Page 1

Page 2

ROBIN

ENGINE

ROBIN

TO

MODEL

AMERICA,

WISCONSIN

INC.

ROBIN

CROSS REFERENCE LIST

ROBIN

EY 08

EY15

EY 15V

EY 20

EY20V

EY23

EY28

EY35

EY40

EY45V

EY2

1

EY44

18-3

EY

EY25

EY27

SIDE

VALVE

OVERHEAD

WISCONSIN

W 1-080

W1-145

W1-145V

W1-185

W1-185V

Wl-230

W 1-280

W 1-340

W

1-390

W

1

-450V

EY21W

EY44W

EY 18-3W

EY25W

EY27W

VALVE

ROBIN

EH11

EH12

EHl5

EHI

7

EH2

1

EH25

EH30

EH30V

EH34

EH34V

EH43 V

EC13V

DY23

DY27

DY30

DY3

5

DY4

1

TWO

CYCLE

DIESEL

WOI-115

WOI-120

WO1-150

WOI-170

wo1-210

WO1-250

WO

1-300

WO 1 -300v

WO1-340

WO

1

-340V

WO1-430V

WT1-125V

WRD

WRD

WRD

1-230

1-270

1-300

WRD1-350

WRD1-410

Page 3

CONTENTS

Section Title Page

Page 4

r

Page 5

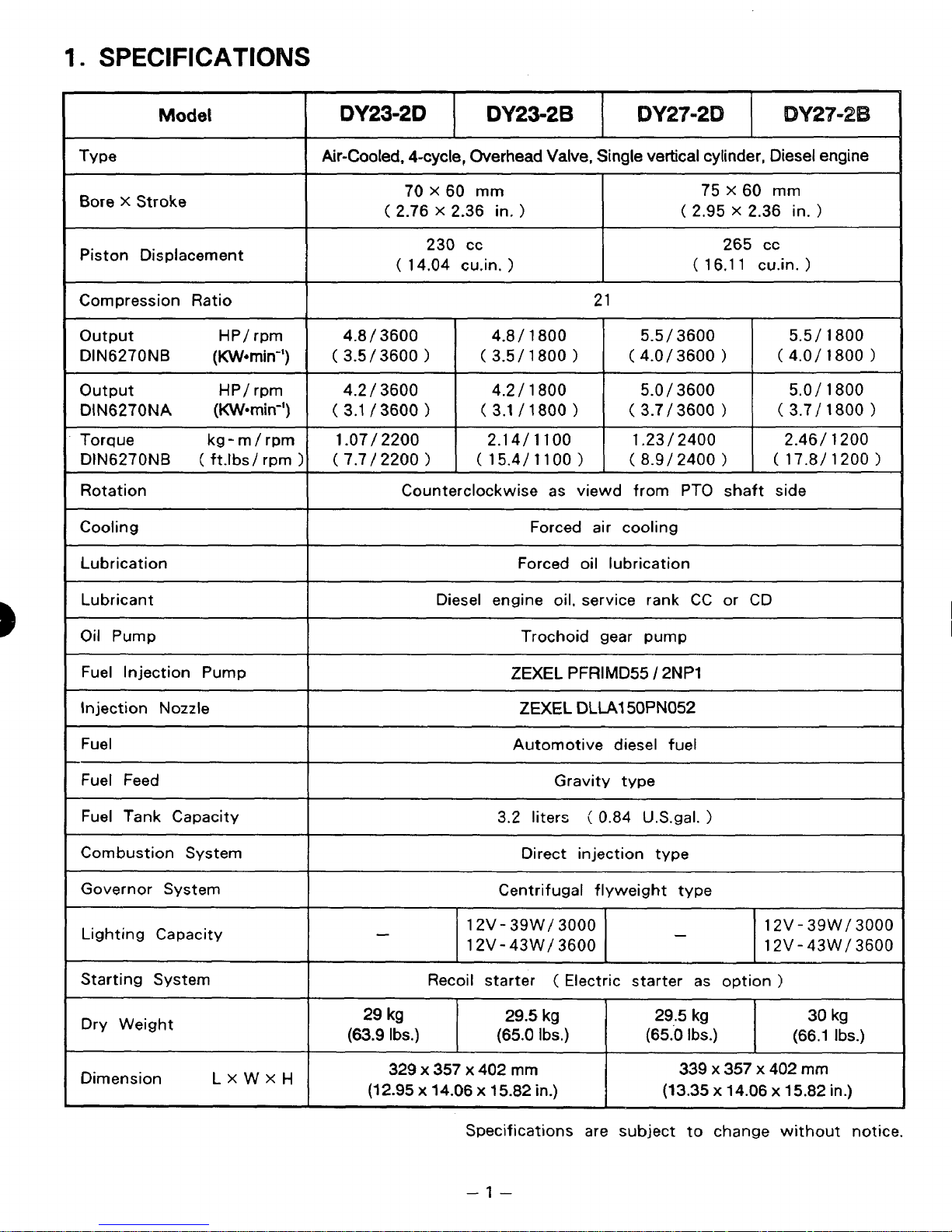

1.

SPECIFICATIONS

Model

Type

Bore X Stroke

Piston Displacement

Compression Ratio

output

DIN6270NB

output

DIN6270NA

Torque kg

DlN6270NB

Rotation

Cool

in

g

Lubrication

(

HP/ rpm

(Warnin”)

HP/ rpm

(KW-min”)

-

m

/

rpm

ft.lbs/

rpm

DY23-2D

DY23-2B

DY27-2

Air-Cooled. 4-cycle, Overhead Valve, Single vertical cylinder, Diesel engine

I

75 X 60 mm

(

2.95 X 2.36

(

16.1 1 cain.

/

3600

/

3600

/

2400

2400

265 cc

1

1

1

in.

1

)

5.5

/

1

800

(

4.0/ 1800

5.0

/

1

800

(

3.7/

1800

2.46/ 1200

(

17.W 1200

(

(

1.07/ 2200

1

(

I

I

I

70

(

2.76 X 2.36

(

14.04 cu.in.

4.8 / 3600

3.5 / 3600

/

3600

4.2

3.1

/

3600

7.7/

2200

Counterclockwise as viewd from PTO shaft side

X

230 cc

)

)

)

60

rnrn

in.

)

4.8

/

(

3.5/ 1800

4.2 / 1800

(3.1

/1800

2.14/ 1100

(15.4/11001

Forced oil lubrication

)

21

1

800

1

1

Forced air cooling

5.5

(

4.0/ 3600

5.0 / 3600

(

3.7

1.23

(

8.9/

1

1

1

Lubricant

Oil Pump

Fuel Injection Pump

Injection Nozzle

Fuel

Fuel Feed

Fuel Tank Capacity

Combustion System

Governor System

Lighting Capacity

Starting System

Dry Weight

I

I

I

(63.9

Diesel engine oil. service rank CC or CD

Recoil starter

Ibs.)

Trochoid gear pump

ZEXEL

ZEXEL

Automotive diesel

3.2 liters ( 0.84 U.S.gal.

Direct injection type

Centrifugal flyweight type

1

2V- 39W/

12V-43W/ 3600

(65.0

PFRIMD55

DLLAI

Gravity

3000

(

Electric starter as option

50PN052

type

Ibs.)

/

2NP1

fuel

(65.0

1

12V

-

39W

/

3000

12V - 43W / 3600

)

30

kg

lbs.) (66.1 Ibs.)

Dimension

LXWXH

329

x

357

x

402

mm

(1

2.95 x 14.06 x 15.82 in.)

Specifications are subject to change without notice.

-1-

339 x 357

(13.35 x 14.06

x

402

x

15.82

mm

in.)

Page 6

2-

1

MAXIMUM OUTPUT

The maximum output

of

an

engine is the output power

of

the engine operating with

its

throttle valve fully open after it has been broken in properly.

Therefore, a brand-new engine

or

an engine which has not been broken in properly may

not produce the maximum output.

2-2

CONTINUOUS RATED OUTPUT

The continuous rated output of an engine is the output power

of

the engine running

at the rated engine speed controlled by its governor system.

The operation of the engine at the continuous rated output

is

most

favorable

from

the

view point

of

engine life and fuel economy.

It

is

recommended, therefore, that the- equipment driven by the engine to be designed

to

require the engine power less than its continuous rated output.

2-3

MAXIMUM

TORQUE

The maximum torque indicates the torque at the output shaft when the engine

is

producing the maximum output.

-2-

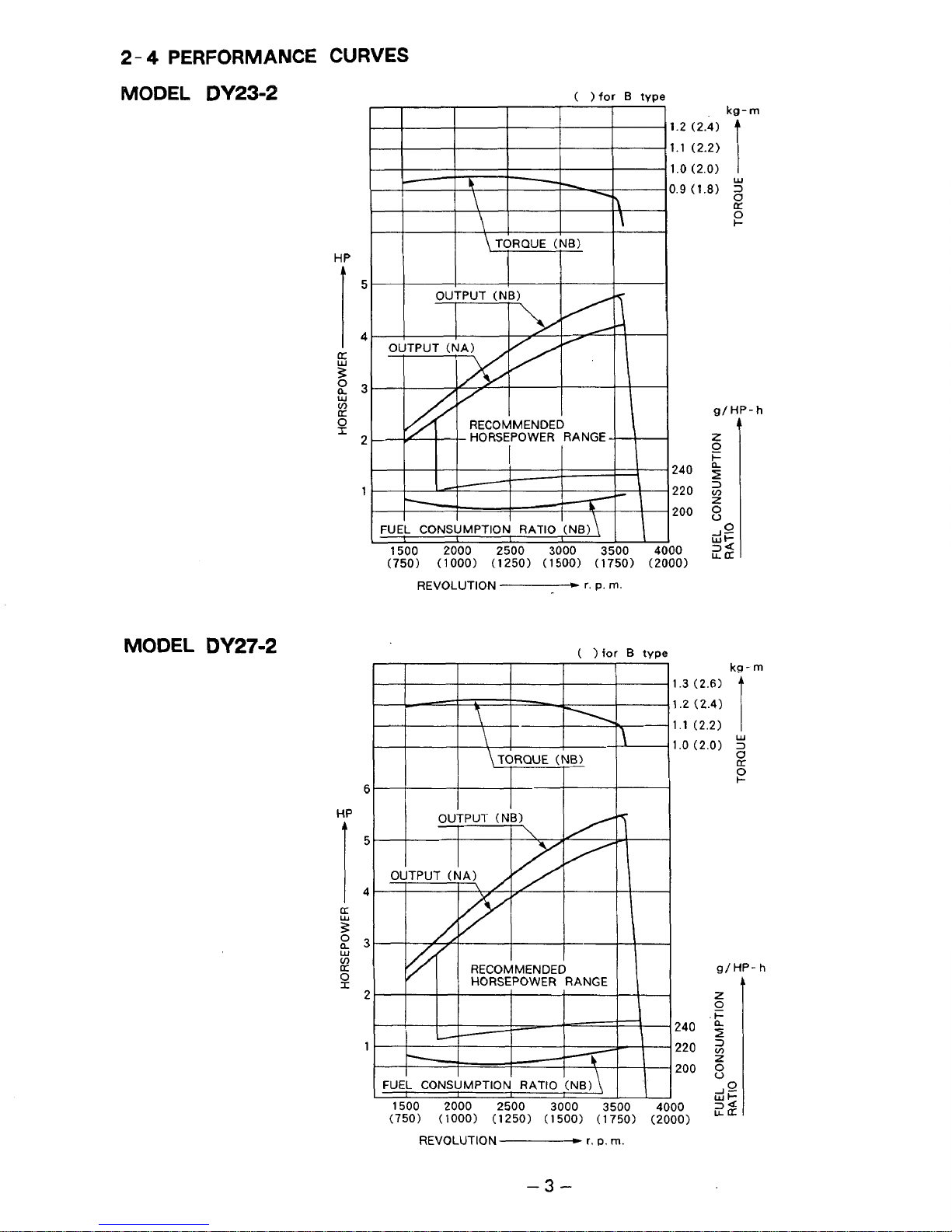

Page 7

2

-

4

PERFORMANCE

CURVES

MODEL

DY23-2

HP

I

5

4

!z

23

W

v)

IT

0

I

2

1

MODEL

DY27-2

6

HP

I

5

4

9

5

P

0-3

W

v)

I1I

2

1

\

TORQUE

(NB)

kg

-

m

1.2 (2.4)

1.1

(2.2)

1

.o

(2.0)

i

3.9

(1.8)

2

c1:

I-

O

W

g/HP-h

240

220

y

200

g

z

0

I-

FUEL CONSUMPTION

RATIO

(NB)

\

I

I

L

L

I

&

-

1500

2000

2500

3000

3500 4/00

22

(750)

(1000)

(1250) (1500) (1750) (2000)

REVOLUTION

"----+

r.

p.

rn.

(

1

for

B

type

(750)

(1000)

(1250) (1500)

(1

750)

(21

1500 2000

2500

3000

3500

41

REVOLUTION

c

r. D.

rn.

kg-

m

.3

(2.6)

.2 (2.4)

.1

(2.2)

.o

(2.0)

Y

2

g/

HP-

h

h

-3-

Page 8

3.

FEATURES

3-

1

ECONOMICAL RUNNING

The direct injection system using the newly developed micro fuel injection pump assures

superior combustion efficiency and minimized fuel consumption.

3-

2

EXTREMELY QUIET OPERATION

0

The precisely synchronized fuel injection and refined combustion chamber allow lower

combustion pressure which results in reduced combustion noise.

Q

Blower housing and cylinder baffle are made from “DUMPING

SHEET”,

a special

material for insulating noise and vibration.

0

Larger super silent muffler and double element air cleaner reduce the exhaust and

intake noise.

3-

3

EASY STARTING

8

Light pull recoil starter and centrifugal automatic decompressor allow effortless

starting similar to a gasoline engine.

0

An auxiliary fuel inlet is provided for easy starting in cold weather.

An

3-

0

air check valve

4

LESS

In

addition to the reduced weight

VIBRATION

for

easy

air

bleeding

from

the fuel line.

of

reciprocating parts, a balancer shaft has been

adopted for extremely smooth running with less vibration.

a

The automatic decompressor prevents shaky vibration at stopping.

3-

5

HIGH PERFORMANCE

Die-cast cylinder head generates

a

stable swirl of air-fuel mixture which results in the

high output power and an exceptional fuel economy.

Its

flat torque characteristic provides tenacious running from slow speed to high speed.

3-

6

SUPERB RELIABILITY

The advanced Robin technology, such as well proven crankcase design, tension bolt

system

for

joining cylinder and cylinder head, and forced lubrication system, for longer

service life under the toughest operating conditions.

3-7

SMALL AND LIGHTWEIGHT

The newly developed micro fuel injection pump and crankcase structure originated in

the gasoline engine have .minimized the size and weight of the engine.

3-8

WIDE RANGE

OF

APPLICATIONS

Robin’s new air - cooled diesel engine series assures maximum adaptability to any

application.

0

Direct output type

Selection

of

P.T.O.

(D

type) and reduction type

shafts for various applications.

(B

type) are available.

Variable muffler exhaust direction.

0

Recoil starter and optional electric starter.

0

Strong power from small and lightweight body.

Q

Lower noise and less vibration.

-4-

Page 9

4.

GENERAL DESCRIPTION

OF

ENGINE

CONST

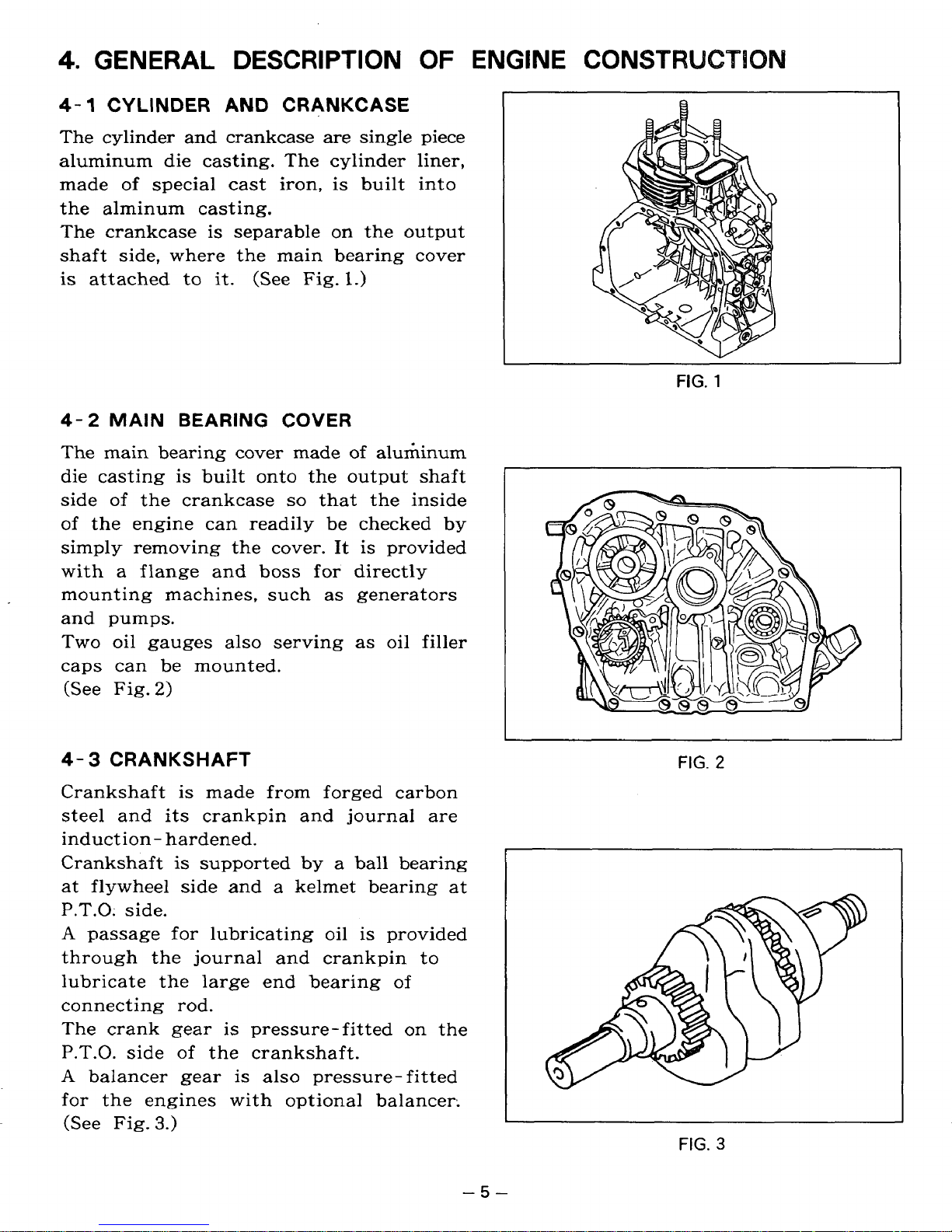

4-1

The cylinder and crankcase are single piece

aluminum die casting. The cylinder liner,

made of special cast iron, is built into

the alminum casting.

The crankcase is separable

shaft side, where the main bearing cover

is

CYLINDER

attached to

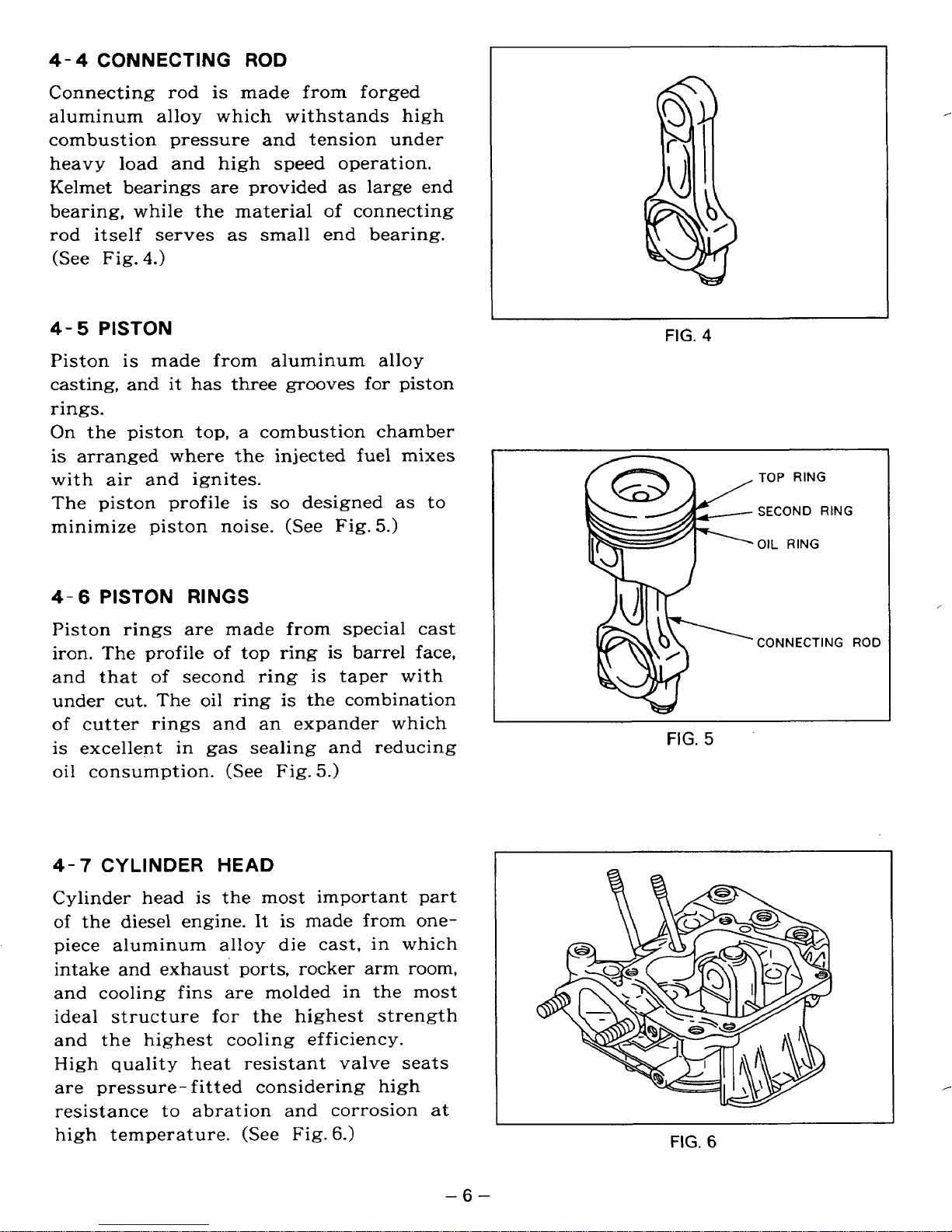

4-2

The main bearing cover made

die casting is built onto the output shaft

side of the crankcase

of the engine can readily be checked by

simply removing the cover. It is provided

with a flange and

mounting machines, such

and pumps.

Two oil gauges also serving

caps can be mounted.

MAIN

(See Fig.

2)

AND

it.

BEARING COVER

CRANKCASE

(See

so

boss

Fig.

for directly

on

the output

1.)

of

aluminum

that the inside

as

generators

as

oil filler

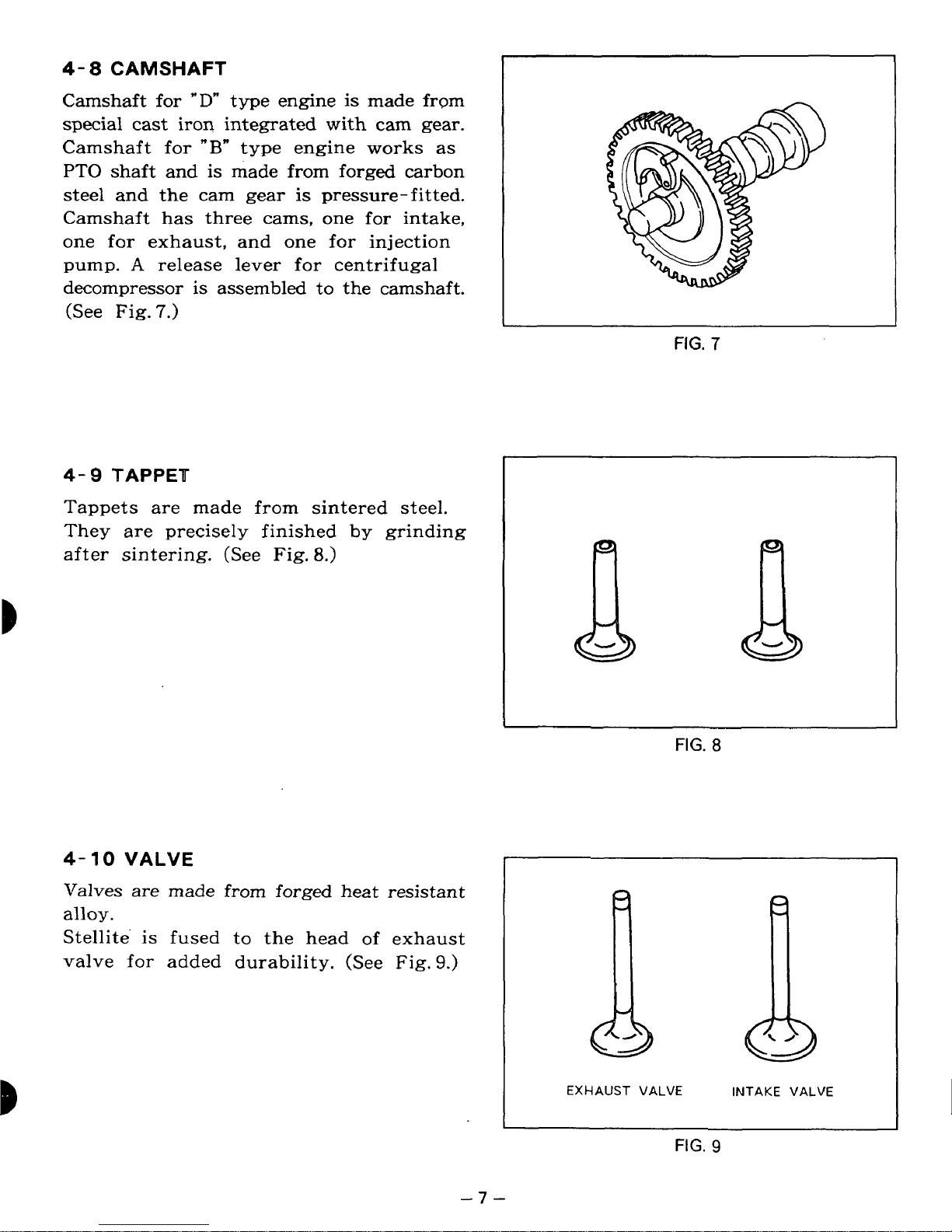

4-

3

CRANKSHAFT

Crankshaft is made from forged carbon

steel and its crankpin and journal are

induct ion

Crankshaft

at flywheel side and a kelmet bearing at

P.T.0:

A

passage for lubricating oil is provided

through the journal and crankpin to

lubricate the large end bearing of

connecting rod.

The crank gear is pressure-fitted

P.T.O. side of the crankshaft.

A

balancer gear is also pressure-fitted

for the engines with optional balancer.

(See Fig.

-

side.

3.)

hardened.

is

supported

by

a ball bearing

on

the

~~

FIG.

FIG.

2

3

-5-

Page 10

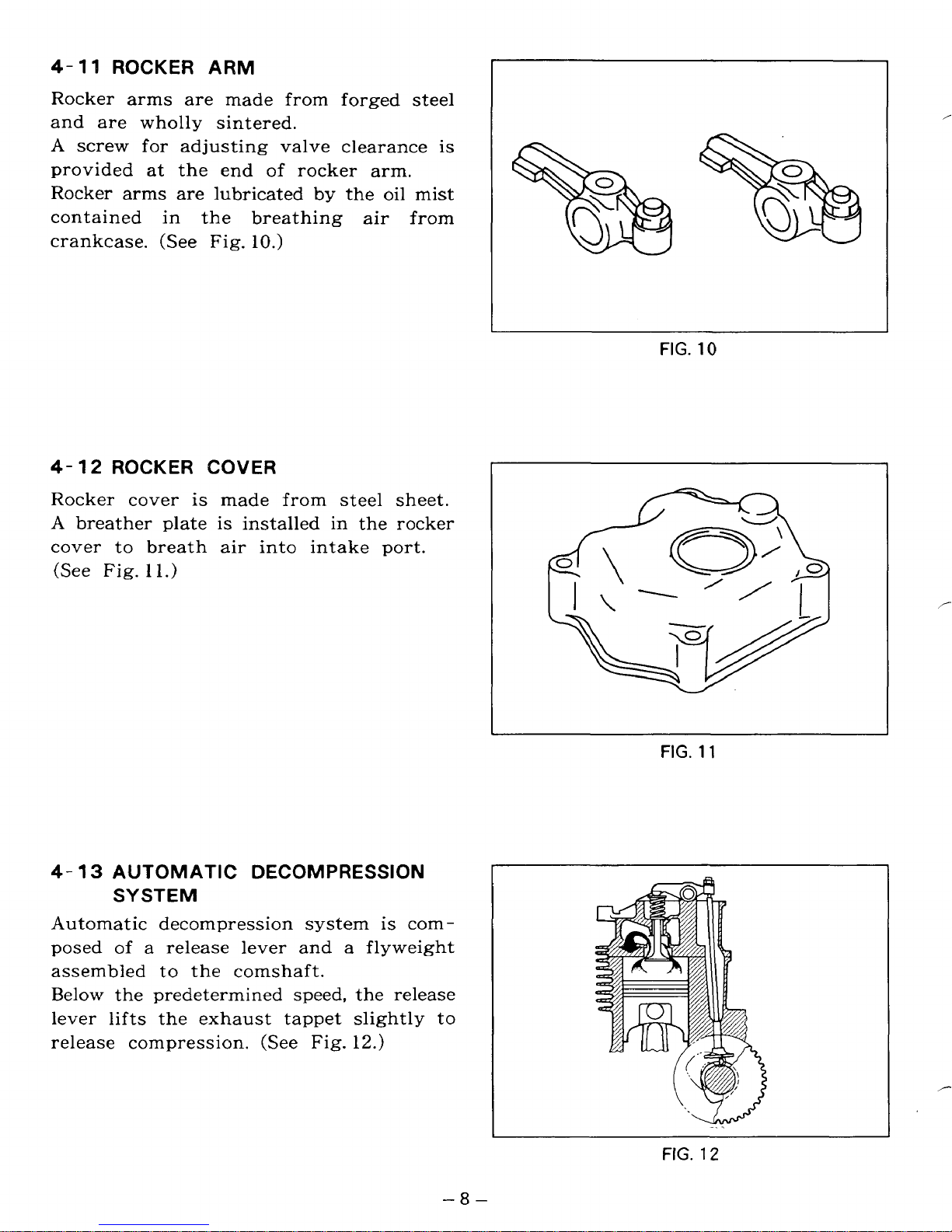

4-4

CONNECTING

ROD

Connecting

rod

is made from forged

aluminum alloy which withstands high

combustion pressure and tension under

heavy load and high speed operation.

Kelmet bearings are provided as large end

bearing, while the material

rod itself serves

(See Fig.

4-

5

Piston

4.)

PISTON

is

casting, and

made from aluminum alloy

it

as

has three grooves

small end bearing.

of

connecting

for

piston

rings.

On

the piston top, a combustion chamber

is arranged where the injected fuel mixes

with air and ignites.

so

The piston profile is

minimize piston noise. (See Fig.

designed as to

5.)

FIG.

,

4

TOP RING

SECOND RING

OIL RING

4-6

PISTON

RINGS

Piston rings are made from special cast

of

iron. The profile

and that

of

second ring is taper with

top ring is barrel face,

under cut. The oil ring is the combination

of cutter rings and an expander which

is

excellent in gas sealing and reducing

oil

consumption. (See Fig.

4-7

Cylinder head

of

CYLINDER

HEAD

is

the most important part

the diesel engine. It

5.)

is

made from onepiece aluminum alloy die cast, in which

intake and exhaust ports, rocker arm room,

and cooling fins are molded in the most

ideal structure

for

the highest strength

and the highest cooling efficiency.

High quality heat resistant valve seats

are pressure- fitted considering high

resistance to abration and corrosion at

high temperature. (See Fig.

6.)

FIG.

FIG.

,

CONNECTING ROD

5

,-

6

-6-

Page 11

4- 8 CAMSHAFT

Camshaft for

"D"

type engine is made

from

special cast

iron

integrated with cam gear.

Camshaft for

"B"

type engine

works

as

PTO

shaft and is made from forged carbon

steel and the cam gear

is

pressure-fitted.

Camshaft has three cams, one for intake,

one

for

exhaust, and one

€or

injection

pump.

A

release lever for centrifugal

decompressor

is

assembled to the camshaft.

(See Fig.

7.)

I

FIG.

7

4-

9

TAPPEU

Tappets are made from sintered steel.

They are precisely finished

by

grinding

after

sintering.

(See

Fig.

8.)

FIG.

8

4-

10

VALVE

Valves are made from

forged

heat resistant

alloy.

Stellite

is

fused to the head

of

exhaust

valve for added durability. (See

Fig.

9.)

EXHAUST VALVE INTAKE VALVE

FIG.

9

-7-

Page 12

4-

11

ROCKER ARM

Rocker arms are made from forged steel

and are wholly sintered.

A

screw for adjusting valve clearance is

of

provided at the end

Rocker arms are lubricated

in

contained

crankcase.

4-

12

ROCKER COVER

the breathing air from

(See

Fig. lo.)

rocker arm.

by

the oil mist

Rocker cover is made from steel sheet.

A

breather plate

is

installed in the rocker

cover to breath air into intake port.

(See Fig.

1

1.)

I

FIG.

10

4-

13

AUTOMATIC DECOMPRESSION

SYSTEM

Automatic decompression system

posed

of

a release lever and a flyweight

assembled to the comshaft.

Below

lever

release compression.

the predetermined speed, the release

lifts

the exhaust tappet slightly to

(See

Fig. 12.)

is

com-

-8-

FIG.

FIG.

11

/-

12

Page 13

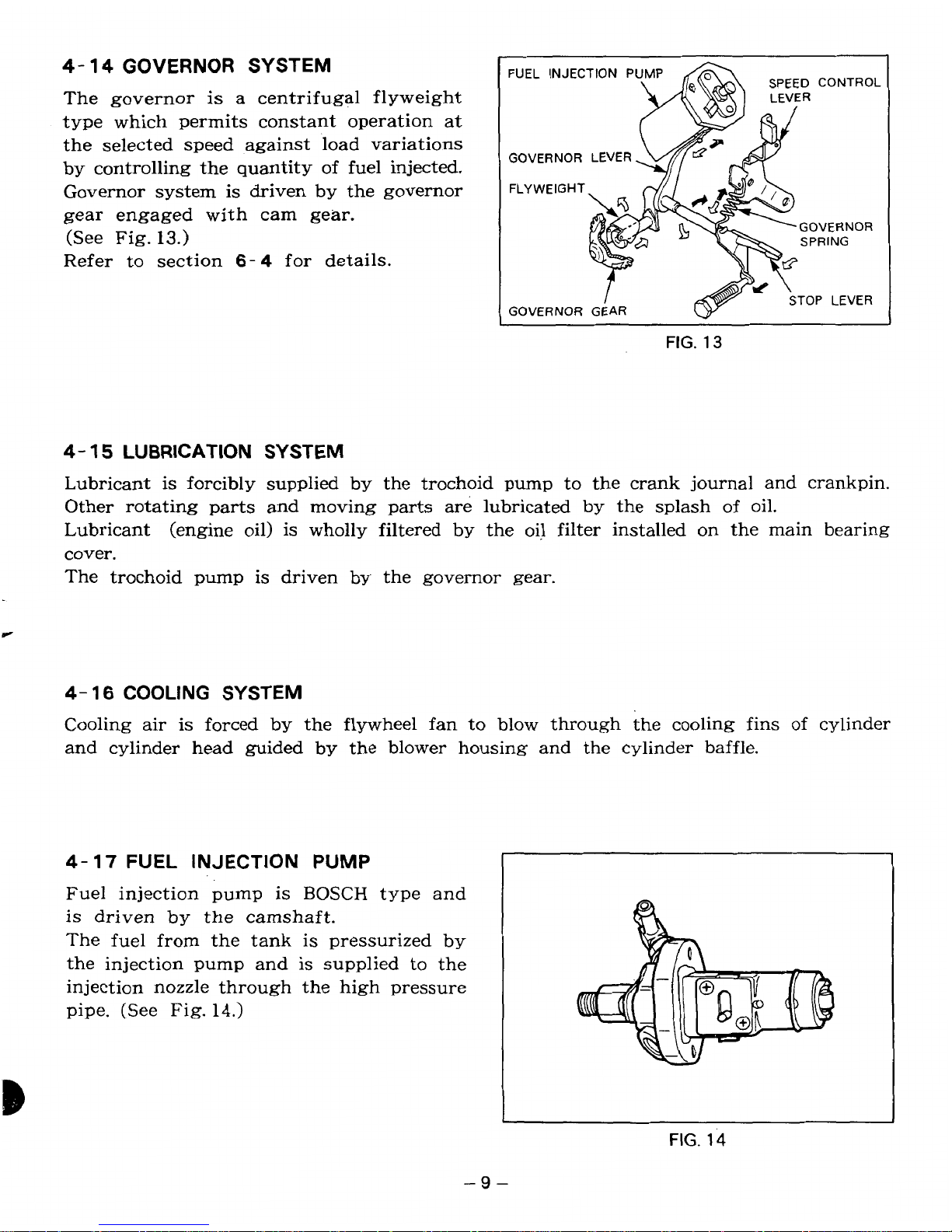

4-

14

GOVERNOR

SYSTEM

The governor is

a

centrifugal flyweight

type which permits constant operation at

the selected speed against load variations

by controlling the quantity of fuel injected.

Governor system

is

driven by the governor

gear engaged with cam gear.

(See Fig.

13.)

Refer

to

section

6-

4

for details.

GOVERNOR LEVER

FIG.

13

4-

15

LUBRICATION

SYSTEM

Lubricant is forcibly supplied by the trochoid pump to the crank journal and crankpin.

Other rotating

parts

and moving parts are lubricated by the splash

of

oil.

Lubricant (engine oil) is wholly filtered by the oil filter installed on the main bearing

cover.

The trochoid pump

is

driven by the governor gear.

c

4-

16

COOLING

SYSTEM

Cooling air

is

forced

by

the flywheel fan to blow through

the

cooling fins of cylinder

and cylinder head guided

by

the blower housing and the cylinder baffle.

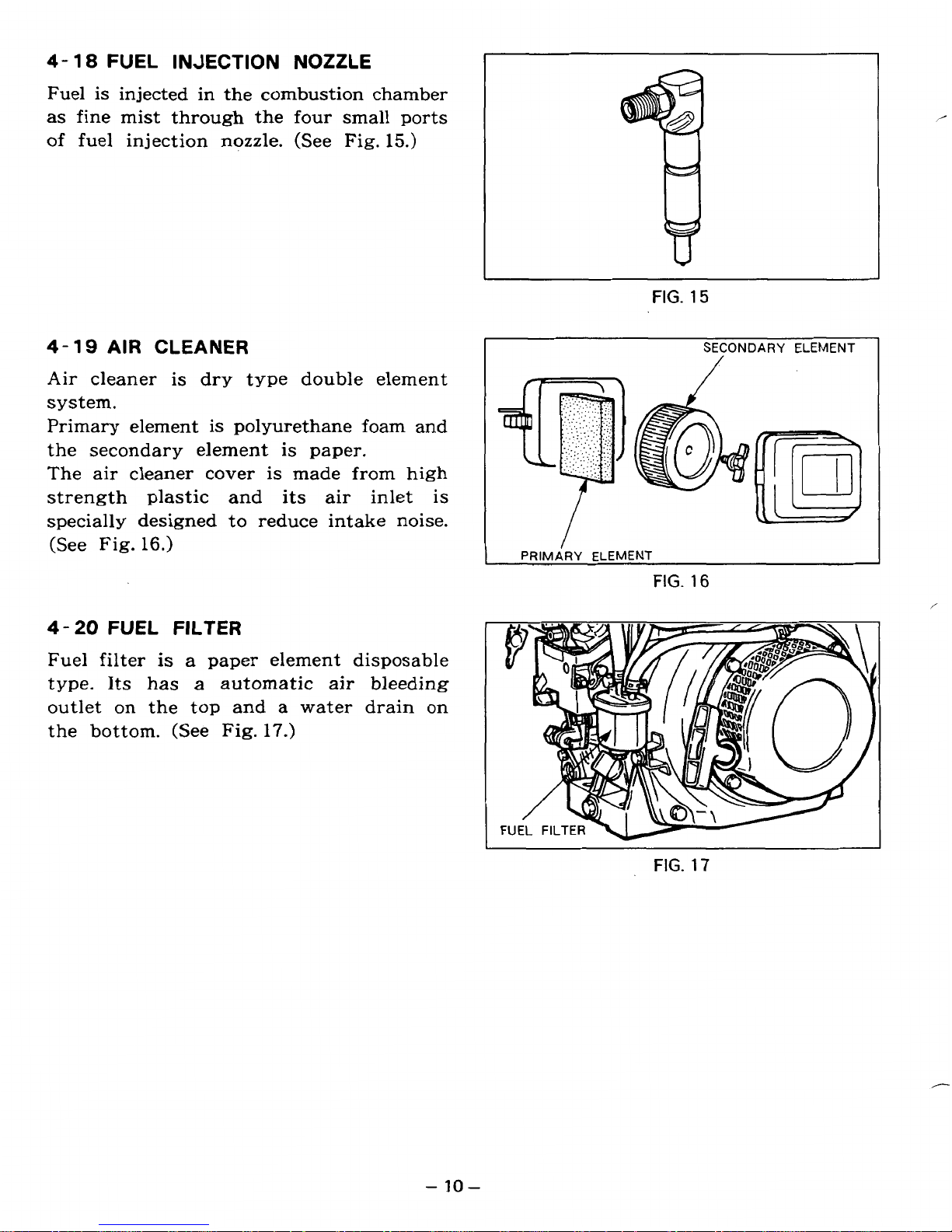

Fuel injection pump is

BOSCH

type and

is

driven

by

the camshaft.

The fuel from the tank is pressurized by

the injection pump and is supplied

to

the

injection nozzle through the high pressure

pipe. (See Fig.

14.)

FIG.

14

-9-

Page 14

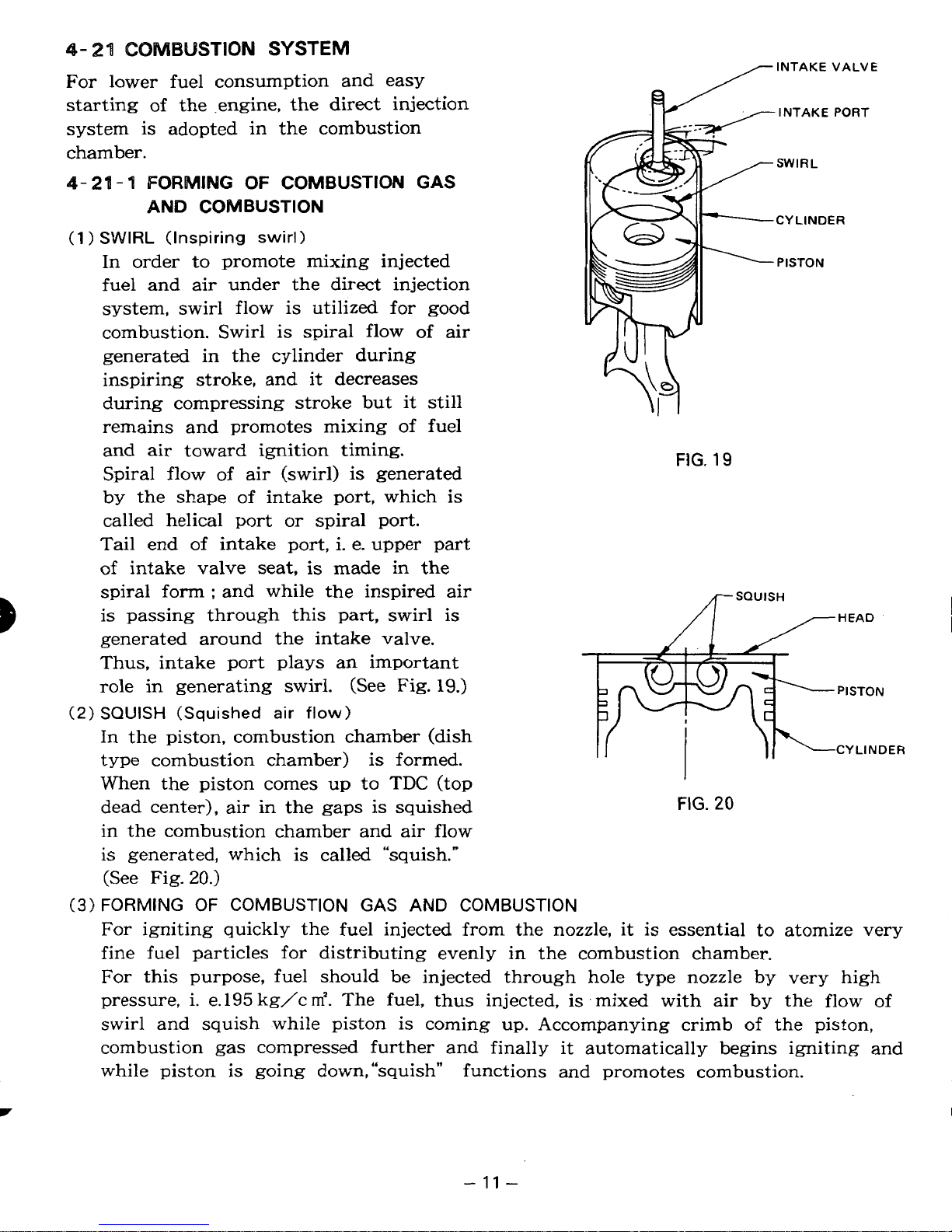

4-18

FUEL

INJECTION NOZZLE

Fuel is injected in the combustion chamber

as fine mist through the

four

small ports

of

fuel injection nozzle. (See Fig.

15.)

4- 19

AIR

CLEANER

Air

cleaner is

dry

type double element

system.

Primary element is polyurethane foam and

the secondary element is paper.

The air cleaner cover

is

made from high

strength plastic and its air inlet is

specially designed to reduce intake noise.

(See Fig.

16.)

4-

20

FUEL

FILTER

Fuel filter

is

a

paper element disposable

type.

Its

has

a

automatic air bleeding

outlet

on

the top and

a

water drain on

the bottom. (See Fig.

17.)

FIG.

15

SECONDARY

ELEMENT

/

PRIMARY ELEMENT

FIG.

16

/

FIG.

17

-

10-

Page 15

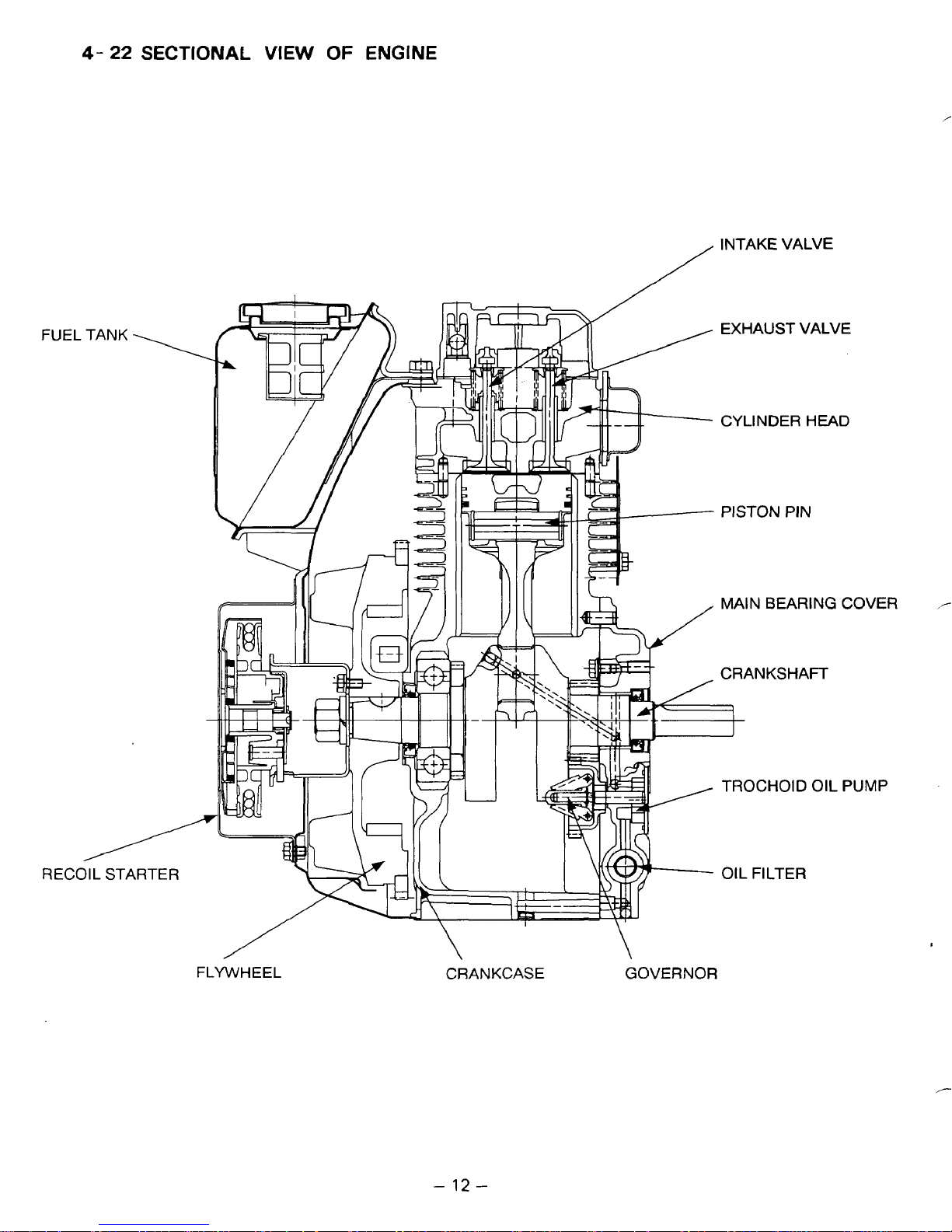

4-

21

COMBUSTION

SYSTEM

For

lower fuel consumption and easy

starting

of

the .engine, the

direct

injection

system is adopted in the combustion

chamber.

4-21-4

FORMING

OF

COMBUSTION

GAS

AND

COMBUSTION

(1

1

SWIRL

(Inspiring swirl)

In order to promote mixing injected

fuel and air under the direct injection

system, swirl flow is utilized for good

combustion. Swirl is spiral flow

of

air

generated in the cylinder during

inspiring stroke, and it decreases

during compressing stroke but it still

remains and promotes mixing of fuel

and

air

toward ignition timing.

Spiral flow

of

air (swirl) is generated

by the shape of intake

port,

which is

called helical port

or

spiral port.

Tail end of intake port, i. e. upper part

of

intake valve seat, is made in the

/INTAKE

VALVE

INTAKE

PORT

SWIRL

CY

LlNDER

PISTON

FIG.

19

/c

SQUISH

FIG.

20

spiral forrn : and while the inspired air

is

passing through this part, swirl is

generated around the intake valve.

Thus, intake port plays an important

role

in

generating swirl.

(See

Fig.

19.)

SQUISH

(Squished

air

flow)

In the piston, combustion chamber (dish

type combustion chamber)

is

formed.

When the piston comes up to

TDC

(top

dead center), air in the

gaps

is squished

in the combustion chamber and air flow

is generated, which is called “squish.”

(See Fig.

20.)

FORMING

OF

COMBUSTION GAS AND COMBUSTION

For igniting quickly the fuel injected from the nozzle, it is essential to atomize very

fine fuel particles for distributing evenly in the combustion chamber.

For

this purpose, fuel should be injected through hole type nozzle by very high

pressure, i. e. 195 kg/c

m’.

The fuel, thus injected, is ‘mixed with air by the flow of

swirl and squish while piston is coming up. Accompanying crimb of the piston,

combustion gas compressed further and finally it automatically begins igniting and

while piston

is

going down,“squish” functions and promotes combustion.

-

11

-

Page 16

4-

22

SECTIONAL VIEW

OF

ENGINE

INTAKE VALVE

/

EXHAUST VALVE

k/

CYLINDER

PISTON

MA‘N

CRANKSHAFT

TROCHOID

HEAD

PIN

BEARING

OIL

COVER

PI

JMP

/

FLYWHEEL

\

CRANKCASE

-

12

-

\

GOVERNOR

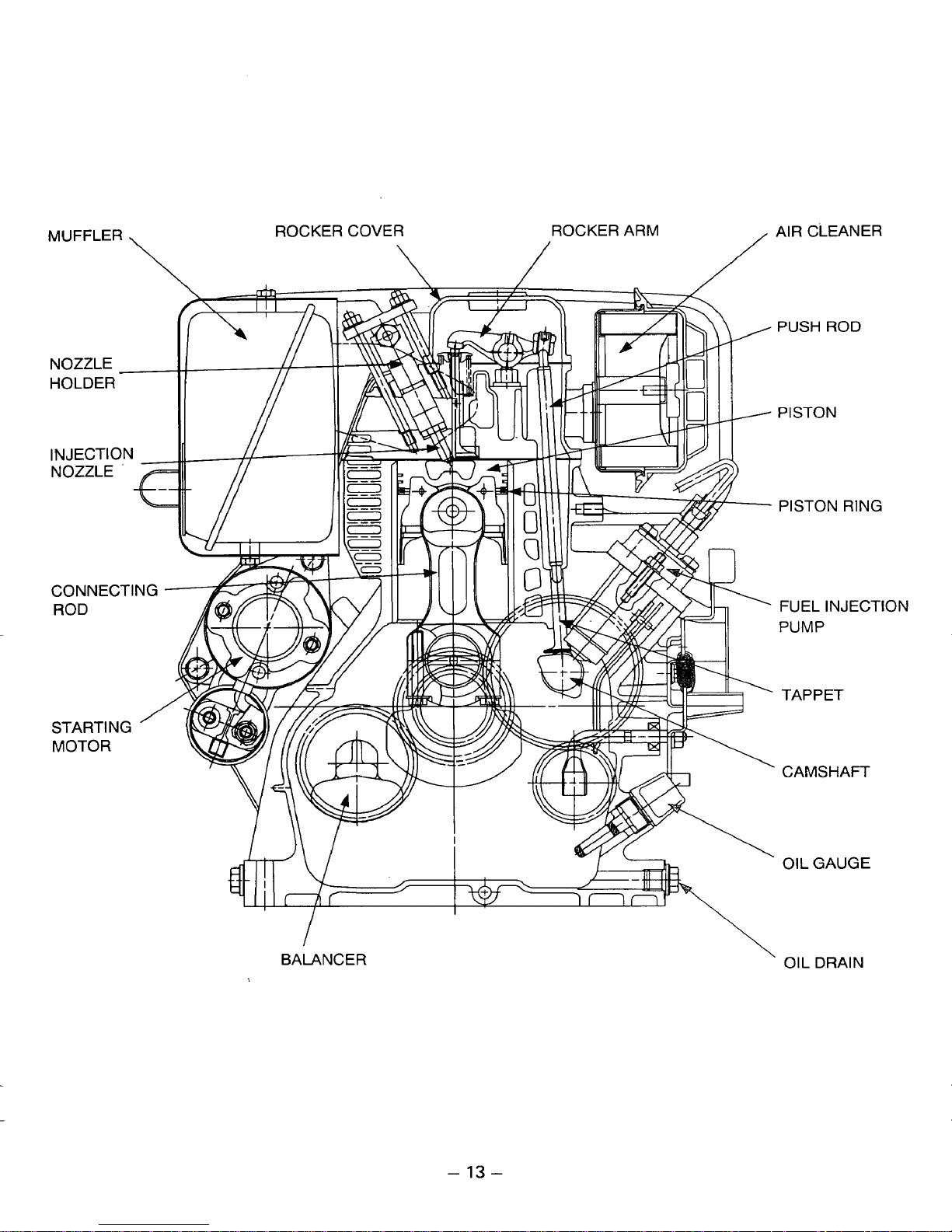

Page 17

ROCKER COVER

AIR CLEANER

MUFFLER

\

\

/

PUSH

PISTON

PISTON RING

PUMP

ROD

FUEL

INJECTION

TAPPET

BALANCER

'

CAMSHAFT

OIL

GAUGE

\

OIL

DRAIN

-

13

-

Page 18

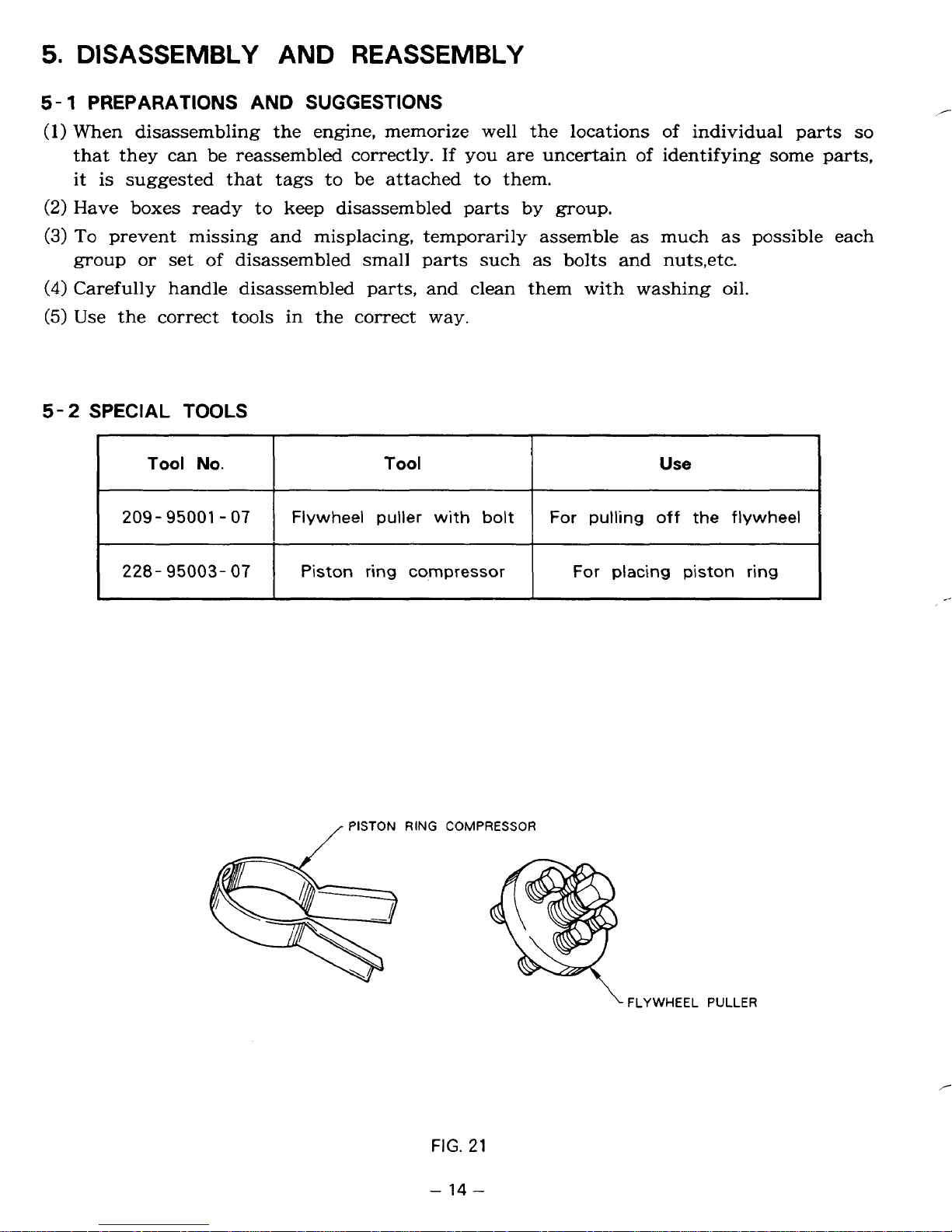

5.

DISASSEMBLY

5-

1

PREPARATIONS AND

(1)

When disassembling the engine, memorize well the locations of individual parts

that they can be reassembled correctly.

AND

REASSEMBLY

SUGGESTIONS

If

you

are uncertain

of

identifying some parts,

it is suggested that tags to be attached to them.

(2)

Have boxes ready to

(3)

To

prevent missing and misplacing, temporarily assemble as much as possible each

group

(4)

Carefully handle disassembled parts, and clean them with washing oil.

(5)

Use the correct tools in the correct way.

5-2

SPECIAL

or

set

of

TOOLS

disassembled small parts such as bolts and nuts,etc.

keep

disassembled parts by

group.

/-

so

Tool

209-

95001 - 07

228-

95003-

No.

07

Tool

Flywheel puller with

Piston ring cqmpressor

PISTON

RING

COMPRESSOR

f

bolt

Use

For pulling

For placing piston ring

off

the

flywheel

.

FIG.

-

14

21

-

FLYWHEEL

PULLER

/-

Page 19

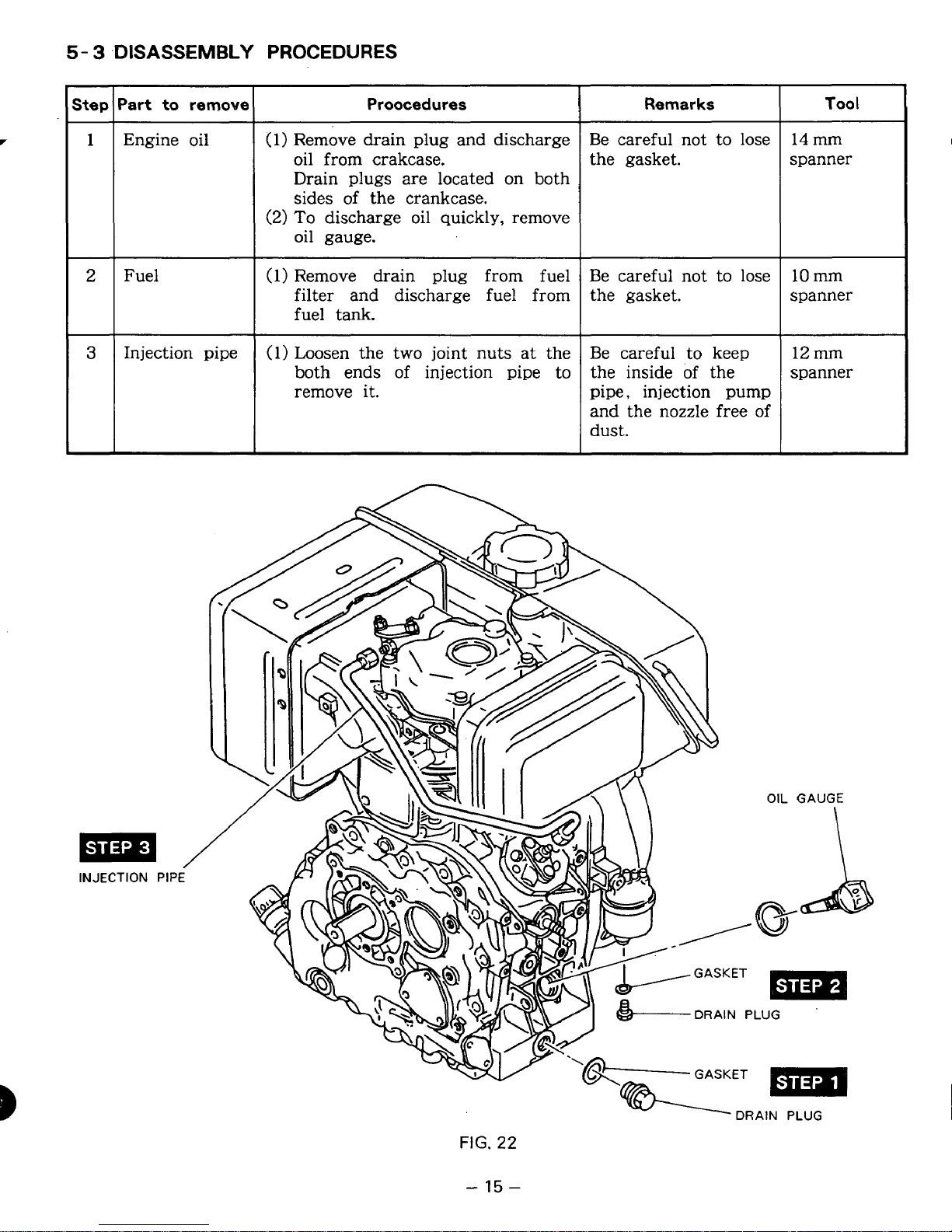

5-

3

-DISASSEMBLY PROCEDURES

-

Step

-

1

Engine oil

2

Fuel

-

3

Injection pipe

(1)

(2)

(1)

(1)

Proocedures

Remove drain plug and discharge

oil from crakcase.

Drain plugs are located on both

sides of the crankcase.

To

discharge oil quickly, remove

oil gauge.

Remove drain plug from fuel

filter and discharge fuel from

fuel tank.

Loosen the two joint nuts at the

both ends of injection pipe

to

remove it.

Remarks

Be careful not to lose

the gasket.

Be careful not to lose

the gasket.

Be careful

to

keep

the inside of the

pipe, injection pump

and the nozzle free of

dust.

Tool

14

mm

spanner

10

mm

spanner

12 mm

spanner

INJECTION

/

PIPE

-

15

-

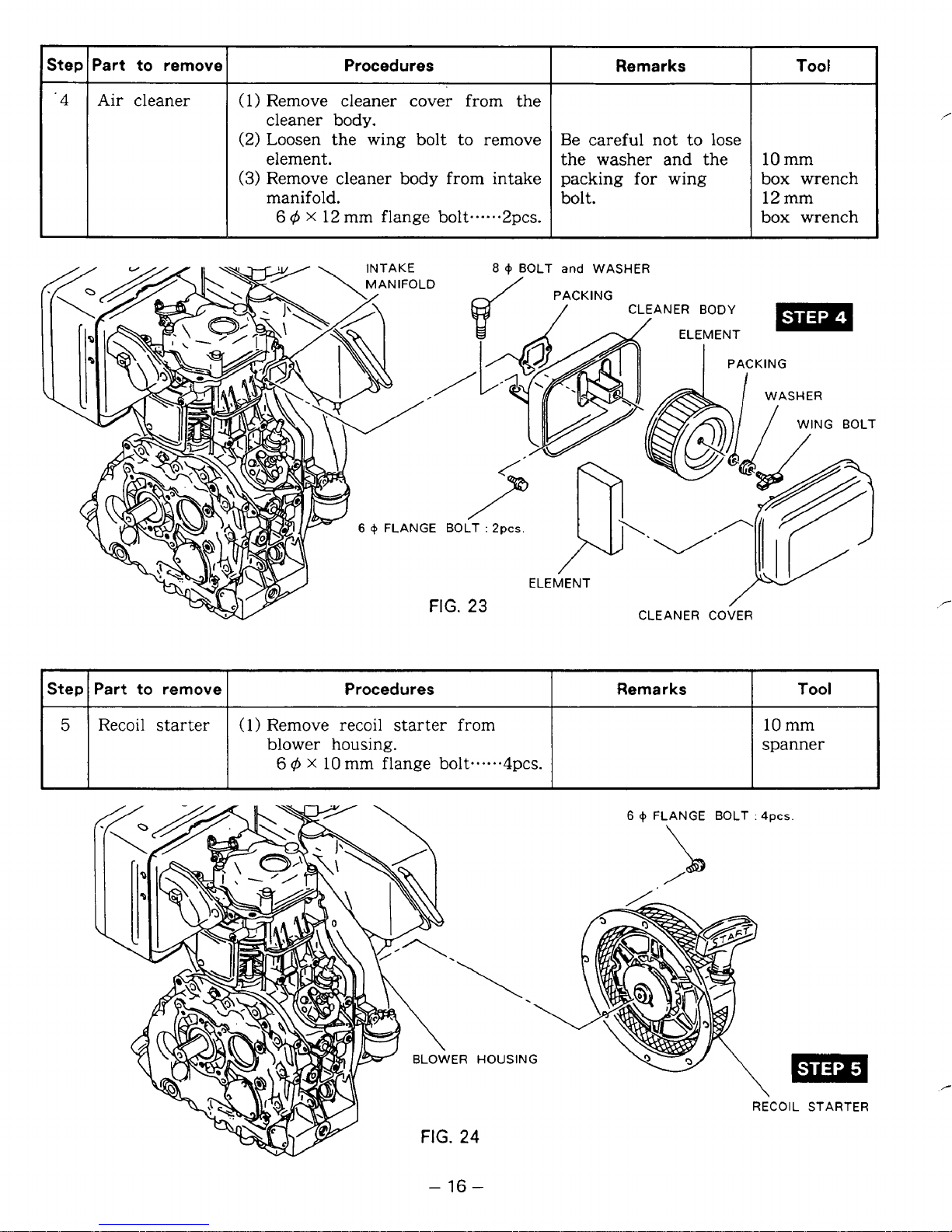

Page 20

Step lPart to remove

’

4

Air cleaner

Procedures

(1)

Remove cleaner cover from the

cleaner body.

(2) Loosen the wing bolt to remove

element.

(3)

Remove cleaner body from intake

manifold.

6

4

X

12

mm flange bolt...-..2pcs

8

0

BOLT and WASHER

Remarks

Be careful not to lose

the washer and the

for

packing

bolt.

wing

.

Tool

10 mm

box wrench

12 mm

box wrench

I

Step I Part

5

Recoil

to

remove

starter

I

(1) Remove

blower housing.

6

4

Procedures

recoil

x

10

mm flange bolt**..**4pcs.

starter

from

PACKING

ELEMENT

I

CLEANER BODY

Remarks

3

spanner

FIG.

-

16

HOUSING

24

-

6

0

FLANGE BOLT

:

4pcs.

m

RECOIL STARTER

Page 21

step

I

Part

to

remove

Procedures

I

Remarks

Tool

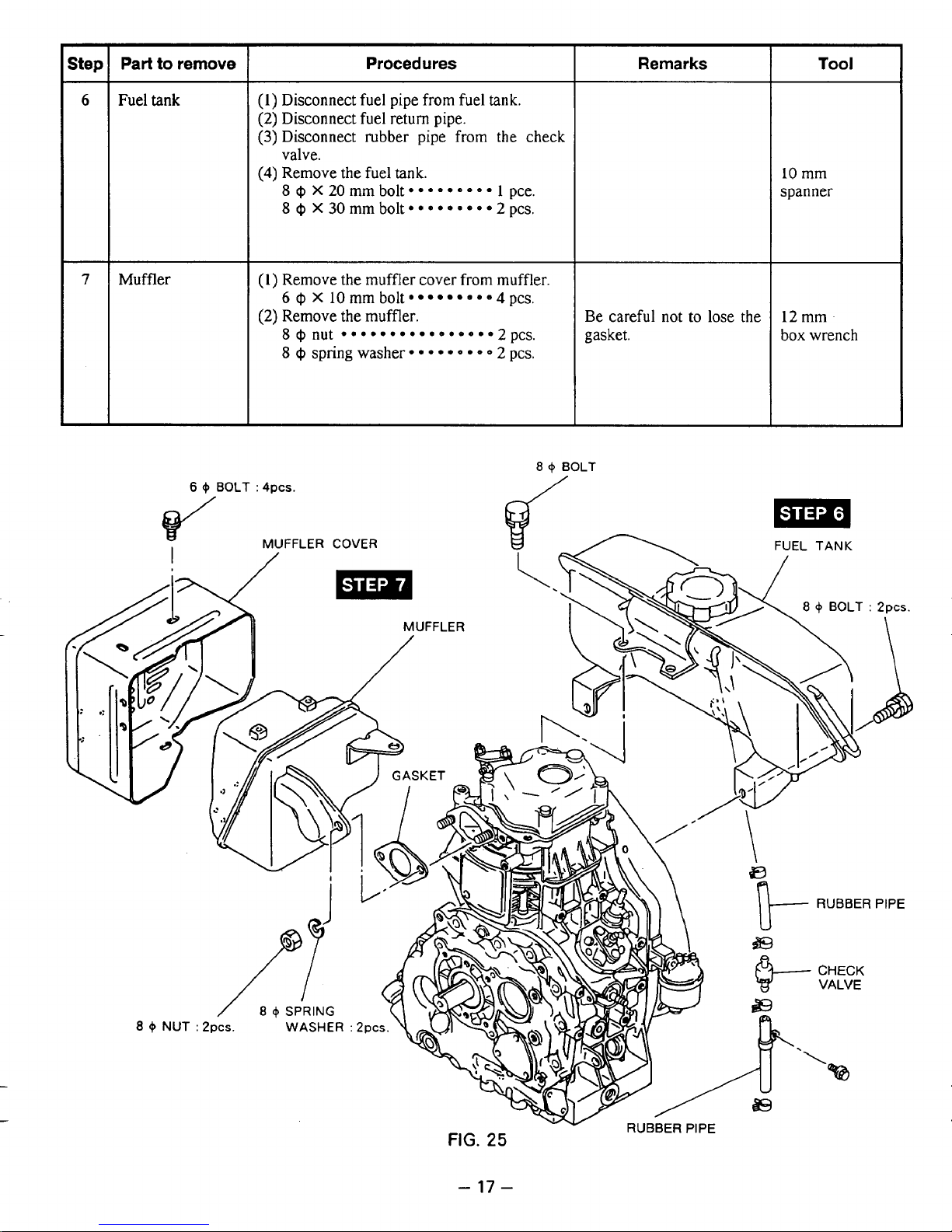

6

7

Fuel

tank

Muffler

6

+

BOLT

(1)

Disconnect fuel pipe from fuel

(2)

Disconnect fuel return pipe.

(3)

Disconnect rubber pipe from the check

tank.

valve.

(4)

Remove

8

8

(1)

Remove the muffler cover from muffler.

6

(2)

Remove the muffler.

8

8

:

4pcs.

the

fuel

tank.

Q

X

20mmbolt*****e.e* 1 pce.

@

X30mmbolt*****~***2pcs.

@

X

10

mm bolt

@nut

9

e

*

*

4

pcs.

Qspringwasher*****~*~~2pcs.

a

/

+

BOLT

Be careful

gasket.

not

to

lose the

10

mm

spanner

12

mm

box wrench

-

17

-

Page 22

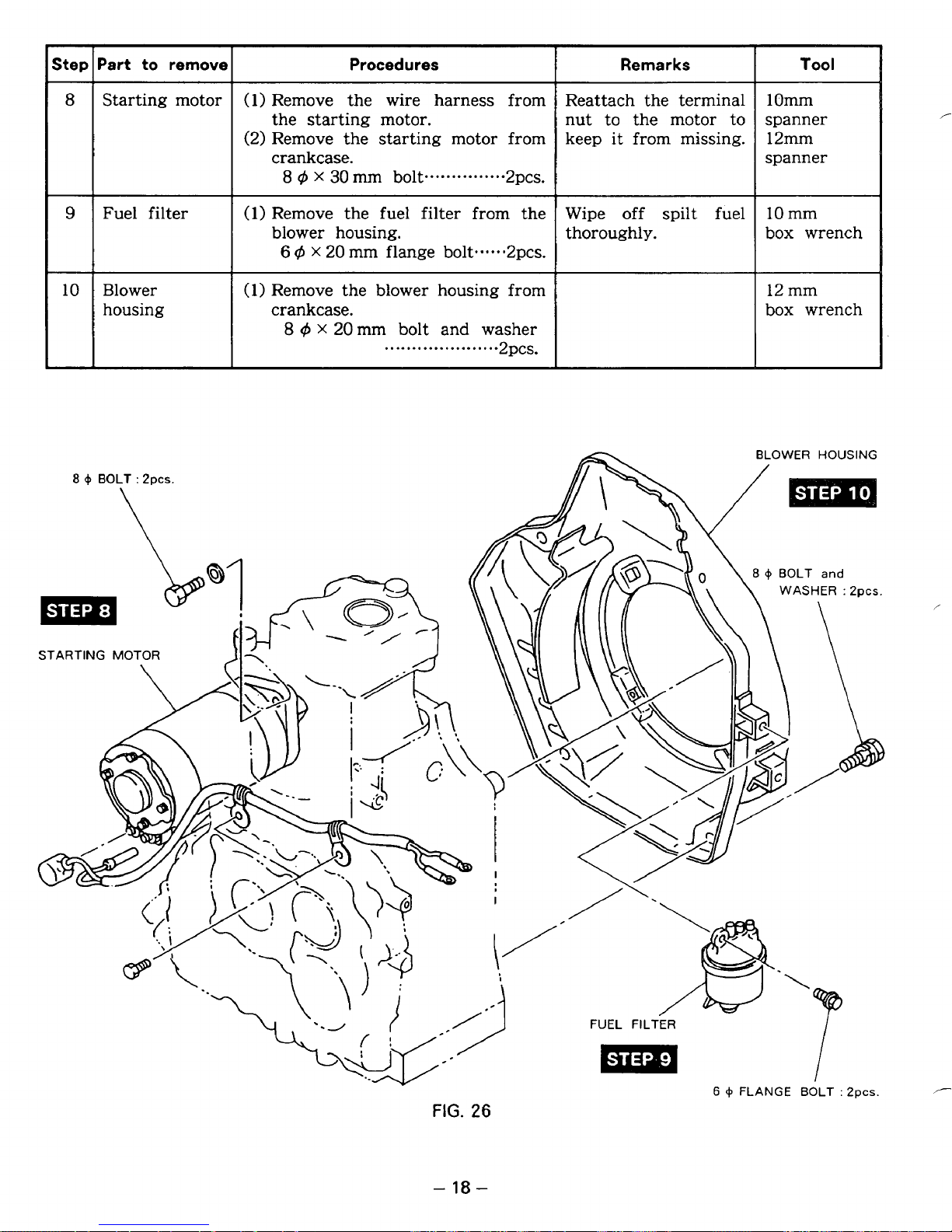

Step Part to remove Procedures Remarks Tool

8

Starting motor

(1)

Remove the wire harness from Reattach the terminal 1Omm

the starting motor. nut to the motor to spanner

(2)

9

Fuel filter

Remove the starting motor from keep

crankcase.

8

4

x

30

mm bolt

(1)

Remove the fuel filter from the Wipe off spilt fuel

...............

2pcs.

it

from missing. 12mm

spanner

10

mm

blower housing. thoroughly. box wrench

6

q-5

X

20

10

Blower

housing

mm flange bolt.....*2pcs

(1)

Remove the blower housing from

crankcase.

8

q5

x

20

mm bolt and washer

.....................

.

12 mm

box wrench

2pcs.

-

18

-

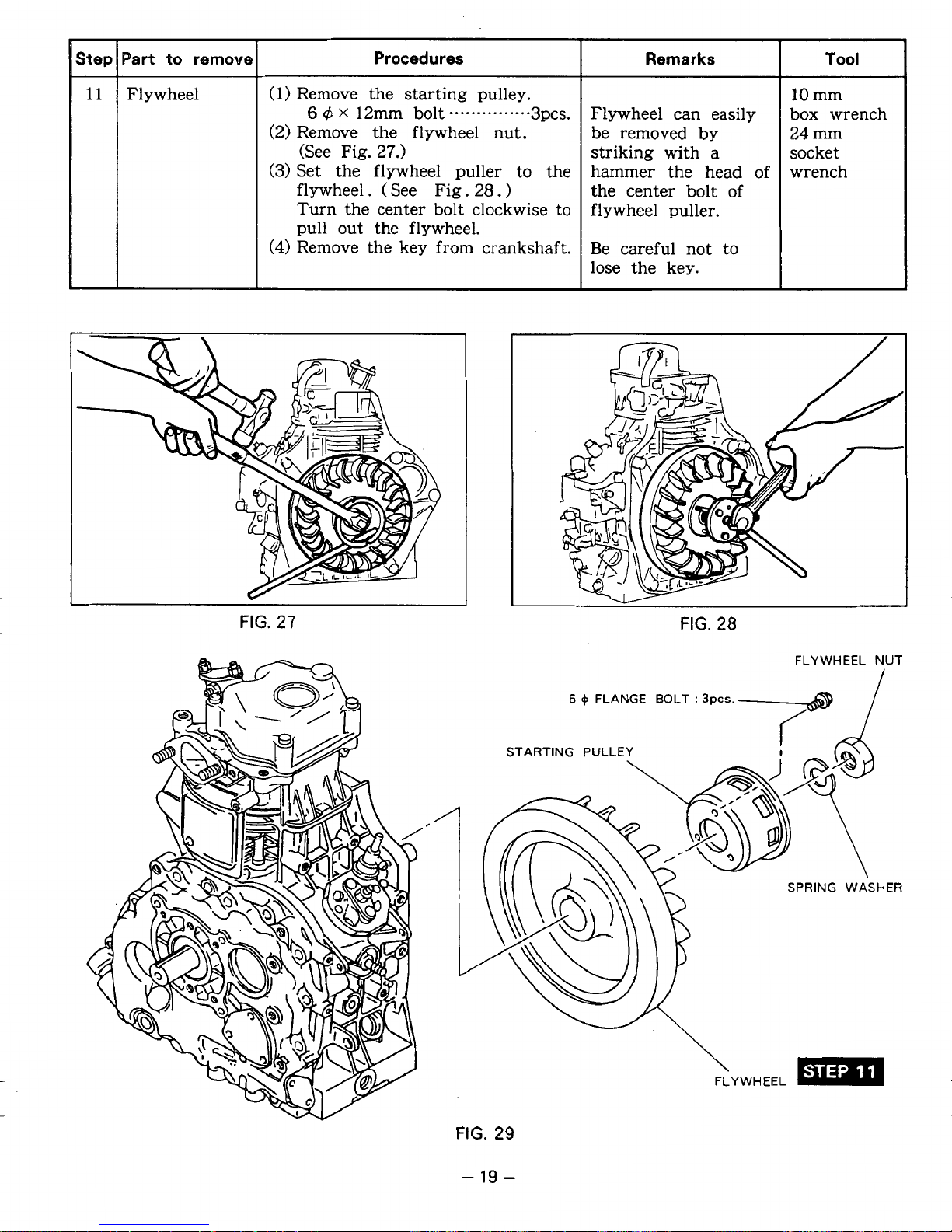

Page 23

-

Step

11

Part

to

remove

Flywheel

Procedures

Remarks

(1)

Remove the starting pulley.

(2)

Remove the flywheel nut.

striking with a

(See Fig.

27.)

be removed

by

(3)

Set the flywheel puller to the

hammer the head of

flywheel. ( See Fig.

28.

)

the center bolt of

Turn the center bolt clockwise to

flywheel puller.

pull out the flywheel.

(4)

Remove the key from crankshaft.

Be careful not to

6

,$

X

12m

bolt

.......

.....

...

3pcs.

Flywheel can easily

lose the key.

FIG.

27

Tool

10

mm

box wrench

24

mm

socket

wrench

v

FIG.

28

FLYWHEEL

NUT

6

+

FLANGE BOLT

:

3pcs.-@

STARTING PULLEY

SPRING WASHER

FLYWHEEL

FIG.

29

-

19

-

Page 24

Step

-

12

13

Part

to

remove

Cylinder

baffle

Rocker cover

Procedures

Remarks

Tool

(1) Remove the cylinder baffle from

cylinder.

6

q5

X

10

~~

(I)

Remove the rocker cover from

cylinder head.

6

4

mm flange bolt-.-..-lpce.

X

40

mm flange bolt-......lpcs

.

10

box

mm

wrench

Fuel injection

nozzle

6

4

NUT

:

NOZZLE BRAC

FUEL

INJECTION

2pcs.

”-e9

NOZZ

(1)

Remove the bracket, nozzle.

6

4

(2)

Remove the fuel injection nozzle

from

I

..............................

nut 2pcs.

cylinder head.

Be careful not to lose

the gasket at the

bottom end of the

nozzle.

-6

ROCKER COVER

4

FLANGE

BOLT

:

4pcs.

LANGE

BOLT

FIG.

-20-

30

Page 25

Step Part to remove

15

Rocker arm

16

Cylinder head

Procedu.res

(1)

Loosen the adjusting bolts on the

rocker arms.

(2)

Push

the

the rocker shaft out from

cylinder

head to remove

rocker arms.

(3)

Remove the push

rods.

Remarks

Make the rocker arms

the

and push rods

distinguishable

of

Tool

10

mm

spanner

screw driver

intake side and

exhaust side.

(1)

Remove the cylinder head

cylinder. spacer.

8

4

flange nut

.......

.....

from

.

....

4pcs.

8

6

FRANGE NUT

Be careful of the

:

4DC.s.

12

mm

socket

wrench

ADJUSTING

BOLT

P

ROCKER

CYLINDER

HEAD

\

I

ARM

ROD

-

FIG.

21

-

32

Page 26

Step

-

17

-

18

)art

to remove

Fuel injection

pump

Main bearing

cover

Procedures

(1) Remove the fuel injection pump

from crankcase.

6

4

nut

..............................

2pcs.

(1) Remove the bolts joining the

main bearing cover and

crankcase.

8

@

X

35

8

@

(2)

Lightly tapping with a plastic

mm bolt..-.----.--. 1 lpcs.

x

40mm bolt

...............

1 pce.

hammer, remove the main

bearing cover from the

Fig.

crankcase. (See

33.)

Remarks

Be

careful of the

position of the

control

Be careful not

rack.

to

damage the oil seal.

Tool

10 mm

socket

wrench

~ ~~

12 mm

box wrench

plastic

hammer

6

+

NUT

:

2pcs.

Page 27

Step

19

20

'art to remove

F

Camshaft

Balancer

(Optional

part)

Procedures

(1)

Remove the camshaft from the

crankcase. (See

(2)

Remove the tappets from the

Fig.

crankcase.

i

(1)

Remove the balancer from the

~

crankcase.

35.)

Remarks

(1)

To

prevent the

tappet from falling

and getting damages,

put the crankcase

injection pump side

down.

(2)

Put marks on the

tappets to distinguish

intake tappet

from

exhaust.

Be

careful

of

the

spacer on the

balancer shaft.

Tool

SPACER

FIG.

-

23

36

-

Page 28

Step

21

r

'art

to

Connecting

rod

remove

Procedures

(1)

Scrape off the carbon deposit

from the piston top and cylinder.

(2)

Remove the connecting rod bolts

and the large end cap.

(3)

Turn the crankshaft to the top

dead center.

Then, push the connecting rod

up and pull the piston and

connecting rod out from the

cylinder.

Remarks

10

box

Tool

mm

wrench

22

PISTON

PISTON

Piston and

piston pin

RING

PIN

(

1)

Remove the two clips from the

piston at the both ends

of

pin.

(2)

Push the piston pin out from the

piston.

Remove the piston from the

connecting

(3)

Remove the piston rings from

rod.

the piston by spreading their

open ends.

CLIP

piston

Be careful not to give

damages to the

piston and connecting

rod.

Be careful not

to

break the rings by

spreading too much

or twisting them.

CONNECTING

LARGE

ROD

END BEARING'

/

IU

I

I

/

Page 29

Step

Tool

Remarks

Procedures

Part

to

remove

23

The ball bearing

(1)

Lightly

tap

the crankshaft end

Crankshaft

at the flywheel side

using

a

(See

Fig.

38.)

from the crankshaft.

crankshaft.

plastic hammer to remove it

comes

off with the

FIG.

38

CRANKSHAFT

\

t

FIG.

39

-

25

-

Page 30

Part to remove Procedures

Step

I

Intake and

exhaust valve remove the retainer locks from

(1)

Press the valve springs and

the valve stems. (See

(2)

Remove the valves from the

cylinder head.

Fig.

40.)

Remarks

Put marks on the

valves, valve springs

and spring retainers

to distinguish them

for

intake side from

exhaust side.

Tool

~~ ~

.pliers

3

Oil

h

filter

FIG.

(1)

Remove the oil filter from the Be careful not to lose

main bearing cover. the

6

4

40

X

12mm

flange bolt...---2pcs.

0-

10

mm

ring. spanner

8-

I

&“----

RETAINER

STEM

LOCK

SEAL

MAIN

BEARING

COVER

7-

OIL

FILTER

6

+

FLANGE

J

FIG.

41

-

26

-

BOLT

:

2pcs

VALVE

Page 31

EASSEMBLY

PROCEDURES

PRECAUTIONS

FOR

REASSEMBLING

(1)

Clean parts thoroughly before reassembly.

(2)

Scrape

off

all

carbon deposits

from

cylinder head, piston top and piston ring grooves.

(3)

Check lips

of

oil

seals. Replace

oil

seal

if

a

lip

is

damaged.

(4)

Replace all gaskets with new ones.

(5)

Replace keys, pins, bolts, nuts, etc.,

if

necessary.

(6)

Torque bolts and nuts to specification refering to the “Table

of

tightening torque”.

(7)

Apply

oil

to

rotating

and

sliding portions.

(8)

Check

and

adjust clearances and end plays where specified in this manual.

Pay most attention to cleanliness

of

piston, cylinder, crankshaft, connecting rod

and

bearings.

Apply

oil

to lips before reassembly.

5-

4- 1 CRANKSHAFT

(1)

Fit the oil seal guide

onto

the

end

of

the crankshaft, and insert the

crankshaft

into the crankcase.

U/

OIL

SEAL

GUIDE

FIG.

42

-

27

-

Page 32

5-

4-

2

PISTON AND PISTON

RING

(1)

If

the piston ring expander is unavailable, install the piston rings

by

placing

the

open

ends

over

the

top

land

of

the piston and

spreading

the

ring ends

only

far

enough

to

slip

them into the correct ring grooves.

1.

Pay attention not to break the piston

ring

by twisting.

2.

Install the oil ring first followed

by

the second ring and then top ring.

3.

Second

ring have “N”marks stamped on

the

ring

ends. These

”N”marks

have to face upward when installed on

the

piston.

OPEN ENDS

OF

PISTON

RING

‘

I

FIG.

43

Top ring

Barrel face

Second

ring

Taper

......

......

......

...

...

...........

...........

....................

.........

Oil

ring Cutter

ring

with

expander

:e

......

.......

................

......

...........

..........

FIG.

44

(2)

Assemble the piston and connecting

rod

with the piston pin.

I

1.

Set the “D”or “B”mark stamped on piston top

to

the

“FAN”mark

side

of

the

2.

Apply

enough oil to the

small

end of the connecting rod.

3.

Be

sure

to set

the

clips

on

both ends

of

the piston

pin.

connecting

rod.

I

,

-

28

-

Page 33

assembly into the cylinder.

Use the piston ring compressor

to

hold

the piston rings.

The “FAN” mark

of

the connecting rod

have to face flywheel side when

assembled. (See Fig.

45.)

1.

Apply enough oil to the piston rings,

connecting rod bearings and cylinder

bore before assembly.

2.

Set the open end

of

the piston rings

90

degrees apart from

one

another

before assembly.

5-4-3

CONNECTING

ROD

(1)

Turn the crankshaft

to

the bottom

dead center, lightly hammer the piston

head until the connecting rod contacts

the crankpin, and assemble,

(2)

When reassembling the large end cap,

match the alignment mark

on

the rod.

1.

No.

lock washer

is

used for the

2.

Tighten the rod bolts securely

by

the

Tightening torque

:

180-200

Kg-

cm

connecting

rod

bolts.

specified tightening torque.

PlSTON

RING

COMPRESSOR

FIG.

45

FIG.

46

-

29

-

Page 34

5-

4- 4

BALANCER (Optional part)

Install the balancer to the crankcase.

Align the matching marks

gear and crank gear as shown in Fig,

of

the balancer

47.

FIG.

47

-I

AFT

5-4-

5

TAPPET AND CAMSHAFT

(1)

Insert the tappets into the tappet holes

of

the crankcase.

Be sure to assemble the intake tappet

to intake side and exhaust tappet to

exhaust side.

(2)

Install the camshaft into the crankcase

matching the timing marks

crank gear and cam gear. (See Fig.

on

the

48.)

FIG.

48

,

-

30

-

Page 35

5-4-

6

MAIN BEARING COVER AND GOVERNOR GEAR

(1)

Installation

of

governor gear

shaft

set.

MAIN BEARING COV VERNOR

GOVERNOR GEAR

S

243-4501 1-01

(GOVERNOR GEAR SHAFT

FIG.

49

GEAR

SET)

a) Insert

GOVERNOR

GEAR

SHAFT

to the main bearing cover.

b)

Put

GOVERNOR

GEAR

on

the governor gear shaft.

c) Press

the

iron sleeve

of

governor gear using

a

pressing machine

to

fit

on the governor

gear shaft. (See

Fig.

50.)

Be sure to make a clearance

of 1 mm

(0.04

in) between governor gear and mounting

boss

of

main

bearing cover. (See Fig.

5

1.)

FIG.

50

FACE

OF

MAIN BEARING COVER

S

THE IRON SLEEVE

OVERNOR GEAR

I

CLEARANCE

1

rnm

(0.04in)

FIG.

51

1.

When replacing the governor gear or governor gear shaft, be sure to replace them

2.

Do

not press the plastic part

of

governor gear at assembling.

at the same time.

-

31

-

Page 36

(2)

Install the main bearing cover

to

the crankcase.

Adjust the side clearance for the crankshaft, camshaft

specified values using the proper spacer and

thrust

and

washer.

balancer shaft to

the

SIDE

CLEARANCE

ADJUSTING

DEVICE

CRANKSHAFT

0.1

-0.3

THRUST

T

T

T

WASHER

=

0.1

=

0.2 mm

=

0.3

mm

mm

mm

.

D

type

I

0.05-0.25 mm

SPACER

T = 0.8

T=

1.0

CAMSHAFT

I

mm

mm

type

0.05-0.3 mm

SPACER

T = 0.6

T

=.0.8

T

=

1.2

mm

mm

mm

BALANCER

SHAFT

I

0.05-0.25 mm

SPACER

T

=

0.8

T

=

1.0

T

=

1.2

I

mm

mm

mm

A

-

32

,

-

Page 37

1.

As the governor gear is mounted on

the main bearing cover side, install

the main bearing cover while checking

that

it

meshes

with

the teeth of the

cam gear.

(See

Fig.

53.)

2.

If

the replacement of oil seal is

necessary, press-fit the new oil seal

before installing the main bearing

cover.

3.

Apply oil to the ball bearing and

oil

seal rip before installing the main

bearing cover.

4.

Be careful not to injure the oil seal

rip at reassembly.

Use

oil seal guide

to protect

it.

1

FIG.

53

(3)

Tighten the twelve bolts evenly to join the main bearing cover

to

the crankcase.

8

@

X

35

mm

bolt and washer assy.

-

-

1 lpcs.

8

q5

X

40

mm bolt and washer assy.

.

* * * *

-

-

1

pce.

Tightening torque

:

170-190 kg- cm

Attach the two clamps to

the

main bearing cover

for

electric start model.

5-4-*7

FLYWHEEL

AND

STARTING

PULLEY

(1)

Put

the woodruff key (for magneto) in place.

(2)

Wipe off oil and grease thoroughly

from

the tapered portion

of

the crankshaft and

flywheel center hole.

(3)

(

ELECTRIC

START

MODEL

)

'

Install the charge coil to the crankcase.

(4)

Install the flywheel to the crankshaft.

Tighten the flywheel nut with

a

spring

washer.

Tightening torque

:

600-650

kg-

cm

(5)

Attach the starting pulley to the flywheel.

6

@

x

12mm bolt and washer

assy.

-. . -.

3pcs.

'Tightening torque

:

70-90 kg-cm

-

33

-

Page 38

5-4-8

FUEL INJECTION PUMP

(1)

Measure the distance between the face

of

the cam base and the pump

mounting face of the crankcase.

(See

Fig.

54.)

Select the gasket (injection pump)

of

the proper thickness

so

as the distance

to be adjusted to

66

-+

0.05mm.

The gasket (injection pump) of three

different thickness are available.

(T

=

0.1

mm,

T

=

0.2

mm

and

T

=

0.3

mm)

(2)

Apply

sealant

(THREE BOND

1215)

to the both side

of

the gasket (injection

pump).

(3)

Install the fuel injection pump to the

crankcase checking the control rack

of the injection pump to engage with

the governor lever correctly.

(See Fig.

55.)

FIG.

54

/-

FIG.

55

,

-

34

-

Page 39

5-4-9

CYtlNDER

HEAD

(1)

Assemble the intake valve and exhaust

valve to the cylinder head.

a) Remove carbon deposits from valves,

valve seats, intake and exhaust

ports,

and valve guides.

b)

If

the valve face

is

worn out, replace

it

with

a

new one.

c) Check the stem seal in the intake valve

guide for

a

damage.

If the rip of the stem seal is injured,

replace

it

with a new one.

d) Insert the intake valve and the exhaust

valve into the valve guide.

e)

Assemble the valve springs, spring

retainers and the retainer locks.

(2)

Check the clearance between the piston

top and the. cylinder top.

(See Fig.

56.)

Select the proper SPACER (head)

so

as the clearance to be within

0.6-0.7

mm.

SPACER (head) of two different

thickness

(T

=

0.6

mm and

0.7

mm)

are

available. (See Fig.

56.)

(3)

Put the cylinder head on the cylinder.

(4)

Apply

sealant (THREE

BOND

1215) to

the two studs on the rocker shaft side.

Apply oil to the other two studs.

(See

Fig.

57.)

(5)

Tighten the four flange nuts evenly

in three steps by the following

tightening torque.

100 kg-cm

200

kg- cm

300-330 kg-

cm

1st step

.............

2.nd step..

...........

3rd step

.............

5-4-

10

ROCKER

ARMS

(1)

Insert the push rods into the tappets

in

FIG.

56

I

APPLY

THREE

BOND

1215.

FIG.

57

the crankcase.

(2)

Apply oil to the rocker arms and install them to the cylinder head using the rocker

shaft. Attach the snap rings to the both ends of the rocker shaft.

-

35

-

Page 40

5-

4-

11

VALVE CLEARANCE

ADJUSTMENT

(1)

Set the crankshaft to the top dead

center by matching the mark

"T"

of the

flywheel with the

"TOP"

mark of the

crankcase.

(2)

Loosen the lock nut on the rocker arm

and turn the adjusting

screw

to adjust

the clearance between the rocker arm

and valve stem end to

0.1

mm.

(both intake and exhaust)

Then, tighten the lock nut.

Adjust the valve clearance while 'the

engine

is

cold.

(3)

Turn the flywheel

by

hand and check

the valves move smoothly without

hitting piston.

FIG.

58

0

INTAKE, EXHAUST VALVE TIMING

The valve clearance shall increase to

0.4

mm while engine is running hot.

In

this condition, the valve timing

is

as

follows

:

Intake valve opens at 16" before TDC.

Intake valve closes at

54"

after BDC.

Exhaust valve opens at

54"

before

BDC.

Exhaust valve closes at

14"

after

TDC.

TDC (TOP DEAD CENTER)

INTAKE VALVE

16"

14"

EXHAUST VALVE

(4)

Apply

sealant

(THREE

BOND

1215)

to

the joining surface

of

the

rocker cover.

INTAKE VALVE

CLOSES.

BDC (BOTTOM DEAD CENTER)

(5)

Install the rocker cover and the gasket

(rocker cover) to the cylinder head.

FIG.

59

,

-

36

-

Page 41

5-

4-

12

FUEL

INJECTION NOZZLE

(1)

Insert the nozzle assembly into the

cylinder head attachi-ng the gasket

(nozzle) to the nozzle

tip.

(2)

Attach the fuel return pipe to the

injection nozzle.

(3)

Attach the BRACKET (nozzle

2)

and

BRACKET (nozzle

l),'

and tighten the

two nuts with spring washers

tentatively.

(4)

Attach the fuel injection pipe

to

the

injection nozzle and the injection pump.

Tighten the lock nuts tentatively.

(5)

Tighten the two nuts on the BRACKET

(nozzle

1).

Tightening torque

:

50-60

kg- em

(6)

Tighten the lock nuts

on

both ends

of the injection pipe.

I

SPRING

WASHER

FIG.

60

5-4-

13

CYLINDER BAFFLE

AND

BLOWER HOUSING

(I)

Attach the cylinder baffle to the cylinder.

(2)

Attach the blower housing to the crankcase.

Tighten the upper two bolts tentatively because these bolts shall be used for

mounting fuel tank afterwards.

5-4-

14

MUFFLER

(1)

Attach the muffler cover to the muffler.

(2)

Attach the muffler and the gasket (muffler) to the cylinder head.

Tighten the bolt and

nuts

tentatively.

5-4-15

FUEL TANK

(1)

Attach the fuel pipes to the fuel tank.

(2)

Install the fuel tank to the engine.

Tighten the bolts and nuts for joining the blower housing and the muffler to the

cylinder head at this step.

-

37

-

Page 42

5-4-16

FUEL

PIPES

(1) Attach the fuel filter to the blower housing.

(2)

Attach the fuel pipes between the fuel tank, fuel filter, injection pump and the

,r

injection

nozzle.

Clamp the each end of rubber pipes

using

the proper hose clamps.

5-4-

17

AIR CLEANER

(1)

Attach the cleaner

body

to the intake manifold.

(2)

Attach the elements to the cleaner body.

(3)

Attach the cleaner cover to the cleaner body.

5-

4-

18

RECOIL STARTER

Install the recoil starter to the blower housing.

6

4

X

10

mm

flange bolt

.

. .

. . .

. . . .

. .

. . . .

.

. . . .

.

4

pcs.

Do

not use the

bolt

longer than

10

mm or the flywheel fan may be damaged.

,”

5-

4-

19

OIL

FILTER

(1) Clean the oil filter

and

check if its mesh

is

not broken.

(2)

Insert the

oil

filter with the O-ring into

the

main

bearing cover.

Tighten the two flange bolts.

5-

4-

20

ENGINE

OIL

Fill the crankcase with

oil

to the upper level

of

the oil

gauge.

I

Be sure to use the diesel engine oil of proper

grade.

Neve use the gasoline engine oil or the engine

may

be seriously damaged.

-

38

-

Page 43

6.

GENERAL

DESCRIPTION

OF FUEL SYSTEM,

GOVERNOR

SYSTEM,

LUBRICAT ON. SYSTEM

AND

AUTOMATIC

DECOMPRESSION

6-

1

FUEL

As

DY23-2

and

DY27-2

are the high speed type diesel engine, be sure

to

use the fuel

of

good

quality automotive diesel fuel.

FUEL TANK

FUEL RETURN

FUEL

INJECTION

PIPE

NOZZLE

W

U

3

m

q-ju

UU%

TIL&

w

a

a

m

m

FUEL INJECTION

PUMP

U

w

3

U

FUEL

SYSTEM

CHECK

VALVE

e

fl

I

FUEL PIPE

I

FUEL FILTER

RUBBER

PIPE

1

FW

EL

PIPE

*

FILTER

-b

TANK

FUEL

FUEL

FUEL

NOZZLE PIPE

PUMP

INJECTION

-b

PRESSURE

-b

INJECTION

-F

FUEL

HIGH

4

L

FUEL RETURN PIPE

4

COMBUSTION

CHAMBER

FIG.

61

-

39

-

Page 44

6-2

FUEL

0

FUEL INJECTION PUMP MECHANISM

It

is

not too much to say that the fuel injection pump

and

it

6

- 2 -

1

INJECTION

PUMP

is

the heart of the diesel engine,

must be precise enough to satisfy the following functions.

FUNCTION

Injecting fuel, starting with high pressure and ending with low pressure.

of

Injecting the predetermined amount

fuel accurately at each stroke.

Injecting fuel at specified time within a specified time interval.

Quantity being injected is closely varied by the governor to suit to varying load.

This engine has no automatic advancing device, but in starting (max. delivery), the

injection timing is to be delayed.

6-2-

2

THEORY

OF

THE INJECTION PUMP

MECHANISM

The plunger of the injection pump is pushed up by the cam of the camshaft, and it

is

pushed down by the plunger spring.

and forced supply

(1

)

SUCTION

OF

of

FUEL

fuel are conducted. (See Fig.

Through the filter in the fuel tank, fuel

of

port

the plunger barrel. When the top of the cam lobe passed the tappet

By

this up and down motion in a stroke, suction

62.)

is

supplied and

is

in full around the intake

and

function ended, plunger spring pushes down the plunger. When the plunger is pushed

down passing the fuel intake, fuel is sucked into the barrel, and suction

until arrival

of

the plunger at the. bottom

of

its

stroke. This is on the stage of

is

continued

“suction.”

(2)

FORCED

The camshaft rotates and pushes up the plunger. Forced supply

only when the upper part

pushed up by the cam rotation. The fuel in the barrel

force

valve and the damping valve, andq then

This

SUPPLY

(100

kg/cm2 and up), and as a result, the force of the fuel pushes up the delivery

is

on the stage of “pressurized supply.”

OF

FUEL

of

the plunger closed the fuel intake

is

it

injects the fuel into combustion chamber.

of

the fuel

in

the course of being

pressurized by a very strong

is

cam

I

started

VERTICAL

SUCTION PORT

(DELIVELY

HOLE

PORT)

DAMPING

DELIVERY

PLUNGER

PLUNGER

LEAD

VALVE

VALVE

BARREL

FIG.

-

40

EFFECTIVE STROKE

62

-

Page 45

6-2-3

VARIATION IN QUANTITY

OF

FUEL

TO

BE

INJECTED

The quantity of fuel injected varies according to the condition of the engine,

i.

e. high

speed

or

low speed operation and loaded

or

unloaded operation.

(See

Figs.

63

and

64.)

The plunger lead is engraved

on

the surface

of

plunger in an inclined curve.

By

rotating

the plunger, the distance between the upper part

of

the plunger and the suction port

is

varied. (Variation in effective stroke)

Rotation

of

the

plunger is made

by

the control rack. When this control rack

is

shifted

to

left and/or right, the geared pinion rotates, which is connected to the plunger

by

means

of

the control sleeve.

In

other words, the plunger turns as much amount as the

rack rotates. Accordingly, the effective stroke varies coincident with the position where

the rack

is

set.

(1

1

RELATION BETWEEN THE PLUNGER

AND

THE BARREL

SUCT

PLUNGER BARREL

'ION

/

DELIVERY

PORT

LEAD

PLUNGER

INJECTION INJECTION INJECTION INJECTION

STARTS. ENDS. STARTS

,

ENDS.

MAX.

DELIVERY HALF DELIVERY

NO

DELIVERY

FIG.

63

(2)

RELATION BETWEEN THE PLUNGER AND THE

RACK

NTROL SLEEVE

MAX. DELIVERY

HALF DELIVERY

FIG.

64

NO DELIVERY

-

41

-

Page 46

6-

2-4

INJECTION

STARTlNG

TIMING

AND EFFECTIVE

When the plunger closes suction port

the barrel, forced delivery

But fuel

is

not injected from the nozzle

at once because of contraction

of

fuel starts.

of

fuel, etc.

Injection timing of this engine is fixed

constant

(23"

before

TDC)

irrespective

engine rpm. On the other hand, in starting,

a proper delay from the timing for high

speed running and increased fuel injection

is

indispensable for effective starting.

For

this

plunger head, which reserves

injection timing by nearly

starting. (See Fig.

purpose a notch

65.)

is

made at the

to

delay the

8"

to facilitate

of

of

FIG.

65

6-

2-5

FUNCTION OF THE DELIVERY VALVE

By

the plunger stroke, fuel pressure is raised. And when it becomes higher than the

pressure remained in the high pressure pipe, the delivery valve spring is pushed down

and the valve opens.

When the plunger lead meets suction port

and the delivery valve is closed by the spring tension

valve prevents reverse flow of the fuel. Also suction back motion around the upper

of

the plunger sucks back the fuel in the equal amount of the stroke

As

the result, the fuel in the high pressure pipe

of

the plunger barrel, delivery

of

the valve.

is

delivered forcibly.

of

fuel ends,

At

this time, delivery

[A]

and decreases

part

remaining pressure in the high pressure pipe. The nozzle jets the fuel clearly off and

prevents after dripping. (See Fig.

66.)

DELIVERY

DELIVERY

VALVE

VALVE

SPRING

,-

FIG.

-

42

66

-

BACK

STROKE

Page 47

6-2-6

FUNCTION

OF

THE DAMPING

VALVE

The damping valve

is

assembled in the

end

of

injection pum-p and

it

reaches the

seat before arrival

of

delivery valve at

the seat. The small orifice in the valve

is the passage

of

fuel to the chamber

in the delivery valve holder. Accordingly,

descending velocity

of

the delivery valve

is decreased, which prevents the negative

pressure being produced suddenly.

As

a result, proper injection

is

conducted

and the engine noise is decreased.

(See Fig.

67.)

DAMPING

VALVE

DELIVERY

VALVE

FIG.

67

FUEL

INJECTION PUMP

PUMP

DELIVERY VALVE DAMPING VALVE

HOLDER

HOUSIN

DAMPING VALVE

DELIVERY VALVE

DELIVERY VALVE

PLUNGER ASSEMBLY

CONTROL RACK

CONTROL SLEEVE

SPRING SEAT

PLUNGER SPRING

SPRING SEAT

PIN TAPPET

FIG.

68

0

SPECIFICATIONS

OF

FUEL INJECTION PUMP FOR THIS DIESEL

ENGINE

Model

Right

hand

twist Lead

6

mm

Lift

5.5

mm

Plunger diameter

ZEXEL

Maker

PFRIMD55/ 2NP1

I

Plunger spring arbitrary~

I

2.21

kg/rnm

I

~~ ~ ~

Delivery valve opening pressure

1.1 kg/mm

Delivery valve spring constant

Approx

1

5

kg/ cm*

~~ ~~ ~~~~ ~~~ ~

I

Rack stroke

I

10mm

I

-

43

-

Page 48

6-3

6-

3-

FUEL

1

INJECTION

SPECIFICATfONS

NOZZLE

I

Part Name

Type

No.

Valve opening pressure

Spring constant

No.

of

nozzle hole

(Diameter)

NOZZLE ASSEMBLY

DLLA150PN52

4

(0.22

mm)

195

kg/

ern'

13.2

kg/ mm

I

6-

3-

2

FEATURES

Both the injection nozzle and the injection pump are very important

fuel mist

the other

combustion. There are two types

is

pintle type.

of

injection nozzle, one is hole type

for

The injection nozzle for DY23 and DY27 Diesel engines is developed as a result of joint

research and development project by Diesel Kiki and our company, and it

combustion system, having the special hole type nozzle.

For producing better air-fuel mixture,

fuel mist most effectively, injection pressure

it

utilizes

is

swirl

raised

and squish

up

to 195 kg/cm2.

parts

flows

for producing

and

is

direct

and deliver the

/-

6-3-3 STRUCTURE

NOZZLE

OF

THE INJECTION

ASSEMBLY

The injection nozzle assembly consists

of nozzle holder and nozzle. The nozzle

holder fixes the nozzle to the cylinder

head and at the same time it plays the

role of fuel passage to the nozzle.

The nozzle consists

of

the nozzle body

and needle valve.

When the fuel pressure reaches up to the

valve opening pressure, the needle valve

is

raised up and the fuel

through the small holes at the

is

tip

injected

of the

nozzle body.

.The valve opening pressure is adjustable

by changing the adjusting washers.

IDENTIFICATION

NOZZLE

VALVE CLOSED VALVE OPENED

MARK

SPRING

ADJUSTING WASHER

FIG.

69

NOZZLE

BODY

FIG.

70

-

44

-

Page 49

6-3-4

FUEL

PASSAGE

From the plunger pump fuel is sent

through the high pressure pipe

1

to the

fuel passage

2.

Then, at the nozzle body

3,

it is pressurized up till

195

kg/c

m’

and

it

lifts up the needle valve 4 for

0.18

mm,

and is injected into the combustion

chamber via the jet hole

5.

An excess fuel which lubricated the inside

of the nozzle and nozzle holder returns

to the fuel tank via the needle valve-,

nozzle spring

6

-overflow pipe

7

+-fuel

tank. (See Fig.

7

1

.>

a

7

3

4

5

FIG.

71

6-

3-

5

INSPECTION

AND

MAINTENANCE

Fuel injecting condition of the nozzle and the valve opening pressure are quite influential

to the engine operation, insufficient output, increase

of

noise and exhaust smoke. Use of

improper fuel

or

contaminated fuel is one of the main causes of the nozzle trouble.

Therefore, exert good care for using good fuel.

As

the nozzle is assembled from very

precisely finished parts, utmost care and attention must

be

paid when inspecting and

checking.

(1

)

INSPECTION

After cleaning nozzle holder outside, inspect

in the following steps

:

a) Visual inspection

Whether

or

not injection hole

is

damaged, or clogged with carbon.

Whether

or

not injection hole is clogged

with dust and carbon.

b) Checking by nozzle tester

Fit the nozzle assy to the nozzle tester.

When removing

the

nozzle

~~QPVI

the

engine

or

fitting, it to tester, be sure

to

.keep

the

nozzle

free

of

dust.

FIG.

72

Move the lever

of

the nozzle tester up

and down for

2-3

times and

suck

the

air inside the nozzle.

Newer bring

your

face

near

the injected

fuel mist

from

the

nozzle.

Also

keep

away

your

hands

from the mist.

-

45

-

Page 50

@Gently push down the lever

of

the nozzle

tester and read the pressure gauge just

before the fuel being injected. If the

figure coincides with the standard

value, the nozzle

in a

good

condition.

is

@Push further and check whether or not

the fuel mist

Good

Just after injection, check “after

dripping.”

(2)

If

the test results are found not good (poor

injection

MAINTENANCE

is

injected straight.

is

straight forward.

injection and “after dripping”), carefully

check and repair in the following

procedure

:

NOZZLE

FIG.

73

a) Disassemble the nozzle holder and nozzle,

and wash in clean light oil.

a

When washing, use

(for instance, wooden toothpick

wooden chip

is

serviceable.) for peeling off the carbon

adhered to the nozzle.

b)

After washing, pull out the needle

halfway

your fingers and then let it

check

dead weight.

c)

If

it

from

if

the needle

the body of nozzle with

does not sink, replace

sinks

by

it

go.

its

in

And

own

the

FIG.

74

form of a set.

d) Frinction surfaces of both the needle and

nozzle body are ultra precise finish.

sure to keep the parts free of dust.

e>

If

“after dripping“

In

such a case, it

body. However, it

is

is

advisable

is

possible

found,

it

is

poor

to

replace

to

coat chrome oxide

contact between the needle valve

it

in the form of a set, needle valve and nozzle

on

the tapered surface of the needle

and get a good contact. Wash very carefully after correction.

f>

The spacer

body. Pay attention

g)

When fitting the nozzle body to the nozzle holder, conform

is

an important part to set positions of the nozzle holder

to

the position of the pin.

to

the specified tightening

toruqe.

Tightening torque

h)

Recheck with the nozzle tester. If the adjustment of valve opening pressure

necessary, adjust it to

The valve opening pressure shall decrease to

:

300-400

200-210

kg-

kg/c

cm

m‘.

195

kg/c

mz

after the running in.

NEEDLE

.

BODY

and

and

So,

be

the seat.

the nozzle

is

,

-

46

-

Page 51

6-4

GOVERNOR MECHANISM

AND

OPERATION

6

-

4-

I

MECHANISM

The governor

is

centrifugal flyweight type, which means

a

flyweight is fitted to

the

governor

gear.

The governor sleeve is assembled

so

that it may slide toward the direction

of

the axis of the pump shaft, and it

is

in

contact with the flyweight. The governor

sleeve gets in touch with the governor yoke, and through the governor lever it makes

the

control

rack of injection pump operate. This mechanism enables to maintain constant

operation irrespective

of

load variation.

\

SMOKE

SET

SMOKE

SET

SPRING

Operation when load

is

applied

or

starting.

+

Operation when load is decreased

or

removed.

4

FIG.

75

-

47

-

Page 52

6-

4-

2

OPERATION

1.

STARTING

When the speed control lever is set to the high speed (start) position, the governor

lever is pulled by the governor spring through the control link. The control link

compress the smoke set spring at the same time to allow the injection pump to deliver

extra fuel for starting.

2.

OPERATION

UNDER

LOAD

When the engine starts up, the flyweights expand by the centrifugal force pushing

the governor sleeve. The governor lever pushed by the governor sleeve moves

to

the control rack of the fuel injection pump in the direction of reducing fuel.

Thus, the engine speed rises up to the predetermined level, and maintains this speed

where the centrifugal force balances with the tension of the governor spring.

When a load is applied to the engine, the engine reduces

At

this moment, as the centrifugal force

at

the flyweights is weakened, the governor

its

speed

for

a moment.

lever being pulled by the governor spring moves to push the control rack of the fuel

injection pump in the direction of increasing fuel. Thus, the engine recovers its speed

or

to the predetermined level. When the load is reduced

removed, the governor’ system

operates exactly in reverse to maintain the engine speed.

When the engine is over-loaded, the control link touches the smoke set. However, the

tension of the governor spring is weaker than the combined force of the centrifugal

force

of

the flyweights and the smoke set spring, the governor iever can not move

further to increase fuel. Under this condition, the engine speed is reduced and the

engine exhausts black smoke.

3.

STOPPING

By

pushing the stop lever, the governor lever pushes the control rack

pump all the way

to

“fuel shut off” position to

stop

the engine.

of

the injection

/-

push

/-

6-5

Forced lubrication system is adopted to

pump

LUBRICATION

is

mounted on the .main bearing cover co- axialy with the governor gear and is

SYSTEM

AND

OIL

PUMP

DY23

and

DY27

engines. The trochoid type oil

driven by the cam gear.

The

oil

in the oil pan

is

filtered by the oil filter and is forcibly delivered by the oil

pump to the crank jounal and then to the crank pin lubricating the main bearing and

the large end bearing.

The oil splashes from the crank journal and the crank pin

to

lubricate cylinder wall,

piston, small end, cam shaft and the governor system. The rocker arms, valve system

etc. inside of the rocker chamber are lubricated by the oil mist contained in the blow

-by gas supplied from crankcase.

The blow- by gas enters into the combustion chamber through the breather valve, and

the

oil

contained in the blow-

by

gas

is

finally burnt out.

-

48

-

Page 53

FORCED LUBRICATION

BY

OIL

PUMP

*

LUBRICATION

BY

SPLASH

111,

1

LUBRICATION

SYSTEM

FIG. 76

0

OIL FILTER

Oil

filter

is

made

of

nylon mesh

and

is

reusable after cleaning.

As

the oil flows from the inside

of

the filter

to

the outside, be sure to clean the inside

thoroughly.

Clean the oil filter every time

of

oil

change.

-

49

-

Page 54

6-

6

AUTOMATIC DECOMPRESSION

The decompression system operates to release compression by lifting up the exhaust

valve at starting.

The release lever mounted on the camshaft has a flyweight at one end and a crescent

cam

exhaust

The exhaust tappet rides

compression.

at

the other end. When starting the engine, the crescent cam juts out from the

.

cam.

over

the crescent cam opening the exhaust valve to release

SYSTEM

,”

TAPPET

FLYWEIGHT

CRESCENT

EXHAUST

When the crank

moves outward by the centrifugal force turning the release lever to retract the crescent

cam. Thus the exhaust valve closes allowing a sufficient compression for the engine to

start up.

CAM

CAM

speed

reaches

EXHAUST CAM

FIG.

a

certain revolution, the flyweight

2LtL

/

77

l/

of

RELEASE LEVER

SNAP RING

CAMSHAFT

the release lever

,--

‘FLYWEIGHT

FIG.

78

The components

engines, however the principle of operation is the same.

of

the decompression system are different by

“D”

LEASE LEVER

type and

SNAP RING

CAMSHAFT

“B”

type

/

-

50

-

Page 55

7.

STARTING

SYSTEM

-

7-

1

RECOIL

STARTER

I

The recoil starter hardly has a trouble in the normal use, .however, in case it has a

trouble

or

at the time

of

lubrication, perform disassembly and reassembly in the

following procedures

:

Tools to be used

:

Box

spanner (spanner), Cutting pliers (pliers) and Screw driver

The following explanation is applicable to the recoil starter for

“D”

type

engines.

For

“B”

type models, reverse the direction

of

rotation to achieve proper service

work.

7-1

-

1

HOW

TO

DISASSEMBLE

(D

Type)

(1)

Remove the recoil starter

from

the

engine with a

box

spanner.

(2)

Pull the starting knob and pull out

the starter rope

for

30

to

40

cm. Firmly

press the reel with a thumb as shown

in Fig.

79

so

that the reel should not

make reverse turn at the place where

the reel notch comes to the outlet

of

starter rope. Pull out the starter rope

to the inside of recoil starter with

a screwdriver.

Then, utilize the reel notch, and rewind

it until the rotation stops in the

arrowhead direction, braking the reel

rotation with a thumb.

(3)

When removing, take out the parts

in the order

of

the numbering in Fig.

80.

1.

“U”

type snap ring

2.

Thrust washer

3.

Friction spring cover

4.

Return spring

5.

Friction spring

6.

Ratchet

Meantime,

for

removing the

“U”

type

snap ring, nip the shaft with cutting

pliers and push

it

out.

STARTER

ROPE

/q

STARTER

NKOB

FIG.

79

2

FIG.

80

-

51

-

Page 56

(4)

Take out the reel from starter case

as shown in Fig.

81.

REEL

In this case, slowly take out it turning

the reel lightly toward left and right

so

that the spring is removed from

the reel hook section.

If the

reel

is suddenly taken out, there

is a fear that the spring jumps out

in the

form

as

it

is

hooked, which

is

very dangerous,

so

be careful1 of it. (If

the spring jumped out, house it in the

starter case as instructed in Fig.

86.)

Finally, release and take out the starter

rope tied to both the reel side and

the starting knob side.

STARTER CASE SPRING

FIG.

81