Page 1

Page 2

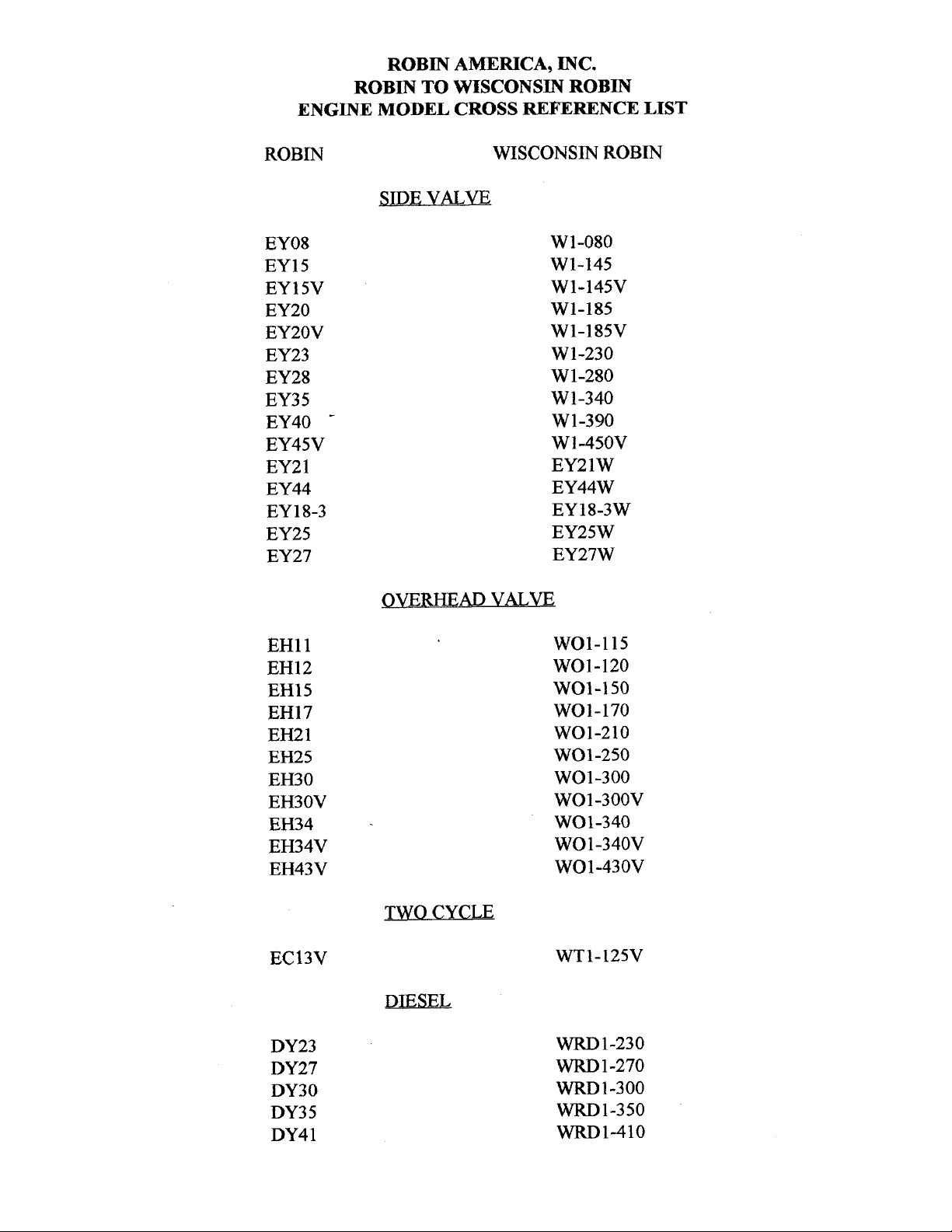

ROBIN

AMERICA, INC.

ROBIN

TO

WISCONSIN

ROBIN

ENGINE

MODEL

CROSS REFERENCE

LIST

ROBIN

EY08

EY15

EY 15V

EY20

EY2OV

EY23

EY28

EY3

5

EY40

-

EY45V

EY2

1

EY44

EY 18-3

EY25

EY27

EH11

EH12

EH15

EH17

EH21

EH25

EH30

EH30V

EH34

EH34V

EH43V

EC13V

DY23

DY27

DY30

DY3

5

DY4 1

WISCONSIN

ROBIN

SIDE

VALVE

W

1-080

W1-145

W1-145V

W1-185

W1-185V

W1-230

W 1-280

W

1-340

W 1-390

Wl-45OV

EY21W

EY44W

EY18-3W

EY25W

EY27W

OVERHEAD

VALVE

WO1-115

wo1-120

WO1-150

WO1-170

wo1-210

WOl-250

WO 1-300

WO1-300V

WO1-340

WO

1

-340V

WO 1-43 OV

TWO CYCLE

WT1-125V

DIESEL

WRD

1-230

WRD

1-270

-1-300

WRD1-350

WRD1-410

0

0

0

Page 3

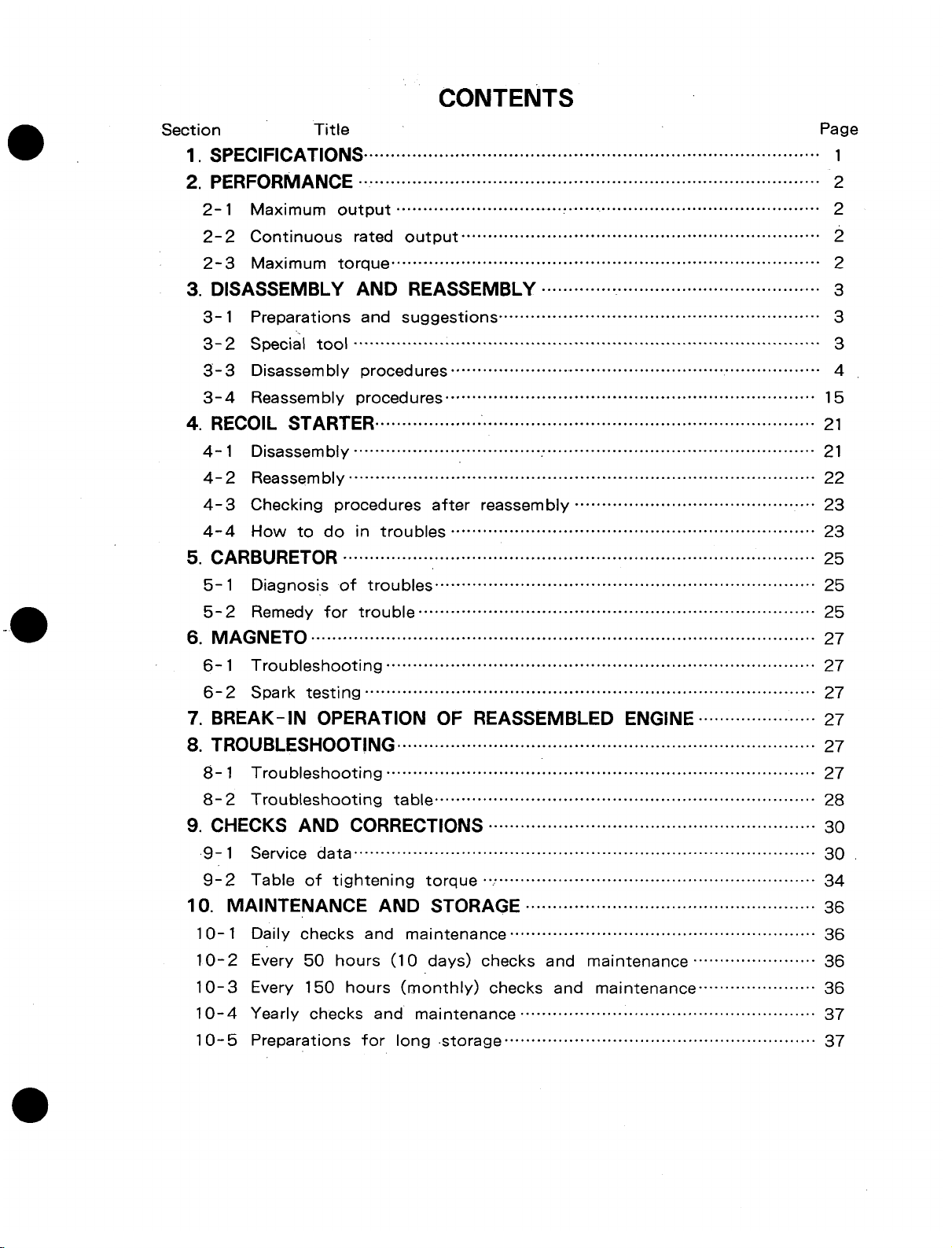

CONTENTS

Section

Title

Page

1.

SPECIFICATIONS" ""."O"""""•"O"O"C".O"""O"O"".O"""'"•""""""S""""""""""""."."""""".--"".--.-......C... 1

2. PERFORMANCE ..."...... ......".........""............ ......"......."".."............. ....."..C.". 2

2-1 Maximum output ...... C................................................"....".................. 2

2-2 Continuous rated output ...................................."............."................ 2

2-3 Maximum torque

................................................................................

2

3. DISASSEMBLY AND REASSEMBLY ......"."....................".."............"..... 3

3-1 Preparations and suggestions ...................................".....".................. 3

3-2 Special tool ............................................................... ........................ 3

3-3 Disassembly procedures .`..............".......................".. ".................."...... 4

3-4 Reassembly procedures .............."..............".. ".................................... 15

4. RECOIL STARTER ...."..... ...............................""................................... 21

4-1 Disassembly .."....."..............".............."... "............."............................. 21

4-2 Reassembly ."..............."............".................""".."............".................... 22

4-3 Checking procedures after reassembly ............................................. 23

4-4 How to do in troubles "........................"........................."................ 23

5. CARBURETOR ..........................".".............................. ....................... 25

5-1 Diagnosis of troubles ....................................................................... 25

5-2 Remedy for trouble ...................."................."................................... 25

6. MAGNETO .-.........."........-...."...."..............".. .........."""............."."............. 27

6-1 Troubleshooting ......"....."..........................................""....................... 27

6-2 Spark testing "".........................................."......................."... "".......... 27

7. BREAK-IN OPERATION OF REASSEMBLED ENGINE ... ................27

8. Troubleshooting ..................."".................• ........ ..................

27

8-1 Troubleshooting ............". "........................................."....................... 27

8-2 Troubleshooting table" ................"............"........................................ 28

9. CHECKS AND CORRECTIONS ..................... ...................... .... 30

9-1 Service data ...............".....................................................".........".".... 30

9-2 Table of tightening torque .... .................................."...................`.... 34

10. MAINTENANCE AND STORAGE ...................... .................. 36

10-1 Daily checks and maintenance ......".................................................. 36

10-2 Every 50 hours (10 days) checks and maintenance ....................... 36

10-3 Every 150 hours (monthly) checks and maintenance ...................... 36

10-4 Yearly checks and maintenance ....................................................... 37

10-5 Preparations for long .storage ......".. "........"....................................... 37

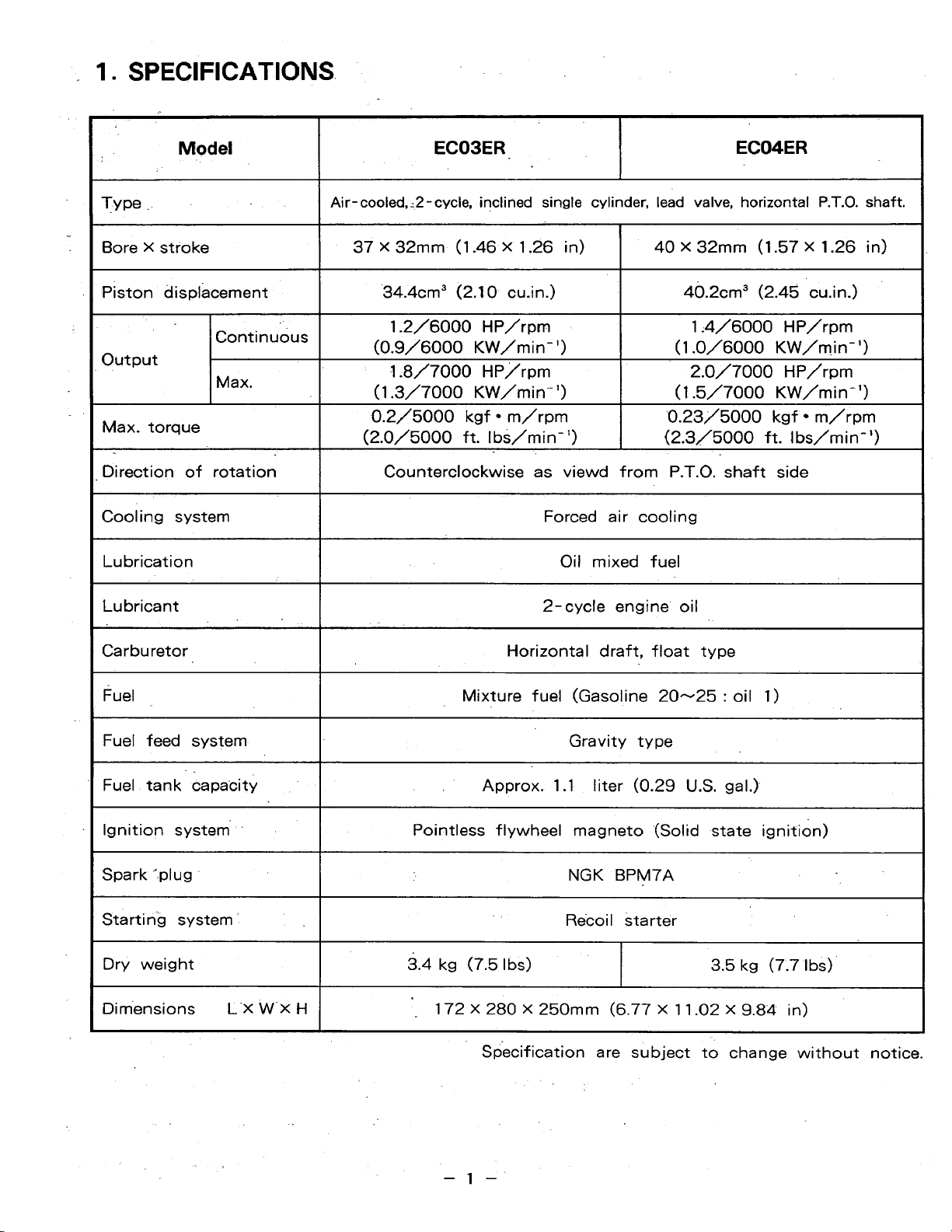

Page 4

1.

SPECIFICATIONS.

I

I

Model

Type

:

Bore X stroke

Piston displacement

output

EC03ER

ECO4ER

1

Air-cooled,~2-cycle,

inclined

single

cylinder,

lead

valve,

horizontal

P.T.O.

shaft.

37

X

32mm

(1.46

X

1.26

in)

40.2cm3

(2.45

cu.in.)

34.4cm3

(2.1

0

cain.)

40

X

32mm (1.57

X

1.26

in)

1.2/6000

HP/rpm

1.4/6000

HP/rpm

(0.9/6000

KW/min")

(1.0/6000

KW/mi

n-

'1

.1.8/7000

HP/rpm

2.0/7000

HP/rpm

(1.3/7000

KW/min")

(1.5/7000

KW/min")

Max. torque

0.2/5000

kgf m/rpm

0.23/5000

kgf

m/rpm

I

(2.0/5000

ft.

Ibs/min")

I

(2.3/5000

ft.

Ibs/min")

Direction of rotation

I

Counterclockwise

as

viewd from P.T.O.'shaft side

Cooling system

I

Forced air cooling

Lubrication

I

Oil mixed fuel

Lubricant

Horizontal draft, float type Carburetor

2-cycle engine oil

Mixture fuel (Gasoline

20-25

:

oil

1)

Fuel

Fuel feed system

I-

Gravity type

Fuel tank capacity

Approx. 1.1 liter

(0.29

U.S.

gal.)

Ignition system

I

Pointless flywheel magneto (Solid state ignition)

Spark *.plug

NGK

BPM7A

Starting system

I

Recoi I starter

Dry weight

3.5

kg

(7.7

Ibs)

3.4

kg

(7.5

Ibs)

Dimensions

L-X

W-X

H

1

72 X 280

X

250mm (6.77

X

1

1.02

X

9.84 in)

a re subject

to

change without

-1-

Page 5

2.

PERFORMANCE

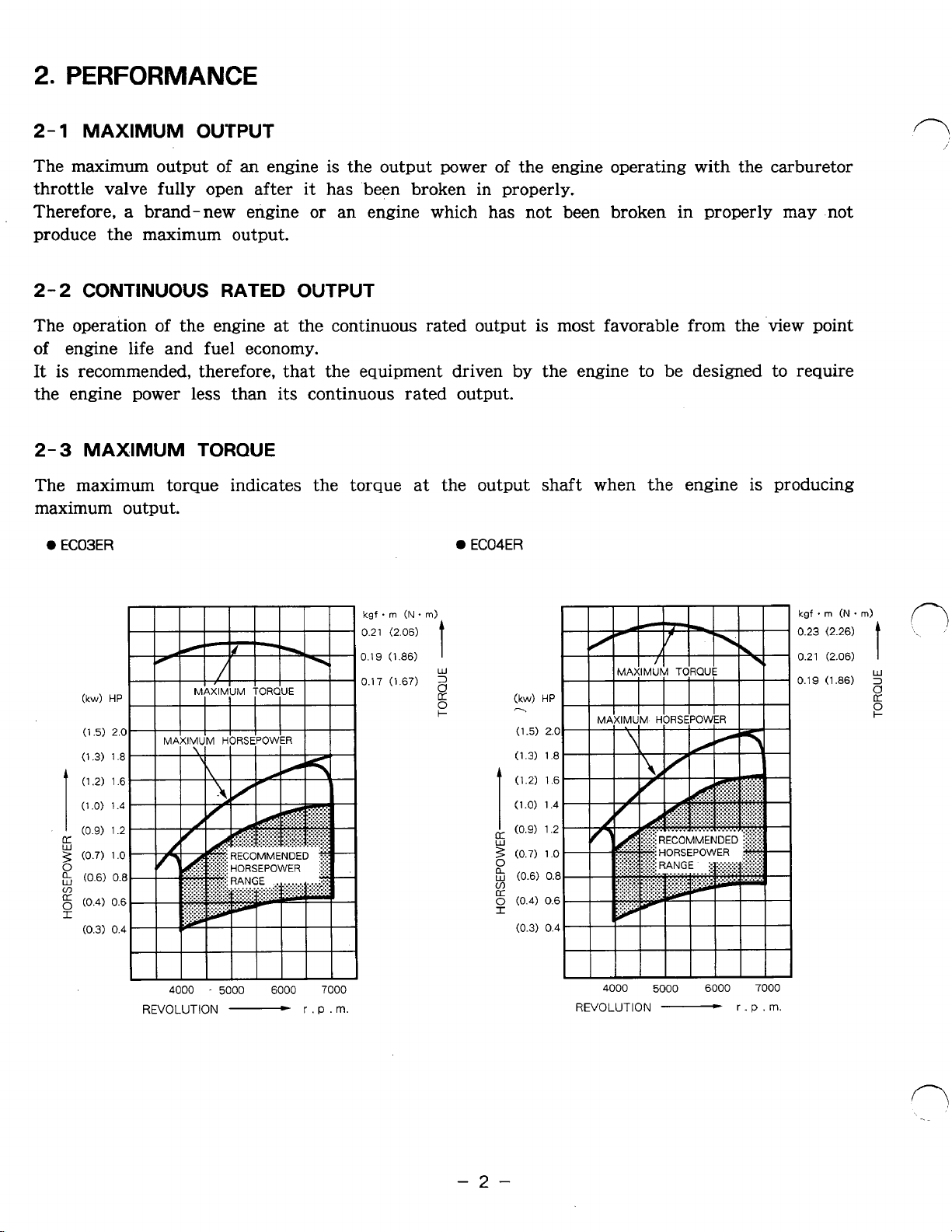

2-1

The maximum output

throttle valve fully open after

Therefore,

MAXIMUM OUTPUT

of

an

engine is the output power

a

brand-new engine

of

the engine operating with the carburetor

it

has .been broken in properly.

or

an engine which has not been broken in properly may not

produce the maximum output.

2-2

The operation of the engine at the continuous rated output

CONTINUOUS

RATED

OUTPUT

is

most favorable from the view point

of engine life and fuel economy.

It

is

recommended, therefore, that the equipment driven

by

the engine to

be

designed to require

the engine power less than its continuous rated output.

2-3

MAXIMUM

TORQUE

The maximum torque indicates the torque at the output shaft when the engine is producing

maximum output.

0

EC03ER

0

EC04ER

4000

.

REVOLUTION

5000

-

6000

kgf

*

m

(N

(2.26)

(2.06)

(1

36)

.

f-?

kgf

.

rn

(N

.

m)

0.21

(2.06)

0.19

(1.86)

0.17 (1.67)

7000

r

.

P .

m.

t

W

3

2

0

F

4000

REVOLUTION

5000

-

6000

r

.P

0.23

0.21

0.19

7000

.m.

-2-

Page 6

3.

DISASSEMBLY AND REASSEMBLY

3-

1

PREPARATIONS

AND

SUGGESTIONS

(1)

When disassembling an engine , memorize well the locations

of

individual

parts

so

that they

can be reassembled correctly.

If

you are uncertain of identifying some

parts,

it is suggested

that tags to be attached to them.

(2)

Have boxes ready to keep disassembled parts by group.

(3)

To

prevent missing and misplacing small parts such

as

bolts and nuts, etc., temporarily

assemble

as

much as possible in each group

or

set.

(4)

Carefully handle disassembled parts, and clean them with washing oil.

(5)

Use correct tools in correct way.

(6)

Standard tools required

for

disassembling and reassembling

:

a) Work table

b) Washing pan

c) Disassembling tools

d)

Washing oil (kerosene

or

light oil)

e) Emery paper, waste '.cloth

(7)

Before starting disassembly

of

the engine, drain fuel.

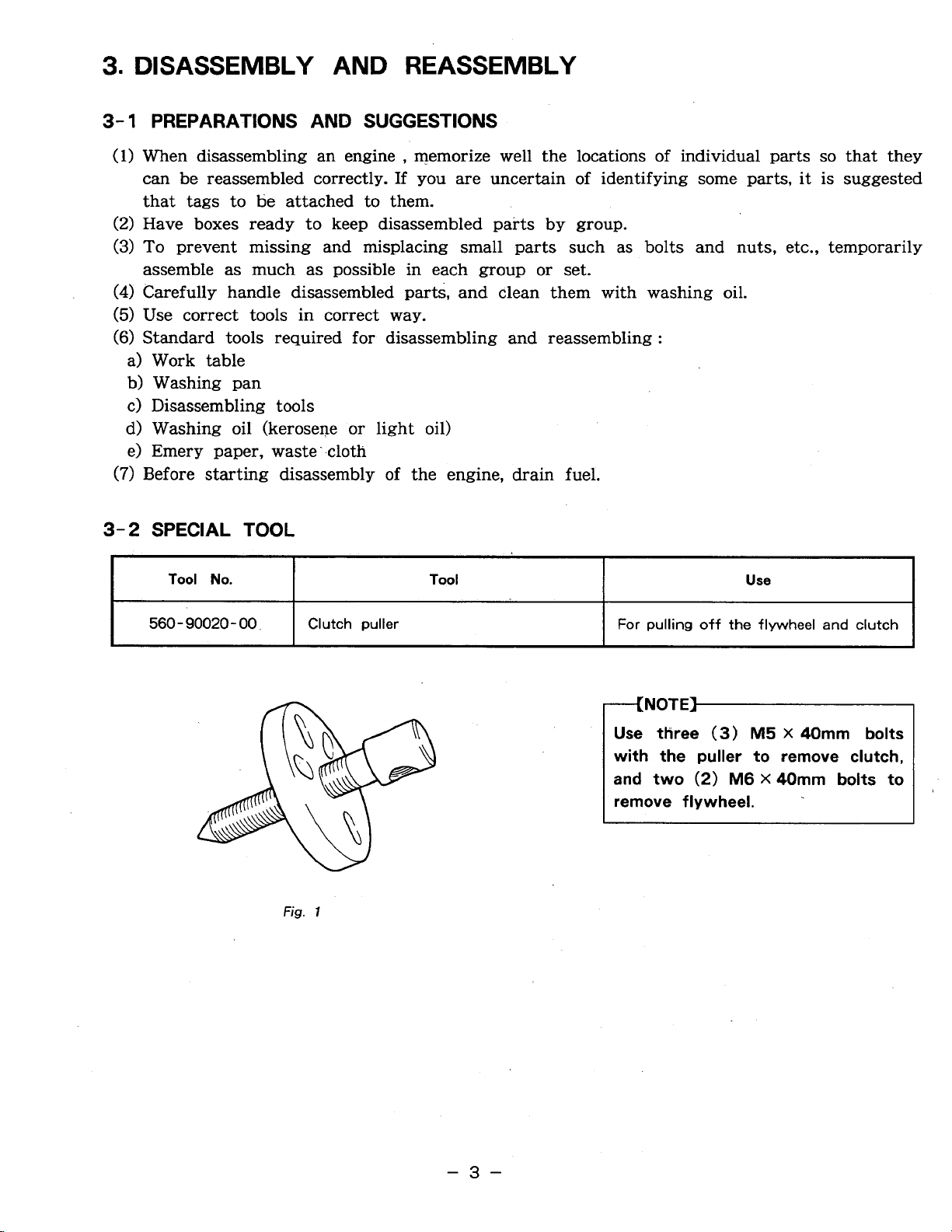

3-2

SPECIAL

TOOL

Tool

No.

Use

Tool

560

-

90020

-

00

For

pulling

off

the flywheel

and

clutch

Clutch puller

"--(NOTE]-

Use tKree

(3)

M5

X

40mm bolts

with the puller to remove clutch,

and

two

(2)

M6

X

4Omm bolts to

remove

flywheel.

Fig.

1

-3-

Page 7

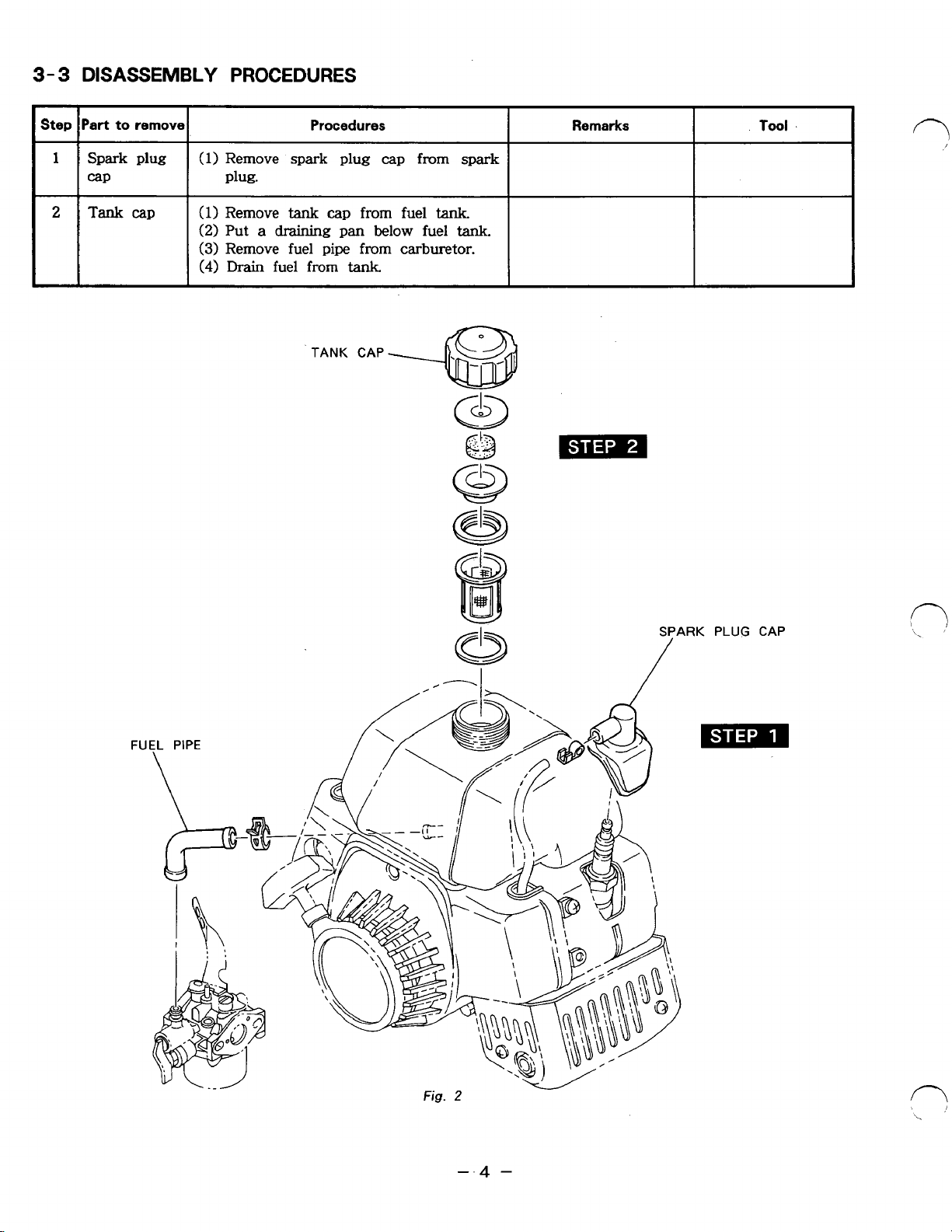

3-

3

Step

DISASSEMBLY

Part

to

remove

PROCEDURES

Procedures

Remarks

Tool

1

2

Spark plug

cap

Tank

cap

(1)

Remove spark plug cap from spark

plug.

(1)

Remove

(2)

Put

(3)

Remove fuel pipe from carburetor.

(4)

Drain

tank

a

draining

fuel from

cap

pan

tank.

TANK CAP

from

below fuel

~ ~ ~~ ~

fuel

tank.

tank.

*

~

SPARK PLUG CAP

Fig.

2

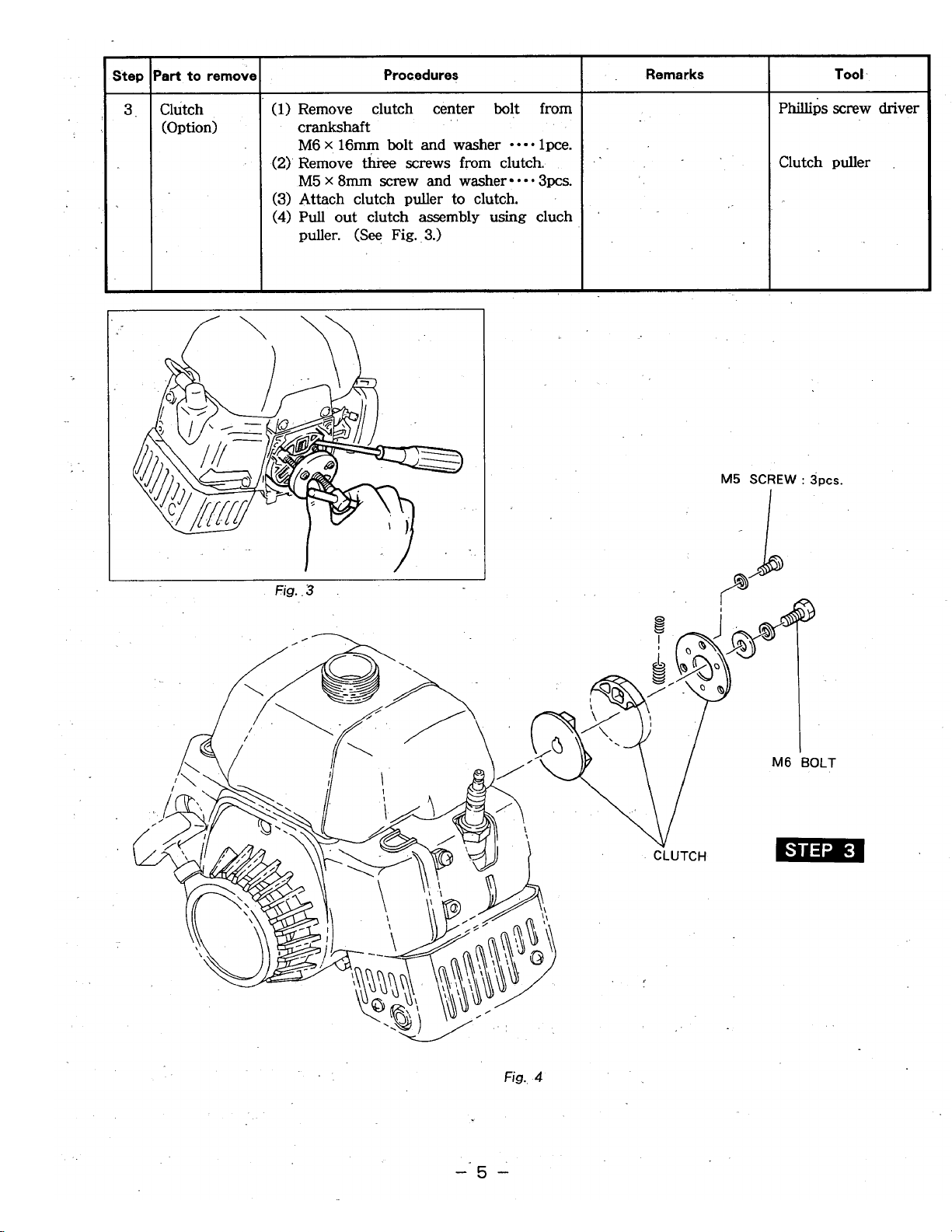

Page 8

(Option)

Procedures

(1)

Remove clutch center bolt from

crankshaft

M6

x

16mm

bolt

and

washer

-

*-*

lpce.

(2)

Remove

ki-ee

screws

from clutch.

M5

x

8mm

screw

and

washer

*e*

Spa.

(3)

Attach clutch puller to clutch.

(4)

Pull

out clutch

assembly

using

cluch

,,

puller.

(See

Fig.

3.)

Fig.

.3

~mps

screw

driver

Clutch puller

M5

SCREW

:

3pcs.

Fig.

4

-5-

Page 9

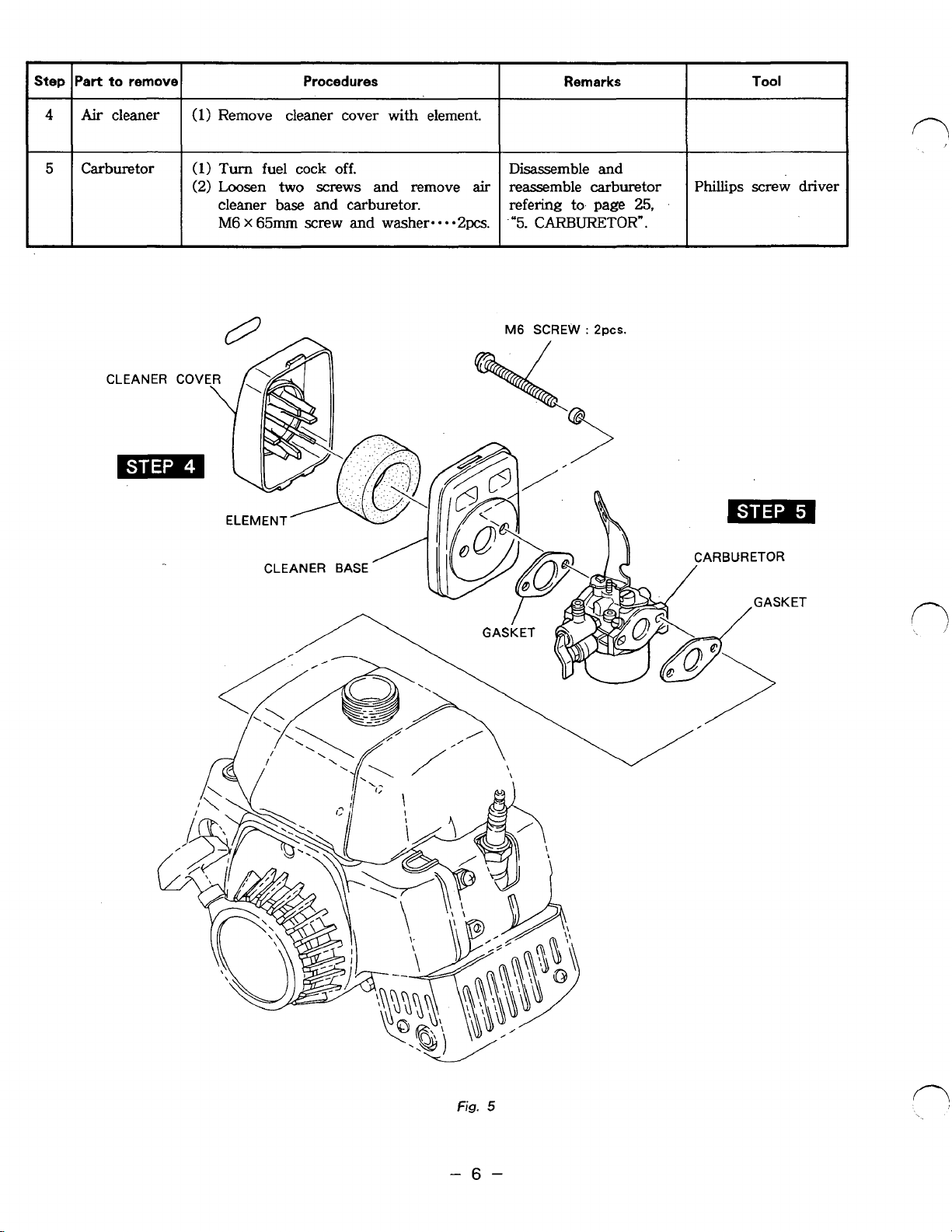

Step

4

Part

Air

to

remove

cleaner

Procedures

(1)

Remove cleaner cover with element.

Remarks

Tool

rl

5

Carburetor

(1)

Turn

(2)

Loosen

cleaner base

M6 x 65mm

fuel

cock

off.

two

screws

and

carburetor.

screw and washer....2

and

remove

Disassemble

air

reassemble carburetor

refering

pcs.

.'5.

CARBURETOR".

to.

and

page

25,

Phillips

screw driver

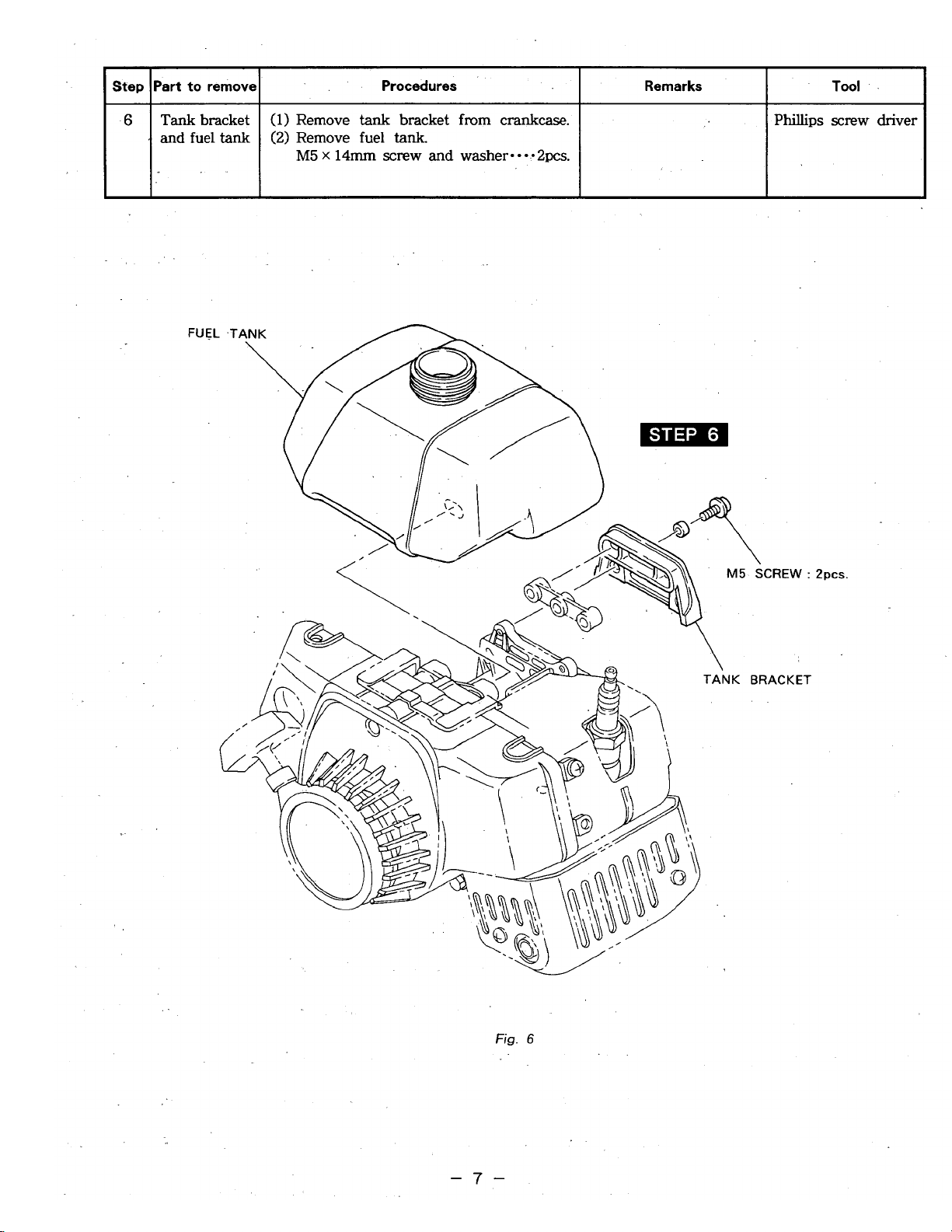

Page 10

-

Step

6

-

Part

to

remove

Tank

bracket

and

fuel

tank

Procedures

I

I

Remarks

Tool

.

I

(1)

Remove

tank

bracket

from

crankcase.

(2)

Remove fuel

tank,

M5

x

14mm

screw

and

washer---.2pcs.

Phillips

screw driver

I

I

I

Fig.

6

-7-

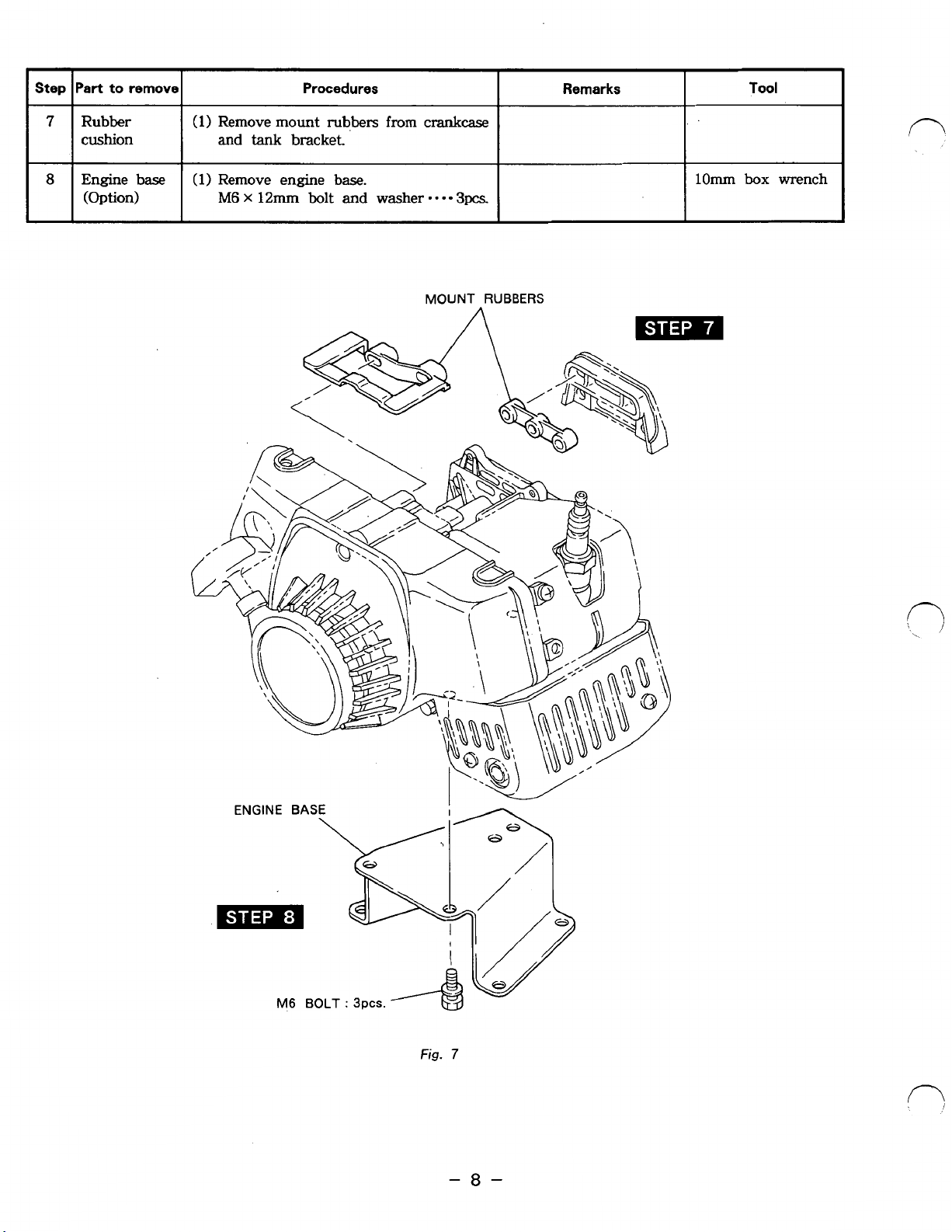

Page 11

I

Step lPart

to

remove1 Procedures

I

Remarks

I

Tool

I

7

8

Rubber

cushion

(Option)

(1)

(1)

Remove

and

tank

Remove engine base. Engine base

M6

x

12mm

mount

bracket.

bolt

rubbers

and

from

washer

crank-

*

- -

-

3pcs.

MOUNT

RUBBERS

lOmm

box

fl

wrench

M6

BOLT

:

3pcs.

I

Fig.

7

-8-

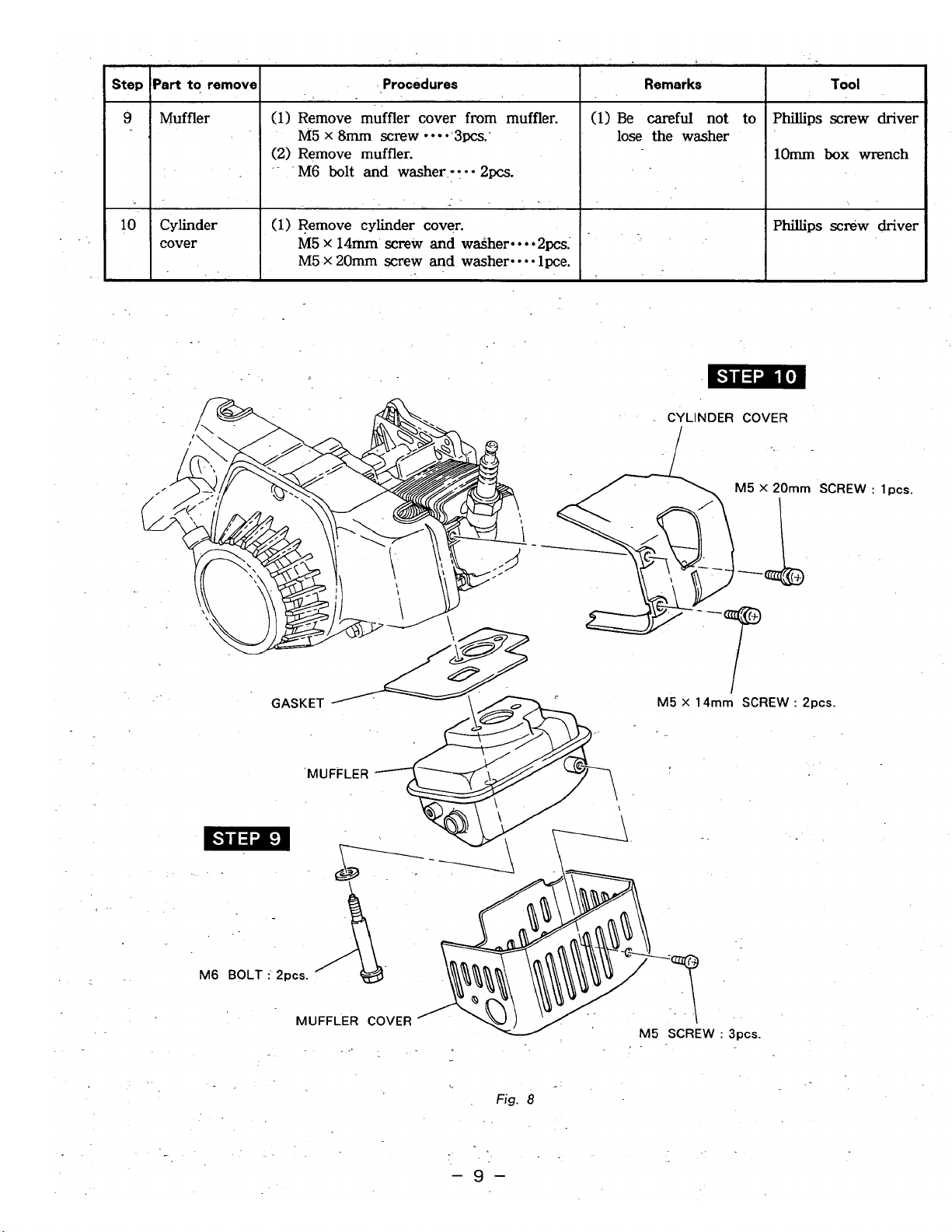

Page 12

&=

Step

Part

to

remove

*

cover

Procedures

(1)

Remove muffler cover from muffler.

(2) Remove muffler.

M5

x

8mm

screw

***a

3pc~:

'

M6

bolt and

washer

-

:

*-2pcs.

(1)

Remove cylinder cover.

M5

X

14mm

screw

and

waSher****2pcs..

M5

X

20mm screw

and

washer-.

0.

lpce.

Remarks

(1)

Be

careful

not

to

lose

the washer

Tool

Phillips

screw driver

lOmm

box

wrench

Phillips

scniw driver

.

..

Fig.

8

..

-9-

Page 13

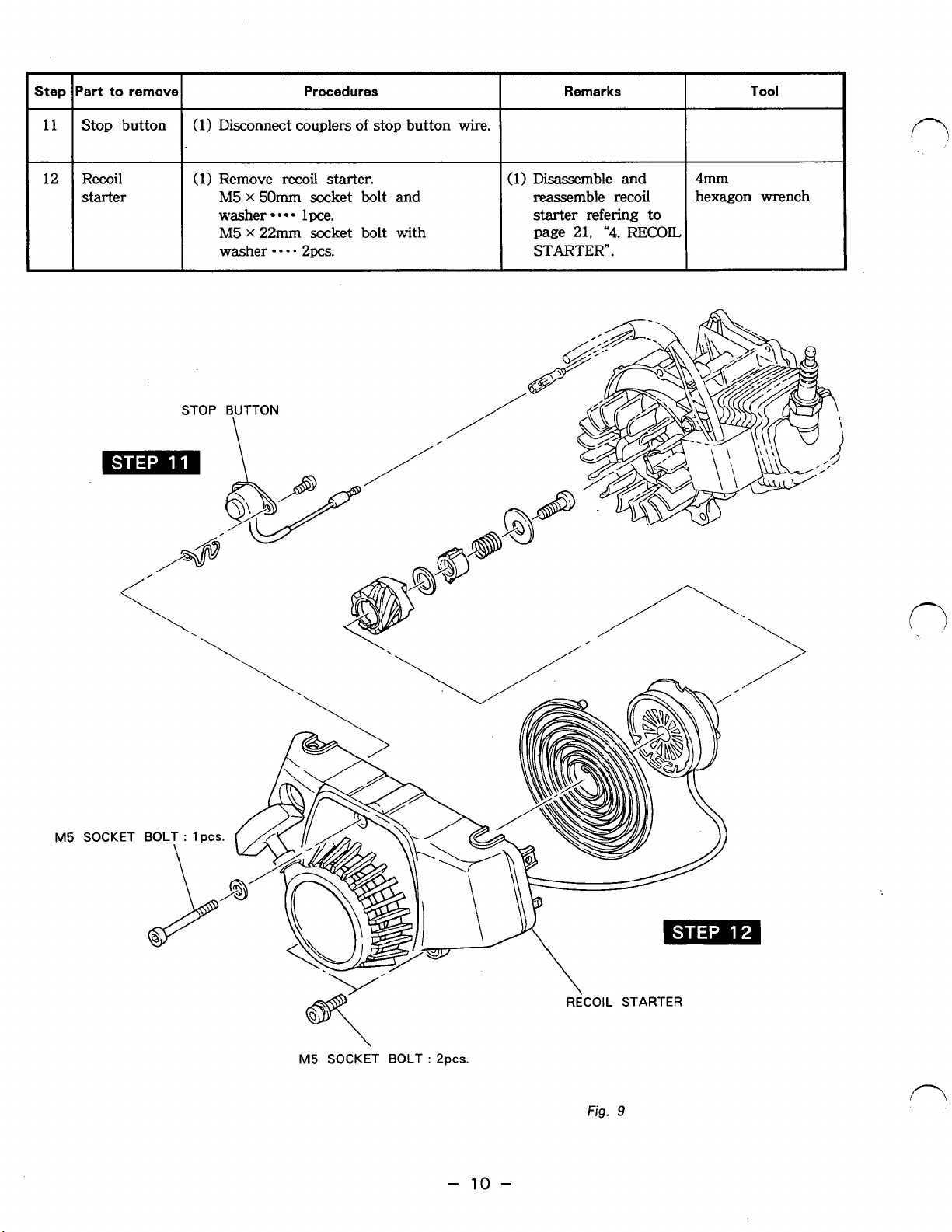

Step

lpart to

remove1

Procedures

I

Remarks

I

Tool

12

Stop button

Recoil

starter

(1)

Disconnect couplers

I.

(1

1

Remove

M5

X

50mm

washer

M5

X

22mm

washer

recoil

socket bolt

lpce.

socket bolt with

- - -

2pcs.

of

starter.

stop button

and

wire.

(1)

Disassemble

reassemble

starter

page 21,

STARTER".

and

recoil

refering

"4.

RECOIL

4mm

hexagon wrench

to

M5

SOCKET

BOLT

:

Ppcs.

-

10

Fig.

n

9

-

Page 14

-

Step

13

-

14

-

Part

to

remove

Procedures

lgnition

coil

Flywheel

magneto

(1)

Remove ignition

coil

from crankcase.

M5

x

2Omm

SCEW

**e*

2pcs.

(1)

Remove flywheel

bolt,

M6

X

16mm

bolt,

spring

washer and

washer

1

pce.

(2)

Set

clutch puller

to

flywheel.

(See

Fig.

10.1

Turn

center bolt clockwise to

pull

out

flywheeL

Remarks

I

Tool

1

Phillips screw driver

(1)

Be

careful

not

to

Clutch puller

lose washer

sd

spring

washer.

(2)

Flywheel

caq

easily

be

removed by

striking with a

hammer

the head

of

center

bolt

of

clutch puller.

Fig.

11

M5

SCREW

:

ZPCS.

.

IGNITION

COIL

-

11

-

Page 15

'art to rernova

Procedures

Remarks

Tool

Woodruff

key

Insulator

and lead

valve

M5

X

SCREW

22mm

:

2pcs.

I

(1)

Remove woodruff key

shaft.

(1)

Remove insulator and lead valve from

Crankcase.

M5

M5

X

20mm

x

22mm

(See

Fig.

12.)

screw and washerscrew and washer-

from

(NOTE1

Lead valve

Replace lead valve

if

necessaly.

$

is

unreplaceable.

~ ~~

WIRE BRACKET

in

completion from

crank

0.

-2pcs.

*a

-2pcs.

-

(1)

Use

a soft hammer

and aluminum stick.

(2)

Be careful not to

lose

key.

(3)

Be

careful not to

damage key and

crankshaft keyway.

Phillips

screw driver

M5

X

20mm

SCREW : 2pcs.

/

INSULATOR

v

PACKINGS

LEAD

VALVE

Fig.

12

Fig.

13

-

12

-

Page 16

..

.,

1-

..

step

Tool

Remarks

Procedures

Part

to

remove'

"1

9mm

(l).Remove spark

plug.

from cylinder.

'Spark plug

17'

plug

wrench

*.

r

..

.L

,

..

18

5mm

(1)

-Remove cylinder from

crankcase.

Cylinder

M6 X 18mm

socket

bolt

*-*a

4pcs.

hexagon wrench

..

..

...

.-

I

PACKING

I

CYLINDER

..

.

.

"_

-

13"

Page 17

Step

-

19

-

20

’art to remove

Crank-

Piston and

piston ring

Procedures

(1)

Disassemble front

M5

x

30mm

(1)

Remove two clips from

piston pin.

(2)

Remove piston pin from piston.

(3)

Remove piston from connecting rod.

(4)

Remove piston ring from piston.

[NOTE]

Connecting rod

Replace connecting rod and crankshaft

in assembly form

PISTON RING

and

socket bolt

is

unreplaceable.

if

necessaly.

mar

both

crankcases.

e

PISTON

4pcs.

ends

Remarks

(1)

Be

careful

damage

of

(1)

Be

careful not to

lose

clips.

(2)

Be

careful

give damage to the

piston

connecting

(3)

Be

careful not to

break piston rings

by spreading, too

much

them.

oil

and

or

not to

sed

not to

rod

twisting

4mm.

hexagon wrench

Long nose pliers

Tool

f7

PISTON

NEEDLE BEARING

CRANKSHAFT

PIN

I

GASKET

OIL

SEAL

\

M5

CRANKCASE (REAR)

SOCKET

BOLT

:

4pcs.

\

OIL

SEAL

CRANKCASE(FRONT1

Fig.

15

-

14

-

Page 18

3-

4

REASSEMBLY PROCEDURES

0

PRECAUTIONS FOR REASSEMBLY

(1)

Clean parts thoroughly before reassembly.

(2)

Scrape off all carbon deposits from cylinder head, piston top

and

piston ring grooves.

(3)

Check lips

of

oil seals. Replace oil seal if I a lip is damaged.

(4)

Replace all gaskets with new ones.

(6)

Torque bolts and. nuts

to

specification refering. to page

34,

“9-2

TABLE

OF

TIGHTENING

(7)

Apply oil to rotating and sliding

parts.

(8)

Check and adjust clearances

and

end plays where specified in this manual.

Pay most attention to cleanliness of piston, cylinder, crankshaft, connecting rod and bearings.

Apply oil to lips before reassembly.

(5)

Replace keys, pins, bolts, nuts, etc., if necessary.

TORQUE”.

3-4-1

PISTON

AND

PISTON RING

(1)

If piston ring expander is unavailable, install piston rings by placing the open ends over the

top land of piston and. spreading the ring ends only far enough

to

slip them into the correct

ring grooves.

-[NOTES]

1.

Pay attention not to break piston ring

by

twisting.

2. Top

ring and second ring are common parts.

3.

Set piston ring ends to location pin as shown in Fig.

16.

Fig.

16

!

TOP

RING

AND

SECOND

RING

TAPER

-

15

-

Page 19

(2)

Install needle bearing to small end of

connecting rod.

(3)

Assemble piston and connecting

piston pin and clips. (See page

14,

rod

Fig.

with

15.)

Set the

flywheel

3-4-2

(1)

(2)

(3)

(4)

(5)

"M"

mark stamped on piston top to

side

of

piston.

CRANKCASE

Insert magneto end of crankshaft into front crankcase bearing.

Put gasket on the fitting surfaces

Insert

Tighten

M5

Insert key to crankshaft.

FTO

end of crankshaft into rear crankcase bearing. (See Fig.

four

(4)

bolts evenly to join rear crankcase to front crankcase.

X

30mm socket bolt

TIGHTENING TORQUE

60

-

80

kgf

590

-

780

N

55

-

65

IN-LB

*cm

crn

0.

4pcs.

of

crankcase. (Use new gasket.)

Fig.

17

17.)

n

,

i

3-4-3

(1)

3-4-4

(1) Put cylinder gasket on the fitting surface of crankcase. (Use new gasket.)

(2) Insert piston to cylinder.

(3)

ENGINE

Install engine base to crankcase.

Tighten three

M6

x

12mm bolt and washer

TIGHTENING TORQUE

590

55

I

CYLINDER

Put cylinder

M6

X

18mm socket bolt

1080

-

-

-

BASE

80

780

65

to

1270

(OPTION)

(3)

bolts evenly

kgf

*cm

N

-

cm

IN-LB

crankcase.

N*cm

-0

-0

*e*

4pcs.

to

join engine base to crankcase.

3pcs.

-

16

-

Page 20

3-4-5

CYLINDER COVER

(1) Install cylinder cover to cylinder.

M5

X

14mm screw and washer 2pcs.

M5 X 20mm

screw and washer

* * *

lpce.

I

.TIGHTENING

TORQUE

I

30

-

40

kgf

cm

295 - 390

N

cm

30

-

35

IN-LB

3-4-6

LEAD VALVE AND INSULATOR

(1) Install gasket lead valve, with gasket, insulator and wire bracket

to

crankc

M5

X

20mm screw and washer 2pcs.

M5

X

22mm screw and washer 2pcs.

395 - 490

N

cm

ase.

r

Apply

sealant

(THREE BOND

#

1360)

to

screws.

I

I

3-4-7

CARBURETOR AND

AIR

CLEANER

(1)

Install carburetor gasket and carburetor, then mount air cleaner base.

(2)

Set cleaner element

to

cleaner cover.

(3)

Set cleaner cover to cleaner base. (See page 6, Fig.

5.)

M6

X

65mm screw and washer 2pcs.

TIGHTENING

TORQUE

40

-

50

kgf

cm

395

-

490

N

cm

35

-

40

IN-LB

3-4-8

MAGNETO

(C.D.I.)

(1)

Install woodruff key

to

crankshaft.

(2)

Install flywheel

to

crankshaft.

M6 X 16mm bolt, spring washer and washer 1 pce.

I

TIGHTENING

TORQUE

I

110

-

130

kgf

*cm

1080

-

1270

N-cm

95

-

110

IN-LB

I

I

(3)

Install ignition coil

to

crankcase.

M5

X

20mm screw 2pcs.

-

17

-

Page 21

(4)

Adjusting air gap between ignition coil

and flywheel. (See Fig.

18.)

I

I

(5)

Tighten ignition coil to crankcase.

I

TIGHTENING TORQUE

Before installing flywheel, wipe out oil from crankshaft and the tapered center hole of flywheel.

r

3-4-9

(1)

Install

0.0079

40

-

395

-

35

-

SPARK

spark

AIR

GAP

-

0.0157

50

kgf

*cm

490 N

40

PLUG

cm

IN-LB

plug to cylinder.

IN

1

I

(NGK

BPM7A

or

the equivalent)

Fig.

18

n

/

I

TIGHTENING TORQUE

1470

130

3-

4-

10

CLUTCH (OPTION)

(1)

Assemble clutch.

M5

X

8mm

30

295

30

(2)

Install clutch

M6 X 16mm

I

TIGHTENING TORQUE

100

-

-

-

-

-

-

2055 N

screw

390

210

kgf

cm

180 IN-LB

and

40

kgf

N

cm

35

IN-LB

to

crankshaft.

bolt

and washer

120

kgf

*cm

crn

washer

cm

I

**

**a*

3pcs.

lpce.

980

90

-

-

1175

100

N

cm

IN-LB

-

18

-

Page 22

3-4-1 1

FUEL TANK

(1)

Set tank cap to fuel tank. (See page 4,

Fig.

2.)

(2) Install mount rubbers to crankcase.

(4)

Put fuel tank

on

crankcase.

I

(3)

Connect fuel pipe to carburetor.

3-4-12

TANK

BRACKET

(1) Attach tank bracket to crankcase.

M5

X

14mm screw and washer

-0

2pcs.

I

TIGHTENING TORQUE

I

40

-

50

kgf

cm

395 - 490

N

cm

35

-

I

40

IN-LB

-

3-

4-

13

MUFFLER

.(

1)

Install muffler to crankcase using muffler gasket. (See Fig.

19.)

-.

M6

muffler bolt and washer

0.

2pcs.

I

TIGHTENING TORQUE

I

00°

CYLINDER

SIDE

'

-

*MUFFLER

SIDE

Fig.

19

[NOTES]

Use new muffler

gasket.

Apply

sealant

(THREE

BOND

#

.1360)

to

muffler bolt and washer.

-

19

-

Page 23

3-4-

14

MUFFLER COVER

(1)

Install muffler cover

M5 X 8mm

I

TIGHTENING

35

345

-

-

screw

440

TORQUE

45

kgf-cm

N-cm

to

3pcs.

I

muffler.

30 - 35

I

3-4-15

(1)

(2)

3-4-

(1)

STOP BUTTON

Connect wire from ignition coil to stop

button.

Check earth spring to protrude from the

mounting surface

(See Fig.

16

Install recoil starter to crankcase.

M5

X

M5

X

20.)

RECOIL STARTER

22mm socket bolt with washer 2pcs.

50mm socket bolt and washer

IN-LB

of

I

recoil starter.

Fig.

20

0.

-0

lpce.

I

'

TIGHTENING TORQUE

35

-

55

345 - 535

30

-

45

3-4-17

(1)

SPARK PLUG CAP

Connect spark plug cap

kgf

*cm

N-cm

IN-LB

I

to

spark plug.

-

20

-

Page 24

4.

RECOIL

STARTER

When repairing recoil starter, disassemble and reassemble in the following procedures.

Tools

:

Socket. wrench, Needle nose pliers, Screw driver.

4-

1

DISASSEMBLY

(1)

Remove recoil starter from engine.

(2)

Pull starting knob to pull out starter rope.

(See

Fig. 21.)

Fig.

21

(3)

Hold reel with thumb and pull starter rope

inside case. (See Fig. 22.)

(4)

Rewind

rope

clockwise until rotation stops

by holding starter rope using the notch on

the reel.

When rewinding the rope, control rotation by

pressing the

reel

with thumb.

Fig.

22

Remove parts in the following

1.

Screw

2:

Washer

3.

Friction spring

4.

Ratchet guide

5.

Thrust washer

6.

Ratchet

Fig.

23

-

21

-

Page 25

(6)

Remove reel from starter case as shown in

24.

Fig.

Take out .reel slowly turning it lightly

toward left and right

to

remove spring from

hook.

-

[NOTE]

Do

not remove reel quickly or the spring may

escape from starter case.

If

the spring escapes, put

as

instructed in page

TROUBLES.

(7)

Untie starter rope from the

23,

it

in the starter case

4-4

HOW

TO

DO'

knob

IN

and

remove.

4-

2

REASSEMBLY

(1) Check that spring is securely set in the reel.

(2)

Adjust the position

spring

so

it catches hook

of

inner end

of

the reel securely.

of

the

Fig.

n

24

[NOTE]

The shape

adjusted with plier

(3)

Prior

of

starter spring inner end can be

if

necessary.

to installing reel in starter case, wind

starter rope in reel for 2.5 turns in

arrowhead direction as shown in Fig. 25.

(4)

Then let rope out

reel. Line up reel

spring

as

shown in Fig.

of

reel from notch

hook

with inner end of

26

and install reel

in starter case.

(5)

Hold starter rope, as

reel

3

times in arrowhead direction.

(6)

Firmly press the reel not

shown

Fig. 27 and turn

to

allow reverse

turn.

on

I

f-7

\

,'

Fig.

25

I

OUTER END

OF

SPRING

INNER

END OF

-

22

-

SPRING

Fig.

26

f-7

Page 26

(7)

Reassemble parts in reverse order

of

disassembly. (See Fig. 23.)

Screw

*****

1

pce.

TIGHTENING

TORQUE

295

-

390

kgf

cm

30

-

40

N*cm

30

-

35

IN-LB

0

This ,is the end of the disassembly and

reassembly procedures.

Test the reassembled recoil starter by the

following checking procedures in the next

section.

Fig.

27

4-

3

CHECKING PROCEDURES AFTER REASSEMBLY

(1)

Pull starting knob

2

or

3

times, and pull out starter rope a little.

a) If starting knob

is

felt heavy to pull

or

cannot be pulled, check whether all the

parts

are

b)

If ratchet does not function, check whether spring is hooked properly.

a)

If

starter rope remains left in reel or starter rope does not return at all, immoderate strain

is imposed on the

spring.

So

rewind starter rope 1 or 2 times as per instruction in

Fig.

22.

b)

If'

return power of

starter

rope is weak

or

starter rope cannot be fully rewind, inject a few

drops

of

mobile oil to the frictional portions.

If

it does not recover yet, wind the rope 1

or

2

times.

(In

this

case, refer to the instructions explained

in

paragraph a) above and confirm whether

or not immoderate strain is imposed on spring.)

c)

If a sound is heard that spring is falling off, and starter rope does not return, reassemble

once again from the biginning.

installed correctly.

(2) Pull starting knob, and pull out starter rope all the way long.

(3)

Push the washer

a)

If

washer

is

loose, retighten the bolts.

4-4

HOW

TO

DO

IN

TROUBLES

(1)

IN

CASE THE

SPRING

JUMPS

OUT

AT DISASSEMBLING.

Remove starter knob

from

rope.

0

Remove reel from starter case.

0

Hook outer end of spring

to

the reel. (See Fig.

26.)

0

Wind spring into the reel.

0

After winding

3

or

4

turns, tape spring

to

the reel

to

prevent the spring from jumping

out.

r

Prass outer end

of

spring

by

a

thumb

or

spiral spring jumps out

from

reel.

-

23

-

Page 27

(2)

Wind

0

Hook

Remove

IN

spring completely.

inner end

tape

CASE

OF

Lubricate the rotating

oil at the time

of

spring to reel.

from

reel.

LUBRICATING

parts,

of

disassembly

frictional

or

at the end

parts

Fig.

28

and spring with heat resistant grease,

of

season

for

use.

or

mobile

-

24

-

Page 28

5.

CARBURETOR

-

b

.

-.

. .-

5-1

-

DIAGNOSIS OF TROUBLES

0

Engine does not. start.

,.

Carburetor needle valve- is held open by dirt

or

gum.

(See remedy

1)

'

.

Pilot, jet is partially clogged. (See' remedy.

2)

..

..

.

..

..

@

Unstable engine operation.

,.

Carburetor needle valve is held open by dirt

or

gum. (See remedy

1.)

Main jet is partially clogged. (See remedy

3)

Pilot

jet

is partially clogged. (See remedy

2)

Main jet is partially clogged. (See remedy

3)

.

-

,

-

@

Carburetor floods.

..

Carburetor needle valve is held open by dirt or

gum:

(See remedy-

1)-

..

@

Idling speed is high or slow.

..

..

Adjust. the slow speed screw. (See remedy

4)

"

@

Engine exhausts white smoke.

5-2

REMEDY

FOR

TROUBLES

L"

..

Remedy

1

(2)

Remove float chamber from body.

"

(1)

Remove' fuel strainer' from body.'

:

(3)

If

needle valve. is . held open, disassemble

float and clean needle valve and fuel line

;in kerosene and blow the remai.nings with

compressed air. (See Fig.

29.)

'

(4)

Clean fuel strainer in kerosene.

(5)

Attach needle valve and float

to

body.

(6)

Attach float chamber

to

body.

I

TIGHTENING

TORQUE

I

70

kgf

cm

685

N'..'

cm

..

(7)

Attach ,fuel strainer

to.

body.

FUEL

STRAINER

4

T

..

Fig.

29

TIGHTENING TORQUE

35

kgf

cm

.

.

..

.I

345

N

cm

-

30

LB

':+

..

..

,_

..

.

I,.

.

.

.

..

.I

..

,-

Page 29

Rznnsdy

(1)

Remove pilot screw from body.

(2)

Clean pilot screw

2

and

vent of screw by

blowing compressed air.

(3)

Clean pilot vent

in

kerosene and blow

compressed air. (See Fig. 30.)

(4)

Reset pilot screw at 1% turns from full

closed position.

Remedy

(1)

Remove float chamber from body.

(2)

Remove main jet from body.

(3)

Clean

(4)

Clean main nozzle in kerosene and blow

3

main

jet

in

kerosene.

compressed air.

(5)

Clean main air vent in kerosene and blow

compressed air. (See Fig.

(6)

Attach float chamber to body.

TIGHTENING TORQUE

70

kgf

crn

685

N

cm

60

IN-LB

Remedy

(1)

Start the engine.

(2)

Check r.p.m.

(3)

Ajust the slow speed

4

by

tachometer.

(2800min”) by turning slow

at

30.)

2800

r.p.m.

set

screw.

(See Fig. 31.)

I

PiLoT

VENT

Fig.

I

30

[NOTE]

Slow

Check the specification

slow

(4)

speed is different

speed.

Stop the engine.

by

,each specification.

of

machinery and ajust

Fig.

31

-

26

-

Page 30

6.

MAGNETO

6-

1

MAGNETO TROUBLESHOOTING

When engine does not

start

or

starts

with difficulty,

or

when its operation is unstable, the following

.tests will clarify if they are caused by a defect in magneto.

(1)

Check ignition cable for possible corrosion, broken, worn insulation or loose connection.

(2)

Check sparks as described in the following - section.

(3)

If

no spark flys, replace ignition coil.

..

6-2

SPARK

TESTING

Remove spark plug from cylinder head and place it on cylinder, with the ignition cable

connected to it.

Crank

the engine several times by recoil starter and observe sparks at the spark gap of spark

plug.

If

spark

is

strong, the ignition system .can be eliminated as the source

of

trouble.

If

the spark

is

weak

or

there is no spark. at all, repeat the checks. according to the trouble-

shooting chart "Ignition system problems caused by" (Refer to section

"

8

TROUBLE

-

SHOOTING").

BREAK-

IN

OPERATION

OF

REASSEMBLED ENGINE

overhauled engine must be operated carefully

to

break-in the parts.

A

thorough break-in is indispensable particularly when the cylinder, piston

or

piston ring are

replaced with new ones.

.For

break-in of' overhauled engines; use mixture fuel

of

gasoline

20

:

1

part

oil for the first

ten

(1

0)

hours

of

operation.

8.

TROUBLESHOOTING

8-

1

TROUBLESHOOTING

The following three conditions must be fulfilled for satisfactory engine starting.

1.

The cylinder filled with a proper fuel- air mixture.

2.

Good compression in the cylinder.

3.

Good spark, properly timed, to ignite the mixture.

The engine cannot be started unless these three coditions are met. There are also other factors

which make engine start difficult, such as

a

heavy load initially applied

to

the engine, and

a high back pressure due

to

a long exhaust pipe.

The most common causes of engine troubles are given in

the

tables in the following pages.

..

.

-

27

-

Page 31

8- 2 TROUBLESHOOTING

TABLE

POSSIBLE

CAUSES

\

Fuel tank empty

Improper or contaminated fuel

Loose fittings or defective fuel

Carburetor not choked enough (cold

engine)

External fuel leaks

Clogged

Vapor lock (Fuel evaporating

lines due to excessive heat around

engine)

Carburetor needle valve held open

dirt

Incorrect mixtuer ratio of gasoline and

two cycle oil

Air

plugged or clogged

High speed jet

clogged

fuel

filters or

or gum.

vent

hole of the fuel tank cap is

in

dirty

carburetor partially

lines

in

lines

fuel

0

by

Clogged air cleaner

Faulty carburetor

Loose or corroded electrical

connections

Faulty ignition coil

Ignition wires disconnected or broken

plug

Spark

cable wet or broken

0

0

0

0

f

-

28

-

Page 32

SYMPTOMS

'

;

P

b

"$

.cn

4-

0

0

4-

4-

0

c

-

-

.-

3r

ma

a,

POSSIBLE

CAUSES

.-

C.t;

15$

Spark

plug

wet

or

dirty

Spark plug gap incorrect

I

'0

Spark timing incorrect

-I

~~~~ ~~~ ~

Incorrect air gap of ignition coil

Lack of lubrication 'on moving parts

due to long storage

Loose or broken spark plug

0

Worn

piston

or

piston ring

0

Scored

or

worn cylinder walls

0

Carbon

or

lead deposits

in

cylinder

or

on piston

Worn

or

damaged piston

-pin

or

needle

bearing

Worn

or

damaged crankshaft bearing

Low

cranking speed

Engine overloaded

Heavy load at low engine speed

I.

Cooling air restricted by dirt

or

debris

I

Engine operated

in

confined space where

cooling air

is

confinually recirculated

Clogged exhaust

Engine cold

TO.

USE

CHART

. ..

1.

Find problem under problem listing.

.2.

Foilow down column to a black dot.

..

'.

,

,"

1-

-.

:$.

3.

Refer to left

of

dot

for

probable cause.

4.

If first probable cause does not solve problem,

go

to next black dot.

-

29

-

Page 33

9.

CHECKS

AND

CORRECTIONS

After disassembling and cleaning engine, check and repair, if necessary, according to the correction

table. The correction table applies whenever engines are repaired.

It

is important

Correct maintenance

The meanings

(1

CORRECTION

Repair, adjustment

(2)

CORRECTION

The limit on wear, damage

engine performance cannot be expected without repairing such

(3)

USE

LIMIT

The limit beyond which parts can no longer be used in respect

(4)

STANDARD

for

the servicemen

is

recommended by observing the correction standards specified.

of

the terms used in correction table are as follows

or

replacement of any engine

LIMIT

DIMENSIONS

to

be familiar with contents of this table.

parts.

or

functional deterioration of engine

:

parts

parts.

of

performance

beyond which normal

or

strength.

The design dimensions of new parts minus tolerance.

(5)

CORRECTION TOLERANCE

of

Tolerance on. dimensions

9-

1

SERVICE

DATA

engine parts refinished

or

adjusted.

Unit : mm

(in)

f-7

/J

I

CYLINDER

0

Inside dia. (average)

PISTON

Piston

(thrust direction)

Ring groove width

(maximum)

size.

ITEM

TOP

TOP

,ECOSER

37.000-37.01 6

36.95-36.98

1.63- 1.65

(0.0642-0.0650)

I

37.035

(1

;4581) (1.4567-1.4573)

1.73

)

40.01 4-40.030

(1.5754-1.5760)

39.95-39.98 36.93

(1.5728- 1.5740) (1.4539) (1.4547- 1.4559)

1.63- 1.65

(0.0642-0.0650) (0.0681

EC04ER

Limit

40.049

(1.5767)

39.93

(1.5720)

1.73

(0.068

1

)

2nd

mt

2nd

1.60- 1.62

(0.0630-0.0638)

1.60- 1.62 1.73

(0.0681

-

30

-

)

(0.0630-0.0638)

1.73

(0.068

1

)

Page 34

Unit

:

rnm

(in)

ITEM

Piston

pin

hole

(maximum)

n

0

Clearance between piston

and cylinder

20mm (0.7874)

-

,

Ring groove side

clearance

0

Clearance between piston

pin

hole and piston

pin

E3

::a::*

...

:..

.*:,

.

.....

TOD

2nd

ECOSER

STD

9.99

1 - 1

0.002

0.3933-0.3938)

0.020-0.066

0.0008-0.0026)

0.07-0.1

1

0.0028-0.0043)

0.04-0.08

0.001

6-0.0031

)

-

0.009-0.008

-

0.0004-0.0003:

Limit

10.03

(0.3949)

0.1

05

(0.0041

0.1 5

(0.0059)

0.15

(0.0059)

i

0.044

(0.001

7)

EC04ER

~~

STD

9.99

1

-

1

0.002

(0.3933-0.3938)

0.034-0.080

(0.001 3-0.0031

0.07-0.1

1

(0.0028-0.0043)

0.04-0.08

(0.001 6-0.0031

-

0.009-0.008

(-

0.0004-0.00031

Limit

10.03

(0.3949)

0.1 19

(0.0047)

0.1 5

(0.0059)

0.1 5

(0.0059)

0.044

(0.001

7)

-

31

-

Page 35

Unit : mm (in)

ITEM

Piston ring end

Piston ring

(minimum)

0

Piston pin outside dia.

(maximum)

gap

width

TOP

2nd

I

TOP

2nd

ECOSER

STD

I

0.1

-0.3 0.8

(0.0039-0.01

0.1 -0.3

(0.0039-0.01 18)

1.54- 1 -56

(0.0606-0.061 4)

1.54- 1 56

(0.0606-0.061 4)

Limit

I

1

8) (0.031 5)

’

(0.031 5)

(0.0591

0.8

1.5

(0.0039-0.01 18)

(0.0039-0.01 18)

<0.0606-0.0614)

(0.0606-0.061 4)

)

EC04ER

STD

0.1

-0.3

0.1 -0.3

1.54-1 -56

1.54- 1.56

Limit

1

.o

(0.0394)

1

.o

(0.0394)

1.5

(0.059

1.5

(0.0591

1

1

CONNECTING

Big

end

Small end inside dia.

ROD

side

ITEM

clearance

9.994- 1 0.000

(0.3935-0.3937)

9.986

(0.3931

)

STD

0-0.’023

(0-0.0009>

9.994-

(0.3935-0.3937)

EC03ER,

1

O.Ob0

EC04ER

9.986

(0.3931

Unit : mm, (in)

Limit

0.7

(0.0276)

)

14.000- 1 4.01

(0.551 2-0.551

-

32

-

1

6)

14.026

(0.5522)

Page 36

Unit

:

mm

(in)

ITEM

XANK

SHAFT

D

Journal dia.

_.

uu

Side clearance between crankcase and crankshaft

(at assembled)

Gasket has a thickness

of

0.4mm (0.0157

in)

(when tighting)

0

Runout of shaft

18.5mm

CARBURETOR

Pilot screw

Spark plug type

Spark timing

Air gap

Spark plug gap

ECOBER

STD

1

4.994- 1 5.002

(0.5903-0.5906)

0.48

(0.01 89)

0.05

(0.0020)

iC04ER. .

..

Limit

..

14.98

(0.5898)

0.8

(0.03

1

5)

0.1

(0.0039)

Return the pilot screw

1

X

turns form

full

closed

position

NGK

BPM7A

B.T.D.C

23.5"

"B.T.D.C.28.5"

0.2-0.4

(0.0079-0.01

57)

0.5-0.8

(0.01

97-0.031

5)

-.33

-

Page 37

9-2

TABLE

OF

TIGHTENING

TORQUE

Description

Bolts for joining crankcase

Bolts for joining cylinder

Screw for joining cylinder cover

Screw for joining insulator and lead valve

Screw for joining carburetor and air cleaner

Bolt for joining flywheel

Tightening torque

60

-

80

kgf

cm

590

-

780 N cm

55-

110"; 130 kgf *cm

1080- 1270

9530

295

30- 35 IN-LB

40-

395

3540

395

35-

110- 130

1080- 1270

95- 110 IN-LB

65 IN-LB

110

-

40 kgf cm

-

390 N cm

50

-.

490

40

-

50

-

490 N cm

40

N

cm

IN-LB

kgf

N

cm

IN-LB

kgf

IN-LB

kgf

-cm

N

cm

cm

cm

Screw for joining ignition coil

Spark plug

Screw for joining tank bracket

Bolts for joining muffler

Screw for joining muffler cover

Screw for

Bolt for joining recoil starter

stop

button

40-

395

35- 40 IN-LB

150- 210 kgf-cm

1470

130- 180 IN-LB

40-

395

35-

100- 120 kgfocm

980-1175 N-cm

90-

35

345

30- 35 IN-LB

12- 18 kgf-cm

115- 175 N-cm

10- 15 IN-LB

35

345

30- 45 IN-LB

50 kgf cm

-

490 N cm

-

2055 N cm

.

50 kgf-cm

-

490 N cm

40

IN-LB

100

IN-LB

-

45

kgf

-

440

N cm

-

55 kgf crn

-

535 N cm

cm

-

34

-

Page 38

OPTION

Description

Tightening torque

60

-

80

kgf

cm

Bolts

for

joining engine

base

590

-

780

N cm

55-

65 IN-LB

30

-

40

kgf

cm

Screw for joining clutch

295

-

390 N cm

100-

120

kgf-cm

30-

35 IN-LB

Bolts

for

joining clutch to engine

980-

1175 N *cm

90-

100 IN-LB

-

35

-

Page 39

10.

MAINTENANCE AND STORAGE

The following maintenance schedule applies to the engines operated correctly under normal

conditions.

The indicated maintenance schedule does not necessarily guarantee maintenance- free operations

during the intervals.

For

example, if an engine

every day instead of every

10-

1

DAILY CHECKS AND MAINTENANCE

is

operated

50

hours.

in

extremely dusty condition,

its

air cleaner should be cleaned

Checks and maintenance works

Remove dust, dirt, .debris, grass and any foreign

obstacles from cylinder, cylinder head, and

carburetor.

Check fuel leakage.

the

loose

joint

Check

Tighten the loose bolt and/or

Check oil level and

10-2

Clean air cleaner.

(See instruction for

I

bolts

and nuts for looseness.

EVERY

Checks and maintenance works Reasons for requiring the maintenance work

If

leakage is found, tighten

and/or replace leaking part.

nut

if

fill

up as necessary. Insufficient oil causes engine seizure.

50

HOURS

use)

(10

DAYS) CHECK AND MAINTENANCE

any.

Reasons for requiring the maintenance work

(1

)

Engine., overheats,

(2)

Engine does not operate properly.

Danger

Engine malfunctions causing damages

and/or

Clogged air cleaner causes poor engine operation.

of

the

fire.

equipment.

to

the engine

Clean

I

10-3

I~-~

I

the

spark

plug.

(See instruction for use)

EVERY

Checks and maintenance works

Checks and maintenance works

Clean the fuel filter.

Clean the fuel filter.

Clean and/or adjust

Clean and/or adjust

(See instruction

(See instruction

Remove

Remove

port.

the

the

150

~

for

for

carbon deposit from the exhaust

carbon deposit from the exhaust

Durty sparkplug causing poor engine operation and

~~~ ~ ~~~~~ ~~

/or poor starting.

HOURS (MONTHLY) CHECKS AND MAINTENANCE

Reasons for requiring the maintenance work

Reasons for requiring the maintenance work

The engine will be out of order.

The engine will be out of order.

the

spark plug.

the

use)

use)

spark plug.

Power drop and hard starting.

Power drop and hard starting.

Power drop.

Power drop.

-

36

36

-

-

-

Page 40

I

0-4

YEARLY

CHECKS

'

AND

MAINTENANCE

I

I

Checks and maintenance works

I

Reasons for requiring the maintenance work

I

Remove

the

carbon deposit, from

the

exhaust

port

and muffler.

Poor operation

of

the engine.

Clean the carburetor.

Poor operation

of

the engine.

10-5

PREPARATION FOR LONG STORAGE

(1) Perform the above maintenance works

10

-

1 through 10

-

4.

(2) Drain fuel from' the tank.

(3)

To

protect cylinder bore from rusting,

pour

a

small amount (2cc)

of

engine oil thr

spark plug hole into the cylinder and pull the recoil starter slowly

2

to 3 times.

ough the

(Do

not

start the engine.)

[NOTE]

Do

.not pour'

too

much oil

or

the oil remaines in the combustion chamber

of

cylinder.

(4)

Pull the recoil starter slowly and

stop

it. at the compression point.

(5)

Clean the engine outside with a oily cloth.

'(6)

Put a cover over the engine and store it in a dry and well ventilated area.

"

37

-

Page 41

Page 42

Industrial

Engines

Loading...

Loading...