Page 1

Page 2

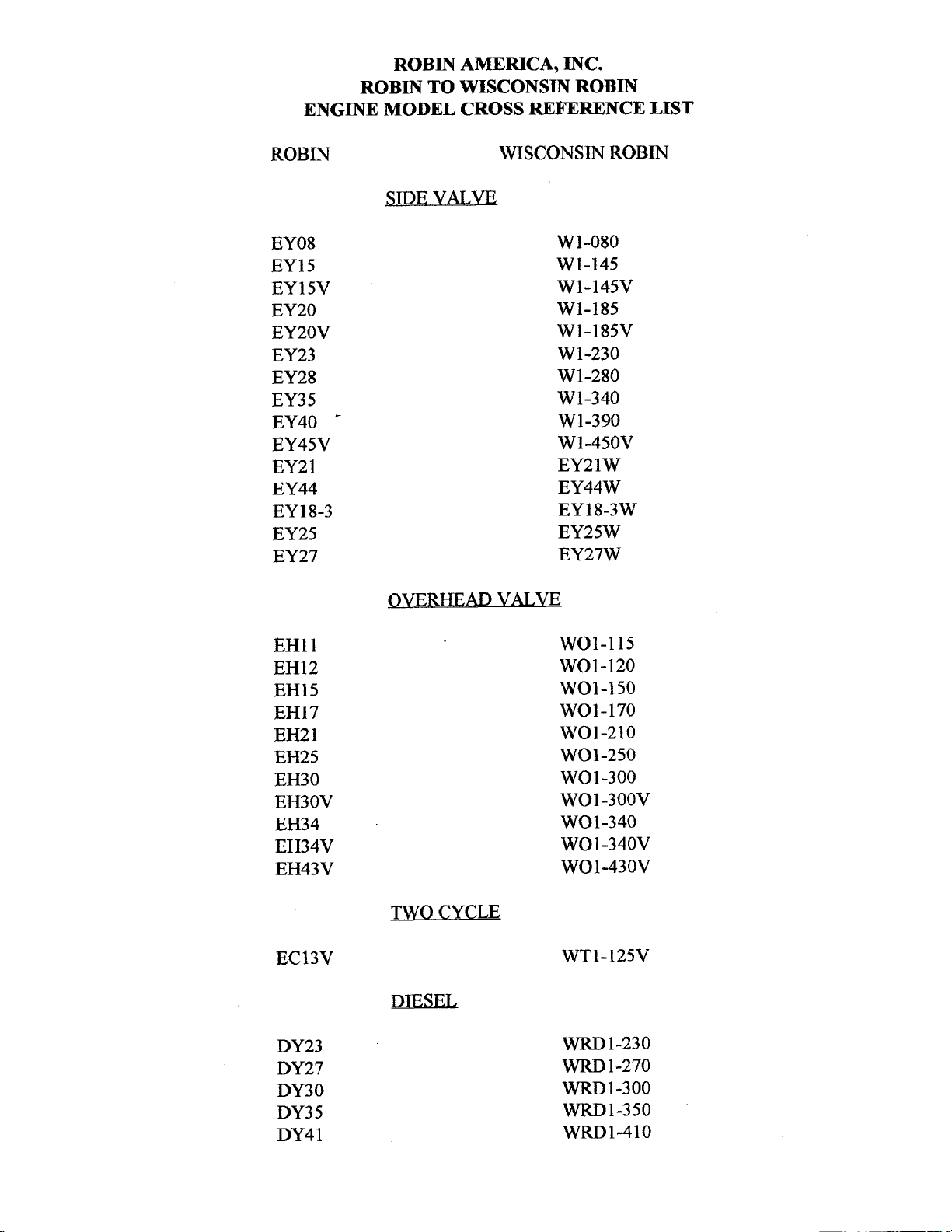

ROBIN

AMERICA, INC.

ROBIN

TO

WISCONSIN

ROBIN

ENGINE

MODEL

CROSS REFERENCE

LIST

ROBIN

EY08

EY15

EY 15V

EY20

EY2OV

EY23

EY28

EY3

5

EY40

-

EY45V

EY2

1

EY44

EY 18-3

EY25

EY27

EH11

EH12

EH15

EH17

EH21

EH25

EH30

EH30V

EH34

EH34V

EH43V

EC13V

DY23

DY27

DY30

DY3

5

DY4 1

WISCONSIN

ROBIN

SIDE

VALVE

W

1-080

W1-145

W1-145V

W1-185

W1-185V

W1-230

W 1-280

W

1-340

W 1-390

Wl-45OV

EY21W

EY44W

EY18-3W

EY25W

EY27W

OVERHEAD

VALVE

WO1-115

wo1-120

WO1-150

WO1-170

wo1-210

WOl-250

WO 1-300

WO1-300V

WO1-340

WO

1

-340V

WO 1-43 OV

TWO CYCLE

WT1-125V

DIESEL

WRD

1-230

WRD

1-270

-1-300

WRD1-350

WRD1-410

0

0

0

Page 3

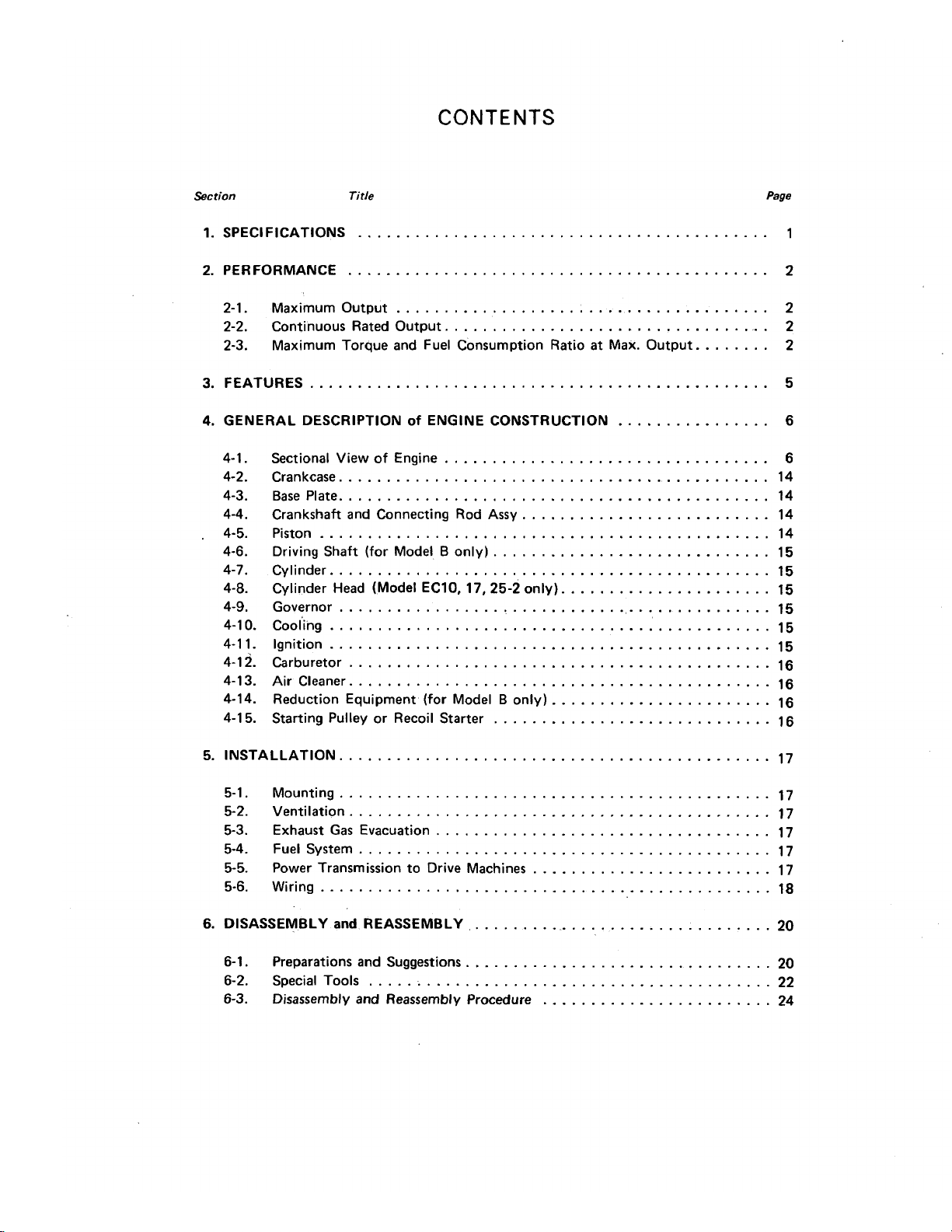

CONTENTS

Section

Title

Page

1

.

SPECIFICATIONS

...........................................

1

2 .

PERFORMANCE

............................................

2

2.1

.

Maximum Output

.......................................

2

2.2

.

Continuous Rated Output

..................................

2

2.3

.

Maximum Torque and Fuel Consumption Ratio

at

Max

.

Output

........

2

3

.

FEATURES

................................................ 5

4

.

GENERAL DESCRIPTION

of

ENGINE CONSTRUCTION

................

6

4.1

.

4.2

.

4.3

.

4.4

.

.

4.5

.

4.6

.

4.7

.

4.a

.

4.9

.

4-1

0

.

4-1 1

.

4- 1

2

.

4-1 3

.

4.14

.

4-1 5

.

Sectional View of Engine

..................................

6

Crankcase

.............................................

14

Baseplate

.............................................

14

Crankshaft and Connecting

Rod

Assy

..........................

14

Piston

...............................................

14

Driving Shaft (for Model B only)

.............................

15

Cylinder

..............................................

15

Cylinder Head (Model EC10.17.2

5.2

only)

......................

15

Governor

..............................,...............

15

Cool'ing

..............................................

15

Ignition

..............................................

15

Carburetor

............................................

16

Air Cleaner

............................................

16

Reduction Equipment

(for

Model B only)

.......................

16

Starting Pulley or Recoil Starter

.............................

16

5

.

INSTALLATION

.............................................

17

5.1

.

Mounting

.............................................

17

5.2

.

Ventilation

............................................

17

5.3

.

Exhaust

Gas

Evacuation

...................................

17

5.4

.

Fuel System

...........................................

17

5.5

.

Power Transmission to Drive Machines

.........................

17

5.6

.

Wiring

...............................................

18

6

.

DISASSEMBLY

and

REASSEMBLY.

...............................

20

6.1

.

Preparations and Suggestions

................................

20

6.2

.

Special Tools

..........................................

22

6.3

.

Disassembly

and

Reassembly Procedure

........................

24

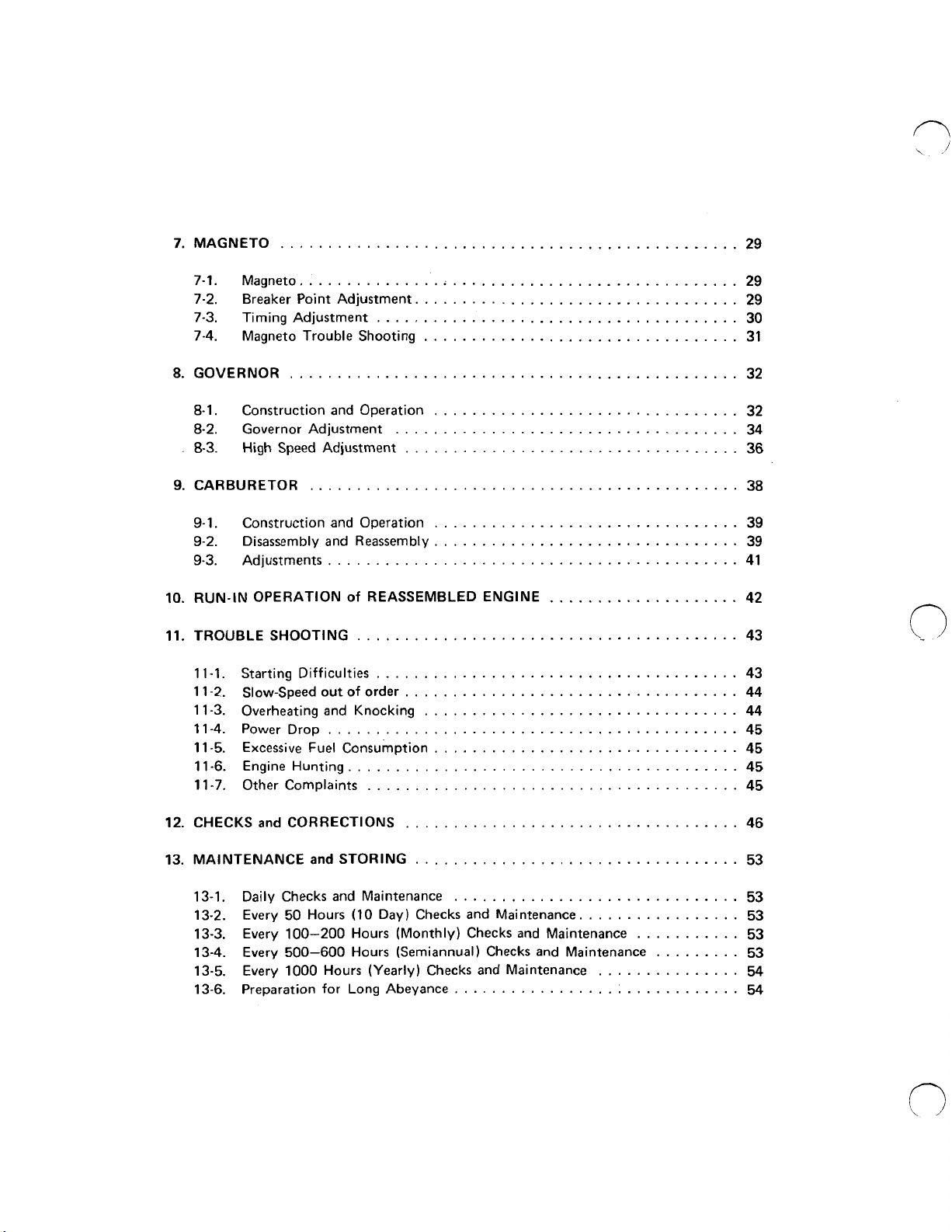

Page 4

7 . MAGNETO

7.1

.

Magneto.

7.2

.

Breaker Point Adjustment

7.3

.

Timing Adjustment

7.4

.

Magneto Trouble Shooting

8

.

GOVERNOR

8.1

.

Construction and Operation

8.2

.

Governor Adjustment

8.3

.

High Speed Adjustment

9

.

CARBURETOR

9.1

.

Construction and Operation

9.2

.

Disassembly and Reassembly

9.3 .

10

.

RUN-IN

I1

.

TROUBLE SHOOTING

11.1

11.2

11.3

11.4

11

11.6

11.7

Adjustments

OPERATION

.

Starting Difficulties

.

Slow-Speed

.

Overheating and Knocking

.

Power Drop

.5

.

Excessive Fuel Consumption

.

Engine Hunting

.

Other Complaints

................................................

..............

;

..............................

..................................

......................................

.................................

...............................................

................................

....................................

...................................

.............................................

................................

................................

...........................................

of

REASSEMBLED ENGINE

....................

........................................

......................................

out

of

order

...................................

.................................

...........................................

................................

.........................................

.......................................

29

29

29

30

31

32

32

34

36

38

39

39

41

42

43

43

44

44

45

45

45

45

0

12

.

CHECKS and CORRECTIONS

13

.

MAINTENANCE and STORING

13.1

.

Daily Checks and Maintenance

13.2

.

Every 50 Hours

13.3

.

Every

100-200

13.4

.

Every

500-600

13.5

.

Every

1000

Hours

13.6

.

Preparation for Long Abeyance

...................................

..................................

..............................

(10

Day) Checks and Maintenance

Hours (Monthly) Checks and Maintenance

Hours (Semiannual) Checks and Maintenance

(Yearly) Checks and Maintenance

.................

...............

..............................

...........

.........

46

53

53

53

53

53

54

54

Page 5

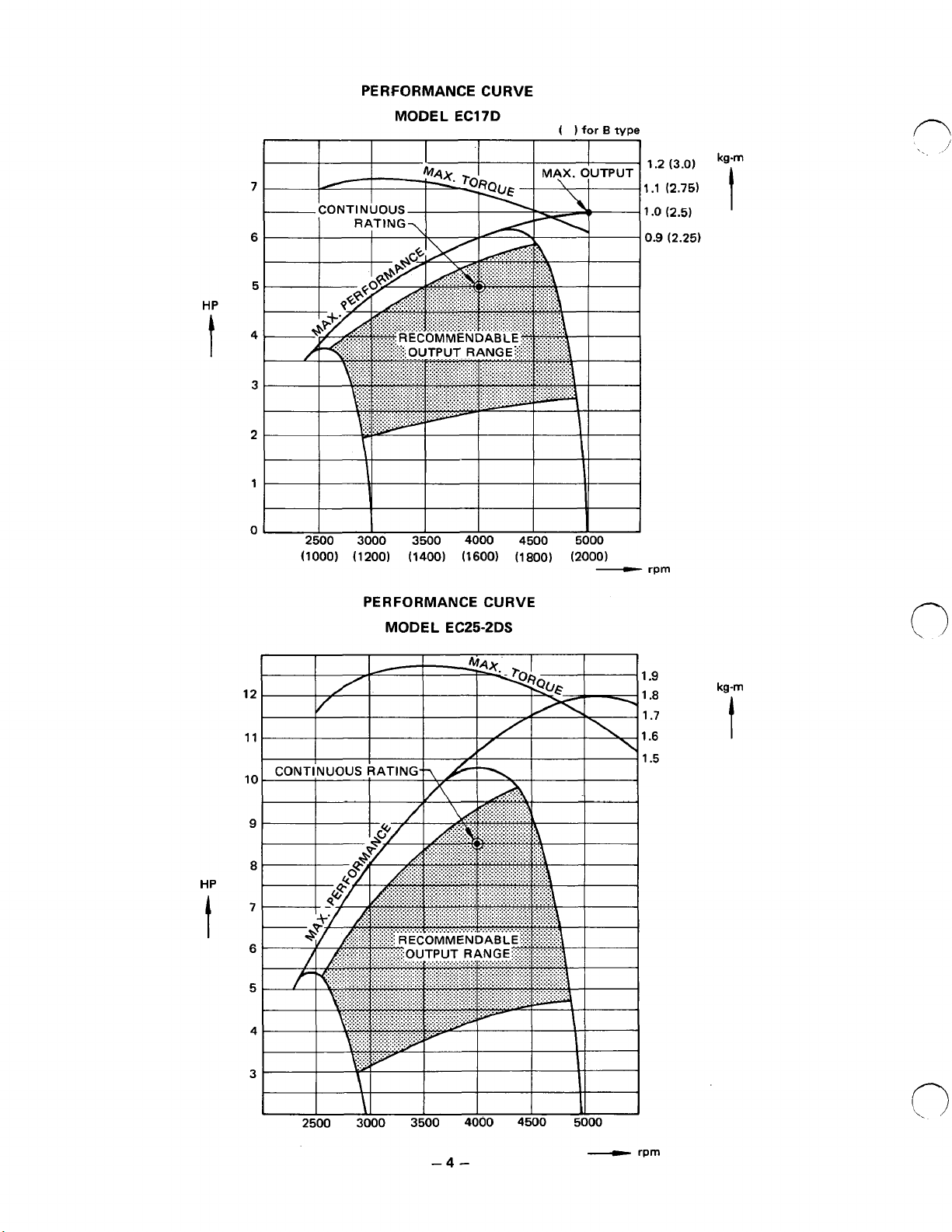

.-

1.

SPECIFICATIONS

1

0

0

'4

c

.

f

Lo

5-

0

m

00

Lo

0

9

.

ln

T

c

a

P

a

-1-

Page 6

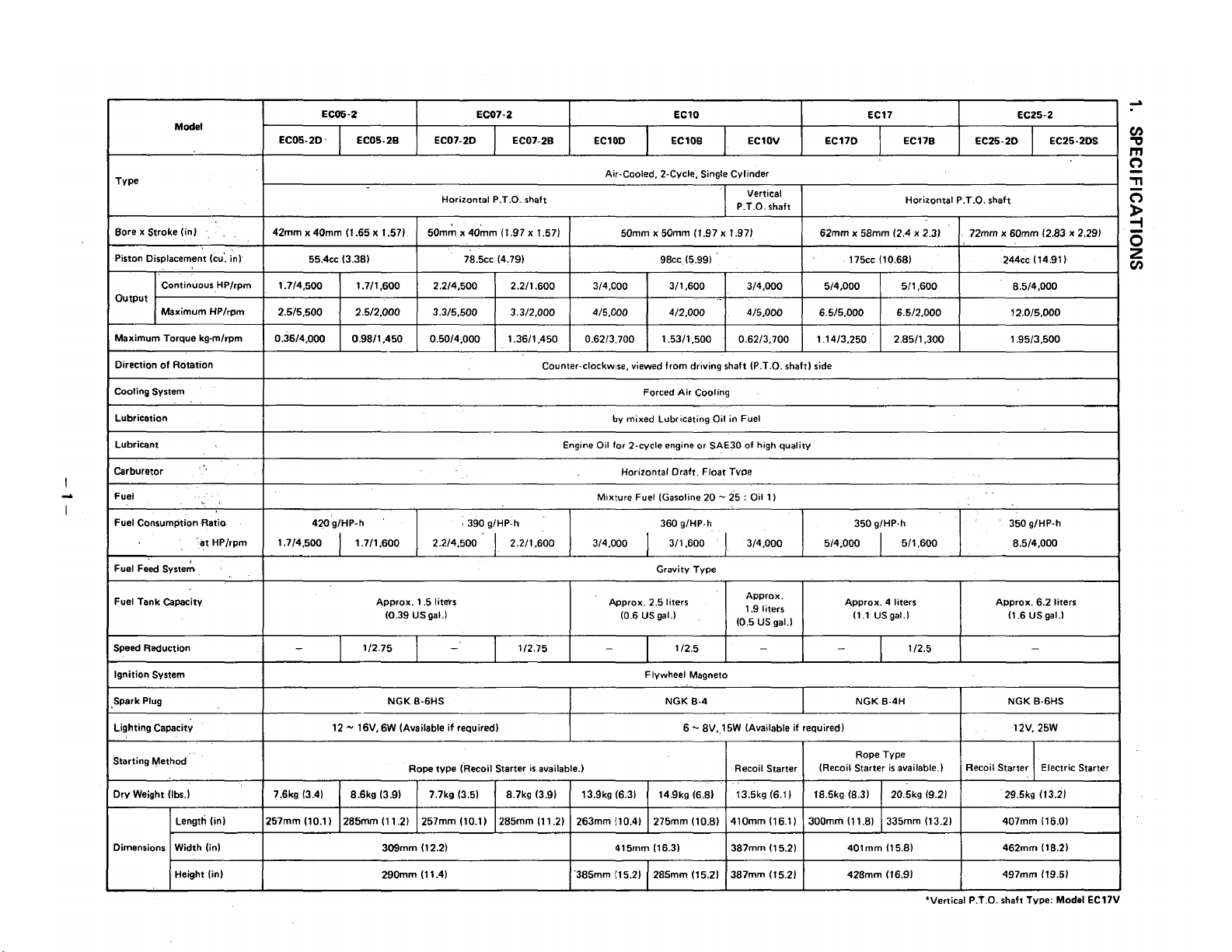

2.

PERFORMANCE

2-1

MAXIMUM OUTPUT

The maximum output

the moving parts properly worn-in, when operating with the fully open throttle valve. Therefore, it follows that a new

engine may not develop this maximum output in the beginning, because moving parts are not in a properly worn-in

condition.

2-2

CONTINUOUS RATED OUTPUT

The continuous rated output

most favorable from the point

driving

er requirement

2-3

The maximum torque of an engine is that driving torque

while the engine is developing its max. output. The fuel consumption ratio at max. output is that fuel consumption ratio

an engine while that engine is running at the max. output.

system

MAXIMUM TORQUE

for

of

of

an

engine is such standard power as developed by that engine, after its initial run-in period with all

of

an engine

of

view of engine life and fuel consumption ratio. Therefore, it follows that when designing a

any mechanism, with a model

that mechanism must

and

FUEL CONSUMPTION RATIO AT MAX. OUTPUT

is

such power as developed by that engine when running at an optimum speed

be

kept below the continuous rated output specified.

EC05-2,07-2,

PERFORMANCE CURVE

MODEL

IO,

17

or

25-2

of

the driving shaft at which the engine is driving an external load,

EC05-2D

engine, as a prime mover, the continuous pow-

of

HP

I

for

B

tvoe

2500 3000 3500'

(910) (1090) (1270) (1460)(1640) (1820) (2000)

4000

4500

5000 5500

0.4

0.3

(1.09)

(0.82)

t

-2-

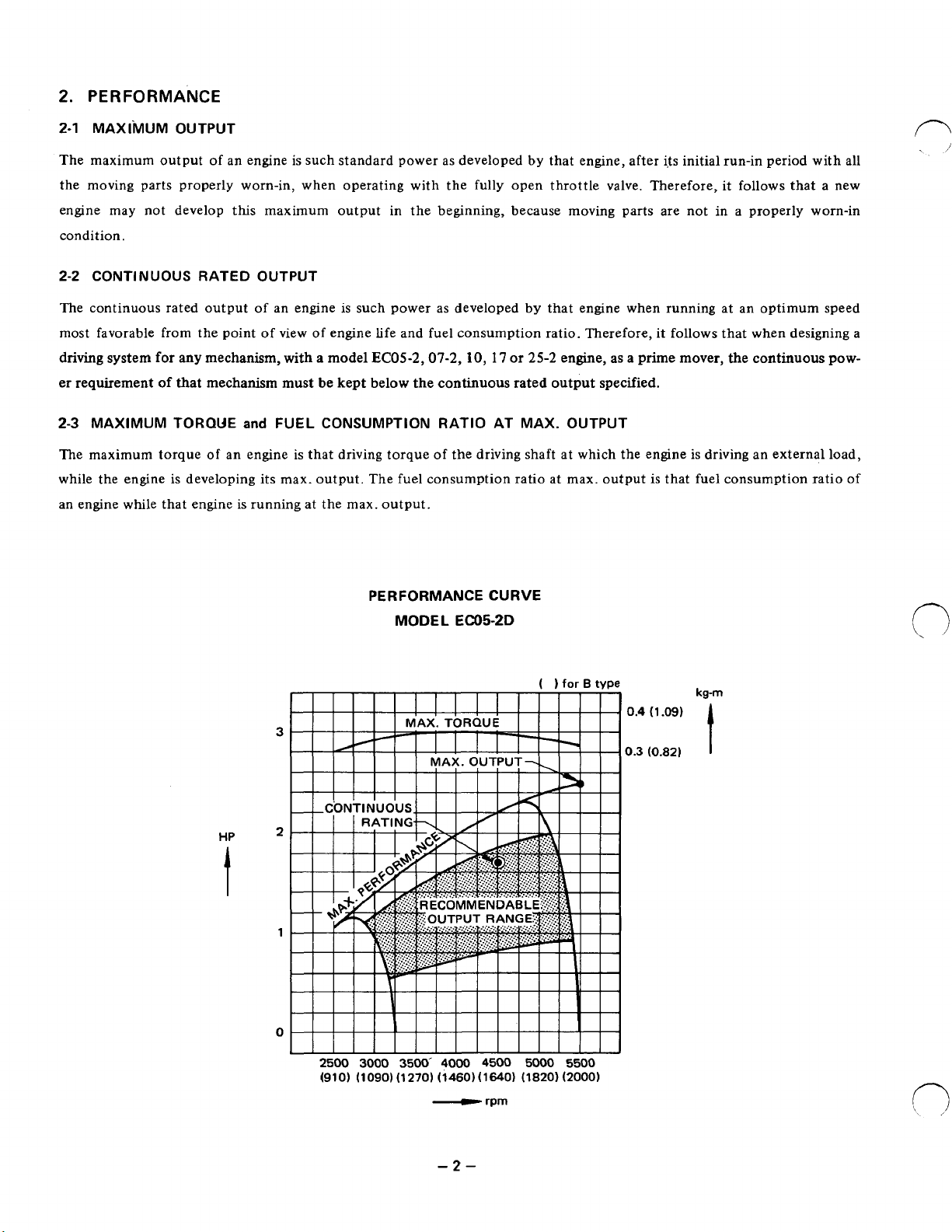

Page 7

PERFORMANCE CURVE

MODEL EC07-2D

( )

for

B

type

HP

t

4

3

HP

t

2

1

0

PERFORMANCE CURVE

MODEL ECIOD

(

)for

B

tj

(1000) (1200) (1400) (1600)

(1800)

(2000)

-

rpm

-3-

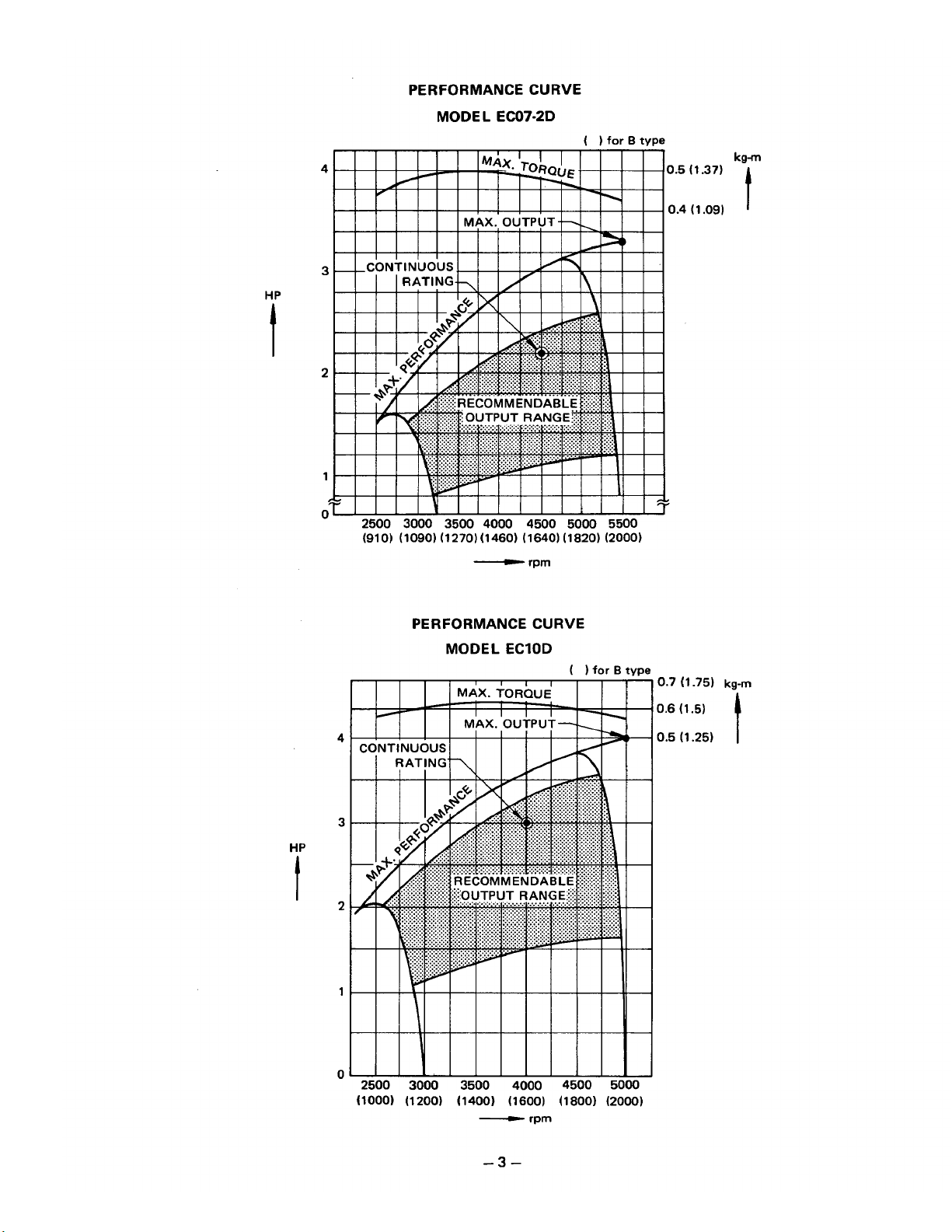

Page 8

HP

PERFORMANCE CURVE

kg-m

HP

t

PERFORMANCE CURVE

MODEL EC25-2DS

kg-m

-4

-

__c

rpm

Page 9

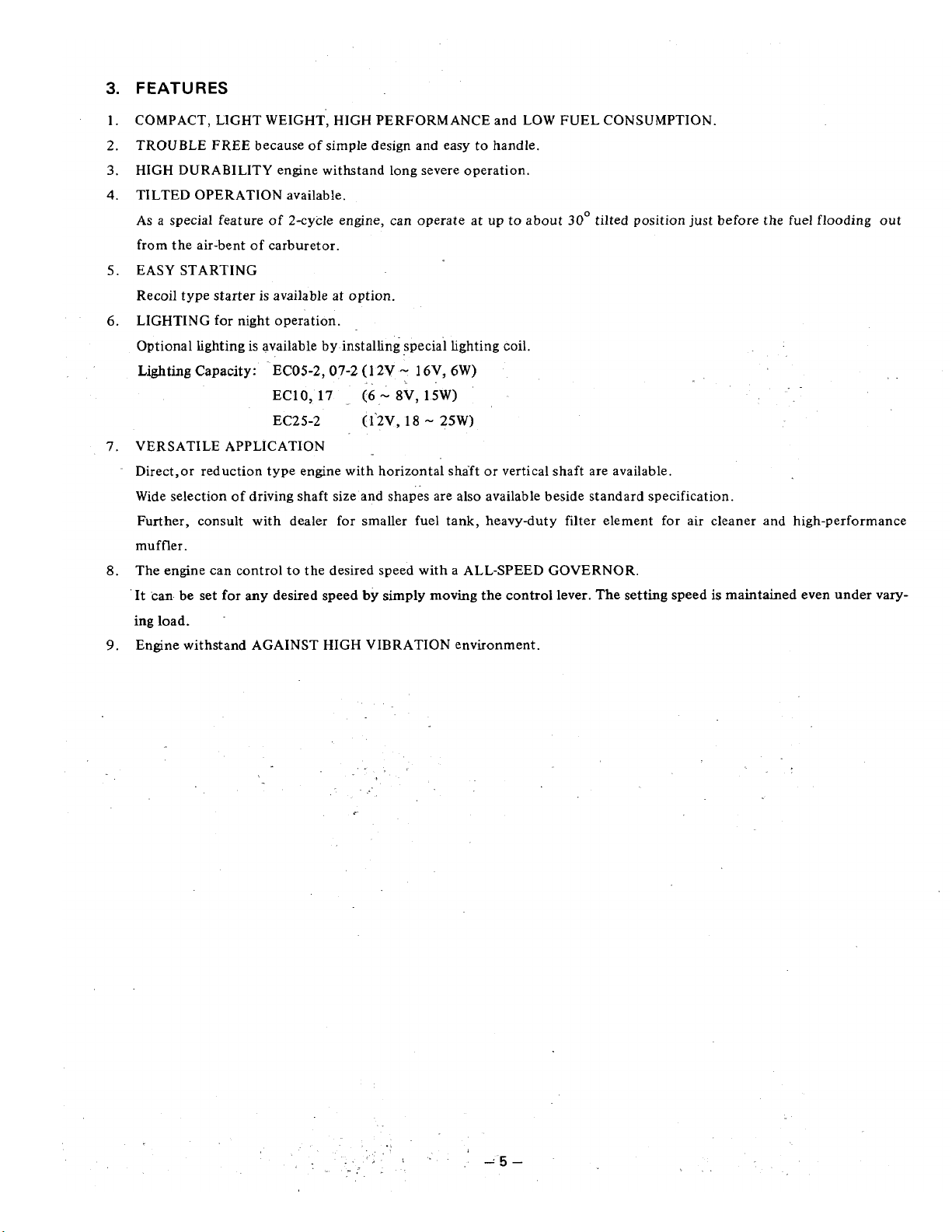

3.

5.

4.

5.

6.

7.

8.

9.

FEATURES

COMPACT, LIGHT WEIGHT, HIGH PERFORMANCE

and

LOW

FUEL CONSUMPTION.

TROUBLE FREE

because of simple design and easy

to

handle.

HIGH DURABILITY

engine withstand long severe operation.

TILTED OPERATION

available.

As

a

special feature

of

2-cycle engine, can operate at up

to

about

30'

tilted position just before the

fuel

flooding out

from the air-bent

of

carburetor.

EASY STARTING

Recoil type starter

is

available at option.

LIGHTING

for night operation.

Optional lighting is available by installing special lighting coil.

Lighting

Capacity:

EC05-2,07-2

(1

2V - 16V,

6W)

..

EC10, 17 (6

-

8V,

15W)

EC25-2 (1'2V,

18 - 25W)

VERSATILE APPLICATION

Direct,or reduction type engine with horizontal shaft or vertical shaft are available.

Wide selection

of

driving shaft size and shapes are also available beside standard specification.

Further, consult with dealer for smaller fuel tank, heavy-duty filter element for air cleaner and high-performance

muffler.

The engine can control

to

the desired speed with a

ALL-SPEED GOVERNOR.

It can. be set

for

any desired speed

by

simply moving the control lever.

The

setting speed

is

maintained even under vary-

ing

load.

-

Engine withstand

AGAINST HIGH VIBRATION

environment.

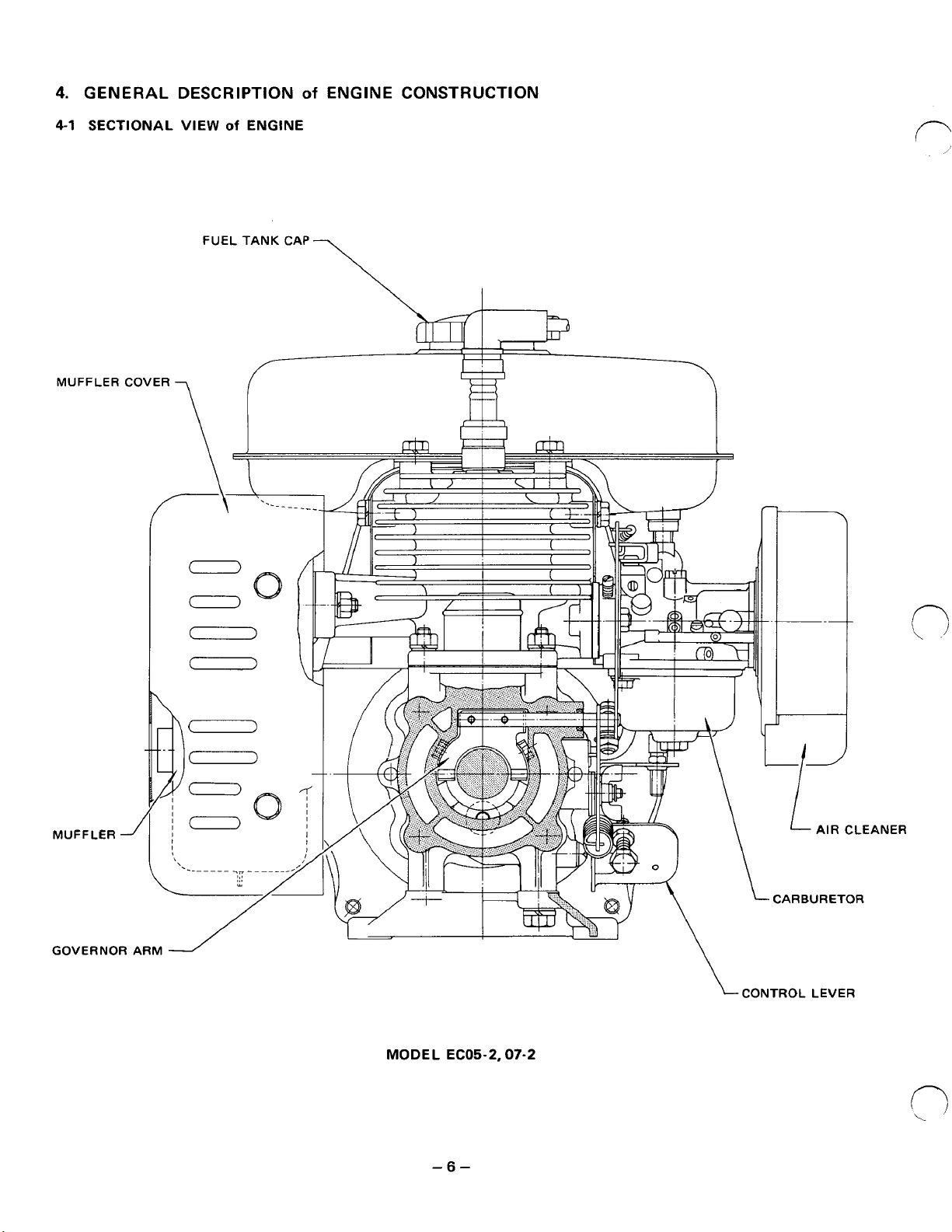

Page 10

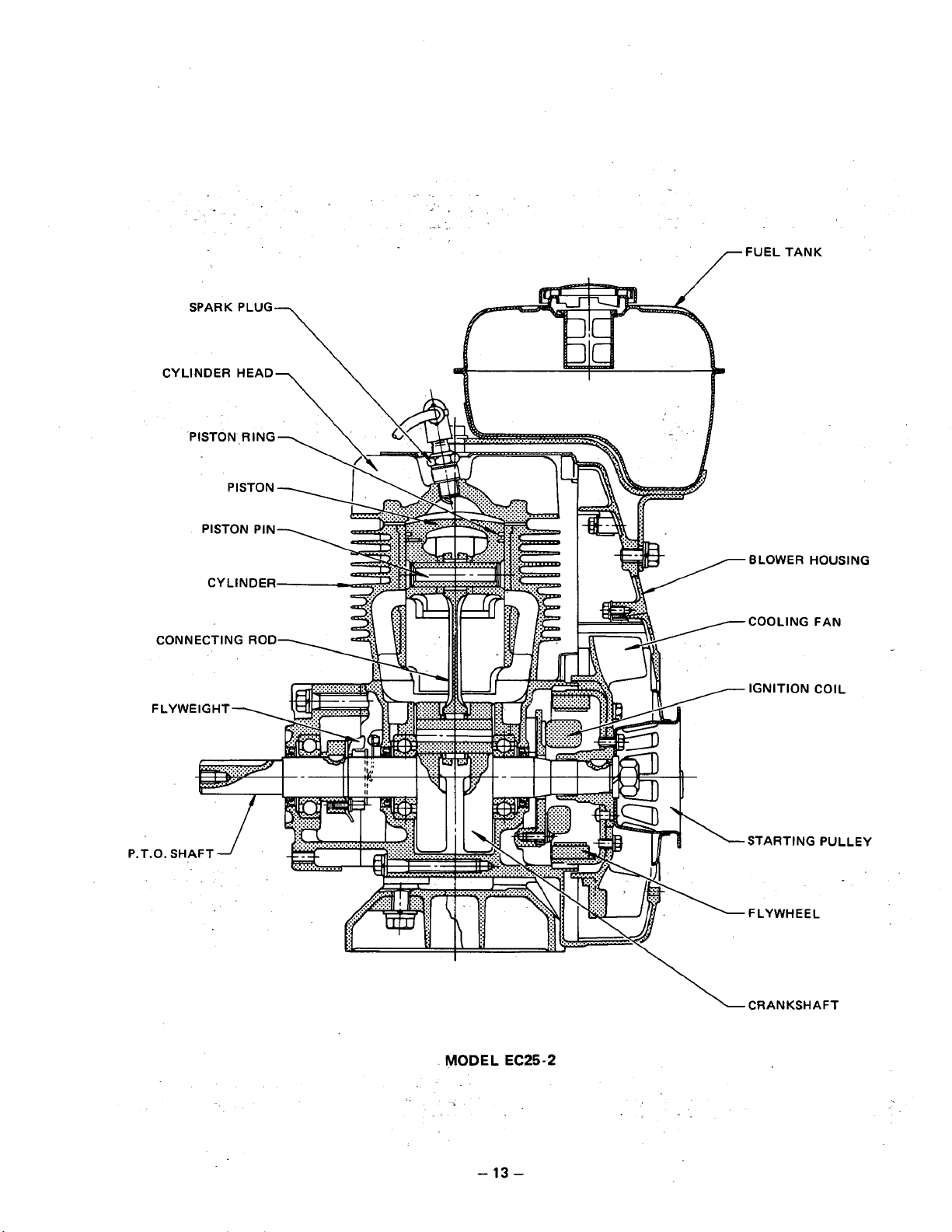

4.

GENERAL DESCRIPTION

4-1

SECTIONAL

VIEW

FUEL TANK CAP

of

ENGINE

of

ENGINE CONSTRUCTION

\

MUFFLER COVER

7

\I

MUFFLER

GOVERNOR

CONTROL LEVER

MODEL EC05-2,07-2

-6-

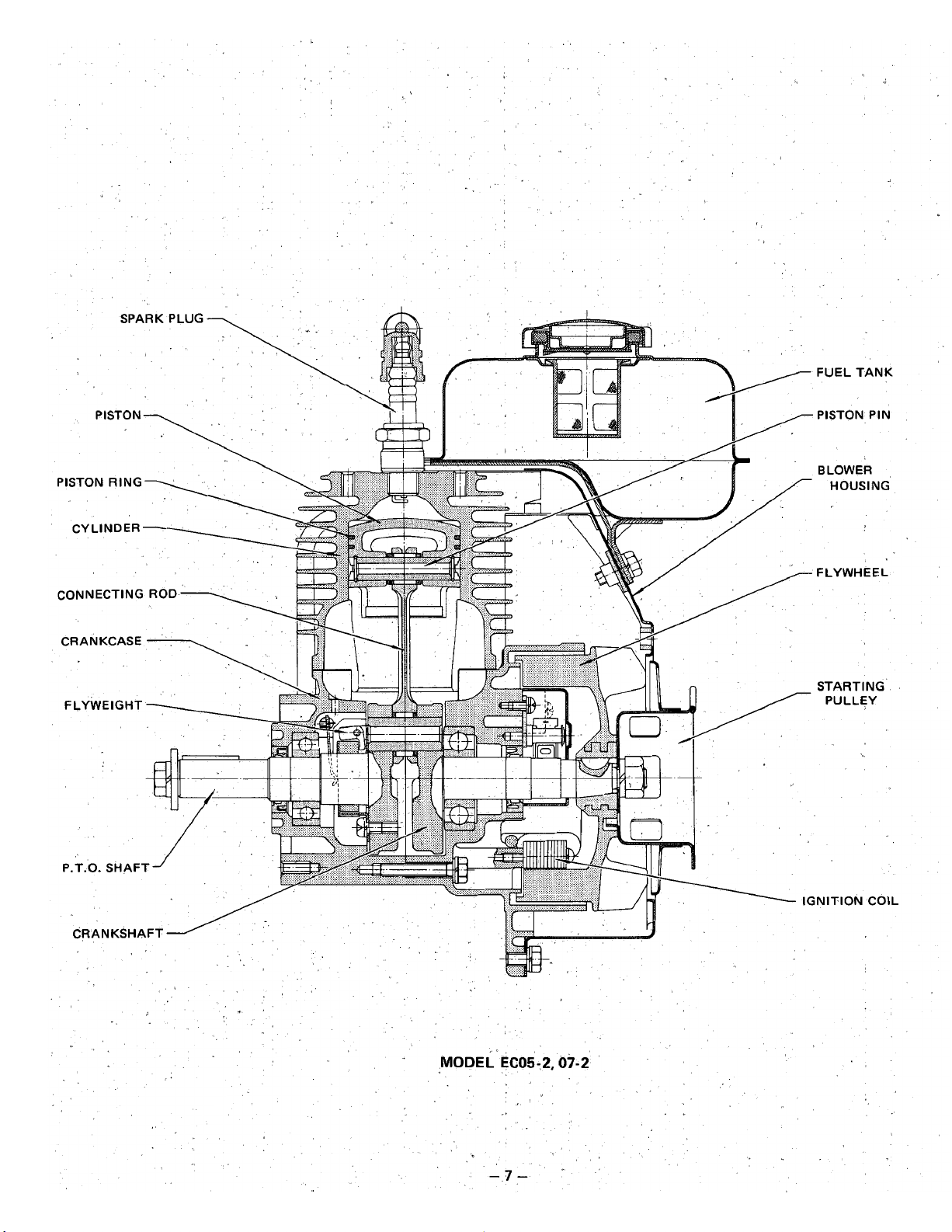

Page 11

FUEL

TANK

PISTON PIN

BLOWER

HOUSING

FLYWHEEL

STARTING

PULLEY

NlTlON

COIL

MODEL'EC05-2.07-2

I.

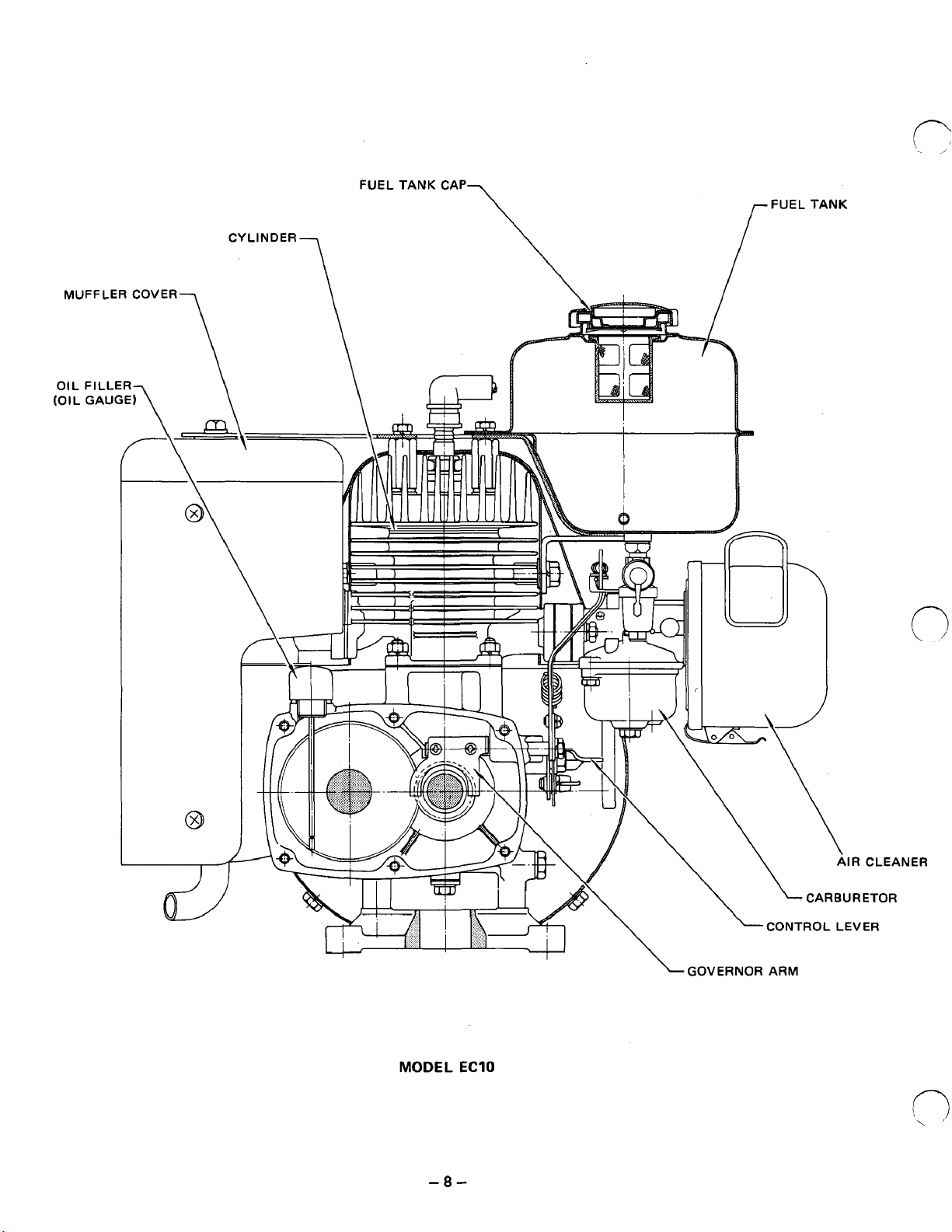

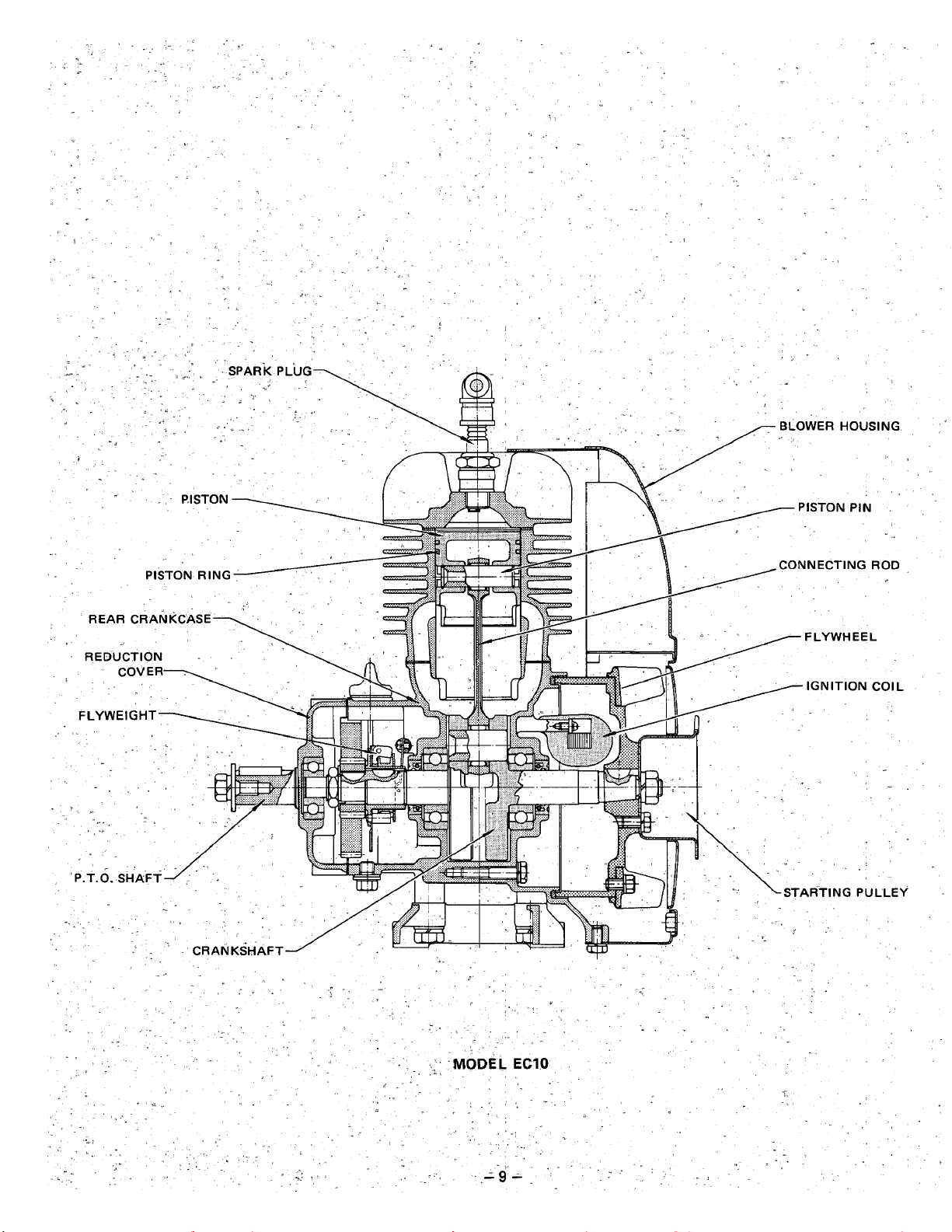

Page 12

FUEL TANK CAP

r

FUEL TANK

MUFFLER COVER-

CYLINDER

7

\

\

MODEL

-8-

CLEANER

ETOR

'ER

GOVERNOR ARM

ECIO

Page 13

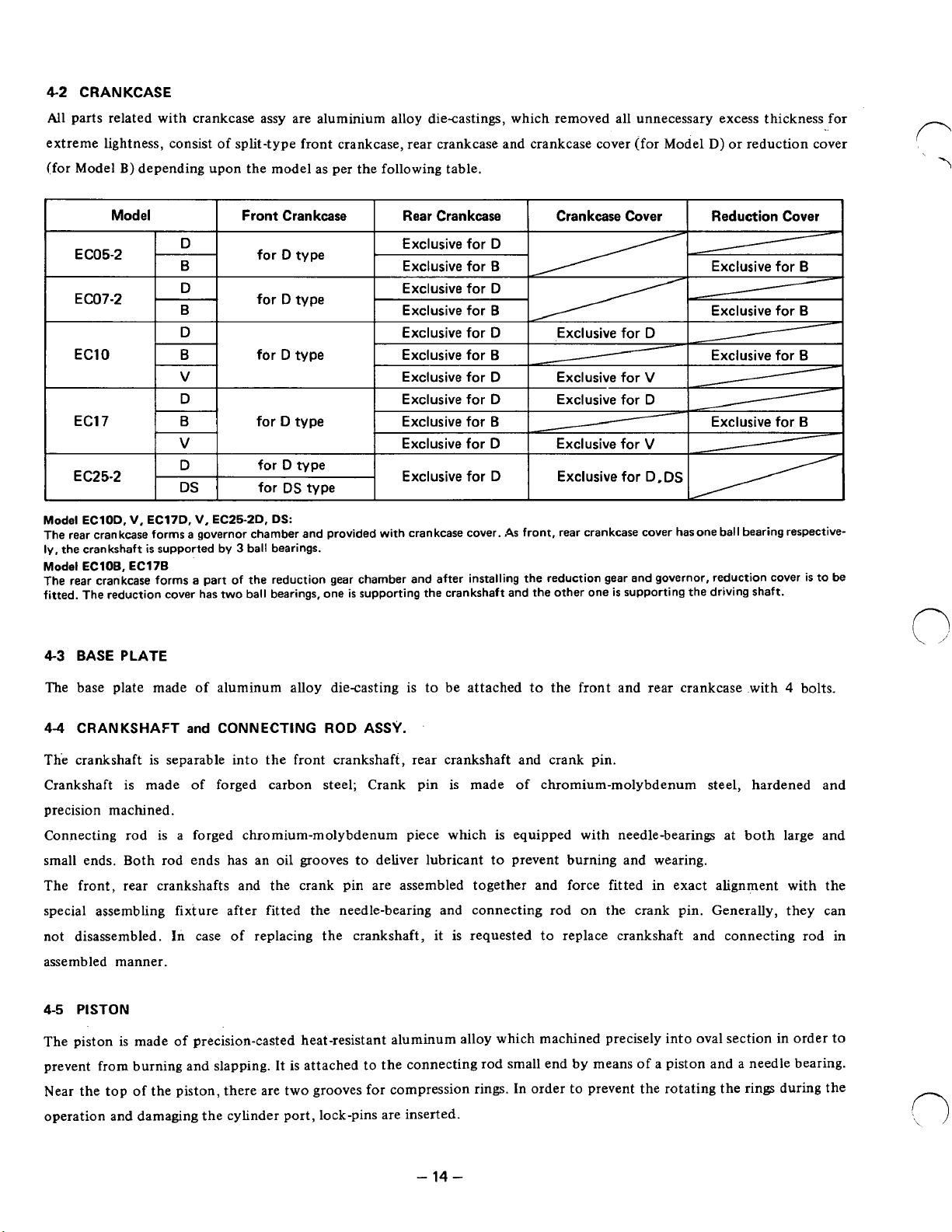

Page 14

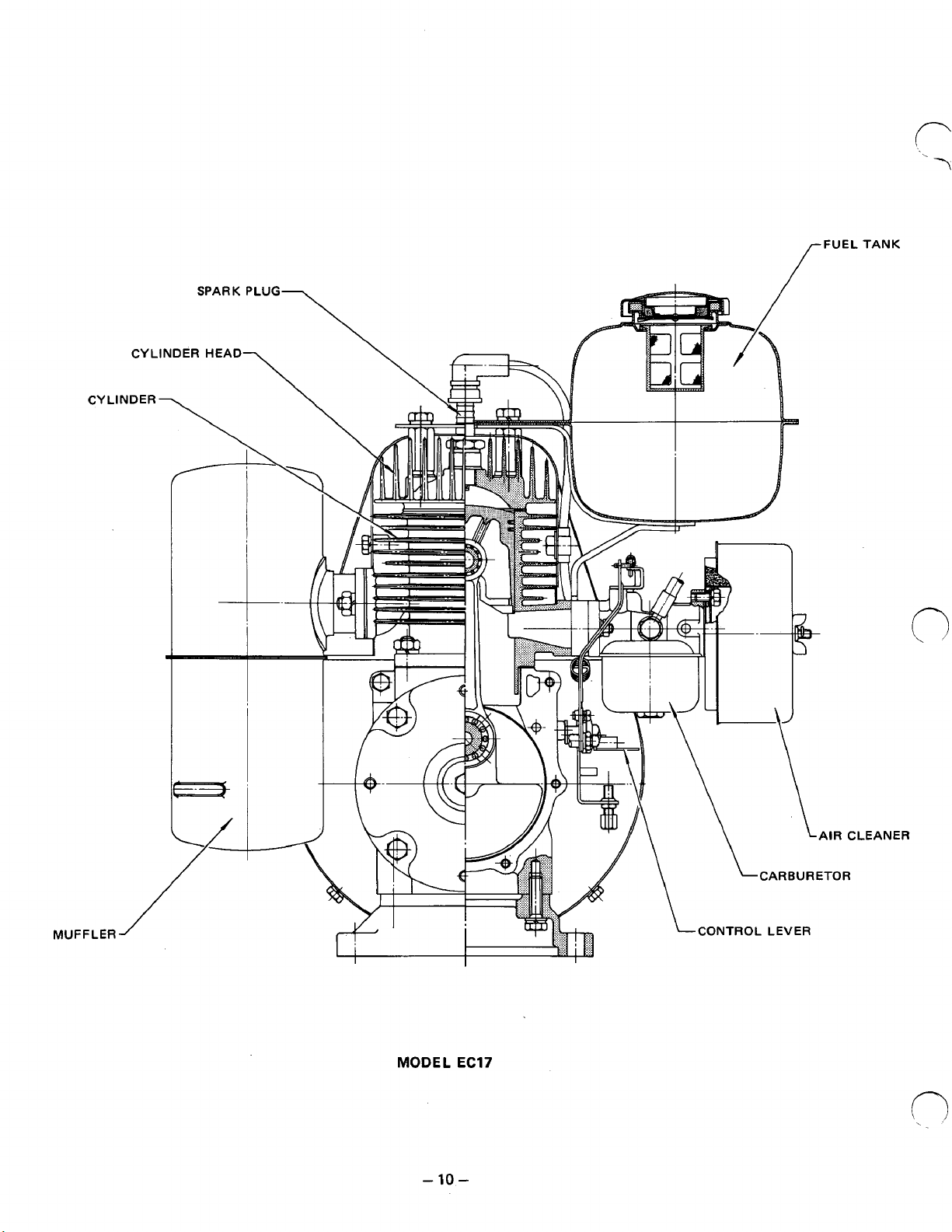

CYLINDE

CYLINDER

\

f

FUELTANK

MUFFLER

MODEL

-10-

:LEANER

EC17

Page 15

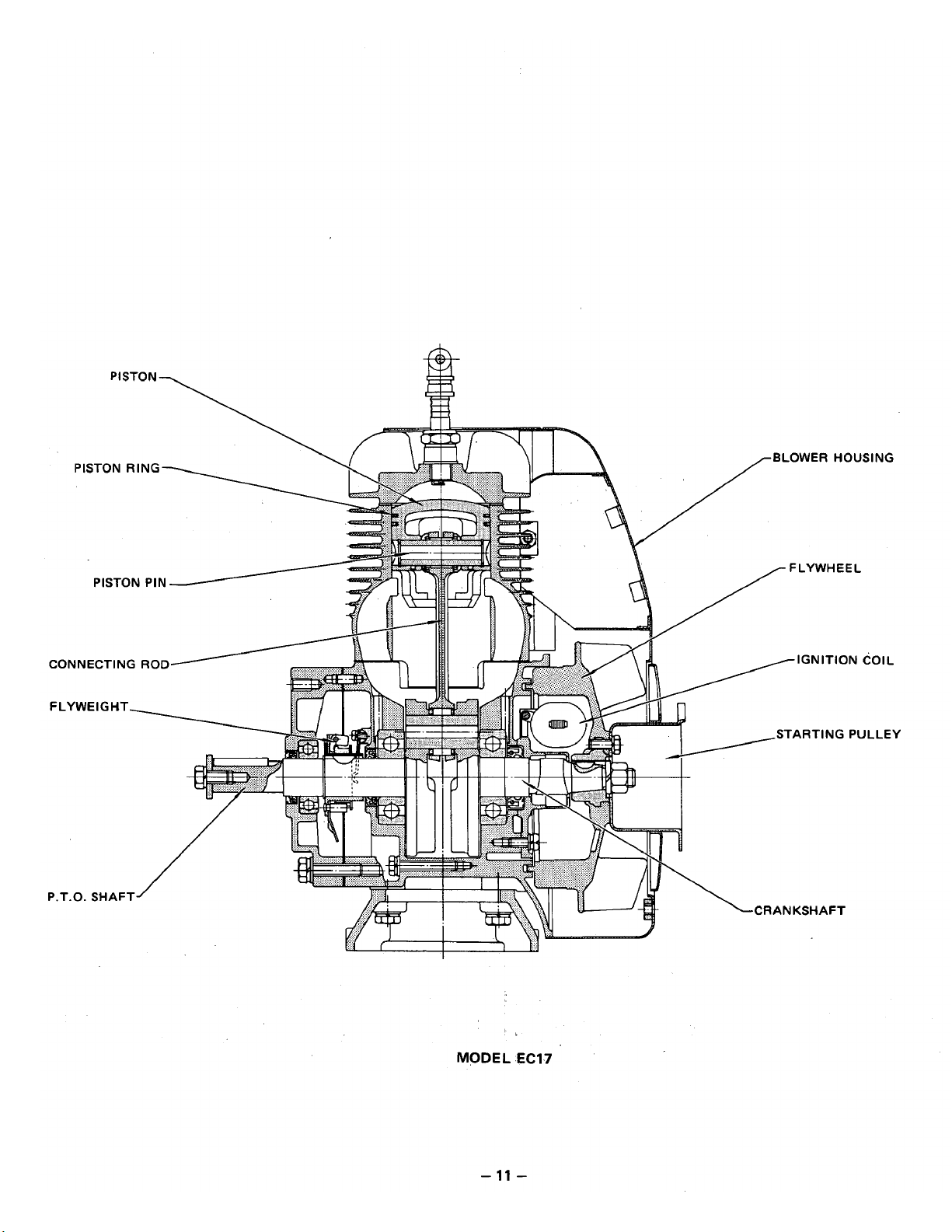

1

1,

MODEL

EC17

-

11

-

Page 16

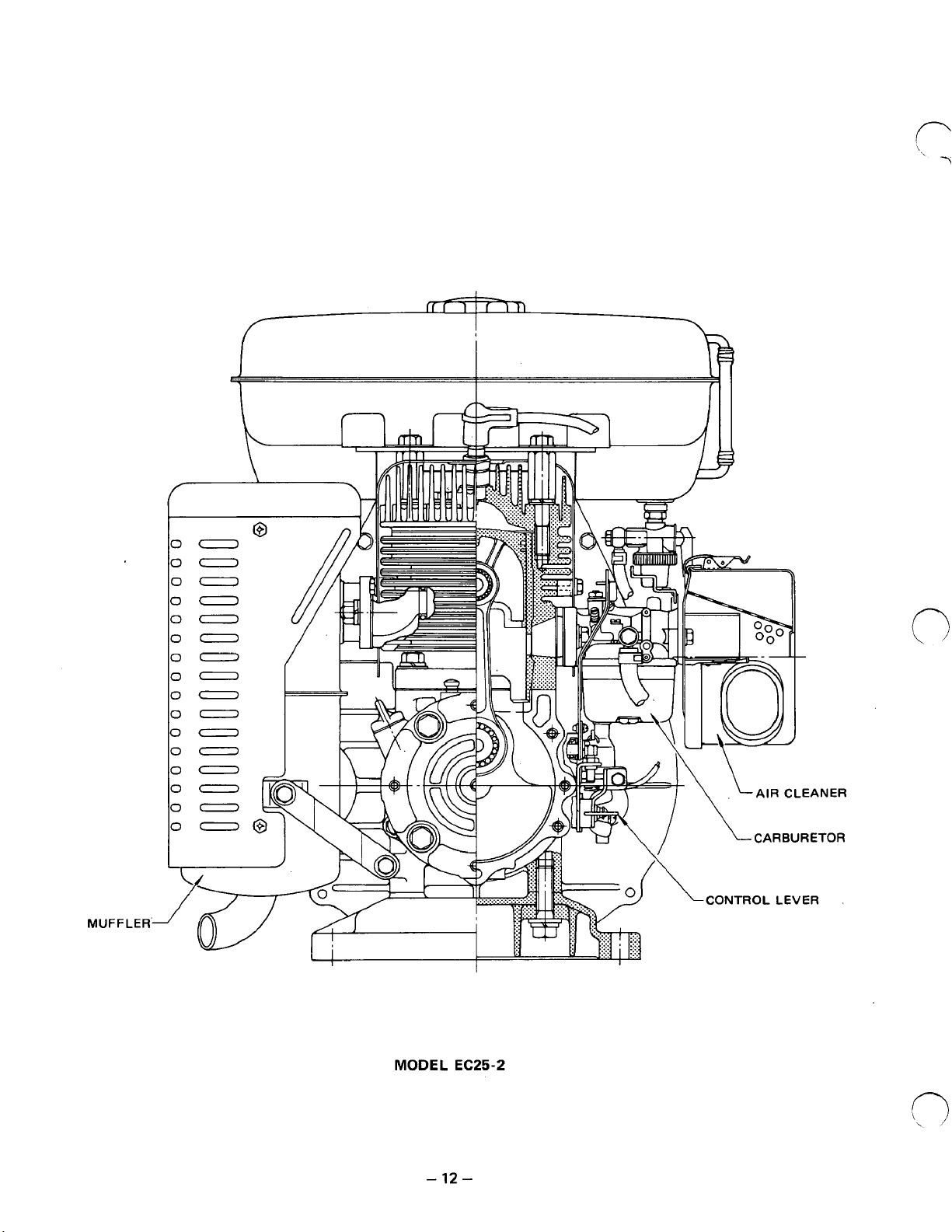

MUFFLER-

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

MODEL EC25-2

-

12-

Page 17

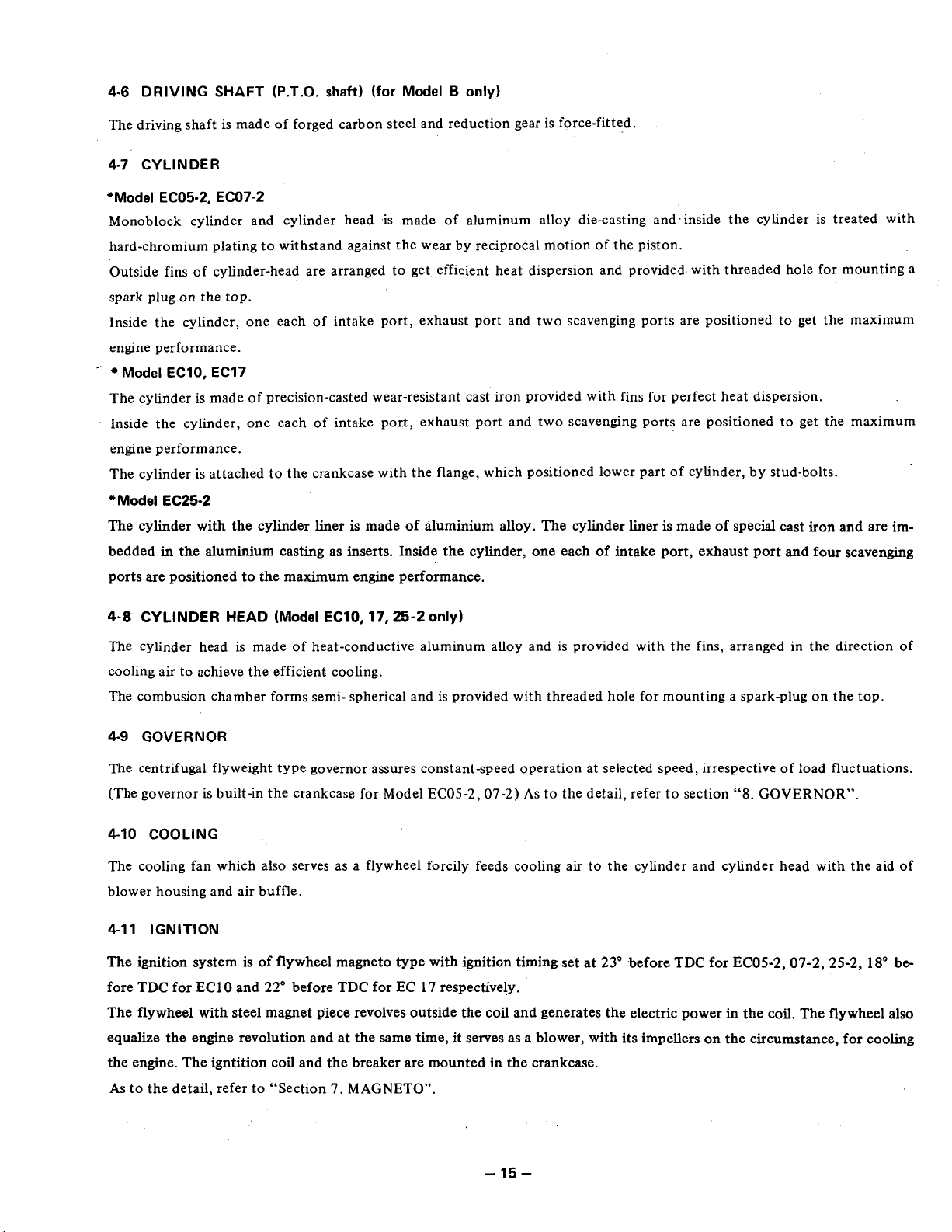

P.

T

7

FUEL

TANK

SPARK PLUG

CYLINDER HEAD7

.BLOWER HOUSING

-COOLING FAN

. IGNITION COIL

.STARTING PULLEY

,FLYWHEEL

-CRANKSHAFT

MODEL

EC25-2

-13-

Page 18

4-2

CRANKCASE

All parts related with crankcase assy are aluminium alloy diecastings, which removed all unnecessary excess thickness for

extreme lightness, consist

split-type front crankcase, rear crankcase and crankcase cover (for Model

D)

or reduction cover

of

(for Model B) depending upon the model as per the following table,

Model

-

D

B

D

B

D

B

EC05-2

EC07-2

EC10 for D type Exclusive for

v

D

EC17

B

v

I

EC25-2

Model EClOD,

The rear crankcase forms a governor chamber and provided with crankcase cover. As front, rear crankcase cover hasone ball bearing respective-

ly,

the crankshaft

Model

The rear crankcase forms

fitted.

The

4-3

BASE PLATE

V.

EClOB,

EC17B

reduction cover has two ball bearings, one

D

DS

EC17D,

is

V.

supported by 3 ball bearings.

a

Front Crankcase

for D type

for

D

type

for

D

type Exclusive for

for D type

for

DS

type

EC25-2D.

part of the reduction gear chamber and after installing the reduction gear and governor, reduction cover

DS:

is

Exclusive for

~

Exclusive for

Exclusive for

Exclusive for

~

Exclusive for

Exclusive for

B

D

B

D

B

D

D

B

Exclusive for

Exclusive for

supporting the crankshaft and the other one

D

D

Crankcase Cover Rear Crankcase

Exclusive for

Exclusive for

~-

Exclusive for

D

V

D

/

Exclusive for

Exclusive for

V

D.DS

is

supporting the driving shaft.

Reduction

Exclusive for

Exclusive for

Exclusive for

Cover

B

B

B

is

to

be

The base plate made

4-4

CRANKSHAFT

of

aluminum alloy diecasting is to be attached

and

CONNECTING ROD ASSY.

to

the front and rear crankcase .with

4

bolts.

The crankshaft is separable into the front crankshaft, rear crankshaft and crank pin.

Crankshaft is made

of

forged carbon steel; Crank pin is made

of

chromium-molybdenum steel, hardened and

precision machined.

Connecting rod is a forged chromium-molybdenum piece which is equipped with needle-bearings at both large and

small ends. Both rod ends has an oil grooves

to

deliver lubricant to prevent burning and wearing.

The front, rear crankshafts and the crank pin are assembled together and force fitted in exact alignment with the

special assembling fixture after fitted the needle-bearing and connecting rod on the crank pin. Generally, they can

not disassembled. In case

of

replacing the crankshaft, it is requested

to

replace crankshaft and connecting rod in

assembled manner.

4-5

PISTON

The piston is made of precision-casted heat-resistant aluminum alloy which machined precisely into oval section in order to

prevent from burning and slapping. It is attached to the connecting rod small end by means

of

a piston and a needle bearing.

Near the top of the piston, there are two grooves for compression rings. In order to prevent the rotating the rings during the

operation and damaging the cylinder port, lock-pins are inserted.

-

14-

Page 19

4-6

DRIVING

SHAFT

(P.T.O.

shaft)

(for

Model B

only)

The driving shaft is made

of

forged carbon steel and reduction gear

is

force-fitted.

4-7 CYLINDER

‘Model

EC05-2, EC07-2

Monoblock cylinder and cylinder head .is made

of

aluminum alloy diecasting and-inside the cylinder is treated with

hard-chromium plating

to

withstand against the wear by reciprocal motion

of

the piston.

Outside fins

of

cylinder-head are arranged to get efficient heat dispersion and provided with threaded hole for mounting a

spark plug on the top.

Inside the cylinder, one each of intake port, exhaust port and two scavenging ports are positioned to get the maximum

engine performance.

-.

Model

ECIO, EC17

The cylinder is made

of

precision-casted wear-resistant cast iron provided with fins for perfect heat dispersion.

Inside the cylinder, one each

of

intake

port,

exhaust port and two scavenging ports are positioned to get the maximum

engine performance.

The cylinder is attached

to

the crankcase with the flange, which positioned lower part of cylinder, by stud-bolts.

*Model

EC25-2

The cylinder

with

the cylinder liner

is

made of aluminium alloy. The cylinder liner

is

made of special cast iron and are

im-

bedded

in

the

aluminium casting as inserts. Inside the cylinder, one each

of

intake port, exhaust port and four scavenging

ports are positioned

to

the maximum engine performance.

4-8

CYLINDER HEAD

(Model

ECIO,

17,25-2

only)

The cylinder head is made

of

heat-conductive aluminum alloy and is provided with the fins, arranged in the direction

of

cooling air to achieve the efficient cooling.

The combusion chamber forms semi- spherical and is provided with threaded hole for mounting a spark-plug on the top.

4-9 GOVERNOR

The centrifugal flyweight type governor assures constantspeed operation at selected speed, irrespective

of

load fluctuations.

(The governor is built-in the crankcase for Model

EC05-2,07-2)

As

to the detail, refer to section

“8.

GOVERNOR”.

4-10 COOLING

The cooling fan which also serves as a flywheel forcily feeds cooling air to the cylinder and cylinder head with the aid

of

blower housing and air buffle.

4-11 IGNITION

The ignition system

is

of

flywheel magneto type with ignition timing set at

23”

before TDC

for

EC05-2, 07-2, 25-2, 18” be-

fore TDC for EC10 and

22”

before TDC for EC 17 respectively.

The flywheel with steel magnet piece revolves outside the coil and generates the electric power

in

the coil. The flywheel

also

equalize the engine revolution and at the same time,

it

serves as a blower, with its impellers on the circumstance, for cooling

the

engine. The igntition coil and the breaker are mounted

in

the crankcase.

As

to

the detail, refer to “Section

7.

MAGNETO”.

-15-

Page 20

4-12

CARBURETOR

A

horizontal draft float type carburetor is employed. Its setting has been carefuily determined after thorough testing to

achieve best starting, accelerating, fuel consumption, output and performances.

As

to the detail such as construction, refer

4-13

AIR CLEANER

Air

cleaner used in this model is a semi-wet type cleaner, which contains oil soaked filtering element that traps all

dust particles floating in the intake air

4-14

REDUCTION EQUIPMENT

(For

to

section

so

that clean air is supplied to the carburetor.

Model

B

“9.

CARBURETOR”.

only)

With the Model B engine, rear crankcase and reduction cover forms the reduction chamber, and the revolution

reduced to 1/2.7 for Model EC05-2, 07-2, to 1/25 for Model EClO and EC17 by reduction-gear and pinion, and then its

P.T.O.

transmitted to

Use SAE

4-15

Optional recoil starter is available for Model D and

Starting pulley

By removing the recoil starter, starting the engine can be made by starting pulley.

30

lubricant.

STARTING PULLEY

shaft. Governer is also equipped with reduction chamber and lubricated by same lubricant.

(for

EClO,

17)

or

RECOIL STARTER

of

Model D and B are identified according

B.

Model V is equipped with recoil starter.

to

the direction

of

engine rotation.

of

crankshaft

-

16-

Page 21

-

5.

INSTALLATION

Since the installation method affects the service life, easy

of

maintenance, frequency

of

check and repair, and operating cost

of

engine,

the following contents

shall

be carefully examined before installing

your

engine.

5-1

MOUNTING

When installing the engine, its mounting position, coupling condition with operating machines, and anchoring or supporting

m&o& must be carefully examined. Particularly when determining its mounting position, due care should be taken

to

assure the convenience

of

such routines as replenishment and checking

of

fuel and oil, checking

of

oil

gauge, spark-plug and

contact breaker point, maintenance

of

oil draining. For details, refer

to

the installation drawing.

Install the engine as much closer as possible to the level. The tilt limit for normal operation should be not more than

30°

from the level.

5-2

VENT1 LATION

The fresh air must be supplied

to

the engine

for

cooling and fuel combustion.

If

the engine

is

operated with a cover or in a

small compartment,' it is required

to

provide a cooling air duct and a baffle plate.for the purpose

of

preventing insufficient

circulation

of

heated air after cooling the engine and/or temperature rise

of

related equipment. High temperature

environment will cause engine vapor-lock, deterioration

of

oil, power reduction,

loss

of

engine life, it is requested to keep

the temperature

of

compartment not to exceed

50°C.

5-3

EXHAUST GAS EVACUATION

As

the exhaust gas is toxic, it must be exhausted outside in case engine is operated indoor.

Output power of 2-cycle engine is considerably influenced by the length

of

exhaust duct,

so

ask for consultation in case any

modification

of

exhaust system is required.

54

FUEL SYSTEM

In case the standard fuel tank can not be used due to space limitation or any other reason, take the following notes into

consideration:-

1) When connecting the fuel pipe, carefully examine heat conductivity, pipe diameter, bend and leakage from fittings to

eliminate air-blocking and vapor-lock.

2)

Men

the

fuel

is

to

be fed by gravity, position of fuel tank bottom should fie

within

the

height

of

5

-

50

cm from

the

fuel

joint

of

the

carburetor.

3)

Fuel must be filtered before it

is

fed to carburetor, by means

of

fuel strainer or filter.

4)

The standard inner diameter

of

fuel pipe is

4

-

5

mm.

.

5)

It is recommended to minimize the length

of

fuel pipe.

5-5

POWER

TRANSMISSION

to

DRIVE

MACHINES

5-5-1

BELT-DRIVE

Be careful with the following items.

Use a V-belt rather thana flat-belt.

Set the driving shaft and the driven shaft of machine in parallel for each other.

Align the driving pulleys

of

engine and machine correctly.

-

17

-

Page 22

*

Mount the driving pulley as close to the engine as possible.

*

Span the driving belt horizontally, if possible.

*

When starting the engine, disconnect the load.

If

a

clutch is not available, a tension pulley or other means must be employed.

5-5-2

FLEXIBLE

When a flexible coupling is used, the run out and mis-alignment between the driven shaft and the engine shaft must be made

as small as possible.

The tolerance on the run

COUPLING

out

and mis-alignment are specified by each coupling manufacturer.

"c3

JIS

CB104 female terminal

JIS

CA104 male terminal

4

LA104 or LA108 plate terminal

p"

SPARK PLUG

CONDENSER

ONTACTBREAKER

IGNITION

LIGHTING SWITCH LAMP

"""

COIL

STOP BUTTON

(6V

-

8V.

r'

\'

15W)

-

18-

Page 23

5-6-2

ENGINE

with STARTING

MOTOR

(for

EC25-2DS

only)

1

START BWTTON

I

R

ECTl

F I

ER

YELLOW^

+

I

PINK

I

I-

-

MAGNETO

LIGHT BLUE

WITH

BLACK TUBE

I

I

I

BATTERY

SPARK PLUG

-

19-

Page 24

6.

DISASSEMBLY

6-1

PREPARATIONS and SUGGESTIONS

and

REASSEMBLY

6-1-1

6-1-2

6-1-3

After disassembing and cleaning the engine parts, check them and, if necessary, correct them according to the

CORRECTION TABLE

Gaskets and fuel pipe shall be replaced to new one.

DISASSEMBLY

When disassembling the engine, memorize where and how each part is assembled

correctly. Tag parts if there is a possibility of confusion.

Take care not to damage packings and gaskets, which are fragile.

In order to prevent missing and misplacing, group related parts together, tentatively assembling them, immediately after disassembled each sub-assemb!y.

Handle the disassembled parts carefully, and wash them in Kerosene.

Use the correct tools in the correct way.

Standard tools required for disassembly and reassembly.

a> Work table

b) Washing pan

c) Disassembling tools

d) Washing

e)

Emery paper, Cloth

Before starting to disassemble the engine, drain fuel and lubricant. (To prevent from danger and stain.)

CLEANING before reassembly

1

)

Check all sliding and rotating parts, such as piston, cylinder, valve, camshaft, crankshaft, gears and bearings for defect.

2) Wash the disassembled parts in Kerosene to remove dust, dirt and contaminated oil thoroughly. Wash them twice, first

time remove visible dirt roughly, and second time using fresh Kerosene.

3)

After washing, blow them thoroughly with compressed air.

4)

Do

not wash electric parts. Wipe them with clean cloth and dry them.

5)

Accumulated carbon

wrap the piston with

6)

Parts

of

7)

Check the cable for any damage.

8)

Clean contact breaker with dry cloth. Check the breaker-point

pitting

9)

Air-cleaner element shall be soaked

1

engine oil, and assemble it after squeezed well.

10) Take special care not to contaminate the parts with dust and apply mobile oil

rust.

CHECKS

oil

(Kerosene or gasoline), Mobile

on

the cylinder-head, gasket, piston, cylinder and inside the muffler to be carefully planed and

oil

stone

to

get smooth surface.

carburetor

or

pyramidding, this should be corrected with

to

be washed carefully with gasoline and blow them thoroughly with compressed

in

the liquid soap and dry

and

CORRECTIONS before reassembly

of

section

''

12.CHECKS and CORRECTIONS".

oil,

Brush

MOO

if

it contact surface is flat. If there

wrapping paper.

thoroughly.

Then put

in

order to be able to reassemble it

air.

is

an evidence of

it

to

mixture

on

the surface in order to prevent from

of

2 - 4

kerosene and

r"

-

20

-

Page 25

'

6-1-4

REASSEMBLY

1)

Before reassembly, wash parts in gasoline.and blow them with compressed'air.

2)

Apply mobile oil on the rotating and sliding surface.

3)

Take care not to contaminate the parts with dust during reassembly.

4)

Be sure to assemble those parts provided with alignment marks by bringing the marks

in

alignment.

5)

Tighten'bolts, nuts and' screws to the correct torque specified. When there

is

no torque specification, tighten them

to torque readings appropriate to the size

Standard Fastening Torque for screws are

as

fallows:

..

6mm-

.

90

kg-cm

(6.5

ft-lbs)

8mm-

250

kgcm

(18

ft-lbs)

10 mm

-

370

kg-cm

(26.7

ft-lbs)

If.small screws are tightened too hard, they may get broken. Tighten the large size screws such as ones for the

magneto flywheel, enough by giving hammer blows

on

the socket wrench handle.

When tightening the several screws fastening the single part, tighten them all evenly, by alternately tightening diagonally

located pairs.

6) Do

not apply

oil

to the part to which packings or sealend to be fitted.

7)

When engine is completely reassembled, make sure that there

is

no

parts remained.

8)

During

the assembly, turn the moving part by hand to check

for

friction and noise.

9)

After the completion of reassembly, turn the engine by hand and check

if

there

is

any disorder or

loose

members.

-

21

-

Page 26

5-2

SPECIAL TOOLS

For

your

reference, the

following'shows

special tools

of

Robin

Engine

for

Disassembly, Meauring

and

Inspection instruments.

f-

Part

No.

2099500407

207 95003.07

Tool

Flywheel Puller

(with bolt)

Valve Spring

Retainer

USe

For

pulling off

Flywheel

For mounting and

dismounting Valvc

Spring Retainer

and Retainer

Lock

Applicable

Model

EY10,13,14

EYl8,25,27

EY33,44

EC05,07,10

EC

17,37

EY10,13,14

EY18,25,27

EY21,80

EY33,44

Shape

20595001 07

2069500107

2079500107

rlalve Guide Puller

For pulling

Valve guide

off

EY13,14

EY18

EY25,27

f

\

-

22

-

Page 27

Part

No.

214 91301

00

1067990100

"20248

PF-2L

~~

-

Tool'

C.

D.

1.

Unit

Checker

T.

C.

1.

Unit

Checker

Timing Tester

Coil

Tester

Uu,

For checking

C.

D.

1.

Unit

For checking

T.C.

1.

Unit

.For adjusting

Timing

For checking

Ignition Coil

Applicable

Model

EY10,13,14

EY18,25,27

EY33,44,21

EY80

EC03,04

EC05,07

EC10,17

EYlO, 13,14

EY 18,25,27

EY33,44,21

EY80

EC03,04,05

EC07,10,17

EC37

EY10,13,14

EY 18,25,27

EY33,44,21

EY80

EC03,04,05

EC07,10,17

EC37

-23

-

Page 28

6-3

DISASSEMBLY

and

REASSEMBLY PROCEDURE

6-3-3 FUEL TANK and FUEL TANK BRACKET

1) Disconnect fuel pipe between strainer and carburetor at carburetor side.

2)

Remove mounting bolts, and detach fuel tank from cylinder head or cylinder.

3)

For Model ECl OV

Unscrew

CAUTION: REPLACE FUEL PIPE ONCE A YEAR

DANGER CAUSED

6-3-2 AIR CLEANER

“Model

1)

Remove air cleaner cover and element.

2)

Unscrew two or three bolts which clamped

Model ECIOV

1) Remove cover and take out outer element and inner element.

2)

Loosen three bolts which clamped base plate to carburetor, and remove base plate.

In reassembly:

Wash element based

‘Model

After washed element with gasoline, soak

drip the oil off.

”

Model EClOV

After washed outer and inner elements with gasoline, soak them into the mixed

6-3-3 CARBURETOR

1)

Remove governor rod and rod spring from carburetor..

2)

Remove carburetor from cylinder block.

In reassembly:

Refer to section

6-3-4 GOVERNOR LEVER

1)

Remove governor lever from governor shaft.

2)

Remove governor spring from control lever.

3)

Control lever and stop plate can be removed by loosing wing-nut

NOTE: When control lever device are disassembled, tentatively assemble them together with governor lever.

In reassembly:

Refer to section

6-3-5

6

x

EC05-2D & 6,07-2D

EC05-2D

“8.

“8.

MUFFLER

’

M8

bolts, then remove fuel tank from blower

BY

THE FUEL LEAKAGE.

&

B,

10D

&

B,

17D

air

on

following procedure before reassembly;

&B,

07-2D

&

6,

1

OD & 6,170

it

into the mixed

GOVERNOR” and section

GOVERNOR”. Assembly shall be made securely including rotation adjustment.

“9.

’

housing.

IN

ORDER

&

B,

25-2D & DS

cleaner base plate to carburetor and remove base plate.

&

B,

and

25-2D

&

oil

of

CARBURETOR”.

TO

PREVENT

FROM

THE

DS

2 - 4

kerosene and 1 engine

oil

of

2

-

or

bolt but do not disassemble unless it necessary.

oil,

then reassemble it after

4

kerosene and 1 engine

OCCURANCE OF

oil.

\

f

\

Unscrew nuts and remove it from cylinder.

6-3-6 BLOWER

1

)

Disconnect stop button wires from Connector.

2)

Unscrew bolts and remove blower housing from crankcase.

HOUSING

-

24

-

Page 29

6-3-7

RECOIL

STARTER

Standard configuration on Model EClOV, 17V.

Optional equipment for other models.

1)

Remove recoil starter from blower housing by unscrew

3

X

M6

bolts

(4

X

M6

bolts for Model EC17)

2)

Remove starting pulley from flywheel by loosing bolts clamped.

NOTE:

Unless it is necessary, do not disassemble recoil starter

as

special tools are required

for

reassembly.

6-3-8

STARTING

PULLEY

and

MAGNETO

(Fig.

6-3-1)

Remove’ starting pulley from flywheel.

Remove flywheel from crankshaft.

Apply a socket wrench over the nut at end of

crankshaft and give the wrench a sharp blow with

a

soft.

hammer.

Remove nut and spring washer. Attach flywheel

puller to flywheel as illustrated in Fig. 6-3-1, turn

center bolt clockwise until flywheel -becomes loose

enough to be removed.

Remove spark plug cap from high tension cable

of

igniton coil and remove ignition coil from crankcase.

Take

off

the point cover and remove contact breaker

and” condenser, from crankcase.

In reassembly:

Fig.

6-3-

1

Refer to “7-2 BREAKER POINT ADJUSTMENT”, “7-3 TIMING ADJUSTMENT” sections.

6-3-9

CYLINDER HEAD

(Model

EC10,

17

only)

1)

Remove spark plug from cylinder head.

2)

Unscrew mounting special bolts and remove cylinder head from cylinder.

3)

Remove cylinder head gasket from cylinder.

In reassembly

:

1)

Clean carbon from combustion chamber and dirt from between the cooling fins of cylinder head.

Check its mounting face for distortion.

2)

Use

new -cylinder head gasket.

NOTE:

Cylinder head gasket must

be

placed folded

edge

upside

(To

the cylinder head).

3)

Cylinder head fin must be placed in paralle with crankshaft.

Fastening torque

of

cylinder head

is

as shown below:

EClO

-

180

-

220

kg-cm

(13

-

16

ft-lbs)

EC17

-

370

-

420

kg-cm (26

-

30

ft-lbs)

EC25-2-

200

-

250

kg-cm (15

-.

18

ft-lbs)

4)

Fastening torque of spark-plug is as shown below:

250

-

300 kg-cm

(18

-

22

ft-lbs)

..

-

25

-

Page 30

,

6-3-10

1) Remove cylinder from crankcase by removing nut and spring washer.

NOTE: For

2)

3)

In reassembly:

1) Clean carbon deposit from cylinder head and combustion chamber.

CAUTION: WITHOUT CLEANING THE CARBON DEPOSIT, IT MAY DAMAGE THE PISTON AND INNER

CYLINDER

Model

EC05:2,07-2 Remove spark plug prior

Remove cylinder gasket.

For Model EClOV remove intake pipe from cylinder.

SURFACE

Replace cylinder gasket

Intake

walls, then after assembled the cylinder securely, make sure

Fastening torque

EC05-2 90-100 kg-cm

EC07-2 90-100 kg-cm

EClO

EC17 180-220 kg-cm (13-1

EC25-2

OF CYLINDER WHEN REASSEMBLY.

to

new one.

of

cylinder should be positioned

of

cylinder

is

as

shown below: Fastening torque

90-100 kgcm

340-400

to

kgcm (25-29 ft-lbs)

the left against view from blower side, Apply

(6.59

(6.5-7

(6.5-7

ft-lbs) E05-2 250-300 kg-cm (18-22 ft-lbs)

ft-lbs) E07-2 250-300 kg-cm (18-22 ft-lbs)

ft-lbs)

6

ft-lbs)

to

removing cylinder.

if

the crankshaft rotate smoothly.

of

spark plug for EC05-2,

oil

to

piston ring and cylinder

07-2:

CAUTIONS:

r)

WHEN

2)

BEFORE REASSEMBLE CYLINDER, APPLY OIL ON NEEDLE BEARING LOCATED TO END OF

CONNECTING

6-3-1

1

PISTON

1) Remove both side piston pin clips

2) Pull out piston pin and disconnect the needle bearing from small end

CAUTION: IN ORDER NOT TO DAMAGE PISTON, PULL OUT PISTON PIN BY FIRMLY HOLD PISTON. ALSO

TAKE A SPECIAL CAUTION WHEN DISASSEMBLE NEEDLE BEARING.

3)

Remove piston rings from piston by expanding the open ends

In'reassembly

PISTON RINGS

If

an expanding tool is not available, install rings by placing the open end

far enough

CAUTIONS:

1)

BE EXTREMELY CAREFUL NOT

2)

STRIKE THE KNOCK PIN TO THE GROOVE LOCATED ON OPEN END OF RINGS (THIS

PREVENT FROM THE ROTATION OF RINGS WHILE OPERATING THE ENGINE.)

31

ASSEMBLE RINGS IN THE ORDER OF 2ND RING AND IST RING.

1ST RING

2ND RING- PERKARIZED SURFACE (2ND RING FOR MODEL EC25-2

FASTENING

:

(Fig.

to

slip over the piston and carry it into correct groove,

-

CYLINDER,

ROD.

TIGHTEN

FOUR

6-3-2, 6-3-3)

TO

DISTORT AND BRAKE THE RING.

CHROMIUM PLATED SURFACE

FACE.)

(RING FOR MODELS EC05-2,07-2

NUTS

UNIFORMLY.

of

of

rings.

of

connecting rod.

the ring

on

(Fig.

IS

NOT CHROMIUM PLATED.)

first land of piston, spread ring only

IS

TO

6-3-3)

IS

CHROMIUM PLATED

SUR-

-

26

-

Page 31

TOP

RING

SECOND

RING

..........

ISTON

RING

Fig.

6-3-2

Fig.

6-3-3

PISTON

1) Position the

“F”

mark

of

piston to blower side and reassemble the piston and connecting rod by firmly striking the

piston pin, and needle bearing.

CAUTION: APPLY

OIL

TO THE NEEDLE BEARING BEFORE REASSEMBLE IT

TO

PISTON-PIN.

2)

Assemble piston pin clip.

CAUTION: REPLACE PISTON PIN CLIP

IF

THERE

IS

ANY LOOSENESS AFTER REASSEMBLE IT.

3)

Be sure that piston and connecting rod moves smoothly after reassembled.

6-3-12

CRANKCASE COVER (Model

D

and

V

only)

(

Fig.

6-3-4)

1) Discharge oil by opening oil drain plug.

(No

discharg-

ing the

oil

is required for Model

EC05-2

and

07-2)

2)

Remove bolt and washer

from

crankshaft end.

3)

Remove bolts on crankcase.

4)

Detach cover gasket.

In reassembly:

1) Replace cover gasket to new one.

2)

Check bail bearing and

oil

seal

if

there is any damage.

And replace it if necessary.

3)

Apply oil on bearing and oil seal, and coat oil-seal

guide to the contact surface

of

crankcase cover.

Fig.

6-34

Attach

oil

seal guide on end

of

crankshaft and mount crankshaft in crankcase with extra care not to damage

lips

of

oil seal. Then fasten the bolts uniformly.

Fastening torque

is:

EClO

180

-

220

kg-cm

(13

-

16

ft-lbs)

EC17

180

-

220

kg-cm

(13

-

16

ft-lbs)

EC25-2

200

-

250

kg-cm

(1

5

-

18

ft-lbs)

6-3-13

GOVERNER PLATE

(Model

D

and

V)

1) Pull out governer plate, governer sleeve, washer and clip from crankshaft.

2)

Remove woodruff key

In reassembly: Reassembly with reverse sequence correctly.

-

27

-

Page 32

6-3-14 REDUCTION COVER

1

)

Discharge

2)

Remove reduction cover by loosen the bolts on crankcase.

3)

Remove washer and bolt on driving shaft end.

4)

PUn

5)

Open tab of lock-washer and pull out pinion, governer platp, governer sleeve, washer and clip from crankshaft, and

detach

In reassembly:

Reassemble with reverse sequences. After tighten the nut, bend the tab of lock-washer without fail.

6-3-15 GOVERNOR SHAFT

1)

Unscrew 2 screws and remove governor arm.

2)

Pull out governor shaft with governor lever from’crankcase.

oil

by opening oil drain plug.

out driving shaft with reduction gear from reduction cover.

2

woodruff keys.

(Model

B)

f

“.

NOTE: Do

In reassembly: Refer to section

6-3-16 CONTROL

Unless it is required, do not remove control lever from crankcase.

In disassembly and reassembly, refer to section

6-3-17 BASE PLATE

Base plate can be removed by loosening 4 bolts on crankcase.

In reassembly

After reassembled base-plate

rod.

6-3-

18

Unscrew 4 bolts which fastening front crankcase and rear crankcase and separate both crankcase by tapping them with soft

hammer, and detach crankshaft connecting rod assy.

In reassembly

Before reassemble the front and rear crankcase, check bearings and oil seals if there is any damage and replace them in

case any damage found.

Apply oil onto the bearings of both crankcase and ascertain there is no warp on the lip of oil seal.

Clean the joint of both crankcases and apply seal end. Assemble the crankshaft and joint both crankcases with press (or

tap them with soft hammer) having extra care not to damage the oil seal.

Fastening torque is:-

not

disassemble if

LEVER

:

C RAN KCASE

:

EC05-2

EC07-2

not

necessary.

“8.

GOVERNOR”.

to

the crankcase, be sure that crankshaft moves smoothly by holding small end of connecting

-

90-100 kg-cm (6.5-7.0 ft-lbs)

-

90-100

kg-cm

(6.5-7.0

“8.

GOVERNOR”.

ft-lbs)

EClO

EC17

EC25-2

-

-

-200-250

90-100 kg-cm (6.5-7.0 ft-lbs)

90-100 kg-cm (6.5-7.0 ft-lbs)

kg-cm (1 5-1 8 ft-lbs)

i

\

CATUION:

BY

NOTE: After reassemble the crankshaft to the crankcase, be sure that crankshaft moves smoothly.

6-3-19 CRANKSHAFT

Reassembly of crankshaft requires special tools.

Sub-assembly of crankshaft and connecting rod assembly

WHEN

TIGHTENING DIAGONALLY LOCATED PAIRS AT SUGGESTED FASTENING

TIGHTEN

and

CONNECTING ROD

THE

SEVERAL

BOLTS

ASSY.

FASTENING

is

available as a spare parts.

-

28

-

CRANKCASE,

,TIGHTEN

TORQUE.

THEM

ALL

EVENL

y

Page 33

..

7.

MAGNETO

.

,

.

7-1

'

MAGNETO

._

.

.'

".

,

r

The spark for ignition is furnished by a magneto assembly. The magneto consists of a flywheel, ignition coil and breaker

'

assembly .(.including condenser),

of

which flywheel is 'mounted on. crankshaft and ignition coil and breaker assembly are

mounted

.-

in crankcase directly.

7-2

BREAKER

POINT

ADJUSTMENT

(Fig.

7-2)

The breaker points, which are mounted

in

the crankcase in-

side the flywheel should be checked twice a season

or

when-

ever the ignition, spark becomes weak. If there is,evidence

of

pitting or pyramidding, the breaker points must be corrected, and then it becomes necessary to readjust the gap to

its proper clearance.

(0.4

mm

for Model EC10)

The normal breaker point opening is

0.4

mm at full separa-

tion. Since the spark timing

of

18"

is

regulated by the

point

opening, use a timihg light to obtain

an

accurate spark ad-

vance. (Refer to

"7-3

TIMING

ADJUSTMENT.")

NOTEI The point gap

of

other engines.than model EC70 is

as

follows:

EC05

:

0.35

mm

EC07-2

:

0.35mm'

ECl7

:

0.30

mm

EC25-2

:

0.35mm

I.

Ftg.

7-2

i'

To adjust breaker poixit opening, remove starting pulley, blower houshg and flywheel from the eingine and proceed as follows:

1-

(See

Fig.

7-2.)

1)

Remove breaker cover from contact breaker.

2)

Turn

crankshaft .over until. breaker arm comes in contact with. the high point

of

the breaker cam. (maximum point

',

.

opening of

0.4

mm)

3)

Loosen contact suppoit plate lock screw just enough

so

that bracket can be moved.

4)

Insert

a

0.4

mm feeler gauge between the points.

CAUTION:

ADJUS?

BREAKER POINT GAP WITHOUT OPENING

IT

MORE THAN

2

mm,

OTHERWISE RATED

,-

HEEL-PRESSING FORCE MAY

NOT

BE: OBTAINED 'DUE

TO

THE BENDING

Of

CONTACT BREAKER

ARM.

5)

Apply a screw driver to.adjusting tab and move the contact support plate just enough

so

that a slight drag is felt while

sliding the feeler gauge from between the points.

6)

kghten lock screw and recheck breaker point gap.

..

7)

Pull a strip of

8 - 10

mm wide white paper through the closed points

to

remove

oil

and dust on the point surfaces.

I.

.

'

CAUTION: WHEN INSERTING A SHEET

OF

PAPER;, NEVER OPEN THE BREAKER POINT GAP MORE THAN:2mm.'

8)

Mount flywheel, blower housing and starting pulley on engine after adjustment.

-. .

..

~

...

,.

..

..

VI

..

Page 34

With the Model

TDC

on

the compression stroke.

vance

is

obtained when the breaker point opening

proper point opening. However, the advance timing

timing

light

NOTE:

Spark advance

EC05, EC07-2, EC25-2

EClO

EC17

EC05-2,07:2,

as shown

in

Fig.

of

each model

10,

This

7-3-3.

23"

:

18

.-

22"

17

and

25-2

spark advance of

is

as

follows:

engines, the spark

is

timed to occur

18"

-

23"

is

controlled

is

adjusted according to the

is

more accurately adjusted through the following procedures using

18" - 23"

by

the breaker point opening and this ad-

BREAKER POINT ADJUSTMENT

before the position reaches

to its

a

NOTE:

7-3-1 ALIGNMENT MARK

For timing adjustment, the following alignment marks are provided as

7-3-2

Refer

to

section

*Line mark

*Line mark

DEFERENCE

D

type and V type: Clockwise

B

type: Counter-clockwise arrow

on

on

"4-1

I

IGNITION.

for

TIMING ADJUSTMENT

crankcase

flywheel circumference and cooling

among

MAGNETO

arrow

"and

"12.

CHECKSand

(See

fan

for

D

TYPE, V TYPE

is

embossed on cooling fan.

is

embossed

CORRECTIONS."

Fig. 7-3-1.)

and

B

on

cooling fan.

shown

TYPE

on

Fig.

(See

Fig. 7-3-2.)

7-3-1.

TIMING

MARKS

Fig.

7-3-

7

Fig.

7-3-2

-

30

-

Page 35

7-3-3

FOR

TIMING ADJUSTMENT, THE FOLLOWING PROCEDURES USING A TIMING,TESTER:

Disconnect the stop button lead wires and the coil primary wire.

Remove blower housing from engine.

Connect the timing tester lead with red rubber cap to

the coil primary wire and ground the lead with black

rubber cap to crankcase. (See

Fig.

7-3-3.)

While the

points are open, the buzzer within tester remains ringing and when the points are closed, the tester remains

silent.

Turn flywheel slowly counter-clockwise (D type and

V

type engines) or clockwise

(B

type engines) until the

buzzer within tester becomes silent.

Then, turn flywheel very slowly clockwise

(D

type and

V

type engines) or counter-clockwise (B type engines)

and stop immediately the moment the buzzer within

TIMI

\

GROUND

WIRE

tester begins ringing.

Fig.

7-3-3

Check

if

line mark

on

the flywheel

is

in

the line with line mark on the crankcase. When the line marks are in alignment,

the timing

is

correct.

If the timing mark lines are not

in

alignment, then readjust the point opening according to the BREAKER POINT

AD-

JUSTMENT, by-removing the flywheel and repeat the checking procedures

3)

through

S).

Afer completing the timing adjustment re-mount the blower housing and connect the coil primary lead to the stop button.

MAGNETO’

TROUBLE

SHOOTING

When the engine does not start or starts with difficulty, or when its operation is unstable, the following tests will clarify

if

they are caused by a defect in the magneto.

1) Check ignition cable for possible corrosion, broken, worn insulator or loose connection.

2)

Check the sparking as described later

in

this section.

3)

Check if the breaker points require cleaning, or adjusting

or

not.

If

the points are badly corroded or pitted. Condenser

may have to be replaced.

Refer to “BREAKER P0IN.T ADJUSTMENT”

4)

If no spark takes place, replace ignition coil.

SPARK

TESTING

Remove spark plug from cylinder head and place it on blower

housing,

with the ignition cable connected to it.

Crank the’ engine several times by starting pulley and observe the spark in the spark gap of spark plug. If the spark is strong,

the ignition system can be eliminated as the source of trouble.

If the spark is weak or there is no spark at all, repeat the checks according

to

the procedures

1)

through

3)

above. The

The correct electrode gap is

0.5

-

0.7

mm.‘ (Refer to section

12.

CHECKS and CORRECTION.”)

-31

-

Page 36

8.

GOVERNOR

8-1

CONSTRUCTION

and

OPERATION

In the model EC05-2,

plete, governor sleeve and governor arm are installed

case (EC05-2D, 07-2D) or

07-2,

EC05-2,

As

the engine speed fluctuates, flyweight on the governor plate complete, rotating together with the crankshaft, changes its

by the mixture fuel).

07-2,

10,

17

and

25-2

engines, a centrifugal flyweight type governor

in

the governor chamber (EClOD,

in

the reduction chamber (type B and

V),

and lubricated

is

used. The governor plate com-

lev,

17D and

by

the lubricating

25-2D),

oil

(in the model

in

the crank-

opening angle and moves the governor sleeve, which in turn rotates the governor shaft through the governor arm. The governor lever

tle lever through

is

connected to the extending

the

governor rod at the other end; thus the throttle valve

part

of the governor shaft and this governor lever

is

opened

is

connected to the carburetor throt-

or

closed and engine speed and output

are controled.

When the crankshaft rotation increases, all the relevant members move

in

the direction indicated by-marks and the car-

buretor throttle valve closes, reducing the fuel supply and consequently reducing the speed and output. When the crankshaft

rotation decreases, the same members

moie

in

the direction indicated by-- --marks and the carburetor throttle valve open,

increasing the fuel supply and consequently recovering the failing speed and output.

GOVERNOR

THROTTLE LEVER

ROD

SPRING GOVERNOR

ROD

THROTTLE VALVE

GOVERNOR LEVER

FLYWEIGHT

GOVERNOR

CRANKSHAFT

GOVERNOR SLEEVE

GOVERNOR SPRING

ARM

CONTROL

LEVER-

CARBURETOR

STOPPER

HIGH SPEED STOPPER

PLATE

BOLT

Fig.

8-

1-

1

Model

-

32

ECO5-2,

-

07-2

Page 37

I.

..,

\-SPACER

\“SET

PIN

GOVERNOR SLEEVE

..

..

..

Fig.

8-1-2

Model

ECIO,

17,25-2

-33-

’

Page 38

8-2

GOVERNOR

The governor linkage should be adjusted, after reassemble it according to the following procedures.

1)

Connect governor rod and rod spring to carburetor throttle lever and governor lever, then install these to governor

shaft.

NOTE: Never tighten adjusting plate set screw at

shaft

2)

Connect governor lever and control lever with governor spring, and install control lever on crankcase.

ADJUSTMENT

this

time, and do not fixed adjusting plate, governor lever and governor

8-2-1

IN

CASE

OF

MODELS

As

shown by arrow mark

er to

high

speed side (clockwise) until stop fully, and

fasten the control lever

Loosen lock nut at the end

screw on adjusting plate.

As

shown

plate

Tighten both lock nut at the end

shown on

by

the

arrow

all

the way until it will not travel

Fig.

8-2-3

EC10,

EC17

(See

Figs.

8-2-1,8-2-2

on

Fig.

8-2-1

turn control lev-

by

tightening wing bolt.

of

governor shaft and set

on

Fig.

8-2-2,

move adjusting

any

more.

of

governor shaft as

and set screw on adjusting plate.

and

8-2-3.)

Fig.

8-2-1

Fig, 8-2-2

-34-

Fig.

8-2-3

Page 39

8-2-2

'

IN

CASE

OF

MODELS EC05-2, EC07-2

(See

Figs.

8-2-4

and

8-2-5.)

1)

As

shown by arrow mark on Fig.

8-2-

5

turn control lever to high speed side (counter-clockwise)

until

stop fully, and

fasten the control lever

by

tightening wing nut.

2)

With a screw driver inserted in the groove of governor shaft, turn it counter-clockwise fully (until it

will

not turn any

more) and then lock governor. lever to governor shaft by tightening clamp nut. (See Figs.

8

-24

and

8

-2-5.)

GOVERNORSHAFT

\I

GOVERNOR

Fig.

8-2-

4

Fig.

8-2-5

8-2-3

IN

CASE

OF

MODEL EC25-2

(See

Fig.

8-2-6.)

Governor adjustment procedure

is

exactly same as that for

model

EC10.

LCLAMP

NUT

Fig.

8

-2-

6

-

35

-

Page 40

8-3

HIGH

SPEED ADJUSTMENT

*

Maximum speed for standard engine:

...............

...............

................

NO

TACHOMETER

8-3-1

EC05-2

EC07-2

EClO

WHEN

(Fig.

8-31

5,500

5,500

5,000

IS

AVAILABLE

r.p.m. EC17

r.p.m. EC2 5-2

r.p.m.

................

...............

5,000

5,000

r.p.m.

r.p.m.

Unless required in the process

crankcase. If it is necessary to remove them,

case, control lever must be turned clockwise

per bolt on control lever (Fig. 8-3-1).

When reassembling, re-establish the recorded dimension

WHEN A TACHOMETER

8-3-2

1)

Install stopper plate, control lever and other related parts.

2) By turning control lever with governer spring on it, increase gradually the engine speed up to specified engine speed.

3)

Then follow the below:

In case of models EC05-2,07-2 and 25-2, locate high speed stopper bolt on the control lever and lock it

as

work

In case

will

Make sure that the governor spring

2 holes (EC05-2),4 holes (EC17) or

Normally, hook governor spring in the second hole from the top (ECl

stopper of control lever against the stopper plate.

of

models EClO and EC17, locate stopper plate and fasten

work as stopper of control lever.

of

disassembling, do not remove control lever stopper plate and/or other related

in

models EClO and EC17 record the dimension

all

the way.) In models EC05-2, EC07-2 and EC25-2, never

"L"

in

models EClO and ECl7.

IS

AVAILABLE

is

put back

3

holes (EC25-2) on the governor lever.

in

the same hole

on

the governor lever as before. There are 5 holes (EC10) or

it

to crankcase

0,

17) or in the lower hole (EC05-2,07-2 and 25-2).

ADJUSTING

"L"

prior to removeing. (This

turn

so

that wing bolt on stopper plate

SCREW

parts

high

speed stop

so

that it will

(THROTTLE

from

WIRE)

GOVERNOR LEVER

GOVERNOR

SPRING

Fig.

8-3-

1

Model

-

36

EC05-2,

-

07-2

CONTROL LEVER

HIGH

SPEED STOPPER BOLT

Page 41

/-

GOVERNOR SPRING

'

ADJUSTING

SCREW

(THROTTLE

WIRE)

Fig.

8-3-2

Model

EClO,

17

SPRING

Page 42

9.

CARBURETOR

PILOT AIR JET

CHOKE LEVER

PILOT SCREW

PILOT OUTLET

BANJO BOLT

STRAINER

BLEED

AIR

JET

CHOKE VALVE

PILOT JET

MAIN AIR JET

MAIN

NOZZLE FLOAT CHAMBER

MAIN JET

/

FUEL

DRAIN

PLUG

NEEDLE VALVE

THROTTLE VALVE

BASIC FUEL LEVEL

““““C

FUEL

-I

Fig-

-38

9

7

-

Page 43

9-1

CONSTRUCTION

and

OPERATION

9-1-1 FLOAT

SYSTEM

The float chamber is located just below carburetor main body and serves to maintain the fuel level at a constant height by a

joint action of float

(F)

and needle valve

(NV)

incorporated. The fuel flows from the fuel tank into float chamber via needle

valve, which is kept open while the fuel level is low, but closed when the fuel level reaches a predetermined level causing the

float to move up.

9-1-2

THROTTLE VALVE

The throttle valve is operated by the control lever and controls the amount

of

air-fuel mixture and controls engine output

power.

The richness

of

mixture or the air-fuel ratio is automatically regulated at the optimum valve regardless

of

the throttle valve

position.

9-1-3

CHOKE VALVE

The choke valve is operated by the choke lever and when it is closed, the air-fuel mixture becomes rich, and as it is opened

the more, the leaner will be the mixture. The choke system serves to facilitate start-up in cold season. When engine is

cranked with choke closed, the negative pressure to main nozzle increases to introduce fuel in large quantities to make

start-up easy.

9-1-4

PILOT SYSTEM

and

MAIN SYSTEM

This pilot system feeds fuel to engine during idle and slow speed operation.

The fuel fed through main jet

(MJ)

is measured by pilot jet

(PJ),

mixed with air measured by pilot air jet

(PAJ),

regulated

by pilot screw, and then fed to engine through pilot outlet

(PO)

and bypass

(BP).

The fuel

is

mainly fed from pilot outlet

(PO)

during idling.

This main system feeds fuel

to

engine during medium and high-speed operation.

The air measured

by

main air jet (MAJ) is mixed into fuel through bleed holes

of

main nozzle

(MN)

and discharged

to

main

bore

(MB)

as

atomized fuel where it is mixed with intake air through air cleaner to become an optimum air-fuel mixture to

be supplied to engine.

9-2

DISASSEMBLY

and

REASSEMBLY

(Fig.

9-2)

Besides mechanical failures, most trouble are caused. by incorrect mixing ratio. The most common causes

of

such incorrect

fuel-air mixtures are clogged jets, restricted air and fuel passages, and variations in fuel level, In order to obtain the full

performance of carburetor, it is necessary

to

keep air cleaner and carburetor clean

so

that air and fuel flow without any

restriction.

Observe following disassembly and reassembly procedures. (see Fig.

9-2)

CAUTION: AFTER DISASSEMBLY, CLEAN ALL PARTS

IN

A SUITABLE SOLVENT, ALL JETS AND VALVES

SHOULD BE BLOWN OUT WITH FRESH COMPRESSED AIR, NEV€R USE A DRILL OR WIRE TO CLEAN OUT

JETS OR IDLE HOLES.

-

39

-

Page 44

31

22

\

25."-3&

9-2-1 THROTTLE SYSTEM

1)

Remove guide screw

CAUTION: TAKE CARE

2)

Remove spring

9-2-2 CHOKE SYSTEM

1)

Take out Philips-screw

2)

When choke shaft

In

reassembly:

1)

Insert spring

2)

When assembling choke, the flat

(24)

is

(32)

and steel ball (31)

Fig.

92

(22),

Philips-screw (171, remove throttle valve (16), and then pull out throttle shaft

NOT

TO

DAMAGE'ENDS

by unscrewing throttle stop screw

(20),

remove choke valve (1

pull out, choke spring

on

(32)

in

the hole and install choke shaft (18).

choke valve must be toward the main air jet side.

OF

THROTTLE

(23).

9),

pull

out

and steel ball

-

40

-

VALVE.

choke shaft

(31)

should be removed, lest they be lost.

(18).

(1

5).

Page 45

9-2-3 PILOT SYSTEM.

..

1) Remove pilot jet (21) using a suitable tool while taking care not to damage it.

2)

Remove pilot screw

(25)

and spring

(26)

In reassembly:

.I

-.

.11

1) Tighten pilot jet and pilot plug firmly to prevent fuel leakage.

2)

Replace pilot screw if tapered end

is

damaged.

*

.

CAUTION:

DO

IQOT

OVERTIGHTEN.

9-2-4 FLOAT

SYSTEM

1) Remove guide holder

(5)

and float chamber (1 1).

2) Remove screw (14) and float arm

(8)

by taking out!float pin

(9).

CAUTION: TAKE CARE NOT TO DAMAGE FLOAT AND FLOAT ARM.

3)

Remove needle valve (7) and packing

(6).

CAUTION: WHEN REPLACING NEEDLE VALVE, REPLACE

IT

TOGETHER WITH VALVE SEAT WITHOUT FAIL.

In assembly:

Wash inside

of

float chamber with gasoline.

9-2-5 MAIN

SYSTEM

1)

Remove main jet

(4)

from guide holder

(5)

using a suitable tool.

CAUTION: TAKE CARE NOT TO DAMAGE

IT.

2)

Remove main nozzle

(3).

NOTE: In case

of

ECIO,

no need to remove main nozzle because

of

main nozzle being incorporated into carburetor body.

In reassembly:

1)

Tighten main jet securely to guide holder and tighten guide holder to carburetor body.

2) Tighten guide holder to

70

-

80

kg-cm

(5.5

lbs-ft).

A

too rich fuel mixture will result

if

not tightened securely.

9-3

ADJUSTMENTS

When the control lever is set at slow speed side, the engine should be operated on idling speed.

*The idling speed

of

engine is adjusted

in

the following sequence.

Specified idling speed:

EC05-2.

.............

1300 r.p.m.

*

100

..

EC25-2.

..............

1500r.p.m. * 100

EC07-2

..............

1300 r.p.m. k 100

EClO 1300 r.p.m.

f

100

.

EC17

.................

1300

r.p.m. k 100

.-

...............

,

1) Adjust pilot screw by turning

it

counterclockwise by 1 turn (1 % turn for Model EC17) after fully, closing

it

once.

CAUTION:

DO

NOT OVERTIGHTEN PILOT SCREW WHEN CLOSING IT FULLY. THE NEEDLE POINTMIGHTBE

DAMAGED

BY

OVERTIGHTENING.

2) THROTTLE STOP SCREW

Turn throttle stop screw clockwise until the specified idling speed is obtained.

If this speed exceeds specified idling speed, turn throttle stop screw counterclockwise.

..

-41

-

Page 46

10.

RUN

IN

OPERATION

An

overhauled engine must

Especially when cylinder, piston or

of

REASSEMBLED ENGINE

be

carefully run-in to get proper surface condition

piston

rings are replaced, a thorough run-in operation

The recommended run-in schedule is as follows:

LOAD

EC05-2

EC17 EClO EC07-2

EC25-2

on

newly installed parts.

is

indispensable.

SPEED TIME

I

1.5 HP

1.8

HP

2.0 HP

2.3 HP

No load

No

load

No

load

3.0

HP

5.0

5.5

HP

HP 3.5 HP

8.0

9.5

HP

HP

I

2,000

rprn

3,000

rprn

4.000 rprn

4,000 rprn

4,500 rprn

I

10

10

10

30

60

rnin.

rnin.

rnin.

min.

rnin.

I

~

-

42

-

Page 47

.I

11.

TROUBLE

SHOOTING

For a gasoline engine

to

start and run satisfactorily, the following three reyuirements must be met:

1)

The cylinder filled with a proper fuel-air mixture.

2)

An

appropriate compression in the cylinder.

3)

Good spark at correct time

to

ignite the mixture.

If

all

the three requirements are

not

met simultaneously, an engine can not be started. There are also other factors such as

heavy load at starting and too long an exhaust pipe causing a high back pressure, which contribute to hard starting.

The most

common

causes

of engine troubles are given below.

11-1

STARTING

DIFFICULTIES

Cause

~

Defects in spark plug

Defects

in

high-tension

cable

Defects

in

contact

breaker

Defects

in

magneto

Other defects

in

electric system

Gas leak through head

gasket'or other parts

Defects in piston

assembly

Remedy

1) If contaminated, wash in gasoline, remove

2)

If

spark plug

is

broken and lost insulation,

3)

Adjust spark gap to

0.5

-

0.6mm. (for Model

foreign material and dry.

replace

plug.

EC10)

If cable

is

burnt, replace cable along with coil.

1)

If breaker points are rough, smooth out

surface with emery paper

(#400).

2)

If

breaker point gap

is

incorrect, adjust

it

to

specified

0.4

*

0.05mm (for Model EC10) by

loosening contact support plate lock screws.

3)

If

spark timing is incorrect, adjust

it

to

18"-23" before TDC. (refer to

4-1 1

)

4)

If

breaker

is

defective in insulation, replace

breaker.

5)

If

condenser

is

defective, replace.

1)

If

wire or insulation

is

broken, replace

2)

If

magnetism

is

weak, re-magnetize (at

the

magneto.

magneto maker) or replace.

'

1)

If

stop-button

is

faulty, (short circuiting)

replace or repair.

2)

If

primary wire

is

grounded to the engine

body, insulate

it

with insulating adhesive

tape.

1)

If

head gasket

is

defective, replace.

2)

If

head bolts are loose, tighten.

3)

If

spark plugs are loose, tighten.

4)

If

spark plugs are defective, replace.

1)

If piston

is

worn, replace.

2)

If

cylinder is worn, re-bore and use oversize

piston and piston ring.

(No

oversize for

EC052 and

07-2.)

3)

If

piston rings are worn, replace.

4)

If

piston rings are stuck, clean or replace

rings.

Preventive measure

1)

Use spark plugs of specified heat range.

Do

not

use

poor grade oil. Clean air cleaner and

avoid dust entry.

2)

When spark gap

is

adjusted, if center

el-

trode

is

hit or bent, insulator may get

damaged.

1) Keep air cleaner always clean.

2)

Do

not use poor grade oil. Change oil

regularly.

-43

-

Page 48

Cause

in

Defects

system

Defects in carburetor

Defects in carburetor

Excess load

fuel tank

Remedy

1)

Clean clogged tank outlet.

2)

Clean clogged fuel strainer.

3)

If incorrect fuel is poured into tank or

water is mixed, drain tank completely and

fill

it

4)

1

2)

1)

2)

If

wear. Replace, if necessary.

1)

2)

with correct fuel.

When fuel pipe is locked with air, expel1 air.

)

If clogged with

If defective, replace.

Clean jets and other orifices,

clogged.

Start engine with fully open choke vatve and

half open throttle valve.

Remove drain plug from crankcase, and

close fuel cock, repeat starting operation

several times to evacuate excess fuel.

fuel overflows, check needle valve seat for

If power transmission

correct tension.

If

load

dust,

clean.

if

belt

is

too tight,

is

still too heavy, install a clutch.

they are

Preventive measure

11

Be sure to use a filter when adding fuel.

2)

Use

mixture (gasoline

1)

Never

close

warm.

2)

When stopping the engine, run it at

speed for a while. This practice not only

favourably affects next starting, but

improves engine life.

3)

Clogged air-cleaner results in

fuel mixture.

C\ean

it

throughly.

Be careful clogged carburetor.

25

:

oil

1

choke valve when engine

)

as fuel.

too

slow

rich air-

is

also

p

\.

'

1)

If piston seizes, correct or replace.

2)

If

connecting rod large end

seize, replace.

or

small end

11-2

SLOW-SPEED

1)

If

the pilot screw in the carburetor is not correctly adjusted, correct it. Refer to section

Piston or Connecting

Rod

seized

out of

order

of CARBURETOR".

2)

Most defects listed as causes

11-3

OVERHEATING

1)