Page 1

DO NOT store or use petrol or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. DO NOT try to light any

appliance.

3. DO NOT use electrical

switches.

4. DO NOT use any telephone

in your building.

5. Leave the building.

6. Immediately call your local

gas supplier after leaving

the building. Follow the gas

suppliers instructions.

7. If you cannot reach your gas

supplier, call the Fire

Department.

®

Blackheat

Vacuum Assisted

Linear & U-Tube

Gas Fired Radiant

Heating

Systems

Installation, Operation &

Service Manual

Improper installation, adjustment, alteration, service

or maintenance can result in death, injury or property

damage. Read the installation, operation and service

manual thoroughly before installing or servicing

this equipment.

Installation must be done by a contractor qualified

in the installation and service of gas-fired heating

equipment.

WARNING

BH15

BH20

BH25

BH30

BH35

BH40

BH45

BH50

Installer

Please take the time to read and understand

these instructions prior to any installation.

Installer must give a copy of this manual to the owner.

Owner

Keep this manual in a safe place to provide your

serviceman with information should it become

necessary.

Hurll Nu-Way Pty Ltd

14 Aristoc Road

GLEN WAVERLEY VIC 3150

Telephone: +61 3 9561 2100

Fax: +61 3 9560 8992

www.rg-inc.com

170101AUNZ Rev. 2 4/03

Page 2

TABLE OF CONTENTS Note: Pages 2,16,17,18,23,32,35,46,54,55 have been deleted as not relevant.

SECTION 1: Heater Safety......................................................1

SECTION 2: Installer Responsibility .....................................1

2.1 Low Level User Instructions.........................................1

2.2 Halogenated Hydrocarbons.........................................1

2.3 National Standards and Applicable Codes ..................1

SECTIO N 3: Critical Consideratio ns ....... .. .................... .. ... ...3

3.1 Minimum Required Clearances to Combustibles.........3

3.2 Clearance Data - Linear ................4

3.3 Clearance Data -U Tube.................6

SECTIO N 4: Spe c if ic a tions ................................ .. ... ......... ... .. . 8

4.1 Material Specifications................................................. 8

4.2 Heater Specifications...................................................8

4.3 Venting Specifications..................................................8

4.4 Suspension Specifications........................................... 8

4.5 Controls Specifications ................................................ 8

4.6 Linear Heater...............................................................9

4.8 U-Tube Heater .............................................................9

4.9 Burner Specifications................................................. 10

SECTION 5: Major Component Descriptions ..................... 11

SECTIO N 6: Gen er a l Sus p e n s io n Details ........ ..................12

6.1 Suspension Details .................................................... 12

SECTION 7: Linear Heater Installation........................... ...13

7.1 Linear Standard Parts List .........................................13

7.3 Burner Tube Installation ............................................ 19

7.4 Coupling and Tube Assembly....................................19

7.5 Tube Clamp Package Installation..............................21

7.6 Reflector Installation .................................................. 21

SECTIO N 1 2: Ventin g ............... .. .. .................... .. ... .......... .. .. ..42

12.1 Flue Installation ........................................................42

12.2 Flueless Installation (U.K. Only)...............................42

12.3 Ventilation Requirements ......................................... 42

12.4 Outside Combustion Air Supply ...............................43

12.5 Common Duct ..........................................................43

SECTIO N 1 3: Ga s P ip in g . ... ................... ... .. .......... .. ... ......... ..44

SECTIO N 1 4: W ir in g.. ................... ... .. .......... .. ... .......... .. ... ...... 4 5

14.1 BLACKHEAT® Typical External Wiring Diagram

(Linear or U Tube)............................................................45

14.5 BLACKHEAT® Internal Wiring Diagram .................47

SECTIO N 1 5: Ope r a tio n ...... ................... ... .. .......... .. ... ......... ..48

15.1 Heater Lockout Indication (Optional)........................48

15.2 Testing......................................................................48

15.3 Commisioning ..........................................................48

15.4 System Checks ........................................................49

15.5 User Instructions......................................................49

SECTIO N 1 6: Se r v ic ing Instru c tio n s .. .. .......... .. ... ................ 5 0

16.1 Annual Procedure ....................................................50

16.2 Component Removal ...............................................50

SECTION 17: Troubleshooting.............................................52

17.1 Troubleshooting Flow Chart (Linear and

U-Tube) ............................................................................52

SECTION 8: U-Tube Heater Installation ..............................24

8.1 U-Tube Standard Parts List........................................24

8.2 Critical Hanger Placement.........................................27

8.3 Burner Tube and Fan Tube Installation ....................27

8.4 U-Tube Support Bracket Assembly Installation .........28

8.5 Coupling and Tube Assembly....................................29

8.6 Tube Installation ........................................................30

8.7 U-Tube Installation .................................................... 30

8.8 Reflector Installation .................................................. 31

SECTION 10: Burner & Fan Installation ..............................33

10.1 Burner Installation.................................................... 33

10.2 Fan Assembly.......................................................... 33

10.3 Linear & U-Tube Fan Installation..............................34

SECTION 11: Optional Heater Accessories........................36

11.1 Reflector Side Extension Installation ....................... 36

11.2 Decorative Grille Installation....................................37

11.3 Protective Grille Installation ..................................... 38

11.4 Sports Hall Guard Installation ..................................39

11.5 Universal Shield Installation.....................................40

11.6 Undershield Installation ...........................................41

17.3 Manifold Gas Pressure Setting ................................56

SECTIO N 1 8: Re p l ac e me n t Pa r ts..... ... ......... ... .. .......... ... .. ....57

© 2001

All rights reserved. No part of this work covered by the copyrights herein may be reproduced

or copied in any form or by any means - graphic, electronic, or mechanical, including

photocopying, recording, taping or information storage and retrieval systems - without the

written permission of Roberts-Gordon.

Page 3

TABLE OF FIGURES

Figure 1: Deleted

Figure 2: Linear Horizontal Mounts ...............4

Figure 3: Linear, One Side Reflector..............4

Figure 4: Linear, Two Side Reflectors ............4

Figure 5: Linear, 45° Mount............................4

Figure 6: Linear, 1 Foot and 2 Foot Deco

Grille ..........................................................................5

Figure 7: Linear, Protective Grille...................5

Figure 8: Linear, Venting ................................5

Figure 9: U-Tube, Horizontal Mount .......................................... 6

Figure 10: U-Tube, One Side Reflector ..................................... 6

Figure 11: U-Tube, Two Side Reflectors ...................................6

Figure 12: U-Tube, Full 45° Mount............................................6

Figure 13: U-Tube, Opposite 45° Tilt......................................... 7

Figure 14: U-Tube, Protective Grille .......................................... 7

Figure 15: U-Tube, Venting ....................................................... 7

Figure 16: BLACKHEAT® Linear and U-Tube ........................10

Figure 17: BLACKHEAT® Linear General Assembly

Overview................................................................ 14

Figure 18: BLACKHEAT® Linear Layout Overviews .............. 15

Figure 19: Deleted

Figure 20: Deleted

Figure 21: Reflector Overlap Detail......................................... 22

Figure 22: BLACKHEAT® BH15UT Assembly Overview .......25

Figure 23: BLACKHEAT® U-Tube Layout Overviews.............26

Figure 24: Deleted

Figure 25: Typical Manifold Layout (Linear and U-Tube

Configuration) ........................................................ 32

Figure 26: Individual Flue Connection Detail..........................42

Figure 27: Fresh Air Intake Spigot .......................................... 43

Figure 28: Air Supply with Flue Configurations.......................43

Figure 29: Gas Connection with Stainless Steel Flex

Connector .............................................................. 44

Figure 30: Sequence of Operation Chart................................ 48

Figure 31: Burner Cup Position............................................... 50

Page 4

SECTION 1: HEATER SAFETY

Your Safety is Important to Us!

This symbol is used throughout the manual

to notify you of possible fire, electrical or burn

hazards. Please pay special attention when

reading and following the warnings in these

sections.

SECTION 1: HEATER SAFETY

A wall tag is supplied with the BLACKHEAT® heater as a

permanent reminder of the safety instructions and the

importance of the minimum required clearances to

combustibles. A copy of the wall tag is illustrated on Page

2, Figure 1. Peel off the backing of the adhesive strips on

the rear surface of the tag and position the tag on a wall

near the BLACKHEAT® heater (e.g. thermostat or

ROBERTS GORDON

®

BZC Microprocessor Controller).

WARNING

Installation, Service and Annual Inspection of heater

must be done by a contractor qualified in the

installation and service of gas-fired heating equipment.

Read this manual carefully before installation,

operation, or service of this equipment.

Failure to follow these instructions can result in death,

injury or property damage.

This heater is designed for heating non-residential indoor

spaces. Do not install in residential spaces. These

instructions, layouts , AS5601/AG 601,local codes and

ordinances, and applicable standards that apply to gas

piping, electrical wiring, venting, etc., must be thoroughly

understood before proceeding with the installation.

SECTION 2: INSTALLER RESPONSIBILITY

• To install the heater, as well as the gas and electrical

supplies, in accordance with applicable specifications

and codes. Roberts-Gordon recommends the

installer contact a local building inspector or Fire

Marshal for guidance.

• To use the information given in a layout drawing and

in the manual together with the cited codes and

regulations to perform the installation.

• To install the heater in accordance with the Clearances to Combustibles.

• To furnish all needed materials not furnished as

standard equipment.

• To plan location of supports.

• To provide access to burners for servicing on all

sides, for burner removal.

• To provide the owner with a copy of this installation,

operation and service manual.

• To never use heater as support for ladder or other

access equipment and never hang or suspend anything from heater.

2.2 Halogenated Hydrocarbons

CAUTION

Do not use heater in an area containing corrosive

chemicals.

Avoid the use of corrosive chemicals to ensure a

longer life of the burner, tubing and other parts.

Failure to follow these instructions can result in

property damage.

Roberts-Gordon cannot be responsible for ensuring that

all appropriate safety measures are undertaken prior to

installation; this is entirely the responsibility of the

installer. It is essential that the contractor, the subcontractor, or the owner identifies the presence of

combustible materials or halogenated hydrocarbons*

anywhere in the premises.

* Halogenated Hydrocarbons are a family of chemical compounds characterized by the presence of halogen elements

(flourine, chlorine, bromine, etc.). These compounds are

frequently used in refrigerants, cleaning agents, solvents, etc. If

these compounds enter the air supply of the burner, the lifespan

of the heater components will be greatly reduced. An outside air

supply must be provided to the burners whenever the presence

of these compounds is suspected. Warranty will be invalid if the

heater is exposed to halogenated hydrocarbons.

2.3 National Standards and Applicable Codes

All Appliances must be installed in accordance with the

latest revision of AS5601/AG 601 and other relevant

codes. This refers also to the electric, gas and venting

installation. Note: Additional standards for installations in

Public Garages, Aircraft Hangars, etc. may be applicable.

2.1 Low Level User Instructions

In all situations, clearances to combustibles must be

maintained. Failure to observe clearances to

combustibles can result in death, severe injury or

property damage. Signs should be posted in storage

areas to specify the maximum stacking height of items

placed below heater to maintain required clearances to

combustibles. Minimum clearances must be maintained

from vehicles parked below the heater. Caution should be

used when running the system near combustible

materials such as wood, paper, rubber, etc.

Consideration should be given to partitions, storage

racks, hoists, building construction,etc.

1

Page 5

SECTION 3: CRITICAL CONSIDERATIONS

WARNING

SECTION 3: CRITICAL CONSIDERATIONS

Fire Hazard

Some objects will catch fire

or explode when placed

close to heater.

Keep all flammable objects,

liquids and vapors the

minimum required

clearances to combustibles

away from heater.

Failure to follow these

instructions can result in

death or injury.

3.1 Minimum Required Clearances to Combustibles

Clearances are the required distances that combustible

objects must be kept away from the heater to prevent

serious fire hazards. Combustibles are materials, which

may catch on fire and include common items such as

wood, paper, rubber, fabric, etc. Maintain clearances to

combustibles at all times for your safety.

Clearances for all heater models are located on Page 4,

Figure 2 through Page 7, Figure 15 in this manual. Check

the clearances on each burner for the model heater being

installed to make sure the product is suitable for your

application and the clearances are maintained. Read and

follow the safety guidelines below:

• Keep petrol or other combustible materials including

flammable objects, liquids, dust or vapours away from

this heater or any other appliance.

• Maintain clearances from heat sensitive material,

equipment and workstations.

• Maintain clearances from vehicles parked below the

heater.

• Maintain clearances from swinging doors, overhead

cranes, vehicle lifts, partitions, storage racks, hoists,

etc.

• In locations used for the storage of combustible

materials, signs must be posted to specify the

maximum permissible stacking height to maintain

required clearances from the heater to the combustibles. Signs must be posted adjacent to the heater

thermostat. In the absence of a thermostat, signs

must be posted in a conspicuous location.

• Consult local Building Inspector, Fire Insurance

Carrier or other authorities for approval of proposed

installation when there is a possibility of exposure to

combustible airborne materials or vapours.

• Hang heater in accordance to the minimum suspension requirements on Page 9, Section 4.6 through

Page 9, Section 4.8.

• If the radiant tubes must pass through the building

structure, be sure that adequate sleeving and fire

stop is installed to prevent scorching and/or fire

hazard.

Burn Hazard

Keep all persons,

especially children, away

from heater.

Do not touch any part of

the heater.

Heater is very hot.

Failure to follow these

instructions can result in

severe injury.

3

Page 6

BLACKHEAT® INSTALLATION OPERATION AND SERVICE MANUAL

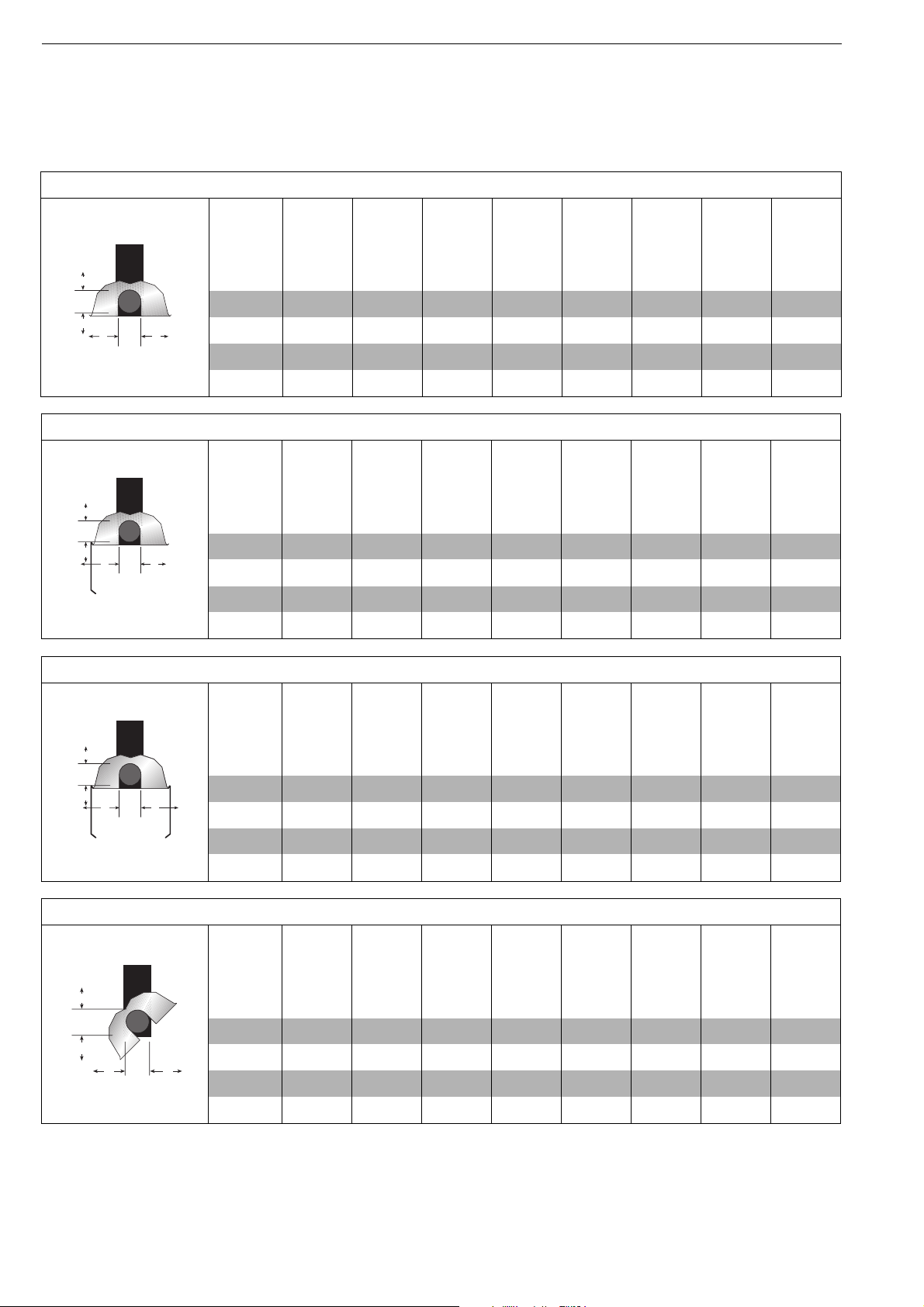

3.2 Clearance Data -

NOTE: 1. All dimensions are from the Tube surface.

2. Clearances B, C and D can be reduced by 50% after 7 m of tubing downstream

from the burner.

3. All measurements are in Millimeters.

FIGURE 2: LINEAR , HORIZONTAL MOUNTS

A

Model

BH15

BH20

A 150 150 150 150 150 150 200 200

C

B

D

B 890 970 970 1020 1170 1220 1280 1330

C 1570 1650 1650 1780 1930 1970 2010 2080

D 890 970 970 1020 1170 1220 1280 1330

FIGURE 3: LINEAR , ONE SIDE REFLECTOR

A

C

B

D

Model

BH15

A 150 150 150 150 150 150 200 200

B 230 230 230 230 230 230 230 230

C 1580 1760 1760 1930 2090 2130 2160 2240

D 1200 1380 1380 1500 1660 1710 1760 1860

BH20

FIGURE 4: LINEAR, TWO SIDE REFLECTORS

BH25

BH25

BH30

BH30

BH35

BH35

BH40

BH40

BH45

BH45

BH50

BH50

A

Model

C

B

D

A 150 150 150 150 150 150 200 200

B 590 640 640 690 820 860 890 1020

C 1660 1810 1810 1960 2110 2160 2210 2320

D 590 640 640 690 820 860 890 1020

FIGURE 5: LINEAR, 45° MOUNT

A

C

B D

Model

A 200 200 200 250 250 275 300 300

B 200 200 200 200 200 200 200 200

C 1500 1660 1660 1860 1960 2030 2110 2160

D 1370 1520 1520 1630 1750 1820 1880 2000

BH15

BH15

BH20

BH20

BH25

BH25

BH30

BH30

BH35

BH35

BH40

BH40

BH45

BH45

BH50

BH50

4

Page 7

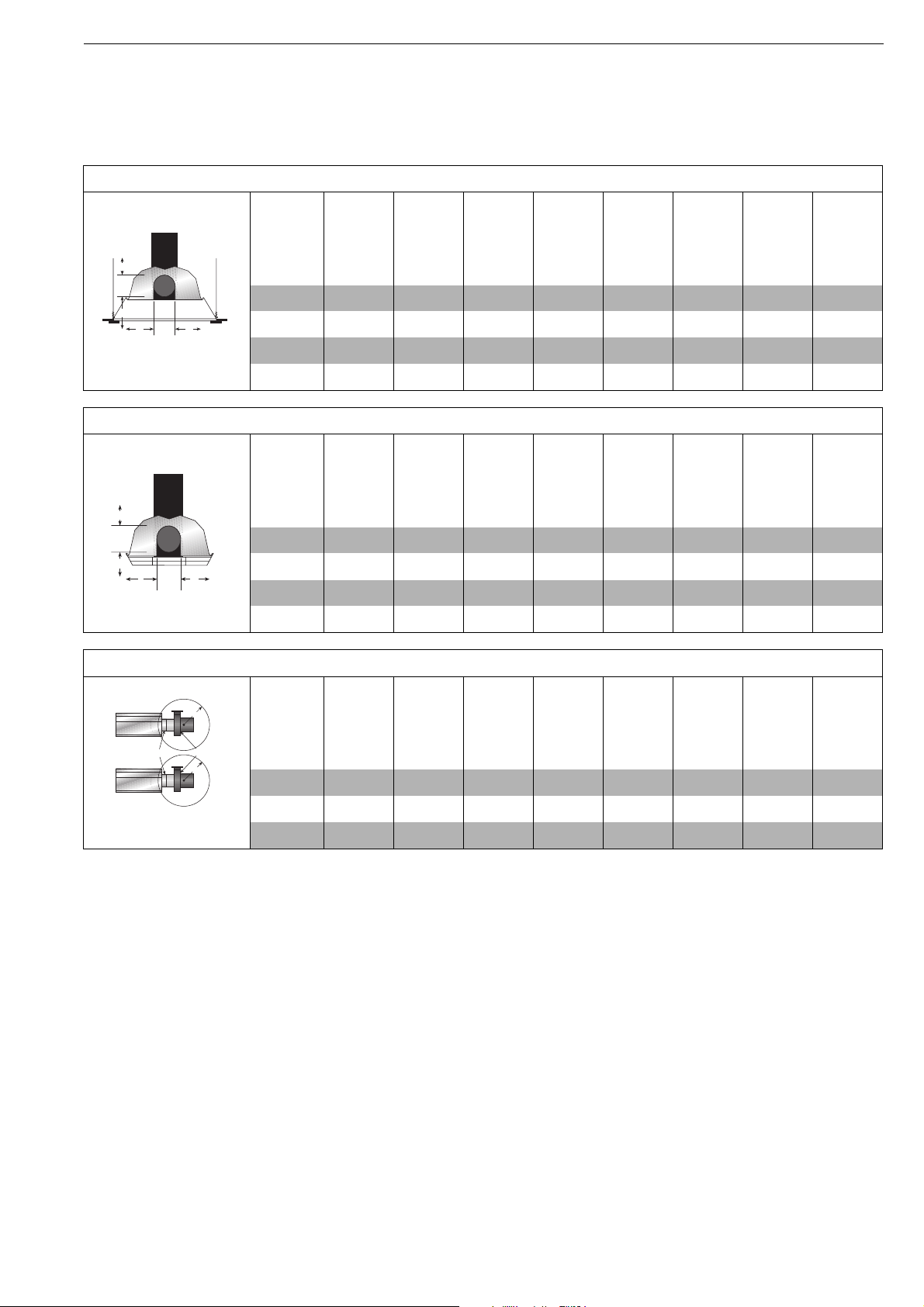

NOTE: 1. All dimensions are from the Tube surface.

A

B

C

D

A

B

C

D

Radiant tubes

Fan

Unvented

Vented

E

F

2. Clearances B, C and D can be reduced by 50% after 7 m of tubing downstream

from the burner.

3. All measurements are in Millimeters.

FIGURE 6: LINEAR , 1 FOOT AND 2 FOOT DECO GRILLE

SECTION 3: CRITICAL CONSIDERATIONS

Model

BH15

A 150 150 150 150 150 150 200 200

B 890 970 970 1020 1170 1220 1280 1330

C 1570 1650 1650 1780 1930 1970 2010 2080

D 890 970 970 1020 1170 1220 1280 1330

FIGURE 7: LINEAR , PROTECTIVE GRILLE

Model

A 150 150 150 150 150 150 200 200

B 890 970 970 1020 1170 1220 1280 1330

C 1570 1650 1650 1780 1930 1970 2010 2080

D 890 970 970 1020 1170 1220 1280 1330

BH15

FIGURE 8: LINEAR , VENTING

BH20

BH20

BH25

BH25

BH30

BH30

BH35

BH35

BH40

BH40

BH45

BH45

BH50

BH50

Model

BH15

BH20

BH25

BH30

BH35

BH40

BH45

BH50

E 1000 1000 1000 1000 1000 1000 1000 1000

F 500 500 500 500 500 500 500 500

5

Page 8

BLACKHEAT® INSTALLATION OPERATION AND SERVICE MANUAL

3.3 Clearance Data -U Tube

NOTE: 1. All dimensions are from the Tube surface.

2. Clearances B, C and D can be reduced by 50% after 7 m of tubing downstream

from the burner.

3. All measurements are in Millimeters.

.

FIGURE 9: U-TUBE, HORIZONTAL MOUNT

A

Model

BH15

BH20

A 150 150 150 150 150 150 200 200

C

DB

B 890 970 970 1020 1170 1220 1270 1380

C 1580 1730 1730 1910 1980 2050 2110 2210

D 760 940 940 1000 1090 1150 1200 1300

FIGURE 10: U-TUBE, ONE SIDE REFLECTOR

A

B

C

D

Model

BH15

BH20

A 150 150 150 150 150 150 200 200

B 230 230 230 230 230 230 230 230

C 1580 1760 1760 1930 2090 2130 2160 2240

D 1200 1380 1380 1500 1660 1710 1760 1860

FIGURE 11: U-TUBE, TWO SIDE REFLECTORS

A

Model

C

DB

A 150 150 150 150 150 150 200 200

B 590 640 640 690 820 860 890 1020

BH15

BH20

BH25

BH25

BH25

BH30

BH30

BH30

BH35

BH35

BH35

BH40

BH40

BH40

BH45

BH45

BH45

BH50

BH50

BH50

C 1660 1810 1810 1960 2110 2160 2210 2320

D 590 640 640 690 820 860 890 1020

FIGURE 12: U-TUBE, FULL 45° MOUNT

A

B

D

C

Model

BH15

A 200 200 200 200 200 200 200 200

B 200 200 200 200 200 200 200 200

C 1500 1650 1650 1860 1960 2040 2110 2160

D 1070 1170 1170 1320 1550 1620 1680 1780

BH20

BH25

BH30

BH35

BH40

BH45

BH50

6

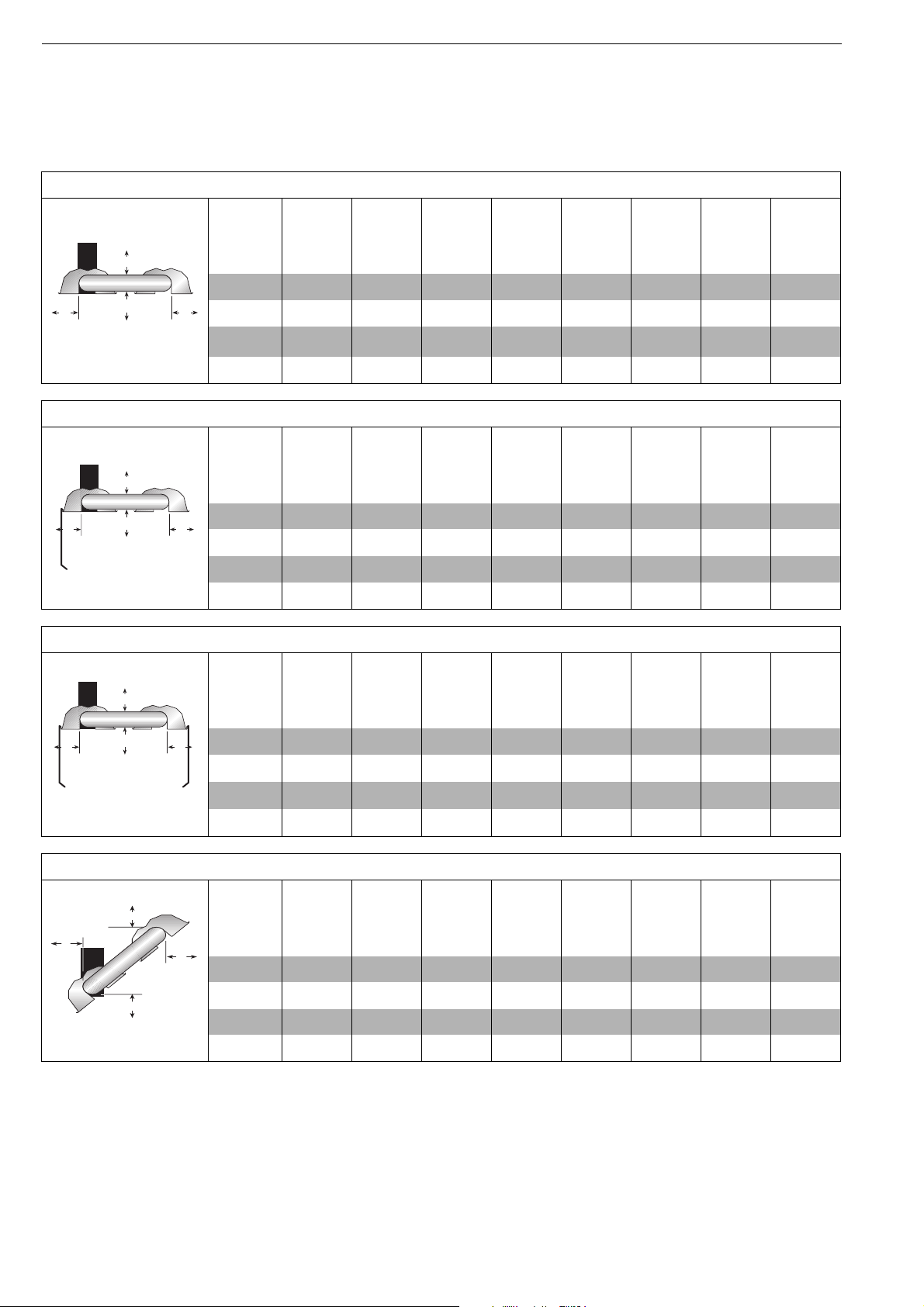

Page 9

NOTE: 1. All dimensions are from the Tube surface.

A

C

B D

A

C

DB

Radiant tubes

Fan

Unvented

Vented

E

F

2. Clearances B, C and D can be reduced by 50% after 7 m of tubing downstream

from the burner.

3. All measurements are in Millimeters.

FIGURE 13: U-TUBE, OPPOSITE 45° TILT

SECTION 3: CRITICAL CONSIDERATIONS

Model

BH15

A 200 200 200 250 250 275 300 300

B 1370 1530 1530 1630 1780 1830 1880 1930

C 1500 1650 1650 1860 1960 2040 2110 2160

D 560 560 560 560 560 560 560 560

FIGURE 14: U-TUBE, PROTECTIVE GRILLE

Model

A 150 150 150 150 150 150 200 200

B 890 970 970 1020 1170 1220 1270 1380

C 1580 1730 1730 1910 1980 2050 2110 2210

D 760 940 940 1000 1090 1150 1200 1300

BH15

FIGURE 15: U-TUBE, VENTING

BH20

BH20

BH25

BH25

BH30

BH30

BH35

BH35

BH40

BH40

BH45

BH45

BH50

BH50

Model

BH15

BH20

BH25

BH30

BH35

BH40

BH45

E 1000 1000 1000 1000 1000 1000 1000 1000

F 500 500 500 500 500 500 500 500

BH50

7

Page 10

BLACKHEAT® INSTALLATION OPERATION AND SERVICE MANUAL

SECTION 4: SPECIFICATIONS

4.1 Material Specifications

4.3 Venting Specifications

4.1.1 Combustion and Tubes

First 3 meters ALUMI-THERM

®

steel tubing.

Remaining tube 100 mm dia. 16 gauge heat treated

aluminised mild steel.

4.1.2 Reflectors

NS3 H14 aluminium or 1.4016 2R stainless

steel (option)

4.2 Heater Specifications

4.2.1 Sequence Controller

Fully automatic single try direct spark 100% shut off

ignition flame rectification module

4.2.2 Electrical

Rating: 230V, 50 Hz, single phase, 1 amp

Connection: 3 pin moulded plug

4.2.3 Gas Supply

Connection: Rc1/2 (1/2" BSP int)

Natural : Nominal - Inlet 1.13kPa

Maximum - Inlet 5.0 kPa

4.3.1 Fans

BH-15, 20, 25, 30 ............ Model: Torin DSF 133-42

BH-35, 40, 45 .................. Model: Torin DSA 524-202

BH-50 .................. Model: Magnetek JF1G

Consult the manufacturer for availability of alternate fans.

4.3.2 Flue

When fitted, the flue must be 100 mm, or greater in

diameter, and must conform to AS5601/AG 601. The flue

must be self supporting. Inlet must be 100 mm diameter.

4.4 Suspension Specifications

Galvanised straight link welded chain.

Working load of 340 kg (750 lbs)

4.5 Controls Specifications

Time switches, thermostats, etc. can be wired into the

electrical supply. External controls supplied as an

optional extra.

ULPG Gas (Propane or Propane/Butane mix):

Nominal - Inlet 2.75 kPa

Maximum - Inlet 5.00 kPa

8

Page 11

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

SECTION 4: Specifications

4.6 Linear Heater

BH15ST

BH20ST

BH25ST

BH30ST

BH35ST

BH40ST

BH45ST

BH50ST

Input – kW 15 20 25 30 35 40 45 50

Input – MJ 54 72 90 110 125 138 162 180

Tube Length – mm 6096 9144 9144 12192 12192 12192 15240 15240

Overall Heater Length - mm 6661 9709 9709 12757 12757 12757 15815 15815

Weight – kg 41 55 55 68 68 68 81 81

Heated Area – m

Minimum Installation

2

20-160 30-210 40-265 50-315 55-370 65-420 70-475 80-525

2.5 2.5 3.0 3.5 4.6 5.0 5.0 5.0

Height* – m

Recommended Installation

3.0 3.5 3.9 4.2 4.8 5.5 6.7 7.6

Height* – m

4.8 U-Tube Heater

BH15UT

BH20UT

BH25UT

BH30UT

BH35UT

BH40UT

BH45UT

BH50UT

Input – kW 15 20 25 30 35 40 45 50

Input – MJ 54 72 90 110 125 138 162 180

Tube Length – mm 3323 4843 4843 6363 6363 6363 7998 7998

Overall Heater Length - mm 3893 5417 5417 6941 6941 6941 8465 8465

Weight – kg 39 54 54 65 65 66 96 96

Heated Area – m

Minimum Installation

2

20-160 30-210 40-265 50-315 55-370 65-420 70-475 80-525

2.5 2.8 3.5 4.0 5.0 5.0 5.0 5.0

Height* – m

Recommended Installation

3.0 3.5 3.9 4.2 4.8 5.5 6.7 7.6

Height* – m

*Heights quoted are from ground level to bottom face of firing tube.

NOTE:- Factory recommended mounting height s are listed above as a guideline. If infra-red heaters are

mounted too low, they may result in heat discomfort. It is generally recommended to observe the

recommended mounting heights to optimize comfort conditions. However, certain applications such as spot

heating, freeze protection, outdoor patio heating or very high ceilings may result in the heaters being

mounted outside of the factory recommended mounting heights. Clearances to combustibles must always be

maintained.

Page 12

BLACKHEAT® INSTALLATION OPERATION AND SERVICE MANUAL

4.9 Burner Specifications

Figure 16: BLACKHEAT® Linear and U-Tube

Reflector

317 mm

Plan View

Burner Tube

Side View

273 mm

End View

171 mm

100 mm

Heat Exchanger Length

Fan

Swirler*

Damper

Heat Exchanger Length

U-Tube

Burner Tube

Fan Tube

Fan

Damper

Plan View

100 mm

Internal Swirler*

*Swirler must always be located in Fan Tube

4.9.1 Burner Air Plate BH15 BH20 BH25 BH30 BH35 BH40 BH45 BH50

Marking 071300+ 20 15 12 06 07 09 11 10

4.9.2 Jet Marking BH15 BH20 BH25 BH30 BH35 BH40 BH45 BH50

Natural #30 3.8 mm #19 4.7 mm #9 #3 #1 D

Propane/Butane #46 2.3 mm #37 #33 3.1 mm 3.3 mm #29 #26

4.9.3 Gas Consumption BH15 BH20 BH25 BH30 BH35 BH40 BH45 BH50

Natural

[MJ/hr]

54 72 90 110 125 138 162 180

ULPG MJ/hr as Natural Gas. Approximate kg/h consumption as below for reference only.

[kg/h]

[1.07] [1.43] [1.79] [2.15] [2.50] [2.86] [3.22] [3.58]

4.9.4 Governor Pressure BH15 BH20 BH25 BH30 BH35 BH40 BH45 BH50

ULPG All Models 2.60 kPa

Natural Gas All Models 0.75 kPa

10

Page 13

SECTION 5: MAJOR COMPONENT DESCRIPTIONS

Burner (shown with T ube

Gasket)

Must be installed with the

flame observation window

facing down.

Reflector

(Alum inium or

Stainless Steel)

Alternate overlap as

shown on overview.

Minimum overlap is 18

cm.

SECTION 5: MAJOR COMPONENT DESCRIPTIONS

Burner Tu be

Supplied in 3m lengths. Burner

tube is always the first tube after

the burner.

Tube and Reflector Hanger

with Tube Clamp Package

Position this hanger no more

than 20cm away from the

burner assembly.

Recommended 100mm.

Tu be a n d R ef lector Hanger

Suspend system from these

hangers.

Reflector S upport Strap, W ir e

Form & #8 x 3/4 (3.9 x 19mm)

Screw

Flex Gas Line

Tube

Heat Treated Aluminized Tube

Supplied in 3m lengths.

Fan Tube with In ternal Swirler

Fan tube is

always the last tube on the heater

where the fan is attached.

Coupling A s sembly

with Lock

Reflector End Cap

Punch out center section to

accommodate heat exchanger

tube.

Fan Assembly (Includes Flange)

Fan Assembly is attached to the last

section of heat exchanger tubing

(Fan Tube).

Damper Flange Assembly

For use on Multiburner Systems.

Tee

Assembly

U-Tube

Assembly

U-Tub e

Support

Bracket

Fan Flange Assembly

and Screws

Turnbuckle

Adjuster

Bow

Shackle

11

Page 14

BLACKHEAT® INSTALLATION OPERATION AND SERVICE MANUAL

SECTION 6: GENERAL SUSPENSION DETAILS

WARNING

Suspension Hazard

Hang heater with general purpose welded link steel

chain, 4 mm or larger in diameter, with working

load of 340 Kg.

Failure of the supports can result in death, injury

or property damage.

Step 6.1 Suspension Details

Side View

Typical Suspension Details

Beam

Clamp

I-Beam

60 cm

minimum*

Turnbuckle

(not included)

I-Beam

10 mm

Rod

30 cm

minimum*

* Allows for thermal expansion of system

Bow Shackle

Concrete

Beam

Anchor

Bow

Shackle

Screw Hook

min. 10 mm

Washer

Locknut

Washer

Wood

Beam

Hanger

100 mm

Max.

Description Part Number

Burner Tube 03051101

Bow Shackle E0007576

Tube/Reflector Hanger 03090100

12

Hanger

Front View

45° Angle

Page 15

SECTION 7: LINEAR HEATER INSTALLATION

The figures in this section provide a general overview of

component placement in a BLACKHEAT® Linear

system. The location of some components

such as supports and couplings is crucial for proper

installation. Assemble the heater components as shown

on Page 14, Figure 17.

7.1 Linear Standard Parts List

SECTION 7: LINEAR HEATER INSTALLATION

For optional reflector configurations for Linear heaters

See Page 4, Figure 2 through Page 5, Figure 8. Install

appropriate suspension hardware, beam clamps, chain or

rod at predetermined locations. Adjustments of chain

length will provide uniform pitch.

If any step is unclear, please contact Roberts-Gordon at

+ 61 [3] 9561 2100 [Hurll Nu-Way Pty Ltd]

Part No. D escriptio n

BLACKHEAT®

07260001 Fan Package XP 1 1 1 1 1 - - - 07260002 Fan Package XP 2 - - - - 1 1 1 07260003Fan Package XP 3 -------1

03051101Burner Tube, 100 mm x 3048 mm 11111111

91409408Tube, 100 mm x 3048 mm -1122233

S5127WFan Tube, 100 mm x 3048 mm, with 3048 mm Swirler 1111111

S5134WFan Tube, 100 mm x 3048 mm with 2134 mm Swirler -------1

01329600Standard Coupling Assembly 12233344

01329700Coupling Lock 12233344

02750303Reflector, Aluminium, 2439 mm 34466677

S5163WReflector, Stainless Steel, 2439 mm (Optional)* 34466677

02750800Reflector End Cap, Aluminium 22222222

C2332B Reflector End Cap, Stainless (Optional)* 2 2 2 22222

Burner Assembly (Input and Fuel Varies)11111111

BH15

BH20

BH25

BH30

BH35

BH40

BH45

BH50

03090100Tube and Reflector Hanger 34455566

01318901 Tube Clamp Package (including Nut, Washer & Bolt) 1 1 1 11111

91908004Wire Form 23355566

94320812 Screw #8 x 3/4 (3.9 x 19mm), (goes with 91908004) 4 6 6 10 10 10 12 12

03050000Reflector Support Strap 23355566

E0007576 Bow Shackle 3 4 4 55566

91107720 U-Clip Package (20 Pieces) 1 1 1 11111

* PVC coating must be removed prior to installation.

13

Page 16

BLACKHEAT® INSTALLATION OPERATION AND SERVICE MANUAL

Figure 17: BLACKHEAT® Linear General Assembly Overview

U-Clips

Fan Assembly

(For Single Heater)

Damper Assembly

(Required for Multiburner)

Reflector

Internal Swirler

Fan Tube

Reflector Support

Coupling

14

Reflector End Cap

Burner Tube

Tube and Reflector Hanger

Burner

Tube Clamp Package

Page 17

SECTION 7: LINEAR HEATER INSTALLATION

Reflector

Figure 18: BLACKHEAT® Linear Layout Overviews -[BH55 Not Available]

b

c

BH15ST

b

c

g

f

de

LEGEND

Burner Box

Reflector

BH20ST

BH25ST

BH30ST

BH35ST

BH40ST

BH45ST

BH50ST

*Loose

Screw

b

c

g

f

g

f

g

de

*Loose

Screw

b

c

de

*Loose

Screw

b

c

de

Tight

Screw

Tight

Screw

Tight

Screw

*Loose

Screw

*Loose

Screw

e

e

Screw

e

Tight

b

c

*Loose

Screw

b

c

e

b

c

e

e

Tube

Tube/Reflector

Hanger

Reflector Support

Coupling Assembly

Fan Assembly

Damper Assembly

*Loose Screws -

f

loosened

2 mm (1/16")

to allow slippage.

*Loose

Screw

b

c

g

de

Screw

Tight

*Loose

Screw

*Loose

Tight

Screw

Screw

e

e

Tight

Screw

b

c

e

e

BH55ST

Model

BH15

BH20..

BH25

BH30..

BH35

BH40..

BH45

BH50..

BH55

f

*Loose

Screw

Tight

Screw

a = reflector width (not shown)

b = end cap to burner/fan

c = end cap to hanger

*Loose

Screw

Tight

Screw

*Loose

Screw

Tight

Screw

*Loose

Screw

e = distance typical between hangers

f = burner height

g = burner length

d = distance first hanger

Reflector

Overlap

(approx.) a b c d e f g

700 mm 365 mm 50 mm 50 mm 2290 mm 3050 mm 366 mm 291 mm

250 mm 365 mm 50 mm 50 mm 2290 mm 3050 mm 366 mm 291 mm

250 mm 365 mm 50 mm 50 mm 2290 mm 3050 mm 366 mm 291 mm

530 mm 365 mm 50 mm 50 mm 2290 mm 3050 mm 366 mm 291 mm

530 mm 365 mm 50 mm 50 mm 2290 mm 3050 mm 366 mm 291 mm

530 mm 365 mm 50 mm 50 mm 2290 mm 3050 mm 366 mm 291 mm

330 mm 365 mm 50 mm 50 mm 2290 mm 3050 mm 366 mm 291 mm

330 mm 365 mm 50 mm 50 mm 2290 mm 3050 mm 366 mm 291 mm

200 mm 365 mm 50 mm 50 mm 2290 mm 3050 mm 366 mm 291 mm

15

Page 18

Step 7.3 Burner Tube Installation

SECTION 7: LINEAR HEATER INSTALLATION

NOTE:

Tubing requires a downward

slope of 13 mm

per 6 m away

from burner.

Bow Shackle

Hanger

Burner Tube

229 cm ± 25cm

Description Part Number

Burner Tube 03051101

Bow Shackle E0007576

Tube/Reflector Hanger 03090100

Weld

Seam

End View

Offset mounting

hole must be

to the top

Bottom

of Tube

Step 7.4 Coupling and Tube Assembly

Close coupling

A

with tab

Open

Closed

Insert tubes into coupling

C

Orient coupling so that

the impact block is in the

2:00 or 10:00 oclock

positions

Tab

Start Slidebar/Coupling Lock

B

onto coupling

Slidebar

8 cm to

10 cm

Tighten coupling to join tubes

D

Wide end

Coupling

Slidebar

Coupling

Tube

Tube

Tube

Description Part Number

Coupling 01329600

Slidebar/Coupling Lock 01329700

Tube 91409408

19

Page 19

BLACKHEAT® INSTALLATION OPERATION AND SERVICE MANUAL

Step 7.4.1 Coupling and Tube Assembly (Continued)

WARNING

Tighten slidebar as shown below.

Tubes will fall down if slidebar is incorrect.

Failure to follow these instructions can result in death,

injury or property damage.

Drive Slidebar until tight.

End of slidebar should be

within tolerance listed below.

± 5 cm

Correct slidebar

dimensions

Incorrect slidebar

position

• Repeat Step 7.4 A - D until all tubes are assembled, See Page 20, Section 7.4.2 shown bel ow.

Step 7.4.2 Coupling and Tube Assembly (Continued)

Model

BH15 6 2

BH20 9 3

BH25 9 3

BH30 12 4

BH35 12 4

BH40 12 4

BH45 15 5

BH50 15 5

229 cm

± 25 cm

Heat Exch anger

Overall Tubing Length (m)

Number

of Tubes

20

305 cm Typ

± 25 cm

Total Overall

Tube Length

Page 20

Step 7.5 Tube Clamp Package Installation

Tube Clamp

SECTION 7: LINEAR HEATER INSTALLATION

Bolt

Description Part Number

Tube Clamp 01396801

Bolt 97113940

Flat Washer 95211600

Nut 92113900

Step 7.6 Reflector Installation

Nut

(Torque 13.56 Nm

120 in lb)

Flat

Washer

Hanger

Burner Tube

Description Part Number

Tube/Reflector Hanger 03090100

Burner Tube 03051101

Reflector 02750303

Reflector

21

Page 21

BLACKHEAT® INSTALLATION OPERATION AND SERVICE MANUAL

Reflector

Reflector

Step 7.6.1 Reflector Installation (Continued)

Reflector

End Cap

U-Clips

Description Part Number

Reflector Support Package 03050010

Wire Form 91908004

Reflector Support Strap 03050000

Screw #8 x 3/4 (3.9 x 19mm) 94320812

U-Clip Package 91107720

Reflector End Cap 027508XX

Wire Form

Reflector

Reflector Support

Strap

U-Clip

(2 clips per alternate

overlaps per side-

see Figure 21)

Sheet Metal

Screw

Tube

Figure 21: Reflector Overlap Detail

Loose screws

loosened 2 mm (1/16")

to allow slippage.

Tight

screws

Install one reflector

support per reflector

as needed.

No

U-Clips

Tight

screws

Install

U-Clips

Loose

screws

No

U-Clips

18 cm (7")

Minimum

Install

U-Clips

18 cm (7")

Minimum

22

Page 22

BLACKHEAT® INSTALLATION OPERATION AND SERVICE MANUAL

SECTION 8: U-T UBE HEATER INSTALLATION

The figures in this section provide a general overview of

component placement in a BLACKHEAT® U-Tube

system. The location of some components such as

supports and couplings is crucial for proper installation.

Assemble the heater components as shown on Page 14,

Figure 17.

For optional reflector configurations for U-tube heaters

See Page 6, Figure 9 through Page 7, Figure 15. Install

8.1 U-Tube Standard Parts List

appropriate suspension hardware, beam clamps, chain or

rod at predetermined locations. Adjustments of chain

length will provide uniform pitch.

If any step is unclear, please contact Roberts-Gordon at

+44 (0) 1902 494425 or +61 [3] 9561 2100

Part No. Descr iption

BLACKHEAT®

0726000 1 Fan Package XP1 1 1 1 1 - - - 0726000 2 Fan Package XP2 - - - - 1 1 1 0726000 3 Fan Package XP3 - - -----1

03051101Burner Tube, 100 mm x 3048 mm 11111111

9140940 8 Tube, 100 mm x 3048 mm - - - 2 2 2 2 2

9140942 3 Tube, 100 mm x 1524 mm - 2 2 - - - 2 2

S5127WFan Tube, 100 mm x 3048 mm, with 3048 mm Swirler 1111111

S5134WFan Tube, 100 mm x 3048 mm with 2134 mm Swirler -------1

01335901U-Bend 11111111

01329600Standard Coupling Assembly 24444466

01329700Coupling Lock 24444466

02750303Reflector, Aluminium, 2439 mm 44466688

S5134W Reflector, Stainless Steel, 2439 mm (Optional)* 4 4466688

Burner Assembly (Input and Fuel Varies) 11111111

BH15

BH20

BH25

BH30

BH35

BH40

BH45

BH50

02750800Reflector End Cap, Aluminium 44444444

C2332B Reflector End Cap, Stainless (Optional )* 4 4444444

03090100Tube and Reflector Hanger 46666688

0131890 1 Tube Clamp Package (including Nut, Washer & Bol t ) 1 1111111

91908004Wire Form 24444466

03050000Reflector Support Strap 24444466

0302050 1 U-Bend Support Bracket 1 1111111

E000757 6 Bow Shackle 4 6666688

91107720 U-Clip Package (20 Pieces) 2 2222222

91912501U-Bolt M6 22222222

C0090BNut M6 66666666

96411500Lockwasher 6mm 66666666

94320812Screw #8 x 3/4 (3.9 x 19mm), (goes with 91908004) 4888881212

S7199K Damper Flange Assembly (For use on Multib urner Systems) 1 Per Heater

*PVC coating must be removed prior to installation.

24

Page 23

Figure 22: BLACKHEAT® BH15UT Assembly Overview

SECTION 8: U-TUBE HEATER INSTALLATION

U-Clips

Internal Swirler

Support

Reflector

Fan Tube

Reflector

Reflector End Caps

457 mm

180° U-Tube

Center to Center

Fan Assembly

(For Single Heater)

Damper Assembly

(Required for Multiburner)

Tube Clamp

Burner

20cm

Maximum

Package

Coupling

Burner Tube

U-Tube

Support Bracket

25

Page 24

BLACKHEAT® INSTALLATION OPERATION AND SERVICE MANUAL

Reflector

Figure 23: BLACKHEAT® U-Tube Layout Overviews

b

c

g

d

LEGEND

Burner Box

BH15

BH20

BH25

BH30

BH35

BH40

h

*Loose

Screw

b

c

g

df

h

*Loose

Screw

b

c

g

de

h

Tight

Screw

*Loose Screws -

Reflector

Tube

Tube/Reflector

Hanger

Reflector Support

Coupling Assembly

U-Tube

loosened

2 mm (1/16")

to allow slippage.

*Loose

Screw

b

c

g

de

Tight

Screw

f

BH45

BH50

a = overall width (not shown)

b = end cap to burner/fan

c = end cap to hanger

Reflector

Overlap

Model

BH15

BH20 ....

BH25

BH30....

BH35

BH40....

BH45

BH50....

(approx.) a b c d e f g

1780 mm 850 mm 50 mm 50 mm 2290 mm 3050 mm 366 mm 291 mm

250 mm 850 mm 50 mm 50 mm 2290 mm 3050 mm 366 mm 291 mm

250 mm 850 mm 50 mm 50 mm 2290 mm 3050 mm 366 mm 291 mm

580 mm 850 mm 50 mm 50 mm 2290 mm 3050 mm 366 mm 291 mm

580 mm 850 mm 50 mm 50 mm 2290 mm 3050 mm 366 mm 291 mm

580 mm 850 mm 50 mm 50 mm 2290 mm 3050 mm 366 mm 291 mm

690 mm 850 mm 50 mm 50 mm 2290 mm 3050 mm 366 mm 291 mm

690 mm 850 mm 50 mm 50 mm 2290 mm 3050 mm 366 mm 291 mm

h

*Loose

Screw

Tight

Screw

d = distance first hanger

e = distance typical between hangers

*Loose

Screw

g = burner length

h = burner height

f = distance between last full tube

hanger and half tube hanger

26

Page 25

Step 8.2 Critical Hanger Placement

Spreader

Bow

Shackle

Suspension

Chain

Washers

Bolt

(Torque:

13.5 Nm

129 in lb)

Configuration

Bar

Threaded

Optional

Hanging

Bar

Tube and Reflector

Hanger

SECTION 8: U-TUBE HEATER INSTALLATION

NOTE: Spreader bar must be used on

single suspension point installations.

Do not hang heater from spreader bar.

Bow

Shackle

Suspension

Chain

First Tube and

Reflector Hanger

229 cm ± 25cm

Description Part Number

Bow Shackle E0007576

Tube/Reflector Hanger 03090100

Spreader Bar 07260010

Step 8.3 Burner Tube and Fan Tube Installation

See Assembly

Drawing

End View

Tube and Reflector

Hanger

Offset mounting

hole must be

to the top

Burner Tube

Description Part Number

Burner Tube 03051100

Fan Tube S5127W

Fan Tube

Weld

Bottom

of Tube

27

Loading...

Loading...