Robot Coupe SM-50-EZ, SHFWEZ-1 Installation Manual

INSTALLATION

AND

OPERATING

R

INSTRUCTIONS

EASY-FILL HOT FOOD WARMER

Models:

SM50EZ, SHFWEZ-12D, SHFWEZ-1,

SHFWEZ-2D, -3D, -4D, -5D, -6D

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the Installation, Operating and

Maintenance Instructions thoroughly before installing or servicing this equipment.

Initial heating of unit may generate smoke or fumes and must be done in a well ventilated area.

Overexposure to smoke or fumes may cause nausea or dizziness.

This equipment has been engineered to provide you with year-round dependable service when used

according to the instructions in this manual and standard commercial kitchen practices.

Phone: +1 (214) 421-7366

Fax: +1 (214) 565-0976

Toll Free: +1 (800) 527-2100

Website: www.apwwyott.com

E-mail: info@apwwyott.com

UNIT MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

!!

P/N 70103009 3/08

APW WYOTT

729 Third Avenue

Dallas, TX 75226

1

TABLE OF CONTENTS

General Installation 2

Specifications: A SM50EZ 4

B SM50EZ-12D 5

C SHFWEZ-1D 6

D SHFWEZ-2, -3, -4, -5, -6 7

SM50EZ Parts List & Exploded View 8

Wiring Diagram 9

SHFWEZ-12D Parts List & Exploded View 10

Wiring Diagram 11

SHFWEZ-1D Parts List & Exploded View 12

Wiring Diagram 13

SHFWEZ-1D w/Shut-Off Valve Parts List & Exploded View 14

SHFWEZ-2, -3, -4, -5, -6 Parts List & Exploded View 16

SHFWEZ-2D, -3D, -4D, -5D, -6D w/Shut-Off Valve Parts List & Exploded View 18

Wiring Diagram 20

Warranty 22

GENERAL INSTALLATION

1. Always clean equipment thoroughly before use. (See general cleaning instructions.)

2. Check rating label for your model designation & electrical rating.

3. For best results, use stainless steel counter tops.

4. All dimensions in parenthesis in centimeters unless noted.

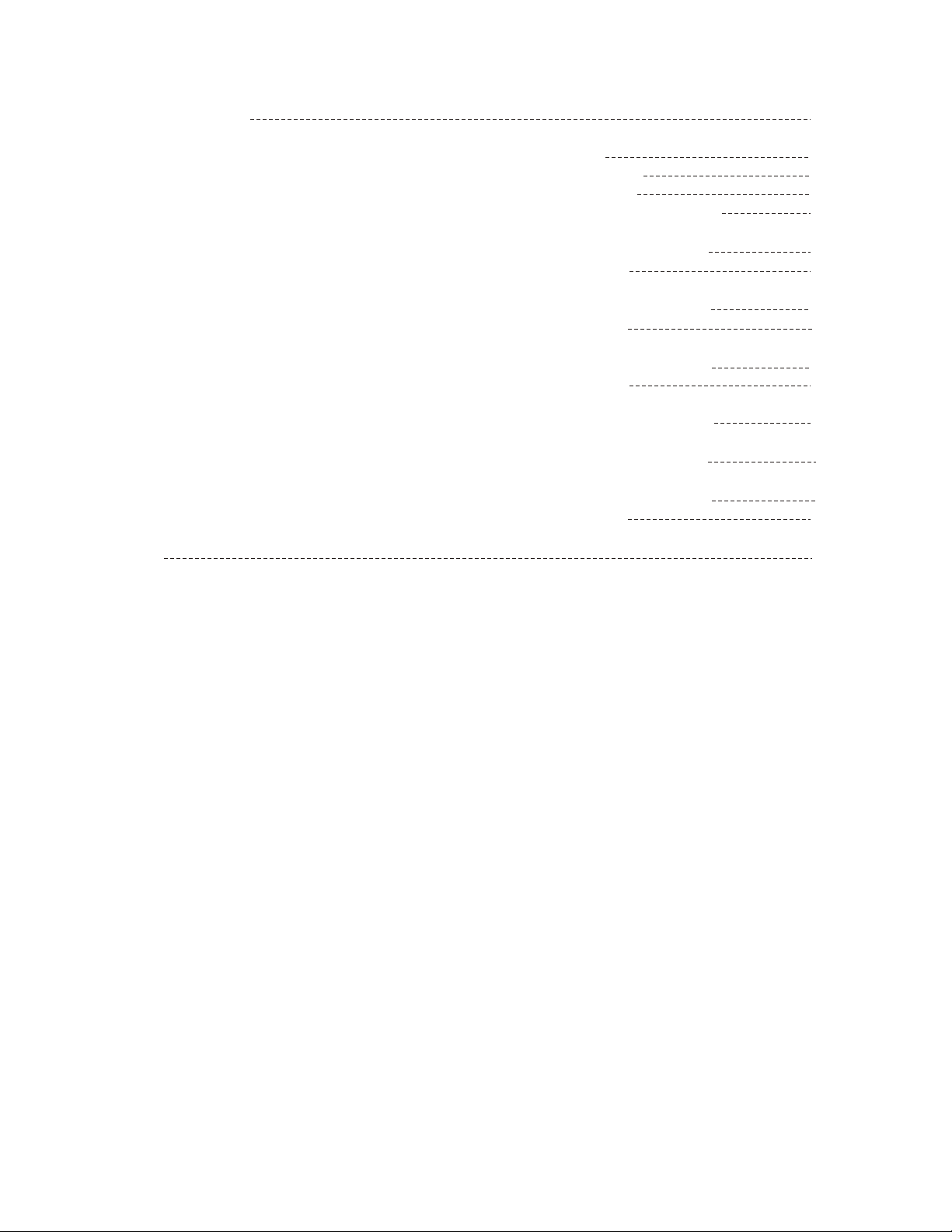

INSTALLATION INSTRUCTIONS FOR EZ WELL SUPPLY LINE

1. Install PIN 54508, brass fitting in each end of the solenoid using Teflon tape (not supplied).

2. Wrap the threads of the fitting as shown in the figure NO.1.

3. Remove the nut from the brass fitting and the sleeve from the inside of the fitting.

4. Place the sleeve and the nut, nut first, over the W copper tubing, PIN 54578, supplied with the

equipment.

5. Install the line into the solenoid and tighten the nut finger tight.

6. Using a wrench, tighten the nut far enough to crush the sleeve and attach the line.

NOTE: Do not over tighten nut. Just enough pressure is required to stop water leaks.

7. Install the 3/8 x 1/4 adapter to the 3/8 stainless steel tube fitting using Teflon tape as shown in

figure NO.2.

8. Using the other end of the copper tube, install the line, nut, and sleeve to the adapter.

9. Tighten using the same procedure as before.

10. Turn on water supply and look for leaks. If any leaks are found, tighten the nuts until leak is stopped.

NOTE: With EZ-fill multi-well units, turning on any of the controls will start water to fill all of the wells.

To fill, turn one control to the first position and allow all wells to fill completely. After wells are full, set

controls to desired settings.

INSTALLATION MUST BE DONE BY AUTHORIZED PLUMBER.

2

FIGURE #1

Part Description: Brass Connector Male 1/8” NPT x 1/8” Tube

1/8 NPT

FIGURE #2

Inlet Tube

1.125

Sleeve

Teflon Tape APW

#89117, as Required

1/4” Copper Tube

Fitting Nut

Coupling

Teflon Tape

3/8” Female to

1/4” Tube Adaptor

GENERAL OPERATION INSTRUCTIONS

1 . All food service equipment should be operated by trained personnel.

2. Do not allow your customers to come in contact with any surface labeled "CAUTION HOT."

3. Do not cook, warm or hold food directly in liner pans (well pans). Always use steam table pans /

insets, etc. Steam table pan depth should not exceed 6".

4. Never hold food below 150°F (66°C).

Wet set-up and operation procedures (Units with drains)

1. Turn thermostat control to "10" setting or if equipped with infinite controls to "7" or "HI". Preheat for

approximately 30 minutes. Pans will fill, to correct level, with water to white probe. . 2. Place covered

inset with preheated product into well. 3. Readjust control after another 30 minutes of operation to

the "6" setting depending on the amount and/or thickness of product. 4. Keep inset / steamtable

pan(s) covered to maintain ideal serving temperature. 5. Water is automatically kept at correct level.

NOTE: Turning on any control will activate autofill.

GENERAL CLEANING INSTRUCTIONS

1. NEVER clean any electrical unit by immersing it in water. Turn off before surface cleaning.

2. Always clean equipment thoroughly before first use. Clean unit daily. Except where noted on charts:

Use warm, soapy water. Mild cleansers & PLASTIC scouring pads may be used to remove bakedon food & water scale.

3. Turn off electrical units before cleaning or servicing. All service should be performed by an APW

authorized agency.

GENERAL TROUBLESHOOTING

Always Ask & Check:

1. Is the unit connected to a live power source?

2. Check the circuit breaker.

3. Is power switch on & pilot light glowing?

4. Check rating label. Are you operating unit on proper voltage?

If the above checks out, and you still have problems, call an APW authorized service agency.

3

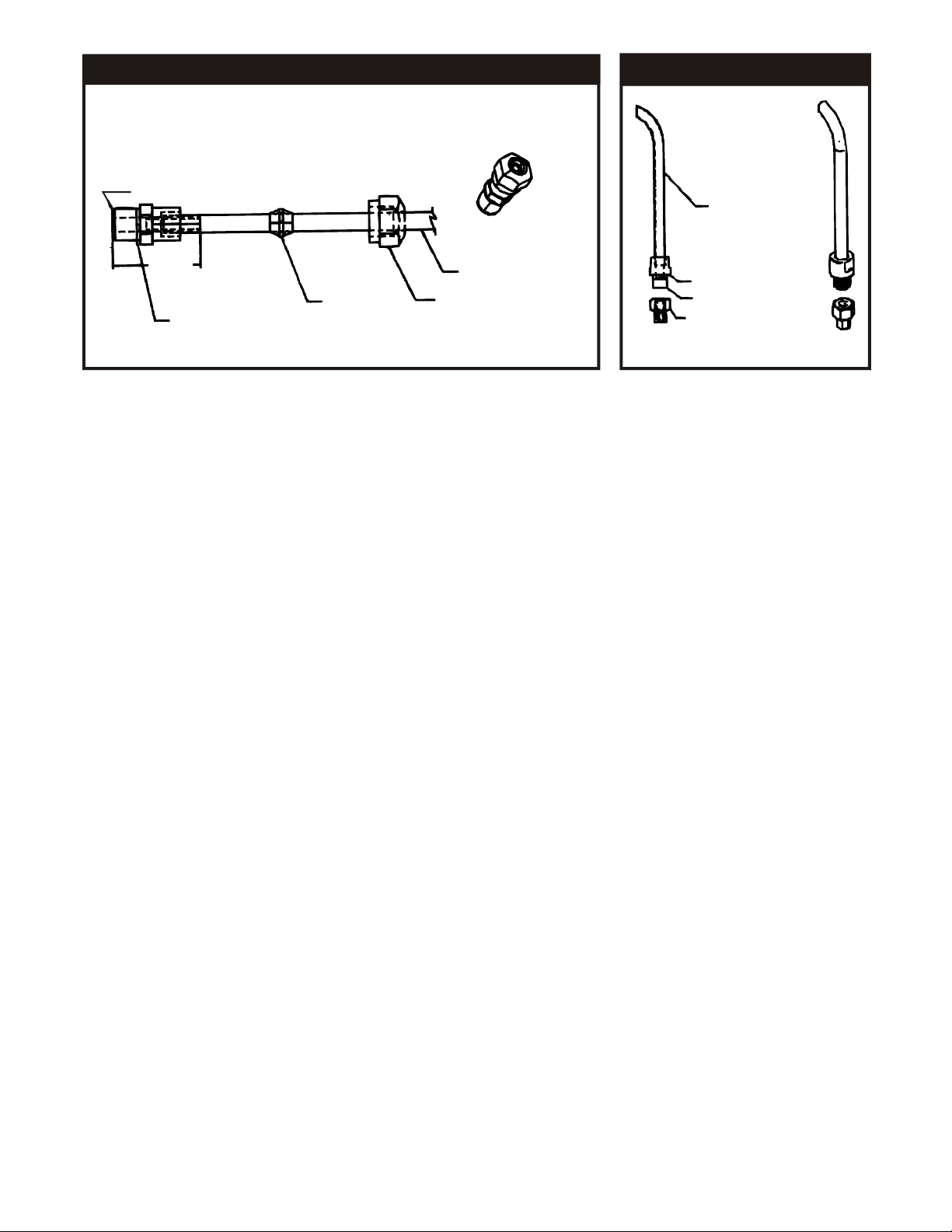

INSTALLATION

APW EZFILL HOT FOOD WELLS

Part Numbers Beginning with WHFW

D

Drain

6.0 (15.2) Minimum

From Counter Edge

E

7.78

(198)

12.02

(305)

7.55

(192)

4.19

(10.6)

10.69

(27.1)

C

1

B

8.12

(20.6)

Water

Inlet

A

610

(155)

2

1. Water fill is 3/8 (1.0) tubing connection on left back of left controls.

2. Main drain is ¾ female NPT.

Soup Well

Cut-out

2.0 (5.1) Minimum

From Counter Top

F

G

Control Cut-Out

1. Fo l l o w g en er al i ns ta ll at io n

instructions on page 3.

2. Make applicable Cut-Out per above

table. Note: Unit is designed for

installation in stainless steel tops.

Optional wood mounting kit available.

3. Apply putty tape to the underside

perimeter of the well rim outer edge.

4. Apply a 1/4" (.6) bead of silicone

sealant adjacent to the putty tape on

the well flange.

5. Drop well into opening from the top

and pus h d own unti l e ntire

parameter of rim is flush with the

counter surface.

6. From below the counter surface

insert an 8" to 10" (20 to 25 cm) flat tip

screwdriver into the locking ring tab

slots and twist in a clockwise motion

to lock well in place.

7. Trim excess putty and sealant from

around well rim.

8. Mount control to front panel using

hardware. Maintain 4" (10.2)

clearance between well and front

panel.

9. Check nameplate for proper voltage.

Connect power.

10. Connect overflow tube on hot food

well to suitable tubing to handle

212°F water. Run to open drain.

Note: Electrically connect units to

comply with local and NEC codes.

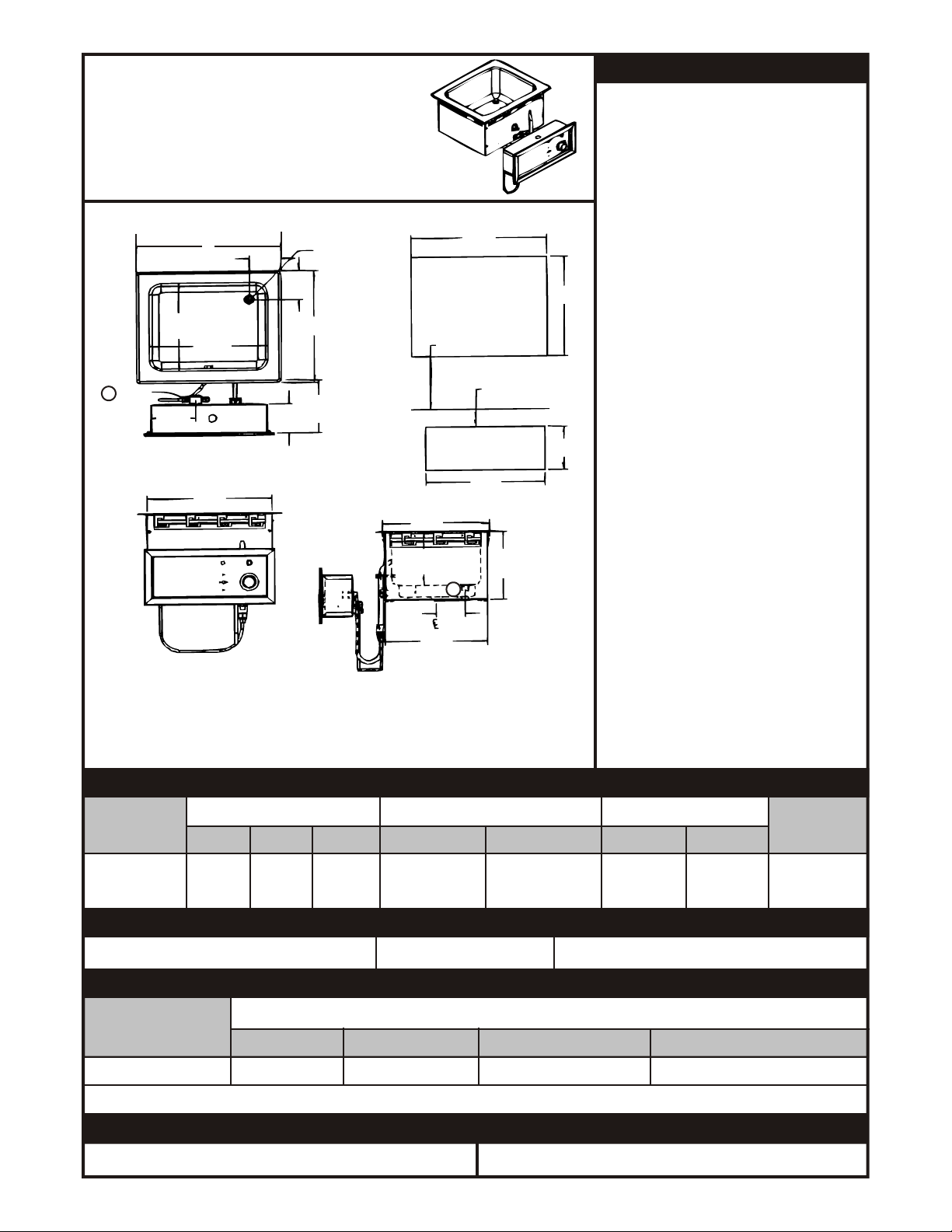

GENERAL SPECIFICATIONS (APW EZFILL HOT FOOD WELLS)

MODEL

OUTSIDE DIMENSIONS INSIDE DIMENSIONS

CUT-OUT CONTROL CUT-OUT

SHIP WT.

A B C E D F G

SM50EZ 10.34” 8.38” 6.44” 8.32” 10.875 5.0 12.5 13 Lbs.

WELL (26.3) (21.3) (16.4) (21.1) (27.6) (12.7) (31.8) (5.9 Kg)

OPTIONS

Description: Lever Operated Drain Valve Stock Number: 56360 Drain Manifold: Fabricated to Unit, Required

ELECTRICAL SPECIFICATIONS

ELECTRICAL RATINGS 500 EA. @ 208V / 660 EA. @ 240V

MODEL

VOLTS WATTS AMPS (1 Phase) MAX AMPS (3 PHASE)

SM50EZ WELL 208/240 500/660 2.4/2.75 N/A

NOTE: CUT-OUT SIZES ARE DIFFERENT FROM STANDARD APW HOT FOOD WELLS (HFW’S)

OPERATION

1. Follow General Operating Instructions on page 3. 1. Follow General Cleaning Instructions on page 3

CLEANING

4

INSTALLATION

APW EZFILL HOT FOOD WELLS

Part Numbers Beginning with WHFW

3.29

3.29

(8.4)

3.28

(8.3)

(8.4)

Drain

B

Cut-Out

Front Edge

6.00

(15.2)

11.23

(28.5)

6.12

(15.6)

10.86

(27.6)

1

Water

Inlet

10.00

(25.4)

4.74

(12.0)

A

12.50

(31.8)

C

1. Water fill is 3/8 (1.0) tubing connection on left back of left controls.

2. Main drain is ¾ female NPT.

D

Hot Food Well

Cut-Out

6.00 (15.2) Minimum

From Counter Edge

2.00 (5.1) Minimum

From Counter Top

G

Control Cut-Out

7.72

(19.6)

2

3.07

(7.8)

1. Fo l l o w g en er al i ns ta ll at io n

instructions on page 3.

2. Make applicable Cut-Out per above

table. Note: Unit is designed for

installation in stainless steel tops.

Optional wood mounting kit available.

3. Apply putty tape to the underside

perimeter of the well rim outer edge.

4. Apply a 1/4" (.6) bead of silicone

sealant adjacent to the putty tape on

E

the well flange.

5. Drop well into opening from the top

and pus h d own unti l e ntire

parameter of rim is flush with the

counter surface.

6. From below the counter surface

insert an 8" to 10" (20 to 25 cm) flat tip

screwdriver into the locking ring tab

F

slots and twist in a clockwise motion

to lock well in place.

7. Trim excess putty and sealant from

around well rim.

8. Mount control to front panel using

hardware. Maintain 4" (10.2)

clearance between well and front

panel.

9. Check nameplate for proper voltage.

Connect power.

10. Connect overflow tube on hot food

well to suitable tubing to handle

212°F water. Run to open drain.

Note: Electrically connect units to

comply with local and NEC codes.

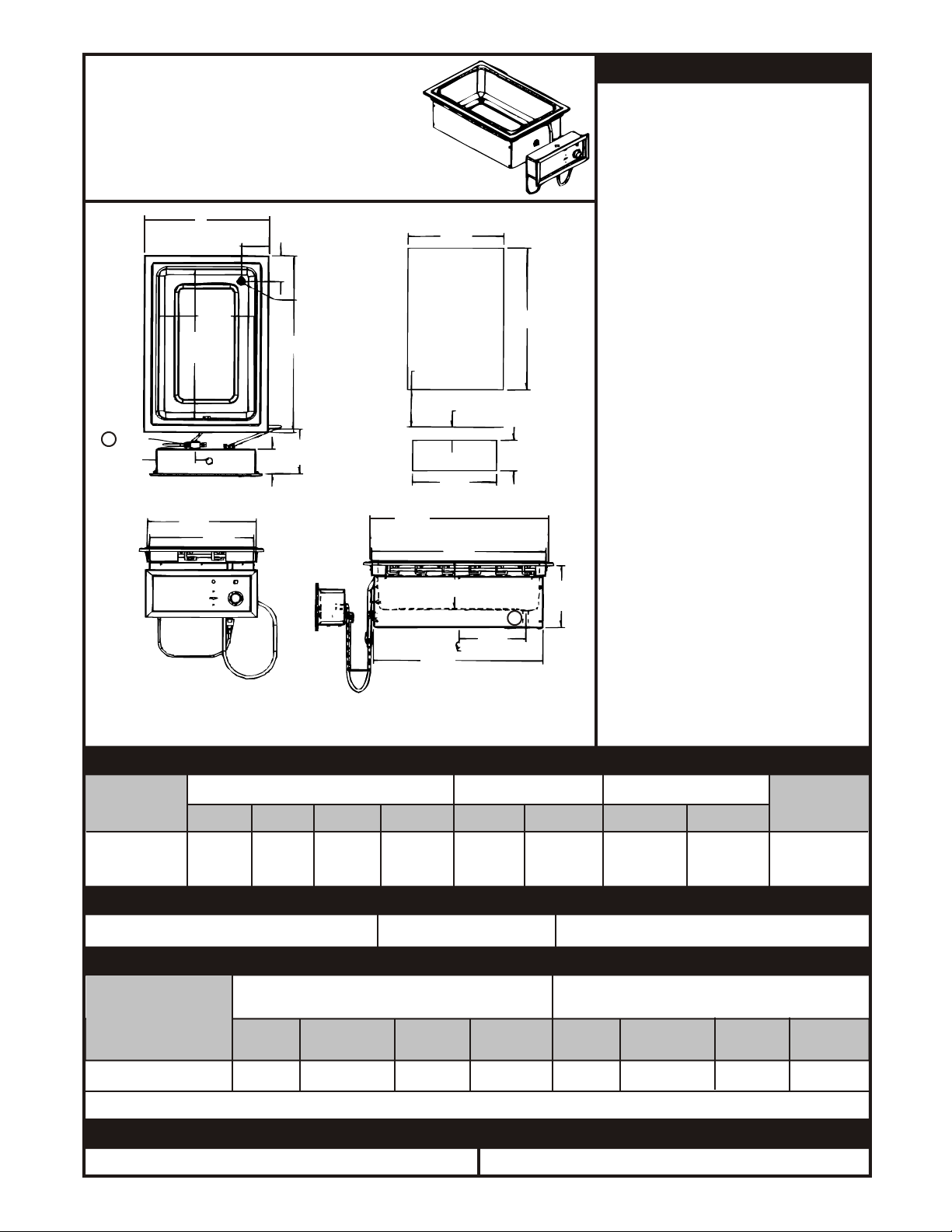

GENERAL SPECIFICATIONS (APW EZFILL HOT FOOD WELLS)

MODEL

OUTSIDE DIMENSIONS

CUT-OUT

CONTROL CUT-OUT

SHIP WT.

A B C E D F G

SM50EZ-12D 15.21 12.71 13.49 13.75 11.50 5.0 12.5 22 Lbs.

WELL (38.6) (32.3) (34.3) (34.9) (29.2) (12.7) (31.8) (10.6 Kg)

OPTIONS

Description: Lever Operated Drain Valve Stock Number: 56360 Drain Manifold: Fabricated to Unit, Required

ELECTRICAL SPECIFICATIONS

ELECTRICAL RATINGS 500 EA. @ 208V / 660 EA. @ 240V

MODEL

VOLTS WATTS AMPS (1 Phase) MAX AMPS (3 PHASE)

SM50EZ-12D WELL 208/240 500/660 2.4/2.75 N/A

NOTE: CUT-OUT SIZES ARE DIFFERENT FROM STANDARD APW HOT FOOD WELLS (HFW’S)

OPERATION

1. Follow General Operating Instructions on page 3. 1. Follow General Cleaning Instructions on page 3

CLEANING

5

INSTALLATION

APW EZFILL HOT FOOD WELLS

Part Numbers Beginning with WHFW

A

3.42

1

Water

Inlet

4.74

(12)

(8.7)

11.75

(29.8)

19.75

(50.2)

C

H

3.28

(8.3)

3.45

(8.8)

Drain

B

Cut-Out

Front Edge

6.00

(15.2)

21.80

(55.4)

1. Water fill is 3/8 (1.0) tubing connection on left back of left controls.

2. Main drain is ¾ female NPT.

D

Hot Food Well

Cut-Out

6.00 (15.2)

Minimum

From

Counter Edge

2.00 (5.1) Minimum

From Counter Top

G

Control Cut-Out

21.44

(54.4)

6.50 (16.5)

8.27

20.84

(52.9)

(21)

E

F

2

8.28

(21)

1. Fo l l o w g en er al i ns ta ll at io n

instructions on page 3.

2. Make applicable Cut-Out per above

table. Note: Unit is designed for

installation in stainless steel tops.

Optional wood mounting kit available.

3. Apply putty tape to the underside

perimeter of the well rim outer edge.

4. Apply a 1/4" (.6) bead of silicone

sealant adjacent to the putty tape on

the well flange.

5. Drop well into opening from the top

and pus h d own unti l e ntire

parameter of rim is flush with the

counter surface.

6. From below the counter surface

insert an 8" to 10" (20 to 25 cm) flat tip

screwdriver into the locking ring tab

slots and twist in a clockwise motion

to lock well in place.

7. Trim excess putty and sealant from

around well rim.

8. Mount control to front panel using

hardware. Maintain 4" (10.2)

clearance between well and front

panel.

9. Check nameplate for proper voltage.

Connect power.

10. Connect overflow tube on hot food

well to suitable tubing to handle

212°F water. Run to open drain.

Note: Electrically connect units to

comply with local and NEC codes.

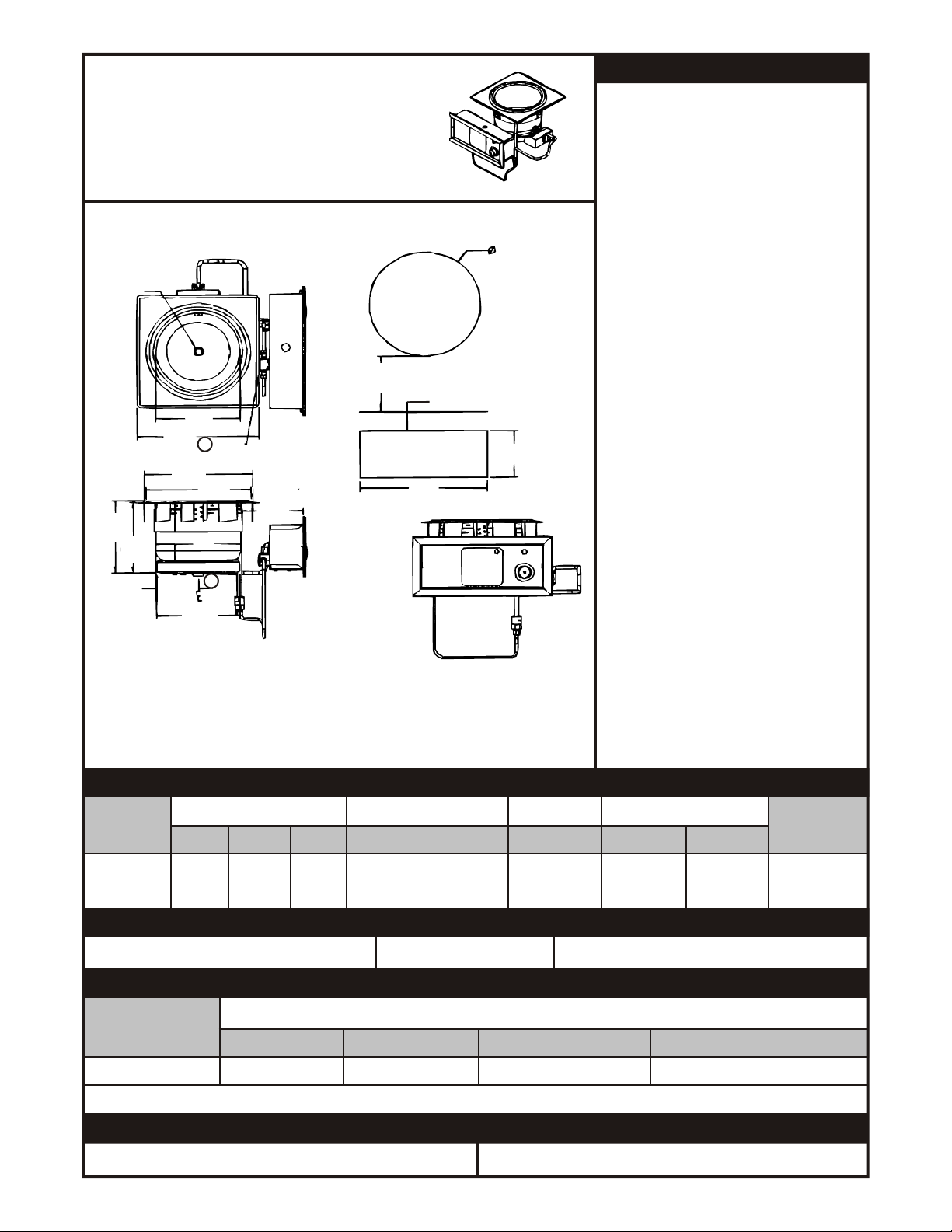

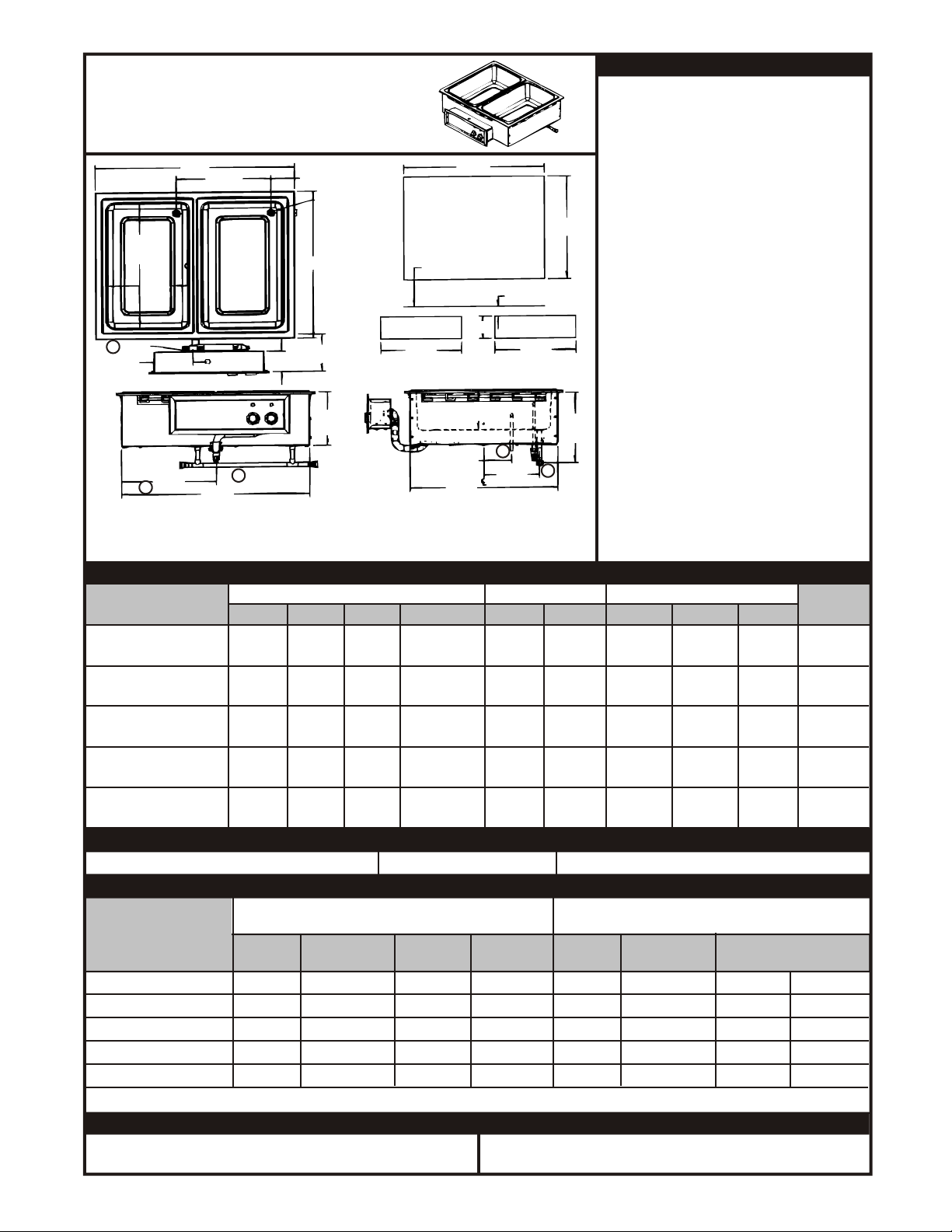

GENERAL SPECIFICATIONS (APW EZFILL HOT FOOD WELLS)

MODEL

OUTSIDE DIMENSIONS

CUT-OUT CONTROL CUT-OUT

SHIP WT.

A B C H D E F G

SHFWEZ-1 15.38” 23.44” 13.80” 12.85” 14.25” 22.25” 5.0” 12.5” 12.4 Lbs.

WELL (39.1) (59.5) (35.10) (32.6) (36.2) (56.5) (12.7) (31.8) (10.9 Kg)

OPTIONS

Description: Lever Operated Drain Valve Stock Number: 56360 Drain Manifold: Fabricated to Unit, Required

ELECTRICAL SPECIFICATIONS

ELECTRICAL RATINGS

1200 EA. @ 208V / 1600 EA. @ 240V

ELECTRICAL RATINGS

1600 EA. @ 208V

MODEL

VOLTS WATTS AMPS AMPS VOLTS WATTS AMPS AMPS

(1 Ph) (3 Ph) (1 Ph) (3 Ph)

SHFWEZ-1 WELL 208/240 1200/1600 5.8 / 6.7 N/A 208 1600 7.7 N/A

NOTE: CUT-OUT SIZES ARE DIFFERENT FROM STANDARD APW HOT FOOD WELLS (HFW’S)

OPERATION

1. Follow General Operating Instructions on page 3. 1. Follow General Cleaning Instructions on page 3

CLEANING

6

INSTALLATION

APW EZFILL HOT FOOD WELLS

Part Numbers Beginning with WHFW

D

Hot Food Well

Cut-Out

6.0 (15.2) Minimum

From Counter Edge

F

Control Cut-Outs

6.50 (16.5)

4.13

(10.5)

21.88

(55.6)

2

8.27

(21.0)

2.0 (5.1) Minimum

From Counter Top

1

19.75

(50.2)

Water

Inlet

11.74

(29.8)

2

Overflow

5.74

(14.6)

J

A

13.981

(35.51)

C

Manifold

3

3.284

(8.34)

3.434

(8.72)

Drain

B

6.0

(15.2)

(22.0)

Cut-Out

Front Edge

8.65

G

1. Water fill is 3/8 (1.0) tubing connection on left back of left controls.

2. Overflow drain is 1/2” (1.3) OD tube outlet

3. Main drain is ¾ female NPT.

H

3

1. Follow general installation instructions

on page 3.

2. Make applicable Cut-Out per above table.

Note: Unit is designed for installa tionin

stainless steel tops. Optional wood

mounting kit available.

3. Apply putty tape to the underside

perimeter of the well rim outer edge.

4. Apply a 1/4" (.6) bead of silicone sealant

E

adjacent to the putty tape on the well

flange.

5. Drop well into opening from the top a n d

push down until entire parameter of rim

is flush with the counter surface.

6. From below the counter surface insert

an 8" to 10" (20 to 25 cm) flat tip

screwdriver into the locking ring tab slots

and twist in a clockwise motion to lock

well in place.

7. Trim excess putty and sealant from

around well rim.

8. Mount control to front panel using

11.27

(28.6)

hardware. Maintain 4" (10.2) clearance

between well and front panel.

9. Check nameplate for proper voltage.

Connect power.

10. Connect overflow tube on hot food well

to suitable tubing to handle 212°F water.

Run to open drain. Note: Electrically

connect units to comply with local and

NEC codes.

GENERAL SPECIFICATIONS (APW EZFILL HOT FOOD WELLS)

MODEL

OUTSIDE DIMENSIONS

A B C J Overflow D E F G H

CUT-OUT CONTROL CUT-OUT

SHIP WT.

SHFWEZ-2D WELL 29.42” 23.44” 27.79” 13.87” 28.5” 22.5” 5.0” 16.50” N/A 48 Lbs

(74.2) (59.5) (70.6) (35.2) (72.4) (57.2) (12.7) (41.9) (21.8 Kg)

SHFWEZ-3D WELL 43.46” 23.44” 41.83” 27.92” 42.5” 22.5” 5.0” 33.50” 68 Lbs

N/A

(110.4) (59.5) (106.2) (70.9) (108) (57.2) (12.7) (85.1) (30.8 Kg)

SHFWEZ-4D WELL 57.50” 23.44” 55.87” 27.92” 56.5” 22.5” 5.0” 16.50” 98 Lbs

12.50”

(146.0) (59.5) (141.9) (70.9) (143.5) (57.2) (12.7) (41.9) (44.4 Kg)

SHFWEZ-5D WELL 71.54” 23.44” 69.92” 41.96” 70.05” 22.5” 5.0” 33.50” N/A 118 Lbs

(181.7) (59.5) (177.6) (106.6) (179.1) (57.2) (12.7) (85.1) (53.5 Kg)

SHFWEZ-6D WELL 85.59” 23.44” 83.96” 41.96” 84.50” 22.5” 5.0” 33.50” N/A 260 Lbs

(217.4) (59.5) (213.2) (106.6) (214.6) (57.2) (12.7) (85.1) (117.9 Kg)

OPTIONS

Description: Lever Operated Drain Valve Stock Number: 56360 Drain Manifold: Fabricated to Unit, Required

ELECTRICAL SPECIFICATIONS

ELECTRICAL RATINGS

1600 EA. @ 208V

MODEL

ELECTRICAL RATINGS

1200 EA. @ 208V / 1600 EA. @ 240V

VOLTS WATTS AMPS AMPS VOLTS WATTS AMPS AMPS

(1 Ph) (3 Ph) (1 Ph) (3 Ph)

SHFWEZ-2D WELL 208/240 2400/3200 12 / 14 10 / 12 208 3200 16 14

SHFWEZ-3D WELL 208/240 3600/4800 18 / 20 10 / 12 208 4800 23 14

SHFWEZ-4D WELL 208/240 4800/6400 24 / 27 16 / 18 208 6400 31 21

SHFWEZ-5D WELL 208/240 6000/8000 29 / 34 20 / 24 208 8000 39 27

SHFWEZ-6D WELL 208/240 7200/9600 35 / 40 20 / 24 208 9600 47 27

NOTE: CUT-OUT SIZES ARE DIFFERENT FROM STANDARD APW HOT FOOD WELLS (HFW’S)

OPERATION

1. Follow General Operating Instructions on page 3. 1. Follow General Cleaning Instructions on page 3

CLEANING

7

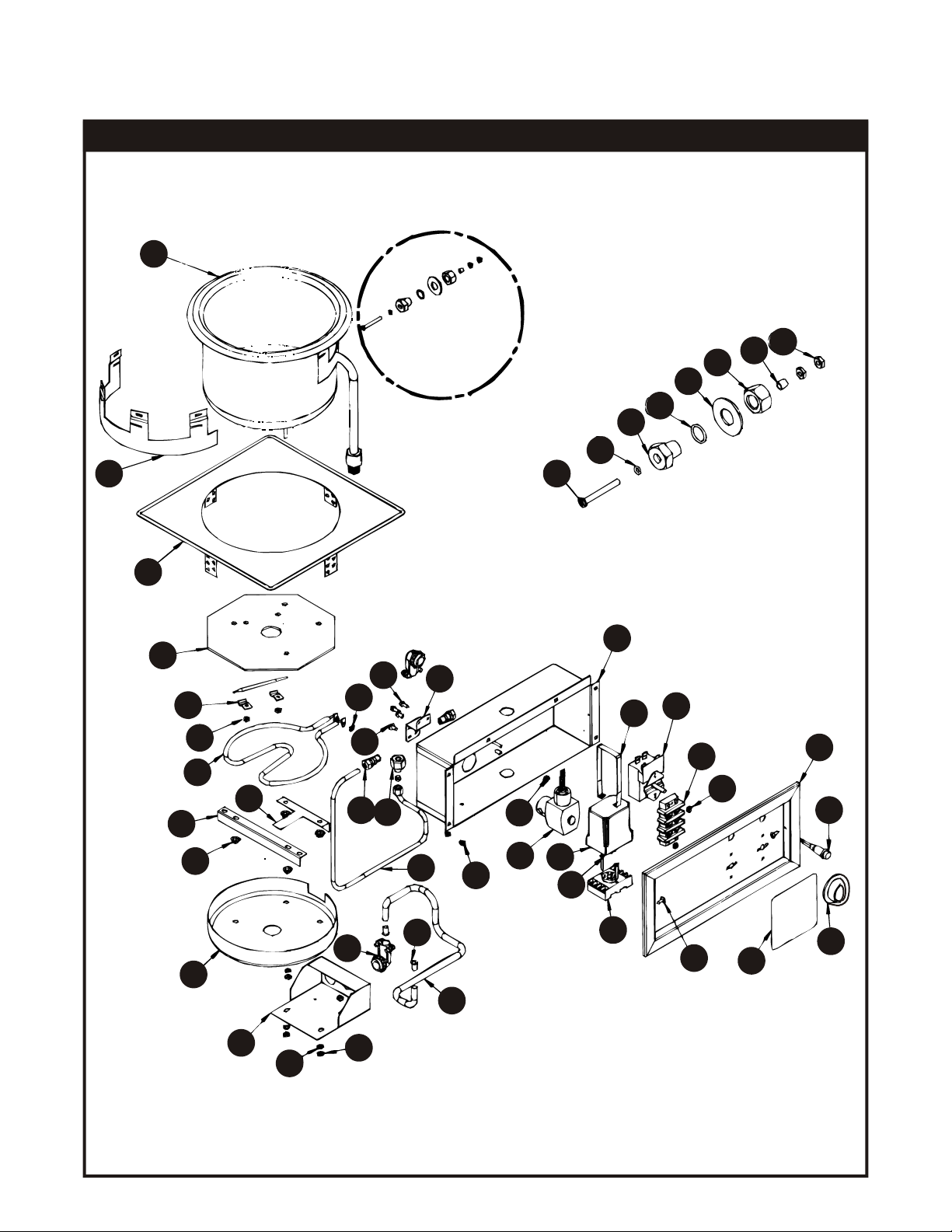

PARTS LIST & EXPLODED VIEW

SM50EZ Round Soup Well Drop-In with EZ Lock P/N EZSM50-7D 208/240V, 500/650W

EXPLODED VIEW SM50EZ

16

32

31

28

27

25

“B”

26

29

45

30

DETAIL “B”

44

17

20

41

22

24

18

21

19

8

23

36

15

37

1

10

13

3

14

2

35

6

7

40

35

34

11

12

43

9

42

33

5

4

39

38

23

24

8

Loading...

Loading...