Page 1

Page 2

ROBIN

AMERICA, INC.

ROBIN

TO

WISCONSIN

ROBIN

ENGINE

MODEL

CROSS REFERENCE

LIST

ROBIN

EY08

EY15

EY 15V

EY20

EY2OV

EY23

EY28

EY3

5

EY40

-

EY45V

EY2

1

EY44

EY 18-3

EY25

EY27

EH11

EH12

EH15

EH17

EH21

EH25

EH30

EH30V

EH34

EH34V

EH43V

EC13V

DY23

DY27

DY30

DY3

5

DY4 1

WISCONSIN

ROBIN

SIDE

VALVE

W

1-080

W1-145

W1-145V

W1-185

W1-185V

W1-230

W 1-280

W

1-340

W 1-390

Wl-45OV

EY21W

EY44W

EY18-3W

EY25W

EY27W

OVERHEAD

VALVE

WO1-115

wo1-120

WO1-150

WO1-170

wo1-210

WOl-250

WO 1-300

WO1-300V

WO1-340

WO

1

-340V

WO 1-43 OV

TWO CYCLE

WT1-125V

DIESEL

WRD

1-230

WRD

1-270

-1-300

WRD1-350

WRD1-410

0

0

0

Page 3

NTEN'TS

Section Title Page

1

.

2

.

3

.

4

.

5

.

6

.

7

.

8

.

SPEClFlCATlONS

............................................................................

PERFORMANCE

............................................................................

2-1 Maximum Output

.......................................................................

2-2 Continuous Rated Output

..............................................................

1

4

4

4

4

5

8

GENERAL

DESCRlPTlON

OF ENGINE COMPONENTS

............................

8

2-3

M~~~~~~T~~~~~

.......................................................................

2-4

performance

curves

...................................................................

FEATURES

...................................................................................

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-1

0

4-1 1

4-1

2

4-1 3

4-1 4

4-1

5

Page 4

13-1

13-2

13-3

13-4

13-5

13-6

13-7

..

"

Page 5

1.

SPECIFICATIONS

Model

~~ ~~ ~

EH12B EH12DS

EH12BS

EH12

EH12D

TY Pe

X

Bore

Piston Displacement

Compression Ratio

output

Stroke

Continuous

Max.

Max.

Torque 0.76/2600 kg*m/rpm

of

Direction

Cooling system Forced Air Cooling

Valve Arrangement Overhead Valve

Lubrication

Lubricant Automobile Oil

Capacity

Fuel

Rotation Counterclockwise

of

Lubricant

Air-Cooled, 4-Cycle, Single-Cylinder. Horizontal P.T.O. Shaft, Gasoline Engine

60

X

43 mm (2.36 X 1.57 in.)

121

cc

(7.38 cu.in.)

8.5

4.0/2000 HP/rpm

/

1300 kgm/rpm

1.52

As

Viewd From P.T.O. Shaft Side

Splash Type

SAE

#20, #30

0.6 liters (0.16

Horizontal Draft, Float Type Carburetor

Automobile Gasoline

2.5/3000 HP/rprn 2.813600 HP/rpm 2.5/1500 HP/rpm 2.8/1800 HP/rpm

U.S.

or

gal.)

4.0

/4000 HP/rpm

1 OW-30

Fuel Feed System

Fuel Tank Capacity

Ignition System

Spark Plug

Charging Capacity

Starting System

Speed Reduction

Governor System

Dry

Weight

Dimensions

Width

Recoil Starter

21

Cam Shaft Drive

14.5kg (31.91b.)

330mm (12.99in.)

366mm (14.41 in.) Height

230 gr/HP-h At Continuous Rated Output Fuel Consumption Rate

Gravity Type

3.6 liters (0.95

Flywheel Magneto (Solid State)

NGK

i

12V- 1.3~

Recoil and Electric

Starter

Centrifugal Flyweight System

17.0kg (37.4Ib.)

303mm (11.93in.) 303mm (11.93in.) Length

345mm (13.58in.)

366mm (14.41

in.)

U.S.

B6HS

1

14.0kg (30.8Ib.)

301 rnm (11.85in.)

330rnm (12.99in.)

gal.)

Recoil

Starter

1

12V- 1.3A

Starter

Recoil and Electric

-

16.5kg (36.3Ib.)

301 mm(11.85in.)

345mm (13.58in.)

366mm (14.41 in.) 366mm (14.41 in.)

-1-

Page 6

Model

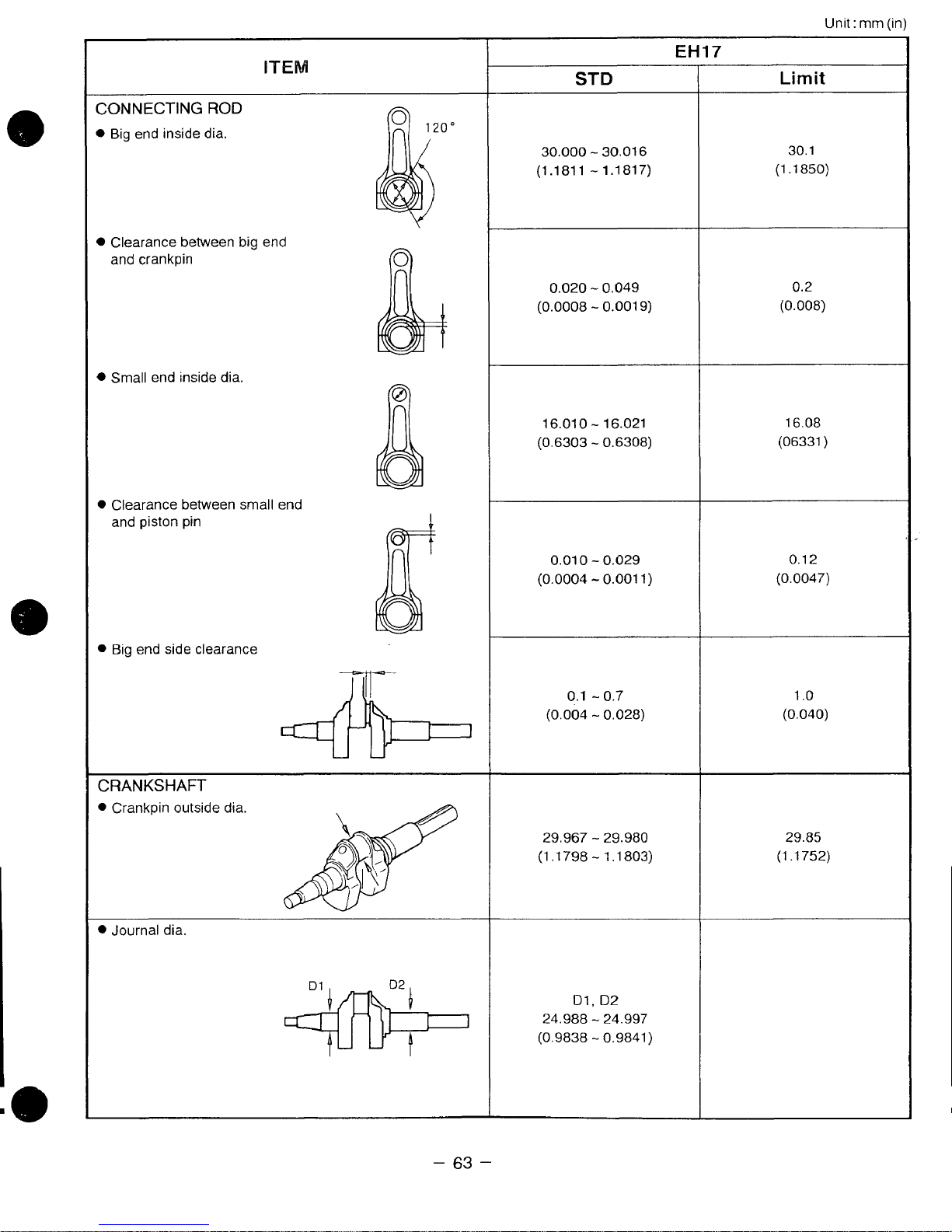

EH17

EH17B EH17BS EH17D EH17DS

TY Pe

X

Bore

Piston Displacement

Compression Ratio

output

Max. Torque

Direction of Rotation

Cooling system

Valve Arrangement

Lubrication

Lubricant

Capacity of Lubricant

Carburetor

Fuel

Stroke

Continuous

Air-Cooled, 4-Cycle, Single-Cylinder, Horizontal

67

X

49

mrn

(2.64 X 1.93 in.)

cc

172

(10.50 cu.in.)

8.5

6.0/2000 HP/rprn

3.5

/

1500 HP/rpm

2.1 8 / 1300 kgm/rpm 1.09 /2600 kg*m/rpm

4.0

/

1800 HP/rpm

Counterclockwise As Viewd From

Forced Air Cooling

Overhead Valve

Automobile Oil

0.65

liters (0.17

Horizontal Draft, Float Type

Automobile Gasoline

I

3.5

Splash Type

SAE

#20, #30 or 1OW-30

U.S.

P.T.O.

13000

P.T.O.

gal.)

Shaft, Gasoline Engine

6.0/4000

HP/rpm 4.0/3600

Shaft Side

HP/rpm

Wrpm

Fuel Consumption Rate

Fuel Feed System

Fuel Tank Capacity

Ignition System

Spark Plug

Charging Capacity

Starting System

Speed Reduction

Governor System

Dry Weight

Length

Dimensions

Width

Height

-

Recoil Starter

2:l Cam Shaft Drive

16.0 kg

~~~~ ~~

315rnrn (12.40in.)

330mrn (12.99in.)

380mrn (14.96in.)

(35.2

Ib.) 1 18.5 kg (40.7

230 gr/ HP-h At Continuous Rated Output

Gravity Type

3.6

liters

(0.95

U.S.

gal.)

Flywheel Magneto (Solid State)

NGK

B6HS

12V - 1.3A

Recoil and Electric

Starter

I

Centrifugal Flyweight System

Ib.) I 15.5 kg (34.1 Ib.)

315mm (12.4Gin.)

mm

361

380rnm

(14.21 in.)

(14.96in.)

I

313mrn (12.32in.) 313mrn(l2.32in.)

330mm (12.99in.)

380mm (14.96in.)

Recoil

-

Starter

12V - 1.3A

1

Starter

Recoil and Electric

I

-

I

18.0 kg (39.6

361 rnm (14.21 in.)

380rnrn (14.9Sin.)

Ib.)

,-

-2-

Page 7

I

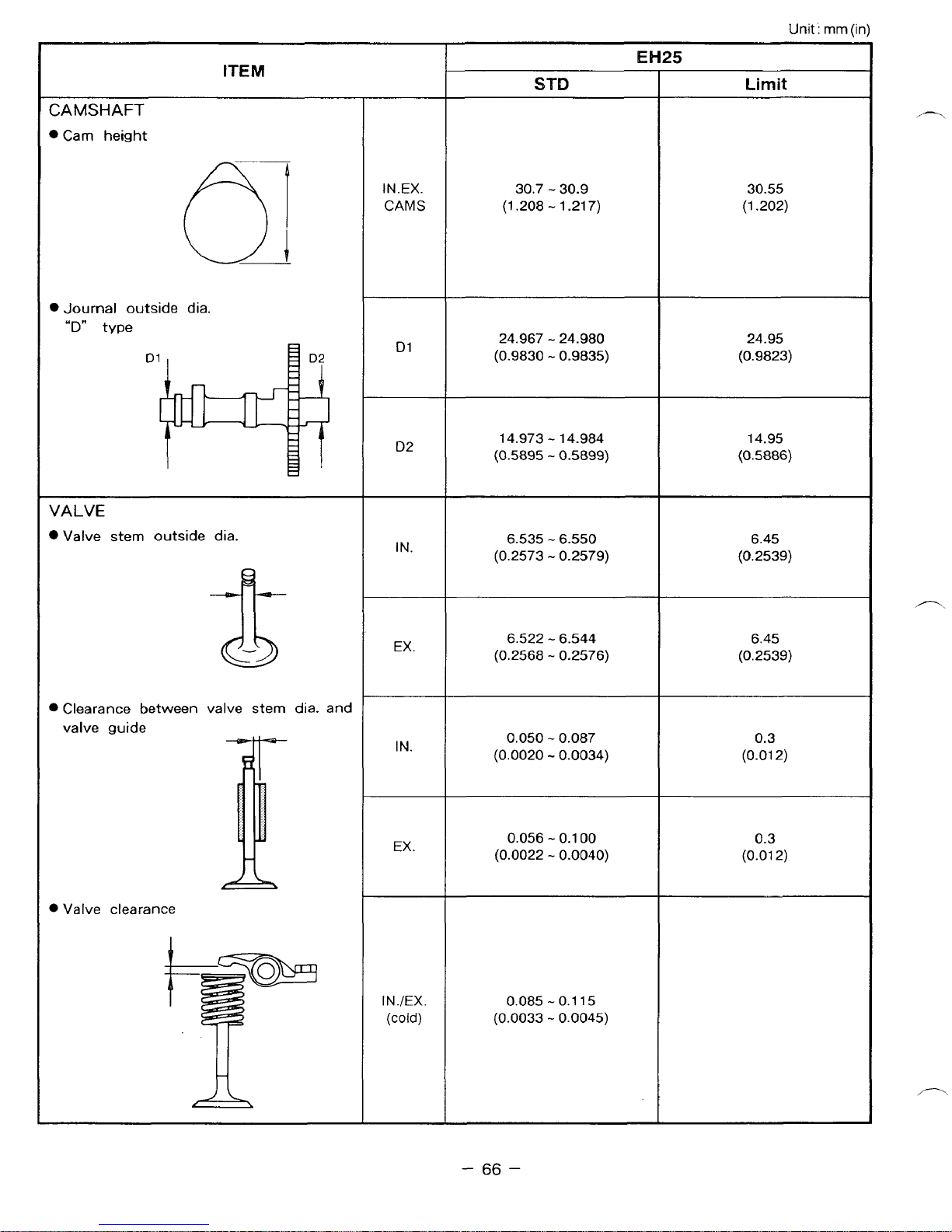

Et125

Model

EH25B EH25BS EH25D EH25DS

TY

Pe

1

Air-Cooled, 4-Cycle, Single-Cylinder, Horizontal P.T.O. Shaft, Gasoline Engine

Bore

X

Stroke

75

X

57 mm (2.95 x 2.24 in.)

Piston Displacement

251

cc (15.31 cu.in.)

Compression Ratio

8.5

Output

Max. Torque

3.38

I1

300

kgWrpm 1.69 / 2600 kg-mlrpm

Continuous 8.5/2000 HP/rpm 8.5/4000 HP/rprn

Max.

5.5/1500 HP/rpm 6.411800 HP/rpm 5.5/3000 HP/rpm 6.4/3600 HP/rpm

Direction

of

Rotation Counterclockwise

As

Viewd From P.T.O. Shaft Side

Cooling system Forced Air Cooling

Valve Arrangement Overhead Valve

Lubrication Splash Type

Lubricant Automobile Oil

SAE

#20,

#30 or 1 OW-30

Capacity

of

Lubricant

1

.O

liters (0.26

U.S.

gal.)

Carburetor Horizontal Draft, Float Type

Fuel

Automobile Gasoline

Fuel Consumption Rate

230

gr/HP-h At Continuous Rated Output

Fuel Feed System

Gravity Type

Fuel Tank Capacity

6.0 liters (1

59

US.

gal.)

Ignition System

Flywheel Magneto (Solid State)

Spark Plug

NGK

B6HS

Charging Capacity

-

12V - 1.3A

-

12V

-

1.3A

Starting System

~~~ ~~

Recoil and Electric

Starter

Recoil

Starter

~~

~~_____

Recoil Starter

Recoil and Electric

Speed Reduction 2:l Cam Shaft Drive

-

Governor System Centrifugal Flyweight System

Dry Weight 24.5 kg (53.9

Ib.)

28.5 kg (62.7

Ib.)

24.0 kg (52.8

Ib.)

28.0 kg (61.6

Ib.)

Length 360rnm (14.17in.)

360mrn (14.17in.)

360rnm (14.17in.)

360mm(l4.17in.)

Dimensions

Width

385mm

(15.15in.)

405mm (15.94in.)

385mm (15.15in.)

405mrn (15.94in.)

Height

440mm (17.32in.) 440rnm (17.32in.)

440mm (17.32in.)

440mm (17.32in.)

-3-

Page 8

2.

PERFORMANCE

2-1 MAXIMUM OUTPUT

The maximum output

is

the output

of

an engine with its throttle valve fully opened under the

condition

that all the moving parts are properly worn in after the initial break-in period.

A

new engine may not produce full maximum output while

2-2 CONTINUOUS

RATED

OUTPUT

its

moving parts are

still

not broken-in.

The continuous rated output is the output of an engine at optimum governed speed which is

favorable

When the engine

required from the engine be kept below

2-3 MAXIMUM TORQUE

The maximum torque

from

the view point of engine’s life and fuel consumption.

is

installed on a certain equipment,

this

continuous rated output.

is

the

torque

at

the output shaft when the engine

it

is

recommended that the continuous output

is

producing maximum output at

certain revolution.

A.

most

-4-

Page 9

2-4

PERFORMANCE

CURVES

0

EH12D,

B

4.0

(2.98 KW)

3.5

(2.61 KW)

3.0

(2.24 KW)

2.5

(1.87 KW)

2.0

(1.49

KW)

1.5

(1.21 KW)

1

.o

(0.75

KW)

0.5

(0.37

KW)

(

)

for

B

type

-

MAXIMUM TORQUE

1

2000

(1

000)

3000

(1

500)

REVOLUTION

--s)

r.p.m.

0.8

(1.6)

kg-m

0.7

(1.4)

I

W

t

I

0.6

(1.2)

0

I-

CONTINUOUS

RETED

HP

RECOMMENDED

HORSEPOWER

\

RANGE

4000

(2000)

i

-5-

Page 10

0

EHf7D,

B

n

( )

for

B

type

..

"

REVOLUTION

"-+

r.p.m.

kg-m

1

.I

0

,(2.2)

t

I

1-00

(2.0)

I

W

Y

0.9

(1.8)

6

CT

0

I-

CoNTiNuous

RETE0

HP

1

RECOMMENDED

\

RANGE

HORSEPOWER

-

6-

Page 11

0

EH25D,

6

-7-

Page 12

FEATURES

3.

1.

The overhead valve design offers a compactness, light weight and ideal combustion characteristics

2.

3.

resulting

An

A

crossflow arrangement

in

more power from less fuel and prolonged engine life.

optimum lubrication and better tilted operation thanks to upright cylinder design.

of

intake and exhaust

ports

ensures stable performance under

high

temperature.

4.

The automatic decompressiom system lightens the recoil pull force by

conventional

5.

An

easy operation

6.

Combustion and mechanical noises have been carefully reviewed for better tonal quality

SV

engines.

thanks

to

integrated engine control system.

40%

comparing to the

cnginc noise.

7.

Optimally designed reciprocating parts reduce the vibration level

of

the engine.

EH25

engine equips

sjnglc through-balancer shaft.

4.

GENERAL DESCRIPTION OF ENGINE COMPONENTS

4-1

CYLINDER

The

cylinder and crankcase is single piece alu-

minum

diecasting. The cylinder liner, made

special cast iron, is molded

AND

CRANKCASE

into

of

the aluminum

casting.

The crankcase has

output

shaft

side, where the main bearing cover

attached. (See Fig.

21

mounting surface

4-1

.)

on

the

is

ambient

and

lower

F.

I-GKR

i

OILGAUGE

-8-

""

CENTERING

Fig.

Fig.

4-1

4-2

""

OIL

~

GAUGE

/,"

Page 13

4-3

CRANKSHAFT

The crankshaft

is

forged carbon steel, and the

crank

pin is induction-hardened.

The output end

of

the shaft has a crankshaft gear,

and balancer gear for

EH25

which are pressed

into

position.

(See

Fig.

4-3.)

4-4

CONNECTtNG

ROD

AND PISTON

The connecting

rod

is

forged

aluminum alloy, and

its

large and small ends function as bearings. The

piston

is an aluminum alloy casting, and carries

two

compression rings and one

oil

ring.

(See

Fig. 4-4.)

4-5

PISTON RINGS

The Piston rings are made

of

special cast

iron.

The profile

of

the

top ring is barrel face and the

second ring has

a

tapered face with

an

under-cut.

The oil ring consists

of

a cutter ring and a coil

expander

for

better sealing and

less

oil

consump-

tion.

I

B

TYPE

1

D

TYPE

Fig.

4-3

Fig.

4-4

--

TOP RING

SECOND

RIN(

OIL

RING

-9-

Page 14

4-6

CAMSHAFT

‘I’he camshaft for the D-type engine

is

made

special cast iron and camshaft gears are casted

togcther

Both

on

‘I’hc

in

one

piece.

sides

of

the shaft

the

crankcase and main bearing cover.

camshaft

for

fit

into the plane bearings

the

B-type engine

is

made

forged carbon stcel and also functions as

shaft.

The cam gear

ball

bearings arc employed

porting the shaft. (See

4-7

VALVE ARRANGEMENT

‘I’he intake v;llve

is

press fitted

is

located

Fig.

on

the

on

both sides

4-6.)

on

flywheel side

shaft

and the

for

cylinder hcad.

‘I’hc

hard

alloy

cylinder head and stcllite

valvc

‘I’hc

valvc

f;KC.

cylindcr

arca

for

valvc

bafflc

seats are molded

is

fused

lo

the exhaust

leads cooling air to the exhaust

the optimum cooling. (See Fig.

PTO

of

in

4-7.)

of

of

sup-

the

the

I

I

B

Fig.

TYPE

I

4-6

D

li’PE

h.

4-8

CYLINDER HEAD

‘I’hc cylindcr hcad is

which utilizcs

thc highcst

wcdgc

combusl.ion

a11

aluminurn die casting

type combustion chamber

cli‘icicncy. (See Fig.

4-13,)

for

Fig.

4-7

Fig.

4-8

-

10

-

Page 15

4-9

GOVERNOR

SYSTEM

The governor is a centrifugal flyweight type which

ensures constant operation

at

the selected speed

against load variations.

The governor gear

with

governor weights is

in-

stalled

on

the main bearing cover. (See Fig.

4-9.)

/

GOVERNOR GEAR

Fig.

4-9

4-10

COOLING

SYSTEM

The large fins on the flywheel provide sufficient cooling air capacity for the inlet

and

exhaust area and

cylinder.

The cylinder baffle helps the cooling air

flow

efficiently.

4-1

1

LUBRICATION

All the rotating and sliding parts are splashlubricated

by

the

oil

scraper

on

the connecting rod.

(See Fig.

4-10.)

I

OIL

SCRAPER

Fig.

4-10

-

11

-

Page 16

4-12

IGNITION

SYSTEM

The ignition system

magneto ignition system which cosists

wheel

and

an

ignition coil with a built

is

a

transistor controlled

of

sistor.

This system has an ignition timing advance

easy starting. (See Fig.

4-13

The

carburetor that

and

The carburetors

starting,

and sufficient

For

CARBURETOR

engines are equipped with

has

a

fixed main

jcl.

are

good

acceleration,

output.

datails,

see

page

“CAKBUKE‘I’OR”.

4-1

1.)

a

horizontal draft

a float controlled fuel system

calibrated carefully

low

fuel consumption

47,

(SCC

section

Fig.

8.

4-12.)

in

for

a

tran-

easy

fly-

for

Fig.

4-

1

I

4-14

‘I’hc

AIR

CLEANER

air

clcancr is a single urcthine foam element system.

elemcnI type is available. (See Fig.

__

..

Single element type

Fig.

4-

”

13-1

~.~

~

4-13-1

and

4-13-2.)

-

12

As

-

an

option,

heavy duty type with a double

Double element type

Fig.

4-

COVER

/”

13-2

Page 17

4-15

SECTIONAL

VIEW

OF

ENGINE

/

FLYWHEEL

FUEL

TANK

/

I

II

+

.

PISTON

I

MAIN BEARING COVER

-

13

-

Page 18

ROCKER

I

ARM

L

-

14

-

Page 19

5.

5-1

CAUTIONS

1)

Because some mating parts with wear surfaces were machined together when the engine was

manifactured,

critical to the performance and life expectancy

THAT THEY WILL

2)

Crankshaft and camshaft bearings should be cleaned

to be damaged

that rotate roughly

3)

Keep clean and handle carefully the disassembled parts, Clean them thoroughly with washing oil

before the reassembly.

4)

Use correct tools

The use

5-2

SPECIAL TOOLS

of

or

have established wear patterns during operation, the reassembly

of

the engine.

BE

DISASSEMBLED AND INSTALLED IN THEIR ORIGINAL

and

or

excessively worn. Remove bearings that are pitted, nicked, burred, discolored,

or

noisily.

in

the proper way

MARK AND SORT ALL PARTS

inspected, and removed only

non-specified tools could cause permanent damage to the engine

of

or

components.

engine parts,

POSITIONS.

if

is

SO

they appear

or

Tool

No.

209 - 95004

Market parts

FLYWHEEL

-

07

PULLER

Flywheel puller

Flywheel puller

Tool

with

bolt

For

pulling

For pulling

FLYWHEEL PULLER

Use

off

the flywheel Eli1

off

the flywheel EH12

7,

EH25

-

15

-

Page 20

5-3

DISASSEMBLY

PROCEDURES

Step

I

Oil

to

remove

drain

(I)

Remove

(2)

‘To

gauge.

Procedures Part

oil

drain

discharge

plug

and

oil

quickly, remove

drain

oil.

oil

Be

careful

gasket.

Remarks

not

to

lose

the

14mm

Tool

box

wrench

Fig.

5-2

-

16

GASKET

I

DRAIN

PLUG

-

Page 21

step

Part

to

remove

Procedures

Remarks

Tool

2

Fuel tank

(1)

Close fuel valve.

(2)

Disconnect fuel hose between fuel strainer

and carburetor.

(3)

Remove fuel tank

M6X14rnm

M8X20mm

bolt

bolt

from

cylinder head.

....

4pcs.

.-..

4pcs.

(EH12,17)

(EH25)

Wipe off

spilt

thoroughly.

fuel

M6

ME

BOLT

BOLT

lOrnrn

socket wrench

:

4

pcs.(EH12,17)

:

4

pcs.(EH25)

(1

2mm)

FUEL

HOSE

-

17-

Page 22

I

Step

3

4

I

Part

Blower

housing

to

remove

1

(I)

(I

Remove recoil from blower housing. Recoil starter

M6

X8mm

)

Remove

M6X

flange

blower

I2mm

Procedures

bolt

-.a-

4pcs.

housing from crankcase.

flange

bolt

-e

-.

4pcs.

~~

I

Remarks

lOmm

lOmm

Tool

box

box

wrench

wrench

5

Oil

scnsor

(Option)

(1)

Remove

to

sensitive

result.

oil

sensor probe. Be careful not

damage stick and sensor since these are

and

an

erratic operation may

Fig.

5-4

-

18-

Page 23

Step

6

-

7

'art

to removc

Muffler cover

Muffler and

Muffler

bracket

Exhaust

manifold and

Manifold

cover

Procedures

(1)

Remove muffler cover.

M5x lOmm flange

bolt

....

3pcs.

(EH12,17)

M5 X lOmm flange

bolt

-

-

4pcs. (EH25)

(2)

Remove muffler from exhaust manifold.

M8 flange nut

-.

-

-

2pcs.

(3)

Remove muffler bracket from crankcase.

M6X 12mmflangebolt

e...

lpc. (EH12,17)

M8X16mmflangebolt

....

lpc. (EH25)

(1) Remove manifold cover from manifold.

M6X8mm flange

bolt

. . .

.

Ipc.

M8 flange

nut

....

2pcs.

(2)

Remove manifold

from

cylinder head.

Remarks

Be careful not

to

lose

muffler gasket.

Be careful not to lose

muffler gasket.

Tool

8mm,

lOmm

and

12mm

socket wrench

IOmm, 12mm socket

wrench

-

19

-

Page 24

Step

a

Part

to

remove

Control box

and Electric

starter

(Option)

Procedures

(I

)

Disconnect wires.

1

blue

light

black

blue

(diode rectifier

I

(diode rectifier

I

(magnetic

(2) Remove black wires

(3)

Remove control box.

(4)

Loosen

two

flange bolts

electric starter.

M8

flange

bolt

)

switch)

from

electric starter.

and

2pcs.

)

remove

Remarks

Fastened together with

fuel tank.

12mm

socket wrench

Tool

M8

FLANGE

BOLT

:

2

\

pcs.

ELECTRIC

,/

STARTER

/’

Fig.

5-6

-

20

-

Page 25

Step I Part to remove

9

10

Air

cleaner

I

(1)

Remove head cover from crankcase. Head cover

M6x

12mrn flange

(1)

Remove cleaner cover, cleaner element

Procedures

bolt

-.--

Ipc.

and element retainer.

(2)

Remove cleaner case.

M6

flange

nut

-..-

2pcs.

~~~~

Fastened together

carburetor.

Remarks

with

Tool

I

Ornm

socket wrench

1

Omm

socket wrench

GASKET

CLEANER CASE

Fig. 5-7

-

21

-

Page 26

Step

-

11

12

13

14

-

I

Part

to

remove

Governor

lever,

Governor rod

and Governor

spring

Carburetor

Speed control

lever

In

take

manifold

M6

FLANGE BOLT

Procedures

(1)

Unhook governor

control lever.

(2) Remove governor lever from governor

spring

from speed

Bolt

governor lever

needs to be loosened.

shaft.

M6X30mm bolt and washer

(3)

Detach governor lever, governor rod and

rod

spring from carburetor.

I

(1)

~

Remove carburetor from intake manifold.

~~ ~ ~~ ~~~ ~

(1)

Remove

stop

plate, friction plate and

---a

Ipc.

I

speed control lever.

M6X30mmflangebolt

(I)

Remove intake manifold

head.

M6 flange

nut

.---

M6X25mmflangebolt.... lpc.

M8x28rnm

~~ ~ ~ ~~~ ~ ~ ~~~ ~

:

1

PC.

-9

bolt

--..

2pcs.

(EH12,17)

and washer

**a.

lpc.

from

(EH12,17)

~PCS.

(EH25)

cylinder

Be careful

insulator and gasket.

Remarks

and washer

not

to

on

only

lose

Tool

lOmm

socket wrench

I

I

lOmm

socket wrench

lOmm, 12mm

socket wrench

SPEED

STOP

PLATE

FRICTION

CONTROL LEVER

PLATE

./a

/“I”..

M6

FLANGE NUT

M6

FLANGE

M6

BOLT

BOLT

and

:

2

pcs(EH12.17)

:

1

WASHER

GOVERNOR

pc(EH12.17) GASKET (INSULATOR)

:

3

pcs.

(EH25)

LEVER

A

ROD

SPRING

,-\

M6

BOLT

and

WASHER

:

1

PC.

-

Fig.

22

.’1

5-8

-

Page 27

Procedures

Remarks

Tool

15

Starter pulley

16

Flywheel

I

17

1

Charge coil

(Option)

(1)

Remove starter pulley from flywheel.

Place socket wrench

nut

and strike tip of the lever

hammer. Refer

(See Fig.

14mm

18mm

M6

(1)

Remove flywheel from crankshaft.

(2) Remove key from crankshaft.

(See

(1)

Remove charge

M6

5-9.)

nut

nut

-.-.

X

14mm flange bolt

Fig.

5-1

1

X

20mm Screw 2pcs.

on

flywheel fastening

to

the illustration below.

lpc. (EH12,EH17)

lpc.

(EH25)

- -

1

pc.

.)

coil.

with

(EH2.5)

Do

not place bar

driver

Use flywheel puller as

illustrated

(See Fig.

in

loosen flywheel

5-10.>

or

flywheel

nut.

below.

screw

fin

to

19mm

(EH12,17)

24mm

(EH25)

socket wrench

~~ ~~

Flywheel

puller

Fig.

5-9

F

LYWHEEL

w

Fig.

5-1

0

Fig.

5-12

-

23

-

Page 28

Part to remove

Step

18

~~ ~ ~~

1

Ignition coil

(I)

Disconnect ignition plug cap and remove

ignition coil from crankcase.

M6

X

25rnm

Procedures

bolt

and washer

-

-

-.

2pcs.

I

Remarks

Tool

1

Omrn

socket wrench

-

19

20

Spark

plug

Breather

(I)

Remove spark plug from cylinder head.

(1

)

Remove breather cover.

M6

X

20mm flange bolt 2pcs.

(2)

Remove gasket (breather cover), breather

plate and gasket (breather plate).

iGNlTiON

M6

COIL

BOLT

and

WASHER : 2

21

rnrn

socket wrench

1

Ornrn

socket wrench

pcs.

Fig.

5-13

-

24

GASKET

M6

FLANGE

-

(BREATHER

BREATHER

BOLT

:

2

COVER)

COVER

pCS.

Page 29

Part to remove

Step

-

21

Rocker

-

22

-

Cylinder head

Procedures

(1)

Remove rocker cover from cylinder head.

M6X 12mm flange bolt 4pcs.

(2)

Remove gasket. (rocker cover)

(1)

Remove cylinder head from crankcase.

M8X65mm flange

bolt

.+..

4pcs.

(EH12,17)

MlOX75mmflange bolt.... 4pcs.

(2)

Detach cylinder

head

gasket from cylinder

head.

(3)

Remove push rods.

L

M6

/

FLANGE

BOLT

:

4

pcs.

(EH25)

I

Remarks

lOmm

Tool

socket wrench

12rnm,

14mm

socket wrench

L

-

25

-

Page 30

Step

Part

to

remove

1

Procedures

Remarks

Tool

23

Main bearing

cover

(I)

Remove main bearing cover fastening

bolts.

M6X30mm bolt

M8X

(2)

Remove

hammer.

Fig.

5-1

5

30mm

main

(See

and

bolt

and

bearing cover using plastic

Fig.

washer 8pcs.

(EHI2,17)

washer

5-15)

.--e

(EH

8pcs.

25)

Be careful not

oil

seal.

to

damage

IOmrn,

12rnrn

socket wrench

-

26

-

Page 31

Step

24

25

-

Part

to

remove

Cam shaft add

Balancer shaft

(EH25

Tappet

only)

I

I

(I)

Remove cam shaft from crankshaft.

(2)

Remove balancer shaft.

(1)

Remove tappets from crankcase.

Procedures

(EH25

only)

Remarks

To

prevent tappets from

getting damaged, put the

crankcase upside down.

(See

Fig.

5-

17.)

Put

a

tag

on

identify intake

exhaust.

tappets

and

to

Tool

-

27

-

Page 32

Step

26

27

Part

to remove

Connecting

rod

and

Piston

Piston and

riugs

.....

(1)

Remove connecting rod bolt after scraping

off

carbon from cylinder head and piston.

M6

X

34mm flange bolt

M7X37mm flange

M8X46mm flange

(2)

Remove connecting rod cap.

(3)

Remove connecting rod from upper side

Procedures

.

. . . ..

. ."

bolt

bolt

.

. . .

-

-

- -

2pcs. (EH 12)

--.-

2pcs. (EH17)

....

2pcs. (EH25)

. .

.

of crankcase after rotating crankshaft

that piston comes

(I)

Remove clips and piston pin.

(2) Remove piston

(3)

Remove piston rings from piston.

up

from

to

top dead

connecting rod. Piston

center.

so

Do

smaller end

rod.

Do

piston rings.

Remarks

not damage the.

of

connecting

not

expand

or

Tool

lOmm

socket wrench

twist

Fig.

5-1

-

9

28

-

M6

M7

M8

FLANGE

FLANGE

FLANGE

BOLT

:

BOLT

:

BOLT : 2

2 pcs. (EH12)

2 pcs. (EH17)

pcs.

(EH25)

Page 33

Step

28

Part

to

remove

Crankshaft

(I)

Remove crankshaft tapping

Fig.

flywheel

5-20

end.

at

the

Be

careful not

oil

seal.

Remarks Procedures

to

damage

Tool

CRANKSHAFT

(D

-

type)

29

fig.

5-21

-

Page 34

Step

29

to

Part

remove

Intake valve

and Exhaust

valve

Procedures

(1)

Loosen adjusting screw on

(2)

Pull

out rocker arm shaft from the intake

side

of

the cylinder head.

(See Fig.

(3)

Remove rocker arms after removing

5-22.)

~~~~

rocker

rocker shaft.

(4)

Press down spring retainer and slide it

release from the groove of valve stem,

then remove spring retainer and valve

spring

(5)

Remove intake and exhaust valve.

(See

Fig.

5-23.)

arms.

to

ROCKER

"

Remarks

Inspect valves, valve

seats and guide.

Do

not remove valve

guides unless they are

worn beyond

shown

in

page

the

57.

-

ARM

Tool

limit

SCREW

DCS.

VALVE

SPRING

SPRING

ROCKER

RETAINER

SHAFT

INTAKE

Fig.

5-24

I

VALVE

-

30

II

I\

Fig.

5-23

-

Page 35

5-4

REASSEMBLY PROCEDURES

0

PRECAUTIONS FOR REASSEMBLY

1)

Clean parts throughly before reassembly.

of

Pay most attention to cleanliness

piston, cylinder, crankshaft, connecting rod

and

2)Scrape off all carbon deposits from cylinder head, piston top and piston ring grooves.

3)Check lip of oil seals. Replace

Apply

oil

to the lip before reassembly.

the lip

is

damaged.

oil

seal

if

4)Replace all the gaskets with new ones.

5)Replace keys, pins, bolts, nuts, etc.,

nuts

6)Torque bolts and

7)Apply

oil

to rotating and sliding portions.

8)Check and adjust clearances

to specification referring to the

and

if

necessary.

“TORQUE SPECIFICATIONS”.

end plays where specified

in

this manual.

bearings.

54-1

(1)

CRANKSHAFT

Install crankshaft

on

crankcase using an oil

seal guide to avoid damage to oil seal.

(See Fig.

(2)

Install woodruff key

5-26.)

for

the

flywheel

on

shaft.

5-4-2

(1)

PISTON AND PISTON RINGS

Install the

top

ring.

Spread

the

oil

ring

ring

first, then second ring and

only

far enough to slip over the

piston and into the correct groove. Use care not

to

distort the ring. (See Fig.

5-27.)

Install the top ring and the second ring with the

punched

side. (See Fig.

mark

“N”

beside the gap

5-29.)

on

crank-

the top

Fig.

OPEN ENDS

5-26

OF

I

PISTON

RING

Fig.

5-27

-

31

-

Page 36

TOP RING

“N”

MARK

I

Fig.

5-4-3

(1)

PISTON

AND

CONNECTING

When installing the piston

rod, place

the

“MAG”

Fig.

(See

‘‘4

side

5-30.)

”

mark

of

the connecting rod.

Apply oil to the small end

rod,

piston and piston pin before installation.

Be

sure

to

use clips on the both end

to

piston pin

secure the pin

5-28

on

of

the piston crown

of

in

position.

SECOND

OIL RING

RlNC

ROD

the connecting

on

the connecting

of

the

Fig.

5-29

“MAG”

SIDE

I

”

4

”

MARK

Fig.

5-30

-

32

-

Page 37

(2)

Install the piston

and

connecting

rod

assembly

into the cylinder.

Use

a

piston ring compressor to hold the piston

rings.

Place

‘‘4

”

mark

of the piston crown on the

magneto side of

the

crankcase.(See Fig.

5-31.)

-[NOTES]

1

(1)

Apply enough oil to piston rings, connecting

rod bearings and cylinder bore before

assembly.

(2)

Set gaps

of

the

piston

rings

90

degrees apart

from each other before assembly.

(See Fig.

5-32.)

5-4-4

CONNECTING

ROD

(1)

Turn crankshaft

to

bottom

dead

center, lightly

tap

top

of

the piston

until

large end

of

the

rod

meet crankpin.

(2)

Install

the

connecting

rod

cap

to

the connecting

rod matching alignment marks. (See Fig.

5-33.)

Torque connecting rod

bolts

to

specification.

M8

X

46

mm

connecting

rod

bo1

t

....

2pcs.

CONNECTING

ROD

BOLT

TIGHTENING TORQUE

I

EH12

I

EH17

I

EH25

I

90-1

15

kg*cm

22-27 Nom

17-19.5 Nom

9-11

N-m

225-275

kgocrn

170-200 kg-cm

6.5-8.3

ft*lb

16.3-19.9

ft4b

12.3-1

4.5

ftdb

PISTON RING COMPRESSOR

CONNECTING

ROD

CRANK CASE (FLYWHEEL

SIDE)

Fig.

5-31

-SECOND

RING

\

Fig.

5-32

ALIGNMENT MARK

h

Fig.

5-33

(3)

Check

for

free movement

of

connecting

rod

by

turning crankshaft slowly.

-

33

-

Page 38

54-5 BALANCER SHAFT (EH25 type only)

Install balancer shaft aligning the timing mark on

the balancer shaft gear

and

the balancer gear

on

the crank shaft as shown

in

Fig.

5-34.

Incorrect timing

of

the gears will cause

malfunction of the engine and may

result

in

damage due to interference of the

parts.

5-4-6

TAPPET AND CAMSHAFT

(1)

Oil the tappets and install them

in

their original

position.

TIMING

MARKS

Fig.

5-34

Push

in

fully

to avoid damage during the installation

of

the camshaft.

(2)

Lubricate the bearing surfaces of camshaft.

Align the timing mark

on

the crankshaft gear

with

the timing

mark

on

the

camshaft and install the

camshaft

in

the crankcase. (See Fig.

5-36.)

Incorrect valve timing

will

cause engine's

malfunction.

5-4-7

ADJUST CRANKSHAFT AND CAMSHAFT END PLAY

(1)

Adjust end play to the specified values using the proper spacer.

The proper spacer may be determined following manner.

MAIN BEARING

COVER

A

c

t

1

A2

GASKET

f

CRANKCASE

I

Fig.

5-35

-

34

-

Page 39

5-4-7-1

(1)

(2)

(Al+

CRANKSHAFT

Measure the depth

Measure the height

END

“Al”

“BI”

(From the mating surface

(From

0.3) - Bl=SIDE CLEARANCE

PLAY

the mating

(For

(SIDE CLEARANCE) - 0.2=THICKNESS

(A+ 0.0123

-’

Bl=SIDE

CLEARANCE

SIDE CLEARANCE - 0.008”=THICKNESS

D

type and B type)

to

to

the crank gear.)

(mm)

OF

CRANKSHAFT

(in)

OF

CRANKSHAFT

the inner race of the ball bearing.)

SHIM

(mm)

SHIM (in)

5-4-7-2 CAMSHAFT

(1)

Measure the depth

(2)

Measure the weight

(A2+

0.3)

-

B=SIDE CLEARANCE

END

PLAY

“A2”

(From the mating surface

“B2”

(Model B=2:1 Reduction

(From

the

mating surface to the camgear inner

(mm)

(SIDE CLEARANCE) - 0.2=THICKNESS

(A2+ 0.012”)

-

B=SIDE

CLEARANCE

SIDE CLEARANCE - 0.008”=THICKNESS

Following are availalbe spacer shims.

EH12,

EH25

EH17

SPACER

type

type

SHIMS

CRANKSHAFT

mm

mm

mm

(0.024”)

(0.031

(0.039”)

T=0.6

T=0.8

T=l

.O

CRANKSHAFT

(in)

to

OF

CAMSHAFT

OF

CAMSHAFT

”)

type

only)

the inner race

SHIM

SHIM

CAMSHAFT

T=0.6

T=0.8

T=l.O

mm

mm

mm

CAMSHAFT

of

the camshaft bearing.)

boss.)

(mm)

(in)

(0.024”)

(0.031

”)

(0.039”)

SPACER

SHIMS

T=2.7

T=2.9

T=3.1

mm

mm

mm

(0.106”)

(0.1

14”)

(0.1

12“)

T=0.6

T=0.8

T=l

.O

mm

(0.024”)

mm

(0.031

mm

(0.039”)

”)

-

35

-

Page 40

(2)

Lubricate the

hold

the gasket

Place spacers chosen

Use

an

oil

seal

Tap

the

cover

Main bearing cover

Fig.

5-36

oil

seal and bearing surfaces. Add a

in

place.

at

procedure

(1)

on

cTankshaft and camshaft.

guide when installing the main bearing cover

into

place

Tightening torque (EH12,17 type) Tightening torque (EH25 type)

.

with

E1412,

Et4

2s

a

17

80-1

8-9.5

6-7

soft

hammer.

M6

X

30

M8

X

30

00 kgcm

Nom

ft*lb

mm

mm

bolt

and washer

bolt

1

-

light

and

I

36

film

washer

-

of

oil

to

avoid

-...

....

170-1

17-1

12.5-13.5

on

the main bearing

damaging

8

pcs.

8

pcs.

90

kgwn

8.5

Nom

ft4b

the

seal.

cover

face

to

Page 41

W

5-4-8

Attach breather plate (breather valve) and breather cover to crankcase using

Replace gaskets with new ones

Replace breather hose at least once a year

5-4-9

(1)

(2)

(3)

(4)

(5)

BREATHER VALVE

proper

if

they

are torn or damaged.

or

when ever a crack was found.

CYLINDER HEAD

Clean carbon and gum deposits from the valves, seats, ports and guides. Inspect the valves, valve

seats and valve guides.

Replace valves that are badly burned, pitted or warped.

When installing the valves in the cylinder head,

Then place the cylinder head on

Valve guides should be replaced when the valve stem clearance exceeds specifications

"SERVICE

Draw the valve guides out and press the new guides in.

Refer to"SERV1CE

After replacing the valves and guides, lap valves

of

the valve. Clean valves and wash cylinder head thoroughly.

Install cylinder head

Tighten five flange bolts evenly

Cylinder head

DATA").

DATA"for

M8 X 65

M10

X

to

cylinder with new head gasket.

mm flange bolt

75

mm flange bolt

a

flat table, install the washer, valve spring and spring retainer.

clearance specifications.

in

three steps by the following tightening torque:

oil

.----

4

....

4

pcs.

the valve stems and insert them into the valve guide.

in

place until a uniform ring

pcs.

(EH12,

17)

(EH25)

gaskets.

shows

around the face

(See

I

~~~ ~ ~~~

5-4-10

(1)

Insert push rods into crankcase.

Put push rod tip in the hollow

(2)

Apply

5-4-11

(1)

Position the piston at

obtained by placing the key

I

I

Tightening torque

rocker

I7B,

2nd

100

10

7.2

25D

1

st

step

50 kgcm

5

Nom

3.6

fblb

ROCKER ARMS AND PUSH RODS

oil

to the

VALVE CLEARANCE ADJUSTMENT

12

o'clock

EH

I2B,

(EH12,

step

kgcm

Nom

ft*lb

arms and assemble them to the cylinder head

the

EH17

type)

of

tappet top.

top dead center

slot

on

the power take

I

I

I

1st step

of

the compression stroke.

of€

shaft to

10

o'clock

EH25B

Tightening torque

:

I

using

2nd

The

(EH25

step

the

rocker

top dead center may be

EH

I

I2D,

type)

final

shaft

17D

step

and

spacer.

I

I

!

_I

(J

I

i

I

1.-

Fig.

5-37

-

37

-

Page 42

(2)

Loosen the lock nut on the

the rocker arm and the valve stem end.

Tighten the lock

I

[NOTE]

Valve clearance

0.085-0.1 15 rnm

nut.

rocker

I

arm and turn the adjusting screw

(See

Fig.

5-38.)

I

to

adjust the clearance between

Check and adjust valve clearance with engine

Check operation

Remeasure tappet clearance.

(3)

Install rocker cover and gasket.

Rocker cover

5-4-12

Install spark

Spark

SPARK

plug

:

EH12

EH17,25:

New

spark plug

120-1

1

1.8-14.7 Nom

plug

50

of.

valves

M6

X

12

PLUG

to

the cylinder head.

:

NGK

NGK

kg*cm

B6ES

B6HS

Tightening toque

by

turning crankshaft

mm

bolt

- - - -

4

pcs.

/CHAMPION N5C

/CHAMPION

Retightening

230-270

22.6-26.5

L86C

kgcm

N-m

coid.

.

8.7-10.9

5-4-13

(I)

(2)

INTAKE AND

Install the intake manifold

EH12,

I%25

1

00-1

Install

Tighten

ft*lb

17

M6

flange

M6

X

M8

X

40

kg-cm

the

exhaust manifold

two

flange nuts.

16.6-1 9.5

EXHAUST

nut

25mm flange bolt

28mm

bolt and

MANIFOLD

to

the cylinder head with gasket.

..................

Tightening toque

9.8-1 3.7 N*m

to

the

ft*lb

..

----...--

washer

cylinder head with gasket.

-

-

- -

2

1

3

pcs.

PC.

pcs.

I

-

38

7.2-1

-

0.1

ft*lb

Page 43

5-4-14

(1)

-

FLYWHEEL

Install the charge coil

[NOTE)

MAGNETO

to

the crankcase. (Option)

B

Be careful not to pinch

coil

and crankcase.

(2)

Put the woodruff key

shaft.

off

Wipe

tapered portion

wheel center hole.

(3)

Install

Tighten the flywheel

pulley. (See

oil and degrease thoroughly from the

the

flywheel

Fig.

coil

wire between charge

in

the key way of crank-

of

the crankshaft and the

to

crankshaft.

nut

5-39.)

I

I

5-4-15 IGNITION COIL

Install

Adjust

the flywheel using

and tighten the bolts. (See Fig.

600-650

the

the air gap between

kg*cm

ignition coil to the crankcase.

the

a

thickness gauge (filler gauge)

with

Tightening toque

ignition coil and

5-40.)

the starter

59-63

Nom

fly-

43-47

ft*lb

Fig.

5-39

I

5-4-16 INTAKE

Install the intake manifold. Tighten

and

M6

28

mm

Then put the gasket and the insulator on the manifold.

5-4-17 CARBURETOR

Install the gasket and the carburetor to the manifold.

54-18

(1)

Connect the governor lever

lever

Install the

shaft. (See

(2)

Install the speed control lever to the cylinder

head.

Air

gap

0.3-0.5

0.012-0.020

X

bolt and washer for

GOVERNOR

on

mm

in.

MANIFOLD,

25mm flange

SYSTEM

carburetor.

governor

Fig.

5-41.)

nut

lever

I

INSULATOR

for

EH12,17,3-

EH25.

and

on

2-

M6

M8

the throttle

the governor

nuts

X

Fig.

5-40

GOVERNOR LEVER

Fig.

5-4

1

-

39

-

Page 44

(3)

Connect the speed control lever and the governor lever with the governor spring. The governor spring

should be hooked to the number

2

hole

on

the speed control lever for the regular specifications.

Refer to the illustrations below. (See Fig.

5-42.)

valve

in

the carburetor

is

at the wide

open

position.

(See Fig.

5-43.)

(4)

Turn

the speed control lever all the way toward the high speed position and make sure that the throttle

(5)

Turn

the

governor shaft clockwise all the way

using

a screw driver, and tighten

the

lock bolt and nut.

P\

For

the generator applications, there are

two

different governor

springs

existing according

to

the speed

setting of

the

engine. The governor springs may be distingnished by the following table.

The governor

spring

employed

on

the

6OHz

application

is

same

as

the

one

from the standard specifi-

cations.

SPEED CONTROL LEVER

GOVERNOR SPRING

\\

f-

GOVERNOR LEVER

Fig.

5-42

Fig.

5-43

Et

50

Hz

(3000

rpm)

Q

12.5

N

9.1 (0.35")

D

49 (1.9")

Color

Gold

N ; SPRING WOUND

12

EH25

EH17

60

Hz

(3600

rprn)

(3000

rprn)

(3600

rpm)

(3000

rpm)

(3600

rpm)

60

Hz

50

HZ

60

Hz

50

HZ

t

t

43

(1.7")

t

38

(1

5")

8.1

(0.32")

c

8.7 (0.34")

9.6

(0.38")

10.7 (0.42")

t

Silver

Gold

Silver

Gold

Silver

16.5 19.5

t

8.5

P

-

40

-

Page 45

5-4-19

Then install the element retainer,

rn

5-4-20

AIR CLEANER

Install the air cleaner gasket and the cleaner case and tighten them with

the

EXHAUST MANIFOLD AND COVER

Install the exhaust manifold and

M6 X 8mm

M8

flange

5-4-21 HEAD COVER

Install the head cover

M6

X

12mm flange bolt

flange bolt

nut

.....f.-.-----

to

...

-

the cylinder head.

---

1

2

-

element and

the

cover.

PC.

pcs.

1

PC.

the

cleaner cover.

2-M6

flange nuts.

@

5-4-22

Install the muffler to the exhaust manifolde

M8

I

Then install the muffler bracket.

M6 X 12mm

M8 X 16mm

Install the muffler cover

M5

M6

5-4-23

Install the blower housing and the recoil. Insert the high tension cord

of

MUFFLER AND MUFFLER COVER

flange nut

Tightening

22.5-26.5

X

lOmm

X

lOmm flange bolt

BLOWER

the blower housing

.---

230-270

16.6-1

9.5

----

---

screw

2

pcs.

torque

kg-crn

Narn

ft*lb

1

PC.

(EH12,

-

1

PC.

(EH25)

*..-..--.

HOUSING, RECOIL

so

that

....

not

3

4

I

17)

pcs.

(EW12,

pcs.

(EH25)

to pintch the cord.

17)

from

the

ignition

coil

into

the notch

5-4-24 FUEL TANK

Install

-

M6

M8

End-

the

fuel tank. Connect the

X

14mm

X

16mm bolt

of

bolt and washer

and

the reassembly

washer

-

fuel

strainer and

---.

1

.--.

1

PC.

PC.

the

fuel

inlet

on

carburetor with the

-

41

-

fuel

hose.

Page 46

5-5

BREAK-IN OPERATION

An

engine that has been completely overhauled by being fitted with a new piston, rings,

connecting rod should be throughly

Good bearing surfaces and

running

RUN-

operating the engine under reduced speed and loads for a short period

While the engine

is

being tested, check

IN

before being put back into service.

clearances between the various parts can only be established by

of

time.

for

oil

leaks.

Make final carburetor adjustment and regulate the engine operating speed.

valves

and

/“

Steps

Step 1

Step

2

3

Step

4

Step

5

6.

IGNITION SYSTEM

6-1

TYPE

OF

IGNITION SYSTEM

EH12

EH17

EH25

EH12

EH17

EH25

Load

No

load

No

load

No

load Step

1.4

2.0

3.2

2.8

4.0

6.4

Engine

2500

3000 rpm

3600

3600 rpm

3600 rpm

speed

rpm

rpm

Time

10

rnin

10

min

10

min

30

min

60

min

EH

12

employs the

El417 and

As

optional parts, these ignition system

6-2

‘1’0

ensure the easy startability

E325

BASIC

THEORY

the ignition coil.

U.

T.

have the

‘I’his

C.

I.

T.

I.

system enables the engine

(Universal type Transistor Controlled

C.

(Transistor Controlled Ignition) pointless ignition system.

may

be implemented with lamp coil, charge coil and excitor

of

the engine, the step advancing ignition timing system

to

have basically two different ignition timings

Ignition) pointless

according to the engine spced. Following are the explanation how the system works.

1)

At

lower speed

Kotation

of

power transister,

As

thc cnginc reaches thc ignition timing, the ignition timing control circuit

is activated and lcts the current

‘l’his gcncrates the collcctor current

I?

because the powcr transistor

‘I’his sudden current change generates

of

the engine

the

flywheel induces current

it

is

activated and the current

I,,

as

this

current flows through the base terminal

Lz

starts flowing.

I,:

flow through the base terminal

I,

is

turned

which

will

off.

a

big voltage

bypass the current

on

of

the power transistor.

I,

and abruptly

the secondary side

for

which sparks thc spark plug.

-

42

-

.ion

ignii

system.

coil.

is

incorporated

of

the lower engine speed

shut

off

the current

of

the ignition coil and

in

the

/”--

Page 47

2)

At the higher engine speed

of

Rotation

power transistor,

As

the engine reaches the ignition timing, the ignition timing control circuit

speed

coIlector current

power transistor

the flywheel generates the current

it

is

activated and the current

is

activated and provides the base current

16

and

will

is

turned

bypass

off.

the

I,

IZ

current

as

this current

starts

of

flow.

Is

to the power transistor. This current induces the

I,

to shut down the current

flows

This sudden current change generates a big voltage on the secondary side

which

The ignition timing control circuit

circuit €or the lower speed and

will

spark the spark plug.

for

the higher engine speed is activated

not

activated when the engine speed is

through the base terminal

for

the higher engine

Ir

abruptly because the

of

the ignition coil

in

a

lower range.

sooner

than

the control

of

the

and

(B.T.D.C.)

15'1

-

43

-

ELECTRONIC ADVANCING

MAGNETO SYSTEM

L

STEP

,

500

,

1000

ENGINE REVOLUTION

FLYWHEEL

ADVANCING

,

2000

Fig.

6-2

,

3000(r.p.m.)

(b)

Page 48

6-3

WIRING

DIAGRAM

STANDARD

r=+

TfT

ElNGlNE

WITH

Spark

Plug

ELECTRIC STARTER

Ignition Coil

-

Flywheel

1

Stop Button

Connector

w

3

_1

m

I

""""""""-

I

MAGNETIC SWITCH

L"""

-

U

DIODE

RECTIFIER

Fig.

6-3

-

44

KEY

SWITCH

-1

-

I

I

12VOLT

BATTERY

MINIMUM

AMP.HR.

24

Page 49

7.

AUTOMATIC

DECOMPRESSION SYSTEM

EH12,

17,

25

engines are employing the automatic decompression system as a standard feature.

The automatic decompression system releases the compression of the engine

by

lifting up the exhaust

valve at the cranking. Following are the explanation using type

“D”

engine

as

a sample how the system

works. The components

of

the

systems are different for the type

“D”

and type

“B”

engines, however, the

principle

of

the function

is

same.

’

This enables easy and

light

start

of

the engine.

At the

end

of

the

compression process,

the

release

lever

lifts

up

the tappet which

in

turns

opens up the

exhaust valve

slightly

to release the compression. The release lever

has

a flyweght

on

its

end and another

end

of

the

lever

is

a crescent cam.

When the engine

is

cranked, the crescent cam projects the camshaft cam profile and

lifts

up the tappet

because the gravity force

on

the weight

is

larger than the centrifugal force on the weight.

CRESCENT

EXHAUST

LEVER

‘7

CAMSHAFT

Fig.

7-1

When the

crank

speed reaches

up

to a certain revolution, the crescent cam

is

retracted into the camshaft

cam

profile because the centrifugal force applied onto the flyweight becomes larger than the

gravity

force

and

the weight and

is

shifted to the position shown

in

the illustration.

FLYWEIGHT

LEVER

Fig.

7-2

-

45

-

Page 50

8.

CARBURETOR

8-1

OPERATION AND CONSTRUCTION

8-1

-1

FLOAT

The float chamber

body

and, with a float

a

constant

Fig.

(See

SYSTEM

is

located below the carburetor

and

a needle

fuel

level during the engine operation.

8-1.)

valve,

maintains

The fuel flows from the fuel tank into the float

chamber through the needle valve.

When

the fuel

rises to a specific level, the float rises, and when its

buoyancy and fuel pressure are balanced, the needle

valve

shuts

off

the fuel, thereby keeping the fuel at

the predetermined level.

/"

PILOT

OUTLET

\

BY-

PASS,,

I

I

!

-

- - -

MAIN

AIR

-a=-

JET

-

-

AIR

INTAKE

-

46

-

Page 51

0

8-1

-2 PILOT SYSTEM

The pilot system feeds the

The fuel

by the pilot air jet.

The fuel-air mixture

At the idling speed, the fuel

is

fed through

the

is

fed to the engine through the pilot outlet and the by-pass.

fuel

to

the engine during idling and low-speed operation.

main jet

is

mainly fed from the pilot outlet.

to

the pilot jet, where

it

is

metered,

and

mixed

with

the air metered

8-1-3

The main system feeds the fuel to the engine at medium-and high-speed operation.

The fuel

mixed with the fuel through the bleed holes

main bore, It is mixed again with the air taken through the

which

8-1-4 CHOKE

The choke may be used

choke, the negative pressure applied to the main nozzle increases and

starting up the engine more easily.

8-2 DISASSEMBLY AND REASSEMBLY

Apart from mechanical failures, most of carburetor troubles are caused by

which may arise mainly due to a clogged up air

assure

disassembly and reassembly procedures are

8-2-1 THROTTLE

(1)

(2)

*

MAIN

is

proper flow

Remove the philips screw

(2),

The spring

throttle stop screw

Be

careful not to damage the throttle valve

SYSTEM

is

metered by the main jet and fed to the

supplied to the engine.

for

easy start when engine

of

air and fuel, the carburetor

SYSTEM

(1)

and throttle valve

and pull out the throttle shaft

(4)

can be taken out by removing the

(5).

(3).

main

in

the main nozzle, and the mixture

or

fuel passage

as

follows : (See Fig.

rim.

nozzle. The air metered by the main air jet

air

cleaner into an optimum fuel-air mixture,

is

cold. When the engine is cranked with

in

jets,

must

be

kept clean at

8-3.)

draws

or

more fuel accordingly

an

fuel level variations.

all

is

atomized out of the

a

closed

incorrect

times. The carburetor

mixing

In

order to

is

this

ratio,

8-2-2

(1)

(2)

8-2-3 PILOT SYSTEM

(1)

(2)

CHOKE

Remove the philips screw

(7),

and pull out the choke

When reassembling the choke shaft, make

that the cutout

air jet.

Meanwhile, when reassembling

and

(10)

Remove the pilot jet

avoid damage

Reassembly

Tighten the pilot jet securely. Otherwise, the fuel

may leak, causing engine malfunction.

SYSTEM

shaft

in

the choke valve faces the

at the right position.

it.

(ll),

to

(6)

using proper

and

(8).

set

choke valve

main

the rings

tools

-

47

sure

(9)

to

-

14

16

15

A

17

19

21

--@

13

.-e

18

12

Fig.

8-3

Page 52

8-2-4

(1)

(2) From the body

(3)

MAIN

SYSTEM

Remove the bolt(l2)and take out float chamber body(l3).

(14)

remove the

(17) from the main nozzle

(15).

main

nozzle

(15),

and then remove the main jet

Reassembly

a) Fasten the main jet securely to the body. Otherwise, the

fuel

malfunction.

b)The bolt tightening torque is 70kg-cm. Be sure to set the gasket

(1

3)-

(16)

and guide holder

may become too rich and cause engine

(19)

and washer

(18)

for

chamber

c,

8-2-5

(1)

FLOAT SYSTEM

Pull out the float pin

(20)

and remove the float.(21) and then remove the. clip

(22)

and needle valve

(23).

If

the needle valve needs to be replaced, replace

When

Never use

fuel

(2)

cleaning

flow.

a

the

jets,

be

sure to use compressed air

drill

or a wire because of possible damage of the orifice which will considerably affect

When removing the needle valve and float, gently tap the reverse side using the rod more slender

than the float pin and remove, since the float pin

it

with rubber needle.

to

blow

them clean.

is

calked to the carburetor body.

-

48

-

Page 53

9.

STARTING

SYSTEM

9-1

RECOIL STARTER

When repairing recoil starter, disassemble and reassemble

in

the following procedures.

Tools

:

Socket wrench, Needle nose pliers, Screw driver

[NOTE]

The following explanation

is

applicable to the recoil starter for"D" type engines.

For"B" type models, reverse the direction

of

rotation to achieve proper service work.

9-1-1

HOW TO

DISASSEMBLE

(D

Type)

(1)

Remove recoil starter

from

engine.

(2)

Pull starter knob and pull out starter rope

for

30-

40cm to line

up

notch

on reel with outlet

hole

for

starter rope.

Hold reel with thumb and pull starter rope

inside the starter case with screw driver.

(See Fig.

9-1.)

Rewind reel clockwise

until

the

rotation stops.

When rewinding the reel, control the rotation

by

holding starter rope using the notch

on

the

reel and pressing the reel with thumb.

(3)

Remove parts

in

the following order.

1.

Center

screw

2.

Friction plate

3.

Friction spring

4.

Ratchet

5.

Ratchet spring

Fig.

9-1

3d

Fig.

9-2

-

49

-

Page 54

(4)

Remove the

reel

from

the starter case as shown

in

Fig.

9-3.

Take out the reel slowly turning

it

lightly

towards the left

and

right to remove spring

from the hook.

Do

not

remove the reel quickly

or

the spring may escape

from

the starter case.

Untie the starter rope from the knob

and

remove.

9-1-2

HOW

TO

REASSEMBLE

(D

Type)

(1)

Put

the

starter

rope

through the starter knob

and

tie

it

as

shown

in

Fig.

9-4.

(‘Tie the

rope

tightly

for

the safety sake.)

Put

the opposite side

of

the rope through the

starter case

and

reel. Tie

it

in

the same way

as

the

starter knob end and

put

the knot

in

the reel

complely.

(2)

Check

that

the spring

is

securely

set

in

the reel.

Adjust the position

of

inner end of the spring

so

it

hooks

on

hook

in

the starter case securely.

The shape

of

starter spring inner end

may

be

adjusted

with

a

plier

if

necessary.

STARTERCASE

Fig.

9-3

Fig.

9-4

/

OUTER

END

OF

SPRING

SPRING

/

..

‘

BEARING REEL

INNER END

OF

SPRING

Fig.

9-5

KEEPER

-

50

-

Page 55

(3)

Prior to installing the reel

in

the starter case,

wind the starter rope

in

the reel for

2.5

turns

in

the arrowhead direction

as

shown

in

Fig.

9-6.

Then

let the rope

out

of the reel from the reel

notch. Line up the reel hook with the inner end

of

the spring and install the reel

in

the

starter

case.

Check that

the

inner end

of

spring

is

securely

hooked onto

the

hook.

(4)

Reassemble the parts

in

reverse order

of

disassembly.

Check that the ratchets are pushed

by

the

ratchet springs toward the center

of

the recoil.

Install the friction plate with

its

two bosses set

inside of the bent portion

of

rachets.

Apply small amount

of

lock-tight

to

the center

screw and torque it.

3.9

Nom

2.9

ft4b

(5)

Hold starter rope as shown

in

Fig.

9-8

and

turn reel 4 times

in

the arrowhead direction.

Firmly press the reel not

to

allow

reverse

turn

and pull starting knob to let starter rope out of

starter case.

Return knob slowly

to

let starter rope rewind

in

reel.

Fig.

9-6

Fig.

9-7

I

I

Fig.

9-8

Page 56

(6)

Test the operation of the recoil starter to see

and retract properly.

Mount

the recoil starter to the engine.

if

the rope recoils satisfactorily and the ratchets project

(7)

If

the

spring

onto the notch

(8)

Lubricate the rotating parts, sliding parts and spring

reassembling the recoil and prior to

escapes from the reel when disassembling the recoil, hook the outer

of

the reel and rewind the spring into the housing.

long

term storage.

with

heat resistant grease

end

of

the spring

or

mobile oil when

-

-

52

-

Page 57

IO.

TROUBLESHOOTING

The following three condit.ionts must be fulflled

1.

The cylinder filled with a proper fuel-air mixture.

2.

Good compression

3.

Good spark, properly timed,

The engine cannot be started unless these three conditions are met. There are also other factors

make engine start difficult, e.

high back pressure due to a

most

The

10-1

10-1-1

(1)

No

(2)

The carburetor

(3)

Water, dust

(4)

lnferior grade gasoline

mixture.

(5)

The carburetor needle valve

out of the carburetor when the engine is idling. (Overflow)

This

the like.

(6)

If

fuel-air mixture too

few

the choke valve open during

start again.

common

STARTING

FUEL

gasoline in

SYSTEM

or

trouble may be remedied by lightly tapping the float chamber with the grip of a screwdriver

the carburetor overflows, excessive fuel

turns

in

order to

in

the cylinder.

to

ignite the mixture.

g.,

a

heavy load on the engine when

long

exhaust pipe.

causes

DIFFICULTIES

the

is

gum

of

engine troubles are given below

fuel

tank ; or

not choked sufficiently especially when

in

the gasoline iterfering the fuel flow to the carburetor.

or

rich

to

let

the rich fuel-air mixture

the

fuel

poor quality gasoline not vaporized enough to produce the correct fuel-air

is

held

open

burn.

If

this

this

operation.

for

satisfactory engine start.

it

is

about to

:

cock closed.

the

engine

by

dirt

or

gum. This trouble can be detected as the fuel

runs

into

the

cylinder when starting the engine, making the

happens, remove the spark plug, and

out

of

the spark plug hole into the atmosphere. Keep

Dry

the spark plug well, screw

is

cold.

start

turn

it

into place, and

which

at

low speed, and a

flows

or

the starting pulley a

try

to

10-1-2

If

starting difficultes

must be checked for possible lack

COMPRESSION

Engine inside

Loose

in

Damaged head gasket

stroke.

Incorrect Valve clearance

If

check further as follows

a)

b)If

or

compression stroke during cranking.

the correct compression

Valve stuck open due

the piston rings

Clean

broken

oy

replace

is

completely dried up because of

SYSTEM

and

loss

spark plug.

or

loose cylinder head. A similar hissing noise is produced during compression

: