Page 1

WARNING

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. DO NOT try to light any appliance.

3. DO NOT use electrical switches.

4. DO NOT use any telephone in

your building.

5. Leave the building.

6. Immediately call your local gas

supplier after leaving the building.

Follow the gas suppliers

instructions.

7. If you cannot reach your gas

supplier, call the Fire Department.

Fire Hazard

Do not store or use petrol or other

flammable vapours and liquids in the

vicinity of this or any other appliance.

Some objects will catch fire or explode

when placed close to heater.

Failure to follow these instructions can

result in death, injury or property

damage.

WARNING

Installation must be done by a registered installer/

contractor qualified in the installation and service of

gas/oil-fired heating equipment or your fuel supplier.

Improper installation, adjustment, alteration, service

or maintenance can result in death, injury or property

damage. Read the installation, operation and service

manual thoroughly before installing or servicing

this equipment.

Installer

Please take the time to read and understand

these instructions prior to any installation.

Installer must give a copy of this manual to the owner.

Owner

Keep this manual in a safe place in order to provide

your serviceman with necessary information.

®

Combat

Cabinet Heaters

Installation, Commissioning,

Operation & Service Manual

OIL-FIRED:

Model POP-ECA

015 to 0100

GAS-FIRED:

Model PGP-ECA

015 to 0100

Quality in Any Language™

© Copyright 2008 Roberts-Gordon LLC

Roberts-Gordon Europe Limited

Unit A, Kings Hill Business Park

Darlaston Road, Wednesbury

West Midlands,WS10 7SH UK

Telephone: +44 (0)121 506 7700

Fax: +44 (0)121 506 7701

Service Telephone: +44 (0)121 506 7709

Service Fax: +44 (0)121 506 7702

E-mail: uksales@rg-inc.com

E-mail: export@rg-inc.com

P/N X523 Rev G 10/08

Page 2

Page 3

© 2008

Roberts-Gordon LLC

All rights reserved. No part of this work covered by the copyrights herein may be reproduced

or copied in any form or by any means - graphic, electronic, or mechanical, including

photocopying, recording, taping or information storage and retrieval systems - without the

written permission of Roberts-Gordon LLC.

TABLE OF CONTENTS

SECTION 1: Heater Safety...................................................... 2

SECTION 2: Installer Responsibility ..................................... 2

2.1 Clearances to Combustibles ........................................ 2

2.2 Corrosive Chemicals.................................................... 2

2.3 National Standards and Applicable Codes .................. 2

SECTION 3: Critical Considerations ..................................... 3

3.1 Basic Information ......................................................... 3

3.2 Location and Suspension ............................................3

3.3 Minimum Required Installation Clearances ................. 3

3.4 Clearances to Combustibles ........................................ 3

3.5 Ventilation ....................................................................3

3.6 Fuel Supply..................................................................3

3.7 Electrical Supply..........................................................3

3.8 Flue..............................................................................3

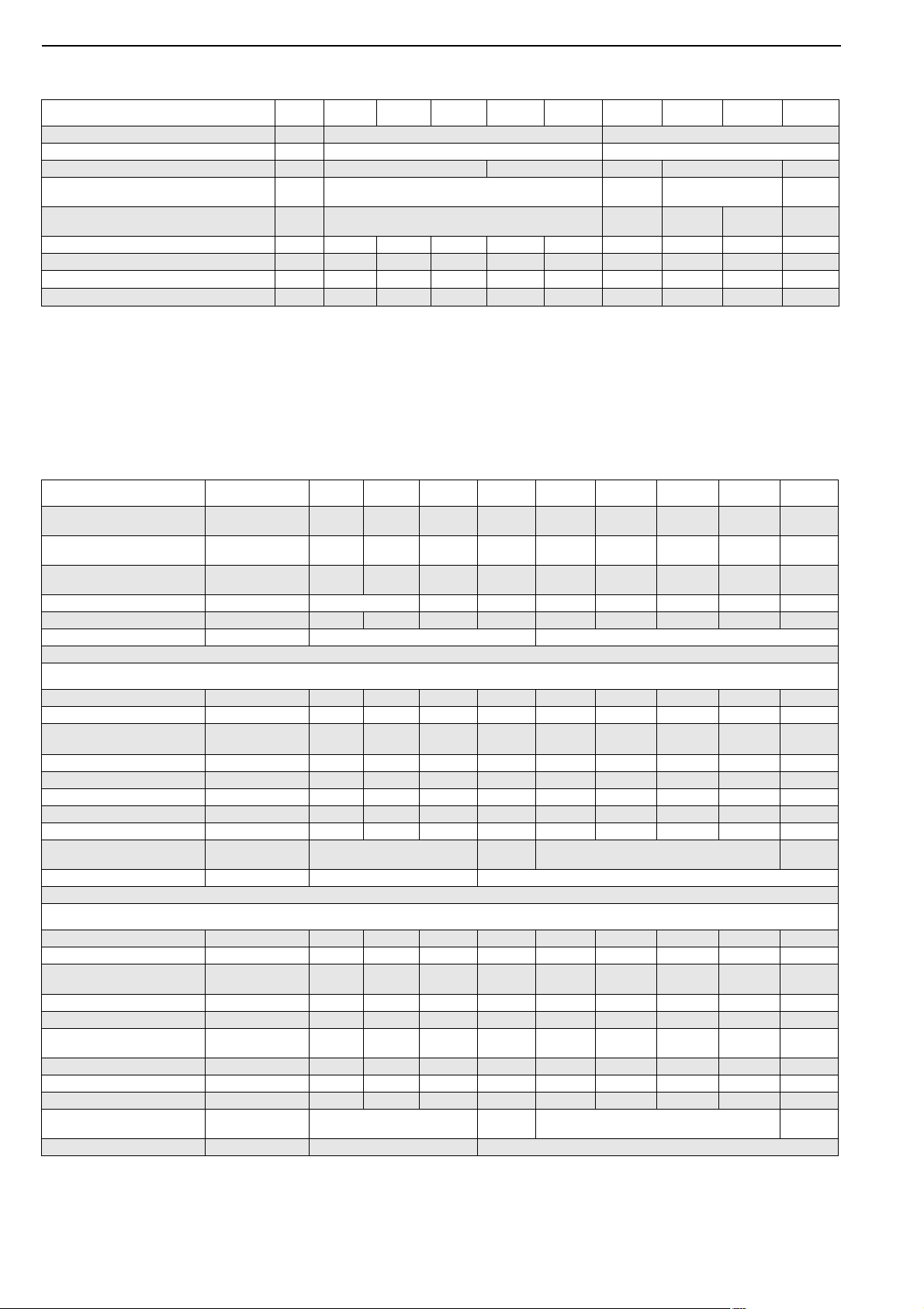

SECTION 4: Specifications ....................................................5

4.1 PGP & POP Internal Heaters....................................... 5

4.2 PGP & POP External Heaters .....................................6

4.3 Air Outlet and Flue Arrangements ...............................7

4.4 General Technical Data Table (all models)

Appliance Category II

4.5 Technical Data - Ecoflam ON/OFF Burners

(all models - burner reference "C") ..............................8

4.6 Technical Data - Ecoflam Modulating Burners

(all models - burner reference "H") ..............................9

4.7 Technical Data - Ecoflam Oil-Fired Burners

(burner reference "G") ............................................... 10

SECTION 5: Heater Installation............................................ 11

5.1 General...................................................................... 11

5.2 Handling .................................................................... 11

SECTION 6: Flue Installation ............................................... 13

6.1 Flue Installation.......................................................... 13

SECTION 7: Air Supply......................................................... 15

7.1 Air Supply................................................................... 15

7.2 Isolated Equipment Rooms ........................................15

7.3 Building Ventilation .....................................................15

7.4 Distribution Ducting .................................................... 15

7.5 Return Air Ducting...................................................... 15

SECTION 8: Fuel Piping........................................................ 16

8.1 Connections............................................................... 16

8.2 Fuel Oil Supply .......................................................... 17

SECTION 9: Wiring and Electrical Information................... 19

9.1 Electrical Supply........................................................ 19

9.2 Remote Controls........................................................ 19

9.3 CCH Wiring Diagram Gas Models 15-30

(floor standing)...........................................................20

9.4 CCH Wiring Diagram Oil Models 15-30

(floor standing)...........................................................21

9.5 CCH Wiring Diagram Gas Models 15-30

(horizontal mounting)................................................. 22

9.6 CCH Wiring Diagram Oil Models 15-30

(horizontal mounting)................................................. 23

9.7 CCH Wiring Diagram Gas Models 40-50

(floor standing)...........................................................24

9.8 CCH Wiring Diagram Oil Models 40-50

(floor standing)...........................................................25

9.9 CCH Wiring Diagram Gas Models 40-50

(horizontal mounting)................................................. 26

9.10 CCH Wiring Diagram Oil Models 40-50

(horizontal mounting)............................................... 27

....................................... 8

2H/L 3B/P

9.11 CCH Wiring Diagram Gas Models 60-100

(floor standing) .........................................................28

9.12 CCH Wiring Diagram Oil Models 60-100

(floor standing) .........................................................29

9.13 CCH Wiring Diagram Gas Models 60-100

(horizontal mounting) ...............................................30

9.14 CCH Wiring Diagram Oil Models 60-100

(horizontal mounting) ...............................................31

9.15 Final Connections to Ecoflam HIGH/LOW or

Modulating Burners (all models) ..............................32

SECTION 10: Commissioning ..............................................33

10.1 Pre-Commission Checks..........................................33

10.2 Commissioning the Burner (gas heaters).................34

10.3 Control - Gas-Fired Heaters .....................................35

10.4 Gas Valves ...............................................................37

10.5 Combustion Testing (all models) ..............................37

10.6 Commissioning the Burner (Oil Heaters)..................38

10.7 Control - Oil-Fired Heaters .......................................38

10.8 Turning Off the Heater (all models) ..........................39

10.9 External Controls......................................................39

10.10 Instruction to the User ............................................39

SECTION 11: User Instructions............................................40

11.1 User Instructions.......................................................40

11.2 Common User Controls (all models).........................40

11.3 Lighting Instructions (all models) ..............................41

11.4 Simple Fault Finding (all models)..............................41

SECTION 12: Servicing.........................................................43

12.1 Servicing Instructions...............................................43

12.2 Burner Maintenance.................................................43

12.3 Fan/Motor Assembly Maintenance (all models) .......43

12.4 Heat Exchanger Maintenance ..................................43

12.5 Thermal Insulation ...................................................43

SECTION 13: Conversion Between FUELS .........................44

13.1 General ....................................................................44

13.2 Burner Conversion ...................................................44

SECTION 14: Troubleshooting .............................................45

14.1 General ....................................................................45

14.2 Troubleshooting for Oil Burners

(see manufacture’s instructions) ..............................46

14.3 Troubleshooting for Gas Burners

(see manufacturer’s instructions) .............................47

14.4 Troubleshooting for Flame Supervision System .......48

14.5 Troubleshooting for Solenoid Valves Circuit .............49

14.6 Troubleshooting for Main Fan Circuit (1 Ø)...............49

14.7 Troubleshooting for Main Fan (3 Ø)..........................50

SECTION 15: Removal and Replacement Parts..................51

15.1 Burner Components ..............................................51

15.2 Direct On-Line Main Fan Starter and

Thermal Overload Unit (3 Ø)...................................51

15.3 Control Circuit Fuse

(10 or 5 A, 1-1/4" long sand filled) ............................51

15.4 Combination Fan/Limit Thermostat ..........................51

15.5 Main Fan Motor (3 Ø Belt Drive) ..............................51

15.6 Main Fan Units .........................................................51

SECTION 16: Parts List.........................................................53

16.1 Spare Parts List........................................................53

Printed in U.K.

Page 4

Page 5

TABLE OF FIGURES

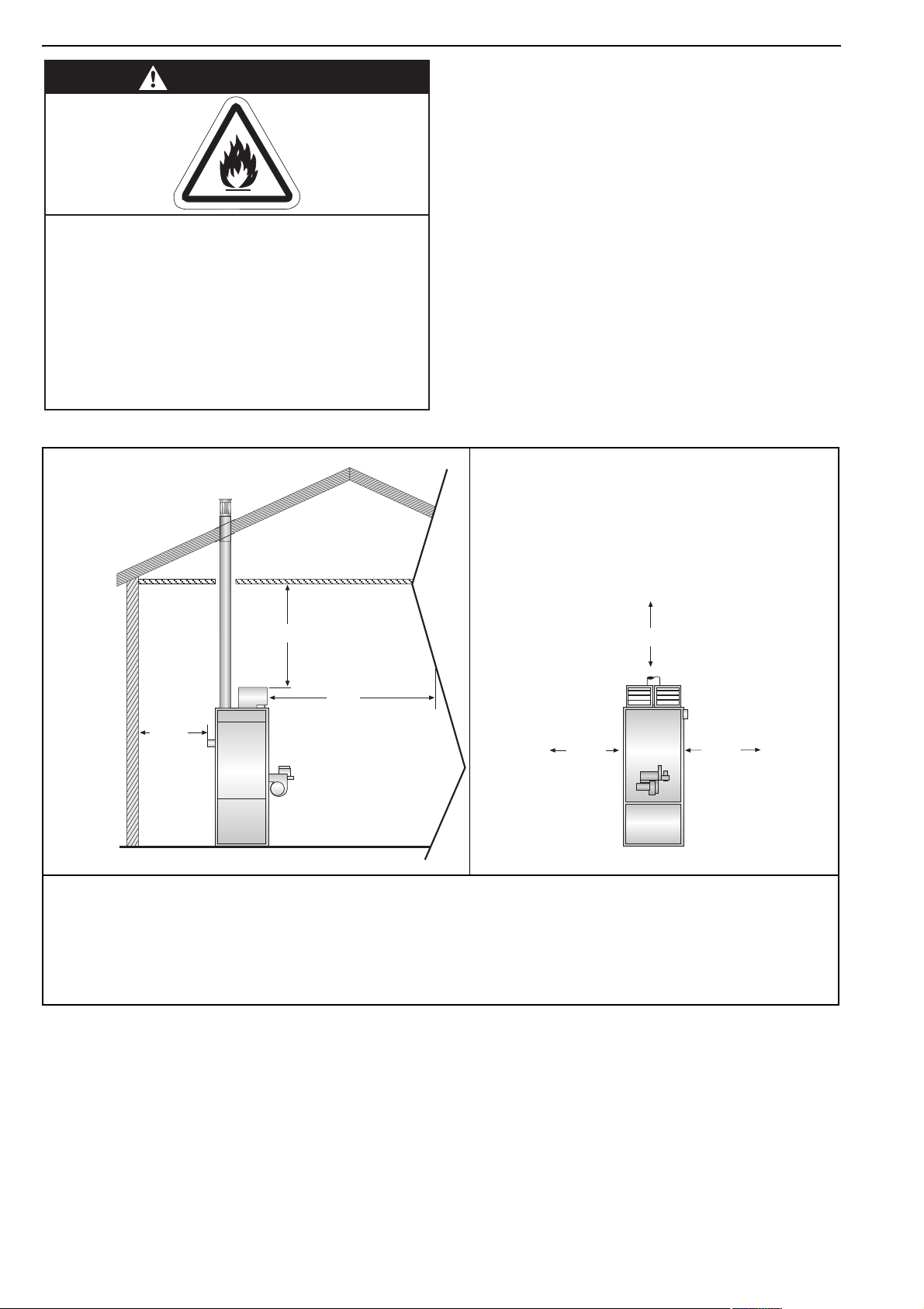

Figure 1: Installation Clearances and Clearances to

Combustibles .............................................................4

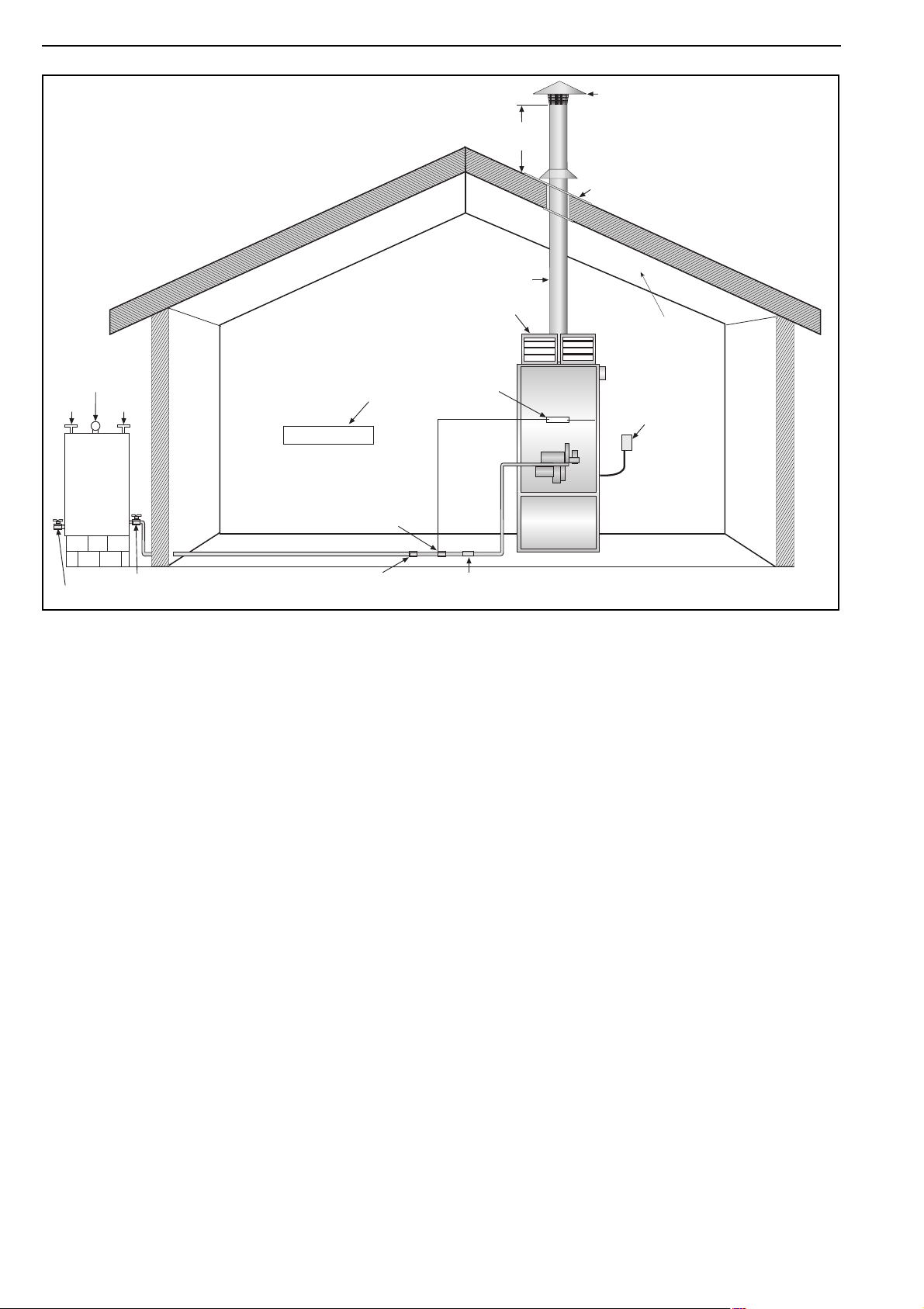

Figure 2: Typical Installation of a Gas Fired Cabinet Heater... 11

Figure 3: Typical Installation of a Oil-Fired Cabinet Heater..... 12

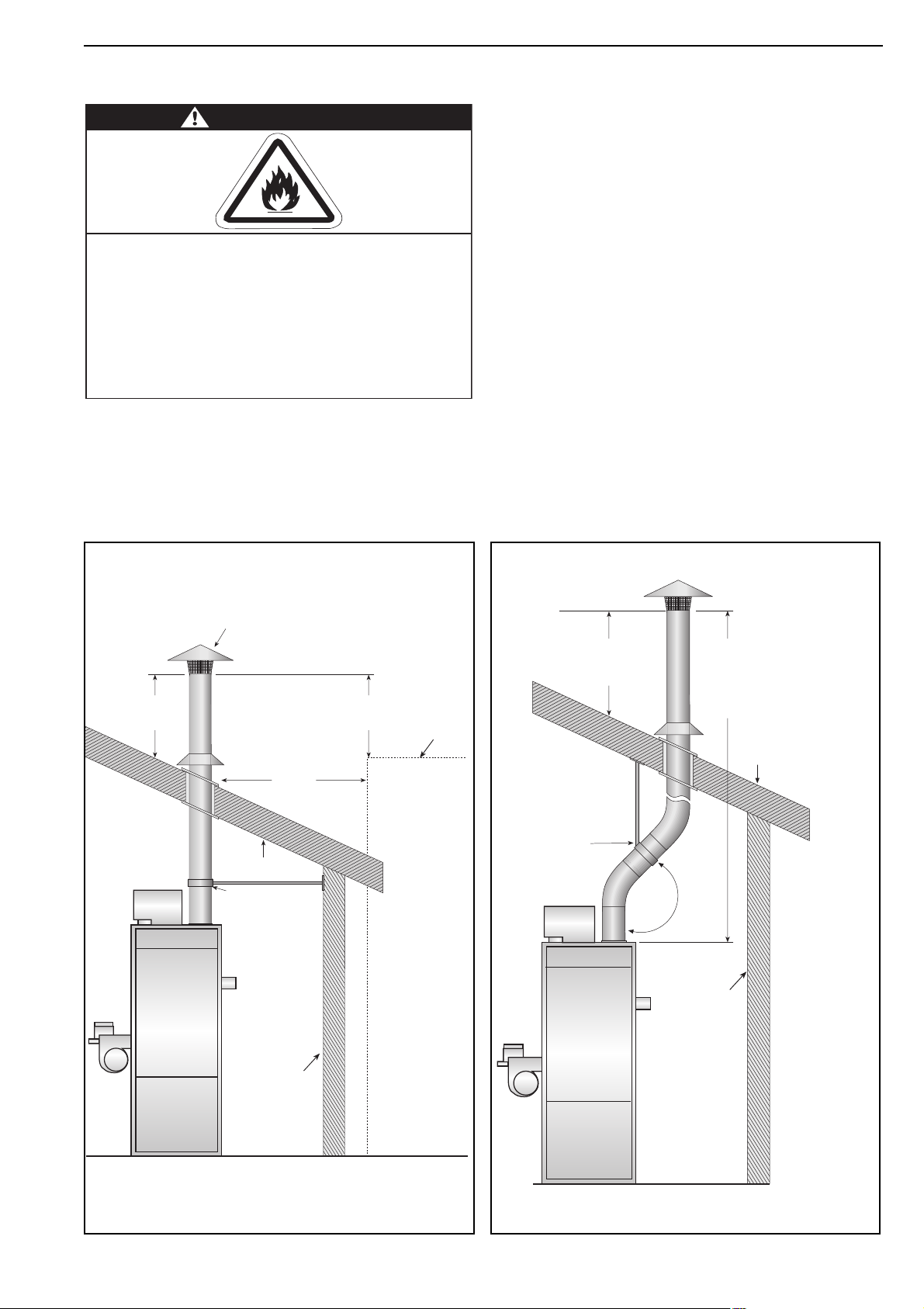

Figure 4: Flue Termination ...................................................... 13

Figure 5: Offset Flues with 135° bends ................................... 13

Figure 6: Guy Wire.................................................................. 14

Figure 7: Socket Direction....................................................... 14

Figure 8: Flue and Roof Detail ................................................14

Figure 9: Flue and Heater Spigot Joint Detail ......................... 14

Figure 10: Gas Connection ..................................................... 16

Figure 11: B. M. Oil Lifter......................................................... 17

Figure 12: Pressurised System Installation - Duplex System ..18

Figure 13: Combination Thermostat (all models)....................34

Figure 14: Gas-Fired Heater Control Box Sequence...............35

Figure 15: Motor Starter (models 040 -100 and Thermal

Overload (models 060 - 100) .................................36

Figure 16: Gas Train Circuit for Dungs Gas Valves

(all models) ............................................................ 36

Figure 17: Dungs Gas Valve ...................................................37

Figure 18: Oil-Fired Heaters Control Box Sequence............... 38

Figure 19: Heater Operating Sequence .................................. 40

Figure 20: Fan/Limit Thermostat ............................................. 40

Figure 21: Belt Tension ...........................................................43

Figure 22: Combination Fan/Limit Thermostat........................52

Page 6

Page 7

ROBERTS GORDON® appliances have been tested and CE certified as complying with the essential

requirements of the Gas Appliance Directive, the Low Voltage Directive, the Electromagnetic

Compatibility Directive and the Machinery Directive for use with natural gas and LPG when installed,

commissioned and maintained in accordance with these instructions.

These instructions refer to gas appliances designed to operate in the European Union.

Appliances designed for other countries (Non-European Union) are available on request.

Oil-fired versions are constructed to the same basic design criteria to burn fuel oil as specified below,

but no similar testing is available for these products at the time of writing. Oil-fired appliances should be

operated in accordance with local rules and laws.

Oil heaters are supplied as standard for use with Gas Oil, also known as 35-second Oil, Red Diesel,

Class D or Class A2. They are also available to order for Kerosine, also known as 28-second Oil or

Class C2.

These appliances must be installed in accordance with the local and national codes in force and used

only in a sufficiently ventilated space, as specified in these instructions.

Before installation, check that the local gas distribution systems, nature of gas and pressure, and

adjustment of the appliance are compatible.

Product Approval

1

Page 8

COMBAT® CABINET HEATERS INSTALLATION, COMMISSIONING, OPERATION AND SERVICE MANUAL

CAUTION

Do not use heater in an area containing corrosive

chemicals.

Corrosive chemicals will damage the burner and

heat exchanger parts.

Failure to follow these instructions can result in

property damage.

SECTION 1: HEATER SAFETY

Your Safety Is Important to Us!

This symbol is used throughout the

clearances to combustibles. Affix the tag on a wall

near the heater.

manual to notify you of possible fire,

electrical or burn hazards. Please pay

2.2 Corrosive Chemicals

special attention when reading and

following the warnings in these sections.

Installation, Service and Annual Inspection of heater

must be done by a registered installer/contractor

qualified in the installation and service of gas/oilfired heating equipment.

Read this manual carefully before installation,

operation, or service of this equipment.

Burner manufacturers manual is also provided to

give detailed instructions on the operation of the

burner. The settings for use of the burner with the

heater are shown in these instructions.

Roberts-Gordon cannot be responsible for ensuring

that all appropriate safety measures are undertaken

This heater is designed for heating non-residential

indoor spaces. Do not install in residential spaces.

These instructions, the layout drawing, local codes

and ordinances, and applicable standards that apply

to gas piping, electrical wiring, venting, etc., must be

thoroughly understood before proceeding with the

installation.

SECTION 2: INSTALLER RESPONSIBILITY

• To install the heater, as well as the fuel and

electrical supplies, in accordance with applicable

specifications and codes. Roberts-Gordon

prior to installation; this is entirely the responsibility

of the installer. It is essential that the contractor, the

sub-contractor or the owner identifies the presence

of combustible materials, corrosive chemicals or

halogenated hydrocarbons* anywhere on the

premises.

* Halogenated Hydrocarbons are a family of chemical

compounds characterized by the presence of halogen

elements (fluorine, chlorine, bromine, etc.). These compounds are frequently used in refrigerants, cleaning

agents, solvents, etc. If these compounds enter the air

supply of the burner, the lifespan of the heater components will be greatly reduced. Warranty will be invalid if

the heater is exposed to halogenated hydrocarbons.

recommends the installer contact a local

building inspector, Fire Officer or insurance

company for guidance.

• To use the information given in this manual

together with the local and national codes to

perform the installation.

• To install the heater in accordance with the

Clearances to Combustibles of this heater.

• To furnish all needed materials not furnished

as standard equipment.

• To plan location of supports, flues and air

intakes.

• To provide access to burners for servicing.

• To provide the owner with a copy of this

installation, commissioning, operation and

service manual.

• To never use heater as support for ladder or

other access equipment and never hang or

suspend anything from heater.

• To ensure that there is sufficient ventilation in the

area to comply with the requirements of

all relevant local and national codes.

2.1 Clearances to Combustibles

In all situations, clearances to combustibles must be

maintained. Caution must be used when running the

heater near combustible materials such as wood,

paper, rubber, etc. A wall tag is on the back cover of

this manual as a permanent reminder of the safety

instructions and the importance of the required

2

2.3 National Standards and Applicable Codes

All appliances must be installed in accordance with

the latest revision of applicable standards and local

and national codes. This refers also to the electric,

gas and venting installation. NOTE: Additional

standards for installations in Public Garages, Aircraft

Hangars, etc. may be applicable.

The main relevant regulations for installation within

the UK are:

• Gas safety (installation and use) regulations,

1984 and amendments - 1996.

• BS6230 - Specification for the installation of gas

fired forced convection air heaters for commercial and industrial space heating of rated input

exceeding 60kW. (This standard also applies to

oil-fired heaters, except for the fuel supply).

• BS6230 - Parts 2 & 3, fire precautions in the

design and construction of buildings.

• BS6891 - Low pressure installation pipes.

• BS5410 - Codes of practice for oil firing. Part 2

installation of 44 kW and above output capacity

for space heaters, hot water and steam supply

purposes.

• Institute of Gas Engineers document IGE/UP/2.

• Building regulations.

• IEE regulations.

• Health and safety at work acts.

• Requirements of local authority, fire officer and

insurance company.

Page 9

SECTION 3: CRITICAL CONSIDERATIONS

3.1 Basic Information

Cabinet heaters are supplied with burners suitable

for on/off operation as standard. As an option, oilfired burners are available with two-stage operation

and gas-fired burners are available with full

modulation.

3.2 Location and Suspension

All models:

• Are designed to be installed indoors within the

heated space. Special versions are available for

installation outdoors.

• Are designed for floor standing vertical installation.

• Must be installed in a manner which allows all

the upper panels and either of the lower side

panels to be removed to provide access to all

serviceable components.

• Must be placed on a firm, level, non-combustible

surface that can support its weight. See Page 5,

Section 4.1 for weight details.

Horizontal models:

• Special versions supplied with steel channels to

support the heater are available and may be

mounted horizontally. When installed horizontally, the heater will normally lie on its left side

when viewed from the burner. The same clearances and comments on panels must be used,

except for the side the heater lies on.

SECTION 3: CRITICAL CONSIDERATIONS

3.7 Electrical Supply

A permanent 230 V, 50 Hz, 1 Ø is required on

models 15 to 30 and 400 V, 50 Hz, 3 Ø and neutral

required on models 40 to 100 (special version PGP

and POP 040 and 050 models are available as belt

drive). The heater also requires suitable energy

controls in accordance with Section 9.

ON/OFF control, temperature control, time control,

and frost protection are available as a remote

control, which needs to be site wired for proper

operation of the heater. Alternatively, any remote

energy controls may be used which must be wired in

accordance with Section 9.3 through Section 9.10.

3.8 Flue

Choose heater siting to allow for the proper location

of the flue. Each heater must be fitted with an

individual and correctly sized sealed flue system

(See Page 13, Section 6).

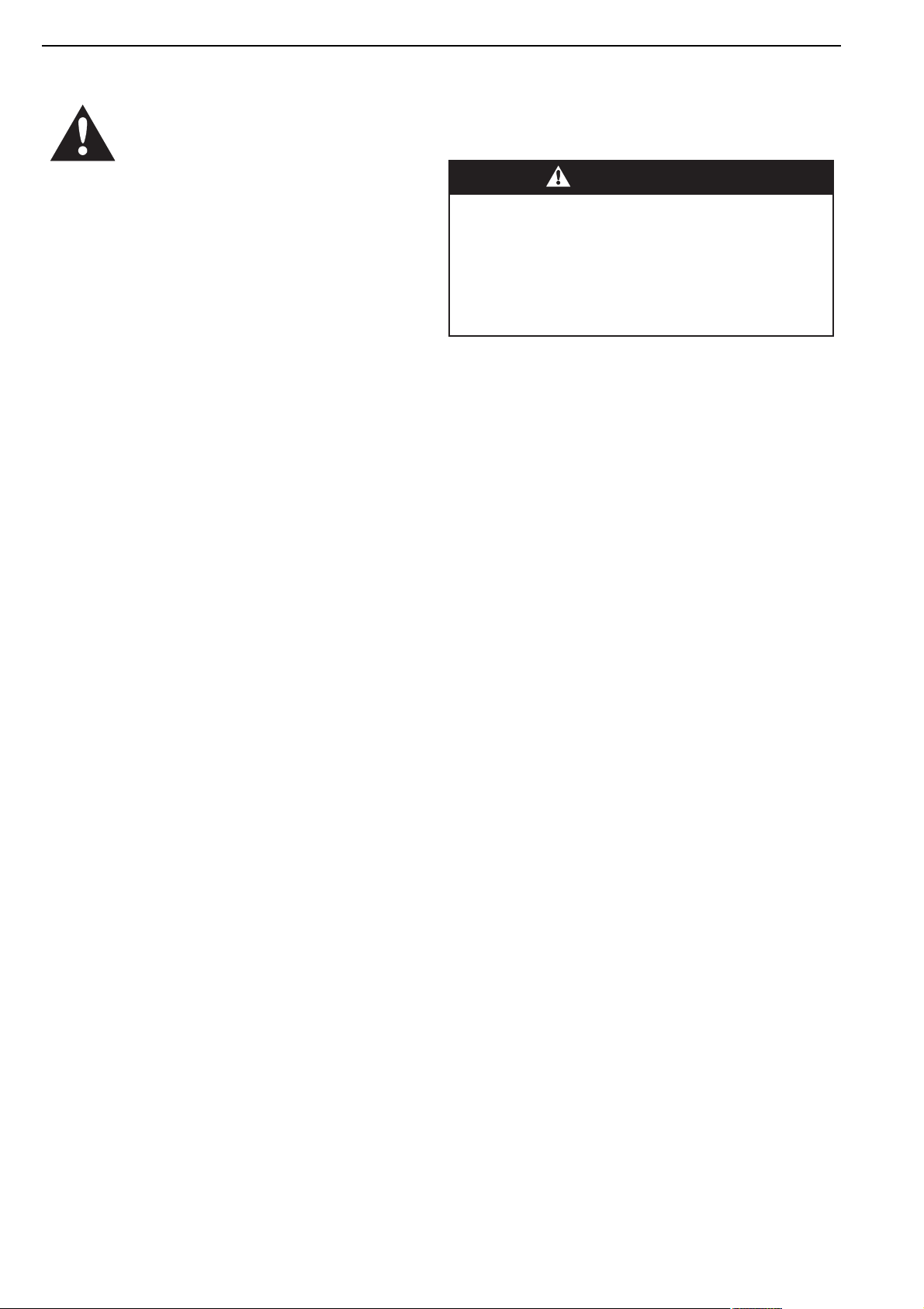

3.3 Minimum Required Installation Clearances

Clearances around the heater and flue must be as

indicated on Page 4, Figure 1 and Page 13, Figure 4

through Figure 5 to ensure access for servicing, and

correct operation.

3.4 Clearances to Combustibles

Clearances must be as indicated on Page 4, Figure

1. If no clearances to combustibles are indicated,

then installation clearances apply.

3.5 Ventilation

It is important to ensure adequate air circulation

around the heater to supply air for combustion,

ventilation and distribution in accordance with local

and national codes.

3.6 Fuel Supply

It is important that the fuel supply pipe is sized

correctly to provide the inlet pressure as stated on

the heater data plate. The fuel supply pipe and

electrical connections must not support any of the

heater's weight.

3

Page 10

COMBAT® CABINET HEATERS INSTALLATION, COMMISSIONING, OPERATION AND SERVICE MANUAL

WARNING

Fire Hazard

Some objects will catch fire or explode when

placed close to heater.

Keep all flammable objects, liquids and

vapours the required distance away from the

heater.

Failure to follow these instructions can result

in death, injury or property damage.

*.6 m *.6 m

.6 m

4 m

.6 m

.6 m

The flue pipe must have clearance from combustibles by 5 cm.

If installed where individuals can come in contact with the pressure relief door or other hot components,

adequate guarding must be provided.

All distances are minimum clearance requirements for service access, air flow and safety.

*A service clearance of 1m is required on one side to allow for fan replacement.

Figure 1: Installation Clearances and Clearances to Combustibles

4

Page 11

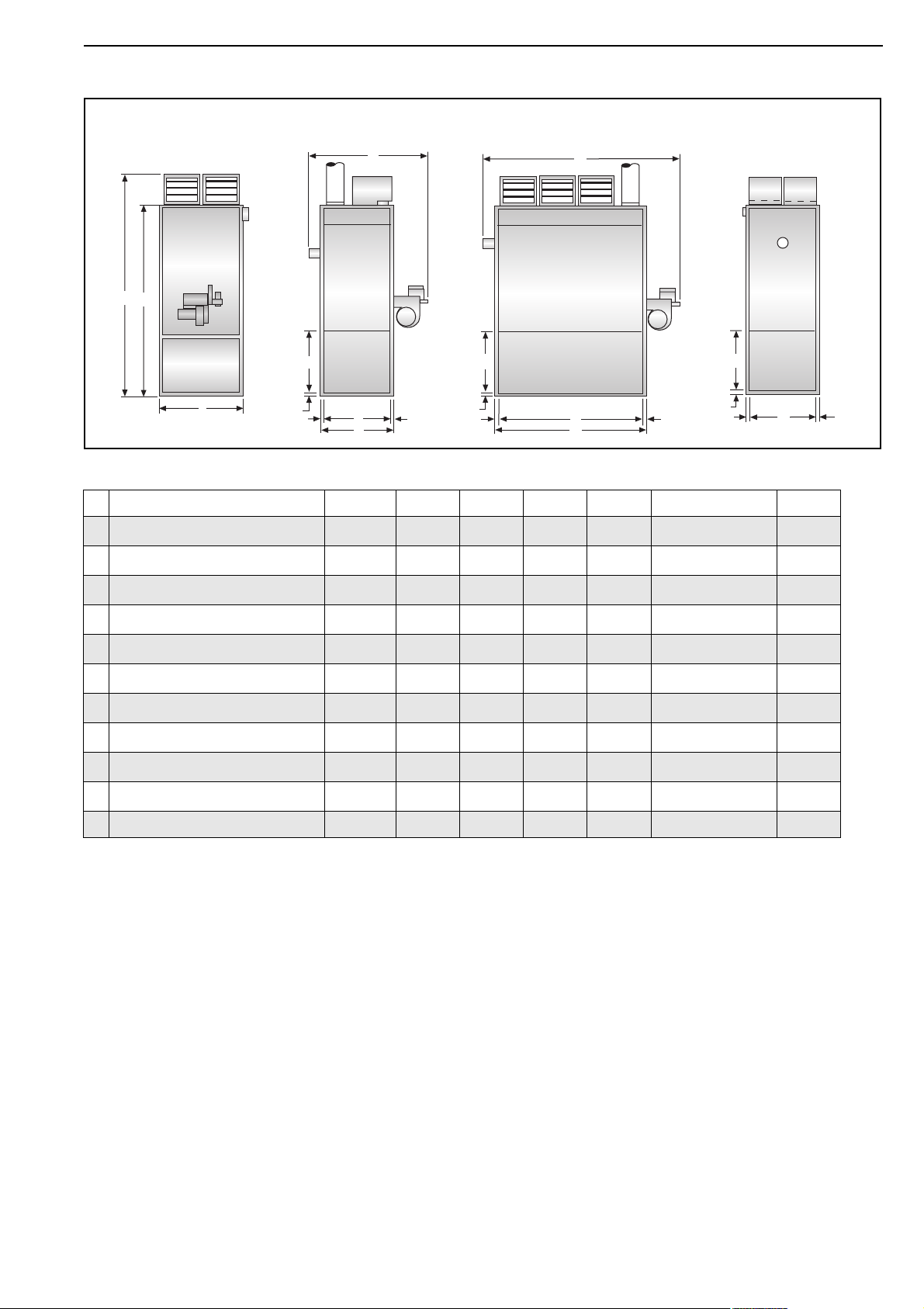

SECTION 4: SPECIFICATIONS

E

C

A

38

70

D

38

G

F

B

38

70

38

D

G

F

B

38

38

108

G

H

Front View

(all models)

Side View

(Models 015 - 050)

Rear View

(all models)

Side View

(Models 060 - 0100)

4.1 PGP & POP Internal Heaters

Dimension Data - PGP & POP Internal Heaters

SECTION 4: SPECIFICATIONS

Model 015/020 030 040 050 060/070/080 0100

A

Width

B

Depth, Cabinet Only

C

Height, Cabinet Only

D

Depth, Overall

E

Height, Including Heads

F

Left/Right Air Inlet Spigot - Depth

G

Left/Right Air Inlet Spigot - Height

H

Rear Air Inlet Spigot - Depth

J

Rear Air Inlet Spigot - Height

Flue Diameter*

Weight kg 200 200 245 270 440 530

mm

(in)

mm

(in)

mm

(in)

mm

(in)

mm

(in)

mm

(in)

mm

(in)

mm

(in)

mm

(in)

mm

(in)

NOTES: Horizontal cabinet heaters are designed to lie on their left side as standard.

For vertical models, add 54 mm (2 in) to the right side of the cabinet for the fan/limit thermostat.

For horizontal models, add 54 mm (2 in) to the top of the cabinet for the fan/limit thermostat.

*All heaters must be connected to a suitable flue constructed of single wall stainless steel.

724

29

857

34

1740

69

1267

50

1988

78

781

31

457

18

648

26

361

14

178

7

724

29

857

34

1740

69

1267

50

2058

81

781

31

457

18

648

26

361

14

178

7

857

34

857

34

1930

76

1337

53

2235

88

781

31

560

22

781

31

446

18

178

7

1016

40

1016

40

1930

76

1496

59

2235

88

940

37

560

22

781

31

446

18

178

7

1016

40

1676

66

1930

76

2156

85

2235

88

1600

63

560

22

NA NA

NA NA

229

9

1016

40

1994

79

1930

76

2496

98

2235

88

1918

76

559

22

229

9

5

Page 12

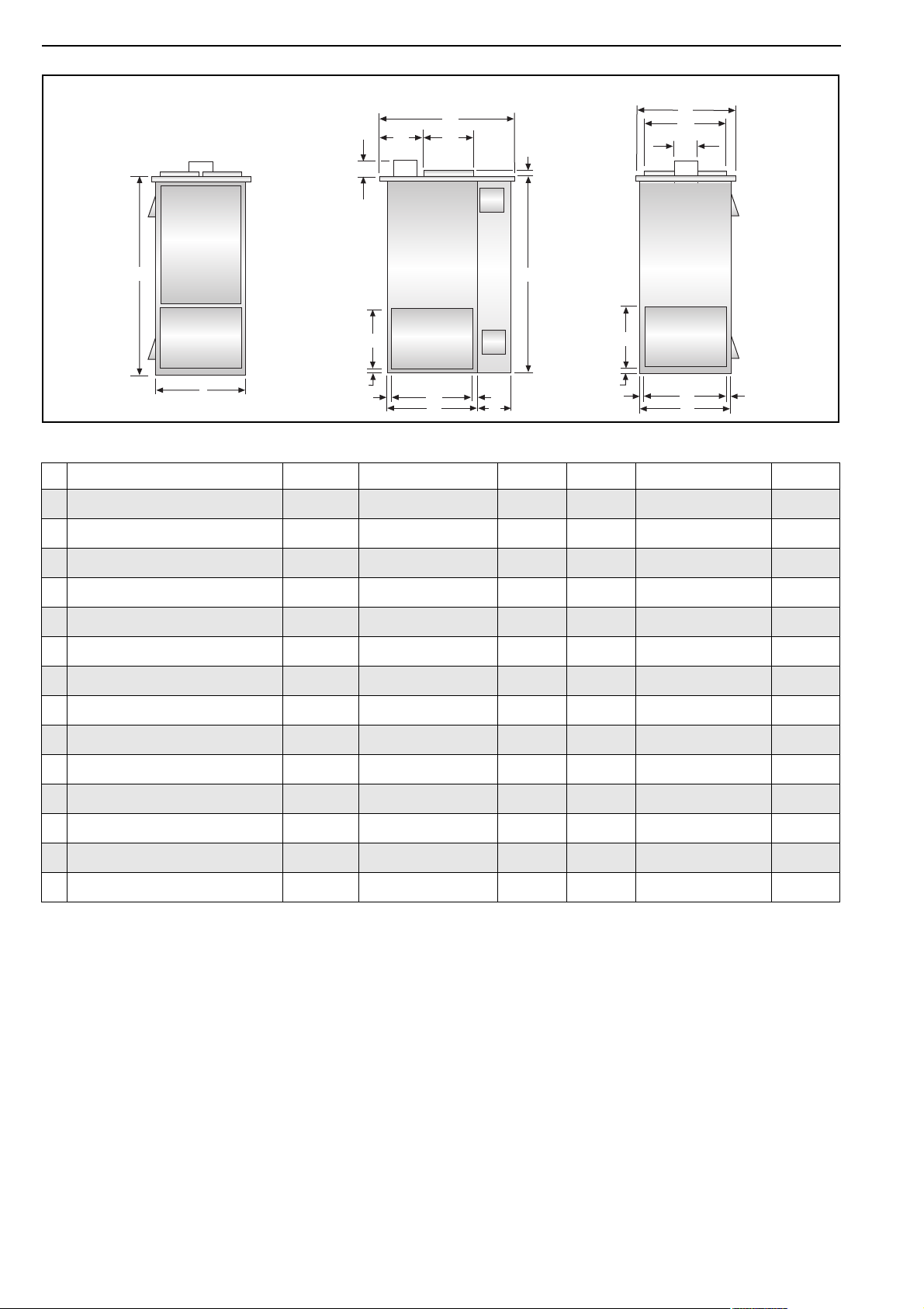

COMBAT® CABINET HEATERS INSTALLATION, COMMISSIONING, OPERATION AND SERVICE MANUAL

C

A

50

38

38

70

275

D

G

P

C

M

N

B

E

38

38

108

F

H

J

L

K

A

Front View

Side View

Rear View

4.2 PGP & POP External Heaters

Dimension Data - PGP & POP External Heaters

Model 015/020/030 040 050 060/070/080 0100

A

Width

B

Depth, Cabinet Only

C

Height, Cabinet Only

D

Depth Overall

E

External Heater Housing

F

Width Overall

G

Air Outlet Spigot - Depth

H

Air Outlet Spigot - Width

J

Flue Diameter

K

Rear Return/Fresh Air Inlet - Width

L

Rear Return/Fresh Air Inlet - Height

M

Left/Right Return Fresh Air Inlet - Height

N

Left/Right Return Fresh Air Inlet - Width

P

Rear of Heater to Air Outlet Spigot*

mm

(in)

mm

(in)

mm

(in)

mm

(in)

mm

(in)

mm

(in)

mm

(in)

mm

(in)

mm

(in)

mm

(in)

mm

(in)

mm

(in)

mm

(in)

mm

(in)

NOTE: *For Models 060-0100, the circular flue spigot is at the front of the heater, with the rectangular air outlet spigot at the rear.

COMBAT

®

external cabinet heaters are designed to be sited externally, with heat ducted into the building. These models

are fitted with a special metal rain drip cover, and all cabinet joints are silicone sealed to ensure that the heaters are

weatherproof.

724

29

857

34

1740

69

1396

55

373

15

840

33

476

19

648

26

178

7

648

26

178

7

457

18

781

31

401

16

857

34

857

34

1930

76

1498

59

474

19

973

38

476

19

781

31

178

7

781

31

178

7

560

22

781

31

401

16

857

34

1016

40

1930

76

1657

65

474

19

973

38

610

24

781

31

178

7

781

31

178

7

560

22

940

37

426

17

1016

40

1676

66

1930

76

2483

98

639

25

1132

45

1238

49

940

37

229

9

NA NA

229

9

560

22

1600

63

96

4

1016

40

1994

79

1930

76

2800

110

639

25

1132

45

1524

60

940

37

229

9

229

9

560

22

1918

76

96

4

6

Page 13

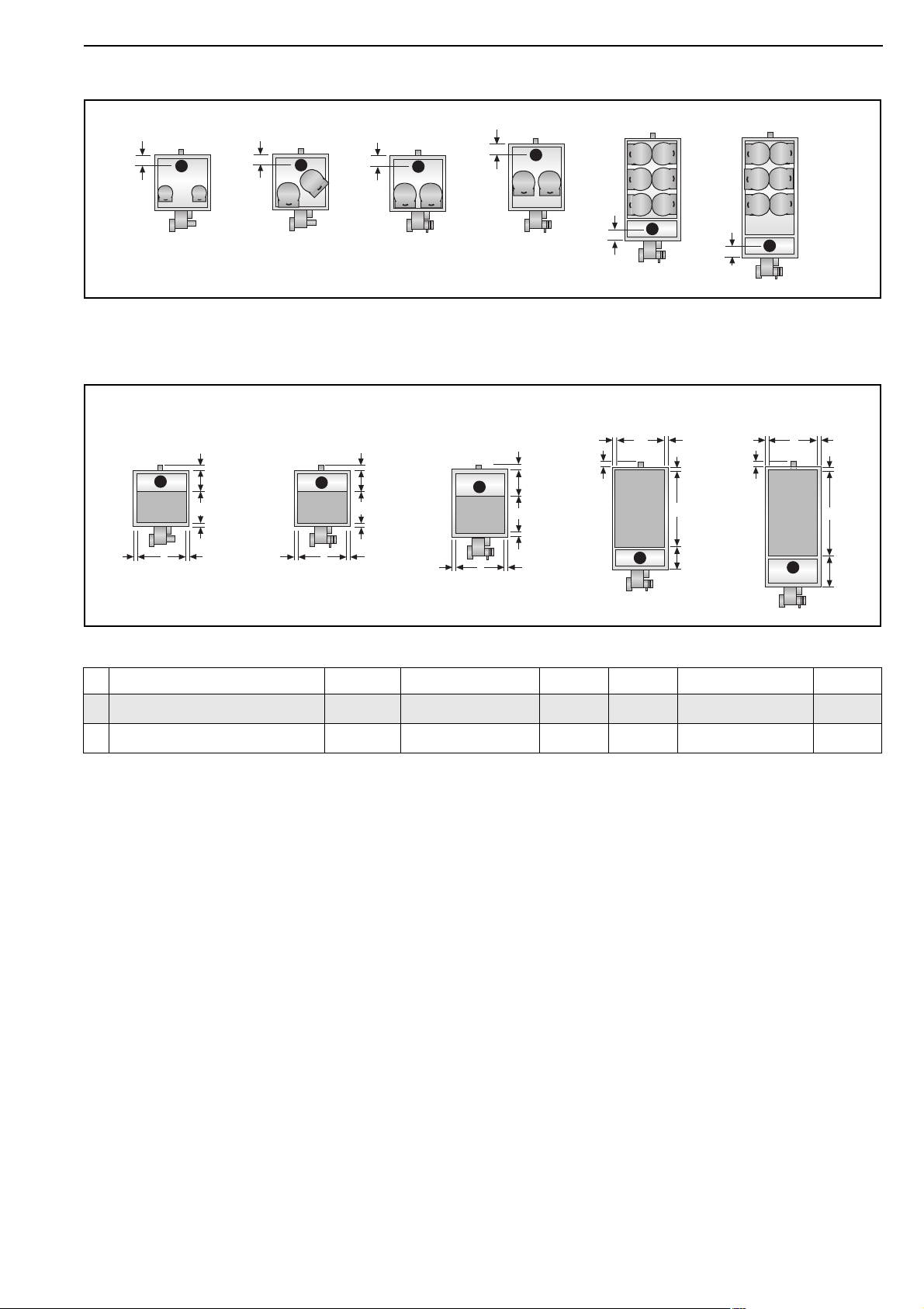

4.3 Air Outlet and Flue Arrangements

165

015/020

165

030

203

040

229

050

184

060/070/080

284

0100

38

38

K

38

100

L

343

015/020/030

38

38

K

38

100

L

343

040

38

38

38

100

L

368

K

050

K

38

100

400

38

38

L

060/070/080

432

K

38

100

38

38

L

0100

4.3.1 Vertical and Horizontal Heaters - Free Blowing (top view)

NOTE: Models 015-020 are fitted with 229 mm (9") diameter discharge heads as standard.

Models 030-0100 are fitted with 356 mm (14") diameter discharge heads as standard.

4.3.2 Vertical and Horizontal Heaters - Air Outlet Spigots (top view)

SECTION 4: SPECIFICATIONS

Outlet Spigot Dimensions

K

Spigot width

L

Spigot Depth

Model 015/020/030 040 050 060/070/080 0100

mm

(in)

mm

(in)

648

26

476

19

781

31

476

19

781

31

610

24

940

37

1238

49

940

37

1524

60

7

Page 14

COMBAT® CABINET HEATERS INSTALLATION, COMMISSIONING, OPERATION AND SERVICE MANUAL

4.4 General Technical Data Table (all models)

Appliance Category II

Model 015 020 030 040 050 060 070 080 0100

Electrical Supply* 230 V / 50 Hz / 1 Ø 400 V / 50 Hz / 3 Ø

Main Fan Motor Type Direct Drive Belt Drive

Motor Size (kW) 0.75 2.2 1.5 2.2 4.0

Motor Pulley (PCD) NA

Fan Pulley (PCD) NA

Start Current (Amps) 24 24 28 21 21 10.2 30 30 35

Run Current (Amps) 5.3 5.3 6.3 6.2 6.2 3.5 5.1 5.1 9.6

Airflow

Free Blowing

NOTE: *Models 40 & 50 are available with 230 V 1 Ø electrical supply as an extra cost option.

A permanent uninterrupted electrical supply is required for all models.

When reading the following data tables, ensure that you are using the correct table for the burner and gas valve

installed. The data tables include a burner reference letter that can be found on the heater data plate. Refer to the

burner manufacturer’s instructions and the specific instructions supplement where applicable. The burner settings

shown in the instructions must be used for burner settings.

2H/L 3B/P

3

(m

/h)

(ft3/min)

2 A x

80 mm

2 A x

180 mm

3398 3398 5097 6796 8495 11044 12443 12443 17330

2000 2000 3000 4000 5000 6500 7500 7500 10200

2 A x 95 mm

2 A x

180 mm

2 A x

180 mm

2 A x

106 mm

2 A x

180 mm

4.5 Technical Data - Ecoflam ON/OFF Burners (all models - burner reference "C")

Model 015 020 030 040 050 060 070 080 0100

Gross Heat Input

Net Heat Input

Heat Output

Pressure Switch Setting (mbar) 1.5 4.5 4.0 6.5 5.0 6.5 7.5 7.0

Flue Static Pressure (mbar) -0.05 -0.05 -0.09 -0.30 -0.05 -0.25 -0.17 0.10 0.45

Gas Connection (in) 3/4" 1 1/4"

(kW)

(Btu/h) x (1000)

(kW)

(Btu/h) x (1000)

(kW)

(Btu/h) x (1000)

55.5

189.4

50.0

170.6

47.4

161.7

73.3

250.1

66.0

225.2

61.2

208.8

93.2

318.0

84.0

286.6

78.4

267.5

129.9

443.2

117.0

399.2

110.2

376.0

162.0

552.7

146.0

498.2

134.5

458.9

208.0

709.7

187.4

639.4

177.7

606.3

242.0

825.7

218.0

743.8

205.3

700.5

275.2

939.0

248.0

846.2

230.4

786.1

348.5

1189.1

314.0

1071.4

293.4

1001.1

Natural Gas (G20) Data - Inlet Pressure 20 mbar (7.8 in WG) Min 17 mbar (6.8 in WG) Max 25 mbar (10 in WG)

Main Burner Gas Pressure mbar 4.0 2.7 4.2 4.8 7.7 5.2 7.1 9.5 10.0

Start Gas Pressure mbar NA NA NA 1.8 2.8 0.9 1.1 1.7 3.4

Gas Rate

Start Gas Orifice (mm dia) 5.0 6.0 7.0 7.0 7.0

Burner Type AZUR 60 BLU 120 BLU 120 BLU 170 BLU 250R BLU 250 BLU 250 BLU 250S BLU 350

Burner Head SSSSSSSSS

Burner Head Setting (mm) 0 10 11 15 14 24 24 24 21

Air Setting 2.6 4.2 6 2.2 3.5 2.9 3.6 1.4 1.6

Valve Type Main Gas

Valve Type Start Gas NA S.I.T. 0 832 051

(m3/h)

3

/h)

(ft

5.3

187

7.0

247

MBDLE

405

8.9

314

12.4

438

MBDLE

407

15.4

546

19.8

701

MBDLE

410

23.1

816

26.2

928

33.2

1175

MBDLE

412

LPG Gas Propane (G31) Data - Inlet Pressure 37 mbar (14.6 in WG) Min 25 mbar (10 in WG) Max 45 mbar (18 in WG)

Main Burner Gas Pressure mbar 4.2 3.3 4.6 4.8 7.5 5.8 7.8 12.0 7.6

Start Gas Pressure mbar NA NA NA 1.6 2.5 0.8 1.0 1.5 3.1

Gas Rate

Start Gas Orifice (mm dia) 5.0 6.0 7.0 7.0 7.0

Main Gas Orifice (mm dia) 8.5 10.0 10.0 14.5 14.5 14.5 14.5 14.5

Burner Type

Burner Head S S S S S S S S LPG

Burner Head Setting (mm) 0 10 13 15 14 24 24 24 20

Air Setting 3.0 4.8 6.6 2.6 4.5 3.1 4.2 1.6 1.8

Valve Type Main Gas

Valve Type Start Gas NA S.I.T. 0 832 051

(m3/h)

(kg/h)

2.1

3.9

AZUR

60 AH

2.8

5.1

BLU

120 AH

MBDLE

405

3.5

6.5

BLU

120 AH

4.9

9.1

BLU

170 AH

MBDLE

407

6.1

11.3

BLU

250R AH

7.8

14.5

BLU

250 AH

MBDLE

410

9.1

16.9

BLU

250 AH

10.4

19.2

BLU

250S AH

13.1

24.3

BLU

350 AH

MBDLE

412

NOTE: For adjustment of head setting, see Ecoflam Instructions

8

Page 15

SECTION 4: SPECIFICATIONS

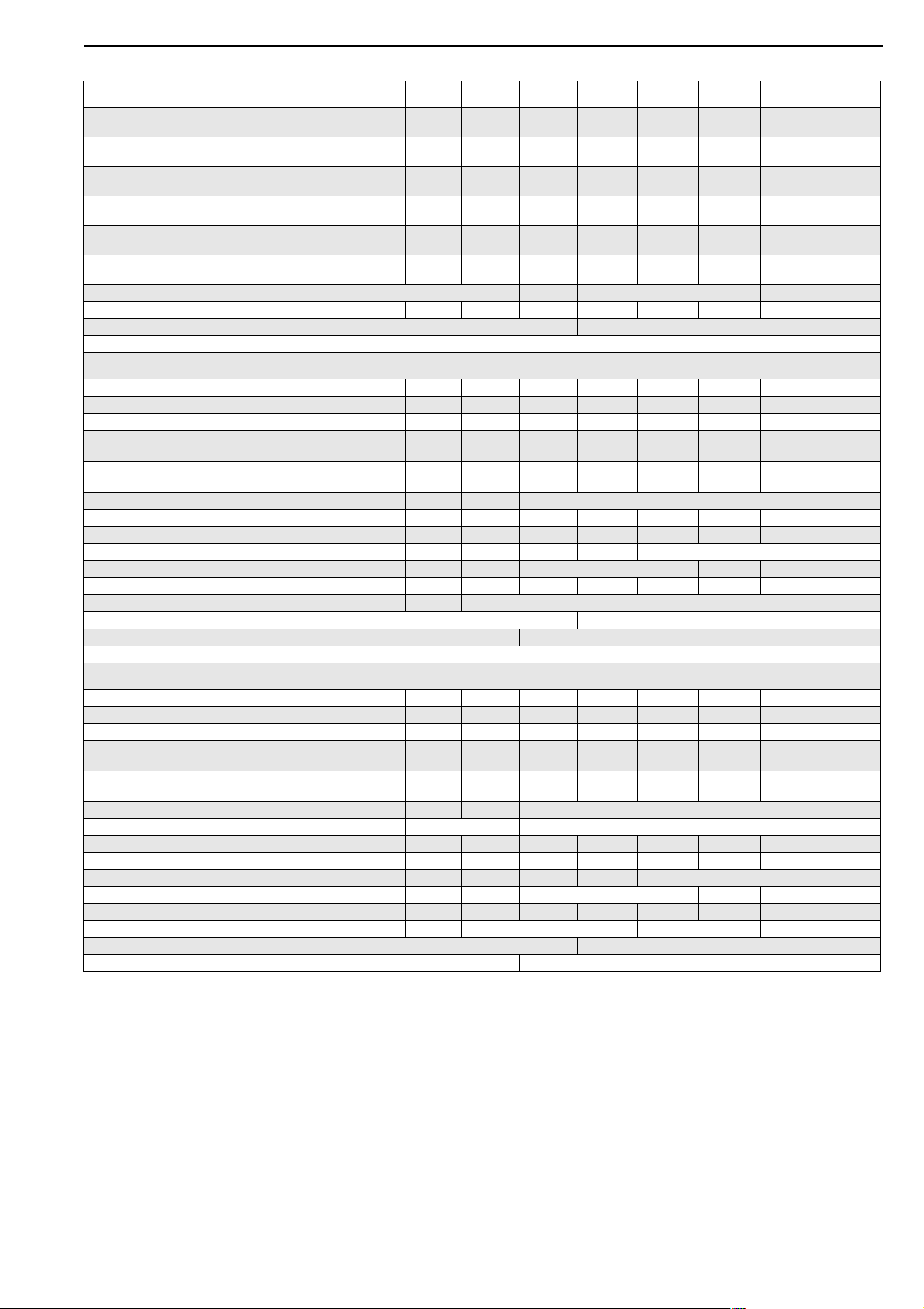

4.6 Technical Data - Ecoflam Modulating Burners (all models - burner reference "H")

Model 015 020 030 040 050 060 070 080 0100

Maximum Gross Heat Input

Maximum Net Heat Input

Minimum Gross Heat Input

Minimum Net Heat Input

Maximum Heat Output

Minimum Heat Output

Pressure Switch Setting (mbar) 1.5 1.0 1.5 2.0 2.5

Flue Static Pressure (mbar) -0.05 -0.05 -0.09 -0.30 -0.05 -0.25 -0.17 0.10 0.45

Gas Connection (in) 3/4" 1 1/4"

(kW)

(Btu/h) x (1000)

(kW)

(Btu/h) x (1000)

(kW)

(Btu/h) x (1000)

(kW)

(Btu/h) x (1000)

(kW)

(Btu/h) x (1000)

(kW)

(Btu/h) x (1000)33113

Natural Gas (G20) Data - Inlet Pressure 20 mbar (7.8 in WG) Min 17 mbar (6.8 in WG) Max 25 mbar (10 in WG)

Main Burner Gas Pressure (mbar) 4.9 2.4 3.3 4.1 6.7 5.2 6.7 8.0 8.6

Min. Burner Gas Pressure (mbar) 3.2 2.8 2.4 2.3 3.7 2.5 3.4 4.3 5.4

Start Gas Pressure (mbar) NA NA NA 1.1 1.8 0.6 0.7 0.9 1.0

Maximum Gas Rate

Minimum Gas Rate

Start Gas Orifice (mm dia) NA NA NA 7.0

Burner Type AZUR 60 BLU 120 BLU 120 BLU 170 BLU 250R BLU 250 BLU 250 BLU 250 BLU 350

Burner Head S S S S S S S S S

Burner Head Setting (mm) 0.0 8.0 10.0 15.0 14 T.O.

Low Flame Air Orange Cam ** 20° 13° 22° 18° 22° 25°

High Flame Air Red Cam ** 33° 40° 80° 30° 32° 30° 35° 55° 60°

Gas Valve Setting 0-1, 5 0-1 0-1, 4

Valve Type Main Gas MBDLE 407 MBDLE 412

Valve Type Start Gas NA S.I.T. 0 832 051

(m3/h)

3

/h)

(ft

3

/h)

(m

3

/h)

(ft

55.5

189.4

50.0

170.6

38.9

132.7

35.0

119.4

47.4

161.7

5.3

187

3.8

134

73.3

250.1

66.0

225.2

51.3

175.0

46.2

157.6

61.2

208.8

43

147

7.0

247

5.0

177

93.2

318.0

84.0

286.6

65.2

222.5

58.8

200.6

78.4

267.5

55

188

8.9

314

6.3

222

129.9

443.2

117.0

399.2

90.9

310.2

81.9

279.5

110.2

376.0

77

263

12.4

438

8.8

311

162.0

552.7

146.0

498.2

113.4

386.9

102.2

348.7

134.5

458.9

94

321

15.4

544

11.0

388

208.0

709.7

187.4

639.4

145.6

496.8

131.2

447.7

177.7

606.3

124

423

19.8

699

14.2

501

242.0

825.7

218.0

743.8

169.4

578.0

152.6

520.7

205.3

700.5

144

491

23.1

816

16.5

583

275.2

939.0

248.0

846.2

192.6

657.2

173.6

592.3

230.4

694.0

161

549

26.2

925

18.7

660

348.5

1189.1

314.0

1071.4

244.0

832.5

219.8

750.0

293.4

1001.1

205

699

33.2

1172

23.7

837

LPG Gas Propane (G31) Data - Inlet Pressure 37 mbar (14.6 in WG) Min 25 mbar (10 in WG) Max 45 mbar (18 in WG)

Main Burner Gas Pressure (mbar) 4.3 5.7 4.7 3.1 5.9 5.3 7.2 9.0 6.4

Min. Burner Gas Pressure (mbar) 2.3 2.9 1.4 1.6 2.0 2.3 2.5 3.2 2.0

Start Gas Pressure (mbar) NA NA NA 1.1 1.7 0.6 0.7 0.7 1.5

Maximum Gas Rate

Minimum Gas Rate

Start Gas Orifice (mm dia) NA NA NA 7.0

Main Gas Orifice (mm dia) 8.5 10.0 14.5 NA

Burner Type AZUR 60 BLU 120 BLU 120 BLU 170 BLU 250R BLU 250 BLU 250 BLU 250 BLU 350

Burner Head S S S S S S S S S

Burner Head Setting (mm) 0.0 8.0 10.0 15.0 14 T. O.

Low Flame Air Orange Cam ** 20° 13° 22° 18° 22° 25°

High Flame Air Red Cam ** 33° 40° 80° 30° 32° 30° 35° 55° 60°

Gas Valve Setting 0-1, 4 0, 3-0, 9 0-1, 1 0-1, 4 0-1, 5 0-0, 85

Valve Type Main Gas MBDLE 407 MBDLE 412

Valve Type Start Gas NA S.I.T. 0 832 051

(m3/h)

(kg/h)

(m3/h)

(kg/h)

2.09

3.87

1.46

2.71

2.76

5.11

1.93

3.58

3.51

6.49

2.46

4.55

4.89

9.05

3.42

6.34

6.10

11.29

4.27

7.90

7.83

14.49

5.48

10.15

9.11

16.86

6.38

11.80

10.36

19.18

7.25

13.42

13.12

24.29

9.18

17.00

NOTE: The air setting is a guide only. The final setting is subject to combustion testing.

When setting the minimum firing rate, a check must be made following the setting of the burner combustion. The

check is made by running the heater on low fire for a minimum of 15 minutes at the full transport air rate and at typical

ambient conditions. During the test, check that the flue gas temperature does not fall below 125° C. Should the flue

gas temperature fall below 100° C, then the low fire gas setting must be increased to a value that will achieve 125° C

flue gas temperature; otherwise condensation may form in the heat exchanger and flue, causing rapid corrosion and

short operational life.

NOTE: For adjustment of head setting, see Ecoflam Instructions.

9

Page 16

COMBAT® CABINET HEATERS INSTALLATION, COMMISSIONING, OPERATION AND SERVICE MANUAL

4.7 Technical Data - Ecoflam Oil-Fired Burners (burner reference "G")

Model 015 020 030 040 050 060 070 080 0100

Gross Heat Input

Heat Output

Burner Type Minor 8 Minor 12 Minor 20 Minor 30 Major 30

Oil Pump Connections (in) 3/8

(kW)

(Btu/h) x (1000)

(kW)

(Btu/h) x (1000)

55.5

189.4

47.4

161.8

73.3

250.1

61.2

208.9

93.2

318.0

78.4

267.4

129.9

443.2

110.2

375.9

162.0

552.7

134.5

458.8

208.0

709.7

177.7

606.5

242.0

825.7

205.3

700.3

275.2

939.0

230.4

786.2

Light Fuel Oil (Gas Oil) Data

Nozzle Size *US (gal/h) 1.00 1.50 1.75 2.50 3.50 4.00 5.00 5.00 7.00

Angle & Type 60S 60A

Make Danfoss Delavan

Head Setting (mm) 8 0 14 (full back) (fixed)

Air Setting (number) 4.2 8.5 5.5 3 4 3.7 4 6.2 1.8

Burner Fuel Pressure

Fuel Consumption

Maximum Oil Pressure to

Pump Inlet

(Bar)

2

)

(lbf/in

(L/h)

*UK (gal/h)

(Bar)

2

(lbf/in

)

12.1

175

5.17

1.14

10.3

150

6.82

1.50

12.4

180

8.68

1.91

11.7

170

12.09

2.66

10.0

145

15.08

3.32

.21

11.0

160

19.36

4.26

3

10.0

145

22.53

4.96

13.0

188

25.62

5.63

Kerosene Data

Nozzle Size *US (gal/h) 1.25 1.75 2.50 3.00 4.00 5.00 6.00 6.50 8.50

Angle & Type 60S 60B

Make Danfoss

Head Setting (mm) 8 0 14 (full back) (fixed)

Air Setting (number) 4 6.6 6 3 4 3.7 4.5 6 1.4

Burner Fuel Pressure

Fuel Consumption

(Bar)

2

)

(lbf/in

(L/h)

*UK (gal/h)

8.6

125

5.47

1.20

9.7

140

7.23

1.59

8.3

120

9.19

2.02

9.7

140

12.81

2.82

8.3

120

15.98

3.51

9.0

130

20.52

4.51

8.3

120

23.87

5.25

9.3

135

27.14

5.97

NOTE: For adjustment of head setting, see Ecoflam Instructions.

* Nozzle sizes are quoted in US gal/h. Fuel consumption is quoted in imperial gal/h.

348.5

1189.1

293.4

1001.0

11.0

160

32.44

7.14

8.3

120

34.37

7.56

10

Page 17

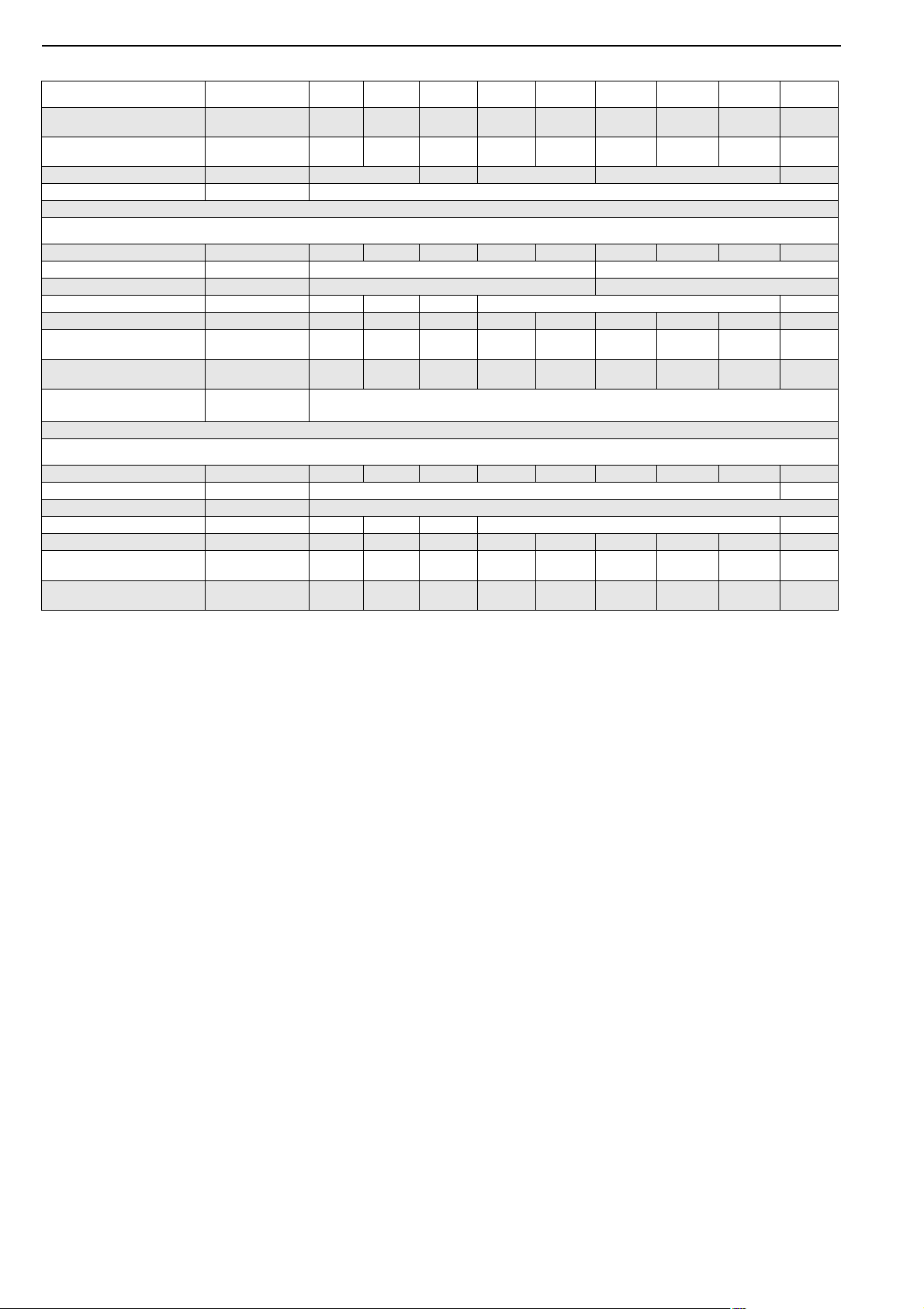

SECTION 5: HEATER INSTALLATION

1 m

Minimum

Roof

Flues up to 200 mm dia. are

fitted with Bird Screens, over

200 mm with a Rain Cap.

Air

Distribution

Heads

Flue

Lead Roof Plate

Building Ventilation

Electric Supply

Gas Isolating Valve

Union

Connection

SECTION 5: HEATER INSTALLATION

5.1 General

Heaters are designed for floor standing vertical

should be placed on a firm, level, non-combustible

surface that can support its weight. See Page 5,

Section 4.1 for weight details.

installation. Special versions supplied with steel

channels to support the heater are available and

may be mounted horizontally. When installed

horizontally, the heater will normally lie on its left

side when viewed from the burner. The heater

5.2 Handling

All cabinet heaters are supplied secured to a

wooden pallet and shrink wrapped. Use the pallet to

support the heater during handling and installation.

Figure 2: Typical Installation of a Gas Fired Cabinet Heater

11

Page 18

COMBAT® CABINET HEATERS INSTALLATION, COMMISSIONING, OPERATION AND SERVICE MANUAL

1 m

Minimum

Roof

Flues up to 200 mm dia. are

fitted with Bird Screens, over

200 mm with a Rain Cap.

Air

Distribution

Heads

Flue

Lead Roof Plate

Building Ventilation

Electric Supply

Fire Valve

Fuel FilterManual Isolating

Valve

Fusible

Link

Fuel

Tank

Gauge

FillerVent

Gate Valve

Plugged Drain Valve

Figure 3: Typical Installation of a Oil-Fired Cabinet Heater

12

Page 19

SECTION 6: FLUE INSTALLATION

WARNING

Fire Hazard

Some objects will catch fire or explode when

placed close to heater.

Keep all flammable objects, liquids and

vapours the required distance away from the

heater.

Failure to follow these instructions can result

in death, injury or property damage.

1 m

Minimum

Roof

Wall

*If the point

of roof

intersection

is within 2.5 m

of a nearby

structure, the

flue must

terminate

at least

1 m above

that structure.

*Less than

2.5 m

Nearby

Structure

*1 m

Minimum

Flues up to 200 mm dia. are fitted

with Bird Screens, over 200 mm

with a Rain Cap.

Use adequate

support to

prevent heater

from carrying

the weight of

the flue.

135°

Roof

Wall

Minimum Total

1m +

(0.5m for each 135° bend) +

(1m for each 0.33m of flue

running in the 135° direction)

1 m

Minimum

above roof

Use adequate

support to

prevent heater

from carrying

the weight of

the flue.

6.1 Flue Installation

Flues must be correctly sized for the model. See

Page 5, Section 4.1. Flues should be assembled as

on Page 13, Figure 4 and Figure 5 and Page 14,

SECTION 6: FLUE INSTALLATION

Figure 6 through Page 14, Figure 9. The joints

between the flue and the roof or wall must be

properly sealed. If the flue passes through a wall or

ceiling of combustible material it must be enclosed

by a sleeve of non-combustible material and be

separated from the sleeve by at least a 25 mm air

gap.

Flues must be adequately supported so that the

heater does not bear the weight of the flue.

For straight and offset flue termination See Page 13,

Figure 4 and Figure 5.

90° bends and horizontal pipe must not be used

in flues except for the immediate connection to

horizontally mounted heaters (1 m max). 135°

bends are used to offset the flue as in Figure 5.

If condensation is likely to occur in the flue, then

provision should be made for drainage.

Figure 4: Flue Termination Figure 5: Offset Flues with 135° bends

13

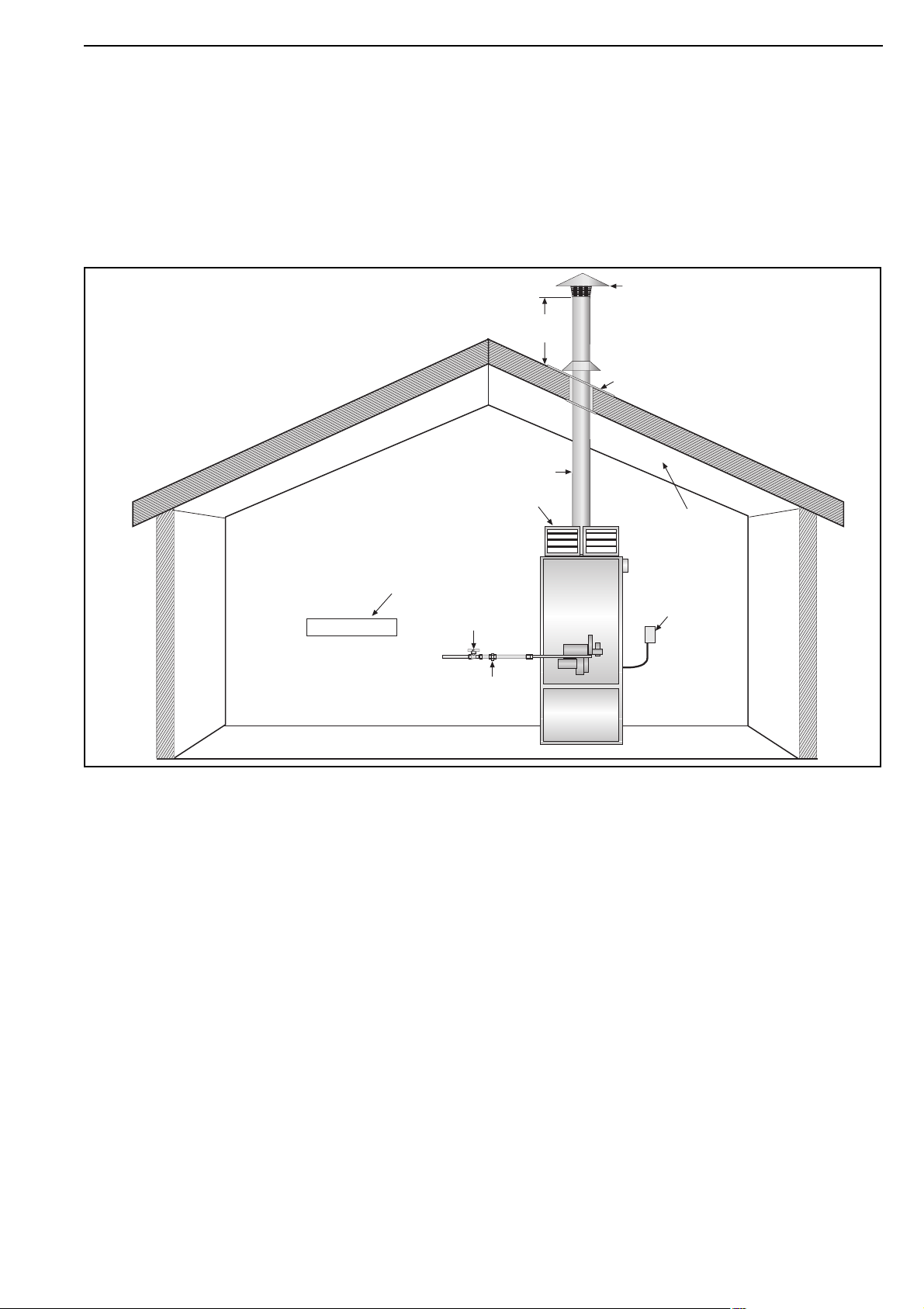

Page 20

COMBAT® CABINET HEATERS INSTALLATION, COMMISSIONING, OPERATION AND SERVICE MANUAL

Over 2 m

use Guy Wires

Roof

Wall

Use adequate

support to

prevent heater

from carrying

the weight of

the flue.

Male spigot

facing down.

Screws,

four typical.

Roof

Flue

Terminal

Conversion Collar -

last joint below

the roof line.

Male spigot

facing up.

Clamp Ring

Metal Sleeve

Masterflash

Soaker Flashing

or Rain Collar.

Screws

Roof

Seal Rain Collar

joint with high

temperature

silicon

sealer

Secure Bolts

Stainless Steel

Roof Tidy Plate

Heat Sealed

Flash Band

Roof Plate

Clamp ring

Screws,

four typical.

Rain Collar

Heater

Spigot

Fire

Cement

Heat

Resistant

Rope

Tidy

Plate

Screws

If it is necessary to cut any section of flue, the

cut is made at the bottom of the lowest section

where it connects to the heater.

Figure 6: Guy Wire

Figure 8: Flue and Roof Detail

Figure 7: Socket Direction

14

Figure 9: Flue and Heater Spigot Joint Detail

Page 21

SECTION 7: AIR SUPPLY

7.1 Air Supply

It is important to ensure adequate air supply at all

times for both combustion and heating requirements

in accordance with BS 6230 for UK installations and

the latest revisions of applicable standards and local

and national codes.

7.2 Isolated Equipment Rooms

Ventilation must prevent the temperature of isolated

equipment room from exceeding 32°C as well as

prevent any negative air pressure within the room.

Any isolated equipment room containing air heaters

will require permanent air vents direct to outside air

in compliance with local codes.

Where natural ventilation is used, suitable

permanent openings at low and high levels,

communicating directly with the outside air, must be

provided.

Where mechanical ventilation is used, extract rate

must be 5% - 10% less than the inlet rate. The

mechanical ventilation must be interlocked with the

burner on the heater.

SECTION 7: AIR SUPPLY

The main fan requires a minimum free air return

path of 1 m

2

per 197 kW of heater output or 0.33 m2,

whichever is greater.

NOTE: When heaters are installed in the horizontal

mode and connected to distribution ducting and/or

inlet ducting, then the natural convected air flow

through the heater, before the main fan turns on may

be disrupted.

To ensure correct operation of the fan under these

circumstances, in all COMBAT

®

cabinet heaters

designed for horizontal mounting, the main fan will

operate in conjunction with the burner sequence by

the use of a time delay or direct acting relay.

It is strongly recommended that when any heater is

connected to installation ducting, a similar approach

to the fan control is used. Any such control must be

in parallel with the fan thermostat so that the fan

"run on" feature is still able to operate (See Page 22,

Section 9.5).

7.2.1 Heaters Installed Within the Heated Space

Where the volume of the heated space is greater

than 4.7 m

3

per kilowatt of total rated heat input and

the air change rate is at least 0.5/h, additional high

and low level ventilation will not be required.

For a building having an air change rate less than

0.5/h, ventilation will be necessary in accordance

with local and national codes.

7.3 Building Ventilation

Where ventilation is required, air must be taken from

an outside point where it is not likely to be

contaminated or obstructed.

7.4 Distribution Ducting

Duct should be full size for at least twice the minor

dimension before change of direction or reduction of

area.

7.5 Return Air Ducting

In installations employing recirculation or fresh air

ducting, this ducting shall comply with the following:

1. There shall be an unobstructed air path connected directly to the heater.

2. The return air or fresh air shall be connected by

ducting directly to the air inlet on the heater.

3. Where automatic or manual dampers are provided for operational adjustment in these ducts,

they shall be proved in the correct position during the operation of the burner.

15

Page 22

COMBAT® CABINET HEATERS INSTALLATION, COMMISSIONING, OPERATION AND SERVICE MANUAL

WARNING

Fire Hazard

Connect gas supply according to Figure 10.

Gas can leak if not installed properly.

Failure to follow these instructions can result in

death, injury or property damage.

Gas Isolating Valve

Drip Leg

Union

Connection

Medium or Heavy

Gauge Tubing

Gas Connector

SECTION 8: FUEL PIPING

8.1 Connections

Connect the heater to the gas supply, ensuring that

the final connections are as follows:

• Gas supply pipe is run in medium or heavy

gauge tubing in compliance with local and

national codes.

• The gas supply pipe is adequately sized to carry

the total volume of gas for the complete

installation.

• An isolating valve and union connection should

be used and fitted into the supply adjacent to the

heater.

IMPORTANT - The complete installation must be

It is important that the gas supply pipe and the

electrical connections do not support any of the

purged and tested for gas soundness in accordance

with local and national codes.

heater’s weight.

A gas meter is connected to the service pipe by the

Gas Supply Company. Any existing meter should be

checked, preferably by the company, to ensure that

the meter is adequate for the rate of gas supply

required.

Installation pipes must be fitted in accordance with

local and national codes. Pipe work from the meter

to the heater(s) must be of adequate size. Pipes of

smaller size than the heater inlet gas connection

should not be used.

Figure 10: Gas Connection

16

Page 23

SECTION 8: FUEL PIPING

Technical Data

Maximum Lift............. 8 m

Maximum Capacity.... 20 L/h

Actual Capacity.......... 10 - 20 L/h

Dependant upon vertical lift and suction

line length.

Max 3m

Min 0.15m

Max 8m

Min 0.15m

Flow Output - L/h

Flow Output - UK gal/h

240 V

Oil Lifter

Air Vent

Filler Pipe

Storage Tank

50 mm

Total Suction Length in Feet

8mm (5/16”) O.D. Copper Tube

Lift in Feet

Lift in Metres

0 5 10 15 20 25

0 1 2 3 4 5 6 7 8

25

20

15

10

5

0

6

5

4

3

2

1

0

33’

65’

99’

132’

165’

Oil

Heater

8.2 Fuel Oil Supply

8.2.1 Fuel Storage Tank

The fuel storage tank should be located outside the

building as close as possible to the heater. The tank

must be installed per local and national codes.

8.2.2 Fuel Pipes

The fuel pipes must be sized to ensure an adequate

supply of oil to the entire installation. Galvanised

pipe must not be used for oil installations. The fuel

pipe must terminate at each heater with an isolating

manual valve, a fire valve and a fuel filter. See Page

12, Figure 3. The fusible link of the fire valve should

be installed 100 mm (4 in) above the burner.

The heater’s oil burner pump inlet is provided with a

flexible oil line which should be used for the final

connection. When making the final connection to the

heater, do not block any of the removable panels of

the heater. All COMBAT

®

oil-fired cabinet heaters are

supplied with burner pumps fitted for one pipe

systems.

8.2.3 Gravity Feed Systems

The simplest installation is a gravity feed system.

This system relies on the head of the fuel to push

the fuel through the system. See Page 12, Figure 3.

8.2.4 B. M. Oil Lifter

Where a gravity feed system cannot be used, a B.

M. oil lifter may be used for small installations up to

the equivalent of a single model 050 on minimum lift

or a single model 020 on maximum lift.

The fuel output from the oil lifter is gravity fed.

The B. M. oil lifter requires a constant 230 V 50 Hz

1 Ø electrical supply. The maximum pipe size to be

used on the suction side is 1/4" ID, 5/16" OD (8

mm). For maximum loading of oil lifters See Page 17,

Figure 11. Consult the manufacturer’s information

regarding the need to prime these devices.

8.2.5 Pressurised Systems

See Page 18, Figure 12. For larger installations, a

pressurised system may be used. In this type of

system the pump draws fuel from the tank, then

pushes it through the installation under pressure.

The pressure is controlled at the pump by a

pressure relief valve at approximately 0.8 BAR (12

psi). When a presurised system is used, a pressure

reducing valve set at approximately 0.3 BAR (5 psi)

should be installed on the fuel inlet to each heater

after the manual isolating valve. This protects the oil

pump from the danger of possible over pressure

under fault conditions.

The electrical supply for the pump installation will

depend upon the type of pumps chosen, but will

normally be set to run continuously.

Figure 11: B. M. Oil Lifter

17

Page 24

COMBAT® CABINET HEATERS INSTALLATION, COMMISSIONING, OPERATION AND SERVICE MANUAL

Check

Valve

Check

Valve

Relief Valve

Pressure Gauge

Check

Valve

Stop

Valve

Stop

Valve

Stop

Valve

Burner

No. 1

Pump

No. 2

Pump

Duplex Pump Set

Burner

Pressure

Reducing

Valve

Pressure

Reducing

Valve

Stop

Valve

Storage Tank

Below Ground

For

Fuel Tanks

above

Pump Set

(The system shown has one pump for run and the

other for standby. The valves allow the standby pump

to be removed for maintenance while the system is still running).

Figure 12: Pressurised System Installation - Duplex System

18

Page 25

SECTION 9: WIRING AND ELECTRICAL INFORMATION

WARNING

Electrical Shock Hazard

Disconnect electrical power before servicing.

Failure to follow these instructions can result in

death or electrical shock.

9.1 Electrical Supply

A 230 V 50 Hz 1 Ø supply is required for all heater

Models 015 to 030 connected to the heater terminals

L1, N and Earth.

Standard models 040 to 0100 and all High Flow

models require a 400 V 50 Hz 3 Ø and neutral

supply connected to the heater terminals L1, L2, L3,

N and Earth.

All heaters and controls must be correctly earthed.

All external wiring must comply with the relevant IEE

and local regulations and be carried out by a

qualified electrician.

It is important that "L and N" polarity is correct for

these heaters, as incorrect polarity may prevent the

burner control box from operating properly. It is also

important that the voltage between N and earth is at

0 V and can never exceed 15 V.

An isolator with a contact separation of at least 3

mm on all poles should be installed adjacent to the

heater, but not attached to it, to disconnect all

supplies to the heater and where necessary to

isolate the remote control panel.

The final connection to the heater should be made in

metal sleeved flexible cable or flexible conduit to the

main terminal block under the front lower panel of

the heater using 1 sq. mm cable. Model 0100 and

High Flow models with 5.5kW or 7.5kW motors use

1.5 sq. mm cable. Cable entry is provided into the

rear horizontal frame of the cabinet.

9.2.2 Positioning Room Thermostats or

Roberts-Gordon Control

A room thermostat or Roberts-Gordon control

should be mounted on a wall or column at a height

of approximately 1.5-1.8 metres from the floor to

measure the ambient temperature. It should be clear

of both cold draughts and the direct path of warm air

from the heater.

9.2.3 Remote Frost Thermostat

When required, connect to terminals 2 and 3 in the

main terminal block.

Locate the thermostat within the heated space

adjacent to the most vulnerable equipment that

requires protection.

See Page 20, Section 9.3 through Page 27, Section

9.10.

9.2.4 Controls for High/Low Burner Operation

For heaters with a high/low burner, the controls will

need to provide two stage signal to operate these

burners. This is best provided by a two stage

thermostat.

The thermostat may control the heater outlet

temperature if the heater is designed for a duct

distribution system or the room temperature.

The site wiring will be across terminals 2 and 3 for

any time control and the on/off function of the burner

(stage two), and across terminals 7 and 8 for the

high fire (first stage) setting.

The burner will then operate as follows:

Temp. from cold up to

the 1st set point ..................... Full fire at max. rate

Temp. above 1st set point

up to 2nd set point................. Low fire at min. rate

Temp. above 2nd set point ...............................Off.

SECTION 9: WIRING AND ELECTRICAL INFORMATION

9.2 Remote Controls

The heater is designed to be operated by controls

installed remotely from the heater. See Page 20,

Section 9.3. through Page 27, Section 9.10.

9.2.1 Burner Controls (Thermostat)

Controls to operate the burner must be voltage free

contacts connected between terminals 2 & 3 of the

main terminal block.

9.2.5 Controls for Fully Modulating Burners

For heaters that incorporate a fully modulating

burner, a special temperature control is provided

with the heater. On-site wiring of the temperature

sensor is required with any time control.

The heater will normally be controlled by the

temperature of the air in the outlet duct, but it is

possible to control on room temperature.

The position of the sensor in the outlet duct is

determined on site. Using a themometer, select a

position in the outlet duct approximately 1 m from

the heater, across the cross section of the duct that

provides a reasonable average of the temperatures

found. Mount the sensor at this position for best

results.

When operating at reduced heat input, the leaving

air temperature may be low when controlled on room

temperature.

The time control and any other on/off controls will be

across terminals 2 and 3. The sensor will be

connected to terminals 8 and 9.

The operation will occur in the following sequence:

1. The burner will fire. When the burner sequence

reaches the release to modulation stage, the

control will begin to monitor the outlet

temperature.

19

Page 26

COMBAT® CABINET HEATERS INSTALLATION, COMMISSIONING, OPERATION AND SERVICE MANUAL

NOTE:

Any of the original wire supplied with

the heater must be replaced with

wiring material having a temperature

rating of at least 105°C and 600 V.

2. The control will then adjust the burner input

continuously to attempt to maintain the

temperature set on the control.

3. If the temperature continues to rise with the

burner operating at minimum fire, the control

If a switch is required to turn on the main fan for

ventilation, this must be voltage free, from external

sources, and may be connected between terminals

L

& 1 for models 015 to 030 and terminals 2 & 1 for

1

all other models.

will turn off the burner until the temperature falls

again, and the burner will restart.

9.3 CCH Wiring Diagram Gas Models 15-30 (floor standing)

GAS BURNER 7 WAY PLUG

PACKAGED

BURNER

Note: Remote fan control

carries full load of fan motor

7 amp inductive

TIME/TEMPERATURE

CONTROLS

FAN CONTROL

L1

N

T2 T1

L1

N

T2 T1

Blue

FAN / LIMIT STAT

Red / White

S3

B4

S3

B4

Red / White

FAN

LIMIT

Red

4

Red / White

3

Red / White

10 A

2

1

L

1

Red / White

Red

Brown

230 V 50 Hz

1 PH SUPPLY

MAIN TERMINALS

IN CONTROL PANEL

20

L

2

L

3

Blue

N

MAIN

FAN

MOTOR

Blue

1 mm Ø Red Tri Rated Flex Cable

Page 27

9.4 CCH Wiring Diagram Oil Models 15-30 (floor standing)

NOTE:

Any of the original wire supplied with

the heater must be replaced with

wiring material having a temperature

rating of at least 105°C and 600 V.

OIL BURNER 6 WAY PLUG

SECTION 9: WIRING AND ELECTRICAL INFORMATION

PACKAGED

BURNER

Note: Remote fan control

carries full load of fan motor

7 amp inductive

TIME/TEMPERATURE

CONTROLS

FAN CONTROL

L1

N

T2 T1

L1

N

T2 T1

Blue

FAN / LIMIT STAT

Red / White

S3

S3

Red / White

FAN

LIMIT

Red

4

Red / White

3

Red / White

10 A

2

1

L

1

Red / White

Red

Brown

230 V 50 Hz

1 PH SUPPLY

L

2

L

3

Blue

N

MAIN TERMINALS

IN CONTROL PANEL

MAIN

FAN

MOTOR

Blue

1 mm Ø Red Tri Rated Flex Cable

21

Page 28

COMBAT® CABINET HEATERS INSTALLATION, COMMISSIONING, OPERATION AND SERVICE MANUAL

Red

1

2

3

4

N

10 A

MAIN TERMINALS

IN CONTROL PANEL

Blue

Blue

Blue

L

L

L

1

2

3

PACKAGED

BURNER

FAN

LIMIT

FAN / LIMIT STAT

Brown

7

8

2

7

R1 COIL 240v

3

1

LOCKOUT SIGNAL

BURNER RUN SIGNAL

LOCKOUT RESET SIGNAL

5

6

REMOTE LOCKOUT

RESET

FOR BURNERS WITH

LANDIS & STEFA

CONTROL BOX

(GAS-FIRED)

N

REMOTE LOCKOUT

LAMP 230V

MAIN FAN

MOTOR

OUTPUTS

FROM

BURNER

TIME/TEMPERATURE

CONTROLS

FAN CONTROL

(OPTIONAL)

B4 S3 T2 T1 N L1

B4 S3 T2 T1 N L1

GAS BURNER 7-WAY PLUG

Red / White

Red / White

Red / White

Red / White

Red

Red / White

Red / White

Red / White

Red / White

Red / White

Blue

230 V 50 Hz

1 PH SUPPLY

FOR GAS BURNER

T1 IS NOT USED

B4 = BURNER RUN TO R1 COIL

ALL OTHER WIRES SAME AS OIL

BURNER

1 mm Ø RED TRI RATED FLEX CABLE

NOTE:

Any of the original wire supplied with

the heater must be replaced with

wiring material having a temperature

rating of at least 105°C and 600 V.

9.5 CCH Wiring Diagram Gas Models 15-30 (horizontal mounting)

22

Page 29

Red

1

2

3

4

N

10 A

MAIN TERMINALS

IN CONTROL PANEL

Blue

Blue

Blue

L

L

L

1

2

3

PACKAGED

BURNER

FAN

LIMIT

FAN / LIMIT STAT

Brown

7

8

2

7

R1 COIL 240v

3

1

LOCKOUT SIGNAL

BURNER RUN SIGNAL

LOCKOUT RESET SIGNAL

5

6

REMOTE LOCKOUT

RESET

N

REMOTE LOCKOUT

LAMP 230V

MAIN FAN

MOTOR

OUTPUTS

FROM

BURNER

TIME/TEMPERATURE

CONTROLS

FAN CONTROL

(OPTIONAL)

Red / White

Red / White

Red / White

Red / White

Red / White

Red

Red / White

Red / White

Red / White

Red / White

Red / White

230 V 50 Hz

1 PH SUPPLY

1 mm Ø RED TRI RATED FLEX CABLE

S3 T2 T1 N L1

S3 T2 T1 N L1

OIL BURNER 6-WAY PLUG

FOR BURNERS WITH

SATRONIC CONTROL BOX

(OIL-FIRED)

NOTE:

Any of the original wire supplied with

the heater must be replaced with wiring

material having a temperature rating of

at least 105°C and 600 V.

9.6 CCH Wiring Diagram Oil Models 15-30 (horizontal mounting)

SECTION 9: WIRING AND ELECTRICAL INFORMATION

23

Page 30

COMBAT® CABINET HEATERS INSTALLATION, COMMISSIONING, OPERATION AND SERVICE MANUAL

Red

1

2

3

4

N

10 A

MAIN

FAN

MOTOR

MAIN TERMINALS

IN CONTROL PANEL

Red

Grey

Black

Brown

CONTACTOR

400 V 50 Hz

3 PH SUPPLY

TIME/TEMPERATURE

CONTROLS

FAN CONTROL

Blue

Blue

Red

Red

L

L

L

1

2

3

FAN

LIMIT

FAN / LIMIT STAT

PACKAGED

BURNER

C1

1 mm Ø RED TRI RATED FLEX CABLE

Red / White

Red / White

Red / White

Red / White

Red / White

Red / White

Red / White

B4 S3 T2 T1 N L1

B4 S3 T2 T1 N L1

GAS BURNER 7-WAY PLUG

NOTE:

Any of the original wire supplied with

the heater must be replaced with wiring

material having a temperature rating of

at least 105°C and 600 V.

9.7 CCH Wiring Diagram Gas Models 40-50 (floor standing)

24

Page 31

9.8 CCH Wiring Diagram Oil Models 40-50 (floor standing)

Red

1

2

3

4

N

10 A

MAIN

FAN

MOTOR

MAIN TERMINALS

IN CONTROL PANEL

Red

Grey

Black

Brown

CONTACTOR

400 V 50 Hz

3 PH SUPPLY

TIME/TEMPERATURE

CONTROLS

FAN CONTROL

Blue

Blue

Red

Red

L

L

L

1

2

3

FAN

LIMIT

FAN / LIMIT STAT

S3 T2 T1 N L1

S3 T2 T1 N L1

OIL BURNER 6-WAY PLUG

PACKAGED

BURNER

C1

1 mm Ø RED TRI RATED FLEX CABLE

Red / White

Red / White

Red / White

Red / White

Red / White

Red / White

Red / White

NOTE:

Any of the original wire supplied with

the heater must be replaced with wiring

material having a temperature rating of

at least 105°C and 600 V.

SECTION 9: WIRING AND ELECTRICAL INFORMATION

25

Page 32

COMBAT® CABINET HEATERS INSTALLATION, COMMISSIONING, OPERATION AND SERVICE MANUAL

NOTE:

Any of the original wire supplied with the

heater must be replaced with wiring material

having a temperature rating of at least 105°C

and 600 V.

9.9 CCH Wiring Diagram Gas Models 40-50 (horizontal mounting)

FOR GAS BURNER

T1 IS NOT USED

B4 = BURNER RUN TO R1 COIL

ALL OTHER WIRES SAME AS OIL

GAS BURNER 7-WAY PLUG

PACKAGED

BURNER

BURNER

OUTPUTS

FROM

BURNER

LOCKOUT SIGNAL

LOCKOUT RESET SIGNAL

BURNER RUN SIGNAL

REMOTE LOCKOUT

RESET

N

REMOTE LOCKOUT

LAMP 230V

B4 S3 T2 T1 N L1

8

7

6

5

FOR BURNERS WITH

LANDIS & STEFA

CONTROL BOX

(GAS FIRED)

B4 S3 T2 T1 N L1

Red / White

R1 COIL 240v

2

Blue

Red / White

Red / White

7

3

1

Red / White

Red / White

Red / White

FAN / LIMIT STAT

FAN

LIMIT

TIME/TEMPERATURE

CONTROLS

FAN CONTROL

(OPTIONAL)

400 V 50 Hz

3 PH SUPPLY

4

3

2

1

L

1

Red

L

2

Red

L

Red

3

Blue

N

1 mm Ø RED TRI RATED FLEX CABLE

MAIN TERMINALS

IN CONTROL PANEL

Red / White

Red

Blue

CONTACTOR

R1

Red / White

10 A

Red / White

Black

Brown

Grey

Red / White

Red / White

MAIN

FAN

MOTOR

26

Page 33

SECTION 9: WIRING AND ELECTRICAL INFORMATION

NOTE:

Any of the original wire supplied with the

heater must be replaced with wiring material

having a temperature rating of at least 105°C

and 600 V.

Red

1

2

3

4

10 A

FAN

LIMIT

FAN / LIMIT STAT

7

8

2

7

R1 COIL 240v

3

1

5

6

FOR BURNERS WITH

SATRONIC CONTROL BOX

(OIL FIRED)

REMOTE LOCKOUT

LAMP 230V

N

REMOTE LOCKOUT

RESET

TIME/TEMPERATURE

CONTROLS

FAN CONTROL

(OPTIONAL)

PACKAGED

BURNER

LOCKOUT SIGNAL

BURNER RUN SIGNAL

LOCKOUT RESET SIGNAL

OUTPUTS

FROM

BURNER

S3 T2 T1 N L1

S3 T2 T1 N L1

OIL BURNER 6-WAY PLUG

N

MAIN

FAN

MOTOR

MAIN TERMINALS

IN CONTROL PANEL

Red

Grey

Black

Brown

CONTACTOR

400 V 50 Hz

3 PH SUPPLY

Blue

Blue

Red

Red

L

L

L

1

2

3

R1

Red / White

Red / White

Red / White

Red / White

Red / White

Red / White

Red / White

Red / White

Red / White

Red / White

1 mm Ø RED TRI RATED FLEX CABLE

Red / White

Red / White

9.10 CCH Wiring Diagram Oil Models 40-50 (horizontal mounting)

27

Page 34

COMBAT® CABINET HEATERS INSTALLATION, COMMISSIONING, OPERATION AND SERVICE MANUAL

1

2

3

10 A

TIME/TEMPERATURE

CONTROLS

FAN CONTROL

L

1

FAN

LIMIT

FAN / LIMIT STAT

4

PACKAGED

BURNER

Red

N

MAIN

FAN

MOTOR

MAIN TERMINALS

IN CONTROL PANEL

Red

Grey

Black

Brown

CONTACTOR

400 V 50 Hz

3 PH SUPPLY

Blue

Blue

Red

Red

L

L

2

3

R1

1 mm Ø RED TRI RATED FLEX CABLE

Red / White

Red / White

Red / White

Red / White

Red / White

Red / White

Red / White

B4 S3 T2 T1 N L1

B4 S3 T2 T1 N L1

GAS BURNER 7-WAY PLUG

NOTE:

Any of the original wire supplied with the

heater must be replaced with wiring material

having a temperature rating of at least 105°C

and 600 V.

9.11 CCH Wiring Diagram Gas Models 60-100 (floor standing)

28

Page 35

9.12 CCH Wiring Diagram Oil Models 60-100 (floor standing)

1

2

3

10 A

TIME/TEMPERATURE

CONTROLS

FAN CONTROL

L

1

FAN

LIMIT

FAN / LIMIT STAT

4

S3 T2 T1 N L1

S3 T2 T1 N L1

OIL BURNER 6-WAY PLUG

PACKAGED

BURNER

Red

N

MAIN

FAN

MOTOR

MAIN TERMINALS

IN CONTROL PANEL

Red

Grey

Black

Brown

CONTACTOR

400 V 50 Hz

3 PH SUPPLY

Blue

Blue

Red

Red

L

L

2

3

R1

1 mm Ø RED TRI RATED FLEX CABLE

Red / White

Red / White

Red / White

Red / White

Red / White

Red / White

Red / White

NOTE:

Any of the original wire supplied with the

heater must be replaced with wiring material

having a temperature rating of at least 105°C

and 600 V.

SECTION 9: WIRING AND ELECTRICAL INFORMATION

29

Page 36

COMBAT® CABINET HEATERS INSTALLATION, COMMISSIONING, OPERATION AND SERVICE MANUAL

1

2

3

4

10 A

Blue

FAN

LIMIT

FAN / LIMIT STAT

7

8

2

7

R1 COIL 240v

3

1

TIME/TEMPERATURE

CONTROLS

FAN CONTROL

(OPTIONAL)

PACKAGED

BURNER

LOCKOUT SIGNAL

BURNER RUN SIGNAL

LOCKOUT RESET SIGNAL

OUTPUTS

FROM

BURNER

Red

N

MAIN

FAN

MOTOR

MAIN TERMINALS

IN CONTROL PANEL

Red

Grey

Black

Brown

CONTACTOR

400 V 50 Hz

3 PH SUPPLY

Blue