Page 1

Custom-Engineered, Low-Intensity

Infrared Heating Systems

Submittal: CRV-Series

Job:

Location:

Engineer:

Gas Specs:

Date:

QTY. MODEL NO. CRV UNIT INPUT BTU/HR

QTY. MODEL NO. CRV UNIT INPUT BTU/HR

QTY. MODEL NO. CRV UNIT INPUT BTU/HR

QTY. MODEL NO. CRV UNIT INPUT BTU/HR

TOTAL INPUT BTU/HR

Important

Before installation and operation of heating equipment, read and understand the

Installation, Operation and Service Manual.

ROBERTS GORDON

the installation and service of gas-fired heating equipment.

1250 William Street 76 Main Street West

P.O. Box 44 Unit 10

Buffalo, New York 14240-0044 Grimsby, Ontario L3M 1R6

Telephone: 716.852.4400 Canada

Fax: 716.852.0854 Telephone: 905.945.5403

Toll Free: 800.828.7450 Fax: 905.945.0511

www.rg-inc.com

Applications, engineering and detailed guidance on systems design, installation and product performance is available upon request.

®

products are to be installed only in accordance with local laws, codes and regulations, and only by a contractor qualified in

Roberts-Gordon Roberts-Gordon

© Copyright 2004 Roberts-Gordon P/N127602NA Rev B 07/04

Page 2

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

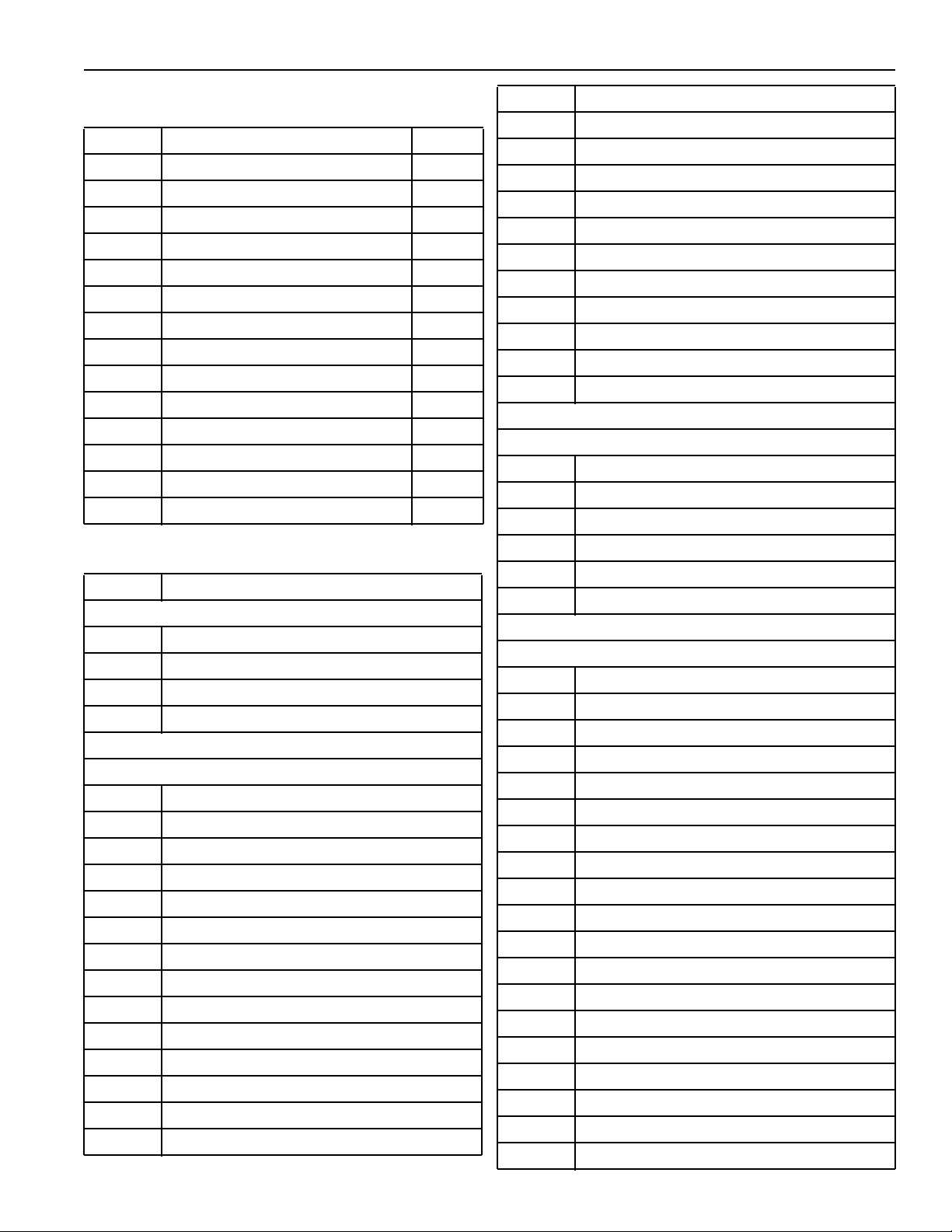

STANDARD PARTS LIST

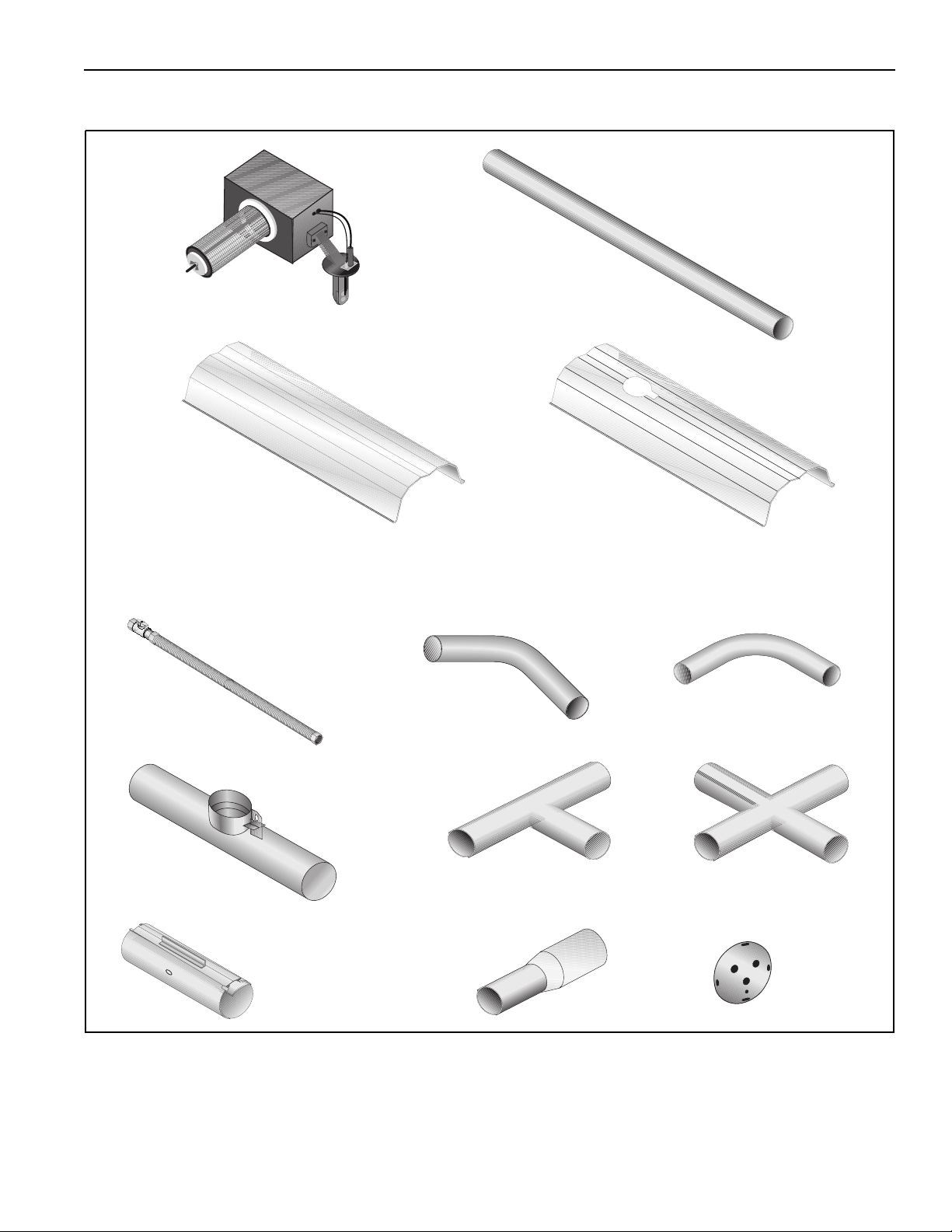

Contents of CRV-Series Burner Carton

Part No. Description Quantity

0270XXXX CRV-S eries Burner (Rate and Fuel Varies) 1

91412200 1/2" Flex Gas Line 1

013676XX End Vent Plate 1

01397300 Accessory Package

01361200 Filter Support Disk 1

01367800 Combustion Chamber Gasket 1

02724901 Door Assembly w/ Hole 1

91115100 Screw #10 - 24x5/8 4

91119500 U-Clip 4

919 05500 Fi l ter Suppor t 1

92123900 Nut 5/16 - 18 2

92511601 Wing Nut #10 - 24 1

96411600 Lock washer 5/16" 2

013 12401 Fi l ter and Gasket 1

0133580D 4" Coated 90° Elbow

01336101 4" Aluminized 45° Elbow

0133610D 4" Coated 45° Elbow

91409300 16 Ga. Hot Rolled S teel 4" dia. 10' T ube

91409403 16 Ga. Non-heat treated Aluminized 4" dia. 10' T ube

91409408 16 Ga. Heat T reated Aluminized 4" dia. 10' Tube

91409420 16 Ga.Non-Heat Treated Aluminized 6" dia. 10' Tube

9141030D 16 Ga. Coated 4" dia. 10' Tube

E0009105 16 Ga. Heat T reated Aluminized 6" dia. 10' Tube

91418200 Aluminized Tube Adapter 6" dia. x 4" dia.

02722100 4" Cast Iron Adapter

91240010 6" Tube Hanger

Venting Accessories

01316000 Outside Air Supply Blower Mounting Kit

01324401 4" Outside Air Supply Takeoff

01326801 Outside Air Filter Housing

Common CRV-Series Components

Part No. Description

Combustion Chamber:

02722300-1P Hot Rolled Steel Combustion Cha mber

02722301-1P Heat-Treated Aluminized Steel Combustion Chamber

0272230D-1P Porcelain Coated Steel Combustion Chamber

02721200-1P Cast Iron Combustion Chamber

T ubing and Related Access ories

01312700 4" Plain Coupling

01312706 6" Plain Coupling

0131270I 4" Lined Coupli ng

01331900 4" Damper Coupling

E0009356 6" Damper Coupling

0133022D 4" Coated Tee

01330203 4" Aluminized T ee

01330204 6" Aluminized T ee

0133092D 4" Coated Cross

01330903 4" Aluminized Cross

01330904 6" Aluminized Cross

01330800 4” Tube Plug

01335801 4" Aluminized 90° Elbow

T0100320 6" Aluminized 90° Elbow

90707501 Air Supply Blower/Power Venter

91409601 4" Outside Air Flex Duct (Box of 8 - 8' secti ons)

90434501 Outside Air Pressure Switch

Reflectors and Related Accessories

01329910 Reflector Side Extension Support

03050010 Reflector Support Package (Tubing)

02712700 Reflector Side Extension, 2 Clips, 2 Screws

02716400 Reflector Support Package (Schedule 40 Pipe)

02750303 Aluminum Reflector

027503SS Stainless Steel Reflector

02750304 Aluminum Reflector with Hole

027503SH Stainless Steel Refle ctor with Hole

02750800 Aluminum Reflector End Cap

027508SS Stainless Steel Reflector End Cap

027508SH Stainless Steel Refle ctor End Cap with Hole

02750900 Reflector Joint

027509SS Stainless Steel Reflector Joint

027127SS Reflector Side Extension, Stainless Steel

03090100 Tube and Reflector Hanger

02790300 Tube and Reflector Hanger, Cast Iron

91907302 “S” Hook

91903201 Turnbuckle

91903300 Spring Hook

© 2004 Rober ts -Gordon

BEFORE INS TALLAT ION AND OPERAT ION OF HEATING EQUIPMENT, READ AND U NDERSTAND THE INSTALLATION, OPERATI ON AND SERVICE MANUA L.

APPLICATIONS , ENGINEERING AND DETA ILED GUIDA NCE ON SYS TEMS DESIGN, INSTALLAT ION AND PRODUCT P ERFORMANCE IS AVAILABLE UPON REQUEST . ROBERTS GORDON® PRODUCT S ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONT RACTOR QUALIFIED IN THE INSTALLA TION AND S ERVICE OF GAS-FI RED HEAT ING EQUIPMENT.

Page 3

ROBERTS GORDON® CRV-SERIES SUBM ITT AL SHEET

91903202 Turnbuckle with Eyebolt

02712100 Universal Shield Support

02751800 Universal Shield with Holes

02751801 Universal Shield

027518SS Universal Shield, Stainless Steel

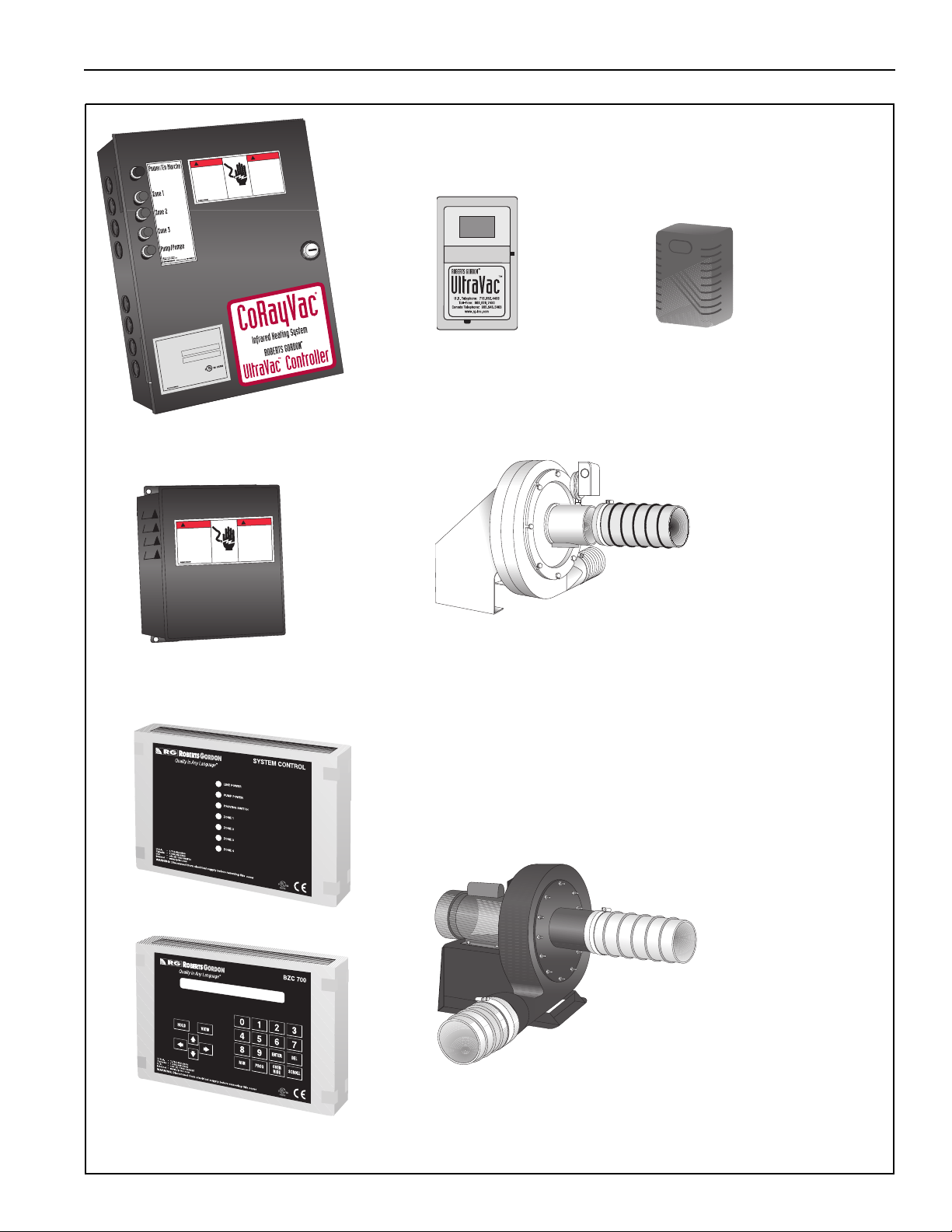

Control Packa ges and Acce ssories

BZC700

ROBERTS GORDON

10001500 Indoor Sensor*, ROBERTS GORDON

®

BZC 700 Controller

®

BZC 700 Controller

* One required pe r z one

10001501 Water Resistant Sensor

02770002 System Control

URVCCM

ROBERTS GORDON® ULTRAVAC™ Cen tral Controller

(with Modem Chip & So ftware ) Includes:

URVSC

ROBERTS GORDON

®

ULTRAVAC™ Controller

10080142 Modem Chip

10081501 Outdoor Sensor

10080410 PC Connection Cable Package

URVCCR

ROBERTS GORDON® ULTRAVAC™ Cen tral Controller

(with RS-485 Converter & Software) Includes:

URVSC ROBERTS GORDON® ULTRAVAC™ Controller

Thermostats

05023000 Load Relay Package

90417600 Transform er Rela y - SPST (12A)

90436300 Transform er Relay - DPDT (12A)

90423000 24V Low Voltage Thermostat (Marked 1-5)

90424300 Thermostat Guard

Deco Grille(1' x 8')

01363003 Bracket

01365901 End Piece

01326801 Reinforcement

01365903 Joint Piece

91406700 1' x 8' Protective Grille

Deco Grille(2' x 4')

01365900 Shield Frame

01370408 Reflector Side Extension 8" x 48"

01370412 Reflector Side Extension 12" x 48"

01370416 Reflector Side Extension 16" x 48"

91407000 Aluminum Grille 2' x 4'

10080430 RS-485 Converter with 9V Power Supply

10081501 Outdoor Sensor

10080410 PC Connection Cable Package

URVCCL

ROBERTS GORDON® ULTRAVAC™ Cen tral Controller

(with TCP/IP Communication Module & Software)

Includes:

URVSC ROBERTS GORDON® ULTRAVAC™ Controller

10080440 TCP/IP Comm unication Module

10081501 Outdoor Sensor

10080410 PC Connection Cable Package

®

URVSC Controller , ROBERTS GORDON

ULTRAVAC™ , 1 Pump 3

Zones (Satellite Control)

VFD75115 Variable Frequency Drive Assembly, 75HP, 115V Input

VFD75230 Variable Frequency Drive Assembly, 75HP, 230V Input

10080142 Modem, Plug-In Chip

10080410 Cable Package, PC connection

10080430 RS-485 Converter with 9V Power Supply

10080440 TCP/IP Communication Module

10081500 Sensor, Adjustable Indoor, Deg F, ROBERTS GORDON

ULTRAVAC™ Controller

Protective Grille

08050001 40" Protective Grille

08050002 Protective Grille End Cap

Shields

02750303 Barrier Shield

02751801 Universal Shield

027518SS Stainless Steel Universal Shield

02751800 Universal Shield with Holes

®

10081501 Sensor, Outdoor, ULTRAVAC™

10081502 Sensor, Adjustable Indoor, Deg C, ULTRAVAC™

© 2004 Roberts-Gordon

B EFORE INSTALLAT I ON AND OPERATION OF HEATI NG EQUIPM ENT, READ AND UNDERSTAND THE INSTALLATION, OPERATION AND SERVICE MANUAL.

A PPLICATIONS, ENGINEERING AND DE TAILED GUIDANCE ON SYSTEMS DES IGN, INSTAL LATION AND PRODUCT PERFORMANCE IS AVAILABLE UP ON REQUES T. ROBERTS GORDON® PRODUCTS ARE TO B E

INSTALLED ONLY IN ACCORDA NCE WITH LOCAL LA WS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTA LLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

Page 4

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

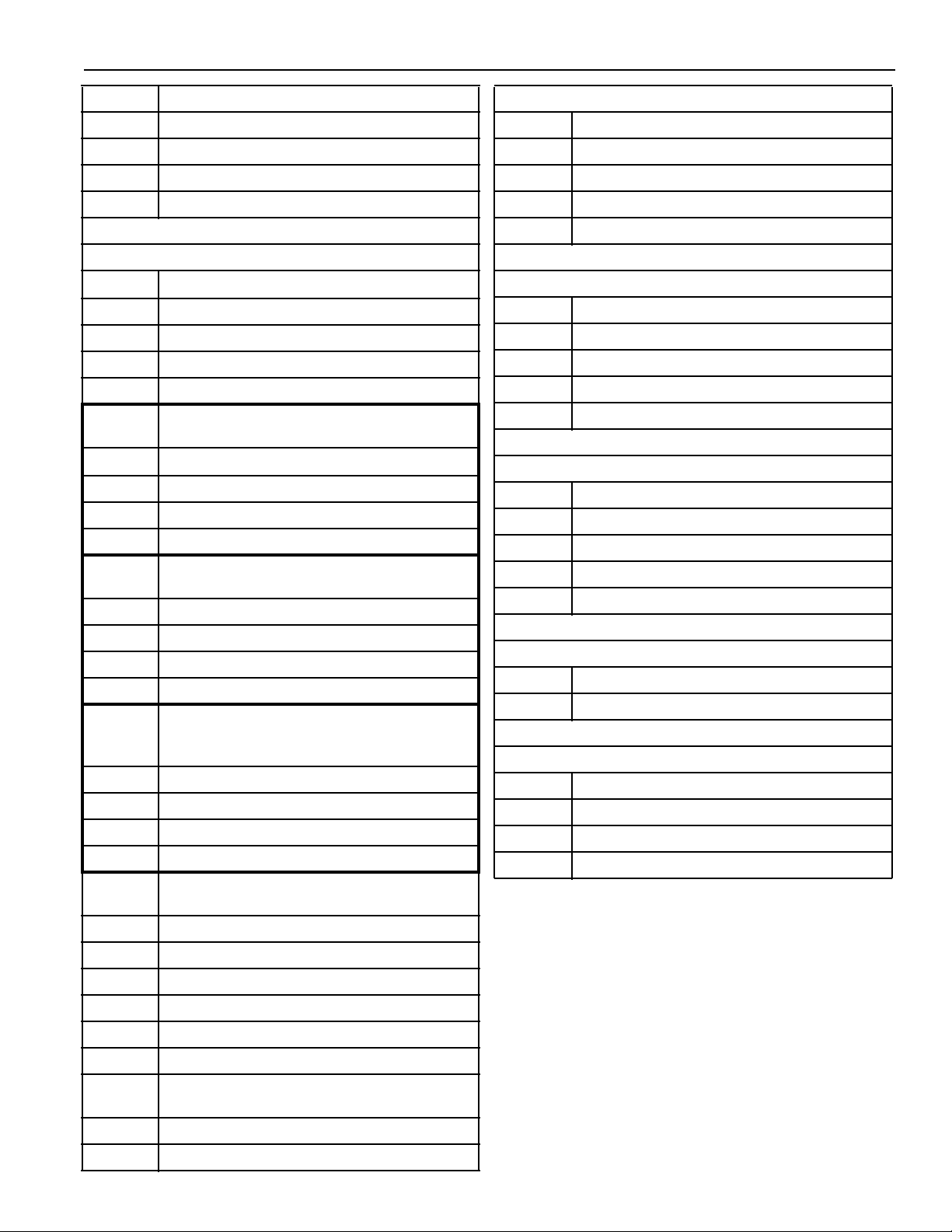

Pump Packages and Accessories

02719105

EP-100 Pump Package

02719100 EP-100 Pump

02724700 Accessory Package

02716305

EP-201 Pump Package

01312001 EP-201 Pump

01317805 Accessory Package

02712034

EP-203 Pump Package

01312002 EP-203 Pump

01317805 Accessory Package

02723014

EP-301 Pump Package 4"

02730101 EP-301 Pump Assembly

02730104 Accessory Package

02723016

EP-301 Pump Package 6"

02730101 EP-301 Pump Assembly

02730106 Accessory Package

Pump Accessories

90430600 Pressu re Switch

0 132700 1 Condens ate Check Valve Assemb ly

02718851 4" Drain Cap

02718852 6" Drain Cap

Starters

10050002 12V DC Starter for EP-201, 1PH

10050003 120V AC Starter for EP-201, 1PH

10050008 120VAC Starter for EP-301, 1PH

10050009 Contactor Package-230VAC Co il for EP-300, 2HP*

*Starter Package c an replace contactor package if pump trip ind ication is

desired when used in conjunction with the ROBERTS GORDON

®

BZC 700

controller.

© 2004 Rober ts -Gordon

BEFORE INS TALLAT ION AND OPERAT ION OF HEATING EQUIPMENT, READ AND U NDERSTAND THE INSTALLATION, OPERATI ON AND SERVICE MANUA L.

APPLICATIONS , ENGINEERING AND DETA ILED GUIDA NCE ON SYS TEMS DESIGN, INSTALLAT ION AND PRODUCT P ERFORMANCE IS AVAILABLE UPON REQUEST . ROBERTS GORDON® PRODUCT S ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONT RACTOR QUALIFIED IN THE INSTALLA TION AND S ERVICE OF GAS-FI RED HEAT ING EQUIPMENT.

Page 5

ROBERTS GORDON® CRV-SERIES SUBM ITT AL SHEET

GENERAL SPECIF ICATIONS

Material Specification

Reflectors

.024 Mill Finish

Steel Type 304).

Aluminium (Optional - 024 Stainless

Heater Specifications

Ignition

Suspension Specifications

Hang heater with materials with a minimum working

load of 75 lbs (33 kg).

Contro ls Specifications

Time switches, thermostats, etc. can be wired into

the electrical supply . Exter nal controls supplied as an

option.

Fully Automatic, Three-Try, Direct Spark, Electr o n ic

Ignition Control, 100% Safety Shut-Off.

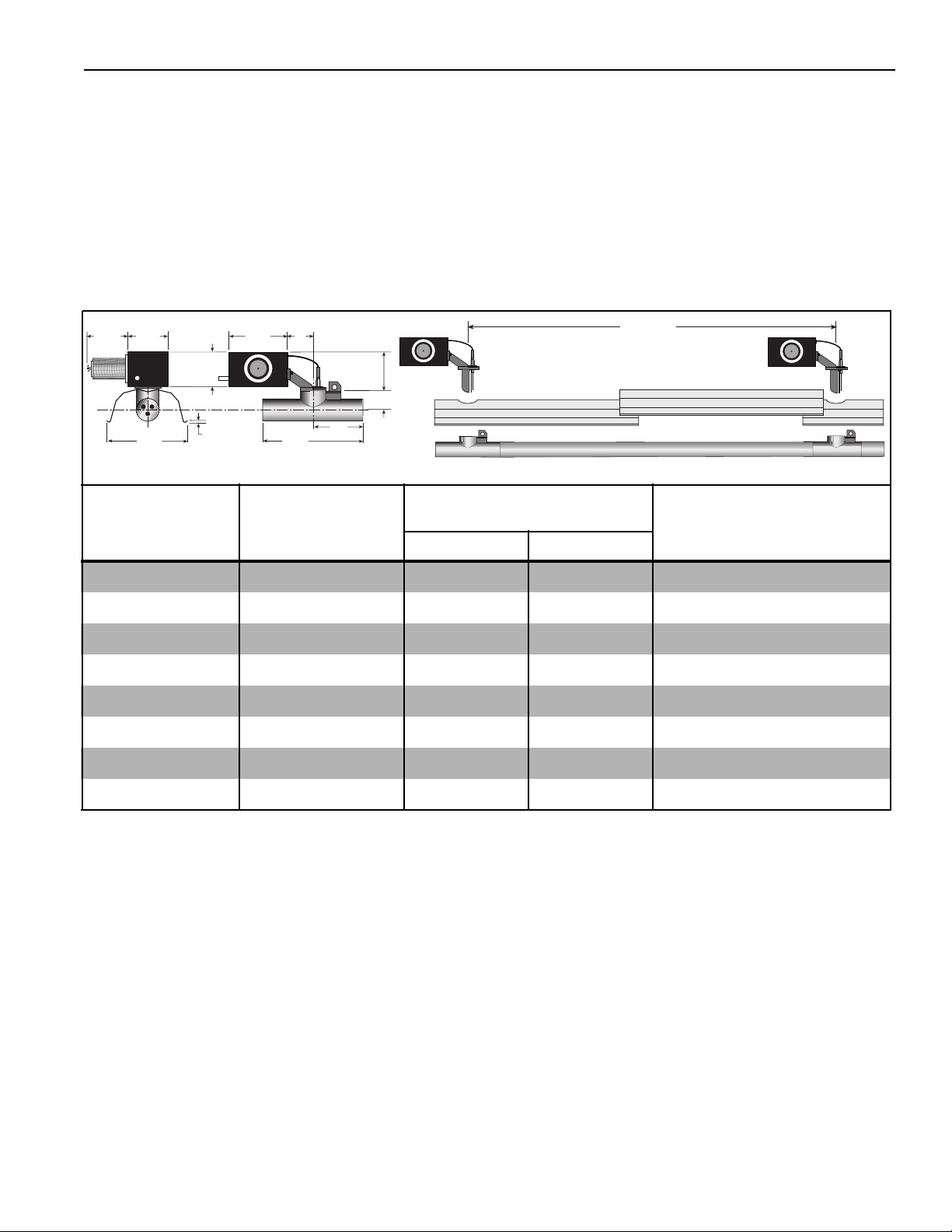

General Specific ations for CRV-Series heaters are as follows:

6 1/2"

9 1/2"

(24 cm)

(16 cm)

14 1/4"

(36 cm)

6 7/8"

(17 cm)

5/32"

(.4 cm)

10 3/4"

(27 cm)

(10 cm)

20"

(51 cm)

4"

7 5/8"

10"

(24.4 cm)

(19 cm)

3 1/2"

(9 cm)

Reflector

Heat Input Rate Length “A”

Length "A"

Recomm ended Minimum

Mounting Height*

Model (BTUH X1000) Minimum Maximum Spot Heating

CRV-B-2 (NG only) 20 10' (3 m) 20' (6.1 m) 8' (2.4 m)

CR V-B-4 40 12.5' (3.8 m) 25' (7.6 m) 8' (2.4 m)

CRV-B-6 60 20' (6.1 m ) 35' (10.7 m) 8' (2.4 m)

CRV-B-8 80 20' (6.1 m) 45' (13.7 m) 10' (3 m )

CRV-B-9 90 25' (7.6 m ) 50' (15.2 m) 10' (3 m)

CRV-B-10 100 30' (9.1 m) 60' (18.3 m ) 15' (4.5 m)

CRV-B-12A (NG only) 110 35' (10.7 m) 70' (21.3 m) 15' (4.5 m)

CRV-B-12 (LP only) 120 35' (10. 7 m) 70' (21.3 m ) 15' (4.5 m)

Pipe Connection

1/2" NPT

(36" Stainless Steel F lex Included with Burner)

Dimensions

Vent Connection Size: 4" (10 cm) or 6" (15 cm)

Gas Inlet Pressure

Natur al Gas: 4.5" w.c. Minimum 14.0" w.c. Maximum

LP Gas: 10.5" w.c. Minimum 14.0" w.c. Maximum

Electrical Rating

120V - 60 Hz., 0.3 Amp

Outside Air Connection Size: 4" (10 cm)

Refer to figure above for dimensional information.

Ignition System

© 2004 Roberts-Gordon

Fully Automatic, Three-Try, Direct Spark, Electronic

Ignition Control, 100% Shut-Off

B EFORE INSTALLAT I ON AND OPERATION OF HEATI NG EQUIPM ENT, READ AND UNDERSTAND THE INSTALLATION, OPERATION AND SERVICE MANUAL.

A PPLICATIONS, ENGINEERING AND DE TAILED GUIDANCE ON SYSTEMS DES IGN, INSTAL LATION AND PRODUCT PERFORMANCE IS AVAILABLE UP ON REQUES T. ROBERTS GORDON® PRODUCTS ARE TO B E

INSTALLED ONLY IN ACCORDA NCE WITH LOCAL LA WS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTA LLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

Page 6

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

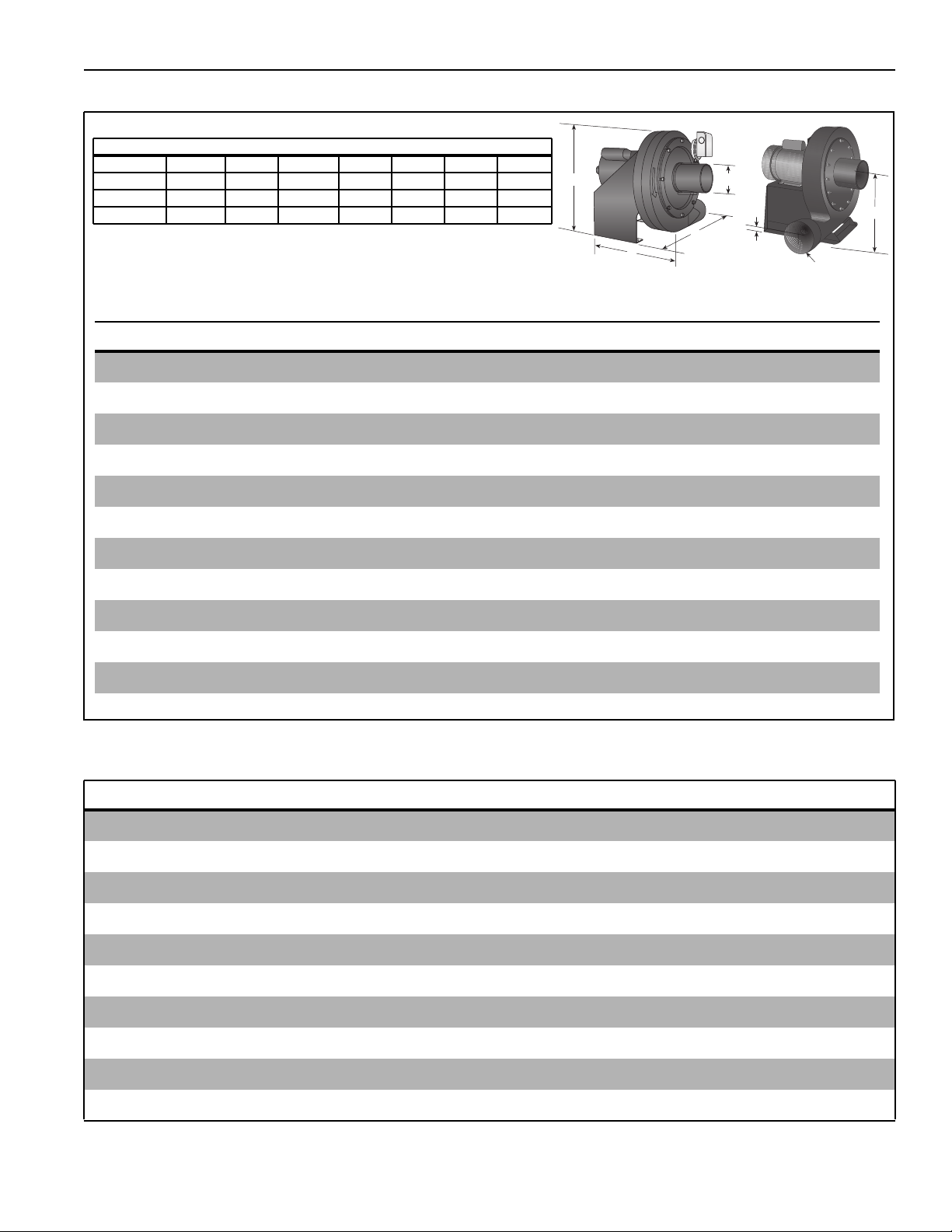

Pump Specifications

Pum p Di m ensional Da ta (in .)

Model ABCDEFG

EP-100 17 14.5 21 3.75 10 4 4

EP-201/203 17.75 17 18.75 3.25 10 4.5 4.5

EP-301 25.6 24.8 22.7 4.8 15.2 6 6

A

C

G

D

B

Pump Specifications

Model EP-100 EP-201 EP-203 EP-301

Horsepower (Hp) 1/3 3/4 3/4 2*

Phase 1 1 3 1

Hertz (Hz) 60 60 60 60

Vol tage (V ) 115/230 115/230 230 230

Full Load Amp (Amps) 4.8/2.4 6.6/3.3 3.0 11.5

E

dia.

F

R.P.M. 3450 3450 3450 3450

Motor Frame 56 56 56 90

Mo tor Enclosure TENV TENV TEF C TEFC

Nois e Level @ 5' (DBA) - 70 70 Inlet/Outlet (In.) 4/4 4/4 4/4 6/6

Wei ght (lbs .) 62 112 112 170

* For starter, see National Electric Code (NEC) requirement for motors 1 hp or higher.

Air Supply Blower Specifications

Capacity 240 CFM @ 0.75" w. c.

P owe r (W) 167

Phase 1

Hertz (Hz) 60

Voltag e ( V) 120

Full Load Amp (Amps) 1.5

R.P.M. 3000

Motor Enclosure OPEN FC

Inlet/Outle t (In.) 5/5

Weight (lbs.) 10

© 2004 Rober ts -Gordon

BEFORE INS TALLAT ION AND OPERAT ION OF HEATING EQUIPMENT, READ AND U NDERSTAND THE INSTALLATION, OPERATI ON AND SERVICE MANUA L.

APPLICATIONS , ENGINEERING AND DETA ILED GUIDA NCE ON SYS TEMS DESIGN, INSTALLAT ION AND PRODUCT P ERFORMANCE IS AVAILABLE UPON REQUEST . ROBERTS GORDON® PRODUCT S ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONT RACTOR QUALIFIED IN THE INSTALLA TION AND S ERVICE OF GAS-FI RED HEAT ING EQUIPMENT.

Page 7

ROBERTS GORDON® CRV-SERIES SUBM ITT AL SHEET

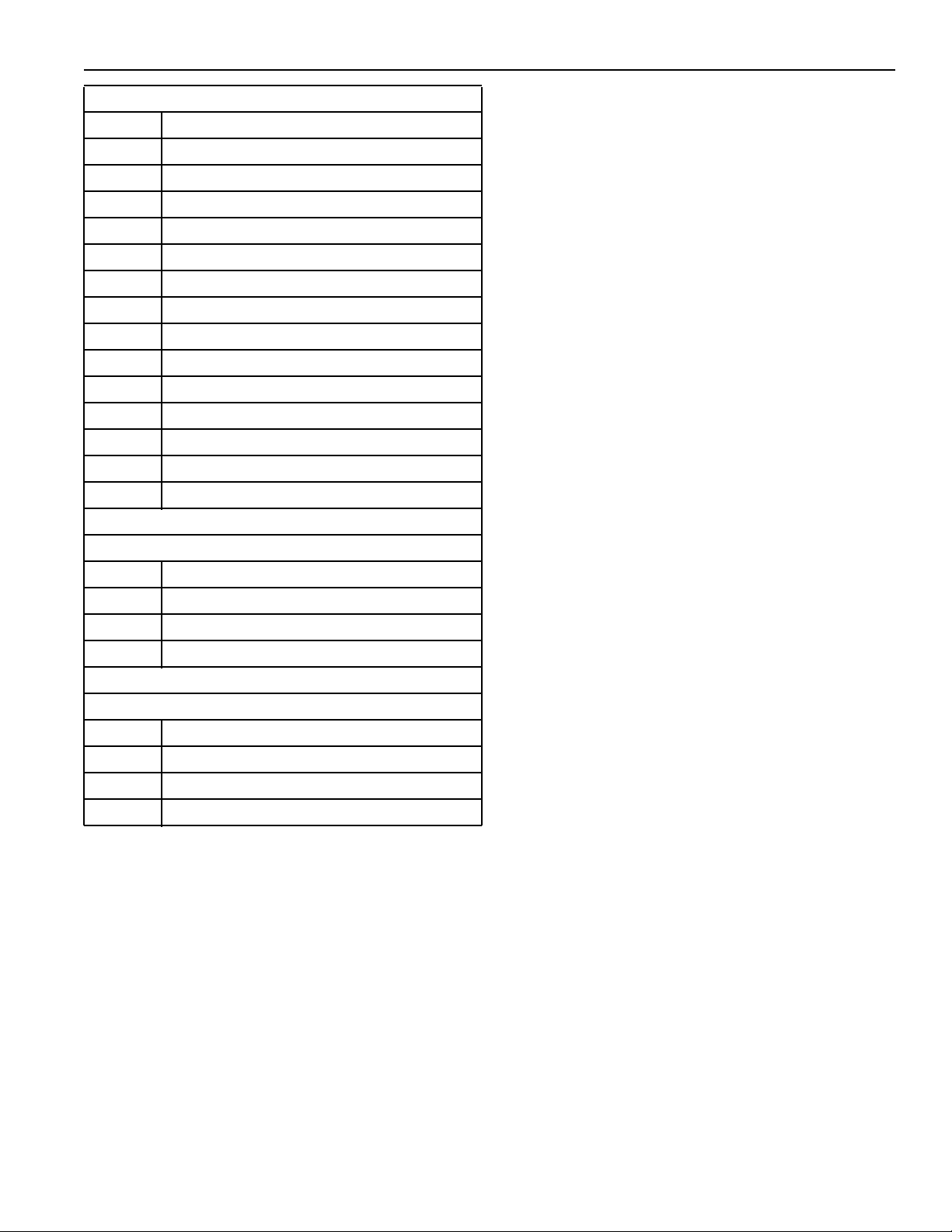

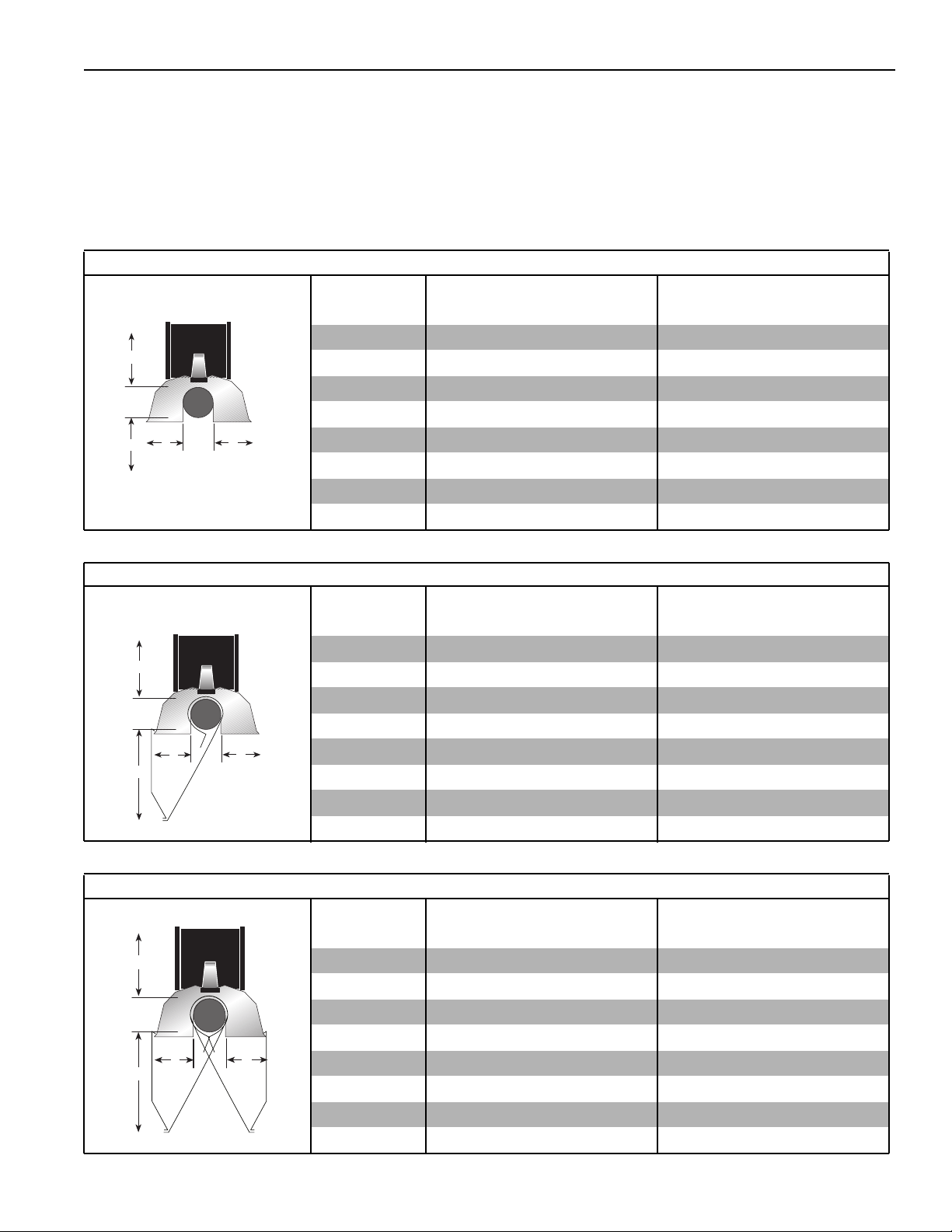

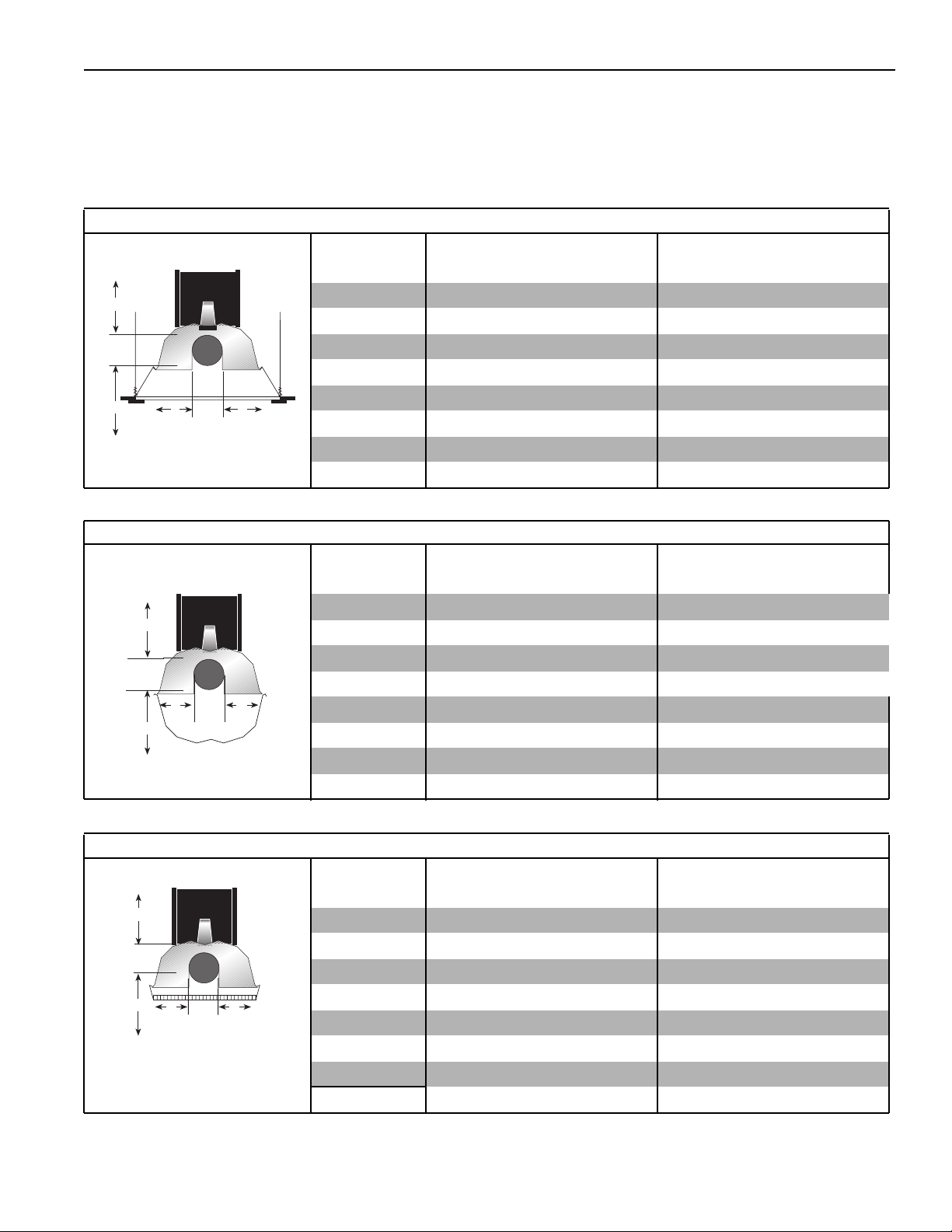

CLEARANCES TO COMBUSTIBLES

NOTE: 1. All dimensions are from the surfaces of al l t ubes, coupl ings , el bows, tees and c r osses.

2. Clearances B, C and D can be reduced by 50% after 25' (7.5 m) of tubing downstream from

where the combusti on chamber and the tube connect.

3. “-” indicates an unapproved applicati on. R oberts-Gor don prohibits the installation of this

he ate r for al l unappr oved ap pl i cat ions.

* Protective Grille clearances are the same as Standard Reflector.

Standard Reflector*

Model ABCDABCD

CRV-B-2 4 20 48 20 11 51 122 51

A

B

C

D

CRV-B-4 4 20 48 20 11 51 122 51

CRV-B-6 4 20 48 20 11 51 122 51

CRV-B-8 4 20 48 20 11 51 122 51

CRV-B-9 4 36 60 36 11 92 153 92

CRV-B-10 4 36 60 36 11 92 153 92

CRV-B-12 4 36 60 36 11 92 153 92

CRV-B-12A 4 36 60 36 11 92 153 92

(inches) (c entimeters)

.

One Side Reflector

A

B

C

Two Side Reflectors

A

B

C

(inches) (c entimeters)

Model ABCDABCD

CRV-B-2 4 12 56 20 11 31 143 51

CRV-B-4 4 12 56 20 11 31 143 51

CRV-B-6 4 12 56 20 11 31 143 51

CRV-B-8 4 12 56 20 11 31 143 51

D

CRV-B-9 4 12 60 42 11 31 153 107

CRV-B-10 4 12 60 42 11 31 153 107

CRV-B-12 4 12 60 42 11 31 153 107

CRV-B-12A 4 12 60 42 11 31 153 107

(inches) (c entimeters)

Model ABCDABCD

CRV-B-2 4 12 56 12 11 31 143 31

CRV-B-4 4 12 56 12 11 31 143 31

CRV-B-6 4 12 56 12 11 31 143 31

CRV-B-8 4 12 56 12 11 31 143 31

D

CRV-B-9 4 12 60 12 11 31 153 31

CRV-B-10 4 12 60 12 11 31 153 31

CRV-B-12 4 12 60 12 11 31 153 31

CRV-B-12A 4 12 60 12 11 31 153 31

© 2004 Roberts-Gordon

B EFORE INSTALLAT I ON AND OPERATION OF HEATI NG EQUIPM ENT, READ AND UNDERSTAND THE INSTALLATION, OPERATION AND SERVICE MANUAL.

A PPLICATIONS, ENGINEERING AND DE TAILED GUIDANCE ON SYSTEMS DES IGN, INSTAL LATION AND PRODUCT PERFORMANCE IS AVAILABLE UP ON REQUES T. ROBERTS GORDON® PRODUCTS ARE TO B E

INSTALLED ONLY IN ACCORDA NCE WITH LOCAL LA WS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTA LLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

Page 8

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

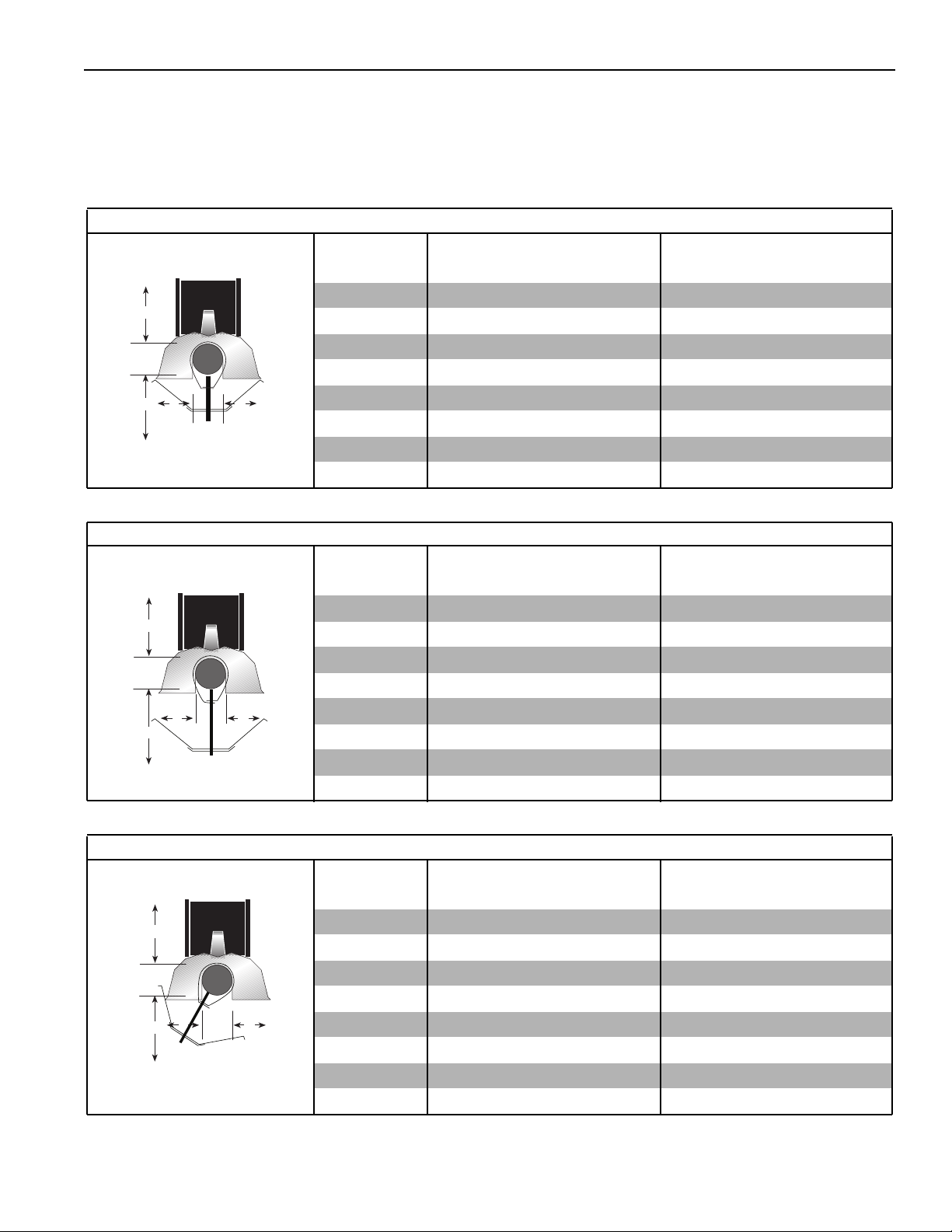

NOTE: 1. Al l dimensions are from the surfaces of all tubes, couplings, elbows, tees and crosses.

2. Cl ear ances B, C and D can be reduced by 50% af ter 25' (7.5 m) of tubi ng downstream from

where the combustion chamber and the tube connect.

3. “- ” indi c a tes an unap pr oved ap pli c ati o n. Robe rts - Gor d on pr oh ib i ts th e in s tal l at io n of t his h ea t er

fo r a l l un app r ov e d app l ica t i on s.

Universal Shield, Position 1

(inches) ( centimeters)

Model ABCDABCD

A

B

C

D

Universal Shield, Position 2

A

B

C

D

CRV-B-2 4 12 12 12 11 31 31 31

CRV-B-4 4 12 12 12 11 31 31 31

CRV-B-6 4 12 12 12 11 31 31 31

CRV-B-8 4 12 12 12 11 31 31 31

CRV-B-9 8 18 24 18 21 46 61 46

CRV-B-10 8 18241821466146

CRV-B-12 8 18 24 18 21 46 61 46

CRV-B-12A 818241821466146

(inches) ( centimeters)

Model ABCDABCD

CRV-B-2 4 24 48 24 11 61 122 61

CRV-B-4 4 24 48 24 11 61 122 61

CRV-B-6 4 24 48 24 11 61 122 61

CRV-B-8 4 24 48 24 11 61 122 61

CRV-B-9 4 36 48 36 11 92 122 92

CRV-B-10 4 36 48 36 11 92 122 92

CRV-B-12 4 36 48 36 11 92 122 92

CRV-B-12A 4 36 48 36 11 92 122 92

Universal Shield, Position 3

A

B

C

© 2004 Rober ts -Gordon

D

BEFORE INS TALLAT ION AND OPERAT ION OF HEATING EQUIPMENT, READ AND U NDERSTAND THE INSTALLATION, OPERATI ON AND SERVICE MANUA L.

APPLICATIONS , ENGINEERING AND DETA ILED GUIDA NCE ON SYS TEMS DESIGN, INSTALLAT ION AND PRODUCT P ERFORMANCE IS AVAILABLE UPON REQUEST . ROBERTS GORDON® PRODUCT S ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONT RACTOR QUALIFIED IN THE INSTALLA TION AND S ERVICE OF GAS-FI RED HEAT ING EQUIPMENT.

(inches) ( centimeters)

Model ABCDABCD

CRV-B-2 4 12 56 30 11 31 143 77

CRV-B-4 4 12 56 30 11 31 143 77

CRV-B-6 4 12 56 30 11 31 143 77

CRV-B-8 4 12 56 30 11 31 143 77

CRV-B-9 8 12 60 42 21 31 153 107

CRV-B-10 8 12 60 42 21 31 153 107

CRV-B-12 8 12 60 42 21 31 153 107

CRV-B-12A 8 12 60 42 21 31 153 107

Page 9

ROBERTS GORDON® CRV-SERIES SUBM ITT AL SHEET

NOTE: 1. All di mensions are from the surfaces of all tubes, couplings, elbows, tees and crosses.

2. Clearances B, C and D can be r educed by 50% after 25' (7.5 m) of tubing downstream from

where the combustion chamber and the tube connect.

3. “ - ” indi cates an unapproved appl icat ion. Roberts -Gordon pr ohibits the installati on of thi s heater

fo r all unapproved applicat ions.

2-Foot Deco Grille

(inches) (c entimeters)

Model ABCDABCD

A

C

B

Barrier Shield

A

B

C

CRV-B-2 4 12 48 12 11 31 122 31

CRV-B-4 4 12 48 12 11 31 122 31

CRV-B-6 4 12 48 12 11 31 122 31

CRV-B-8 4 12 48 12 11 31 122 31

D

CRV-B-9 4 18 56 18 11 46 143 46

CRV-B-10 4 18 56 18 11 46 143 46

CRV-B-12 4 18 56 18 11 46 143 46

CRV-B-12A 4 18 56 18 11 46 143 46

(inches) (c entimeters)

Model ABCDABCD

CRV-B-2 4 12 12 12 11 31 31 31

CRV-B-4 4 12 12 12 11 31 31 31

CRV-B-6 4 12 12 12 11 31 31 31

CRV-B-8 4 12 12 12 11 31 31 31

D

CRV-B-9 - - - - - - - -

CRV-B-10-------CRV-B-12 - - - - - - - -

CRV-B-12A--------

1-Foot Deco Grille

A

C

B

D

© 2004 Roberts-Gordon

(inches) (c entimeters)

Model ABCDABCD

CRV-B-2 4 12 48 12 11 31 122 31

CRV-B-4 4 12 48 12 11 31 122 31

CRV-B-6 4 12 48 12 11 31 122 31

CRV-B-8 4 12 48 12 11 31 122 31

CRV-B-9 4 18 56 18 11 46 143 46

CRV-B-10 4 18 56 18 11 46 143 46

CRV-B-12 4 18 56 18 11 46 143 46

CRV-B-12A 4 18 56 18 11 46 143 46

B EFORE INSTALLAT I ON AND OPERATION OF HEATI NG EQUIPM ENT, READ AND UNDERSTAND THE INSTALLATION, OPERATION AND SERVICE MANUAL.

A PPLICATIONS, ENGINEERING AND DE TAILED GUIDANCE ON SYSTEMS DES IGN, INSTAL LATION AND PRODUCT PERFORMANCE IS AVAILABLE UP ON REQUES T. ROBERTS GORDON® PRODUCTS ARE TO B E

INSTALLED ONLY IN ACCORDA NCE WITH LOCAL LA WS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTA LLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

Page 10

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

CRV-SER IES ASSEMBLY O VE RVIEW

Major Component Descriptions

Burner

Reflec tor

(Aluminum or

Stainless Steel)

Alternate overlap as

shown on overview.

Minimum overlap is 7"

(18 cm).

Tube

Hot Rolled, Heat Treated or

Coated Aluminized Tube

supplied in 10' (3 m) lengths.

Reflector with Hole

(Aluminum or

Stainless Steel)

Alternate overlap as

shown on overview.

Minimum overlap is 7"

(18 cm).

Flex Gas Line

with shut-off cock

Combustion Chamber

Coupling Assembly

with Lock

45° Elbow

Tee

Tu be Ad a p t e r

90° Elbow

Cross

End Vent

© 2004 Rober ts -Gordon

BEFORE INS TALLAT ION AND OPERAT ION OF HEATING EQUIPMENT, READ AND U NDERSTAND THE INSTALLATION, OPERATI ON AND SERVICE MANUA L.

APPLICATIONS , ENGINEERING AND DETA ILED GUIDA NCE ON SYS TEMS DESIGN, INSTALLAT ION AND PRODUCT P ERFORMANCE IS AVAILABLE UPON REQUEST . ROBERTS GORDON® PRODUCT S ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONT RACTOR QUALIFIED IN THE INSTALLA TION AND S ERVICE OF GAS-FI RED HEAT ING EQUIPMENT.

Page 11

ROBERTS GORDON® CRV-SERIES SUBM ITT AL SHEET

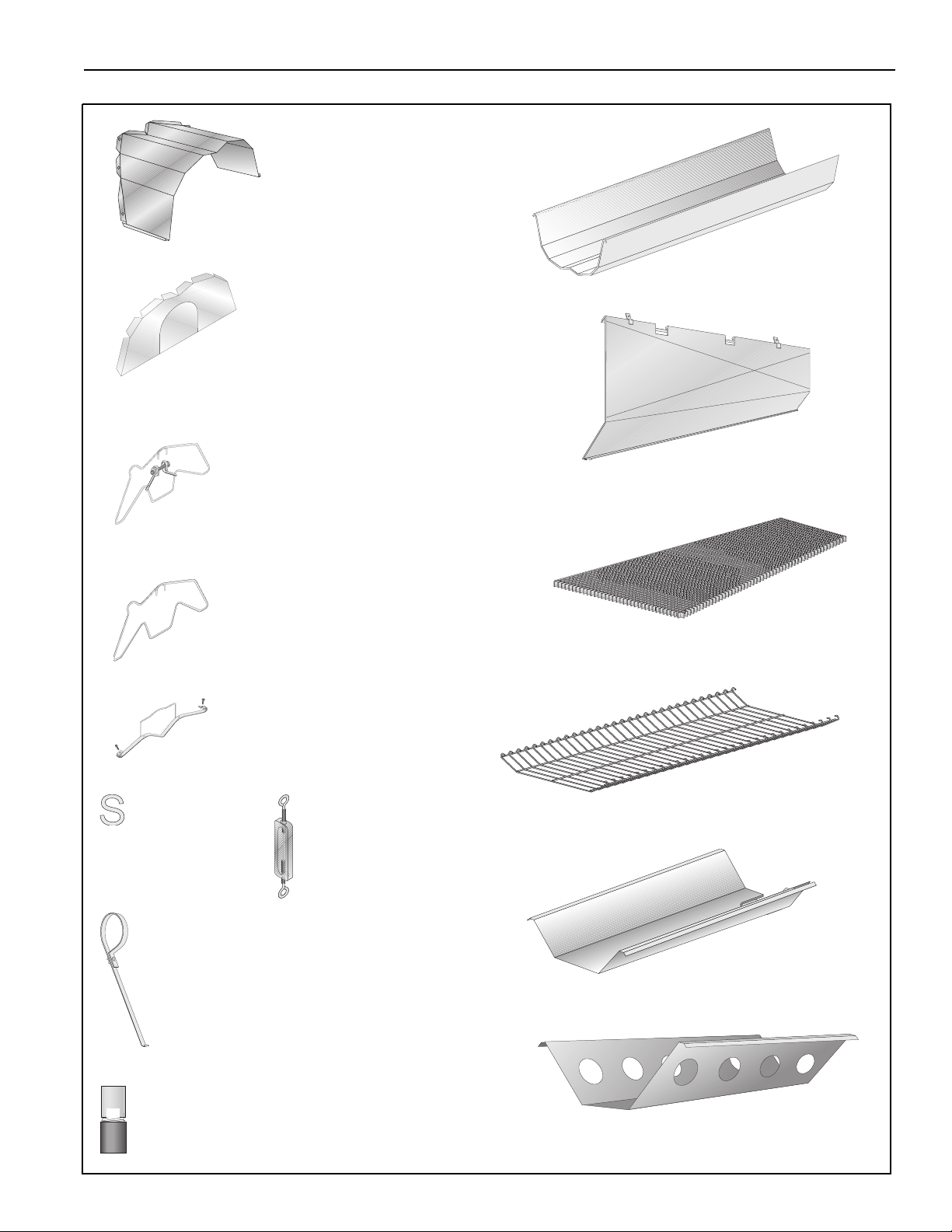

Major Component Descriptions (Continued)

Reflector Joint

Reflector End Cap

(Aluminum or Stainless

Steel)

Remove center section to

accommodate heat

ex cha nger tube when

necessary.

Tube and Reflector Hanger

with Clamp Package

Position this hanger no more

than 4" (10 cm) away from

the burner.

Tube and Reflector Hanger

Suspend system from these

hangers.

Reflector Support Strap &

Wire Form

Barrier Shield

Reflector Side Extension

Deco Grille

“S” Hook

Reflector Side

Extension Bracket

Condensate Valve

Assembly

© 2004 Roberts-Gordon

Turnbuckle

Prote c tive Grille

Universal Shield

Universal Shield with Holes

B EFORE INSTALLAT I ON AND OPERATION OF HEATI NG EQUIPM ENT, READ AND UNDERSTAND THE INSTALLATION, OPERATION AND SERVICE MANUAL.

A PPLICATIONS, ENGINEERING AND DE TAILED GUIDANCE ON SYSTEMS DES IGN, INSTAL LATION AND PRODUCT PERFORMANCE IS AVAILABLE UP ON REQUES T. ROBERTS GORDON® PRODUCTS ARE TO B E

INSTALLED ONLY IN ACCORDA NCE WITH LOCAL LA WS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTA LLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

Page 12

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

Major Component Descriptions (Continued)

R

E

G

N

A

D

e

u

q

i

r

t

c

e

R

E

G

N

A

D

d

r

a

z

a

H

k

c

o

h

S

l

a

c

i

r

t

c

e

l

E

l

a

c

i

r

t

c

e

l

e

t

c

e

n

n

o

c

.

s

g

i

n

i

D

c

i

v

r

e

s

e

r

o

f

e

b

r

e

w

o

p

e

b

t

s

u

m

e

c

n

a

i

l

p

p

a

s

y

i

l

r

h

e

T

p

o

r

p

a

o

t

d

e

t

c

e

e

c

r

n

u

n

o

o

s

c

l

a

c

i

r

t

c

e

l

e

d

e

d

n

u

o

r

g

e

s

e

h

t

w

o

l

l

o

f

o

t

e

r

u

l

i

t

l

a

u

F

s

e

r

n

a

c

s

n

o

i

t

c

c

u

o

r

t

h

s

s

n

l

i

a

c

i

r

t

c

e

l

e

r

o

h

t

a

e

d

n

i

.

c

n

i

-

g

r

.

w

w

w

©

®

N

O

D

r

R

O

G

S

T

lle

R

E

B

o

O

R

r

t

n

o

C

c

a

V

a

r

lt

U

:

r

e

b

:

m

e

u

c

N

è

i

t

r

P

a

a

l

P

e

d

o

r

é

m

u

N

u

N

l

a

i

r

e

S

S

e

d

.

o

N

s

g

n

i

t

a

R

s

t

r

e

b

o

R

x

o

B

.

O

.

P

,

o

l

a

f

f

u

B

o

h

p

e

l

e

T

1

7

:

x

a

F

e

r

F

l

l

o

T

r

.

w

w

w

©

:

r

e

b

m

:

e

i

r

é

0

2

1

t

u

p

n

I

:

n

o

d

r

o

G

4

4

0

0

4

2

4

1

Y

N

2

5

8

.

6

1

7

:

e

n

4

5

8

0

.

2

5

8

.

6

.

8

2

8

.

0

0

8

:

e

m

o

c

.

c

n

i

g

t

u

p

t

u

O

A

5

2

,

C

A

V

o

d

r

o

G

-

s

t

r

e

b

t

o

e

e

R

r

t

S

n

i

a

M

6

7

0

1

t

i

n

a

t

U

n

O

,

4

y

4

b

0

s

m

i

r

G

0

0

4

a

4

d

.

a

n

a

0

C

9

:

e

n

o

h

p

e

l

e

5

T

4

9

.

5

0

0

5

9

4

:

7

x

a

F

in U.S.A/Imprimé aux Etats-Unis P/N 91008005 Rev B

Printed

)

l

a

t

o

t

8

(

A

3

,

C

A

V

0

2

1

s

n

t

s

e

W

Y

G

R

E

6

N

T

R

E

N

1

E

D

E

M

M

S

P

I

3

O

U

L

L

Q

C

E

o

N

i

T

E

r

N

E

M

E

G

B

A

S

N

8

A

5

M

3

0

4

5

.

5

4

9

.

5

1

1

5

0

.

l

É

c

o

h

C

e

d

r

e

g

n

a

D

t

n

a

r

u

o

c

e

l

r

e

h

c

n

a

r

b

é

e

t

D

u

o

t

t

n

a

v

a

e

u

q

i

r

t

c

e

l

é

.

n

o

i

s

i

v

é

r

e

r

t

ê

t

i

o

d

l

i

e

r

a

p

e

p

d

a

t

e

e

c

r

C

u

o

s

e

n

u

à

r

e

t

c

.

e

e

n

r

r

n

e

o

t

c

á

e

s

i

m

c

e

v

a

t

n

a

r

u

o

c

.

k

o

c

s

e

c

e

r

v

i

u

s

a

e

l

d

r

e

e

t

n

î

u

a

a

r

t

F

n

e

t

u

e

p

s

n

.

o

i

s

t

e

c

u

u

r

q

t

i

r

s

t

n

c

i

e

l

é

c

o

h

c

s

e

l

u

o

t

r

o

1

0

0

m

8

0

0

1

9

.

m

N

/

P

A

.

S

.

U

e

h

t

n

i

d

e

t

n

i

r

P

s

i

n

U

s

t

a

t

E

x

u

a

é

m

i

r

p

m

I

ROBERTS GORDON®

ULTRAVAC™

Adjustable Indoor Sen s or

ROBERTS GORDON

BZC Indoor Sensor

®

ROBERTS GORDON

®

ULTRAVAC™ Cont rolle r

D

d

r

a

z

a

H

k

c

o

h

S

l

a

c

i

r

t

c

e

l

E

l

a

c

i

r

t

c

e

l

e

t

c

e

n

n

o

c

s

i

D

.

g

n

i

c

i

v

r

e

s

e

r

o

f

e

b

r

e

w

o

p

e

b

t

s

u

m

e

c

n

a

i

l

p

p

a

s

i

h

T

y

l

r

e

p

o

r

p

a

o

t

d

e

t

c

e

n

n

o

c

.

e

c

r

u

o

s

l

a

c

i

r

t

c

e

l

e

d

e

d

n

u

o

r

g

e

s

e

h

t

w

o

l

l

o

f

o

t

e

r

u

l

i

a

F

t

l

u

s

e

r

n

a

c

s

n

o

i

t

c

u

r

t

s

n

i

.

k

c

o

h

s

l

a

c

i

r

t

c

e

l

e

r

o

h

t

a

e

d

n

i

n

i

r

P

i

r

p

m

I

m

o

c

.

c

n

i

g

r

.

w

w

w

©

ROBERTS GORDON

e

u

q

i

r

t

c

e

l

É

c

o

h

C

e

d

r

e

g

n

a

D

t

n

a

r

u

o

c

e

l

r

e

h

c

n

a

r

b

é

D

e

t

u

o

t

t

n

a

v

a

e

u

q

i

r

t

c

e

l

é

.

n

o

i

s

i

v

é

r

e

r

t

ê

t

i

o

d

l

i

e

r

a

p

p

a

t

e

C

e

d

e

c

r

u

o

s

e

n

u

à

r

e

t

c

e

n

n

o

c

.

e

r

r

e

t

á

e

s

i

m

c

e

v

a

t

n

a

r

u

o

c

s

e

c

e

r

v

i

u

s

e

d

e

t

u

a

F

a

l

r

e

n

î

a

r

t

n

e

t

u

e

p

s

n

o

i

t

c

u

r

t

s

n

i

.

s

e

u

q

i

r

t

c

e

l

é

c

o

h

c

s

e

l

u

o

t

r

o

m

A

.

S

.

1

U

0

e

0

h

8

t

0

n

0

i

1

d

9

e

t

N

/

P

s

i

n

U

s

t

a

t

E

x

u

a

é

m

®

R

E

G

N

A

D

R

E

G

N

A

ULTRAVAC™

Variable Fr equency Drive

EP-100 Pu mp Package - 4" dia.

For more information, refer to the EP-100 Installation,

Operation and Service Manual (P/N 127201NA).

EP-201 Pu mp Package - 4" dia.

For more information, refer to the EP-201/203

Installation, Operation and Service Manual

(P/N 127200NA).

EP-203 Pu mp Package - 4" dia.

For more information, refer to the EP-201/203

Installation, Operation and Service Manual

(P/N 127200NA).

System Control

ROBERTS GORDON

BZC 700 Controller

© 2004 Rober ts -Gordon

EP-301 Pump Package - 4" dia.

EP-301 Pump Package - 6" dia.

®

For more inf ormation, refer to the EP-301 Installation,

Operation and Service Manual (P/N 127202NA).

BEFORE INS TALLAT ION AND OPERAT ION OF HEATING EQUIPMENT, READ AND U NDERSTAND THE INSTALLATION, OPERATI ON AND SERVICE MANUA L.

APPLICATIONS , ENGINEERING AND DETA ILED GUIDA NCE ON SYS TEMS DESIGN, INSTALLAT ION AND PRODUCT P ERFORMANCE IS AVAILABLE UPON REQUEST . ROBERTS GORDON® PRODUCT S ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONT RACTOR QUALIFIED IN THE INSTALLA TION AND S ERVICE OF GAS-FI RED HEAT ING EQUIPMENT.

Page 13

ROBERTS GORDON® CRV-SERIES SUBM ITT AL SHEET

CRV-Series Assembly Overview

Controller

ULTRAVAC

®

BZC Controller

®

System Control

or ROBERTS GORDON

ROBERTS GORDON

Exhaust

to Outside

Relay*

Pressure Switch

Pump

Boot

Flexible

Reflector

Reflector

with Hole

Coupling

Tube &

Reflector

Tube

Hanger

U-Clips

S

Support

Reflector

requires zone sensors and additional

®

ULTRAVAC

®

BZC Controllers require zone sensors. System Control requires

®

© 2004 Roberts-Gordon

End

Vent

Chamber

Combustion

Zone 1 Sensor or Thermostat**

appropriate controller Installation, Operation and Service Manual for details.

* May not be needed with certain pumps and controllers. Refer to wiring diagram in the

**ROBERTS GORDON

control equipment. See the appropriate controller installation manual for details.

thermostats. ROBERTS GORDON

Burner

End Cap

Reflector

B EFORE INSTALLAT I ON AND OPERATION OF HEATI NG EQUIPM ENT, READ AND UNDERSTAND THE INSTALLATION, OPERATION AND SERVICE MANUAL.

A PPLICATIONS, ENGINEERING AND DE TAILED GUIDANCE ON SYSTEMS DES IGN, INSTAL LATION AND PRODUCT PERFORMANCE IS AVAILABLE UP ON REQUES T. ROBERTS GORDON® PRODUCTS ARE TO B E

INSTALLED ONLY IN ACCORDA NCE WITH LOCAL LA WS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTA LLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

Page 14

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

HEATER I NSTALLATION

Critical Hanger Placement

Typical Suspension Details

Beam Clamp

Rod (3/8")

24" min.

(61 cm)

"X" (see table)

Chain size

3/16" minimum

Turnbuckle

Locknut

(Typical)

Anchor

Screw Hook

(3/8")

S Hook

Concrete Beam

Wood Beam

Locknut

Washers

Side View Towards Pump

Description Part Number

Turnbuckle 91903201

S-Hook 91907302

Tube/Ref lector Hanger 03090100

7'6" (2.3 m)

Turnbuckle

Hanger

Reflector

Front View

Run Length Typical Expa nsion Min imum “X ” Lengt h

50' (1 5 m) ±1" (3 cm) 1 2" (30 cm)

100' ( 31 m) ±2 " ( 5 cm) 24" (61 cm)

150' ( 46 m) ±3 " ( 8 cm) 36" (91 cm)

200' ( 61 m) ±4 " (1 0 cm) 46" (122 cm)

250' ( 76 m) ±5 " (1 3 cm) 57" (145 cm)

© 2004 Rober ts -Gordon

BEFORE INS TALLAT ION AND OPERAT ION OF HEATING EQUIPMENT, READ AND U NDERSTAND THE INSTALLATION, OPERATI ON AND SERVICE MANUA L.

APPLICATIONS , ENGINEERING AND DETA ILED GUIDA NCE ON SYS TEMS DESIGN, INSTALLAT ION AND PRODUCT P ERFORMANCE IS AVAILABLE UPON REQUEST . ROBERTS GORDON® PRODUCT S ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONT RACTOR QUALIFIED IN THE INSTALLA TION AND S ERVICE OF GAS-FI RED HEAT ING EQUIPMENT.

Page 15

ROBERTS GORDON® CRV-SERIES SUBM ITT AL SHEET

Tube Installation

Combustion

Chamber

NOTE: Tubing requires a downward slope of

1/2" (13 mm) per 20' (6 m) away from

burner. Tailpipe Tubing requires a

downward slope of 1" (26 mm) per

20' (6 m) away from burner.

End View

Weld

Seam

Bottom

of Tube

7' 6"

(229 cm)

Description Part Number

Tube 91409XXX

Turnbuckle 91903201

Tube/Ref lector Hanger 03090100

Coupling and Tube Assembly

Close c oupli ng with tab

A

Open

Tab

Tube

10'

maximum

(3 m)

B

Hanger

Turnbuckles

Combustion

Chamber

Start slide bar/coupling lock

onto coupli ng

Slide Bar/Coupling Lock

Wide end

Coupling

3" (8 cm) to

4" (10 cm)

Closed

Insert tubes into coupling

C

Tube

© 2004 Roberts-Gordon

Ti ght en coupli ng t o join tubes

D

Slide Bar/Coupling Lock

Orient coupling so that

the impact block is in the

2:00 or 10:00 oclock

positions

Tube

B EFORE INSTALLAT I ON AND OPERATION OF HEATI NG EQUIPM ENT, READ AND UNDERSTAND THE INSTALLATION, OPERATION AND SERVICE MANUAL.

A PPLICATIONS, ENGINEERING AND DE TAILED GUIDANCE ON SYSTEMS DES IGN, INSTAL LATION AND PRODUCT PERFORMANCE IS AVAILABLE UP ON REQUES T. ROBERTS GORDON® PRODUCTS ARE TO B E

INSTALLED ONLY IN ACCORDA NCE WITH LOCAL LA WS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTA LLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

Description Part Number

Coupling 01329600

Slide Bar /Coup l ing Lock 01329700

Tube 91409XXX

Tube

Coupling

Page 16

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

Coupling and Tube Assembly (Continued)

Tighten Slide B ar as show n below.

Drive Slide Bar until tight.

End of Slide Bar should be

within tolerance listed below.

± 2" (5 cm)

Correct Slide Bar

dimensions

Repeat A - D until all tubes are assem bled.

NOTE: If Coupling is not tight, loss of vacuum can occur.

ELBOW PACKAGE CONFIGURATIO N

Elbow Installatio n

Tube

Incorrect Slide Bar

position

Description Part Number

Elbow Package 02718702

90° Elbow 01335801

Coupling 01312700

Reflector End Cap 02750800

Reflector Joint Piece 02750900

U-Cl ip Package 91107720

Elbow Installatio n (continued)

Coupling

90° Elbow

Tube

Coupling

© 2004 Rober ts -Gordon

BEFORE INS TALLAT ION AND OPERAT ION OF HEATING EQUIPMENT, READ AND U NDERSTAND THE INSTALLATION, OPERATI ON AND SERVICE MANUA L.

APPLICATIONS , ENGINEERING AND DETA ILED GUIDA NCE ON SYS TEMS DESIGN, INSTALLAT ION AND PRODUCT P ERFORMANCE IS AVAILABLE UPON REQUEST . ROBERTS GORDON® PRODUCT S ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONT RACTOR QUALIFIED IN THE INSTALLA TION AND S ERVICE OF GAS-FI RED HEAT ING EQUIPMENT.

Page 17

ROBERTS GORDON® CRV-SERIES SUBM ITT AL SHEET

REFLECTOR INSTALLATION

Reflector Inst a llation with Hole

Reflector

with Hole

Slide Reflector

with hole

through hanger.

Unhook combustion

chamber from chain

and insert through hole.

Reconnect chain.

Hanger

Tube

Descript ion Par t Numbe r

Tube/ R e fl ec to r Ha ng er 03 09 01 00

Tube 91409XX X

Reflector with Hole 02750304

Reflector Inst a llation

Wire Form

Reflector

Reflector Support

Strap

Desc ription P art Nu mber

Reflect or Support Package 03050010

U-Clip Package 91107720

Reflector End Cap 027508XX

Sheet Metal

Screw

Tube

Combustion

Chamber

U-Clip

(2 clips per

alternate overlaps

per side)

© 2004 Roberts-Gordon

B EFORE INSTALLAT I ON AND OPERATION OF HEATI NG EQUIPM ENT, READ AND UNDERSTAND THE INSTALLATION, OPERATION AND SERVICE MANUAL.

A PPLICATIONS, ENGINEERING AND DE TAILED GUIDANCE ON SYSTEMS DES IGN, INSTAL LATION AND PRODUCT PERFORMANCE IS AVAILABLE UP ON REQUES T. ROBERTS GORDON® PRODUCTS ARE TO B E

INSTALLED ONLY IN ACCORDA NCE WITH LOCAL LA WS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTA LLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

Page 18

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

Reflector, U-Clip and Reflector Support Installation

The pictorial drawings of the heater construction in

this Section are schematic only and provide a general guideline of where hangers, reflector supports

and U-clips are to be installed.

To ensure proper expansion and contraction movement of the reflectors, a combination of U-clips and

reflector supports are used. The positioning of reflec-

1. The first reflector after the burner must be affixed in

the middle of the reflector with a reflector support and

tight screws.

Reflector

End Cap

First Reflector

U-Clips

tor supports and U-clips depend on the individual

installation. Use either pop rivets or sheet metal

screws instead of u-clips when installing end caps

and joint pieces in areas where impact and high w ind

may be a factor. The following rules must be

observed.

Tight

Sheet Metal

Wire Form

Reflector Support

Strap

Screw

Overlap must be a

minimum of 6" (16 cm)

6"

(16 cm)

2. The overlap at the first and second reflector is a slip overlap.

Thereafter, every third reflector joint is a slip overlap. A slip

overlap is achieved by either:

a.) both reflectors lay inside a hanger.

(no reflector support needed).

b.) using a reflector support with

loose screws at the reflector

overlap.

3. The remaining reflector overlaps require a non-slip

overlap connection. To affix the reflectors together in

a non-slip overlap either:

a.) use reflector support and tight screws.

b.) if both reflectors lay inside a hanger, u-clips or

sheet metal screws may be used.

This section of three reflectors joined together must

be affixed to the tube with at least one reflector support

with tight screws.

Description Part Number

Re flector Suppor t Package 0305001 0

Wire Form 91908004

Reflector Support Strap 03050000

S crew # 8 x 3/4 94320812

U-Cl ip Package 91107720

Reflector End Cap 027508XX

Option B

Non-Slip Overlap

Option A

Slip Overlap

Option B

Slip Overlap

Option A

Non-Slip Overlap

U-Clip

(2 clips per

non-slip overlap

inside a hanger)

Reflector

Reflector

Support

Loose screws

loosened 1/16"

to allow slippage.

Reflector

Tight

screws

© 2004 Rober ts -Gordon

BEFORE INS TALLAT ION AND OPERAT ION OF HEATING EQUIPMENT, READ AND U NDERSTAND THE INSTALLATION, OPERATI ON AND SERVICE MANUA L.

APPLICATIONS , ENGINEERING AND DETA ILED GUIDA NCE ON SYS TEMS DESIGN, INSTALLAT ION AND PRODUCT P ERFORMANCE IS AVAILABLE UPON REQUEST . ROBERTS GORDON® PRODUCT S ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONT RACTOR QUALIFIED IN THE INSTALLA TION AND S ERVICE OF GAS-FI RED HEAT ING EQUIPMENT.

Page 19

ROBERTS GORDON® CRV-SERIES SUBM ITT AL SHEET

Burner Installation

Burner

Description Part Number

Bolt 94273914

Burner 0270XXXX

Lock Washer 96411600

Gasket 01367800

End Vent 013676XX

Combustion

End

Vent

Clips

End Vent

Burner

Combustion

Chamber

Gasket

End

Vent

Chamber

NOTE:

Install End Vent

at end combustion

chamber position only

Rating

Number

© 2004 Roberts-Gordon

B EFORE INSTALLAT I ON AND OPERATION OF HEATI NG EQUIPM ENT, READ AND UNDERSTAND THE INSTALLATION, OPERATION AND SERVICE MANUAL.

A PPLICATIONS, ENGINEERING AND DE TAILED GUIDANCE ON SYSTEMS DES IGN, INSTAL LATION AND PRODUCT PERFORMANCE IS AVAILABLE UP ON REQUES T. ROBERTS GORDON® PRODUCTS ARE TO B E

INSTALLED ONLY IN ACCORDA NCE WITH LOCAL LA WS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTA LLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

Page 20

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

OPTIONAL HEATER ACCESSORIES

Tee Installation

Tube

Coupling

Tee

Desc ription Part N umb er

Tee 01330XXX

Tube/Reflector Hanger 03 090100

Tube 91409XXX

Coupling 01312700

Reflector Joint Installation

Reflector

Scribe

Contour

Reflector

Joint

Flatten Edge

© 2004 Rober ts -Gordon

1" (2.5 cm)

maximum

BEFORE INS TALLAT ION AND OPERAT ION OF HEATING EQUIPMENT, READ AND U NDERSTAND THE INSTALLATION, OPERATI ON AND SERVICE MANUA L.

APPLICATIONS , ENGINEERING AND DETA ILED GUIDA NCE ON SYS TEMS DESIGN, INSTALLAT ION AND PRODUCT P ERFORMANCE IS AVAILABLE UPON REQUEST . ROBERTS GORDON® PRODUCT S ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONT RACTOR QUALIFIED IN THE INSTALLA TION AND S ERVICE OF GAS-FI RED HEAT ING EQUIPMENT.

Page 21

ROBERTS GORDON® CRV-SERIES SUBM ITT AL SHEET

Reflector Joint Installation (continued)

Reflector Joint Detail

Cut away contour

with tin snips.

Punch/Drill six 3/32" (2 mm) holes

Install Reflector

End Cap

Reflector Joint Detail

Attach Reflector Joint

with six #8 sheet

metal screws

Reflector

Reflector

Joint

© 2004 Roberts-Gordon

B EFORE INSTALLAT I ON AND OPERATION OF HEATI NG EQUIPM ENT, READ AND UNDERSTAND THE INSTALLATION, OPERATION AND SERVICE MANUAL.

A PPLICATIONS, ENGINEERING AND DE TAILED GUIDANCE ON SYSTEMS DES IGN, INSTAL LATION AND PRODUCT PERFORMANCE IS AVAILABLE UP ON REQUES T. ROBERTS GORDON® PRODUCTS ARE TO B E

INSTALLED ONLY IN ACCORDA NCE WITH LOCAL LA WS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTA LLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

Page 22

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

REFLECTOR SIDE EXTENSION

Bracket Installation

Tube

Descript ion Part Number

Reflecto r Si de Ext ens i on Packa ge 027 1270 0

Reflect or Si de Exte nsion 01368000

Re tain er Clips 02751 200

Sheet Metal Screws 94118106

Reflector

Tube and Reflector Hanger

Reflector Support

Reflector Side

Extension Bracket

(2 per reflector)

Use additional supports

in high air movement

applications.

Orde r Separ atel y

Reflect or Si de Exte nsion 01329910

Side Reflector Inst a llation

#8 x 3/8" Sheet Metal Screw

© 2004 Rober ts -Gordon

Retainer Clip

(2 per side)

Reflector Side Extension

BEFORE INS TALLAT ION AND OPERAT ION OF HEATING EQUIPMENT, READ AND U NDERSTAND THE INSTALLATION, OPERATI ON AND SERVICE MANUA L.

APPLICATIONS , ENGINEERING AND DETA ILED GUIDA NCE ON SYS TEMS DESIGN, INSTALLAT ION AND PRODUCT P ERFORMANCE IS AVAILABLE UPON REQUEST . ROBERTS GORDON® PRODUCT S ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONT RACTOR QUALIFIED IN THE INSTALLA TION AND S ERVICE OF GAS-FI RED HEAT ING EQUIPMENT.

Page 23

ROBERTS GORDON® CRV-SERIES SUBM ITT AL SHEET

Universal Shield

Universal shields are adjustable aluminum reflectors that

can be angled and height

adjusted to direct heat to or

away from a desir ed area.

Tube

Universal Shield

Desc ription Part N umb er

Un iv ersal Sh ield 027518 01

Un iv ersal Sh ield with Holes 02 7518 00

Universal Shi eld Support Package 02712100

Tube and R eflector S upport Assembly 01329802

Universal Shield Support 02751700

S hield Br acket Assembly 02 721400

Stud 02790900

Hex Nut 92114800

Flattened

Section

Bracket Assembly*

Standard Reflector

Tube and Reflector Support Assembly*

Stud*

Shield Support Bracket*

Hex Nut*

* Included in Universal Shield

Support Package.

Barrier Shield

Do not install barrier shield less than 20' (6 m) downstream of any burner.

Do not attach end caps to the ends of the barrier shields. For lengths

greater than 8' (2.6 m), use universal shields.

Do not use barrier shields for burner sizes larger than 80,000 btu/Hr.

Tube and Reflector Hanger

Flatten Reflector Edges

Reflector Support Strap Cut Relief Notch

Attach U-Clips

Standard Reflector

Barrier Shield

D esc ri pt i on Par t Numb e r

Barrier Shield 02750303

U- Clip Package 911 0772 0

© 2004 Roberts-Gordon

B EFORE INSTALLAT I ON AND OPERATION OF HEATI NG EQUIPM ENT, READ AND UNDERSTAND THE INSTALLATION, OPERATION AND SERVICE MANUAL.

A PPLICATIONS, ENGINEERING AND DE TAILED GUIDANCE ON SYSTEMS DES IGN, INSTAL LATION AND PRODUCT PERFORMANCE IS AVAILABLE UP ON REQUES T. ROBERTS GORDON® PRODUCTS ARE TO B E

INSTALLED ONLY IN ACCORDA NCE WITH LOCAL LA WS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTA LLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

Page 24

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

TWO-FOOT DECORATIVE GRILLE INSTALLATION

Grille Installat ion

Reflector

Heat Exchanger

Tube

Tube and Reflector

Hanger

2' x 4' (60 x 120 cm) Aluminum Grille

Suspended Ceiling Frame

Frame Shield Installation

Shield

Description Par t Number

Aluminium Grille 2' x 4' 9140700 0

© 2004 Rober ts -Gordon

Descript ion Par t Numb e r

De c o Grille Shield 01365 900

BEFORE INS TALLAT ION AND OPERAT ION OF HEATING EQUIPMENT, READ AND U NDERSTAND THE INSTALLATION, OPERATI ON AND SERVICE MANUA L.

APPLICATIONS , ENGINEERING AND DETA ILED GUIDA NCE ON SYS TEMS DESIGN, INSTALLAT ION AND PRODUCT P ERFORMANCE IS AVAILABLE UPON REQUEST . ROBERTS GORDON® PRODUCT S ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONT RACTOR QUALIFIED IN THE INSTALLA TION AND S ERVICE OF GAS-FI RED HEAT ING EQUIPMENT.

Page 25

ROBERTS GORDON® CRV-SERIES SUBM ITT AL SHEET

Reflector Side Extension Installation for Decorative Grilles

NOTE: If the Decorative Grille system is to be installed in an area

with considerable air movement, it is recommended that one

#8 x 3/8 (3.9 x 9.5mm) sheet metal screw be installed per reflector

extension to prevent it from blowing over.

Cut Relief Notches for Tube

and Reflector Hangers

A

6" (15 cm) Minimum

Allow 6" (15 cm)

minimum clearance

between Burner Box

and overhead

obstructions for

service.

Insert Screw

here

(See NOTE)

Reflector Side Extension

Descript ion Par t Numb e r

Reflector Side Extension 01370412

ONE-FOOT DECORATIVE GRILLE INSTALLATION

One-Foot Decorative Grille Bracket

#8 Sheet Metal Screws

Decorative Grille Bracket

Description Part Number

Bracket 01363003

Cut relief notches for

supports and hangers.

D is ta n ce "A" E xt en s io n

Minimum Maximum Part No. Widt h

2" (4 cm) 6" (15 cm) 01370408 8" (20 cm)

6" (15 cm) 1 0" ( 26 cm ) 0 1370412 12" (30 c m )

10" (26 cm) 14 " (3 7 c m ) 01370416 16 " (4 0 c m )

In order to maintain reflector shape, do

not fasten brackets together. Do not

fasten bracket to adjoining reflector s.

Maintain same slipjoin t p osition as

reflectors.

2"

Minimum

Bracket

Overlap

© 2004 Roberts-Gordon

B EFORE INSTALLAT I ON AND OPERATION OF HEATI NG EQUIPM ENT, READ AND UNDERSTAND THE INSTALLATION, OPERATION AND SERVICE MANUAL.

A PPLICATIONS, ENGINEERING AND DE TAILED GUIDANCE ON SYSTEMS DES IGN, INSTAL LATION AND PRODUCT PERFORMANCE IS AVAILABLE UP ON REQUES T. ROBERTS GORDON® PRODUCTS ARE TO B E

INSTALLED ONLY IN ACCORDA NCE WITH LOCAL LA WS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTA LLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

Page 26

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

Spread apart brackets

and install

Decorative Grille.

#8 Sheet Metal Screws

Joint Piece

Reinforcement

Slip joint piece into

support bracket

and fasten to

bracket on one side

of the joint only.

Joint Piece

Decorative Grille

Description Part Number

Decorative Grille 8’ x 1’ 91406700

Joint Piece and Reinforcemen t

Description Par t Number

Joint Piece 01365903

Reinforcement 01365902

© 2004 Rober ts -Gordon

BEFORE INS TALLAT ION AND OPERAT ION OF HEATING EQUIPMENT, READ AND U NDERSTAND THE INSTALLATION, OPERATI ON AND SERVICE MANUA L.

APPLICATIONS , ENGINEERING AND DETA ILED GUIDA NCE ON SYS TEMS DESIGN, INSTALLAT ION AND PRODUCT P ERFORMANCE IS AVAILABLE UPON REQUEST . ROBERTS GORDON® PRODUCT S ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONT RACTOR QUALIFIED IN THE INSTALLA TION AND S ERVICE OF GAS-FI RED HEAT ING EQUIPMENT.

Page 27

ROBERTS GORDON® CRV-SERIES SUBM ITT AL SHEET

Fasten end piece

to brackets using two

#8 sheet metal screws

and replace reflector end cap.

Insert end piece

between grille and

brackets.

End Piece

Reflector

End Cap

Insert

End Piece

between

grille and

brackets.

Joint Piece

Cut grille bracket at

reflector joint piece.

Grille Brackets

Inside

Corner

Decorative Grille

Brackets

Joint Piece

End Piece and Reflector End Cap

90° Elbow

Description Pa rt Number

End Piece 01365901

© 2004 Roberts-Gordon

B EFORE INSTALLAT I ON AND OPERATION OF HEATI NG EQUIPM ENT, READ AND UNDERSTAND THE INSTALLATION, OPERATION AND SERVICE MANUAL.

A PPLICATIONS, ENGINEERING AND DE TAILED GUIDANCE ON SYSTEMS DES IGN, INSTAL LATION AND PRODUCT PERFORMANCE IS AVAILABLE UP ON REQUES T. ROBERTS GORDON® PRODUCTS ARE TO B E

INSTALLED ONLY IN ACCORDA NCE WITH LOCAL LA WS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTA LLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

Page 28

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

PROTECTIVE GRILLE INSTALLATION

Silicone Cap Installation

Silicone Cap

Grille

Finger

Desc ription P art Numb er

Grille Section 08050001

Grille End Cap 08050002

Silic one Cap 9 19 1595 1-6P

Grille End Cap Ins tallation

A

Grille

Grille End Cap

B

CD

Bend up 90°

Pull outward

Grille Installat ion

40 "

(101 cm)

© 2004 Rober ts -Gordon

Reflector

Final Grille

Section

Grille

Grille

End Cap

BEFORE INS TALLAT ION AND OPERAT ION OF HEATING EQUIPMENT, READ AND U NDERSTAND THE INSTALLATION, OPERATI ON AND SERVICE MANUA L.

APPLICATIONS , ENGINEERING AND DETA ILED GUIDA NCE ON SYS TEMS DESIGN, INSTALLAT ION AND PRODUCT P ERFORMANCE IS AVAILABLE UPON REQUEST . ROBERTS GORDON® PRODUCT S ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONT RACTOR QUALIFIED IN THE INSTALLA TION AND S ERVICE OF GAS-FI RED HEAT ING EQUIPMENT.

Page 29

ROBERTS GORDON® CRV-SERIES SUBM ITT AL SHEET

CRV-Series Classic Cast-Iron Components

WARNING

Suspension Hazard

Hang heater with materials

with a minimum working load

of 750 lbs. (340 kg).

Use special tube and reflector

hangers when suspending

the schedule 40 steel pipe

system.

Schedule 40 steel pipe is

heavy and will fall

if not supported properly.

Distance between supports

must be 7' (2.13 m) or less.

Failure to follow these

instructions can result in

death, injury or property

damage.

Special Tube and Reflector Hanger

7' (2.13 m) Maximum

Schedule 40 Steel Pipe

Cast-Iron Combustion Chamber

with Schedule 40 Steel Pipe

The total weight of each burner and

combustion chamber is 40.25 lbs (18 kg).

4" Schedule 40 pipe weighs 10.9 lbs.

(5 kg) per foot.

Coupling

4" Tube

ROBERTS-GORDON

CORAYVAC® Classic

Cast-Iron Combustion

Chamber

ROBERTS-GORDON

Tur nb uckle

Hang cast-iron combustion chamber with a turnbuckle

(spring clips will not fit around cast-iron hanging loop).

End Vent

Clips

®

Cast-Iron Adapter

End Vent Plate for

End Burner only

End Vent

Clips

®

Cast-Iron Combustion Chamber with

Standard 4" O.D. Infrared Tubing

The total weight of each burner and

combustion chamber is 40.25 lbs (18 kg).

4" O.D. 16 Ga. tubing weighs 2.8 lbs.

(1.3 kg) per foot.

© 2004 Roberts-Gordon

B EFORE INSTALLAT I ON AND OPERATION OF HEATI NG EQUIPM ENT, READ AND UNDERSTAND THE INSTALLATION, OPERATION AND SERVICE MANUAL.

A PPLICATIONS, ENGINEERING AND DE TAILED GUIDANCE ON SYSTEMS DES IGN, INSTAL LATION AND PRODUCT PERFORMANCE IS AVAILABLE UP ON REQUES T. ROBERTS GORDON® PRODUCTS ARE TO B E

INSTALLED ONLY IN ACCORDA NCE WITH LOCAL LA WS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTA LLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

Cast-Iron Adapter

End Vent Plate for

End Burner only

Desc ription P art Number

Sp ec i a l Tube & Refl ect or Hanger 0 2790 300

Turnbuckle 91903201

Cast-Iron Combustion Chamber 02721200-1P

Cast-Iron A dapter 02722100

Coupling 01312700

Page 30

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

PUMP I NST ALLA T ION

EP-200 Condensate Valve Asse mbly

1" BSP threaded hole.

Use 1" x ¾" reducer.

(not supplied)

Copper or

galvanized pipe

3/4" female

Wall

36" Minimum

vertical drop

between pump

and condensate

valve assembly.

Condensate

Valve

Assembly

3/4" female

flow

Must be connected

to a drain system

in accordance with

local codes.

© 2004 Rober ts -Gordon

BEFORE INS TALLAT ION AND OPERAT ION OF HEATING EQUIPMENT, READ AND U NDERSTAND THE INSTALLATION, OPERATI ON AND SERVICE MANUA L.

APPLICATIONS , ENGINEERING AND DETA ILED GUIDA NCE ON SYS TEMS DESIGN, INSTALLAT ION AND PRODUCT P ERFORMANCE IS AVAILABLE UPON REQUEST . ROBERTS GORDON® PRODUCT S ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONT RACTOR QUALIFIED IN THE INSTALLA TION AND S ERVICE OF GAS-FI RED HEAT ING EQUIPMENT.

Page 31

ROBERTS GORDON® CRV-SERIES SUBM ITT AL SHEET

VENTING

Vertical V enting Configurati on

Approved

Vent Cap

2' (610 mm)

Minimum

Approved

Thimble

Flexible Boot

Clamps

HORIZONTAL VENTING 4" (10 CM) PIPE

EP-100 Horizont al Venting Configur ations

25' (8 m) and 3 Elbows Maximum

Aluminized Tee

Drain Cap

4" (10 cm) Single Wall Pipe

1" (250 mm)

P.V.C to drain

system in

accordance

with local

codes.

6"(150 mm)

20" (510 mm) for EP-300

18" (46 cm) Minimum 40" (102 cm) Maximum

Bird

Screen

Approved Thimbles

18" (46 cm) Minimum 40" (102 cm) Maximum

© 2004 Roberts-Gordon

Vent Terminal

Tjernlund VH1-4

5" to 4" Reducer

(12.5 mm to 10 cm)

5" (12.5 cm) Single Wall Pipe

50' (15 m) and 3 Elbows Maximum

B EFORE INSTALLAT I ON AND OPERATION OF HEATI NG EQUIPM ENT, READ AND UNDERSTAND THE INSTALLATION, OPERATION AND SERVICE MANUAL.

A PPLICATIONS, ENGINEERING AND DE TAILED GUIDANCE ON SYSTEMS DES IGN, INSTAL LATION AND PRODUCT PERFORMANCE IS AVAILABLE UP ON REQUES T. ROBERTS GORDON® PRODUCTS ARE TO B E

INSTALLED ONLY IN ACCORDA NCE WITH LOCAL LA WS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTA LLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

6" to 5" Reducer

(15 cm to 12.5 cm)

Vent Terminal

Tjernlund VH1-6

Page 32

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

EP-200 Series Horizontal Venting Configurations

18" (46 cm) Minimum 40" (102 cm) Maximum

5" to 4" Reducer

(12.5 cm to 10 cm)

5" (12.5 cm) Single Wall Pipe

25' (8 m) and 3 Elbows Maximum

6" to 4" Reducer

(15 cm to 10 cm)

4" (10 cm) Single Wall Pipe

10' (3 m) Maximum and No Elbows

6" to 5" Reducer

(15 cm to 12.5 cm)

Bird

Screen

Approved Thimbles

18" (46 cm) Minimum 40" (102 cm) Maximum

4" (10 cm) Vent Terminal

Vent Terminal

Tjernlund VH1-4

Vent Terminal

Tjernlund VH1-6

6" (15 cm) Single Wall Pipe

50' (15 m) and 3 Elbows Maximum

EP-300 Series Horizontal Venting Configurations

10' (3 m) Maximum and 1 Elbow

10' (3 m) Maximum and 1 Elbow

Single Wall Pipe/Tube 6" (15 cm)

Pitch single wall pipe

downward away from pump

1/4" every 10' (3 m).

Vent Terminal

Tjernlund VH1-6

18" (46 cm) Minimum 40" (102 cm) Maximum

6" (15 cm)

Bird Screen

(Included)

6" (15 cm)

Band Clamp

Thimble

Vent Terminal

Tjernlund VH1-

6" (15 cm)

or Equivalent

(Not Included)

© 2004 Rober ts -Gordon

BEFORE INS TALLAT ION AND OPERAT ION OF HEATING EQUIPMENT, READ AND U NDERSTAND THE INSTALLATION, OPERATI ON AND SERVICE MANUA L.

APPLICATIONS , ENGINEERING AND DETA ILED GUIDA NCE ON SYS TEMS DESIGN, INSTALLAT ION AND PRODUCT P ERFORMANCE IS AVAILABLE UPON REQUEST . ROBERTS GORDON® PRODUCT S ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONT RACTOR QUALIFIED IN THE INSTALLA TION AND S ERVICE OF GAS-FI RED HEAT ING EQUIPMENT.

Page 33

ROBERTS GORDON® CRV-SERIES SUBM ITT AL SHEET

OUTSIDE COMBUSTION AIR SUPPLY

Filter Housing Assembly

Door-Control

Housing

Filter Housing

Wing Nut

4" (10 cm)

Air Flex Duct

Air Supply Blower Suppo rt

Clamp

Filter

Top Gasket

and Disk

Bottom Gasket

Descri p tion Part Num ber

Filter Housing 01326801

Filter and Gaskets 01312401

Filter Support 91905500

Wing Nut 92511601

4” Air Flex Duct (box of eight 8’ sections) 91409601

Outside

Air Supply

Blower

Filter

Support

Descript ion Par t Numb e r

Blower 90707501

Mounting Bracket 01316000

© 2004 Roberts-Gordon

Mounting

Bracket

Wall

Outside

Wall

B EFORE INSTALLAT I ON AND OPERATION OF HEATI NG EQUIPM ENT, READ AND UNDERSTAND THE INSTALLATION, OPERATION AND SERVICE MANUAL.

A PPLICATIONS, ENGINEERING AND DE TAILED GUIDANCE ON SYSTEMS DES IGN, INSTAL LATION AND PRODUCT PERFORMANCE IS AVAILABLE UP ON REQUES T. ROBERTS GORDON® PRODUCTS ARE TO B E

INSTALLED ONLY IN ACCORDA NCE WITH LOCAL LA WS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTA LLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

Page 34

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

Pressurized Outside Air Supply

Description Par t Number

Filter Housing 01326801

4" Take O ff 01324401

Blower 90707501

Outside

Burner

Air Supply

Blower

Filter

4" (10 cm)

Housing

Air Flex Duct

Mounting

Bracket

4" (10 cm)

Clamp

Take Off

Outside

Wall

Non-Pressurized Outside Air Sup ply

Sheet Metal

or PVC

Vent Cap

Bird Screen

Outside Wall

or

Description Par t Number

P r essure Sw i tch K i t 90434501

4" B ird Screen 01365400

4" V ent Cap 90502300

6" V ent Cap 90502302

Pressure Switch

Lock Nuts

7/16" Diameter Hole

6' (1.8 m)

Maximum

© 2004 Rober ts -Gordon

BEFORE INS TALLAT ION AND OPERAT ION OF HEATING EQUIPMENT, READ AND U NDERSTAND THE INSTALLATION, OPERATI ON AND SERVICE MANUA L.

APPLICATIONS , ENGINEERING AND DETA ILED GUIDA NCE ON SYS TEMS DESIGN, INSTALLAT ION AND PRODUCT P ERFORMANCE IS AVAILABLE UPON REQUEST . ROBERTS GORDON® PRODUCT S ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONT RACTOR QUALIFIED IN THE INSTALLA TION AND S ERVICE OF GAS-FI RED HEAT ING EQUIPMENT.

Page 35

ROBERTS GORDON® CRV-SERIES SUBM ITT AL SHEET

GAS PIPING

Gas Connection with Stainless Steel Flex Gas Connector

Shut-Off Valve must be parallel to burner gas inlet. The 2" (50 mm)

displacement shown is for the cold condition. T his displacement

may reduce when the system is fired.

3/4" NPT Pipe

Shut-Off Valve

(included

with connector)

12"

2" (5 cm)

(30 cm)

Stainless

Steel Flex

Gas Connector

Horizontal

De sc ript ion Part Number

1/2" Flex Gas Line 91412200

3/4" Flex Gas Line 91412203

Hold gas nipple securely with

pipe wrench when attaching

the flex gas connector.

Failure to follow these instructions can result in product

damage.

45°

Rear ViewBurner

© 2004 Roberts-Gordon

B EFORE INSTALLAT I ON AND OPERATION OF HEATI NG EQUIPM ENT, READ AND UNDERSTAND THE INSTALLATION, OPERATION AND SERVICE MANUAL.

A PPLICATIONS, ENGINEERING AND DE TAILED GUIDANCE ON SYSTEMS DES IGN, INSTAL LATION AND PRODUCT PERFORMANCE IS AVAILABLE UP ON REQUES T. ROBERTS GORDON® PRODUCTS ARE TO B E

INSTALLED ONLY IN ACCORDA NCE WITH LOCAL LA WS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTA LLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

Page 36

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

WIRING

One Zone Ope ration without Control Panel

WARNING

Electrical Shock Hazard

Disconnect electrical power and gas supply before

servicing.

This appliance must be connected

to a properly grounded electrical source.

Failure to follow these instructions can result in

death or electrical shock.

120V

1ph

60Hz

L

N

Ground

SPST (12A)

Transformer

Thermostat

Black

Black

White

Relay

C

R

W

G

Y

1

3

2

4

COIL COIL

6

5

Pressure

Switch

(Pump)

Description Par t Number

S PST Tr ansfor mer Rela y 90417600

Red

LN

NL

Pump

Motor

Zone 1

Burners

Nine Burners Maximum

© 2004 Rober ts -Gordon

BEFORE INS TALLAT ION AND OPERAT ION OF HEATING EQUIPMENT, READ AND U NDERSTAND THE INSTALLATION, OPERATI ON AND SERVICE MANUA L.

APPLICATIONS , ENGINEERING AND DETA ILED GUIDA NCE ON SYS TEMS DESIGN, INSTALLAT ION AND PRODUCT P ERFORMANCE IS AVAILABLE UPON REQUEST . ROBERTS GORDON® PRODUCT S ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONT RACTOR QUALIFIED IN THE INSTALLA TION AND S ERVICE OF GAS-FI RED HEAT ING EQUIPMENT.

Page 37

ROBERTS GORDON® CRV-SERIES SUBM ITT AL SHEET

Two Zone Operation without C ontro l Panel

Zone 1

Thermostat

120V

1ph

60Hz

L

COIL

White

DPST (12A)

Transformer

Relay

C

R

G

W

Y

Purple Red

1

3

2

6

4

COIL

5

Red

Black

Black Black

Zone 2

Thermostat

Red/Yellow

Purple

Black

DPST (12A)

Transformer

Relay

R

C

G

W

1

2

4

COIL

5

Y

3

6

COIL

Red/YellowWhite

N

Pressure

Switch

(Pump)

Description Part Number

DPST Transformer Relay 90436300

LNLN

NL

Pump

Motor

Zone 1

Burners

Zone 2

Burners

Nine Burners Total Maximum Between Zones

© 2004 Roberts-Gordon

B EFORE INSTALLAT I ON AND OPERATION OF HEATI NG EQUIPM ENT, READ AND UNDERSTAND THE INSTALLATION, OPERATION AND SERVICE MANUAL.

A PPLICATIONS, ENGINEERING AND DE TAILED GUIDANCE ON SYSTEMS DES IGN, INSTAL LATION AND PRODUCT PERFORMANCE IS AVAILABLE UP ON REQUES T. ROBERTS GORDON® PRODUCTS ARE TO B E

INSTALLED ONLY IN ACCORDA NCE WITH LOCAL LA WS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTA LLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

Page 38

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

CRV-Series Burner Internal Wiring

Black

120 V

Power Supply

TRANSFORMER

White

Green

1

3

5

Yellow

4

Blue

Green

Yellow

GAS

VALVE

Brown

Yellow

TH

V1

S1

V2/GND

Black

IGNITION

MODULE

BURNER

If any of t he original wire as supplied with the heater must be replaced, it must be replaced with wir-

ing material having a temperature rating of at least 105°C and 600 volts.

CRV-Series Burner Internal Ladder Diagram

L1

TRANSFORMER

Black

L2

White

Yellow

ELECTRODE

Gap

© 2004 Rober ts -Gordon

Blue

Yellow

Brown

Black

GAS VALVE

S1 V1

V2

Gnd

BEFORE INS TALLAT ION AND OPERAT ION OF HEATING EQUIPMENT, READ AND U NDERSTAND THE INSTALLATION, OPERATI ON AND SERVICE MANUA L.

APPLICATIONS , ENGINEERING AND DETA ILED GUIDA NCE ON SYS TEMS DESIGN, INSTALLAT ION AND PRODUCT P ERFORMANCE IS AVAILABLE UPON REQUEST . ROBERTS GORDON® PRODUCT S ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONT RACTOR QUALIFIED IN THE INSTALLA TION AND S ERVICE OF GAS-FI RED HEAT ING EQUIPMENT.

TH

IGNITION

MODULE

Page 39

ROBERTS GORDON® CRV-SERIES SUBM ITT AL SHEET

INTERNAL BURNER DIAGRAM

Gasket (Burner to Mixing Chamber)

Burner Head

Electrode

Electrode Gasket

Mixing Chamber

Combustion

Chamber

Gasket

OFF

ON

Gas Valve

Transformer

Ignition Module

Regulator

© 2004 Roberts-Gordon

B EFORE INSTALLAT I ON AND OPERATION OF HEATI NG EQUIPM ENT, READ AND UNDERSTAND THE INSTALLATION, OPERATION AND SERVICE MANUAL.

A PPLICATIONS, ENGINEERING AND DE TAILED GUIDANCE ON SYSTEMS DES IGN, INSTAL LATION AND PRODUCT PERFORMANCE IS AVAILABLE UP ON REQUES T. ROBERTS GORDON® PRODUCTS ARE TO B E

INSTALLED ONLY IN ACCORDA NCE WITH LOCAL LA WS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTA LLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

Page 40

ROBERTS GORDON® CRV-SERIES SUBMITTAL SHEET

THE ROBERTS GORDON® CORAYVAC® LIMITED WARRANTY

ROBERTS-GORDON WILL PAY FOR:

Within 42 months from date of shipme nt from RobertsGordon, replacement parts will be provided free of

charge for any part of the controller whi ch fails due to a

manufac turing or material defect.

Roberts-Gordon will require the part i n question to be

returned to the factory. Roberts-Gordon will, at i ts sole

discretion, repair or replace after determining the

nature of the defect and disposition of part in question.

ROBERTS GOR DON® warrants the cast iron

combustion chamber of the CORAYVAC® Classic

System will be free from defects in material and

workmans hip. This warranty is limited to twenty-five

(25) years from the date of shi pment by RobertsGordon. All other components of the COR AYVAC®

Clas sic Sy stem adhere to the standard warranty listed

in the paragraph above.

ROBERTS GOR DON® Replacement Parts are

warranted for a period of 18 m onths from date of

shipment fr om Rober ts-Gordon or the remaining

CORAYVAC® warranty.

ROBERTS-GORDON WILL NOT PAY FOR:

Service trips, service calls and labor charges.

Shipm ent of replacement par ts.

Cl aims where the total price of the goods have not

been pai d.

Damage due to:

• Improper i nstal lation, oper ation or maintenance.

• M isuse, abuse, neglect, or m odificati on of the

CORAYVAC® in any way.

• U se of the CORAYVAC® for other than i ts intended

purpose.

• Incorrect gas or electrical supply, accident, fire,

fl oods, acts of God, wa r , ter roris m, or other casual ty.

• Improper ser vice, us e of replacement parts or

access ories not specified by R oberts- Gordon.

• Failure to in s ta ll or m aintain the CORAYVAC® as

directed in the Installation, Operation and Service

manual.

• R elocation of the CORAYVAC® after initial inst allation

• The use of the CORAYVAC® in a corrosive

atmospher e containing contaminants.