Warp controls shift center frequencies half an

octave up and half an octave down for precise adjustment. Input and

output gains are utilized for proper gain settings while a pair of LED

monitors track input levels. The high output voltage available from

the OEQ2 allows it to also be used as a line driver, and its low output

impedance supports the connection of several amplifiers without

signal degradation. The OEQ2 is a versatile, high performance

equalizer with convenient features that will fine tune any system and

help solve response problems.

ACCESSORY PACK

Installation and Operation Manual

(4) Mounting Screws

(1) Power Connector

– 1 –

TECHNICAL DESIGN FEATURES

◆ High-Q Filters

Hi-Q filters are utilized for adjusting narrow frequency bands in an

equalizer. Filter “Q” or Quality Factor is a measure of the “narrowness” of the filter response. Using Low-Q (wide) filters in an equalizer

allows adjustments made on one control to strongly effect neighboring frequencies during boost or cut. Hi-Q filters avoid problems like

adjacent band overlap which minimize the time needed to remove

frequency response errors.

THE RESULT: Avoids adjacent band overlap through precise filtering.

◆ Frequency Warp

The Frequency Warp controls shift the center frequency of each band

higher or lower in frequency (up to 1/2 octave). This enables the

equalizer to pinpoint “dips” and “peaks” in the response curve. The

frequency warp is useful when using an RTA (Real Time Analyzer) to

find and correct problems located between the equalizer's center

frequencies.

THE RESULT: Easier to equalize response errors by pinpointing

problem frequencies.

◆ Balanced Line Inputs

Using the BLT (Balanced Line Transmitter) provides the last word in

achievable rejection of noise induced in the cable between the

source and the signal processor. The differential input circuitry used

in the balanced input system rejects whatever signals are common to

both of the shielded, twisted pair conductors. Balanced line is

universally used in concert installations where the stage and mixing

consoles are hundreds of feet apart. Long signal cables and electrically-noisy environments make signal integrity and noise rejection

an extremely difficult challenge.

THE RESULT: Quiet transmission of audio from source to signal

processor.

– 2 –

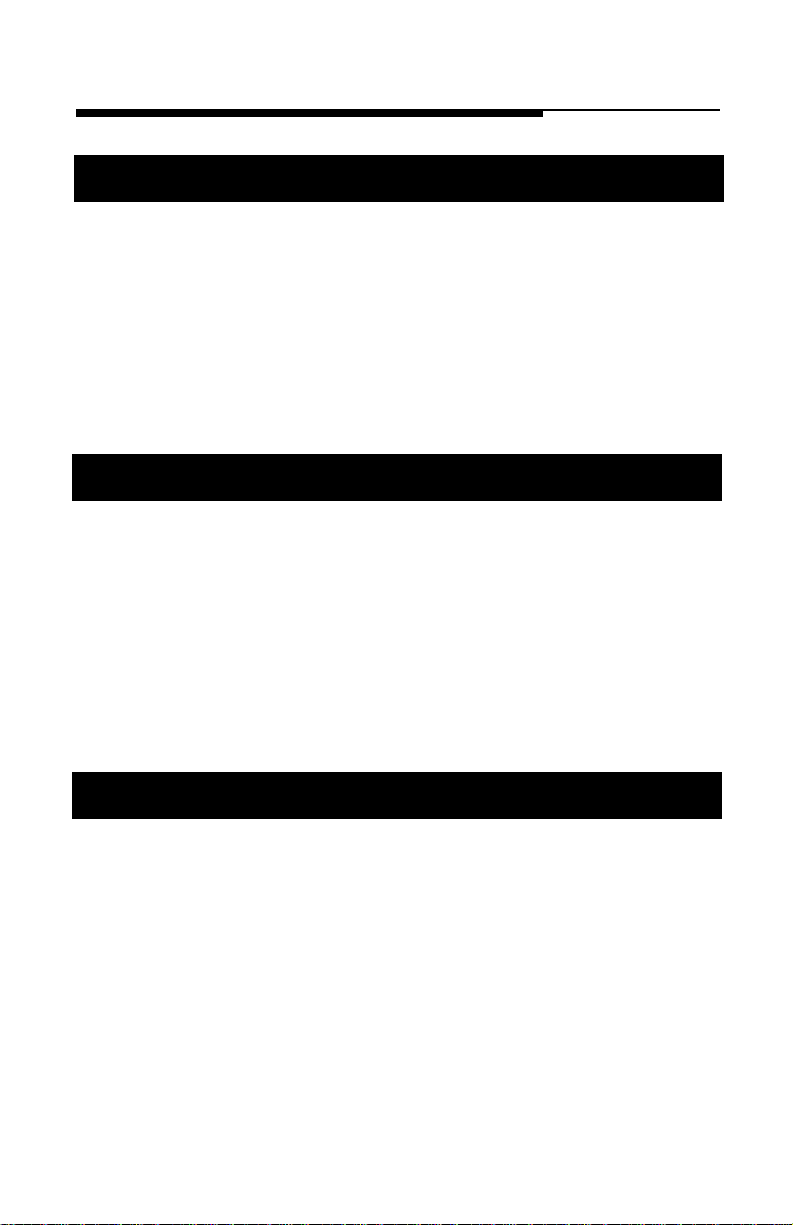

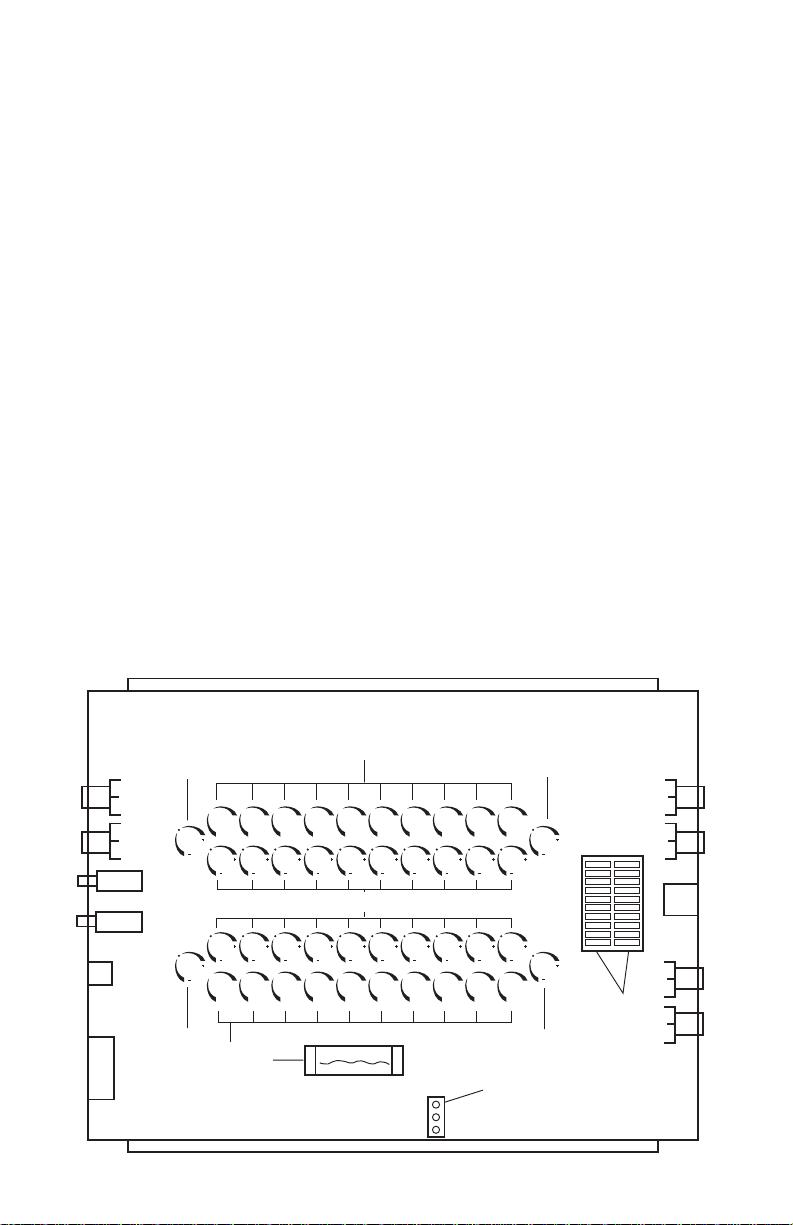

DESIGN FEATURES

LEFTINRIGHT

IN

1432 12

RIGHT LEFT

6

BYPASS

ENGAGE

BAL OUT

7

BAL

BAL INRCA

RIGHT LEFT

GND B+ REM

6

1. RCA Input Jacks – The industry standard RCA jacks provide easy

connections for signal level input. They are gold-plated to resist the

signal degradation caused by corrosion.

2. Balanced Line Input – This input will allow the optional Balanced

Line Transmitter to be used for better noise rejection.

3. Signal Input Switch– This switch allows selection of either RCA or

Balanced Line inputs.

4. Engage/Bypass Switch – This switch enables the OEQ2 to process the

signal or bypass the Boost/Cut and Frequency Warp controls for a

“dry” output.

5. Input Sensitivity Controls – The input sensitivity controls are preset

for

500mV

can be adjusted to match input levels ranging from

which will match the output of most source units. They

500mV to 9.3V

6. RCA Output Jacks – The RCA Output Jacks provide a parallel output

and are used to connect the signal to the next component's input

jacks. They are gold-plated to resist the signal degradation caused by

corrosion.

7. Balanced Line Output – The balanced output allows a balanced line

cable to be used between the output of the OEQ2 and the input of the

next component to provide better noise rejection.

– 3 –

.

8. Output Level Attenuators – The Output Level Attenuators are

used to cut the output level for matching the input of the amplifier.

They can be adjusted to levels ranging from a minimum ratio of

1:0 (no output) to a maximum ratio of 1:1.

9. Boost/Cut Controls – These controls provide up to 12dB of boost

or cut to the selected frequency.

10. Frequency Warp Controls – These controls provide up to an

octave range (1/2 octave up and 1/2 octave down) from the center

frequency to pinpoint “dips” and “peaks”.

11. LED Level Indicators – The level indicators monitor the input level

of the OEQ2. The indicators utilize green, amber and red LEDs to

represent low, high and maximum signal level.

12. Power Connector – The power connector provides a convenient

connection for ground, power and remote. The connector uses

“screw lock” terminals to secure the power wires and is removable for quick disconnects.

13. B+ Fuse – The B+ fuse protects the power supply and battery from

short circuits and power failures.

14. DGND/AGND Jumper – This jumper is used for troubleshooting

systems which may exhibit noise due to ground loops or lack of

ground potential.

9

5

F

T

E

0

0

0

0

0

0

0

0

+

+

+

+

+

L

12

12

12

-12

-12

12

-12

-12

+

12

12

-12

-12

0

+

+

12

12

-12

-12

-12

8

0

+

+

12

12

-12

10

R

I

G

H

0

0

0

0

0

0

0

0

-12

CHS

AGND

0

+

+

12

+

12

12

-12

-12

11

8

14

0

+

+

+

+

+

+

12

12

12

12

T

-12

-12

-12

5

9

13

12

-12

-12

+

12

12

-12

-12

DGND

– 4 –

INSTALLATION CONSIDERATIONS

The following is a list of tools you will need for installing the OEQ

Red power wire Wire strippers

Blue remote turn-on wire Wire cutters

Black grounding wire Voltmeter

Electric hand drill w/assorted bits Jeweler's slotted screwdriver

Battery post wrench

This section focuses on some of the vehicle considerations for installing

your new OEQ2. Pre-planning your system layout and best wiring routes

will save installation time. When deciding how to lay out your new

system, be sure that each component will be easily accessible for making

adjustments.

Before beginning any installation, be sure to follow these simple rules:

1. Be sure to carefully read and understand the instructions before

attempting to install the OEQ2.

2. For safety, disconnect the negative lead from the battery prior to

beginning the installation.

3. For easier assembly, we suggest you run all wires prior to mounting

your OEQ2 in place.

4. Route all of the RCA cables close together and away from any high

current wires.

5. Use high quality connectors for a reliable installation and to minimize signal or power loss.

6. Think before you drill! Be careful not to cut or drill into gas tanks, fuel

lines, brake or hydraulic lines, vacuum lines or electrical wiring when

working on any vehicle.

7. Never run wires underneath the vehicle. Running the wires inside the

vehicle provides the best protection.

8. Avoid running wires over or through sharp edges. Use rubber or

plastic grommets to protect any wires routed through metal, especially the firewall.

9. ALWAYS protect the battery and electrical system from damage with

proper fusing. Install the appropriate fuseholder and fuse on the

+12V power wire within 18” (45.7 cm) of the battery terminal.

10. When grounding to the chassis of the vehicle, scrape all paint from

the metal to ensure a good, clean ground connection. Grounding

connections should be as short as possible and always be connected

to metal that is welded to the main body, or chassis, of the vehicle.

2

– 5 –

MOUNTING LOCATION

The mounting location for the OEQ2 should allow easy access to the

controls for making necessary adjustments. The OEQ2 will most likely be

adjusted only at the time of installation and will not need further

adjustment unless changes to the audio system are performed. To ensure

optimum performance, care should be taken when mounting the equalizer in the following locations:

Engine Compartment

Mounting the OEQ2 in the engine compartment will void your warranty.

The only thing that should be mounted in the engine compartment is that

big metal thing that makes the vehicle go fast.

Passenger Compartment Mounting

Mounting the equalizer in the passenger compartment will provide easy

access for making adjustments by ear. Select an area which is free from

excessive dirt or dust. If mounting under the seat, be sure the OEQ2 will

avoid misadjustment from driver or passenger seat movement.

Trunk Mounting

Mounting the equalizer in the trunk will provide easy access for making

adjustments with an RTA (Real Time Analyzer) and pink noise. Select an

area which will avoid possible damage or misadjustment from loading

and unloading items such as groceries, golf clubs and packages from the

trunk.

WIRING THE SYSTEM

For safety, disconnect the negative lead from the car battery prior to

beginning the installation.

1. Wire the Power Connector

The B+ lead should be connected to a source of non-switched 12 volts

DC. Prepare a length of cable from the constant +12V by stripping 3/8"

of insulation from the end of the wire. Insert the bared wire into the B+

terminal of the power connector and fasten the screw.

NOTE: The B+ lead of the audio system MUST be fused 18" or less from

the vehicle's battery. Install a fuseholder, along with the necessary

fuse, under the hood. Connections should be water tight.

The REM lead should be connected to the remote turn-on or power

antenna output from the source unit. Prepare a length of cable from the

source of switched voltage by stripping 3/8" of insulation from the end

– 6 –

of the wire. Insert the bared wire into the REM terminal of the power

connector and fasten the screw. Total current consumption through

this lead is negligible.

The GND lead should be connected to the chassis ground of the

vehicle. Prepare a length of cable (approximately 12" long) to be used

for the ground lead by stripping 3/8" of insulation from each end.

Insert one end of bared wire into the GND terminal of the power

connector and fasten the screw. Prepare the chassis ground by

scraping any paint from the metal surface and thoroughly clean the

area of all dirt and grease. Strip the other end of the wire and attach

a ring connector. Fasten the cable to the chassis using a non-anodized

screw and star washer.

2. Connect the Source Inputs

To accept RCA inputs, the signal input switch should be OUT.

Connect the front RCA outputs from the source unit to the “LEFT IN”

and “RIGHT IN” connectors on the OEQ2.

To accept Balanced Line Inputs, the signal input switch should be IN.

Connect the front RCA outputs from the source unit to the inputs on

the BLT. Connect the balanced line cable from the BLT to the “BAL

IN” connector on the OEQ2.

3. Connect the Outputs

Connect the appropriate outputs from the OEQ2 to the corresponding

inputs on the amplifier(s) or signal processor(s). For greater system

flexibility, all outputs from the OEQ2 are configured in parallel (refer

to the System Diagrams section of this manual for examples).

4. Adjust System Levels

Set the gain controls on the amplifier(s) as well as the input gain and

output attenuators on the OEQ2 to minimum. Adjust all Boost/Cut

and Frequency Warp controls to their center position. Adjust 1kHz

Boost/Cut to maximum. Using a 1kHz test tone recorded at ”0dB” or

“all bits high,” adjust the source unit for its maximum unclipped

output. Adjust the input sensitivity on the OEQ2 until the first red LED

on the OEQ2 starts to illuminate. Stop the test tone and do not readjust

the volume control. Readjust 1kHz on Boost/Cut to its center position.

Play a musical track with high dynamic content and adjust the output

attenuators on the OEQ2 to the desired output level (be sure Left and

Right channels are matched). Typically, the amplifier gain controls

will be left at minimum for optimum signal-to-noise ratio. For more

information on adjusting system levels, refer to the Installation

section of this manual.

– 7 –

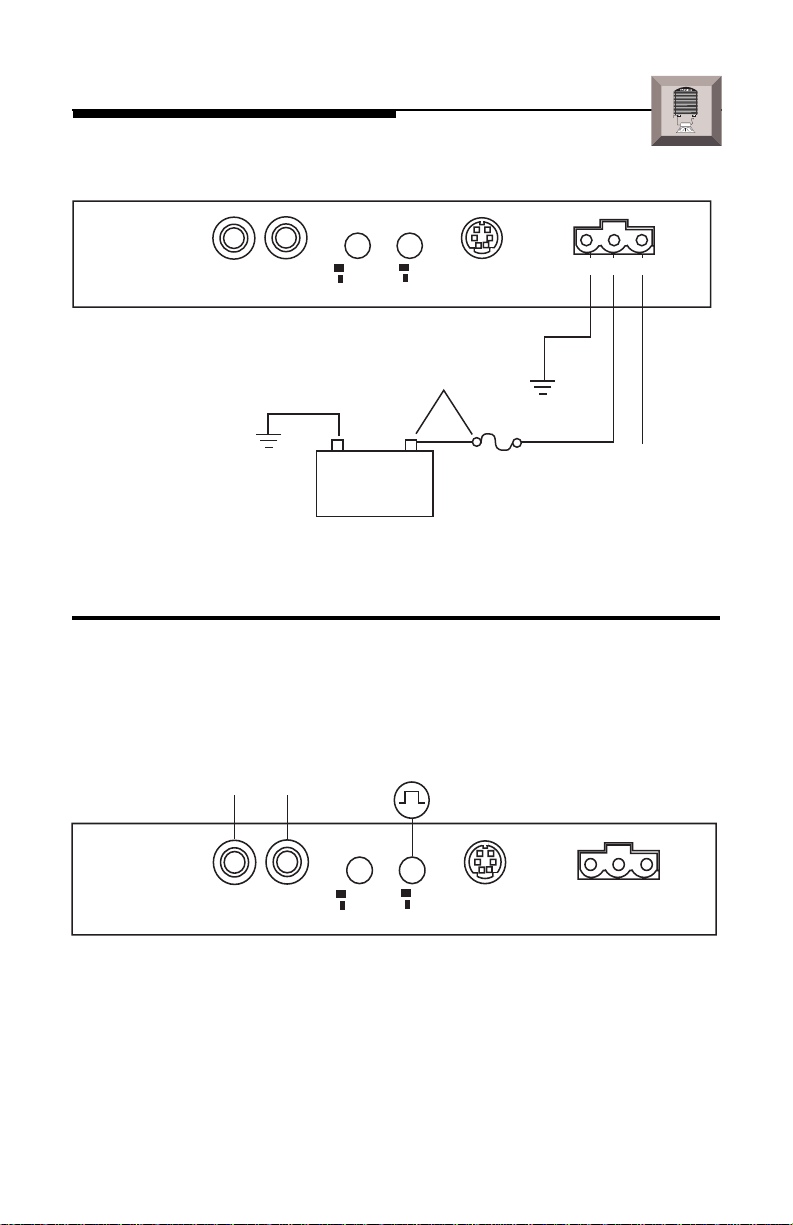

OEQ2 INSTALLATION

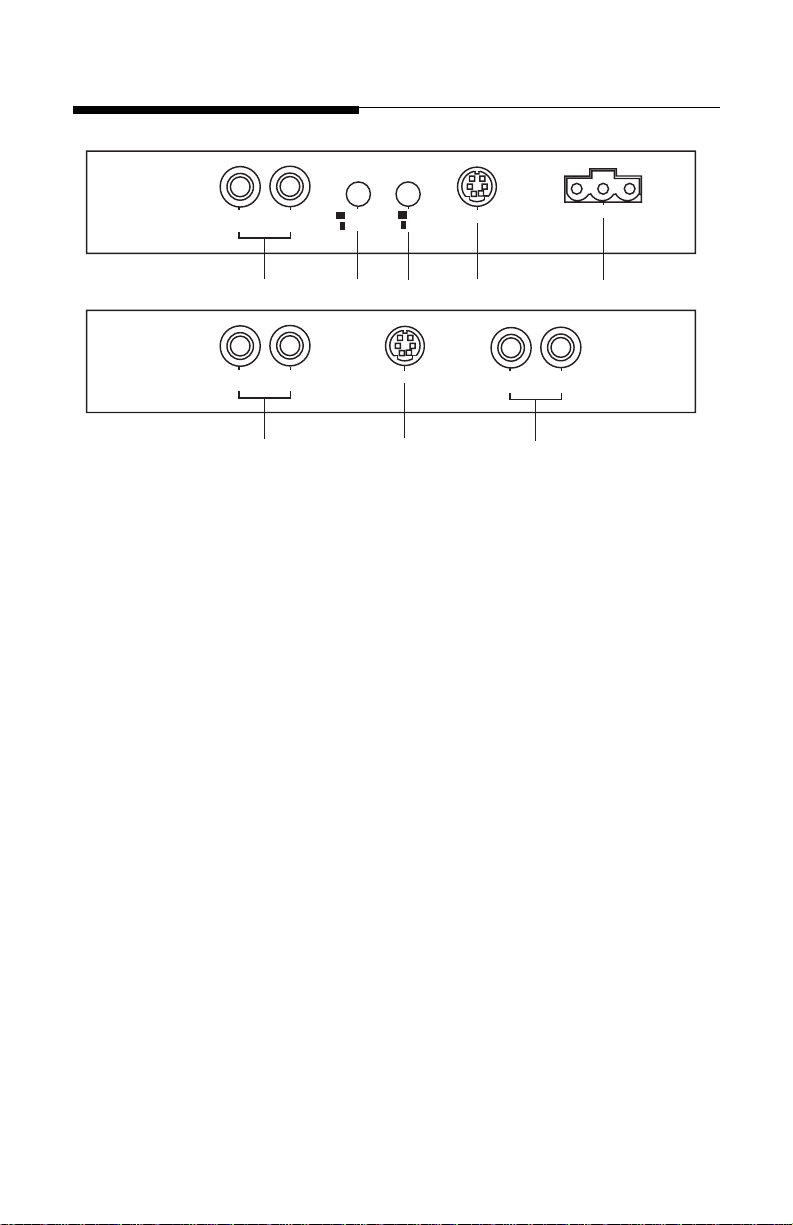

Power Connections

I

® ®

N

S

T

A

L

L

A

T

I

O

N

LEFTINRIGHT

IN

Connect to B+ of battery

with a 2 amp fuse.

RCA Input Connections

RCA

Input

–

BYPASS

ENGAGE

BAL INRCA

BAL

Less than 18"

+

GND B+ REM

Connect to chassis

ground of vehicle.

Connect to remote

turn-on lead of

source unit.

and

GND B+ REM

RIGHT IN

of OEQ

LEFTINRIGHT

IN

BYPASS

ENGAGE

BAL

• RCA Outputs from source connect to

• Signal Input Switch is

out

for RCA Input

BAL INRCA

LEFT IN

NOTE: DO NOT use RCA and Balanced Line Inputs simultaneously.

– 8 –

2

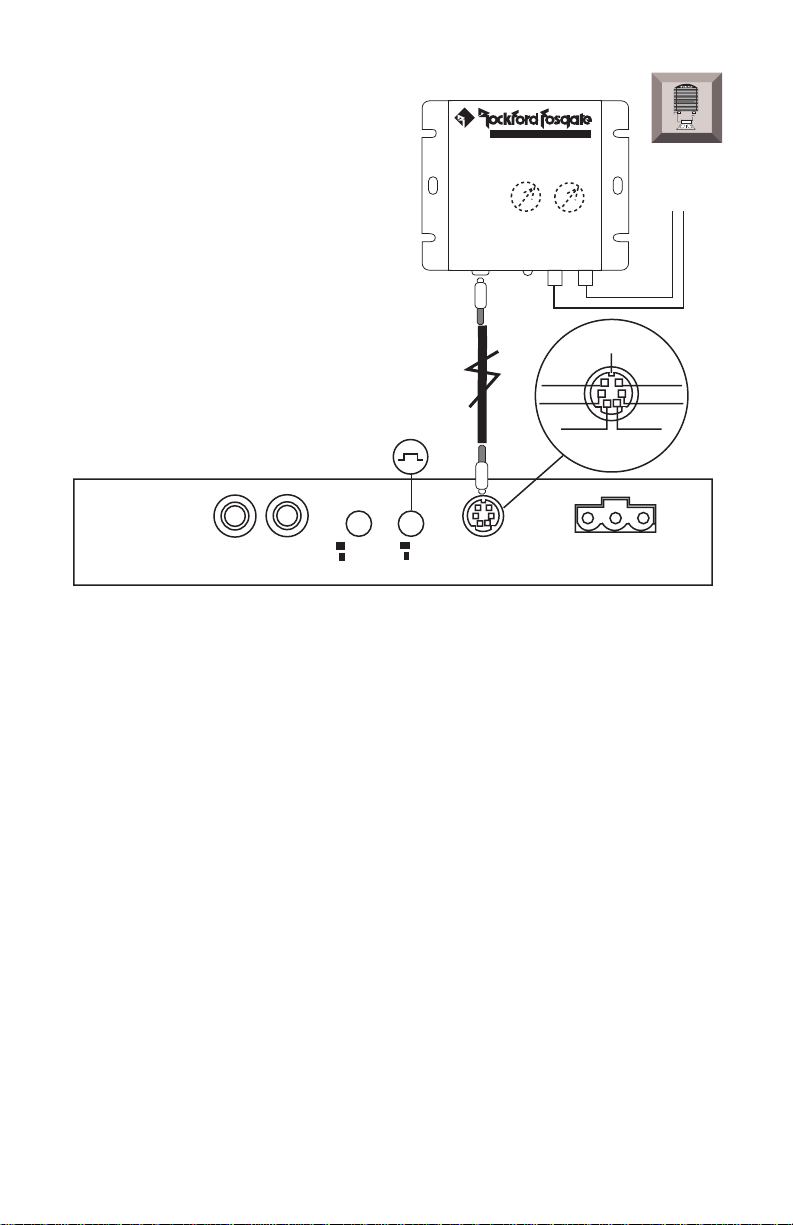

BLT Input Connections

®

BALANCED LINE TRANSMITTER

I

® ®

N

S

T

A

L

L

A

T

®

I

O

N

RCA Input

BALANCED LINE

OUTPUT

INPUT

LED

L R

Shield

+ R Signal

– R Signal

+ L Signal

– L Signal

–15V+15V

LEFTINRIGHT

IN

BYPASS

ENGAGE

BAL

BAL INRCA

GND B+ REM

• RCA Outputs from source connect to input of Balanced Line Transmitter

• Balanced Line Cable from BLT connects to

• Signal Input Switch is

pressed in

for balanced line input

BAL IN

of OEQ

2

NOTE: DO NOT use RCA and Balanced Line Inputs simultaneously.

– 9 –

Loading...

Loading...