OPERATION MANUAL

FOR

MODELS

R8 and R8U

robot coupe U.S.A., Inc.

P.O. Box 16625, Jackson, MS 39236-6625

280 South Perkins St., Ridgeland, MS 39157

email: robocoup@misnet.com

website: www.robotcoupeusa.com

1-800-824-1646

IMPORTANT NOTICE

3-PHASE MOTORS

DRIVE SHAFT ROTATION

Three phase motors may rotate either direction.

The required motor rotation is counterclockwise.

Check the rotation before attaching the cutter blades.

Changing the motor rotation requires a qualified electrician.

Also, see the note attached to the end of the power cord.

2

Introduction

Robot Coupe offers the most complete line of food processors available in the food service industry. The Robot Coupe

model R8, 8 quart Vertical Cutter Mixer, is specifically designed for quality, high-speed food preparation. The R8 can

prepare a variety of foods ranging from a coarse chop to a

fine puree. You can prepare fresh salads, sauces, pates,

mousses, salad dressings, prepare fine and coarse sausage

mixtures, meat salads, mashed potatoes, mix and knead all

doughs, pie crusts, flake pastries, and emulsify meats, nuts,

and other fruits and vegetables.

The R8 is constructed of sturdy stainless steel, fiberglass,

and cast aluminum. The stainless steel bowl with the adjustable knife is designed to allow for small and large batches

without any mixing baffle required. A large see-through lid

with a funnel opening allows you to carefully control the consistency of the product as it is being processed. The Robot

Coupe model R8 is designed to give years of safe quality

food preparation.

Maintain a copy of this manual for reference by all users.

Follow the instructions as indicated in this manual. Pay close

attention to the special notes of caution.

I. Introduction

II. Operation Instructions

A. Blade Assembly

B. Controls

C. Operation

D. Emptying the bowl

E. Cleaning

III. Preventative Maintenance

MODEL SPECIFICATIONS

R8 & R8U * 8 Quart Capacity

208-240 Volt, 3 phase,

2.0 / 3.0 Hp, 8.2/ 8.3 Amp

2 speed, 1725/3450 RPM

R8U *

Is the same as an R8 but with a 3-1/2 qt. mini

bowl attachment. The mini bowl may be

purchased with the machine as model R8U

or separate as part number R8U090

The R8 is equipped with auto-reset thermal overload protection. If the unit overheats due to an overload condition, it will

automatically shut off. After a cooling period of ten to fifteen

minutes the thermal overload protection will automatically reset and the unit may then be restarted. It will not restart until

the thermal overload has reset.

The suggested breaker size is 20 AMPS. Check the local

codes they may supersede the suggested breaker size.

3

II. Operating Instructions

This manual is broken down into step by step instructions to

assist the operator in easy and quality food preparation. This

manual should be read completely before use by each operator. Additionally, this manual should be kept as a reference for future operators. Adherence to the guidelines set

forth by this manual will ensure a safe, long life utilization of

the vertical cutter mixer.

A. Blade Assembly

Wear cut-resistant gloves when handling the

blades.

The R8 blade assembly comes assembled from the factory.

The blade assembly is designed so that the blades can be

adjusted for large or small batches. The blade assembly

should be completely disassembled after each days use,

washed completely, and allowed to air dry before reassembling. Additionally, the blades should be kept sharp to provide the best performance. The blades can be sharpened by

means of a fine stone; a stone is provided with each machine.

There are seven important points to remember about the blade

assembly:

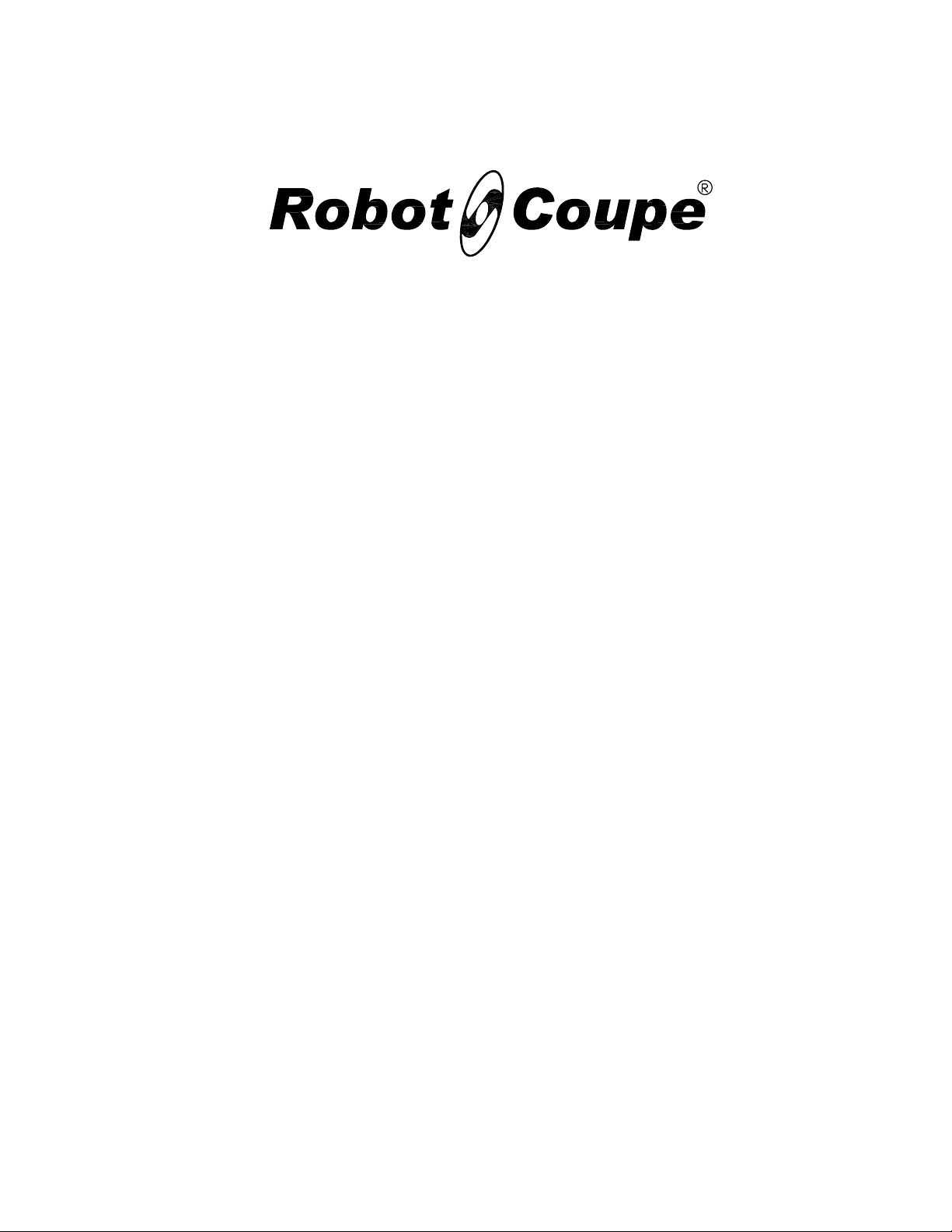

(1) The blades are sharp, always wear cut-resistant gloves

when handling the blades.

(2) The bottom blade must always stay on the bottom of the

blade support.

(3) The blade assembly, when installed, should drop to the

bottom of the bowl such that the bottom blade is almost touching the bottom of the bowl.

(4) Disassemble the blade assembly at least after each days

use, wash completely, and allow to air dry before reassembly. Lubricate the threads with a food-grade grease periodically.

(5) Ensure that the blade assembly is correctly assembled,

and all parts fit tightly together before beginning each operation.

(6) Sharpen the blades as necessary.

The blades are set at the factory to allow for most operations.

The bottom blade should always stay on the bottom, followed

by two small spacers, then the second blade, followed by the

large aluminum spacer. Note: the white Nylon spacer should

always be used between the locking nut and large aluminum

spacer. Most low speed operations can be run using this

blade configuration. High speed operations and operations

using heavy loads such as dough and cheese should use

only one small spacer between the lower and second blade

with the second small spacer above the second blade.

NOTE: The placement of the blades is very important to

maintain the correct cutting performance and balance. The

blades should always be located 180 degrees apart.

BLADE

LOCKING

NUT

NYLON

SPACER

BIG

SPACER

THE BEVELLED SIDE OF BLADES

SHOULD ALWAYS BE UP

LOW

SPEED

(7) A large spacing between the blades can cause excessive, vibration, especially on high speed.

BLADE

LOCKING

NUT

HIGH

SPEED

SMALL

METAL

SPACER

NYLON

SPACER

BIG

SPACER

SMALL

METAL

SPACERS

BLADE

SUPPORT

TOP

VIEW

SMALL

METAL

SPACER

BLADE

SUPPORT

4

B: Blade Disassembly:

C: Lid Seal Installation

Wear cut-resistant gloves when handling the

blade assembly

Included with the machine is a blade disassembly tool. This

consists of two pieces; the blade stop, and the pry bar. The

blade stop rests on the front bowl locking bracket, this prevents the blade from rotating during assembly and disassembly. Place the blade stop on the front bracket, and place the

blade on the motor shaft.

To disassemble, rotate the blade counterclockwise until a

blade rests against the blade stop. Slide the pry bar into the

slot under the lip of the blade locking nut, and twist counterclockwise to loosen the nut. Remove the blade locking nut

and adjust or clean the blades and spacers as required. A

light food-grade grease may be applied to the threaded area

to assist in easy removal. Reverse this procedure for assembly.

If the blades are not disassembled on a regular basis, they

will become hard to disassemble and adjust. If the blade

locking nut cannot be removed, service may be required.

When installing the lid seal, it must be in

the correct position. If not, lid damage can

occur.

1

PLACE THE

BLADE STOP

ON THE FRONT

BRACKET

PLACE THE BLADE ON THE

2

MOTOR SHAFT.

INSERT PRY BAR.

4

AND TURN CLOCKWISE

TO TIGHTEN OR

COUNTERCLOCKWISE TO

LOOSEN

3

ROTATE THE BLADE UNTILL IT RESTS AGAINST THE BLADE STOP.

CLOCKWISE TO TIGHTEN COUNTERCLOCKWISE TO LOOSEN.

5

D: Mini Bowl Instructions

E. Controls

The Robot Coupe Model R8 Vertical Cutter Mixer has available a 3 1/2 quart mini bowl attachment. The mini bowl kit

may be purchased with the machine as model R8U or separate as part number R8U090. The mini bowl fits inside the

larger 8 quart bowl and uses the same lid. Extra mini bowl

kits may be purchased and are available through the regular

distribution network.

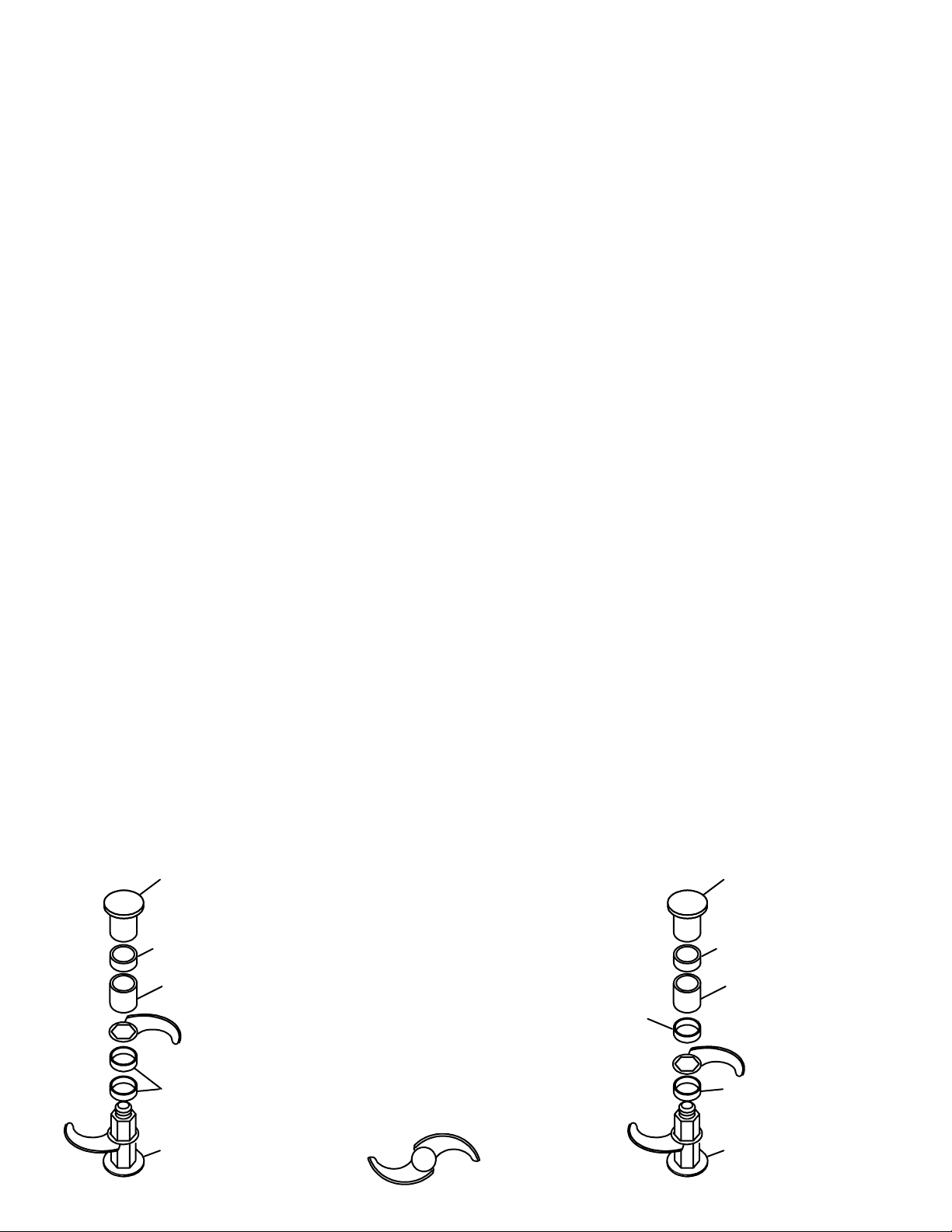

Included in the mini bowl kit is a 3 1/2 quart bowl, S-blade

assembly with disassembly tool, and gasket for lid.

ASSEMBLY OF THE MINI BOWL

The mini bowl fits inside the larger 8 quart bowl and is held in

place by the lid. To assemble the mini bowl, secure the larger

8 quart bowl and lid assembly to the motor base. The center

stem of the large bowl has a notch cut into the top which fits

to a pin located on the under side of the mini bowl. Place the

mini down on to the center stem of the large bowl and rotate

until the pin of the mini bowl drops into the notch of the large

bowl stem. Note: The large S-blade is not used with the mini

bowl assembly. The mini bowl must be fully seated on the

stem to work correctly.

Place the mini bowl gasket on to the center ring of the lid

assembly with the bevel of the seal down. This seal secures

the mini bowl in place when the lid is closed. Place the mini

bowl S-blade assembly down into the bowl and over the motor shaft. Rotate the blade so that it drops completely on the

shaft; the bottom blade should be located just off the bowl

bottom when assembled correctly.

CAUTION: The blades are very sharp, use protective cutresistant gloves when handling.

The S-blade should be disassembled after each session or

minimally once per day. Supplied with the mini bowl kit is a

stainless steel rod. To disassemble the blade, place the

small end of the tool into the hole of the top locking nut of the

blade assembly. Lay the blade on it’s side on top of a cutting

board and carefully rotate the locking nut counter clockwise

to loosen. Wash each part separately and allow to air dry

before reassembly. Lubricate the threads periodically with a

food-grade grease.

FRONT VIEW

BOWL ASSEMBLY

LID

SEAL

MINI BOWL

NOTCH

LARGE BOWL

SIDE VIEW

OF SEAL

BLADE

ASSEMBLY

CLOCKWISE TO

TIGHTEN

COUNTERCLOCKWISE

TO LOOSEN

TOOL

NYLON

SPACER

The Robot Coupe model R8 is designed with an easy to use

control panel. This machine offers a two speed selector

switch, push button run switch, push button pulse switch,

oversized mushroom type off switch, and a power on and

running indicator lamps. The following gives a brief description of each.

Two Speed Selector: This switch allows the user to select

either Low (1725 RPM) or High (3450 RPM) speed for the

operation. For best results, the speed selector should only

be moved while the machine is off and not running. A speed

must be selected before the power on lamp will light, also

the lid must be closed - closing the safety switch.

Run Switch: This switch is used to start the machine. The

machine will not run unless the lid/safety switch is closed

and a speed has been selected.

Pulse Switch: This switch is used to jog or pulse the motor

off and on. The machine will not pulse on unless the lid/

safety switch is closed and a speed has been selected.

Stop Switch: The stop switch will stop the motor from running after the run switch has been pressed. Always use this

switch to turn the machine off. Do not open the lid without

pressing the off switch.

Red (power) Indicator Lamp: This lamp will light when the

machine is plugged in, the lid/safety switch is closed and a

speed has been selected.

NOTE: The red lamp will not light

if the overload protector has been tripped.

Green (running) Indicator Lamp: This will light when the

machine is running.

The preceding description of the controls is considered as

normal operating conditions. If for any reason they do not

perform as indicated, the machine should be serviced. The

machine should not be operated if it has malfunctioned in

any way. Robot Coupe authorized service agencies are located across the United States. Refer to the list provided to

locate the service company nearest you.

Automatic Overload Protection: The R8 is equipped with

auto-reset thermal overload protection. If the unit overheats

due to an overload condition, it will automatically shut off.

After a cooling period of ten to fifteen minutes the thermal

overload protection will automatically reset and the unit may

then be restarted. It will not restart until the thermal overload

has reset.

6

F. Operation

G. Emptying The Bowl

Because of the special bowl and blade design of the Robot

Coupe Vertical Cutter Mixers, most operations are completed

in a matter of seconds. The operator should pay close attention to the product as well as the amount of time required to

process. Operations should be run on Low speed, using High

speed only when an extremely fine puree consistency is desired.

There are two ways to run your VCM. First of all, you may

run the unit continuously by filling the bowl with food and simply letting it run until the desired consistency has been

reached. Use this method to grind, mix, blend, puree, or

emulsify. Secondly, you may chop with your unit by pulsing

the machine.

Cut round vegetables into halves or quarters and prep long

vegetables into 3 to 4 inch pieces. Place these into the bowl,

and using Low speed, pulse the unit on the off quickly. Usually 4 to 5 pulses yields an evenly mixed chopped substance.

SPECIAL NOTE: The model R8 three phase must be limited

to no more than 80 pulses (quick starts and stops) within a

one hour period. Exceeding this limitation can cause damage to the electrical components of the machine which is not

covered under warranty.

After the product has been run in the bowl, make certain that

the speed selector is in the middle off position, and for extra

safety unplug the machine. NEVER attempt to open the lid

until the blades have come to a complete stop.

To remove the bowl, loosen the knob on the front of the bowl

and twist the bowl clockwise, thus releasing the locking lugs.

Then lift the entire bowl, with the blade assembly intact, up

and off of the motor shaft. The bowl can then be emptied by

holding the blade in place and tilting the bowl to one side into

a catch pan or other container.

H. Cleaning

Cleaning is one of the most important measures to ensure

safe quality food preparation. The machine should be cleaned

after each session. Failure to keep the machine clean can

result in high repair costs and shortened machine life. Follow

the cleaning instructions detailed below, or according to local

Health Department Regulations.

NOTE: The aluminum bowl lid and the blade assembly should

be washed in a soft-metal-safe detergent. Detergents containing caustic soda will cause soft metals to oxidize leaving

an undesirable black residue on the surface.

TO CHOP

To achieve a chopped consistency for vegetables, cheese,

meats, etc. fill the bowl with the product no more than 3/4 full,

or as low as two to three onions. Small batches would require lowering the top cutting blade. With the lid secured,

and the speed selector in Low speed, press the pulse button

quickly then release. Repeat this pulsing action, allowing the

blades to stop each time, until the desired cut is achieved.

TO PUREE OR MIX

Fill the bowl with the product no more than 3/4 full. Start the

machine in Low speed and allow to run until the product is

completely reduced. If necessary, turn the machine off and

select High speed to finish the product. It may be necessary

to add some liquids to a puree to achieve the desired consistency.

DOUGHS AND PASTRIES

Prepare doughs and pastries on Low speed only. In many

cases it may be helpful to first mix all dry products then add

the liquids. The unit should be run continuously until the product is completely processed. For thick doughs, such as for

pizza, the machine will form a ball of dough when the mixing

is complete. When a ball is formed the machine should be

turned off immediately to prevent over processing. Preparation times and all ingredients should be noted for different

recipes.

The bowl, blades, and lid can be removed and cleaned in a

pot sink or dishwasher. Take care not to bend, drop, or break

any of the components.

The lid is removed by removing the lid hinge pin located at

the base of the lid. The blades can be lifted out, and the bowl

removed by loosening the locking nut on front of the bowl and

twisting the bowl clockwise.

The blade assembly should be disassembled and cleaned

completely. Assemble the blade only after it has dried completely.

With the bowl removed, the motor shaft and seal should be

cleaned. Use a soft brush or cloth to clean the seal area. The

seal is designed to prevent penetration of liquids and food

products into the motor housing. Clean the seal area completely, but do not damage the seal. Do not allow food or

liquids to remain built up around the seal area. The seal should

not be cleaned by use of spraying water. Inspect the seal

during each cleaning for damage or wear. This seal is designed for easy removal by use of a large wrench. The seal

should be replaced if any wear or damage is noted. Contact

an authorized service agent for additional seals.

NOTICE: It is recommended that the seal be lubricated

at least once a week or after cleaning as practical. A

food grade grease, vegetable oil, or mineral oil will work

well.

7

Clean the motor base housing using a cloth lightly dampened

with a soapy water solution. Maintaining a clean machine will

improve the overall life of the unit.

SPECIAL NOTE: Pressure cleaning with water

can cause damage to the electrical components

contained within the housing. Do not allow the

motor base to be sprayed or immersed in any

liquid.

III. PREVENTATIVE MAINTENANCE

Motor Seal Replacement

NOTE: ONLY QUALIFIED SERVICE OR REPAIR TECHNICIANS SHOULD PREFORM THIS SERVICE.

The machine comes equipped with a removable seal assembly that is screwed down around the motor shaft. To replace

the seals, this assembly must be unscrewed. A tool is supplied for use in removing the insert.

Follow steps 1-6 below to replace the motor seals.

The Robot Coupe Vertical Cutter Mixers are designed to give

years of maximum trouble free performance. Adherence to

the operating instructions as well as keeping the unit clean

will further ensure good performance.

An examination should be made periodically to ensure that

all parts are in good working condition. Special attention

should be given to all seals to insure that they are well lubricated and clean. Replacement of the seals may be necessary if they are dry rotted or torn.

If service is required, contact the nearest authorized service

agency, or your distributor, to see where service is available.

If you wish your machine to be serviced at the factory, call for

a Return Merchandise Authorization (RMA) number and upon

receipt of the same, ship the unit, prepaid and insured, to our

factory address.

Robot Coupe, USA Inc.

730 South Ridgewood Rd.

Ridgeland MS 39157

1-800-824-1646

1. Remove the seal assembly:

Place the tool over the shaft and

around the seal assembly.

Turn the tool counterclockwise

to loosen. Place a heavy-duty

screwdriver through the holes

in the tool for more leverage.

4. Clean the shaft, then tape the step on the

shaft with plastic electrical tape for protection

during reassembly.

Using a food-grade grease, lightly lubricate

the shaft.

2. Pry out the seals and clean

the seal cavity.

5. Install new seals with

grooved greased sides facing

each other. The seals must be

fully seated. Gentely tap them

into place with a hammer and

small block of wood if necessary, but do not damage them.

3. Grease the seals

6. Reinstall the seal assembly:

Before reassembly, lightly grease the threads on

the seal assembly insert. Place the seal assembly over the motor-shaft and screw it down gently

turning first by hand, then with the tool in a clockwise rotation until it is firmly in place.

Remove the plastic tape and excess grease before using the machine.

8

9

10

R8-R8U

Part List

R8U

CL689 SEAL REMOVAL TOOL R8U009 15MM S.S. SPACER

R1004 TOP SEAL, MOTOR R8U010 45MM S. S. SPACER

R1005 FOOT R8U012 BLADE LOCKING NUT

R1006 BRACKET, FOOT R8U013 BLADE ONLY (SMOOTH)

R1023 COVER, SCREW * R8U013A BLADE ONLY, (SERRATED)

R1024 SCREW, MOTOR SUPPORT R8U017 BLADE ASSEMBLY

R1027 SEAL ASSEMBLY, MOTOR SUPPORT R8U021 SCREW & NUT/LID SWITCH

R1029 Seal, MOTOR SUPPORT R8U022 LID SEAL

R1034 COVER, SCREW R8U023 LID ASSEMBLY

R1036A SCREW, LID LEVER R8U024 BOWL

R1046 THERMAL OL (LR2 D1314) (7-10 AMP) R8U026 MOTOR SUPPORT

R1049 BOWL MAGNET ASSEMBLY R8U026.1 MOTOR SUPPORT SCREW

R1062 BOLTS, SHOCK ABSORBING R8U028 BUSHING FOR MECHANICAL SWITCH

R1075 TOOL, BLADE LOCKING R8U029 LID HINGE

R1077 PLASTIC SPACER (10CM) R8U030 HINGE PIN

R1090 CONTROL RELAY R8U031 FRONT DATA PLATE

R1091B LEVER, LATCH ASSEMBLY LID R8U032 MOTOR

R114 SWITCH ONLY R8U033 BACK ACCESS COVER SEAL

R1547 BUSHING, HINGE PIN R8U034 MAGNETIC SWITCH ASSEMBLY

R237 BEARING R8U035 BACK ACCESS COVER

R25126A BOWL MAGNET R8U036 BRACKET FOR MAGNETIC SWITCH

R25127 BOWL MAGNET CP R8U038 SPEED SELECTOR SWITCH

R2534A MECHANICAL SWITCH R8U055 TOOL BLADE DISASSEMBLY

R3062U OFF PUSH BUTTON/RED R8U057 MINI BOWL BLADE SUPPORT

R3063U PULSE PUSH BUTTON/BLACK R8U058 MINI BOWL BLADE ONLY, SMOOTH

R3067U ON PUSH BUTTON/GREEN * R8U058E MINI BOWL BLADE, SERRATED

R403 CORD WITHOUT PLUG R8U059 4MM SPACER (MINI BOWL)

R40351TP GREEN LAMP 220V R8U062 1.5CM SPACER (MINI BOWL)

R40371TP RED LAMP 220V R8U064 MINI BOWL BLADE LOCKING NUT

R413 VOLTAGE RELAY R8U065 MINI BOWL

R4904 PLUG, 3 PHASE R8U066 MINI BOWL BLADE ASSEMBLY

R611 MOTOR SUPPOR SEAL R8U070 MINI BOWL LID SEAL

R662 BEARING, TOP MOTOR * R8U071 MACHINE STAND (25-1/4" x 33 -1/4" x 21 - 3/16")

R8U003 BASE R8U072 RELAY BRACKET (9" x 4.5")

R8U004 SWITCH PLATE R8U090 MINI BOWL ASSEMBLY

R8U008 BLADE SUPPORT RA490 STRAIN RELIEF

Robot Coupe Vertical Cutter Mixer with eight quart bowl

and 3 quart mini bowl assembly

*Denotes Accessories 6/6/02

U.S.A., Inc.U.S.A., Inc.

U.S.A., Inc.

U.S.A., Inc.U.S.A., Inc.

PP

.O. Box 16625, Jackson, MS 39236-6625.O. Box 16625, Jackson, MS 39236-6625

P

.O. Box 16625, Jackson, MS 39236-6625

PP

.O. Box 16625, Jackson, MS 39236-6625.O. Box 16625, Jackson, MS 39236-6625

280 South Perkins St., Ridgeland, MS 39157280 South Perkins St., Ridgeland, MS 39157

280 South Perkins St., Ridgeland, MS 39157

280 South Perkins St., Ridgeland, MS 39157280 South Perkins St., Ridgeland, MS 39157

email: robocoup@misnet.comemail: robocoup@misnet.com

email: robocoup@misnet.com

email: robocoup@misnet.comemail: robocoup@misnet.com

website: www.rwebsite: www.r

website: www.r

website: www.rwebsite: www.r

1-800-824-16461-800-824-1646

1-800-824-1646

1-800-824-16461-800-824-1646

obotcoupeusa.comobotcoupeusa.com

obotcoupeusa.com

obotcoupeusa.comobotcoupeusa.com

ROBOT COUPE U.S.A., INC. LIMITED WARRANTY

YOUR NEW ROBOT COUPE PRODUCT IS WARRANTED TO THE ORIGINAL PURCHASER

FOR A PERIOD OF ONE YEAR FROM THE DATE OF PURCHASE.

This LIMITED WARRANTY is against defects in the material and/or workmanship, and includes labor for

replacement of defective parts, provided repairs are performed by an authorized service agency (see attached

list). The

copy of the dated sales or delivery receipt BEFORE WARRANTY REPAIRS ARE BEGUN. Replacement parts

and accessories are warranted for ninety (90) days from the date of purchase when purchased separately and

will be verified by dated sales receipt OR packing slip which lists that item. All parts or accessories replaced

under warranty must be returned to the Service Agency.

CUSTOMER must inform the Service Agency of the possibility of warranty coverage and provide a

THE FOLLOWING ARE

1. Damage caused by abuse, misuse, dropping, or other similar incidental damage caused by or as

a result of failure to follow assembly, operating, cleaning, user maintenance, or storage

instructions.

2. Labor to sharpen and/or parts to replace knife assemblies or blades which have become dull,

chipped, or worn due to normal use.

3. Material or labor to renew or repair scratched, stained, chipped, dented or discolored surfaces,

blades, knives, attachments, or accessories.

4. Transportation charges to or from an authorized service agency for repairs of a machine designated

as “CARRY IN SERVICE” (table top models). NOTE: R4N/R6N are now field service units.

5. Labor charges to install or test attachments or accessories (i.e., bowls, cutting plates, blades,

attachments) which are replaced for any reason.

6. Charges to change Direction-of-Rotation of Three Phase electric motors (INSTALLER IS

RESPONSIBLE).

7. SHIPPING DAMAGE IS NOT COVERED BY WARRANTY. Visible and hidden damages are the

responsibility of the freight carrier. The consignee must file a damage claim promptly against the

carrier, or upon discovery in the case of hidden damage.

KEEP ALL ORIGINAL CONTAINERS AND PACKING MATERIALS FOR CARRIER INSPECTION.

“NOT” COVERED UNDER WARRANTY:

Robot Coupe U.S.A., Inc., Robot Coupe S.A. or any of their affiliates, distributors, officers, directors, agents,

employees, or insurers will not be obligated for consequential or other damages, losses, or expenses in connection

with or by reason of the use of or inability to use the machine for any purpose.

THIS WARRANTY IS GIVEN EXPRESSLY AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED, FOR MERCHANTABILITY AND FOR FITNESS TOWARD A PARTICULAR PURPOSE

AND CONSTITUTES THE ONLY WARRANTY MADE BY ROBOT COUPE, U.S.A., Inc.

Loading...

Loading...