Page 1

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. DO NOT try to light any appliance.

3. DO NOT use electrical switches.

4. DO NOT use any telephone in

your building.

5. Leave the building.

6. Immediately call your local gas

supplier after leaving the building.

Follow the gas suppliers

instructions.

7. If you cannot reach your gas

supplier, call the Fire Department.

®

Gas-Fired, Low-Intensity

Infrared Heaters for

WARNING

Fire Hazard

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

Some objects will catch fire or explode

when placed close to heater.

Failure to follow these instructions can

result in death, injury or property

damage.

Residential Garages and

Light Industrial/Commercial

Applications

Installation, Operation &

Service Manual

CGTH-30

CGTH-40

CGTH-50

WARNING

Improper installation, adjustment, alteration, service

or maintenance can result in death, injury or property

damage. Read the Installation, Operation and Service

Manual thoroughly before installing or servicing

this equipment.

Installation must be done by a contractor qualified

in the installation and service of gas-fired heating

equipment or your gas supplier.

Quality in Any Language™

© Copyright 2005 Roberts-Gordon

Installer

Please take the time to read and understand

these instructions prior to any installation.

Installer must give a copy of this manual to the owner.

Owner

Keep this manual in a safe place in order to provide

your serviceman with necessary information.

Roberts-Gordon, LLC

1250 William Street

P. O . B o x 4 4

Buffalo, New York 14240-0044

Telephone: 716.852.4400

Fax: 716.852.0854

Toll Free: 800.828.7450

www.rg-inc.com

P/N 180100NA Rev. G 11/05

Page 2

Page 3

TABLE OF CONTENTS

SECTION 1: Before You Begin............................................... 1

1.1 Read This Manual........................................................ 1

1.2 Questions, Comments or Suggestions......................... 1

SECTION 2: Introduction........................................................ 2

2.1 About Roberts-Gordon ................................................ 2

2.2 About the Heater.......................................................... 2

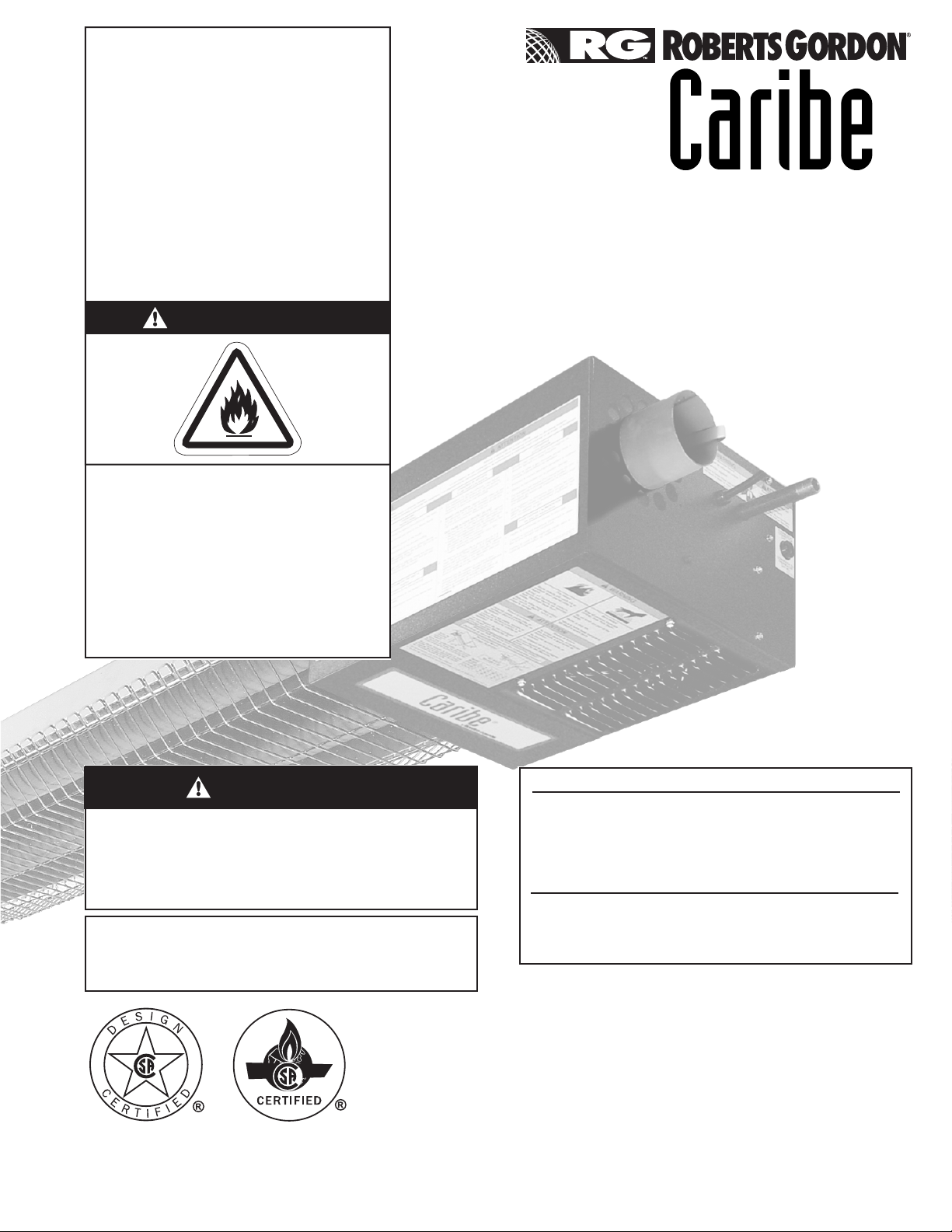

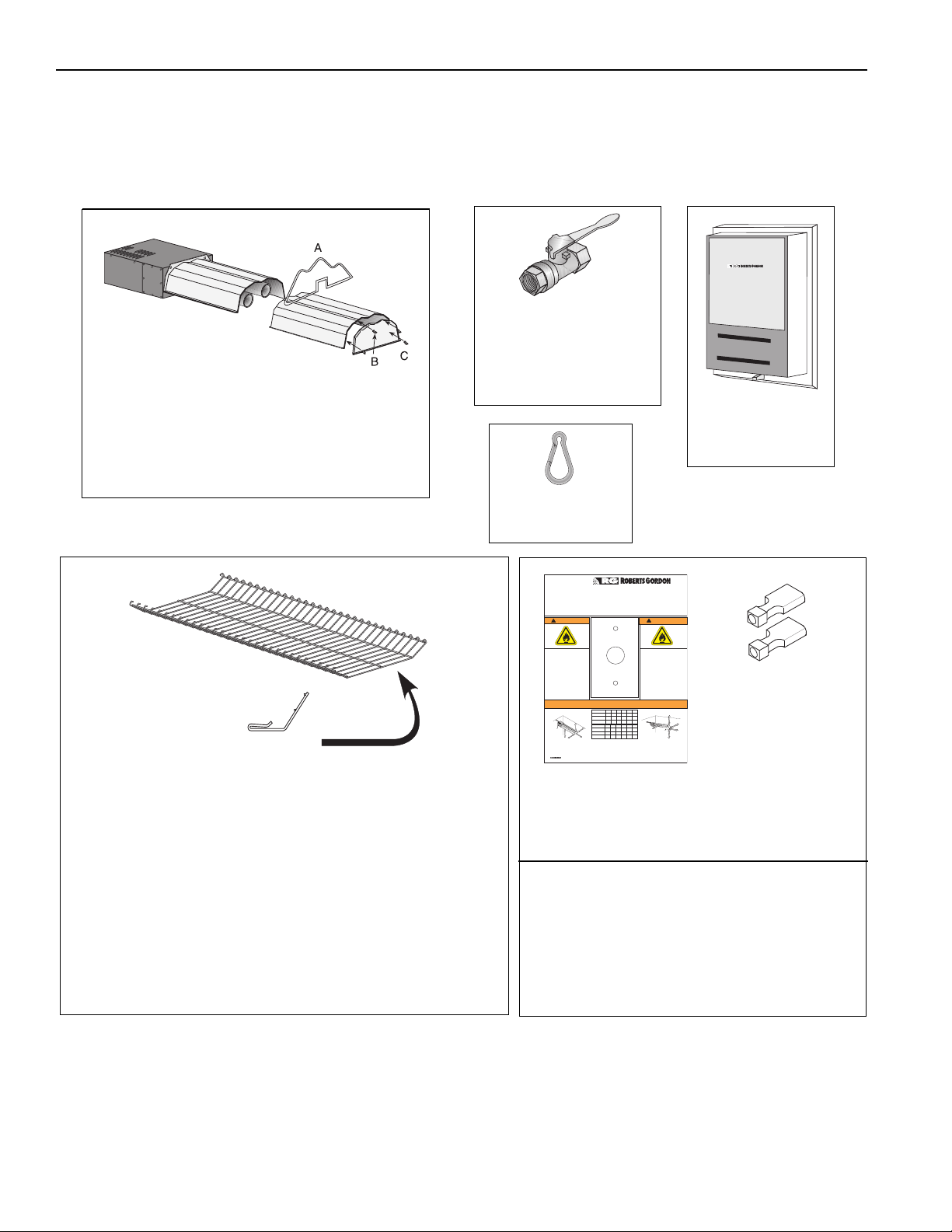

2.3 Unpacking the Heater.................................................. 2

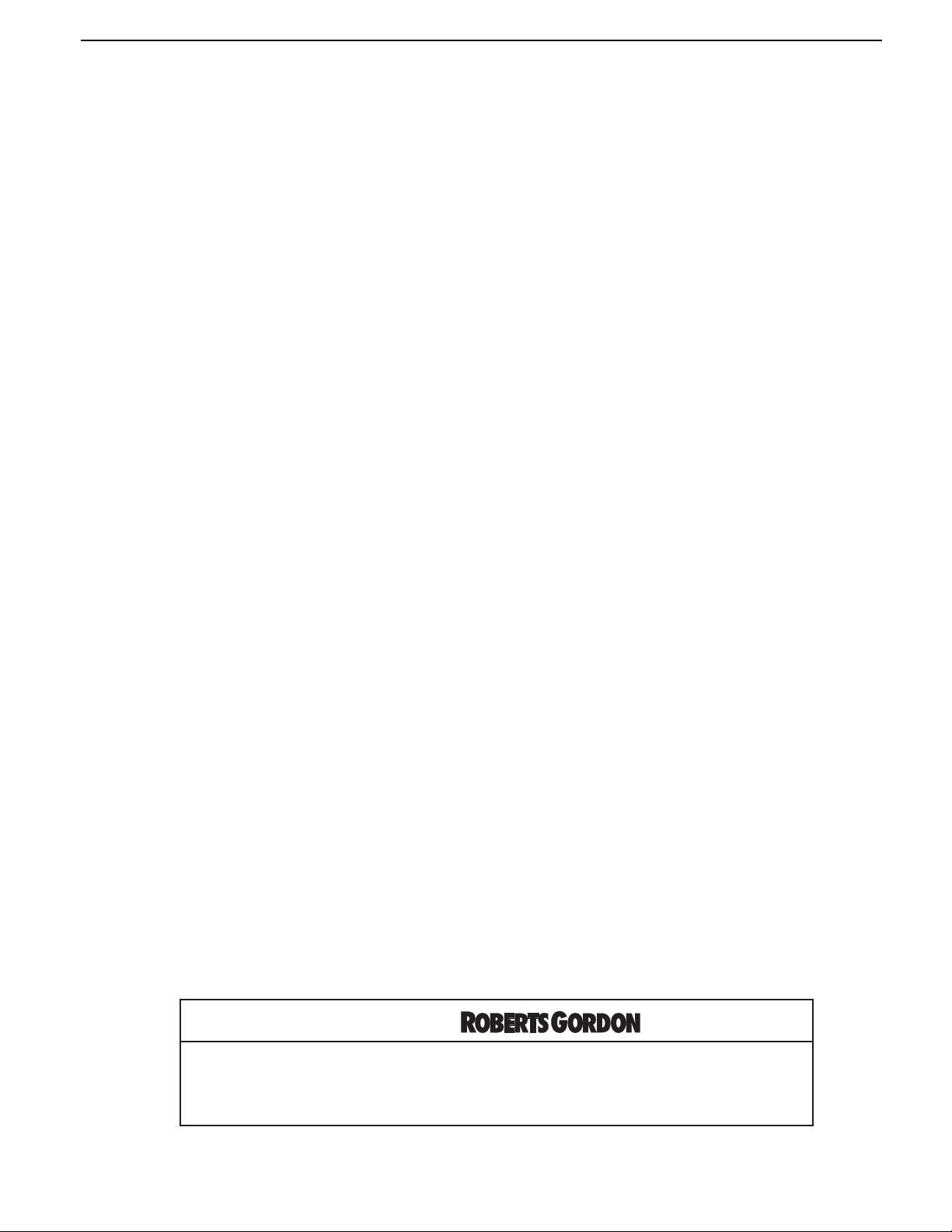

2.4 Carton Contents of Heaters with Galvanized Venting .. 3

2.5 Carton Contents of Heaters with Cox Geelen Venting . 4

2.6 Available Accessories for Galvanized Vent ..................5

2.7 Available Accessories for Cox Geelen Vent................. 6

2.8 Components Identification ...........................................7

2.9 Technical Specifications............................................... 8

2.10 Where Can the Heater Be Installed? .........................9

2.11 Where Can't the Heater Be Installed? ........................ 9

2.12 Installer's Responsibility.............................................9

SECTION 3: Planning............................................................ 10

3.1 General...................................................................... 10

3.2 Gas Service Requirements........................................ 10

3.3 Electrical Service Requirements................................ 10

3.4 Venting Requirements................................................ 11

3.5 Non-Residential Installations ..................................... 11

SECTION 4: Installation........................................................ 13

4.1 Safety Equipment ...................................................... 13

4.2 Installation Tools ........................................................ 13

4.3 Installation Materials.................................................. 13

4.4 Choose Location for Heater....................................... 13

4.5 General Venting Guidelines ....................................... 14

4.6 Required Safe Distances from Combustibles............. 15

4.7 Hang the Heater ........................................................ 17

4.8 Remove Shipping Screw from Control Housing Door 17

4.9 Heater Assembly ....................................................... 17

4.10 Typical Installation.................................................... 18

4.11 Heater Orientation.................................................... 18

4.12 Horizontal Installation............................................... 18

4.13 45° Tilted Installation................................................ 19

4.14 Grille Installation (for Select Models Only)............... 20

SECTION 5: Venting Installation.......................................... 21

5.1 General Venting Requirements.................................. 21

5.2 Install Galvanized Collar ............................................21

5.3 Galvanized Horizontal Venting ................................... 22

5.4 Cox Geelen Horizontal Venting.................................. 27

5.5 Cox Geelen Vertical Venting ...................................... 29

SECTION 6: Electrical Service Installation ......................... 31

6.1 System Requirements................................................ 31

6.2 Grounding.................................................................. 31

6.3 Important Notes ......................................................... 31

6.4 Thermostat Placement .............................................. 31

6.5 Thermostat Installation ..............................................31

SECTION 7: Gas Service Installation .................................. 33

7.1 Install Gas Supply Lines............................................. 33

SECTION 8: Operation.......................................................... 34

8.1 Operating Instructions ............................................... 34

8.2 To Turn Off Gas To Heater ......................................... 34

8.3 Sequence of Operation.............................................. 34

8.4 Testing ....................................................................... 34

SECTION 9: Troubleshooting............................................... 36

9.1 General...................................................................... 36

SECTION 10: Maintenance................................................... 41

10.1 Pre-Season Maintenance......................................... 41

SECTION 11: Wiring Diagrams............................................. 42

11.1 Connection Diagram................................................. 42

11.2 Ladder Diagram........................................................ 43

SECTION 12: Replacement Parts ........................................ 44

12.1 Illustrated Parts List for Burner ................................ 44

12.2 lllustrated Parts List for Tube and Reflector .............46

12.3 Replacement Parts List for Tube & Reflector ........... 46

SECTION 13: The ROBERTS GORDON

Warranty................................................................................. 47

®

CARIBE® LIMITED

© 2005

All rights reserved. No part of this work covered by the copyrights herein may be reproduced

or copied in any form or by any means - graphic, electronic, or mechanical, including

photocopying, recording, taping or information storage and retrieval systems - without the

written permission of Roberts-Gordon.

Printed in the U.S.A.

Page 4

Page 5

TABLE OF FIGURES

Figure 1: Components Identification ......................................... 7

Figure 2: Specifications............................................................. 8

Figure 3: Balanced Flue.......................................................... 11

Figure 4: Horizontal Installations ............................................. 16

Figure 5: 45° Tilted Installations.............................................. 16

Figure 6: Shipping Screw........................................................ 17

Figure 7: Suspension Details.................................................. 17

Figure 8: Heater Assembly .....................................................17

Figure 9: Typical Installation.................................................... 18

Figure 10: Horizontal Installation............................................. 19

Figure 11: 45° Tilted Installation.............................................. 19

Figure 12: Silicone Cap Installation ........................................20

Figure 13: Grille End Cap Installation...................................... 20

Figure 14: Reflector and Grille ................................................20

Figure 15: Rear View .............................................................. 21

Figure 16: Horizontal Installation Side View............................ 23

Figure 17: Bird Screen Installation.......................................... 23

Figure 18: Horizontal Installation Top View ............................24

Figure 19: Elbow Assembly End View ....................................24

Figure 20: Elbow Assembly Cross Section View ....................24

Figure 21: Elbow Assembly ....................................................25

Figure 22: Elbow Assembly for Vent Collar ............................25

Figure 23: Vent Collar and 5" Vent Attachment ...................... 25

Figure 24: Assembly Overview ............................................... 26

Figure 25: Horizontal Installation Side View

Cox Geelen Venting ............................................... 27

Figure 26: Flue Collar and Adapter......................................... 28

Figure 27: Horizontal Venting Configurations .........................28

Figure 28: Vertical Venting Configurations .............................29

Figure 29: Vent Clamp............................................................ 30

Figure 30: Thermostat Installation ..........................................31

Figure 31: Thermostat Installation Rear View......................... 32

Figure 32: Gas Supply Lines................................................... 33

Figure 33: Pressure Testing.................................................... 35

Figure 34: Manometer Reading .............................................. 38

Figure 35: Connection Diagram ..............................................42

Figure 36: Ladder Diagram .................................................... 43

Figure 37: Illustrated Parts List ............................................... 44

Figure 38: Tube and Reflector................................................. 46

Page 6

Page 7

SECTION 1: BEFORE YOU BEGIN

1.1 Read This Manual

Read this manual carefully before installing or servicing this equipment. Improper installation, servicing or

maintenance can result in death, injury or property

damage. Check the required safe distances from

combustibles given on the outside of each burner to

make sure that the product is suitable for your application. The required safe distances from combustibles are also found on Pages 15 and 16 of this

manual. Installer must be a contractor qualified in the

installation and service of gas-fired heating equipment. After the installation is complete, check product

operation as provided in these instructions.

1.2 Questions, Comments or Suggestions

Please direct any questions, comments or suggestions to:

Roberts-Gordon, LLC

1250 William Street

P. O . B o x 4 4

Buffalo, New York 14240-0044

Telephone: 716.852.4400

Fax: 716.852.0854

Toll Free: 800.828.7450

SECTION 1: BEFORE YOU BEGIN

1

Page 8

CGTH INSTALLATION, OPERATION AND SERVICE MANUAL

SECTION 2: INTRODUCTION

2.1 About Roberts-Gordon

Roberts-Gordon pioneered low-intensity infrared

heating systems in 1962 with the introduction of its

®

revolutionary, custom-engineered CORAYVAC

system. After more than 40 years of infrared expertise in

commercial and industrial applications, Roberts-Gordon now offers the CGTH-Series heater for use in

residential garages and light industrial/commercial

applications.

2.2 About the Heater

The CGTH-Series is a factory-assembled, gas-fired,

low-intensity heating system that incorporates a balanced flue. The system has been designed for easy

installation and will provide years of economical

operation and trouble-free service. Not only is infrared heat efficient, it also provides the most comfortable conditions in open areas, such as garages.

lifted from the carton at the same time. The burner

should be lifted by gripping the bottom. The reflector

of the heater should be lifted using the hanger.

2.3.2 Safety

WARNING

Cut Hazard

Wear protective gloves when handling aluminum

reflectors.

Edges are sharp.

Failure to follow these instructions can result in injury.

Gas-Fired means it uses clean-burning natural or LP

gas.

Low-Intensity means that the radiant surface of the

tube does not glow red. Instead, it operates at a

lower temperature (less than 1000°F) and radiates

energy at a lower intensity per square foot of radiating surface. The lower temperature and intensity levels are within a range that is most effective in

establishing and maintaining personal comfort levels.

An aluminum reflector directs the radiant energy

downward to the occupied area.

Balanced Flue means that the burner draws combustion air from outdoors and exhausts the products

of combustion, also to the outdoors, through a shared

opening. This is accomplished through two concentric tubes.

Radiant refers to the energy radiated by the CGTHSeries heater. Because the energy is in the form of

infrared rays, it does not directly heat the air. Instead,

the rays heat objects such as the floor, cars, machines

and people. The warm objects, in turn, heat the air.

Thin sheet metal parts, such as the reflector portion

of the heater and the various venting components,

have sharp edges. To prevent injury, the use of work

gloves is recommended. The use of gloves will also

prevent the transfer of body oils from the hands to the

surface of the reflector.

These combined features are the key to the exceptional comfort and fuel efficiency provided by the

CGTH-Series heater.

2.3 Unpacking the Heater

2.3.1 Manpower Requirements

To prevent personal injury and damage to the heater,

two persons will be required to remove the heater

from the carton. Both ends of the heater should be

2

Page 9

SECTION 2: INTRODUCTION

A

D

E

A

F

2.4 Carton Contents of Heaters with Galvanized Venting

Please check the cartons. It should contain the items shown on this page. Contact your ROBERTS GORDON®

independent distributor if any items are missing.

(*) Additional package included with select models; also available as an accessory. See Page 5.

Heater Assembly:

A

B

CGTH-30; CGTH-40; CGTH-50

A.) (1) Hanger P/N 08080000

B.) (1) Reflector End Cap P/N 02750800

C.) (4) U-Clips P/N 91107720

(1) Vent Termination

P/N 08031001

(1) Bird Screen

P/N 08036000

* 5' (125 mm) Balanced Flue

Vent package (P/N 08039000)

includes:

°F 40

50 60 70

l l l l l

°

C 5 10 15 20

OFF

FRONT

C

(1) Thermostat

P/N 90409702

(1) 3" (80 mm) Flue Pipe

66"(168 cm) Long

P/N 08035000

(1) 5" (125 mm) Vent Pipe

60" (1520 mm) Long

P/N 90502800

(1) 3/8" (10 mm) Manual Gas

Shut-off Valve P/N 90100200

(1) Flue Collar

P/N 91911701

(4) Snap Hooks

P/N 91903300

Grille (P/N 08050001)

Grille End Cap

(P/N 08050002)

Side View

Protective Grille Kits - Included with select models. Also

available as an accessory under kit part numbers.

CGTH-30 Kit (P/N 08051000) includes:

(1) Grille End Cap P/N 08050002

(2) Grille without End Cap P/N 08050001

(2) Silicone Cap P/N 91915951-6P

CGTH-40 and CGTH-50 Kit (P/N 08051001) includes:

(3) Grille without End Cap P/N 08050001

(1) Grille End Cap P/N 08050002

(3) Silicone Cap P/N 91915951-6P

ATTENTION

Risque d'incendie

Certains objets placés près du

radiateur peuvent s'enflammer ou

exploser.

Tenir tous les objets, iquides et

vapeurs inflammables à la

distance de sécurité requise du

radiateur.

Surveiffer les enfants. Gardes les

vêtements, les meubles loin de

l'appareil.

Le non-respect de ces consignes

peut causer dommage au matériel.

45° Mount

Montage à 45°

61 cm)

24" Min. (

D

Approx.

45

°

E

2.Les chiffres noirs sont en pouces. Les chiffres oranges

sont en centimètres.

3.Vous devrez connaître le numéro de votre modèle. Il se

trouve sur létiquette de classement. (Voir le dessin du

montage horizontal pour lemplacement de létiquette de

classement).

P/N 91037903 Rev F

®

(2) Female Terminals

to connect

A

A

thermostat wire

F

P/N 91317300

by

CGTH-Series

This thermostat controls your overhead tube heater. Keep burner, control compartment and reflector clean. Read

your CGTH-Series Use and Care Manual (P/N 180101NA or GH80101NA) and follow all Safety Requirements which

include checking your heater monthly. Installation, Service and Annual Inspection must be done by a contractor

qualified in the installation and service of gas-fired heating equipment. Please call (716) 852-4400 (USA) or (905)

945-5403 (Canada) if you need a manual or have questions.

Ce thermostat commande votre radiateur. Gardez le module de contrôle et le reflécteur propres. Lisez le manuel

dutilisation et dentretien CGTH-Series (P/N 180101NA ou GH80101NA) et respectez tous les conseils de sécurité,

notamment le contrôle mensuel du radiateur. Linstallation, l'entretien et linspection annuelle doivent être effectués

par un agent agréé. Veuillez nous contactez au 716-852-4400 (USA) ou au 905-945-5403 (Canada) pour toutes

questions ou demandes de manuel.

WARNING

Fire Hazard

Some objects will catch fire or

explode when placed close to

heater.

Keep all flammable objects,

liquids and vapors the required

safe distances away from heater.

Keep children, clothing and

furniture away from the heater.

Failure to follow these

instructions will result in death,

injury or property damage.

Horizontal Mount

Montage Horizontal

24" Min. (61 cm)

Rating Tag

Éttiquette de

Classement

NOTES: 1. All dimensions are from the reflector.

2.Black numerals are in inches.

centimeters.

3.Know your model number. Model number is found on the

rating tag. (See horizontal mount drawing for location of

rating tag).

©

MOUNT

THERMOSTAT

HERE

MONTER LE

THERMOSTAT ICI

Required Safe Distances from Combustibles

Distances de Dégagement par Rapport aux Combustibles

Model A B C D E F

CGTH-30 4 16 36 28 34 6

CGTH-40 4 18 48 30 34 6

CGTH-50 4 20 48 32 36 6

Modèle A B C D E F

A

CGTH-30 11 41 92 72 87 16

B

C

CGTH-401146 122 77 87 16

F

CGTH-50 11 51 122 82 92 16

B

NOTES: 1. Toutes les dimensions sont mesurées à partir du réflecteur.

Orange numerals are in

Printed in U.S.A./Imprimé aux Etats-Unis

www.rg-inc.com

(1) Thermostat Tag P/N 91037903

(3) Vent Collar Mounting Screws

to attach vent collar to heater

P/N 94118106

Documents:

(1) Installation Manual P/N 180100NA

(1) Use and Care Manual

P/N180101NA

(1) Owner Warranty Registration Card:

P/N CGTHWCNA

3

Page 10

CGTH INSTALLATION, OPERATION AND SERVICE MANUAL

A

D

E

A

F

2.5 Carton Contents of Heaters with Cox Geelen Venting

Please check the cartons. It should contain the items shown on this page. Contact your ROBERTS GORDON

independent distributor if any items are missing.

Heater Assembly:

(1) 3/8" (10 mm)

CGTH-30; CGTH-40; CGTH-50

A.) (1) Hanger P/N 08080000

B.) (1) Reflector End Cap P/N 02750800

Manual Gas

Shut-off Valve

P/N 90100200

°F 40

50 60 70

l l l l l

°

C 5 10 15 20

OFF

FRONT

(1) Thermostat

P/N 90409702

C.) (4) U-Clips P/N 91107720

(4) Snap Hooks

P/N 91903300

®

Grille (P/N 08050001)

Grille End Cap

(P/N 08050002)

Side View

Protective Grille Kits - Included with select models. Also

available as an accessory under kit part numbers.

CGTH-30 Kit (P/N 08051000) includes:

(1) Grille End Cap P/N 08050002

(2) Grille without End Cap P/N 08050001

(2) Silicone Cap P/N 91915951-6P

CGTH-40 and CGTH-50 Kit (P/N 08051001) includes:

(3) Grille without End Cap P/N 08050001

(1) Grille End Cap P/N 08050002

(3) Silicone Cap P/N 91915951-6P

by

CGTH-Series

This thermostat controls your overhead tube heater. Keep burner, control compartment and reflector clean. Read

your CGTH-Series Use and Care Manual (P/N 180101NA or GH80101NA) and follow all Safety Requirements which

include checking your heater monthly. Installation, Service and Annual Inspection must be done by a contractor

qualified in the installation and service of gas-fired heating equipment. Please call (716) 852-4400 (USA) or (905)

945-5403 (Canada) if you need a manual or have questions.

Ce thermostat commande votre radiateur. Gardez le module de contrôle et le reflécteur propres. Lisez le manuel

dutilisation et dentretien CGTH-Series (P/N 180101NA ou GH80101NA) et respectez tous les conseils de sécurité,

notamment le contrôle mensuel du radiateur. Linstallation, l'entretien et linspection annuelle doivent être effectués

par un agent agréé. Veuillez nous contactez au 716-852-4400 (USA) ou au 905-945-5403 (Canada) pour toutes

questions ou demandes de manuel.

WARNING

Fire Hazard

Some objects will catch fire or

explode when placed close to

heater.

Keep all flammable objects,

liquids and vapors the required

safe distances away from heater.

Keep children, clothing and

furniture away from the heater.

Failure to follow these

instructions will result in death,

injury or property damage.

Horizontal Mount

Montage Horizontal

24" Min. (61 cm)

Rating Tag

Éttiquette de

Classement

NOTES: 1. All dimensions are from the reflector.

2.Black numerals are in inches.

centimeters.

3.Know your model number. Model number is found on the

rating tag. (See horizontal mount drawing for location of

rating tag).

©

MOUNT

THERMOSTAT

HERE

MONTER LE

THERMOSTAT ICI

Required Safe Distances from Combustibles

Distances de Dégagement par Rapport aux Combustibles

Model A B C D E F

CGTH-30 4 16 36 28 34 6

CGTH-40 4 18 48 30 34 6

CGTH-50 4 20 48 32 36 6

Modèle A B C D E F

A

CGTH-30 11 41 92 72 87 16

B

C

CGTH-401146 122 77 87 16

F

CGTH-50 11 51 122 82 92 16

B

NOTES: 1. Toutes les dimensions sont mesurées à partir du réflecteur.

Orange numerals are in

Printed in U.S.A./Imprimé aux Etats-Unis

www.rg-inc.com

®

ATTENTION

Risque d'incendie

Certains objets placés près du

radiateur peuvent s'enflammer ou

exploser.

Tenir tous les objets, iquides et

vapeurs inflammables à la

distance de sécurité requise du

radiateur.

Surveiffer les enfants. Gardes les

vêtements, les meubles loin de

l'appareil.

Le non-respect de ces consignes

peut causer dommage au matériel.

45° Mount

Montage à 45°

A

61 cm)

24" Min. (

D

Approx.

45

°

E

2.Les chiffres noirs sont en pouces. Les chiffres oranges

sont en centimètres.

3.Vous devrez connaître le numéro de votre modèle. Il se

trouve sur létiquette de classement. (Voir le dessin du

montage horizontal pour lemplacement de létiquette de

classement).

P/N 91037903 Rev F

(2) Female Terminals

to connect

thermostat wire

A

F

P/N 91317300

(1) Thermostat Tag P/N 91037903

(3) Vent Collar Mounting Screws

to attach vent collar to heater

P/N 94118106

Documents:

(1) Installation Manual P/N 180100NA

(1) Use and Care Manual

P/N180101NA

(1) Owner Warranty Registration Card:

P/N CGTHWCNA

4

Page 11

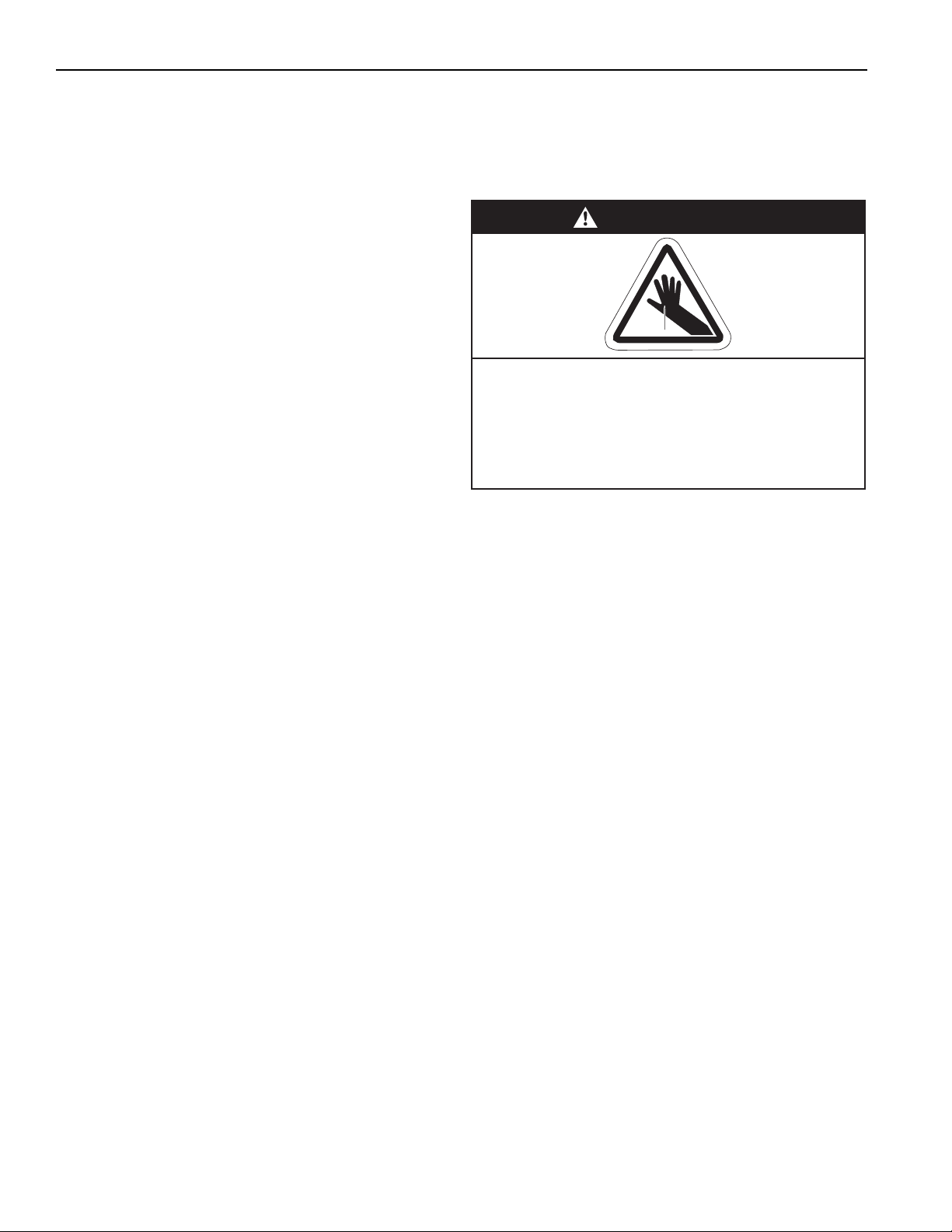

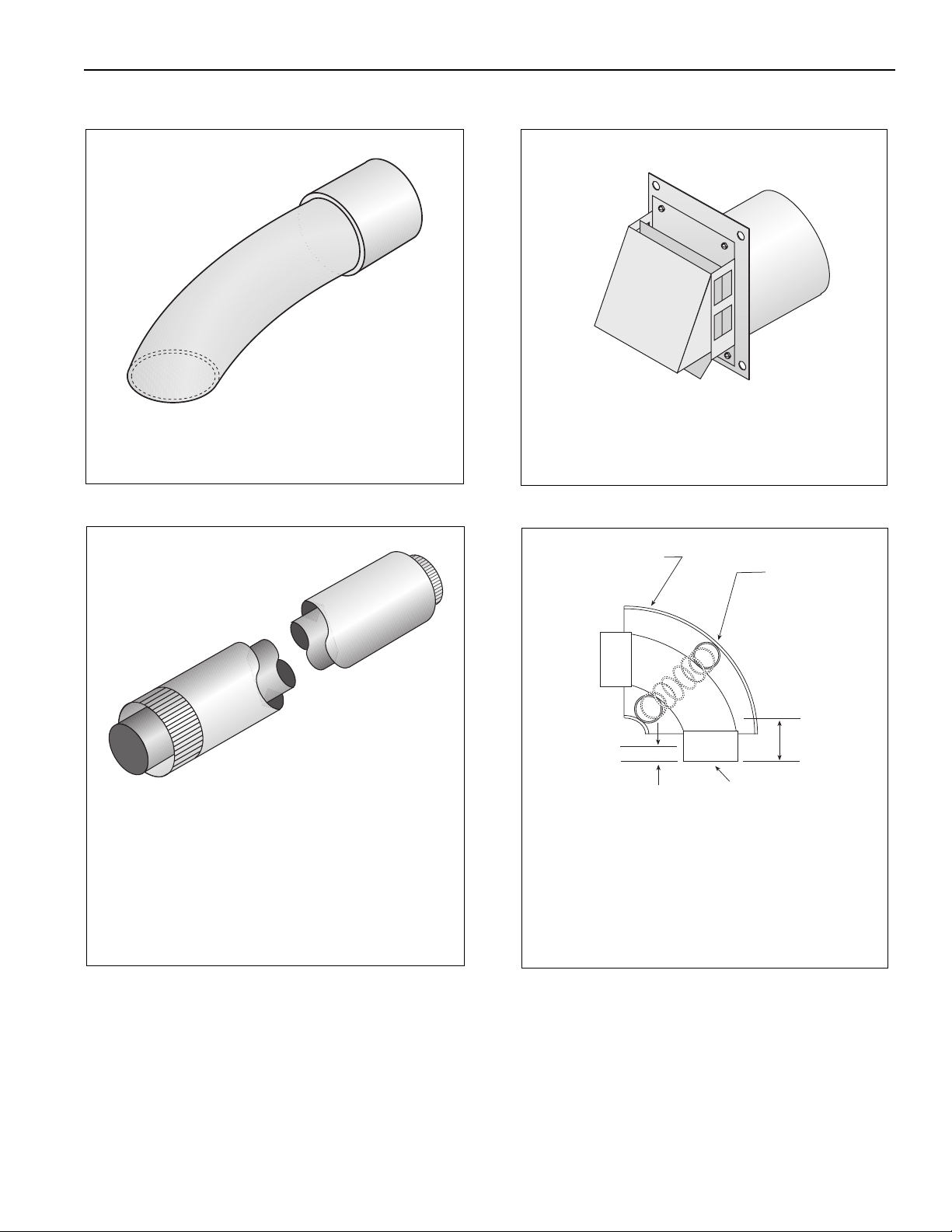

2.6 Available Accessories for Galvanized Vent

SECTION 2: INTRODUCTION

Vent Terminal Extension

P/N 08037000

5' (1524 mm) Balanced Flue Vent

(P/N 08039000) includes:

(1) 5" (125 mm) Vent Pipe - 60"

P/N 90502800

(1) 3" (80 mm) Flue Pipe - 66"

P/N 08035000

Tjernlund Wall Vent

P/N 08033000

5" (125 mm)

Diameter Elbow

2.75" (57 mm)

1" (25 mm)

Diameter Spring

6" (152 mm)

3" (80 mm)

Diameter Elbow

90° Elbow Kit (P/N 08038000) includes:

(1) 5" (125 mm) Diameter Elbow

P/N 90503000

(1) 3" (80 mm) Diameter Elbow

P/N 90503100

(1) Coil Spring Spacer P/N 90503200

5

Page 12

CGTH INSTALLATION, OPERATION AND SERVICE MANUAL

2.7 Available Accessories for Cox Geelen Vent

Roof Venting Kit (P/N 08032100) includes:

(1) Elbow 90°

P/N 90506001

(1) Storm Collar

P/N 90506015

Wall Venting Kit (P/N 08032200) includes:

(1) Burner/Vent Adapter P/N 90506012

(1) Burner/Vent Adapter

(1) Roof Terminal

P/N 90506012

50.5” (1283 mm)

P/N 90506008

Concentric Flue 250 mm = 10” P/N 90506003

Concentric Flue 500 mm = 20” P/N 90506004

Concentric Flue 1000 mm = 39” P/N 90506005

6

(1) Wall Terminal 25” (635 mm)

with wall plate (P/N 90506011) includes:

(4) Screws P/N 94118106

(2) Wall Plates P/N 90506013

Elbow 45° = 39” P/N 90506002

Page 13

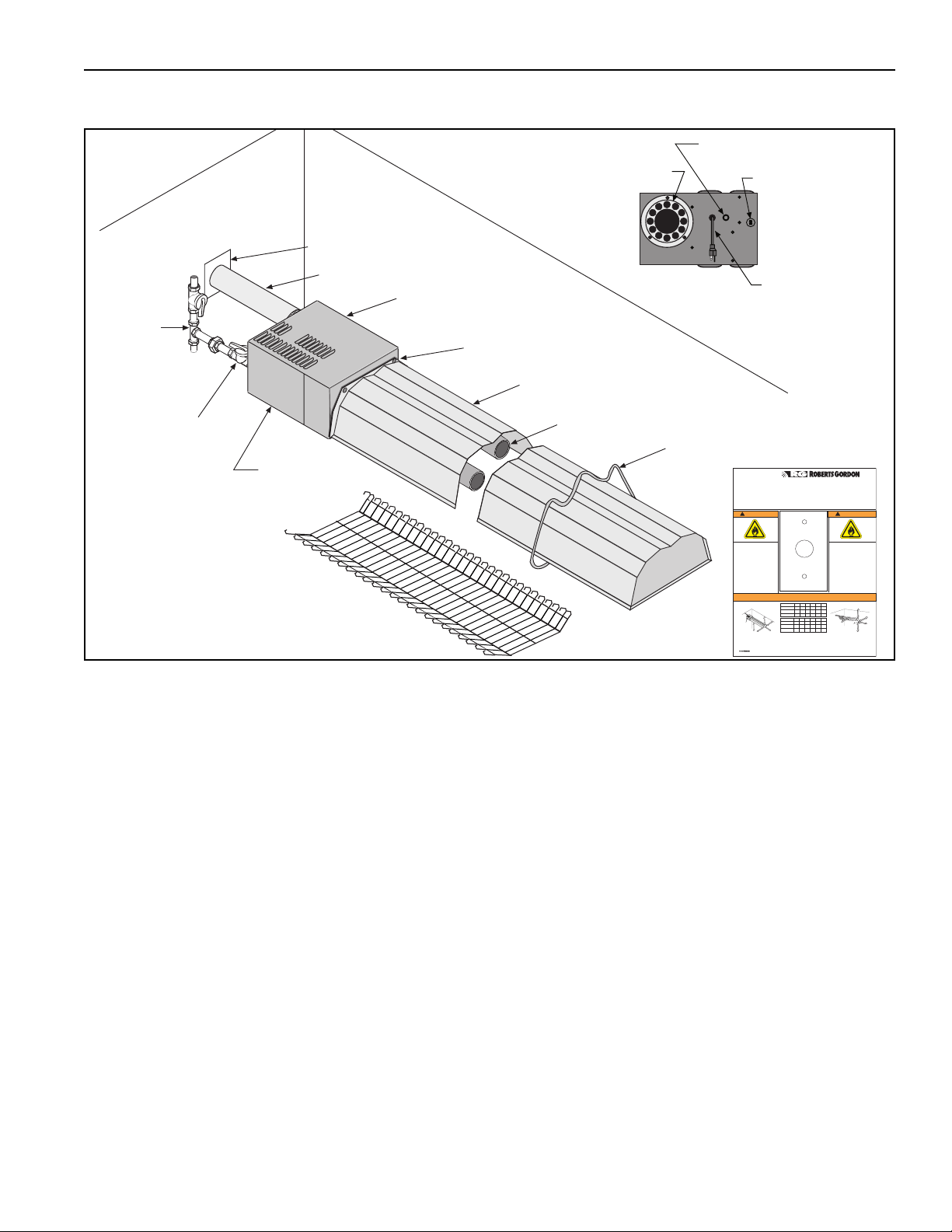

2.8 Components Identification

A

D

E

A

F

FIGURE 1: Components Identification

Wall Termination Plate

Venting

Gas Line

Burner

Front Fixed Hanger

Reflector

Vent Collar

SECTION 2: INTRODUCTION

Nipple 3/8

(10 mm) NPT

Thermostat

Connection

Power

Cord

Manual Gas

Shut-off Valve

Service Door

Protective Grill

Burner - Contains the electrical components (i.e.

blower motor, power transformer, etc.) and gas distribution components (i.e. gas valve, etc.) that make

the heater work. There are no owner serviceable

items contained in this box.

Front Fixed Hanger - Provides rigid support and

mounting surface for the reflector. Holes are provided

in the upper corners of the bulkhead to accommodate suspension hardware required for installation of

the heater.

Reflector - The reflector is made from formed aluminum and reflects the radiant energy downward to the

space to be heated.

Heat Exchanger - A U-shaped tube through which

the heated products of combustion pass.

Rear Movable Hanger - Provides support for the tube

and reflector at the end that is furthest from the burner.

The support may be moved (within limits) to accommodate hanging of the unit.

Service Door - To be removed only by a contractor

qualified in the installation and service of gas-fired

heating equipment or your gas supplier. Removal of

Heat Exchanger

Rear Movable

Hanger

by

CGTH-Series

This thermostat controls your overhead tube heater. Keep burner, control compartment and reflector clean. Read

your CGTH-Series Use and Care Manual (P/N 180101NA or GH80101NA) and follow all Safety Requirements which

include checking your heater monthly. Installation, Service and Annual Inspection must be done by a contractor

qualified in the installation and service of gas-fired heating equipment. Please call (716) 852-4400 (USA) or (905)

945-5403 (Canada) if you need a manual or have questions.

Ce thermostat commande votre radiateur. Gardez le module de contrôle et le reflécteur propres. Lisez le manuel

dutilisation et dentretien CGTH-Series (P/N 180101NA ou GH80101NA) et respectez tous les conseils de sécurité,

notamment le contrôle mensuel du radiateur. Linstallation, l'entretien et linspection annuelle doivent être effectués

par un agent agréé. Veuillez nous contactez au 716-852-4400 (USA) ou au 905-945-5403 (Canada) pour toutes

questions ou demandes de manuel.

WARNING

Fire Hazard

Some objects will catch fire or

explode when placed close to

heater.

Keep all flammable objects,

liquids and vapors the required

safe distances away from heater.

Keep children, clothing and

furniture away from the heater.

Failure to follow these

instructions will result in death,

injury or property damage.

Horizontal Mount

Montage Horizontal

24" Min. (61 cm)

Rating Tag

Éttiquette de

Classement

NOTES: 1. All dimensions are from the reflector.

2.Black numerals are in inches.

centimeters.

3.Know your model number. Model number is found on the

rating tag. (See horizontal mount drawing for location of

rating tag).

©

MOUNT

THERMOSTAT

HERE

MONTER LE

THERMOSTAT ICI

Required Safe Distances from Combustibles

Distances de Dégagement par Rapport aux Combustibles

Model A B C D E F

CGTH-30 4 16 36 28 34 6

CGTH-40 4 18 48 30 34 6

CGTH-50 4 20 48 32 36 6

Modèle A B C D E F

A

CGTH-30 11 41 92 72 87 16

B

C

CGTH-401146 122 77 87 16

F

CGTH-50 11 51 122 82 92 16

B

NOTES: 1. Toutes les dimensions sont mesurées à partir du réflecteur.

Orange numerals are in

Printed in U.S.A./Imprimé aux Etats-Unis

www.rg-inc.com

ATTENTION

Risque d'incendie

Certains objets placés près du

radiateur peuvent s'enflammer ou

exploser.

Tenir tous les objets, iquides et

vapeurs inflammables à la

distance de sécurité requise du

radiateur.

Surveiffer les enfants. Gardes les

vêtements, les meubles loin de

l'appareil.

Le non-respect de ces consignes

peut causer dommage au matériel.

45° Mount

Montage à 45°

61 cm)

24" Min. (

D

App

ro

x.

45

°

E

2.Les chiffres noirs sont en pouces. Les chiffres oranges

sont en centimètres.

3.Vous devrez connaître le numéro de votre modèle. Il se

trouve sur létiquette de classement. (Voir le dessin du

montage horizontal pour lemplacement de létiquette de

classement).

P/N 91037903 Rev F

®

A

A

F

this service door provides access to the electrical

and gas distribution components.

Gas Line - Must only be installed and serviced by a

licensed contractor or gas fitter.

Wall Termination Plate - Placed on the outside wall

over the venting.

Venting - Installer must properly exhaust the heater

outside. The 5” outer duct carries fresh air to the

burner. The 3” inner duct carries the products of combustion to the outside.

Thermostat - 24 Volt Thermostat mounted with

Safety Tag.

Protective Grille - Included with select models. See

Page 20, Section 4.14 for details.

Vent Collar - Accommodates a 5" (125 mm) diameter combustion air inlet duct that delivers fresh air to

the burner. The fresh air enters the burner through

the twelve equally spaced holes shown above. The

3" (80 mm) diameter hole in the center of the flue collar accommodates the venting duct that carries the

products of combustion to be vented outdoors.

7

Page 14

CGTH INSTALLATION, OPERATION AND SERVICE MANUAL

Nipple-3/8" (10 mm) NPT - Point at which the gas

supply is connected to the heater.

Thermostat Connection - Two terminals to which

the thermostat wires will be connected.

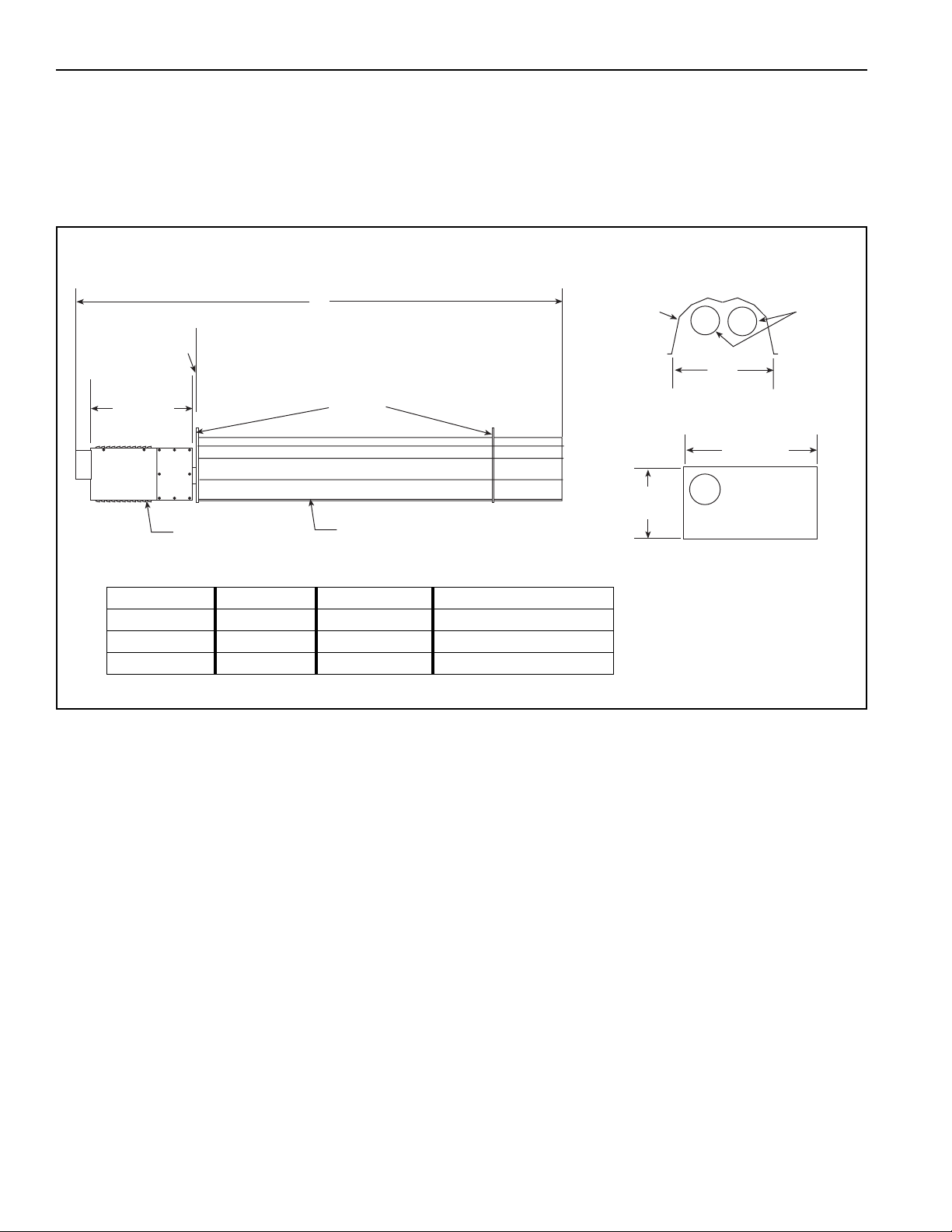

2.9 Technical Specifications

FIGURE 2: Specifications

- Side View - -End View-

A

1" (25 mm)

Maximum

15"

(381 mm)

Burner

Suspension

Points

Reflector

Power Cord - Includes a three-prong plug that must

be connected to a dedicated and properly grounded

three-prong ceiling outlet.

Reflector

14

(356 mm)

-Rear View-

(356 mm)

8.7"

(220 mm)

Heat

Exchanger

14"

Model No. BTU/hr Weight A

CGTH-30 30,000 85 lbs. 8'0" (2438 mm)

CGTH-40 40,000 96 lbs. 11'6" (3505 mm)

CGTH-50 50,000 96 lbs. 11'6" (3505 mm)

HEATER SPECIFICATIONS

Electrical

Rating: 120 V, 60 Hz, 1 Ø, 1 A

Connection: 3 pin molded plug

Gas Inlet Connection

Connection: 3/8" Male NPT

Gas Inlet Pressure

Natural Gas:

Minimum:Inlet5.0" w.c. (12.4 mbar)

Maximum:Inlet14.0" w.c. (34.8 mbar)

LP Gas (Propane):

Minimum:Inlet11.0" w.c. (37.4 mbar)

Maximum:Inlet14.0" w.c. (34.8 mbar)

Inputs and Dimensions

VENTING SPECIFICATIONS

Vent/Flue

Length:10' (3 m) (Maximum)

2' - 6" (1 m 15 cm) (Minimum)

Flue Pipe:3.0" (80 mm) diameter

Vent Pipe:5.0" (125 mm) diameter

Manifold Pressure

Natural Gas: 3.5" w.c. (8.7 mbar)

LP Gas (Propane): 10.5" w.c. (26.1 mbar)

8

Page 15

SECTION 2: INTRODUCTION

2.10 Where Can the Heater Be Installed?

The CGTH-Series heater is intended for installation

in the following areas:

• Residential applications, such as:

- garages

- hobby greenhouses

- workshops

• Light industrial/commercial applications, such

as:

- entranceways

- lobby areas

- lunch rooms

- aircraft hangars (See Page 11, Section 3.5.1

for restrictions)

- public garages (See Page 11, Section 3.5.2

for restrictions)

2.11 Where Can't the Heater Be Installed?

The CGTH-Series heater is not intended for installation in the following areas:

• Residential living or sleeping areas

ments of this manual. The installer must give this

manual and the Use and Care Manual to the owner.

• Basements

Due to high temperatures, ensure that the heater

area is kept clear of furniture, draperies, clothing

or other combustible materials. Children and

adults should be alerted to the hazard of high

surface temperatures and should stay away to

avoid burns and clothing ignition. Young children

should be carefully supervised when they are in

the same room as the heater.

2.12 Installer's Responsibility

The CGTH-Series heater, the gas and electrical supplies, as well as the venting, must be installed in

accordance with applicable specifications and codes.

Only firms (or individuals) well qualified in this type of

work should install the system. Consult local Building

Inspectors, Fire Marshals or your local ROBERTS

®

GORDON

independent distributor for guidance.

Use the information given in this manual together

with the cited codes and regulations to perform the

installation. If any aspects of the installation are

®

unclear, consult your ROBERTS GORDON

independent distributor for clarification. The installer must furnish all needed materials that are not furnished as

standard equipment. It is also the installer's responsibility to see that the materials and installation methods used result in a job that is workmanlike in

appearance and is in compliance with the require-

9

Page 16

CGTH INSTALLATION, OPERATION AND SERVICE MANUAL

SECTION 3: PLANNING

3.1 General

3.3 Electrical Service Requirements

This section provides the following information:

• Defines the gas, electric and venting requirements

for the CGTH-Series heater.

• Specifies the national standards and applicable

codes that apply to the gas, electric and venting

requirements.

• Specifies the national standards and applicable

codes that apply to non-residential installations.

3.2 Gas Service Requirements:

3.2.1 Gas Type

The type of gas appearing on the nameplate must be

the type of gas used. Installation must comply with local

codes and recommendations of the local gas company.

United States: Refer to National Fuel Gas Code, ANSI

Z223.1 - latest revision (same as NFPA Bulletin 54).

Canada: Refer to CSA B149.1 and B149.2: Installation

Codes for Gas Burning Appliances.

3.2.2 Gas Supply Lines

The size of the gas supply lines must comply with local

codes and recommendations of the local gas company.

United States: Refer to National Fuel Gas Code, ANSI

Z223.1 - latest revision (same as NFPA Bulletin 54).

Canada: Refer to CSA B149.1 and B149.2: Installation

Codes for Gas Burning Appliances.

WARNING

Electrical Shock Hazard

Plug heater into grounded

three-prong ceiling receptacle.

Do not cut or remove the grounding

prong from this plug.

Do not use with an extension cord.

Failure to follow these instructions

can result in death or electrical

shock.

3.3.1 Grounding

The heater must be electrically grounded in accordance

with the following codes: United States: Refer to National

Electrical Code, ANSI/NFPA-70 - latest revision. Wiring

must conform to the most current National Electrical

Code and local ordinances. Canada: Refer to Canadian

Electrical Code, CSA C22.1 Part 1 - latest revision.

3.3.2 Thermostat

It is important to note that the CGTH-Series heater is

controlled by a low voltage (24V AC) thermostat supplied with the heater. The control transformer located

inside the burner supplies the necessary electrical

power to operate the thermostat. No other electrical

power to the thermostat is required.

A 1/8" NPT plugged tap must be installed in the gas line

connection immediately upstream of the burner that is

farthest from the gas supply meter. The tap is required

for checking system gas pressure.

3.2.3 Meter and Service

Meter and service must be large enough to handle all

the heaters being installed plus any other connected

load. The gas line which feeds the system must be large

enough to supply the required gas with a maximum

pressure drop of 1/2" (13 mm) w.c. When gas piping is

not included in the layout drawing, the local gas supplier

will usually help in planning the gas piping.

10

Page 17

SECTION 3: PLANNING

3.4 Venting Requirements

3.4.1 System Requirements

The CGTH-Series heater must be installed with the

venting system supplied or with the optional venting

kit available from Roberts-Gordon. DO NOT connect

this heater to a separate chimney and do not common vent with any other fuel burning appliance.

The CGTH-Series heater employs a balanced flue/air

venting duct system and must conform to the following length requirements:

Maximum Length:10' (3048 mm)

Minimum Length:2' - 6" (760 mm)

Maximum Elbows:Two (2) with natural gas units,

one (1) with propane gas units

3.4.2 Venting Codes

WARNING

Carbon Monoxide Hazard

Heater must be exhausted outside.

Use materials supplied.

This heater needs fresh air for safe

operation and must be installed so

there are provisions for adequate

combustion and ventilation air.

Failure to follow these instructions

can result in death or injury.

The location, size, installation and termination of

vents, as well as the required safe distances from

combustibles when penetrating combustible walls,

must comply with local codes and recommendations

of the local gas company. United States: Refer to

National Fuel Gas Code, ANSI Z223.1 - latest revision (same as NFPA Bulletin 54). Canada: Refer to

CSA B149.1 and B149.2: Installation Codes for Gas

Burning Appliances.

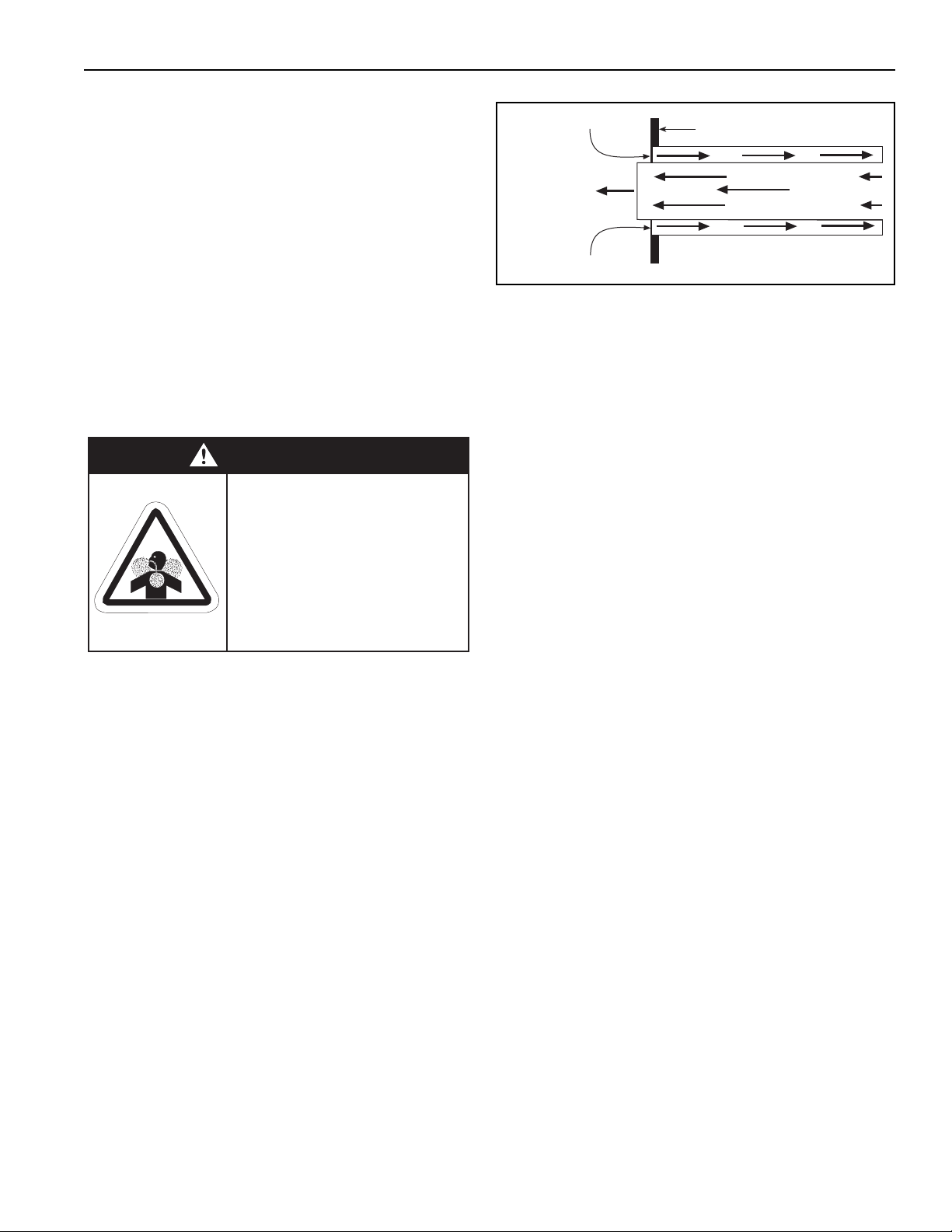

3.4.3 Balanced Flue Construction

The balanced flue consists of a 3" (80 mm) diameter

flue which is concentrically positioned inside a 5"

(125 mm) diameter vent pipe (See Figure 3). The 5"

(125 mm) diameter vent supplies outside air for combustion while the 3" (80 mm) diameter flue carries the

products of combustion from the heater.

The balanced flue is applicable for both horizontal

and vertical venting arrangements. Vertical venting

will require the optional roof venting kit available from

Roberts-Gordon.

FIGURE 3: Balanced Flue

Outside Air

Exhaust

Outside Air

Exterior Wall

Exhaust

3.5 Non-Residential Installations

3.5.1 Aircraft Hangars

The CGTH-Series heater may be used in certain areas

of aircraft hangars. Installation in aircraft hangars must

be in accordance with the following codes: United

States: Refer to Standard for Aircraft Hangars, ANSI/

NFPA-409 - latest revision. Canada: Refer to Standard

CSA B149.1 and B149.2.

• Heaters in aircraft storage or service areas must be

installed a minimum of 10' (3048 mm) above the

upper surface of wings or engine enclosures of the

highest aircraft which may be housed in the hangar.

(This should be measured from the bottom of the

heater to the top of the wing, or engine enclosure,

whichever is highest from the floor).

• In other sections of aircraft hangars, such as shops

or offices, heaters must be installed a minimum of 8'

(2438 mm) above the floor.

• Heaters installed in aircraft hangars shall be located

so as not to be subject to damage by aircraft,

cranes, movable scaffolding or other objects.

• When installed over hoists, the required safe distances from combustibles must be maintained from

the uppermost point of the combustible materials

placed on the hoist.

3.5.2 Public Garages

The CGTH-Series heater may be used in public

garages. Installation in public garages must be in accordance with the following codes: United States: Standard

for Parking Structures NFPA-88A - latest revision or the

Code for Fuel Dispensing Facilities and Repair

Garages, NFPA-30A - latest revision. Canada: Refer to

CSA B149.1 and B149.2: Installation Codes for Gas

Burning Appliances.

• Heaters must be installed a minimum of 8' (2438

mm) above the floor. Required safe distances to

11

Page 18

CGTH INSTALLATION, OPERATION AND SERVICE MANUAL

combustibles must be maintained from vehicles

parked below the heater.

• When installed over hoists, the required safe distances from combustibles must be maintained from

the uppermost point of the combustible materials

placed on the hoist.

3.5.3 Hazardous Locations

Where there is the possibility of exposure to combustible airborne material or vapor, consult the local Fire

Marshal, the Fire Insurance Carrier or other authorities for approval of the proposed installation.

12

Page 19

SECTION 4: INSTALLATION

SECTION 4: INSTALLATION

WARNING

Several steps are involved in the installation of the

heater.

Do not attempt to operate the heater until all steps of

the installation have been accomplished.

Failure to follow these instructions can result in death,

injury or property damage.

4.1 Safety Equipment

Use of the following safety equipment is recommended for installation of the CGTH-Series heater:

• Work gloves

• Safety glasses

4.2 Installation Tools

Tools required for the installation of the CGTH-Series

heater include at a minimum the following:

• Tape measure

• Electric drill (with an assortment of drill bits)

• Pipe wrenches - 2 required

• Screwdriver

• Tin snips

• Hacksaw

• Wire strippers

• Staple gun

• Level

• Pliers

• Crimping tool

• Hole saw - 5” (125 mm)

• Stud Finder (if garage is finished)

4.3 Installation Materials

Materials required for the installation of the CGTHSeries heater include at a minimum the following:

• High temperature silicone sealant (such as General Electric RTV106 or Permatex

®

ket

Red)

• Suspension hooks (capable of supporting 75 lbs.

each)

• Sheetmetal screws

The following items may be required for your particular installation:

®

Form-A-Gas-

• Plastic drain hose

• Additional vent pipe

• Roof flashing

• Rain collar

• Chain - 75 lbs., or equivalent

• Snap hooks (as required)

4.4 Choose Location for Heater

When selecting a suitable mounting location for the

CGTH-Series heater it is important to consider the

following:

• The heater must meet the minimum mounting

height requirement of 7' (2134 mm) above the

floor. For aircraft hangars and public garages, the

heater must meet the minimum mounting height

requirement of 8' (2438 mm) above the floor.

• The proposed mounting location allows for the

required safe distances from combustibles such

as vehicles, wood, gasoline and flammable

objects, liquids and vapors.

• The proposed location of the heater will not

restrict motion of passageway doors or windows.

• The proposed location will not interfere with operation of the overhead garage door or allow the

door to enter the required safe distances from

combustibles.

• The proposed location will provide the best coverage of the total area to be heated.

• Consideration be given to the types of vehicles

that will be parked in the garage (cars, vans,

boats, RV's, etc.).

• The proposed location will allow for the required

safe distances from combustibles with respect to

the vehicles parked in the garage.

• The proposed location will allow the required utilities (i.e.: gas and electric) and venting to be

installed (maximum vent length is 10' [3048 mm]).

• Sufficient clearances will exist to allow for easy

access to the service door.

• Overhead structural members (rafters, beams,

etc.) are accessible for attaching the heater.

13

Page 20

CGTH INSTALLATION, OPERATION AND SERVICE MANUAL

4.5 General Venting Guidelines

Regardless of the venting arrangement that will be

connected to the heater, the following general guidelines for venting must be followed:

1. The 3" (80 mm) flue pipe must be centered inside

the 5" (125 mm) air supply pipe.

2. The total length of vent pipe (horizontal and vertical runs combined, plus the length of the exterior

termination) must not exceed 10' (3048 mm), and

must not be less than 2' 6" (762 mm). A maximum

of two elbows are allowed with natural gas, one

elbow with propane.

3. The vent terminal, mounted outside of the building,

should not be located above walkways. Condensate produced during operation of the heater

could drip onto the walkway forming ice during

cold weather.

4. Be sure that the venting installation is in accordance with all applicable local codes and recommendations of the local gas company.

5. DO NOT connect this heater to a separate chimney and DO NOT common vent with any other fuel

burning appliance.

IMPORTANT: For standard flue, seal all vent pipe

connections with high temperature silicone sealant. Where required, drill holes and secure each

connection with three sheetmetal screws.

NOTE: Failure to seal all flue connections 3" (80

mm) will result in erratic heater operation.

14

Page 21

4.6 Required Safe Distances from Combustibles

In all situations, the required safe distances from

combustibles must be maintained. Combustibles are

materials which may catch fire and include many

common items such as wood, paper, rubber, fabrics,

etc. Combustible materials such as those noted, and

any other combustible materials, must not be placed

closer to any base or side of the CGTH-Series heater

than the distances noted in the diagrams on the fol-

lowing page. If you have any questions about the

required safe distances from combustibles, or the

associated diagrams, please contact your installer,

®

ROBERTS GORDON

independent distributor, or

Roberts-Gordon at 716.852-4400 or 1.800.828.7450,

during normal business hours which are Monday

through Friday, 8:15 a.m. to 4:45 p.m., Eastern Time.

For owner safety, a thermostat tag is supplied with

the CGTH-Series as a permanent reminder of the

importance of maintaining the required safe distances from combustibles. Instructions for installing

the tag are located on Page 31, Section 6.5. Immedi-

®

ately contact your ROBERTS GORDON

independent distributor or Roberts-Gordon if the tag is

missing.

WARNING

Fire Hazard

Some objects will catch fire

or explode when placed

close to heater.

Keep all flammable objects,

liquids and vapors the

required safe distances to

combustibles away from

heater.

Failure to follow these

instructions can result in

death, injury or property

damage.

SECTION 4: INSTALLATION

Burn Hazard

Keep all persons,

especially children, away

from heater.

Do not touch any part of

the heater.

Heater is very hot.

Failure to follow these

instructions can result in

death, injury or property

damage.

It is important to keep the required safe distances

from combustibles at all times. Clearances from vehicles parked beneath heaters must be maintained.

The thermostat tag (included with the heater) must

be posted to identify any possible violation of the

clearance distances from the heater in vehicle areas.

Maximum allowable stacking height in storage areas

should be identified with signs or appropriate markings. See Page 16, Figure 4 and Figure 5 for the

required safe distances from combustibles.

Due to high temperature, ensure that the heater

area is kept clear of furniture, draperies, clothing

or other combustible materials. Children and

adults should be alerted to the hazards of high

surface temperatures and should stay away to

avoid burns and clothing ignition. Young children

should be carefully supervised when they are in

the same room as the heater.

15

Page 22

CGTH INSTALLATION, OPERATION AND SERVICE MANUAL

A

D

E

A

F

FIGURE 4: Horizontal Installations

24" Min. (609 mm)

A

Rating Tag

FIGURE 5: 45° Tilted Installations

24" Min. (609 mm)

C

D

B

Approx. 45°

B

F

A

A

F

E

Required safe distances from combustibles*

Inches Metric (cm)

Model ABCDEFABCDEF

CGTH-30 4 16 36 28 34 6 11 41 92 72 87 16

CGTH-40 4 18 48 30 34 6 11 46 122 77 87 16

CGTH-50 4 20 48 32 36 6 11 51 122 82 92 16

*All dimensions are from the reflector.

NOTE: All dimensions indicate the required safe distances from combustibles. Dimensions "C" and "E" DO

NOT indicate the required mounting height. The minimum mounting height is 7' (2133 mm), except for aircraft

hangars and public garages (See Page 11, Sections 3.5.1 and 3.5.2).

Flue clearances from combustibles are zero. It is not necessary to provide additional clearance on

penetrations through the wall or roof.

Know your model number. Model number is found on the rating tag.

16

Page 23

SECTION 4: INSTALLATION

4.7 Hang the Heater

Residential garages come in a variety of sizes,

shapes, styles and methods of construction.

Because of all these variables, it is not possible to

include mounting hardware with the CGTH-Series

heater. Although wooden rafters and joists are the

most common overhead structural members in residential garage applications, other structural configurations are also illustrated below.

In the typical suspension methods shown in Figure 7,

lengths of chain are shown as a means of lowering

the heater.

Whichever method of suspension is selected, the

three required suspension points must be capable of

supporting a minimum of 75 lbs. (33 kg) each.

WARNING

Suspension Hazard

Hang heater with materials with a

minimum working load of 75 lbs

(33 kg).

Failure of the supports can result

in death, injury or property

damage.

FIGURE 7: Suspension Details

Most common for

residential applications

Wood Beam

Wood Screw

Thread Wire

Eye Bolt

Most common for

non-residential applications

Wood Beam

Screw Hook

min. 3/8" (10mm)

Washer

Locknut

I-Beam

Beam Clamp

As required

Concrete Beam

Anchor

Snap

Hook

4.8 Remove Shipping Screw from Control

Housing Door

The blower inside the burner box has a shipping

screw installed to protect the blower from damage in

shipping. Before hanging or operating heater, remove

the shipping screw and paper label from the control

housing door, see Figure 6. A nylon washer inside

the control housing will fall loose. It is not mandatory

to remove the washer from the control housing.

FIGURE 6: Shipping Screw

ATTENTION

Remove shipping screw before

heater instrallation or use. After

removing screw, discard the

screw and this label.

w

w

w.rg-inc

.com

Printed in the U

.S

.A.

P/N

9103

74

00

Remove

screw

before use.

R

etirez la vis

avant l'utilisation.

ATTENTION

Retirez la vis dexpédition avant

linstallation ou lutilisation du

chauffage. Après avoir retiré la

vis, jetez la et jetez cette étiquette.

w

ww.rg-inc

.com

Im

prim

é ou U

.S

.A.

P/N

9103

74

00

Snap

Hook

4.9 Heater Assembly

• Slide rear movable hanger onto reflector as

shown in Figure 8.

• Attach reflector end cap with U-Clips as shown in

Figure 8.

FIGURE 8: Heater Assembly

Rear Movable

Hanger

Shipping Screw

and Label

4 U-Clips

Reflector

End Cap

17

Page 24

CGTH INSTALLATION, OPERATION AND SERVICE MANUAL

4.10 Typical Installation

Figure 9 is a typical installation of the CGTH-Series heater. The installation drawing shown has a straight

horizontal venting arrangement and specifies the minimum space required for maintenance, as well as the

allowable range of distances between the two suspension points.

Detailed venting arrangements are illustrated in the venting section of this manual.

FIGURE 9: Typical Installation

1" (25 mm)

Maximum

Minimum

Recommended

for Servicing

X

6" (152 mm) Minimum

24"

(610 mm)

Exterior Wall

Vent Terminal

15"

(381 mm)

Burner Box

X Dimension

Model Minimum Maximum

CGTH-30 60" (1524 mm) 72" (1829 mm)

CGTH-40 102" (2590 mm) 114" (2895 mm)

CGTH-50 102" (2590 mm) 114" (2895 mm)

4.11 Heater Orientation

The CGTH-Series heater may be installed in any of

the three orientations indicated below. Select the

heater orientation that is best suited for the location

that you have chosen for your heater.

• Horizontal

• Tilted 45° Right

• Tilted 45° Left

NOTE: If the heater is going to be vented through the

roof, be sure to carefully review the roof option

installation instructions on Pages 29 and 30.

Ensure that the selected mounting site will satisfy

the measurement parameters (vent length not to

exceed 10' [3048 mm]) described in that section.

Suspension

Points

Reflector

Minimum Mounting

Height - 7' (2133 mm)*

(*) For minimum mounting height in aircraft

hangars and public garages,

See Page 11,

Sections 3.5.1 and 3.5.2.

welded steel chain 75 lbs. (33 kg), to the two

uppermost holes in the front fixed hanger.

2. Slip the free end of both chains onto another snap

hook (See Page 19, Figure 10).

3. The uppermost snap hook can now be installed on

the suspension hardware that you have installed

for suspension of the unit. An additional length of

chain may also now be installed, if required, to

lower the heater.

4.12 Horizontal Installation

For Horizontal Installation:

1. Using snap hooks, attach two equal lengths of

18

Page 25

FIGURE 10: Horizontal Installation

Front Fixed Hanger

4.13 45° Tilted Installation

For tilted installations:

1. Determine if the heater is going to be tilted left or

tilted right (Figure 11). Select the suspension point

for left or right tilting. Two suspension points must

be used for the front hanger.

SECTION 4: INSTALLATION

Snap Hooks

Rear Movable Hanger

2. The uppermost snap hook can now be installed on

the suspension hardware that you have installed

for suspension of the unit. An additional length of

chain may also now be installed, if required, to

lower the heater.

FIGURE 11: 45° Tilted Installation

Use both suspension

points for installation

Tilted Left

Snap Hooks

Tilted Right

19

Page 26

CGTH INSTALLATION, OPERATION AND SERVICE MANUAL

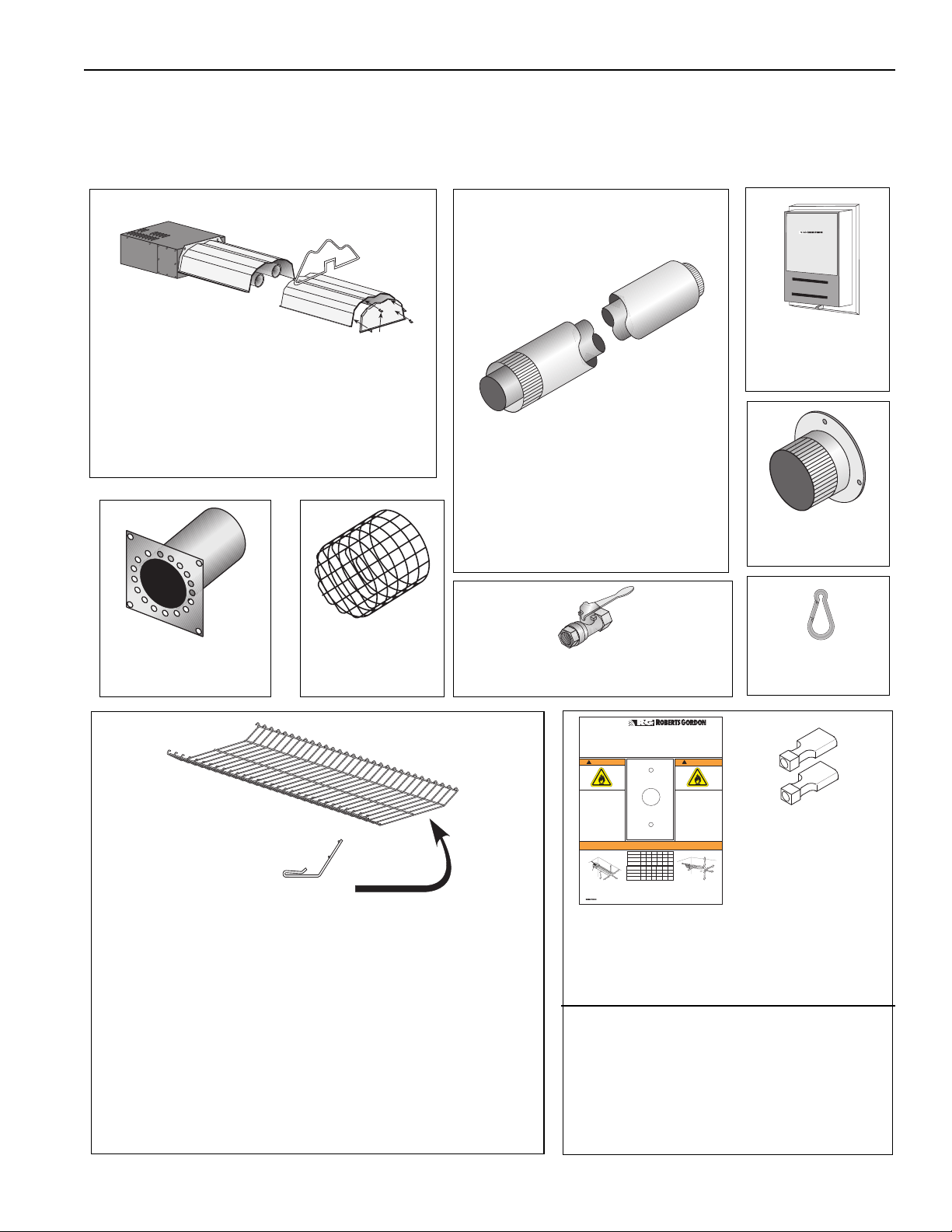

4.14 Grille Installation (for Select Models Only)

A protective grille is included with select models of the

CGTH-Series heater. This grille is supplied in sections

and must be installed on the underside of the reflector

prior to operation.

Grille sections are held in position by a channel formed

by the rolled edge of the reflector. The shorter length

8' (2438 mm) heater requires installation of two

protective grille sections, while the longer heater (11' 6")

(3505 mm) requires three protective grille sections.

Grille Section (P/N 08050001) is open-ended and

installed along the length of the reflector. Grille End Cap

(P/N 08050002) is the formed end cap and is installed

at the end of the grille that is furthest from the burner.

Installation:

Step 1. Silicone Cap Installation (See Figure 12).

• Silicone caps (P/N 91915951) are to be placed

along each side of the grille at both end fingers and

the center finger.

FIGURE 12: Silicone Cap Installation

Silicone Cap

Grille

Finger

P/N 91915951

Silicone Caps are supplied

for the ends of the grille.

Step 2. Attach grille end cap to final grille section

(See Figure 13).

Step 3. Install grille sections as follows: (See Figure 14)

• Attach first grille section(s) (P/N 08050001) to underside of reflector as shown. The wires of the grille will

rest in the channel formed by the rolled edges of the

reflector. Be certain the silicone caps have been

installed.

• Attach final grille section with end cap to under side

of reflector. Butt grille toward the front fixed hanger

that is adjacent to the burner and to each other as

shown.

FIGURE 13: Grille End Cap Installation

1

Grille

Grille End Cap

2

FIGURE 14: Reflector and Grille

Burner

First Grille Sections

Front Fixed Hanger

SIDE VIEW

3

Pull outward

Reflector

4

Bend up 90°

Description Part Number

Grille Section 08050001

Grille End Cap 08050002

20

Final Grille Section

Grille

End Cap

Page 27

SECTION 5: VENTING INSTALLATION

Vent configuration 1 is for the galvanized vent material, See Pages 22 through 25. Vent configuration 2 is

for the Cox Geelen vent material, See Pages 26

through 30. The galvanized vent material is available

for horizontal installation only. The Cox Geelen vent

style can be installed horizontally or vertically. The

maximum overall vent length is 10’ (3 m) with only

one 90° elbow. The flue must be self supporting.

SECTION 5: VENTING INSTALLATION

above grade.

5.2 Install Galvanized Collar

For all galvanized flue installations, the galvanized

collar (See Figure 15) is shipped loose in the carton.

For ease of installation, the vent collar should be

installed on the rear surface of the burner before the

heater is suspended. Install the galvanized collar as

follows:

WARNING

Carbon Monoxide Hazard

Heater must be exhausted outside.

Use materials supplied.

This heater needs fresh air for safe

operation and must be installed so

there are provisions for adequate

combustion and ventilation air.

Failure to follow these instructions

can result in death or injury.

5.1 General Venting Requirements

This heater must be vented in accordance with the

following national codes and any local codes which

may apply:

United States: Refer to ANSI Z223.1 - latest revision.

Canada: Refer to CAN/CGA-B149.1 and B149.2 latest revision.

Vent terminal must be installed at a height sufficient

to prevent blockage by snow and protect building

materials from degradation by flue gasses.

1. Apply a bead of high temperature silicone sealant

to the mating surface of the galvanized collar

mounting flange.

2. Align the three mounting holes of the galvanized

collar with the three galvanized collar mounting

holes on the rear surface of the burner.

3. Using a #2 phillips head screwdriver, or 1/4" nut

driver, secure the galvanized collar to the rear surface of the burner with the three screws (#8 x 3/8"

10 mm long) provided in the accessories bag supplied with the heater.

FIGURE 15: Rear View

Turbulator end tab bent

over the heat exchanger

Vent Collar

Vent must exit a building not less than 7' (2.1 m)

above grade when located adjacent to public

walkways.

For galvanized venting, seal all joints with high temperature silicone sealant.

United States Requirements

Vent must terminate at least 3' (.9 m) above any

forced air inlet located within 10' (3 m).

Vent must terminate at least 4' (1.3 m) below, 4'

(1.3 m) horizontally from, or 1' (.3 m) above any door,

window, or gravity inlet into any building.

Vent terminal shall be located at least 1' (.9 m) from

any opening through which vent gasses could enter a

building.

Canadian Requirements

Vent terminal must not be installed less than 3' (.9 m)

from any building opening.

Vent terminal must be installed at least 3' (.9 m)

3x #8 3/8

Mounting Screws

21

Page 28

CGTH INSTALLATION, OPERATION AND SERVICE MANUAL

5.3 Galvanized Horizontal Venting

WARNING

Carbon Monoxide Hazard

Heater must be exhausted outside.

Use materials supplied.

This heater needs fresh air for safe

operation and must be installed so

there are provisions for adequate

combustion and ventilation air.

Failure to follow these instructions

can result in death or injury.

After the heater has been properly suspended in

accordance with the preceding headings of this section, proceed to install the venting as described

below (See Page 23, Figure 16):

1. Using a tape measure, measure the distance from

the floor to the center of the vent collar on the rear

surface of the burner. Note this dimension here

__________.

2. Using the tape measure, transfer this measure-

ment to the inside surface of the exterior wall that

the vent will penetrate; make a reference mark.

Check the location of the hole to ensure that there

are no internal wall structures (i.e. studs) to prevent penetration. Also check that the outlet of the

vent does not compromise the general venting

requirements, See Section 5.1.

3. Using the tape measure, measure the distance

between the rear surface of the heater and the

exterior wall. Note this dimension here _________.

IMPORTANT: The 3" (80 mm) flue pipe must extend

a minimum of 6" (150 mm) beyond the

exterior surface of wall/fresh air intake.

6. Assemble or cut the 5" (125 mm) air supply pipe to

run between the vent collar on the rear surface of

the burner and the outside surface of the exterior

wall. Be sure to seal any joints in the 5" (125 mm)

air supply pipe with high temperature silicone sealant and secure them with three sheetmetal screws.

7. From the exterior of the building, slip the assembled or cut 5" (125 mm) air supply pipe over the

installed 3" (80 mm) flue pipe. Connect the 5" (125

mm) pipe to the vent collar on the rear surface of

the burner with high temperature silicone sealant

and secure the connection with three sheetmetal

screws.

8. From the exterior of the building, slip the vent terminal onto the 3" (80 mm) flue pipe and guide the

sleeve portion of the vent terminal over the 5" (125

mm) air supply pipe that is flush with exterior surface of wall. Secure air vent pipe to the vent terminal collar with silicone sealant.

9. Secure the vent terminal to the exterior surface of

the wall.

NOTE: If the protruding 3" (80 mm) flue pipe is

directly below and within 24" (609 mm) of the

building soffit, the optional vent extension

should be used.

NOTE: If the distance between the rear surface of

heater and the exterior wall is greater than 5'

(1.5 m), a 5’ (1.5 m) balanced flue vent extension kit (P/N 08039000) will be required.

4. From the reference mark made in step 2, measure

down vertically 1/4" (6 mm) per foot measured in

step 3. Cut 5” (125 mm) vent terminal clearance

hole at the lower reference.

5. Install 3" (80 mm) flue pipe from the vent collar, on

the rear surface of the burner, and through the

exterior wall. Be sure to seal any joints in the 3" (80

mm) flue pipe with high temperature silicone sealant and secure them with three sheetmetal screws.

22

Page 29

FIGURE 16: Horizontal Installation Side View

SECTION 5: VENTING INSTALLATION

Side View

3" (80 mm) pipe is

slid through

end of terminal

Vent

Terminal

Optional Vent

Extension

Bird

Screen

6" (152 mm)

min.

10' (2048 mm) max.

2', 6" (762 mm) min.

Slope down 1/4"

(6 mm) per foot

towards vent

terminal

5" (125 mm) Air

Supply Pipe

5.3.1 Bird Screen Installation

The bird screen supplied with the heater must always

be installed with the galvanized vent option. The

screen is to be installed directly in the end of the 3"

(80 mm) flue pipe or in the vent terminal extension

available as an option. Both screen installations are

described below.

Installing bird screen in 3" (80 mm) flue pipe:

1. Insert the bird screen into the inside diameter of

the 3" (80 mm) flue pipe as shown on Page 23,

Figure 17.

Heater

3" (80 mm)

Flue Pipe

FIGURE 17: Bird Screen Installation

5" (125 mm)

Vent Pipe

3" (80 mm)

Flue Pipe

Bird Screen

Optional Vent

Extension

2. Secure the bird screen in position with a sheetmetal screw.

Installing bird screen in optional vent terminal exten-

sion:

1. Insert the bird screen into the inside diameter of

the vent terminal extension as shown on Page 23,

Figure 17.

2. Using the handle from a hammer, or other similar

device, push the bird screen into the vent extension as far as possible.

3. Orient the vent extension as shown in Figure 17.

Slip the extension onto 3" (80 mm) flue pipe as far

as possible; secure the vent extension to the flue

pipe with three sheetmetal screws.

Galvanized Horizontal Venting with an Elbow

5.3.2

WARNING

Carbon Monoxide Hazard

Heater must be exhausted outside.

Use materials supplied.

This heater needs fresh air for safe

operation and must be installed so

there are provisions for adequate

combustion and ventilation air.

Failure to follow these instructions

can result in death or injury.

After the heater has been properly suspended in

accordance with the preceding headings of this section, proceed to install the venting as described

below:

NOTE: The 90° elbow kit (P/N 08038000) will be

required for this installation.

1. Using a tape measure, measure the distance from

the floor to the center of the vent collar on the rear

23

Page 30

CGTH INSTALLATION, OPERATION AND SERVICE MANUAL

surface of the burner. Note this dimension here

________.

2. Using the tape measure, transfer this measurement to the inside surface of the exterior wall that

the vent will penetrate; make a reference mark.

Check the location of the hole to ensure that there

are no internal wall structures (i.e. studs) to prevent penetration. Also check that the outlet of the

vent does not compromise the general venting

requirements, See Section 5.1.

3. Using a tape measure, measure distances ‘A’, ‘B’,

‘C’ and ‘D’ as shown in Figure 18. Note these

dimensions here (A= ______, B= ______,

C=______, D=______) and add them together.

NOTE: If the total of dimensions above are greater

than 5' (1524 mm), a 5’ (1524 mm) balanced flue

vent extension kit (P/N 08039000) will be required.

FIGURE 18: Horizontal Installation Top View

- Top View -

Optional Vent

Extension

C

D

B

3" (80 mm)

Always cut a non-swaged end.

6. Wrap the 1" (2.5 cm) diameter spring around the

outside diameter of the 3" (80 mm) elbow as

shown in Figure 19.

FIGURE 19: Elbow Assembly End View

Interlock Loops

as shown

1" (25 mm)

Diameter Spring

3" (80 mm)

Elbow

Vent

Terminal

3" (80 mm)

pipe is slid

through end

of terminal

6" (152 mm)

Minimum

Heater

5" (125 mm)

A

4. From the reference mark made in step 2, measure

down vertically 1/4" (6 mm) per foot measured in

step 3. Cut 5” (125 mm) vent terminal clearance

hole at the lower reference.

5. Cut the 3” (80 mm) vent to length as follows:

Length A

3” diameter = A – 8”

Length B

3” diameter = B + C + D – 7 3/4”

7. Interlock the loops at each end of the spring coils

together as shown in Figure 19. The loops will lock

together to produce a continuous coil spring

spacer around the outside diameter of the 3" (80

mm) elbow.

8. Fit the 5" (125 mm) elbow over the 3" (80 mm)

elbow (Figure 20).

FIGURE 20: Elbow Assembly Cross Section View

5" (125 mm)

Diameter Elbow

2.75" (57 mm)

Diameter Elbow

1" (25 mm)

Diameter Spring

6" (152 mm)

3" (80 mm)

24

Page 31

SECTION 5: VENTING INSTALLATION

9. Attach 3" (80 mm) elbow portion of 90° elbow kit to

the 3" (80 mm) flue pipe (length 'A'). Use high

temperature silicone sealant and 3 sheetmetal

screws. (See Figure 21)

FIGURE 21: Elbow Assembly

High

Temperature

Silicone

Spring

3x Self

Drill Screws

10. Completely assemble the 3” (80 mm) vent

lengths A, B and elbow and attach to the heater.

Put the vent collar on the 3” (80 mm) vent. All

joints must be sealed with high temperature

sealant and sheet metal screws. (See Figure 22)

FIGURE 22: Elbow Assembly for Vent Collar

FIGURE 23: Vent Collar and 5" Vent Attachment

1 1/2 Min. (38 mm)

3 (80 mm)

5 (125 mm)

1 1/2 Min. (38 mm)

1 1/2 Min.

(38 mm)

3x Sheetmetal Screws and

High Temperature Sealant

1 1/2 Min. (38 mm)

12. Insert vent terminal and repeat step 11 for 5” (125

mm) from the elbow through the wall. Secure the

vent terminal to the exterior surface of the wall.

NOTE: If the protruding 3" (80 mm) flue pipe is

directly below and within 24" (610 mm) of the

building soffit, the optional vent extension

should be used and secured with three sheetmetal screws.

3x Self Drill Screws and

High Temperature Silicone

Stainless

Heater

5 (125 mm) Vent Collar

Steel Tab

on

Turbulator

5 (125 mm)

Elbow

Spring

11. Attach the vent collar to the heater. Hold the 5”

(125 mm) vent material up to the 3" (80 mm) vent

and mark the required length. Note the length

must be sufficient for a minimum of 1 1/2” (38 mm)

overlap at both ends. Cut the vent to length from

the non crimped end. Wrap the 3” (80 mm) tube

with the 5” (125 mm) vent and snap the vent

together. Attach the 5” (125 mm) vent at both

ends. All joints must be sealed with high temperature sealant and sheet metal screws. (See Figure

23)

25

Page 32

CGTH INSTALLATION, OPERATION AND SERVICE MANUAL

5.3.3 Vent Assembly Overview

The figures in this section provide a general overview of a Cox Geelen vent for the CGTH-Series burner.

Assemble the heater components as shown in Figure 24.

FIGURE 24: Assembly Overview

Burner/Vent Adapter

P/N 90506012

Wall Terminal 570 mm = 22.5”

P/N 90506011

Concentric Flue

254 mm = 10”

P/N 90506003

Elbow 90°

P/N 90506001

Elbow 45°

P/N 90506002

Storm Collar 690 mm = 25.5"

P/N 90506015

Roof Terminal

1283 mm = 50.5”

P/N 90506008

26

Concentric Flue 500 mm = 20”

P/N 90506004

Concentric Flue 1000 mm = 39”

P/N 90506005

Page 33

SECTION 5: VENTING INSTALLATION

5.4 Cox Geelen Horizontal Venting

WARNING

Carbon Monoxide Hazard

Heater must be exhausted outside.

Use materials supplied.

This heater needs fresh air for safe

operation and must be installed so

there are provisions for adequate

combustion and ventilation air.

Failure to follow these instructions

can result in death or injury.

After the heater has been properly suspended in

accordance with the preceding headings of this section, proceed to install the venting as described

below:

1. Using a tape measure, measure the distance from

the floor to the center of the vent collar on the rear

surface of the burner. Note this dimension here

__________.

2. Using the tape measure, transfer this measure-

ment to the inside surface of the exterior wall that

the vent will penetrate; make a reference mark.

Check the location of the hole to ensure that there

are no internal wall structures (i.e. stud) to prevent

penetration. Also check that the outlet of the vent

does not compromise the general venting requirements, See Section 5.1. Cut 5” (125 mm) vent terminal clearance hole as required.