Page 1

SERVICE

MAIINJAL

Model

EC12

OIL MIX & OIL INJECTION ENGINES

puB-Esl173

Rev. 8/98

Page 2

CONTENTS

Section

Title

Page

1

.

2

.

3

.

4

.

5

.

6

.

7

.

8

.

9

.

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-1

0

4-1

1

Page 3

Page 4

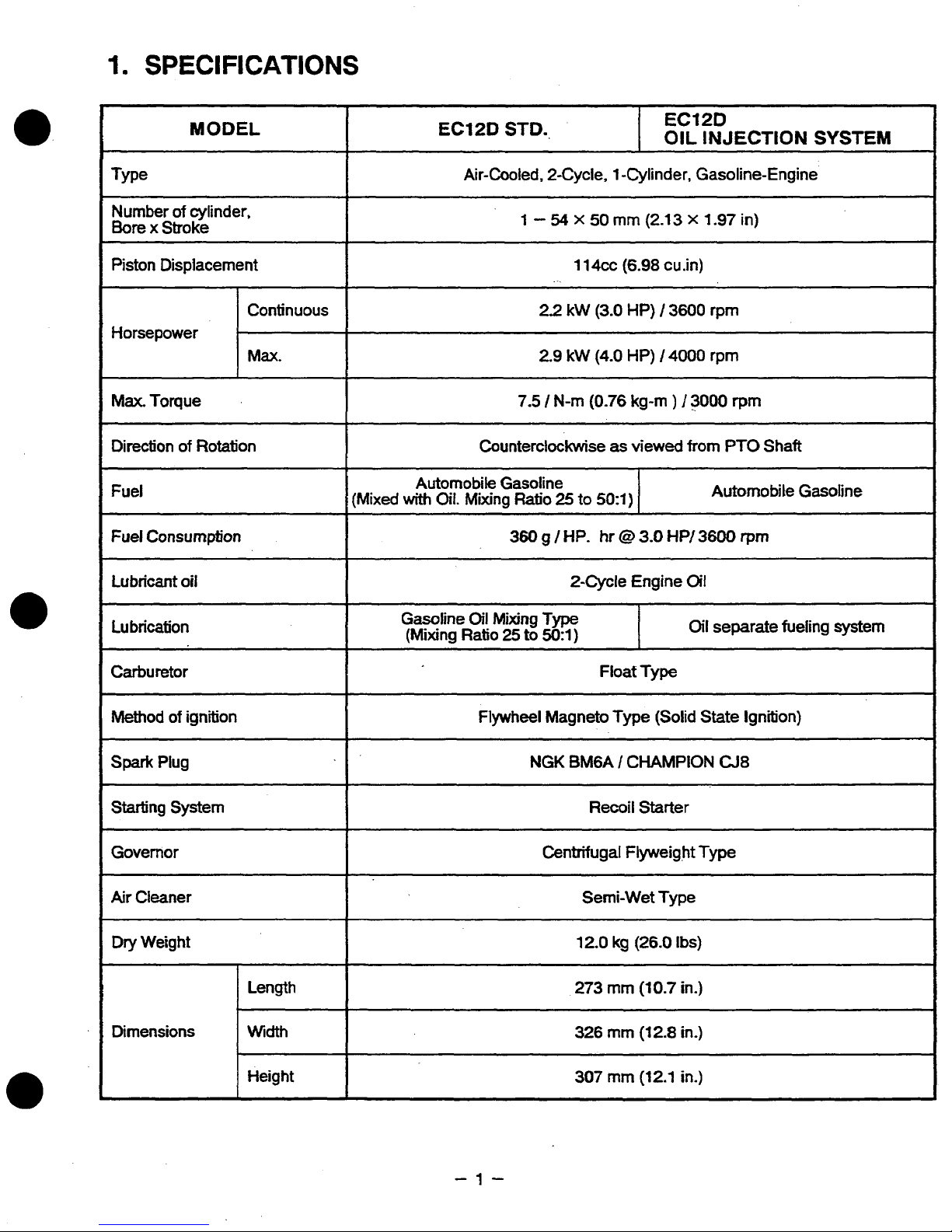

MODEL

ECIPD

STD.,

EC12D

1

OIL

INJECTION SYSTEM

Type

of

Number

Bore

Piston Displacement

Horsepower

Max.

Direction

Fuel

Fuel

Lubricant

Lubrication

cylinder,

x

Stroke

Toque

of

Rotation

Consumption

oil

Continuous

(Mixed

Air-Cooled, 2-Cycle, 1 -Cylinder, Gasoline-Engine

1

7.5

Counterclockwise

Automobile Gasoline

with

Oil.

Mixing

Ratio

360

Gasoline

(Mixing

Oil

Mixing Type

Ratio

25

to

-

54

x

50

1

14cc

.

-.

22

kW

(3.0

2.9 kW

I

g

50:l)

(4.0

N-rn

(0.76

25

to

50:l)

/

HP.

hr

2-Cycle Engine

mrn

(2.13 x 1.97

(6.98

HP)

HP)

kg-m

as

viewed

I

I

0

3.0

I

cu.in)

/

3600

I4000

)

I3000

from

HP/

3600

Oil

O~I

in)

rpm

rpm

rprn

PTO

Shaft

Automobile Gasoline

rprn

separate fueling system

Carburetor

Method

spark

Starting System

Governor

Air

Dry Weight

Dimensions Width

of

Plug

Cleaner

ignition

Length

Height

Float Type

Flywheel Magneto

NGK

BMGA I CHAMPION

~ ~ ~

Recoil Starter

12.0

273

326

307

Type

kg

mrn

rnrn

rnm

(Solid State Ignition)

CJ8

(26.0

Ibs)

(10.7

in.)

(12.8

in.)

(12.1

in.)

-1-

Page 5

2.

2-1

MAXIMUM

OUTPUT

The maximum output

is

the output

of

an engine with its throttle valve fully opened under the condition

that all the moving parts are properly

worn

in after the initial break-in period.

A

new engine may not produce full maximum output while its moving parts are still

not

broken-in.

2-2

CONTINUOUS

RATED

OUTPUT

The

continuous rated output

is

the output

of

an

engine at optimum

governed

speed which is most

favorable from the view point

of

engine’s life and fuel consumption.

When the engine

is

installed on a certain equipment, it

is

recommended. that the continuous output

required from the

engine

be

kept below this continuous rated output.

2-3

MAXIMUM

OUTPUT

The maximum torque is the torque at the output shaft

when

the engine

is

producing

maximum output at

certain revolution.

-2-

Page 6

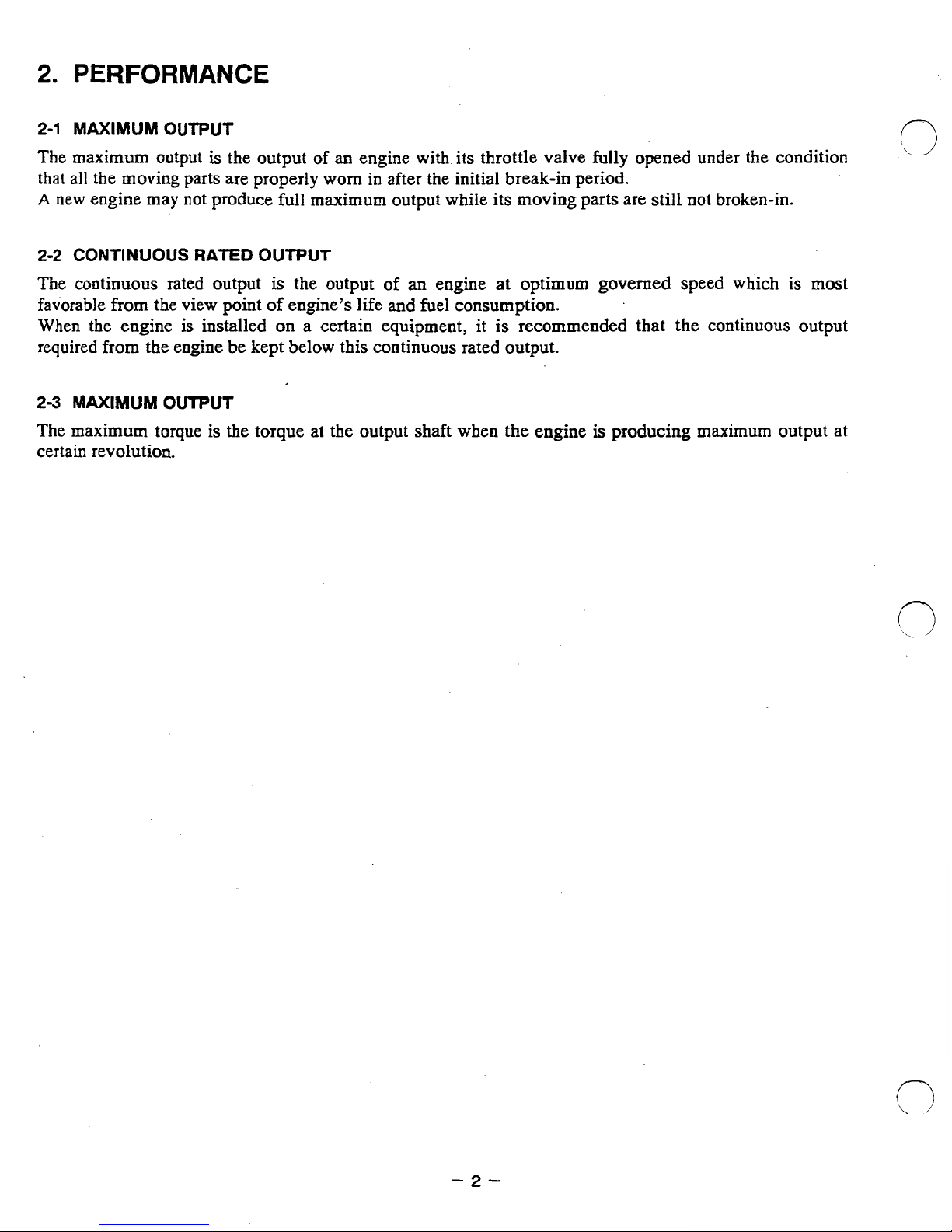

2-4

PERFORMANCE

CURVES

Nm

(kgf-m)

HP

4

3

0

kW

3

2

1

-0

2000

3000

4000

5000

REVLOUTION

-

r.p.m.

Page 7

3.

FEATURES

3-1

COMPACT,

LIGHT

WEIGHT

AND

HIGH

POWER

Compact and light weight engine thanks to

3-2

SUPERB

Rugged design on each engine components and employment

a long lasting durability even

3-3

SfMPLE

Maintenance free and

governor system.

Easy

34

SUITABLE

Robin

your equipment,

3-5

OIL

Oil

and gasoline are placed into separate tanks. Therefore, mixing the fuel/oil which

troublesome, is

Because the fuel

Since

The mixture ratio has become leaner, which will decrease white smoke during operation.

DURABILITY

STRUCTURE,

start

with decompression

FOR

EC12

INJECTION

only

engine has the identical mounting flange

gasoline

in

harsh applications.

EASY

high

REPLACEMENT ENGINE

EC12

SYSTEM

now

is

engine

done automatically

gasoline, the

is

in the carburetor, there

MAINTENANCE

vibration proof

hole

on

can

replace

(OIL

INJECTION

start

short

connecting rod and aluminum cylinder.

have

exhaust system.

EClO

by

ability

engines.

TYPE)

engine function.

of

the

engine for the reason

will

be

of

high

anti-vibration dust cover enable

been achieved

as

EClO

no

jet choking due to the deterioration

thanks

engines. Without

to the crankcase built in

can

be improved.

any

modification on

often

can

of

be

oil.

4.

GENERAL

4-1

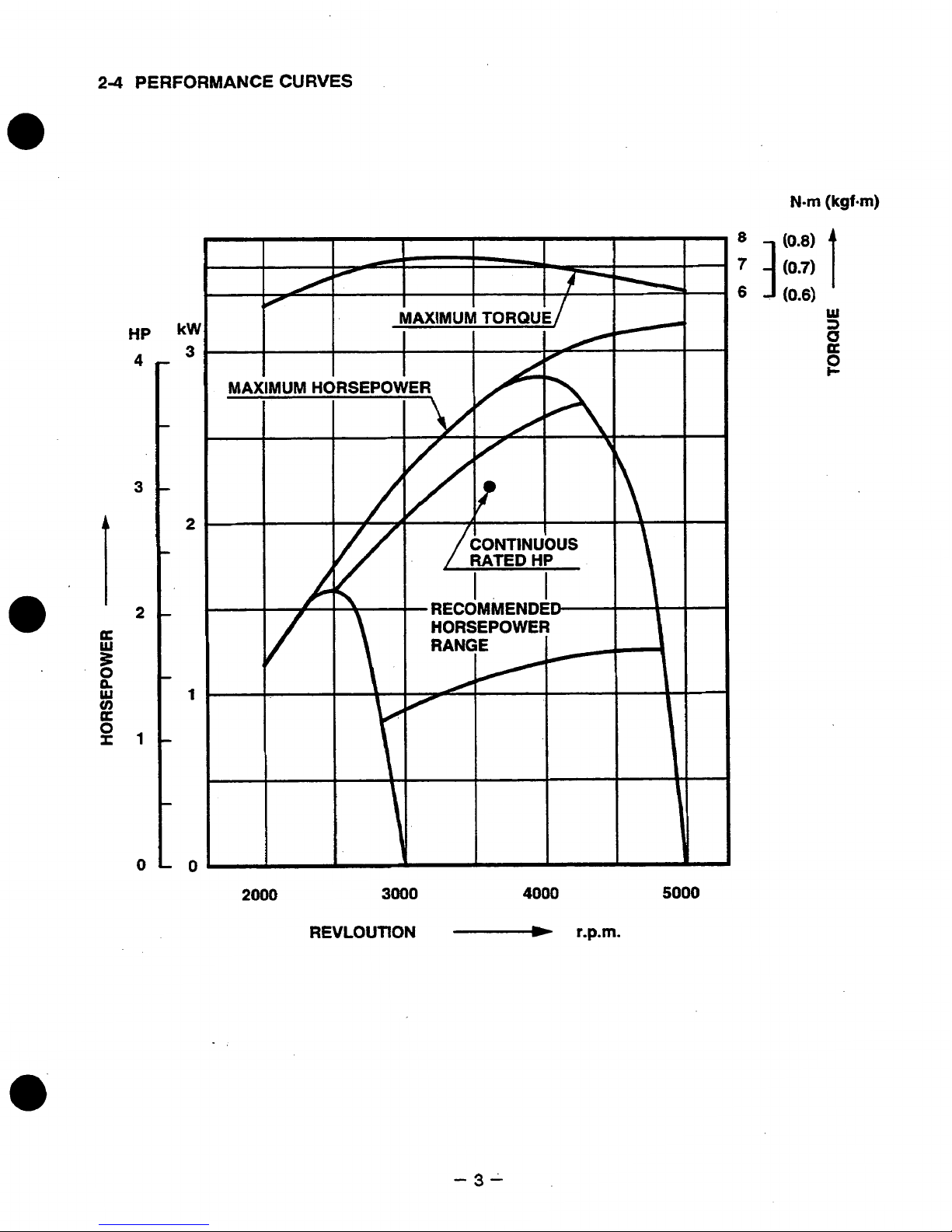

ALUMINUM CYLINDER AND CRANKCASE

Aluminum die-cast cylinder with molded-in cast

iron liner has intake, exhaust

on the liner. For easy starting, decompression hole

is implemented on the exhaust port.

Crankcase is divided into two pieces

(Flywheel

Governor chamber

gasoline-oil mixture fuel lubricates the governor

system.

side) and crankcase

DESCRIPTION

and

scavenging

:

2

(P.T.O.

is

built in

the

crankcase

OF

ports

crankcase

side).

2

and

1

ENGINE

-4-

COMPONENTS

Fig.

4-7

Page 8

4-2

CYLINDER

HEAD

Alumin’um die-cast made cylinder head has semi-

for

sphere shaped combustion chamber

optimal

combustion and higher efficiency.

49

CRANKSHAFT

AND CONNECTING

ROD

Forged steel crankshaft assembled with hardened

crank

pin

and

connecting rod, precision balanced

for low engine vibration, durability, greater shock

loading resistance

are implemented

rod.

As

these

special

jig

and

crankshaft assembly

crankshaft

or

and

longer life. Needle bearings

on

both

ends

of

the connecting

parts

are

press-fitted together

are

unable to be disassembled,

needs

to

be serviced

in

case

connecting rod need to be replaced.

by

1

Fig.

4-2

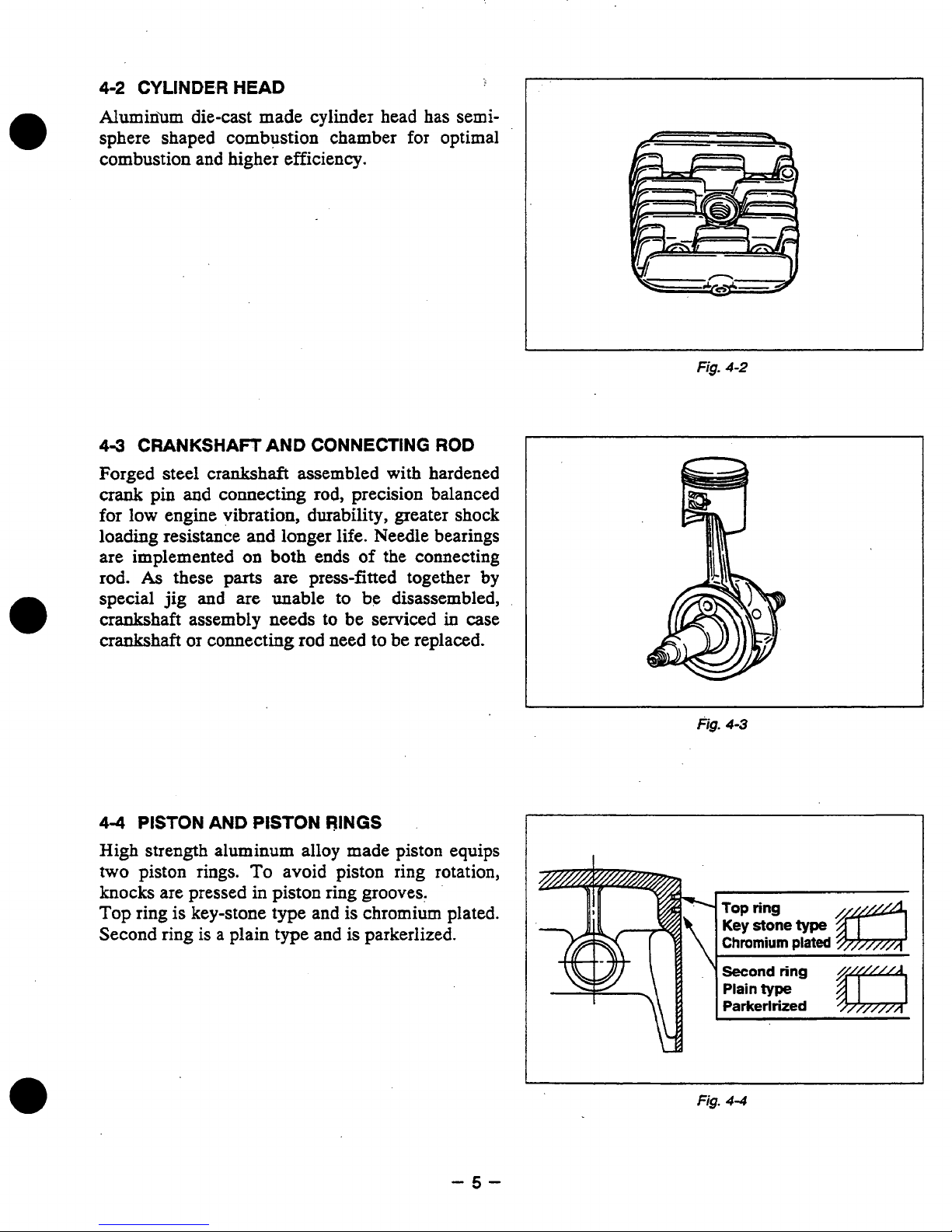

4-4

PISTON

High strength aluminum alloy made

two

piston rings.

knocks are pressed

Top

ring is key-stone type and is chromium plated.

Second ring is a plain type and

AND

PISTON

RINGS

piston

To

avoid piston ring rotation,

in

piston ring grooves.

is

parkerlized.

equips

fig.

4-3

Top

Key stone

Chromium

Plain

Parkerlrized

ring

type

plated

type

-5-

Page 9

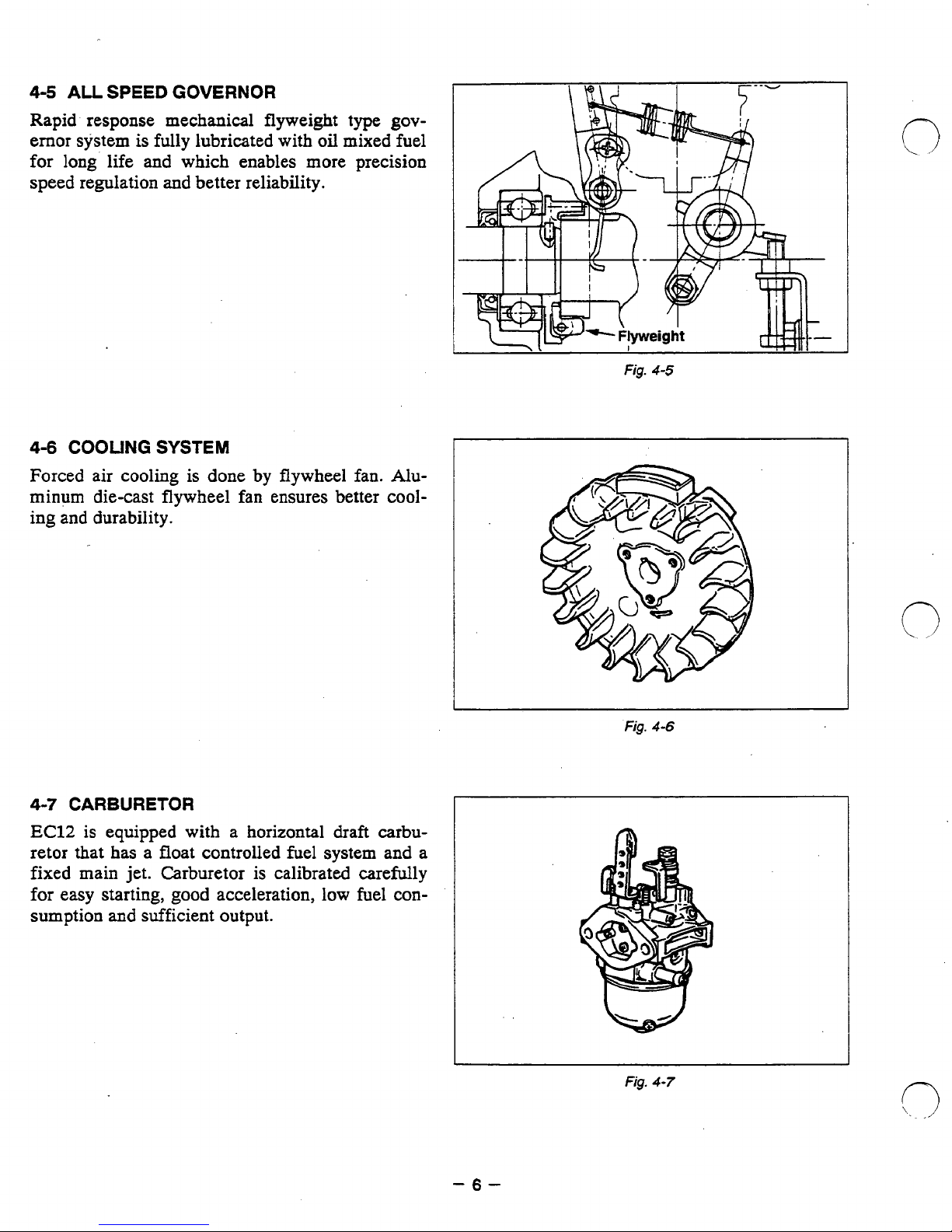

4-5

ALL

SPEED

GOVERNOR

Rapid response mechanical flyweight type

ernor system

for

long'

speed regulation

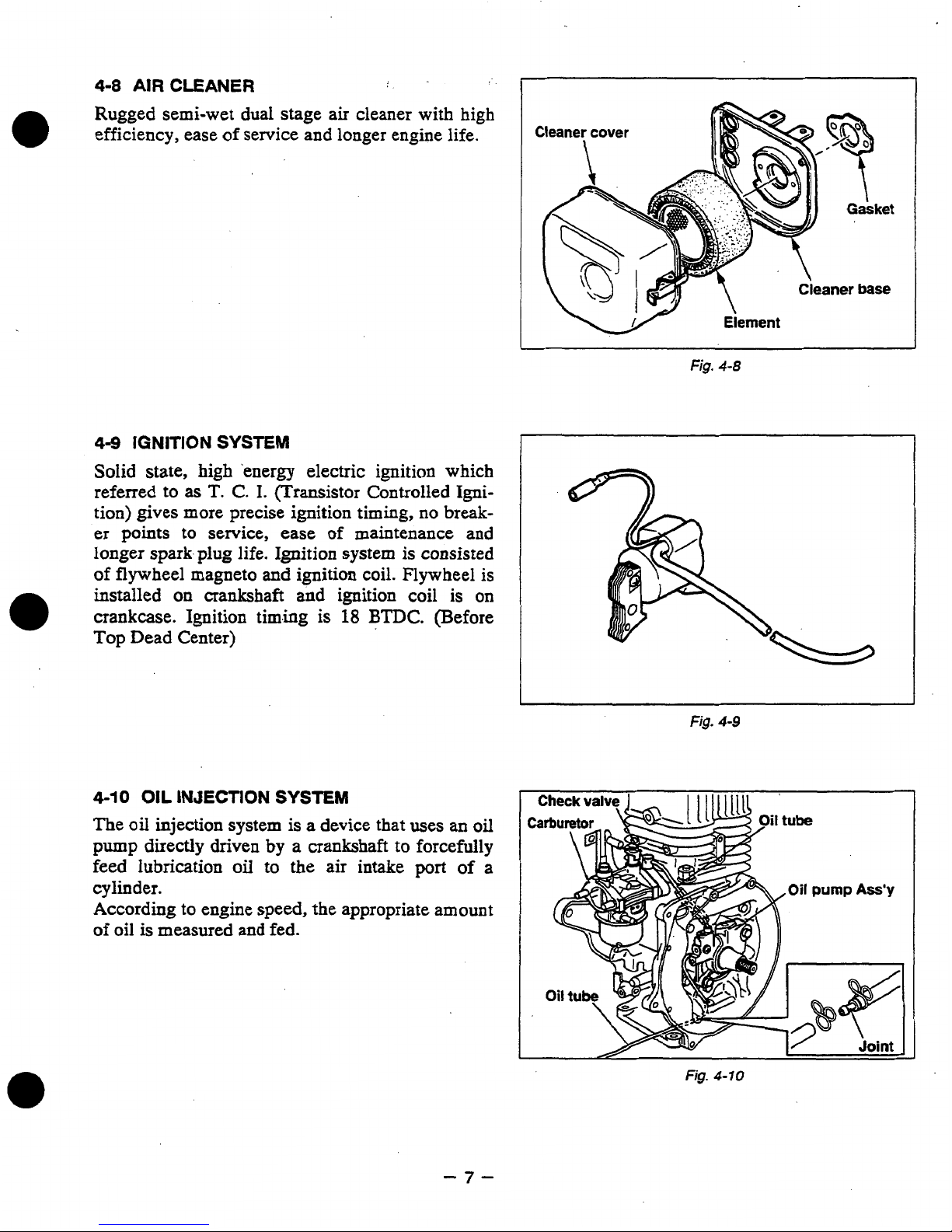

4-6

COOLING

Forced air

is

fully lubricated with oil mixed fuel

life and which enables more precision

and

better reliability.

SYSTEM

cooling

is done by flywheel

fan.

gov-

Alu-

minum die-cast flywheel fan ensures better cooling and durability.

I

4-7

CARBURETOR

EC12

retor that

is

equipped with a horizontal draft carbu-

has

a float controlled

fuel

system and a

fixed main jet. Carburetor is calibrated carefully

good

for easy starting,

sumption

and

sufficient output.

acceleration, low fuel

con-

Fig.

Fig.

4-6

4-7

-6-

Page 10

4-8

AIR

CLEANER

Rugged semi-wet dual stage air cleaner with high

0

efficiency, ease

of

service

and

longer engine life.

4-9

IGNITION

SYSTEM

Solid state, high 'energy electric ignition

which

referred to

as

T.

C.

I.

(Transistor Controlled Igni-

tion) gives more precise ignition timing,

no

break-

er points

to

service, ease

of

maintenance and

longer spark.plug life. Ignition system

is

consisted

of

flywheel

magneto and

ignition

coil.

Flywheel

is

installed

on

crankshaft

and

ignition coil is

on

crankcase.

Ignition timing

is

18

BTDC.

(Before

Top Dead Center)

4-10

OIL

INJECTION

SYSTEM

The

oil

injection system

is

a device that uses

an

oil

pump

directly

driven

by

a

crankshaft

to forcefully

feed

lubrication

oil

to

the

air intake

port

of

a

cylinder.

According to engine speed, the appropriate amount

of

oil is measured and fed.

Element

\

Fig.

4-8

I

Fig.

4-9

Fig.

4-10

-7-

Page 11

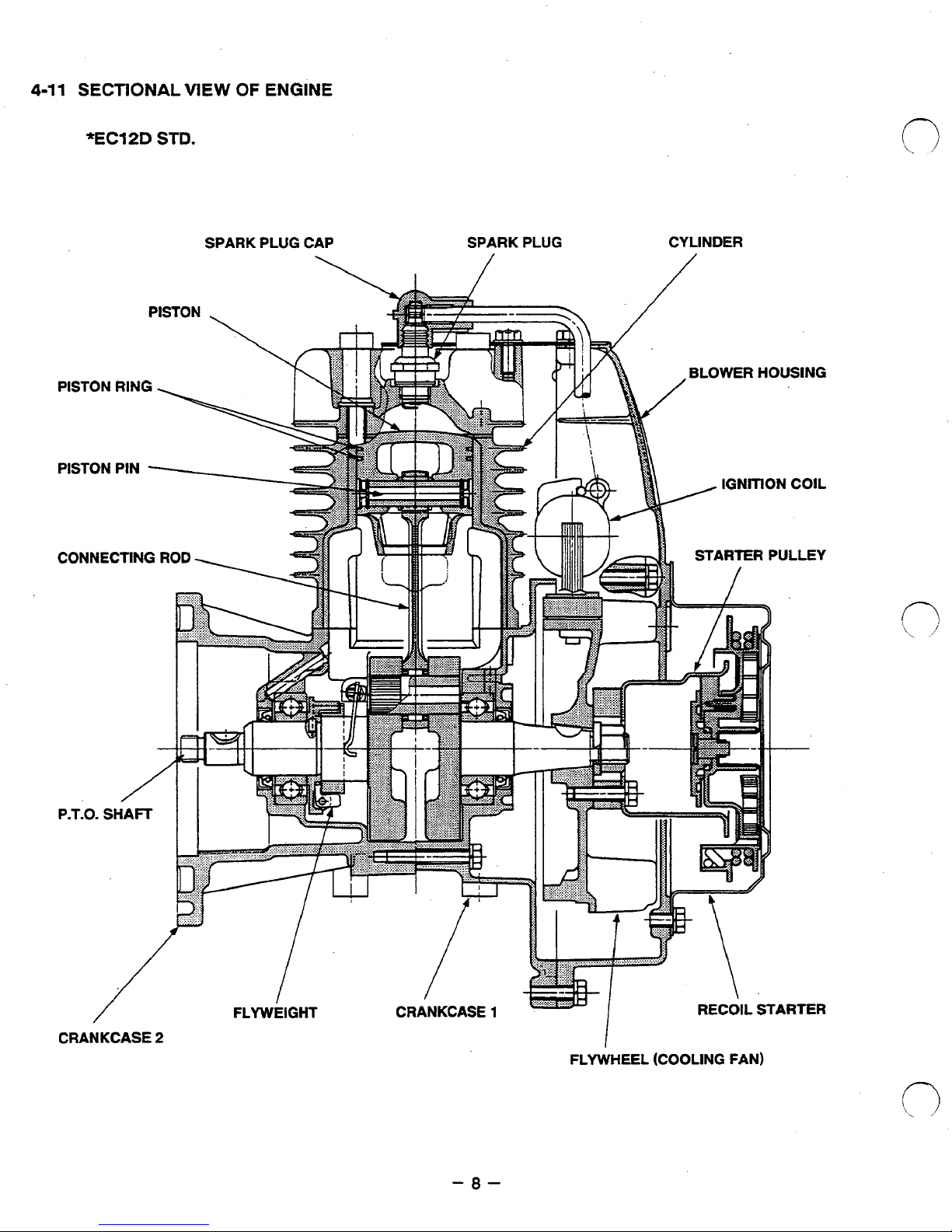

4-11

SECTIONAL

VIEW

OF

ENGINE

*EC12D

STD.

SPARK PLUG CAP

SPARK

PLUG

CYLINDER

CRANKCASE

2

-8-

I

FLYWHEEL

(COOLING FAN)

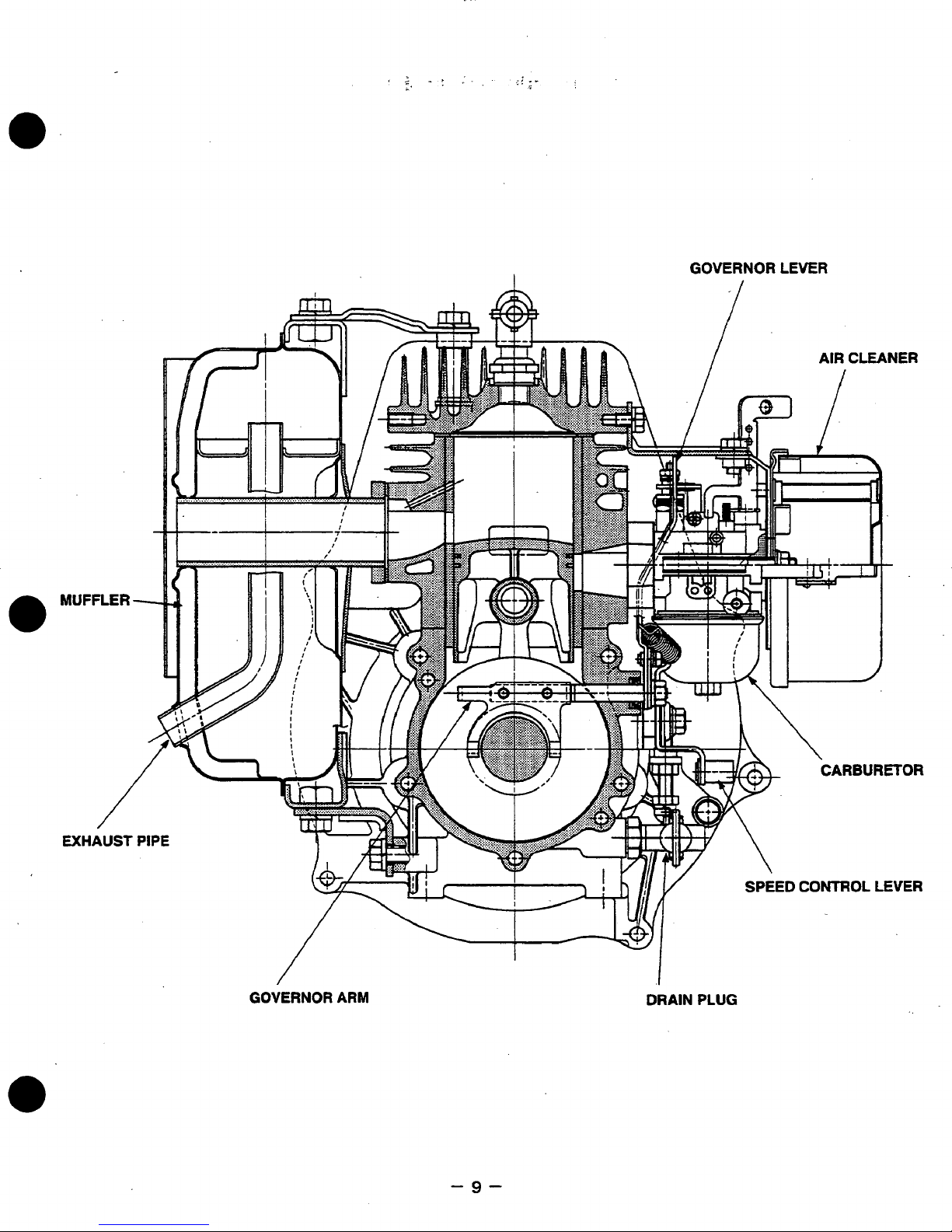

Page 12

GOVERNOR

I

/

LEVER

/

EXHAUST

-9-

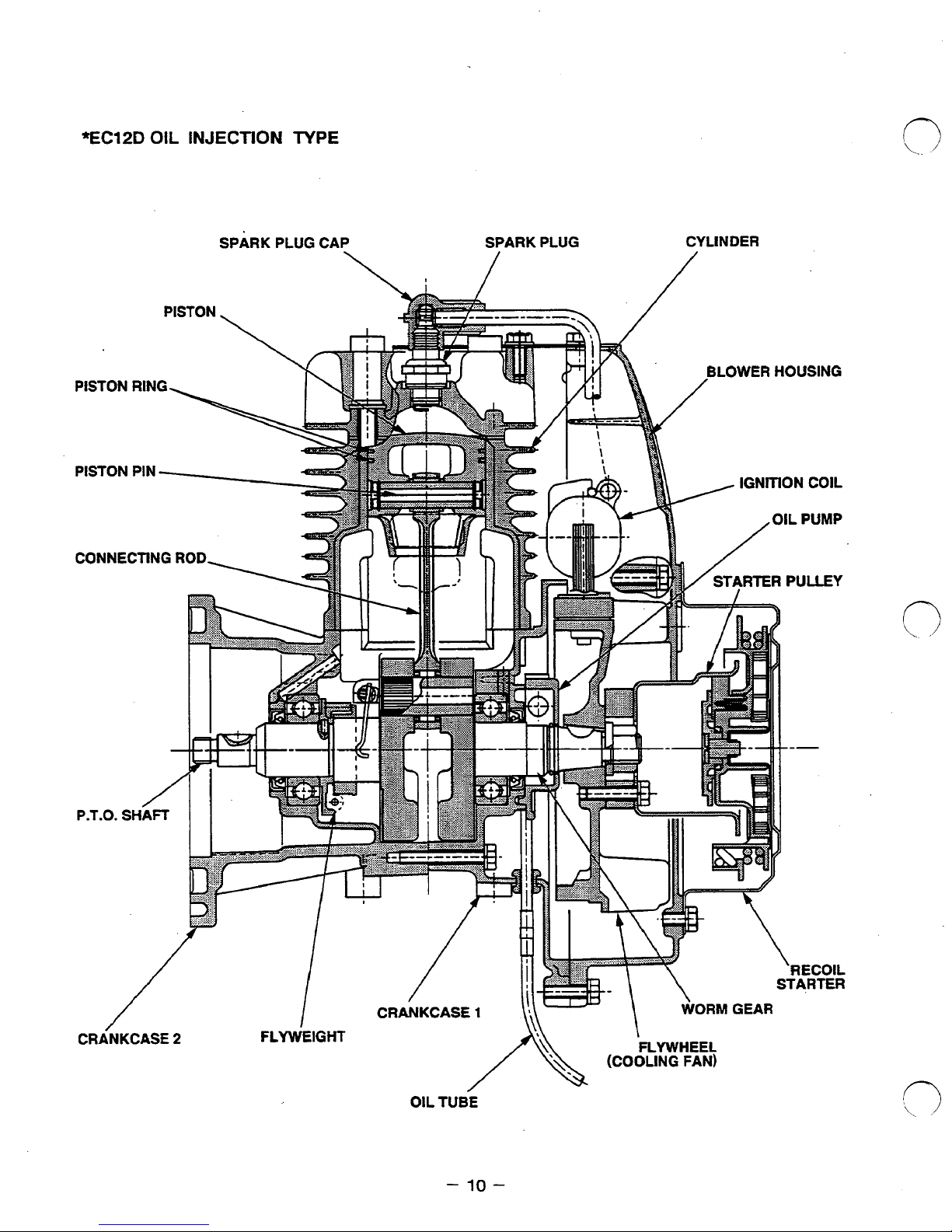

Page 13

*EC12D

OIL

INJECTION

TYPE

SPARK

PLUG CAP SPARK PLUG

CYLINDER

OIL

TUBE

-

10-

Page 14

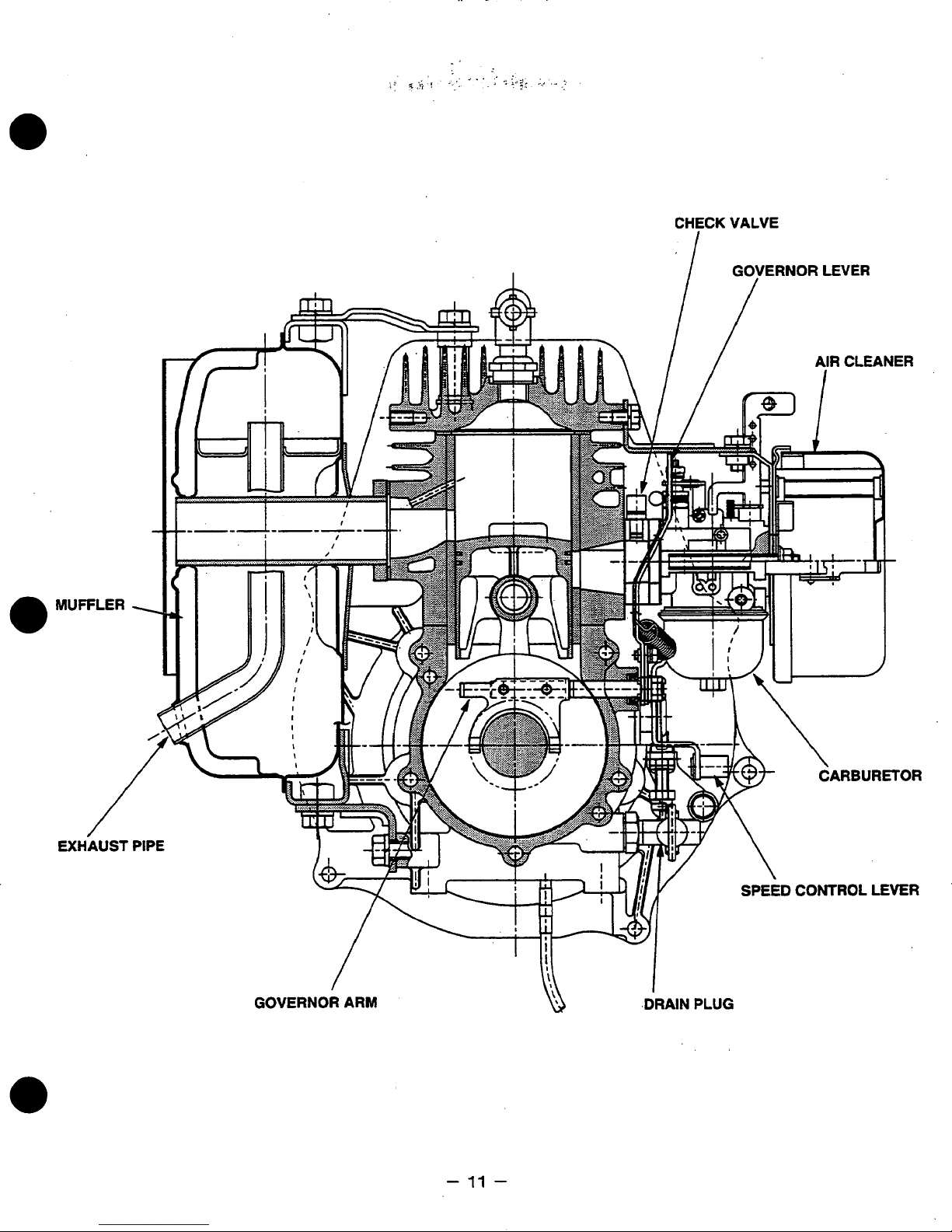

MUFFLER

/

EXHAUST

-

17

-

Page 15

5.

DISASSEMBLY

5-1

PREPARATIONS

AND

SUGGESTIONS

(1)

When disassembling the engine, memorize the locations

of

individual parts

so

that

they

can be

reassembled correctly.

If

you are uncertain

of

identifying some parts,

it

is suggested that tags be

attached to them.

(2)

Have boxes ready

to

keep disassembled

parts

by

group.

(3)

To

prevent losing and misplacing, temporarily assemble each

group

of

disassembled parts.

(4)

Carefully handle disassembled

parts,

and

clean

them

with

washing

oil

if

necessary.

(5)

Use

the

correct tools in the correct

way.

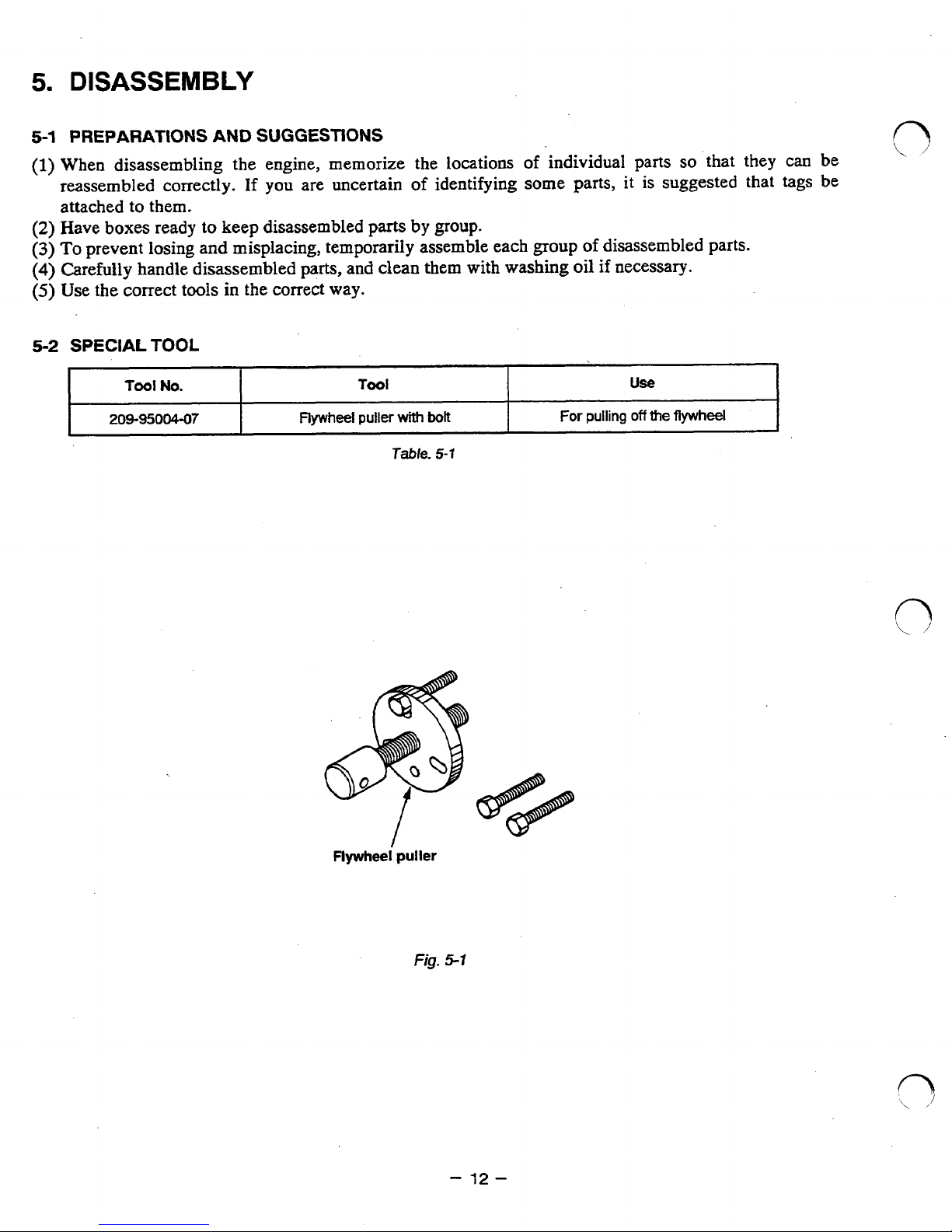

5-2

SPECIAL

TOOL

Tool

No.

US€!

Tool

209-95004-07

For

pulling

off

the

flywheel

Flywheel puller

with

bolt

Table.

5-1

Flywheei puller

fig.

5.1

-

12-

Page 16

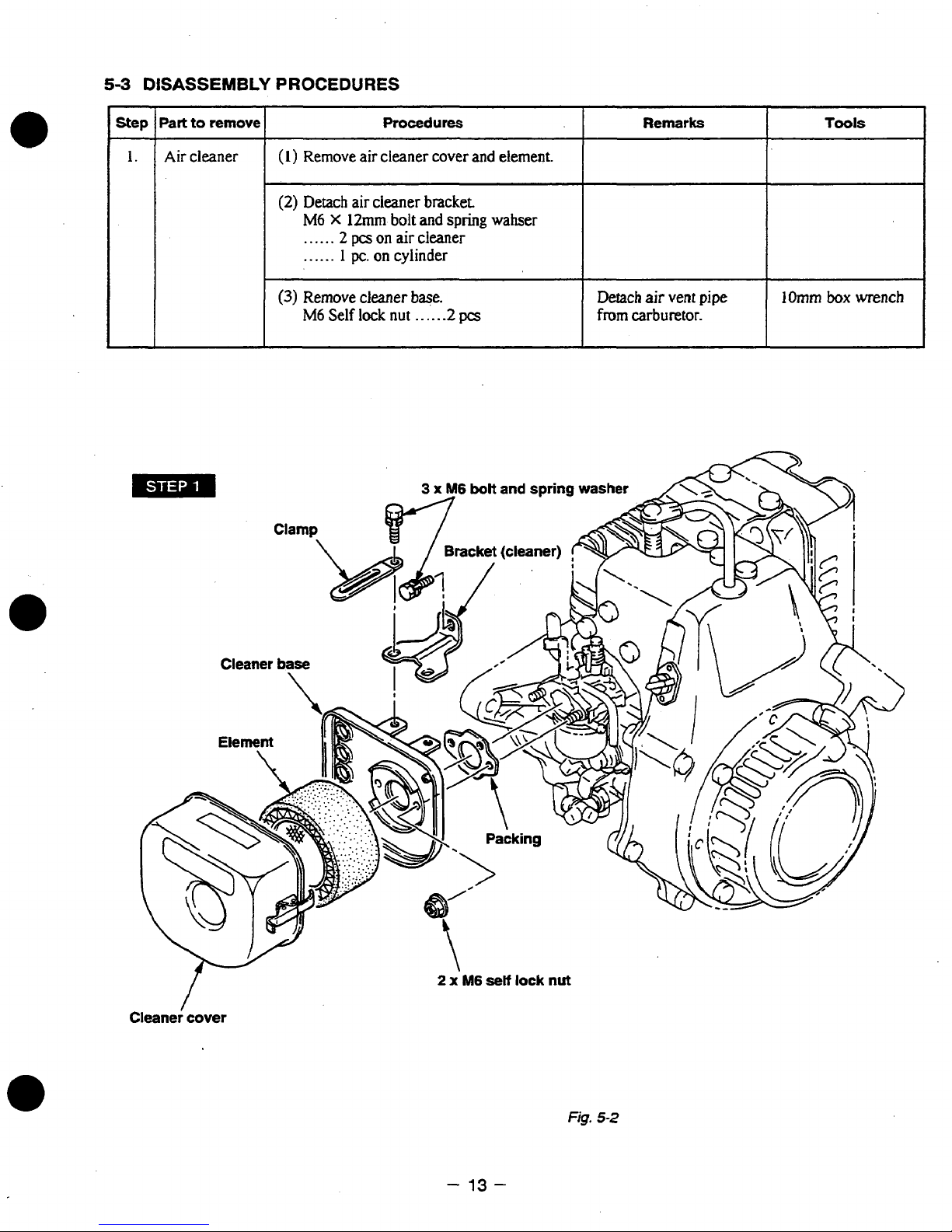

53

DISASSEMBLY

Part

Step

1

1.

1

Air

I

to

remove

cleaner

PROCEDURES

1

(1)

Remove

(2)

Detach

M6

......

......

I

(3)

Remove cleaner base.

M6

air

air

cleaner bracket

X

12mm

2

pcs

on

1

pc.

on cylinder

Self

lock

Procedures

cleaner

bolt

air

nut

cover

and

cleaner

.....

and element.

spring

-2

pcs

wahser

1

Detach

from

Remarks

air

vent

carburetor.

pipe

I

lOmm

Tools

box

wrench

I

I

Cleaner cover

1

-

13-

Fig.

5-2

Page 17

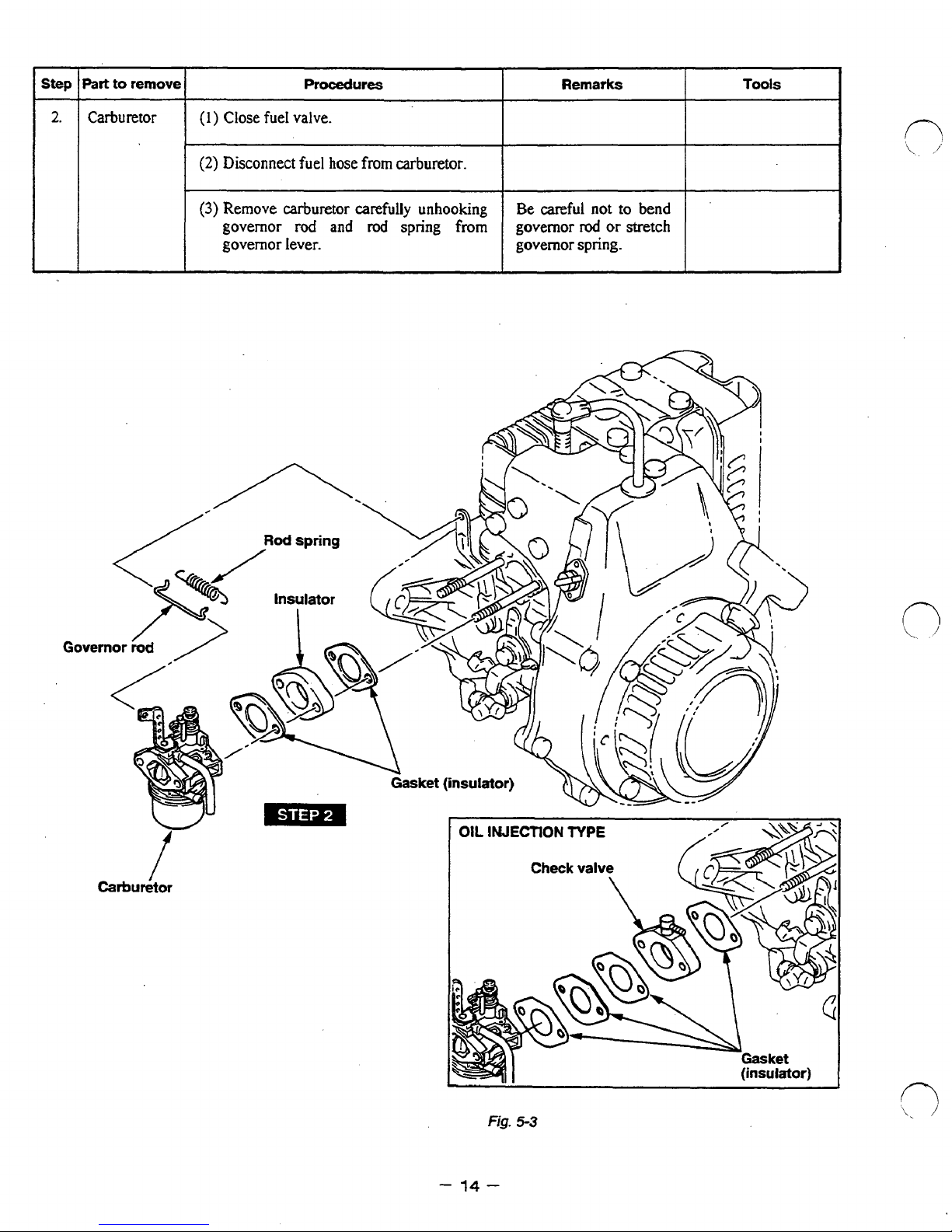

Part

to

remove

Procedures

1

(2)

Disconnect fuel hose

(3)

Remove carburetor carefully unhooking

governor

governor lever.

I

rod

and

from

rod

carburetor.

spring

from

I

Be careful

governor

governor

I

Remarks

not

rod

or

spring.

to

bend

stretch

Tools

I

Carburetor

I

-

OIL

lNJECTlON

Fig.

14

-

TYPE

(insulator)

5-3

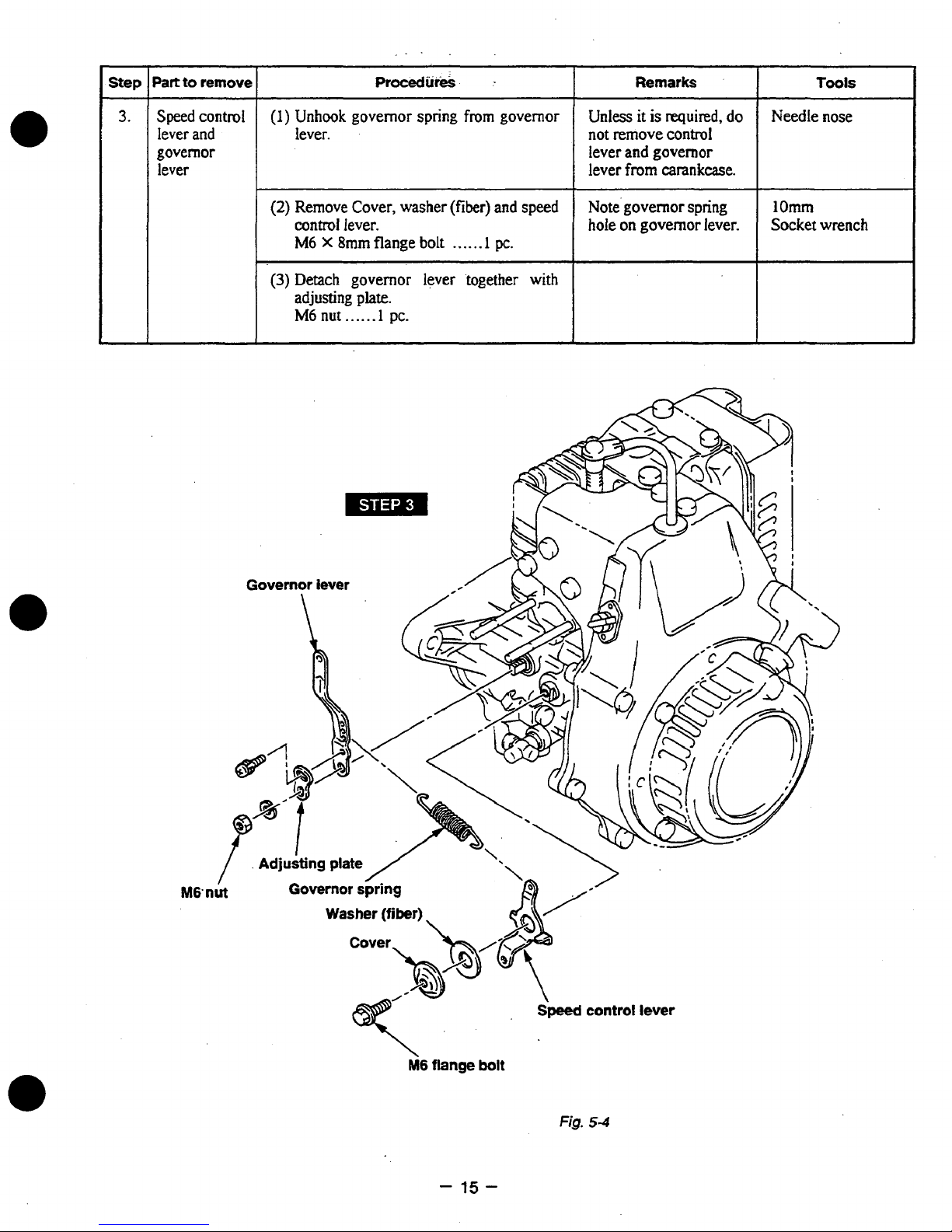

Page 18

%art

to

remove

ProcedureS

:

Remarks

Speed

control

lever

and

governor

lever

(1)

Unhook governor spring

lever. not

(2)

Remove Cover, washer

control

M6

(3)

Detach governor lever 'together with

adjusting

M6

X

8mm

nut

lever.

flange bolt

~~ ~

plate.

. . ..

.

-1

PC.

from

(fiber)

......

governor

and

1

pc.

speed

Unless

lever

lever

Note'governor spring

hole

it

is

required,

remove

on

and

governor

from

carankcase.

governor

control

do

lever.

Needle nose

1

1

Omm

Socket wrench

M6

-

15-

Fig.

5-4

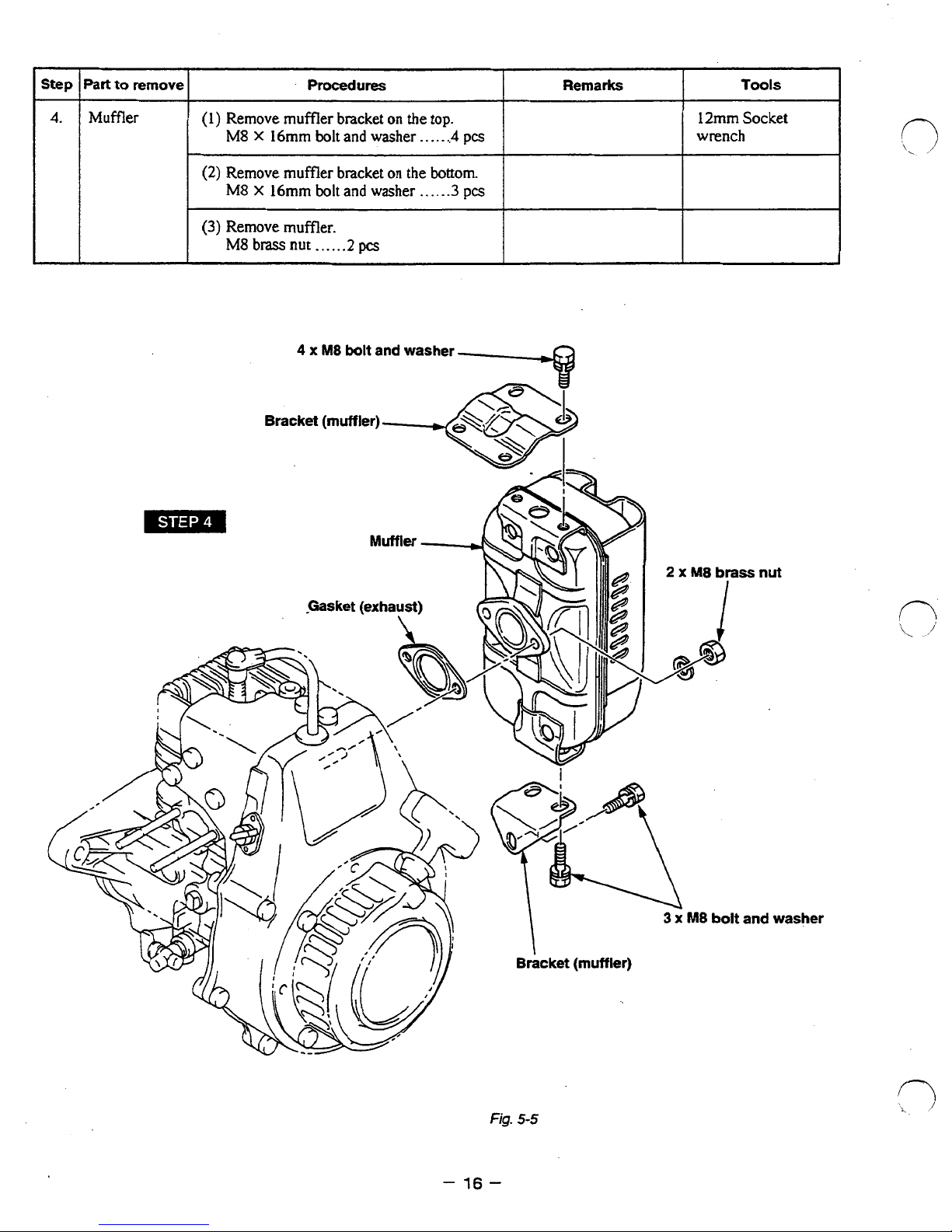

Page 19

%art

to

remove

Muffler

Procedures

Tools

Remarks

~~ ~

(1)

Remove muffler bracket

on

the

top.

12mm

Socket

M8

X

16mm

bolt

and

washer

. .

..

.

.,4

pcs

wrench

(2)

Remove muffler bracket

on

the

bottom.

M8

X

16mm

bolt

and

washer

......

3

pcs

(3)

Remove muffler.

M8

brass

nut

......

2

pcs

fig.

5-5

-

16-

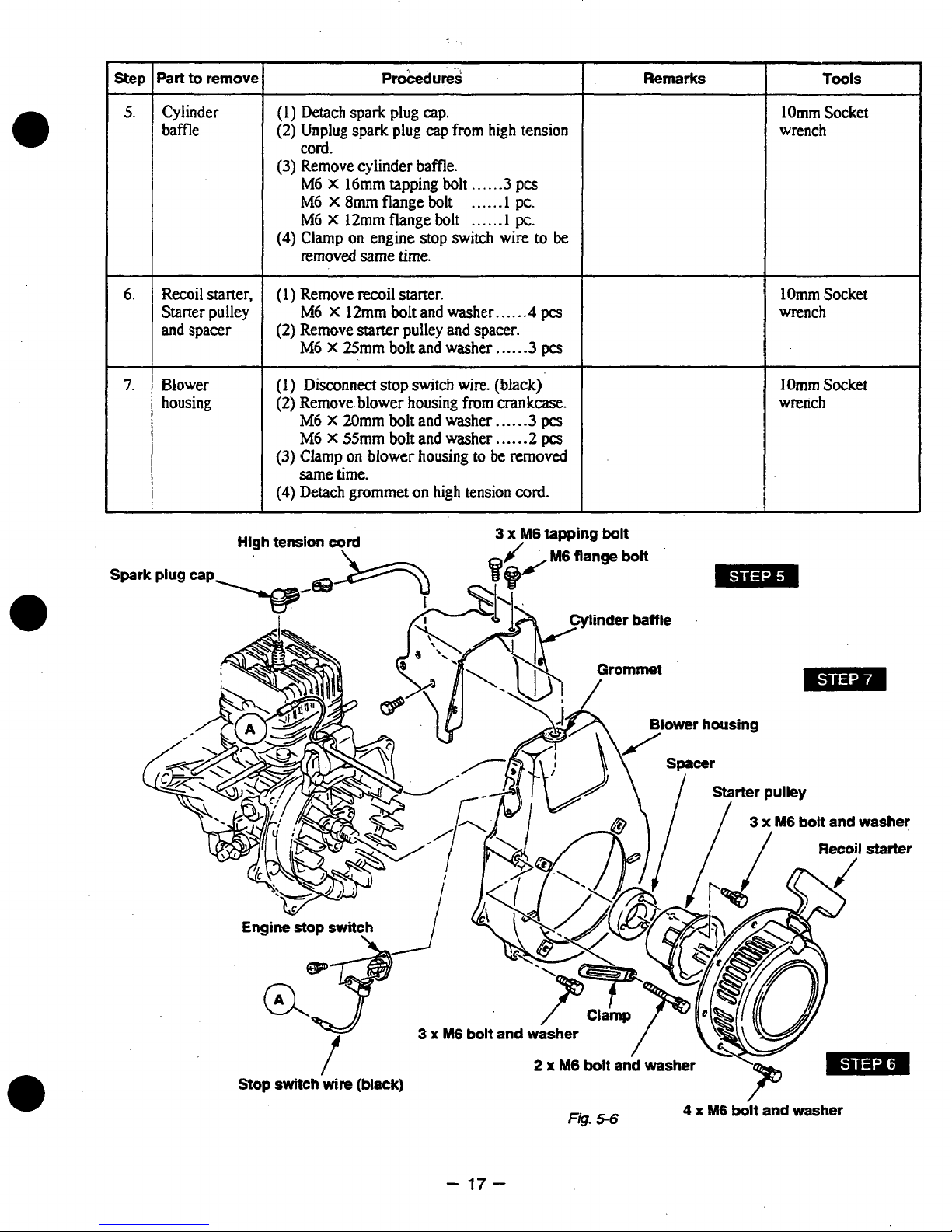

Page 20

Step

Part

to

remove

PtO&d"&!.

Remarks

Tools

5.

Cylinder

Recoil starter.

6.

Starter

7.

Blower

housing

pulley

(I)

Detach spark plug

(2)

Unplug spark plug cap

cap.

from

cord.

(3)

Remove cylinder baffle.

M6 X 16mm tapping

M6

X

8mm

flange

M6 X 12mm flange

(4)

Clamp

removed

(1)

Remove recoil starter.

(2)

Remove starter pulley

M6

(1)

(2)

Remove blower housing

M6

on

engine stop switch wire

same time.

X

12mm

bolt

X

25mm bolt and washer

Disconnect

X

stop switch

20mm

bolt

M6 X55mmboltandwasher

(3)

(4)

Clamp

Same

Detach

on

blower

time.

grommet

bolt

bolt

bolt

and washer

and

wire.

and washer

housing

on

high tension

high tension baffle

.....

......

......

spacer. and spacer

from

to

be

(black)

.3

pcs

1

pc.

1

pc.

to

be

......

4

pcs

.....

-3

pcs

crankcase.

.....

-3

pcs

......

2pcs

removed

cord.

lOmm

Socket

wrench

1

Omm Socket

wrench M6

I

Omm

Socket

wrench

-

17-

Page 21

'art

to

remove

Ignition

coil Remove ignition coil.

M6

X

20mm

Procedures

bolt

and washer

Remarks

,.

.

. .

.2

pcs

lOmm

wrench

Tools

Socket

Flywheel

Oil

L

pump

(1)

Remove flywheel nut. 19mm Socket

MI4

nut

and

spring

washer

(2)

Remove flywheel

(See Fig.

(3)

Remove the key from crankshaft. Be careful

(1)

Remove the body

crankcase.

M6

(2)

Take

which

5-8.)

X

20m bolt

out

fixed

the clip of

at

the

using

and

crankshaft.

. .

....

1

PC.

flywheel puller. Flywheel

of

oil

pump

washer

the

.

. . .

.

pump

from

.2

pcs

gear

can

removed

head

of

with

the

by

of

the center bolt

the flywheel puller

hammer.

key.

easily

striking

not

to

be

the

lose

wrench

Flywheel puller

209-95004-07

U

OIL

INJECTION

TYPE

Fig.

2 x M6

5-9

bolt

and

washer

-18-

Flywheel

I

-

Fig.

5-7

M14

flywheel

I

nut

Page 22

Step

1

I.

Part

to

remove

Cylinder

head

PTOCedUreS

(I)

Remove spark plug.

(2)

Remove cylinder head.

MSX35mm

*

2

pcs

bolt and washer

on

muffler side

are

.

. . .

-.

*4

special

-

pcs

bolt.

Remarks

Champion

NGK

Gasket, between

cylinder head and

cylinder.

US

BM6A

Tools

21

mm

Plug wrench

12mm

wrench

socket

4

12.

x

M8

bolt

Spark

and

Cylinder

Remove cylinder. Cylinder

M8

nut

......

4

pcs

plug

x

M8

/

head

p=

special

bolt

s-

I

\@

12mm

socket

wrench

GaskG

Cylinder

4xM8nut

BID

-

19-

Fig.

5-70

Page 23

Step

13.

Part

Piston

piston

to

remove

and

pin

Procedures

(1)

Remove

(2)

Remove piston

clips.

pin

to

remove piston

needle bearing.

(3)

Remove piston rings from piston.

and

Remarks

Be

careful

not

damage piston.

Be

careful

the

too

rings

by

much

or

not

twisting.

to

to

break

spreading

~~~ ~

Ring

expander

Piston

ring

~

-

20

Fig.

-

5-1

1

Page 24

14.

Crankcase

Remove

crankcase

and

M6

bolts

2

governor

X

40rnrn

M6 X 55mm

Procedures

fastening crankcase

1

together to remove crankshaft

sleeve

bolt

and

bolt

washer..

and

washer

. . . .

-. . . .

2pcs

.3pcs

and

Tools

1

Omm

Socket

wrench

Governor

plate

\

Governor

sleeve

bolt

and washer

-

21

-

2 x M6

Fig.

5-72

bolt

/

and

washer

Page 25

6.

REASSEMBLY

6-1

CLEANING

Check all sliding and rotating parts, such as piston, cylinder,crankshaft and bearings for defect.

Wash the disassembled parts

them twice, first time remove visible dirt roughly, and second time using fresh kerosene.

After washing, blow them thoroughly with compressed air.

Do

not wash electric parts. Wipe them with clean cloth and dry them.

Accumulated carbon on the cylinder-head, gasket, piston, cylinder and inside the muffler

carefully removed, and finish the piston with oil stone to get smooth surface.

Parts

of

air.

Check the cable for any damage.

Air-cleaner element shall be washed in

to 4 kerosene and 1 engine oil, and assemble it after squeezed well.

Take special care not to contaminate the parts with dust and apply mobile oil on the surface

to prevent rust.

6-2

CHECKS

After disassembling and cleaning the engine parts, check them and, if necessary, correct them according

to the section"CLEARANCE DATA

pipes shall

BEFORE

REASSEMBLY

in

kerosene to remove dust, dirt and contaminated oil thoroughly.

Wash

to

carburetor to be washed carefully with gasoline and blow them thoroughly with compressed

the

detergent and dry thoroughly. Then put it to mixture of

in

order

AND

CORRECTIONS BEFORE REASSEMBLY

and

be

replaced with new ones.

LIMITS

/

TORQUE

SPECIFICATIONS."

Gaskets and rubber

be

2

\.

I'

6-3

PRECAUTIONS

(1)

Clean

crankshaft, connecting rod and bearings.

(2)

Take care not

(3)

Check lip of oil seals. Replace oil seal if the lip

Apply

(4)

Replace all the gaskets with new ones. Use only designated sealing agent.

where packings or sealing agents are used.

(5)

Replace keys, pins, bolts, nuts, etc., if necessary.

(6)

Be sure to assemble those parts provided with alignment marks by bringing the marks in alignment.

(7)

Tighten

tighten them to torque readings appropriate to'the size.

Standard Tightening Torque for screws are as

If small screws are over torqued, they may get broken. When tightening several screws fastening

single part, tighten them all evenly, by alternately tightening diagonally located parts.

(8)

Apply oil to rotating and sliding parts.

(9)

Check and adjust clearances and end plays where specified in this manual.

(10)

During the assembly,

(11)

After the completion of reassembly, turn the engine by hand and check if there is any disorder or

loose members.

parts

oil

to

bolts,

6mm

gmrn

IOmm

.............................

.............................

.............................

FOR

REASSEMBLY

thoroughly before reassembly. Pay most attention to cleanliness of piston, cylinder,

to

contaminate the

the

lip before reassembly.

nuts and screws to the correct torque specified. When there is no torque specification,

parts

with dust during reassembly.

is

damaged.

Do

not apply oil to parts

follows:

90

turn

the moving part

250

370

kgf-cm

kgf-cm

kgf-cm

(6.5

ft. Ib)

(18

ft. Ib)

(26.7

ft. lb)

by

hand to check for friction and noise.

a

0

'\

1

n

'.

,)

-22-

Page 26

6-4

REASSEMBLY

6-4-1 CRANKCASE1

(1)

Before reassembling the crankcase, check bearing and

If

there

is

any

(2)

Put crankcase 2 with mounting flange down on a firm stand

PROCEDURES

damage, replace them with

new

ones.

installed.

(3)

Apply oil to the bearings of crankcase and ascertain that there

(4)

Put governor plate

Place the notch of governor plate to cylinder

(5)

Assuring that knock pin

crankshaft with press (or

and

governor sleeve

on

tap

it with a

on

crankshaft

soft

the

bearing of crankcase

(or

spark plug)

and

notch

hammer) taking

oil

seals.

so

that crankshaft move freely when

is

no

warp

on

the lip of oil seals.

2.

side.

on

governor plate are aligned, assemble the

care

not to damage the oil seal.

it

is

Governor

sleeve

-

23

Fig.

-

6-1

Page 27

6-4-2

ADJUST

CRANKSHAFT

END

PLAY

Select one spacer

so

that

the

crankshaft end play

to

be

0-

0.2mm(0”-

0.008

’

)

SPACER

THICKNESS

0.1

(0.004”

)

P/N

161-25001-03

0.3 (0.012”

)

P/N

161-25002-03

Crankcase

2

Crankcase

1

Fig.

6-2

6-44

CRANKCASE

2

(1)

Clean

the

join

of

both

crankcases and apply sealing agent (THREE

BOND

1215

or

equivalent).

Joint crankcase

1

with

press (or tap

it

with a

soft

hammer). Fasten

them

with

bolts.

M6

X

40

bolt and washer

Ass’y.

* *

2

pcs

M6

X

55

bolt and washer

Ass’y-

-

-

3

pcs

88

-

9.8

N

m

90

-

100

kgfocm

6.5

-

7.2

ft

Ib

CAUTION

:When reassembling

the

crankcase,

tighten the

diagonally

located

pairs

of

bolts

according

to

the specified tightening torque.

NOTE

:

After

reassembling the crankshaft

to

the

crankcase, check

if

the

crankshaft

rotates

smoothly.

0

‘\

.

’

-

24

-

Page 28

6-49

If

then spread the ring only

PISTON

an expander

RINGS

is

unavailable,

far

install

enough

the ring

to

slip over the piston and into

by

placing the open ends

of

the ring

the

correct groove.

on

first

land

of

piston,

CAUTION

E

\

/

:

1)

Be extremely careful not

2)

Put

the

(This

3)

Assemble

Top

ring

Second ring

is

open

to

ends

prevent

the

rings in

.---.-...-

------

f"\

I

Open Ends

Fig.

6-3

of

Piston

to

distort

of

piston rings

the

rings

the

from

order

Chromium

Parkerized surface

and break

to

the

rotation while operating

of

the

plated

surface

(looks

\

Ring

the

ring.

lock

pins in

second ring and then

(looks

the

white

grooves.

the

top

silver

dark in color)

lop

ring

Key

stone

Chromium

Plain

type

Parkerlrized

Second

engine.)

ring.

in

color)

type

plated

ring

-

25

-

Page 29

6-44

1)

2)

PISTON

Position the

with the needle bearing by gently striking the piston pin.

CAUTION : Apply oil to the needle bearing before reassembling

Assemble piston pin clip.

“F”

mark

of

piston top to flywheel side and reassemble the piston and connecting rod

it

to piston pin.

rl

0

CAUTION : Replace piston pin clip

3)

Be sure that piston and connecting

646

1)

2)

3)

4)

CYLINDER

Clean carbon deposit

CAUTION

Wipe oil from crankcase

Replace cylinder gasket with a new one.

Placing open ends

NOTES

:

If

carbon deposits are not removed

be

:

(1)

Apply

(2)

Mark

(3)

After assembling cylinder make

from

damaged

joint

of

piston

oil

to

sure

that

cylinder head and combustion chamber.

when reassembling.

surface

rings

piston

intake

M8nutandwasher

I

TIGHTENING

17.6

-

180

-

13.0

-

TORQUE

215

Nom

220

kgf

-

159.ft-Ib

I

cm

if

there

rod

move smoothly after reassembled.

and

to

the

lock

and

piston pin before reassembling.

and

exhaust

----.----

is

any looseness after reassembling

the

piston and inner

apply sealing agent

pins in the grooves. Install piston to the cylinder.

ports

are

facing

sure

the

crankshaft

4pcs.

(THREE

the

right

rotates

surface

BOND

side

smoothly.

it.

of

1215

or equivalent).

cylinder may

-

26

-

Page 30

0

6-4-7

1)

2)

CYLINDER

Clean carbon from combustion chamber and dirt from between the cooling fins

Check its mounting face for distortion.

Use

new

cylinder head gasket.

HEAD

of

cylinder head.

NOTE

3)

Install the cylinder head

M8

NOTE

I

Cylrider head

X

35

mm

bolt and washer

:

Special

~~~~ ~ ~~

17.6

-

21.5 N-m

180

-

220bf-cm

180

-

15.9

bolts

ft*

gasket

so

are

Ib

must

be

placed folded edge

that the alignment marks on the cylinder head and cylinder match.

*

- * -

4pcs.

to

be

instak?d

on

the mumer

side

up.

of

the

roward

cylinder

cylinder head)

head.

Fig.

6-5

6-44

Check Carbon deposits and wear

Replace spark plug with a new one

SPARK

Spark Plug

I

I

NEW

11.8

-

120

-

8.7

-

PLUG

:

CHAMPION

NGK

SPARK

14.7

10.8

BM6A

TIGHTENING

PLUG

N

150

kgfecm

ft

-

m

on

U8

TORQUE

I

Ib 18.0

the spark plug terminal.

if

necessary.

or

REllGHTENlNG

24.5

-

29.4

N

-

m

250

-

300

kgf

cm

-

21.7

ft

-

Ib

I

I

-

27

-

Page 31

64-9

1)

2)

OIL

PUMP

Worm gear

Mesh each gear at the proper position,

secure with C-clip.

Put grease

(equivalent to Shell Albania

After assembling pump,

be rotated a few times by hand to be spread the

grease.

How

to eliminate air from oil tube

Remove

Allow

out the remaining air.

After checking, reassemble the tube to the

inlet, then clamp securely.

the

the tube to

on

tube

(OIL

INJECTION

drive

from

fill

TYPE)

worm

gear about

#3)

the

crankshaft should

oil pump inlet.

with

oil, which will force

0.5

then

cc

fig.

r'

6-6

.

6410

1)

2)

3)

CAUTION

FLYWHEEL

Wipe

Put the

Install

off

the

M14

Nut with spring washer-

I

TlGfiTENlNG

:

1)

When air is

size will result.

2)

When air

Then

system. After running

No

oil

and

woodruff

flywheel to the crankshaft. Tighten the nut with spring washer.

mixed fuel/oil must be used

need

grease thoroughly from the tapered portion

key in the key way

TORQUE

in

is

observed

to

I

the

*

-

oil

tube, insufficient oil will

- -

in the

of

1

PC.

tube,

1

mixed

crankshaft.

air must

fuel/oil

be

be

eliminated by

until

air has been eliminated

tank,

you

of

the crankshaft and flywheel.

carried to the engine

the

above procedure.

may continue with gasoline only.

and

from

engine

entire

I

-

28

-

Page 32

6-4-1

1

IGNITION

COIL

When installing the ignition unit

on

the crankcase, use a non-metallic feeler gauge to measure the air gap

,

its hold down screws.

between the ignition coil and flywheel. The ignition coil

can

be moved to adjust the air-gap

by

loosening

M6

X

20mm

bolt and washer

-

*

-

- - -

2

pcs.

1

AIR

GAP

0.3

-

0.5mm

0.012

-

0.020

in

Fig.

6-7

6412

BLOWER

HOUSING

Through high tension

cord

from

inside the blower housing and put the .grommet

on

the cord to

the

blower

housing. Then install the blower housing

to

the crankcase. A clamp is fastened together

on

the air cleaner

side bolt.

M6

X

20mm bolt and washer

-

-

*

*

-

-

3

pcs.

M6

X

55mm bolt and washer.

- - -

-

2

P-

64-13

RECOJL

STARTER,

STARTER

PULLEY

AND

SPACER

I)

Install spacer and starter pulley

to

the flywheel.

2)

Install recoil starter. Make sure the recoil

knob

is pointing the right direction.

M6

X

25mm

bolt

and washer

- -

3

pcs.

M6

X

12mm bolt and washer

- - - -

-

4

pa.

64114

CYLINDER

BAFFLE

A

clamp

is

fastened together on the air cleaner side

of

the cylinder baffle.

M6

X

16mm tapping bolt

-

- * -

-

- - -

3

pcs.

M6

X

12mm flange bolt

- - - -

- - - -

I

PC.

M6

X

8mm

flange bolt

- - - - - - - -

*

-

I

PC.

6415

.MUFFLER

1)

Replace muffler gasket with a new one.

2)

Install muffler and muffler bracket. First temporary tighten nuts

and

bolts

on

the muffler

and

the

bracket.

Then

tighten the

nuts

on

?he muffler and the

bolts

on the bracket.

M8

brass nut

and

spring

washer

- - - - - - -

-

-

-

2

pcs.

M8 X 16mm

bolt and spring washer

- -

-

-

-

-

7

pcs.

-

29

-

Page 33

6416

SPEED

CONTROL

LEVER

AND

GOVERNOR

LEVER

1) Install governor lever

to

governor shaft with adjusting plate being temporary tightened.

M6nutandspringwasher-.-.----.--.-..-

1

PC.

M4

X

8mm

screw and spring washer

-

- -

-

1

PC.

2)

Install governor control lever, washer (fiber) and cover

to

the

crankcase

in

this sequence.

M6

X

8mmflangebolt

-.-....-..........

1

PC.

3)

Hook

governor

spring

to

the governor lever and speed control lever.

Governor lever

M4

screw

and spring washer

Speed

control

lever

Fig.

6-8

-

30

-

Page 34

6417

1)

2)

3)

CARBURETOR

Install packing and insulator

Connect governor lever and throttle lever

install carburetor together with air cleaner base plate.

M6selflocknut

Install air cleaner bracket.

M6

X

12mmboltandwasher---.--..--... 3 pa.

AND

AIR

CLEANER

to

the cylinder. Replace packing

........................

on

with

a new one.

the

carburetor by governor rod

2

pa.

and

rod spring. And then

6-4-18

Refer

6-4-19

1)

2)

GOVERNOR

to

section

WIRING

Connect wire from stop switch

Connect spark plug cap

-

End

of

the reassembly

ADJUSTMENT

“7-2

Governor Adjustment”

to

high

-

and

primary

tension cord then plug it

wire

from

ignition coil. Clamp wire to cylinder baffle.

to

spark plug.

-

31

-

Page 35

6-5

BREAK-IN

An

engine that has been completely overhauled by being fitted with a new piston,

assembly

should

Good bearing surfaces

operating the engine under reduced speed and loads for a

While the engine

OPERATION

be thoroughly

and

running clearances between the various

is

being tested, check

BREAK-IN

for

oil leaks.

before being put

short

back

period

into service.

parts

of

time.

Make final carburetor adjustment and regulate the engine operating speed.

Load

I

%PS

%PS

1

1

2

2

3

3

4

4

5

5

1.5

1.5

3.0

3.0

Hp

Hp

Hp

Hp

Load

No

No

No

No

No

No

or

or

or

or

load

load

load

load

load

load

40%

40%

75%

75%

Load

Load

Load

Load

Table

Table

Engine

Engine

61

61

2500

2500

3OOo

3OOo

3600

3600

3600

3600

3600

3600

Speeed

Speeed

rpm

rpm

rpm

rpm

rpm

rpm

rpm

rpm

rpm

rpm

I

Time

Time

IO

min

IO

min

10

min

10

min

10

min

10

min

30

min

30

min

60

min

60

min

rings

can

only be established

.

.

and crankshaft

by

.-

NOTE : Use

25

:

1

Oil

fuelmix

for

break-in

period.

-

32

-

Page 36

7.

-GOVERNOR

0

7-1

CONSTRUCTION

A

centrifugal flyweight type governor

installed

As

changes its opening angle and moves the governor sleeve, which in turn rotates the governor shaft

through the governor

and this governor lever is connected to the carburetor throttle lever through the governor rod at the other

end

When the crankshaft speed increases, all the relevant' members move in the direction indicated

C

marks and the carburetor throttle valve

speed and output. When the crankshaft speed decreases, the same members move

indicated by

recovering the failing speed and output.

in

the crankcase, and lubricated

the engine speed fluctuates, flyweights on the governor plate, rotating together with the crankshaft,

;

thus the throttle valve

r)

marks and the carburetor throttle valve

AND

yoke.

The governor lever is connected

is

OPERATION

is

used. The governor plate, governor sleeve and governor yoke are

by

the oil mixed fuel.

to

the extending part

opened or closed and engine speed and output are controlled.

closes,

reducing the fuel supply and consequently reducing the

opens,

increasing the fuel supply and consequently

of

the governor shaft

in

the direction

by

-

33

Fig.

-

7-1

Page 37

7-2

GOVERNOR ADJUSTMENT

The

governor system should be adjusted

1)

Connect governor rod and rod spring to carburetor throttle lever and governor lever, then install

at

reassembly

by

the following procedures.

governor lever to governor shaft.

NOTE

2)

Connect govemor lever and control lever

And the governor adjustment

a)

Attach the governor lever

:

Never tighten

plate, governor lever

the

on

set screw for the adjusting plate

and

governor

with

is

to be made in the following sequence:

the governor shaft.

b)To the governor shaft, fasten temporarily the

adjusting plate with nut and spring washer.

c)To

the governor lever, fasten temporarily

adjusting plate with screw

At

this

moment, the adjusting plate is free to

(1)

and nut

(2).

move. (See Fig.7-2.)

Push

d)

the adjusting plate clockwise.

(See Fig.7-3.)

e)

Set the governor lever

tighten the screw

(1)

at

the high position and

and nut

(2).

(See Fig.7-4.)

at

this

time,

and do

not

fix

adjusting

shaft.

governor spring, and install control lever to crankcase.

the

fig.

7-2

/

7-3

HIGH

7-3-1

Unless required

related parts from.

crankcase. (See

SPEED

WHEN

ADJUSTMENT

NO

TACHOMETER

in

the process

crankcase.

Fig.7-5.)

IS

AVAILABLE

of

disassembling,

If it is necessary

Fig.

7-4

do

not remove governor control lever and

to

remove them, never turn high speed stop bolt on

-

34

-

/

or

other

Page 38

7-3-2

WHEN A TACHOMETER

IS AVAIL;;ABI;E

i

1)

Install control lever and other related parts.

2)

By

turning control lever with governor spring

on

it, gradually increase the engine speed up

to

3)

Locate high speed

stop

bolt

on

the control lever and lock it

so

they it will stop control lever against

specified engine speed.

the stopper plate.

Make sure that the governor spring

is

hooked

in

the same hole

on

the governor lever

as

original.

There are

3

holes

on

the governor lever.

Normally, hook governor spring in the center hole.

Governor

lever

"-

"

Speed

control

lever

Fig.

7-5

-

35

-

Page 39

8.

MAGNETO

EC12

ignition divice which utilizes the power transister as an element for controlling electric unit.

This

efficiency because

mechanical parts.

8-1

This

As

ignition coil with built-in transistor, and lead wires to spark

engine is equipped with a pointless Solid State Ignition system. This is a circuit breaker type

system' is free from start-up failure due to dirty,

of

moisture, rough breaker point surface and incorrect timing resulting from worn

OPERATION

system is referred

illustrated

OF

in

Fig.S-l.,

Connector

ME

IGNITION

as

T.C.I.

this

SYSTEM

(Transistor Controlled Ignition) system.

is

a simple system, consisting

IGNITION

Black

COIL

Ignition

WITH

burnt

BUILT-IN TRANISITOR

Coil

plug

1

or

oxidized point surfaces, low ignition

of

a flywheel with magnetic fields,

and stop switch.

Spark

k

Plug

an

n

,.,

/

al

TST

Stop

Switch

Fig.

&I

Magneto

WRING

;

Flywheel

DIAGRAM

SOLID

STATE

IGNITION

-

36

-

Page 40

8-1-1

PRfNCIPLE

1)

Rotation

By this voltage, electric current

2)

With further rotation

flows

current

11’

3)

With further move rotation

it

(collector) and E (emitter) Terminals of signal transistor. Current

which induct SCR.

4)

Current

This

through power transistor base terminal

(b)

did.

passes its peak. Current

(h)

current change causes high voltage on secondary coil which produces sparks at spark plug.

OF

THE

OPERATION

of

the flywheel generates a voltage

(11)

flows

of

the flywheel, electric current

and

(14)

in

signal transistor. The current

of

the flywheel, the current generated by primary coil starts to decrease

(Is)

starts flowing because there is

turns into current

(16)

with induction

on

the primary side

and it charges condenser.

(h),

(B).

This actuates power transistor and results electric

(14)

charges the condenser reversely as the current

of

the

SCR,

of

the ignition device.

which is reversed of electric current

no

electric potential difference in the

(Is)

this cuts

flows into the gate

off

anent b abruptly.

(G)

of

(h),

as

C

SCR

0

Fig.

8-2

8-2

IGNITION

In

the event of malfunction of the ignition

Broken, frayed, loose

Faulty spark plug-wet, dirty, insulation broken

If difficulty

should be checked

Remove spark plug-then with the ignition cable connected to it, lay the spark plug

part

of

the engine

the recoil starter.

trouble.

1)

2)

Using a

ignition lead and the engine stop switch wire.

This resistance reading should

infinite, this indicates open winding in the ignition unit, a loose

failed high tension lead.

If a very low reading

itself is determined to

If

Check to make sure that the external magnet, mounted

Since the solid state ignition unit

secondary coil resistance..

good

SYSTEM

is

experienced in starting the engine or if engine misfires,

:

so

If

there is

a

quality ohm-meter, check the secondary coil resistance between the plug terminal of

CHECK

system,

or

disconnected ignition wires.

check the following first:

or

incorrect plug gap.

the

that the gap can be observed as

a good strong spark occurs, the ignition system

weak

spark or no spark at all, check the ignition system as follows:

is

self-contained, the only testing which

be

approximately

is

taken,the secondary coil

be

faulty, then it will

have

you

rotate the crankshaft several times by means of

on

the flywheel is in a good condition.

10,000

is

to be replaced.

to

probably shorted.

12,000

can

ohms.

or

broken spark plug connector or

If,

strength

be eliminated as the source

can

If

the

after testing, the ignition unit

of

the ignition spark

on a convenient metal

be performed

resistance reading

is

on

the

the

of

is

a

-

37

-

Page 41

9.

CARBURETOR

9-1

FLOAT

CARBURETO'R

9-1-1

1)

The float chamber

body and, with a float and a needle valve,

OPERATION

FLOAT

SYSTEM

is

AND

CONSTRUCTION

located below the carburetor

main-

tains a constant fuel level during engine operation.

Fig.9-2.)

(See

The

fuel

flows

chamber

to

through

a

specific level, the float rises,

from

the fuel

tank

.into the

float

needle valve. When the fuel rises

and

when

its

buoyancy and fuel pressure are balanced, the

needle valve closes to shut

off

the fuel, there

by

keeping the fuel at the predetermined level.

PI1

Fig.

9-2

-

30

-

Page 42

2)

PILOT

The pilot system feeds the fuel to the engine

The fuel is fed

the pilot

The fuel-air mixture

At idling speed,

3)

MAIN

The main system feeds the fuel to the engine at medium and high-speed operation.

The fuel is metered

mixed with the fuel through the bleed holes in the main nozzle, and the mixture is atomized out

main bore. It

which

4)

CHOKE

The choke is used

choke, the negative pressure applied to the

starting

SYSTEM

through

air

jet.

the

SYSTEM

is

mixed again with the air taken through the air cleaner into an optimum fuel-air mixture,

is

supplied

up

the engine more

to

during

the main jet to the pilot jet, where it

is

fed to the engine through the pilot outlet and the bypass.

fuel is

by

the engine.

for.

mainly

the main jet

easy starting when ' the engine is cold. When the starter

fed from

and

fed

the

to

main

idling and low-speed operation.

is

metered and mixed with the air metered by

pilot

outlet.

the main nozzle. .The air metered

nozzle increases and draws more fuel accordingly thus

easily.

by

the main air

is

operated with a closed

jet

of

is

the

-

39

-

Page 43

9-1-2

DISASSEMBLY

AND

REASSEMBLY

A

part from mechanical failures, most of the

carburetor troubles are caused by an incorrect

mixing

ratio, which may arise mainly due to a

clogged

up

air

or

fuel passage in the jets,

or

fuel

level variations.

In

order to assure proper

flow

of

air

and

fuel,

the

carburetor must be kept clean at all times.

The carburetor disassembly and reassembly procedures are

as

follows : (See Fig.9-3.)

1)

THROTTLE

SYSTEM

a)Remove the Phillips screw

(1)

and throttle

valve

(2),

and

pull

out the throttle shaft

(3).

b)The spring

(4)

can

be taken out

by

removing

the

throttle stop screw

(5).

*

Be

careful

not to damage the throttle valve

ends.

2)

CHOKE

SYSTEM

a) Remove the Phillips screw

(6)

and choke valve

(7),

and pull out the choke shaft

(8).

b)

When reassembling the choke shaft, make sure

that the cutout in the choke valve

faces

the

main air jet.

3)

MAlN

SYSTEM

a)Remove the bolt

(9)

and take out the float

chamber body

(10).

b)From the body remove the main nozzle

(11)

and then remove the main jet

(12)

from the

main nozzle

(11).

a)Fasten the main jet securely to the body.

Otherwise, the fuel may become too rich and

cause engine malfunction.

c)

Reassembly

b)The

bolt

tightening torque is

5

ft

lb

6

17

3

1

13

10

Fig.

9-3

n

'\

,)

(7Okgf-cm). Be sure to set

the

gasket

(13)

and

washer

(14)

for chamber

(10).

4)

FLOAT

SYSTEM

a) Pull out the float

pin

(15)

and remove the float

(16)

then the clip

(17)

and needle valve

(18).

CAUTlON

:

When cleaning the jets, use neither a drill

nor

a

wire (because

of

possible damage

to

the orifice

which

will adversely affect

fuel

flow).

Be

sure

to

use

compressed

air

to blow them

clean.

b)When

removing

the

needle valve and float, gently tap

on

the reverse side

using

the rod more slender

than the float pin and remove, since

the

float pin

is

calked to the carburetor body.

-

40

-

Page 44

9-2

DIAPHRAGM

CARBURETOR

9-2-1

1)

OPERATION

PUMP

AND

CONSTRUCTION

The diaphragm of the fuel pump is moved by

pressure fluctuations

in

the engine crankcase.

When it moves towards the engine, the inlet valve

(E)

of the pump opens and the outlet valve

shuts, and the pump sucks

diaphragm swings back, the

and the fuel is forced

A

compensating chamber

out

in

fuel. When the

inlet

valve

of

the outlet valve

(W),

situated between

(E)

the inlet and the outlet valves cushions the

(A)

closes

(A).

oscil-

lations of the fuel flowing past. The diaphragm of

the chamber

sphere fuel pressure builds up,

springs

upwards towards the atmo-

and

contracts again

when the pressure drops.

After the pump, the fuel flows through the fine

filter

(F).

This

traps

residual particles

of

dirt,

but

is

not a

substitute for the large-area filter, which must be

fitted

in the

fuel flow before the carburetor.

2)

PRESSURE

A

diaphragm pressure regulator ensures, almost

REGULATOR

independently of the pump pressure, a constant

vacuum before the jet systems.

If

the vacuum in the carburetor inlet pipe

mitted

moves the regulator lever

(M),

An

to

the pressure regulator via the jets, it

against a spring and

even

flow

of fuel then

(R)

opens

passes

via the diaphragm

the feed valve

through the valve

is

trans-

(N).

into the regulator and through the jets into the

carburetor port. The diaphragm

lever

(R)

and the feed valve

any

to

3)

If

given

HIGH

full power is required

flow

SPEED

quantity.

OPERATION

(M),

the regulator

(N)

constantly adjust

from

the engine, the

throttle valve and choke are fully opened.

The vacuum in the carburetor sucks fuel into

main system via main mixture screw

non-return valve

tem via idle mixture screw

drilling

The fuel

(LA)

flow

(V),

and through the idling

(L),

and the bypass drillings

can be altered by opening and

(H)

the idling outlet

(BP).

the

and the

sys-

closing main mixture screw and idle mixture

screw.

I1

L”7+

Fig.

9-4

3

High

speed

-

41

-

Page 45

4)

MID-RANGE

If

only

reduced engine output is required and the

throttle valve

vacuum

the

gine. The fuel now

system.

main system closes, thus preventing air

tering the pressure regulator, where it could im-

pede the fuel flow.

5)

IDLING

When the engine

far

the engine

(LA).

outlet drilling

drilling

out.

sufficient to

space between the throttle valve and the en-

As

closed that the vacuum between the valve and

While fuel is being sucked out

(BP),

OPERATION

is

accordingly portially closed,

suck

fuel

is

present only

only

a result,

flows

the

non-return valve

through the idling

(V)

from

OPERATION

is

idling, the throttle valve is

only

acts

on

the idling outlet drilling

of

the idling

(LA),

which mixes with the fuel coming

air

is

entering the bypass

in

in the

en-

so

a

N

The

idling speed

and

the matching fuel quantity with idle mixture

screw

6)

To

throttle valve

Each attempt to

uum

through

When starting

must first

must be flushed out of the carburetor systems.

Several attempts at starting-usually

essary before the first firing occurs.

The choke must then be opened and the next

attempt will

(L).

STARTING

start the engine, the choke

in the carburetor

both jet systems.

be

is

set with the stop screw

is

closed, with the

@>

roughly

start

a

hot or cold engine, the carburetor

filled with fuel,

half-open.

the engine produces a vac-

port,

which draws fuel

as

air

and fuel vapour

four,

start

the engine

running.

GAS)

are

nec-

n

-

42

-

Fig.

9-7

Page 46

9-2-2

DISASSEMBLY

I.

A

part from mechanical failures, most of the carburetor troubles are caused

by

an incorrect mixing ratio,

In order

to

assure proper

flow

of air and fuel; the carburetor must

be

kept clean at all times.

The carburetor disassembly

and

reassembly procedures are

as

follows : (See

Fig.9-8.)

which may arise mainly

due

to a clogged

up

air or fuel passage in the jets,

or

fuel level variations.

1)

FUEL

PUMP

a)

Remove the screw

(1)

and

pump

cover

(2).

b)

Remove pump gasket

(3)

and diaphragm

(4).

c)

Inspect diaphragm

(4),

replace

if

diaphragm

d)

Remove strainer

(5).

shows

any

signs

of

wear

and

curing.

2)

METERING

DIAPHRAGM

a) Remove the screws

(6)

and metering chamber

b) Remove metering diaphragm

(8)

and the

gas-

c)

Inspect metering diaphragm

(8)

for

dirt

and

cover

(7).

ket

(9).

foreign matter.

3)

INLET

NEEDLE

VALVE

a) Remove the

screw

(10)

of

metering lever

(11).

b)

Remove metering lever

(ll),

pin

(12)

and lever

spring

(13).

c)

Remove inlet needle valve

(14).

d) Inspect inlet needle valve

(14).

Rubber tip

should

not

be deformed where

it

contacts

the

seat.

4)

MIXTURE

SCREW

a) Remove idle

(15)

and main

(16)

mixture screw

and

washer

(17).

b)

Remove the spring

(18).

c)

Inspect each screw

(15,

16)

for damage, espe-

cially the needle

points

which should have.

no

deformation of the tapered surfaces.

5)

THROTT'LE

AND

CHOKE

a)

Remove the E-ring

(19)

and

the screw

(20)

and

throttle valve

(21),

and pull

out

the throttle

shaft

(22).

b)

Remove

the

screw

(23)

and

the choke valve

8

7

a

(24),

and pull

out

the choke shaft

(25).

-

43

-

Fig.

9-8

Page 47

9-2-3

Reassembly

and

Adjustment

Replace all

1)

MIXTURE

Install idle and main mixture screws.

a) For the nominal setting, tighten the screws

turns

In

accordance with the actual operation and fuel consumption condition, adjust the screws

2)

INLET

a)

Inspect

Assemble the lever onto the pin and rotate the

worn

with new ones. Make sure to clean all

parts

before reassembly.

SCREW

fulIy

and

then turn back counterclockwise at the following

;

Idle mixture screw Main mixture screw

2

turns

Turning

NEEDLE

the metering lever

back

for

nominal setting

One

turn

VALVE

the

and

the

Fig.

pin.

9-9

1

and

112

turns

Turning direction

air

fuel ratio adjustment

for

pin.

a

The lever should be

should

b)

Install the inlet needle valve, metering

metering lever,

c)

The free end of the metering lever should

to

gasket flange

If

the free end of the lever, then carefully push

down

is

the lever.

not

stick.

pin

0.3

rnm

(0

to

of

carburetor body.

the metering lever

on

the inlet needle. If the metering lever

too

low,

pry

up

(Fig.

9-11)

free fit

and

retaining

0.012”)

is

too

carefully

on

the

pin

and

spring,

screw.

be

below the metering

(Fig.

9-10}.

high,

push

down

on

the free end of

on

0

as

necessary.

Push

down

here

n

V

Then push

down

needle here

Fig.

-44-

9-1

1

Page 48

'

10.

1b-1

(1)

OiI

(2)

Mixture

I

I

OIL

SEPARATE

Idle

Load

NJECTION

I

flow

ratio

I

I

SYSTEM

OIL

INJECTION / FUEL

19

:

1

@

1600

25

to30

:

1

@3800

rpm

rpm

SYSTEM

I

I

10-2

BASIC

STRUCTURE

OF

THE

SEPARATE

OIL

ONJECTION 1 FUEL

2000

Fig.

10-1

SYSTEM

Gasoline

4000

r.p.m.

tank

-

45

F;g.

-

10-2

pTA

:

Gasoline

Page 49

Carburetor

Fig.

10-3

10-3

10-3-1

OIL PUMP OPERATION / FUNCTION

OIL PUMP

(1M64-01)

OPERATING

PRINCIPLE

(1)

The

crankshaft

turns

which rotates the

gear. The plinger which directly gose to the

worm rotates at

(2)

The plinger wilI

by

the spring.

Then

it

moves

motion due

1/17th

to

to

the configuration

be

left

of

pushed

and

engine speed.

down to the pins

right with a rotating

of

the edge

lead.

(3)

The

sub

plunger will be stabilized into the

plug

by

the spring via E ring.

By

above

stroke, pumping will occur.

worm

of

(2)

Oil

outlet

-46-

Fig.

10-4

Page 50

Sub

planger

oil

;nlet

I

Piuriger

V

ring

\

I

/

Pinion gear

Detail

A

&

Cam

top

A

mbase

0'.

90'

190'

270"

360"

'1

Lead

configuration

'1

Development

of

lead

height

(P

view)

Fig.

70-5

-

47

-

Page 51

10-3-2

OIL

INTAKE

AND

DISCHARGE

CYCLE

AT

OIL

PUMP

The plunger rotates

(1)

Intake

The plunger remains in the

The plunger strokes

The volume

of

360

oil

chamber

degree

to

the right.

with

a

closed

is

position.

expanded.

cycle. (Shared area means oil.)

Closed

Cam

top'&

Direction

of

position

Pin

plunger roatating

(2)

Discharge

The plunger

The plunger strokes

The

volume

of

is

raised

oil

to

the

to

the left.

chamber

open position

is

decreased.

Oil

inlet

ir'

/m

Fig.

70-6

by

the

pin.

funger

Cam

Direction

Closed

base

of

position

Pin

'A

plunger

m

top

roatating

piiiq

Fig.

70-7

-

48

-

Page 52

10-3-3

(1)

CHECK

Check valve

This

valve

VALVE

is

AND

composed

seat.

The

ball

is

stabilized

by

overrides the spring at time the pressure

ceeds

prevents air

its

setting load.

from

When

entering into oil tube due

vacuum.

Also

this prevents

oil

from

storage.

(2)

Floating switch

This

floating switch

is

located

FLOATING SWITCH

of a ball and body

a

spring. The

ball

ex-

engine stops, this

to

leaking when long

in

the oil

tank.

Lt

Body

Oil inlet

seat

I

t

Ball

Spring

Fig.

Washer

10-8

1.

Structure of floating

switch

(1)

Float located

(2)

Float

located

above

below

limit

This

illustration

shows on position

-

49

Fig.

-

10-3

-.

due

to

exciting

Page 53

11

-

RECOIL

STARTER

When

Tools

I

(1) Remove the recoil starter

(2) Pull the starter

repairing the recoil starter, disassemble and reassemble according

:

Needle nose pliers screw driver.

1

-{,'DISASSEMBLY

from

the engine.

knob

rope

about

on

the reel with the outlet hole

rope.

Hold the reel with your thumb and pull the

starter rope inside the starter case with a screw

driver. (See Fig.11-1.)

While rewinding the reel, control the rotation

by

holding the starter rope the notch

and pressing the reel with your

12

in.

.

and

(30cm)

pull

to

line

thumb.

out the starter

up

the notch

for

the starter

on

the reel

to

the following procedures.

(3)

Remove the

1.

Center

2.

Ratchet guide

3.

Friction plate

4.

Ratchet

5.

Return spring

6.

Reel

(4)

Untie the starter rope from the

move.

CAUTION

Take

towards the

spring

out

from

quickly

starter

Note

:

If

to

case.

power

section

:

or

parts in

screw

the reel

left

the

the

spHng

1

the

slowly

and

hook.

spring

escapes

1-2.

following

right

Do

may

order.

knob

and re-

turning it slightly

to

remove

not

remove

escape

from

the reel

from

i

housing

refer

the

the

Fig.

11-1

1

2

I

3-

-

50

-

Fig.

1

1-2

Page 54

11-2

REASSEMBLY

(1)

Put

the starter rope through the starter

knob

and tie it as

shown

in

Fig.11-3-1. (Tie the rope

tightly for safety sake.)

Put

the opposite side of the rope through starter

case and reel. Tie it securely as shown

in

Fig.11-3-2.

and put the knot

in

the reel

com-

pletely.

Then apply grease a little to starter shaft and

power spring.

(2)

Check that the spring

is

securely

set

in

the reel.

Adjust the position

of

the inner end

of

the

spring to

0.04

”

-

0.08

(1-

2mm)

from

the reel

bush

so

that

it

hooks

on

the hook

in

the starter

case securely.

The

shape

of

the power

spring

inner end can

be

adjusted with a plier

if

necessary.

(3)

Prior

to

installing

the

reel

in

the

starter case,

wind

the

starter rope in the reel for

2.5

turns

in

the arrowhead direction as

shown

in Fig.11-5.

Then let the

rope

out

of

the reel

from

the

reel

notch. Line up the

hook

on

the

starter case with

the

inner end

of

the

spring

and instal the reel

in the starter case.

Check that the inner end

of

the

spring

is

se-

curely hooked

on

the starter case

hook.

I

0.79 - 1.18

in

0.79

-

1

.f

8

in

Fig.

1

1-3-

1

Fig.

1

1-3-2

1.

position

of

the

per

end

Reel

\

n

of

the

inner

end

7

4.

0.04

-

0.08

in

Fig.

1

1-4

(4)

Hold

the starter rope as shown

in

Fig.11-5.

and

I

turn the reel

4

to

5

times

in

the arrowhead

direction.

Firmly press

the

reel not to allow reverse turn-

ing

and pull

the

starter

knob

to let the starter

rope out

of

the starter case.

Return the

knob’

slowly to let the starter rope

rewind

in

the reel.

(5)

Reassemble the parts

in

reverse order

of

disas-

sembly.

Apply- a small amount

of

lock-tight to

set

screw and torque it.

I

TIGHTENING

TORQUE

I

3.4

-

5.4

N

m

55

kgf

*crn

25.2

-

39.6

ft

Ib

w

Fig.

1

1-5

-

51

-

Page 55

11

-3

CHECK AFTER REASSEMBLY

(1)

Test the operation

and retract properly.

(2)

Pull the starter

If

there

is

once or twice. (See

If the starter rope return

grease or

If it does

(After doing

If the starter rope does not retract, the power spring is

from the first step.

not

of

the recoil starter to

knob

all

the way

starter rope left

Fig.11-1.)

mobile

oil

to rotating and sliding parts.

cure the

so

check that the power spring

problem,

and

in

the groove

is

weak

wind

see

if the rope recoils satisfactorily

check following.

of

the reel, the power spring

or

stops before it completely returns to original position, apply

the

starter rope

is

not

once

or

twice.

over loaded,

not

hooked. Reassemble the recoil starter

by

preceding paragraphs method.)

and

if the ratchets project

is

overloaded. Rewind the reel

,i

114

WHEN POWER SPRING ESCAPES

Make a spring holder

from

a

piece of

the spring assembly over the recess

over

the tension

wire ring-start with the outer loop of the spring and wind

Place

is

holder) and

into

12

the recess

or

tab

for

the power spring-form a ring a little smaller than power spring housing

16

ga.

soft

iron

on

the

reel.

(Fig.ll-4.)

in

the housing.

FROM

wire and twist

in

HOUSING

the

housing,

Carefully press the

the

ends together. Wind the power

in

a counter clockwise direction.

so

that

the

hook

in

the outer

spring

out

Fig.

of

the

7

7-6

spring

loop

wire

of

ring

inside

the

spring

(Spring

I.D.

the

-

52

-

Page 56

12.

TROUBLESHOOTING

For a gasoline engine to start and

1)

A

proper fuel-air mixture

2)

Appropriate compression in the cylinder.

3) Good spark at correct

If

all the three requirements are not met simultaneously, an engine

factors such as

contribute to hard

The

most common

12-1

STARTING

Defects in spark plug

Defects in high-tension

cord

Defects

heavy

Cause

in

magneto

starting.

causes

DIFFICULTIES

time

load

of

1)

2)

3)

If cord is burnt or damaged, replace

ignition coil unit.

1)

2)

run

satisfactorily, the following three requirements must be met:

is

supplied

to

at

starting

engine

ignite

to

the

or

too