Page 1

MODEL 158A 909GF197B

INSTRUCTION MANUAL

MODEL 158A

LEVEL-TEL

FOR

We do our level best

Industrial Products Division

1602 Mustang Drive

Maryville, Tennessee 37801

Phone: (865) 981-3100 Fax: (865) 981-3168

- 1 -

Probe, Cable and Conduit Outlet Box

shown for illustration only.

Must be ordered separately.

INSTRUCTION MANUAL NUMBER

909GF197B

P-2410

Page 2

MODEL 158A 909GF197B

Section I – DESCRIPTION

1.1 GENERAL

The Robertshaw Model 158A Level-Tel is a

capacitance operated DC current transmitter with

noninteracting and independent zero and span

adjustments internally located. The transmitter is

remotely mounted from the probe with a triax

cable interconnected between the probe and the

transmitter.

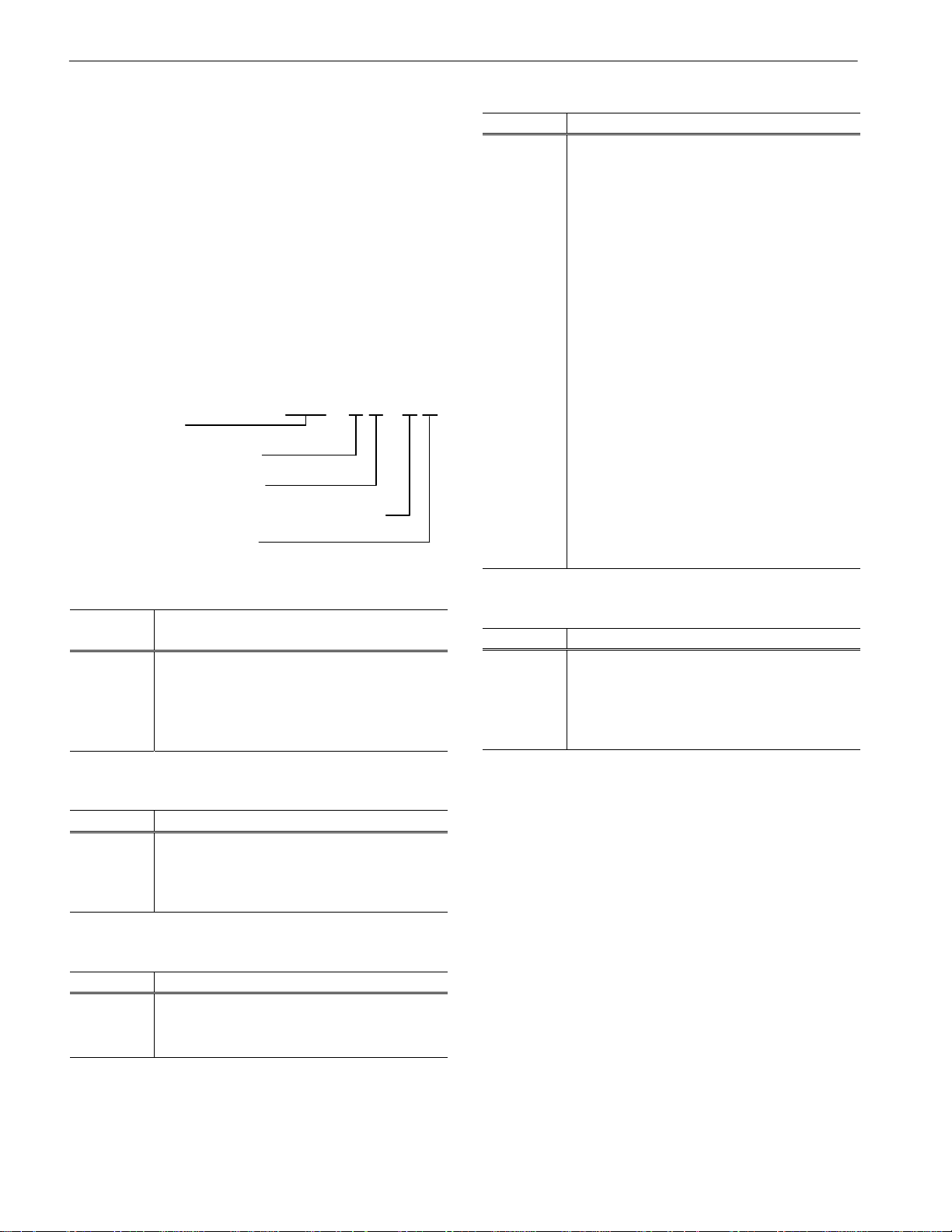

1.2 MODEL IDENTIFICATION

Identify instrument models in accordance with the

descriptions and variations listed in each table.

158A - B 1 - A 1

Key Model No.

Table 1 – Output Current

Table 2 – Supply Voltage

Table 3 – Display Housing and Indication

Table 4 – Alarm Options

KEY MODEL NO.

Model

No.

158A Capacitance-to-current transmitter

system for remotely mounted probe

assemblies. Control Unit is

available with or without indication

and optional alarms.

Table 1 – OUTPUT CURRENT

Desig. Description

A 1-5 mADC

B 4-20 mADC

C 10-50 mADC

D 0-10 mADC

Table 2 – SUPPLY VOLTAGE

Desig. Description

1

2

3

26.5 VDC, ± 10%

120 VAC, ± 10%, 50/60 Hz

240 VAC, ± 10%, 50/60 Hz

Description

¾ May only be used with Designation E on

Table 3.

Table 3 – DISPLAY HOUSING AND

INDICATION

Desig. Description

A Water tight enclosure without

indicator.

Meets NEMA Type 4 and CSA

Enclosure 5.

B Water tight housing with indicator.

Meets NEMA Type 4 and CSA

Enclosure 5.

C Explosion proof housing without

indicator.

For Class I, Division 1, Groups C

and D; Class II, Division 1, Groups

E, F and G, areas.

D Explosion proof housing with

indicator.

For Class I, Division 1, Groups C

and D; Class II, Division 1, Groups

E, F and G, areas.

E Large weatherproof enclosure with

indicator to be used with optional

alarms.

Meets NEMA Type 12 & 13 and

CSA Encl 3.

Table 4 – ALARM OPTIONS

Desig. Description

1 None

2 ¾Alarm Relays for High or Low

Alarm.

3 ¾Alarm Relays for High and Low

Alarms.

- 2 -

Page 3

MODEL 158A 909GF197B

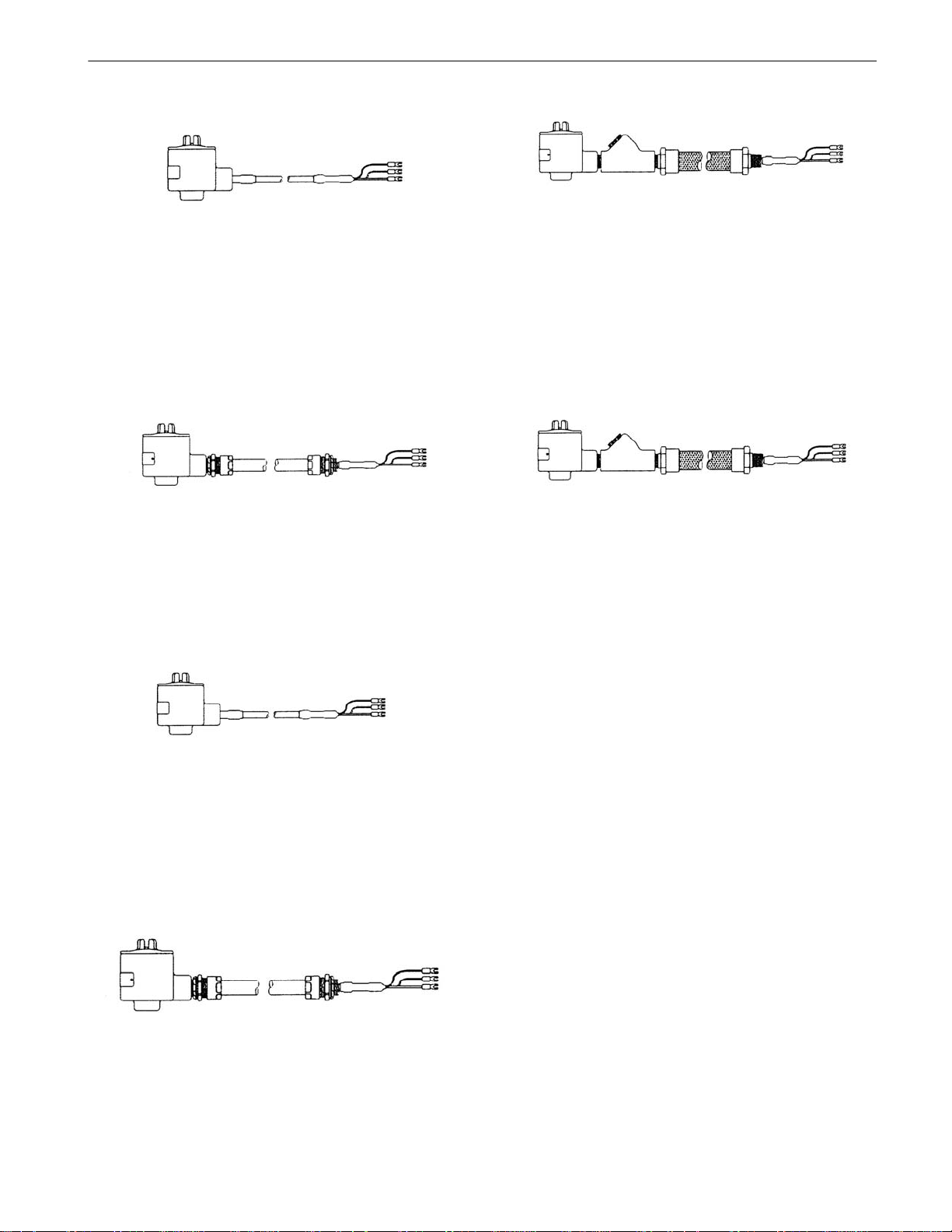

1.3 TRIAXIAL CABLE ACCESSORY ITEMS

032KE03X-XX¾

GENERAL PURPOSE (polyethylene insulated)

Triax Cable with probe connection conduit

outlet box. (Recommended for use with

customer supplied rigid or flexible conduit.)

Maximum temperature 185° F.

032KE05X-XX¾

GENERAL PURPOSE (polyethylene insulated)

Triax Cable in flexible conduit (protective

armor) with probe connection conduit outlet

box. Maximum temperature 185° F.

032KE04X-XX¾

HIGH TEMPERATURE (Teflon insulated) Triax

Cable with probe connection conduit outlet box.

(Recommended for use with customer supplied

rigid or flexible conduit.) Maximum

temperature 350° F.

032KE06X-XX¾

HIGH TEMPERATURE (Teflon insulated) Triax

Cable in flexible conduit (protective armor) with

probe connection conduit outlet box. Maximum

temperature 350° F.

032KE090-05 (5 ft long)

032KE090-10 (10 ft long)

GENERAL PURPOSE (polyethylene insulated)

Triax Cable in explosion proof flexible conduit

(protective armor) with seal fitting and probe

connection conduit outlet box. Maximum

temperature 185° F.

032KE100-05 (5 ft long)

032KE100-10 (10 ft long)

HIGH TEMPERATURE (Teflon insulated) Triax

Cable in explosion proof flexible conduit

(protective armor) with seal fitting and probe

connection conduit outlet box. Maximum

temperature 350° F.

¾ Substitute length in feet for X-XX in part

number.

Example: For 10 feet substitute 0-10

For 120 feet substitute 1-20

Explosion proof cables are standard in 5 and

10 foot lengths.

- 3 -

Page 4

MODEL 158A 909GF197B

Section II - SPECIFICATIONS

2.1 ENVIRONMENTAL

Ambient Temperature Limits.......-40° F to +160° F

Vibration Limits................± 2 G from 10 to 200 Hz

2.2 ELECTRICAL

Supply Voltage............. 120 VAC ± 10%, 50/60 Hz

240 VAC ± 10%, 50/60 Hz

26.5 VDC ± 10%

2.4 ENCLOSURE

Water Tight ...............NEMA 4, CSA Enclosure 5,

Polyurethane painted cast aluminum

Explosion Proof...Class I, Division 1, Groups C, D;

Class II, Division 1, Groups E, F, G;

Polyurethane painted cast aluminum

Weatherproof..... NEMA 12, 13, CSA Enclosure 3,

Polyurethane painted steel

2.5 INTRINSIC SAFETY

Models 158A – (A, B) (1, 2) – (A, B, C, D) – 1:

Supply Power........................... 5 watts, 7 VA max.

Terminal Capacitance Range............ 0 to 1000 pF

Probe circuit is CSA Certified intrinsically

safe for Class I, Division 1, Group C & D;

Class II, Division 1, Group E, F & G

Span Capacitance Range........ 10 pF plus 1 pF for

each 10 feet of Triax

cable up to 2000 pF

Maximum Recommended

Terminal/Span Ratio....................................... 10:1

Output Signal

and Load...................1-5 mADC into 0-2500 ohms

4-20 mADC into 0-700 ohms

10-50 mADC into 0-250 ohms

0-10 mADC into 0-1000 ohms

hazardous locations when connected as

shown on drawing 907GA518 (Figure 8).

2.6 AGENCY CERTIFICATIONS

Models 158A – (A, B) (1, 2) – (A, B, C, D) – 1:

CSA Certified .............................File LR 18690

Connecting Cable Length.................150 feet max.

2.3 PERFORMANCE

Linearity.................................. 0.5% max. for span

less than 1000 pF

1% max. for span

greater than 1000 pF

Repeatability...............................................± 0.1%

Sensitivity......................................0.01% minimum

Frequency Response.........................-3 db at 1 Hz

Supply Variation Effect ...............0.5%/10% supply

Ambient Temperature Effect:

Span................................................0.01%/° F

Zero............................. 0.01%/F or 0.01 pF/F,

whichever is greater

Output Signal Ripple............................. 0.2% max.

Output Meter Accuracy.................................. ± 2%

- 4 -

Page 5

MODEL 158A 909GF197B

Section III - INSTALLATION

3.1 GENERAL

Examine the instrument for possible shipping

damages. IMPORTANT: If for any reason it is

determined that parts should be returned to the

factory, please notify the nearest Robertshaw

sales representative prior to shipment. Each unit

must be properly packaged to prevent damage.

Robertshaw assumes no responsibility for

equipment damaged in shipment due to improper

packaging.

Choose the location in accordance with good

instrument practice, avoiding extremes of

temperature, humidity and vibration (see

Specifications, Section II).

3.2 PROBE MOUNTING

3.3 TRANSMITTER UNIT MOUNTING

The Model 158A is designed for vertical surface

mounting: e.g. wall, panel or column. Choose the

mounting location to avoid extremes of ambient

temperature or vibration (see Specifications,

Section II).

3.4 WATER TIGHT & WEATHERPROOF

TRANSMITTER MOUNTING & ELECTRICAL

CONNECTIONS

See Figures 1, 3, 4, 5, 6 and 7 for the mounting

dimensions and electrical connections of the

Water Tight and Weatherproof Transmitters. See

Figure 8 for interconnection diagram for those

models certified for intrinsically safe probe

installations.

3.5 EXPLOSION PROOF TRANSMITTER

MOUNTING & ELECTRICAL CONNECTIONS

Level-Tel probes for use with the Model 158A are

purchased separately from a variety of styles and

types which provide for various specific

applications involving liquids or granular

materials. Insulated rod-type probes are normally

used for liquid solutions or liquid-interface

junctions.

Since many materials have a tendency to build up

on the probe over extended periods of operation,

it is advisable on horizontally mounted probes to

place the probe so that its lower tip is below the

gland entrance. This encourages self-cleaning by

permitting the material to drip from the probe.

However, some materials will continue to build up

and cause the Level-Tel to become insensitive or

fail to operate. If such material is being used, the

installation should be made so that the probe is

easily removed for periodic cleaning.

The face of the gland on the rod-type probes

must be installed until nearly flush with the vessel

wall. DO NOT install the probe in a nozzle,

recess, or open-end well, unless the probe was

supplied with a factory assembled sheath as

there is danger of material collecting in such a

recess and causing false operation.

- 5 -

See Figures 2, 3 and 5 for the mounting

dimensions and electrical connections of the

Explosion Proof Transmitter. See Figure 8 for the

interconnection diagram for those models certified

for intrinsically safe probe installations.

Page 6

MODEL 158A 909GF197B

MM

INCHES

SEE FIGURE 5 FOR DIMENSIONS OF

PROBE MOUNTED CONDUIT OUTLET BOX.

MOUNTING DIMENSIONS FOR MODEL 158A WATER TIGHT ENCLOSURE WITH

AND WITHOUT INDICATOR, MODELS 158A – ( ) ( ) – A1 AND 158A – ( ) ( ) B1.

FIGURE 1

- 6 -

Page 7

MODEL 158A 909GF197B

FIGURE 2

MOUNTING DIMENSIONS FOR MODEL 158A EXPLOSION PROOF ENCLOSURE WITH

AND WITHOUT INDICATOR, MODELS 158A – ( ) ( ) – C1 AND 158A – ( ) ( ) – D1.

MM

INCHES

SEE FIGURE 5 FOR DIMENSIONS OF PROBE

MOUNTED CONDUIT OUTLET BOX.

- 7 -

Page 8

MODEL 158A 909GF197B

TERMINAL CONNECTION REMARKS

NOTES:

1

PROBE TRIAX WHITE LEAD

SHLD TRIAX RED LEAD

GND TRIAX BLACK LEAD

1 N ( ) SUPPLY

2 H (+) SUPPLY

GND CHASSIS GROUND

3 ( ) OUTPUT SIGNAL

4 (+) OUTPUT SIGNAL

. REMOVE JUMPER ACROSS OUTPUT TERMINALS 3 AND 4 WHEN RECORDER,

CONTROLLER, ETC. IS USED.

TERMINAL

FIGURE 3

ELECTRICAL CONNECTIONS FOR WATER TIGHT AND EXPLOSION PROOF ENCLOSURES,

MODELS 158A – ( ) ( ) – (A, B, C, D) ( ).

SEE RATING PLATE

(120 VAC, 240 VAC OR 26.5 VDC)

SEE NOTE 1

- 8 -

Page 9

MODEL 158A 909GF197B

MOUNTING DIMENSIONS FOR LARGE WEATHERPROOF ENCLOSURE WITH INDICATOR (USED WITH

OPTIONAL ALARMS) MODEL 158A – ( ) ( ) – E ( ).

FIGURE 4

MILLIMETER

INCH

SEE FIGURE 5 FOR DIMENSIONS OF PROBE

MOUNTED CONDUIT OUTLET BOX.

- 9 -

Page 10

MODEL 158A 909GF197B

–

( ) ( )

FIGURE 5

DIMENSIONS OF PROBE MOUNTED CONDUIT OUTLET BOX SUPPLIED WITH TRIAX CABLE.

(TRIAX CABLE ORDERED SEPARATELY)

ELECTRICAL CONNECTIONS FOR LARGE WEATHERPROOF ENCLOSURE,

MODEL 158A

FIGURE 6

–E ( ).

- 10 -

Page 11

MODEL 158A 909GF197B

TERMINAL CONNECTION REMARKS

TB2

TB7

TB8

TB9

PROBE TRIAX WHITE LEAD

SHLD TRIAX RED LEAD

GND TRIAX BLACK LEAD

G CHASSIS GROUND

1 N ( ) SUPPLY

2 H (+) SUPPLY

3 ( ) OUTPUT

4 (+) OUTPUT

5

6

7

NO CONNECTION SEE NOTE 5

8

9 N.C.

10 COM.

11 N.O.

12 N.C.

13 COM.

14 N.O.

15

16

NO CONNECTION

17 N.C.

18 COM.

19 N.O.

20 N.C.

21 COM.

22 N.O.

FIELD WIRING

NOTES:

1. THE ALARM RELAY CONTACTS ARE SHOWN IN THE DE-ENERGIZED CONDITION. FOR

NORMAL OPERATION THE RELAY IS ENERGIZED AND BECOMES DE-ENERGIZED WHEN

THE OUTPUT SIGNAL REACHES THE ALARM POINT.

2. REMOVE JUMPER ACROSS OUTPUT TERMINALS 3 AND 4 WHEN RECORDER,

CONTROLLER, ETC. IS USED.

3. UNLESS OTHERWISE SPECIFIED ALARM NO. 1 SUPPLIES HLFS.

4. UNLESS OTHERWISE SPECIFIED ALARM NO. 2 SUPPLIES LLFS.

5. TERMINALS 3 AND 4, 5 AND 6, 7 AND 8 ARE NORMALLY JUMPERED TOGETHER.

FIGURE 7

ELECTRICAL CONNECTIONS FOR LARGE WEATHERPROOF ENCLOSURE,

MODEL 158A – ( ) ( ) – E ( ).

SEE RATING PLATE

(120 VAC, 240 VAC OR 26.5 VDC)

SEE NOTES 2 AND 5

OPTIONAL NO. 1 ALARM CONTACTS

SEE NOTES 1 AND 3

OPTIONAL NO. 2 ALARM CONTACTS

SEE NOTES 1 AND 4

- 11 -

Page 12

MODEL 158A 909GF197B

–

(

–

(

NOTES:

1. IN FIGURE 1, THE TRANSMITTER IS CSA CERTIFIED FOR HAZARDOUS LOCATIONS, CLASS I, DIVISION 1, GROUPS C & D;

CLASS II, DIVISION 1, GROUPS E, F & G. THE PROBE IS INTRINSICALLY SAFE FOR CLASS I, DIVISION 1, GROUPS A, B, C &

D; CLASS II, DIVISION 1, GROUPS E, F & G.

IN FIGURE 2, THE TRANSMITTER IS CSA CERTIFIED FOR ENCLOSURE 5. THE PROBE IS INTRINSICALLY SAFE FOR

CLASS I, DIVISION 1, GROUPS A, B, C & D; CLASS II, DIVISION 1, GROUPS E, F & G.

2. R. STAHL INC., MODEL 8901/33-293/000-79 OR CSA CERTIFIED EQUIVALENT (28.1V MAX., 300 OHM MIN.) POSITIVEPOTENTIAL SIGNAL RETURN LINE BARRIER WITH INTRINSICALLY SAFE TERMINALS 2 (GROUND) AND 3. BARRIER MUST

BE MOUNTED AND GROUNDED OUTSIDE THE HAZARDOUS AREA IN ACCORDANCE WITH THE INSTRUCTIONS PACKED

WITH BARRIER. POTENTIAL TO GROUND MUST NOT EXCEED 250V RMS (360V PEAK).

3. ROBERTSHAW MODELS 158A – (A, B) (1, 2) – (C, D) 1.

4. ROBERTSHAW MODELS 158A – (A, B) (1, 2) – (A, B) 1.

5. ROBERTSHAW MODEL 702, 728, 729, 736, 738, 739, 740 0R 741 PROBE. INSULATED PROBES ONLY MAY BE USED IN

CLASS II, GROUPS E & F AREAS.

6. 650 OHMS MAXIMUM TOTAL LOOP RESISTANCE, EXCLUDING BARRIER RESISTANCE.

7. FOR AN INTRINSICALLY SAFE INSTALLATION, ALL WIRING BETWEEN THE BARRIER AND THE TRANSMITTER MUST BE

INSTALLED IN RIGID METAL CONDUIT.

FIGURE 8 – DRAWING 907GA518

- 12 -

DIAGRAM FOR INTRINSICALLY SAFE INTERCONNECTIONS FOR

MODELS 158A

A, B) (1, 2)

A, B, C, D) 1.

Page 13

MODEL 158A 909GF197B

Section IV – OPERATION

4.1 CALIBRATION ADJUSTMENTS

Alarm Module No. 2. Refer to Figure 9 and the

following paragraphs for detailed instructions on

how to change the links to obtain the desired

mode. The supply voltage to the instrument

All the adjustments for calibrating the Model 158A

Level-Tel are located on the printed circuit board

assembly and consist of the following (see Figure

8):

4.1.1 Zero Adjustment (0% Process Level

Point)

The zero adjustment can be obtained by the use

of the Fine and Coarse Zero adjustments. The

Fine Zero adjustment is a multi-turn

potentiometer (approximately 20 turns). The

Coarse Zero adjustment is a 12 position switch.

Clockwise rotation of the zero adjustments will

increase the output signal. When used in

combination, the zero adjustments are capable of

varying the 0% Process Level Point through an

approximate range between 0 and 1000 pF of

terminal capacitance.

4.1.2 Span Adjustment

The span adjustment can be obtained by the use

of the Fine and Coarse Span adjustments. The

Fine Span adjustment is a multi-turn

potentiometer (approximately 20 turns). The

Coarse Span adjustment is a 12 position switch.

Clockwise rotation of the span adjustments will

increase the output signal.

4.1.3 Null Adjustment

The Null adjustment is a multi-turn potentiometer

(approximately 20 turns) that prevents interaction

between the zero adjustment and the span

adjustment during calibration of the instrument.

This adjustment is factory set and should not

require readjustment. However, calibration of

the null adjustment (Ref. Para. 4.3.2) will be

required if a shift of the 0% Process Level Point

of the instrument is experienced following

calibration of the span.

4.2 OPERATIONAL MODE

(For Models 158A – ( ) ( ) – E (2, 3) only)

Unless otherwise specified, the operational mode

for the optional alarms No. 1 & No. 2 of Models

158A – ( ) ( ) – E (2, 3) when they leave the

factory are as specified in Figure 7 of this manual.

The operational mode of either of the alarms may

be changed by relocating the links on the Alarm

Relay Modules. See Figure 6 for location of the

modules. TB3 is Alarm Module No. 1 and TB4 is

- 13 -

should be disconnected when making this

change.

4.2.1 Low Level Fail Safe

Applications for low level detection should utilize

the Low Level Fail Safe (LLFS) mode which is

defined as a decrease in input signal level to

cause the relay to become de-energized or

“alarmed”. This mode is accomplished by

jumpering “A” to “B” and “C” to “D”. (Ref. Figure

9.)

4.2.2 High Level Fail Safe

Applications for high level detection should utilize

the High Level Fail Safe (HLFS) mode which is

defined as an increase in input signal level to

cause the relay to become de-energized or

“alarmed”. This mode is accomplished by

jumpering “A” to “D” and “B” to “C”. (Ref. Figure

9.)

A C

JUMPER LINKS

(SEE NOTES 1 & 2)

B D

TB3 OR TB4

AS SHOWN IN

FIGURE 6

NOTES:

1. JUMPER “A” TO “B” AND “C” TO “D” FOR LLFS

MODE OF OPERATION.

2. JUMPER “A” TO “D” AND “B” TO “C” FOR HLFS

MODE OF OPERATION.

FIGURE 9

MODES OF OPERATION

Page 14

MODEL 158A 909GF197B

CALIBRATION PROCEDURE

4.3.1 Zero and Span Calibration

With the Model 158A Level-Tel mounted and

electrical connections made, the following

procedures should be followed in calibrating the

instrument:

a) On units not containing an indicator, connect

an accurate milliammeter in series with the

output terminals 3(-) and 4(+).

b) Adjust the Coarse Span switch to position

No. 10.

c) With the process level in the vessel or tank

at the desired 0% (low) level, adjust the

Coarse and Fine Zero until the output current

indicates 0% (1, 0, 4 or 10 mA depending on

the output signal range of the Model 158A

Level-Tel being used). Clockwise rotation of

the zero adjustments will increase the output

current.

CALIBRATION ADJUSTMENTS

FIGURE 10

- 14 -

d) Change the process level in the tank to the

desired 100% (high) level and adjust the

Coarse and Fine Span until the output or

meter indicates 100% (5, 10, 20 or 50 mA

depending on the output signal range of the

Model 158A Level-Tel being used).

Clockwise rotation of the span adjustments

will increase the output current.

e) The instrument is now calibrated and ready

for operation. However, it is recommended

that the zero and span calibration be

repeated to obtain optimum accuracy.

4.3.2 Null Adjustment Calibration

THIS ADJUSTMENT IS FACTORY SET AND

SHOULD NOT BE REQUIRED. However, should

calibration of the null adjustment be required,

perform the following procedure:

a) With the Model 158A Level-Tel mou nted and

the electrical connections made, adjust the

Coarse Span switch to position 10.

b) With the process level in the vessel or tank at

the desired 0% (low) level, adjust the Coarse

and Fine Zero adjustments until the output

current indicates 0% (1, 0, 4 or 10 mA

depending on the output of the Model 158A

Level-Tel being used). Clockwise rotation

increases the output current.

c) Adjust the Coarse Span switch to the No. 1

position.

d) Adjust the Null adjustment until the output

current or meter indicates 0%. Clockwise

rotation increases the output current.

e) Repeat steps “a” through “d” until the output

current remains at 0% when the Coarse

Span switch is rotated from position No. 1 to

position No. 10.

Page 15

MODEL 158A 909GF197B

Section IV – SPARE PARTS

DESIG. DESCRIPTION SUPPLY OUTPUT USED ON PART NO.

TB2

TRANSMITTER

PRINTED CIRCUIT ASSY

F1 FUSE, 1/8 A, SLO-BLO ALL ALL ALL 130GD020

K1 RELAY ALL ALL

SPARE PARTS

26.5 VDC

120 VAC

50/60 Hz

240 VAC

50/60 Hz

1-5 mADC 158A-A1-XX 044KB766-01

4-20 mADC 158A-B1-XX 044KB766-04

10-50 mADC 158A-C1-XX 044KB766-07

0-10 mADC 158A-D1-XX 044KB766-10

1-5 mADC 158A-A2-XX 044KB766-02

4-20 mADC 158A-B2-XX 044KB766-05

10-50 mADC 158A-C2-XX 044KB766-08

0-10 mADC 158A-D2-XX 044KB766-11

1-5 mADC 158A-A3-XX 044KB766-03

4-20 mADC 158A-B3-XX 044KB766-06

10-50 mADC 158A-C3-XX 044KB766-09

0-10 mADC 158A-D3-XX 044KB766-12

158A-XX-E2

158A-XX-E3

250KB051-02

- 15 -

Page 16

MODEL 158A 909GF197B

Q-3882 (1/03) Printed in U.S.A.

- 16 -

Loading...

Loading...