Page 1

OPERATION MANUAL

FOR

MODEL

R4X and R6X

Series D

Series D Serial Numbers

R4X- 233xxxxx03

R6X- 237xxxxx03

robot coupe U.S.A., Inc.

P.O. Box 16625, Jackson, MS 39236-6625

280 South Perkins St., Ridgeland, MS 39157

email: robocoup@misnet.com

website: www.robotcoupeusa.com

1-800-824-1646

Page 2

R4X and R6X Operation Manual

2

Page 3

R4X and R6X Operation Manual

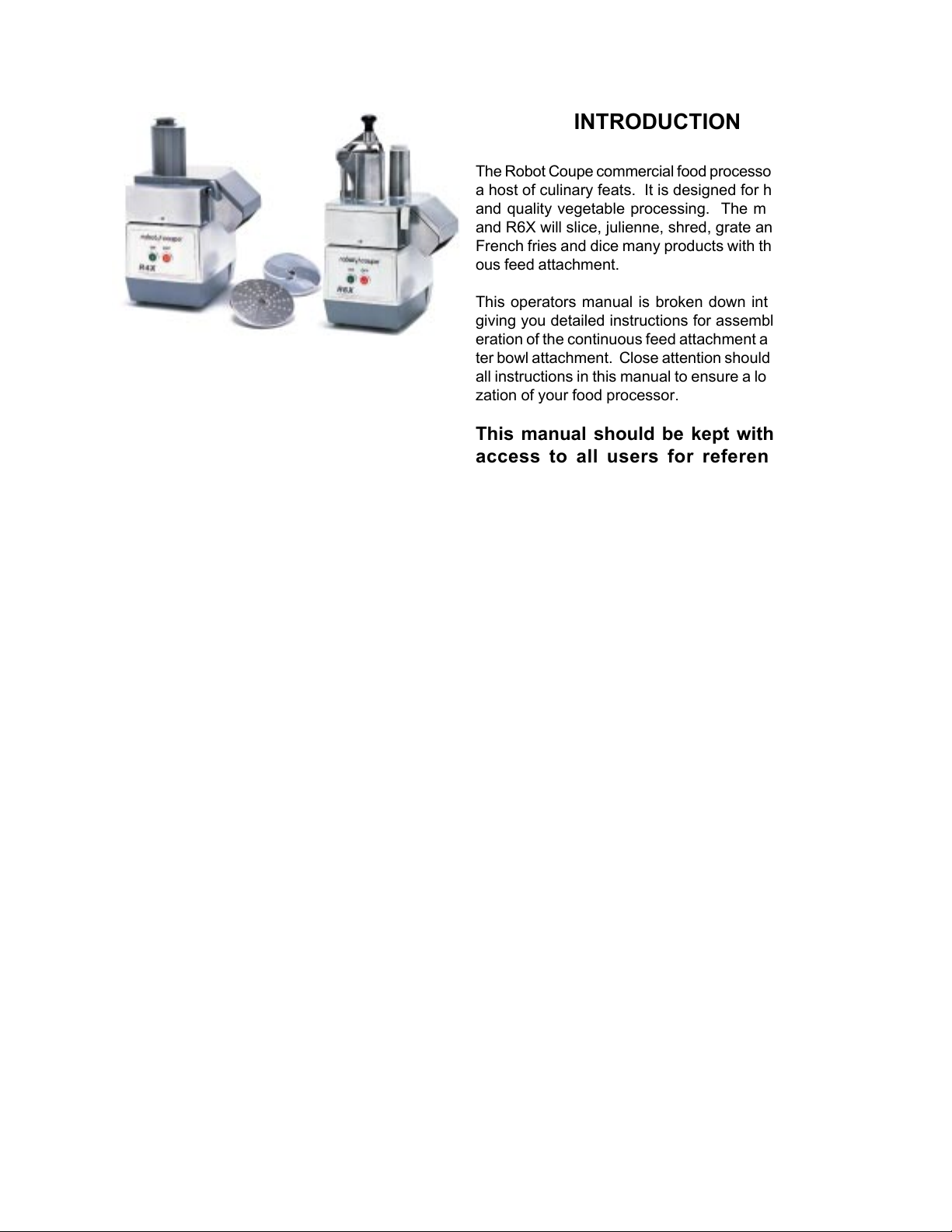

INTRODUCTION

The Robot Coupe commercial food processor performs

a host of culinary feats. It is designed for high speed

and quality vegetable processing. The models R4X

and R6X will slice, julienne, shred, grate and also cut

French fries and dice many products with the continuous feed attachment.

This operators manual is broken down into sections

giving you detailed instructions for assembly and operation of the continuous feed attachment and the cutter bowl attachment. Close attention should be paid to

all instructions in this manual to ensure a long life utilization of your food processor.

This manual should be kept within easy

access to all users for reference, and

should be read completely by all first time

users of the machine.

I. INTRODUCTION

II. ASSEMBLY/DISASSEMBLY

INSTRUCTIONS

III. OPERATING INSTRUCTIONS

IV. PREVENTIVE MAINTENANCE

GUIDE

V. TROUBLE SHOOTING AIDS

VI. SERVICE AGENCY LISTING

Maintaining the food processor in good working condition is one of the most important measures to be taken.

Inspect the machine and all parts regularly to make

sure they are in good working condition.

DO NOT operate a machine that has malfunctioned in any way.

Discard any food processed at the time of

a malfunction and have the machine inspected and

repaired at one of the Robot Coupe Authorized Service Agencies, a list is provided in the back of this

manual. Contact one of these service agencies for all

of your service, parts, and accessory requirements.

CAUTION: Your Robot Coupe comes with

sharp cutting plates. Always handle with

safety in mind. We suggest that a pair of

cut-resistant gloves be worn when handling the cutting plates.

Machine Specifications:

The Models R4X and R6X are equipped with a high

speed motor generating 1 Hp which plugs into a standard 120 volt/ 60 Hz, 15 amp power outlet. The full

load amperage rating for the R4X is 7.5 amps, and the

amperage rating for the R6X is 7.6 amps. The standard machines are supplied with a continuous feed attachment, and two cutting plates. The machines are

equipped with push type on and off buttons. The R6X

has a metal feed lead with a hinged pusher and the

R4X has a plastic feed lead.

3

Page 4

R4X and R6X Operation Manual

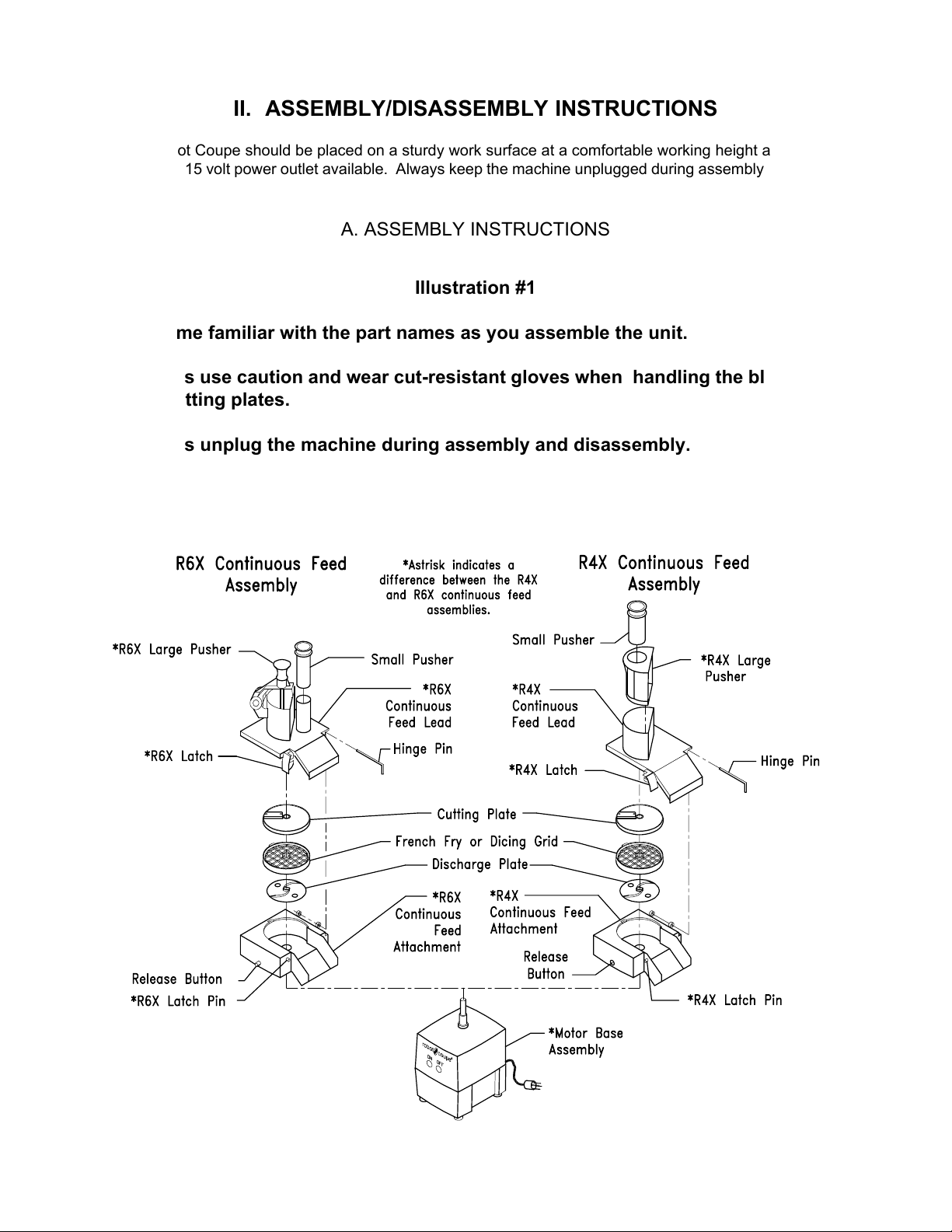

II. ASSEMBLY/DISASSEMBLY INSTRUCTIONS

Your Robot Coupe should be placed on a sturdy work surface at a comfortable working height and have a

standard 115 volt power outlet available. Always keep the machine unplugged during assembly and disas-

sembly.

A. ASSEMBLY INSTRUCTIONS

Illustration #1

Become familiar with the part names as you assemble the unit.

Always use caution and wear cut-resistant gloves when handling the blade or

the cutting plates.

Always unplug the machine during assembly and disassembly.

4

Page 5

ASSEMBLY INSTRUCTIONS

R4X and R6X Operation Manual

1 Place the motor base assembly at a comfortable

height on a sturdy work surface. Remove the plastic

discharge plate from inside the continuous feed at-

tachment. Place the continuous feed attachment on

the motor base with the release button at front center

of the motor base assembly (see drawing). Rotate

the attachment counterclockwise until it locks into

place with a snap action. When the attachment is in

the proper position, it should be level with the top sur-

face of the motor base assembly. NOTE: The ma-

chine will not operate correctly unless the continuous

feed attachment is fully seated and secured in place.

2 Place the discharge plate on the motor shaft with

the appropriate side up. Use the side with the small

straight fins for all julienne cuts or other delicate cuts.

The large finned side may be used for dicing or shred-

ding. The product will not exit the machine without

the discharge plate.

Warning: The plates are sharp. Always use caution and we suggest that a pair of cut-resistant

gloves be worn when handling the plates and

grids.

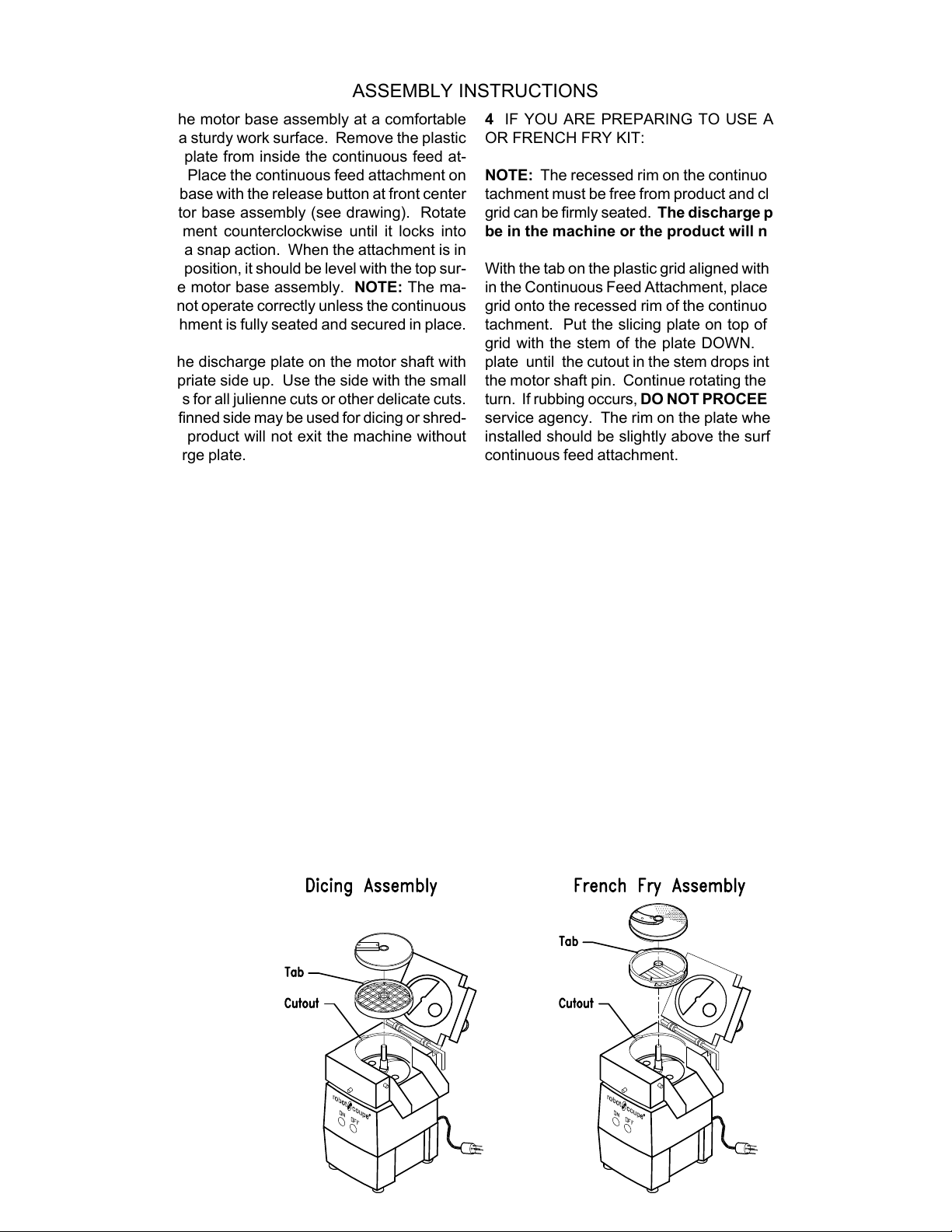

4 IF YOU ARE PREPARING TO USE A DICING

OR FRENCH FRY KIT:

NOTE: The recessed rim on the continuous feed at-

tachment must be free from product and clean so the

grid can be firmly seated. The discharge plate must

be in the machine or the product will not exit.

With the tab on the plastic grid aligned with the cutout

in the Continuous Feed Attachment, place the plastic

grid onto the recessed rim of the continuous feed attachment. Put the slicing plate on top of the dicing

grid with the stem of the plate DOWN. Rotate the

plate until the cutout in the stem drops into place on

the motor shaft pin. Continue rotating the plate a full

turn. If rubbing occurs, DO NOT PROCEED-call your

service agency. The rim on the plate when properly

installed should be slightly above the surface of the

continuous feed attachment.

5 Place the continuous feed lead on the continuous

feed attachment and secure in place with the holding

pin. The lead should fit flush on the continuous feed

attachment. Close the lead and lock the latch.

3 IF YOU ARE PREPARING TO SLICE, GRATE,

OR JULIENNE: Place the plate of your choice on the

motor shaft and turn it clockwise until it drops into

place and is fully seated. The top of the plate should

be just above the surface of the continuous feed attachment. Proceed to step 5.

6. Place the pushers in their corresponding openings in the continuous feed lead.

7. DO NOT OPERATE THE MACHINE UNLESS IT IS PROPERLY ASSEMBLED AND

THE CONTINUOUS FEED LEAD IS FULLY

SEATED AND CENTERED OVER THE

ATTACHMENT!

5

Page 6

R4X and R6X Operation Manual

B. DISASSEMBLY OF THE

CONTINUOUS FEED ATTACHMENT

1 Turn the unit OFF and UNPLUG it from the wall

socket.

2 Pull the plastic pushers out of the openings.

3 Pull out hinge pin from continuous feed lead and lift

up latch at upper right front of machine (see draw-

ing). Remove the continuous feed lead.

4 Remove cutting plate. Rotate plate slightly coun-

terclockwise, then lift free of shaft. Remove dicing or

French fry grid if any, then lift out the plastic discharge

plate.

5 Press the release button (see drawing) on the con-

tinuous feed attachment and at the same time turn

the continuous feed attachment clockwise. The continuous feed attachment releases and can be lifted

off over the motor shaft.

Before continuing, you should completely read the instructions contained in

the rest of this manual.

The continuous feed lead has two feed openings, one

large and one small, with matching pushers. The food

is inserted in the chosen opening by removing the

pusher with one hand and then depositing the food

into the chute with the other hand. The pusher should

then be used to push the food through the opening.

III. OPERATING INSTRUCTIONS

THE UNIT SHOULD BE OFF EXCEPT WHEN PROCESSING IS UNDERWAY.

It is recommended that the machine be operated on

a 50% duty cycle. This is easily accomplished since

the preparation time (cleaning, coring, peeling, and

loading) takes longer than the processing time. This

will yield the longest life for your machine.

The Robot Coupe Food Processor will slice, grate,

shred and julienne. These processes will be performed in a matter of seconds. Because of the speed

of the process, it is necessary that the operator perform preliminary steps before turning the machine on.

Food preparation, feed chute loading, and availability

of a receptacle (catch pan) for receiving the finished

product are some of the steps to assure positive control of the processing operation.

Food preparation will be required to assure that the

produce will fit a feed chute opening. Additionally,

according to personal preference, some products may

or may not be cored or peeled. Feed chute selection

should be made depending upon the product to be

processed. As an example, good consistency of small

round produce (carrots, cucumbers, etc.) necessitates

use of the small feed chute to allow better operator

control. Use of the larger port for this type of produce

may result in an undesired finished product, e.g., slicing with the grain. In general, more control of the

processing operation can also be obtained by filling

the selected feed chute and placing the pusher in position before turning the machine on.

Adherence to certain operational techniques will also

enhance the processing operation. For instance, a

consistent pressure with the pusher upon the produce

will yield a consistent output. Application of more pressure will increase the thickness of the product, e.g.,

thicker slice, while reduction in pressure will result in

a finer product. However, do not apply enough pressure to stall or slow the motor. This will cause damage to both the plate and the motor. If no pressure is

applied at all and the produce is permitted to bounce

around, an inconsistent product may result. When

the pusher has settled fully in the feed chute, press

the off switch and re-load the entry port for a repeat

process.

6

Page 7

R4X and R6X Operation Manual

DO NOT remove the continuous feed lead

when the motor is running. Wait until the

motor has come to a full stop.

DO NOT attempt to run frozen products

through the cutting plates.

DO NOT put anything other than food

products in the feed chute.

Wear cut-resistant gloves when handling

the cutting plates.

Keep hands out of the feed openings.

Always use the food pushers.

(1) Slicing Operation: When preparing food to be

sliced, make sure the food will fit into the proper feed

chute. Produce such as carrots, cucumbers, etc.,

should be “squared” at both ends. This will provide a

consistent slice throughout the whole product. With

cabbage, lettuce or any product that has an undesirable core, the core should be removed. Medium

size heads of lettuce or cabbage may be cut into

thirds to fit in the feed chute. It is also suggested that

the rounded half be squared to permit a consistent

cut. The rounded portion can be dropped into the

chute at the end and with no pressure applied, it will

normally be processed uniformly. Larger heads of

cabbage or lettuce may be more effectively processed

if they are cut into fourths. When the preparation has

been accomplished, fill the selected feed chute, place

the pusher in position, turn the machine on and observe the results.

(2) Grating Operation: Again, prepare the product

as to allow insertion into the feed chute. Consider

which chute will be used. As an example, placement

of carrots horizontally in the large chute will result in

a long grated product, while vertical insertion in the

smaller chute will result in a short grated product. It

is recommended that chilled cheese be used when

grated cheese is desired, otherwise a gumminess may

result. A fine coating of cornstarch applied to the

cheese before grating will aid in keeping the finished

product separated. A fine coating of cornstarch will

not be visible and is tasteless. Grating cheese is one

of the most trying processes and may cause overheating of the motor if not done in the recommended

manner. It is recommended that a slight pulsating

pressure be applied with the pusher while grating,

alternating slight pressure on the pusher—no pressure—continuing in this manner until the block of

cheese is completely grated. It is recommended that

the cheese be prepared to fit the opening in volumes

which will permit motor cool-down time during long

production runs.

(3) Julienne Operation: Insertion of the product to

be cut must be horizontal if a long stick is to be

achieved, e.g., squash sticks. Vertical insertion will

result in finely chopped products, e.g., chopped celery. A finely chopped onion product may also be

obtained with this operation.

DO NOT attempt to julienne meats or

cheeses.

(4) Dicing Operation: The dicing operation requires

that product be sliced both horizontally and vertically

by the machine. The smaller the dice required, the

more difficult the cut is to achieve. Soft or juicy produce will tend to mush if the dice is too small or the

produce is too soft. Cheeses and meats represent

the opposite extreme.

DO NOT ATTEMPT TO DICE MEATS OR

CHEESES. Damage could occur to the

blades and/or the motor and will not be

covered under warranty. NOTE; You cannot julienne or dice meats or cheeses on

any food processor.

During the dicing operation, attention should be given

to the finished product. A visible change in the product will occur when the dicing grid requires cleaning.

If this occurs remove the continuous feed lead and

the slicing plate, then take a stiff bristle brush and

force any product on the grid through.

7

Page 8

R4X and R6X Operation Manual

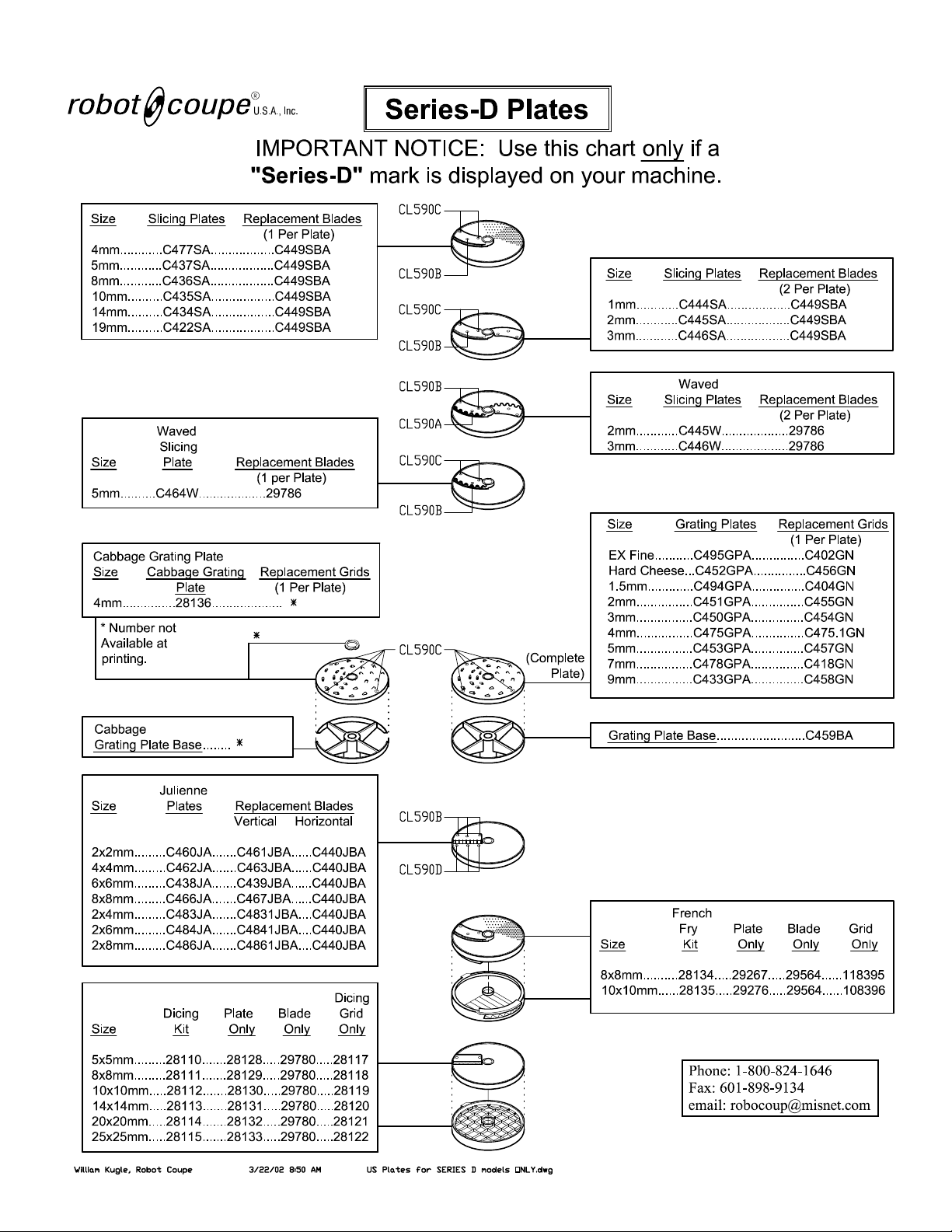

PLATE UTILIZATION:

NEVER attempt to process frozen

products!

The standard machine comes with 2 plates (C446SA

slicing and the C450GPA grating) at the time of print-

ing. Check your most current price list for which plates

are included as standard. User applications may re-

quire additional plates. The Robot Coupe processor

will preform a variety of functions: slicing grating, dic-

ing, and julienne. There are a total of 34 different

plates available to perform these functions (see be-

low).

8 slicing plates

8 grating plates

6 dicing plates

7 julienne plates

3 wave slicing plates

3 straight french fry plate combina

tions

The eight (8) slicing plates range form 1mm (approx.

1/64") to 14mm (approx. 1/2"):

Part Number MM Slicing Inches (Approx.)

C444SA 1mm 1/32"

C445SA 2mm 5/64"

C446SA 3mm 1/8"

C477SA 4mm 5/32"

C437SA 5mm 3/16"

C436SA 8mm 5/16"

C435SA 10mm 3/8"

C434SA 14mm 9/16"

The C444SA (1/32") slicing plate offers a very fine

cut. A possible use for such a fine cut is the preparation of Japanese style vegetables. Typically these

products (such as carrots or celery) will be placed in

the pusher horizontally to obtain a long thin product.

The C477SA (5/32") and C437SA (3/16") slicing plates

are also ideal for salad bar use, for the stock pot where

thicker cuts are desired. This blade is excellent also

for orange or lemon slices as well as tomatoes, where

a nice smooth surface is desired. NOTE: You can

not slice meats or cheeses on any food processor.

The C434SA, C435SA, C436SA slicing plates are

used in conjunction with the dicing grids. In addition

thicker slices can be obtained for use in soups and

stews. The C434SA (9/16") slicer also provides an

excellent cut of lettuce for use in a salad.

There are eight grating plates available:

Part Number Size MM Inches (Approx.)

C495GPA X-Fine

C452GPA Hard cheese

C494GPA 1.5 mm 1/16"

C451GPA 2 mm 5/64"

C450GPA 3 mm 1/8"

C453GPA 5 mm 3/16"

C478GPA 7 mm 5/16"

C433GPA 9 mm 3/8"

The C452GPA hard cheese grating plate is designed

specifically to grate Parmesan or Romano cheese.

CAUTION: Softer cheese will tend to gum up the

plate. The grated product is very fine. This plate can

be used for making cracker or cookie crumbs. Dried

bread crumbs can be obtained CAUTION: the moisture in fresh bread will cause clogging and poor results.

Use of either the C451GPA, C450GPA, or C453GPA,

fine, medium, and course grating plates are much

dependent upon personal choice and specific application. The medium and coarse grating plates offer

a quality grated product with cheese, carrots, cabbage for cole slaw, etc..

There are seven Julienne plates available:

The C445SA (5/64") slicing plate. Cabbage may be

sliced with this plate for New York Style Cole Slaw.

Carrots curls which adorn many dishes can be

achieved with this slicer. The carrot slices should be

dropped into cold water to permit curling. A nice carrot coin for salads can also be obtained.

The C446SA (1/8") slicing plate is ideal for salad bars

i.e.., cucumber slices, carrot “coins” (vertically sliced

Carrots). Lettuce sliced by this plate is readily used

with sandwiches, tacos, etc..

Part Number Size MM Inches (Approx.)

C460JA 2 x 2 mm (5/64")

C483JA 2 x 4 mm (5/64" x 5/32")

C484JA 2 x 6 mm (5/64" x 1/4")

C486JA 2 x 8 mm (5/64" x 5/16")

C462JA 4 x 4 mm (5/32")

C438JA 6 x 6 mm (1/4")

C466JA 8 x 8 mm (5/16")

Products such as julienne carrots, chopped

celery and finely chopped onions are

obtainable as well as julienned celery roots.

DO NOT ATTEMPT TO JULIENNE MEATS

OR CHEESES!

8

Page 9

R4X and R6X Operation Manual

A diced product requires two actions. First, a hori-

zontal slice is made and then this slice is forced by

the machine through the dicing grid to obtain a verti-

cal cut. This results in a cubed product. The dimen-

sions of this cube are varied via the selection of the

slicing plate and dicing grid.

dicing

grid 5x5 mm 8x8 mm 10x10 mm 14x14 mm 20x20 mm 25x25 mm

Plate

5 mm 28110

8 mm 28111

10 mm 28112

14 mm 28113

20 mm 28114

25 mm 28115

The shaded areas indicate additional combinations that can be used.

The 5mm dicing combination is generally used for

potatoes and squash because of its small size.

The 8mm smaller dicing combinations can be used

for finely diced carrots, celery, etc. and readily used

in soups or stews. The larger (14 mm or greater)

dicing combinations work well with fruits such as

apples, pears, pineapple, etc.

There are three (3) wave slicing plates available:

Part Number MM Slicing Inches (Approx.)

C445W 2mm Waved 5/64”

C446W 3mm Waved 1/8”

C464W 5mm Waved 3/16”

The waved slicing plates work just like the straight slicing

plates, except that the product has waved or ruffled sides.

This can be an attractive alternative to the flat slices that

are so prevalent on salad bars. By adding a waved plate,

you can dramatically alter the presentation of the food. As

with the straight slicing plates, remember that harder foods

slice best when cut thinner and softer foods slice best when

cut thicker.

While the standard Robot Coupe comes with two specific

plates (C446SA and C450GPA) at time of printing, many

user applications may require some of the optional plates

available with the unit. Typically 5 - 7 plates will perform

most of the functions called by any one customer.

When dicing tomatoes, green peppers, onions, or

celery always insure that the product is introduced

into the machine so that the slicing plate will be slicing across the grain of the vegetable.

CAUTION: The softer the produce, the

less acceptable will be the finished product.

When dicing tomatoes, green peppers, onions, or

celery always insure that the product is introduced

into the machine so that the slicing plate will be slicing across the grain of the vegetable.

After a time of use, the dicing grid will require cleaning. A visible difference in the finished product will

occur when cleaning is required. The best way to

clean the grid is: remove the slicing plate, take a stiff

bristle brush and force the product that is on the grid

to go through.

9

Page 10

R4X and R6X Operation Manual

IV. PREVENTIVE MAINTENANCE

TROUBLE SHOOTING AIDS:

The Robot Coupe has been designed to provide maxi-

mum trouble free performance. Adherence to the as-

sembly and operating instructions will further assure

good performance. Additionally, if simple common

sense rules are applied to the unit, a long life utiliza-

tion will be achieved.

(1) Care: While the Robot Coupe is a ruggedly con-

structed machine, overall handling should be accom-

plished with a sense of use rather than abuse. The

motor housing is made of rugged cast aluminium and

will yield a long life if not maltreated. While the ma-

chine is reasonably portable, care should be taken

not to drop it. Remove the continuous feed assem-

bly and any plates or other attachments before relo-

cating the machine. Your machine should never

be picked up by the continuous feed lead or the

cord. Always lift from the bottom of the motor

base assembly. Equal caution should be exercised

in handling all of the parts for your own safety and to

assure they are not subject to undue force.

Many other cleaning detergents can also cause corrosion of soft metals.

Clean the aluminum parts using only soft

metal (Aluminum) safe detergents.

The continuous feed assembly, pushers, and plates

are dishwasher safe if used with a soft metal safe

detergent. These attachments can also be washed

in a three tank system pot sink.

NOTE: The high temperatures of dish machines

will tend to shorten the life of the plastic and rubber parts. Hand washing using a three pot sink

will provide for the longest life of these parts.

Pre-rinse the attachments before washing to remove

any bulk food on the parts. A stiff bristle brush or

power sprayer faucet attachment is effective in knocking the food out of the crevices especially when cleaning the cutting plates. The washer should have an

industry standard wash, rinse, and sanitization cycle.

Allow the parts to air dry after sanitizing and before

reassembly.

(2) Cleaning: The machine should be cleaned per

the following instructions or as required by local health

department regulations. Proper cleaning of the machine is one of the MOST IMPORTANT preventive

maintenance measures the user can employ. The

high acid content of some foods can cause harm to

the seals protecting the electrical parts contained

within the housing. It is recommended that the machine be cleaned after each operational use and minimally once per day.

Correct cleaning procedures are required to assure

that damage is not inflicted in the cleaning process.

The motor base assembly contains the motor and

electrical components.

DO NOT IMMERSE THE MOTOR BASE

ASSEMBLY IN WATER!

Cleaning of the motor/base assembly must be done

with care. First, unplug the unit - A sponging

with a soluble soft metal (Aluminum) safe detergent

is acceptable, making sure the water is not permitted

to penetrate the seals. Clean around the seals with a

small brush, taking care to remove all food. Clean

the motor shaft with a small brush.

Read the label for the dish machine detergent you

are using to determine if it is safe for soft metals. If

you can not determine if it is safe for soft metals, then

contact your supplier for this information.

(3) Preventive Maintenance: In addition to cleaning

the seals, an examination should be made periodically to assure that a seal against food is being maintained. With proper care, and depending on use, the

seals should last for a year or more. However, they

can and should be replaced when wear or erosion is

noted or at least once every three to six months to

prevent motor bearing damage. It is recommended

that the seals be replaced by an authorized repair

agency.

Good operational performance is obtained when the

blades are sharp. Continued use can dull the blades.

All of the cutting plates are made so that the blades

or grids can be replaced when they become dull. Always store the plates in the plate holders. Additional

plate holders can be obtained from your food service

distributor.

In general, the best preventive measure that can be

applied is close adherence to the assembly and operation instructions along with common sense and

regular cleaning.

Your Robot Coupe is a piece of kitchen equipment

and like all other kitchen equipment, care and caution should be used when operating. Although training requirements are minimal, only responsible individuals familiar with this operation manual should be

allowed to operate your machine.

10

Page 11

R4X and R6X Operation Manual

V. TROUBLE SHOOTING AIDS

The following section indicates potential problems and

the probable solution which should be

implemented by users. Problems which extend be-

yond these will require an experienced serviceman.

A list of authorized service agencies is supplied.

A. Unit does not start.

1. Are all the attachments tightly in place? Be

sure the continuous feed lead is flush with the

continuous feed attachment.

2. Press the off button and unplug the machine.

3. Remove continuous feed lead.

4. Remove any product from inside continuous

feed lead and attachment.

5. Is there any product jamming the plate? If so

press the OFF button and unplug the machine.

Wear cut-resistant gloves when removing a jam!

6. Try another outlet.

B. Continuous feed lead will not fit flush with motor

base.

1. Processing plate is not in it’s proper position.

2. Rim of plate should be slightly above the upper edge of continuous feed attachment.

C. Unit stops running.

1. Turn off and unplug the machine.

2. Follow A. above and try again.

D. If unit does not operate after following A above

1. Check outlet for current (breaker for fuse).

2. Try unit again.

3. Call local service agency.

G. Food is going into machine, but not coming out.

1. The discharge Plate is not in the continuous

feed attachment.

H. Cucumbers coming out with torn skins.

1. Blade is dull on plate and must be changed.

NOTE: cucumber condition before process

ing should be considered.

2. Make sure the small “vane” side of the dis

charge plate is up.

VI. SERVICING OF YOUR

ROBOT COUPE

Your Robot Coupe has a one year limited warranty

against defects in parts and workmanship. Should

the unit require service, check with your distributor to

see where local service is available. If not or if you

wish your unit to be serviced at the factory, call for a

return merchandise authorization (RMA) number, and

upon receipt of same, ship it PREPAID and insured

to our factory address.

Robot Coupe USA, Inc.

Service Dept. Phone:1-800-824-1646

601-898-8411

E. Unit starts to spark or smoke.

1. Turn the unit off, unplug it and call local authorized service agency.

F. Unit Makes a grinding noise.

1. Turn off and unplug the machine, disassemble, check the continuous feed lead and processing plate to see if they have been rubbing

together.

2. If this was the case, the processing plate was

not fully seated. Discard any food processed.

Check for and remove any food particles inside

stem of processing plate. Replace the plate insuring that the processing plate is fully

seated. Make sure there are no food particles

on the motor shaft.

11

Page 12

Page 13

Page 14

Page 15

Model Price list for USA only Model Price list for USA only

A

A

g

X

g

X

X

R4X

Series D

PRICES AND OTHER INFORMATION SUBJECT TO CHANGE WITHOUT NOTICE

Series D

Serial Numbers

233xxxxx03

Use "Series D" Cutting Plates Use "Series D" Cutting Plates

R6X

Series D

Series D

Serial Numbers

237xxxxx03

Part # Description Part # Description

27198

28107

29620

29784

102690

117770

118433

BX658

C420

CL520

CL523

CL575

R199

R237

R255

R475

R4906

R4907

R4911

R492

R496

R604S

R611

R662

R662

R664S

RA402

RA406

RA409

RA411

RA412

RA418

RA419

RA429

RA441

RA441.1

RA441.2

RA442

RA443

RA455

RA467

RA477

RA489

RA490

RA493

RA494

RA495 Front Data Plate R4X RA442

RA497

RA604E No lon

S16213632

S17586350

S18388701

S194565

* (D) Cont Feed Kit/R4

(D)Locking Pin Assy

(E) Plastic Base, Low Profile

(D)Cont Feed Bowl (R4 Series D)

(K)Discharge Plate

(D) Din Rail 2"L, R4/R6 'D"

(D)Locking Collar

Base Bolt W/Washer

Mag Swtch w/Hse (single)

Hinge Pin

Hinge Pin Bushing

* Plate Rack (wall mount)

* Robo-Cart

6203 Bearing R2 Top/Btm

* Plate Rack

* Plate Rack (Individual)

Start Capacitor R4X Mtr

Run Capacitor R4X

Circuit Breaker/R4X/10A

Shaft Pin (new style)

Cord W/Plug (R4X,S,P,Y)

Seal, Motor

Motor Support Seal

Bearing, Motor Top

Bearing, Motor Top

Relay DPST

Foot

Motor Support

Continuous Feed Lead

Large Pusher

Small Pusher

Green "On" Switch Assy

Red "Stop" Switch Assy

Latch

Support/Pad,Front

Gasket

Metal Plate

Support,Magnetic Switch

Pad,Rear

Plate, Motor Mounting

Seal Assembly (Seal Support)

Pin for Latch

O Ring, Seal Support

Strain Relief

Base

Baffle

R4X Motor Base Assy

er available RA455

(D) Start Cap. R4X/R6X

(D) Run Cap R4X/R6

(D) Electronic Switch R4X/R6X

(D) Motor R4X/R6X Low Profile

27199

28107

29102

29501

29620

29695

29696

29697

100556

100581

102690

117770

118324

118374

118376

118377

118433

BX658

C420

CL520

CL523

CL569

CL573

CL575

CL576

CL588

R199

R237

R255

R475

R4906

R4907

R4911

R492

R496

R604S

R611

R662

R664S

RA402

RA406

RA418

RA419

RA441

RA441.1

RA441.2

RA443

RA467

RA489

RA490

RA493

RA494

RA604E No lon

RA612

RA698

S16213632 (D) Start Cap. R4X/R6X

S17586350 (D) Run Cap R4X/R6

S18388701 (D) Electronic Switch R4X/R6X

S194565

* (D) Cont Feed Kit W/Extra Safety/R6

(D)Locking Pin Assy

(D)Bracket-Pusher Return Assy

(K)Lock for Feed Cover

(E) Plastic Base, Low Profile

(D) Hinge Bracket

(D)Cont Feed Lead Assy W/Extra Safety

(D)Cont Feed Bowl (R6 Series D)

Description NA

(K)Bushing for Spring

(K)Discharge Plate

(D) Din Rail 2"L, R4/R6 'D"

(L)Small Pusher

(K)Pivot, Pusher Return Bracket

(D)Cont Feed Lead w/Extra Safety

(K)Extra Safety Rod

(D)Locking Collar

Base Bolt W/Washer

Mag Swtch w/Hse (single)

Hinge Pin

Hinge Pin Bushing

Pusher Knob

Stud Bolt, Latch

* Plate Rack (wall mount)

Large Pusher Assembly

Insert, Plastic

* Robo-Cart

6203 Bearing R2 Top/Btm

* Plate Rack

* Plate Rack (Individual)

Start Capacitor R4X Mtr

Run Capacitor R4X

Circuit Breaker/R4X/10A

Shaft Pin (new style)

Cord W/Plug (R4X,S,P,Y)

Seal, Motor

Motor Support Seal

Bearing, Motor Top

Relay DPST

Foot

Motor Support

Green "On" Switch Assy

Red "Stop" Switch Assy

Support/Pad,Front

Gasket

Metal Plate

Support,Magnetic Switch

Pad,Rear

Plate, Motor Mounting

Seal Assembly (Seal Support)

O Ring, Seal Support

Strain Relief

Base

Baffle

er available

Front Data Plate (R6X)

R6X Motor Base Assy

(D) Motor R4X/R6X Low Profile

* Denotes Accessories

NA -Not Available

1/20/2004

Page 16

U.S.A., Inc.U.S.A., Inc.

U.S.A., Inc.

U.S.A., Inc.U.S.A., Inc.

PP

.O. Box 16625, Jackson, MS 39236-6625.O. Box 16625, Jackson, MS 39236-6625

P

.O. Box 16625, Jackson, MS 39236-6625

PP

.O. Box 16625, Jackson, MS 39236-6625.O. Box 16625, Jackson, MS 39236-6625

280 South Perkins St., Ridgeland, MS 39157280 South Perkins St., Ridgeland, MS 39157

280 South Perkins St., Ridgeland, MS 39157

280 South Perkins St., Ridgeland, MS 39157280 South Perkins St., Ridgeland, MS 39157

email: robocoup@misnet.comemail: robocoup@misnet.com

email: robocoup@misnet.com

email: robocoup@misnet.comemail: robocoup@misnet.com

website: www.rwebsite: www.r

website: www.r

website: www.rwebsite: www.r

1-800-824-16461-800-824-1646

1-800-824-1646

1-800-824-16461-800-824-1646

obotcoupeusa.comobotcoupeusa.com

obotcoupeusa.com

obotcoupeusa.comobotcoupeusa.com

ROBOT COUPE U.S.A., INC. LIMITED WARRANTY

YOUR NEW ROBOT COUPE PRODUCT IS WARRANTED TO THE ORIGINAL PURCHASER

FOR A PERIOD OF ONE YEAR FROM THE DATE OF PURCHASE.

This LIMITED WARRANTY is against defects in the material and/or workmanship, and includes labor for

replacement of defective parts, provided repairs are performed by an authorized service agency (see attached

list). The

copy of the dated sales or delivery receipt BEFORE WARRANTY REPAIRS ARE BEGUN. Replacement parts

and accessories are warranted for ninety (90) days from the date of purchase when purchased separately and

will be verified by dated sales receipt OR packing slip which lists that item. All parts or accessories replaced

under warranty must be returned to the Service Agency.

CUSTOMER must inform the Service Agency of the possibility of warranty coverage and provide a

THE FOLLOWING ARE

1. Damage caused by abuse, misuse, dropping, or other similar incidental damage caused by or as

a result of failure to follow assembly, operating, cleaning, user maintenance, or storage

instructions.

2. Labor to sharpen and/or parts to replace knife assemblies or blades which have become dull,

chipped, or worn due to normal use.

3. Material or labor to renew or repair scratched, stained, chipped, dented or discolored surfaces,

blades, knives, attachments, or accessories.

4. Transportation charges to or from an authorized service agency for repairs of a machine designated

as “CARRY IN SERVICE” (table top models). NOTE: R4N/R6N are now field service units.

5. Labor charges to install or test attachments or accessories (i.e., bowls, cutting plates, blades,

attachments) which are replaced for any reason.

6. Charges to change Direction-of-Rotation of Three Phase electric motors (INSTALLER IS

RESPONSIBLE).

7. SHIPPING DAMAGE IS NOT COVERED BY WARRANTY. Visible and hidden damages are the

responsibility of the freight carrier. The consignee must file a damage claim promptly against the

carrier, or upon discovery in the case of hidden damage.

KEEP ALL ORIGINAL CONTAINERS AND PACKING MATERIALS FOR CARRIER INSPECTION.

“NOT” COVERED UNDER WARRANTY:

Robot Coupe U.S.A., Inc., Robot Coupe S.A. or any of their affiliates, distributors, officers, directors, agents,

employees, or insurers will not be obligated for consequential or other damages, losses, or expenses in connection

with or by reason of the use of or inability to use the machine for any purpose.

THIS WARRANTY IS GIVEN EXPRESSLY AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED, FOR MERCHANTABILITY AND FOR FITNESS TOWARD A PARTICULAR PURPOSE

AND CONSTITUTES THE ONLY WARRANTY MADE BY ROBOT COUPE, U.S.A., Inc.

Loading...

Loading...