Roberts Gorden BH15 UT, BH20 UT, BH25 UT, BH30 UT, BH35 UT Installation & Servicing Instructions Manual

...Page 1

VVaaccuuuumm AAssssiisstteedd

SSiinnggllee-bbuurrnneerr aanndd

DDoouubbllee LLiinneeaarr SSyysstteemmss

IInnssttaallllaattiioonn && SSeerrvviicciinngg

IInnssttrruuccttiioonnss

Roberts-Gordon products are designed, tested, manufactured and cer-

tified to meet the highest technical standards in the infrared heating

industry. To ensure safe operation it is essential that systems using

Roberts-Gordon products be installed and commissioned in accor-

dance with the manufacturer’s instructions and other applicable

codes and regulations. Failure to inspect and maintain equipment

properly constitutes a serious safety hazard.

Roberts-Gordon Europe, Ltd.

12 Cobham Road,

Ferndown Industrial Estate

Wimborne, Dorset BH21 7PS

Telephone: +44 (0) 1202 896510

Fax: +44 (0) 1202 861397

http://www.rg-inc.com

© Copyright 1999 Roberts-Gordon P/N 170101UK Rev.F 8/99

Installer

Please take the time to read and understand

these instructions prior to any installation. Installer

must give a copy of this manual to the owner.

Owner

Keep this manual in a safe place to provide your

serviceman with information should it become

necessary.

0063

BH15 ST

BH20 ST

BH25 ST

BH30 ST

BH35 ST

BH40 ST

BH45 ST

BH50 ST

BH2 15 ST

BH2 20 ST

BH2 25 ST

BH2 30 ST

BH2 35 ST

BH15 UT

BH20 UT

BH25 UT

BH30 UT

BH35 UT

BH40 UT

BH45 UT

BH50 UT

Blackheat

®

Page 2

TTaabbllee ooff CCoonntteennttss

11.. IInnttrroodduuccttiioonn .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..11

Read this section carefully. Improper installation,

adjustment, operation or maintenance constitutes a

serious health and safety hazard.

22.. SSppeecciiffiiccaattiioonnss .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..22

Material Specifications . . . . . . . . . . . . . . . . . . . . . . . . .2

Heater Specifications . . . . . . . . . . . . . . . . . . . . . . . . . .2

Venting Specifications . . . . . . . . . . . . . . . . . . . . . . . . .2

Suspension Specifications . . . . . . . . . . . . . . . . . . . . . .2

Controls Specifications . . . . . . . . . . . . . . . . . . . . . . . . .2

Clearances to Combustibles . . . . . . . . . . . . . . . . . . . . .3

Burner Specification . . . . . . . . . . . . . . . . . . . . . . . . . . .4

33.. UU-TTuubbee HHeeaatteerr IInnssttaallllaattiioonn .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..55

Health and Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Clearances To Combustibles . . . . . . . . . . . . . . . . . . . .5

Initial Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Final Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Heater Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Model BH15UT U-Tube Assembly . . . . . . . . . . . . . . . . .7

Model BH20UT/BH25UT U-Tube Assembly . . . . . . . . . .8

Model BH30UT/BH35UT/BH40UT U-Tube Assembly . .9

44.. LLiinneeaarr HHeeaatteerr IInnssttaallllaattiioonn .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..1100

Health and Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Clearances To Combustibles . . . . . . . . . . . . . . . . . . .10

Initial Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Final Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Heater Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Model BH15ST Assembly . . . . . . . . . . . . . . . . . . . . . .12

Model BH20ST/BH25ST Assembly . . . . . . . . . . . . . . .13

Model BH30ST/BH35ST/BH40ST Assembly . . . . . . .14

Model BH45ST/BH50ST Assembly . . . . . . . . . . . . . . .15

55.. DDoouubbllee LLiinneeaarr HHeeaatteerr IInnssttaallllaattiioonn .. .. .. .. .. .. .. .. .. .. .. .. ..1166

Health and Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Clearances To Combustibles . . . . . . . . . . . . . . . . . . .16

Initial Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Final Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Heater Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Typical Installation Layout . . . . . . . . . . . . . . . . . . . . .18

66.. GGaass aanndd EElleeccttrriicc SSuuppppllyy .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..1199

Gas Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Electric Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

External Wiring Diagram (Single Burner) . . . . . . . . . .20

External Wiring Diagram (Double Linear Burner) . . . .20

Internal Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . .21

77.. DDiisscchhaarrggee ooff CCoommbbuussttiioonn PPrroodduuccttss .. .. .. .. .. .. .. .. .. .. .. ..2222

General Requirements . . . . . . . . . . . . . . . . . . . . . . . .22

Flue Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Flueless Installation . . . . . . . . . . . . . . . . . . . . . . . . . .22

Ventilation Requirements . . . . . . . . . . . . . . . . . . . . . .22

Air Supply to Burner . . . . . . . . . . . . . . . . . . . . . . . . . .22

Air Supply Requirements . . . . . . . . . . . . . . . . . . . . . . .23

Common Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

88.. OOppeerraattiinngg tthhee SSyysstteemm .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..2244

Detailed Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

System Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

User Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

99.. SSeerrvviicciinngg IInnssttrruuccttiioonnss .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..2255

Annual Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Component Removal . . . . . . . . . . . . . . . . . . . . . . . . . .25

Troubleshooting Flow Chart . . . . . . . . . . . . . . . . . . . .28

1100.. GGaass CCoonnvveerrssiioonn IInnssttrruuccttiioonnss .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..2266

Gas Conversion Kits . . . . . . . . . . . . . . . . . . . . . . . . . .26

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Conversion Procedure . . . . . . . . . . . . . . . . . . . . . . . .26

Adjustment of Step-Flow Rate . . . . . . . . . . . . . . . . . .26

1111.. RReeppllaacceemmeenntt PPaarrttss .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..3300

1122.. TThhee BBllaacckkhheeaatt WWaarrrraannttyy .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..3322

1. Blackheat U-Tube and Linear Tube Configurations . . . .4

2. Bracket Suspension . . . . . . . . . . . . . . . . . . . . . . . . . . .5

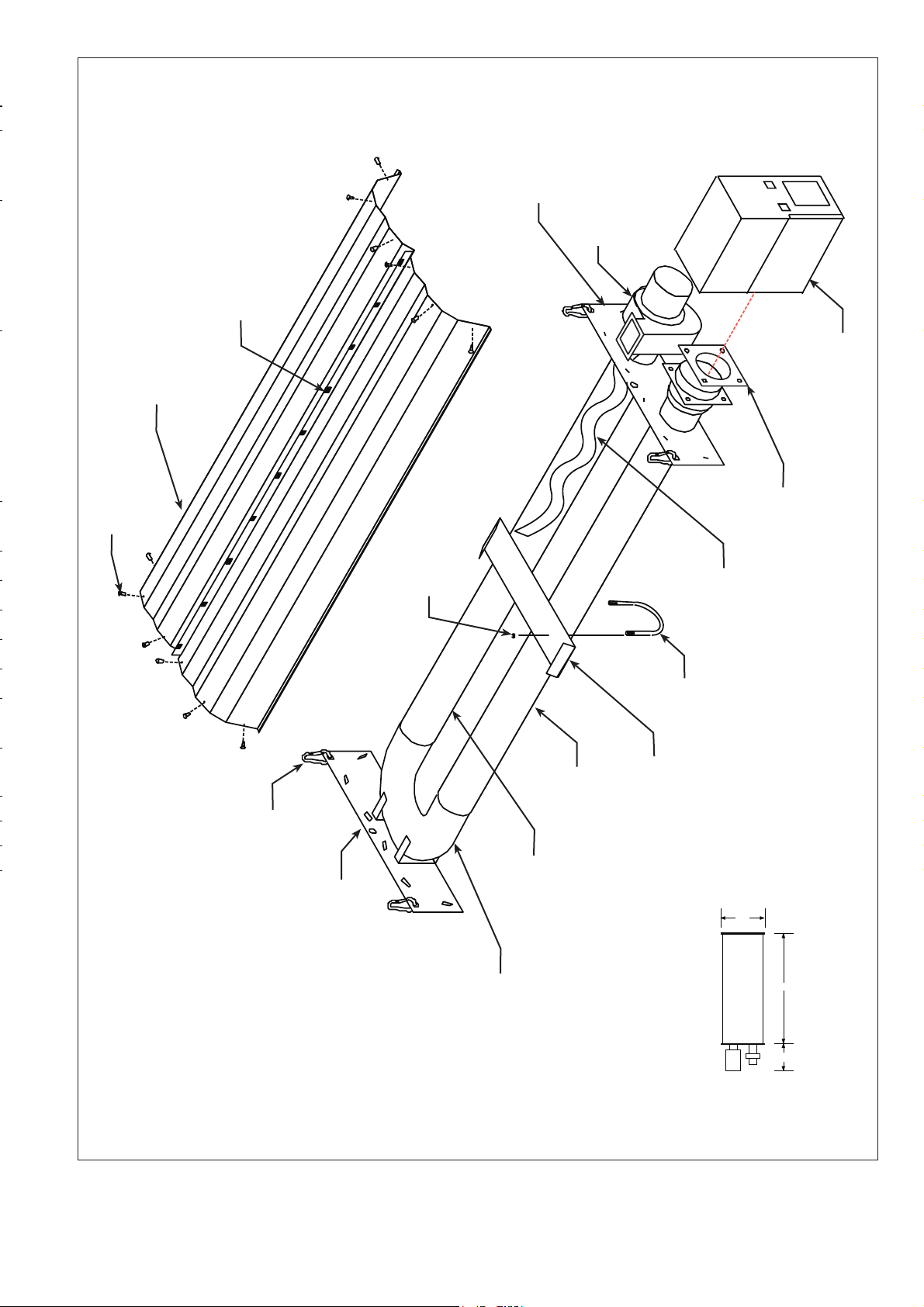

3. Model BH15UT U-Tube Assembly . . . . . . . . . . . . . . . . .7

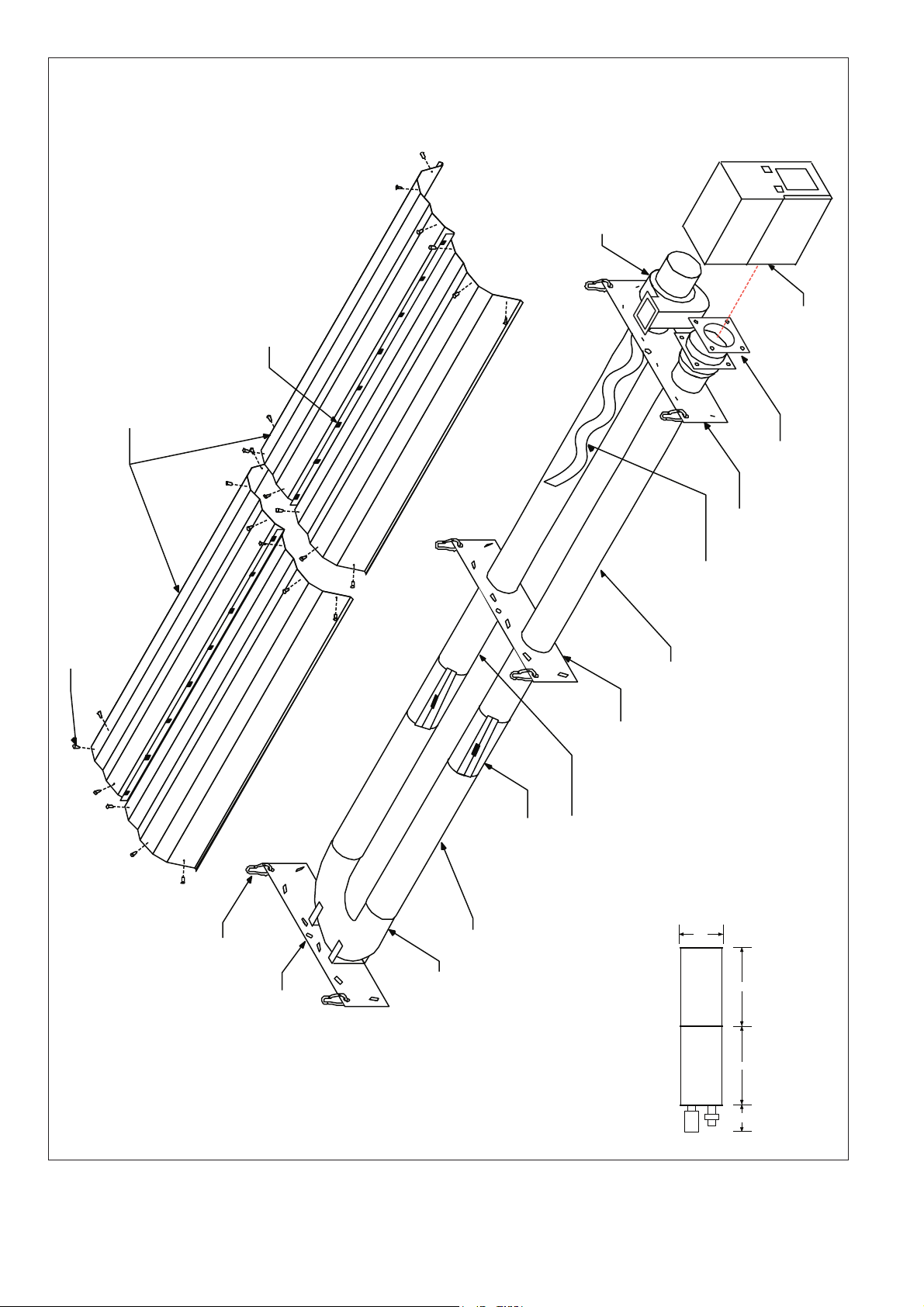

4. Model BH20UT/BH25UT U-Tube Assembly . . . . . . . . .8

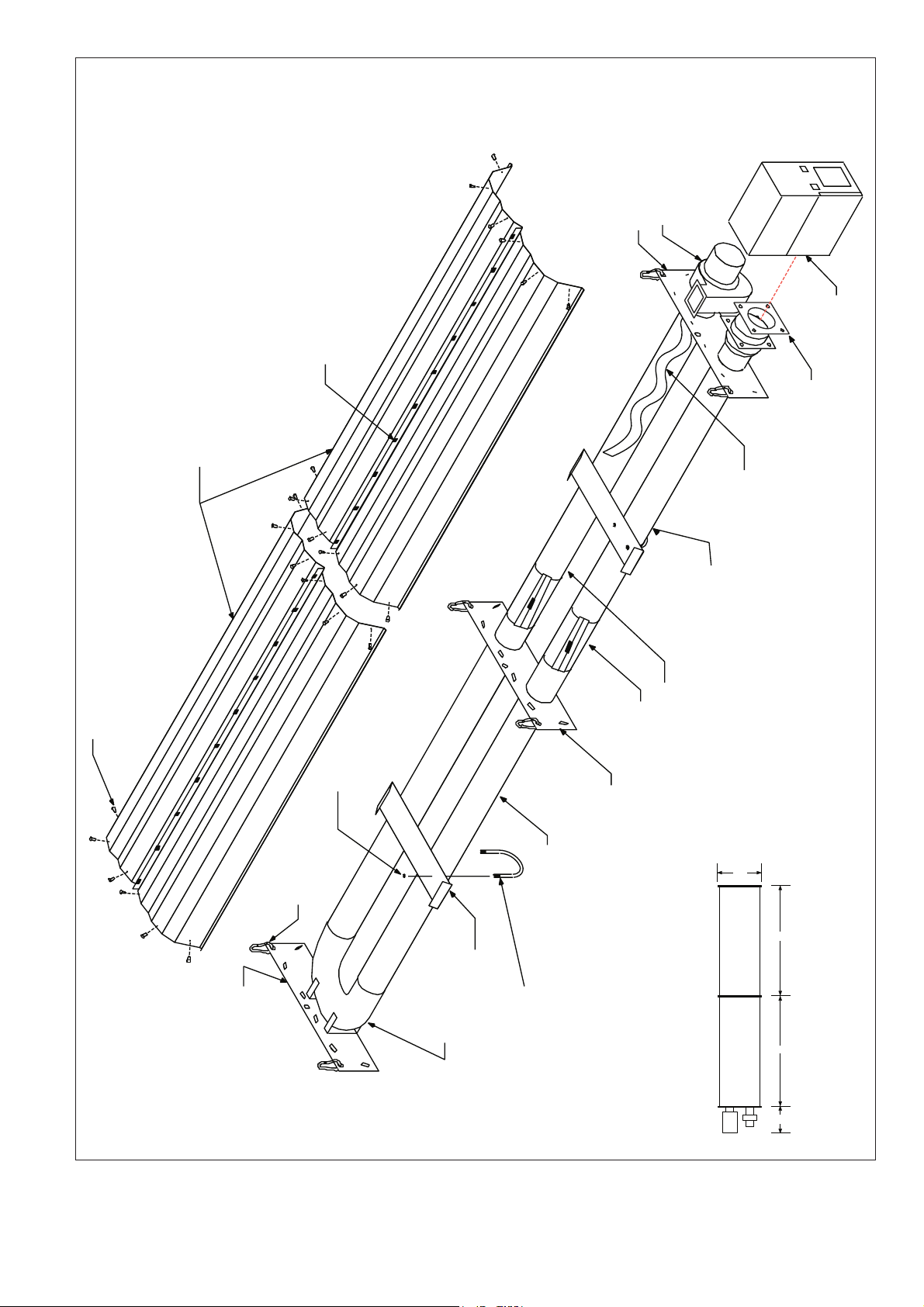

5. Model BH30UT/BH35UT/ BH40UT U-Tube Assy . . . . . .9

6. Tube Clamp Package . . . . . . . . . . . . . . . . . . . . . . . . .10

7. Coupling Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . .10

8. Reflector Support Strap . . . . . . . . . . . . . . . . . . . . . . .11

9. Model BH15ST Assembly . . . . . . . . . . . . . . . . . . . . . .12

10. Model BH20ST/BH25ST Assembly . . . . . . . . . . . . . .13

11. Model BH30ST/BH35ST/ BH40ST Assembly . . . . . .14

12. Model BH40ST/BH50ST Assembly . . . . . . . . . . . . . .15

13. Typical Installation Layout (Dbl. Linear) . . . . . . . . . . .18

14. Typical Gas Line Installation . . . . . . . . . . . . . . . . . . .19

15. Typical External Wiring (Single Burner) . . . . . . . . . . .20

16. Typical External Wiring (Double Linear) . . . . . . . . . . .20

17. Burner Internal Wiring . . . . . . . . . . . . . . . . . . . . . . . .21

18. Flue Connection Detail . . . . . . . . . . . . . . . . . . . . . . . .22

19. Fresh Air Intake Spigot . . . . . . . . . . . . . . . . . . . . . . . .23

20. Air Supply w/Flue Configurations . . . . . . . . . . . . . . . .23

21. TEKNIGAS Valve Spring Replacement . . . . . . . . . . . .27

22. SIT Valve Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

23. TEKNIGAS Valve Detail . . . . . . . . . . . . . . . . . . . . . . . .27

24. Burner Cup Position . . . . . . . . . . . . . . . . . . . . . . . . . .27

25. Troubleshooting Flow Chart . . . . . . . . . . . . . . . . . . . .28

26. Burner Internal Components . . . . . . . . . . . . . . . . . . .30

LLiisstt ooff FFiigguurreess::

Page 3

1

SSeeccttiioonn 11.. IInnttrroodduuccttiioonn

THAT THE FOLLOWING POINTS HAVE BEEN CAREFULLY CONSID-

ERED.

1.4.1 Highly elevated installations:

1. Do you have the proper equipment to install and

maintain the system in the proposed location?

2. Do you have suitable equipment to access the system for maintenance after the system is installed?

3. Will the proposed location allow future access to

the system (i.e., will machinery be erected at a later

date that may make access to the system difficult

or impossible)?

NO

TE:

DDOO NNOOTT

lean ladders against a suspended

heater system. The BH unitary systems

employ a non-rigid attachment system that

will not support external apparatus.

4. Is the installed height within the parameters specified by the manufacturer?

1.4.2 Ventilation/Air Supply:

1. Will a flue be added to the system? If so, have you

checked the flue recommendations specified by

the manufacturer?

2. Is there an adequate supply of fresh air to support

combustion

1.4.3 Environment of the Facility:

1. Are there halogenated hydrocarbons* and/or other

combustible materials (i.e., cleaning agents, wood,

paper, rubber, etc.) within the area to be heated?- If

so, is there adequate exhaust ventilation and clearances?

NO

TE: In poorly vented, dusty areas, fresh outside

air should be provided to prevent premature

aging of the equipment.

In very dusty areas (i.e., woodworking facilities) regular dusting of the tubes and reflectors is essential as a fire preventative

measure.

1.4.4 Clearances to Combustibles:

1. Be sure that the clearances (as recommended by

the manufacturer) to halogenated hydrocarbons

and/or other combustible materials is observed.

2. Be sure that the manufacturer recommended

clearances between the heater system and vehicles parked below are maintained.

3. Be sure that signs are posted in storage areas to

specify maximum stacking height below the heater

system.

4. If the radiant tubes must pass through the building

structure, be sure that adequate sleeving and fire

stop is installed to prevent scorching and/or risk of

* Halogenated Hydrocarbons are a family of chemical compounds characterized by the presence of halogen elements (fluorine, chlorine,

bromine, etc.). These compounds are frequently used in refrigerants, cleaning agents, solvents, etc. If these compounds enter the air

supply of the burner, the lifespan of the heater components will be greatly reduced. An outside air supply must be provided to the burners whenever the presence of these compounds is suspected. Warranty may be invalidated if the heater is exposed to halogenated hydrocarbons.

11..11 WWHHAATT IISS AA BBLLAACCKKHHEEAATT UUNNIITTAARRYY HHEEAATTEERR SSYYSS-

TTEEMM??

The Blackheat BH is a gas-fired, vacuum-assisted, lowintensity radiant heating system. The BH was developed by Blackheat in partnership with

Roberts-Gordon, who pioneered low-intensity heating

in 1962 with their revolutionary CoRayVac system.

Please note that the Blackheat BH is available in several configurations. This manual describes the single

burner and double linear versions. The single burner

systems are available in both linear tube and U-tube

configurations. The double linear systems are comprised of two linear heaters with a common fan

assembly.

Optionally, HiLo models are available that incorporate

an extra solenoid valve to operate at a low (approx

80%) rate. Linked to a secondary thermostat, this provides a low rate at an intermediate setting below the

“off” stat. These models are described in manual

174900UK.

Multi-burner systems are covered in manual

172101UK. These systems manifold several heaters

to a single vacuum pump.

11..22 AABBOOUUTT RRAADDIIAANNTT HHEEAATT

Radiant heat is the most effective way of providing

comfortable environmental conditions in large open

spaces. Radiant energy operates like light, travelling in

straight lines and can be directed to specific individuals and areas which require heating. Comfort levels

are created when the radiant energy is absorbed by

the floor, plant and machinery, and lower walls without

initially losing energy to the air space between.

The objects which have absorbed the radiant energy in

turn release heat to the air and act as low power radiators. In this way, all useable energy is absorbed and

utilised in the occupied zone – the lower 2 metres –

not in the entire structure and roof space. Comfort

conditions are achieved using lower air temperatures

and as a result lower heat losses with a subsequently

lower fuel bill.

11..33 UUSSEE OOFF AACCCCRREEDDIITTEEDD IINNSSTTAALLLLEERR

Installation of this equipment must only be carried out

by a registered installer. (In the United Kingdom,

installer must be CORGI registered.)

11..44 GGEENNEERRAALL RREEQQUUIIRREEMMEENNTTSS

P

LEASE NOTE THAT FAILURE TO COMPLY STRICTLY WITH THESE

INSTALLATION AND SERVICING INSTRUCTIONS MAY INVALIDATE THE

LIMITED WARRANTY SET OUT IN SECTION

11

OF THESE INSTRUC

-

TIONS

.

BEFORE PROCEEDING WITH THE INSTALLATION OF THE

B

LACKHEAT UNITARY SYSTEM IT WILL BE HELPFUL TO CHECK

Page 4

2

SSeeccttiioonn 22.. SSppeecciiffiiccaattiioonnss

22..22 HHEEAATTEERR SSPPEECCIIFFIICCAATTIIOONNSS

2.2.1 Sequence Controller

Fully automatic direct spark 100% shut off

ignition flame rectification module

2.2.2 Electrical

Rating: 230V, 50 Hz, single phase, 1 amp

Connection: 3 pin moulded plug

2.2.3 Gas Supply

Connection: Rc1/2 (1/2" BSP int)

Natural G20:

Minimum - Inlet 15.00 mbar (6 in wg)

Maximum - Inlet 50.00 mbar (20 in wg)

Natural G25:

Minimum - Inlet 17.50 mbar (7 in wg)

Maximum - Inlet 50.00 mbar (20 in wg)

LP Gas (propane or butane):

Minimum - Inlet 32.50 mbar (13 in wg)

Maximum - Inlet 50.00 mbar (20 in wg)

22..11 MMAATTEERRIIAALL SSPPEECCIIFFIICCAATTIIOONNSS

2.1.1 Combustion and Emitter Tubes

100 mm dia. 16 gauge heat treated aluminised

mild steel

2.1.2 Reflectors

NS3 H14 aluminium or 1.4016 2R stainless steel

(option)

22..33 VVEENNTTIINNGG SSPPEECCIIFFIICCAATTIIOONNSS

2.3.1 Fans

BH-15, 20, 25, 30 Model: Airflow 45BTFR

BH-35, 40, 45 Model: Torin AUO75871

BH-35, 40, 45, 50 Model: Magnetek JF1G

BH2-15, 2-20 Model: Airflow 45BTFR

BH2-25, 2-30 Model: Torin AUO75871

BH2-25, 2-30, 2-35 Model: Magnetek JF1G

NNoottee::

For Models BH-35, BH-40, BH-45, BH2-25

and BH2-30, the Magnetek fan is provided

as standard, and the Torin fan is available

as an alternate.

2.3.2 Flue

When fitted, the flue must be 100 mm , or greater in

diameter, and must conform to National Codes. The

flue must be self supporting. Inlet must be 100 mm

diameter.

22..44 SSUUSSPPEENNSSIIOONN SSPPEECCIIFFIICCAATTIIOONNSS

Galvanised straight link welded chain.

22..55 CCOONNTTRROOLLSS SSPPEECCIIFFIICCAATTIIOONNSS

Time switches, thermostats etc. can be wired into the

electrical supply. External controls supplied as an

optional extra.

Page 5

3

UU-TTuubbee HHeeaatteerr

BH15UT BH20UT BH25UT BH30UT BH35UT BH40UT BH45UT BH50UT

Rate - Gross (kW) 15 kW 20 kW 25 kW 30 kW 35 kW 40 kW 45kW 50kW

Rate - Net (kW) 13.5 kW 18 kW 22.5 kW 27 kW 31.5 kW 36 kW 40.5kW 45kW

Heat Exchanger Length (mm) 3323 4843 4843 6363 6363 6363 7998 7998

Overall Heater Length (mm) 3406 5236 5236 6456 6456 6456 8328 8328

Weight (kg) 39 kg 54 kg 54 kg 65 kg 65 kg 66 kg 96kg 96kg

Heated Area (m

2

) 20-160 30-210 40-265 50-315 55-370 65-420 70-475 80-525

Min. Installed Ht (m) 3.5 m 3.5 m 4.0 m 4.7 m 5.0 m 5.0 m 5.0m 5.0m

Clearances to Combustibles

Above (mm) 100 100 100 100 100 100 100 100

Side (mm) 760 840 840 840 910 910 1140 1140

Below (mm) 1520 1600 1600 1600 1680 1680 1980 1980

DDoouubbllee LLiinneeaarr HHeeaatteerr

BH2-15ST BH2-20ST BH2-25ST BH2-30ST BH2-35ST

Rate - Gross (kW) 30 kW 40 kW 50 kW 60 kW 70 kW

Rate - Net (kW) 27 kW 36 kW 45 kW 54 kW 63 kW

Heat Exchanger Length (mm) 12802 18898 18898 24994 24994

Overall Heater Length (mm) 13630 19738 19738 25030 25030

Weight (kg) 82 kg 110 kg 110 kg 136 kg 136 kg

Heated Area (m

2

) 50-315 65-420 80-525 100-630 110-740

Min. Installed Ht (m) 3.5 m 3.5 m 3.5 m 3.5 m 4.6 m

Clearances to Combustibles

Above (mm) 100 100 100 100 100

Side (mm) 760 840 840 840 910

Below (mm) 1520 1600 1600 1600 1680

LLiinneeaarr HHeeaatteerr

BH15ST BH20ST BH25ST BH30ST BH35ST BH40ST BH45ST BH50ST

Rate - Gross (kW) 15 kW 20 kW 25 kW 30 kW 35 kW 40 kW 45 kW 50 kW

Rate - Net (kW) 13.5 kW 18 kW 22.5 kW 27 kW 31.5 kW 36 kW 40.5 kW 45 kW

Heat Exchanger Length (mm) 6096 9144 9144 12192 12192 12192 15240 15240

Overall Heater Length (mm) 6685 9739 9739 12785 12826 12826 15876 16120

Weight (kg) 41 kg 55 kg 55 kg 68 kg 68 kg 68 kg 81 kg 81 kg

Heated Area (m

2

) 20-160 30-210 40-265 50-315 55-370 65-420 70-475 80-525

Min. Installed Ht (m) 3.5 m 3.5 m 3.5 m 3.5 m 4.6 m 5.0 m 5.0 m 5.0 m

Clearances to Combustibles

Above (mm) 100 100 100 100 100 100 100 100

Side (mm) 760 840 840 840 910 910 1140 1140

Below (mm) 1520 1600 1600 1600 1680 1680 1980 1980

Table 1. U-Tube Heater Specifications

Table 2. Linear Heater Specifications

Table 3. Double Linear Heater Specifications

Page 6

4

Swirler

Fan Tube

PLAN VIEW

100 mm

254 mm

Heat Exchanger Length

Fan

U-Tube

Flanged Burner Tube

171 mm

273 mm

SIDE VIEW

PLAN VIEW

317 mm

100 mm

Heat Exchanger Length

Fan

Swirler

END VIEW

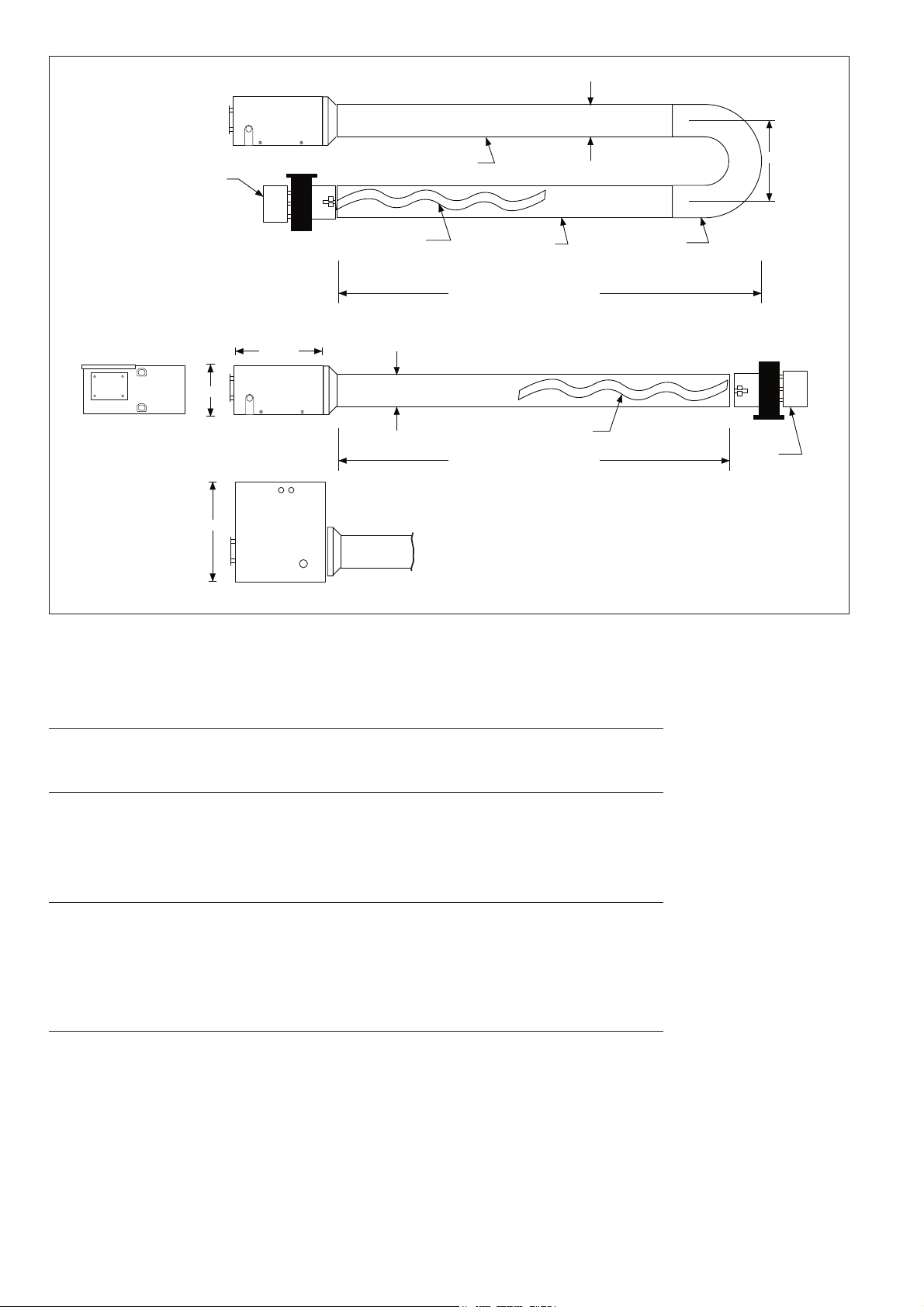

Figure 1. Blackheat U-Tube and Linear Tube Configurations

22..66 BBUURRNNEERR SSPPEECCIIFFIICCAATTIIOONN

BBuurrnneerr AAiirr PPllaattee

BH15 BH20 BH25 BH30 BH35 BH40 BH45 BH50

Identification Number: 14 15 12 6 7 9 10 11

GGaass CCoonnssuummppttiioonn **

BH15 BH20 BH25 BH30 BH35 BH40 BH45 BH50

Natural G20 (m

3

/h) 1.43 1.91 2.38 2.86 3.34 3.81 4.29 4.77

Natural G25 (m

3

/h) 1.66 2.22 2.77 3.32 3.88 4.43 4.99 5.54

Propane (m

3

/h) 0.56 0.75 0.94 1.13 1.32 1.51 1.69 1.88

Butane (m

3

/h) 0.43 0.57 0.72 0.86 1.00 1.15 1.29 1.43

GGoovveerrnnoorr PPrreessssuurree

BH15 BH20 BH25 BH30 BH35 BH40 BH45 BH50

Butane (mbar) 21.4 19.7 19.2 17.4 18.2 17.9 16.9 18.4

Butane (in wg) 8.6 7.9 7.7 7.0 7.3 7.2 6.8 7.4

Natural G20: 8.7 mbar 3.5 in wg

Natural G25: 11.1 mbar 4.5 in wg

Natural G20 Hi/Lo : 8.7/5.0 mbar 3.5/2.0 in wg

Natural G25 Hi/Lo : 11.1/6.5 mbar 4.5/2.6 in wg

Propane: 27 mbar 10.5 in wg

JJeett NNuummbbeerr

BH15 BH20 BH25 BH30 BH35 BH40 BH45 BH50

Natural G20 & G25

3.4 mm 3.8 mm 4.3 mm 4.7 mm 4.9 mm 5.4 mm 5.8 mm 6.0 mm

Propane/Butane

2.1 mm 2.35 mm 2.7 mm 3.0 mm 3.2 mm 3.4 mm 3.6 mm 3.75 mm

Pressure Couple

1.95 mm 2.25 mm 2.5 mm 2.7 mm 2.9 mm 3.2 mm 3.25 mm 3.4 mm

(*) Based on Gross Caloric Value

Page 7

5

SSeeccttiioonn 33.. UU-TTuubbee HHeeaatteerr IInnssttaallllaattiioonn

3.1 HEALTH AND SAFETY

Blackheat cannot be responsible for ensuring that all

appropriate safety measures are undertaken prior to

installation; this is entirely the responsibility of the

installer. If Blackheat installs the appliance, it is

essential that the contractor, the sub-contractor, or

the owner indicate the presence of combustible materials or halogenated hydrocarbons anywhere in the

premises.

3.2 RELATED DOCUMENTS

Notwithstanding their limited scope, the appliance

should be installed in accordance with relevant

National Codes.

33..33 CCLLEEAARRAANNCCEESS TTOO CCOOMMBBUUSSTTIIBBLLEESS

Before proceeding with installation, ensure that

proper clearances to combustible materials will be

observed in the final installed position of the heater.

Clearance distances may be found in Section 2 of

these instructions.

33..44 IINNIITTIIAALL AASSSSEEMMBBLLYY

3.4.1 Prepare a work area corresponding to the size of

heater selected. The area should be clear and free of

debris. The manufacturers approved layout drawing

should be referred to so that the work area is convenient for the final system position.

3.4.2 Layout the appropriate Figure (3, 4, or 5 depending on

heater model) and keep it at a convenient place for

frequent reference. Pull out every part from the package and lay them out roughly at the position shown in

the assembly drawings. For BH35UT and BH40UT

make sure that the end of the fan tube with the swirler

points away from the U-bend. Keep the bolts and

screws at a convenient place for later usage.

3.4.3 With the suspension holes uppermost, slide the first

and intermediate brackets onto the fan and burner

tubes. For Model BH15, there is no intermediate

bracket. In the following assembly procedures, please

pay attention to this point.

3.4.4 Use two bolts to connect the U-bend and end bracket

together with the suspension holes uppermost. Insert

the plain ends of the burner tube and fan tube into the

two legs of the U-bend, and secure them with four

bolts.

3.4.5 Place intermediate bracket over the ends of the

tubes. Slide bracket onto tubes approximately 500

mm.

3.4.6 Join the burner tube and the remaining plain end tube

using the couplings and bolts provided. See section

4.4.5 for details.

3.4.7 Place the reflectors over the brackets as shown in the

assembly diagrams, and secure them using six screws

at each end. Seal the seam on top of the reflectors

using U-clips at least every 300 mm.

NOTE: Remove PVC coat from stainless steel reflec-

tors.

3.4.8 Insert the quick-links into the holes at the top edges of

the end, intermediate and first brackets.

3.4.9 Prepare the hanging chains at the position where the

heater will be located. Suspend the heating system as

recommended below. Use the center holes of the end

and first bracket to lift the heating system into position. Chains used should have 100 kg minimum

breaking load and preferably should be galvanised

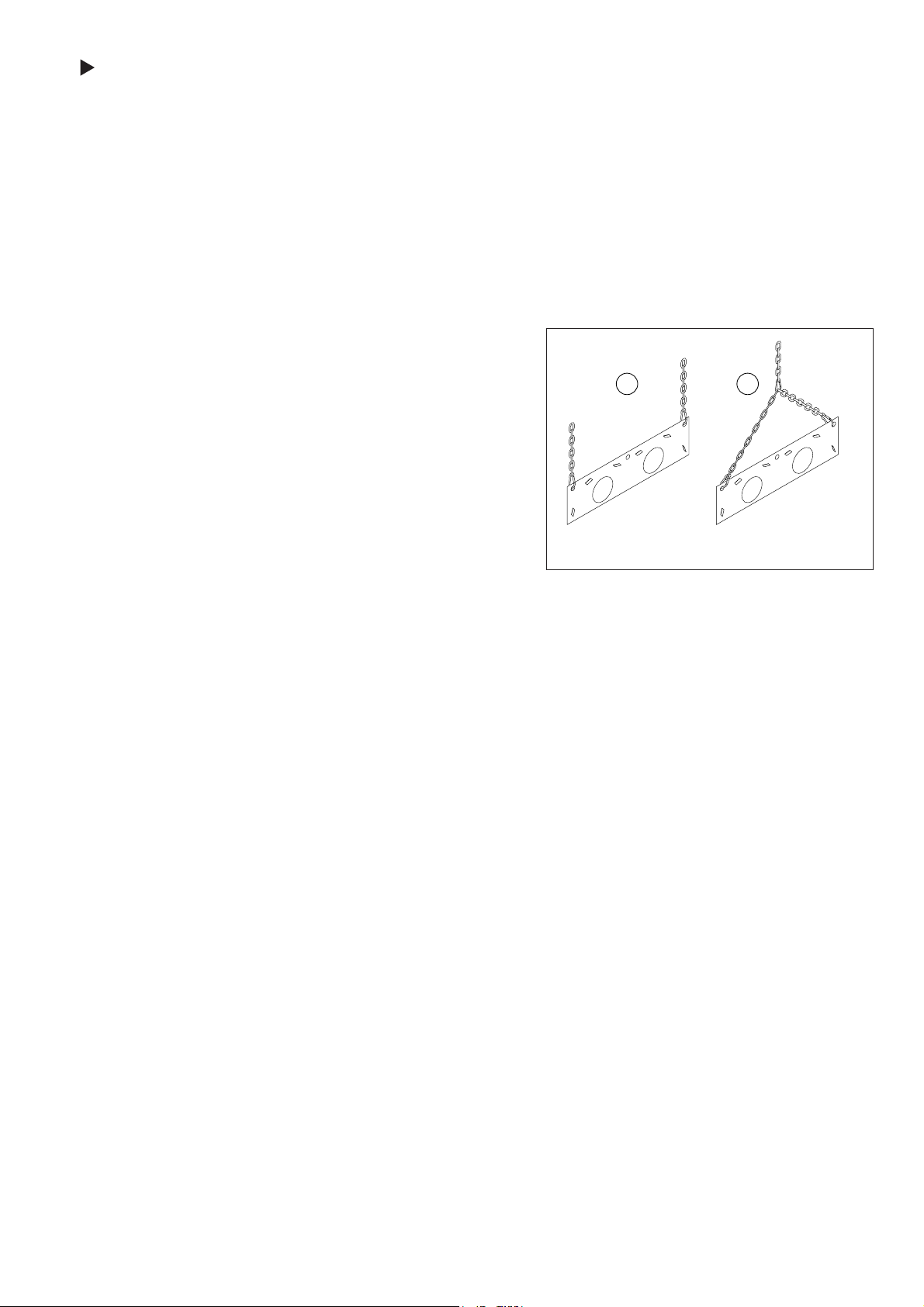

finish. Figure 2 shows two suspension methods.

Method A is recommended because it provides a

semi-rigid suspension. Method B is acceptable.

Figure 2. Bracket Suspension

3.4.10 Never lift the assembled heater by passing ropes

around the reflector which would cause severe damage to the reflectors.

3.4.11 When angle mounting the heater, the burner tube

must be the tube nearest the floor and the fan tube is

always furthest from the wall (when suspended adjacent to a wall). It is recommended wherever possible

that the heater is suspended from above from

unequal length chains to effect the necessary angle

(maximum 20° from horizontal). Always allow extra

lengths of chain so that adjustment of angle can be

made to provide the best heat distribution for your

customer.

33..55 FFIINNAALL AASSSSEEMMBBLLYY

3.5.1 Place the gasket on the flange of the burner tube.

Carefully insert the flanged end into the burner box.

Secure the burner on the burner tube using the four

mounting bolts and washers. Use a spanner to tighten

the bolts evenly.

3.5.2 Place the fan assembly onto the end of the last fan

tube. Slide the fan assembly up to its stop. Tighten

the pinch screw on the assembly making sure that the

fan outlet is positioned as required.

Recommended

Suspension

Acceptable

Suspension

A

B

Page 8

6

Table 4. Blackheat U-Tube Heater Parts List

Part No. Description BH15UT BH20UT BH25UT BH30UT BH35UT BH40UT BH45UT BH50UT

1 Burner Assembly with Gasket 1 1 1 1 1 1 1 1

2 S7340K Fan Assembly (includes flange) - Airflow 45 BTFR 1 1 1 1 - - - 3 S7104K Fan Assembly (includes flange) - Torin - - - - 1 1 1 4 S7320K Fan Assembly (includes flange)- Magnetek - - - - - - - 1

5 03051100 Burner Tube, 100 mm x 3048 mm 1 1 1 1 1 1 1 1

6 91409408 Heat Treated Aluminised Tube, 100 mm x 3048 mm - - - 2 2 2 2 2

7 S5127W Fan Tube, 100 mm x 3048 mm with 3048 mm Swirler - 1 1 1 1 1 1 1

8 S5140W Heat Treated Aluminised Tube, 1702 mm - 2 2 - - - 2 2

9 S5134W Fan Tube, 100 mm x 3048 mm with 2134 mm Swirler 1 - - - - - - -

10 S7302K Reflector Kit, 2439 mm, 4 pcs, Alum. - 1 1 - - - - 11 S7301K Reflector Kit, 3048 mm, 2 pcs, Alum. 1 - - - - - - 12 S7303K Reflector Kit, 3048 mm, 4 pcs, Alum. - - - 1 1 1 - 13 S7318K Reflector Kit, 2430 mm, 4 pcs, 3048mm Long, 2pcs,Alum - - - - - - 1 1

14 S7338K Reflector Kit, 2439 mm, 4 pcs, Stls Steel (optional) - 1 1 - - - - 15 S7337K Reflector Kit, 3048 mm, 2 pcs, Stls Steel (optional) 1 - - - - - - 16 S7339K Reflector Kit, 3048 mm, 4 pcs, Stls Steel (optional) - - - 1 1 1 - 17 S7440K Reflector Kit, 2430mm, 4 pcs, 3048mm Long 2pcs Stls Steel (optl) - - - - - - 1 1

18 07290000 U-Bend Assembly 1 1 1 1 1 1 1 1

19 C0176B Quick Link 6 9 9 9 9 9 12 12

20 07281000 First Bracket 1 1 1 1 1 1 1 1

21 07282000 End Bracket 1 1 1 1 1 1 1 1

22 07283000 Intermediate Bracket - 1 1 1 1 1 2 2

23 91107720 U-Clip Package (20 per package) 1 1 1 1 1 1 2 2

24 S7311K Screw Kit 1 1 1 1 1 1 - 25 S7317K Screw Kit - - - - - - 1 1

26 S7401K Support Bracket Package - - - 1 1 1 - 27 S7402K Support Bracket Package - - - - - - 1 1

28 01329600 Standard Coupling Assembly - 2 2 2 2 2 4 4

29 01329700 Coupling Lock - 2 2 2 2 2 4 4

30 S7402K Support Bracket Package 1 - - - - - 1 1

Page 9

7

(1) Fan Assembly

(1) Fan Tube 100 mm x 3048 mm

with Swirler

(1) Burner Tube

100 mm x 3048 mm

(1) Burner Assembly

(1) Reflector Kit

(2) 3048 mm long pieces

U-Clips (package of 20)

(4) Quick Links

(1) End Bracket

(1) First Bracket

(1) U-Bend Assembly

(1) Gasket

(1) Swirler

(included in heating tube)

(12) Sheet Metal Screws

Reflector Support Bracket

(1) Nut

(1) U-Bolt

Figure 3. Model BH15UT U-Tube Assembly

c

a

b

a = 534 mm b = 356 mm c = 3050 mm

Page 10

8

(1) Fan Assembly

(1) Burner Tube

100 mm x 3048 mm

(1) Burner Assembly

(1) Reflector Kit

(4) 2439 mm long pieces

(1) Swirler

(included in fan tube)

U-Clips (package of 20)

(6) Quick Links

(1) End Bracket

(1) Intermediate Bracket

(1) First Bracket

(1) U-Bend Assembly

(1) Gasket

(1) Fan Tube

100 mm x 3048 mm

with Swirler

(24) Sheet Metal Screws

(2) Stainless Steel Coupling

(2) Aluminised Tube

100 mm x 1829 mm

Figure 4. Model BH20UT/BH25UT U-Tube Assembly

c

a

b d

a = 534 mm b = 356 mm

c = 2440 mm d = 2440 mm

Page 11

9

(1) Fan Assembly

(1) Fan Tube

100 mm x 3048 mm

with Swirler

(1) Burner Assembly

(1) Reflector Kit

(4) 3048 mm long pieces

U-Clips (package of 20)

(6) Quick Links

(1) End Bracket

(1) Intermediate Bracket

(1) First Bracket

(1) U-Bend Assembly

Gasket

(1) Swirler

(included in fan tube)

(24) Sheet Metal Screws

(1) U-Bolt

Reflector Support Bracket

(Typical 2 Places)

(1) Nut

(2) Stainless Steel Coupling

(1) Burner Tube

100 mm x 3048 mm

(2) Aluminised Tube

100 mm x 3048 mm

Figure 5. Model BH30UT/BH35UT/BH40UT U-Tube Assembly

c

a

b d

a = 534 mm b = 356 mm

c = 3050 mm d = 3050 mm

Page 12

10

(1) Fan Assembly

(1) Fan Tube

100 mm x 3048 mm

with Swirler

(1) Burner Assembly

(6) Quick Links

(1) First Bracket

(1) U-Bend Assembly

Gasket

(1) Swirler

(included in fan tube)

(1) U-Bolt

Reflector Support Bracket

(Typical 3 Places)

(2) Stainless Steel Coupling

(1) Burner Tube

100 mm x 3048 mm

(2) Aluminised Tube

100 mm x 3048mm

(1) Nut

(1) Intermediate Bracket

(1) Intermediate Bracket

(2) Aluminised Tube

100 mm x 1702 mm

(2) Stainless Steel Coupling

(1) Reflector Kit

(2) 3048 mm long pieces

U-Clips (package of 20)

(24) Sheet Metal Screws

(1) Reflector Kit

(4) 2439 mm long pieces

(1) End Bracket

Figure 6. Model BH45UT/BH50UT U-Tube Assembly

Page 13

11

SSeeccttiioonn 44.. LLiinneeaarr HHeeaatteerr IInnssttaallllaattiioonn

4.1 HEALTH AND SAFETY

Blackheat cannot be responsible for ensuring that all

appropriate safety measures are undertaken prior to

installation; this is entirely the responsibility of the

installer. If manufacturer installs the appliance, it is

essential that the contractor, the sub-contractor, or

the owner indicate the presence of combustible materials or halogenated hydrocarbons anywhere in the

premises.

4.2 RELATED DOCUMENTS

Notwithstanding their limited scope, the appliance

should be installed in accordance with relevant

National Codes.

4.3 CLEARANCES TO COMBUSTIBLES

Before proceeding with installation, ensure that

proper clearances to combustible materials will be

observed in the final installed position of the heater.

Clearance distances may be found in Section 2 of

these instructions.

44..44 IINNIITTIIAALL AASSSSEEMMBBLLYY

4.4.1 Prepare a work area corresponding to the size of

heater selected. The area should be clear and free of

debris. The manufacturers approved layout drawing

should be referred to so that the work area is convenient for the final system position.

4.4.2 Layout the appropriate Figure (9, 10, 11, or 12,

depending on heater model) and keep it at a convenient place for frequent reference. Pull out every part

from the package and lay them out roughly at the

position shown in the assembly drawing. Keep the

bolts and screws at a convenient place for later

usage.

4.4.3 Prepare the hanging chains at the position where the

heater will be located. Chains used should have 100

kg minimum breaking load and preferably should be

galvanised finish. Assemble the two halves of the tube

clamp package using the hex carriage bolt, hex nut

and flat washer. Attach the clamp to the tube and

reflector hanger, and slide the hanger into place on

the burner tube (see Figure 6).

4.4.4 The hanger must be located within 150 mm of the

flange. Slide the next tube and reflector hanger onto

the end of the burner tube. Making sure that the suspension hooks of the hangers are uppermost, lift the

burner tube into the position required. Suspend the

burner tube by connecting the tube and reflector

hangers to chains using the quick links provided.

4.4.5 Slide another tube and reflector hanger onto the next

tube and locate it according to the appropriate Figure.

Lift the tube into its position and connect it with the

burner tube using a stainless steel coupling. Repeat

this procedure to suspend the remaining tube(s) and

connect them to the heater one by one.

4.4.6 For details of the coupling connection, see the following diagram:

Figure 8. Coupling Assembly

To assemble the coupling, hook the free end of the

coupling sleeve into the lanced clip. Place the wide

end of the tapered slide bar on the coupling so that it

moves toward the lanced clip. Insert the two tube ends

into the coupling. Be sure the tube ends are in line

and are flush against the stop pins inside the coupling.

Hammer-drive the slide bar until the coupling is

secured snugly to the tubes. Overdriving the slide bar

will distort the coupling or slide bar lip and will

decrease the holding capability of the coupling.

Impact Block

Tighten

Loosen

When assembling coupling, the wide end of

the slide bar moves toward the lanced clip

Orient coupling so that the impact

block is above tube centerline.

C

L

Stainless Steel

Coupling

Slide Bar

Lanced Clip

Position tube and

reflector hanger no

more than 10 cm (4")

away from the burner

assembly.

Flat washer

and hex nut

Tube clamp

Carriage bolt

Transition tube

Burner assembly

Bow Shackle

Figure 7. General Arrangement Using

Tube Clamp Package

Page 14

12

Coupling should be tight when the slide bar is ±50

mm from the end of the coupling.

4.4.7 Place a reflector over the flanged burner tube and

slide it inside the first tube and reflector hanger. Slide

the next reflector under the first reflector. Overlap the

reflectors using the distance specified in the assembly drawings. Secure the two reflectors in place using

the reflector support straps. Assemble the reflector

support strap according to the following figure:

NOTE: Remove PVC coat from stainless steel reflec-

tors.

Figure 9. Reflector Support Package

4.4.8 Attach the remaining reflectors to the heater using the

same method. Be sure to alternate the overlap of the

reflectors as shown in the assembly drawings.

Reflector

Reflector Support Strap

Wire Form

Reflector Support Package

includes Support Strap, Wire Form, and (2) Screws

For slip joint, loosen screws approx. 2 mm

Heating Tube

Sheet Metal

Screw

Starting at the first reflector support, and alternating

every other support down the length of the heater, the

screws should be loosened 2 mm to allow for expansion of the heating tubes during operation.

4.4.9 After assembling the reflectors, attach the reflector

end caps to the open ends of the reflectors. Punch out

the center section of the end cap, and attach the end

cap to the reflector using at least 6 of the U-clips provided.

44..55 FFIINNAALL AASSSSEEMMBBLLYY

4.5.1 Place the gasket on the flange of the burner tube.

Carefully insert the flanged end into the burner box.

Secure the burner on the burner tube using the four

mounting bolts and washers. Use a spanner to tighten

the bolts evenly.

4.5.2 Place the fan assembly onto the end of the last fan

tube. Slide the fan assembly up to its stop. Tighten the

pinch screw on the assembly making sure that the fan

outlet is positioned as required.

4.5.3 Carefully adjust system pitch at each support to level

the heater. Pitch down (away from burner) 6 mm in

1000 mm.

Table 5. Blackheat Linear Heater Parts List

Part No. Description BH15 BH20 BH25 BH30 BH35 BH40 BH45 BH50

1 Burner Assembly with Gasket 11111111

2 S7353K Fan Assembly (includes flange) - Airflow 45 BTFR 1111 ----

S7103K Fan Assembly (includes flange) - Torin ----111S7105K Fan Assembly (includes flange) - Magnetek -------1

3 03051100 Burner Tube, 100 mm x 3048 mm 11111111

4 S5127W Fan Tube, 100 mm x 3048 mm, with 3048 mm Swirler - 1111111

5 91409408 Heat Treated Aluminised Tube, 100 mm x 3048 mm - 1122233

6 S5134W Fan Tube, 100 mm x 3048 mm, with 2134 mm Swirler 1 -------

7 02750303 Aluminium Reflector, 2439 mm 34466677

8 S5163W Stainless Steel Reflector, 2439 mm 34466677

9 03090100 Tube and Reflector Hanger 34455566

10 01318901 Tube Clamp Package 11111111

11 01329600 Standard Coupling Assembly 12233344

12 01329700 Coupling Lock 12233344

13 03050000 Reflector Support Strap 23355566

14 02750800 Reflector End Cap 22222222

15 E0007576 Bow Shackle 34455566

16 91107720 U-Clip Package 11111111

17 91908004 Wire Form 23355566

Page 15

13

(1) Burner Tube, 100 mm x 3048 mm

(1) Burner Assembly

(3) Reflectors 2439 mm long

(reflectors overlap approx. 700 mm)

Swirler

(included in Fan Tube)

(4) U-Clips

Bow Shackle (Typ.)

Gasket

(1) Tube Clamp Package

(2) Reflector End Caps

(2) Reflector Support Straps

(3) Tube and Reflector Hangers

loose screws

tight screws

(4) U-Clips

(1) Fan Assembly

(1) Stainless Steel Coupling

(1) Fan Tube, 100 mm x 3048 mm,

with Swirler

Figure 10. Model BH15ST Assembly

a = reflector width = 365 mm

b = end cap to burner/fan = 150 mm

c = end cap to hanger = 50 mm

d = distance between hangers = 2848 mm

e = burner length = 273 mm

f = burner width = 171 mm

ebc

d

a

d

cb

f

Page 16

14

(1) Fan Assembly

(1) Fan Tube, 100 mm x 3048 mm

with Swirler

(2) Stainless Steel Coupling

(1) Burner Tube, 100 mm x 3048 mm

(1) Burner Assembly

(4) Reflectors 2439 mm long

(reflectors overlap approx. 250 mm)

Swirler

(included in Fan Tube)

U-Clips (package of 20)

(4) Bow Shackles

Gasket

(1) Tube Clamp Package

(2) Reflector End Caps

(3) Reflector Support Straps

(4) Tube and Reflector Hangers

loose screws

tight screws

loose screws

(1) Aluminised Tube, 100 mm x 3048 mm

Figure 11. Model BH20ST and BH25ST Assembly

a = reflector width = 365 mm

b = end cap to burner/fan = 150 mm

c = end cap to hanger = 50 mm

d = distance between hangers = 2915 mm

e = burner length = 273 mm

f = burner width = 171 mm

ebc

d

a

d

cb

d

f

Page 17

15

(1) Fan Tube, 100 mm x 3048 mm

with Swirler

(3) Stainless Steel Coupling

(1) Burner Tube, 100 mm x 3048 mm

(1) Burner Assembly

(6) Reflectors 2439 mm long

(reflectors overlap approx. 530 mm)

Swirler

(included in Fan Tube)

Bow Shackle (Typ.)

Gasket

(1) Tube Clamp Package

(2) Reflector End Caps

(5) Reflector Support Straps

(4) Tube and Reflector Hangers

loose screws

tight screws

loose screws

loose screws

tight screws

(4) U-Clips

(4) U-Clips

Damper

(2) Aluminised Tube, 100 mm x 3048 mm

Figure 12. Model BH30ST, BH35ST and BH40ST Assembly

a = reflector width = 365 mm

b = end cap to burner/fan = 150 mm

c = end cap to hanger = 50 mm

d = distance between hangers = 2948 mm

e = burner length = 273 mm

f = burner width = 171 mm

ebc

d

a

d

cb

dd

f

Page 18

16

(1) Fan Assembly

(1) Fan Tube, 100 mm x 3048 mm

with Swirler

(4) Stainless Steel Couplings

(3) Aluminised Tube, 100 mm x 3048 mm

(1) Burner Assembly

(7) Reflectors 2439 mm long

(reflectors overlap approximately 330 mm)

Swirler

(included in Fan Tube)

U-Clips (package of 20)

(6) Bow Shackle

Gasket

(1) Tube Clamp Package

(2) Reflector End Caps

(6) Reflector Support Straps

(6) Tube and Reflector Hangers

loose screws

tight screws

loose screws

loose screws

tight screws

tight screws

(1) Burner Tube, 100 mm x 3048 mm

Figure 13 Model BH45ST and BH50ST Assembly

a = reflector width = 365 mm

b = end cap to burner/fan = 150 mm

c = end cap to hanger = 50 mm

d = distance between hangers = 2968 mm

e = burner length = 273 mm

f = burner width = 171 mm

d d

f

ebc

d

a

d

cb

d

Page 19

17

5.1 HEALTH AND SAFETY

Blackheat cannot be responsible for ensuring that all

appropriate safety measures are undertaken prior to

installation; this is entirely the responsibility of the

installer. If the manufacturer installs the appliance, it

is essential that the contractor, the sub-contractor, or

the owner indicate the presence of combustible materials or halogenated hydrocarbons anywhere in the

premises.

5.2 RELATED DOCUMENTS

Notwithstanding their limited scope, the appliance

should be installed in accordance with relevant

National Codes.

5.3 CLEARANCES TO COMBUSTIBLES

Before proceeding with installation, ensure that

proper clearances to combustible materials will be

observed in the final installed position of the heater.

Clearance distances may be found in Section 2 of

these instructions.

55..44 IINNIITTIIAALL AASSSSEEMMBBLLYY

5.4.1 Prepare a work area corresponding to the size of

heater selected. The area should be clear and free of

debris. The manufacturers approved layout drawing

should be referred to so that the work area is convenient for the final system position.

5.4.2 Establish both the centre point for the unit, and the

centre line of the heater run within the area to be

heated. Along the established centre line of the heating run, layout two of the appropriate heater configurations (Figure 9, 10 or 11). The burner assemblies

should be at opposite ends of the heater run and

should be configured as shown in Figure 13.

5.4.3 At a point directly above the established centre of the

heater system, install a suspension chain for the fan

assembly. Moving outward from this point, and along

the established centre line, establish the remainder of

the chain suspension locations.

5.4.4 Suspend the tube and reflector hangers for the fan

tube, and raise the fan tubes into position.

5.4.5 Assemble the two halves of the tube clamp package

using the hex carriage bolt, hex nut and flat washer.

Attach the clamp to the tube and reflector hanger, and

slide the hanger into place on the burner tube (see

Figure 6).

5.4.6 The hanger must be located within 150 mm of the

flange. Slide the next tube and reflector hanger onto

the end of the burner tube. Making sure that the suspension hooks of the hangers are uppermost, lift the

burner tube into the position required. Suspend the

burner tube by connecting the tube and reflector

hangers to chains using the bow shackles provided.

Repeat procedure for the burner tube at the other end.

5.4.7 Connect the burner and fan tubes using the stainless

steel couplings. Raise the centre tee into position

SSeeccttiioonn 55.. DDoouubbllee LLiinneeaarr HHeeaatteerr IInnssttaallllaattiioonn

between the end of the fan tubes and secure using

the damper couplings provided.

5.4.8 Slide another tube and reflector hanger onto the next

tube and locate it according to the appropriate Figure.

Lift the tube into its position and connect it with the

burner tube using a stainless steel coupling. Repeat

this procedure to suspend the remaining tube(s) and

connect them to the heater one by one. For details of

the coupling connection, see Figure 7.

5.4.9 To assemble the coupling, hook the free end of the

coupling sleeve into the lanced clip. Place the wide

end of the tapered slide bar on the coupling so that it

moves toward the lanced clip. Insert the two tube

ends into the coupling. Be sure the tube ends are in

line and are flush against the stop pins inside the coupling.

Hammer-drive the slide bar until the coupling is

secured snugly to the tubes. Overdriving the slide bar

will distort the coupling or slide bar lip and will

decrease the holding capability of the coupling.

Coupling should be tight when the slide bar is ±50

mm from the end of the coupling.

5.4.10 Place a reflector over the flanged burner tube and

slide it inside the first tube and reflector hanger. Slide

the next reflector under the first reflector. Overlap the

reflectors using the distance specified in the assembly drawings. Secure the two reflectors in place using

the reflector support straps. Assemble the reflector

support strap (see Figure 8).

NOTE: Remove PVC coat from stainless steel reflec-

tors.

5.4.11 Attach the remaining reflectors to the heater using the

same method. Be sure to alternate the overlap of the

reflectors as shown in the assembly drawings.

Starting at the first reflector support, and alternating

every other support down the length of the heater, the

screws should be loosened 2 mm to allow for expansion of the heating tubes during operation.

5.4.12 After assembling the reflectors, attach the reflector

end caps to the open ends of the reflectors. Punch out

the center section of the end cap, and attach the end

cap to the reflector using at least 6 of the U-clips provided.

55..55 FFIINNAALL AASSSSEEMMBBLLYY

5.5.1 Place the gasket on the flange of the burner tube.

Carefully insert the flanged end into the burner box.

Secure the burner on the burner tube using the four

mounting bolts and washers. Use a spanner to tighten

the bolts evenly.

5.5.2 Place the fan assembly onto the branch of the tee;

slide the fan assembly up to its stop. Tighten the pinch

screw on the assembly making sure that the fan outlet is positioned as required. Attach hanging chain to

the flange.

Page 20

18

Table 6. Blackheat Double Linear Heater Parts List

Part No. Description BH2-15ST BH2-20ST BH2-25ST BH2-30ST BH2-35ST

1 Burner Assembly with Gasket 2 2 2 2 2

2 S7353K Fan Assembly (including flange) - Airflow 1 1 - - -

S7105K Fan Assembly (including flange) - Magnatek - - 1 1 1

3 03051100 Burner Tube, 100 mm x 3048 mm 2 2 2 2 2

4 91409408 Heat Treated Aluminised Tube, 100 mm x 3048 mm - 2 2 4 4

5 S5127W Fan Tube, 100 mm x 3048 mm, with 3048 mm Swirler - 2 2 2 2

6 S5134W Fan Tube, 100 mm x 3048 mm, with 2134 mm Swirler 2 - - - -

7 E0009170 Tee, 100 mm x 100 mm x 100 mm 1 1 1 1 1

8 02750303 Aluminium Reflector, 2439 mm 6 8 8 12 12

9 S5163W Stainless Steel Reflector, 2439 mm (optional) 6 8 8 12 12

10 03090100 Tube and Reflector Hanger 6 8 8 10 10

11 01318901 Tube Clamp Package 2 2 2 2 2

12 01329600 Standard Coupling Assembly 4 6 6 8 8

13 01329700 Coupling Lock 4 6 6 8 8

14 03050000 Reflector Support Strap 4 6 6 10 10

15 02750800 Reflector End Cap 4 4 4 4 4

16 E0007576 Bow Shackle 6 8 8 10 10

17 91107720 U-Clip Package 2 2 2 2 2

18 91908004 Wire Form 4 6 6 10 10

Page 21

19

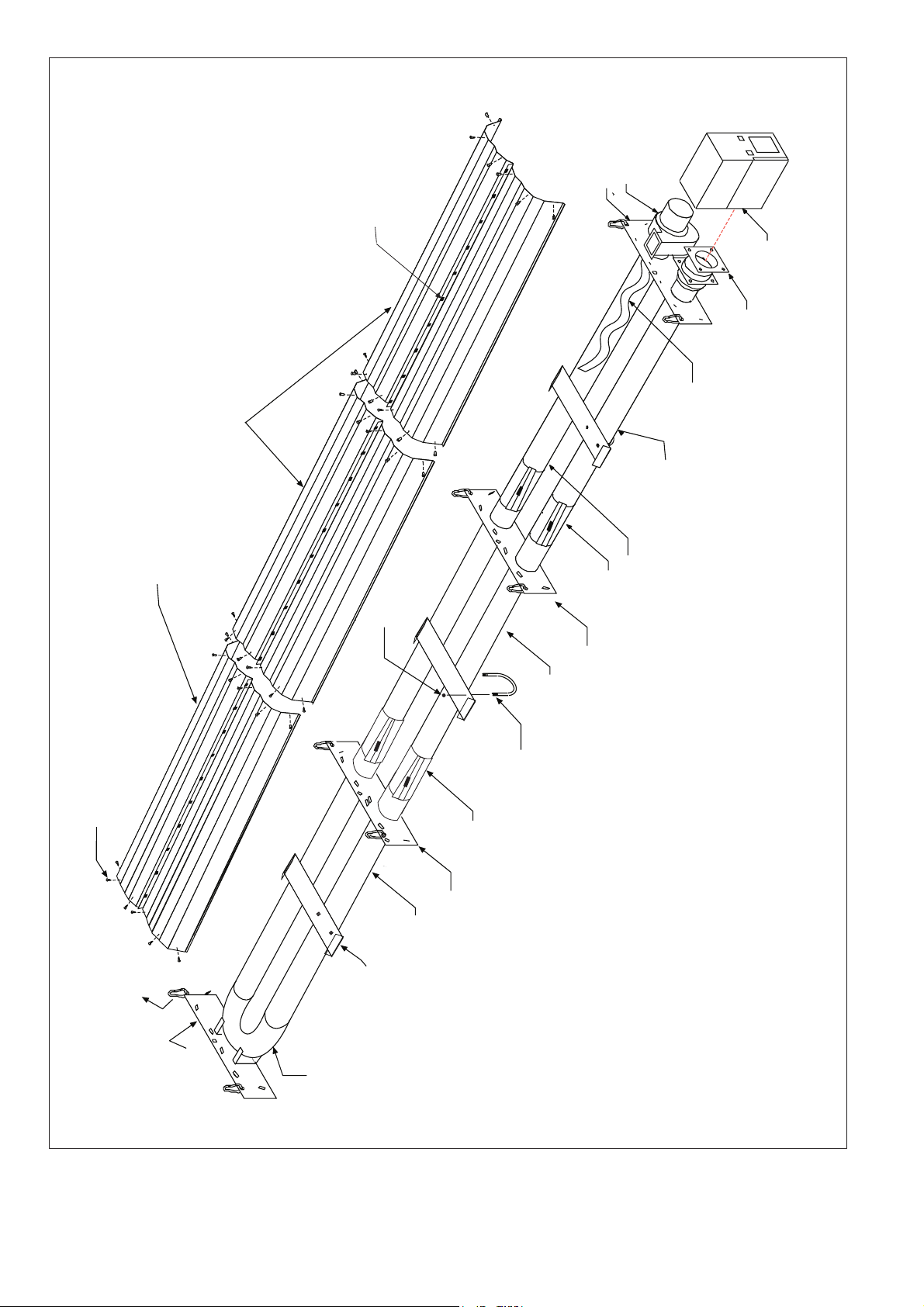

Figure 14. Typical Installation Layouts (Double Linear Heaters)

BH2-15ST

BH2-20ST / BH2-25ST

BH2-30ST / BH2-35ST

BH15

BH20ORBH25

BH30ORBH35

BH15

BH20ORBH25

BH30ORBH35

FAN ASSEMBLY

(Typical)

TEE

(Typical)

STAINLESS STEEL

COUPLING (Typical)

STAINLESS STEEL

COUPLING (Typical)

NOTE: For general arrangement of components (tube

and reflector hangers, reflectors, etc.) refer to

Figures 9, 10 or 11, as required.

Page 22

20

66..11 GGAASS SSUUPPPPLLYY

6.1.1 A gas meter is connected to the service pipe by the

Gas Supply Company. An existing meter should be

checked, preferably by the Company to ensure that

the meter is adequate to deal with the rate of gas supply required.

6.1.2 Installation pipes should be fitted in accordance with

National Standards. Pipework from the meter to the

heater(s) must be of adequate size. Pipes of smaller

size than the heater inlet gas connection should not

be used.

6.1.3 Connect the heater to the gas supply ensuring that the

final connections are as follows:

a) Gas supply pipework is run in medium or heavy

gauge tubing to National Standards terminating in

a Rc1/2 (1/2") BSP thread within 300 mm of the

heater gas inlet.

b) An Rc1/2 (1/2" BSP) mm union cock should be

used and fitted into the supply adjacent to the

heater.

c) A flexible metal hose is connected directly to the

Rc1/2 (1/2" BSP int) connection on the burner.

This metallic hose must conform to National

Standards.

6.1.4 IMPORTANT - The complete installation must be

tested for gas soundness in accordance with National

Standards.

Figure 14. Typical Gas Line Installation (Install According to National Standards)

300 mm

Burner Box

Flex Line Connector

Stainless Steel Flexible Hose

500 mm long

Minimum bend radius 140 mm

Shutoff Cock

REAR VIEW

DOOR-SIDE VIEW

45° 45°

66..22 EELLEECCTTRRIICC SSUUPPPPLLYY

6.2.1 Connect to the electrical supply using a 3 pin plug via

a locally mounted double pole fused switch having a

minimum disconnection of 3 mm on each pole. This

switch should be fused to 3 amps. The burner is fused

at 2 amps. There are no control connections in the

standard burner. Control is affected by interruption of

the main power inlet. See Figures 15 and 16 for the

external wiring details for the single-burner and double

linear heater systems.

6.2.2 All wiring must comply with current I.E.E. Wiring

Regulations and any local regulations which may

apply. Always switch off the supply to the burner and

disconnect by removing the plug before removing the

burner side panel.

6.2.3 In compliance with EN416 clause 4.1.9 Electrical

Operational Safety, any temperature and time control

must be located in the heated area.

SSeeccttiioonn 66.. GGaass aanndd EElleeccttrriicc SSuuppppllyy

Page 23

21

230V

1ph

50Hz

Burner 1

Burner 2

Burner 3

L

N

Earth

Fan 1 Fan 2 Fan 3

Earth

N

L

Blackheat

Thermostat or

Time Clock

Figure 15. Typical External Wiring Diagram (Single-burner Systems)

Figure 16. Typical External Wiring Diagram (Double Linear Systems)

230V

1ph

50Hz

Burner 1 Burner 2

L

N

Earth

Blackheat

Thermostat or

Time Clock

Fan

Earth

N

L

230V

1ph

50Hz

Burner 1 Burner 2

L

N

Earth

Blackheat

Thermostat or

Time Clock

Fan

Earth

N

L

ALTERNA

TE #1

ALTERNATE #2

Page 24

22

L

N

E

BURNER

NEON

FAN

NEON

12345678910

AUTOMATIC CONTROL UNIT

ELECTRODE

purple

grey

230V, 50 Hz

MAINS IN

SOCKET

FAN

SOCKET

green/

yellow

L

E

N

green/

yellow

brown

blue

PRESSURE

SWITCH

NC NO

C

EARTH STUD

green/

yellow

yellow

white

black

black

2A, 230V FUSE

yellow

sense

black

black

blue

blue

brown

green/

yellow

GAS VALVE

EV1

EV2COM

NOISE

FILTER

blue

blue

EARTH

brown

brown

green

blue

Figure 17. Burner Internal Wiring Diagram

Page 25

23

77..11 GGEENNEERRAALL RREEQQUUIIRREEMMEENNTTSS

Heater must be vented in accordance with the proper

national and local codes. The fan may vent to the out-

doors either vertically or horizontally (see Figure 20).

For horizontal venting:

1. Vent must exit building not less than 2.1 m above

grade when located adjacent to public walkways.

2. Vent must terminate at least 1 m above any forced

air inlet located within 3 m.

3. Vent shall terminate at least 1.2 m below, 1.2 m

horizontally from, or 0.3 m above any door, window

or gravity air inlet into building.

4. Locate vent terminal at least 3 m from any open-

ing through which vent gases could enter a building.

5. Use only corrosion resistant materials for the dis-

charge line from the fan to the point of discharge.

6. Vent terminal opening must extend beyond any

combustible overhang.

7. Install vent terminal at a height sufficient to pre-

vent blockage by snow.

8. Protect building materials from degradation by flue

gases.

9. Any portion of flue pipe passing through a com-

bustible wall must be dual insulated or an

approved thimble must be used.

77..22 FFLLUUEE IINNSSTTAALLLLAATTIIOONN

The fan outlet may discharge vertically or horizontally.

Connection should be made using 100 mm minimum

diameter Aluminium or Stainless Steel flue material to

National Standard and must be adapted to insert into

the 100 mm flue adapter. The combined length of flue

run plus fresh air inlet duct should not exceed 16000

mm. Do not use bends in excess of 45°. Consult the

manufacturer if more than 2 x 45° offset bends are

necessary. The flue must be self supporting.

77..33 FFLLUUEELLEESSSS IINNSSTTAALLLLAATTIIOONN ((UU..KK.. OONNLLYY))

If the heater is being installed in an area where combustion products can be dissipated within the building, ensure that the fan outlet is horizontal and away

from the burner. Where installation is close to a wall

(Perimeter system) or other obstruction close to the

fan outlet or wall angle mounted, install the heater so

that the fan tube is the tube furthest from the wall or

obstruction, i.e. the fan will always blow into the building or away from the obstruction.

Figure 18. Flue Connection Detail

77..44 VVEENNTTIILLAATTIIOONN RREEQQUUIIRREEMMEENNTTSS

Detailed recommendations for air supply are given in

the relevant National Standards. There must be an

adequate supply of air for both combustion and general ventilation. Air vents should have negligible resistance. Do not locate air vents where they can be easily

blocked or flooded, or adjacent to any flues or extraction systems carrying flammable vapour.

7.4.1 Flued Installation

Where the heater(s) is flued the space containing it

must have a permanent outside air vent with a minimum effective area of 4.5 cm

2

per kW of heat input. If

mechanical ventilation is employed, the minimum

proven airflow rate shall be 2.35m

3

/h per kW of heat

input.

If the flue is to be horizontally vented through a wall, a

wind-proof terminal must be fitted to outdoor vent pipe

to prevent a back draught.

7.4.2 Flueless Installation

Minimum airflow rate shall be 37.5m

3

/h per kW of

total rated heat input where mechanical ventilation is

used. Where the air change rate is below this minimum, provide additional openings equal to 52 cm

2

per kW total rated heat input; or 1.45 cm2 for each

1m

3

/h per kW below 37.5m3/h per kW of total rated

heat input.

77..55 AAIIRR SSUUPPPPLLYY TTOO BBUURRNNEERR

Where necessary, clean air may be ducted into the

burner box through an added spigot on top of the

burner replacing the existing dust arrest baffle plate.

SSeeccttiioonn 77.. DDiisscchhaarrggee ooff CCoommbbuussttiioonn PPrroodduuccttss

Fan Assembly

Fan Tube

Flue Adapter

Flue Pipe

Attach Flue Adapter with (4) screws,

nuts, and lockwashers.

L

N

E

BURNER

NEON

FAN

NEON

12345678910

AUTOMATIC CONTROL UNIT

ELECTRODE

purple

grey

230V, 50 Hz

MAINS IN

SOCKET

green/

yellow

L

E

N

green/

yellow

brownblue

blue

PRESSURE

SWITCH

NC NO

C

EARTH STUD

blue

green/

yellow

red

yellow

white

black

black

2A, 230V FUSE

yellow

sense

black

black

blue

blue

brown

green/

yellow

GAS VALVE

EV1

EV2

COM

MAINS

FILTER

Page 26

24

Figure 19. Fresh Air Intake Spigot

See section 7.2 for recommendations on duct length.

Air duct should be as straight as possible. Do not use

bends in excess of 45°. Consult the manufacturer if

more than 2 x 45° offset bends are necessary. The

fresh air duct must be self supporting.

77..66 AAIIRR SSUUPPPPLLYY RREEQQUUIIRREEMMEENNTTSS

When fresh air duct is used, follow one of these rules:

A. The flue must penetrate the roof while the fresh

air can penetrate any wall.

B. The flue and fresh air supply must penetrate the

same roof, at a minimum of one meter apart.

C. The flue must penetrate one meter higher than

the fresh air inlet on the same wall.

Figure 20. Air Supply with Flue Configurations

77..77 CCOOMMMMOONN DDUUCCTT

When using a common air inlet duct, always ensure

that the area of the common air inlet duct exceeds

the total area of all air ducts by 20%.

100 mm diameter

Fresh Air Intake Spigot

Dust Arrest

Baffle Plate

Burner

Inlet

Flue

Inlet

Flue

Min. 1 m

Inlet

Flue

Min. 1 m

Roof

Wall

A

C

B

Page 27

25

SSeeccttiioonn 88.. OOppeerraattiinngg tthhee SSyysstteemm

88..11 DDEETTAAIILLEEDD SSEEQQUUEENNCCEE

On connection of power supply the fan motor will start

creating a suction in the tube. Power is also supplied,

via a relay safety circuit, to the fan proving switch and

when suction is created, changes contacts to feed

power to the Automatic Control Unit. At this stage one

neon will light up.

8.1.1 Power to the control causes initiation of an approximate ten (10) seconds purge period following which

the solenoid valves open passing gas at a full rate to

the burner. At the same time a spark is created and

ignition should take place. If ignition of the gas is not

successful the spark will cease and the solenoid will

close after approximately ten (10) seconds. Lockout

will occur. If the gas is ignited, the detection circuit is

energised and switches off the ignition circuit. Both

neons will now light up indicating full running condition.

8.1.2 The heater will continue to run until the power supply

or gas supply is interrupted. Interruption of the electrical supply results in the shutdown of the heater.

Restoration will restart the whole sequence.

Interruption of the gas supply results in loss of flame

followed by one attempt at reignition followed by lockout if unsuccessful.

88..22 TTEESSTTIINNGG

Establish that a satisfactory purged gas supply and an

electrical supply is available to the heater. Ensure that

all time clocks and thermostats are set to call for heat.

8.2.1 With the gas supply cut off at the appliance isolating

cock and the electrical supply isolated by switching off

at the local switch and removing the appliance inlet

plug, open the control chamber secured by the centre

screw. Remove the sealing screw from the pressure

test point and remove the cover cap from the governor.

8.2.2 Turn on appliance isolating cock and connect appliance electrical plug. Ensure that the timer or thermostat, if fitted, are set to call for full gas rate. Switch on

at the local switch. The sequence as described should

take place. If not, refer to detailed fault finding

sequence. When flame is established, check the gas

pressure reading and adjust if necessary. See data

label.

8.2.3 Check the gas pressure at the outlet of the gas valve

to ensure minimum 8.7 mbar (3.5 in. w.g.) pressure

for G20 natural gas or 27 mbar (10.5 in. w.g.) pressure

for propane. See Section 2 for G25 and Butane settings.

8.2.4 Switch off the electrical supply (shutting down the

heater), remove pressure gauge - refit pressure testpoint screw, ensuring a tight gas seal. Replace governor cover cap. Close burner side cover.

88..33 SSYYSSTTEEMM CCHHEECCKKSS

Switch on again at the local switch to ensure smooth

ignition. Carry out the following system checks.

8.3.1 When running turn off the gas supply at the appliance

isolating cock. The heater will immediately shut down

followed by one attempt at restoration followed by

lockout.

8.3.2 When running disconnect the fan plug from the

burner. The unit should shut down within three seconds proving operation of the pressure switch.

88..44 UUSSEERR IINNSSTTRRUUCCTTIIOONNSS

Having satisfactorily tested these Blackheat units

ensure that the client is fully aware of the operation of

the system. Bring this manual to the attention of the

user or purchaser; instruct them in the safe operation

of the heater(s). Advise the user that if the system is

unflued, any reduction in the natural ventilation of the

building may require a flue to be fitted, or additional

ventilation grills will be required.

Page 28

26

SSeeccttiioonn 99 SSeerrvviicciinngg IInnssttrruuccttiioonnss

IMPORTANT: Never use the heater as a support for

ladders or other access equipment. Always test for

gas soundness with a suitable detection fluid after

completing any servicing or exchange of gas carrying

component. On completion of any service/fault finding tasks which require the breaking and remaking of

electrical connections then the checks:- A:Earth

Continuity, B:Polarity and C:Resistance to Earth must

be repeated.

99..11 AANNNNUUAALL PPRROOCCEEDDUURREE

Carry out the following procedure annually. The preferred time would be immediately before the winter

heating period. If very dirty conditions arise it may be

necessary to carry out this procedure more often. If the

unit takes in air through an air duct or filter assembly,

more frequent service may be necessary.

9.1.1 Isolate the heater from the gas and electricity supply

by shutting off the appliance cock and disconnecting

the union connector, switching off the local electrical

supply and removing the appliance plug.

9.1.2 Remove the fan plug from the burner. Unscrew the

securing screws on the burner flange. The burner can

now be removed. Unscrew the securing screw on the

fan flange spigot. The fan can now be removed.

9.1.3 Remove the fan and burner independently to floor

level and clean both items internally using a soft

brush and compressed air if available. Take care not

to damage the internal parts of the burner. Check fan

impeller for cleanliness and that free rotation is available. When removing burner take care not to disturb

the gasket on the flanged burner tube.

9.1.4 The electrodes are an integral part of the Burner

Head. To check spark gap remove the securing screws

on the electrode and withdraw it ensuring the gasket

is not damaged. Spark gap on electrode should be

approximately 3 mm.

9.1.5 With burner and fan removed, clean the outer surfaces of the tubes using a brush and wipe the inner

surface of the reflector with a soft damp cloth - use a

household detergent if necessary. Never use abrasive

cleaners on the the reflectors.

9.1.6 Re-assemble the burner and fan in reverse order.

Carry out the Testing Procedure 8.2.

99..22 CCOOMMPPOONNEENNTT RREEMMOOVVAALL

First isolate the heater from the gas and electricity

supply; shut off the appliance cock, disconnect the

gas union connection; switch off the local electrical

supply and remove the appliance plug.

Entry to the burner assembly is gained by removing

the two (2) door screws and opening the hinged side

cover. Entry to the combustion chamber is gained by

removing the combustion chamber cover (7 screws).

9.2.1 Electrode (see section 9.1.4)

9.2.2 Burner Head/Injector Jet

When the cover is removed completely, the burner

assembly is exposed. Unscrew the burner cup.

Remove brass injector jet (orifice). Replace in reverse

sequence.

9.2.3 Solenoid Valve/Governor

Remove burner head as 9.2.2. Unscrew 4 mm slotted

screws on top of burner securing the solenoid/governor body. Withdraw the four wires tagged to the solenoid (TEKNIGAS), or the four wires between the

solenoids (SIT). The solenoid/governor and fittings can

now be withdrawn from the compartment.

The solenoid(s) can be removed from the body by

extracting the circlip and sliding (TEKNIGAS), unscrewing central screw (SIT). Replace in reverse sequence.

Note: Earth is green/yellow.

9.2.4 Automatic Flame Control Unit

Remove grey ignition lead. Withdraw the 10 point edge

connector. Unscrew four (4) screws from the cover.

Replace if faulty. Refit in reverse sequence.

9.2.5 Pressure Switch

Disconnect the two (2) rubber tubes. Remove wires

from the three blades. Remove two (2) screws which

secure the pressure switch to the burner. Remove

pressure switch.

Replace pressure switch if faulty and refit in reverse

sequence ensuring that the rubber tubes are reconnected to the switch correctly.

Not

e: Wires fitted as follows:

NO - Yellow

NC - White

Common - Black

9.2.6 Neons

Remove the two push on connectors and remove the

neons by pushing downwards. Replace in reverse

sequence.

9.2.7 Fuse

Pull out drawer containing fuse in the panel mounted

mains socket.

Page 29

27

It is the installer’s responsibility to follow these instructions and

to insure that all local and national codes are followed. Insure

that you are capable of performing all steps and read the

entire section before beginning this procedure.

NOTE: For conversion between G20 and G25, or Propane and

Butane, no change in jet size is necessary; remove (2)

screws from control side door, open and proceed to step

10.3.5.

1100..11 GGAASS CCOONNVVEERRSSIIOONN KKIITTSS IINNCCLLUUDDEE::

- Jet as required; see burner specifications (pg. 4)

* - Governor spring. (Propane/Butane: Green)

(Natural: Silver)

- Valve/governor label.

- Burner unit label for gas conversion (to natural G20,

G25, propane or butane).

(*) TEKNIGAS valves only

1100..22 RREEQQUUIIRREEDD TTOOOOLLSS::

- Spanner 13 mm (1/2") - to remove jet.

- Manometer - minimum 0-28 mBar (0-11" W.G.)

- Phillips screwdriver (#2)

-or-

- 1/4” Nut Driver

- Flat blade screwdriver.

- Spanner 8mm - to adjust Governor (SIT valve only)

1100..33 CCOONNVVEERRSSIIOONN PPRROOCCEEDDUURREE::

10.3.1 Isolate gas and electric supply; remove fresh air duct

if necessary.

10.3.2 Remove cover screws; withdraw the edge connector

and the ignition lead from the automatic control unit;

set cover aside.

10.3.3 This step is for the TEKNIGAS model valve only.

Remove governor screw and spring; replace with

spring included in kit and refit governor screw. See

Figure 21 - Governor Spring Replacement.

10.3.4 Remove burner cup and jet; replace with the jet provided in the kit. Reinstall the burner cup. See Figure

24 for proper position of cup relative to the air plate.

10.3.5 Attach valve/governor label to side of valve body.

10.3.6 Attach gas conversion label indicating gas type to

burner housing adjacent to data plate; fill in governor

pressure setting.

10.3.7 Replace door assembly and refit edge connector and

ignition lead to the automatic control unit; do not

attach screws to control side door at this time.

NOTE: For propane/butane pressure couple (TEKNIGAS valve, Italy only): turn governor screw down

(clockwise) until the regulator is at the bottom;

replace the plastic capscrew over the governor spring;

proceed to step 10.3.12.

10.3.8 Attach one end of hose to the governor pressure tap

and the other end to the pressure side of a manometer.

10.3.9 Turn on gas and electrical supply, operate unit.

10.3.10 Set governor pressure according to the burner specifications (pg. 4) by turning the governor screw until the

proper pressure is read on the manometer.

10.3.11 Shut off unit and remove manometer. Return the shut

off screw in the governor pressure tap to the off position and replace the screw cap over the governor

spring (TEKNIGAS valve only).

10.3.12 Reinstall screws to the control side door and refit the

fresh air duct if necessary.

10.3.13 Review section 9.1 servicing instructions: annual pro-

cedure. Return unit to service.

1100..44 AADDJJUUSSTTMMEENNTT OOFF SSTTEEPP-OOPPEENNIINNGG FFLLOOWW RRAATTEE

((SSIITT VVAALLVVEE OONNLLYY))::

10.4.1 To adjust, gradually turn screw marked “I Step” until

ignition is prompt and silent. Clockwise rotation: start

flow decreases. (see Figure 22). The step-open flow

rate should allow 2.5 mbar (1.0 in wg) gas pressure to

the jet. After proper adjustment of the step-open flow

rate, the valve will fully open within a few seconds and

the governor pressure may then be set.

10.4.2 Wait at least 40 seconds after deenergization of solenoids before checking for proper ignition.

SSeeccttiioonn 1100.. GGaass CCoonnvveerrssiioonn IInnssttrruuccttiioonnss

Page 30

28

Governor Screw

(no replacement spring)

I-Step Adjustment

Outlet Pressure Tap Inlet Pressure Tap

Teknigas Gas Valve

Plastic Capscrew

Replacement Spring

Governor Screw

Air Plate

Burner Cup

(center horizontally)

Jet

Electrode

16 mm

Governor Screw

and Spring

Inlet Pressure TapOutlet Pressure Tap

Figure 21 TEKNIGAS Valve Spring Replacement

Figure 22 SIT Valve Detail Figure 24 Burner Cup Position

Figure 23 TEKNIGAS Valve Detail

Page 31

29

Replace automatic

control unit.

(P/N 90438700)

YES

NO

Remove obstruction.

Is the flue pipe or the inlet of

the burner obstructed?

YES

NO

Carefully reset spark gap

to 3 mm.

Is the igniter gap

set at 3 mm?

YES

NO

Replace Electrode and

ignition wire as needed.

(P/N 90427403)

Replace air switch.

Fan bearings may have

failed. Replace fan.

NO

YES

Check relay wiring

(if applicable) and wiring

to the burner.

Unplug burner. Does the

fan turn freely?

NO

YES

Is there power (230V) at

the burner?

Check thermostat wiring

and replace thermostat if

necessary.

NO

YES

Unplug burner and check

Electroder and ignition wire.

Are they damaged?

START

YES

NO

NO

YES

Place a jumper across the

thermostat terminals.

Does the fan turn on?

Is there spark at the igniter?

YES

NO

Turn up thermostat.

Does the fan turn on?

NO

Is the fan obstructed?

Replace fan.

NO

YES

Are the hoses to the air

switch secure and leak free?

Repair, replace, or tighten

hoses as necessary.

Check 2-Amp fuse in Mains

Inlet. Replace as required.

NO

Remove Black & White

leads from the air switch;

place jumper between leads.

Does the fan turn on?

NO

YES

Remove obstruction.

Remove Black & Yellow

leads from the air switch;

place jumper between leads.

Is there a spark?

Replace air switch

(P/N 90436711)

Is there power out from

pin 10 on ignition module?

Replace ignition module.

NO

YES

Figure 25. Troubleshooting Flow Chart

Page 32

30

Page 33

31

SSeeccttiioonn 1111.. RReeppllaacceemmeenntt PPaarrttss

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

Figure 26. Burner Internal Components

Page 34

32

TTaabbllee 77.. RReeppllaacceemmeenntt PPaarrttss

Item Part Number Description

A 90438700 Automatic Control Unit

B 91319900 Fuse, 2 amp, 5 mm x 20 mm

C 91220700 Flex Line Adapter

D 90436711 Air Switch

E 91320602 Amber Neon Lamp

F 90033100 Gas Valve

G Regulator Spring and Governor Screw

H Governor Pressure Tap

I 03090702T Flex Manifold

J 96212100 Star Washer

K Jet (see section 2 of these instructions) - Orifice

L 03020100 Burner Cup Assembly

M 02553203 Mica Window Assembly

N 90427403 Electrode Assembly

not shown 02558501 Electrode Gasket

O 07230000 Dust Arrest Baffle Plate

not shown 90438900 Filter, Noise - RFI

not shown 91319601 Edge Connector - 10 way

not shown 90427704 Ignition Wire

not shown 07260000 Outside AIr Kit

91911700 100 mm Collar

07261000 Outside Air Mounting Plate

94118106 #8 x 3/8 Washer Head Screws

not shown 02568200 Burner Tube Gasket

Page 35

33

All Blackheat product bear CE marking signifying that

they comply with all relevant CE directives.

The Blackheat Warranty means that only the best

material and workmanship are employed in the manufacture of Blackheat products.

WARRANTY COVERAGE:

Blackheat Ltd. (“Seller”) warrants that entire heating

systems sold by it (individually a “System”) and any replacement parts which it sells relating to any System (“Parts”)

shall be free from defects in workmanship and material for

the time periods described as follows. With respect to a

System this warranty shall apply for a period of one year

from delivery to the original purchaser (“Buyer”). With

respect to Parts, this warranty shall apply for the longer of

the original System warranty period or for a period of one

year. (“Systems” and “Parts” are hereinafter collectively

referred to as “Products”.) This warranty extends only to the

original purchaser of Products.

Seller manufactures products which are designed only

to provide predetermined ranges of heat rises in various

enclosures when properly used in systems designed by purchaser or others and installed by others. Seller makes no

representation or warranty with respect to the effect upon

enclosure, or upon any of the contents of the enclosure,

including, without limitation, all plant or animal life, kept or

processed in the enclosure subject to the limitations outlined below.

WARNING:

This warranty is void if the products have been damaged due to accident, abuse, mishandling or any other