Page 1

WARNING

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. DO NOT try to light any appliance.

3. DO NOT use electrical switches.

4. DO NOT use any telephone in

your building.

5. Extinguish any open flame.

6. Leave the building.

7. Immediately call your local gas

supplier after leaving the building.

Follow the gas supplier’s

instructions.

8. If you cannot reach your gas

supplier, call the Fire Department.

Fire Hazard

Keep all flammable objects, liquids and

vapors the minimum required clearances to combustibles away from

heater.

Some objects will catch fire or explode

when placed close to heater.

Failure to follow these instructions can

result in death, injury or property

damage.

WARNING

Installation must be done by a registered installer/

contractor qualified in the installation and service

of gas-fired heating equipment or your gas supplier.

Improper installation, adjustment, alteration, service

or maintenance can result in death, injury or

property damage. Read the installation, operation

and service manual thoroughly before installing or

servicing this equipment.

®

Blackheat

HE

Vacuum Assisted

Linear, Double Linear,

U-Tube, and Multi-Burner

Gas Fired Heating Systems

Installation, Operation &

Service Manual

HE15UT

HE20UT

HE25UT

HE30UT

HE15ST

HE20ST

HE25ST

HE30ST

HE30DL

HE40DL

HE50DL

HE60DL

© 2010 Roberts-Gordon LLC

HE35UT

HE40UT

HE45UT

HE50UT

HE35ST

HE40ST

HE45ST

HE50ST

HE70DL

IP55 Protected Burner Box

Installer

Please take the time to read and understand

these instructions prior to any installation.

Installer must give a copy of this manual to the owner.

Owner

Keep this manual in a safe place in order to provide

your serviceman with necessary information.

Roberts-Gordon Europe Limited

Unit A, Kings Hill Business Park

Darlaston Road, Wednesbury

West Midlands WS10 7SH UK

Telephone: +44(0)121 506 7700

Fax: +44(0)121 506 7701

Service Telephone: +44(0)121 506 7709

Service Fax: +44(0)121 506 7702

E-mail: uksales@rg-inc.com

E-mail: export@rg-inc.com

www.rg-inc.com

170102UK Rev E 09/10

Page 2

Page 3

TABLE OF CONTENTS

© 2010

Roberts-Gordon Europe Limited

All rights reserved. No part of this work covered by the copyrights herein may be reproduced

or copied in any form or by any means - graphic, electronic, or mechanical, including

photocopying, recording, taping or information storage and retrieval systems - without the

written permission of Roberts-Gordon Europe Limited.

SECTION 1: Heater Safety ............................................2

1.1 Manpower Requirements ....................................2

1.2 IP55 Protection....................................................2

1.3 Safety Labels and Their Placement ....................2

SECTION 2: Installer Responsibility............................4

2.1 Low Level User Instructions................................4

2.2 Corrosive Chemicals...........................................4

2.3 National Standards and Applicable Codes .........4

SECTION 3: Clearances To Combustibles..................5

3.1 Required Clearances to Combustibles ...............5

3.2 Clearances Data - Linear and Double Linear .....6

3.3 Clearances Data - U-Tube ..................................8

SECTION 4: Major Component Descriptions............ 10

SECTION 5: General Suspension Details ................. 11

SECTION 6: Linear & Double Linear Heater

Installation .............................................. 13

6.1 Linear Standard Parts List ................................13

6.2 Double Linear Standard Parts List....................16

6.3 Burner Tube Installation ...................................19

6.4 Coupling and Tube Assembly...........................19

6.5 Tube Clamp Package Installation .....................21

6.6 Reflector Installation .........................................22

6.7 Double Linear Tee Installation

(For Double Linear Heaters Only) .....................24

SECTION 7: U-tube Heater Installation .....................25

7.1 U-tube Standard Parts List ................................25

7.2 U-tube Hanger Placement ................................29

7.3 Burner Tube and Fan Tube Installation ............29

7.4 U-tube Support Bracket Assembly

Installation.........................................................30

7.5 Coupling and Tube Assembly...........................31

7.6 Tube Installation ...............................................32

7.7 U-tube Installation.............................................32

7.8 Reflector Installation .........................................33

SECTION 8: Multiburner Configuration &

Installation ..............................................35

8.1 Initial Assembly.................................................35

SECTION 9: Burner & Fan Installation ......................37

9.1 Burner Installation.............................................37

9.2 Standard Fan Assembly ...................................37

9.3 IP55 Fan Assembly...........................................38

9.4 Linear & U-tube Fan Installation .......................38

9.5 Double Linear Fan Installation ..........................39

9.6 Multiburner 83/90 BWLG Fan Assembly

(Horizontal and Vertical Outlets).......................40

9.7 Condensate Drain Assembly ............................40

SECTION 10: Optional Heater Accessories ..............41

10.1 Reflector Side Extension Installation...............42

10.2 U-Tube Cover Installation................................43

10.3 Decorative Grille Installation ...........................44

10.4 Protective Grille Installation.............................45

10.5 Sports Hall Guard Installation.........................46

10.6 Undershield Installation ..................................47

10.7 Wall Mounting .................................................48

SECTION 11: Venting and Fresh Air Supply ............. 49

11.1 Type C12 , C32 & C62 Appliance ....................49

11.2 Type B22 Appliance.........................................49

11.3 Flue Installation ............................................... 49

11.4 Ventilation Requirements................................. 49

11.5 Fresh Air Supply .............................................. 49

11.6 Outside Combustion Air Supply....................... 50

11.7 Common Duct ................................................. 51

SECTION 12: Gas Piping ............................................ 52

SECTION 13: Wiring.................................................... 54

13.1 Typical External Wiring Diagram

(Linear or U-Tube) .......................................... 54

13.2 Typical External Wiring Diagram

Double Linear Option 1) ................................. 55

13.3 Typical External Wiring Diagram

(Double Linear Option 2) ................................55

13.4 Typical External Wiring Diagram

(Multiburner) ................................................... 55

13.5 Internal Wiring Diagram ................................. 56

SECTION 14: Operation..............................................57

14.1 Heater Lockout Indication (Optional) .............. 57

14.2 Testing ............................................................58

14.3 Commissioning (Multiburner)..........................58

14.4 System Checks ............................................... 58

14.5 User Instructions.............................................58

SECTION 15: Servicing Instructions .........................59

15.1 Annual Procedure ...........................................59

15.2 Sealing Gaskets ............................................. 59

15.3 Component Removal......................................59

15.4 Maintenance Checklist.................................... 60

SECTION 16: Troubleshooting................................... 62

16.1 Troubleshooting Flow Chart (Linear, Double

Linear and U-Tube)......................................... 63

16.2 Troubleshooting Flow Chart (Multiburner) ...... 65

16.3 Manifold Gas Pressure Setting .......................67

SECTION 17: Replacement Parts............................... 68

17.1 Replacement Packages................................... 70

SECTION 18: Specifications....................................... 71

18.1 Material Specifications .................................... 71

18.2 Heater Specifications......................................71

18.3 Venting Specifications.....................................71

18.4 Suspension Specifications..............................71

18.5 Controls Specifications ................................... 71

18.6 Linear Heater..................................................72

18.7 Double Linear Heater...................................... 72

18.8 U-tube Heater ................................................. 72

18.9 Burner Specifications......................................73

Printed in U.K.

Page 4

Page 5

TABLE OF FIGURES

Figure 1: Bottom and Back Panel Label Placement ........2

Figure 2: Control Side Label Placement..........................3

Figure 3: Linear & Double Linear, Horizontal Mounts......6

Figure 4: Linear & Double Linear, One Side Reflector ....6

Figure 5: Linear & Double Linear, Two Side Reflectors ...6

Figure 6: Linear & Double Linear, 45° Mount ..................6

Figure 7: Linear & Double Linear, 2 Foot Deco Grille,

Protective Grille ................................................7

Figure 8: Undershield .....................................................7

Figure 9: Linear & Double Linear, Venting.......................7

Figure 10: U-Tube, Horizontal Mount...............................8

Figure 11: U-Tube, One Side Reflector............................8

Figure 12: U-Tube, Two Side Reflectors ..........................8

Figure 13: U-Tube, Full 45° Mount...................................8

Figure 14: U-Tube, Opposite 45° Tilt ...............................9

Figure 15: U-Tube, Protective Grille.................................9

Figure 16: U-Tube, Venting ..............................................9

Figure 17: Critical Hanger Placement ...........................12

Figure 18: Linear General Assembly Overview .............14

Figure 19: Linear Layout Overview................................15

Figure 20: Double Linear General Assembly

Overview ...................................................... 17

Figure 21: Double Linear Layout Overview ................... 18

Figure 22: BLACKHEAT

Overview ......................................................27

Figure 23: BLACKHEAT

Overview ......................................................28

Figure 24: Multiburner Damper Flange Installation .......35

Figure 25: Typical Manifold Layout

(Linear and U-Tube Configuration) ...............36

Figure 26: U-tube (Horizontal).......................................48

Figure 27: U-tube (Angle Mounted)...............................48

Figure 28: Linear ...........................................................48

Figure 29: Individual Flue Connection Detail.................50

Figure 30: Flue Connection Dimensions .......................50

Figure 31: Air Supply with Flue Configurations .............51

Figure 32: Gas Connection with Stainless Steel Flex

Connector.....................................................53

Figure 33: Sequence of Operation Chart ......................57

Figure 34: Burner Cup Position.....................................60

Figure 35: BLACKHEAT

Specifications ...............................................73

®

HE U-tube Assembly

®

HE U-tube Layout

®

HE Linear and U-tube

Page 6

Page 7

ROBERTS GORDON® appliances have been tested and CE certified as complying with the essential

requirements of the Gas Appliance Directive, the Low Voltage Directive, the Electromagnetic

Compatibility Directive and the Machinery Directive for use on natural gas and LPG when installed,

commissioned and maintained in accordance with these instructions.

These instructions refer to appliances designed to operate in the European Union.

Appliances designed for other countries (Non-European Union) are available on request.

This appliance must be installed in accordance with the local and national codes in force and used

only in a sufficiently ventilated space, as specified in these instructions.

Before installation, check that the local gas distribution systems, nature of gas and pressure, and

adjustment of the appliance are compatible.

Product Approval

1 of 73

Page 8

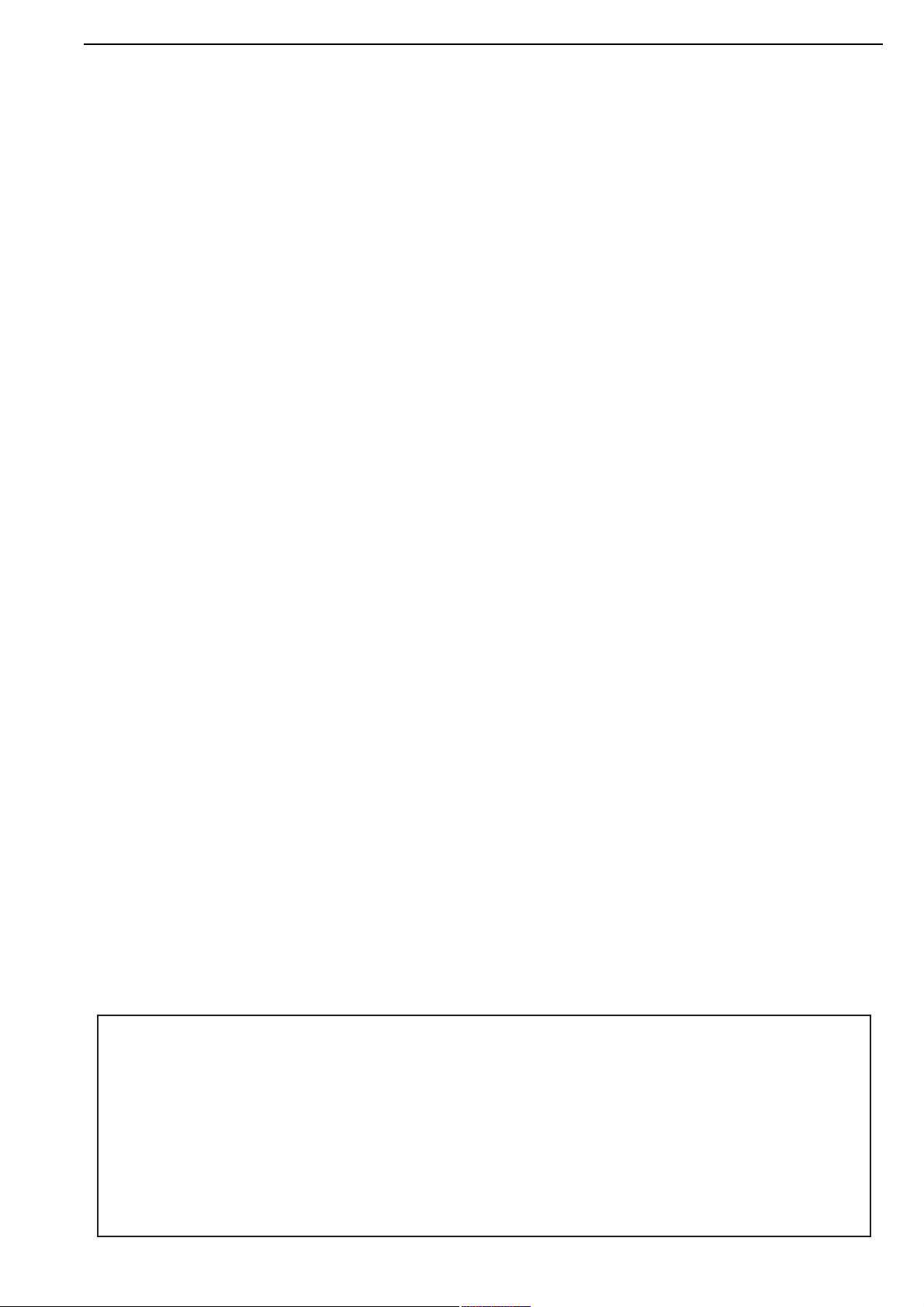

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

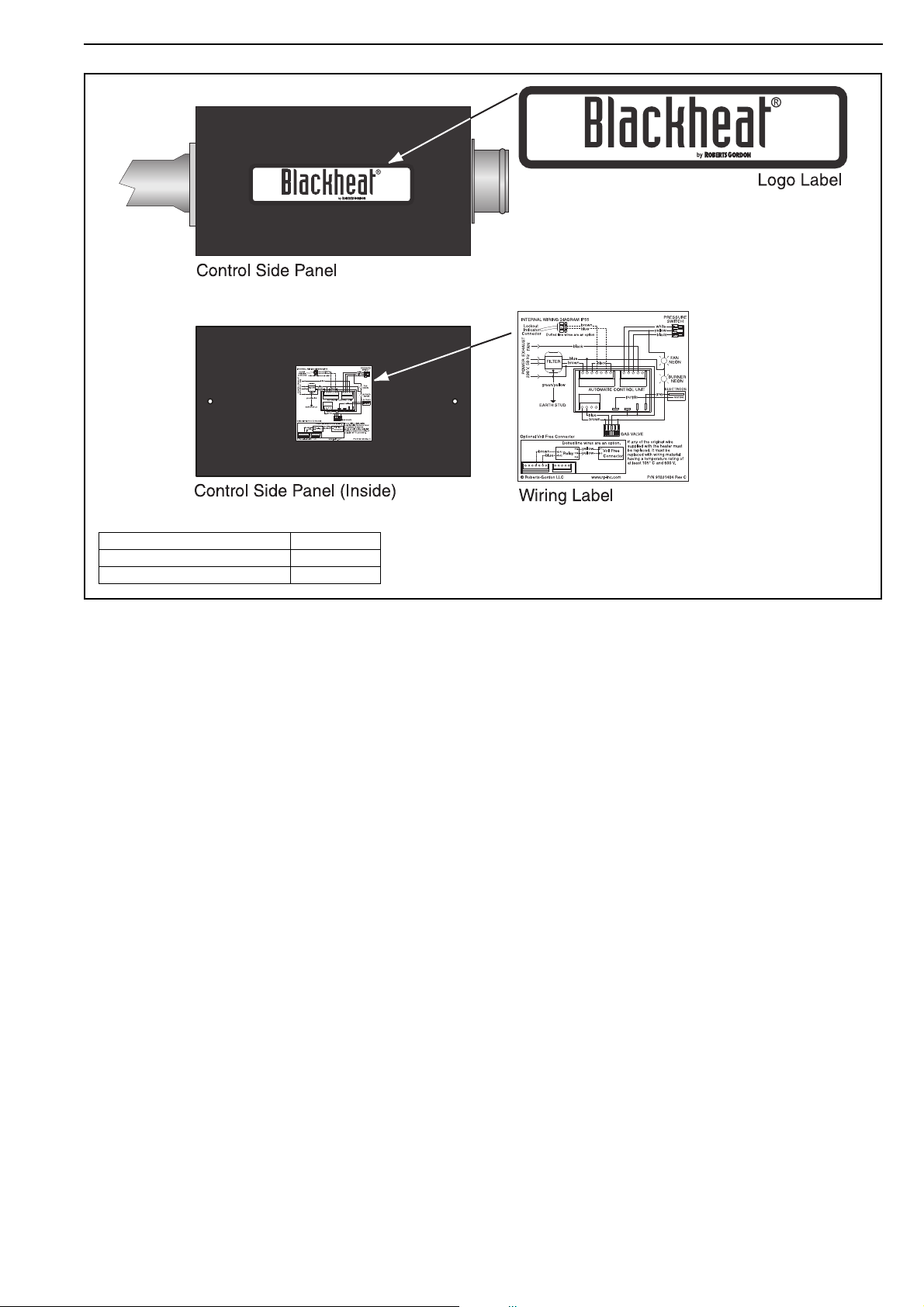

Logo Label

Fan/Burner Label

Bottom Panel

Rating Plate Label

Back Panel

Model No.

Serial No.

Appliance Type

Gas Pressure

at Manifold

Normal Input Rating

(Net Calorific Value)

Min. Input Rating

(Net Calorific Value)

Country of

Destination

Year of

Production

Category

Orifice Size

Electrical

Rating

V

Hz

W

Gas Type

Infrared Radiant Tube Heater

This applicance must be installed in accordance with the

rules in force, and used only in a sufficiently ventilated space.

Consult instructions before installation and use of this applicance.

0063

Model No.

Serial No.

Appliance Type

Gas Pressure

at Manifold

Normal Input Rating

(Net Calorific Value)

Min. Input Rating

(Net Calorific Value)

Country of

Destination

Year of

Production

Category

Orifice Size

Electrical

Rating

V

Hz

W

Gas Type

Infrared Radiant Tube Heater

This applicance must be installed in accordance with the

rules in force, and used only in a sufficiently ventilated space.

Consult instructions before installation and use of this applicance.

0063

Description Part Number

Logo Label 91033200

Rating Plate Label 91031300

Fan/Burner Label 91033300

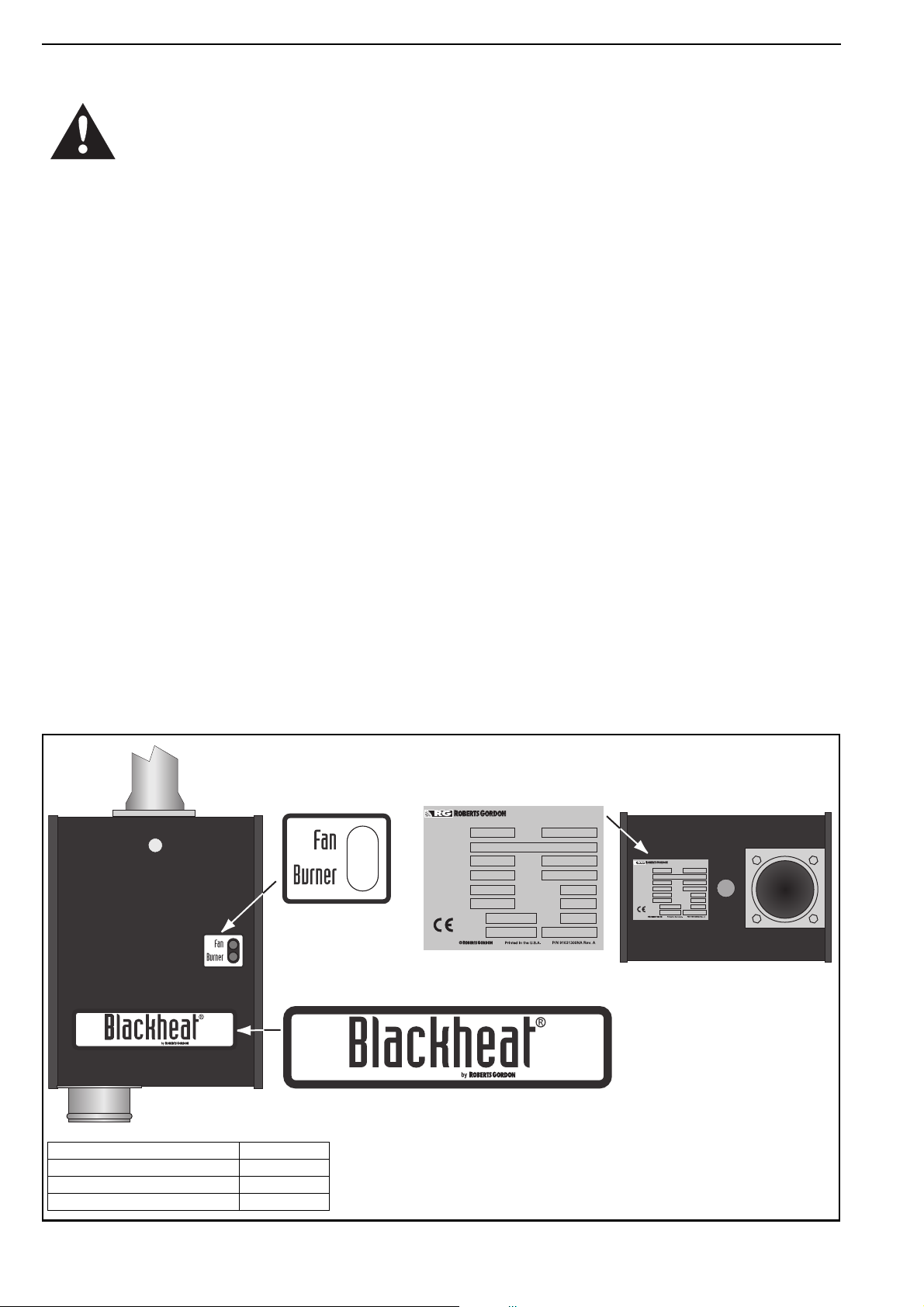

SECTION 1: HEATER SAFETY

Your Safety is Important to Us!

This symbol is used throughout the manual

to notify you of possible fire, electrical or burn

hazards. Please pay special attention when

reading and following the warnings in these

sections.

Installation, service and annual inspection of heater must

be done by a registered installer/contractor qualified in

the installation and service of gas-fired heating

equipment.

Read this manual carefully before installation, operation

or service of this equipment.

This heater is designed for heating nonresidential indoor

spaces. Do not install in residential spaces. These

instructions, the layout drawing, local codes and

ordinances, and applicable standards that apply to gas

piping, electrical wiring, venting, etc. must be thoroughly

understood before proceeding with the installation.

Protective gear is to be worn during installation, operation

and service. Thin sheet metal parts, such as the reflector

portion of the heater and the various venting

components, have sharp edges. To prevent injury, the use

of work gloves is recommended. The use of gloves will

also prevent the transfer of body oils from the hands to

the surface of the reflector.

Before installation, check that the local distribution

conditions, nature of gas and pressure, and adjustment of

the appliance are compatible.

The heater must be applied and operated under the

general concepts of reasonable use.

For additional copies of the Installation, Operation and

Service Manual, please contact Roberts-Gordon LLC.

Figure 1: Bottom and Back Panel Label Placement

1.1 Manpower Requirements

To p re vent personal injury and damage to the heater, two

persons will be required for installation.

1.2 IP55 Protection

The burner is certified to protection class of IP55. This

means that the internal components of the burner are

protected against extreme dusty atmosphere and water

jets from all sides. Outside air supply and flue are

mandatory for this heater. The standard exhaust fans

mentioned in this manual do NOT have IP55 protection

and must be outside the wet environment. If the fan is to

be installed in the wet environment, a special IP54

protected fan must be used. Consult Roberts-Gordon

LLC for alternative exhaust fans. Optional stainless steel

burner box provides long life in the most corrosive

applications. Always ensure that the environment to be

heated is not of an explosive or flammable nature. For

more information, please consult your ROBERTS

GORDON

®

independent distributor.

In order to have trouble free performance of your heater

and maintain the IP55 protection, follow all instructions in

this manual, especially the replacement of sealing

gaskets.

1.3 Safety Labels and Their Placement

Product safety signs or labels should be replaced by the

product user when they are no longer legible. Please

contact Roberts-Gordon LLC or your ROBERTS

GORDON

signs or labels. See Page 2, Figure 1 through Page 3,

Figure 2.

®

independent distributor to obtain replacement

2 of 73

Page 9

Figure 2: Control Side Label Placement

Description Part Number

Logo Label 91033200

Wiring Diagram Label 91031404

SECTION 1: HEATER SAFETY

3 of 73

Page 10

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

CAUTION

Product Damage Hazard

Do not use heater in area containing

corrosive chemicals.

Refer to appropriate Material Safety Data

Sheets (MSDS).

Failure to follow these instructions can result

in product damage.

SECTION 2: INSTALLER RESPONSIBILITY

• To install the heater, as well as the gas and electrical

supplies, in accordance with applicable specifications

and codes. Roberts-Gordon LLC recommends the

installer contact a local Building Inspector or Fire

Marshal for guidance.

• To use the information given in a layout drawing and

in the manual together with the cited codes and

regulations to perform the installation.

• To install the heater in accordance with the

clearances to combustibles.

• To furnish all needed materials not furnished as

standard equipment.

• To plan location of supports.

• To provide access to burners for servicing on all

sides, for burner removal.

• To provide the owner with a copy of this Installation,

Operation and Service Manual.

• To never use heater as support for ladder or other

access equipment and never hang or suspend

anything from heater.

• To ensure there is adequate air circulation around the

heater and to supply air for combustion, ventilation

and distribution in accordance with local codes.

• To safely and adequately install heater using materials with a minimal working load of 33 kg.

• To ensure the heater is placed in an approved

application.

2.1 Low Level User Instructions

In all situations, clearances to combustibles must be

maintained. Signs should be posted in storage areas to

specify the maximum stacking height of items placed

below heater to maintain required clearances to

combustibles. Minimum clearances must be maintained

from vehicles parked below the heater. Caution should be

used when running the system near combustible

materials such as wood, paper, rubber, etc. Consideration

should be given to partitions, storage racks, hoists,

building construction, etc.

A laminated wall tag is available for the heater as a

permanent reminder of the safety instructions and the

importance of the required clearances to combustibles.

Please contact Roberts-Gordon or your ROBERTS

GORDON

Affix the tag by peeling off the backing of the adhesive

strips on the rear surface and position the tag on a wall

near the heater (e.g. thermostat).

A copy of the wall tag (P/N 91037912) is illustrated on the

back cover. This copy of the wall tag can be affixed on the

wall near the heater. Know your model number and

installed configuration. Model number and installed

configuration are found on the burner and in the

Installation, Operation and Service Manual. Write the

largest clearance dimensions with permanent ink

according to your model number and configuration in the

open spaces on the tag.

®

independent distributor to obtain the wall tag.

2.2 Corrosive Chemicals

Roberts-Gordon LLC cannot be responsible for ensuring

that all appropriate safety measures are undertaken prior

to installation; this is entirely the responsibility of the

installer. It is essential that the contractor, the subcontractor, or the owner identifies the presence of

combustible materials, corrosive chemicals or

halogenated hydrocarbons* anywhere in the premises.

* Halogenated Hydrocarbons are a family of chemical

compounds characterized by the presence of halogen

elements (fluorine, chlorine, bromine, etc.). These compounds are frequently used in refrigerants, cleaning

agents, solvents, etc. If these compounds enter the air

supply of the burner, the lifespan of the heater components will be greatly reduced. An outside air supply must

be provided to the burners whenever the presence of

these compounds is suspected. Warranty will be invalid

if the heater is exposed to halogenated hydrocarbons.

2.3 National Standards and Applicable Codes

All appliances must be installed in accordance with the

latest revision of the applicable standards and national

codes. This refers also to the electric, gas and venting

installation. Note: Additional standards for installations in

Public Garages, Aircraft Hangars, etc. may be applicable.

The heater must not be operated in environmental

temperatures below 0° C.

4 of 73

Page 11

SECTION 3: CLEARANCES TO COMBUSTIBLES

WARNING

Fire Hazard

Keep all flammable objects, liquids and

vapors the minimum required clearances to

combustibles away from heater.

Some objects will catch fire or explode when

placed close to heater.

Failure to follow these instructions can result

in death, injury or property damage.

SECTION 3: CLEARANCES TO COMBUSTIBLES

3.1 Required Clearances to Combustibles

Clearances are the required distances that combustible

objects must be away from the heater to prevent fire

hazards. Caution should be used when running the

system near combustibles. Combustibles are materials

that may catch on fire and include common items such as

wood, paper, rubber, fabric, etc. Maintain clearances to

combustibles at all times for safety.

Clearances for all heater models are located on Page 6,

Figure 3 through Page 9, Figure 16 in this manual. Check

the clearances on each burner for the model heater being

installed to make sure the product is suitable for your

application and the clearances are maintained. Read and

follow the safety guidelines below:

• Keep petrol or other combustible materials including

flammable objects, liquids, dust or vapours away from

this heater or any other appliance.

• The stated clearances to combustibles represents a

surface temperature of 32°C (90° F) above room tem-

perature. Building materials with a low heat tolerance

(such as plastics, vinyl siding, canvas, tri-ply, etc)

may be subject to degradation at lower temperatures.

It is the installer’s responsibility to assure that adjacent materials are protected from degradation.

• Maintain clearances from heat sensitive equipment

and workstations.

• Maintain clearances from vehicles parked below the

heater.

• Maintain clearances from swinging and overhead

doors, overhead cranes, vehicle lifts, partitions,

storage racks, hoists, building construction, etc.

• In locations used for the storage of combustible materials, signs must be posted to specify the

maximum permissible stacking height to maintain

required clearances from the heater to the

combustibles. Signs must be posted adjacent to the

heater thermostat. In the absence of a thermostat,

signs must be posted in a conspicuous location.

• Consult local Building Inspector, Fire Insurance

Carrier or other authorities for approval of proposed

installation when there is a possibility of exposure to

combustible airborne materials or vapours.

• Hang heater in accordance to the minimum

suspension requirements on Page 11, Section 5.

5 of 73

Page 12

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

A

C

D

B

A

C

D

B

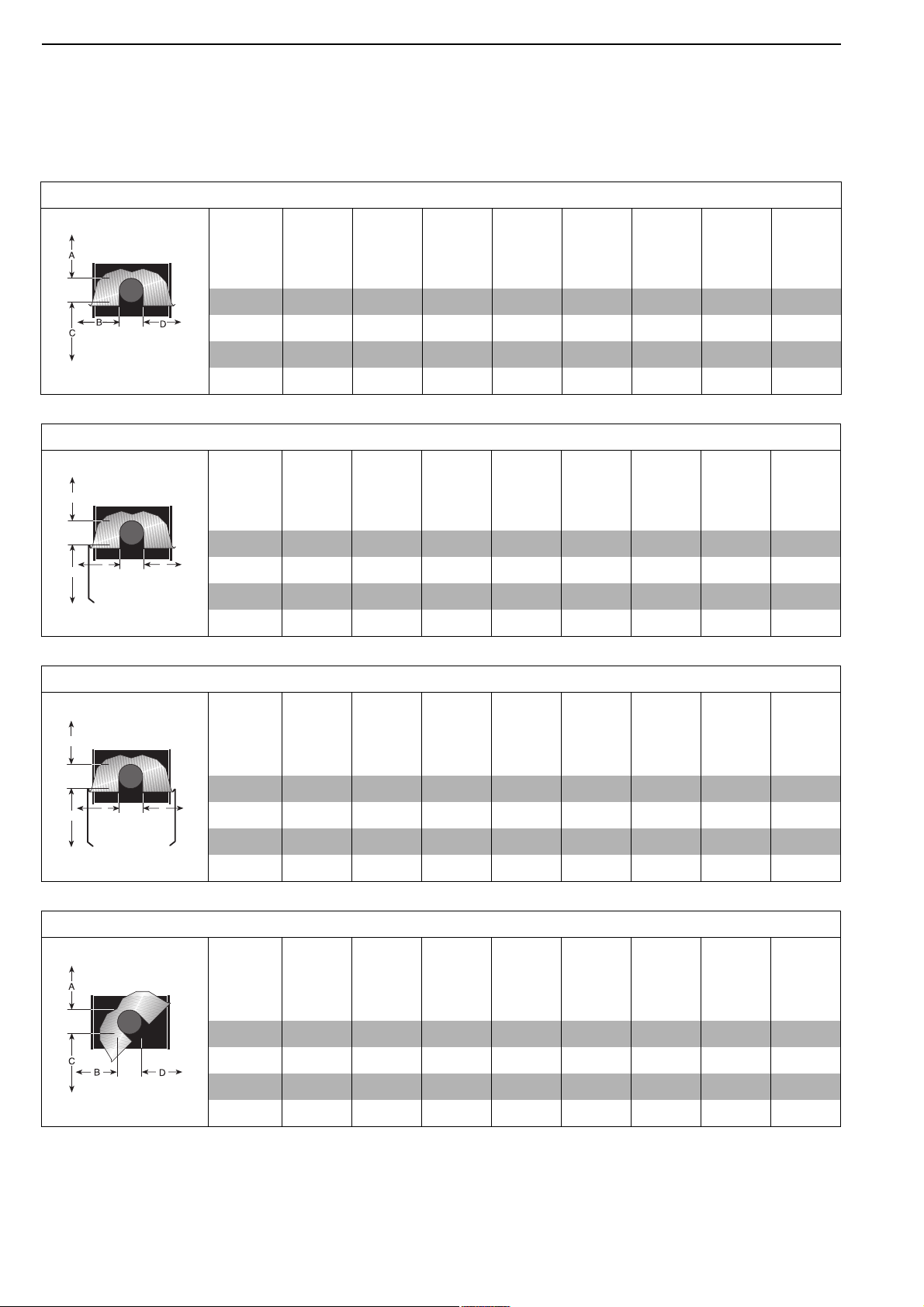

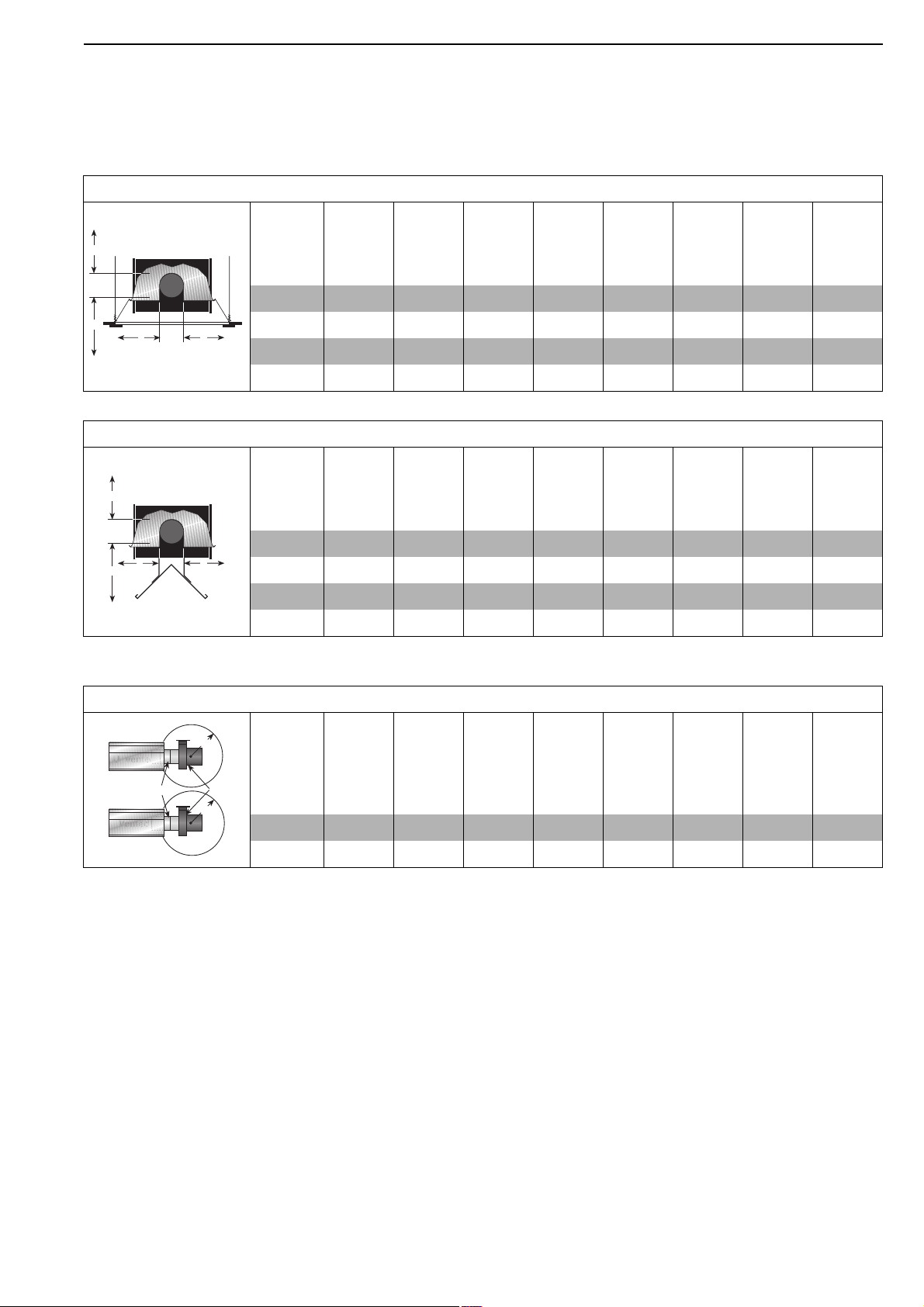

3.2 Clearances Data - Linear and Double Linear

NOTE: 1. All dimensions are from the surfaces of all tubes, couplings, tees, elbows and crosses.

2. Clearances B, C and D can be reduced by 50% after 7500 mm of tubing downstream

from the burner.

3. All measurements are in millimeters.

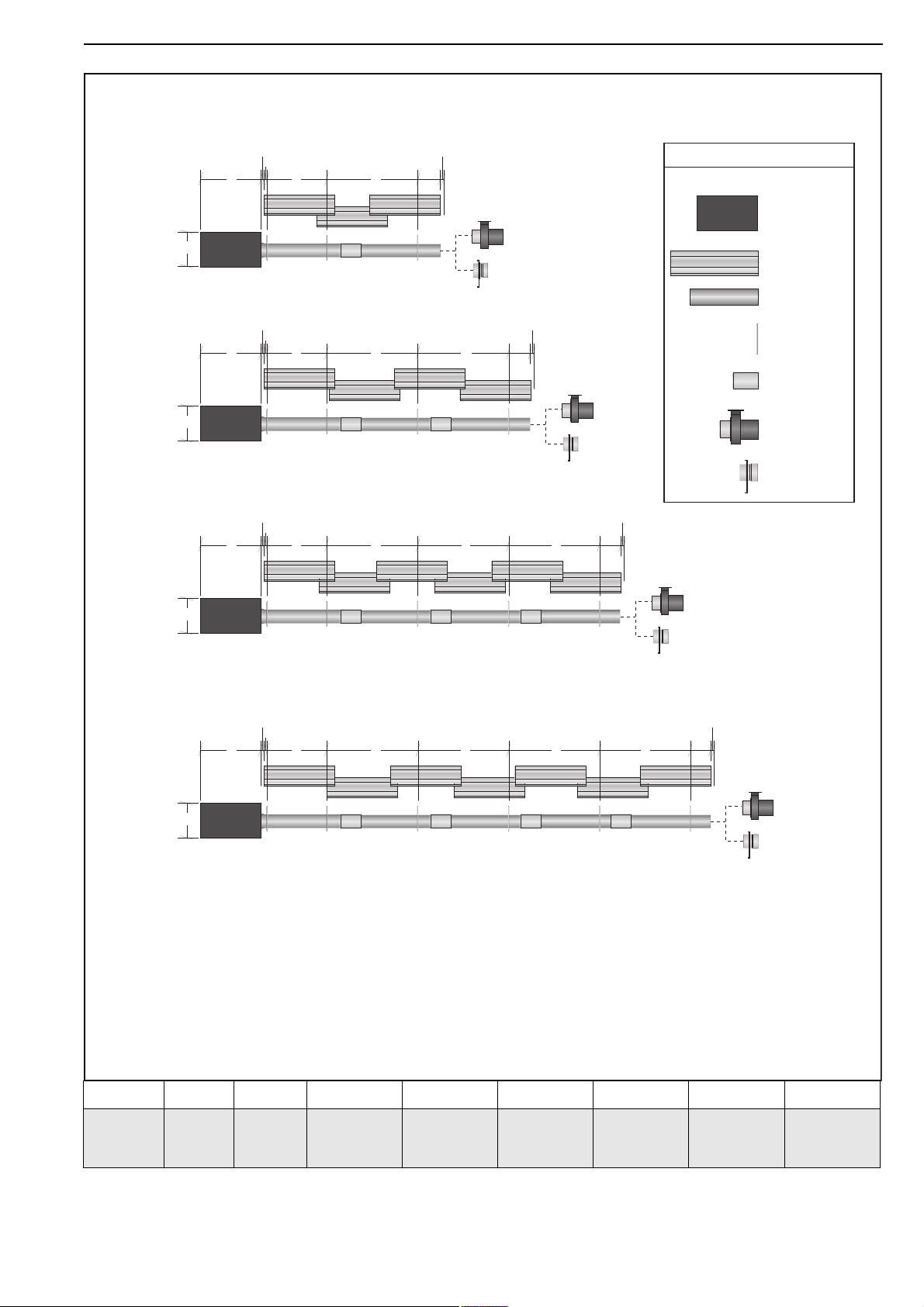

FIGURE 3: LINEAR & DOUBLE LINEAR, HORIZONTAL MOUNTS

Model

A 150 150 150 150 150 150 200 200

B 890 970 970 1020 1170 1220 1280 1330

C 1570 1650 1650 1780 1930 1970 2010 2080

D 890 970 970 1020 1170 1220 1280 1330

HE15ST

HE30DL

HE20ST

HE40DL

HE25ST

HE50DL

HE30ST

HE60DL

FIGURE 4: LINEAR & DOUBLE LINEAR, ONE SIDE REFLECTOR

Model

A 150 150 150 150 150 150 200 200

B 230 230 230 230 230 230 230 230

C 1580 1760 1760 1930 2090 2130 2160 2240

D 1200 1380 1380 1500 1660 1710 1760 1860

HE15ST

HE30DL

HE20ST

HE40DL

HE25ST

HE50DL

HE30ST

HE60DL

FIGURE 5: LINEAR & DOUBLE LINEAR, TWO SIDE REFLECTORS

HE35ST

HE35ST

HE70DL

HE70DL

HE40ST

HE40ST

HE45ST

HE45ST

HE50ST

HE50ST

Model

A 150 150 150 150 150 150 200 200

B 590 640 640 690 820 860 890 1020

C 1660 1810 1810 1960 2110 2160 2210 2320

D 590 640 640 690 820 860 890 1020

HE15ST

HE30DL

FIGURE 6: LINEAR & DOUBLE LINEAR, 45° MOUNT

Model

A 200 200 200 250 250 275 300 300

B 200 200 200 200 200 200 200 200

C 1500 1660 1660 1860 1960 2030 2110 2160

D 1370 1520 1520 1630 1750 1820 1880 2000

HE15ST

HE30DL

HE20ST

HE40DL

HE20ST

HE40DL

HE25ST

HE50DL

HE25ST

HE50DL

HE30ST

HE60DL

HE30ST

HE60DL

HE35ST

HE70DL

HE35ST

HE70DL

HE40ST

HE40ST

HE45ST

HE45ST

HE50ST

HE50ST

6 of 73

Page 13

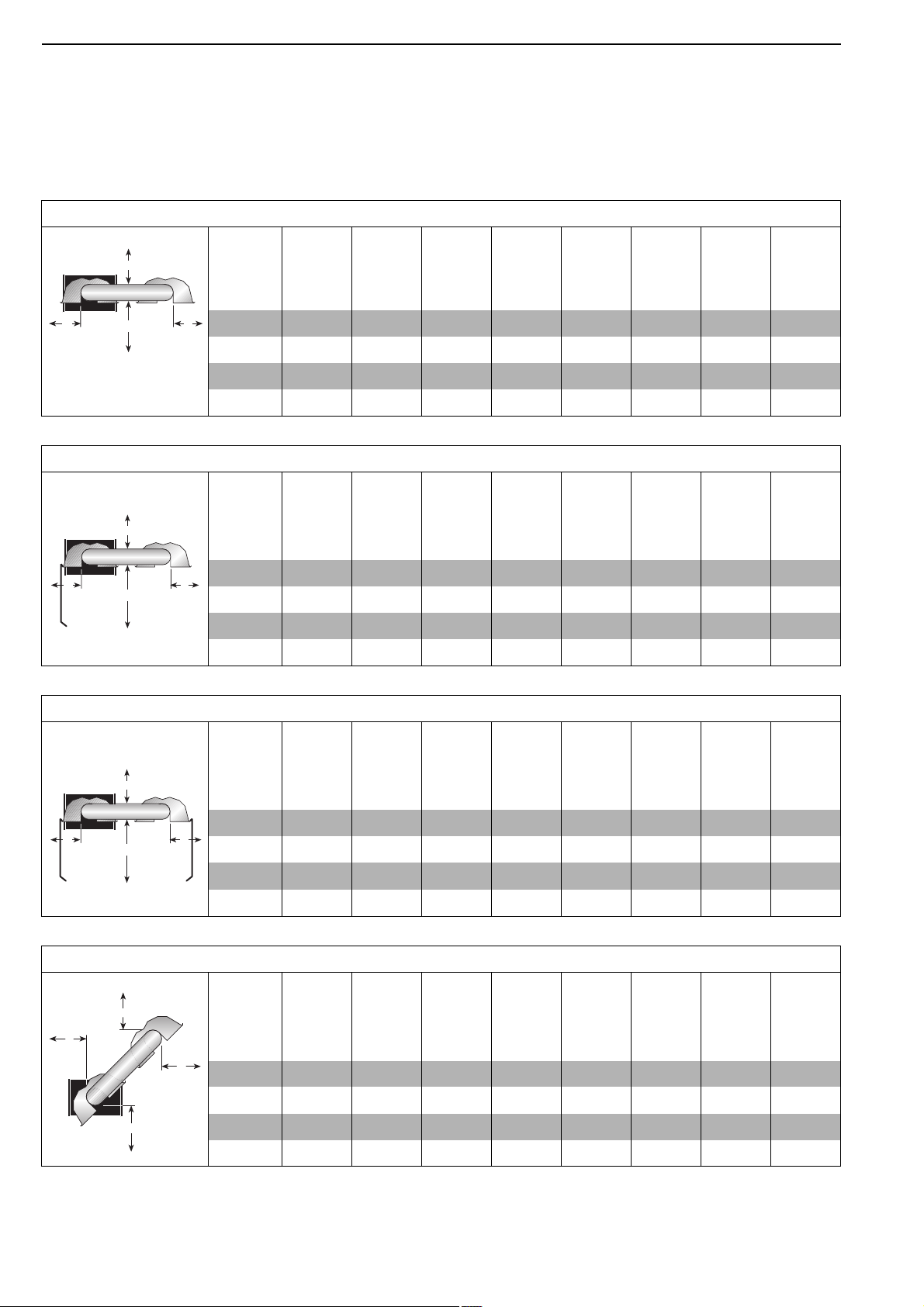

SECTION 3: CLEARANCES TO COMBUSTIBLES

A

C

D

B

A

C

D

B

Radiant tubes

Fan

Unvented

Vented

E

F

NOTE: 1. All dimensions are from the surfaces of all tubes, couplings, tees, elbows and crosses.

2. Clearances B, C and D can be reduced by 50% after 7500 mm of tubing downstream

from the burner.

3. All measurements are in millimeters.

FIGURE 7: LINEAR & DOUBLE LINEAR, 2 FOOT DECO GRILLE, PROTECTIVE GRILLE

Model

HE15ST

HE30DL

HE20ST

HE40DL

A 150 150 150 150 150 150 200 200

B 890 970 970 1020 1170 1220 1280 1330

C 1570 1650 1650 1780 1930 1970 2010 2080

D 890 970 970 1020 1170 1220 1280 1330

FIGURE 8 : UNDERSHIELD **

Model

A 150 150 150 150 150 150 - -

B 990 1020 1270 1270 1370 1400 - -

C 840 965 11 20 11 2 0 1220 1270 - -

D 990 1020 1270 1270 1370 1400 - -

** When installed in the first 3 m.

HE15ST

HE30DL

HE20ST

HE40DL

FIGURE 9: LINEAR & DOUBLE LINEAR, VENTING

HE25ST

HE50DL

HE25ST

HE50DL

HE30ST

HE60DL

HE30ST

HE60DL

HE35ST

HE70DL

HE35ST

HE70DL

HE40ST

HE40ST

HE45ST

HE45ST

HE50ST

HE50ST

Model

HE15ST

HE30DL

HE20ST

HE40DL

HE25ST

HE50DL

HE30ST

HE60DL

HE35ST

HE70DL

HE40ST

HE45ST

HE50ST

E 1000 1000 1000 1000 1000 1000 1000 1000

F 500 500 500 500 500 500 500 500

7 of 73

Page 14

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

A

C

D

B

A

C

D

B

A

C

D

B

B

C

D

A

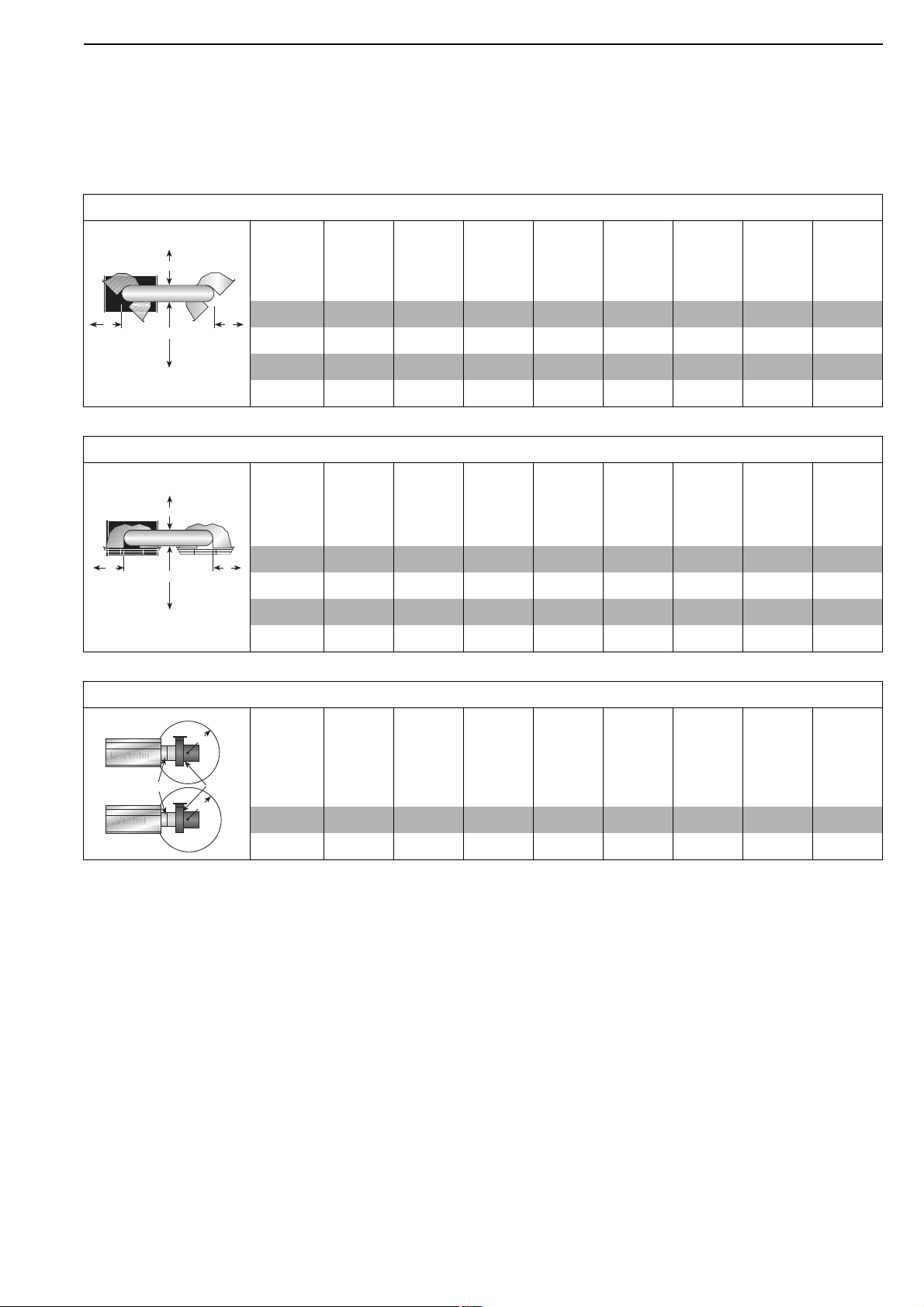

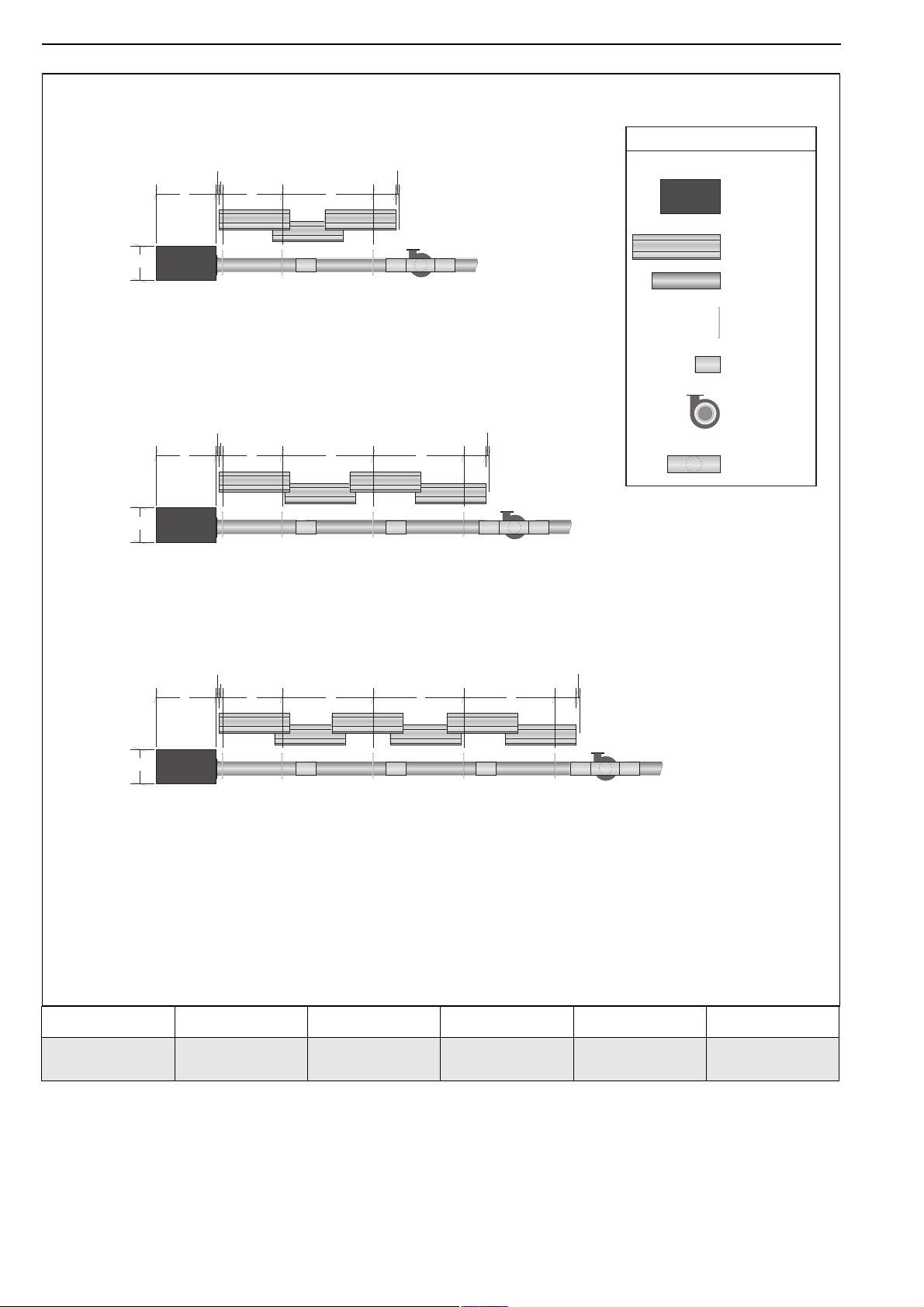

3.3 Clearances Data - U-Tube

NOTE: 1. All dimensions are from the surfaces of all tubes, couplings, tees, elbows and crosses.

2. Clearances B, C and D can be reduced by 50% after 7500 mm of tubing downstream

from the burner.

3. All measurements are in millimeters.

4. Add 60 mm clearance to uncovered u-tube.

.

FIGURE 10: U-TUBE, HORIZONTAL MOUNT

Model

HE15UT

HE20UT

A 150 150 150 150 150 150 200 200

B 890 970 970 1020 1170 1220 1270 1380

C 1580 1730 1730 1910 1980 2050 2110 2210

D 760 940 940 1000 1090 1150 1200 1300

FIGURE 11: U-TUBE, ONE SIDE REFLECTOR

Model

A 150 150 150 150 150 150 200 200

B 230 230 230 230 230 230 230 230

C 1580 1760 1760 1930 2090 2130 2160 2240

D 1200 1380 1380 1500 1660 1710 1760 1860

HE15UT

HE20UT

FIGURE 12: U-TUBE, TWO SIDE REFLECTORS

HE25UT

HE25UT

HE30UT

HE30UT

HE35UT

HE35UT

HE40UT

HE40UT

HE45UT

HE45UT

HE50UT

HE50UT

Model

A 150 150 150 150 150 150 200 200

B 590 640 640 690 820 860 890 1020

C 1660 1810 1810 1960 2110 2160 2210 2320

D 590 640 640 690 820 860 890 1020

FIGURE 13: U-TUBE, FULL 45° MOUNT

Model

A 200 200 200 200 200 200 200 200

B 200 200 200 200 200 200 200 200

C 1500 1650 1650 1860 1960 2040 2110 2160

D 1070 1170 1170 1320 1550 1620 1680 1780

8 of 73

HE15UT

HE15UT

HE20UT

HE20UT

HE25UT

HE25UT

HE30UT

HE30UT

HE35UT

HE35UT

HE40UT

HE40UT

HE45UT

HE45UT

HE50UT

HE50UT

Page 15

NOTE: 1. All dimensions are from the surfaces of all tubes, couplings, tees, elbows and crosses.

A

C

D

B

A

C

D

B

Radiant tubes

Fan

Unvented

Vented

E

F

2. Clearances B, C and D can be reduced by 50% after 7500 mm of tubing downstream

from the burner.

3. All measurements are in millimeters.

4. Add 60 mm clearance to uncovered u-tube.

FIGURE 14: U-TUBE, OPPOSITE 45° TILT

SECTION 3: CLEARANCES TO COMBUSTIBLES

Model

HE15U

A 200 200 200 250 250 275 300 300

B 1370 1530 1530 1630 1780 1830 1880 1930

C 1500 1650 1650 1860 1960 2040 2110 2160

D 560 560 560 560 560 560 560 560

FIGURE 15: U-TUBE, PROTECTIVE GRILLE

Model

A 150 150 150 150 150 150 200 200

B 890 970 970 1020 1170 1220 1270 1380

C 1580 1730 1730 1910 1980 2050 2110 2210

D 760 940 940 1000 1090 1150 1200 1300

HE15UT

FIGURE 16: U-TUBE, VENTING

HE20UT

HE20UT

HE25UT

HE25UT

HE30UT

HE30UT

HE35UT

HE35UT

HE40UT

HE40UT

HE45UT

HE45UT

HE50UT

HE50UT

Model

HE15UT

HE20UT

HE25UT

HE30UT

HE35UT

HE40UT

HE45UT

HE50UT

E 1000 1000 1000 1000 1000 1000 1000 1000

F 500 500 500 500 500 500 500 500

9 of 73

Page 16

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

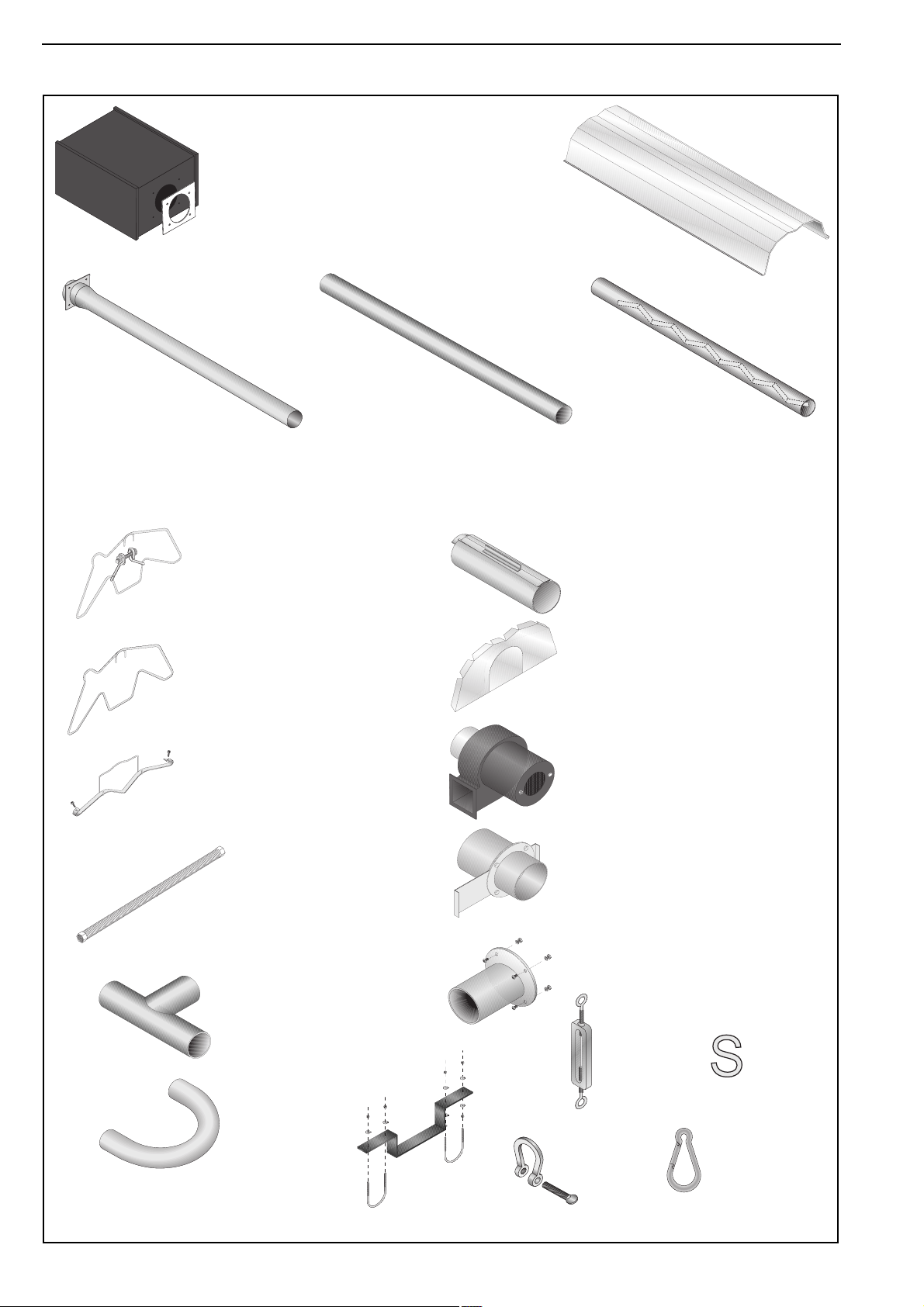

Burner (shown with Tube

Gasket)

Must be installed with the

flame observation window

facing down.

Reflector

(Aluminium or

Stainless Steel)

Alternate overlap as

shown on overview.

Minimum overlap is 160 mm.

Coupling Assembly

with Lock

Reflector End Cap

Punch out center section to

accommodate tube.

Fan Assembly (Includes Flange)

Fan assembly is attached to the last

section of heat exchanger tubing

(fan tube).

Tube and Reflector Hanger

Suspend system from these

hangers.

Flex Gas Line

Tube

Heat treated aluminised tube

supplied in 3000 mm lengths.

Burner Tube

Supplied in 3000 mm lengths.

Burner tube is always the first

tube after the burner.

Reflector Support Strap, Wire

Form & #8 x 3/4 Screw

Fan Tube with Internal Swirler

Supplied in 3000 mm lengths. Fan

tube is always the last tube on the

heater where the fan is attached.

The swirler is welded inside of the

tube end.

Fan Flange Assembly

and Screws

U-tube

Height

Adjuster

Bow

Shackle

Tee

Assembly

U-tube

Support

Bracket

Damper Flange Assembly

For use on Multiburner Systems.

Tube and Reflector Hanger

with Clamp Package

Position this hanger no more

than 100 mm away from the

burner assembly.

Spring

Hook

S-hook

SECTION 4: MAJOR COMPONENT DESCRIPTIONS

10 of 73

Page 17

SECTION 5: GENERAL SUSPENSION DETAILS

WARNING

Severe Injury Hazard

Secure burner to burner tube with bolts and

lockwashers.

Hang heater with materials with a minimum

working load of 75 lbs (33 kg).

Failure to follow these instructions can result

in death, injury or property damage.

WARNING

Cut/Pinch Hazard

Wear protective gear during installation,

operation and service.

Edges are sharp.

Failure to follow these instructions can result

in injury.

SECTION 5: GENERAL SUSPENSION DETAILS

To ensure your safety, and comply with the terms of the

warranty, all units must be installed in accordance with

these instructions.

The gas or the electrical supply lines must not be used to

support the heater.

Do not locate the gas or electrical supply lines directly

over the path of the flue products from the heater.

The heater must be installed in a location that it is readily

accessible for servicing.

The heaters must be installed with clearances to

combustibles as indicated on the rating plate and in this

manual.

The minimum and maximum gas inlet pressures must be

maintained as indicated on the rating plate. Typical

installation configurations are shown on Page 12, Figure

17.

NOTE: Some models may receive S-hooks (P/N

91907302) or spring hooks (P/N 91903300), rather than

bow shackles.

11 of 73

Page 18

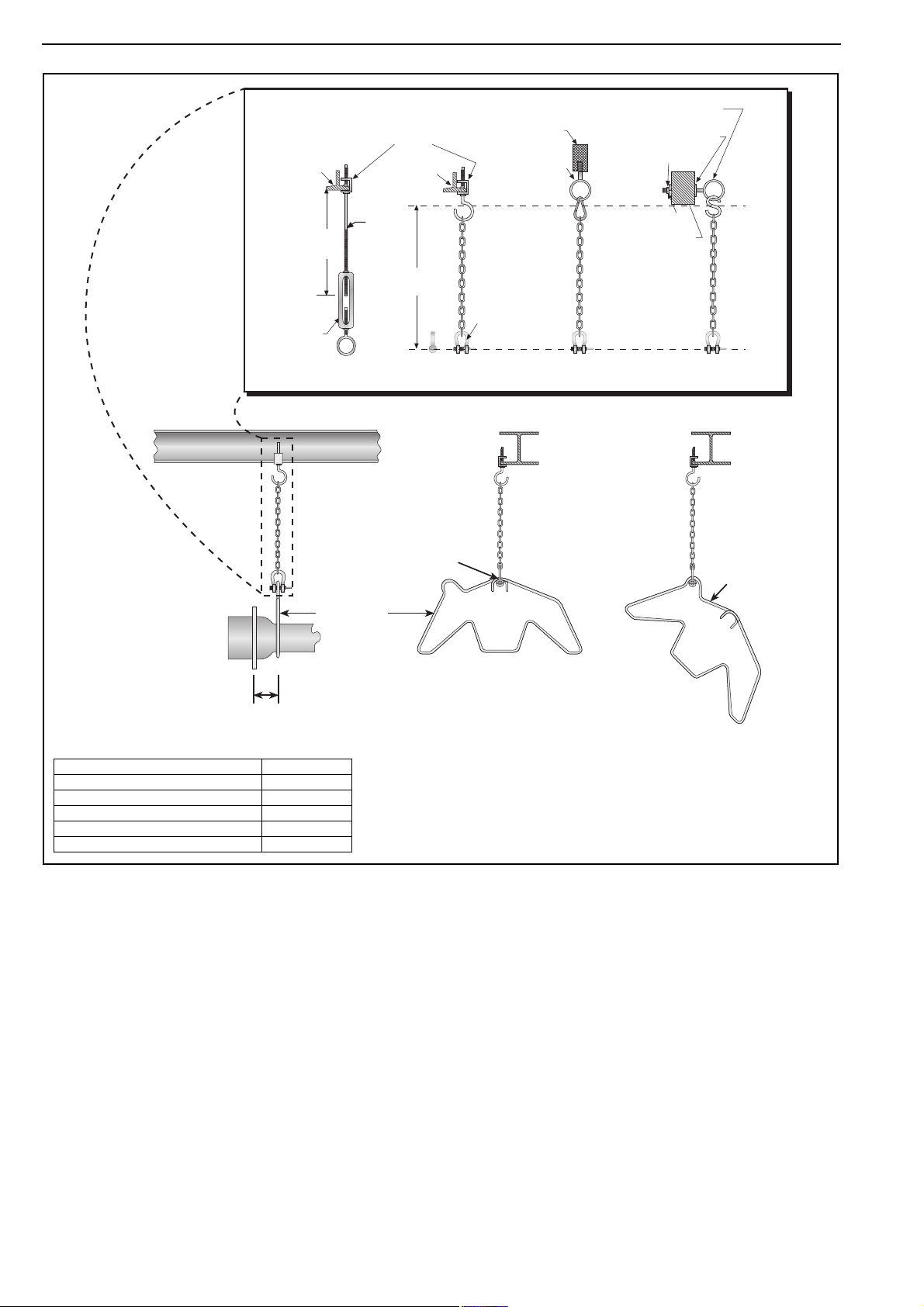

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

* Allows for thermal expansion of system.

Hanger

Side View

Front View

Hanger

Bow Shackle

I-Beam

I-Beam

Beam

Clamp

Bow

Shackle

Anchor

Concrete

Beam

Locknut

Washer

Screw Hook

min. 10 mm

Washer

Wood

Beam

Turnbuckle

(not included)

600 mm

minimum*

300 mm

minimum*

10 mm

Rod

Typical Suspension Details

45° Angle

100 mm

Max.

Description Part Number

Burner Tube 03051100

S-hook 91907302

Spring Hook 91903300

Bow Shackle E0007576

Tube/Reflector Hanger 03090100

Figure 17: Critical Hanger Placement

12 of 73

Page 19

SECTION 6: LINEAR & DOUBLE LINEAR HEATER INSTALLATION

WARNING

Cut/Pinch Hazard

Wear protective gear during installation,

operation and service.

Edges are sharp.

Failure to follow these instructions can result

in injury.

SECTION 6: LINEAR & DOUBLE LINEAR HEATER INSTALLATION

The figures in this section provide a general overview of

component placement in a Linear and Double Linear

system. The location of some components such as

supports and couplings is crucial for proper installation.

Assemble the heater components as shown on Page 14,

Figure 18.

For optional reflector configurations for linear heaters see

Page 6, Figure 3 through Page 7, Figure 9. Install

appropriate suspension hardware, beam clamps, chain or

rod at predetermined locations. Adjustments of chain

length will provide uniform pitch.

If any step is unclear, please contact Roberts-Gordon

LLC at +44 (0)121 506 7700.

6.1 Linear Standard Parts List

Part No. Description

033XXXXX Burner Assembly (Input and Fuel Varies) 1 1 111111

07260001 Fan Package XP 1 1 1 1 1 1 - - -

07260002 Fan Package XP 2 (optional) - -------

07260003 Fan Package XP 3 - ----111

07260051 Fan Package 1 IP55 (optional)** 1 1 1 1 1 - - -

07260052 Fan Package 2 IP55 (optional)** - -------

07260053 Fan Package 3 IP55 (optional)** - ----111

03051100Burner Tube, 100 mm x 3048 mm 11111111

91409408Tube, 100 mm x 3048 mm - 1122233

S5127WFan Tube, 100 mm x 3048 mm, with 3048 mm Swirler -1111111

S5134WFan Tube, 100 mm x 3048 mm, with 2134 mm Swirler 1-------

01329600Standard Coupling Assembly 12233344

01329700Coupling Lock 12233344

02750303Reflector, Aluminium, 2439 mm 34466677

027503SSReflector, Stainless Steel, 2439 mm (Optional)* 34466677

02750800Reflector End Cap, Aluminium 22222222

HE15ST

HE20ST

HE25ST

HE30ST

HE35ST

HE40ST

HE45ST

HE50ST

027508SHReflector End Cap, Stainless (Optional)* 22222222

03090100Tube and Reflector Hanger 34455566

01318901Tube Clamp Package (including Nut, Washer & Bolt) 11111111

91908004Wire Form 23355566

94320812 Screw #8 x 3/4, (Goes with 03050000) 4 6 6 10 10 10 12 12

03050000Reflector Support Strap 23355566

E0007576Bow Shackle*** 34455566

91107720 U-Clip Package (20 Pieces) 1 1 111111

S7199K Damper Flange Assembly (For use on Multiburner Systems) 1 Per Heater

* PVC coating must be removed prior to installation.

** If an IP55 protected fan is required, this fan replaces

07260001, 07260002, or 07260003.

*** Some models may receive S-hooks (P/N 91907302)

or spring hooks (P/N 91903300), rather than bow

shackles.

13 of 73

Page 20

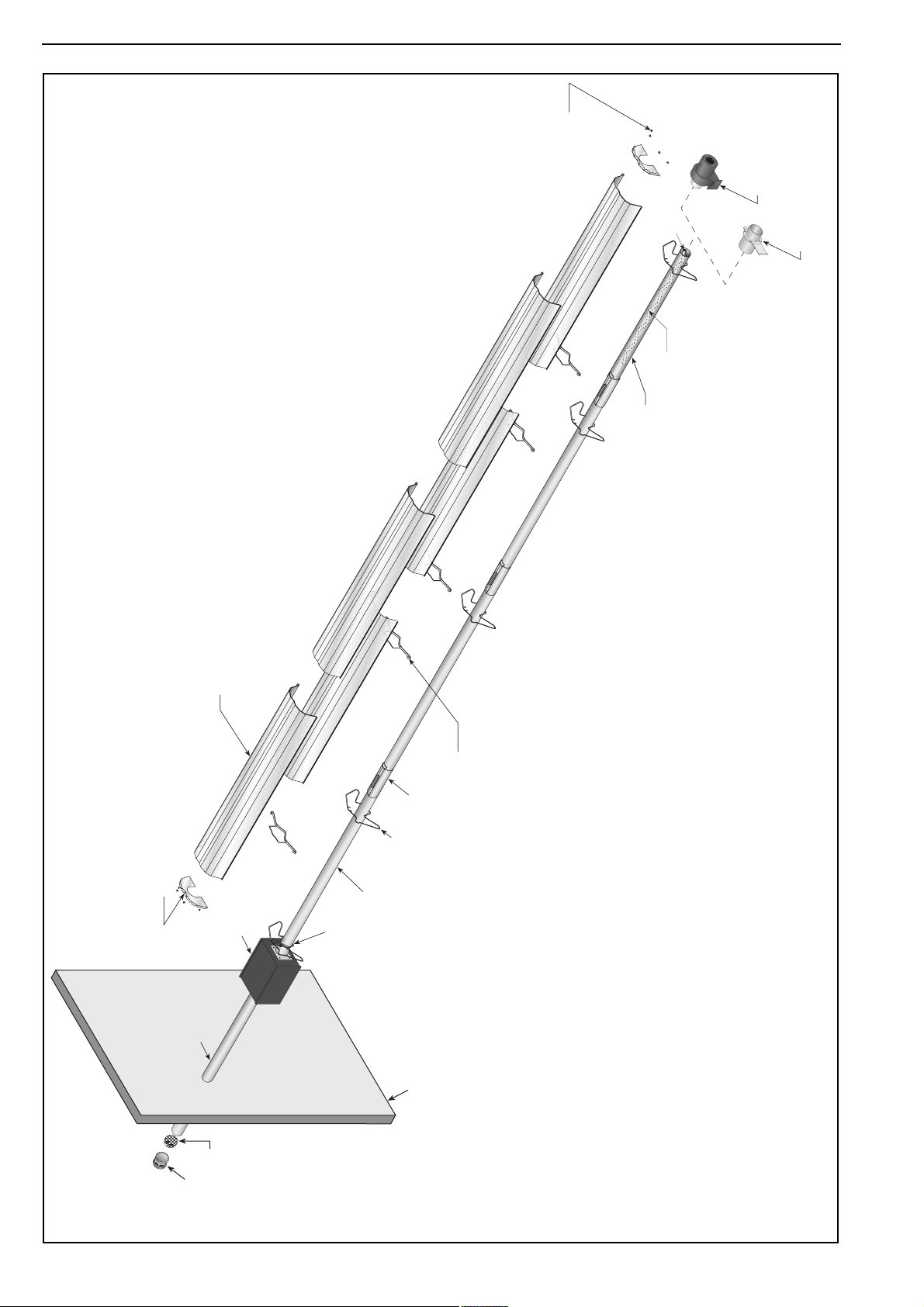

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

Vent Cap or

Bird Screen

Outside Wall

Fan Tube

Reflector

Reflector End Cap

Reflector Support

Burner

Coupling

U-Clips

Burner Tube

Tube and Reflector Hanger

Tube Clamp

Package

Fan Assembly*

(For Single Heater)

Damper Assembly

(Required for Multiburner)

*NOTE: Locate fan away from wet environment

or use the IP54 protected fan.

Fresh Air

Supply

Internal Swirler

Weld Spot

Figure 18: Linear General Assembly Overview

14 of 73

Page 21

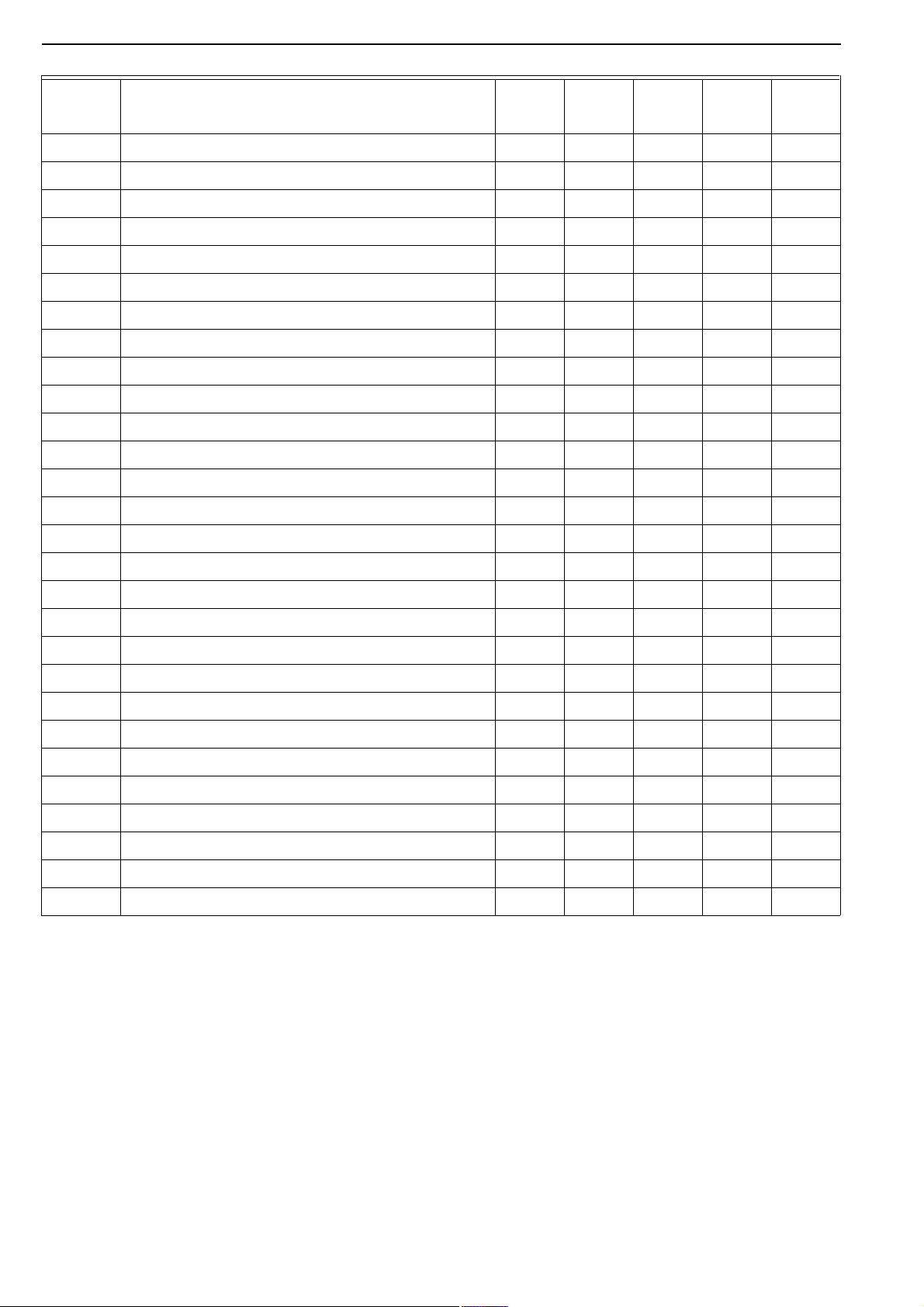

Figure 19: Linear Layout Overview

a = reflector width (not shown) - 365 mm

b = end cap to burner/fan - 50 mm

c = end cap to hanger - 50 mm

d = distance first hanger - 2290 mm

e = distance typical between hangers - 3050 mm

f = burner height - 241 mm

g = burner length - 445 mm

Burner

Reflector

Tube

Tube/Reflector

Hanger

Coupling

Assembly

Fan

Assembly

LEGEND

Damper

Assembly

HE20ST

HE25ST

c

b

de

b

e

HE30ST

HE35ST

HE40ST

c

b

de

b

e e

HE45ST

HE50ST

c

b

de

b

e e e

g

c

b

de

b

HE15ST

f

g

f

g

f

g

f

SECTION 6: LINEAR & DOUBLE LINEAR HEATER INSTALLATION

Model HE15ST HE20ST HE25ST HE30ST HE35ST HE40ST HE45ST HE50ST

Reflector

Overlap

700 mm 250 mm 250 mm 530 mm 530 mm 530 mm 330 mm 330 mm

(approx.)

15 of 73

Page 22

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

6.2 Double Linear Standard Parts List

Part No.

033XXXXX Burner Assembly (Input and Fuel Varies) 2 2 2 2 2

07260002 Fan Package XP 2 1 1 - - -

07260003 Fan Package XP 3 1 1 1 1 1

07260052 Fan Package 2 IP55 (optional)** 1 1 - - -

07260053 Fan Package 3 IP55 (optional)** - - 1 1 1

03051100 Burner Tube, 100 mm x 3048 mm 2 2 2 2 2

91409408 Tube, 100 mm x 3048 mm - 2 2 4 4

S5127W Fan Tube, 100 mm x 3048 mm, with 3048 mm Swirler - 2 2 2 2

S5134W Fan Tube, 100 mm x 3048 mm, with 2134 mm Swirler 2 - - - -

E0009170 Tee, 100 mm x 100 mm x 100 mm 1 1 1 1 1

01329600 Standard Coupling Assembly 6 8 8 10 10

01329700 Coupling Lock 6 8 8 10 10

02750303 Reflector, Aluminium, 2439 mm 6 8 8 12 12

027503SS Reflector, Stainless Steel, 2439 mm (Optional)* 6 8 8 12 12

Description

HE30DL

HE40DL

HE50DL

HE60DL

HE70DL

02750800 Reflector End Cap, Aluminium 4 4 4 4 4

027508SH Reflector End Cap, Stainless (Optional)* 4 4 4 4 4

03090100 Tube and Reflector Hanger 6 8 8 10 10

01318901 Tube Clamp Package (including Nut, Washer & Bolt) 2 2 2 2 2

91908004 Wire Form 4 6 6 10 10

03050000 Reflector Support Strap 4 6 6 10 10

E0007576 Bow Shackle*** 6 8 8 10 10

91107720 U-Clip Package (20 Pieces) 2 2 2 2 2

E0007582 Height Adjuster 6 8 8 10 10

94320812 Screw #8 x 3/4, (Goes with 03050000) 8 12 12 20 20

* PVC coating must be removed prior to installation.

** If an IP55 protected fan is required, this fan replaces

07260001, 07260002, or 07260003.

*** Some models may receive S-hooks (P/N 91907302)

or spring hooks (P/N 91903300), rather than bow

shackles.

16 of 73

Page 23

Figure 20: Double Linear General Assembly Overview

Vent Cap or

Bird Screen

Fresh Air

Supply

1200 mm approx.

Fan Tube

Burner

Fresh Air

Supply

Tube Clamp Package

Reflector

Reflector End Cap

Reflector Support

Coupling

Fan Assembly*

Burner Tube

Tube and Reflector Hanger

Tube Clamp

Package

U-Clips

Optional Tube Length

*NOTE: Locate fan away from wet environment

or use the IP54 protected fan.

Internal Swirler

Weld Spot

Outside Wall

SECTION 6: LINEAR & DOUBLE LINEAR HEATER INSTALLATION

17 of 73

Page 24

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

Tee Assembly

Burner

Reflector

Tube

Tube/Reflector

Hanger

Coupling

Assembly

Fan

Assembly

LEGEND

HE60DL

HE70DL

c

b

de

b

e e

Repeated

Opposite

Side

HE40DL

HE50DL

c

b

de

b

e

Repeated

Opposite

Side

HE30DL

g

c

b

de

b

f

Repeated

Opposite

Side

a = reflector width (not shown) - 365 mm

b = end cap to burner/fan - 50 mm

c = end cap to hanger - 50 mm

d = distance first hanger - 2290 mm

e = distance typical between hangers - 3050 mm

f = burner height - 241 mm

g = burner length - 445 mm

g

f

g

f

Figure 21: Double Linear Layout Overview

Model HE30DL HE40DL HE50DL HE60DL HE70DL

Reflector

Overlap (approx.)

700 mm 250 mm 250 mm 530 mm 530 mm

18 of 73

Page 25

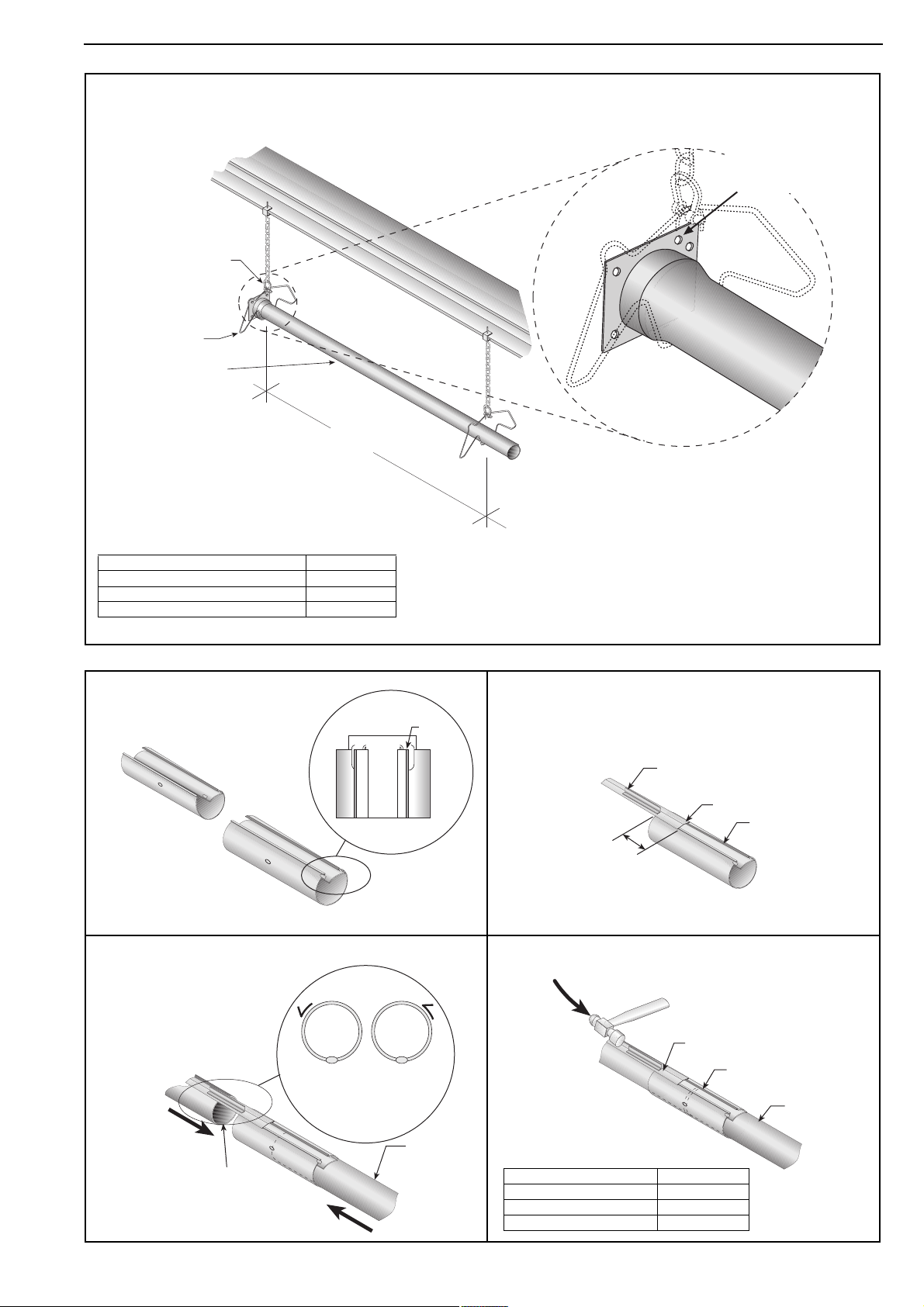

Step 6.3 Burner Tube Installation

Bow Shackle

Burner Tube

Hanger

2290 mm ± 250 mm

Note:

Tubing requires a downward

slope of 13 mm per 6000 mm

away from burner.

Weld seam

must be to the

bottom of the tube.

Offset mounting

hole must be

to the top.

Description Part Number

Burner Tube 03051100

Bow Shackle E0007576

Tube/Reflector Hanger 03090100

Tube

Tube

Orient coupling so that

the impact block is in the

2:00 or 10:00 oclock

positions

Closed

Open

Tab

76 mm to

101 mm

Slide Bar

Coupling

Wide End

Coupling

Tube

Slide Bar

A

Close coupling

with tab

B

Start slide bar/coupling lock

onto coupling

C

Insert tubes into coupling

D

Tighten coupling to join tubes

Description Part Number

Coupling 01329600

Slide Bar/Coupling Lock 01329700

Tube 91409408

SECTION 6: LINEAR & DOUBLE LINEAR HEATER INSTALLATION

Step 6.4 Coupling and Tube Assembly

19 of 73

Page 26

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

Incorrect Slide Bar

position

Correct Slide Bar

dimensions

± 50 mm

Drive slide bar until tight.

End of slide bar should be

within tolerance listed below.

• Repeat Step 6.4 A - D until all tubes are assembled. See Page 20, Section 6.4.2 shown below.

Tighten slide bar as shown below.

3050 mm Typ

± 250 mm

2290 mm

± 250 mm

Total Overall

Tube Length

Weld spot

at end of

heat exchanger

Model Overall Tube Length (mm)

Number

of Tubes

HE15ST 6000 2

HE20ST 9000 3

HE25ST 9000 3

HE30ST 12,000 4

HE35ST 12,000 4

HE40ST 12,000 4

HE45ST 15,000 5

HE50ST 15,000 5

HE55ST 18,000 6

Step 6.4.1 Coupling and Tube Assembly (Continued)

Step 6.4.2 Coupling and Tube Assembly (Continued)

20 of 73

Page 27

Step 6.5 Tube Clamp Package Installation

Description Part Number

Tube Clamp Package01318901

Tube Clamp 01396801

Bolt 97113940

Flat Washer 95211600

Nut 92113900

SECTION 6: LINEAR & DOUBLE LINEAR HEATER INSTALLATION

21 of 73

Page 28

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

WARNING

Fire Hazard

Support reflector with reflector hanger

and support strap.

Reflector must not touch tube.

Failure to follow these instructions can result

in death, injury or property damage.

Hanger

Burner Tube

Reflector

Description Part Number

Tube/Reflector Hanger 03090100

Burner Tube 03051100

Reflector 02750303

Step 6.6 Reflector Installation

22 of 73

Page 29

SECTION 6: LINEAR & DOUBLE LINEAR HEATER INSTALLATION

2. The overlap at the first and second reflector is a slip

overlap. Thereafter, every third reflector joint is a

slip overlap. A slip overlap is achieved by either:

a.) both reflectors lay inside a hanger.

(no reflector support needed).

b.) using a reflector support with

loose screws at the reflector

overlap.

3. The remaining reflector overlaps require a

non-slip overlap connection. To affix the

reflectors together in a non-slip overlap

either:

a.) use reflector support and tight screws.

b.) if both reflectors lay inside a hanger,

u-clips or sheet metal screws may be

used.

This section of three reflectors joined

together must be affixed to the tube with

at least one reflector support with tight

screws.

Reflector

End Cap

U-clips

Wire Form

Reflector Support

Strap

Tight

Sheet Metal

Screw

1. The first reflector after the burner must be affixed in

the middle of the reflector with a reflector support and

tight screws.

Loose screws

loosened 2 mm

to allow slippage.

Option A

Slip Overlap

Reflector

Support

Option B

Slip Overlap

Reflector

Tight

Screws

Option B

Non-Slip Overlap

U-clip

(2 clips per

non-slip overlap

inside a hanger)

Reflector

Option A

Non-Slip Overlap

First

Reflector

Overlap must

be a minimum

of 160 mm

160 mm

Description Part Number

Reflector Support Package 03050010

Wire Form 91908004

Reflector Support Strap 03050000

Screw #8 x 3/4 94320812

U-clip Package 91107720

Reflector End Cap 027508XX

Step 6.6.1 Reflector, U-clip and Reflector Support Installation

The pictorial drawings of the heater construction in

Section 6 are schematic only and provide a general

guideline of where hangers, reflector supports and

u-clips are to be installed.

To ensure proper expansion and contraction movement of

the reflectors, a combination of u-clips and reflector

supports are used. The positioning of reflector supports

and u-clips depend on the individual installation. Use

either pop rivets or sheet metal screws instead of u-clips

when installing end caps and joint pieces in areas where

impact and high wind may be a factor. The following rules

must be observed:

23 of 73

Page 30

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

Tee

Coupling

Coupling

Fan Tube

Fan Tube

Weld Spot

Weld Spot

Description Part Number

Tee E0009170

Fan Tube S51XXW

Coupling 01329600

Slide Bar/Coupling Lock 01329700

Tube/Reflector Hanger 03090100

Step 6.7 Double Linear Tee Installation (For Double Linear Heaters Only)

24 of 73

Page 31

SECTION 7: U-TUBE HEATER INSTALLATION

WARNING

Cut/Pinch Hazard

Wear protective gear during installation,

operation and service.

Edges are sharp.

Failure to follow these instructions can result

in injury.

7.1 U-tube Standard Parts List

SECTION 7: U-TUBE HEATER INSTALLATION

The figures in this section provide a general overview of

component placement in a u-tube system. The location of

some components such as supports and couplings is

crucial for proper installation. Assemble the heater

components as shown on Page 27, Figure 22.

For optional reflector configurations for u-tube heaters,

see Page 8, Figure 10 through Page 9, Figure 16. Install

appropriate suspension hardware, beam clamps, chain or

rod at predetermined locations. Adjustments of chain

length will provide uniform pitch.

If any step is unclear, please contact Roberts-Gordon

LLC at +44 (0)121 506 7700.

Part No. Description

033XXXXX Burner Assembly (Input and Fuel Varies) 1 1 111111

07260001 Fan Package XP1 1 1 1 1 1 - - -

07260002 Fan Package XP2 (optional) - -------

07260003 Fan Package XP3 - ----111

07260051 Fan Package 1 IP55 (optional)** 1 1 1 1 1 - - -

07260052 Fan Package 2 IP55 (optional)** - -------

07260053 Fan Package 3 IP55 (optional)** - ----111

03051100Burner Tube, 100 mm x 3048 mm 11111111

91409408Tube, 100 mm x 3048 mm - - -22222

91409423 Tube, 100 mm x 1524 mm - 2 2 - - - 2 2

S5127WFan Tube, 100 mm x 3048 mm, with 3048 mm Swirler -1111111

S5134WFan Tube, 100 mm x 3048 mm, with 2134 mm Swirler 1-------

01335901U-tube 11111111

01329600Standard Coupling Assembly 24444466

01329700Coupling Lock 24444466

02750303Reflector, Aluminium, 2439 mm 44466688

027503SS Reflector, Stainless Steel, 2439 mm (Optional)* 4 4 466688

02750800Reflector End Cap, Aluminium 44444444

HE15UT

HE20UT

HE25UT

HE30UT

HE35UT

HE40UT

HE45UT

HE50UT

027508SHReflector End Cap, Stainless (Optional)* 44444444

03090100Tube and Reflector Hanger 46666688

01318901 Tube Clamp Package (including Nut, Washer & Bolt) 1 1 111111

91908004Wire Form 24444466

03050000Reflector Support Strap 24444466

03020501 U-tube Support Bracket 1 1 111111

E0007576Bow Shackle*** 46666688

91107720 U-clip Package (20 Pieces) 2 2 222222

91912501U-bolt M6 22222222

C0090BNut M6 66666666

25 of 73

Page 32

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

Part No. Description

HE15UT

HE20UT

HE25UT

HE30UT

HE35UT

HE40UT

HE45UT

HE50UT

96411500Lockwasher 6mm 66666666

94320812Screw #8 x 3/4, (Goes with 03050000) 4888881212

S7199K Damper Flange Assembly (For use on Multiburner Systems) 1 Per Heater

*PVC coating must be removed prior to installation.

** If an IP55 protected fan is required, this fan replaces

07260001, 07260002, or 07260003.

***Some models may receive S-hooks (P/N 91907302) or

spring hooks (P/N 91903300), rather than bow shackles.

26 of 73

Page 33

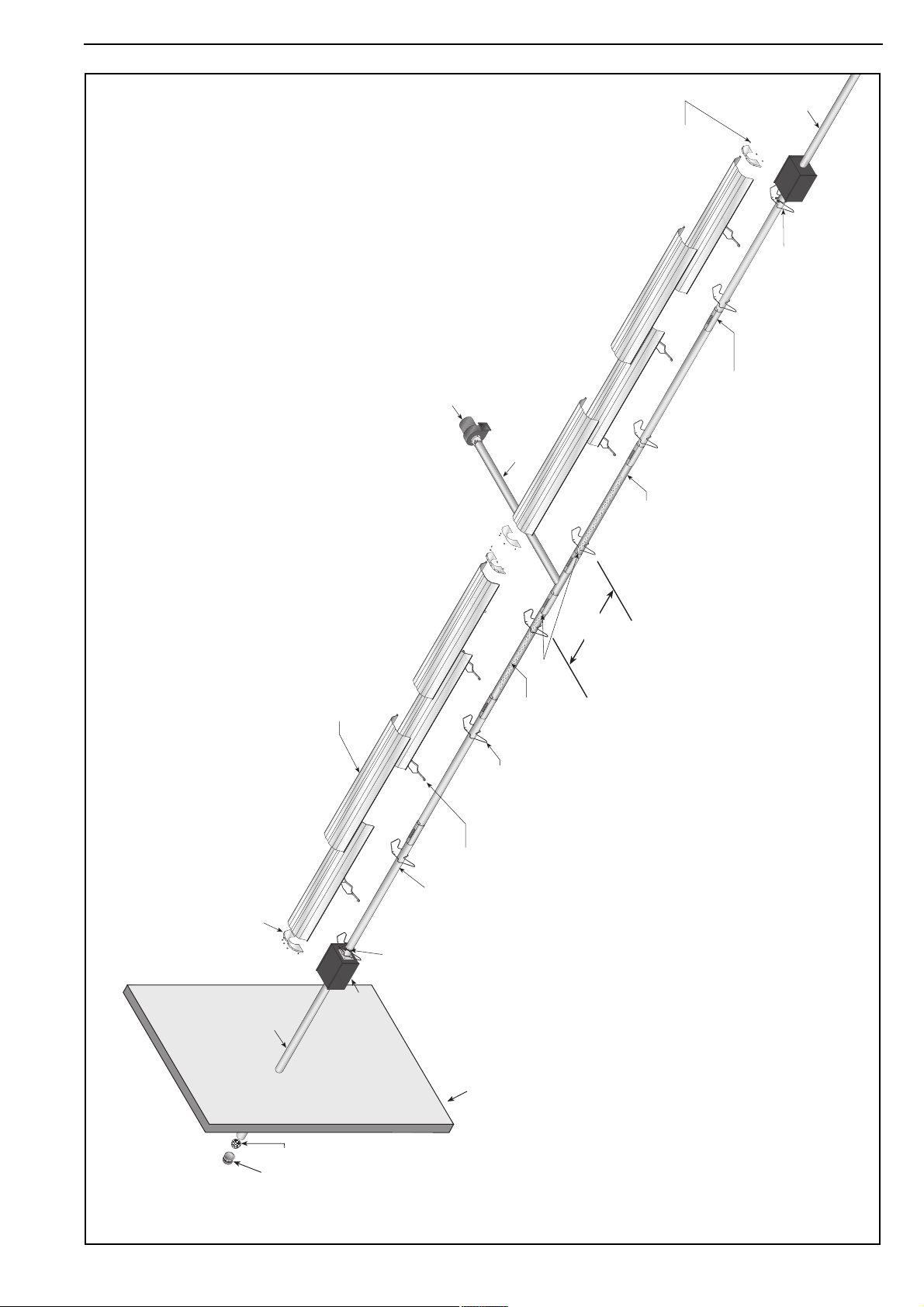

Figure 22: BLACKHEAT® HE U-tube Assembly Overview

200 mm

Maximum

Coupling

U-clips

Reflector

End Caps

180° U-tube

460 mm

Center to Center

Fresh Air

Supply

Burner

Reflector

U-tube

Support Bracket

Internal Swirler

Tube Clamp

Package

Burner Tube

Fan Tube

Reflector

Support

*NOTE: Locate fan away from wet environment

or use the IP54 protected fan.

*Fan Assembly

(For Single Heater)

Damper Assembly

(Required for Multiburner)

Flue Pipe or

Optional Heat

Exchanger

Outside Wall

Vent Cap or

Bird Screen

Weld Spot

SECTION 7: U-TUBE HEATER INSTALLATION

27 of 73

Page 34

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

HE20UT

HE25UT

HE15UT

HE30UT

HE35UT

HE40UT

HE45UT

HE50UT

a = overall width (not shown) - 850 mm

b = end cap to burner/fan - 50 mm

c = end cap to hanger - 50 mm

d = distance first hanger - 2290 mm

e = distance typical between hangers - 3050 mm

f = distance between last full tube

hanger and half tube hanger - 1900 mm

g = burner height - 241 mm

h = burner length - 445 mm

U-Tube

Burner

Reflector

Tube

Tube/Reflector

Hanger

Coupling

Assembly

LEGEND

h

c

b

d

g

c

b

d

f

c

b

de

c

b

de

f

h

g

h

g

h

g

Figure 23: BLACKHEAT® HE U-tube Layout Overview

Model HE15UT HE20UT HE25UT HE30UT HE35UT HE40UT HE45UT HE50UT

Reflector

Overlap

1780 mm 250 mm 250 mm 580 mm 580 mm 580 mm 690 mm 690 mm

(approx.)

28 of 73

Page 35

Step 7.2 U-tube Hanger Placement

2290 mm ± 250 mm

See Assembly

Drawing

First Tube and

Reflector Hanger

Bow

Shackle

Tube and Reflector

Hanger

Suspension

Chain

Optional

Hanging

Configuration

Washers

Bolt

(Torque:

13.5 Nm

129 in lb)

Bow

Shackle

NOTE: Spreader bar must be used on

single suspension point installations.

Do not hang heater from spreader bar.

Threaded

Bar

Tube and Reflector

Hanger

Suspension

Chain

Spreader

Bar

Description Part Number

Bow Shackle E0007576

Tube/Reflector Hanger 03090100

Spreader Bar 07260010

Fan Tube

Burner Tube

Weld seam

must be to the

bottom of the tube.

Offset mounting

hole must be

to the top.

Weld

Spot

Description Part Number

Burner Tube 03051100

Fan Tube S5127W

SECTION 7: U-TUBE HEATER INSTALLATION

Step 7.3 Burner Tube and Fan Tube Installation

29 of 73

Page 36

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

Tube Clamp

Bolt

Lock Washer

Nut

(Torque: 13.56 Nm

120 in lb)

Weld

Spot

Description Part Number

Tube Clamp Package01318901

Tube Clamp 01396801

Bolt 97113940

Flat Washer 95211600

Nut 92113900

Tight

U-bolt

100 mm u-bolt,

secured to burner tube

with M6 lockwashers

and M6 nuts.

TIGHT.

Loose

U-bolt

100 mm u-bolt,

secured to bracket

with M6 lockwashers

and M6 nuts on top and

bottom to allow for tube

expansion and contraction.

U-tube, Standard U-tube, Opposite 45°

Tight

U-bolt

100 mm u-bolt,

secured to burner tube

with M6 lockwashers

and M6 nuts.

TIGHT.

Loose

U-bolt

100 mm u-bolt,

secured to bracket

with M6 lockwashers

and M6 nuts on top and

bottom to allow for tube

expansion and contraction.

Nut (Torque:

90 in lb

10.2 Nm)

Lock Washer

Lock Washer

U-bolt

Fan Tube

Burner

Tube

U-bolt

Tight to

Tube

U-bolt

Tight to

Bracket

Nut

(Torque: 90 in lb

10.2 Nm)

Step 7.3.1 Tube Clamp Package Installation

Step 7.4 U-tube Support Bracket Assembly Installation

30 of 73

Page 37

Step 7.5 Coupling and Tube Assembly

Tube

Tube

Orient coupling so that

the impact block is in the

2:00 or 10:00 oclock

positions

Closed

Open

Tab

76 mm to

101 mm

Slide Bar

Coupling

Wide End

Coupling

Tube

Slide Bar

A

Close coupling

with tab

B

Start slide bar/coupling lock

onto coupling

C

Insert tubes into coupling

D

Tighten coupling to join tubes

Description Part Number

Coupling 01329600

Slide Bar/Coupling Lock 01329700

Tube 91409408

Incorrect Slide Bar

position

Correct Slide Bar

dimensions

± 50 mm

Drive slide bar until tight.

End of slide bar should be

within tolerance listed below.

• Repeat Step 7.5 A - D until all tubes are assembled.

Tighten slide bar as shown below.

SECTION 7: U-TUBE HEATER INSTALLATION

Step 7.5.1 Coupling and Tube Assembly (Continued)

31 of 73

Page 38

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

Tube

Coupling

Weld Spot

Coupling

U-tube

U-tube Support

Bracket Assembly

Weld Spot

Description Part Number

Coupling 01329600

Slide Bar/Coupling Lock 01329700

U-tube 01335901

Step 7.6 Tube Installation

Step 7.7 U-tube Installation

32 of 73

Page 39

Step 7.8 Reflector Installation

WARNING

Fire Hazard

Support reflector with reflector hanger

and support strap.

Reflector must not touch tube.

Failure to follow these instructions can result

in death, injury or property damage.

Reflector

Weld Spot

Description Part Number

Reflector 02750303

SECTION 7: U-TUBE HEATER INSTALLATION

33 of 73

Page 40

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

2. The overlap at the first and second reflector is a slip

overlap. Thereafter, every third reflector joint is a

slip overlap. A slip overlap is achieved by either:

a.) both reflectors lay inside a hanger.

(no reflector support needed).

b.) using a reflector support with

loose screws at the reflector

overlap.

3. The remaining reflector overlaps require a

non-slip overlap connection. To affix the

reflectors together in a non-slip overlap

either:

a.) use reflector support and tight screws.

b.) if both reflectors lay inside a hanger,

u-clips or sheet metal screws may be

used.

This section of three reflectors joined

together must be affixed to the tube with

at least one reflector support with tight

screws.

Reflector

End Cap

U-clips

Wire Form

Reflector Support

Strap

Tight

Sheet Metal

Screw

1. The first reflector after the burner must be affixed in

the middle of the reflector with a reflector support and

tight screws.

Loose screws

loosened 2 mm

to allow slippage.

Option A

Slip Overlap

Reflector

Support

Option B

Slip Overlap

Reflector

Tight

Screws

Option B

Non-Slip Overlap

U-clip

(2 clips per

non-slip overlap

inside a hanger)

Reflector

Option A

Non-Slip Overlap

First

Reflector

Overlap must

be a minimum

of 160 mm

160 mm

Description Part Number

Reflector Support Package 03050010

Wire Form 91908004

Reflector Support Strap 03050000

Screw #8 x 3/4 94320812

U-clip Package 91107720

Reflector End Cap 027508XX

Step 7.8.1 Reflector, U-clip and Reflector Support Installation

The pictorial drawings of the heater construction in

Section 6 are schematic only and provide a general

guideline of where hangers, reflector supports and

u-clips are to be installed.

To ensure proper expansion and contraction movement of

the reflectors, a combination of u-clips and reflector

supports are used. The positioning of reflector supports

and u-clips depend on the individual installation. Use

either pop rivets or sheet metal screws instead of u-clips

when installing end caps and joint pieces in areas where

impact and high wind may be a factor. The following rules

must be observed:

34 of 73

Page 41

SECTION 8: MULTIBURNER CONFIGURATION & INSTALLATION

WARNING

Severe Injury Hazard

Secure burner to burner tube with bolts and

lockwashers.

Hang heater with materials with a minimum

working load of 75 lbs (33 kg).

Failure to follow these instructions can result

in death, injury or property damage.

WARNING

Cut/Pinch Hazard

Wear protective gear during installation,

operation and service.

Edges are sharp.

Failure to follow these instructions can result

in injury.

Fan Tube

Damper Flange

Assembly

Note:

Install in the

fully open position

Weld Spot

SECTION 8: MULTIBURNER CONFIGURATION & INSTALLATION

8.1 Initial Assembly

See Page 13, Section 6 for linear heater assembly

instructions.

See Page 25, Section 7 for u-tube heater assembly

instructions.

Check layout drawings for location of manifold pipe

installation.

Figure 24: Multiburner Damper Flange Installation

35 of 73

Page 42

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

*Typical Fan

Arrangement

150 mm Hanger

150 mm Manifold

Damper (Typical)

Cross

(100 x 150 x 100 x 150)

100 mm Manifold

100 mm Hanger

ID/ID Sleeve

Tee

(100 x 100 x 100)

Cross

(100 x 150 x 100 x 150)

Max

3000 mm

HE25ST

HE25UT

HE25ST

HE25UT

HE25ST

HE25UT

NOTE: Be sure to

silicone seal all

manifold joints.

Reducer

(100 x 150)

Max

1000

mm

*Locate fan

away from wet

environment.

Figure 25: Typical Manifold Layout (Linear and U-Tube Configuration)

36 of 73

Page 43

SECTION 9: BURNER & FAN INSTALLATION

Lock

Washer

Gasket

Bolt

(Torque: 13.5 Nm

120 in lb)

Burner

Description Part Number

Bolt 072600XX

Lock Washer 96411600

Gasket 02568200

Burner 033XXXXX

NOTE: Tube Clamp Package not shown for clarity.

For details, see Page 21, Step 6.5.

Fan Assembly

Vent Adapter

Screw

(Torque: 2 Nm

18 in lb)

Note: Apply Silicone

(Recommended)

Install vent adapter

with clamp in the

up position.

Description Part Number

Fan Assembly 072600XX

Vent Adapter C1323B

Screw C0061B

Step 9.1 Burner Installation

SECTION 9: BURNER & FAN INSTALLATION

Step 9.2 Standard Fan Assembly

37 of 73

Page 44

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

Fan Assembly

Vent Adapter

Nut

(Torque:

2 Nm

18 in lb)

Note: Apply Silicone

(Recommended)

Install vent adapter

with clamp in the

up position.

Wire Gland

(tighten securely)

Washer

Description Part Number

Fan Assembly 072600XX

Vent Adapter C1323B

Nut M6 C0061B

Washer M6 C0039B

Fan Tube

Fan Assembly

Tighten securely until tube

cannot be removed.

Weld Spot

9.3 IP55 Fan Assembly

9.4 Linear & U-tube Fan Installation

38 of 73

Page 45

Step 9.5 Double Linear Fan Installation

Tee

Fan Assembly

Tighten securely until tube

cannot be removed.

Fan Assembly

Height Adjuster

Bow

Shackle

Suspension Chain

Tee

Weld Spot

SECTION 9: BURNER & FAN INSTALLATION

Step 9.5.1 Double Linear Fan Installation (Continued)

39 of 73

Page 46

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

Tee

Condensate Cap

Non-Return Valve

83/90 BWLG Fan

Inlet Cone

Horizontal

Exhaust Bend

Vertical Exhaust Tee

Spiral Aluminum

Tube

ID/ID Sleeve

Horizontal

Exhaust Sleeve

Horizontal

Exhaust Louver

Condensation

runs to low level

3/4" CPVC pipe

1" BSP threaded hole.

Use 1" x ¾" reducer.

(not supplied)

Must be connected

to a drain system

in accordance with

local codes.

Description Part Number

Vertical Exhaust Tee C1324B

Horizontal Exhaust Bend C1325B

Horizontal Exhaust Sleeve C1326B

Horizontal Exhaust Louver S5055F

Condensate Cap 4" 02718851

Condensate Cap 6" 02718852

Non-Return Valve 90201200

Tee

Condensate Cap

Wall

1" BSP threaded hole.

Use 1" x ¾" reducer.

(not supplied)

Must be connected

to a drain system

in accordance with

local codes.

3/4" CPVC Pipe

Flow

Non-Return

Valve

3/4" CPVC

Pipe

3/4" Female

Fan

Description Part Number

Condensate Cap 4" 02718851

Condensate Cap 6" 02718852

Non-Return Valve 90201200

Step 9.6 Multiburner 83/90 BWLG Fan Assembly (Horizontal and Vertical Outlets)

Step 9.7 Condensate Drain Assembly

40 of 73

Page 47

SECTION 10: OPTIONAL HEATER ACCESSORIES

WARNING

Cut/Pinch Hazard

Wear protective gear during installation,

operation and service.

Edges are sharp.

Failure to follow these instructions can result

in injury.

SECTION 10: OPTIONAL HEATER ACCESSORIES

41 of 73

Page 48

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

Reflector Side

Extension Bracket

(2 per reflector)

Use additional supports

in high air movement

applications.

Tube and Reflector Hanger

Reflector

Tube

Reflector Support

Description Part Number

Reflector Side Extension Package S7377K

Reflector Side Extension 01368000

Retainer Clips 02751200

Reflector Side Extension 01329910

Retainer Clip

(2 per side)

Cut relief notches for

supports and hangers

Reflector Side Extension

#8 x 3/8 Sheet Metal Screw

10.1 Reflector Side Extension Installation

Step 10.1.1 Bracket Installation

Step 10.1.2 Side Reflector Installation

42 of 73

Page 49

SECTION 10: OPTIONAL HEATER ACCESSORIES

4' Reflector

Section

Reflector

Joint

Flatten

Edge

250 mm

maximum

Scribe

Contour

Cut away contour

with tin snips.

Punch/Drill six

3 mm holes

Reflector

End Cap

(Do not remove

cut out)

Attach Reflector

Joint with six #8

sheet metal screws.

Secure overlap

with six #8

sheet metal screws.

4' Reflector Sections

10.2 U-Tube Cover Installation

The package contains two reflector joint pieces (P/N 02750901), one 8' reflector and 18 x #8 sheet metal screws.

Install the u-tube cover using the following procedure.

Step 10.2.1

Cut the 8' reflector in half to be used on both sides to

cover the u-tube.

Step 10.2.2

Flatten 4' reflector edge where joint piece matches. Put a

mark on the 4' reflector, directly over the tube center.

Center the accessory joint piece on the mark and scribe

its contour on the reflector. Scribe the location of the

mounting holes.

Step 10.2.3

Cut away the reflector to clear the tube, leaving about 25

mm of material inside the scribed contour to attach the

accessory joint. Drill or punch six 3 mm diameter holes in

reflector in the positions shown below.

Step 10.2.4

Use six #8 sheet metal screws to attach the joint piece.

Repeat Steps 10.2.1 through 10.2.4 to attach the reflector joint piece on the other reflector.

Step 10.2.5

The overlap of both reflector joint pieces is attached with six #8 sheet metal screws.

43 of 73

Page 50

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

Description Part Number

Aluminium Grille 91407000

Description Part Number

Deco Grille Shield 01365900

Distance "A" Extension

Minimum Maximum Part No. Width

40 mm 150 mm 01370408 200 mm

150 mm 260 mm 01370412 300 mm

260 mm 370 mm 01370416 400 mm

Description Part Number

Reflector Side Extension 01370412

10.3 Decorative Grille Installation

Step 10.3.1 Grille Installation

Step 10.3.2 Frame Shield Installation

Step 10.3.3 Reflector Side Extension Installation for Decorative Grilles

44 of 73

Page 51

10.4 Protective Grille Installation

Silicone Cap

Grille

Finger

Description Part Number

Grille Section 08050001

Grille End Cap 08050002

Silicone Cap 91915951-6P

Bend up 90°.

Pull outward.

Grille

Grille End Cap

AB

CD

Grille

Grille

End Cap

Reflector

Final Grille

Section

1010 mm

Step 10.4.1 Silicone Cap Installation

Step 10.4.2 Grille End Cap Installation

SECTION 10: OPTIONAL HEATER ACCESSORIES

Step 10.4.3 Grille Installation

45 of 73

Page 52

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

Tube and

Reflector Hanger

Reflector

Tube

Reflector Support

Strap - Stainless Steel

Mesh Guard

Description Part Number

Mesh Guard 2438 mm E0009855

Mesh Guard 1524 mm C2329B

Strap Stainless Steel S5218W

Description Part Number

Nut Spire C1088B

Screw #8 x 3/8 C1089B

10.5 Sports Hall Guard Installation

Step 10.5.1 Grille Installation

Step 10.5.2 Fastener Installation

Step 10.5.3 Mesh Guard Connection

46 of 73

Page 53

10.6 Undershield Installation

Reflector

Tube

Assembly Hanging Bracket

Stud

Hex Nut

Description Part Number

Undershield Reflector Package 1010 mm S7399K

Assembly Hanging Bracket C0318B

Stud M6 x 90 C0693B

Nut M6 C0090B

Undershield Reflector

Hex Nut

Shield Support Bracket

Description Part Number

Undershield Reflector Package 1010 mm S7399K

Undershield Reflector 1010 mm C0521B

Nut M6 C0090B

Shield Support Bracket 02751700

1010 mm

10.6.1 Hanger Installation

10.6.2 Undershield Installation

SECTION 10: OPTIONAL HEATER ACCESSORIES

10.6.3 Adjust Undershield Height

47 of 73

Page 54

BLACKHEAT® HE INSTALLATION OPERATION AND SERVICE MANUAL

Burner must

be below fan

10.7 Wall Mounting

Install wall mounting brackets at the height shown in the

layout drawing provided by the estimator. Space wall

mounting brackets and hangers as indicated by

dimensions d, e and f in the relevant Layout Overview

drawing for your heater. For Linear heaters see Page 15,

Figure 19, for Double Linear heaters see Page 18, Figure

21 and for u-tube heaters see Page 28, Figure 23.

10.7.1 Hardware Installation

The wall mounting brackets must be attached to a

suitable wall through all mounting holes. Screw sizes less

than M8 (5/16") may not be used. In order for the wall

mounting brackets to adequately carry the weight of the

heater, it must be installed with best building practice.

Figure 26: U-tube (Horizontal)

Model

HE15UT 2 HE15ST 3

HE20UT 3 HE20ST 4

HE25UT 3 HE25ST 4

HE30UT 3 HE30ST 5

HE35UT 3 HE35ST 5

HE40UT 3 HE40ST 5

HE45UT 4 HE45ST 6

HE50UT 4 HE50ST 6

Quantity of Wall

Mounting Brackets

Model

Quantity of Wall

Mounting Brackets

Figure 27: U-tube (Angle Mounted) Figure 28: Linear

48 of 73

Page 55

SECTION 11: VENTING AND FRESH AIR SUPPLY

WARNING

Carbon Monoxide Hazard

Multiburner systems are not approved for

unvented use and must be vented outdoors.

Unitary heaters installed unvented must be

interlocked with sufficient building exhaust.

Heaters must be installed according to the

installation manual.

Failure to follow these instructions can result

in death or injury.

WARNING

Cut/Pinch Hazard

Wear protective gear during installation,

operation and service.

Edges are sharp.

Failure to follow these instructions can result

in injury.

Fresh Air Adapter

Fresh Air

Supply Duct

100 mm OD

SECTION 11: VENTING AND FRESH AIR SUPPLY

flue must be self supporting. Suitable terminals must be

fitted for horizontal and vertical flue.

In order to locate fans that are not IP54 protected away

from the wet environment, a 100 mm diameter extension

tube between the heat exchanger end and fan must be

installed. This length must be subtracted from the

maximum flue length.

Fans

83 BWLG 190 mm x 75 mm (hole) 150 mm dia.

90 BWLG 190 mm x 75 mm (hole) 150 mm dia.

Horizontal Vertical

11.4 Ventilation Requirements

Detailed recommendations for air supply are given in the

relevant National Standards. There must be an adequate

supply of air for both combustion and general ventilation.

Air vents should have negligible resistance. Do not locate

air vents where they can be easily blocked or flooded, or

adjacent to any flues or extraction systems carrying

flammable vapour.

11.5 Fresh Air Supply

The burner is equipped with a fresh air adapter which has

a silicone gasket incorporated. This adapter accepts

tubes with 100 mm outside diameter.

11.1 Type C

Room Sealed

The heaters are designed to be installed as room sealed

appliances. The flue and air intake are run as separate

pipes to the special concentric wall or roof terminal. The

wire mesh inside the fresh air adapter on the heater must

be removed prior to installation. See Page 51, Figure 31.

11.2 Type B22 Appliance

The flue must be fitted with a low resistance terminal. See

Page 51, Figure 31.

, C32 & C62 Appliance

12