Page 1

PILOT’S OPERATING HANDBOOK

SUPPLEMENT

DR400/135CDI

Document n° 1001639GB

Page 2

Page 3

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Pilot´s Operating Handbook

Supplement

for the

DR400/120D

DR400/140B

DR400/180R

DR400/200R

DR400/RP

Equipped with TAE 125 Installation

TYPE ................................ DR 400

MODEL No. ......................

SERIAL No. ......................

REGISTER No. ................

This supplement must be attached to the EASA approved Pilot´s

Operating Handbook of the DR400/120D, DR400/140B, DR400/180R,

DR400/200R or DR400/RP when the TAE 125-01 or TAE 125-02-99

installation has been installed in accordance with EASA.A.S.01380 or

EASA STC 10014219.

The information contained in this supplement supersedes or adds to the

information published in the EASA approved Pilot´s Operating Handbook

only as set forth herein.

For limitations, procedures, performance and loading information not

contained in this supplement, consult the EASA approved Pilot´s

Operating Handbook.

This supplement Pilot‘s Operating Handbook is approved with EASA

STC 10014219.

Doc.Nr.: 1001639GB

Issue 3 – July 2014 Page i

Page 4

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Page - ii Issue 3 - July 2014

Page 5

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

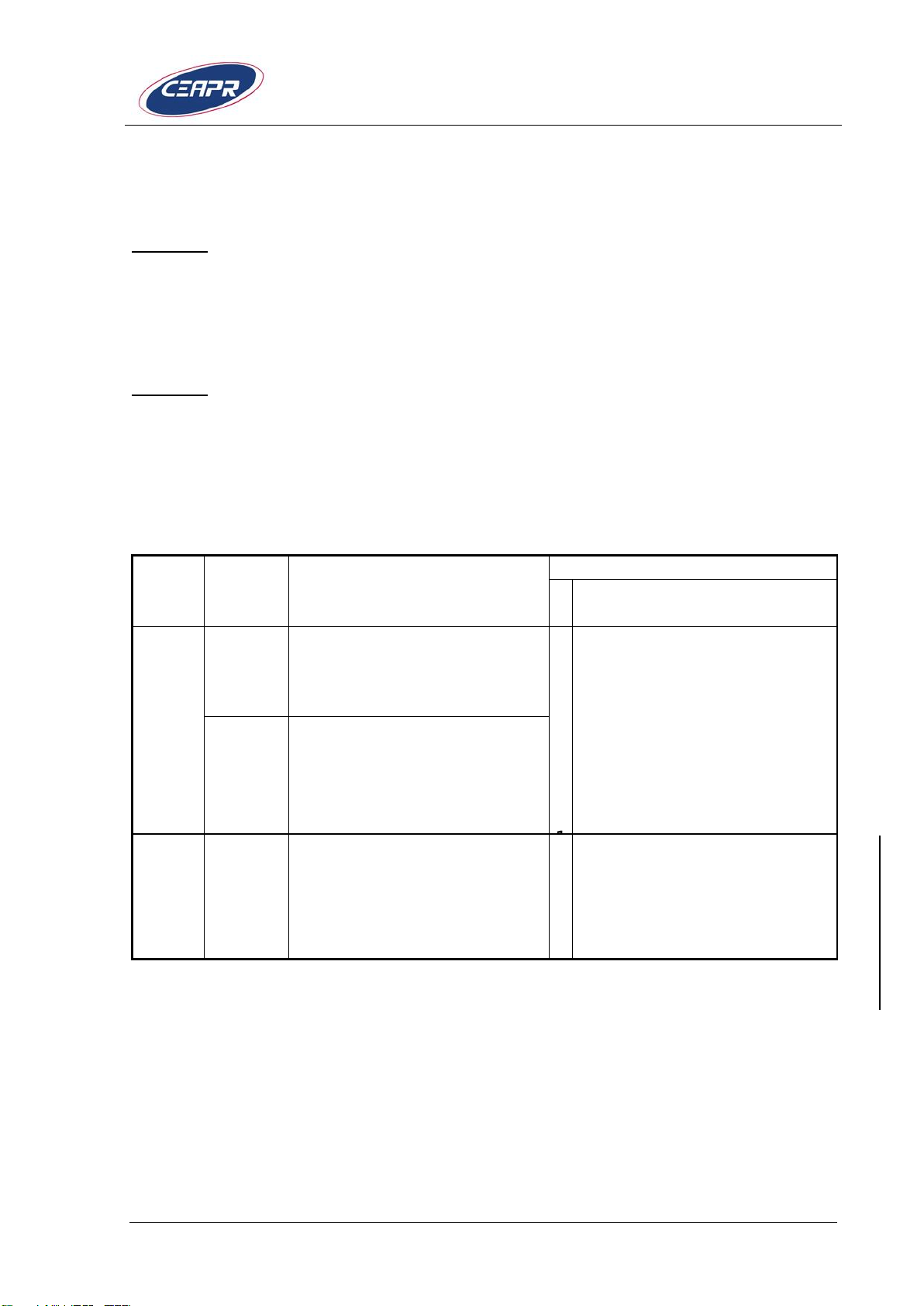

Issue/

Rev.

Section

Description

Approval

D

at

Endorsed

2/1

2

New fuel,

new gearbox oil

M

ar

c

h

1

6

2

0

Revision No. 1 to AFM

supplement ref 60-0310-

60022 is approved under

the authority of DOA ref.

EASA.21J.010.

Date: March 16 ,2012

Office of Airworthiness

4

Procedures updated

3/0

all

Change of TC holder

Initial issue C.E.A.P.R

Numbering of CEAPR

documents

J

ul

y

2

0

EASA STC 10014219

transfer

APPROVAL

Issue 2:

The content of approved sections is approved by EASA. All other content

is approved by TAE under the authority of EASA DOA No.

EASA.21J.010 in accordance with Part 21.

Issue 3:

The content of approved sections is approved by EASA, transfer of STC

10014219. C.E.A.P.R is TC holder.

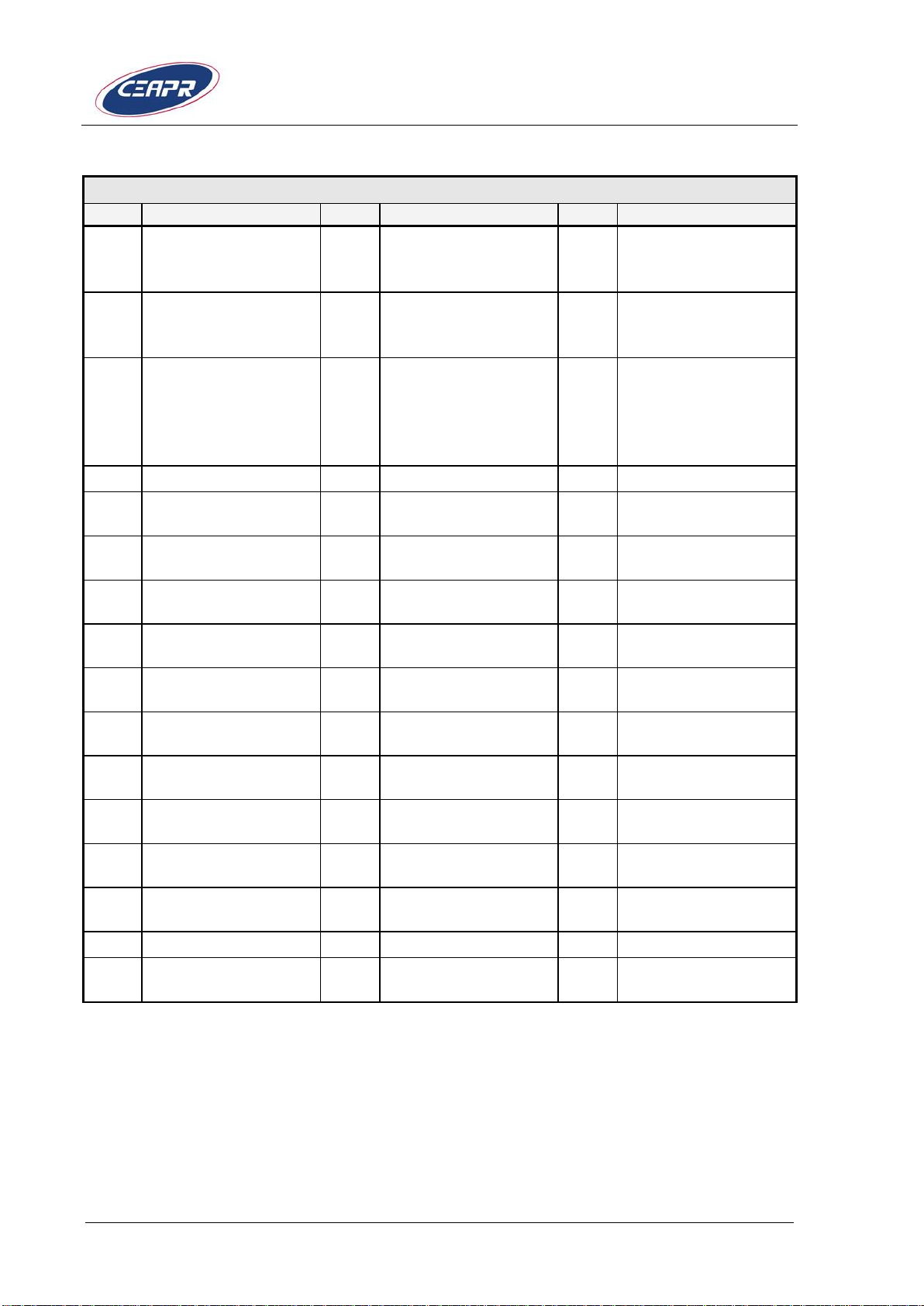

LOG OF REVISIONS

The parts of the text which changed are marked with a vertical line on

the margin of the page.

Issue 3 – July 2014 Page iii

Page 6

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

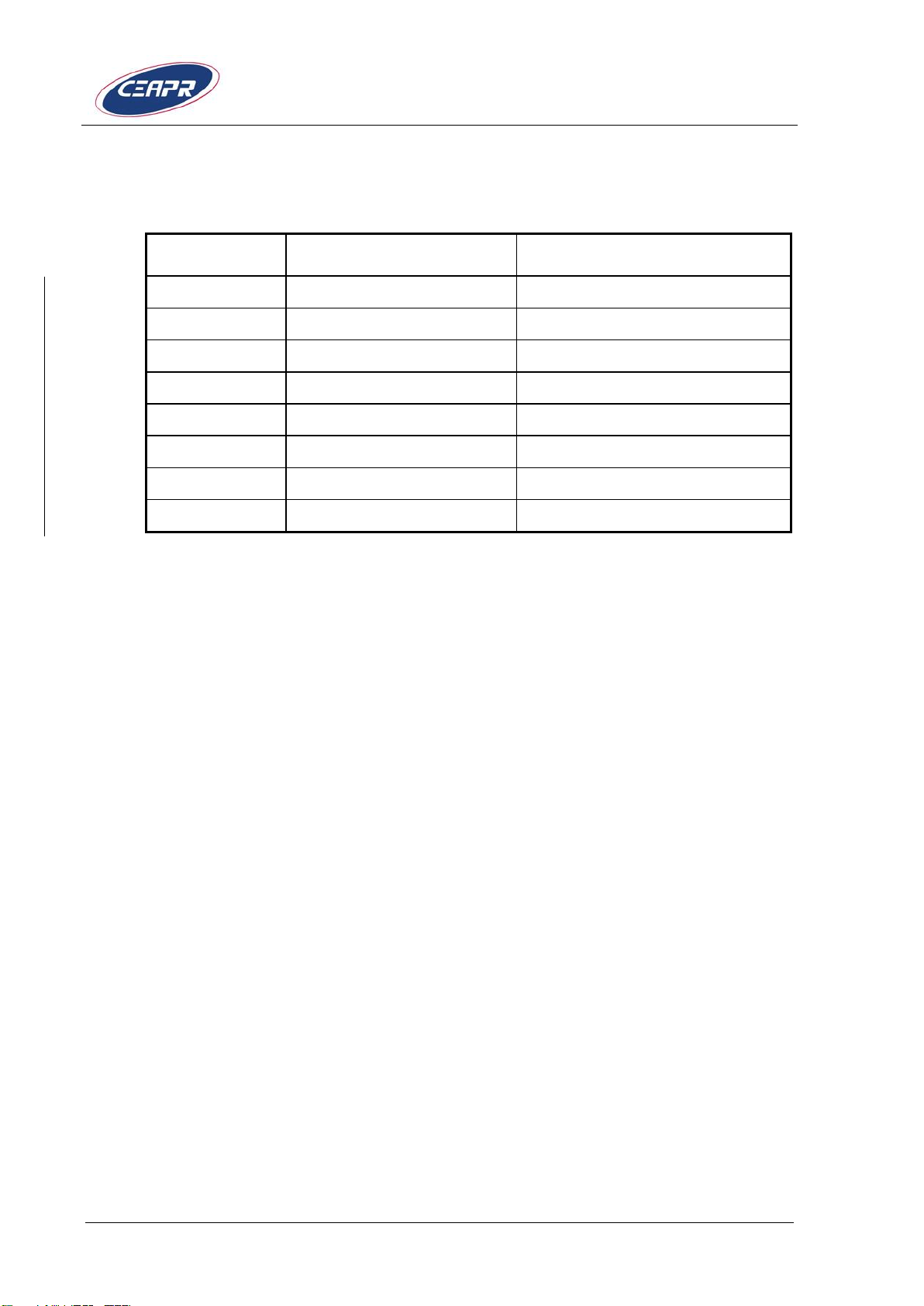

Section

Issue/ Revision

Date

0

3/0

July 2014

1

3/0

July 2014

2

3/0

July 2014

3

3/0

July 2014

4

3/0

July 2014

5

3/0

July 2014

6

3/0

July 2014

7

3/0

July 2014

LIST OF EFFECTIVE SECTIONS

Page - iv Issue 3 - July 2014

Page 7

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

TABLE OF CONTENTS

APPROVAL .............................................................................................. iii

LOG OF REVISIONS ............................................................................... iii

LIST OF EFFECTIVE SECTIONS ........................................................... iii

ABBREVIATIONS .................................................................................... xi

SECTION 0

GENERAL

CONVENTIONS IN THIS HANDBOOK ................................................. 0-1

FOR DR400 AIRCRAFT FROM SERIAL NUMBER 2500 AND UP ...... 0-1

UPDATE AND REVISION OF THE MANUAL ....................................... 0-1

SECTION 1

DESCRIPTION

OVERALL DIMENSIONS ...................................................................... 1-1

ENGINE ................................................................................................. 1-1

PROPELLER.......................................................................................... 1-2

NOISE LIMITATION ............................................................................... 1-2

ELECTRICAL SYSTEM ......................................................................... 1-3

FADEC-RESET ...................................................................................... 1-6

FUELS, OILS and LIQUIDS ................................................................... 1-6

ENGINE OIL........................................................................................... 1-7

FUEL SYSTEM ...................................................................................... 1-7

OPTIONAL EXTENDED RANGE TANK ............................................... 1-8

INSTRUMENT PANEL.........................................................................1-11

HEATING AND VENTILATION ............................................................1-20

Issue 3 – July 2014 Page v

Page 8

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

SECTION 2

LIMITATIONS

APPROVED OPERATION .................................................................... 2-1

MAXIMUM ALTITUDE........................................................................... 2-1

FLIGHT LOAD FACTOR LIMITS AT MAXIMUM WEIGHT .................. 2-2

MAXIMUM AUTHORIZED WEIGHTS .................................................. 2-2

WEIGHT AND BALANCE ..................................................................... 2-2

LOAD PLANNING ................................................................................. 2-3

ENGINE OPERATING LIMITS .............................................................. 2-3

ENGINE INSTRUMENT MARKINGS ................................................... 2-6

GROUNDING (EARTHING) BEFORE AND DURING FUELING ......... 2-6

PERMISSIBLE FUEL GRADES ............................................................ 2-7

MAXIMUM FUEL QUANTITIES ............................................................ 2-7

PERMISSIBLE OIL GRADES ............................................................... 2-7

PERMISSIBLE COOLING LIQUID ....................................................... 2-8

LOAD LIMITS ........................................................................................ 2-8

OPERATIONAL LIMITATIONS IN THE “U” CATEGORY .................... 2-8

PLACARDS ........................................................................................... 2-9

Page - vi Issue 3 - July 2014

Page 9

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

SECTION 3

EMERGENCY PROCEDURES

ENGINE FAILURE OR LOSS OF POWER ........................................... 3-2

During takeoff roll ................................................................................... 3-2

Immediately after takeoff ....................................................................... 3-2

During flight ............................................................................................ 3-3

LANDING WITHOUT ENGINE POWER ............................................... 3-4

Restart after engine failure .................................................................... 3-5

FADEC malfunction in flight ................................................................... 3-6

ENGINE SHUT-DOWN IN FLIGHT ....................................................... 3-8

FIRE ....................................................................................................... 3-9

Engine fire on the ground, during starting ............................................. 3-9

Engine fire in flight ................................................................................ 3-9

Electrical fire ........................................................................................3-10

ROUGH ENGINE OPERATION ..........................................................3-11

Oil pressure too low .............................................................................3-11

Oil temperature too high ......................................................................3-12

Coolant temperature too high ..............................................................3-12

“Cool level” light illuminates .................................................................3-13

Gearbox temperature too high .............................................................3-13

Fuel temperature too low .....................................................................3-13

Propeller RPM too high ........................................................................3-14

Fluctuations in propeller RPM ..............................................................3-14

ICING ...................................................................................................3-14

ELECTRICAL POWER SUPPLY MALFUNCTION .............................3-16

If the “ALT” light is lit or the ammeter shows battery discharge during

normal engine operation for more than 5 minutes ...............................3-17

INADVERTENT SPIN ..........................................................................3-18

LOSS OF ELEVATOR CONTROL ......................................................3-18

Issue 3 – July 2014 Page vii

Page 10

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

SECTION 4

NORMAL PROCEDURES

NORMAL OPERATING SPEEDS ......................................................... 4-1

Best rate of climb speed ........................................................................ 4-1

Maximum operating speed in turbulent air ............................................ 4-1

Never Exceed speed ............................................................................. 4-1

Maximum speed .................................................................................... 4-1

Landing speed, final approach .............................................................. 4-1

PRE-FLIGHT INSPECTION .................................................................. 4-2

CABIN INTERIOR CHECK BEFORE START-UP ................................ 4-5

STARTING THE ENGINE ..................................................................... 4-6

AFTER ENGINE START ....................................................................... 4-7

FADEC BACKUP BATTERY TEST ...................................................... 4-7

WARM UP ............................................................................................. 4-8

TAXIING ................................................................................................ 4-8

BEFORE TAKEOFF .............................................................................. 4-8

TAKEOFF ............................................................................................ 4-11

Short takeoff ....................................................................................... 4-11

Crosswind takeoff ................................................................................ 4-11

CLIMB .................................................................................................. 4-12

Normal climb (flaps up) ....................................................................... 4-12

CRUISE ............................................................................................... 4-12

DESCENT ........................................................................................... 4-13

Approach or downwind ........................................................................ 4-13

Final ..................................................................................................... 4-13

LANDING ............................................................................................. 4-14

Short landing ....................................................................................... 4-14

Overshoot procedure........................................................................... 4-14

AFTER LANDING ................................................................................ 4-14

ENGINE SHUT-DOWN ....................................................................... 4-14

After the engine stops ......................................................................... 4-14

PARKING BRAKE USE ...................................................................... 4-15

Brake on .............................................................................................. 4-15

Brake off .............................................................................................. 4-15

Page - viii Issue 3 – July 2014

Page 11

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

SECTION 5

PERFORMANCE

AIRSPEED INSTALLATION CALIBARTION ......................................... 5-1

STALL SPEEDS .................................................................................... 5-1

TAKEOFF PERFORMANCE ................................................................. 5-2

Takeoff distance, 1100 kg ...................................................................... 5-3

Takeoff distance, 1000 kg ...................................................................... 5-4

CLIMB PERFORMANCE ....................................................................... 5-5

Climb speeds ......................................................................................... 5-5

Rate of climb, Flaps retracted, 1100 kg ................................................. 5-6

Rate of climb, Flaps retracted, 1000 kg ................................................. 5-7

Time, fuel and distance to climb, Flaps retracted, 1100kg .................... 5-8

Time, fuel and distance to climb, Flaps retracted, 1000kg .................... 5-9

Maximum angle of climb in takeoff position .........................................5-10

Glide performance ...............................................................................5-10

CRUISE PERFORMANCE ..................................................................5-11

At maximum take-off weight, 1100 kg .................................................5-12

At take-off weight 980 kg .....................................................................5-15

LANDING PERFORMANCE ................................................................5-18

SECTION 6

WEIGHT AND BALANCE

USE OF WEIGHT AND BALANCE DIAGRAM ..................................... 6-3

Example of loading problem (dashed line on the diagram) ................... 6-3

SECTION 7

SUPPLEMENTS

No supplements

Issue 3 – July 2014 Page ix

Page 12

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Page -x Issue 3 - July 2014

Page 13

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

ABBREVIATIONS

TAE Thielert Aircraft Engines GmbH, developing and

manufacturing company of the Centurion 2.0 S engine, (since

July 2013, Technify Motors GmbH).

FADEC Full Authority Digital Engine Control

CED 125 Compact Engine Display. Multifunctional instrument for

indication of engine data of the TAE 125-01 and TAE 125-02-

99 engine.

Issue 3 – July 2014 Page xi

Page 14

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Page -xii Issue 3 – July 2014

Page 15

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

SECTION 0

GENERAL

CONVENTION IN THIS HANDBOOK

This manual contains the following convention and warnings. They

should be strictly followed to rule out personal injury, property damage,

and impairment to the aircraft´s operating safety or damage to it as a

result of improper functioning.

▲ WARNING: Non-compliance with these safety rules could lead to

injury or even death.

CAUTION: Non-compliance with these special notes

and safety measures could cause damage to the engine

or to the other components.

Note: Information added for a better understanding of an

instruction.

FOR DR400 AIRCRAFT FROM SERIAL NUMBER 2500 AND UP

This supplement is valid if the TAE 125-01 or TAE 125-02-99 aircraft

engine is installed.

UPDATE AND REVISION OF THE MANUAL

▲ WARNING: A safe operation is only assured with an up to date POH

supplement.

Note: The document number of this POH supplement is

published on the cover sheet of this supplement.

Issue 3 – July 2014 Page 0 - 1

Page 16

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Page 0 - 2 Issue 3 – July 2014

Page 17

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

SECTION 1

DESCRIPTION

OVERALL DIMENSIONS

Wing span ................................................................ (28 ft 7.3 in) 8.72 m

Overall length ...............................................................(23 ft 8 in) 7.20 m

Overall height ........................................................... (7 ft 3.79 in) 2.23 m

Propeller ground clearance ............................................... (9.5 in) 0.26 m

ENGINE

Engine manufacturer ........................................... Technify Motors GmbH

Engine models ........................................ TAE 125-01 or TAE 125-02-99

The TAE 125-02-99 is the successor of the TAE 125-01. Both engine

variants have the same power output and the same propeller speeds but

different displacement. While the TAE 125-01 has 1689 ccm, the TAE

125-02-99 has 1991 ccm.

Both engine variants are liquid cooled in-line four-stroke 4-cylinder

engines with DOHC (double overhead camshaft) and are direct Diesel

injection engines with common-rail technology and turbocharging. Both

engine variants are controlled by a FADEC system. The propeller is

driven by a built-in gearbox (i = 1.69) with mechanical vibration damping

and overload release. The engine variants have an electrical self-starter

and an alternator.

▲ WARNING: The engine requires an electrical power source for

operation. If the main battery and alternator fail

simultaneously, the engine will operate for a very limited

time on FADEC backup battery power (TAE 125-02-99

installation).

Therefore, it is important to pay attention to indications of

alternator failure.

Issue 3 – July 2014 Page 1 - 1

Page 18

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Due to the specific characteristic of the TAE 125 engine, all of the

information from the original DR400 flight manual recognized by EASA

are no longer valid with the reference to:

carburetor and carburetor pre-heating,

ignition magnetos and spark plugs, and

mixture control and priming system.

PROPELLER

Manufacturer ....................................... MT Propeller Entwicklung GmbH

Model ........................................................................... MTV-6-A/187-129

Number of blades ................................................................................... 3

Diameter ......................................................................................... 1.87m

Type ................................................................................ Constant Speed

NOISE LIMITATION

In compliance with the regulation ICAO, annex 16, Volume I, Part II,

Chapter X, the maximum acceptable noise level for the DR400/120D,

DR400/140B, DR400/180R, DR400/200R, DR400/RP at a certified max.

take-off weight of 980 kg (2161 lb) is 78.4 dB(A).

For the TAE 125-01 installation:

The noise level determined under the conditions of the abovementioned

regulation, with the MT Propeller MTV-6-A/187-129 propeller together

with "Akrapovic type for TAE 125" muffler, is 70.9 dB(A).

The noise level determined under the conditions of the abovementioned

regulation, with the MT Propeller MTV-6-A/187-129 propeller together

with no installed muffler, is 74.4 dB(A).

For the TAE 125-02-99 installation:

The noise level determined under the conditions of the abovementioned

regulation, with the MT Propeller MTV-6-A/187-129 propeller together

with "Akrapovic type for TAE 125" muffler, is 70.2 dB(A).

The noise level determined under the conditions of the abovementioned

regulation, with the MT Propeller MTV-6-A/187-129 propeller together

with “Langer LA 44” muffler, is 69.1 dB(A).

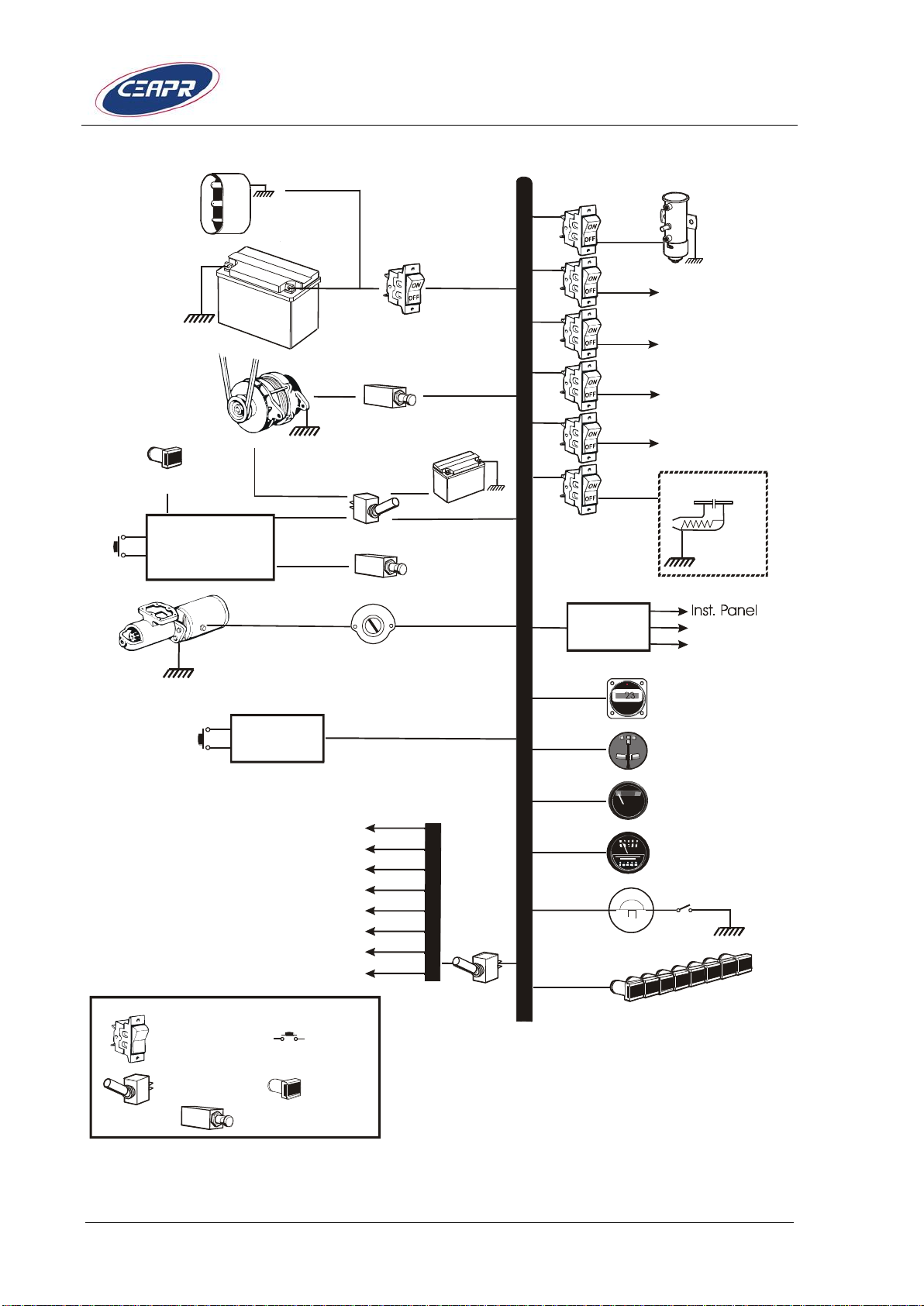

ELECTRICAL SYSTEM

The electrical system of the TAE 125 installation differs from the previous

Page 1 - 2 Issue 3 – July 2014

Page 19

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

installation and is equipped with the following operating and display

elements:

1. Rocker Switch "Battery"

The battery must be switched ON in normal operation.

2. The circuit breaker below the Rocker Switch "Battery" disables the

alternator. The alternator can be left ON always.

3. Key Switch "Starter"

This switch controls the starter motor only.

4. Voltmeter

5. Warning lamp "Alternator".

Illuminates when the power output of the alternator is too low or the

circuit breaker “Alternator” (Switch resp.) is switched off. Normally, this

warning lamp always illuminates when the “Engine Master” (“IGN” resp.)

is switched on without revolution and extinguished immediately after

starting the engine.

6. Switch "Engine Master"

The Engine Master switch controls the two redundant FADEC

components, and the back-up alternator excitation battery, with three

independent contacts. It is protected against unintentional switching with

a pull-to-actuate mechanism and a guard. The alternator excitation

battery is used to ensure that the alternator continues to function in any

circumstances even if the main battery fails.

7. Switch "FORCE B"

If the FADEC does not automatically switch from A-FADEC to the BFADEC in case of an emergency despite of obvious necessity, this

switch allows to switch manually to the B-FADEC.

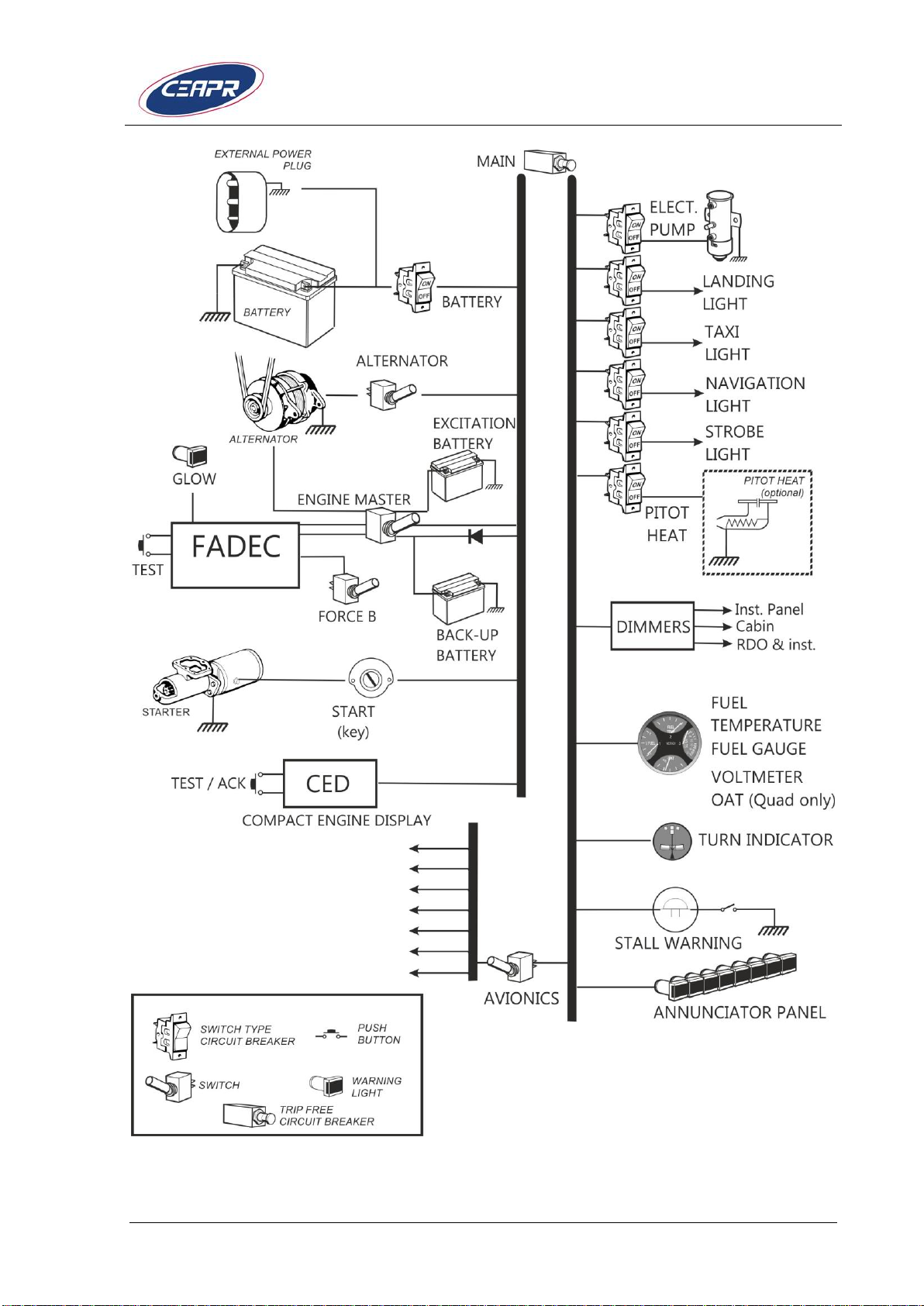

8. FADEC Backup Battery (TAE 125-02-99 installation)

The backup battery ensures power supply to A-FADEC only when supply

from main battery and alternator is interrupted. This allows continued

engine operation for limited time only.

Issue 3 – July 2014 Page 1 - 3

Page 20

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

STARTER

PITOT HEAT

(optional)

ALTERNATOR

BATTERY

EXTERNAL POWER

PLUG

SWITCH TYPE

CIRCUIT BREAKER

TRIP FREE

CIRCUIT BREAKER

SWITCH

PUSH

BUTTON

WARNING

LIGHT

FADEC

PULL TO

FORCE B

ENGINE MASTER

ALTERNATOR

BATTERY

TEST

START

(key)

GLOW

CED

COMPACT ENGINE DISPLAY

TEST / ACK

TURN INDICATOR

VOLTMETER

STROBE

LIGHT

NAVIGATION

LIGHT

TAXI

LIGHT

LANDING

LIGHT

ELECT.

PUMP

FUEL

TEMPERATURE

PITOT

HEAT

DIMMERS

AVIONICS

STALL WARNING

FUEL GAUGE

ANNUNCIATOR PANEL

FUEL

TEMPERATURE

ICE ZONE

ELECTRONICS INTERNATIONAL

C

RDO & inst.

Cabin

Figure 1-1 Simplified block diagram

Page 1 - 4 Issue 3 – July 2014

Page 21

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Figure 1-2 Simplified Block Diagram with FADEC backup battery installed

Issue 3 – July 2014 Page 1 - 5

Page 22

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

FADEC-RESET

In case of a FADEC-warning, one or both FADEC warning lamps are

flashing. If then the "FADEC" Test Knob is pressed for at least 2

seconds:

a) the active warning lamps will extinguish if it was a LOW category

warning.

b) the active warning lamps will be illuminated steady if it was a

HIGH category warning.

CAUTION: If a FADEC-warning occurred, contact your

service center. Next flight is not permitted.

When a high category warning occurs the pilot should land as soon as

practical, since the affected FADEC ECU has diagnosed a severe fault.

A low category fault has no significant impact on engine operation.

Refer also to the engine manual OM-02-01 or OM-02-02 for additional

information.

FUELS, OILS and LIQUIDS

Approved fuels, oil and liquids are published in Section 2 - Limitations of

this POH Supplement.

▲ WARNING: The engine must not be started if the oil or coolant level is

too low.

CAUTION: Use of unapproved fuels, oil and coolant may result in

damage to the engine and fuel system components,

resulting in possible engine failure.

CAUTION: Normally it is not necessary to fill the cooling liquid or

gearbox oil between maintenance intervals. If the level is

too low, please notify the service department

immediately.

Page 1 - 6 Issue 3 – July 2014

Page 23

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

ENGINE OIL

Oil quantity between dipstick min and max indication: .................. 1 liter

Total engine capacity including filters and coolers: .................. 6.7 liters

Approved grades: .................................. Refer to Section 2 – Limitations

CAUTION: Use the approved oil with exact declaration only!

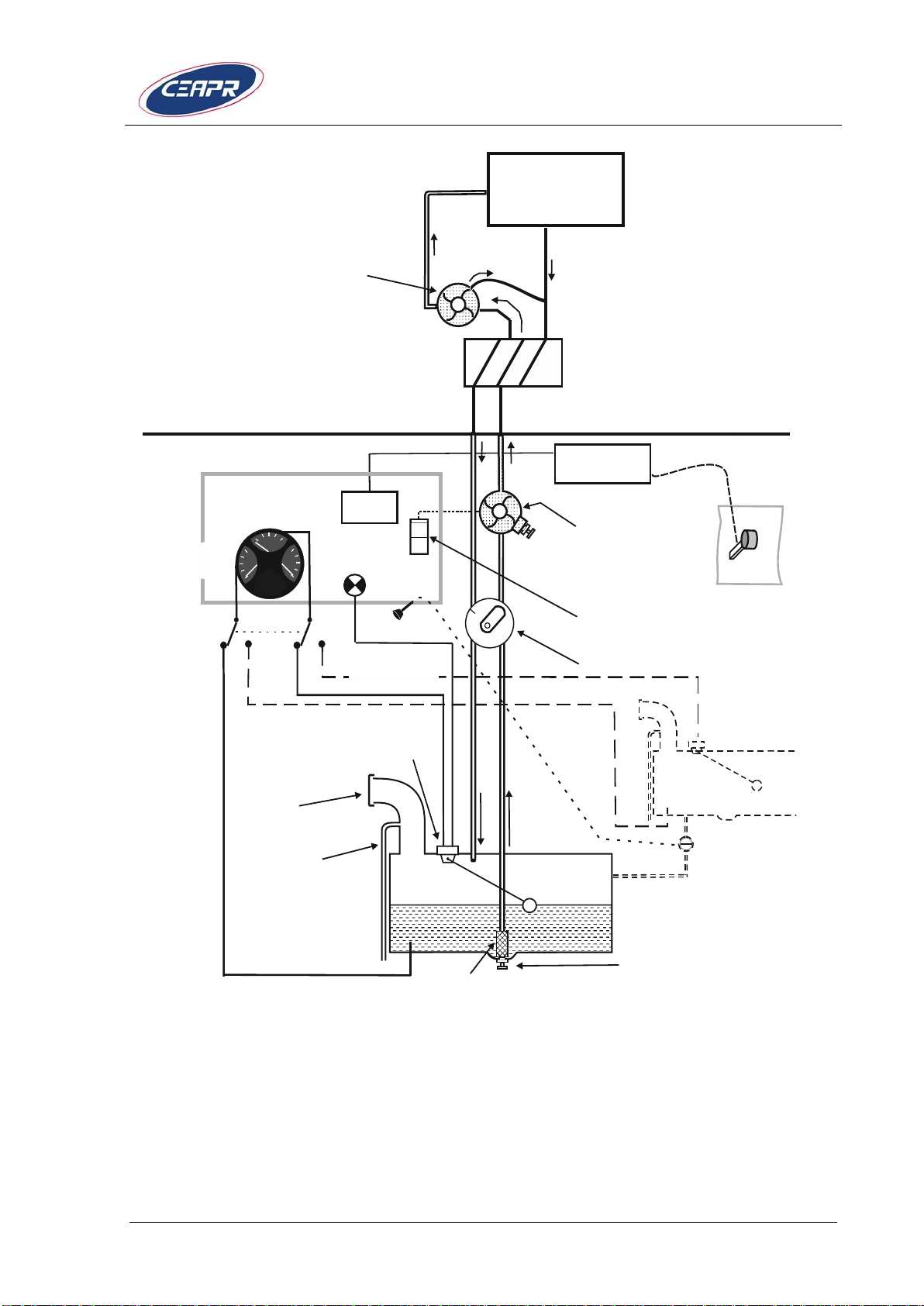

FUEL SYSTEM

The fuel system of the TAE 125 installation includes a variant of the

original standard tank of the DR400, plus a level sender and display, and

an independent low-level warning light. An additional sensor and display

for fuel temperature is installed.

The fuel flows out of the tank to the Fuel Selector Valve which has

positions ON and OFF.

The electrically driven fuel pump supports the fuel flow to the filter

module if required. Upstream to the fuel filter module a thermostatcontrolled fuel pre-heater is installed. Then, the engine-driven feed pump

and the high-pressure pump supply the rail, from where the fuel is

injected into the cylinders depending upon the position of the thrust lever

and regulation by the FADEC.

Surplus fuel flows to the filter module and then through the fuel selector

valve back into the tank. A temperature sensor in the filter module

controls the heat exchange between the fuel feed and return. Since

Diesel fuel tends to form paraffin at low temperatures, the information in

Section 2 “Limitations“ pertaining to fuel temperature have to be

observed. The fuel return ensures a quicker warm up of the fuel in the

tank.

Issue 3 – July 2014 Page 1 - 7

Page 24

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Fuel capacity

Tank

Total usable

fuel

Total unusable fuel

Total capacity

109 liters

28.7 US gal

24 imp gal

1 liter

0.26 US gal

0.22 imp gal

110 liters

29 US gal

24.2 imp gal

If Diesel fuel is used, Diesel fuel according DIN EN 590 has to be used

exclusively.

Note: There are differences in the national

supplements to EN 590. Approved are Diesel fuels with

the addition DIN EN 590.

Table 1-1 Fuel Capacity

OPTIONAL EXTENDED RANGE TANK

▲ WARNING: The optional tank is only approved for Jet-A1

The total fuel capacity can be increased to 160 l / 35.2 Imp gal / 42.24

US gal (159 l / 35 Imp gal / 42 US gal usable) by installing an optional

fuel tank of 50 l / 11 Imp gal / 13.2 US gal.

The optional tank is located in the fuselage, aft of the rear seat. The fuel

from the optional tank can be transferred into the main tank by pulling the

transfer valve control, located on the instrument panel. The fuel

temperature and the fuel level of the optional tank are displayed either on

the triple indicator or on the quad indicator (depending on the instrument

panel model) when a momentary switch is pushed (warning LED signal).

Note: The main fuel tank must be empty enough

to receive full quantity from the optional fuel tank.

Since the optional fuel tank is not heated, it is limited to the use of

JET A-1 only to prevent a potential clogging of Diesel Fuel to low

temperature.

Page 1 - 8 Issue 3 – July 2014

Page 25

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

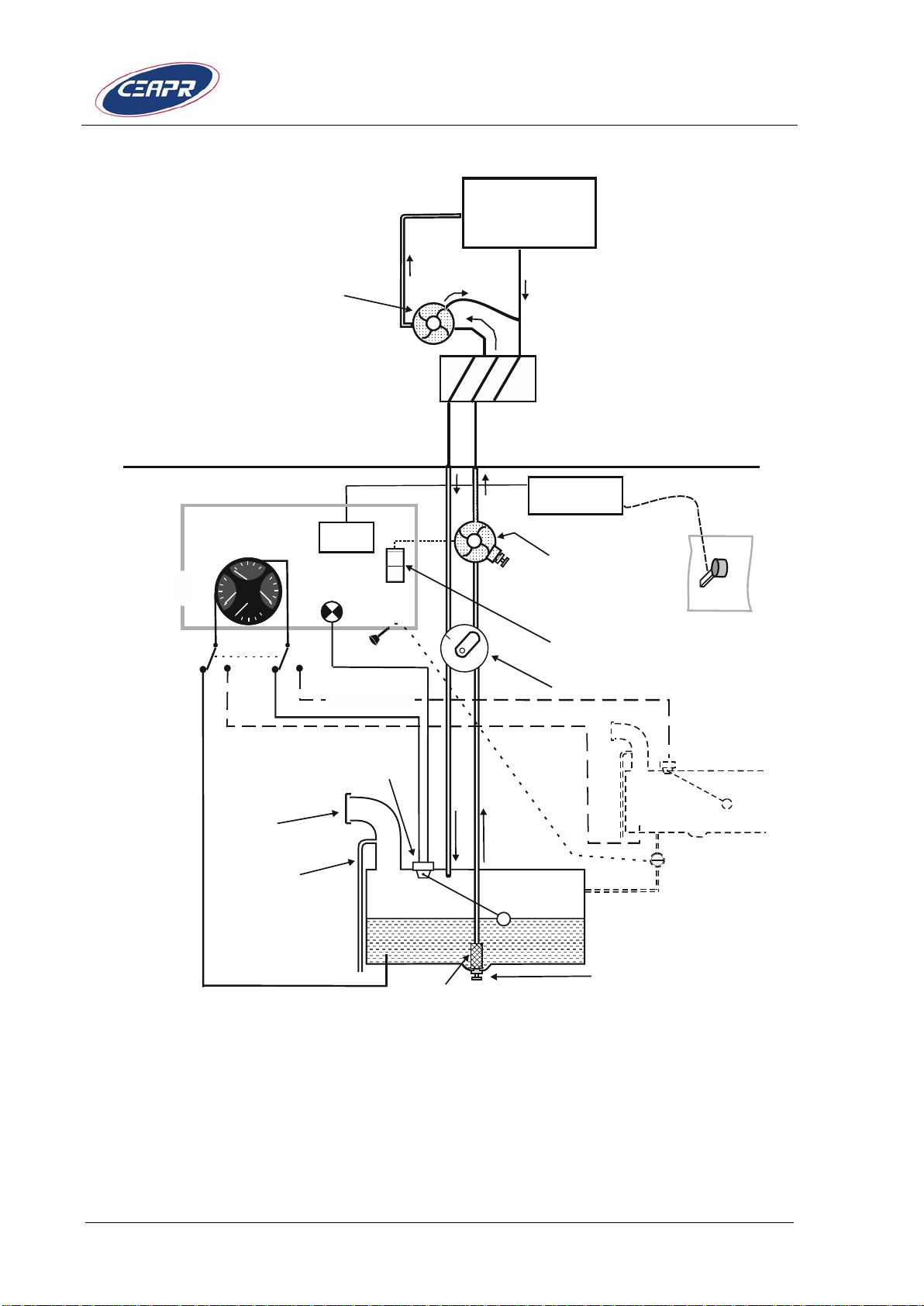

Fuel shut-off

with fuel filter

and

drain-valve

Electric

fuel pump,

Switch

Fire-wall

Fuel quantity

transmitter

Vent/overflow line

Filler

port

Drain valve

Strainer

Power lever

Fuel

quantity

ON

OFF

Option.fuel

quantity

CED

6

8

10 12 14

16

FUEL

F

½EFUEL

2

1

3WESTACH

Fuel

low-level

Fuel

temperature

Optional

switch

Optional tank

50 litres

Engine-driven

fuel pump

FU EL

FIL T E R

Excess from

fuel injectors

Excess from

fuel pump

ENGINE

VOLTSFUEL

F

½

½

EEFUEL

FUEL

2

1

3

4

WESTACH

F

FADEC

Figure 1-3/1 fuel system simplified diagram (Instrument panel models #1

and #2)

Issue 3 – July 2014 Page 1 - 9

Page 26

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Fuel shut-off

with fuel filter

and

drain-valve

Electric

fuel pump,

Switch

Engine-driven

fuel pump

Fire-wall

Fuel quantity

transmitter

Vent/overflow line

Filler

port

Drain valve

Strainer

Power lever

Fuel

quantity

ON

OFF

Option.fuel

quantity

FU EL

FIL T ER

CED

Excess from

fuel injectors

Excess from

fuel pump

6

8

10 12

14

16

FUEL

F

½EFUEL

2

1 3WESTACH

Fuel

low-level

Fuel

temperature

Optional

switch

Optional tank

50 litres

VOLTS

FUEL

°C

½

E

OAT

FUEL

2

1 3

4

WESTACH

F

ENGINE

FADEC

Figure 1-2 Fuel system simplified diagram (Instrument panel model #3)

Page 1 - 10 Issue 3 – July 2014

Page 27

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

G

M

A

3

4

0

K

M

D

1

5

0

V

H

F

/

V

O

R

K

X

1

5

5

-

4

2

1

5

6

8

1

0

1

1

1

2

1

3

1

5

2

7

9

1

6

1

7

1

8

1

9

2

9

2

8

2

7

2

6

2

5

2

4

2

4

3

0

3

1

3

2

3

4

3

6

3

5

3

7

4

2

3

9

2

0

2

2

2

2

2

3

2

3

3

3

3

4

3

8

4

0

4

1

4

3

4

4

R

P

M

OPO

T

2

3

6

5

0

1

4

0

b

arC

L

O

A

D

%

t

r

/

m

i

n

2

3

0

0

6

0

1

0

5

1

2

0

C

C

CTG

T

1

0

0

O

F

F

L

R

B

O

T

H

S

T

2

0

707

070707060

4

0

4

0

2

0

2

1

1

4

5

1

4

5

Q

U

A

R

T

Z

-

C

H

R

O

N

O

M

E

T

E

R

L

C

-

2

R

S

T

S

T

/

S

P

M

O

D

E

S

E

T

D

T

/

V

T

I

M

E

R

C

L

O

C

K

3

6

3

6

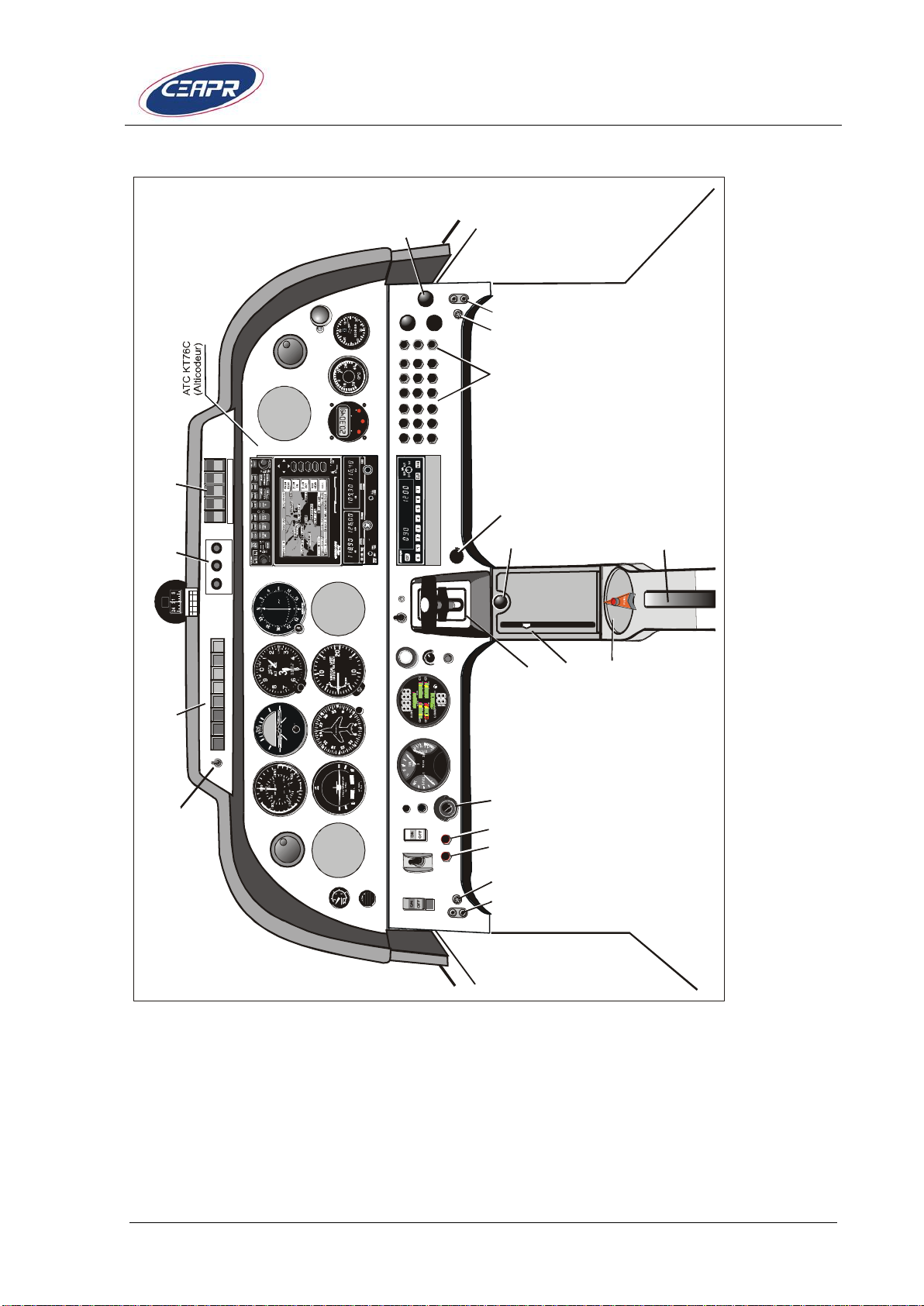

Figure 1-5 Instrument panel model #1

Note: The avionics instrument panel is shown as an example

only.

Issue 3 – July 2014 Page 1 - 11

Page 28

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Instrument panel model #1

Pos

Fonction

Pos

Fonction

Pos

Fonction

1

Airspeed indicator

16

Warning lights

31

Fuel tank valve

2

Gyro horizon

17

Lights test &

day/night dimmer

switch

32

Elevator trim control

valve

3

Altimeter

18

Instrument panel

light

33

Elevator trim

position indicator

4

Turn coordinator

19

Safety switches:

landing light, taxi

light, strobe light,

navigation light,

pitot heat

34

Cabin heat /

windshield defrost

control

5

Directional gyro

20

Circuit breakers

35

Cabin heat

6

Rate of climb

indicator

21

Electric throttle

control

36

Instrument cut-off

7

Vacuum gauge

22

ANR jacks

37

VOR/LOC indicator

8

Engine indicator

CED-125

23

Mike and headset

jacks

38

Hourmeter

9

Parking brake

control knob

24

Fresh air vent

39

Outside air

temperature (OAT)

10

Westach triple

indicator

25

Battery safety

switch

40

Clock / chronometer

11

FADEC & alternator

excitation battery

26

Key starter

41

Stall warning

12

Electrical fuel pump

control

27

Glow light

42

Music jack

13

Alt. Induction air

28

FADEC test button

43

Auxiliary 12V

14

Force FADEC B

29

CED test / warning

switch off

44

Avionics Master

switch

15

Magnetic compass

30

CED-125 lighting

knob

45

Alternator relay

breaker

Table 1-2 Instrument panel #1 description

Page 1 - 12 Issue 3 – July 2014

Page 29

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

1

5

6

8

1

0

1

1

1

2

1

3

1

4

1

5

2

7

9

1

6

1

7

1

8

1

9

2

9

2

8

2

7

2

6

2

5

2

4

2

4

3

0

3

1

3

2

3

4

3

6

3

5

3

7

4

2

3

9

2

0

2

2

2

2

2

3

2

3

3

3

3

4

3

8

4

0

4

1

4

3

4

4

R

P

M

O

POT

2

3

6

5

0

1

4

0

b

a

r

C

L

O

A

D

%

t

r

/

m

i

n

2

3

0

0

6

0

1

0

5

1

2

0

C

C

CTG

T

1

0

0

O

F

F

L

R

B

O

T

H

S

T

2

0

707

0

707

0

706

0

4

0

4

0

2

0

2

1

4

5

5

C

H

R

O

N

O

M

E

T

E

R

L

C

-

6

R

S

T

S

T

/

S

P

M

O

D

E

S

E

T

A

D

V

4

6

4

7

G

M

A

3

4

0

K

M

D

1

5

0

K

X

1

5

5

-

3

8

E

L

T

A

U

T

O

M

A

N

U

A

L

4

6

Note: The avionics instrument panel is shown as an example

Figure 1-6 Instrument panel model #2

only.

Issue 3 – July 2014 Page 1 - 13

Page 30

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Instrument panel model #2

Pos

Fonction

Pos

Fonction

Pos

Fonction

1

Airspeed indicator

17

Lights test &

day/night dimmer

switch

33

Elevator trim

position indicator

2

Gyro horizon

18

Instrument panel

light

34

Cabin heat /

windshield defrost

control

3

Altimeter

19

Safety switches:

landing light, taxi

light, strobe light,

navigation light,

pitot heat

35

Cabin heat

4

Turn coordinator

20

Circuit breakers

36

Interphone on board

5

Directional gyro

21

Electric throttle

control

37

VOR/LOC indicator

6

Rate of climb

indicator

22

ANR jacks

38

Hourmeter

7

Vacuum gauge

23

Mike and headset

jacks

39

Outside air

temperature (OAT)

8

Engine indicator

CED-125

24

Fresh air vent

40

Clock / chronometer

9

Parking brake

control knob

25

Battery safety

switch

41

Instrument cut-off

10

Westach triple

indicator

26

Key starter

42

Instrument cut-off

11

FADEC & alternator

excitation battery

27

Glow light

43

Auxiliary 12V

12

Electrical fuel pump

control

28

FADEC test button

44

Avionics Master

switch

13

Alt. Induction air

29

CED test / warning

switch off

45

Alternator relay

breaker

14

Force FADEC B

30

CED-125 lighting

knob

46

ELT control

15

Magnetic compass

31

Fuel tank valve

47

Music jack

16

Warning lights

32

Elevator trim control

valve

Table 1-3 Instrument panel #2 description

Page 1 - 14 Issue 3 – July 2014

Page 31

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

1

5

6

1

2

1

1

9

1

0

1

3

1

5

2

8

2

7

2

2

2

7

2

6

2

9

3

0

2

0

1

8

1

7

1

6

8

3

7

3

7

1

9

2

5

2

3

3

3

4

3

3

2

4

2

3

4

3

6

4

7

4

7

4

8

4

8

2

4

3

4

4

4

4

6

4

0

R

P

M

O

P

O

T

2

3

6

5

0

1

4

0

b

a

r

C

L

O

A

D

%

t

r

/

m

i

n

2

3

0

0

6

0

1

0

5

1

2

0

C

C

CTG

T

1

0

0

O

F

F

L

R

B

O

T

H

S

T

2

0

707

0

707

0

706

0

4

0

4

0

2

0

2

1

1

4

5

C

H

R

O

N

O

M

E

T

E

R

L

C

-

6

R

S

T

S

T

/

S

P

M

O

D

E

S

E

T

A

D

V

G

M

A

3

4

0

K

M

D

1

5

0

K

X

1

5

5

-

3

8

O

A

T

°

c

i

s

e

i

3

5

4

5

4

1

4

9

G

T

X

3

3

0

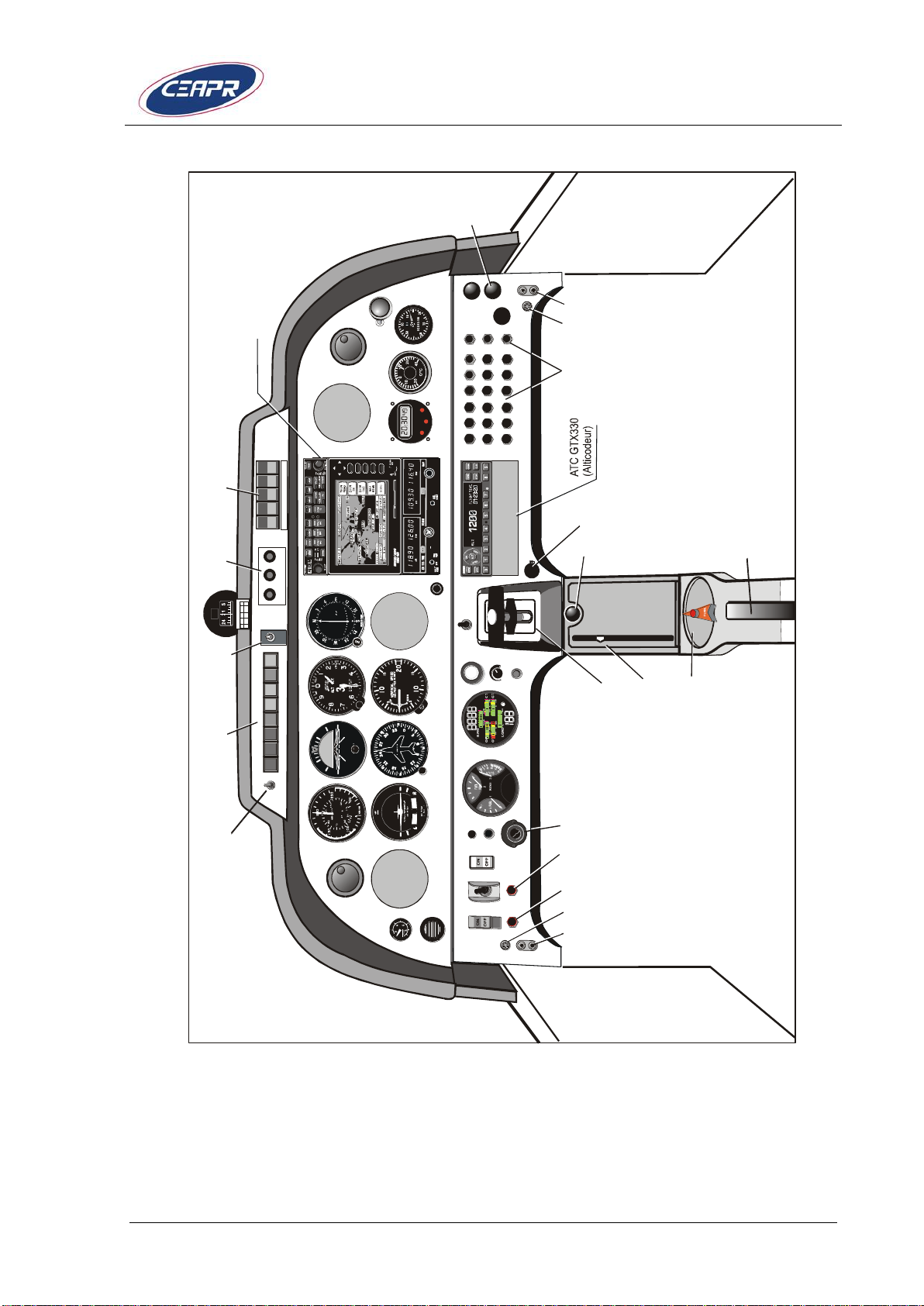

Note: The avionics instrument panel is shown as an example

only.

Figure 1-7 Instrument panel model #3

Issue 3 – July 2014 Page 1 - 15

Page 32

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Instrument panel model #3

Pos

Fonction

Pos

Fonction

Pos

Fonction

1

Airspeed indicator

17

Glow light

34

Clock / chronometer

2

Gyro horizon

18

FADEC test button

35

Hourmeter

3

Altimeter

19

CED-125 lighting

knob

36

Circuit breakers

4

Turn coordinator

20

CED test / warning

switch off

37

Fresh air vent

5

Directional gyro

21

Electric throttle

control

40

Avionics Master

switch

6

Rate of climb

indicator

22

Parking brake

control knob

41

Avionics circuit

breakers

7

Vacuum gauge

23

Elevator trim control

42

VOR/LOC indicator

8

Battery safety

switch

24

Elevator trim

position indicator

43

ELT (optional)

9

FADEC & alternator

excitation battery

25

Fuel tank valve

44

Instrument cut-off

10

Electrical fuel pump

control

26

Lights test &

day/night dimmer

switch

45

Instrument cut-off

11

Westach quad

indicator

27

Warning lights

46

Auxiliary 12V

12

Engine indicator

CED-125

28

Magnetic compass

47

ANR jacks

13

Alt. Induction air

29

Instrument panel

light

48

Mike and headset

jacks

14

Alternator relay

breaker

30

Safety switches:

landing light, taxi

light, strobe light,

navigation light,

pitot heat

49

Music jack

15

Force FADEC B

32

Cabin heat

56

Transfer valve

control (optional)

16

Key starter

33

Cabin heat /

windshield defrost

control

57

Tank fuel T°C &

level display select

push-button

(optional)

Table 1-4 Instrument panel #3 description

Page 1 - 16 Issue 3 – July 2014

Page 33

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

1

5

6

1

2

1

1

9

1

0

1

3

1

5

2

8

2

7

2

2

2

7

2

6

2

9

3

0

2

0

1

8

1

7

1

6

8

3

7

3

7

1

9

2

5

2

3

3

3

4

3

3

2

4

2

3

4

3

6

4

7

4

7

4

8

4

8

2

4

3

4

4

4

4

6

4

0

R

P

M

O

P

O

T

2

3

6

5

0

1

4

0

b

a

r

C

L

O

A

D

%

t

r

/

m

i

n

2

3

0

0

6

0

1

0

5

1

2

0

C

C

CTG

T

1

0

0

O

F

F

L

R

B

O

T

H

S

T

2

0

707

07070

706

0

4

0

4

0

2

0

2

1

3

1

1

4

5

C

H

R

O

N

O

M

E

T

E

R

L

C

-

6

R

S

T

S

T

/

S

P

M

O

D

E

S

E

T

A

D

V

G

M

A

3

4

0

K

M

D

1

5

0

K

X

1

5

5

-

3

8

O

A

T

°

c

i

s

e

i

3

5

4

5

4

1

4

9

G

T

X

3

3

0

Note: The avionics instrument panel is shown as an example

Figure 1-8 Instrument panel model #4

only.

Issue 3 – July 2014 Page 1 - 17

Page 34

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Instrument panel model #4

Pos

Fonction

Pos

Fonction

Pos

Fonction

1

Airspeed indicator

17

Glow light

33

Cabin heat /

windshield defrost

control

2

Gyro horizon

18

FADEC test button

34

Clock / chronometer

3

Altimeter

19

CED-125 lighting

knob

35

Hourmeter

4

Turn coordinator

20

CED test / warning

switch off

36

Circuit breakers

5

Directional gyro

21

Electrical throttle

control

37

Fresh air vent

6

Rate of climb

indicator

22

Parking brake

control knob

40

Avionics Master

switch

7

Vacuum gauge

23

Elevator trim control

41

Avionics circuit

breakers

8

Battery safety

switch

24

Elevator trim

position indicator

42

VOR/LOC indicator

9

FADEC & alternator

excitation battery

25

Fuel tank valve

43

ELT (optional)

10

Electrical fuel pump

control

26

Lights test &

day/night dimmer

switch

44

Instrument cut-off

11

Westach quad

indicator

27

Warning lights

45

Instrument cut-off

12

Engine indicator

CED-125

28

Magnetic compass

46

Auxiliary 12V

13

Alt. Induction air

29

Instrument panel

light

47

ANR jacks

14

Alternator relay

breaker

30

Safety switches:

landing light, taxi

light, strobe light,

navigation light,

pitot heat

48

Mike and headset

jacks

15

Force FADEC B

31

Optional tank fuel

T°C qty display

select.

49

Music jack

Table 1-5 Instrument panel #4 description

Page 1 - 18 Issue 3 – July 2014

Page 35

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

”Three-display“ and “four-display“ instruments

Example Of the Westach triple

indicator installed on models #1

and #2

Compact Engine Display CED-125

Example of the Westach quad

indicator installed on model #3

Figure 1-4 CED-125 detail

Issue 3 – July 2014 Page 1 - 19

Page 36

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

2

3

4

5

1

1

1

1

6

9

10

1

7

7

8

8

HEATING AND VENTILATION

1 Fresh Air Intake 2 Heat Exchanger

3 Warm Air Distribution Box 4 Warm Air Distribution Box

5 Forward / Aft Selection 6 Defrost / Heating Selection Box

7 Defrost Jet 8 Forward Heating

9 Aft Heating 10 Heating Controls

Figure 1-5 Heating and Ventilation

Page 1 - 20 Issue 3 – July 2014

Page 37

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Heating Control Settings

Function

Pulled

Pushed

Control 0

- Button Lock

Heat ON/OFF

ON

OFF

Control 1

Heating ON/OFF

ON

OFF

Control 2

Defrost / Heating

FRONT

HEATING

WINDSHIELD

DEFROST

Control 3

Front / Rear select.

REAR

FRONT

Table 1-6 Heating Control Settings

Figure 1-6 Heat Control Placard, Right Cabin Side Wall

This STC installation has a fourth control (Control 0 in table above). It

must be OFF (Push) when cabin heat is not required (hot outside air

temperature)

Issue 3 – July 2014 Page 1 - 21

Page 38

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Page 1 - 22 Issue 3 – July 2014

Page 39

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

AIRSPEED LIMITATIONS

km/h

kt

Vne, never exceed

270

146

Vno, normal operation

260

140

Va, maneuvering speed

215

116

Vfe, flaps extended limit speed

170

92

AIRSPEED INDICATOR MARKINGS

km/h

kt

Red line (never exceed)

Vne

270

146

Yellow arc (operate with caution

and only in "smooth air")

Vno-Vne

260 - 270

140 - 146

Green arc (normal operating

range)

Vs1-Vno

99 - 260

53 - 140

White arc

Vso-Vfe

87 - 170

47 - 92

APPROVED OPERATION

Table 2-1 Airspeed Limitations

SECTION 2

LIMITATIONS

Table 2-2 Airspeed Indicator Markings

MAXIMUM ALTITUDE

The DR400 with TAE 125-01 or TAE 125-02-99 engine installation has

been qualified up to 16.500 ft.

Issue 3 – July 2014 Page 2 - 1

Page 40

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Cat. “U“

Cat. “N“

On Take off

2006 lb (910 kg)

2161 lb (980 kg)

On Landing

2006 lb (910 kg)

2161 lb (980 kg)

FLIGHT LOAD FACTOR LIMITS AT MAXIMUM WEIGHT

(2006 lb) 910 kg (category “U“):

Flaps up ............................................................ n between -2.2 and +4.4

Flaps down .................................................................................... n = +2

(2161 lb) 980 kg (category "N"):

Flaps up ............................................................ n between -1.9 and -3.8

Flaps down ................................................................................... n = + 2

CAUTION: Avoid extended negative g-loads duration.

Extended negative g-loads can cause propeller control

and engine problems.

Note: The load factor limits for the engine must

also be observed. Refer to the Operation & Maintenance

Manual for the engine.

MAXIMUM AUTHORIZED WEIGHTS

Table 2-3 Maximum Authorized Weights

WEIGHT AND BALANCE

Levelling ........................................................... upper fuselage longeron

Datum .........................................wing leading edge, rectangular section

Reference Chord ............................................................ (67.3 in) 1.71 m

Page 2 - 2 Issue 3 – July 2014

Page 41

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Weight

kg (lb)

Arm

m (in)

Front Seats

2 x 77

(2 x 170)

0.36 - 0.46

(14 - 18)

Rear Seats (*)

2 x 77

(2 x 170)

1.19

(47)

Fuel, main fuselage tank

88

(194)

1.12

(44)

Baggage (**)

40

(88)

1.9

(75)

LOAD PLANNING

(Refer also to weight and balance chart, section 6)

The weight of the engine oil, as well as the unusable fuel must be

included in the empty weight of the aircraft.

Table 2-4 Load Planning

* The carriage on the rear seats of more than two passengers (whose

total weight remain below or equal to the maximum indicated) is

authorized, provided that passenger seat belts are installed for each

passenger and that weight and balance are kept within the authorized

limits.

** Within the authorized weight and balance limits.

ENGINE OPERATING LIMITS

Engine manufacturer ........................................... Technify Motors GmbH

Engine model .......................................... TAE 125-01 or TAE 125-02-99

Takeoff and max. continuous power .............................. 99 kw (135 HP)

Takeoff and max. continuous RPM ................................................. 2300

Note: In the absence of any other explicit

statements, all of the information on RPM in this

supplement to the Pilot´s Operating Handbook are

propeller RPM.

Issue 3 – July 2014 Page 2 - 3

Page 42

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Engine operating limits for takeoff and continuous operation

▲ WARNING: It is not allowed to start the engine outside of these

temperature limits.

Note: The operating limit temperature is a

temperature limit below which the engine may be started,

but not operated at the takeoff RPM. The warm-up RPM

to be selected can be found in Section 4 of this

supplement.

Oil temperature:

Minimum engine starting temperature: ........................................ -32 °C

Minimum operating limit temperature: .............................................50 °C

Maximum operating limit temperature: ..........................................140 °C

Coolant temperature:

Minimum engine starting temperature: ........................................ -32 °C

Minimum operating limit temperature: .............................................60 °C

Maximum operating limit temperature: ..........................................105 °C

Gearbox temperature:

Minimum operating limit temperature: ........................................... -30 °C

Maximum operating limit temperature: ..........................................120 °C

Oil pressure:

Minimum oil pressure ................................................................... 1.2 bar

Minimum oil pressure (at take-off power)..................................... 2.3 bar

Minimum oil pressure in flight ...................................................... 2.3 bar

Maximum oil pressure .................................................................. 6.0 bar

Maximum oil pressure (cold start <20 sec.) ................................. 6.5 bar

Maximum oil consumption ............................................................. 0.1 l/h

Page 2 - 4 Issue 3 – July 2014

Page 43

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Fuel

Minimum permissible fuel

temperature in the fuel

tank before takeoff

Minimum permissible fuel

temperature in the fuel

tank during the flight

Jet A-1, JET A,

Fuel No.3 JP-8,

JP-8+100, TS-1

- 30°C

- 35°C

Diesel

Greater than 0°C

- 5°C

Minimum fuel temperature limits in the fuel tanks:

Table 2-5 Min. Fuel Temperature Limits in the fuel tank

▲ WARNING: The following applies to Diesel and Jet A-1 mixtures in

the tank:

As soon as the proportion of Diesel in the tank is more

than 10%, the fuel temperature limits for Diesel operation

must be observed. If there is uncertainty about which fuel

is in the tank, the assumption should be made that it is

Diesel.

Issue 3 – July 2014 Page 2 - 5

Page 44

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Instrument

Red

Range

Amber

Range

Green

Range

Amber

Range

Red

Range

Tachometer

[rpm]

-

-

0-2300

-

> 2300

Oil Pressure

[bar]

0-1.1

1.2-2.2

2.3-5.2

5.3-6.0

> 6.0

Coolant

temperature [°C]

< -32

-32...

+59

60-100

101-

105

> 105

Oil Temperature

[°C]

< -32

-32...

+49

50-124

125-

140

> 140

Gearbox

Temperature [°C]

-

-

< 115

115-

120

> 120

Load

[%]

-

-

0-100

-

-

ENGINE INSTRUMENT MARKINGS

The engine data of the TAE 125 installation to be monitored are

integrated in the combined engine instrument CED-125. The ranges of

the individual engine monitoring parameters are shown in the following

table.

Table 2-6 Markings of the Engine Instruments

Note: If an engine reading is in the yellow or red

range, the "Caution" lamp is activated. It only

extinguishes when the "CED-Test / confirm" button is

pressed. If this test button is pressed longer than one

second, a self-test of the instrument is initiated.

GROUNDING (EARTHING) BEFORE AND DURING FUELING

Use the engine exhaust pipe for draining static charge.

Page 2 - 6 Issue 3 – July 2014

Page 45

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

PERMISSIBLE FUEL GRADES

CAUTION: Using non-approved fuels and additives

can lead to dangerous engine malfunctions.

Fuel: ..................................................................... JET A-1 (ASTM 1655)

Alternative: ............................................................. Diesel (DIN EN 590)

Fuel additive for Diesel: .............. Liqui Moly “Diesel Fliess Fit” No. 5130

..................................... JP-8 (MIL-DTL-83133E)

............................. JP-8+100 (MIL-DTL-83133E)

................................. Fuel No.3 (GB 6537-2006)

Only TAE 125-02-99 (C2.0):

...................................... TS-1 (GOST 10227-86)

.................. TS-1 (GSTU 320.00149943.011-99)

MAXIMUM FUEL QUANTITIES

Standard tank:

Total capacity ......................................... 110 l / 29 US gal / 24.2 imp gal

Total usable fuel ..................................... 109 l / 28.7 US gal / 24 imp gal

Total unusable fuel .................................. 1 l / 0.26 US gal / 0.22 imp gal

Optional extended range tank (JET A-1 fuel only)

The total fuel capacity can be increased to 160 l / 35.2 imp gal / 42.24

US gal (159 l / 35 imp gal / 42 US gal usable) by installing an optional

fuel tank of 50 l / 11 imp gal / 13.2 US gal, which flows into the main tank

on command, most safely when the main tank can receive 50 liters. The

fuel level in the optional tank may be displayed on the instrument panel

fuel gauge indicator by pressing on the push-button switch.

Issue 3 – July 2014 Page 2 - 7

Page 46

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

PERMISSIBLE OIL GRADES

CAUTION: Use approved oil with exact designation only!

Engine oil: ........................................................ AeroShell Oil Diesel Ultra

......................................................... Shell Helix Ultra 5W-30

......................................................... Shell Helix Ultra 5W-40

.................................................AeroShell Oil Diesel 10W-40

Gearbox oil: .......................................... Shell Spirax S6 GXME 75W-80

.................................................. Shell Spirax S4 G 75W-90

............................... Shell Getriebeöl EP 75W-90 API GL-4

...................................................... Shell Spirax EP 75W-90

.......................................... Shell Spirax GSX 75W-80 GL-4

PERMISSIBLE COOLING LIQUID

Coolant: ............................ Water/Radiator Protection at a ratio of 50:50

Radiator Protection: .......................... BASF Glysantin Protect Plus/G48

..................................... Mobil Antifreeze Extra/G48

.................................... ESSO Antifreeze Extra/G48

........... Comma Xstream Green - Concentrate/G48

............................................... Zerex Glysantin G48

LOAD LIMITS

No change

OPERATIONAL LIMITATIONS IN THE “U” CATEGORY

CAUTION: Intentionally initiating negative G maneuvers is

prohibited!

Refer to original Pilot‘s Operating Handbook.

Intentionally initiating spins and negative G maneuvers is prohibited.

Page 2 - 8 Issue 3 – July 2014

Page 47

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

JET A1 (ASTM 1655)

DIESEL (EN590)

24.2 imp / 29 US Gal

110litres

JET A1 (ASTM 1655)

ONLY

11 imp / 13.2 US Gal

50litres

HUILE DR 400/135 CDI

OIL DR 400/CDI

PLACARDS

Figure 2-1 Near the Fuel Tank Caps: 110 liters JET/Diesel Fuel

Figure 2-2 Optional Extended Range Tank

or

Figure 2-3 On the oil funnel or at the engine cowling access door

Issue 3 – July 2014 Page 2 - 9

Page 48

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

FUEL

E = 0

¼ = 25

½ = 50

¾ = 75

F = 100

( LITERS )

TE ST / AC K

ENGINE

CAUTION

ALT

FUEL

LOW

LEVEL

FADECAFADECBFLAPS

DOWN

PITOT

HEATING

COOLANT

LEVEL

PRISE DE

PARC

AUSSENBORD

STROMANSCHLUSS

EXTERNAL

POWER

12 V

Figure 2-4 Near the CED

Figure 2-5 Near their respective gauges or switches

Figure 2-6 Annunciator Lights at the Top of the Instrument Panel

Figure 2-7 If installed, at the access door to the external power receptacle behind the wing on the aircraft's right side.

Note: The receptacle has "one way only" feature for polarity

protection.

Page 2 - 10 Issue 3 – July 2014

Page 49

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

FUEL T(°C)

indicated

MAIN TANK

OPT. TANK

FUEL QTY (litres)

Figure 2-8

If optional extended range fuel tank is installed, placard must be placed

near to the fuel gauge.

or

Figure 2-9

If optional extended range fuel tank is installed, placard must be placed

near the fuel transfer control.

Issue 3 – July 2014 Page 2 - 11

Page 50

Page 51

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

SECTION 3

EMERGENCY PROCEDURES

INDEX OF CHECKLISTS

ENGINE FAILURE OR LOSS OF POWER ........................................... 3-2

During takeoff roll ................................................................................... 3-2

Immediately after takeoff ....................................................................... 3-2

During flight ............................................................................................ 3-3

LANDING WITHOUT ENGINE POWER ............................................... 3-4

Restart after engine failure .................................................................... 3-5

FADEC malfunction in flight ................................................................... 3-6

ENGINE SHUT-DOWN IN FLIGHT ....................................................... 3-9

FIRE .....................................................................................................3-10

Engine fire on the ground, during starting ...........................................3-10

Engine fire in flight ..............................................................................3-10

Electrical fire.........................................................................................3-11

ROUGH ENGINE OPERATION ..........................................................3-12

Oil pressure too low .............................................................................3-12

Oil temperature too high ......................................................................3-13

Coolant temperature too high ..............................................................3-13

“Cool level” light illuminates .................................................................3-14

Gearbox temperature too high .............................................................3-14

Fuel temperature too low .....................................................................3-14

Propeller RPM too high ........................................................................3-15

Fluctuations in propeller RPM ..............................................................3-15

ICING ...................................................................................................3-16

ELECTRICAL POWER SUPPLY MALFUNCTION .............................3-17

If the “ALT” light is lit or the ammeter shows battery discharge during

normal engine operation for more than 5 minutes ...............................3-18

INADVERTENT SPIN ..........................................................................3-19

LOSS OF ELEVATOR CONTROL ......................................................3-19

Issue 3 – July 2014 Page 3 - 1

Page 52

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

ENGINE FAILURE OR LOSS OF POWER

During takeoff roll

1) Thrust Lever .............................................................................. IDLE

2) Apply brakes and hold direction. Avoid obstructions.

3) Engine Master switch ................................................................ OFF

4) Battery and ALT CB .................................................................. OFF

5) Fuel selector.............................................................................. OFF

6) Emergency ground egress ............................................. As required

Immediately after takeoff

1) Establish glide

Speed (flaps retracted) ..................................... (78 KIAS) 144 km/h

Speed (flaps T/O position) ............................... (75 KIAS) 139 km/h

2) Land straight ahead, with only small direction changes to avoid

obstructions.

3) If complete engine failure:

FADEC A/B Switch .............................................................. Force B

4) Battery and ALT switch .................................................... Check ON

When landing inevitable:

5) Engine Master ........................................................................... OFF

6) Battery and ALT CB .................................................................. OFF

7) Fuel selector.............................................................................. OFF

8) Wing flaps ........................................ T/O or Landing recommended

9) Touch down with minimum speed

10) When aircraft has stopped ..................... Emergency ground egress

▲ WARNING: Never try to turn back to the runway, as altitude just after

takeoff is seldom sufficient.

Page 3 - 2 Issue 3 – July 2014

Page 53

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

During flight

1) Establish glide:

Flaps retracted .................................................. (78 KIAS) 144 km/h

(In these conditions, without wind, the aircraft covers approx. 8 times

its height above ground). Locate suitable field.

If altitude is sufficient to restart:

2) Electric fuel pump ........................................................................ ON

3) FADEC A/B switch .............................................................. Force B

if this doesn't improve engine operation, return switch to "Auto"

4) If no restart ......................... Reset Engine Master (OFF then to ON)

5) Battery and ALT CB ......................................................... Check ON

6) Engine and fuel level gauges /alarm panel

................................................................. Check for cause of failure

7) FADEC A, B circuit breakers ........................................... Check ON

8) In case the tank has been run to empty with still some fuel available

in the auxiliary tank

(if so equipped) ................................. Open aux. tank transfer valve

If the propeller does not turn:

9) Starter .......................................................................................... ON

The propeller will normally continue to turn as long as the airspeed

is above 120 km/h (65 KIAS). Should the propeller stop at airspeed

of more than 120 km/h or more, the reason for this should be found

out before attempting a restart.

If it is obvious that the engine or propeller is blocked, do not use the

Starter.

If power is not restored, prepare for "landing without engine power".

If the tank has been run to empty, both FADEC lights will be flashing.

▲ WARNING: The engine high pressure pump must be checked before

the next flight.

Issue 3 – July 2014 Page 3 - 3

Page 54

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

LANDING WITHOUT ENGINE POWER

Look for a suitable landing area:

1) Airspeed .................................... 144 km/h (78 KIAS) flaps retracted

139 km/h (75 KIAS) flaps T/O

2) Seat belts and harness ............................................................. Tight

Before landing:

3) Electric pump ............................................................................ OFF

4) Fuel selector.............................................................................. OFF

5) Engine master switch ................................................................ OFF

6) Battery + Alternator switches .................................................... OFF

7) Flaps, when field can easily be reached: ................. T/O or Landing

8) Touch down with minimum speed

9) Brakes ............................................................................ As required

10) When aircraft has stopped ..................... Emergency ground egress

Page 3 - 4 Issue 3 – July 2014

Page 55

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

Restart after engine failure

Note: If altitude permits and a restart is possible.

1) Airspeed ................................. Flaps retracted (78 KIAS) 144 km/h

[max. 100 KIAS, min. 70 KIAS]

2) Reliable restart altitude ......................................... Below 13 000 ft

3) Battery and ALT CB ....................................................... Check ON

4) Fuel selector ......................................................................... OPEN

5) Electric fuel pump ...................................................................... ON

6) Power lever .................................................................. max. power

7) Engine master switch............................................... OFF, then ON

if the propeller does not turn, the starter may be used.

CAUTION: If the propeller is jammed, operate the starter briefly.

If it is obvious that the engine or propeller is blocked

(speed has been maintained above 70 KIAS all the time),

do not use the starter.

8) Engine parameters ............................................................... Check

9) Power lever, once engine runs

smoothly at idle ..................................................................... Adjust

10) Engine operation ...................................... Check available power /

engine parameters

Note: If the engine still does not start, prepare for

"Landing without Engine Power". Refer to page 3-4.

Issue 3 – July 2014 Page 3 - 5

Page 56

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

FADEC malfunction in flight

Note: The FADEC consists of two components

that are independent of each other: FADEC A and

FADEC B. In case of malfunctions in the active FADEC,

it automatically switches to the other.

a) One FADEC Lamp is flashing

(1) Press FADEC-Test knob at least 2 seconds

(2) FADEC Lamp extinguished (LOW category warning):

a) Continue flight normally

b) Inform service center after landing.

(3) FADEC Lamp steady illuminated (HIGH category warning):

a) Observe the other FADEC lamp,

b) Land as soon as practical,

c) Airspeed should be below 100 KIAS (185 km/h),

d) Inform service center after landing.

Page 3 - 6 Issue 3 – July 2014

Page 57

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

b) Both FADEC Lamps are flashing

Note: The load display may not correspond to the current

value.

(1) Press FADEC-Test knob at least 2 seconds (refer to section 1

“FADEC Reset”)

(2) FADEC Lamps extinguished (LOW):

a) Continue flight normally,

b) Inform service center after landing.

(3) FADEC Lamps steady illuminated (HIGH):

a) Check the available engine power,

b) Expect engine failure.

c) Flight can be continued, however the pilot should

i) Select an airspeed below 100 KIAS (185 km/h)

ii) Land as soon as possible

iii) Be prepared for an emergency landing.

(4) Inform service center after landing.

Issue 3 – July 2014 Page 3 - 7

Page 58

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

c) Abnormal engine behavior

Note: The FADEC system normally switches

automatically between FADEC A and B in case of

malfunction, in order to select the "healthiest"

component.

If this automatic switching doesn't work, it is possible to

manually force the system to switch to FADEC B only,

and check for improvement in engine behavior.

1) Maximum airspeed ........................................ (100 KIAS) 185 km/h

2) "FADEC A/B" switch........................................................FORCE B

3) If no engine operation improvement ......... Return switch to "Auto"

Note: The switching from one FADEC to the other

one is usually accompanied by a short RPM fluctuation.

Page 3 - 8 Issue 3 – July 2014

Page 59

Supplement POH DR400/120D, DR400/140B,

DR400/180R, DR400/200R, DR400/RP

ENGINE SHUT-DOWN IN FLIGHT

Note: If it is necessary to shut down the engine in

flight (for instance, abnormal engine behavior does not