Robot Coupe R10 Service Manual

OPERATION MANUAL

FOR

MODEL

R10, R10P, and R10U

robot coupe U.S.A., Inc.

P.O. Box 16625, Jackson, MS 39236-6625

280 South Perkins St., Ridgeland, MS 39157

email: robocoup@misnet.com

website: www.robotcoupeusa.com

1-800-824-1646

I. Introduction

II. Operation Instructions

A. Blade Assembly

B. Controls

C. Operation

D. Emptying the bowl

R10 Operation Manual

E. Cleaning

III. Preventative Maintenance

IMPORTANT NOTICE

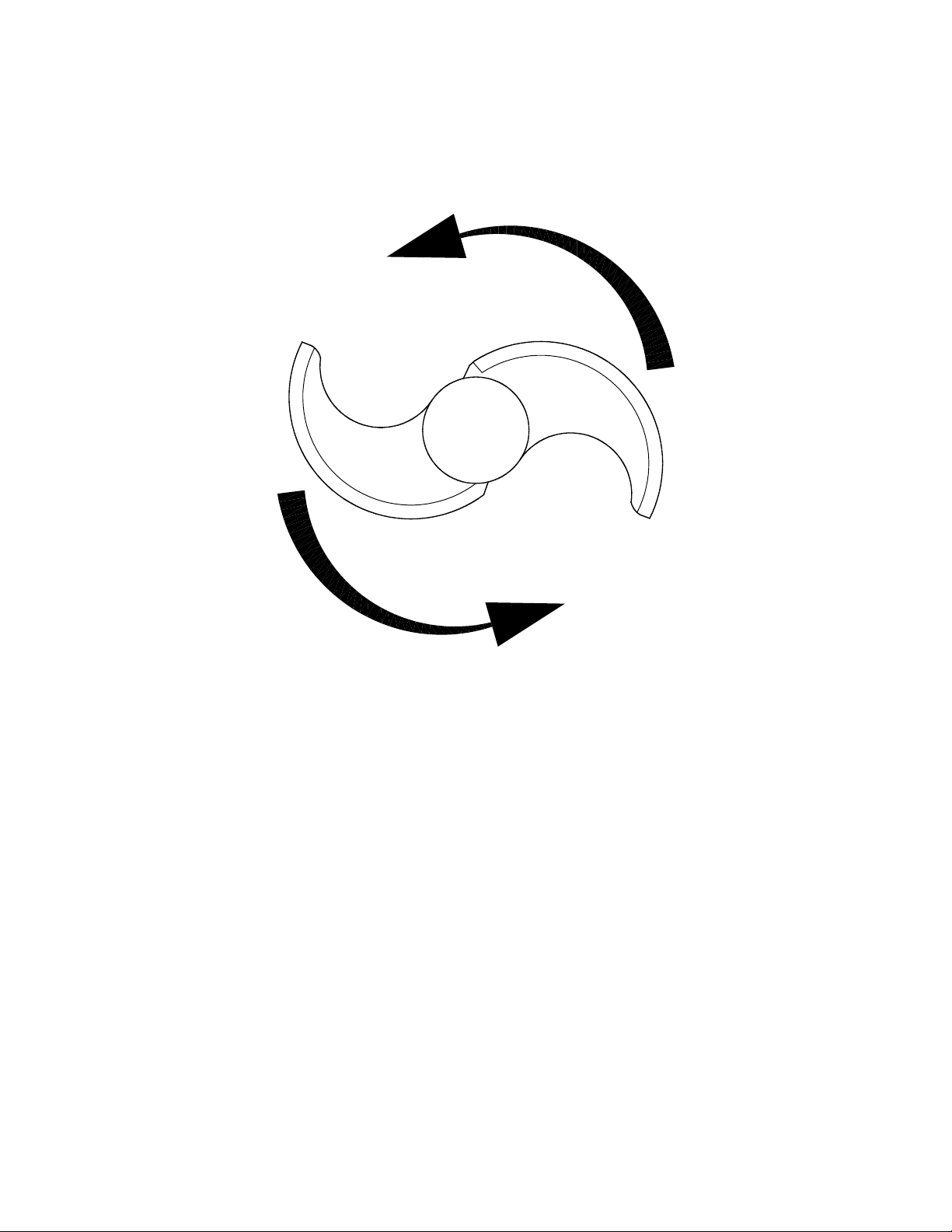

DRIVE SHAFT ROTATION

R10 Operation Manual

Three phase motors may rotate either direction.

Required motor rotation is counterclockwise.

Changing the motor rotation requires a qualified electrician.

See note on end of power cord.

R10 Operation Manual

Introduction

Robot Coupe offers the most complete line of food processors available in the food service industry. The

Robot Coupe model R10, 10 quart Vertical Cutter Mixer, is specifically designed for quality, high speed food

preparation. The R10 can prepare a variety of foods ranging from a coarse chop to a fine puree. You can

prepare fresh salads, sauces, pates, mousses, salad dressings, blends, prepare fine and coarse sausage

mixtures, meat salads, mashed potatoes, mix and knead all doughs, pie crusts, flake pastries, and emulsify

meats, nuts, and other fruits and vegetables.

The R10 is constructed of sturdy stainless steel, fiberglass, and cast aluminum. The stainless steel bowl with

the adjustable knife is designed to allow for small and large batches without any mixing baffle required. A

large see-thru lid with a funnel opening allows you to carefully control the consistency of the product as it is

being processed. The Robot Coupe model R10 is designed to give years of safe, quality food preparation.

Maintain a copy of this manual for reference by all users. Follow the instructions as indicated in this manual.

Pay close attention to the special notes of caution.

MODEL SPECIFICATIONS

R10 * 10 Quart Capacity

208-240 Volt, 3 phase,

3/4.5 Hp, 9/12.5 A

2 speed, 1725/3450 RPM

R10P * 10 Quart Capacity

208-240 Volt, Single Phase,

3 Hp, 14.5 Amp

Single Speed, 1725 RPM

R10U * 10 Quart Capacity

Same as R10 but with

3-1/2 qt. mini bowl attachment.

The mini bowl may be purchased with the machine

as model R10Uor

separate as part number R8U090.

* Capacities may vary with the products ability to circulate in the bowl.

The R10 is equipped with auto-reset thermal overload protection. If the unit overheats due to an overload

condition, it will automatically shut off. After a cooling period of ten to fifteen minutes the thermal overload

protection will automatically reset and the unit may then be restarted. It will not restart until the thermal

overload has reset.

The suggested breaker size is: R10-20 AMPS, R10U-20 AMPS, R10P-30 AMPS. Check the local codes

they may supersede the suggested breaker size.

R10 Operation Manual

II. Operation Instructions

This manual is broken down into step by step instructions to assist the operator in easy and quality food

preparation. This manual should be read completely before use by each operator. Additionally, this manual

should be kept as a reference for future operators. Adherence to the guidelines set forth by this manual will

ensure a safe, long life utilization of the vertical cutter mixer.

A. Blade Assembly

The R10 blade assembly comes assembled from the factory. The blade assembly is designed so that the

blades can be adjusted for large or small batches. The blade assembly should be completely disassembled

after each days use, washed completely, and allowed to air dry before reassembled. Additionally, the blades

should be kept sharp to provide the best performance. The blades can be sharpened by means of a fine

stone; a stone is provided with each machine.

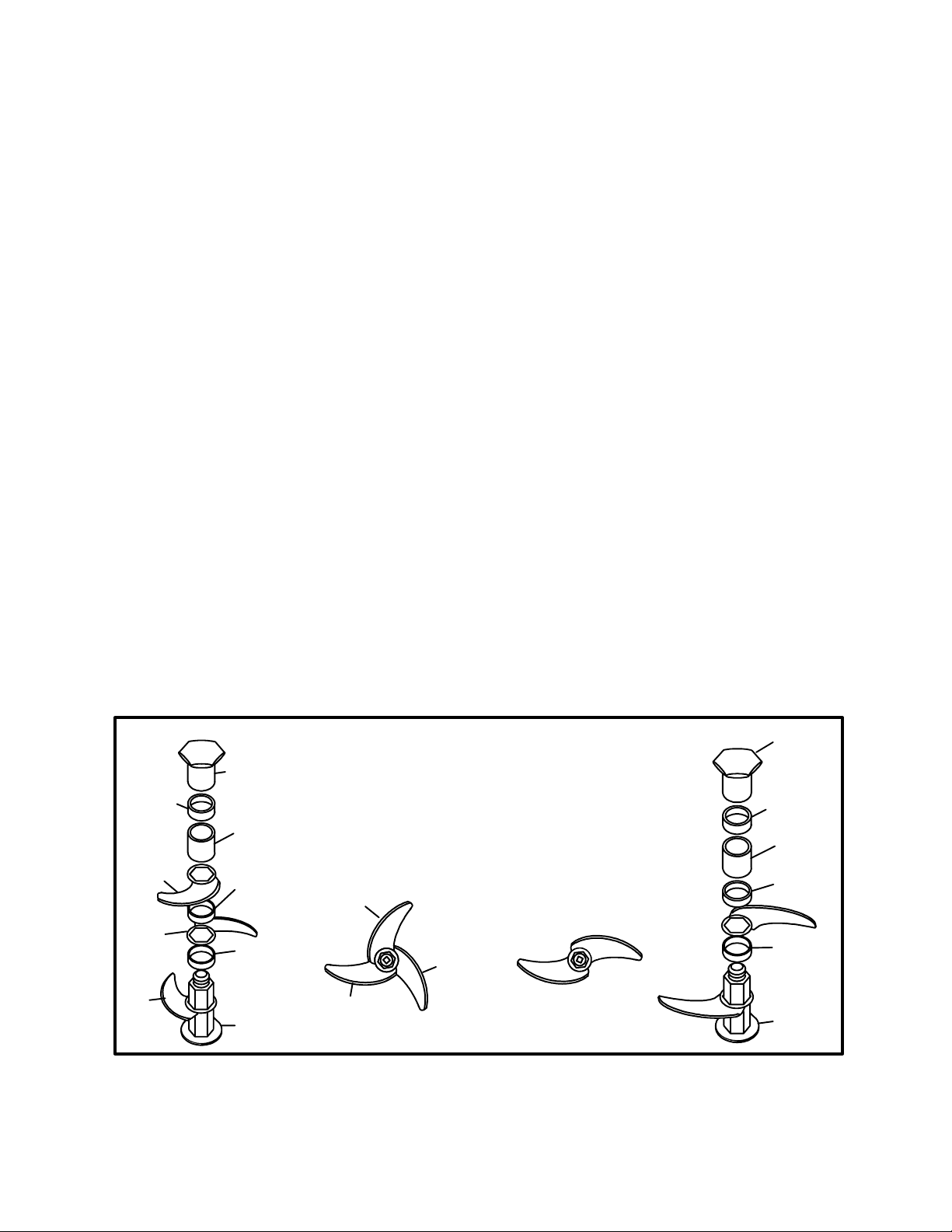

The blades are set at the factory to allow for most operations (See figure). The bottom blade should always

stay on the bottom, followed by one small spacer, then the second blade, followed by the second smaller

spacer then the third blade. Note: the white Nylon spacer should always be used between the locking nut and

large aluminum spacer. Most low speed operations can be run using this blade configuration. High speed

operations and operations using heavy loads such as dough and cheese should use only two blades. For

high speed operations, use only one small spacer between the lower and second blade.

Use the following diagram as a guide. NOTE: The placement of the blades is very important to maintain the

correct cutting performance and balance. The blades should always be located 120 degrees apart when

using the three blade system. The second blade should always follow the bottom blade, not lead the bottom

blade. Refer to the diagram below.

BLADE

LOCKING

NUT

NYLON

SPACER

BIG

SPACER

SMALL

SPACER

SMALL

SPACER

BLADE

SUPPORT

NYLON

SPACER

3

2

1

BLADE

LOCKING

NUT

BIG

SPACER

SMALL

SPACER

SMALL

SPACER

BLADE

SUPPORT

THE BEVELLED SIDE OF BLADES

SHOULD ALWAYS BE UP

TOP

VIEW

THREE BLADE CONFIGURATION

FOR LOW SPEED.

3

1

BOTTOM

2

BLADE

TWO BLADE CONFIGURATION

FOR HIGH SPEED.

R10 Operation Manual

There are seven important points to remember about the blade assembly:

(1) The blades are extremely sharp, take care when working around and handling the blades.

(2) The bottom blade must always stay on the bottom of the blade support.

(3) When placing the blade assembly on the motor shaft for operation, ensure that the blade assembly seats

completely on the motor shaft. The blade assembly should drop all the way to the bottom of the bowl such

that the bottom blade is almost touching the bottom of the bowl.

(4) Disassemble the blade assembly at least after each days use, wash completely, and allow to air dry

before assembly.

(5) Ensure that the blade assembly is correctly assembled, and all parts fit tightly together before beginning

each operation.

(6) Sharpen the blades as necessary.

(7) A large spacing between the blades can cause excessive , vibration, especially on high speed.

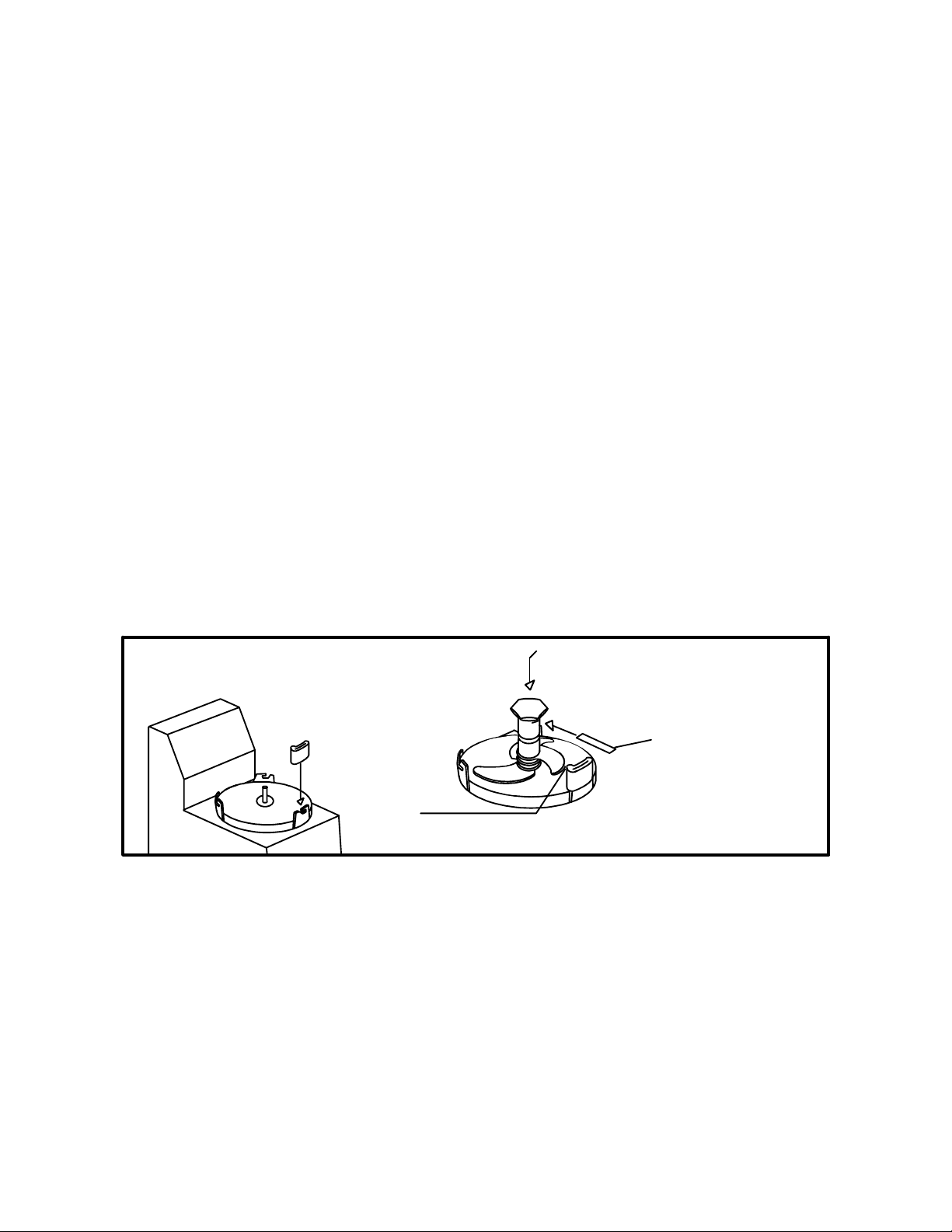

Blade disassembly: Included with the machine is a blade disassembly tool. This consists of two pieces; the

blade stop, and the pry bar. Refer to the drawing below. The blade stop rests on the front bowl locking

bracket, this prevents the blade from rotating during assembly and disassembly. Place the blade stop on the

front bracket, and place the blade on the motor shaft. To disassemble, rotate the blade counterclockwise

until a blade rests against the blade stop. Slide the pry bar into the slot underneath the blade locking nut, and

twist counterclockwise to loosen the nut. Remove the blade locking nut and adjust or clean the blade as

required. Reverse this procedure for assembly.

PLACE THE BLADE ON THE

2

PLACE THE

1

BLADE STOP

ON THE FRONT

BRACKET

MOTOR SHAFT.

INSERT PRY BAR.

4

AND TURN CLOCKWISE

TO TIGHTEN OR

COUNTERCLOCKWISE TO

LOOSEN

3

ROTATE THE BLADE UNTILL IT RESTS AGAINST THE BLADE STOP.

CLOCKWISE TO TIGHTEN COUNTERCLOCKWISE TO LOOSEN.

Alternate method to disassemble the blade; place the blade assembly carefully on its side on a cutting block

or board. It is recommended that a pair of protective cutting gloves be used when handling the blades. With

the blade on its side, loosen the locking nut by turning it in a counterclockwise rotation. Remove all the

spacers and blades for cleaning. Allow all parts to dry before reassembly. A light food grade grease may be

applied to the threaded area to assist in easy removal.

If the blades are not disassembled on a regular basis, they will become hard to disassemble and adjust. If

the blade locking nut will not remove, service may be required.

Loading...

Loading...