Page 1

SERVICE

MANUAL

Models

EC06,EC08

1193s1 20

Page 2

ROBIN

AMERICA, INC.

ROBIN

TO

WISCONSIN

ROBIN

ENGINE

MODEL

CROSS REFERENCE

LIST

ROBIN

EY08

EY15

EY 15V

EY20

EY2OV

EY23

EY28

EY3

5

EY40

-

EY45V

EY2

1

EY44

EY 18-3

EY25

EY27

EH11

EH12

EH15

EH17

EH21

EH25

EH30

EH30V

EH34

EH34V

EH43V

EC13V

DY23

DY27

DY30

DY3

5

DY4 1

WISCONSIN

ROBIN

SIDE

VALVE

W

1-080

W1-145

W1-145V

W1-185

W1-185V

W1-230

W 1-280

W

1-340

W 1-390

Wl-45OV

EY21W

EY44W

EY18-3W

EY25W

EY27W

OVERHEAD

VALVE

WO1-115

wo1-120

WO1-150

WO1-170

wo1-210

WOl-250

WO 1-300

WO1-300V

WO1-340

WO

1

-340V

WO 1-43 OV

TWO CYCLE

WT1-125V

DIESEL

WRD

1-230

WRD

1-270

-1-300

WRD1-350

WRD1-410

0

0

0

Page 3

CONTENTS

Section

1 . SPECIFICATIONS

2

.

PERFORMANCE

2-1

2-2

2-3

3

.

FEATURES

4

.

DISASSEMBLY and REASSEMBLY

44-2

4-3

4-4

5

.

CONTACT BREAKER ADJUSTING PROCEDURE (EC06)

6

.

CARBURETOR ADJUSTMENT

7

.

GOVERNOR ADJUSTMENT

Maximum Output

Rated Continuous Output

Maximum Torque and Fuel Consumption Ratio

1

Preparations and Suggestions

Special Tools

.

Disassembly Procedure

Reassembly Procedure

Title

..............................................

................................................

........

:

.................................

..................................

at

Maximum Output

........

....................................................

..................................

..................................

.............................................

......................................

.......................................

..................

.....................................

.......................................

;

Page

.

1

2

2

2

2

4

5

5

5

6

9

13

14

15

8

.

TROUBLE-SHOOTING

8-1

8-2

8-3

8-4

8-5

8-6

8-7

9

.

CHECKS and CORRECTIONS

9-

9-2

10

.

MAINTENANCE and STORING

10-

10-2

10-3

10-4

10-5

Starting Trouble

Idling Improper

Overheating and Engine Knocking

Power Drop

Excessive Fuel Consumption

Hunt.ing

Other Troubles

1

Engine Standard Correction Table

Table of Tightening Torque

1

Daily Checks and Maintenance

Every

Every

Yearly Checks and Maintenance

Preparation for Long Abeyance

................................................

50

Hours Checks and Maintenance

150

Hours Checks and Maintenance

...........................................

...........................................

...........................................

...............................

:

.............................................

...................................

..............................................

......................................

...............................

...................................

.....................................

..................................

:

.........................

..........................

................................

.................................

16

16

19

19

19

20

20

20

21

22

24

25

25

25

25

25

25

Page 4

ECOGD

Fuel

Tank

Cap

Recoil Starter

Muffler Cover

Base

Engine

(optional)

Spark

Plug

overnor Lever

Governor Chamber

(Engine base

is

opti

n

onal.)

ECOGB

Page 5

Model

Bore

x

Stroke 44mmx40mm

Piston Displacement .60.8 cc 78.5 cc

ECOGD

Air-Cooled, 2-Cycle, Vertical, Piston Valve Type, Single Cylinder Gasoline Engine

ECOGB

I

I.

ECOID

50

mm

ECO~B

x

40

mm

Continuous Rated Output (HP/rpm)

Maximum Output (HP/rpm)

~~

Maximum Torque (kg-m/rpm)

.

Lubrication

~~

Lubricant

I

Carburetor'

Fuel Gasoline-lubricant Mixture (20- 25: 1)

Fuel Consumption Ratio (gr/HP-h)

Fuel Feed Gravity Type

Fuel Tank Capacity 1.5 iitres

Ignition System

Spark Plug

'Starting System

.

_-

.-

~ ~~~

1.6/3600,1.9/4500 11.6/1440, 1.9/1800

2.5/5000

I

0.38/3700

..

I

2.5/2000

.

0.95/1480. 0.51/3600 1.27li440

.'

Counterclockwise

~

Fuel-lubricant Mixture Type

I

390

at

Rated Continuous Output 380

Flywheel Magneto Type

(Contactless Magneto Type

also available.)

NGKB6HS

I

2-Cycle Engine Oil

I

I

as

viewed from

Float Type

is

I

Recoil Starter

2.2/4500

3.3/5500

P.T.O.

~~

Shaft Side Direction of Rotation

at

Rated Continuous Output

L.

Contactless Magneto Type

NGKB7HS

1

1

2.2/1800

3-3/2200

..

..

~ ~~

Speed Governor

Speed Reduction System

Reduction Chamber Oil

.Air Cleaner Semi-wet Type

Dry Weight

I

"

Dimensions

Length

Width 307

Height

..

-

-

mm

256

mm

287 mm 287

Centrifugal Flyweight Type

1/2.5 Reduction 1/2.5 Reduction

Gear Gear

SAE #30

285

mm

307

mm

.

mm

-.

-

256

mm

307

mm

287

mm

-

SAE#30.

285

307

287

mm

mm'

mrn

Page 6

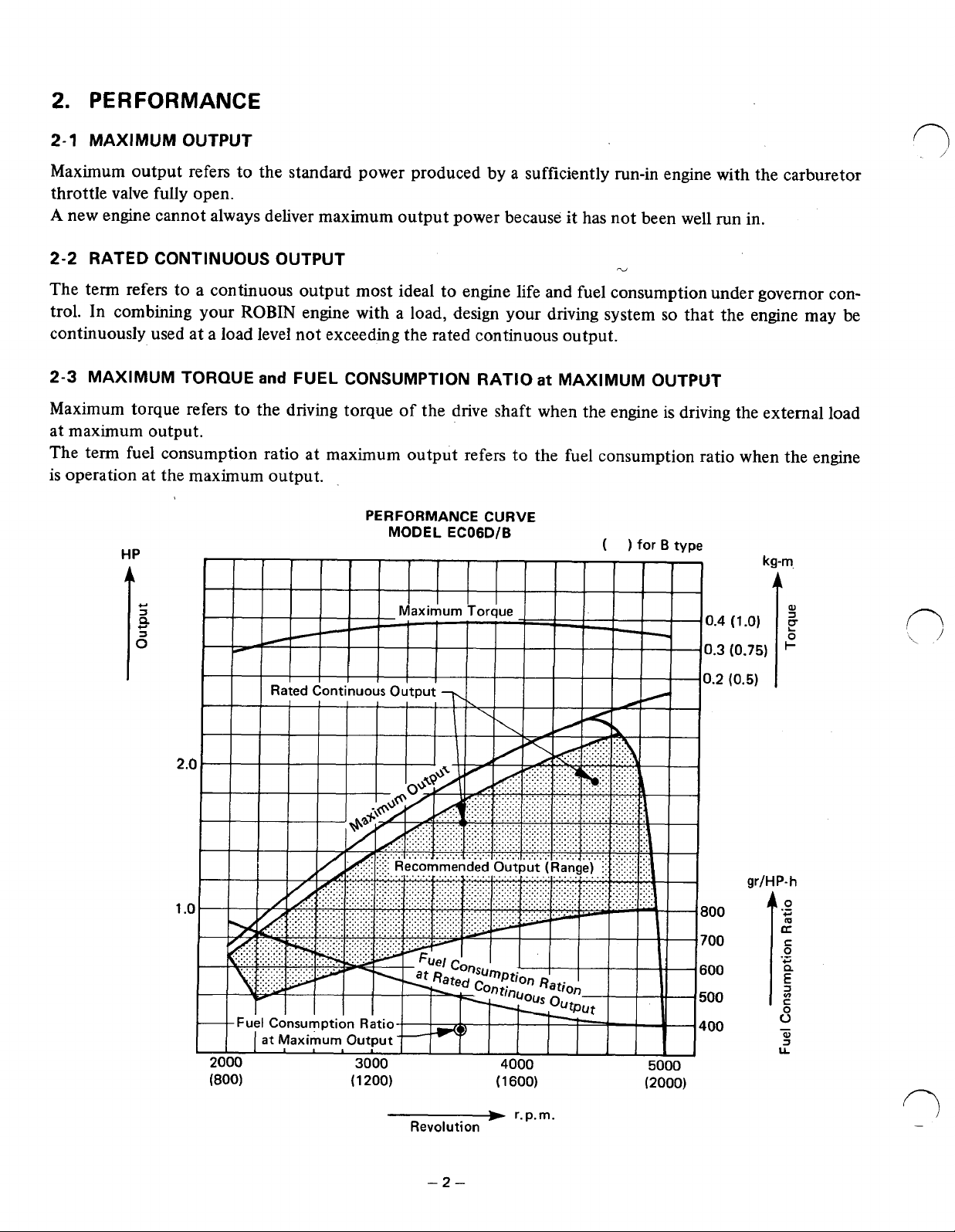

2.

PERFORMANCE

2-1

MAXIMUM OUTPUT

Maximum output refers

throttle valve fully open.

A

new engine cannot always deliver maximum output power because it has not been well run in.

2-2

RATED CONTINUOUS OUTPUT

The term refers to a continuous output most ideal to engine life and fuel consumption under governor con-

In

trol.

continuously used at a load level not exceeding the rated continuous output.

combining your

to

the standard power produced by a sufficiently run-in engine with the carburetor

ri/

ROBIN

engine with a load, design your driving system

so

that the engine may be

0

1

2-3 MAXIMUM TORQUE

Maximum torque refers to the driving torque of the drive shaft when the engine

at maximum output.

The term fuel consumption ratio at maximum output refers

is operation at the maximum output.

HP

w

2

P

+

and

FUEL CONSUMPTION RATIO

PERFORMANCE

MODEL ECOGD/B

to

CURVE

at

MAXIMUM OUTPUT

the fuel consumption ratio when the engine

(

1

for B type

6

I

is

driving the external load

(1

200)

--W

Revolution

-2-

(1

600)

(2000)

r.p.m.

Page 7

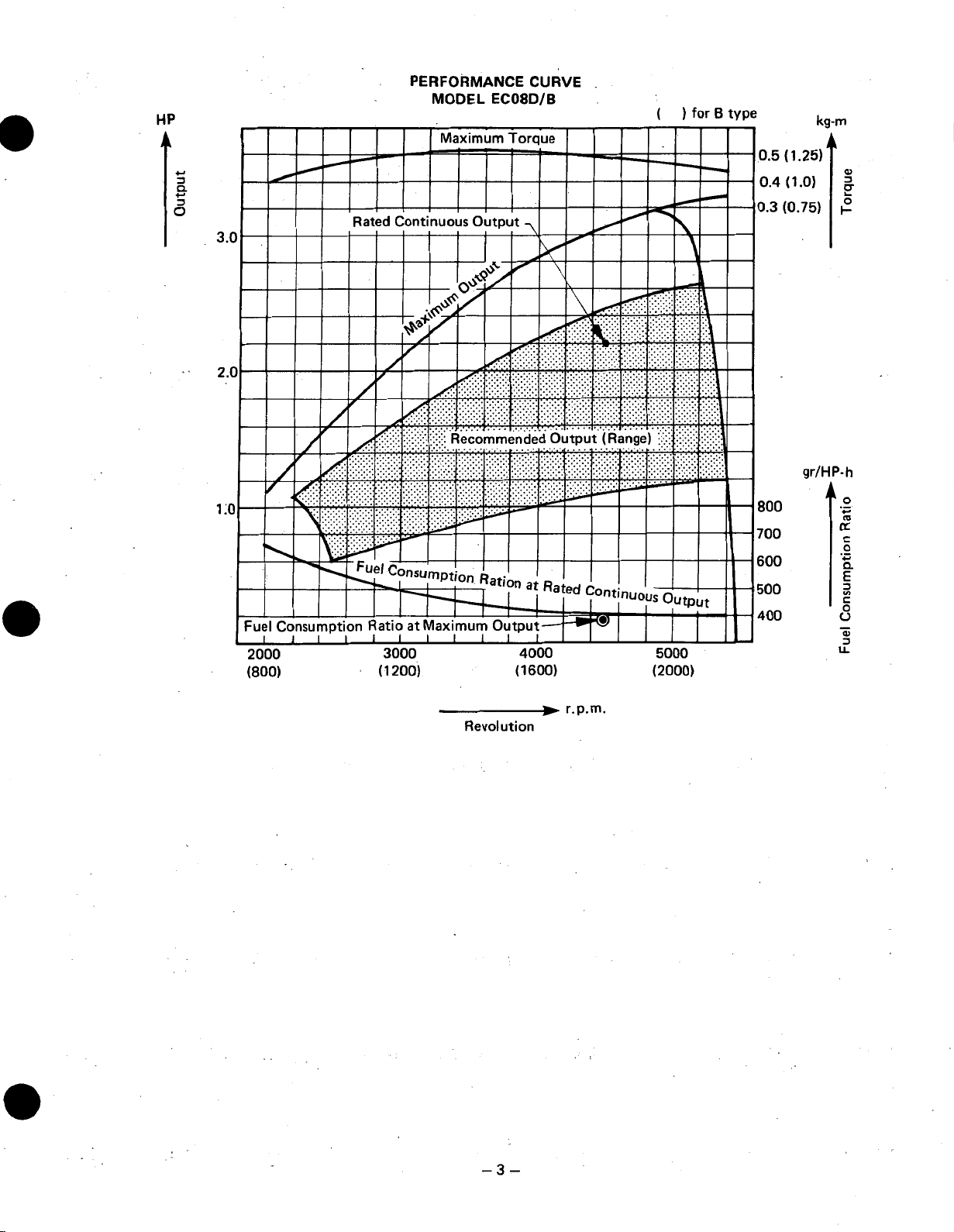

HP

PERFORMANCE

MODEL

EC08D/B

CURVE

.

( )

for

B

type

(

1.25)

kg-m

W

(0.75)

gr/H

P-

h

(1

200)

--*

Revolution

(1

600)

(2000)

r.p.m.

-3-

Page 8

3.

FEATURES

Compact, lightweight, high-powered engine with reliable operation also in the low speed range

1.

2.

Extremely simple in construction, trouble-free, and very easy

Quiet running engine using a lined aluminium cylinder

3.

4.

Equipped with T.C.I. (Transistor Circuit Ignition)

5.

So

durable that the engine can stand hours of tough work.

Needle bearings are used for the crank pins and piston bearings to enable the engine to withstand high-

speed operation under heavy load.

The carburetor works at inclinations of up to aboaut

6.

overflows from its air vent.

The recoil starter permits easy starting.

7.

Useful in a wide range of applications

8.

A

direct-coupled, reduction type engine, and other types that differ from the standard models in drive

shaft dimensions and shape are also available.

The all-speed governor operates at any engine speed.

9.

The desired rpm. can be obtained by simply moving the control lever, and it remains constant even if

the load changes.

Resistant to vibration (EC08)

IO.

Manufacturers of rammers and plates (machines

are using these ROBIN engines.

(EC06)

30"

for

compacting earth by vibration) around the world

to

use

so

that the engine can operate until the fuel

-4-

Page 9

m

4.

DISASSEMBLY

4-1

PRE-PARATIONS

.Disassembly

-1)

In"disassembling, remember the location

in the right way. Attach tags to those parts which might be mistaken for others.

and

REASSEMBLY

and

SUGGESTIONS

of

each part

so

that the disassembled partsEcan be reassembled

...

..

,.

2) Carefully handle the gaskets because they can easily break.

3)

Temporarily fasten disassembled parts in their original positions to prevent them from missing and wrong

reassembly.

4)

Carefully handle disassembled parts and clean them with kerosene.

5)

Use thecorrect tools in the correct way.

6)

Items necessary for disassembly and reassembly

pan

oil

before disassembling.

7)

a. 'Work bench b. Kerosene

e.

Be sure

sandpaper,

to

discharge the'fuel and

spatula, waste cloth

I

c. Disassembly tools d. Kerosene or gasoline

1

-

1.

..

..

.Reassembly

1)

Use new packing and gaskets in reassembling the engine.

2) Clean the parts with fresh gasoline, and blow them dry with compressed air before reassembling.

3)

Apply 2-cycle oil to the rotary and sliding parts.

4)

Keep the.parts free

of

dust during reassembly.

Tighten.the bolts, nuts, and screws.with the specified torques.

5)

Each'time a set

6)

After reassembling the engine, turn

of

main parts is installed, manually'turn it and check for smoothness and noise.'

it

manually and check

for

abnormalities and looseness.

.

.

I

4-2

SPECIAL TOOLS

.

.%

"

..

..

..

Flywheel

Fig.

Pulley

1

Page 10

4-3

DISASSEMBLY

4-3-

1

DISCHARGING FUEL

PROCEDURE

Discharge the fuel from the fuel tank.

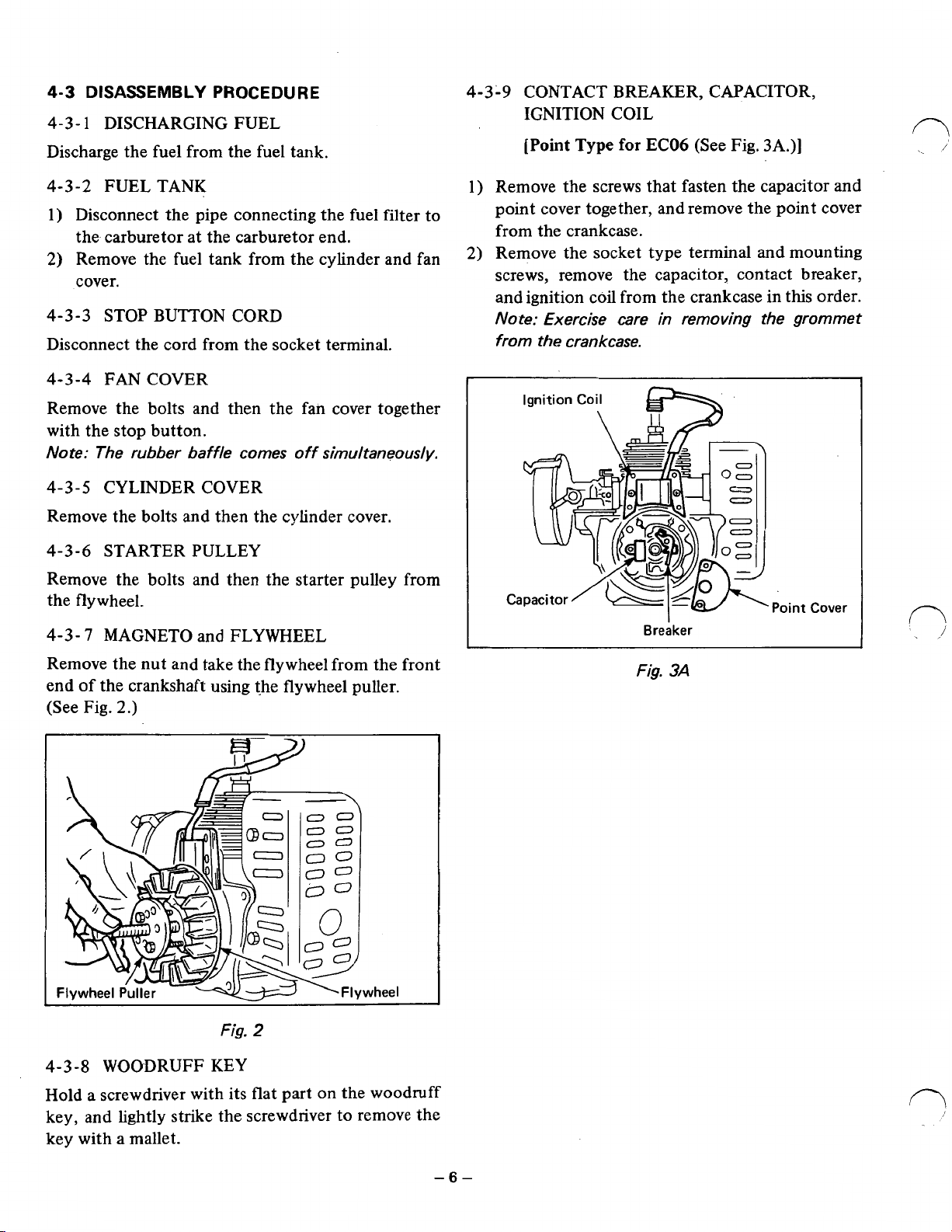

4-3-9

CONTACT BREAKER, CAPACITOR,

IGNITION COIL

[Point

Type

for

EC06

(See Fig.

3A.)]

n

\/

4-3-2

FUEL TANK

1) Disconnect the pipe connecting the fuel filter to

the carburetor at the carburetor end.

2)

Remove the fuel tank from the cylinder and fan

cover.

4-3-3

STOP BUTTON CORD

Disconnect the cord from the socket terminal.

4-3-4

FAN COVER

Remove the bolts and then the fan cover together

with the stop button.

Note: The rubber baffle comes off simultaneously.

4-3-5

CYLINDER COVER

Remove the bolts and then the cylinder cover.

4-3-6

STARTER PULLEY

Remove the bolts and then the starter pulley from

the flywheel.

4-3-

7

MAGNETO and FLYWHEEL

1) Remove the screws that fasten the capacitor and

point cover together, and remove the point cover

from the crankcase.

2)

Remove the socket type terminal and mounting

screws, remove the capacitor, contact breaker,

and ignition coil from the crankcase in this order.

Note: Exercise care in removing the grommet

from the crankcase.

Ignition

Coil

Breaker

Point

Cover

Remove the nut and take the flywheel from the front

end of the crankshaft using the flywheel puller.

(See Fig.

4-3-8

2.)

Fig.

WOODRUFF KEY

2

Hold a screwdriver with its flat part on the woodruff

key, and lightly strike the screwdriver to remove the

key with a mallet.

Fig.

3A

-6-

Page 11

[

T.

C.

I.

(Transistor Control Ignition) magneto]

1

)

Features

The T.C.I. magneto completely solves the prob-

lems with the conventional point type magneto,

is,

that

ignition timing deviation due to mechanical wear,

etc.

2)

Construction

The components

shown in Fig.

are explained.

stains, burns, rusting during long storage,

of

the magneto assembly are as

3B.

T.C.I.

The main parts

Unit

Generating Assembly

of

the magneto

Flywheel Complete

./

FLYWHEEL COMPLETE

The FLYWHEEL COMPLETE has perma-

so

nent- magnets

magnets generates an AC electromotive force

in the primary coil

bly.

GENERATING ASSEMBLY

The GENERATING ASSEMBLY consists

the primary coil and secondary coil. The rotation

erates a voltage in the primary coil and feeds

a current. At the same time a high voltage

induced in the secondary coil. This high voltage causes the spark plug

T.C.I. UNIT

The T.C.I.

and

primary current waveform generated in the

GENERATING ASSEMBLY,

the transistor

rent.

This abrupt current change causes a high voltage to be induced in the secondary coil.

of

the FLYWHEEL COMPLETE gen-

other semi-conductor parts. It senses the

that the rotation of these

of

the generating assem-

to

spark.

UNIT

consists maily

to

cut

off

and

the primary coil cur-

of

an SCR

switches

of

is

~

Fig.

3B

3)

Wiring diagram

Prim r Wir

r

Plug

Spark

-

T.C.I.

Unit

-7-

*

Assembly

Fig.

3C

Page 12

4-3-

10

CARBURETOR, GOVERNOR LEVER

4-

3 - 13

REDUCTION GEAR (Type B only)

1) Remove the nut and then the carburetor from

the cylinder.

2)

Loosen the nut, and remove the governor lever

from the governor shaft.

3)

Remove the governor spring from the governor

lever.

c

Carburetor

Governor Lever

L

1) Remove the drain plug from the reduction chamber to discharge the

2)

Remove the reduction chamber cover from the

oil.

engine.

3)

Remove the nuts, and pull the reduction pinion

out from the crankshaft.

(See Fig.

4)

Remove the woodruff key.

Reduction Cover

6.)

%@"

Reduction Pinion

eduction Chamber

'Drain Plug

%

Woodruff Key

Fig.

4

4-3-

1

1

SPARK PLUG

Remove the spark plug using a box wrench.

4-3

-

12

MUFFLER (MUFFLER

COVER)

Remove the nuts, and then the muffler from the cyl-

Nut

5.)

p/

Muffler Cover

inder. (See Fig.

Note: Keep the muffler cover on.

Fig.

6

4-3-14

CYLINDER

Remove the nuts, and carefully lift the cylinder off,

exercising care not to damage the contact surfaces

of

the piston and cylinder. (See Fig.

Note: Hold the piston when the cylinder

a

certain height from the crankcase,

cylinder off the piston. Damage to them can be prevented this way.

Cylinder

7.)

and

is

lifted

raise the

rankcase

to

n

\

fig.

5

-8-

Fig.

7

Page 13

4-3-

15 DIVIDING CRANKCASE

4-4

REASSEMBLY

PROCEDURE

Remove the bolts, and carefully strike the crankcase

with a mallet to part it. (See Fig.

8.)

Clean the divided crankcase with gasoline, and apply

engine oil to the bearing, and grease to the oil seal

lips.

Note: Be careful not to damage the crankcase joint.

\

Rear Crankcase

I

Crankshaft

Fig.

8

Fro"; Crankcase

4-4-1 CRANKSHAFT COMPLETE and PISTON

Apply engine oil to the needle bearing, and fit

it

onto

the small end of the connecting rod. With the mark

M

on the piston head on the flywheel (magneto) side,

fit

the piston head on the piston. Apply engine

oil

to

the piston, and lightly strike the pin into the piston

with a mallet (until the pin

is

poisitoned inward

of

the clip grooves). Then fit two clips into the clip

10

grooves. (See Fig.

Note: Be careful not to damage the piston pin hole

in the piston. Be sure to use new clips. The mark

must be in the direction of the front

crankshaft.

.)

M

end

of the

4-3- 16 PISTON, PISTON PIN, NEEDLE BEAR-

ING, and CLIPS (See Fig.

Remove the clips. With a iron rod

9.)

10

to 1 1 mm in

diameter on the piston pin, lightly strike it with a

plastic Hammer to remove the piston pin. Pull out

the iron rod, and remove the piston and needle bearing.

Note: Be careful not to damage the.piston pin hole

in

the piston.

Fig.

-10

.

I

4-4-2 INSERTING CRANKSHAFT INTO

CRANKCASE

Place the rear half

of

the crankcase

on

the work

bench securely, and insert the crankshaft into the

crankcase bearing by hand.

Note: See that the front and rear halves of the crank-

case can

4-4-3

Wipe the joint surfaces

of

from them, apply a sealant

be

reassembled properly.

CRANKCASE REASSEMBLY (See Fig.

of

the front and rear halves

1

the crankcase until oil is completely removed

to

them, and with the

1.)

dowels in line with their matching holes, reassemble

the crankcase.

Note: Exercisegood care not to damage the governor

sleeve, yoke assembly, and oil seals. Keep the joint

surfaces of the front and rear halves of the crankcase

parallel to each other

the original assembly.

in

pressing them together into

-9-

Page 14

Crankshaft

Rear Crankcase

\

Governor

Yo

1

ke

4-4-7

I

Tighten the spark plug into the cylinder.

Note: Tightening torque.

4-4-8

Tighten the governor lever to the governor shaft with

the nut. (For the adjusting procedure, refer to the

section on governor adjustments.)

SPARK PLUG

.

. .

GOVERNOR LEVER

. .

.

275

+25

kg-crn

E

I

Front Crankcase

4-4-4

Tighten the bolts with spring washers and plain washers.

Note: Tightening torque

4-4-5

Replace the old cylinder gasket with a new one, apply oil to the cylinder and piston, make sure that the

piston

and install the cylinder.

Note: Be careful not to let the gasket slide

place.

Governors'

Fig.

CRANKCASE

CYLINDER REASSEMBLY

rings

and

cylinder are positioned correctly,

Cylinder

I

1

1

.

. . . . .

1

10

(See

'I

f

20

kg-cm

Fig. 12.)

out

of

4-4-9

Hook the governor spring to the governor lever and

governor. (See Fig.

Note: Be careful of the hooking positions.

4-4-

GOVERNOR SPRING

13.)

/

Governor Lever

Fig.

10 CARBURETOR

Governor Spring

(attached

13

to

bottom)

n

Fig.

12

4-4-6

Tighten the nuts with spring washers and plain washers.

Note: Tigtening torque.

CYLINDER TIGHTENING

.

. . . . . .

Tighten all the four nuts evenly.

1

10

k

IO

kg-crn

-

a

Replace the old gasket with

the carburetor.

Note: Tightening torque

4-4-

11 MUFFLER (MUFFLER COVER)

Replace the old gasket with a new one, and tighten

the muffler to the cylinder.

Note: Tightening torque

4-4-

12 WOODRUFF

Drive the woodruff key into the keyway in the crankshaft using a mallet.

Note: Drive it parallel

4-4-

13

IGNITION

TIGHTENING

With the high-tension cord (to be connected

spark plug) up, temporarily tighten the ignition

10

-

.

. .

KEY

to

the shaft axis.

COIL

new one, and install

.

.

.

. . . .

80

2

.

. . . .

.

80

f

TEMPORARY

IO

IO

kg-cm

kg-cm

to

n

the

coil.

Page 15

4-4-

14

CONTACT BREAKER (POINT)

CAPACITOR (EC06)

Install the contact breaker by inserting'its shaft into

the matching hole in the rcrankcase. Pass the cord

under the capacitor into the cord hole in the crankcase.

Temporarily tighten the capacitor.

4-4- 15 IGNITION TIMING CHECK (EC06)

Temporarily install the flywheel, and check and ad-

just the ignition timing.

(For ignition timing adjustment, refer to the section

on contact breaker adjusting procedure.)

Note: Ignition timing

...............

23"

k2'

4-4-

17

FLYWHEEL (MAGNETO)'

Install the flywheel on the crankshaft by tightening

the nut'with plain and spring washers.

Note: Completely remove oil from the tapered por-

tion.

Tightening torque

.......

400

k

20

kg-cm

4-4- 18 IGNITION COIL

Adjust the air gap with a searcher, and tighten the

ignition coil with plain and spring washers. (See Fig.

15.)

Note: Air gap.

Tightening torque

....

.0.5

foe.

..........

mm

50

f5

kg-cm

4-4- 16 POINT COVER (EC06)

,

,'

Remove the flywheel, fit the point-to-capacitor lead

into the crankcase groove, and install the.point cover. (See Fig. 14.)

Tighten the temporarily tightened capacitor securely.

Note: Tightening torque

Lead

Capacitor Lead

Primary Wire

Turn primary wire once and

pull

it in direction

A.

.........

Wiring Method

Crankcase Groove

II

-./

I

w

I

25

f

2

kg-cm

//

I

Capacitor lead

primary wire here.

Fig.

14

is

above

15

Fig.

4-4-,19 STARTER PULLEY

to

Tighten the starter pulley

the flywheel with the

bolt. (Use plain and spring washers.)

Note: Tightening torque

........

90

f

IO

kg-cm

4-4-20 FAN COVER, STOP BUTTON,

GROMMET (See Figs. 16 and

Install the stop button with lockwasher

17.)

on

the fan

cover. Insert the high-tension cord into the grommet, and install baffle rubber on the fan cover. Fit

the grommet into the fan cover groove and, with the

tip

of

the rubber baffle at the round boss

in

the

crankcase, fasten the fan cover on the crankcase

with the bolt.

Note: Be careful not to pinch the stop button cord

fan

between the crankcase and

care not to drop the rubber baffle during fan cover

reassembly.

Tightening torque

.L

........

cover.

90

Also

2

10

exercise

kg-cm

-11

-

Page 16

4-4-21

CYLINDER COVER

Insert the cylinder cover tips into the matching slots

in the crankcase, and tighten the cylinder cover on

the cylinder. (See

Note: Insert the cylinder cover tips in

both sides.

Tightening torque

Fig.

18.)

.

. . .

. . .

.

80

to

f

the

10

slots

kg-cm

on

(Position

Fig.

16

Buffle

Whichever type, D or

the

punched marks on the crankcase in reassembing.

Flat surface inside

Note:

Rubber

Type

Install

right

installing Method

B,

your engine

Punched Mark (case)

Baffle Rubber

D

of

is,

Wider end up

the magneto.

in

Model

be careful of

Dl

4-4-22

Cylinder Cover

FUEL

TANK

Installing Method

Crankcase

Fig.

18

Insert the fuel pipe into the carburetor, clamp it,

fan

10

cover.

kg-cm

and mount the fuel tank on the cylinder

Note: Tightening torque

. . . .

. . . .

90

f

f7

,’

Wider end up

Punched Mark (case)

Flat surface inside

Baffle Rubber

Type

,

.Note:

Install left

fig.

of

the magneto.

17

-

12

-

Page 17

5.

CONTACT

1)

Remove the fan cover.

2)

Remove the starter pulley.

3)

Remove the flywheel.

4)

Loosen the capacitor screws.

5)

Remove the point cover.

6)

Remove carbon and other foreign particles from the point, polish-the contact surface with sandpaper

No.400

7)

Temporarily fasten the flywheel, bring the mark F in line with the matching mark on the crank case, and

remove the flywheel, exercising care not to turn it.

8)

Now, in this state, adjust the contact breaker

or equivalent, and wipe dirt off with a cloth.

BREAKER

ADJUSTING PROCEDURE (EC06)

as

shown below. (See Fig. 19.)

Mark

Fig.

19

Note: If the points are open in the sate illustrated above, ignition timing goes wrong

Be careful not to move the points especially when tigtenirig the breaker mount screw.

.

Ignition timing

a). Loosen the breaker mounting screw.

b) Push the breaker in the arrow direction

timing tester, for example), and tighten'the breaker mounting screw.

c) After the point adjustment, install the point cover, capacitor, magneto, and fan cover in this order.

. . . . .

. . . . . .

.

. . . .

. .

.

.I.

. .

.

.

.

. .

23"

*2''

to a position just before the points begin

to

a serious extent.

to

open (using a

-

13

-

Page 18

6.

CARBURETOR ADJUSTMENT

The carburetor is carefuuly adjusted in the factory before shipment. Never attempt to adjust it except when

necessary.

n

I

1) Idling Adjustment (See Fig.

20.)

Move the governor lever to the lowest speed position

(so

that the carburetor throttle valve fully

closes), and check that the engine idles quiet and

smooth. This is the ideal idling condition. Normally, the engine is set to an idling speed of 1600

k

100

rpm, for which the following two methods

may be used.

a) Low-speed stopper screw

Engine speed increases if the low-speed stopper screw

on

the carburetor is turned clockwise, or decreases if it is turned counterclockwise.

b)

Pilot screw (Do not turn it except

when necessary.)

When the pilot screw

is

turned clockwise,

the fuel-air mixture decreases and the engine

slows down. If the pilot screw is turned counterclockwise, the fuel-air mixture increases

to raise engine speed. The normal position

the pilot screw

is

one turn and a quarter back

from the clockwise extremity.

of

Fig.

20

2)

Maximum Speed Adjustment (See Fig.

The standard maximum speed

EC06,

or

5500

rpm for EC08.

is

2

5000

Move the governor lever to the highest speed

position, adjust the crankshaft rpm to

(EC06) or

5500

(EC08) with the high-speed

stopper bolt, and lock the bolt with the nut.

1.)

rpm for

5000

Low Speed

Fig.

21

Governor

Lever

-

14

-

Page 19

7.

GOVERNOR ADJUSTMENT

Fully open the carburetor butterfly valve, fasten the

governor lever, turn the governor shaft fully counterclockwise, and fasten the governor lever on the

ernor shaft with the nut. (See

Figs.

22

and,23.)

gov-

Fig.

22

Governor Rod Spri

Throttle Lever

Governor Lever

Crankshaft

Governor Rod

Carburetor

eed

Stopper

Bolt

Governor

Sleev

Control Lever

Fig.

-

15

23

-

Page 20

8.

TROUBLE-SHOOTING

The following three conditions must be satisfied for satisfactory engine start:

1)

The cylinder filled with a proper fuel-air mixture

2)

An appropriate compression in the cylinder

3)

Good

spark at correct time to ignite mixture

The engine cannot be started unless these three conditions are met. There are also other factors which make

engine start difficult, e.g., a heavy load on the engine when it

is

about

to

start at low speed, and a high back

pressure due to a long exhaust pipe, just to say a few,

The most common causes of engine troubles are given below:

8-1

STARTING

Trouble

No

or little

spark

TROUBLE

Cause

Spark plug defective

High-tension cable

defective

Contact breaker

defective

I

I

(1)

If spark plug is dirty, clean it well with gasoline

or polish it with sand-paper. Remove foreign

matter if any.

(2)

Adjust spark gap to

(3)

If spark plug hasfaulty instulation due to

breakage, replay it with a new one.

If defective, replace the cable and ignition coil

together.

(1)

If points are rough, polish them with sand-

No.

paper

(2)

If point gap is wrong, loosen contact mount

screw, and adjust it to

Also

adjust ignition timing if possible.

(3)

If ignition timing is wrong, adjust it to

23' f 2'

(4)

If breaker has faulty insulation, replace

the breaker with

(5)

If capacitor is defective, replace

a new one.

Remedy

0.6 - 0.7

400.

before top dead center.

a

new one.

mm.

0.35 ? 0.05

it

mm.

with

Preventive hints

(1)

Use a spark plug of the speci-

Do

fied heat value.

low-quality oil. Clean the air

cleaner to prevent dust from

entering.

(2)

Be carefid not to strike the

center pole or forcibly twist

it in adjusting spark gap.

Otherwise, insulation breaks

down.

not use

-

16

-

Page 21

rrouble

Vo

or little

;park

No

or

little compression

Cause

Magneto defective

Electrical system

defective

Fuel leaks from

gaskets

or

other

Piston defective

Remedy

(1)

If coil is broken or its insulation defective,

replace magneto with a new one.

(2)

If magnetism

has

decreased, have it remagnetized at magneto manufacturer's or

replace magneto.with

~~ ~ ~~

(1)

If stop button is defective (grounded),

a

new one.

repair or replace it.

(2)

If primary wire is grounded to the engine

body, insulate it with tape.

(1)

If head gasket is defective, replace it

with a new one.

(2) If spark plug is loose, retighten it securely.

(3)

If spark plug is defective, replace

it

with

a new one.

(1)

If piston is worn, replace it with a new one.

(2) If piston rings are worn, replace them

with new ones.

Preventive

[l)

Keep air cleaner clean.

:2)

Do

not use lowquality oil.

(3)

Change

oil

periodically.

hints

No

fuel

feed

Excessive

fuel

suction

Fuel tank defective

Carburetor

defective

Carburetor

defective

(1)

Clean tank outlet if clogged up.

(2)

Clean fuel strainer if clogged up.

(3)

If wrong fuel is used or if water is in fuel

tank, change fuel.

(4)

If air is trapped in fuel pipe, discharge air.

(1) Clean carburetor if clogged up.

(2) Replace carburetor with a new one if

defective.

if

Clean jets and orifices

(1)

Fully open choke, half open throttle valve,

clogged up.

'

and start engine.

(2j Remove crankcase drain plug, close fuel cock,

actuate starter a few times to discharge

excess fuel.

(1)

If carburetor overflows, check needle

valve seat for wear, and replace if

necessary.

(1)

Pour fuel into the fuel tank

through filter.

(2)

Use gasoline-oil

(25

mixture.

(1)

Never close choke if engine

is warm.

(2)

Be sure to idle engine for

some time before stopping it.

This'not only

makes

starting easy but helps extend

engine life.

(3)

Completely clean air cleaner

because a clogged up

cleaner thickness

fuel.

to

next

air

1)

.

Excessive

resistance

to starting

Excessive load

Piston or

connecting rod

sticky

(1

j

Adjust power transmission belt tension

if

too high.

(2)

If it is still hard to start, install a clutch.

(1)

If

piston

is

sticky, replace it with a new one.

If

connecting rod is sticky at large or

(2)

small end, replace it with a new one.

-

17

-

(1)

Do

not use lowquality oil.

(2) Use-fuel of correct gasoline-

oil

ratio.

Page 22

Spark plugs won't spark.

w

OK

-

Wire connector loose

L

Connect connector securely.

Not

~

on engine

-

OK

T.C.I. unit faulty

Generating assembly faulty

1)

Continuity test on T.C.I. unit

Conduct this test using the T.C.I. unit checker (Part

No.106

Select either

79902

AC

or

00).

DC.

(Battery

stalled inside.)

Connect the unit's primary lead (black

for

type

D,

or yellow for type

E

(black) and the unit casing (or the

B)

crankcase if the unit is mounted on the

engine) to jack

C

(red) with the supplied

cable.

Turn the select dial to the position cor-

respoilding to the,engine type.

Keep the check switch

in

the

ON

tion, and wait until the pilot lamp

lights.

Wire damaged

securely mounted

is

in-

to jack

Check Switch Select

posi-

(LED)

Mount it on engine securely.

Conduct continuity test on

T.C.I.

Conduct continuity test on

coil. [See

Robin Checker

Fig.

Replace damaged parts.

for

Dial

24

T.C.I.

Spark

unit. [See

5.2).]

Gap

5.

I).]

Unit

Check Window

wer

Select

Switch

i

r"\

\I

-

la

-

Page 23

e) When the pilot lamp turns on, return the check switch to the

OFF

position. The

normal if a spark is observed at that instant.

If the T.C.I. unit checker is not available, use

"i) Connect the positive

Connect the negative

Resistance:

80

*ii) Connect the negative

Connect the positive

7

Resistance:

If

the

T.C.I.

2)

Continuity test on generating assembly

unit is found not normal by the above test, replace the unit.

to

(+)

terminal

(-)

terminal of the tester to the unit casing.

to 150 ohms (Tester range

(-)

terminal

(+)

terminal

10 k oiims

(Tester range

of

of

a

circuit tester as described below.

the tester to the primary lead.

x

1

ohm)

of

the tester to the p$mary lead.

the tester to the unit casing.

x

100

ohms)

Measure the resistance with a circuit tester.

a) Resistance between primary lead and core:

b) Resistance between secondary lead and core:

1.1

to 1.5 ohms

10

to

13

k ohms

'

If the generating assembly is found not normal by the above test, replace the assembly.

Note: A circuit tester is not

pending on the type

so

accurate that the resistance values measured by the tester may vary de-

of

tester, or the condition

of

battery, or the skill of operator.

T.C.I.

-

unit is

-

0

8-2

IDLING

1)

If the carburetor's pilot screw is not correctly adjusted, adjust it. (Refer

IMPROPER

adjustments.)

2)

Any

of

starting trouble causes leads to improper idling.

8-3

OVERHEATING

1)

If

ignition timing is advanced, adjust it to

2)

If

the cmbustion chamber has excessive carbon deposits, clean it.

3)

If a spark plug

for EC06,

4)

If the gasoline air-mixture is

NGK

and

ENGINE KNOCKING

23"

*

2".

(EC06)

'

of

a heat value too low is used, use one of the specified heat value. Example:

B7HS

for

EC08

too

lean, clean the jets and orifices

of

the carburetor.

cleaner.

5)

If

overload is the case, reduce it to normal level or below.

8-4

POWER

1)

Replace the cylinder, piston, and/or piston rings if worn.

2)

If

the carburetor is faulty, adjust or clean it.

3)

If the spark plug is faulty (dirty, leaky, or not properly insulated), clean or replace it.

4)

Retighten the cylinder if gas leaks.

5)

Replace or adjust if the magneto

6)

Clean the air cleaner if clogged up.

7)

Replace the crankshaft oil seals

DROP'

or

contact breaker is faulty.

if

compressed gas leaks due to seal wear.

to

the section on carburetor

NGK

Also

clean the air-

B6HS

-19-

Page 24

8-5

EXCESSIVE FUEL CONSUMPTION

1)

If the gasoline-air mixture fuel is too rich, clean the carburetor jets and orifices.

2)

Replace the carburetor if its throttle shaft is worn.

3)

Retighten or replace parts if fuel leaks.

4)

Take the steps against power drop described in Paragraph

also results from power drop.

8-6

HUNTING

1)

If the governor lever, governor shaft, or governor spring is not properly set or adjusted, readjust or correct it.

2)

If the mixture fuel is too lean, clean the carburetor.

3)

If the carburetor pilot screw is the cause, readjust it.

4)

If the governor spring is worn, replace it.

5)

If the governor sleeve does not work properly, correct it.

6)

Replace the flyweight or governor sleeve if

7)

If

the governor shaft does not work properly, correct it.

8-7

OTHER TROUBLES

worn.

8-4

above because excessive fuel consumption

1)

Carburetor overflow

If

the fuel overflows the carburetor to the air cleaner, or collects excessively in the crankcase during

stoppage, either the float valve or float is faulty. Replace or correct the faulty one.

2)

If the engine abruptly stops with an abnormal noise, it is due to a sticky piston, crankshaft, or connecting rod. Adjust or replace the faulty parts.

3)

If

any abnormal noise

start the engine again until the cause is determined.

If you cannot find the cause, contact your nearest dealer or service shop, and observe their advice.

is

heard during engine operation, be sure to stop the engine immediately.

Do

not

f"\

/

-

20

-

Page 25

..

..

. .

':

0.

-.

._

.

.

.

..

..

..

..

..

..

.I

'9.

CHECKS

~-

-.

.

.

After disassembiing and cleaning the'engine, check and adjust the parts according to the Standard Correction

.

;Table, .-which provides important information to be referred to in adjusting

'

.

;.fWiliar-with the table and conform to the.standards specified in servicing the engine.

"

.

..

I.

.

...

.-

,%

and

..

.

.j

.

CORRECTIONS

.."

...

I

.

,.

,

.I

8

...

.,

,,

-.,

or

repairing the engine. Be

The terms used in the table are defined as follows:

.

1)

-

Correction

Repair, adjustment, or replacement of any engine part

2)

Correction limit

'

-

The limit

.

of

wear, damage,

.-

or

function degradation beyond which an engine part can hardly serve its

purpose unless if is corrected.

.

:

3)

Standard dimensions

Design dimensions less tolerance

..

-21

-

Page 26

9-1

ENGINE

STANDARD

CORRECTION

TABLE

Measuring/Correcting

I

Point Model

Clearance between

piston and cylinder

Bore EC06

dia.

Piston ring

side clearance

Correction

T

EC06 0.18L Calculate from parts

EC08

Standard Dimensions

Perpendicular to pin

0.07-0.1

Pin direction

0.09-0.146L

Perpendicular to pin

0.04-0.076

Pin direction

0.07-0.1 26L

06L

L

tO.016

0

44@

EC08

M.016

0

Limit

+0.08

Measuring

measurements.

Average

and minimum

of

maximum

inside diameters

5w

EC06

EC08

EC06

43.930

49.960

First ring

0.05-0.09L

Second ring

0.04-0.08L

-0.05

0.1 5L

Average

and minimum outside

diameters

Measure after

removing carbon.

of

maximum

Instrument

Cylinder gauge

Micrometer

Searcher

Correction

/

Replace

Replace

Replace Piston outside

Replace

EC08

Piston ring

groove width

Piston ring width Em, EC08

Ring

gap

Clearance between

piston and piston

pin

Piston pin

Piston pin

outside diameter

hole

EC06, EC08

EC06, EC08

EC06, EC08

EC06, EC08

EC06, EC08

First ring

0.06-0.1OL

Second ring

0.03-0.07L

1.8

1.8

0.1

-0.3

0.005T-0.014L

4-0.13

-0.10

.o

1

0.03L Calculate from parts

-0.017

Measure maximum

groove width.

Measure minimum

Lvidrh.

Ring in contact with

cylinder wall

measurements

Measure maximum

inside diameter

~~ ~~

Measure minimum

outside diameter.

Block gauge Replace

Replace Micrometer

Searcher Replace

Replace

Cylinder gauge

Micrometer Replace

Replace M.03

-

22

-

Page 27

MeasuringlCorrecting

I

Point

Model Standard Dimensions

Correction

Limit

Measuring instrument

Correction

Connecting rod

large end side

clearance

Crankshaft

deviation

Crankshaft

axial play

Main bearing

outside

diameter

Housing inside

diameter

Bearing outside

diameter

Main bearing

outside diameter

clearance

EC06, EC08 0.1

~

EC06. EC08

EC08

EC06,

EC06,

EC08

EC06, EC08 Front case

EC06, EC08 Measure bearing

EC06, EC08

-0.6L

0.05 or less

0.1 5-0.69

0.050T-0.01.4T

47@

Rear case

Front case 470

Rear case

Front

0.013T-0.006L

Rear

0.01

420

420

T-0.009L

0.8

L

0.1

0.1

0

-0.04

-0.016

0.01

0.01

2L

5L

Measure after

reassembly

in

reassembled state,

support both ends

of

crankshaft, and

measure

7.5

web.

Measure after

reassembly.

Calculate from

parts measurements

Housing

outside diameter

Calculate from parts

measurements.

it

mm

from crank

about

Searcher

Dial gauge

Dial gauge

Cylinder gauge

Micrometer

Replace

Replace

Replace

Replace

Replace

Replace

Bearing inside

diameter

Crankshaft outside

diameter

Connecting rod

small end inside

diameter

Ignition timing

Point gap

Air gap EC06

EC06,

EC06, EC08 Measure crankshaft

EC06, EC08

~

EC06

EC06

EC08

20@

23'

0.35

0.5

0.6-0.7

M.005

-0.02

+0.026

f

2O

*

0.05

0

-0.1

Measure bearing

inside diameter.

outside diameter

Cylinder gauge Replace

Micrometer

Cylinder gauge

Timing tester

Searcher Adjust

Searcher

Searcher Adjust

Replace

Adjust

Adjust

-

23

-

Page 28

9-2

TABLE

of

TIGHTENING TORQUE

No.

1

2

3

4

5

6

7

8

9

10

11

12

Parts

to tighten

Cylinder Cover, Muffler Cover

Fan Cover, Tank Support Plate,

Starter, Starter Pulley

Crankcase

Air Cleaner

Reduction Cover

Muffler

Cylinder

Carburetor

Governor Yoke

Governor

Ignition coil

Contact Breaker, Condensor

Point Cover

Plate

Tightening torque

kgcm

80*10

90k10

110 -+20

50

+5

110+20

80+10

110+10

80

+lo

18 *2

5025

50 *5

25

+2

.

Screw

diameter

M6 5T

M6 5T

M6 7T

M5 5T

M6

7T

M6

M6 7T

M6 4T

M3 4T

M5 4T

M5 4T

M4 4T

Remarks

Type

B

only

Nut

Nut

Nut

Apply screw lock (FT15 or equivalent)

and install (as in the

case

of

EC05, EC07)

13

14

15

16

17

18

Note:

Reduction Pinion

Spark Plug

Magneto Flywheel

Governor Lever

Stop Button

Rear Half of Crankcase

Be

careful not to apply screw lock more than necessary.

340 220

275 *25

+

20

400

80*10

40 +5

-

MI2 4T

MI4

M10 6T

M6 4T

M4 4T

M6

(Stand)

Nut, Type

Apply screw lock (FT15 or equivalent)

and install

B

only

(as

in the

case

of EC05, EC07)

-

24

-

Page 29

0

10.

,

The following maintenance jobs apply when the engine is operated correctly under normal conditions. The

indicated maintenance intervals are by

MAINTENANCE and STORING

..

no

means guarantees- for maintenance free operations during these

intervals. For example, if the engine is operated in extremely dusty conditions, the air cleaner should be

cleaned every day, instead of every

50

hours.

0

.10-1

2)

3)

4)

10-2

DAILY CHECKS and.MAINTENANCE

1)

Remove just from whatever which accumulated dust.

Check external fuel leakage.

If

any, retighten or replace.

Check screw tightening. If any lose one is found, retighten.

Clean air cleaner.

EVERY

50

HOURS

CHECKS

and

MAINTENANCE

Check spark plug. If contaminated, wash in gasoline or polish with emery paper.

10-3-

1)

2)

3)

10-4

EVERY

150

HOURS CHECKS and MAINTENANCE

Clean fuel straine-r and fuel tank.

Clean contact breaker points.

Clean exhaust

YEARLY CHECKS and MAINTENANCE

port

of cylinder and both inlet and outlet

..

of

muffler.

1) Remove carbon from cylinder head and piston head.

2)

Clean fuel tank inside.

3)

Clean carburetor float chamber inside.

4)

Clean contact breaker and adjust point gap.

5)

Replace fuel pipe once a year.

10-5

1) Perform the above 10- 1 and

2)

3)

PREPARATION

for

LONG ABEYANCE

10-2

maintenance jobs.

Drain fuel from the fuel tank and carburetor float chamber.

Remove spark plug, and apply 5 to

10

cc of lubricating oil through the spark plug hole. Perform idle

operation several times by pulling the recoil starter handle slowly. Re-install the spark plug.

4)

Clean the engine outside with oiled cloth.

5)

Put a vinyl

.'

.

...

or

other cover over the engine and store the engine in dry place.

-.

L.

I

-

25

-

Page 30

Page 31

Industrial

Engines

Loading...

Loading...