Page 1

FIGURE 15: Linear Heater Assembly Overview

Tube

Reflector

Reflector End Cap

Reflector Support

Burner

Coupling

U-Clips

Burner Tube

Tube and Reflector Hanger

Tube Clamp

Package

Vent Adapter

Turbulator

(With Select Models)

SECTION 6: HEATER INSTALLATION

15

Page 2

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

a = 14" (36 cm)

reflector width (not shown)

b = 2" (5 cm)

end cap to burner

c = 2" (5 cm)

end cap to hanger

d= 7

'

6" (2.3 m)

distance first hanger

e= 10' (3 m)

distance between hangers

f = 12.5" (32 cm)

burner height

g = 11" (28 cm)

burner length

Vent Adapter

Burner

Reflector

Tube

Tube/Reflector

Hanger

Coupling Assembly

LEGEND

g

c

b

d

f

g

c

b

de

f

g

c

b

de

f

e

g

c

b

de

f

e e

g

c

b

de

f

e e e

10' (3 m) Tube Length

20

' (6.1 m) Tube Length

30

' (9.1 m) Tube Length

40

' (12.2 m) Tube Length

50

' (15.2 m) Tube Length

FIGURE 16: Linear Heater Layout Overview

16

Page 3

FIGURE 17: Linear Heater Layout Overview (Continued)

g

c

b

de

f

e e e e

g

c

b

de

f

e e e e e

g

c

b

de

f

e e e e e e

60' (18.3 m) Tube Length

70

' (21. 3 m) Tube Length

80

' (24.4 m) Tube Length

7' 6" ± 1'

(229 cm ± 25 cm)

NOTE:

Tubing requires a downward

slope of 1/2" (13 mm)

per 20

' (6 m) away

from burner.

S-Hook

Burner Tube

Hanger

Offset mounting

hole must be

to the top.

Weld seam

must be to the

bottom of the tube.

Description Part Number

Burner Tube 03051XXX

S-Hook 91907302

Tube/Reflector Hanger 03090100

SECTION 6: HEATER INSTALLATION

Step 6.1 Burner Tube Installation

17

Page 4

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

Bolt

Tube Clamp

Flat

Washer

Nut

(Torque 120 in/lb

13.56 Nm)

Description Part Number

Tube Clamp Package01318 901

Tube Clamp 01396801

Bolt 97113940

Flat Washer 95211600

Nut 92113900

Tube

Tube

Orient coupling so that

the impact block is in the

2:00 or 10:00 oclock

positions.

Closed

Open

Tab

3" (8 cm) to

4" (10 cm)

Slide Bar/Coupling Lock

Coupling

Wide End

Coupling

Tube

Slide Bar/Coupling Lock

A

Close coupling

with tab.

B

Start slide bar/coupling lock

onto coupling.

C

Insert tubes into coupling.

D

Tighten coupling to join tubes.

Description Part Number

Coupling 01329600

Slide Bar/Coupling Lock 01329700

Tube 91409XXX

Step 6.2 Tube Clamp Package Installation

Step 6.3 Coupling and Tube Assembly

18

Page 5

Step 6.3.1 Coupling and Tube Assembly (Continued)

Incorrect slide bar

position

Correct slide bar

dimensions

± 2" (5 cm)

Drive slide bar until tight.

End of slide bar should be

within tolerance listed below.

• Repeat Step 6.3 A - D until all tubes are assembled. See Page 19, Step 6.3.2.

Tighten slide bar as shown below.

10' ± 1'

(3 m ± .25 m)

Total Overall

Tube Length

7' 6" ± 1'

(2.3 m ± .25 m)

Model

Tube Length

Min im um

BH-40 10' (3 m)

BH-60 20' (6 m)

BH-80 20' (6 m)

BH-100 30' (9 m)

BH-115 30' (9 m)

BH-125 40' (12 m)

BH-140 40' (12 m)

BH-150 50' (15 m)

BH-175 50' (15 m)

BH-200 60' (18 m)

SECTION 6: HEATER INSTALLATION

Step 6.3.2 Coupling and Tube Assembly (Continued)

19

Page 6

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

T

w

i

s

t

Pull String

Ta b

Fold tab around outside

of tube nearest to the vent to

hold turbulator in place.

Turbulator

Section

Turbulator

Adapter

Description Part Number

Turbulator Adapter 2.5' (76.2 cm) 03051503

Turbulator Section 2' (61 cm) 03051504

Turbulator Section 2.5' (76.2 cm)(Stainless) 03051505

Tube 91409XXX

Turbulator must be installed in the last

standard section of tube. Turbulator is

not required on the BH-125/150/175/200.

Turbulator Installation

Model Tube Section

BH-40 1st 10' (3 m) Section

BH-60 2nd 10' (3 m) Section

BH-80 2nd 10' (3 m) Section

BH-100 3rd 10' (3 m) Section

BH-115 3rd 10' (3 m) Section

BH-125 N/A

BH-140 4th 10' (3 m) Section

BH-150 N/A

BH-175 N/A

BH-200 N/A

Turbulator section 2.5'

(76.2 cm) (stainless) used in

BH-40 heaters must be in the

section of turbulator nearest

to the burner.

Step 6.4 Turbulator Installation

20

Page 7

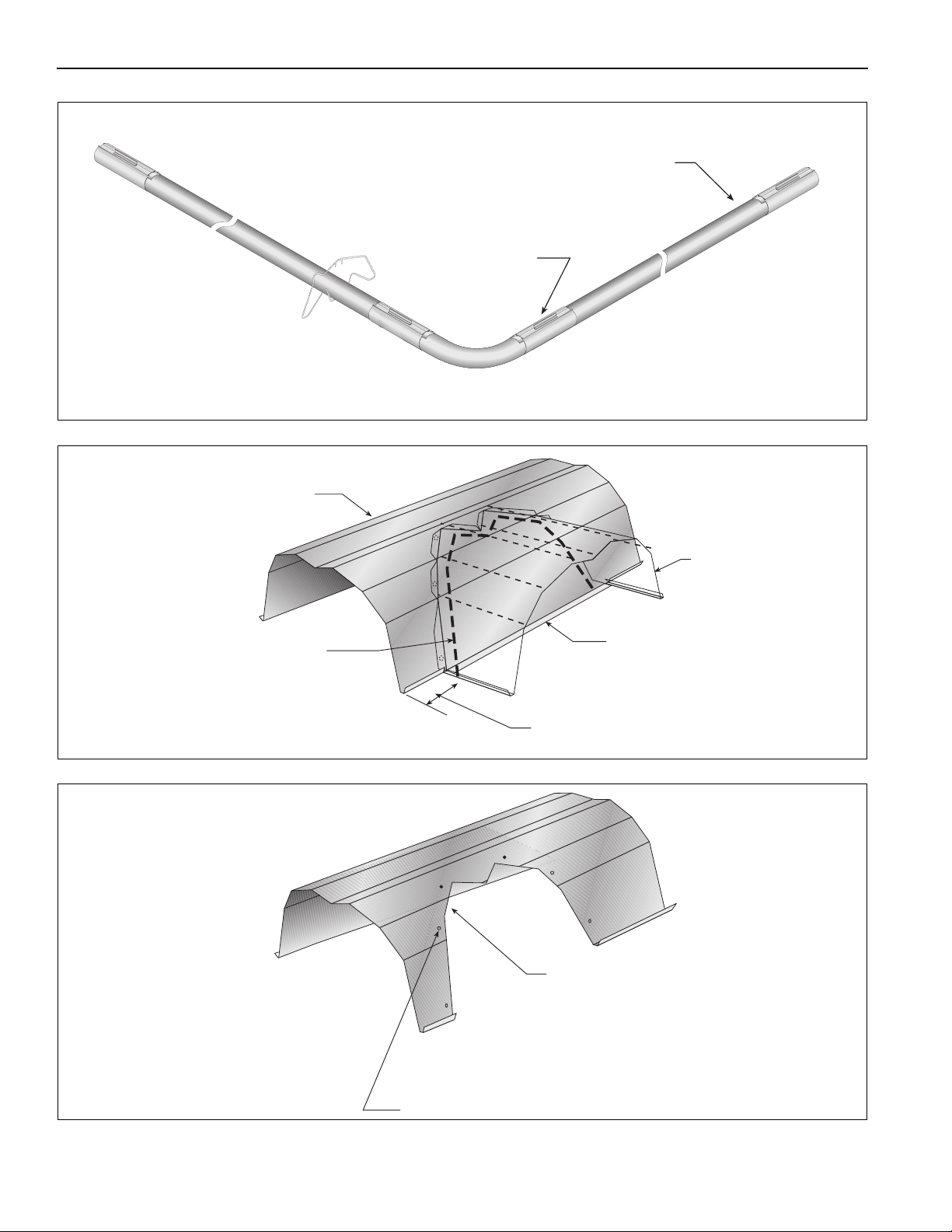

Step 6.5 Reflector Installation

WARNING

Fire Hazard

Support reflector with reflector hanger

and support strap.

Reflector must not touch tube.

Failure to follow these instructions can result

in death, injury or property damage.

Hanger

Burner Tube

Reflector

Description Part Number

Tube/Reflector Hanger 03090100

Burner Tube 03051XXX

Reflector 02750303

NOTE: All tube surfaces must be covered

by a reflector, except for a U-tube.

SECTION 6: HEATER INSTALLATION

21

Page 8

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

2. The overlap at the first and second reflector is a slip overlap.

Thereafter, every third reflector joint is a slip overlap. A slip

overlap is achieved by either:

a.) both reflectors lay inside a hanger.

(No reflector support needed.)

b.) using a reflector support with

loose screws at the reflector

overlap.

3. The remaining reflector overlaps require a non-slip

overlap connection. To affix the reflectors together in

a non-slip overlap either:

a.) use reflector support and tight screws.

b.) if both reflectors lay inside a hanger, u-clips or

sheet metal screws may be used.

This section of three reflectors joined together must

be affixed to the tube with at least one reflector support

with tight screws.

Reflector

End Cap

U-clips

1. The first reflector after the burner must be affixed in

the middle of the reflector with a reflector support and

tight screws.

First Reflector

6"

(16 cm)

Overlap must be a

minimum of

6

" (16 cm).

Loose screws

loosened 1/16"

(.16 cm) to allow

slippage.

2 A

Slip Overlap

Reflector

Support

2 B

Slip Overlap

Reflector

Tight

Screws

3 B

Non-Slip Overlap

U-clip

(2 Clips per

Non-slip Overlap

Inside a Hanger)

Reflector

3 A

Non-Slip Overlap

Wire Form

Reflector Support

Strap

Tight

Sheet Metal

Screw

Description Part Number

Reflector Support Package 03050010

Wire Form 91908004

Reflector Support Strap 03050000

Screw #8 x 3/4" 94320812

U-Clip Package 91107720

Reflector End Cap 027508XX

Step 6.5.1 Reflector, U-Clip and Reflector Support Installation

The pictorial drawings of the heater construction in

Section 6 are schematic only and provide a general

guideline of where hangers, reflector supports and

U-clips are to be installed.

To ensure proper expansion and contraction

movement of the reflectors, a combination of U-clips

and reflector supports are used. The positioning of

reflector supports and U-clips depend on the

individual installation. The following rules must be

observed.

22

Page 9

Step 6.6 Burner Installation

Lock

Washer

Gasket

Burner

Bolt

(Torque 120 in/lb

13.56 Nm)

S-hook

Burner Tube

Extra chain min.

12" (30 cm)

Description Part Number

Bolt 94273914

Burner 071XXXXX

Lock Washer 96411600

Gasket 02568200

SECTION 6: HEATER INSTALLATION

23

Page 10

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

WARNING

Cut/Pinch Hazard

Wear protective gear during installation,

operation and service.

Edges are sharp.

Failure to follow these instructions can result

in injury.

SECTION 7: OPTIONAL HEATER ACCESSORIES

7.1 U-Tube Configuration

Heaters (except BH-40) are approved for optional

U-tube configurations.

The U-tube may be installed in either a standard

horizontal position, a 45° position or in an opposite

45° position as shown on Page 6, Figure 7 through

Page 7, Figure 9. When using a U-tube configuration,

the following additional rules must be adhered to:

• A minimum of 10' (3 m) on BH-60/80 and a

minimum of 15

150/175/200 is required between the burner and

the U-tube.

• The correct turbulator (See Page 20, Step 6.4)

must be installed in the last standard section of

the tube.

• The burner must never be operated in a tilted

position.

• The heater must be properly supported at all

locations. See Page 26, Figure 19.

'

(4.5 m) on BH-100/115/125/140/

24

Page 11

FIGURE 18: U-Tube Heater Assembly Overview

U-tube

18" (46 cm)

Center to Center

U-clips

Reflector

End Caps

12

Burner

Reflector

Turbulator

(With Select

Models)

Tube Clamp

Package

Burner

Tube

Tube

U-tube

Support Bracket

Reflector

Support

Couplings

U-tube, Standard

Nut

Lock Washer

Lock Washer

Nut

U-bolt

12

12

U-tube,

Opposite 45°

Vent Adapter

1

U-tube,

45°

2

Tight U-bolt

4" (10 cm) u-bolt,

secured to burner tube

with 1/4" (.6 cm)

lockwashers and

1/4"(.6 cm) -20 hex nuts.

Loose U-bolt

4" (10 cm) u-bolt,

secured to bracket with

1/4" (.6 cm) lockwashers

and 1/4" (.6 cm)-20 hex

nuts on top and bottom to

allow for tube expansion

and contraction.

SECTION 7: OPTIONAL HEATER ACCESSORIES

25

Page 12

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

LEGEND

a = 14" (36 cm)

Reflector Width (Not Shown)

b = 2" (5 cm)

End Cap to Burner

c = 2" (5 cm)

End Cap to Hanger

d= 7

'

6" (2.3 m)

Distance First Hanger

e = 10

'

(3.0 m)

Distance Between Hangers

f = 5' (1.5 m)

Distance Between Last Full Tube

Hanger and Half Tube Hanger

g = 12.5" (32 cm) Burner Length

h = 11" (28 cm) Burner Height

* Requires the last reflector

before the u-tube to be cut in

half for use on both sides.

** Requires the last tube before

the u-tube to be cut in half for

use on both sides.

U-tube

Burner

Reflector

Tube 10

' (3.0 m)

Tube/Reflector

Hanger

Coupling

Assembly

Tube 5' (1.5 m)**

c

b

de

g

h

40' (12.2 m) Tube Length

c

b

d

f

g

h

30' (9.1 m) Tube Length**

20

'

(6.1 m) Tube Length*

g

c

b

h

e

c

b

de

f

g

h

50' (15.2 m) Tube Length* **

Vent Adapter

(Not Shown)

FIGURE 19: U-Tube Heater Layout Overview

26

Page 13

FIGURE 20: U-Tube Layout Overview (Continued)

g

c

b

de

h

e

f

g

c

b

de

h

e e

g

c

b

de

h

e

60' (18.3 m) Tube Length

70

' (21.3 m) Tube Length**

80

' (24.4 m) Tube Length

Tube

90° Elbow

Coupling

Description Part Number

Elbow Package 02718702

90° Elbow 01335801

Coupling 01312700

Reflector End Cap 02750800

Reflector Joint Piece 02750900

U-Clip Package 91107720

Minimum Distance Required

Between Burner and Elbow

Model

Minimum

Distance

BH-40 10' (3 m)

BH-60 10' (3 m)

BH-80 10' (3 m)

BH-100 15' (4.5 m)

BH-115 15' (4.5 m)

BH-125 15' (4.5 m)

BH-140 15' (4.5 m)

BH-150 15' (4.5 m)

BH-175 15' (4.5 m)

BH-200 15' (4.5 m)

SECTION 7: OPTIONAL HEATER ACCESSORIES

7.2 Elbow Package Configuration

Step 7.2.1 Elbow Installation

27

Page 14

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

Tube

Coupling

Reflector

Reflector

Joint

Flatten Edge

1" (2.5 cm)

Maximum

Scribe

Contour

Cut away contour

with tin snips.

Punch/drill six 3/32" (2 mm) holes.

Step 7.2.2 Elbow Installation

Step 7.2.3 Reflector Joint Installation

Step 7.2.4 Reflector Joint Installation

28

Page 15

Step 7.2.5 Reflector Joint Detail

Install reflector

end cap.

Attach reflector joint

with six #8 sheet

metal screws.

Reflector

Reflector

Joint

FIGURE 21: Reflector Joint Detail

SECTION 7: OPTIONAL HEATER ACCESSORIES

29

Page 16

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

Reflector Side

Extension Bracket

(2 per Reflector)

Use additional supports

in high air movement

applications.

Tube and Reflector Hanger

ReflectorTube

Reflector Support

Description Part Number

Reflector Side Extension Package 02712700

Reflector Side Extension 01368000

Retainer Clips 02751200

Sheet Metal Screws 94118106

Order Separately

Reflector Side Extension Bracket 01329910

Retainer Clip

(2 per Side)

Cut relief notches for

supports and hangers.

Reflector Side Extension

#8 x 3/8 (3.9 x 9.5 mm) Sheet Metal Screw

7.3 Reflector Side Extension

Step 7.3.1 Bracket Installation

Step 7.3.2 Side Reflector Installation

30

Page 17

7.4 Lower Clearance Shield Installation

12"

(30 cm)

Reflector

Lower Clearance Shield

17"

(43 cm)

Washers

Screws

Locknuts

Align Pilot Holes

Description Part Number

Lower Clearance Shield Package 01397501

Shield Support Strap 01397500

Lower Clearance Shield 8' (2.4 m) 02793000

Locknut #8 92311400

Flat Washer #8 95310800

Screw #8 x 3/8'' 93511406

Suspended Ceiling Frame

Tube

2

' x 4' (.6 m x 1.2 m) Aluminum Grille

Reflector

Tube and Reflector

Hanger

Description Part Number

Aluminum Grille 2' x 4' (61 x 122 cm) 91407000

Step 7.4.1 Shield Support Strap Assembly

SECTION 7: OPTIONAL HEATER ACCESSORIES

7.5 Two-Foot Decorative Grille Installation

Step 7.5.1 Grille Installation

31

Page 18

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

Shield

Description Part Number

Deco Grille Shield 01365900

NOTE: If the decorative grille system is to

be installed in an area with considerable

air movement, it is recommended that one

#8 x 3/8" sheet metal screw be installed per

reflector extension to prevent it

from blowing over.

A

Reflector Side

Extension

Cut relief notches for tube

and reflector hangers.

Insert screw

here.

Description Part Number

Reflector Side Extension 01370412

Distance "A" Extension

Minimum Maximum Part No. Width

2" (4 cm) 6" (15 cm) 01370408 8" (20 cm)

6" (15 cm) 10" (26 cm) 01370412 12" (30 cm)

10" (26 cm) 14" (37 cm) 01370416 16" (40 cm)

Step 7.5.2 Frame Shield Installation

Step 7.5.3 Reflector Side Extension Installation for Decorative Grilles

32

Page 19

7.6 Protective Grille Installation

Silicone Cap

Grille

Finger

Description Part Number

Grille Section 08050001

Grille End Cap 08050002

Silicone Cap 91915951-6P

Bend up 90°.

Pull outward.

Grille

Grille End Cap

A

B

C

D

Grille

Grille

End Cap

Reflector

Final Grille

Section

40"

(101 cm)

Step 7.6.1 Silicone Cap Installation

Step 7.6.2 Grille End Cap Installation

SECTION 7: OPTIONAL HEATER ACCESSORIES

Step 7.6.3 Grille Installation

33

Page 20

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

WARNING

Carbon Monoxide Hazard

Heaters installed unvented must be interlocked

with sufficient building exhaust.

Heaters must be installed according to the

installation manual.

Failure to follow these instructions can result

in death or injury.

WARNING

Cut/Pinch Hazard

Wear protective gear during installation,

operation and service.

Edges are sharp.

Failure to follow these instructions can result

in injury.

SECTION 8: VENTING

combustible wall must have an approved thimble

to conform with the above listed codes.

Vent pipe must be sloped downward away from the

heater 1/2'' (1 cm) for every 20' (6 m).

The heater may be individually vented or common

vented. When venting horizontally, a maximum of two

heaters can be commonly vented. See Page 37,

Section 8.9. When venting vertically, a maximum of

four heaters can be commonly vented. See Page 38,

Section 8.10.

The heater may also be installed unvented in certain

circumstances according to building ventilation

codes. Refer to the above codes and Page 35,

Section 8.2 for further information. Unvented

operation also requires compliance with the

clearances to combustibles given on Page 8, Figure

12.

The bottom of the vent or air intake terminal shall not

be located less than 1' (0.3 m) above grade level.

8.1 Venting

This heater must be vented in accordance with the

rules contained in this manual and with the following

national codes and any state, provincial or local

codes which may apply:

United States: Refer to National Fuel Gas Code

NFPA 54/ANSI Z223.1 - latest revision.

Canada: Refer to Natural Gas and Propane

Installation Code CSA B149.1 - latest revision.

Exhaust end of heater will accept a 4'' (10 cm) vent

pipe using the vent adapter (P/N 90502700). To

prevent leakage of condensation, install the vent

adapter with the seam on top and seal the joint using

a high temperature silicone sealant.

Any portion of vent pipe passing through a

34

The vent shall not terminate less than 7' (2.1 m)

above grade where located adjacent to public

walkways.

Vent terminal must be installed at a height sufficient

to prevent blockage by snow, and building materials

protected from degradation by flue gases.

Secure all joints with #8 x 3/8 sheet metal screws.

Seal all joints with high temperature silicone sealant.

Vent terminal must be beyond any combustible

overhang.

8.1.1 United States Requirements

Vent must terminate at least 3' (0.9 m) above any

forced air inlet located within 10' (3.1 m).

Vent must terminate at least 4' (1.2 m) below, 4'

(1.2 m) horizontally from, or 1' (0.3 m) above any

door, operable window, or gravity air inlet into any

building.

8.1.2 Canadian Requirements

The vent shall not terminate within 6' (1.8 m) of a

mechanical air supply inlet to any building.

The vent shall not terminate within 3' (0.9 m) of a

window or door that can be opened in any building,

any non-mechanical air supply inlet to any building,

or of the combustion air inlet of any other appliance.

Page 21

SECTION 8: VENTING

WARNING

Combustion by-products contain a chemical

known to the State of California to cause

cancer and birth defects or other

reproductive harm.

8.2 Unvented Operation

Sufficient ventilation must be provided in the amount

of 4 cfm per 1000 Btu/h firing rate (United States); 3

cfm per 1000 Btu/h firing rate (Canada).

Use of optional outside combustion air is not

recommended with unvented heaters.

If exhaust fans are used to supply ventilation air, an

interlock switch must be used to prevent the heater

from coming on when the fans are off. This may be

done using a pressure switch.

8.3 Horizontal Venting

In noncombustible walls only, vent terminal

(P/N 02537801-1P) may be used.

For 4" (10 cm) vents in either combustible or

noncombustible walls, use Tjernlund VH1-4 (P/N

90502100) or equivalent, insulated vent terminal.

Follow the manufacturer's instructions for proper

installation.

FIGURE 22: Tube Termination

8.6 Length Requirements

The maximum vent length allowed is 45' (13.7 m).

The maximum outside air supply duct length allowed

is 45' (13.7 m).

The total vent length, plus outside air duct length,

plus any extensions to minimum heat exchanger

lengths, cannot exceed 65' (19.8 m).

Vent length should be limited to less than 20' (6 m). If

using vent lengths greater than 20' (6 m),

condensation will form in the vent pipe. Insulation

and additional sealing measures (high temperature

silicone at all seams) are required. Optional heat

exchanger beyond minimum lengths is considered as

vent length for length determination.

Subtract 15' (4.6 m) of maximum allowed vent or duct

length per vent elbow if more than two are used.

For 6" (15 cm) common vents in either combustible

or noncombustible walls, use Tjernlund VH1-6 (P/N

90502101) or equivalent, insulated vent terminal.

Follow the manufacturer's instructions for proper

installation.

8.4 Vertical Venting

For 4'' (10 cm) common vent, an approved vent cap

(P/N 90502300) must be used.

For 6'' (15 cm) common vent, an approved vent cap

(P/N 90502302) must be used.

For common vertical venting of more than two

heaters, See Page 38, Section 8.10.

A vent shall not extend less than 2' (0.6m) above the

highest point where it passes through a flat roof of a

building.

8.5 Unvented Operation Tube Termination

Turndown type vent terminal with a screen must be

installed at the exhaust end of the tube. Vent terminal

design shall not incorporate backdraft flap.

35

Page 22

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

4" (10 cm)

Single Wall Pipe

Vent Adapter

Vent Terminal

Combustible or

Non-Combustible Wall

Vent Adapter

18" (46 cm)

Min.

Vent Terminal

4" (10 cm) Single Wall Pipe

Non-Combustible Wall Only

SIDE VIEW

Description Part Number

Vent Terminal (Comb. Wall) 90502100

Vent Terminal 02537801-XX

Wall Thimble 4" (10 cm) 90505600

4" (10 cm) Single Wall Pipe

4" (10 cm) Type "B" vent cap

Roof

Roof

Flashing

Approved

Thimble

(If Applicable)

18" (46 cm)

Min.

4" (10 cm) Type "B" vent pipe

The last section of vent pipe

passing through the roof or

wall may be Type "B" vent pipe.

All other vent materials in the

building must be single wall

vent pipe.

Vent Adapter

SIDE VIEW

Description Part Number

Vent Cap 4" (10 cm) 90502300

8.7 Horizontal Ventilation 4'' (10 cm) Pipe

8.8 Vertical Ventilation 4'' (10 cm) Pipe

36

Page 23

8.9 Common Side Wall Venting

4" (10 cm) Single Wall Pipe

Outside Wall

Vent Adapter

Sweeping 'T'

Connection

Sweeping 'Y'

Connection

Outside Wall

6" (15 cm) Single Wall Pipe

Vent Terminal

Tjernlund VH1-6 or Equivalent

Outside Wall

4" (10 cm) Single Wall Pipe

Vent Adapter

Vent Terminal

Tjernlund VH1-6 or Equivalent

Vent Adapter

Vent Adapter

TOP VIEW

4" (10 cm) Single Wall Pipe

6" (15 cm) Single Wall Pipe

Description Part Number

Vent Terminal 6" (15 cm) 90502101

SECTION 8: VENTING

Requirements:

• Maximum of two heaters can be commonly

vented through a side wall.

• Heaters must be of the same BTU output.

• Heaters must be controlled by a common

thermostat.

37

Page 24

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

8.10 Common Vertical Venting

Requirements:

• Maximum of four heaters can be commonly

vented through the roof.

• Heaters must be of the same BTU output.

• Heaters must be controlled by a common

thermostat.

• Connections to a common stack must be

positioned to avoid direct opposition between

streams of combustion gases.

38

Page 25

SECTION 8: VENTING

Band Clamp

(Recommended)

Flex Hose

(Recommended)

Vent Cap

Roof

4" (10 cm)

Single Wall Pipe

Burner

18" (46 cm)

Min.

Description Part Number

Vent Cap 4" (10 cm) 90502300

Band Clamp

(Recommended)

Flex Hose

(Recommended)

Vent Cap

Wall

4" (10 cm)

Single Wall Pipe

Burner

Description Part Number

Vent Cap 4" (10 cm) 90502300

8.11 Outside Combustion Air Supply

IMPORTANT: If the building has a slight negative

8.11.1 Length Requirements

Follow the constraints listed on Page 35, Section 8.6.

pressure or corrosive contaminants, such as

halogenated hydrocarbons, are present in the air, an

outside combustion air supply to the heater is

required. Seal all combustion air pipe joints.

Use of optional outside combustion air is not

recommended with unvented heaters.

The air supply duct may have to be insulated to

prevent condensation on the outer surface. The

outside air terminal must not be more than 1' (31 cm)

above the vent terminal.

8.11.2 Vertical Outside Air Supply for Single Heater Installation

8.11.3 Horizontal Outside Air Supply for Single Heater Installation

39

Page 26

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

Sweeping 'T'

Connection

6" (15 cm) Single Wall Pipe

Vent Cap

4" (10 cm)

Single Wall Pipe

Band Clamp

(Recommended)

BurnerBurner

Flex Hose

(Recommended)

Flex Hose

(Recommended)

Roof

Description Part Number

Vent Cap 6" (15 cm) 90502302

Sweeping 'Y'

Connection

Vent Cap

Outside Wall

4" (10 cm) Single Wall Pipe

(Seal All Joints)

6" (15 cm) Single Wall Pipe

Flex Hose

(Recommended)

Band Clamp

(Recommended)

Burner

Burner

Description Part Number

Vent Cap 6" (15 cm) 90502302

8.11.4 Vertical Outside Air Supply for Double Heater Installation

Requirements:

• Heaters must be controlled by a common thermostat.

8.11.5 Horizontal Outside Air Supply for Double Heater Installation

Requirements:

• Heaters must be controlled by a common thermostat.

40

Page 27

SECTION 9: GAS PIPING

WARNING

Fire Hazard

Tighten gas hose fittings to connect gas

supply according to Figure 23.

Gas hose can crack when twisted.

Gas hose moves during normal operation.

Use only 36" (91 cm) long connector of 1/2" or

3/4" nominal ID.

Connector supplied with heater for U.S.

models (not with Canadian models).

Failure to follow these instructions can result

in death, injury or property damage.

WARNING

Explosion Hazard

Leak test all components of gas piping

before operation.

Gas can leak if piping is not installed properly.

Do not high pressure test gas piping with

burner connected.

Failure to follow these instructions can result

in death, injury or property damage.

SECTION 9: GAS PIPING

Install the gas hose as shown in Figure 23. The gas

hose accommodates expansion of the heating

system and allows for easy installation and service of

the burner. Before connecting the burners to the

supply system, verify that all high pressure testing of

the gas piping has been completed.

There is an expansion of the tube with each firing

cycle; this will cause the burner to move with respect

to the gas hose. This can cause a gas leak resulting

in an unsafe condition if the gas connection is not

made strictly in accordance with Figure 23.

Meter and service must be large enough to handle all

the burners being installed plus any other connected

load. The gas hose which feeds the system must be

large enough to supply the required gas with a

maximum pressure drop of 1/2" w.c. When gas piping

is not included in the layout drawing, the local gas

supplier will usually help in planning the gas piping.

Gas lines must meet applicable codes:

United States: The Flexible Stainless Steel Gas

Hose (US models) supplied with the heater is certified per the Standard for Connectors for Gas Appliances, ANSI Z21.24/CSA 6.10 - latest revision.

Canada: The Rubber Type 1 Gas Hose (Canadian

models) optional with the heater is certified as being

in compliance with the Standard for Elastomeric

Composite Hose and Hose Couplings for Conducting

Propane and Natural Gas, CAN/CGA 8.1 - Latest

revision.

• Check the pipe and tubing ends for leaks

before placing heating equipment into

service. When checking for gas leaks, use a

soap and water solution; never use an open

flame.

41

Page 28

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

90° Pipe Elbow

(Not Included)

Shut-Off Valve (included with gas hose) must

be parallel to burner gas inlet. The 3" (8 cm)

displacement shown is for the cold condition.

This displacement may reduce when the

system is fired.

CORRECT POSITIONS

Vertical (as shown left)

Alternate

positions

okay

Flexible Gas Hose

36" (91 cm) length

3" (8 cm)

max. displacement

Side View

Heater Movement

12"

(30 cm)

45°

Burner Assembly

(Shown Without Blower Assembly)

Pipe Nipple

Rear View

45°

CAUTION

Product Damage Hazard

Hold gas nipple securely with pipe wrench

when attaching gas hose.

Failure to follow these instructions can result

in product damage.

INCORRECT POSITIONS (WRONG INSTALLATION)

Heater Movement

Heater Movement

Heater Movement Heater Movement

Description Part Number

1/2" Flexible Stainless Steel Gas Hose (US Models) 91412200

3/4" Flexible Stainless Steel Gas Hose (US Models) 91412204

1/2" Rubber Type 1 Gas Hose (Canadian Models) 91412206

3/4" Rubber Type 1 Gas Hose (Canadian Models) 91412207

FIGURE 23: Gas Connection with Flexible Gas Hose

42

Page 29

SECTION 10: WIRING

DANGER

Electrical Shock Hazard

Disconnect electric before service or

maintenance.

Heater must be connected to a properly

grounded electrical source.

Failure to follow these instructions can

result in death or electrical shock.

L1

L2

Gnd.

N H

Gnd.

N H

Gnd.

Additional

Burners

120 V-60 Hz

Supply Circuit

Line Voltage Thermostat

Burner 1 Burner 2

Maximum 5 Burners

Per Thermostat

10.1 Line Voltage Thermostat Wiring

SECTION 10: WIRING

Heaters can be controlled using several methods.

Normally thermostats are used to control the heaters

but they can also be controlled by an energy

management system. Section 10.1 illustrates the

connection for heaters controlled by a line voltage

thermostat.

For heaters on a low voltage thermostat, See Page

44, Section 10.2. Heaters must be grounded in

accordance with applicable codes: United States:

Refer to National Electrical Code

®

NFPA 70 - latest

revision; Canada: Refer to Canadian Electrical Code

CSA C22.1 Part I - latest revision.

If any of the original internal wiring must be replaced,

it must be replaced with wiring materials having a

temperature rating of at least 105°C and 600 volts.

43

Page 30

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

R

C

W

G

Y

1

2

3

4

5

6

COIL

L1

L2

Gnd.

N

H

Gnd.

N

H

Gnd.

Additional

Burners

120 V-60 Hz

Supply Circuit

Low Voltage Thermostat

Burner 1

Burner 2

Maximum 8 Burners

Per Relay

Black

SPST Transformer Relay

Black

Red

White

COIL

FRONT VIEW BACK VIEW

Description Part Number

SPST Transformer Relay 90417600

Low Voltage Thermostat 90425100

10.2 Low Voltage Thermostat Wiring

44

Page 31

10.3 Internal Wiring

Pressure Switch

BLUE

BLUE

BLUE 24 V A/C

BLACK Flame Sense

YELLOWGround

BROWN Main Valve

Electrode

BLACK

BLACK

BLACK

BROWN

YELLOW

YELLOW

YELLOW

GREEN

GREEN

GREEN

WHITE

WHITE

DSI Ignition Module

NO

C

Gas Valve

Burner Ground

Blower Connection

Motor/Blower

Electrical Connection

120 V-60 Hz

L1

L2

L

G

N

Transformer

SECTION 10: WIRING

45

Page 32

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

Power

Valve

Sense

Ground

Spark

Transformer

Blower

Pressure

Switch

Ignition Module

Gas Valve

Power Supply

120 V - 60 Hz

Gap

Electrode

120 V

24 V

Conduit Hole

BX or Romex Connector

Burner Box

Internal Wire Bundle

Green

White

Black

L1

L2

Gnd.

Connect wires together with

suitable approved wire connections.

Green to Gnd.

White to L2

Black to L1

Electrical Cord or

Flexible Conduit

10.4 Ladder Diagram

10.5 Electrical Connection to the Burner

46

Page 33

SECTION 11: OPERATION AND MAINTENANCE

Cut/Pinch Hazard

Wear protective gear

during installation,

operation and service.

Edges are sharp.

WARNING

Failure to follow these instructions can result in death, electric shock, injury or property damage.

Burn Hazard

Allow heater to cool

before service or

maintenance.

Tubing may still be hot

after operation.

Explosion Hazard

Turn off gas supply to

heater before service

or maintenance.

DANGER

Electrical Shock Hazard

Disconnect electric

before service or

maintenance.

Heater must be

connected to a properly

grounded electrical

source.

SECTION 11: OPERATION AND MAINTENANCE

raising it again to desired temperature, or by

This heater is equipped with a direct spark ignition

system.

11.1 S e quence of Operation

1. Turn the thermostat up. When the thermostat

calls for heat, the blower motor will energize.

2. When the motor approaches nominal running

RPM, the pressure switch closes and activates

the ignition module.

3. After a 45 second prepurge, the ignition module

then opens the gas valve and energizes the

spark igniter.

4. When the flame is established, the sparking

sequence ceases.

5. If the flame is not established during the ignition

sequence, the ignition module closes the gas

valve and purge begins. Module will try 2

additional times for ignition (with purges in

between trials). If ignition is not established, the

module will lockout.

6. If the flame extinguishes during operation, the

ignition module will attempt the multiple trial

sequence described in step 5. If ignition is not

re-established, the module will lockout for one

hour or until reset.

7. After lockout, the control can be reset by turning

down thermostat for five seconds, and then

disconnecting power and then reconnecting.

8. When thermostat is satisfied, all power to the

unit is shut off.

11.2 To Shut Off Heater

Set thermostat to lowest setting.

Turn OFF electric power to heater.

Turn OFF manual gas valve in the heater supply line.

11.3 To Start Heater

Turn gas valve and electric power OFF and wait five

minutes for unburned gases to vent from heater.

Turn ON main gas valve.

Turn ON electric power.

Set thermostat to desired temperature.

Burner should light automatically.

11.4 Pre-Season Maintenance and Annual

Inspection

To ensure your safety and years of trouble-free

operation of the heating system, service and annual

inspections must be done by a contractor qualified in

the installation and service of gas-fired heating

equipment.

Turn off gas and electric supplies before performing

service or maintenance. Allow heater to cool before

servicing.

Before every heating season, a contractor qualified in

the installation and service of gas-fired heating

equipment must perform a thorough safety

inspection of the heater.

47

Page 34

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

For best performance, the gas, electrical, thermostat

connections, tubing, venting, suspensions and

overall heater condition should be inspected

thoroughly.

NOTE: Gas flow and burner ignition are among the

first things that should be inspected.

Please see Page 49, Section 11.5 for suggested

items to inspect.

48

Page 35

11.5 Maintenance Checklist

SECTION 11: OPERATION AND MAINTENANCE

Installation Code and Annual Inspections:

All installation and service of ROBERTS GORDON

equipment must be performed by a contractor

qualified in the installation and service of equipment

sold and supplied by Roberts-Gordon and conform to

all requirements set forth in the ROBERTS

GORDON

®

manuals and all applicable governmental

To help facilitate optimum performance and safety,

®

Roberts-Gordon recommends that a qualified

contractor conduct, at a minimum, annual

inspections of your ROBERTS GORDON

®

equipment

and perform service where necessary, using only

replacement parts sold and supplied by RobertsGordon.

authorities pertaining to the installation, service and

operation of the equipment.

The Vicinity of the Heater Do not store or use flammable objects, liquids or vapors near the heater.

Immediately remove these items if they are present.

See Page 4, Section 3.

Vehicles and Other

Objects

Maintain the clearances to combustibles.

Do not hang anything from, or place anything on, the heater.

Make sure nothing is lodged underneath the reflector, in between the tubes or

in the decorative or protective grilles (included with select models).

Immediately remove objects in violation of the clearances to combustibles.

See Page 4, Section 3.

Reflector Support reflector with reflector hanger and support strap.

Reflector must not touch tube.

Make sure there is no dirt, sagging, cracking or distortion.

Do not operate if there is sagging, cracking or distortion.

Make sure reflectors are correctly overlapped. See Page 22, Section 6.5.1.

Clean outside surface with a damp cloth.

Vent Pipe Venting must be intact. Using a flashlight, look for obstructions, cracks on the

pipe, gaps in the sealed areas or corrosion.

The area must be free of dirt and dust.

Remove any carbon deposits or scale using a wire brush.

See Page 34, Section 8.

Outside Air Inlet Inlet must be intact. Look for obstructions, cracks on the pipe, gaps in the

sealed areas or corrosion.

The area must be free of dirt and dust. Clean and reinstall as required.

Tubes Make sure there are no cracks.

Make sure tubes are connected and suspended securely.

See Page 13, Section 6.

Make sure there is no sagging, bending or distortion.

Clean or replace as required.

Gas Line Check for gas leaks. See Page 41, Section 9.

Burner Observation

Window

Blower Scroll, Wheel and

Make sure it is clean and free of cracks or holes.

Clean and replace as required.

Compressed air or a vacuum cleaner may be used to clean dust and dirt.

Motor

49

Page 36

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

Burner Cup and Orifice Clear of obstructions (even spider webs will cause problems).

Carefully remove any dust and debris from the burner.

Electrode Replace if there are cracked ceramics, excessive carbon residue, or erosion

of the electrode.

The electrode gap should be 1/8" (3.2 mm).

Thermostat There should be no exposed wire or damage to the thermostat.

See Page 43, Section 10.

Suspension Points Make sure the heater is hanging securely. Look for signs of wear on the chain

or ceiling.

See Page 14, Figure 14.

Decorative and Protective

Grille (optional)

The grille must be securely attached.

Check that the side reflector extensions are installed correctly and secured in

place if necessary. (Decorative grille only.)

See Page 31, Section 7.5 and Page 33, Section 7.6

Make sure shield is installed correctly and secured in place if necessary.

(Decorative grille only.) See Page 32, Section 7.5.2.

Lower Clearance Shield

(optional)

The lower shield must be securely attached. Inspect shield support straps

and lower clearance shield anchor points.

See Page 31, Section 7.4.

Make sure shield is installed correctly and secured in place if necessary.

See Page 31, Section 7.4.

Wall Tag If wall tag is present, make sure it is legible and accurate. Please contact

Roberts-Gordon LLC or your ROBERTS GORDON

®

independent distributor,

if you need a wall tag. See Page 3, Section 2.1

50

Page 37

SECTION 12: TROUBLESHOOTING

DANGER

Electrical Shock Hazard

Disconnect electric before service or

maintenance.

Heater must be connected to a properly

grounded electrical source.

Failure to follow these instructions can

result in death or electrical shock.

Fire Hazard

Keep all flammable

objects, liquids and

vapors the minimum

required clearances to

combustibles away

from heater.

Some objects will catch

fire or explode when

placed close to heater.

Cut/Pinch Hazard

Wear protective gear

during installation,

operation and service.

Edges are sharp.

WARNING

Failure to follow these instructions can result in death, injury or property damage.

Burn Hazard

Allow heater to cool

before service or

maintenance.

Tubing may still be hot

after operation.

Explosion Hazard

Turn off gas supply to

heater before service

or maintenance.

SECTION 12: TROUBLESHOOTIN G

51

Page 38

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

Replace pressure switchYES

NO

Replace transformer.

YES

NO

Remove obstruction.YES

NO

YES

NO

Replace blower.

NO

YES

NO

YESNO

YES

YES

NO

NO

YES

Is there spark at the igniter?

YES

NO

NO Is the blower obstructed?

Remove obstruction.

NO

NO

YES

Replace ignition module.

With the blue and yellow

wires still removed, is the

voltage at the transformer

black and white leads 120 V?

YES

Is there power 120 V at

the burner?

Turn up thermostat.

Does the blower turn on?

Remove the blue and yellow

wires from the transformer.

Is there 24 V at the

transformer secondary?

Reconnect transformer

wires. Place a jumper wire

across the pressure switch.

Is there a spark?

Check wiring between the

power cord, blower motor

and transformer.

Replace igniter and

ignition wire as needed.

Carefully reset spark gap

to 1/8"

Are the air hoses to the

pressure switch secure and

leak free?

Repair, replace, or tighten

hoses as necessary.

Is the vent pipe or the inlet of

the burner obstructed?

Is the igniter gap

set at 1/8"?

Unplug burner and check

igniter and ignition wire. Are

they damaged?

Blower bearings may have

failed. Replace blower.

Check relay wiring

(if applicable) and wiring

to the burner.

Check thermostat wiring

and replace thermostat if

necessary.

Place a jumper across the

thermostat terminals.

Does the blower turn on?

Unplug burner. Does the

blower turn freely?

12.1 Troubleshooting Flow Chart

52

Page 39

SECTION 12: TROUBLESHOOTIN G

53

Page 40

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

10.5"

Natural

Propane

6

5

4

3

2

1

0

1

2

3

4

5

6

3.5"

6

5

4

3

2

1

0

1

2

3

4

5

6

Top View of Heater

Manometer

12.2 Manifold Gas Pressure Setting

54

Page 41

SECTION 13: REPLACEMENT PARTS

Carbon Monoxide Hazard

WARNING

Use only genuine ROBERTS GORDON® replacement parts per this installation, operation and

service manual.

Failure to follow these instructions can result in death, electric shock, injury or property damage.

Explosion Hazard

DANGER

Electrical Shock Hazard

Fire Hazard

SECTION 13: REPLACEMENT PARTS

55

Page 42

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

Blower Outlet Gasket

REAR VIEW

TOP VIEW

DSI Ignition Module

Blower Assemby

Electrode

Burner Cup Assembly

Gas Valve

Pressure Switch

Transformer

Mica Window Assembly

Tube Gasket

56

Page 43

SECTION 13: REPLACEMENT PARTS

Description Part Number

Mica Window Assembly 02553203

Electrode Gasket 02558501

Tube Gasket 02568200

Burner Cup Assembly 03020100

Gas Valve (Natural) 90032500

Gas Valve (LP) 90032502

Electrode 90427400

DSI Ignition Module 90439500K

Transformer 90436900K

Pressure Switch

(200) 90439801K

(115, 140, 175) 90439802K

(150) 90439803K

(60, 80, 100, 125) 90439805K

(40) 90439808K

Motor/Blower Assembly 90709700-P

Blower Outlet Gasket 90709801

57

Page 44

BH-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

Turbulator (select models)

Side View

Reflector

12.5"

(32 cm)

End View

11"

(28 cm)

Minimum Length A

Burner Tube

12.5"

(32 cm)

Heat Input Rate Length “A”

Recommended

Minimum Mounting Height*

Model (Btu/h) x (1000) Minimum Space Spot

BH-40 40 10' (3 m) 8-10' (2.4 - 3 m) 8'(2.4 m)

BH-60 60 20' (6 m) 10-12' (3 - 3.6 m) 9' (2.7 m)

BH-80 80 20' (6 m) 12-15' (3.6 - 4.5 m) 11' (3.3 m)

BH-100 100 30' (9 m) 12-15' (3.6 - 4.5 m) 12' (3.7 m)

BH-115 115 30' (9 m) 15-20' (4.5 - 6 m) 15' (4.6 m)

BH-125 125 40' (12 m) 15-20' (4.5 - 6 m) 15' (4.6 m)

BH-140 140 40' (12 m) 20-25' (6 - 7.6 m) 20' (6.1 m)

BH-150 150 50' (15 m) 20-25' (6 - 7.6 m) 20' (6.1 m)

BH-175 175 50' (15 m) 25' (7.6 m) 23' (7 m)

BH-200 200 60' (18 m) 25' (7.6 m) 25' (7.6 m)

SECTION 14: GENERAL SPECIFICATIONS

14.1 Material Specifications

14.1.1 Reflectors

.024 Aluminum

(Optional .024 Stainless Steel Type 304)

14.2 Heater Specifications

14.2.1 Ignition

Fully automatic spark ignition with safety shut-off.

14.3 Suspension Specifications

Hang heater with materials with a minimum working

load of 75 lbs (33 kg). See Page 14, Figure 14.

14.4 Controls Specifications

Time switches, thermostats, etc. can be wired into

the electrical supply. External controls supplied as an

optional extra.

General Specifications for BH-Series heaters are as follows:

*See Page 4, Section 3 for clearances to combustibles.

GAS PRESSURE AT MANIFOLD:

Natural Gas: 3.5" wc

LP Gas: 10.5" wc

PIPE CONNECTION:

1/2" NPT (for BH-40, 60, 80, 100, 115 & 125)

3/4" NPT (for BH- 140, 150,175 & 200)

DIMENSIONS:

Vent Connection Size: 4" (10 cm)

Outside Air Connection Size: 4" (10 cm)

Refer to figure above for dimensional information.

58

GAS INLET PRESSURE:

Natural Gas:

for BH-40, 60, 80, 100,

115, 125, 140, 150 4.6" wc Minimum

for BH-175, 200 5.0" wc Minimum

LP Gas: 11.0" wc Minimum

ELECTRICAL RATING (ALL MODELS):

120 V - 60 Hz, 1 A

14.0" wc Maximum

14.0" wc Maximum

Page 45

SECTION 15: THE ROBERTS GORDON® GORDONRAY® BH WARRANTY

®

SECTION 15: THE ROBERTS GORDON

GORDONRAY

®

BH WARRANTY

ROBERTS-GORDON LLC WILL PAY FOR:

Within 36 months from date of purchase by buyer or 42

months from date of shipment by Roberts-Gordon LLC

(whichever occurs first), replacement parts will be

provided free of charge for any part of the product which

fails due to a manufacturing or material defect.

Roberts-Gordon LLC will require the part in question to be

returned to the factory. Roberts-Gordon LLC will, at its sole

discretion, repair or replace after determining the nature of

the defect and disposition of part in question.

®

ROBERTS GORDON

Replacement Parts are warranted

for a period of 12 months from date of shipment from

Roberts-Gordon LLC or the remaining ROBERTS

GORDON

®

GORDONRAY® BH warranty.

ROBERTS-GORDON LLC WILL NOT PAY FOR:

Service trips, service calls and labor charges.

Shipment of replacement parts.

Claims where the total price of the goods have not

been paid.

Damage due to:

• Improper installation, operation or maintenance.

• Misuse, abuse, neglect, or modification of the

ROBERTS GORDON

®

GORDONRAY® BH in any

way.

• Use of the ROBERTS GORDON

®

GORDONRAY®

BH for other than its intended purpose.

• Incorrect gas or electrical supply, accident, fire,

floods, acts of God, war, terrorism, or other casualty.

• Improper service, use of replacement parts or

accessories not specified by Roberts-Gordon.

• Failure to install or maintain the

ROBERTS GORDON

®

GORDONRAY® BH as

directed in the Installation, Operation and Service

Manual.

• Relocation of the ROBERTS GORDON

GORDONRAY

• Use of the ROBERTS GORDON

®

BH after initial installation

®

®

GORDONRAY®

BH in a corrosive atmosphere containing

contaminants.

• Use of the ROBERTS GORDON

®

GORDONRAY®

BH in the vicinity of a combustible or explosive

material.

• Any defect in the ROBERTS GORDON

GORDONRAY

®

BH arising from a drawing, design,

®

or specification supplied by or on behalf of the

consumer.

• Damage incurred during shipment. Claim must be

filed with carrier.

WARRANTY IS VOID IF:

The ROBERTS GORDON® GORDONRAY® BH is not

installed by an contractor qualified in the installation and

service of gas fired heating equipment.

You cannot prove original purchase date and required

annual maintenance history.

The data plate and/or serial number are removed,

defaced, modified or altered in any way.

The ownership of the ROBERTS GORDON

®

GORDONRAY® BH is moved or transferred. This warranty

is non-transferable.

Roberts-Gordon LLC is not permitted to inspect the

damaged equipment and/or component parts.

READ YOUR INSTALLATION, OPERATION AND

SERVICE MANUAL.

If you have questions about your equipment, contact your

installing professional. Should you need Replacement

Parts or have additional questions, call or write:

Roberts-Gordon LLC

1250 William Street

P. O . B o x 4 4

Buffalo, New York 14240-0044

716.852.4400

On the web at: www.rg-inc.com

Roberts-Gordon LLC's liability, and your exclusive

remedy, under this warranty or any implied warranty

(including the implied warranties of merchantability

and fitness for a particular purpose) is limited to

providing replacement parts during the term of this

warranty. Some jurisdictions do not allow limitations on

how long an implied warranty lasts, so this limitation may

not apply to you. There are no rights, warranties or

conditions, expressed or implied, statutory or otherwise,

other than those contained in this warranty.

Roberts-Gordon LLC shall in no event be responsible

for incidental or consequential damages or incur

liability for damages in excess of the amount paid by

you for the ROBERTS GORDON

®

GORDONRAY® BH .

Some jurisdictions do not allow the exclusion or limitation

of incidental or consequential damages, so this limitation

or exclusion may not apply to you. This warranty gives you

specific legal rights, and you may also have other rights

which vary from jurisdiction to jurisdiction.

Roberts-Gordon LLC shall not be responsible for failure to

perform under the terms of this warranty if caused by

circumstances out of its control, including but not limited to

war, fire, flood, strike, government or court orders, acts of

God, terrorism, unavailability of supplies, parts or power.

No person is authorized to assume for Roberts-Gordon

LLC any other warranty, obligation or liability.

LIMITATIONS ON AUTHORITY OF

REPRESENTATIVES:

No representative of Roberts-Gordon LLC, other than an

Executive Officer, has authority to change or extend these

provisions. Changes or extensions shall be binding only if

confirmed in writing by Roberts-Gordon LLC's duly

authorized Executive Officer.

59

Page 46

Page 47

®

OWNER WARRANTY REGISTRATION CARD

About the Owner:

Name:__________________________________________________________________________________________________

Address:______________________________________City:_________________________ State:__________Zip Code:________

Phone:_________________________ Fax:_________________________ E-mail:______________________________________

About the Installer:

Name:__________________________________________________________________________________________________

Address:______________________________________City:_________________________ State:_________Zip Code:_________

Phone:__________________________Fax:_________________________ E-mail:______________________________________

Purchased From (if different than installer):

Name:__________________________________________________________________________________________________

Address:______________________________________City:_________________________ State:__________Zip Code:________

Phone:_________________________ Fax:_________________________ E-mail:______________________________________

About your Heater:

Model#:_______________________ Serial #:___________________________ Fuel:____________ Installation Date:__________

Type of Installation (check one):

o Automotive o Manufacturing o Warehouse o Recreational o Aircraft

o Public Building o Office o Retail o Agricultural o Other______________

Mail or Fax to:

Roberts Gordon LLC •1250 William Street, P.O. Box 44 • Buffalo, NY 14240-0044 • Phone: 716-852-4400 • Fax: 716-852-0854

Toll Free: 800-828-7450 • www.rg-inc.com

Installation Code and Annual Inspections: All installation and service of ROBERTS GORDON® equipment must be performed by a

contractor qualified in the installation and service of equipment sold and supplied by Roberts-Gordon and conform to all

requirements set forth in the ROBERTS GORDON

®

manuals and all applicable governmental authorities pertaining to the

installation, service and operation of the equipment.

To help facilitate optimum performance and safety, Roberts-Gordon recommends that a qualified contractor conduct, at a

minimum, annual inspections of your ROBERTS GORDON

®

equipment and perform service where necessary, using only

replacement parts sold and supplied by Roberts-Gordon.

These products are not for residential use.

This product is intended to assist licensed professionals in the exercise of their professional judgment.

© 2009 Roberts-Gordon LLC - All rights reserved. No part of this work covered by the copyrights

herein my be reproduced or

copied in any form or by any means – graphic, electronic, or mechanical, including photcopying, recording, taping, or information

storage and retrieval systems – without written permission of Roberts Gordon LLC. Printed in

the U.S.A.

Page 48

Page 49

Page 50

Infrared Heating

Maintain clearance

to the side and

clearance below

the heater from vehicles

and combustible materials.

www.rg-inc.com Printed in U.S.A. P/N 91037912 Rev. H

Attach this information to a wall near the ROBERTS GORDON

®

heater.

Read the Installation, Operation, and Service Manual thoroughly before installation, operation, or service.

Know your model number and installed configuration.

Model number and installed configuration are found on the burner and in the Installation, Operation and Service Manual.

Write the largest clearance dimensions with permanent ink according to your model number and configuration in the open spaces below.

OPERATING INSTRUCTIONS

1. STOP! Read all safety instructions on this information sheet.

2. Open the manual gas valve in the heater supply line.

3. Turn on electric power to the heater.

4. Set the thermostat to desired setting.

1. Set the thermostat to off or the lowest setting.

1. Set the thermostat to off or the lowest setting.

2. Turn off electric power to the heater.

3. Turn off the manual gas valve in the heater supply line.

4. Call your registered installer/contractor qualified in the

installation and service of gas-fired heating equipment.

IF THE HEATER WILL NOT OPERATE, TO ENSURE YOUR SAFETY,

FOLLOW THESE INSTRUCTIONS TO SHUT DOWN YOUR HEATER

Fire Hazard

Keep all flammable objects, liquids and vapors the minimum

required clearances to combustibles away from heater.

Some objects will catch fire or explode when placed close to

heater.

Failure to follow these instructions can result in death, injury

or property damage.

TO TURN OFF THE HEATER

Service Telephone: +44 (0)121 506 7709

Service Fax: +44 (0)121 506 7702

E-mail: uksales@rg-inc.com

E-mail: export@rg-inc.com

Roberts-Gordon LLC

1250 William Street

P.O. Box 44

Buffalo, NY 14240-0044 USA

Telephone: 716.852.4400

Fax: 716.852.0854

Toll Free: 800.828.7450

WARNING

Roberts-Gordon Europe Limited

Unit A, Kings Hill Business Park

Darlaston Road, Wednesbury

West Midlands WS10 7SH UK

Telephone: +44 (0)121 506 7700

Fax: +44 (0)121 506 7701

®

Installation Code and Annual Inspections:

All installation and service of ROBERTS GORDON® equipment must be performed by a contractor qualified in the installation and service of equipment sold and supplied by Roberts-Gordon and

conform to all requirements set forth in the ROBERTS GORDON

®

manuals and all applicable governmental authorities pertaining to the installation, service and operation of the equipment. To help

facilitate optimum performance and safety, Roberts-Gordon recommends that a qualified contractor conduct, at a minimum, annual inspections of your ROBERTS GORDON

®

equipment and

perform service where necessary, using only replacement parts sold and supplied by Roberts-Gordon.

Further Information: Applications, engineering and detailed guidance on systems design, installation and equipment performance is available through ROBERTS GORDON® representatives.

Please contact us for any further information you may require, including the Installation, Operation and Service Manual.

This product is not for residential use.

© 2009 Roberts-Gordon LLC All rights reserved. No part of this work covered by the copyrights herein may be reproduced or copied in any form or by any means – graphic, electronic, or mechanical, including photocopying,

recording, taping, or information storage and retrieval s

ystems – without written permission of Roberts-Gordon LLC.

Loading...

Loading...