Page 1

F

2317 (R

Sales Manual Section 332

PRODUCT SPECIFICATION PS 83939-E

Lockout Relay

83939-E1

GENERAL DESCRIPTION

The No. 83939-E1 Lockout Relay is a two-way,

diaphragm-actuated, non-venting, normally open

valve. It is used in the safety system to lock out or

block certain portions of the control system or a line in

a control system upon receipt of a signal at PORT 1.

(See Figure 1). It will reopen with the loss of pressure

at PORT 1, and has a connection which may be used to

cancel the actuating pressure at PORT 1.

SPECIFICATIONS

Construction:

Aluminum body; stainless steel cover,

bracket and springs; elastomer coated fabric

diaphragms and gaskets; stainless steel and

aluminum valve with resilient seat.

Supply Pressure: ...........................................

CAUTION: DO NOT EXCEED MAXIMUM PRESSURES

Maximum Pressure: ......................................

Mounting: .................................................................

Dimensions: ...................................................

Connections: ................................................

Approximate Shipping Weight: .............

Ordering Information:

See Figure 2.

See Figure 2.

Surface

See Figure 1.

1/8"-27 NPT.

12 ozs. (.340 kg)

Specify: No.

83939-E1

INSTALLATION

A. General

Tubing and fittings used to connect the relay

must be free of chips, dirt, and moisture or other

foreign material.

It is recommended that an "anti-seize" type

thread compound be applied to the second or third

male thread in moderate amount. Do not allow

compound to be deposited inside the relay. Thread

sealing tape is not recommended.

For continuous, trouble-free operation, the

supply to the relay must be clean and dry.

*AIR OR GAS

J. I. C. Symbol

B. Mounting

When installing the No. 83939-E 1 Lockout

Relay,

care should be taken to prevent any foreign matter

from entering the ports. Provisions should be

made to

prevent foreign matter from entering the ports

which are left open to the atmosphere.

The relay may be installed in any position, but

vertical (upright) is recommended. The relay

should be

securely mounted, using the two slots (clearance

for No. 10 screws), provided in the mounting

bracket (See Figure 1).

orm No. P-

ev. B)

1

Page 2

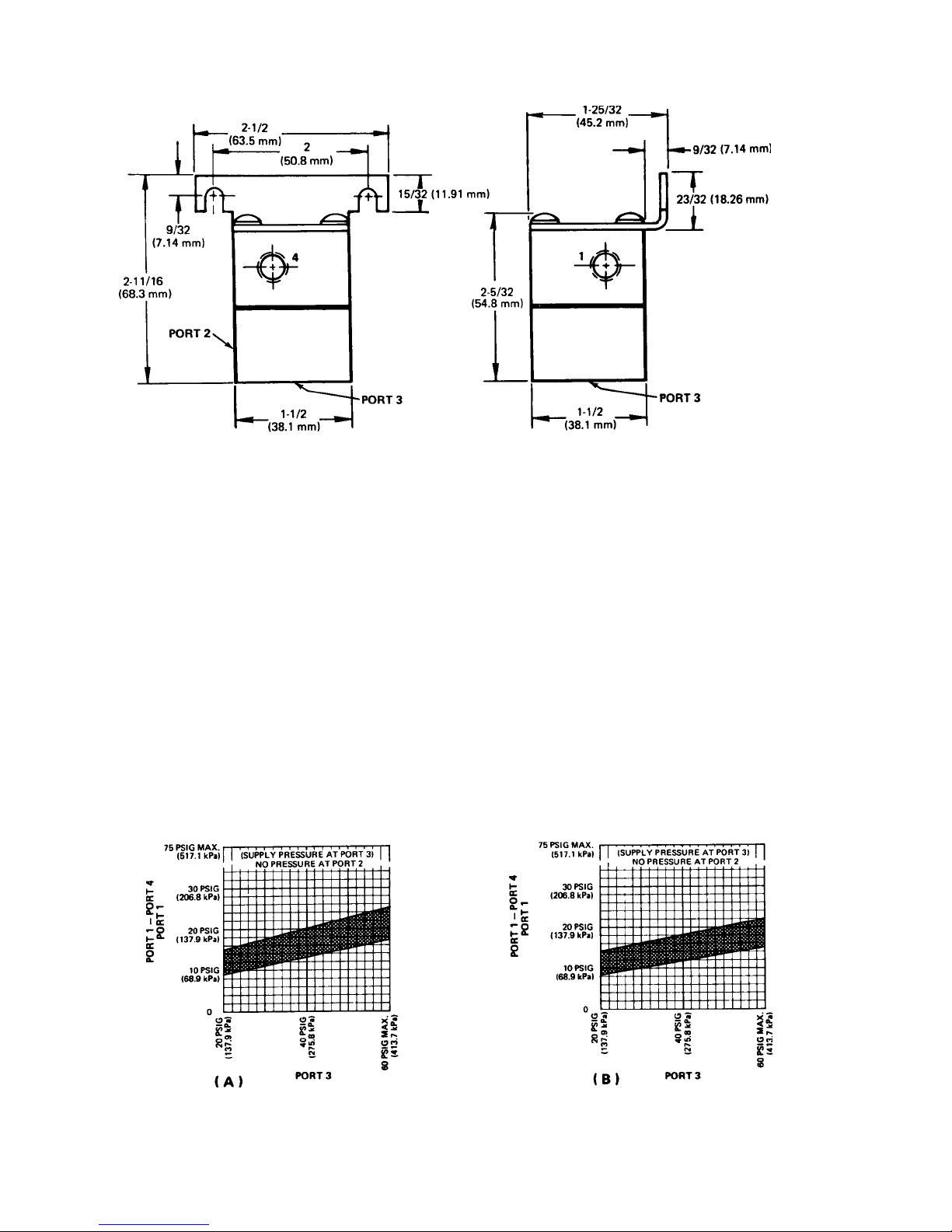

DIMENSIONS

NOTE

NOTE

Figure 1

OPERATION (See Figure 3 )

With no pressure applied to the diaphragm

through Port 1, Port 3 (supply port) is connected

through this normally open relay to Port 2.

When sufficient pressure is applied to the

diaphragm through Port 1, the stem moves down and

forces the lower poppet on seat,

: Graph A indicates actuating pressure (Port

1) required to keep valve closed at various

supply pressures (Port 3). Also, Graph A

indicates actuating pressure (Port 1) minus

equalizing pressure (Port 4) required to

keep valve closed at various supply

pressures (Port 3).

closing Port 3 to Port 2. Loss of pressure through Port

1 will allow the stem to return to its original position.

At the same time, the lower spring will force the

lower poppet off seat, opening Port 3, again, to Port

2. Also, the relay may be reopened by applying an

equalizing pressure through Port 4.

: Graph B indicates decreasing actuating

pressure (Port 1) required to open valve at

various supply pressures (Port 3). Also,

Graph B indicates decreasing actuating

pressure (Port 1) minus equalizing

pressure (Port 4) required to permit same

action.

CAUTION: DO NOT EXCEED MAXIMUM PRESSURES.

Figure 2

2

Page 3

Figure 3

Figure 4

MAINTENANCE

WARNING: Disassemble carefully - spring load

forces present.

A. If excessive leakage occurs at valve seat,

disassemble the relay. Clean poppet and seat with

soft, dry cloth (See Figure 4).

B. If relay does not function properly due to

contamination by foreign matter, disassemble and

clean all metal parts with non-flammable solvent

and dry thoroughly.

C. After reassembly, check for external leakage.

Retighten assembly screws as necessary. Gasket

cement should not be used to seal leaks due to the

possibility of plugging small passages or

damaging the operating characteristics of the

diaphragms.

CAUTION:

If cleaning is required, do not subject "O" rings,

valve poppets, diaphragms or gaskets to cleaning

fluid, acetone, or any halogenated hydrocarbons such

as vapor degrease liquids, etc. Clean only with a soft,

dry cloth.

Upon reassembly, all "O" rings are to be

lubricated with a silicone-type lubricant. Do not

permit lubricant to get on poppet or valve seats.

3

Page 4

PARTS LIST

PARTS LIST

DET.

NO.

NO.

REQ’D

DESCRIPTION

DWG.

NO.

1 4 Screw 33713-H2409

2 4 Lockwasher 36600-L0609

3 1 Mounting Bracket 24637-C2

4 1 Relay Body 31857-E1

5 1 Head & Stem

85013-81

Assembly

6 1 O-Ring 36240-C10

7 1 Plug & Guide

99264-B1

Assembly

8 1 Nameplate 30036-G2

9 1 Relay Body 31857-D1

10 1 Spring 25121-A1

11 2 Gasket 33665-B 1

12 1 Spring 24598-A1

13 1 Diaphragm 24498-A1

14 1 Spacer 33430-A2

NOTE: For complete kit containing all "O" Rings, gaskets,

diaphragms, and poppet to service one unit, order Repair Kit No.

82665-B3. Repair Kit includes Details 6,7,11 and 13 - also

instruction manual and lubricant.

4

Q-3580 (5/01) Printed in U.S.A.

Loading...

Loading...