Page 1

Refrigerant Recovery Machine

Model No. RG6

Operating Manual

Bedienungsanleitung

Manual de operaciones

Manuel d’utilisation

1

Page 2

Safety PrecautionS

WARNING : TO PREVENT PERSONAL INJURY AND / OR EQUIPMENT DAMAGE,

ALLOW ONLY QUALIFIED PERSONNEL TO OPERATE THIS UNIT. Before operating the unit,

read and follow the instructions and warnings in this manual. The operator must be familiar with air

conditioning and refrigeration systems, refrigerants, and the dangers of pressurized components. If

the operator cannot read this manual, operating instructions and safety precautions must be read and

discussed in the operator’s native language.

PRESSURIZED TANK CONTAINS LIQUID REFRIGERANT. Do not overll storage vessels, because

overfilling may cause explosion and personal injury or death. Do not recover refrigerants into

nonrellable containers; use only federally authorized rellable containers (DOT spec. 4BW or 4BA).

HOSES MAY CONTAIN LIQUID REFRIGERANT UNDER PRESSURE. Contact with refrigerant may

cause personal injury. Wear protective equipment, including safety goggles and protective gloves.

Disconnect hoses using extreme caution.

AVOID BREATHING A/C REFRIGERANT AND LUBRICANT VAPOR OR MIST. Exposure may

irritate eyes, nose, and throat. To remove refrigerant from the A/C systen, use only equipment certied

for the type of refrigerant being removed. Use the unit in locations with mechanical ventilation that

provides at least four air changes per hour. If accidental system discharge occurs, ventilate the work

area before resuming service.

TO REDUCE THE RISK OF FIRE, USE THE SHORTEST POSSIBLE EXTENSION CORD WITH A

MINIMUM SIZE OF 14 AWG. Using an undersized extension cord may result in electrical equipment

failure.

TO REDUCE THE RISK OF FIRE, do not use the unit in the vicinity of spilled or open containers of

gasoline or other ammable substances.

CAUTION – DO NOT PRESSURE TEST OR LEAK TEST EQUIPMENT OR VEHICLE AIR

CONDITIONING SYSTEMS WITH COMPRESSED AIR. Some mixtures of air and refrigerant have

been shown to be combustible at elevated pressures. These mixtures, if ignited, may cause injury or

property damage.

DO NOT MIX REFRIGERANT TYPES THROUGH A SYSTEM OR IN THE SAME CONTAINER.

Mixing of refrigerants causes severe damage to the unit and the system being serviced.

HIGH VOLTAGE ELECTRICITY INSIDE THE UNIT HAS A RISK OF ELECTRICAL SHOCK. Exposure

may cause personal injury. Disconnect power before servicing the unit.

Additional health and safety information may be obtained from

refrigerant and lubricant manufacturers.

Explanation of SafEty Signal WordS

WARNING : Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION : Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

CAUTION : Used without the safety alert symbol indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

2

Page 3

table of contentS

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Explanation of Safety Signal Words . . . . . . . . . . . . . . . . . . . . . . . . .2

Understanding Refrigerant Recovery . . . . . . . . . . . . . . . . . . . . . . . .4

Standard Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Recovery Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Purge the Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Operating Instructions for Bulk Liquid Systems . . . . . . . . . . . . . . . . . . . 7

Push – Pull Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Liquid Recovery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Vapor Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Purge Non-Condensable Gas from a Storage Cylinder . . . . . . . . . . . . . . .8

Recovery Cylinder Information. . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Rebuild Kits and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installation of the Filter and Filter / Drier . . . . . . . . . . . . . . . . . . 13

Burned-out System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

German. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Spanish. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

French . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Warranty Statement . . . . . . . . . . . . . . . . . . . . . . . .Inside Back Cover

3

Page 4

underStanding refrigerant recovery

NOTE: Throughout this operating manual the term “unit”

is used when referring to all models of RG6 refrigerant

recovery machines.

Refrigerant recovery is the process of taking refrigerant

out of a system and storing it in a cylinder. The following

information is critical to achieving the best refrigerant

recovery results.

Refrigerant

Identify the refrigerant type and quantity in the system to

be serviced.

The unit is approved for use with the following category

III, IV, and V refrigerants (per ARI-740) :

R-12, R-22, R-134a, R-401a, R-401b,R-401c, R-402a,

R-402b, R-404a, R-406a, R-407a, R-407b, R-407c,

R-407d, R-408a, R-409a, R-410a, R-411a, R-411b,

R-412a, R-500, R-502, R-507 R-509

Filters and Filter / Driers

CAUTION : Filters prevent contamination from entering

the unit, which reduces the risk of damage to the unit

and the system being serviced.

The unit is shipped with a lter screen installed behind

the inlet tting. Robinair strongly recommends that a

clean lter screen be used for every service job. Failure

to use a lter screen will invalidate your warranty.

Robinair also strongly recommends using a lter / drier

(Part No. 100343; not provided) at the inlet tting. Each

in-line lter / drier must be labeled and used for only one

type of refrigerant.

Valves

WARNING : To prevent personal injury, open

service and cylinder valves SLOWLY to allow

rapid shut-off of gas flow if necessary. Once it is

determined there is no danger, the valves may be

opened fully.

Isolate large amounts of refrigerant and close valves

after use, so if a leak should develop anywhere in the

system, refrigerant will not escape to the atmosphere.

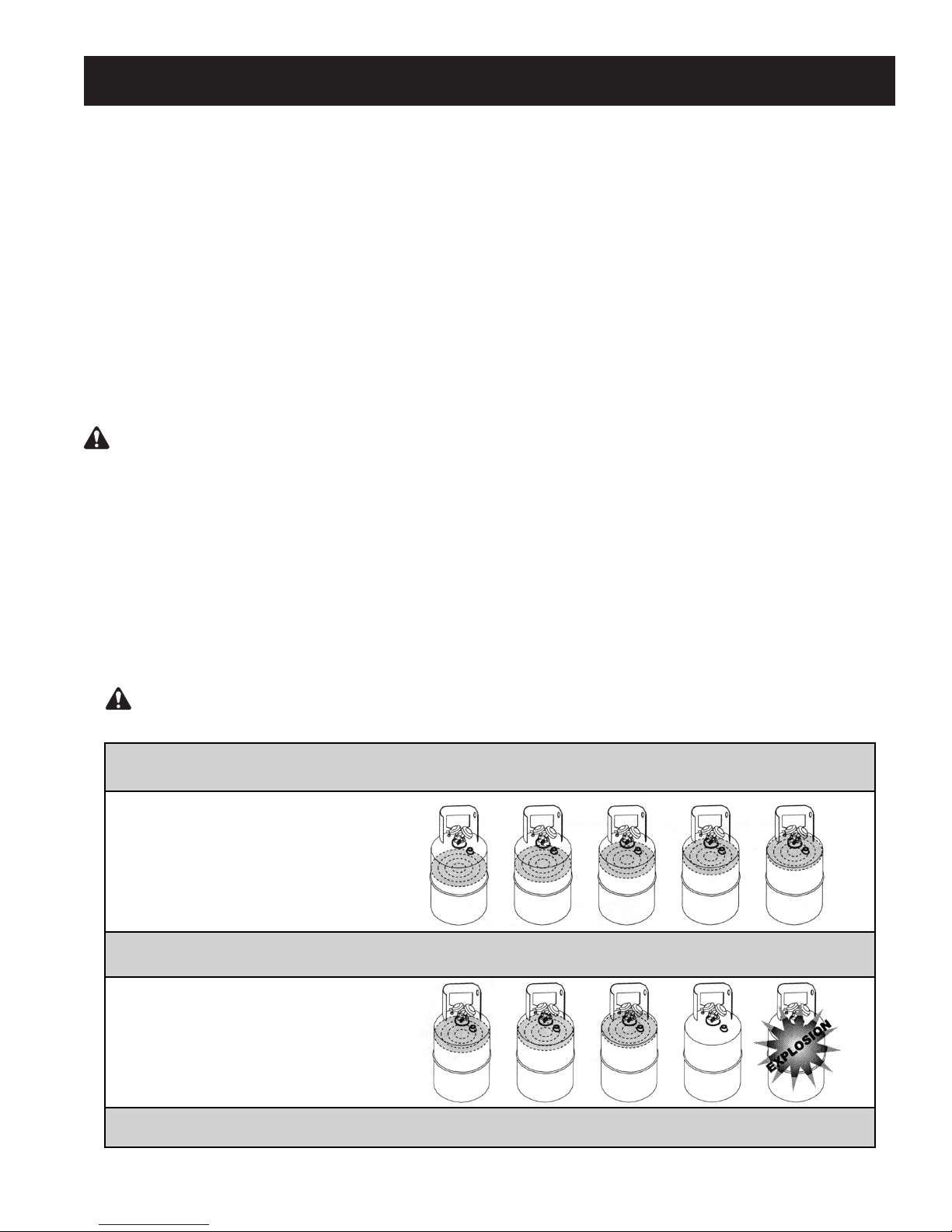

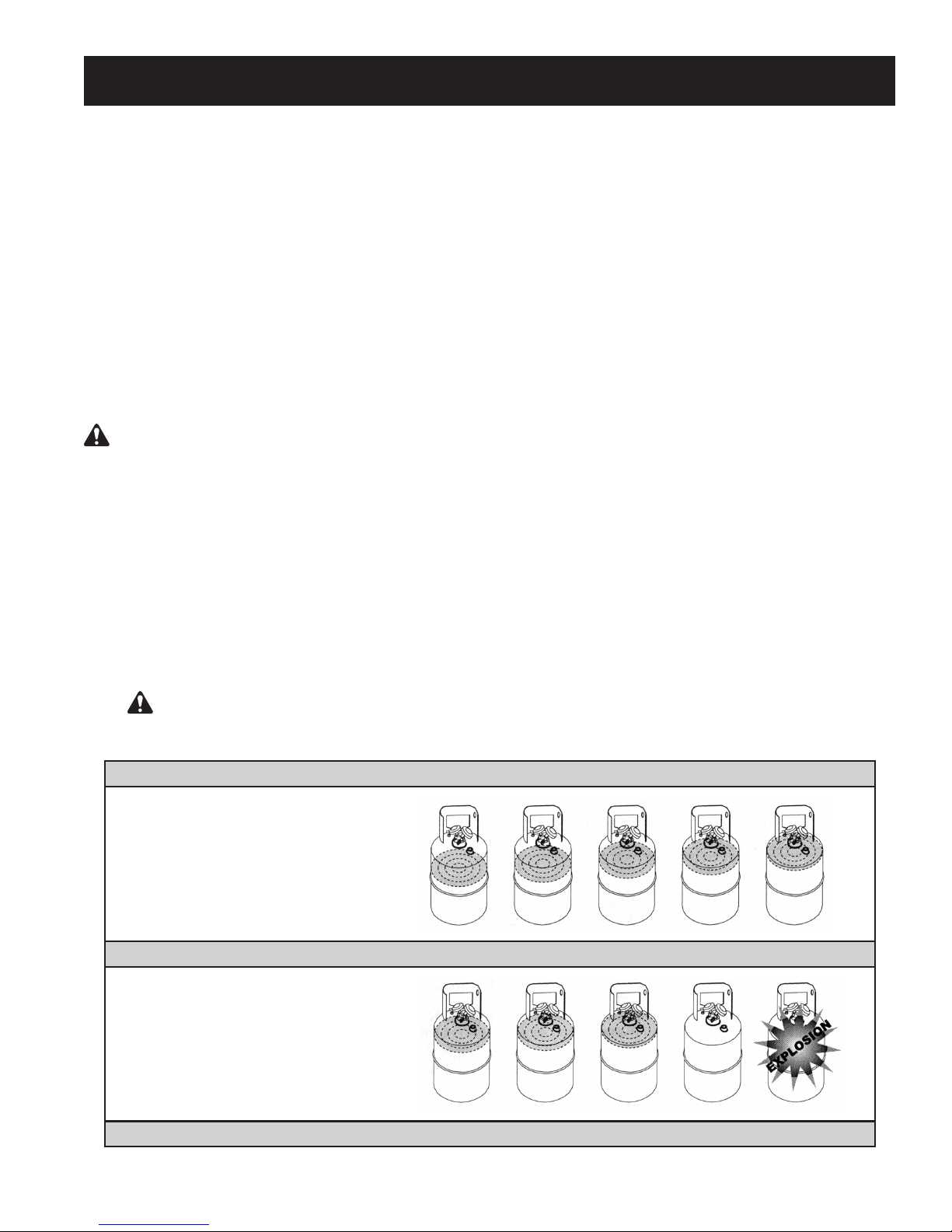

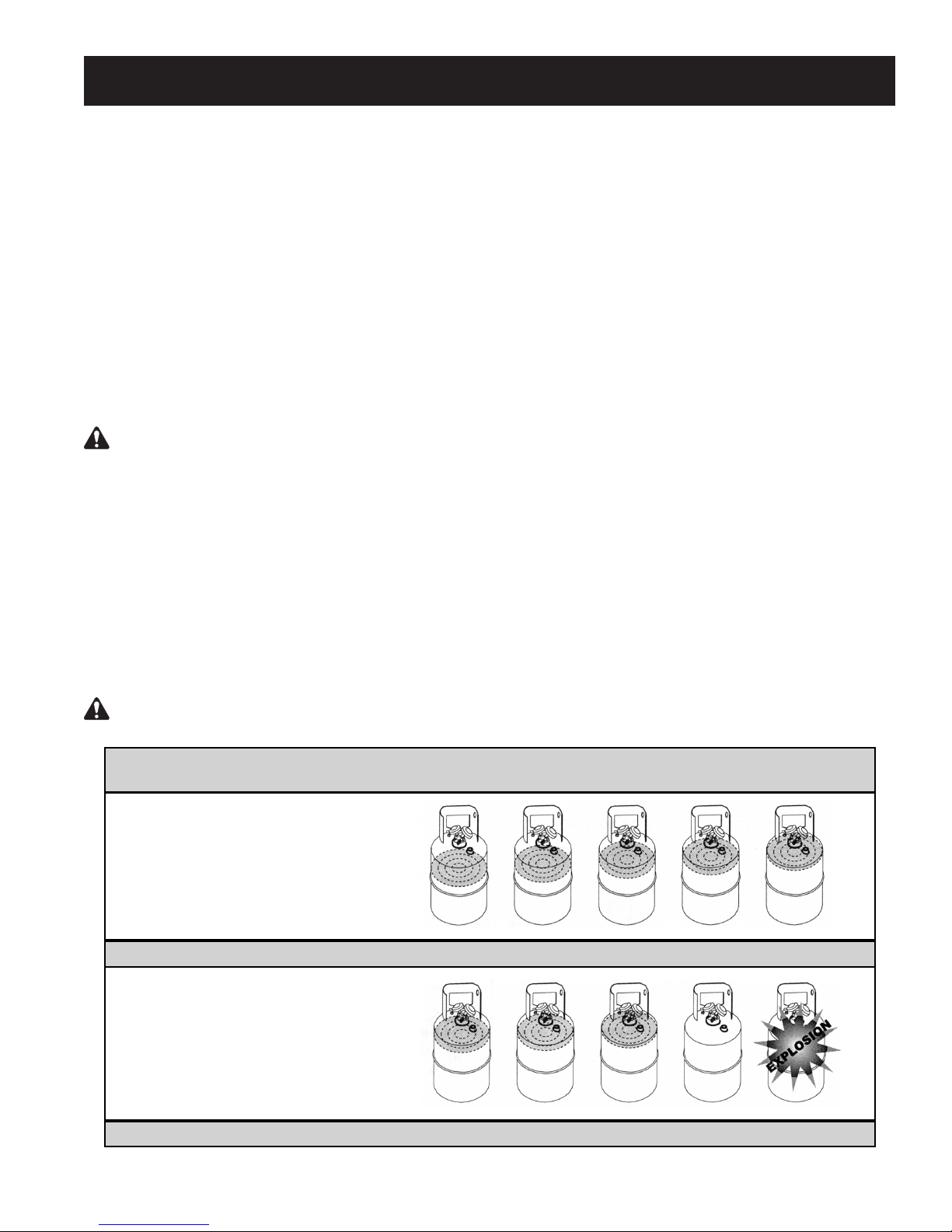

Storage Cylinders

WARNING : A storage cylinder is full when it

reaches 80% volume. DO NOT OVERFILL. Due to

liquid expansion, the cylinder could explode if filled

to more than 80% volume, possibly causing personal

injury and equipment damage. Use a scale, such

as the TIF9010A, to avoid overfilling the storage

cylinder.

Robinair recommends using the optional 80% Capacity

Shutoff Kit (p/n SK-5001) with this unit. After the kit is

installed and used with a recovery cylinder having an

internal oat switch, the unit automatically shuts down

when the cylinder is 80% full. (Your unit is pre-wired at

the factory for this kit.)

Hoses

Hoses must be equipped with low-loss ttings and have

pressure ratings appropriate for the refrigerant in the

system being serviced.

Shut-off Switch

This unit has an internal, high-pressure, shut-off switch.

If system pressure rises above 550 psi, the unit shuts

off. The shut-off switch automatically resets itself after

pressure drops below 400 psi.

WARNING : The internal pressure shut-off

switch does NOT prevent cylinder overfill. If the

system shuts off automatically and is connected

to a cylinder, the cylinder may be dangerously

overfilled. Take immediate measures to relieve the

high pressure and / or cylinder overfill situation, or

personal injury may result.

Push / Pull Procedure

When recovering large amounts of liquid (over 15 lbs.),

use the Push / Pull method described in this manual.

Maximum Vacuum and Recovery Rates

To achieve the deepest nal vacuum, use an evacuated

recovery cylinder. To maximize recovery rates :

Use the shortest possible length of 3/8 in. or larger

•

hose. (A hose no longer than 3 feet is recommended.)

Remove unnecessary hose core depressors, and

•

remove Schrader valves from port connections.

Deformed rubber seals and core depressors in hoses,

as well as faulty or unnecessary Schrader valves, can

restrict ow.

If you are certain the refrigerant in the system being

•

serviced is clean or new, the lter screen may be

removed from the inlet tting.

Purge the unit during the end of the vapor recovery

•

phase, especially when recovering large amounts

of vapor. Purge again after the recovery process is

complete and the desired vacuum has been achieved.

Refer to “Purge the Unit” at the end of the Standard

Operating Instructions section of this operating

manual.

Maintenance

CAUTION :

system dry and clean. Damage will occur if moisture

is allowed to enter the system.

Keep all connections to the refrigeration

4

Page 5

Standard oPerating inStructionS

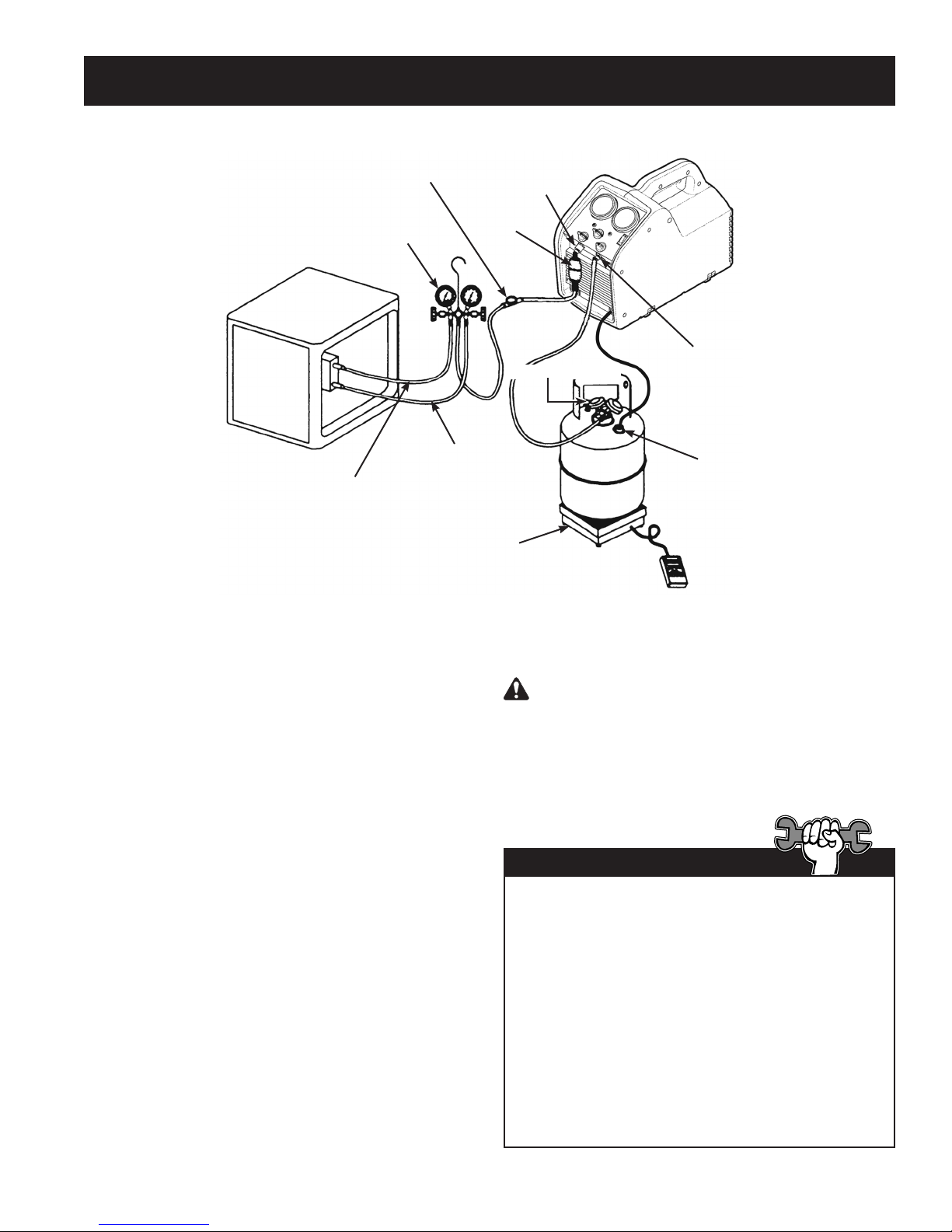

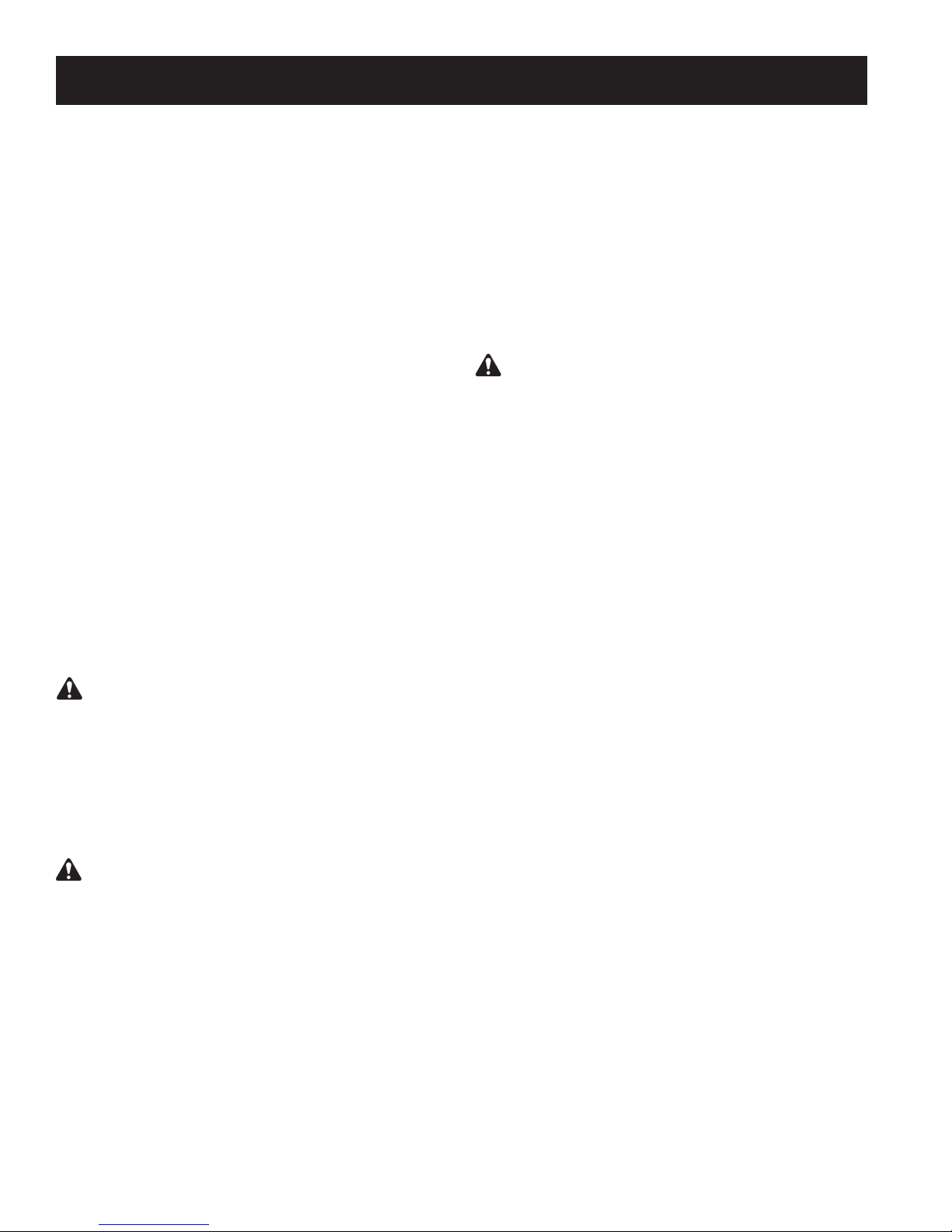

Sight

Glass

Manifold

Gauge Set

System Being

Serviced

Liquid

Vapor

The following instructions are for a standard or

“common” recovery procedure.

Setup Procedure

1. Place the unit on a at, level surface.

2. Verify a clean lter screen is installed behind

the inlet tting.

Inlet

Fitting

Filter / Drier

Scale

WARNING : A storage cylinder is full when

it reaches 80% volume. DO NOT OVERFILL. Due

to liquid expansion, the cylinder could explode

if lled to more than 80% volume, possibly

causing personal injury and equipment damage.

Recovery

Cylinder

Outlet

Fitting

Liquid Port

Float Switch

Connection

(RG6 w/ SK-5001

kit installed)

3. Connect a hose from the outlet tting of the

unit to the liquid port on the recovery cylinder.

4. Connect a hose from the inlet tting of the unit

to the output port of a manifold gauge set.

Robinair recommends using a sight glass and

a lter / drier in this line.

5. Connect a hose from the liquid (low pressure)

side of the manifold gauge set to the liquid side

of the system being serviced.

6. Connect a hose from the vapor (high) side of

the manifold gauge set to the vapor side of the

system being serviced.

RG6 with SK-5001 kit installed: Attach tank

connection harness (No. 549977) to oat

switch connection on the recovery cylinder.

7. Verify the inlet and outlet valves on the unit are

closed.

8. Place the recovery cylinder on a scale (such as

TIF9010A) to avoid overlling the cylinder.

Tech Tips

The unit will perform at its peak when voltage

entering the machine (while operating) is between

115—122 VAC.

Lower supply voltages may result in difculty

starting under high head pressure, reduced

performance, and / or motor overheating.

Use an outlet that does not have other applicances

(such as lights, machines, etc.) plugged into it.

Do not use an extension cord unless needed. If

an extension cord is used, it must be 14 AWG

minimum and as short as possible to reduce

voltage drops.

5

Page 6

Standard oPerating inStructionS

Recovery Procedure

1. Connect the unit to an appropriate 115 V outlet.

2. Slowly open the liquid valve of the recovery

cylinder while watching hoses and connections for

leaks.

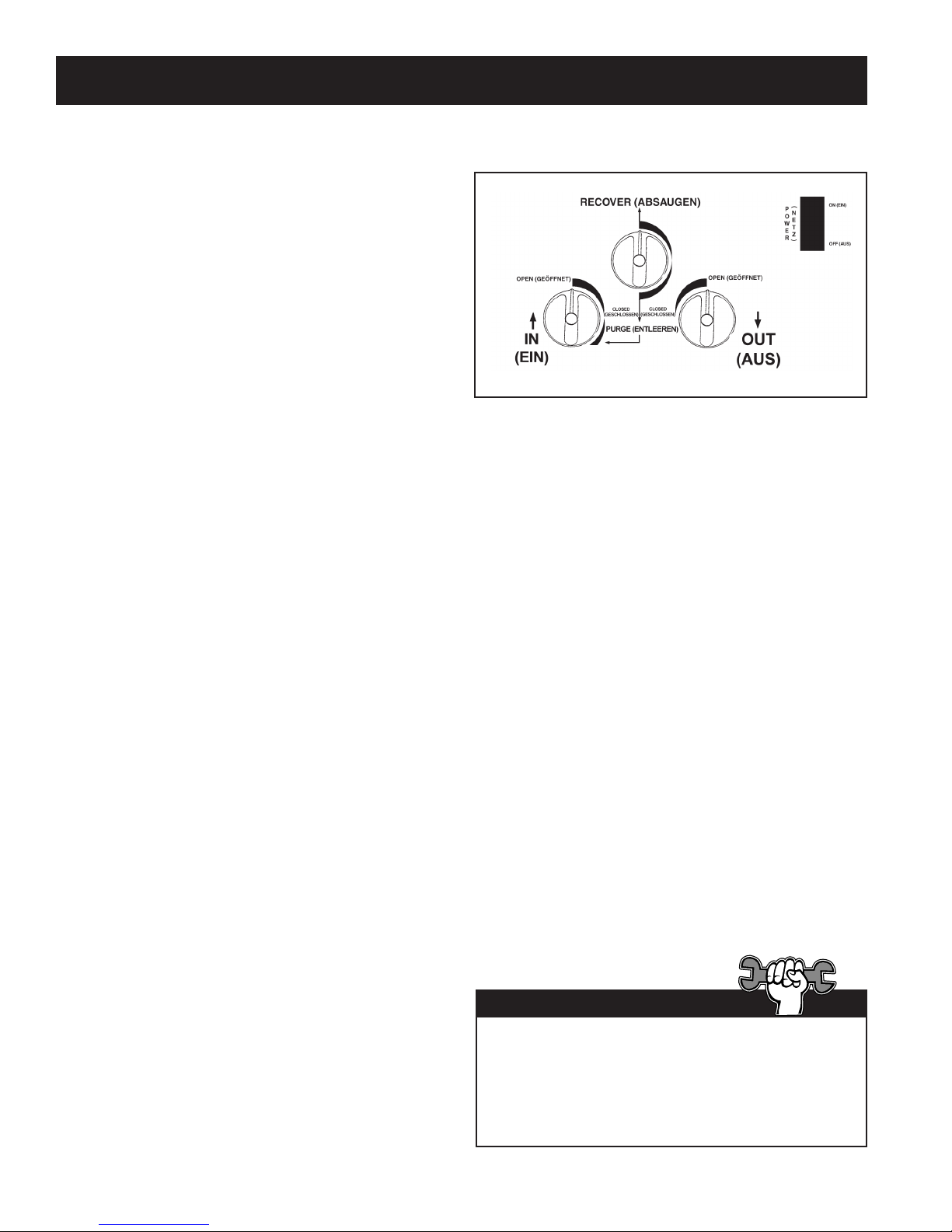

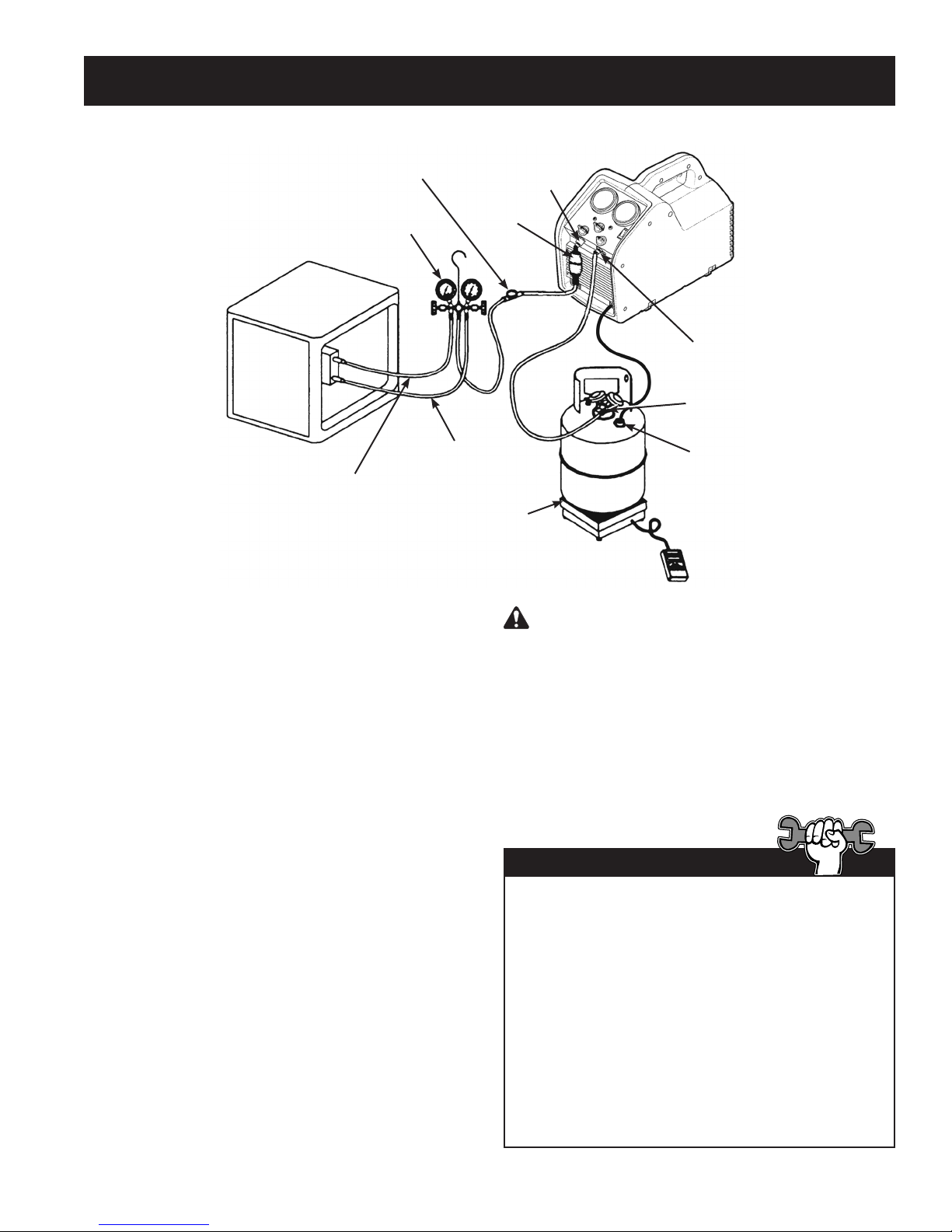

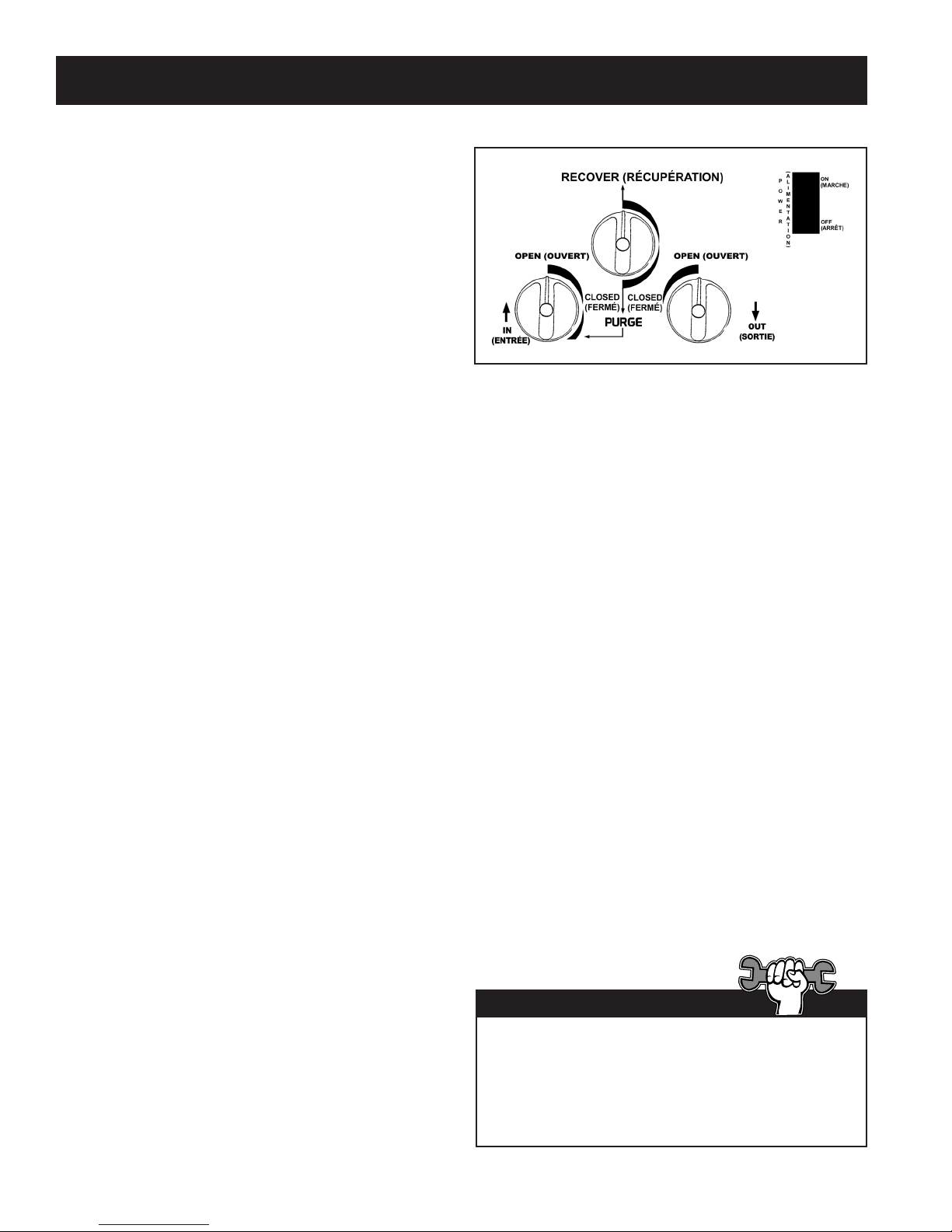

3. Set the recover / purge valve on the unit to

RECOVER.

4. Open the liquid valve on the manifold gauge set.

Note: Opening the liquid valve removes liquid from

the system rst, greatly reducing recovery time.

5. Open the outlet valve on the unit.

6. Toggle the power switch to the ON position.

7. Slowly open the inlet valve on the unit. Note: If the unit begins to “knock”, slowly throttle back (close)

the inlet valve until the noise stops.

8. Once the liquid has been removed from the system, open the vapor valve on the manifold gauge set to

nish evacuating the system.

9. Run the unit until the desired vacuum is achieved.

10. Close the vapor and liquid valves on the manifold gauge set.

11. Turn the inlet valve on the unit to the CLOSED position.

12. Toggle the power switch OFF.

Purge the Unit

CAUTION : Purge the unit after a recovery

procedure. Failure to purge the remaining

refrigerant from the unit could result in acidic

degradation of internal components, ultimately

causing premature failure of the unit.

1. Verify the liquid and vapor valves on manifold

gauge set are closed (if applicable).

2. Close the valves on the system being serviced

(if applicable).

3. Verify the outlet valve on the unit is open and

the inlet valve is closed.

4. Verify the liquid valve on the recovery cylinder

is open.

5. Turn the recover / purge valve to the PURGE

position.

6. Toggle the power switch ON.

7. Slowly turn the inlet valve toward the PURGE

position. As the inlet side pressure decreases,

open the valve to the full purge position.

8. Run the unit until the desired vacuum is

achieved.

9. Close the inlet and outlet valves on the unit.

10. Toggle the power switch OFF.

11. Close the ports on the recovery cylinder.

12. Turn the recover / purge valve to the

RECOVER position.

13. Disconnect all accessories and replace the inline lter.

If you have trouble starting or re-starting the unit

due to high head pressure, rst close the inlet

valve. Then slowly turn the inlet valve toward the

purge position until the inlet pressure rises. Close

the inlet valve again and re-start the unit.

6

Tech Tip

Page 7

oPerating inStructionS for bulk liquid SyStemS

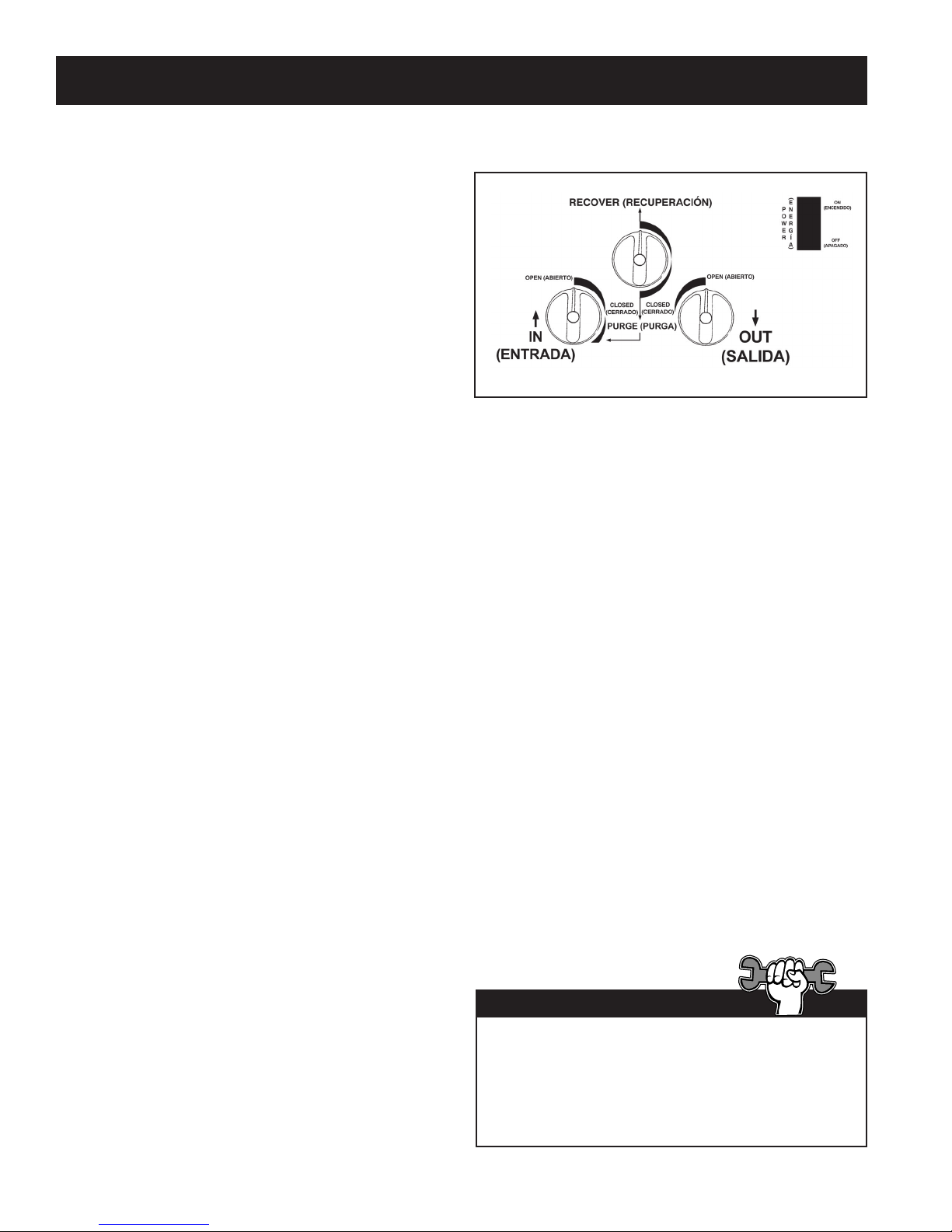

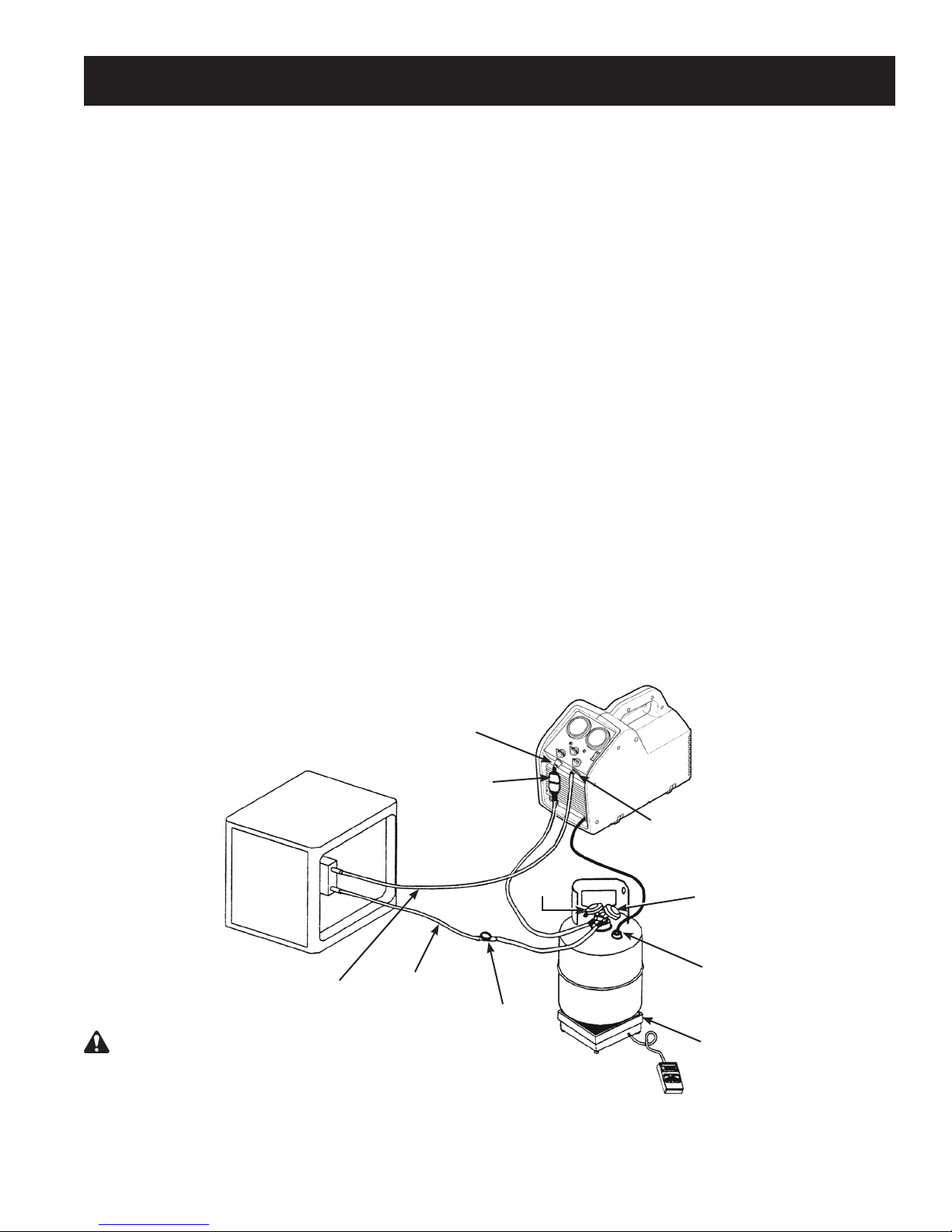

“Push – Pull” Procedure

The push – pull method removes bulk liquid from a system using the pressure differential created by the unit.

This method works only with large systems where the liquid is readily accessible; it may not work on systems

that contain less than 15 lbs. (6.8 kg) bulk liquid.

This method is used :

• on systems with receiver cylinders.

• on systems containing more than 20 lbs. (9.1 kg) of refrigerant.

• when transferring bulk liquid refrigerant from one cylinder to another.

Liquid Recovery

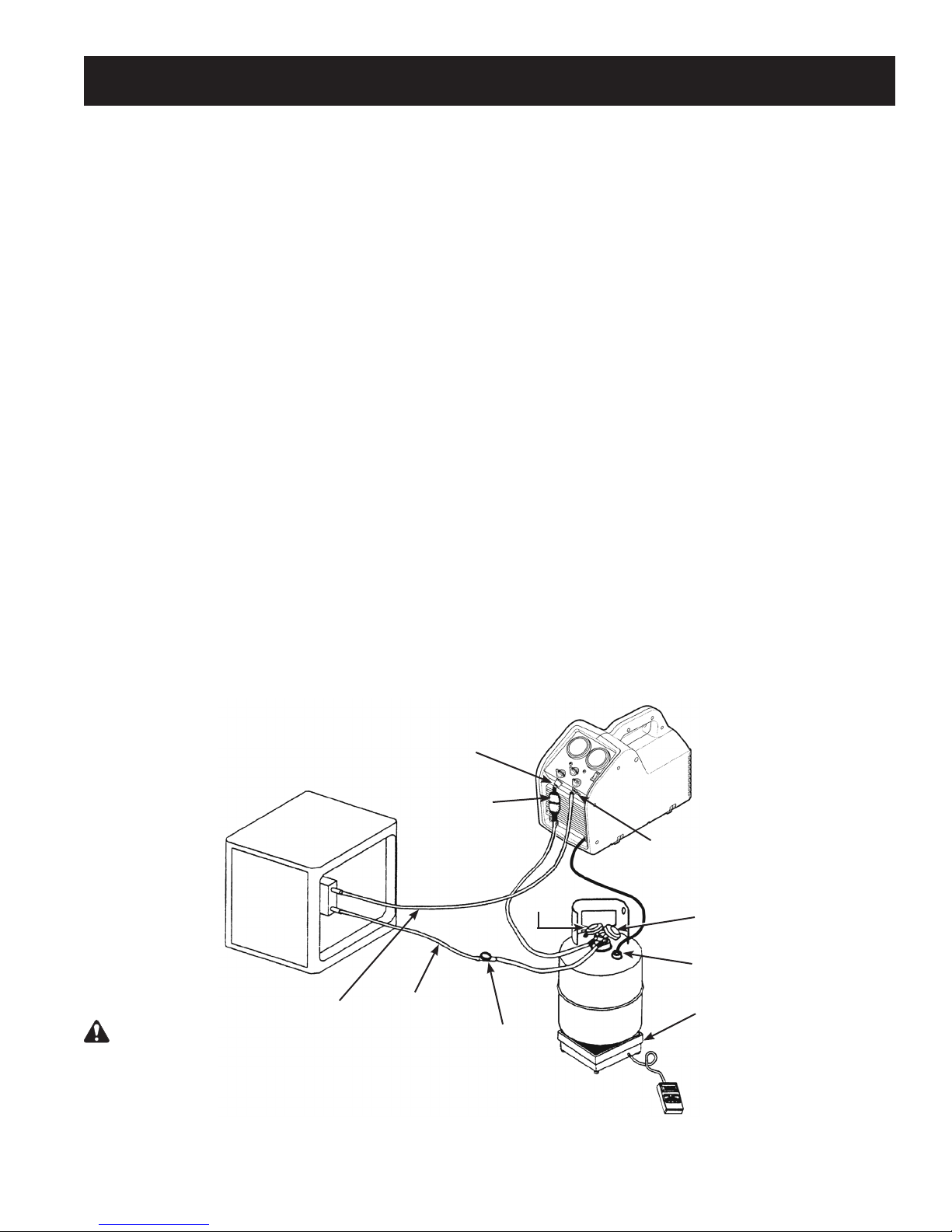

1. Place the unit on a at, level surface.

2. Connect a hose from the outlet tting of the unit

to the vapor port on the system being serviced.

3. Connect a hose from the inlet tting of the

unit to the vapor port of a recovery cylinder.

Robinair recommends using a lter / drier in

this line.

4. Connect a hose from the liquid side of the

recovery cylinder to the liquid port of the

system being serviced. Robinair recommends

using a sight glass in this line as a method of

determining when the liquid has been removed.

RG6 with SK-5001 kit installed: Attach tank

connection harness (No. 549977) to oat

switch connection on the recovery cylinder.

5. Place the recovery cylinder on a scale (such as

TIF9010A) to avoid overlling the cylinder.

Filter/Drier

System Being

Serviced

6. Verify inlet and outlet valves on unit are closed.

7. Turn the recover / purge knob to RECOVER.

8. Open the recovery cylinder valves.

9. Open the outlet valve on the unit.

10. Toggle the power switch ON.

11. SLOWLY open the inlet valve on the unit.

12. When the weight reading on the scale stops

increasing, close the inlet valve on the unit

rst; then close the liquid valve on the recovery

cylinder.

13. Toggle the power switch OFF.

14. Close the valves on the recovery cylinder, and

close the outlet valve on the unit.

15. Proceed to Vapor Recovery.

Inlet

Fitting

Outlet Fitting

WARNING : Manually close the valves on both the

storage cylinder and the unit to prevent overfilling the

cylinder. Once the siphon is started, it can overfill the

storage cylinder, even if the cylinder is equipped with a

float level sensor. The siphon can continue even when

the unit is turned off.

Vapor

Liquid

7

Sight

Glass

Scale

Vapor

Recovery

Cylinder

Liquid

Float Switch

Connection

(RG6 w/ SK-5001

kit installed)

Page 8

oPerating inStructionS for bulk liquid SyStemS

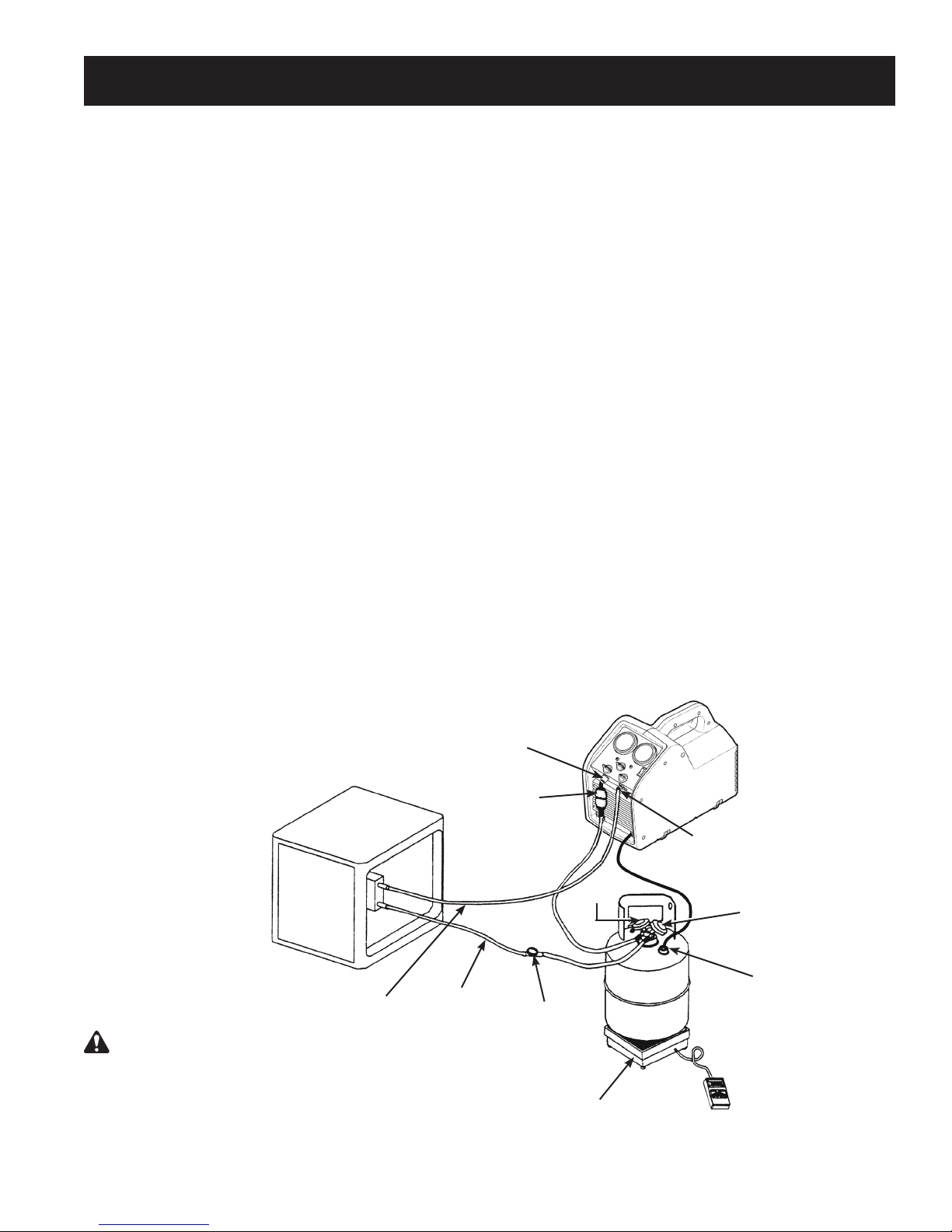

Vapor Recovery

1. Place the unit on a at, level surface.

2. Connect a hose from the inlet side of the unit to

the liquid port of the system being serviced.

Tech Tip

3. Connect a hose from the outlet side of the unit

to the liquid port on a recovery cylinder.

CAUTION: The recovery cylinder should be

on a scale to avoid overlling the cylinder.

4. Open the liquid valve on the recovery cylinder.

5. Turn the recover / purge knob to RECOVER.

6. Open the outlet valve on the unit.

7. Toggle the power switch ON.

8. Slowly open the inlet valve on the unit.

9. Run the unit until the desired vacuum is

achieved.

10. Close the inlet and outlet valves on the unit.

11. Toggle the power switch OFF.

12. Close the ports on the recovery cylinder.

For a faster recovery procedure, recover from both

the liquid and vapor ports of the system being

serviced by using a tee tting or manifold gauge

set in the hose setup.

Purge non-condenSable gaS from a Storage cylinder

1. Allow the storage cylinder to sit undisturbed for

24 hours to allow air to rise to the top.

2. Connect a manifold gauge set to the cylinder.

Read the amount of pressure in the cylinder as

indicated by the output pressure gauge.

3. Determine the ambient temperature in the

room.

4. Refer to a refrigerant pressure/temperature

chart and nd the ambient temperature. Read

across the chart to the corresponding pressure

for the type of refrigerant in the cylinder.

Determine how that relates to the reading on

the gauge.

5. If the pressure reading in the cylinder is

higher than the pressure shown on the chart,

VERY SLOWLY crack open the vapor port

valve. (This is done slowly to cause as little

turbulence inside the cylinder as possible.)

Watch the pressure on the gauge decrease. To

prevent venting, add 4–5 psi (0.26—0.34 bar)

to the pressure shown on the chart.When the

gauge corresponds to that pressure, close the

vapor port valve.

6. Allow the cylinder to sit for 10 minutes and then

check pressure again.

7. Repeat the process, if necessary.

8

Page 9

recovery cylinder information

Type of Cylinder

Use only authorized, rellable, refrigerant storage

cylinders. Federal regulations require refrigerant

to be transported only in containers meeting DOT

specs. 4BW or 4BA.

NEVER use a standard disposable 30 lb.

(13.6 kg) cylinder (the type of container in which

new refrigerant is sold) to recover refrigerant.

Working Pressure

Recovery cylinders are designed for different

working pressures. Robinair strongly recommends

the use of 400 psi (27.6 bar) cylinders.

WARNING: To prevent personal injury, do

not exceed the rated working pressure of the

cylinder. At minimum, the RG6 requires the use

of a 350 psi (24.1 bar) recovery cylinder.

NOTE: The use of a 400 psi (27.6 bar) cylinder is

mandatory when recovering R-410A refrigerant.

Refer to the Parts and Accessories section of this

manual for more information.

If you expect temperatures in excess of 135º F

(57° C), consult the refrigerant supplier.

Capacity

Safety codes state that closed cylinders should

not be lled with liquid over 80% of volume. (The

remaining 20% is called head pressure room.)

Do not exceed 80% of cylinder capacity. Robinair

recommends the use of the TIF9010A Refrigerant

Scale for monitoring cylinder capacity.

Refrigerants

Cylinders and lter / driers should each be

designated for only one type of refrigerant.

If you must use a cylinder previously used for

a different refrigerant, prepare the cylinder by

completely emptying it, perform an evacuation,

purge it using dry nitrogen, and then perform

another evacuation.

Storage

Store refrigerant cylinders in a cool, dry place.

Leakage

Some cylinders have valves that were not correctly

seated when manufactured. Keeping caps on the

valves will guard against refrigerant leakage.

WARNING : To prevent personal injury, never transport an overfilled cylinder.

Refrigerant expands when it gets warm and may cause an overfilled cylinder to explode.

Storage Cylinder Temperature 60°F 70°F 100°F 130°F 150°F

15.6°C 21.1°C 37.8°C 54.4°C 65.6°C

STARTING WITH CYLINDER

80% BY VOLUME

Space Occupied by Liquid 80% 81% 83% 90% 94%

STARTING WITH CYLINDER

90% BY VOLUME

Space Occupied by Liquid 90% 92% 96% 100%

9

Page 10

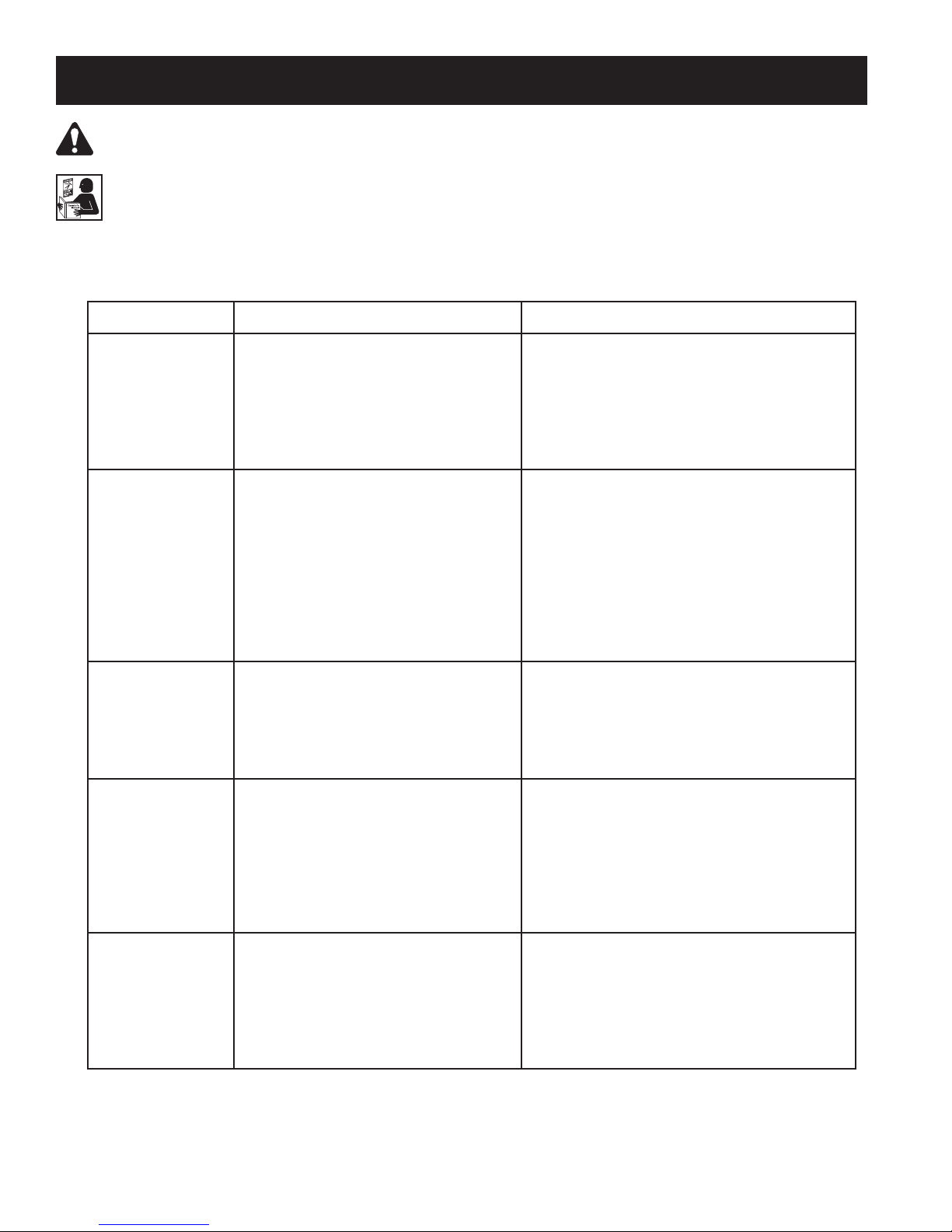

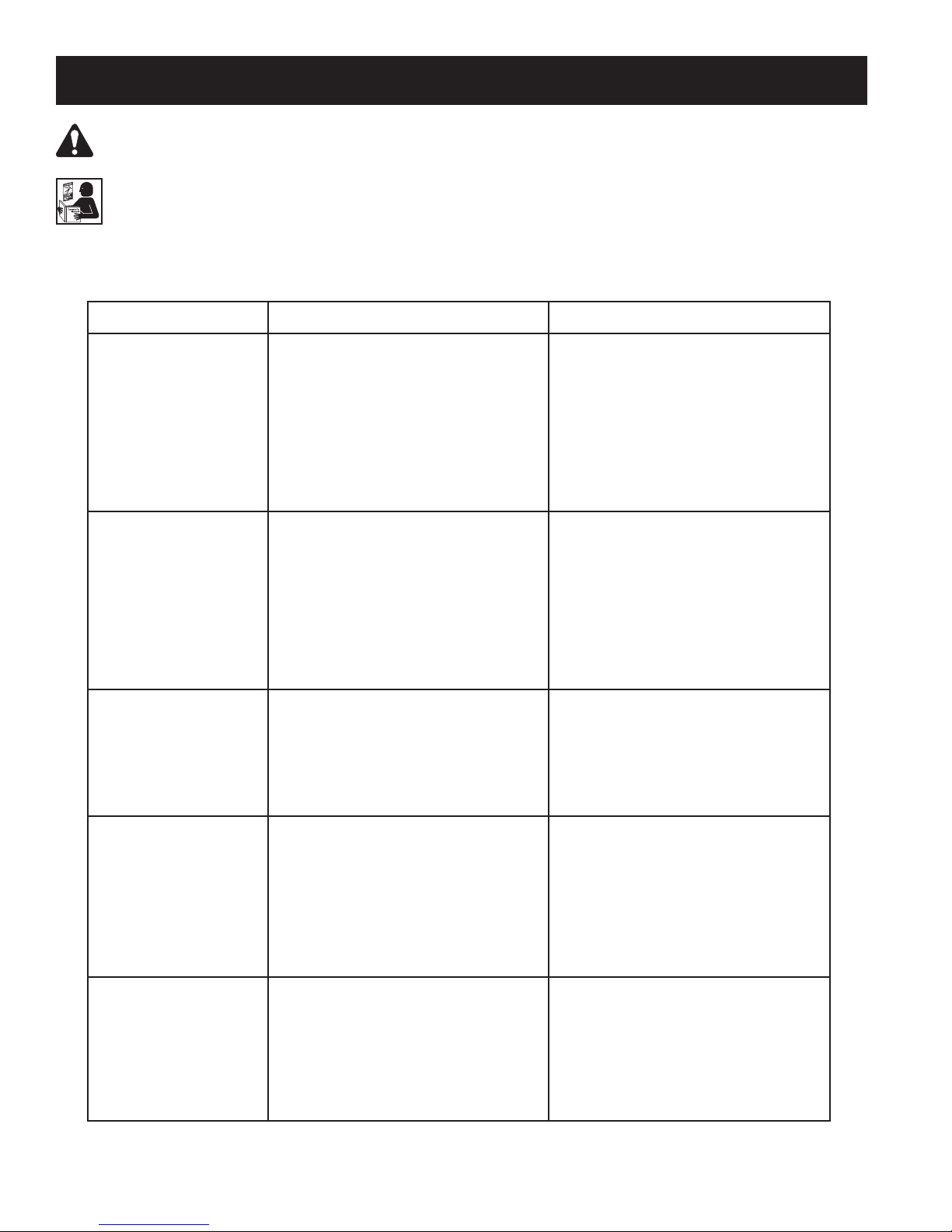

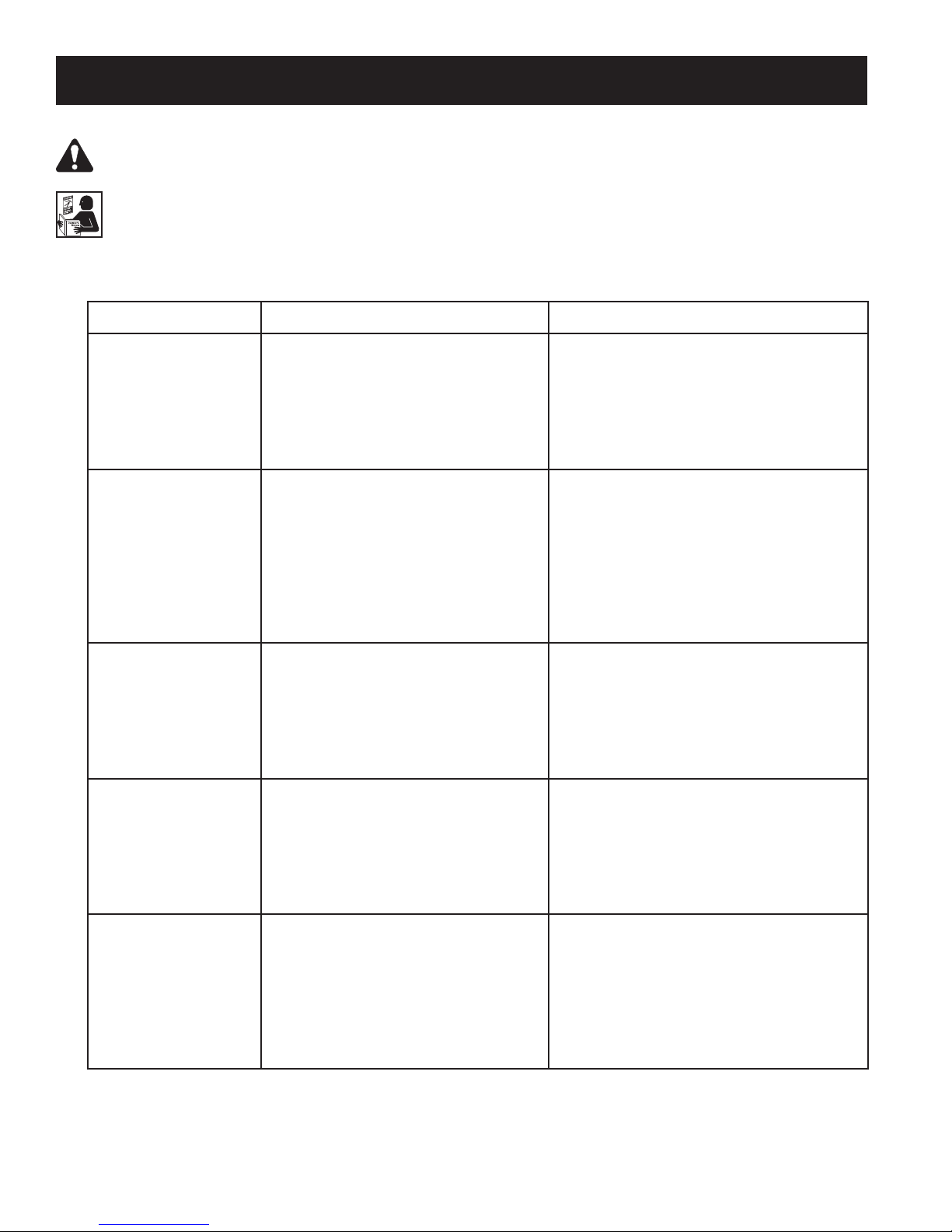

troubleShooting

WARNING: TO PREVENT PERSONAL INJURY AND / OR EQUIPMENT DAMAGE,

ALLOW ONLY QUALIFIED PERSONNEL TO OPERATE AND REPAIR THIS UNIT. Before operating

or repairing the unit, read and follow the instructions and warnings in this manual. The technician must

be familiar with air conditioning and refrigeration systems, refrigerants, and the dangers of pressurized

components. If the technician cannot read this manual, operating instructions and safety precautions

must be read and discussed in the technician’s native language.

Symptom Possible Cause Possible Solution

Unit will not turn on 1. Power cord not plugged in.

2. Bad power outlet.

3. Unit is in high-pressure shut-off.

4. Motor is in thermal overload.

5. Circuit breaker tripped.

Compressor tries to

start, but just buzzes

Unit pumps into highpressure shut-off

Slow recovery 1. Trapped liquid in system.

Circuit breaker trips 1. Low voltage at power source.

1. Low voltage at power source.

2. Extension cord too long, or too

small.

3. Head pressure too high.

1. Output valve on unit is closed.

2. Recovery cylinder valve closed.

3. Head pressure too high.

2. Restriction in refrigerant ow path.

2. Extension cord too long, or too

small.

3. Excessive load on compressor /

motor.

1. Check power cord at wall and unit.

2. Try a different outlet.

3. Reduce head pressure to below

400 psi (27.6 bar).

4. Allow motor / unit to cool down.

5. Check / reset circuit breaker.

1. Locate / use better outlet.

2. Reduce length of extension cord.

Increase size (gauge) of extension

cord (14 AWG minimum).

3. Reduce head pressure. Turn inlet

valve slightly past closed toward

PURGE to equalize high-side / low side pressure.

1. Check output valve.

2. Check recovery cylinder valve.

3. Check output hoses for restrictions

or kinks. Reduce head pressure.

1. Momentarily cycle system compressor

to move trapped refrigerant.

2. Check inlet hose for restrictions or

kinks. Remove Schrader valves and

core depressers from hoses (if

possible). Use larger hoses.

1. Locate / use better outlet.

2. Reduce length of extension cord.

Increase size (gauge) of extension

cord (14 AWG minimum).

3. Reduce head pressure. Throttle inlet

valve to reduce load on compressor.

10

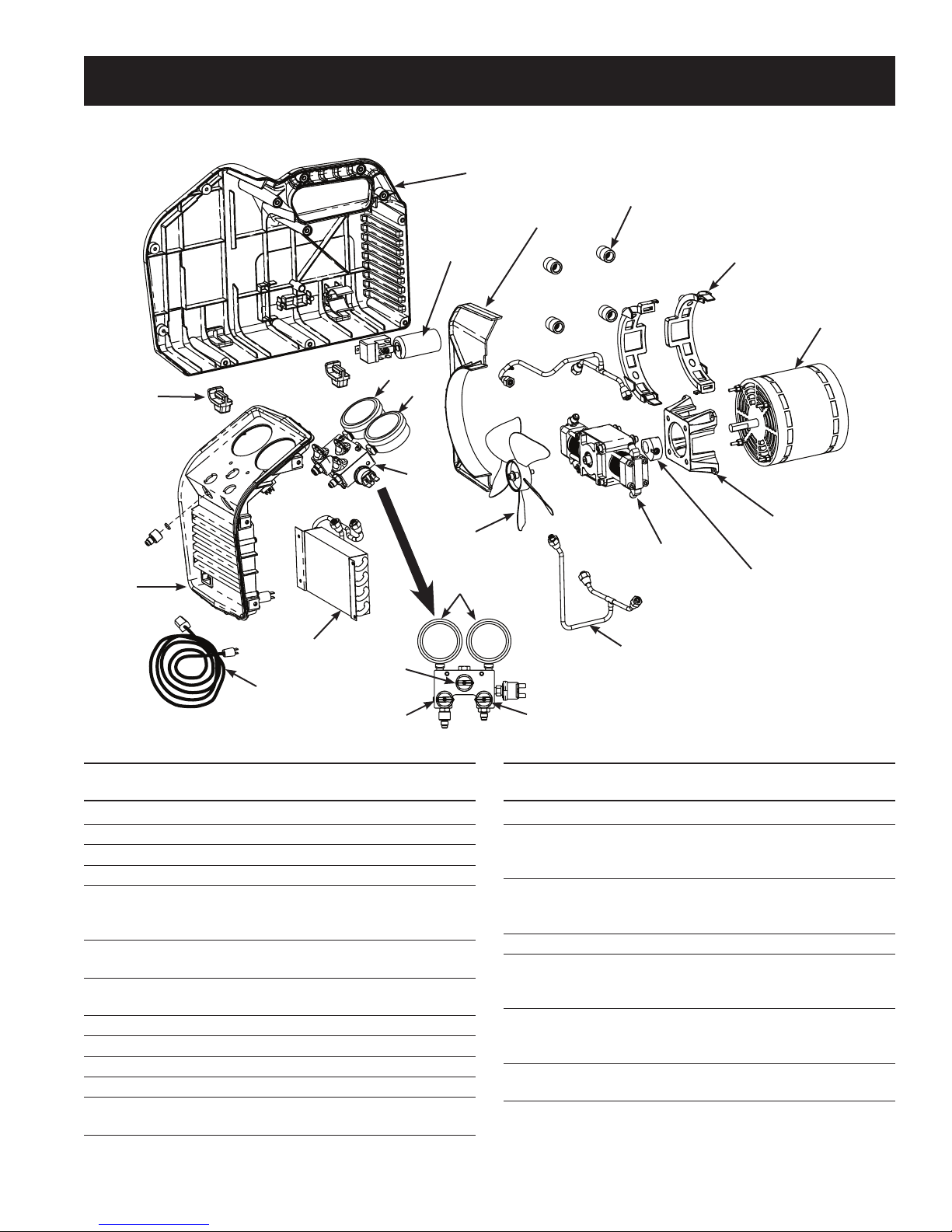

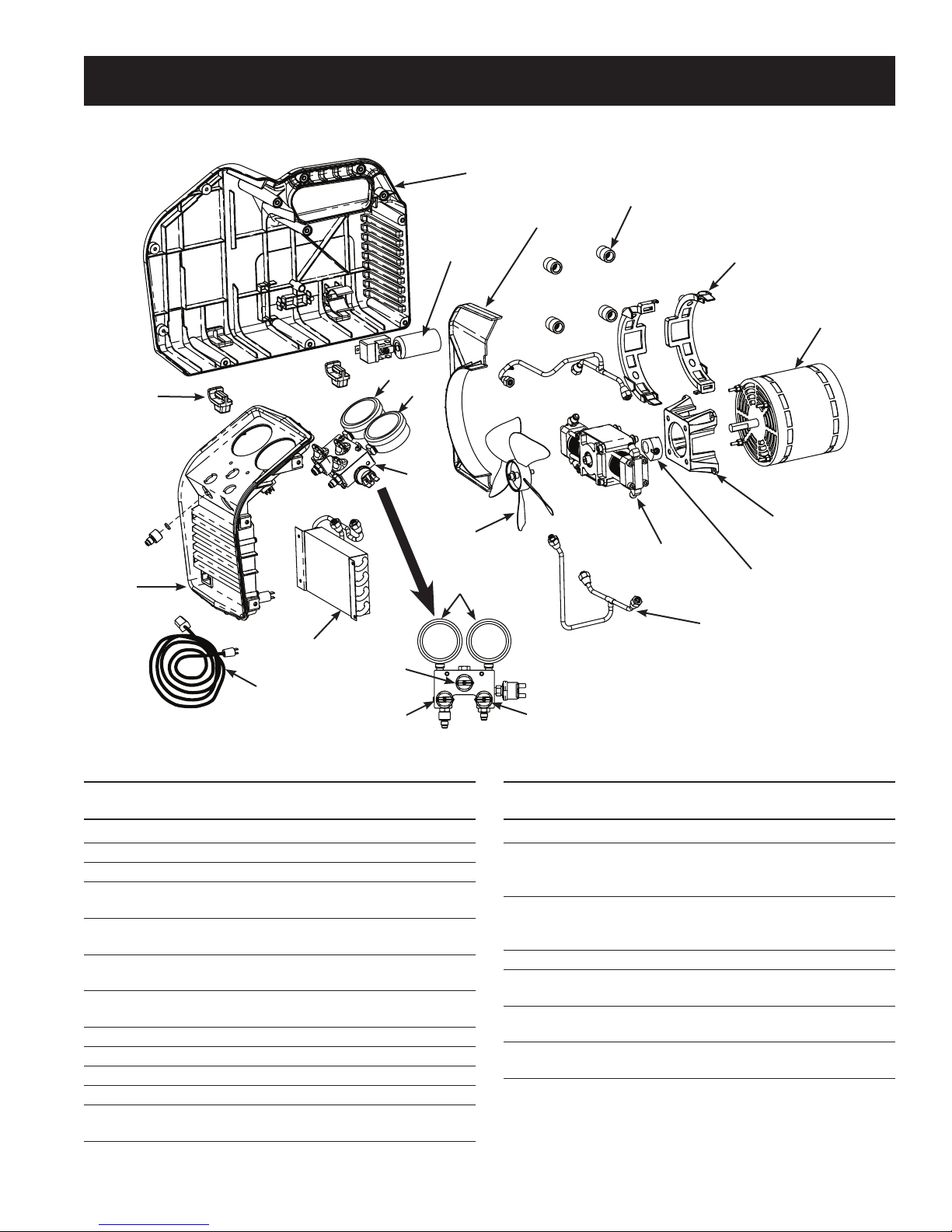

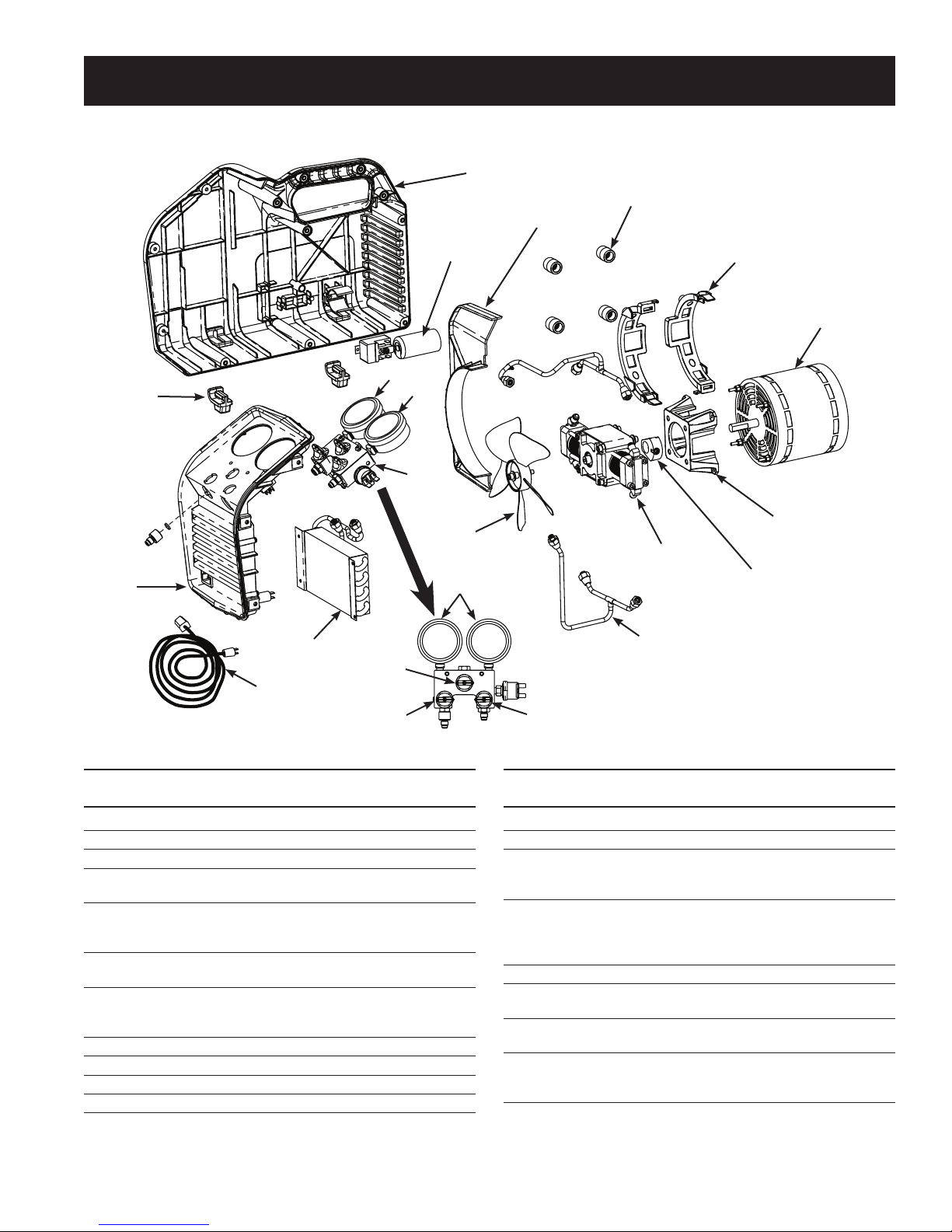

Page 11

13

14

15

rePlacement PartS

1 (left side shown)

2

Motor Relay

& Capacitor

16

17

18

}

6

7

Divider

3

4

Motor Interface

5

Counterbalance

11

10

12

9

Item Part

No. No. Qty. Description

1 567913 1 Case Half (left)

567915 1 Case Half (right)

2 550503 1 Grommet (1 ea.)

3 SK-6013 1 Motor Clamp Kit (4 pieces)

4 SK-6005 1 Motor Kit (includes motor, relay,

capacitor, hardware)

5 SK-6023 1 Compressor Kit (includes

compressor, hardware)

6 SK-6008 1 Fan Kit (includes fan, spacer

mounting hardware)

7 GA1000 1 Gauge Lens (1 ea.)

8 100124 1 Manifold Knob (red)

9 100123 1 Manifold Knob (blue)

10 100122 1 Manifold Knob (black)

11 SK-6014 1 Condenser Kit (includes condenser

assembly, hardware)

Inlet / Outlet

Tubes

8

Item Part

No. No. Qty. Description

12 551628 1 Power Cord

13 SK-6012 1 Bezel Kit (includes bezel, power

switch, circuit breaker, power entry

module, hardware)

14 SK-6001 1 Inlet Fitting / Filter Screen Kit

(includes inlet tting, lter screen,

o-ring)

15 550502 1 Foot (1 ea.)

16 SK-6003 1 Low-side Gauge Kit (includes

low-side gauge, lens)

17 SK-6022 1 High-side Gauge Kit (includes

high-side gauge, lens)

18 SK-6016 1 Manifold Kit (includes manifold

assembly, hardware)

11

Page 12

rebuild kitS and acceSSorieS

Part

No. Description

SK-5001 80% Tank Shut-off Kit

SK-6001 Filter Screen Replacement Kit

SK-6002 Filter / Drier Kit (includes lter / drier, 6 inch hose)

SK-6005 Motor Replacement Kit

SK-6007 Valve Rebuild / Replacement Kit (includes inlet /oulet valves and springs, o-rings)

SK-6008 Fan Replacement Kit

SK-6012 Bezel Replacement Kit

SK-6014 Condenser Replacement Kit

SK-6015 Piston Seal Rebuild Kit (includes piston seals, energizer o-ring, wear bands)

SK-6016 Manifold Replacement Kit

SK-6023 Compressor Replacement Kit

SK-6022 Gauge Replacement Kit

TIF9010A Refrigerant Scale

17572 Recover Cylinder (50 lb. capacity, 400 psi working pressure, capacity sensor)

SK-6013 Motor Clamp Kit (4 pieces)

12

Page 13

maintenance

CAUTION : To prevent personal injury, disconnect the unit from the power supply before

performing maintenance.

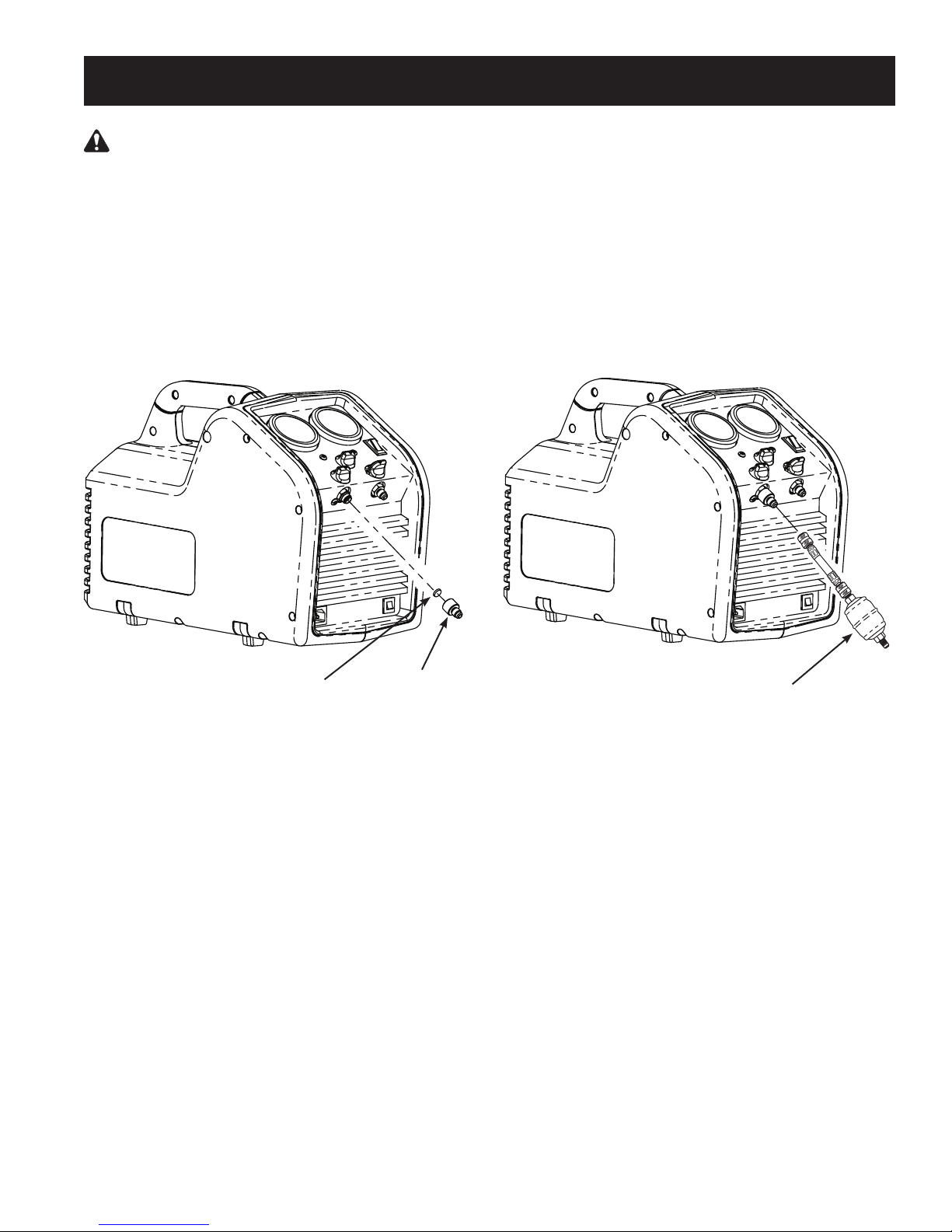

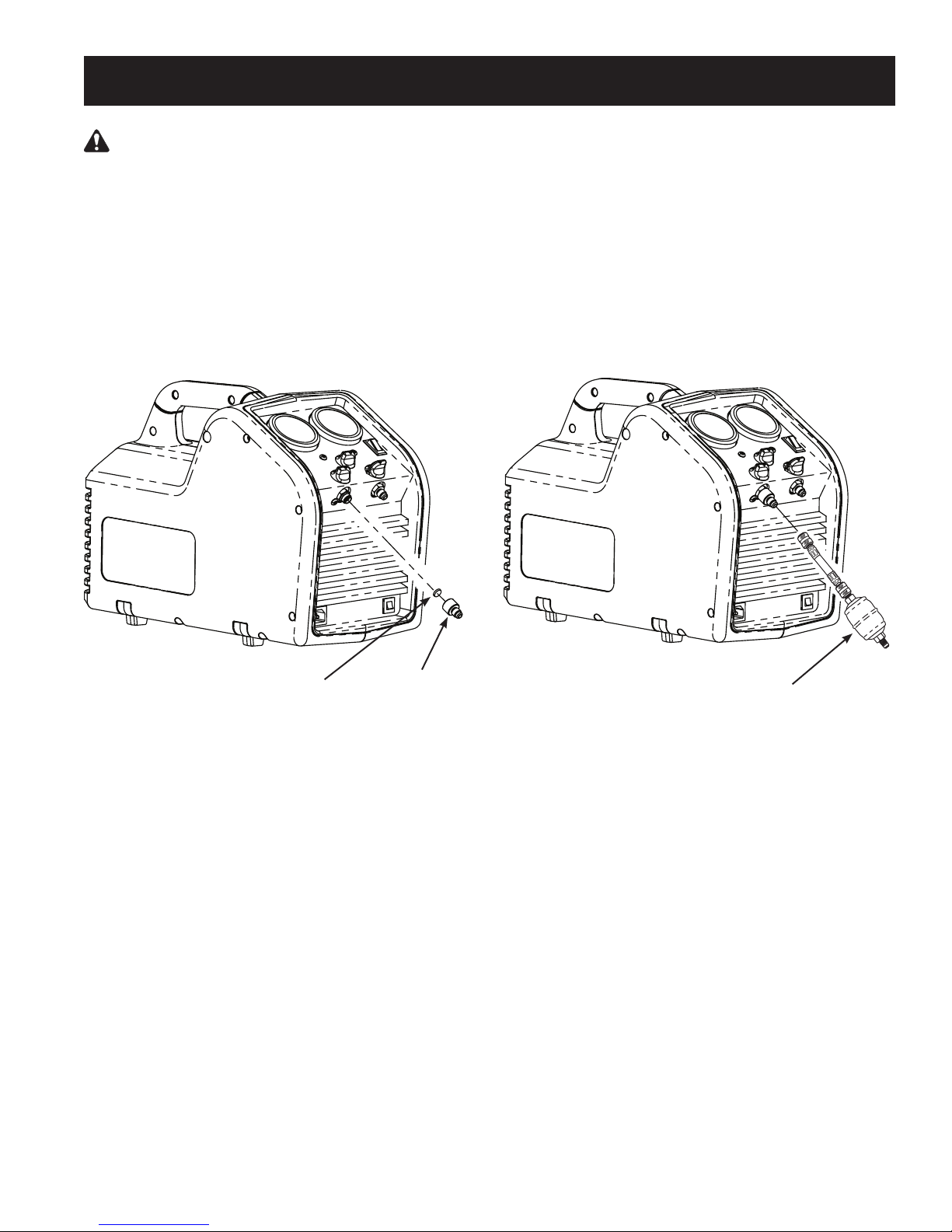

Installation of the Filter and Filter / Drier

1. Before performing a refrigerant recovery, always inspect and clean the filter screen in the inlet fitting

on the unit. Replace the filter screen (p/n SK-6001) if necessary. A filter screen greatly reduces the

risk of damage to the unit by preventing foreign material from entering the unit and the system being

serviced. Failure to use a filter screen will invalidate the warranty.

Robinair also strongly recommends using an in-line filter / drier (p/n 100343) in the inlet line.

Filter

Screen

Inlet

Fitting

Filter /Drier

p/n 100343

Burned-out System

1. Use two high-acid capacity lter / driers in series when recovering from a “burned-out” system. Robinair

recommends Alco type EK-162-F or Sporlan type C-162-F lters.

When you have nished recovering from the system, ush the unit with a small amount of clean

refrigerant and refrigerant oil to purge any foreign substances left in the unit.

Storage

1. Empty refrigerant from the unit into a storage cylinder. Liquid refrigerant left in the unit’s condenser may

expand, causing damage to components.

2. Completely evacuate the unit of any residual refrigerant and purge it with dry nitrogen before putting it

in storage for a long period of time.

13

Page 14

14

Page 15

Kältemittel-Absauggerät

Model No. RG6

Bedienungsanleitung

15

Page 16

Vorsichtsmassnahmen

WARNUNG: UM VERLETZUNGEN UND/ODER GERÄTESCHÄDEN ZU VERMEIDEN,

LASSEN SIE DIESES GERÄT NUR VON QUALIFIZIERTEM PERSONAL BEDIENEN. Vor

Inbetriebnahme des Geräts lesen und befolgen Sie die Anweisungen und Warnhinweise in dieser

Bedienungsanleitung. Der Bediener muss mit Klimaanlagen und Kältesystemen, Kältemitteln und der

Gefahr von unter Druck stehenden Komponenten vertraut sein. Falls der Bediener dieses Handbuch

nicht lesen kann, müssen Bedienungsanweisungen und Vorsichtsmaßnahmen dem Bediener in seiner

Sprache vorgelesen und erklärt werden.

UNTER DRUCK STEHENDER BEHÄLTER ENTHÄLT FLÜSSIGES KÄLTEMITTEL. Die

Kältemittelbehälter dürfen keinesfalls überfüllt werden. Andernfalls können die Flaschen explodieren

und schwere oder tödliche Verletzungen verursachen. Verwenden Sie keine Einwegaschen zum

Absaugen von Kältemitteln. Verwenden Sie ausschließlich vom US-Verkehrsministerium zugelass-

ene, nachfüllbare Behälter (DOT Spezikation 4BW oder 4BA).

SCHLÄUCHE ENTHALTEN UNTER UMSTÄNDEN UNTER DRUCK STEHENDES FLÜSSIGES

KÄLTEMITTEL ENTHALTEN. Kontakt mit Kältemittel kann Verletzungen verursachen. Tragen Sie

stets Schutzausrüstung, einschließlich Schutzbrille und Schutzhandschuhe. Gehen Sie beim Abklemmen der Schläuche äußerst vorsichtig vor.

ATMEN SIE KEINE KÄLTE- UND SCHMIERMITTELGASE ODER DÄMPFE EIN. Kontakt mit Kälte- oder

Schmiermitteldämpfen oder -gasen kann Verletzungen, insbesondere an Augen, Nase, Hals und

Lunge, verursachen. Verwenden Sie das Gerät nur an Standorten mit mechanischer Belüftung, an

denen die Luft mindestens vier Mal stündlich ausgetauscht wird. Falls das System versehentlich

ausläuft, müssen Sie den Arbeitsbereich lüften, bevor Sie das Gerät wieder einschalten.

VERWENDEN SIE NUR EIN MÖGLICHST KURZES VERLÄNGERUNGSKABEL MIT EINER

KABELSTÄRKE VON MINDESTENS 14 AWG. Die Verwendung eines zu dünnen Verlängerungska-

bels kann zu einem Ausfall von Elektrogeräten führen.

UM DAS BRANDRISIKO SO GERING WIE MÖGLICH ZU HALTEN, verwenden Sie das Gerät nicht

in der Nähe von verschüttetem Benzin oder offenen Benzinkanistern oder anderen entzündlichen

Stoffen.

VERWENDEN SIE KEINE DRUCKLUFT, UM EINE DRUCK- ODER DICHTIGKEITSPRÜFUNG DES

GERÄTS ODER DER KLIMAANLAGE DURCHZUFÜHREN. Einige R-134a Kältemittel- und Luftgemische

sind bei erhöhtem Druck brennbar. Diese Gemische sind möglicherweise gefährlich und können einen

Brand oder eine Explosion und somit Verletzungen oder Sachschäden verursachen.

MISCHEN SIE NIEMALS VERSCHIEDENE KÄLTEMITTELTYPEN IN EINEM SYSTEM ODER IM

SELBEN BEHÄLTER. Durch Mischen verschiedener Kältemittel entstehen schwere Schäden am

Gerät sowie am System, das entleert wird.

HOCHSPANNUNG IM GERÄT BIRGT STROMSCHLAGGEFAHR. Kontakt kann Verletzungen

verursachen. Trennen Sie die Stromzufuhr, bevor Sie das Gerät instandsetzen.

Zusätzliche und Sicherheitsgesundheitsinformation kann von den Kühlmittel- und

Schmiermittelherstellern eingeholt werden.

ErläutErung dEr sichErhEitsspEzifischEn signalwörtEr

WARNUNG: Weist auf eine möglicherweise gefährliche Situation hin, die schwere oder tödliche

Verletzungen verursachen kann.

VORSICHT: Weist auf eine möglicherweise gefährliche Situation hin, die leichte oder mittelschwere

Verletzungen verursachen kann

VORSICHT: Die Verwendung ohne das Warnsymbol weist auf eine möglicherweise gefährliche Situation hin,

die Sachschäden verursachen kann.

16

Page 17

inhaltsVerzeichnis

Vorsichtsmaßnahmen

Erläuterung der sicherheitsspezifischen Signalwörter

Informationen über das Absaugen von Kältemitteln

Grundlegende Bedienungsanweisungen

Einrichtungsverfahren

Absaugverfahren

Entleeren des RG6 Geräts

Bedienungsanweisungen für Flüssigkeits-Großsysteme

Druck-Zugverfahren

Absaugen von Flüssigkeit

Absaugen von Dampf

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Entleeren von nicht-kondensierbarem Gas aus einer Kältemittelflasche

Informationen über die Kältemittelflasche

Fehlersuche

Ersatzteile

Umbaukits und Zubehör

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . .

16

16

18

19

19

20

20

21

21

21

22

22

23

24

25

26

Wartung

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation von Filter und Filter/Trockner

Ausgebranntes System

Aufbewahrung

Garantieerklärung

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

im Rückeinband

27

27

27

27

17

Page 18

informationen über das absaugen Von Kältemitteln

Bei der Rückgewinnung von Kältemittel wird Kältemittel

aus einem System abgesaugt und in einer Flasche

aufbewahrt. Die folgenden Informationen sind wichtig,

um die besten Resultate beim Absaugen zu erzielen.

Kältemittel

Identizieren Sie den Typ und die Menge des Kältemittels

im jeweiligen System.

Das Gerät RG6 ist zugelassen für die Verwendung mit

den folgenden Kältemitteln der Kategorie III, IV und V

(gemäß ARI-740):

R-12, R-22, R-134a, R-401a, R-401b,R-401c, R-402a,

R-402b, R-404a, R-406a, R-407a, R-407b, R-407c,

R-407d, R-408a, R-409a, R-410a, R-411a, R-411b,

R-412a, R-500, R-502, R-507 R-509

Filter und Filter/Trockner

VORSICHT: Filter verhindern, dass Schmutzstoffe in

das Gerät eindringen und reduzieren so das Risiko

einer Beschädigung von Gerät und System.

Das Gerät RG6 wird mit einem Filtersieb hinter dem

Einlassanschluss geliefert. Robinair empehlt unbedingt,

für jeden neuen Serviceauftrag ein sauberes Filtersieb

zu verwenden. Wenn Sie das Gerät ohne Filter betreiben,

wird die Garantie ungültig.

Robinair empehlt ebenfalls unbedingt die Verwendung

eines Filter/Trockners (Teile-Nr. 100343, nicht mitgeliefert)

am Einlassanschluss. Jeder Leitungslter mit Trockner

muss gekennzeichnet werden und darf nur für einen

Kältemitteltyp verwendet werden.

Ventile

WARNUNG: Um Verletzungen zu vermeiden,

öffnen Sie Ablass- und Flaschenventile nur LANGSAM,

damit Sie den Gasstrom nach Bedarf schnell sperren

können. Sobald Sie festgestellt haben, dass keine

Gefahr vorliegt, können die Ventile vollständig

geöffnet werden.

Isolieren Sie große Mengen Kältemittel und schließen

Sie die Ventile nach der Verwendung, damit kein

Kältemittel in die Atmosphäre austritt, falls eine

Undichtigkeit im System entsteht.

Kältemittelaschen

WARNUNG: Eine Kältemittelflasche ist bei einer

Füllmenge von 80 % vollständig gefüllt. NICHT

ÜBERFÜLLEN. Aufgrund der Ausdehnung von

Flüssigkeit kann die Flasche explodieren, wenn sie

zu mehr als 80 % gefüllt wird und Verletzungen und

Sachschäden verursachen. Verwenden Sie eine

Waage, wie die TIF9010A, um ein Überfüllen der

Kältemittelflasche zu vermeiden.

Robinair empehlt die Verwendung des optionalen

Abschaltkits bei 80 % Füllmenge (Teile-Nr. SK-5001) mit

diesem Gerät. Wenn das Kit eingebaut wurde und mit

einer Kältemittelasche mit internem Schwimmerschalter

verwendet wird, schaltet sich das Gerät automatisch ab,

wenn die Flasche zu 80 % gefüllt ist. (Ihr Gerät wurde

werksseitig für dieses Kit vorverdrahtet.)

Schläuche

Schläuche müssen mit verlustarmen Armaturen

ausgestattet sein und einen Nenndruck aufweisen, der

für das im System enthaltene Kältemittel angemessen ist.

Überdruckschalter

Das Gerät ist mit einem internen Überdruckschalter

ausgestattet. Wenn der Systemdruck über 37,9 Bar

(550 psi) ansteigt, schaltet sich das Gerät aus. Der

Überdruckschalter wird automatisch zurückgesetzt,

wenn der Druck unter 27,6 Bar (400 psi) fällt.

WARNUNG: Der interne Überdruckschalter

verhindert NICHT das Überfüllen der Flasche.

Wenn sich das System automatisch abschaltet

und noch an eine Flasche angeschlossen ist, kann

diese Flasche auf ein gefährliches Niveau überfüllt

werden. Entlasten Sie umgehend den Druck in

der Flasche, indem Sie die Flasche entsprechend

entleeren, um Verletzungen zu vermeiden.

Druck-Zugmethode („Push-Pull“)

Beim Absaugen großer Mengen Flüssigkeit

(über 6,8 kg [15 lb.]), gehen Sie nach der in dieser

Bedienungsanleitung beschriebenen Druck-Zugmethode

(„Push-Pull“) vor.

Maximale Vakuum- und Absaugraten

Um optimales Endvakuum zu erziehen, verwenden

Sie eine evakuierte Kältemittelasche. So erzielen Sie

optimale Absaugraten:

• Der verwendete Schlauch muss so kurz wie möglich

sein und einen Durchmesser von mindestens 0,95 cm

(3/8 Zoll) aufweisen. (Wie empfehlen die Verwendung

eines Schlauchs von max. 90 cm [3 Fuß] Länge.)

• Lösen Sie unnötige Ventilkerndrücker und

Schraderventile von den Anschlüssen. Deformierte

Gummidichtungen und Ventilkerndrücker in Schläuchen

sowie defekte oder unnötige Schrader-Ventile können

den Druck drosseln.

• Wenn Sie sicher sind, dass das Kältemittel im System

sauber oder neu ist, kann das Filtersieb aus dem

Einlassanschluss entfernt werden.

• Entleeren Sie das Gerät RG6 am Ende der

Dampfabsaugphase, besonders beim Absaugen

großer Dampfmengen. Entleeren Sie es erneut

nach dem Absaugverfahren, wenn das gewünschte

Vakuum erzielt wurde. Siehe hierzu „Entleeren des

Geräts RG6 “ am Ende des Abschnitts Grundlegende

Bedienungsanweisungen.

Wartung

VORSICHT:

Kältesystem trocken und sauber. Durch

eindringende Feuchtigkeit wird das System

beschädigt.

Halten Sie alle Anschlüsse zum

18

Page 19

grundlegende bedienungsanweisungen

Schauglas

Messgeräte der

Verteilerstation

System, das

entleert wird

Flüssigkeit

Dampf

Folgende Anweisungen gelten für ein

standardmäßiges bzw „geläuges“ Absaugverfahren.

Einrichtungsverfahren

1. Setzen Sie das RG6 auf eine ache, ebene

Oberäche.

2. Stellen Sie sicher, dass hinter dem

Einlassanschluss ein sauberes Filtersieb

eingesetzt ist.

3. Schließen Sie einen Schlauch zwischen

dem Auslassanschluss am Gerät und dem

Flüssigkeitsanschluss an der Kältemittelasche an.

4. Schließen Sie einen Schlauch zwischen dem

Einlassanschluss am Gerät und dem

Auslassanschluss einer Verteilerstation mit

Messgeräten an. Robinair empehlt die

Verwendung eines Schauglases und Filter/

Trockners in diesem Schlauch.

5. Schließen Sie einen Schlauch zwischen der

Flüssigseite (Niederdruck) der Messgeräte-

Verteilerstation und der Flüssigseite des Systems,

das entleert wird, an.

6. Schließen Sie einen Schlauch zwischen der

Dampfseite (Hochdruck) der Messgeräte-

Verteilerstation und der Dampfseite des Systems,

das entleert wird, an.

RG6 wenn die SK-5001 Ausrüstung installiert

ist

: Schließen Sie den Tankanschlusskabelbaum

(Nr. 549977) an den Schwimmerschalteranschluss

an der Kältemittelasche an.

7. Stellen Sie sicher, dass die Ein- und Auslassventile

am Gerät RG6 geschlossen sind.

Einlass-

anschluss

Filter/

Trockner

Auslass-

Flüssigkeitsanschluss

Kältemitte-

lasche

Waage

anschluss

Schwimmerschalteranschluss

(RG6 wenn die SK-5001

Ausrüstung installiert ist)

8. Stellen Sie die Kältemittelasche auf eine

Waage (z. B. TIF9010A), um ein Überfüllen der

Flasche zu vermeiden.

WARNUNG: Eine Kältemittelasche ist bei

einer Füllmenge von 80 % vollständig gefüllt.

NICHT ÜBERFÜLLEN. Aufgrund der Ausdehnung

von Flüssigkeit kann die Flasche explodieren,

wenn sie zu mehr als 80 % gefüllt wird und so

Verletzungen und Sachschäden verursachen.

Technische Tipps

Das Gerät RG6 funktioniert optimal, wenn die

Eingangsspannung der Maschine (während des

Betriebs) zwischen 115 V AC und 122 V AC liegt.

Niedrigere Eingangsspannungen können zu

Startschwierigkeiten bei hohem Staudruck, niedrigerer

Leistung und/oder einem Überhitzen des Motors führen.

Verwenden Sie eine Steckdose, an die keine anderen

Geräte (z. B. Lampen oder Maschinen) angeschlossen

sind.

Verwenden Sie Verlängerungskabel nur wenn

unbedingt notwendig. Wenn Sie ein Verlängerungskabel

verwenden, muss es eine Kabelstärke von mindestens

14 AWG aufweisen und so kurz wie möglich sein, um

einen Spannungsabfall zu vermeiden.

19

Page 20

grundlegende bedienungsanweisungen

Absaugverfahren

1. Schließen Sie das Gerät an eine 115-VSteckdose an.

2. Öffnen Sie langsam das Flüssigkeitsventil

an der Kältemittelasche, und beobachten

Sie dabei die Schläuche und Anschlüsse auf

Undichtigkeiten.

3. Stellen Sie das Absaug-/ Entleerungsventil am

RG6 auf RECOVER (ABSAUGEN).

4. Öffnen Sie das Flüssigkeitsventil an der

Messgeräte-Verteilerstation. Hinweis: Durch

Öffnen des Flüssigkeitsventils wird zuerst

Flüssigkeit aus dem System gesaugt, was die

Absaugzeit erheblich verkürzt.

5. Öffnen Sie das Auslassventil am RG6.

6. Schalten Sie den Netzschalter auf ON (EIN).

7. Öffnen Sie langsam das Einlassventil am Gerät. Hinweis: Falls das Gerät anfängt zu „klopfen“,

drosseln (schließen) Sie das Einlassventil langsam, bis das Geräusch aufhört.

8. Sobald die Flüssigkeit aus dem System abgesaugt wurde, öffnen Sie das Dampfventil an der

Messgeräte-Verteilerstation, um die Evakuierung des Systems abzuschließen.

9. Betreiben Sie das RG6, bis das gewünschte Vakuum erzielt wurde.

10. Schließen Sie die Dampf- und Flüssigkeitsventile an der Messgeräte-Verteilerstation.

11. Drehen Sie das Einlassventil am RG6 in die Position CLOSED (GESCHLOSSEN).

12. Schalten Sie den Netzschalter auf OFF (AUS).

Entleeren des RG6 Geräts

VORSICHT: Nach jedem Absaugverfahren müssen

Sie das RG6 entleeren. Wenn das restliche

Kältemittel nicht aus dem Gerät entfernt wird,

können interne Komponenten durch Säure

beschädigt werden, was zu einem vorzeitigen

Ausfall des Geräts führt.

1. Prüfen Sie, dass die Flüssigkeits- und

Dampfventile an der Messgeräte-Verteilerstation

geschlossen sind (falls zutreffend).

2. Schließen Sie die Ventile des Systems,

das entleert wird (falls zutreffend).

3. Stellen Sie sicher, dass das Auslassventil

am Gerät geöffnet und das Einlassventil

geschlossen ist.

4. Prüfen Sie, dass das Flüssigkeitsventil an der

Kältemittelasche geöffnet ist.

5. Drehen Sie das Absaug-/Entleerungsventil auf

PURGE (ENTLEEREN).

6. Schalten Sie den Netzschalter auf ON (EIN).

7. Drehen Sie das Einlassventil langsam in

Richtung PURGE (ENTLEEREN). Wenn der

Druck an der Einlassseite sinkt, öffnen Sie das

Ventil vollständig.

8. Betreiben Sie das Gerät, bis das gewünschte

Vakuum erzielt wurde.

9. Schließen Sie das die Ein- und Auslassventil

am Gerät.

10. Schalten Sie den Netzschalter auf OFF (AUS).

11. Schließen Sie die Armaturen an der

Kältemittelasche.

12. Drehen Sie das Absaug-/Entleerungsventil auf

RECOVER (ABSAUGEN).

13. Klemmen Sie alle Zubehörteile ab und tauschen

Sie den Leitungslter aus.

Technische Tipps

Wenn Sie Probleme mit dem Starten oder Neustarten

des Geräts aufgrund von zu hohen Staudrucks

haben, schließen Sie zunächst das Einlassventil.

Drehen Sie dann das Einlassventil ganz langsam in

die Position Purge (Entleeren), bis der Einlassdruck

ansteigt. Schließen Sie das Einlassventil wieder und

versuchen Sie erneut, das Gerät zu starten.

20

Page 21

bedienungsanweisungen für flüssigKeits-grosssysteme

Druck-Zugmethode („Push-Pull“)

Mit der Druck-Zugmethode („Push-Pull“) werden große Mengen Flüssigkeit aufgrund des vom Absauggerät geschaffenen

Differenzdrucks aus dem System gezogen. Diese Methode funktioniert nur bei großen Systemen, bei denen die Flüssigkeit

leicht zugänglich ist. Sie funktioniert ggf. nicht bei Systemen, in denen sich weniger als 6,8 kg (15 lb.) Flüssigkeit

befindet.

Diese Methode wird bei folgenden Systemen verwendet:

•

Systeme mit Sammelaschen.

•

Systeme mit mehr als 9,1 kg (20 lb.) Kältemittel.

•

Transfer von großen Mengen üssigen Kältemittels von einer Flasche in eine andere.

Absaugen von Flüssigkeit

1.

Setzen Sie das RG6 auf eine ache, ebene Oberäche.

2. Schließen Sie einen Schlauch zwischen

dem Auslassanschluss am Gerät und dem

Dampfanschluss am zu entleerenden System an.

3. Schließen Sie einen Schlauch zwischen dem

Einlassanschluss am Gerät und dem Dampfanschluss

einer Kältemittelasche an. Robinair empehlt die

Verwendung eines Filter/Trockners in dieser Leitung.

4. Schließen Sie einen Schlauch zwischen der

Flüssigkeitsseite der Kältemittelasche und dem

Flüssigkeitsanschluss des zu entleerenden Systems

an. Robinair empehlt die Verwendung eines

Schauglases in dieser Leitung um sehen zu können,

wenn die Flüssigkeit abgezogen wurde.

RG6 wenn die SK-5001 Ausrüstung installiert ist

Schließen Sie den Tankanschlusskabelbaum (Nr.

549977) an den Schwimmerschalteranschluss an der

Kältemittelasche an.

5. Stellen Sie die Kältemittelasche auf eine Waage

(z. B. TIF9010A), um ein Überfüllen der Flasche zu

vermeiden.

Einlassanschluss

:

6. Prüfen Sie, dass die Ein- und Auslassventile am Gerät

geschlossen sind.

7. Drehen Sie den Absaug-/Entleerungsknopf auf

RECOVER (ABSAUGEN).

8. Öffnen sie die Armaturen an der Kältemittelasche.

9. Öffnen Sie das Auslassventil am RG6.

10. Schalten Sie den Netzschalter auf ON (EIN).

11. Öffnen Sie LANGSAM das Einlassventil am Gerät.

12. Wenn das auf der Waage angezeigte Gewicht

nicht weiter ansteigt, schließen Sie zunächst das

Einlassventil am Gerät, dann das Flüssigkeitsventil an

der Kältemittelasche.

13. Schalten Sie den Netzschalter auf OFF (AUS).

14. Schließen Sie die Armaturen an der Kältemittelasche

und das Auslassventil an der Maschine.

15. Fahren Sie fort mit Dampfabsaugung.

zu entleerendes

System

Dampf

WARNUNG: Schließen Sie die Ventile an der

Kältemittelflasche und dem Gerät RG6, um ein

Überfüllen der Flasche zu vermeiden. Sobald die

Siphonwirkung begonnen hat, kann die Kältemittelflasche

überfüllt werden, selbst wenn die Flasche mit einem

Schwimmerschalter ausgestattet ist. Die Siphonwirkung

kann auch dann noch andauern, wenn die Maschine

ausgeschaltet wurde.

Filter/Trockner

Flüssigkeit

Dampf

Schauglas

21

Kältemittel-

asche

Auslassanschluss

Flüssigkeit

Schwimmerschalteranschluss

(RG6 wenn die SK-5001

Ausrüstung installiert ist)

Waage

Page 22

bedienungsanweisungen für flüssigKeits-grosssysteme

Dampfabsaugung

1. Setzen Sie das RG6 auf eine ache, ebene

Oberäche.

2. Schließen Sie einen Schlauch zwischen

dem Einlassanschluss am Gerät und dem

Flüssigkeitsanschluss am zu entleerenden

System an.

3. Schließen Sie einen Schlauch zwischen

dem Auslassanschluss am Gerät und dem

Flüssigkeitsanschluss an der Kältemittelasche an.

VORSICHT: Die Kältemittelasche sollte auf

einer Waage stehen, um ein Überfüllen der

Flasche zu vermeiden.

4. Öffnen Sie das Flüssigkeitsventil an der

Kältemittelasche.

5. Drehen Sie den Absaug-/Entleerungsknopf auf

RECOVER (ABSAUGEN).

6. Öffnen Sie das Auslassventil am RG6.

7. Schalten Sie den Netzschalter auf ON (EIN).

8. Öffnen Sie langsam das Einlassventil am Gerät.

9. Betreiben Sie das Gerät, bis das gewünschte

Vakuum erzielt wurde.

10. Schließen Sie das Ein- und Auslassventil am

Gerät.

11. Schalten Sie den Netzschalter auf OFF (AUS).

12. Schließen Sie die Armaturen an der

Kältemittelasche.

Das Absaugverfahren geht schneller, wenn ein

T-Stück oder eine Messgeräte-Verteilerstation

in die Schläuche für die Flüssigkeits- und

Dampfanschlüsse des Systems gesetzt wird.

Technische Tipps

entleeren Von nicht-Kondensierbarem gas aus einer Kältemittelflasche

1. Lassen Sie die Kältemittelasche 24 Stunden

lang still stehen, damit Luft nach oben steigen

kann.

2. Schließen Sie eine Messgeräte-Verteilerstation

an die Flasche an. Lesen die den Druck in der

Flasche am Manometer ab.

3. Bestimmen Sie die Raumtemperatur.

4. Suchen Sie die festgestellte Raumtemperatur

in der Kältemitteldruck-/Temperaturtabelle.

Lesen Sie den entsprechenden Druck für

den Kältemitteltyp in der Flasche ab. Stellen

Sie fest, wie sich dieser Wert zu dem vom

Manometer angezeigten Wert verhält.

5. Falls der Druck in der Flasche höher ist als

der in der Tabelle angezeigt Druck, öffnen Sie

GANZ LANGSAM das Dampfanschlussventil.

(Dies muss langsam erfolgen, um möglichst

wenig Verwirbelung in der Flasche zu

verursachen.)

Achten Sie darauf, ob der Druck auf dem

Manometer abfällt. Um eine Entlüftung zu

vermeiden, addieren Sie 0,3-0,35 Bar (4-5 psi)

zu dem in der Tabelle angegebenen Druckwert.

Wenn das Manometer auf diesen Druck abfällt,

schließen Sie das Dampfanschlussventil.

6. Lassen Sie die Flasche 10 Minuten lang still

stehen und prüfen Sie den Druck erneut.

7. Wiederholen Sie das Verfahren nach Bedarf.

22

Page 23

informationen über die Kältemittelflasche

Flaschentyp

Verwenden Sie ausschließlich zugelassene,

nachfüllbare Kältemittelaschen. Gemäß

Bundesverordnungen darf Kältemittel nur in

Behältern transportiert werden, die die Spezikationen

4BA oder 4BW des DOT (Department of

Transportation - US-Verkehrsministerium) erfüllen.

Verwenden Sie NIEMALS eine standardmäßige

13,6 kg (30 lb.) Einwegasche (Behälter, in dem neues

Kältemittel verkauft wird), um Kältemittel abzusaugen.

Betriebsdruck

Kältemittelaschen sind auf verschiedene

Betriebsdrücke ausgelegt. Robinair empehlt

unbedingt die Verwendung einer Flasche, die auf

einen Betriebsdruck von 27,6 Bar (400 psi) ausgelegt ist.

WARNUNG: Um Verletzungen zu vermeiden,

darf der Nenndruck der Flasche nicht überschritten

werden. Das RG6 benötigt eine Flasche, die auf

einen Betriebsdruck von mindestens 24 Bar

(350 psi) ausgelegt ist.

HINWEIS: Bei Absaugung von Kältemittel Typ

R-410A ist die Verwendung einer auf 27,6 Bar

(400 psi) ausgelegten Kältemittelasche

Picht. Weitere Informationen können Sie dem

Abschnitt „Ersatzteile und Zubehör“ in dieser

Bedienungsanleitung entnehmen.

Wenn Sie Temperaturen von über 57°C (135°F)

erwarten, wenden Sie sich an den Kältemittel-Lieferanten.

Füllmenge

Laut Sicherheitsnormen darf die Füllmenge in

geschlossenen Kältemittelaschen 80 % des

Fassungsvermögens nicht überschreiten. (Die

restlichen 20 % sind die sogenannte Staudruckhöhe.)

Füllen Sie die Flasche nicht zu mehr als 80 % des

Fassungsvermögens. Robinair empehlt die

Verwendung der Kältemittelwaage TIF9010A, um die

Füllmenge der Flasche zu kontrollieren.

Kältemittel

Flaschen und Filter/Trockner dürfen nur für einen

Kältemitteltyp verwendet werden.

Falls Sie eine Flasche benutzen müssen, die vorher

für ein anderes Kältemittel verwendet wurde, bereiten

Sie die Flasche vor, indem Sie sie vollständig

entleeren, eine Evakuierung durchführen, sie mit

Trockenstickstoff reinigen und dann eine weitere

Evakuierung durchführen.

Aufbewahrung

Lagern Sie Kältemittelaschen an einem kühlen,

trockenen Ort.

Undichtigkeit

Die Ventile einiger Flaschen wurden bei der

Herstellung ggf. nicht richtig montiert. Kappen auf

den Ventilen schützen vor einem Auslaufen von

Kältemittel.

WARNUNG: Um Verletzungen zu vermeiden, transportieren Sie niemals eine überfüllte Flasche.

Das Kältemittel dehnt sich bei Wärme aus, und eine überfüllte Flasche kann explodieren.

Temperatur der Kältemittelflasche 16°C 21°C 38°C 54°F 66°F

(60°F) (70°F) (100°F) (130°F) (150°F)

AUSGANGSFÜLLMENGE

VON 80 % IN DER FLASCHE

Raum, der von der Flüssigkeit

eingenommen wird 80 % 81 % 83 % 90 % 94 %

AUSGANGSFÜLLMENGE

VON 90 % IN DER FLASCHE

Raum, der von der Flüssigkeit

eingenommen wird 90 % 92 % 96 % 100 %

23

Page 24

fehlersuche

WARNUNG: UM VERLETZUNGEN UND/ODER GERÄTESCHÄDEN ZU VERMEIDEN,

LASSEN SIE DIESES GERÄT NUR VON QUALIFIZIERTEM PERSONAL BEDIENEN UND

REPARIEREN. Vor Inbetriebnahme oder Reparatur des Geräts lesen und befolgen Sie die

Anweisungen und Warnhinweise in dieser Bedienungsanleitung. Der Techniker muss mit

Klimaanlagen und Kältesystemen, Kältemitteln und der Gefahr von unter Druck stehenden

Komponenten vertraut sein. Falls der Techniker dieses Handbuch nicht lesen kann, müssen

Bedienungsanweisungen und Vorsichtsmaßnahmen dem Techniker in seiner Sprache vorgelesen

und erklärt werden.

Problem Mögliche Ursache Mögliche Abhilfe

1.

Gerät lässt sich

nicht einschalten

Kompressor

versucht

zu starten,

aber summt nur

Maschine pumpt

bis zu einer

Abschaltung

durch Überdruck

Langsames

Absaugen

Sicherungsautomat wird ausgelöst

1. Netzkabel nicht eingesteckt.

2. Steckdose defekt.

3. Maschine hat sich aufgrund

Überdrucks abgestellt.

4. Thermische Überlastung des Motors.

5. Sicherungsautomat ausgelöst.

1. Niedrige Spannung an der Stromquelle.

2.

Verlängerungskabel zu lang oder zu

dünn.

3. Staudruck zu hoch.

1. Auslassventil an der Maschine

geschlossen

2. Ventil an der Kältemittelasche

geschlossen.

3. Staudruck zu hoch.

1. Eingeschlossene Flüssigkeit

im System.

2. Drosselung im Kältemittelstrom.

1. Niedrige Spannung an der

Stromquelle.

2.

Verlängerungskabel zu lang oder zu

dünn.

3. Überlastung des Kompressors/Motors.

Netzkabel an der Steckdose und am Gerät

prüfen.

2. Eine andere Steckdose ausprobieren.

3. Staudruck auf einen Wert unter 27,6 Bar

(400 psi) senken.

4. Motor/Gerät abkühlen lassen.

5. Sicherungsautomaten prüfen/rücksetzen.

1. Eine bessere Steckdose verwenden.

2. Ein kürzeres Verlängerungskabel

verwenden. Ein stärkeres Verlängerungskabel

(min. 14 AWG) verwenden.

3. Den Staudruck senken. Das Einlassventil

etwas über die Position CLOSED

(GESCHLOSSEN) hinaus auf PURGE

(ENTLEEREN) drehen, um den Druck

auf der hohen und niedrigen Seite

auszugleichen.

1. Auslassventil prüfen.

2. Kältemittelaschenventil prüfen.

3. Auslassschläuche auf Drosselungen oder

Knicke untersuchen. Staudruck senken.

1. Den Systemkompressor kurz aus- und wieder

einschalten, um eingeschlossenes Kältemittel

zu bewegen.

2. Den Einlassschlauch auf Drosselungen

oder Knicke untersuchen. Schraderventile

und Ventilkerndrücker aus den Schläuchen

entfernen (falls möglich). Größere Schläuche

verwenden.

1. Eine bessere Steckdose verwenden.

2. Ein kürzeres Verlängerungskabel verwenden. Ein stärkeres Verlängerungskabel (min.

14 AWG) verwenden.

3. Den Staudruck senken. Einlassventil

drosseln, um die Belastung des Kompressors

zu senken.

24

Page 25

13

14

15

ersatzteile

1 (linke Seite abgebildet)

2

Motorrelais

und

Kondensator

16

17

18

}

6

7

Trennplatte

3

4

Motor-Zwischenstück

5

Gegengewicht

11

10

12

9

Position Teile Nr. Nr. Anz. Beschreibung

1 567913 1 Gehäusehälfte (links)

567915 1 Gehäusehälfte (rechts)

2 550503 1 Durchführungstülle (je 1)

3 SK-6013 1 Motorklammern, kpl. (4 Stück)

4 SK-6005 1 Motor, kpl. (mit Motor,

Relais, Kondensator,

Befestigungselementen)

5 SK-6023 1 Kompressor, kpl. (mit Kompressor,

Befestigungsteilen)

6 SK-6008 1 Lüfter, kpl. (mit Lüfter, Distanzstück,

Montageteilen)

7 GA1000 1 Messanzeige (je 1)

8 100124 1 Verteilerstationsregler (rot)

9 100123 1 Verteilerstationsregler (blau)

10 100122 1 Verteilerstationsregler (schwarz)

11 SK-6014 1 Kondensator, kpl. (mit Kondensator,

Befestigungsteilen)

Ein-/Auslassleitung

8

Position Teile Nr. Nr. Anz. Beschreibung

12 551628 1 Netzkabel

13 SK-6012 1 Blende, kpl. (mit Blende,

Netzschalter, Sicherungsautomat,

Leistungsmodul, Befestigungsteilen)

14 SK-6001 1 Einlassanschluss/Filtersieb, kpl.

(mit Einlassanschluss, Filtersieb,

O-Ring)

15 550502 1 Fuß (je 1)

16 SK-6003 1 Ausgangsseitiges Manometer, kpl.

(mit ausgangsseitigem Manometer,

Abdeckung)

17 SK-6022 1 Ausgangsseitiges Manometer, kpl.

(mit ausgangsseitigem Manometer,

Abdeckung)

18 SK-6016 1

Verteilerstation, kpl. (mit Verteilerstation,

Befestigungsteilen)

25

Page 26

umbauKits und zubehör

Teile Nr. Beschreibung

SK-5001 Absperrventil bei 80 % Füllmenge, kpl.

SK-6001 Filtersieb-Austauschkit

SK-6002 Filter/Trockner, kpl. (mit Filter/Trockner, 15,2 cm Schlauch (6 Zoll)

SK-6005 Motor-Austauschkit

SK-6007 Ventilumbau-/Austauschkit (mit Ein-/Auslassventilen und Federn, O-Ringen)

SK-6008 Lüfter-Austauschkit

SK-6012 Blenden-Austauschkit

SK-6014 Kondensator-Austauschkit

SK-6015 Kolbendichtring-Umbaukit (mit Kolbendichtringen, Erreger-O-Ring, Verschleißringen)

SK-6016 Verteiler-Austauschkit

SK-6023 Kompressor-Austauschkit

SK-6022 Messgerät-Austauschkit

TIF9010A Kältemittelwaage

17572 Kältemittelasche (22,7 kg [50 lb.] Fassungsvermögen, 27,6 Bar [400 psi]

Betriebsdruck, Füllstandgeber)

SK-1013 Bewegungsklammern-Ausrüstung (4 Stücke)

26

Page 27

wartung

VORSICHT: Um Verletzungen zu vermeiden, ziehen Sie stets das Netzkabel des RG6 aus der

Steckdose, bevor Sie Wartungsarbeiten am Gerät durchführen.

Installation von Filter und Filter/Trockner

1. Vor dem Absaugen von Kältemittel prüfen und reinigen Sie stets das Filtersieb im Einlassanschluss

des Geräts RG6. Tauschen Sie das Filtersieb (Teile-Nr. SK-6001) nach Bedarf aus. Das Filtersieb

reduziert das Risiko einer Beschädigung des Geräts, indem es verhindert, dass Fremdkörper in das

Gerät und in das System, das entleert wird, eindringt. Wenn Sie das Gerät ohne Filtersieb betreiben,

wird die Garantie ungültig.

Robinair empfiehlt ebenfalls unbedingt den Einsatz eines Filter/Trockners (Teile-Nr. 100343) in der

Einlassleitung.

Filtersieb

Einlassanschluss

Filtertrockner

Teile-Nr. 100343

Ausgebranntes System

1. Wenn Sie aus einem „ausgebrannten“ System absaugen, verwenden Sie zwei säurebeständige Filter/

Trockner hintereinander. Robinair empehlt Filter von Alco Typ EK-162-F oder Filter von Sporlan Typ

C-162-F.

Wenn die Absaugung des Systems beendet ist, spülen Sie das RG6 mit einer geringen Menge

sauberen Kältemittels und Kältemittelöls, um Fremdkörper aus dem Gerät zu entfernen.

Aufbewahrung

1. Leeren Sie das Kältemittel aus dem Gerät in eine Kältemittelasche. Flüssiges Kältemittel im

Kondensator des Geräts kann sich ausdehnen und eine Beschädigung der Komponenten verursachen.

2. Sie müssen restliches Kältemittel vollständig aus dem Gerät RG6 evakuieren und das Gerät mit

Trockenstickstoff reinigen, bevor Sie es längere Zeit lagern.

27

Page 28

28

Page 29

Máquina de recuperación de refrigerante

Model No. RG6

Manual de operaciones

29

Page 30

Precauciones de seguridad

ADVERTENCIA: PARA EVITAR LESIONES PERSONALES Y / O DAÑO AL EQUIPO,

PERMITA LA OPERACIÓN DE ESTA UNIDAD SOLAMENTE A PERSONAL CALIFICADO. Antes

de operar la unidad, lea y siga las instrucciones y advertencias de este manual. El operador debe

estar familiarizado con los sistemas de aire acondicionado y refrigeración, refrigerantes y los peligros

de los componentes presurizados. Si el operador no puede leer este manual, las instrucciones de

funcionamiento y las precauciones de seguridad se deben leer y discutir en el idioma nativo del

operador.

EL TANQUE PRESURIZADO CONTIENE REFRIGERANTE LÍQUIDO. No llene excesivamente los

depósitos de almacenamiento, ya que puede provocar una explosión, lesiones personales o la muerte.

No recupere los refrigerantes en recipientes que no se pueden volver a llenar, utilice únicamente

recipientes que se pueden volver a llenar autorizados por la ley federal (espec. 4BW ó 4BA del

Departamento de transporte).

LAS MANGUERAS PUEDEN CONTENER REFRIGERANTE LÍQUIDO BAJO PRESIÓN. El contacto

con el refrigerante puede ocasionar lesiones personales. Utilice equipo de protección, incluyendo

gafas de seguridad y guantes protectores. Desconecte las mangueras con extremo cuidado.

EVITE INHALAR EL VAPOR O ROCÍO DE REFRIGERANTE Y LUBRICANTE DE AIRE. La exposición

podría irritar los ojos, la nariz y la garganta. Para eliminar el refrigerante del sistema de A/C, use

solamente equipo certicado para el tipo de refrigerante que eliminó. Utilice la unidad la ventilación

por medios mecánicos cambie el aire por lo menos 4 veces por hora. Si ocurre una descarga del

sistema accidental, ventile el área de trabajo antes de reanudar el servicio.

PARA REDUCIR EL RIESGO DE INCENDIO, UTILICE EL CABLE DE EXTENSIÓN MÁS CORTO

POSIBLE CON UN TAMAÑO MÍNIMO DE 14 AWG. Utilizar un cable de extensión de menor tamaño

puede resultar en una falla eléctrica del equipo.

PARA REDUCIR EL RIESGO DE INCENDIO, no utilice la unidad cerca de recipientes que se han

derramado o están abiertos y que contengan gasolina u otras sustancias inamables.

PRECAUCIÓN – NO REALIZAR PRUEBAS DE PRESIÓN O PRUEBAS DE FUGAS EN EL EQUIPO

O SISTEMAS DE AIRE ACONDICIONADO DEL VEHÍCULO CON AIRE COMPRIMIDO. Se ha

demostrado que algunas mezclas de aire y refrigerante son combustibles a presiones elevadas. Estas

mezclas, si se encienden, pueden provocar lesiones y daños a la propiedad.

NO MEZCLE DISTINTOS TIPOS DE REFRIGERANTES A TRAVÉS DE UN SISTEMA O EN EL

MISMO CONTENEDOR. Mezclar los refrigerantes causa un gran daño a la unidad y al sistema al

que se le está haciendo el servicio.

LA ELECTRICIDAD DE ALTO VOLTAJE DENTRO DE LA UNIDAD PRESENTA UN RIESGO DE

DESCARGA ELÉCTRICA. La exposición puede ocasionar lesiones personales. Desconecte la energía

antes de dar servicio a la unidad.

Se puede obtener información adicional sobre salud y seguridad de

los fabricantes del refrigerante y lubricante.

Explicación dE las palabras dE sEñalización dE sEguridad

ADVERTENCIA: Indica que hay una situación de peligro que si no se evita podrá causar la muerte o

una lesión grave.

PRECAUCIÓN: Indica una situación de peligro que si no se evita podrá causar lesiones menores o

moderadas.

PRECAUCIÓN: Utilizado sin el símbolo de alerta de seguridad indica una situación peligrosa que si no se

evita podrá causar daño a la propiedad.

2

Page 31

Índice

Precauciones de seguridad

Explicación de las Palabras de señalización de seguridad

Comprender la recuperación de refrigerante

Instrucciones estándares de funcionamiento

Configuración

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedimiento de recuperación

Purgue la unidad RG6

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrucciones de operación para Sistemas de líquido a granel

Procedimiento Empuje – Tire

Recuperación de líquidos

Recuperación de vapores

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

Purgar gas no condensable de un cilindro de almacenamiento

Información de cilindros de recuperación

Solución de problemas

Repuestos

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipos de reconstrucción y accesorios

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . .

30

30

32

33

33

34

34

35

35

35

36

36

37

38

39

40

Mantenimiento

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instalación del filtro y del filtro / secador

Sistema quemado

Almacenamiento

Declaración de garantía

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

Dentro de la cubierta trasera

41

41

41

41

31

Page 32

comPrender la recuPeración de refrigerante

La recuperación del refrigerante es el proceso de sacar

refrigerante de un sistema y almacenarlo en un cilindro.

La siguiente información es crítica para lograr los mejores

resultados de recuperación de refrigerante.

Refrigerante

Identique la cantidad y el tipo de refrigerante en el sistema

al que le va a hacer el servicio.

La unidad RG6 está aprobada para el uso de refrigerantes de

las siguientes categorías III, IV y V (según ARI-740) :

R-12, R-22, R-134a, R-401a, R-401b,R-401c, R-402a,

R-402b, R-404a, R-406a, R-407a, R-407b, R-407c, R-407d,

R-408a, R-409a, R-410a, R-411a, R-411b, R-412a, R-500,

R-502, R-507 R-509

Filtros y ltros / secadores

PRECAUCIÓN: Los ltros previenen que entre

contaminación a la unidad, lo que reduce el riesgo de

daño a la unidad y al sistema recibiendo el servicio.

La unidad RG6 se envía con una pantalla de ltro instalada

detrás del adaptador de entrada. Robinair recomienda

ampliamente la utilización de una pantalla de ltro limpia para

cada servicio. No utilizar una pantalla de ltro invalidará su

garantía.

Robinair también recomienda ampliamente utilizar un ltro /

secador (parte nº. 100343; no provisto) en el adaptador de

entrada. Cada ltro / secador en línea debe estar identicado y

utilizarse para un solo tipo de refrigerante.

Válvulas

ADVERTENCIA: Para prevenir las lesiones

personales, abra las válvulas de servicio y de cilindro

LENTAMENTE para permitir un cerrado rápido de flujo de

gas si es necesario. Una vez que se ha determinado que no

hay peligro, las válvulas pueden abrirse completamente.

Aísle grandes cantidades de refrigerante y cierre las válvulas

después de su uso, para que si sucediera una fuga en cualquier

parte del sistema, el refrigerante no se escape a la atmósfera.

Cilindros de almacenamiento

ADVERTENCIA: Un cilindro de almacenamiento está

lleno cuando llega al 80% del volumen. NO LO LLENE

EN EXCESO. Debido a la expansión de los líquidos,

el cilindro puede explotar si se llena más del 80% del

volumen, posiblemente causando lesiones personales

y daño al equipo. Utilice una balanza, tal como la

TIF9010A, para evitar el llenado en exceso del cilindro de

almacenamiento.

Robinair recomienda utilizar el Equipo opcional para cierre

con capacidad del 80% (número de parte SK-5001) con esta

unidad. Después de que el equipo ha sido instalado y usado

con un cilindro de recuperación que tiene un conmutador

interno de otador, la unidad se apaga automáticamente

cuando el cilindro se llena en un 80%. (Su unidad está

precableada de fábrica para este equipo).

Mangueras

Las mangueras deben estar equipadas con adaptadores

de pérdida baja y tener la capacidad de presión apropiada

para el refrigerante en el sistema al que se le va a hacer el

servicio.

Conmutador de válvula de cierre

Esta unidad tiene un conmutador interno de válvula de cierre

de alta presión. Si la presión del sistema se eleva por encima

de los 550 psi, la unidad se apaga. El conmutador de válvula

de cierre se reinicia automáticamente después de que la

presión desciende por debajo de las 400 psi.

ADVERTENCIA: El conmutador de válvula de cierre

de presión interna NO previene que el cilindro se llene

en exceso. Si el sistema se apaga automáticamente y

está conectado al cilindro, el cilindro puede llenarse en

exceso de manera peligrosa. Tome medidas inmediatas

para rebajar la presión alta y / o el llenado en exceso del

cilindro, o pueden suceder lesiones personales.

Procedimiento Empuje / tire

Cuando se recuperan grandes cantidades de líquidos (más

de 15 libras), utilice el método de Empuje / tire descrito en

este manual.

Tasas máximas de vacío y recuperación

Para alcanzar el vacío nal más profundo, utilice un cilindro

de recuperación evacuado. Para maximizar las tasas de

recuperación:

Utilice una manguera de medida más corta posible de 3/8”

•

o más grande. (Se recomienda una manguera de no más

de 3 pies de longitud).

Quite los depresores centrales innecesarios de la manguera

•

y las válvulas Schrader de las conexiones de puertos.

Los sellos de caucho deformados y los depresores

centrales, como también las válvulas Schrader con fallas o

innecesarias, pueden restringir el ujo.

Si usted está seguro que el refrigerante en el sistema al

•

que se le va a hacer el servicio está limpio o es nuevo,

se puede remover la pantalla de ltro del adaptador de

entrada.

Purgue el RG6 durante el nal de la fase de recuperación

•

de vapor, especialmente cuando se recuperan grandes

cantidades de vapor. Purgue de nuevo después de que se

complete el el proceso de recuperación y se obtendrá el

vacío deseado. Consulte “Purgue la unidad RG6” al nal de

la sección Instrucciones estándares de funcionamiento.

Mantenimiento

PRECAUCIÓN: Mantenga limpias y secas todas las

conexiones del sistema de refrigeración. Ocurrirán daños

si se permite que entre humedad al sistema.

32

Page 33

instrucciones estándares de funcionamiento

Vidrio

visor

Juego de

indicadores

del colector

Sistema recibiendo

servicio

Vapor

Filtro / secador

Líquido

Las siguientes instrucciones son para procedimientos

de recuperación estándares o “comunes”.

Conguración del procedimiento

1. Ubique la unidad RG6 en una supercie plana

y nivelada.

2.

Verique que se encuentre instalada una pantalla

de ltro limpia detrás del adaptador de entrada.

3. Conecte una manguera del adaptador de

salida a la unidad al puerto de líquidos en el

cilindro de recuperación.

4. Conecte un manguera desde el adaptador de

entrada de la unidad al puerto de salida de

un juego de indicadores del colector. Robinair

recomienda utilizar un vidrio visor y un ltro /

secador en esta línea.

5. Conecte una manguera del lado líquido (baja

presión) del juego de indicadores del colector

al lado líquido del sistema al que se le está

haciendo el servicio.

6. Conecte una manguera del lado de vapor

(alta) del juego de indicadores del colector al

lado de vapor del sistema al que se le está

haciendo el servicio.

RG6 con el equipo SK-5001 instalado:

una el arnés para conexión del tanque

(No. 549977) a la conexión del conmutador

interno en el cilindro de recuperación.

7. Verique que las válvulas de entrada y salida

de la unidad RG6 estén cerradas.

8. Ubique el cilindro de recuperación en una

balanza (tal como TIF9010A) para evitar el

llenado en exceso del cilindro.

Adaptador

de entrada

Adaptador

de salida

Puerto

líquido

Cilindro de

recuperación

Balanza

Conexión del conmutador interno

(RG6 con el equipo SK-5001

instalado)

ADVERTENCIA: Un cilindro de

almacenamiento está lleno cuando llega al 80%

del volumen. NO LO LLENE EN EXCESO. Debido

a la expansión de los líquidos, el cilindro puede

explotar si se llena más del 80% del volumen,

posiblemente causando lesiones personales y

daño al equipo.

Recomendaciones técnicas

El RG6 va a desempeñarse de la mejor manera

cuando el voltaje que entra en la máquina

(mientras opera) se encuentre entre 115V AC

y 122V AC. Los suministros de voltaje menores

pueden resultar en dicultades al iniciar bajo presión

alta en la cabecera, desempeño reducido y / o

sobrecalentamiento del motor.

Utilice una salida que no tenga otros dispositivos

(tales como luces, máquinas, etc.) conectados.

No utilice un cable de extensión a menos que sea

necesario. Si se utiliza un cable de extensión, debe

ser como mínimo de 14 AWG y tan corto como sea

posible para reducir las caídas de tensión.

33

Page 34

instrucciones estándares de funcionamiento

Procedimientos de recuperación

1. Conecte la unidad a una salida de 115V.

2. Abra lentamente la válvula de líquidos del

cilindro de recuperación mientras observa las

mangueras y las conexiones por fugas.

3. Establezca la válvula de recuperación / purga

en la unidad RG6 a RECUPERACIÓN.

4. Abra la válvula de líquidos en el juego de

indicadores del colector. Nota: Al abrir la

válvula de líquido remueve primero el líquido

del sistema, reduciendo mucho el tiempo de

recuperación.

5. Abra la válvula de salida de la unidad RG6.

6. Gire el interruptor de energía en la posición

ENCENDIDO.

7. Abra lentamente la válvula de entrada en la unidad. Nota: Si la unidad empieza a “dar golpes”,

lentamente desacelere (cierre) la válvula de entrada hasta que el ruido se detenga.

8. Una vez que se removió el líquido del sistema, abra la válvula de vapor en el juego de indicadores del

colector para terminar de evacuar el sistema.