Page 1

INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR

MODEL 365A

MODEL E365A

ROBERTSHAW INDUSTRIAL PRODUCTS

1602 Mustang Drive

Maryville, TN 37801

Telephone 865-981-3100

Fax 865-981-3168

909GF294

Revision F

8 January 2008

Page 2

MODEL 365A & E365A INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR 909GF294

CAUTION

NO CHANGES WITHOUT AGENCY APPROVAL

ATEX (DEMCO) VIA UL HAZARDOUS LOCATIONS GROUP.

RECORD OF CHANGES

Revision

F

Design

Engineer’s

Approval

P. Kronau

Engineering

Manager’s

Approval

Brien Evans

Approval

Date

14JAN08

COS

Number

96557

Brief Description

Added “CAUTION” note

and “RECORD OF

CHANGES” table.

PAGE a

Page 3

MODEL 365A & E365A INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR 909GF294

TABLE OF CONTENTS

1 DESCRIPTION.............................................................................................................................1

1.1 GENERAL.....................................................................................................................................1

1.2 MODEL IDENTIFICATION.......................................................................................................2

2 SPECIFICATIONS.......................................................................................................................3

2.1 ENVIRONMENTAL.....................................................................................................................3

2.2 CE PRODUCT CERTIFICATION.............................................................................................3

2.3 ELECTRICAL...............................................................................................................................3

2.4 PERFORMANCE .........................................................................................................................4

3 INSTALLATION ..........................................................................................................................5

3.1 GENERAL.....................................................................................................................................5

3.2 MOUNTING..................................................................................................................................5

3.3 SPACE HEATER..........................................................................................................................6

3.4 WIRING.........................................................................................................................................6

4 OPERATION...............................................................................................................................11

4.1 GENERAL...................................................................................................................................11

4.2 ADJUSTMENTS OF OPERATING SETPOINT ....................................................................12

5 MAINTENANCE ........................................................................................................................15

5.1 FUNCTIONAL TEST.................................................................................................................15

5.2 TROUBLESHOOTING ..............................................................................................................15

5.2.1 VIBRASWITCH® WILL NOT RESET...................................................................................15

5.2.2 UNABLE TO ADJUST SETPOINT TO OBTAIN TRIP........................................................16

5.2.3 SWITCH DOES NOT ACTUATE.............................................................................................16

PAGE i

Page 4

MODEL 365A & E365A INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR 909GF294

LIST OF TABLES

A KEY MODEL NUMBER .............................................................................................................2

1 SWITCH CONTACTS .................................................................................................................2

2 REMOTE RESET OPTION ........................................................................................................2

3 ENCLOSURE FINISH .................................................................................................................2

3.1 SPACE HEATER RESISTOR VALUES....................................................................................6

5.1 RESET COIL RESISTANCE....................................................................................................15

LIST OF FIGURES

3.1 MODEL IDENTIFICATION & MOUNTING DETAILS........................................... 7

3.2 CONNECTIONS.............................................................................................................. 8

3.3 METHODS OF MOUNTING THE VIBRASWITCH®, MODEL 365A...........................9

3.4 PREPARATION OF CONDUIT WIRING........................................................................10

3.5 CONNECTION OF CONDUIT WIRING TO UNIT ......................................................10

4.1 OPERATING PRINCIPLE FOR THE VIBRASWITCH®, MODEL 365A.........................11

4.2 SETPOINT ADJUSTMENT ......................................................................................................12

4.3 SUGGESTED SETTINGS WHEN “NORMAL” g-LEVEL IS >1.0 g...................................14

PAGE ii

Page 5

MODEL 365A & E365A INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR 909GF294

1. DESCRIPTION

1.1 GENERAL

The Model 365A & E365A Vibraswitch® Malfunction Detector provides protection for large motors,

pumps, compressors and other rotating equipment. Failing bearings, bent shafts, broken blades over

speeding and other similar malfunctions cause increased imbalance or high frequency vibration that is

detectable by the Model 365A & E365A Vibraswitch®. The Vibraswitch® may be wired to actuate an

alarm or cause a shutdown before costly damage occurs. It is designed for maintenance-free service in

permanently mounted installations.

The Vibraswitch® is an acceleration sensitive device that sensitive to the total acceleratory

shock/vibration that is present on the machine. Acceleration is a vibration characteristic of prime

importance in cases of failure on reciprocating or rotating machinery. Newton’s second law of motion

states that the force exerted on a body by its’ mass is multiplied by its’ acceleration (F=M*A). Thus the

destructive force acting on a bearing is directly dependent on the acceleration of the masses involved at

the shaft, which is supported by the bearings.

It should be noted that the measurements made by the Vibraswitch® are the summation of all of the

individual accelerations acting on the machine, giving the maximum possible protection.

It can be supplied with, or without, a remote reset coil. The remote reset coil provides a means of

resetting the switch after a trip, or holding the switch in the “normal” condition during transient

conditions, such as machine startup. The Vibraswitch® is also available with low power contacts for use

when interfacing with computer systems and PLC’s.

Up to a total of eight (8) Model 365A & E365A can be used in conjunction with the Robertshaw Model

563A Vibraswitch® Monitor to provide startup and monitor delays for a single machine being

monitored.

PAGE 1

Page 6

MODEL 365A & E365A INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR 909GF294

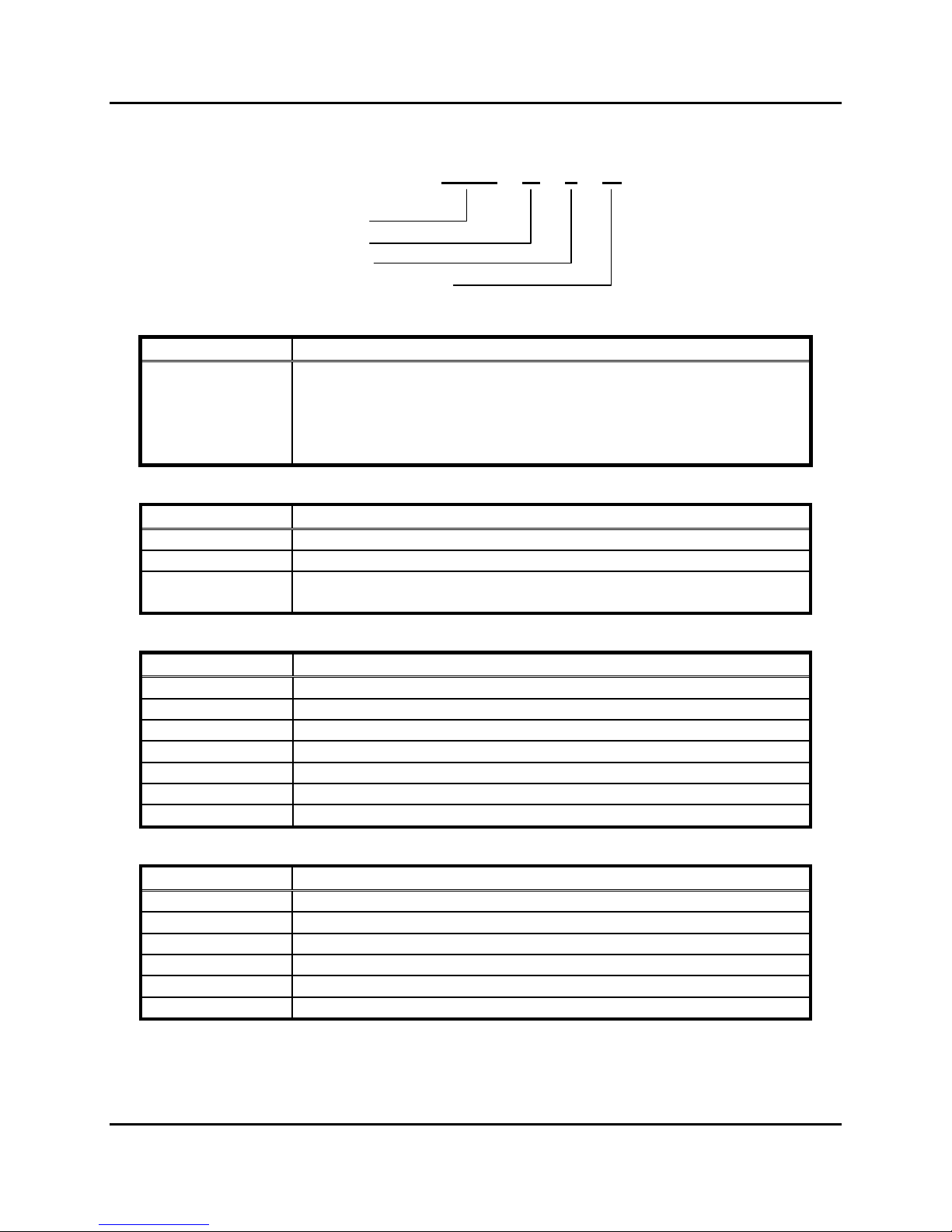

1.2 MODEL IDENTIFICATION

365A – A – 4 – H

Table A – Key Model Numbers

Table 1 – Switch Contacts

Table 2 – Remote Option Reset

Table 3 – Enclosure Finish

Table A – KEY MODEL NO.

Model No. Description

365A

E365A

Designation Description

A SPDT – Single pole, Double throw switch.

D DPDT – Two single pole, double throw switches.

G DPDT – Two single pole, double throw sealed switches with gold plated

Designation Description

0 No reset coil.

1 12 VDC reset coil.

2 24 VDC reset coil.

3 240 VAC reset coil.

4 48 VDC reset coil.

7 120 VDC reset coil.

8 120 VAC reset coil.

Designation Description

(None) Aluminum Alloy, no finish

B Black anodize.

E Gray epoxy paint.

H Space heater installed to reduce internal moisture.

BH Black anodize and space heater installed to reduce internal moisture.

EH Gray epoxy paint and space heater to reduce internal moisture..

Vibraswitch®, 0-4.5g’s, housed in an explosion-proof and weatherproof

enclosure (see specifications section for complete ratings).

Vibraswitch®, 0-4.5g’s, housed in an explosion-proof and weatherproof

enclosure with CE (ATEX) certification (see specifications section for

complete ratings).

Table 1 – SWITCH CONTACTS

contacts for low voltage/current applications

Table 2 – REMOTE OPTION RESET

Table 3 – Enclosure Finish

PAGE 2

Page 7

MODEL 365A & E365A INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR 909GF294

2 Specifications

2.1 Environmental

Housing Aluminum Alloy, 356-T6

Weight 8 lbs approximately

Mounting Location Indoor or Outdoor, unprotected

Enclosure Classification Approved for

Class I, Division 1, Group B, C, & D

Class II, Division 1, Group E, F, & G; Enclosure 4 & 4X

Class I, Zone 1, AEx d IIB +H2 T6; Ex d IIB+H2 T6; IP66

ATEX EEx d IIB+H2 T6 IP66

CE 0539

Ambient Temperature Limits -13°F to +140°F (-25°C to +60°C)

Humidity To 95% RH @ 100°F (+37.8°C), non-condensing

Shock 40g @ 11 ms maximum

2.2 CE PRODUCT CERTIFICATION

Vibraswitch® models with CE (ATEX) Approval are distinguished by the addition of the CE

mark on the Nameplate. The nameplate includes additional information:

Robertshaw Industrial Products, 1602 Mustang Drive, Maryville, TN 37801 = manufacturer’s name and address

E365A = the manufacturer’s Model Number

Serial number = unique serial number assigned by manufacturer which includes a code for year of construction

IIB+H2 = marking according to Group II

T6 = marking essential for safe use

IP66 = Enclosure Rating

Cert. Nr. DEMKO 05 ATEX 0436069

Essential information for safe use:

1. The equipment temperature code is T6.

2. The ambient temperature range for the equipment is -13°F (-25°C) to +140°F (+60°C).

3. The equipment must be bolted closed before power is applied.

4. All cable entry devices and blanking elements shall be certified in type of explosion protection flameproof

enclosure “d”, suitable for the conditions of use and correctly installed

5. Unused apertures shall be closed with suitable blanking elements.

2.3 ELECTRICAL

II 2 G

Standard Contact rating:

SPDT (Table 1 – Designation “A”)

7 A max, 460 VAC max, 50/60 Hz non-inductive;

0.5 A max, 120 VDC max. non-inductive;

1 A max, 48 VDC max. non-inductive;

2 A max, 24 VDC max. non-inductive;

5 A max, 12 VDC max. non-inductive.

DPDT (Table 1 – Designation “D”)

5 A max, 240 VAC max, 50/60 Hz non-inductive;

5 A max, 30 VDC max, non-inductive

PAGE 3

Page 8

MODEL 365A & E365A INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR 909GF294

Gold Contact rating:

DPDT (Table 1 – Designation “G”)

0.1 A max, 125-250 VAC, non-inductive;

0.1 A max, 30 VDC, non-inductive;

1 mA min, 24 VDC, non-inductive;

2 mA min, 12 VDC, non-inductive;

5 mA min, 6 VDC, non-inductive

Reset Coil Power:

12 VDC, 1.5 A

24 VDC, 0.5 A

48 VDC, 0.2 A

120 VDC, 0.14 A

120 VAC, 0.3 A

240 VAC, 0.3 A

Maximum Energized Time:

4 minutes

2.4 PERFORMANCE

Vibration Measurement Range:

0 to 4.5g (peak) from 0 to 300 Hz (18,000 RPM) – when horizontally mounted.

0 to 3.5g (peak) from 0 to 300 Hz (18,000 RPM) – when vertically mounted.

Setpoint Range:

0 to 4.5 g

Setpoint Adjustment:

Approximately 1g per turn

Accuracy:

± 5% of full range from 0 to 300 Hz (18,000 RPM)

Operating Temperature Range:

-25°C to +60°C (-13°F to +140°F)

Ambient Temperature Effects:

± 10% / 100°F (55.5°C) max

PAGE 4

Page 9

MODEL 365A & E365A INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR 909GF294

3 INSTALLATION

3.1 GENERAL

Examine the Vibraswitch® for possible shipping damages. IMPORTANT: If for any reason it is

determined that the equipment should be returned to the factory, please notify the nearest Robertshaw

Sales representative prior to shipment. Each unit must be properly packaged to prevent damage.

Robertshaw assumes no responsibility for equipment damaged in shipment due to improper packaging.

Choose the location in accordance with good instrument practice, avoiding extremes of temperature,

humidity and vibration. (See SECTION 2 – SPECIFICATIONS)

The Model 365A Vibraswitch® is UL, and

section 2 -- SPECIFICATIONS. The Model E365A Vibraswitch® is UL,

UL Certified for use in hazardous locations as indicated in

c

UL and ATEX Certified for

c

use in hazardous locations as indicated in section 2 -- SPECIFICATIONS.

In locations where moisture condensation within explosion proof junction boxes is a problem, a 2-watt

resistor may be placed across terminals 6 and 7 inside the Vibraswitch® and wired to provide continuous

heating and air circulation. (See Table 3-1 for resistance values.)

3.2 MOUNTING

Figure 3-2 illustrates the methods of mounting on various pieces of equipment. Figure 3-1 shows the

mounting dimensions and external wiring for the Vibraswitch®, Model 365A.

The vibration sensitive axis of the Vibraswitch® is perpendicular to its mounting base. Therefore, the

Vibraswitch® must be mounted on a plane that will detect the vibratory motion for which protection is

desired. The Vibraswitch® may be mounted at any location along the length of machines containing

rotating shafts that are horizontal and parallel to the base of the machine: the preferred location being in

line with the rotating shaft (ref Figure 3-3). Do not mount the Vibraswitch® perpendicular to the ends of

rotating shafts unless the endplay or end-thrust measurement is desired. Normally, bent shafts,

unbalances on the rotating mass of the shaft, worn bearings, and other anomalies are detected near the

bearing housings and at right angles to the shaft.

The Vibraswitch® may be mounted in any position between the side (vertical) or the top (horizontal) of

bearings or machine housings. It should be noted that when mounting the Vibraswitch® on top

(horizontal position) of equipment, the vibration measurement range is as stated in the SPECIFICATION

SECTION. However, when the Vibraswitch® is mounted on a side position (90° from the horizontal), 1

g is subtracted from the measurement range.

If a mounting bracket assembly is used to mount the Vibraswitch® due to irregular mounting surface, it

must be constructed of steel having sufficient thickness and properly reinforced so that mechanical

resonance’s are not introduced; usually ½” steel plate is satisfactory if the dimensions of the bracket are

minimal (ref Figure 3-3). It is extremely important that all four corners of the Vibraswitch® as well as

the mounting assembly be rigidly secured to the machine. Exact location is not as critical as the

adjustment procedure of the Vibraswitch®. The Vibraswitch® automatically accounts for the normal

vibration at that location.

The Vibraswitch®, when properly adjusted, trips on a relative increase in vibration.

When installing the Vibraswitch®on existing equipment where several convenient mounting positions

are available, it is advisable to check the existing vibration level at each possible position before

permanently mounting the unit. The Vibraswitch® can be used to measure existing vibration by holding

PAGE 5

Page 10

MODEL 365A & E365A INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR 909GF294

or clamping it against the running machine and determining the trip point as described under

“ADJUSTMENT” in this manual. Should normal vibration exceed the range of the Vibraswitch®, it is

recommended that consideration be given to a Robertshaw Velocity-Acceleration Vibration Monitor,

Model 566.

3.3 SPACE HEATER

In some outdoor installations, it may be necessary to install a space heater to prevent moisture

condensation. A small conventional carbon 2-watt resistor should be installed across terminals 6 and 7 in

the detector. It should be noted that the Vibraswitch® might be ordered from the factory with the space

heater already installed. Proper values for the resistor are shown in Table 3-1.

Table 3-1. SPACE HEATER RESISTOR VALUES

VOLTAGE (AC OR DC) SPACE HEATER RESISTOR (Ohms)

120/120 12,000

48 2,200

24 620

12 150

3.4 WIRING

The Vibraswitch® Model 365A & E365A is equipped with a threaded hub for ¾” conduit. When the

vibration amplitude is large (ie, greater than 5 mils) it is good practice to use a short length of flexible

conduit to serve as an isolator between the rigid conduit and the Vibraswitch®. Wiring into the unit

should be done with #18 stranded wire, although #14 can be used where necessary. The

Vibraswitch®was not designed for wiring with heavy, solid wire. However, where necessary to use a

heavier wire, as in low voltage DC, a junction box near the Vibraswitch® should be used.

The instrument must be sealed at the conduit outlets with a suitable

compound or “trap” to prevent infiltration of moisture laden air or

corrosive gases into the housing.

All instrument installation wiring must be done in accordance with local

codes and commonly acceptable practices.

All cable entry devices and blanking elements shall be certified in type of

explosion protection flameproof enclosure “d”, suitable for the conditions of

use and correctly installed.

NOTE

NOTE

NOTE

Unused apertures shall be closed with suitable blanking elements.

NOTE

PAGE 6

Page 11

MODEL 365A & E365A INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR 909GF294

Figure 3.1 – Model Identification & Mounting Details

PAGE 7

Page 12

MODEL 365A & E365A INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR 909GF294

Figure 3.2 – Connections

PAGE 8

Page 13

MODEL 365A & E365A INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR 909GF294

Figure 3-3. Methods of Mounting the Vibraswitch®, Model 365A

PAGE 9

Page 14

MODEL 365A & E365A INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR 909GF294

To avoid unnecessary difficulty in wiring the unit, the following recommended procedure should be used:

• Wires should be trimmed to project beyond the cover mating surface of the enclosure base by

approximately 1 ½”. Do not pull wires tight, as you may be unable to remove cover subassembly.

• Strip the wires ¼” and install solderless terminals as necessary.

• Rest the cover sub-assembly on the mating surface and connect the wires to the appropriate

terminals.

• Flatten wires entering housing against wall on the conduit hub side and rotate cover sub-assembly

into place, pushing extra wire into corners near hub.

• Replace the cover bolts and torque them to 75-100 inch pounds.

Figure 3.4 - Preparation of Conduit Wiring

Figure 3.5 – Connection of Conduit Wiring to unit

PAGE 10

Page 15

MODEL 365A & E365A INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR 909GF294

4 OPERATION

4.1 GENERAL

The Model 365A & E365AVibraswitch® (Ref. Figure 4-1) is sensitive to vibration in a direction (the

sensitive axis) perpendicular to its mounting base. It contains an acceleration sensitive mechanism, which

also functions as a “mechanical amplifier”, to activate a snap action switch when the selected level of

vibration is exceeded and the detecting mechanism “trips”.

Figure 4-1. Operating Principal for the Vibraswitch®, Model 365A & E365A

The detecting mechanism consists of an armature suspended on a flexible pivot, which is restrained from

motion by a permanent magnet (the hold down magnet). In the “armed” condition, the armature is held

against the stop pin by the hold down magnet. The stop pin maintains a precise air gap between the

armature and the hold down magnet. On the opposite end of the armature, the compression spring

provides an adjustable force to oppose the force of the hold down magnet. Whenever the peak vibration

inertial force (mass x acceleration) plus the adjustable compression spring force exceeds the force of the

holding magnet, the armature is released and is pulled into the latching magnet (tripped position).

Simultaneously, it activates the snap action switch. This detecting mechanism has a uniform response

from 0 to 300 Hz over a range of 0 to 4.5 g’s.

The mechanism may be reset to the “armed” position manually (locally) or electrically (remotely).

Manually, depress the RESET button to move the armature away from the latching magnet (“tripped”

position) until it is held against the stop pin (“armed” position). Electrically, the reset coil may be

activated to pull the armature into the “armed” position against the stop pin.

A reset/holding coil, when specified, is provided, in the DC or AC voltage as specified, so that accidental

shutdowns on starts can be prevented. External time delay relay circuits are required to maintain voltage

at the holding coil during startup period and then release this voltage when operation is normal. At full

voltage, the reset coil should not be energized for more than four (4) minutes to prevent overheating.

Then, the reset coil must be de-energized for a period of 10 minutes before reenergizing. For longer holdin requirements, the rest coil should be energized at full voltage and then held-in at one-half the rated

voltage.

The Vibraswitch®, Model 365A &E365A may be used in conjunction with the Vibraswitch® Monitor,

Model 563A. The Monitor is a solid state electronic system designed to “sort out” false signals received

PAGE 11

Page 16

MODEL 365A & E365A INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR 909GF294

by the Vibraswitch® so that Alarm and/or Shutdown of operating machine will not result from false,

transient disturbances. Examples of transient disturbances are the closing of pipeline check valves on

pumping applications, the start up of additional pumps on a line, and the initial start up of various

operating machines. These disturbances may cause the Vibraswitch® to “trip” if the vibratory shock

level is in excess of its setpoint.

The purpose of the Vibraswitch® Monitor is to “supervise” and “sort out” the transient disturbances so

that Alarm or Shutdown is not falsely imposed on the machine being monitored, but any continuous

vibration level, which exceeds the Setpoint of the Vibraswitch®, will cause Alarm and/or Shutdown.

4.2 ADJUSTMENTS OF OPERATING SETPOINT

The operating setpoint for the Vibraswitch® varies with the type of machine and its location

(measurement point) on the machine. The setpoint adjustments suggested in this manual are for

machines, which are functioning in a “good” or “normal” condition. This method follows the concept of

vibration tolerance for the machine and in this case is dependant upon an individual who is experienced in

the operation of the machine vibration as “normal”, “fair”, “slightly rough”, etc. These various degrees of

machine vibration are therefore, based on the individual’s physical perception between normal and

abnormal roughness while the machine is operating.

This method can lead to differences in the classification of the degree of vibration between individual

observers. Robertshaw believes that if the machine is operating satisfactorily, as previously defined, and

the acceleration sensed by the Vibraswitch® is within certain limits, the settings made as outlined in the

following instructions will offer protection of the machine and prevent catastrophic failure.

For example, assume that a relatively new machine, which, to an experienced observer, is operating as

“smooth” or “good” regarding vibration and the Vibraswitch,® measures this acceleration level to be 0.25

g above its static condition (zero). Experience suggests that an acceptable setting for alarm conditions

would be a minimum of twice this value, or 0.5 g. It is acknowledged that such a definition of upper

vibration limit (alarm condition) on the machine may not adequately define the upper tolerance limit of

the machine before major repairs are required or excessive machine damage occurs. It does, however

define a limit that has proven to be “safe”. As the user becomes more experienced using the

Vibraswitch® as a monitoring device, his experience may indicate that a higher setpoint is acceptable on

the particular machine.

Note: Each scale division is ~0.1g and One full revolution is ~1.0 g.

Figure 4-2. Setpoint Adjustment

PAGE 12

Page 17

MODEL 365A & E365A INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR 909GF294

The Model 365A & E365A Vibraswitch® is adjusted by a simple three-step procedure (Ref., Figure 4-

2).

1. Zero Vibration Level Measurement

With the equipment on which the Vibraswitch® is mounted not operating, back off the

SETPOINT adjustment screw counterclockwise (CCW) two (2) turns and press the

RESET button. Then turn the SETPOINT adjustment screw slowly clockwise until

actuation occurs (the armature assembly is against the latch magnet, Figure 4-1). This is

the zero vibration point, or actuating point, with the machine not operating. A mark

should be made with a pencil or other convenient means to permanently record this

“zero” vibration point. Subsequent measurements are made relative to this point.

2. Normal g-Level Measurements

With the machine (equipment) operating, back off the Setpoint adjusting screw one turn

CCW and reset. If it will not reset, back off the Setpoint adjusting screw two turns CCW.

Again turn the Setpoint adjusting screw slowly clockwise until actuation occurs. Mark

this position with a pencil or other convenient means. The difference between the two

actuating points in Steps 1 and 2 is the normal g-level of the operating machine, in

scale divisions. One scale division is ~0.1 g; one full revolution is ~1.0 g.

3. Final Setpoint Adjustment

If the “normal” g-level is less than 1.0 g above the zero level, rotate the Setpoint

adjusting screw CCW ~0.5 g (five graduations) from the point where actuation occurs in

Step 2 above. If the “normal” g-level is greater than 1.0 g refer to figure 4-3 for the

proper Final Setpoint setting with respect to the “normal g-level vibration point” obtained

in Step 2.

NOTE

In preceding adjustments, actuation can be heard

as an audible click. In very noisy surroundings, it

may be necessary to use an ohmmeter or wire the

Vibraswitch to the control circuit to tell when

actuation occurs.

PAGE 13

Page 18

MODEL 365A & E365A INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR 909GF294

Figure 4.3 – Suggested Settings When “Normal” g-Level is >1.0g

PAGE 14

Page 19

MODEL 365A & E365A INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR 909GF294

5. MAINTENANCE

The Vibraswitch® does not normally require any maintenance or repair; however, listed below are some

of the possible malfunctions that may occur and their recommended solutions.

5.1 FUNCTIONAL TEST (Ref. Figure 4-1)

1. With the Vibraswitch® cover sub-assembly removed, place the Vibraswitch® on a table

with its mounting surface horizontal.

2. Press RESET button. If switch does not “reset” (armature latched on stop pin), turn set point

adjustment screw CCW until switch can be manually reset.

3. Slowly turn SETPOINT adjustment screw CW until switch trips. This is the Zero trip point

or the amount of spring tension required to overcome the 1 g force exerted by the earth’s

gravitational pull.

4. Note SETPOINT adjustment. One complete turn equals approximately 1 g. Set point scale is

marked in 0.1 g increments. Turn the set point adjusting screw 1 complete turn CCW. This

is a 1 g setting above the earth’s gravitational pull.

5. Manually reset the switch (press RESET button).

6. With the RESET button to your right and the SETPOINT adjustment screw to your left,

slowly rotate the Vibraswitch® toward you 90°. The switch will trip when the mounting

surface is in a vertical plane and the earth’s gravitational pull is not aiding the lower magnet

to hold the armature against the stop pin.

5.2 TROUBLESHOOTING

There are several possible failure mode for the Vibraswitch® and the following paragraphs provide

information to diagnose the possible causes:

5.2.1 Vibraswitch® Will Not Reset

1. Dirt and/or metal chips on magnets

Clean magnets

2. Broken leaf spring (Refer to Figure 4-1).

®

Return Vibraswitch

to the factory for repair.

3. Open reset coil

Check for continuity and proper coil resistance (refer to Table 5-1). If reading is not

acceptable return Vibraswitch

®

to the factory for repair.

Table 5-1. RESET COIL RESISTANCE

NOMINAL VOLTAGE RESISTANCE (Ohms ± 10%)

12 VDC 12

24 VDC 56

48 VDC 233

117 VDC 1012

120 VAC

240 VAC

(Diode prevents actual resistance reading)

Check for continuity only.

PAGE 15

Page 20

MODEL 365A & E365A INSTRUCTION MANUAL

VIBRASWITCH® MALFUNCTION DETECTOR 909GF294

5.2.2 Unable to Adjust Set point Setting to Obtain Trip

An improper air gap exists between hold down (lower) magnet and armature.

®

Return the Vibraswitch

to the factory for repair.

5.2.3 Switch Does Not Actuate

Defective Switch – verify by manually moving the Armature to the latched (tripped) position and

listen for an audible click of the switch. Verify contact change-of-state by performing a

continuity check.

If the switch does not pass either of the tests above, return the Vibraswitch

repair.

®

to the factory for

PAGE 16

Loading...

Loading...