Page 1

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. DO NOT try to light any appliance.

3. DO NOT use electrical switches.

4. DO NOT use any telephone in

your building.

5. Leave the building.

6. Immediately call your local gas

supplier after leaving the building.

Follow the gas suppliers

instructions.

7. If you cannot reach your gas

supplier, call the Fire Department.

WARNING

®

Combat

UHA-Series

Tubular Unit Heaters

(Standard Range)

Installation, Operation

& Service Manual

Models UHA[S]

150, 175, 200, 225

Fire Hazard

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

Some objects will catch fire or explode

when placed close to heater.

Failure to follow these instructions can

result in death, injury or property

damage.

WARNING

Improper installation, adjustment, alteration, service

or maintenance can result in death, injury or property

damage. Read the Installation, Operation and Service

Manual thoroughly before installing or servicing

this equipment.

Installation must be done by a contractor qualified

in the installation and service of gas-fired heating

equipment or your gas supplier.

250, 300, 350, 400

Installer

Please take the time to read and understand

these instructions prior to any installation.

Installer must give a copy of this manual to the owner.

Owner

Keep this manual in a safe place in order to provide

your serviceman with necessary information.

Quality in Any Language™

© Copyright 2007 Roberts-Gordon, LLC

Roberts-Gordon, LLC

1250 William Street

P. O . Box 44

Buffalo, New York 14240-0044

Telephone: 716.852.4400

Fax: 716.852.0854

Toll Free: 800.828.7450

www.rg-inc.com

P/N 111101NA 10 / 0 7 R e v. D

Page 2

Page 3

TABLE OF CONTENTS

SECTION 1: Heater Safety...................................................... 1

1.1 Manpower Requirements .............................................1

SECTION 2: Installer Responsibility .....................................2

2.1 Wall Tag ....................................................................... 2

2.2 Corrosive Chemicals....................................................2

2.3 National Standards and Applicable Codes .................. 2

SECTION 3: Critical Considerations .....................................3

3.1 Basic Information.........................................................3

3.2 Location and Suspension ............................................3

3.3 Minimum Required Installation Clearances .................3

3.4 Clearances to Combustibles ........................................3

3.5 Ventilation .................................................................... 3

3.6 Gas Supply ..................................................................3

3.7 Electrical Supply .......................................................... 3

3.8 Vent..............................................................................3

3.9 Separated Combustion Installation..............................3

SECTION 4: National Standards and Applicable Codes .....5

4.1 Gas Codes................................................................... 5

4.2 Aircraft Hangars ...........................................................5

4.3 Parking Structures and Repair Garages......................5

4.4 Electrical ...................................................................... 5

4.5 Venting.........................................................................5

4.6 High Altitude ................................................................ 5

SECTION 5: Major Components ............................................ 6

5.1 General........................................................................ 6

5.2 Suspension..................................................................6

SECTION 6: Venting................................................................ 7

6.1 Venting.........................................................................7

6.2 Vent Installation ...........................................................7

6.3 Unvented Operation.....................................................8

6.4 Horizontal Venting........................................................ 8

6.5 Vertical Venting............................................................8

6.6 Length Requirements ..................................................8

6.7 Vent Material................................................................9

SECTION 7: Air Supply......................................................... 13

7.1 Separated Combustion Installation............................. 13

7.2 Unvented Installation .................................................. 13

7.3 Building Ventilation .....................................................13

7.4 Outside Combustion Air Supply.................................. 13

SECTION 8: Gas Piping........................................................14

8.1 Connections............................................................... 14

SECTION 9: Wiring................................................................15

9.1 Positioning Thermostats ............................................ 15

9.2 Low Voltage Thermostat with One Heater ................. 15

9.3 UHA(S) Series Internal Wiring Diagram .................... 16

9.4 UHA(S) Series Ladder Wiring Diagram ..................... 17

9.5 Electrical Connection to the Heater ........................... 18

SECTION 10: Operation and Maintenance.......................... 19

10.1 Pre-Start-Up Checks ................................................ 19

10.2 Begin Start-Up ......................................................... 19

10.3 Complete the Start-Up .............................................21

SECTION 11: User Instructions............................................22

11.1 User Instructions .......................................................22

11.2 Heater Operation ......................................................22

11.3 Common User Controls.............................................22

11.4 Lighting Instructions ..................................................22

11.5 Simple Troubleshooting.............................................22

SECTION 12: Servicing.........................................................24

12.1 Servicing Instructions...............................................24

12.2 Burner Maintenance.................................................24

12.3 Fan/Motor Assembly Maintenance...........................24

12.4 Heat Exchanger Maintenance..................................24

12.5 Gas Valve Maintenance ...........................................24

12.6 Combustion Fan.......................................................24

12.7 Venting and Air Intake Pipe ......................................24

12.8 Maintenance Checklist .............................................25

SECTION 13: Troubleshooting .............................................27

13.1 General ....................................................................27

13.2 Troubleshooting For Automatic Ignition Burner

Systems...................................................................28

13.3 Troubleshooting for Flame Supervision System .......29

13.4 Troubleshooting for Gas Valves................................30

13.5 Troubleshooting for Combustion Fan........................30

SECTION 14: Replacement Parts .........................................31

14.1 Gas Valve .................................................................31

14.2 Burner Compartment ...............................................32

14.3 Ignition Electrode and Flame Probe.........................33

14.4 Combustion Fan Vertical Installation ........................34

14.5 Pressure Switch........................................................35

14.6 Ignition Control .........................................................36

14.7 Axial Fan/Guard/Motor Assembly.............................36

14.8 Limit Switches ..........................................................36

SECTION 15: Specifications.................................................37

15.1 Standard (Models 150 - 400) UHA(S) Series

Dimension Data .........................................................37

15.2 General Technical Data Table (All Models) ..............38

15.3 Technical Data Table (All Models) ............................38

SECTION 16: The ROBERTS GORDON® COMBAT

UHA-Series Warranty.....................................39

®

© 2007

Roberts-Gordon, LLC

All rights reserved. No part of this work covered by the copyrights herein may be reproduced

or copied in any form or by any means - graphic, electronic, or mechanical, including

photocopying, recording, taping or information storage and retrieval systems - without the

written permission of Roberts-Gordon, LLC.

Printed in U.S.A.

Page 4

Page 5

TABLE OF FIGURES

Figure 1: Installation Clearances and Clearances to

Combustibles.............................................................4

Figure 2: Suspension Methods ................................................. 6

Figure 3: Vent and Roof Detail .................................................. 9

Figure 4: Standard Vented Heater - Vertical and

Horizontal Vent Termination ...................................... 9

Figure 5: Standard Vented Heater - Common Vertical Vent

Termination.............................................................. 10

Figure 6: Separated Combustion Heater - Vertical and

Horizontal Vent Termination .................................... 11

Figure 7: Concentric Vent Box ................................................ 11

Figure 8: Concentric Vertical and Horizontal Vent

Termination - Separated Combustion Heater........... 12

Figure 9: Gas Connection....................................................... 14

Figure 10: Automatic Burner Control Sequence...................... 20

Figure 11: Gas Valve for Models UHA(S) 150 - 400................20

Figure 12: LED Diagnostic Codes...........................................22

Page 6

Page 7

SECTION 1: HEATER SAFETY

Your Safety is Important to Us!

This symbol is used throughout

the manual to notify you of

possible fire, electrical or burn

hazards. Please pay special

attention when reading and

following the warnings in these

sections.

Installation, Service and Annual

Inspection of heater must be done by a contractor

qualified in the installation and service of gas-fired

heating equipment.

Read this manual carefully before installation,

operation or service of this equipment.

Heaters are not approved for residential installation.

These instructions, the layout drawing, local codes

and ordinances and applicable standards that apply

to gas piping, electrical wiring, venting, etc. must be

thoroughly understood before proceeding with the

installation.

Thin sheet metal parts, including the various venting

components, have sharp edges. To prevent injury,

the use of work gloves is recommended.

Before installation, check that the local distribution

conditions, nature of gas and pressure and

adjustment of the appliance are compatible.

SECTION 1: HEATER SAFETY

1.1 Manpower Requirements

To prevent personal injury and damage to the

heater, two persons will be required for installation.

1

Page 8

COMBAT® UHA UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL

SECTION 2: INSTALLER RESPONSIBILITY

The installer is responsible for the following:

2.2 Corrosive Chemicals

• To install the heater, as well as the gas and

electrical supplies, in accordance with applicable

specifications and codes. Roberts-Gordon

recommends the installer contact a Local

Do not use heater in an area containing corrosive

chemicals.

Building Inspector or Fire Marshal for guidance.

• To use the information given in a layout drawing

and in the manual together with the cited codes

and regulations to perform the installation.

• To install the heater in accordance with the

Avoid the use of corrosive chemicals to ensure a

longer life of the burner, heat exchanger and other

parts.

Failure to follow these instructions can result in

property damage.

clearances to combustibles.

• To furnish all needed materials not furnished as

standard equipment.

Roberts-Gordon cannot be responsible for ensuring

that all appropriate safety measures are undertaken

prior to installation; this is entirely the responsibility

• To plan location of supports, vents and air

intakes.

• To provide access for servicing.

• To provide the owner with a copy of this

Installation, Operation and Service Manual.

of the installer. It is essential that the contractor, the

sub-contractor, or the owner identifies the presence

of combustible materials, corrosive chemicals or

halogenated hydrocarbons* anywhere in the

premises.

CAUTION

• To never use heater as support for a ladder or

other access equipment and never hang or

suspend anything from heater.

• To ensure there is adequate air circulation

around the heater and to supply air for

combustion, ventilation and distribution in

accordance with local codes.

2.1 Wall Tag

A laminated wall tag is included with the heater as a

permanent reminder of the safety instructions and

the importance of the required clearances to

combustibles. Affix the tag by peeling off the backing

of the adhesive strips on the rear surface and

position the tag on a wall near the heater.

A copy of the wall tag (P/N 91040031) is illustrated

on the back cover.

Know your model number. Model number is found

on the heater and in the Installation, Operation and

Service Manual.

See Page 9, Figure 3 through Page

14, Figure 9.

* Halogenated Hydrocarbons are a family of chemical

compounds characterized by the presence of halogen elements (fluorine, chlorine, bromine, etc.). These compounds are

frequently used in refrigerants, cleaning agents, solvents, etc. If

these compounds enter the air supply of the burner, the life

span of the heater components will be greatly reduced. An outside air supply must be provided to the burners whenever the

presence of these compounds is suspected. Warranty will be

invalid if the heater is exposed to halogenated hydrocarbons.

2.3 National Standards and Applicable Codes

All appliances must be installed in accordance with

the latest revision of the applicable standards and

national codes. This refers also to the electric, gas

and venting installation. Note: Additional standards

for installations in public garages, aircraft hangars,

etc. may be applicable.

2

Page 9

SECTION 3: CRITICAL CONSIDERATIONS

3.1 Basic Information

UHA(S) heaters have automatic ignition burners for

ON/OFF operation only.

3.2 Location and Suspension

All models:

• Must be installed indoors.

• Must be installed in a level position with

horizontal discharge.

• May be mounted on a shelf of non-combustible

material.

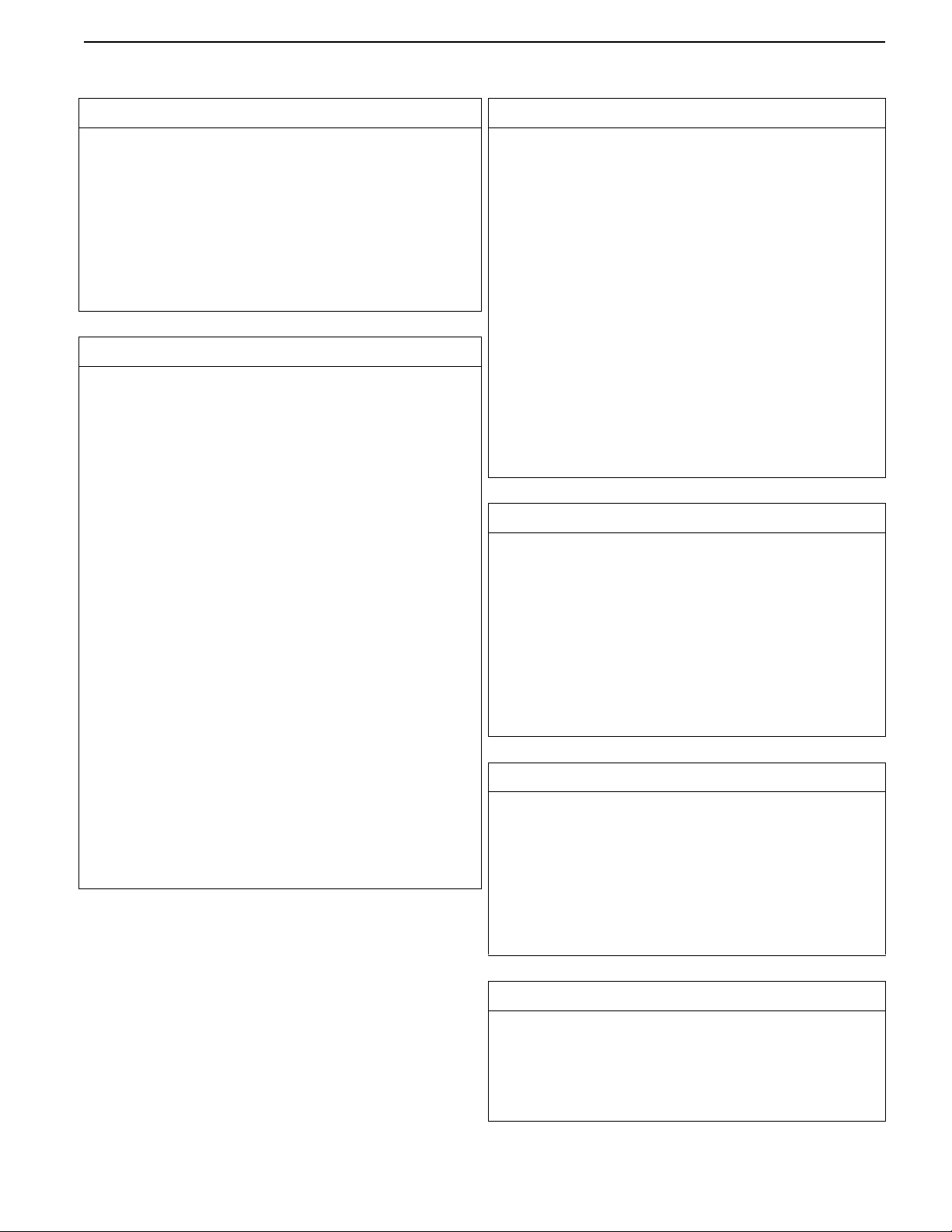

• May be suspended from above (See Page 6,

Figure 2) or from wall brackets of sufficient

strength to support the heater as listed in the

Dimension Data Table

on Page 37, Section 15.1.

Drop rods must be a minimum of 3/8" diameter

mild steel. Four suspension points (3/8" nuts)

are located on top of the heater.

• Must be installed in a manner which allows

access to all serviceable components.

See Page 4, Figure 1 for details.

SECTION 3: CRITICAL CONSIDERATIONS

3.7 Electrical Supply

A permanent 120 V 60 Hz 1 Ø electrical supply is

required for the main electrical power. The heater

also requires suitable controls in accordance with

Section 9.

3.8 Vent

Choose heater orientation to allow for the proper

location of the vent. Each heater must be fitted with

a correctly sized sealed vent system.

If vented horizontally, no other appliance may be

connected to the vent.

See Page 7, Section 6.

3.9 Separated Combustion Installation

For separated combustion installation, the vent and

air intake must be fitted with an individual and

correctly sized sealed system and the vent and air

intake must terminate at approved wall and roof

terminals.

Separated combustion units may not be common

vented.

See Page 7, Section 6.

3.3 Minimum Required Installation Clearances

Clearances around the heater and vent must be as

indicated

on Page 4, Figure 1; Page 9, Figure 3

through Page 12, Figure 8 to ensure access for

servicing, and correct operation.

3.4 Clearances to Combustibles

Clearances must be as indicated on Page 4, Figure

1. If clearances to combustibles are not indicated,

then installation clearances apply.

3.5 Ventilation

It is important to ensure that there is adequate air

space around the heater to supply air for

combustion, ventilation and distribution in

accordance with local and national codes.

3.6 Gas Supply

It is important that the gas supply pipe is sized

correctly to provide the inlet pressure as stated on

the heater data plate. The gas supply pipe and

electrical connections must not support any of the

heater's weight.

3

Page 10

COMBAT® UHA UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL

WARNING

Fire Hazard

Some objects will catch fire or explode when placed

close to heater.

Keep all flammable objects, liquids and vapors the

required clearances to combustibles away from heater.

Failure to follow these instructions can result in death,

injury or property damage.

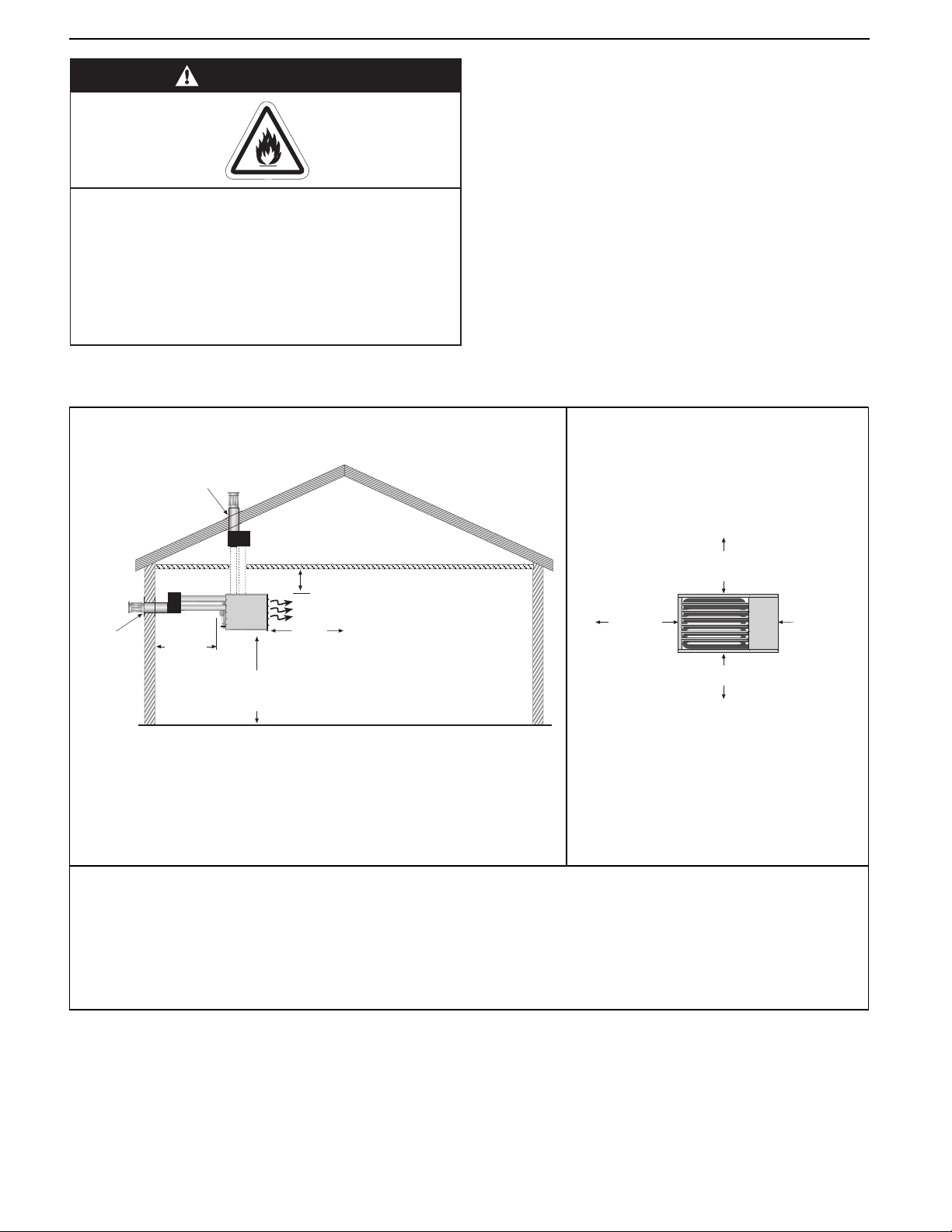

Figure 1: Installation Clearances and Clearances to Combustibles

Installation Clearances

Roof Terminal

(Optional separated

combustion concentric

venting shown.)

Top

Wall

Terminal

24" for

adequate

air flow access

axial fan.

20' (6.0 m) - 30' (9.1 m)

Max. Mounting Height*

10'

(3 m)

* Recommended mounting height varies with heater input.

Clearances to Combustibles

6"**

(15 cm)

Clearance to Vent: 2" (5 cm)

Heaters may be mounted at a higher level if destratification

fans are installed.

Note: Venting directly from top of heater not applicable

**31" (79 cm) minimum is necessary

for servicing.

on Models 150 - 400.

The heater must always be installed at least 6' (2 m) above the floor.

The vent pipe must have clearance from combustibles by 2" (5 cm).

If installed at low levels where individuals can come in contact with hot heat

exchanger components, adequate guarding must be provided.

6"

(15 cm)

31"

(79 cm)

3"

4

Page 11

SECTION 4: NATIONAL STANDARDS AND APPLICABLE CODES

SECTION 4: NATIONAL STANDARDS AND APPLICABLE CODES

4.1 Gas Codes

The type of gas appearing on the nameplate

must be the type of gas used. Installation must

comply with national and local codes and

requirements of the local gas company.

United States: Refer to NFPA 54/ANSI Z223.1 latest revision, National Fuel Gas Code.

Canada: Refer to CSA B149.1 Natural Gas and

Propane Installation Code.

4.2 Aircraft Hangars

Installation in aircraft hangars must be in

accordance with the following codes:

United States: Refer to Standard for Aircraft

Hangars, NFPA 409 - latest revision.

Canada: Refer to Standard CSA B149.1 Natural

Gas and Propane Installation Code.

• In aircraft storage and servicing areas, heaters

shall be installed at least 10' (3 m) above the

upper surface of wings or of engine enclosures

of the highest aircraft which may be housed in

the hangar. The measurement shall be made

from the wing or engine enclosure (whichever is

higher from the floor) to the bottom of the heater.

• In shops, offices and other sections of aircraft

hangars communicating with aircraft storage or

servicing areas, heaters shall be installed not

less than 8' (2.4 m) above the floor.

• Suspended or elevated heaters shall be so

located in all spaces of aircraft hangars that they

shall not be subject to injury by aircraft, cranes,

movable scaffolding or other objects. Provisions

shall be made to assure accessibility to

suspended heaters for recurrent maintenance

purposes.

4.3 Parking Structures and Repair Garages

Installation in garages must be in accordance

with the following codes:

United States: Standard for Parking Structures

NFPA 88A - latest revision or the Code for Motor

Fuel Dispensing Facilities and Repair Garages,

NFPA 30A - latest revision. Canada: Refer to

CSA B149.1 Natural Gas and Propane

Installation Code.

• In accordance with the Standard for Parking

Structures NFPA 88A, heaters must be located

a minimum of 18" (50 cm) below the floor-ceiling

assembly or 18" (50 cm) above the floor.

• In accordance with the Code for Motor Fuel

Dispensing Facilities and Repair Garages,

NFPA 30A - latest revision, heaters must not be

installed less than 8' (2.4 m) above the floor.

4.4 Electrical

The heater must be electrically grounded in

accordance with the following codes:

United States: Refer to National Electrical

®

Code

, NFPA 70 - latest revision. Wiring must

conform to the most current National Electrical

®

Code

, local ordinances and any special

diagrams furnished.

Canada: Refer to Canadian Electrical Code,

CSA C22.1 Part 1 - latest revision.

4.5 Venting

The venting must be installed in accordance

with the requirements within this manual and

the following codes:

United States: Refer to NFPA 54/ANSI Z223.1 latest revision, National Fuel Gas Code.

Canada: Refer to CSA B149.1 Natural Gas and

Propane Installation Code.

4.6 High Altitude

These heaters are approved for installations up

to 2000' (610 m) (US), 4500' (1370 m) (Canada)

without modification. Consult factory if US

installation is above 2000' (610 m) or Canadian

installation is above 4500' (1370 m).

5

Page 12

COMBAT® UHA UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL

Cone Point

Set Pin

Window

Clamp

Unistrut

3/8"

Threaded

Rod

Nut

Washer

Riv

Nut

Washer

3/8"

Threaded

Rod

Nut

Unistrut

Channel Nut

SECTION 5: MAJOR COMPONENTS

5.1 General

Heaters are designed for installation above 6'

(1.8 m). These heaters must be installed within the

heated space. Duct delivery systems are not

permitted with axial fan units. When handling or

supporting the heater from below, ensure that the

weight is taken at the support points.

5.2 Suspension

WARNING

Crush Hazard

Use 3/8" threaded rod

minimum.

Failure of the supports can

result in death, injury

or property damage.

For typical suspension, See Page 6, Figure 2.

Figure 2: Suspension Methods

Ensure all suspension

hardware is torqued to

a minimum of 20 ft lbs.

6

Support Points

Page 13

SECTION 6: VENTING

6.1 Venting

This heater must be vented in accordance with the

rules contained in this manual and with the following

national codes and any state, provincial or local

codes which may apply: United States: Refer to

NFPA 54/ANSI Z223.1 - latest revision, National

Fuel Gas Code; Canada: Refer to CSA B149.1

Natural Gas and Propane Installation Code.

Any portion of vent pipe passing through a

combustible wall must have an listed thimble to

conform with the above codes.

The heater may be installed unvented in

certain circumstances according to building

ventilation codes. Refer to the above codes

and

Page 8, Section 6.3 for further information.

Unvented operation also requires compliance with

the clearances to combustibles given

on Page 4,

Figure 1.

The bottom of the vent or air intake terminal shall not

be located less than 1' (.3 m) above grade level.

The vent shall not terminate less than 7' (2.1 m)

above grade where located adjacent to public

walkways.

Vent terminal must be installed at a height sufficient

to prevent blockage by snow and building materials

protected from degradation by flue gasses.

Vent terminal must be beyond any combustible

overhang.

Secure all joints with corrosion resistant #8 x 3/8"

sheet metal screws.

For single wall venting, pressure sensitive aluminum

tape or silicone sealant must be used to seal all

joints.

Aluminum tape shall have a minimum temperature

rating of 400° F (204° C) and meet SMACNA AFTS100-73 standards. High temperature silicone

sealant must have a minimum temperature rating of

480° F (250° C).

6.1.1 United States Requirements

Vent must terminate at least 3' (.9 m) above any

forced air inlet located within 10' (3.1 m).

Vent must terminate at least 4' (1.2 m) below,

4' (1.2 m) horizontally from, or 1' (.3 m) above any

door, operable window, or gravity air inlet into any

building.

NFPA 54/ANSI Z223.1 - latest revision, National

Fuel Gas Code specifies a 4' (1.2 m) horizontal vent

terminal clearance from gas and electric meters,

regulators and relief equipment.

6.1.2 Canadian Requirements

The vent shall not terminate within 6' (1.8 m) of a

SECTION 6: VENTING

mechanical air supply inlet to any building.

The vent shall not terminate within 3' (.9 m) of a

window or door that can be opened in any building,

any non-mechanical air supply inlet to any building,

or of the combustion air inlet of any other appliance.

6.2 Vent Installation

WARNING

Fire Hazard

Some objects will catch fire or explode when placed

close to heater.

Keep all flammable objects, liquids and vapors the

required clearances to combustibles away from heater.

Failure to follow these instructions can result in death,

injury or property damage.

For vented units, the vent must terminate outside of

the building.

Vents must be fully sealed and correctly sized for

the model. If the vent passes through a wall or

ceiling of combustible material, it must be enclosed

by a listed thimble and be separated from the

thimble by at least a 2" (5 cm) air gap.

For separated combustion models, vents and air

intakes must be a fully sealed system and correctly

sized for the model. Vent should be assembled as

detailed

Figure 8. The joints between the vent terminal and

the roof or wall must be properly sealed. If the vent

passes through a wall or ceiling of combustible

material, it must be enclosed by a listed thimble and

be separated from the thimble by at least a 2" (5 cm)

air gap.

Vents and air intakes must be adequately

supported so that the heater does not bear the

weight of the pipes.

For vent termination See Page 9, Figure 3 through

Page 12, Figure 8.

6.2.1 Standard Vented Heaters

(Models UHA 150 - 400)

The vent must be fitted with a low resistance

terminal.

Figure 4. Standard vented heaters do not allow

outdoor air intake for combustion air.

on Page 9, Figure 3 through Page 12,

See Page 9, Figure 3 through Page 9,

7

Page 14

COMBAT® UHA UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL

6.2.2 Separated Combustion Heaters

(Models UHAS 150 - 400)

The heaters are designed to be installed as

separated combustion heaters. The vent and air

intake are run as separate pipes to the wall or roof

terminals.

See Page 12, Figure 8. As an option, the

vent and air intake are run as separate pipes to a

concentric vent box and a concentric vent/air intake

pipe penetrates the wall or roof.

6.3 Unvented Operation

WARNING

Carbon Monoxide Hazard

Heaters installed unvented must

be interlocked with sufficient

building exhaust.

Heaters must be installed

according to the installation

manual.

Failure to follow these

instructions can result in death

or injury.

For unvented operation in commercial installations,

sufficient ventilation must be provided in the amount

of 4 cfm per 1000 Btu/h firing rate (United States); 3

cfm per 1000 Btu/h firing rate (Canada).

WA RN IN G: Combustion by-products contain a

chemical known to the State of California to cause

cancer and birth defects or other reproductive

harm.

6.4 Horizontal Venting

Horizontally vented heaters must be individually

vented.

Vent pipe must be sloped ¼" (.6 cm) for every 1' (.3

m). For vent lengths greater than 5' (1.5 m),

condensation will form. Insulation is recommended

and condensation drains may be desired. For vents

pitched up toward the vent terminal, place the

condensation drain within 5' (1.5 m) of the heater.

In noncombustible walls only, vent terminal

(P/N 02537801-1P) may be used.

For 4'' (10 cm) vents in either combustible or

noncombustible walls, use vent terminal (P/N

90502100) or equivalent insulated vent terminal.

Follow the manufacturer's instructions for proper

installation.

Instead of an insulated vent terminal, a listed thimble

(with 2" air gap) may be used with a 4" vent cap (P/N

90502102).

6.5 Vertical Venting

Vertically vented heaters can be common vented

(up to 4 heaters).

For vent lengths greater than 5' (1.5 m),

condensation will form. Insulation is recommended

and condensation drains may be desired. Vent from

the rear of the heater cabinet then run the vent

vertically and use a condensate drain at the bottom

of the vertical vent.

Vent pipe must be sloped 1/4'' (.6 cm) for every

1' (.3 m).

For 4'' (10 cm), an approved vent cap

(P/N 90502102) must be used.

For 6'' (15 cm) common vent, an approved vent cap

(P/N 90502103) must be used.

For common vertical venting of more than two

heaters,

See Page 10, Figure 5.

A vent shall not extend less than 2' (.6m) above the

highest point where it passes through a flat roof of a

building.

6.6 Length Requirements

If using vent lengths greater than 5' (1.5 m),

condensation will form in the vent pipe. Insulation

and additional sealing measures (high temperature

silicone at all seams) are required.

The entire vent should be insulated with foil faced

fiberglass insulation (1/2" thick, 1-1/2# density

minimum).

Maximum Vent Lengths Table

Model UHA(S)

150 - 400

40 ft (12.2 m) 1

35 ft (10.7 m) 2

30 ft (9.1 m) 3

25 ft (7.6 m) 4

20 ft (6.1 m) 5

# of Elbows

8

Page 15

SECTION 6: VENTING

6.7 Vent Material

Vent material may be single wall 26 ga. (minimum)

galvanized steel or equal thickness stainless steel.

Completely seal all joints, refer to

Page 7, Section

6.2.

If penetrating a combustible wall or roof, a listed

thimble with 2" (5 cm) clearance must be used.

Where local codes permit, a single section of type

B-1 vent material may be used at the roof or wall

penetration instead of a thimble. Ensure vent

manufacturer's clearance from vent material is

maintained. Seal annular space of the type B-1 vent

as well as all joints in the remaining vent.

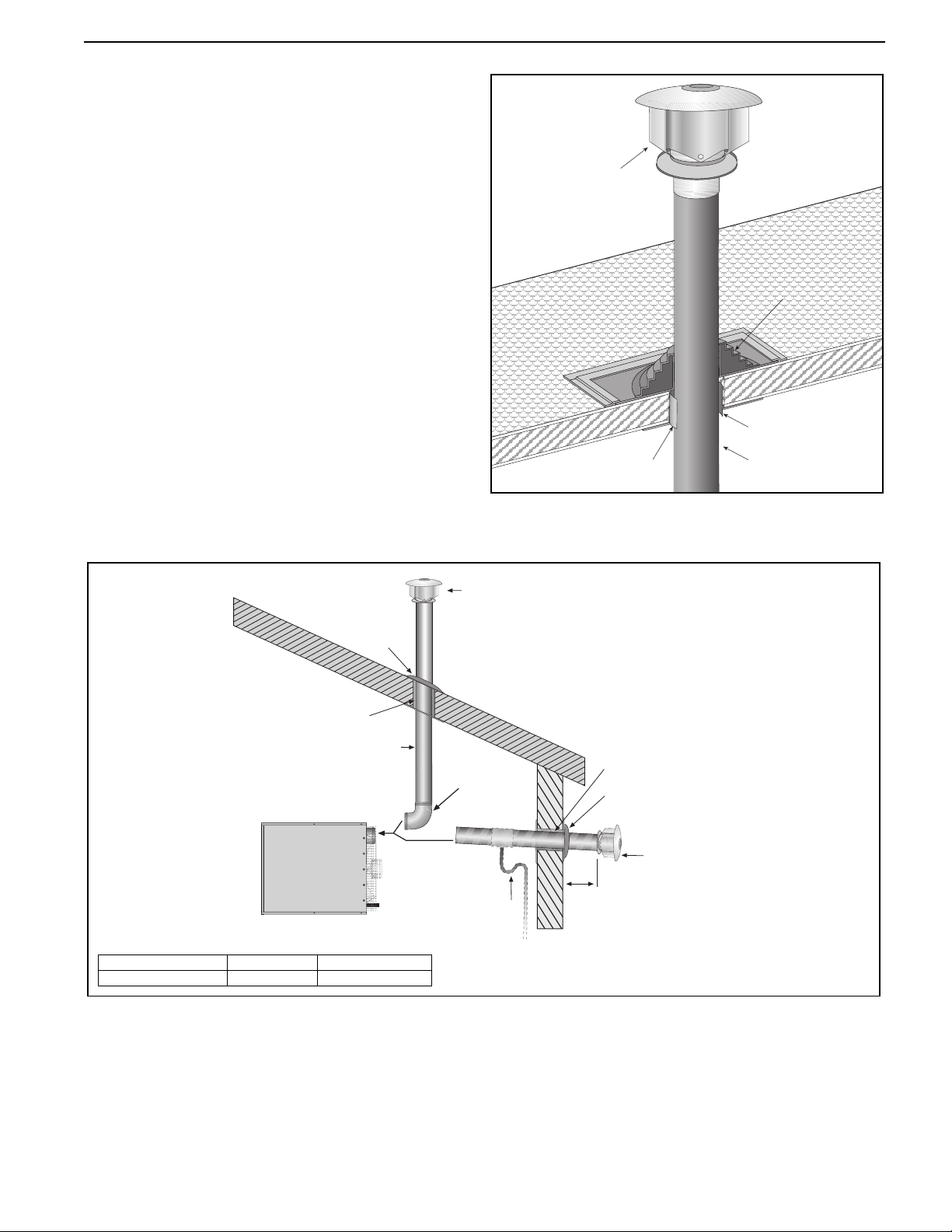

Figure 3: Vent and Roof Detail

Vent

Terminal

Roof

2" Air Gap to

Combustible Material

Flashing

or Rain Collar

Listed Thimble

Vent

Figure 4: Standard Vented Heater - Vertical and Horizontal Vent Termination

Vent Terminal

Flashing

(By Others)

Listed

Thimble

(2" Clearance)

4" Dia.Vent

Vertical

Option

Model Vent Diameter Part Number

UHA 150 - 400 4" (10 cm) 90502102

90°

Bend

Horizontal

Option

Vent

Condensate

Trap to Drain

(Optional)

Listed

Thimble

(2" Clearance)

Flashing

(By Others)

12" (31 cm)

Minimum

Vent

Terminal

Note: Vent supports

not shown.

9

Page 16

COMBAT® UHA UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL

Figure 5: Standard Vented Heater - Common Vertical Vent Termination

Type "B" vent cap

(7" or 8") may be used.

(These are not available

SIDE VIEW

from Roberts-Gordon.)

Type "B" Vent Pipe

TOP VIEW

18" (46 cm)

Min.

The last section of vent pipe

passing through the roof or

wall may be Type "B" vent pipe.

All other vent materials in the

building must be single wall

vent pipe.

4" (10 cm)

Single Wall Pipe

"D"

Roof

Flashing

Roof

Approved

Thimble

(If Applicable)

Single Wall Pipe

"D" Area must equal sum

of open area of

individual vents.

4" (10 cm)

Single Wall Pipe

10

Page 17

Figure 6: Separated Combustion Heater - Vertical and Horizontal Vent Termination

12" (31 cm)

Minimum from air inlet to vent

termination (may be horizontal

or vertical clearance).

SECTION 6: VENTING

Air Intake*

90°

Bend

Model Vent Diameter Terminal P/N

UHAS 150 - 400 4" (10 cm) 90502102

Model *Air Intake Diameter Terminal P/N

UHAS 150 - 250 4" (10 cm) 90502102

UHAS 300 - 400 5" (13 cm) 90502105

Figure 7: Concentric Vent Box

Vertical

Option

Vent

Horizontal

Option

Air Intake

Vent

Condensate

Trap to Drain

(Optional)

Listed Thimble through

Combustible Wall

12" (31 cm)

Minimum from air inlet to vent

termination (may be horizontal

or vertical clearance).

Air Intake

Termination

Vent

Termination

12" (31 cm)

Minimum from wall

to vent termination.

Note: Vent supports not shown

4" (10 cm) or

5" (13 cm)

Seal joint between single wall

and Type B vent with silicone sealant.

Toward

Heater

4" (10 cm) Single

Wall Vent Pipe

(By Others)

One Piece Double Wall Type B-1 Vent Pipe (By Others)

Concentric

Use 3 sheetmetal

screws equally

spaced around joint.

Use 3 sheetmetal

screws equally

Vent Box

spaced around collar.

Toward

Outside

6" (15 cm) or 8" (20 cm)

Single Wall Inlet Air Pipe

(By Others)

11

Page 18

COMBAT® UHA UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL

Figure 8: Concentric Vertical and Horizontal Vent Termination

4" Type B-1

UHA 150-250:

6" Dia. Single Wall

UHA 300-400:

8" Dia. Single Wall

Concentric

Vent Box

Air Intake*

Vent

Vertical

Option

10' (3 m)

Maximum

Combustion

Air Terminal

Vent

Air Intake*

Vent Terminal

with Baffle Plate

Storm Collar (By Others)

(Attach with 3 sheet metal screws.)

Flashing

(By Others)

Condensate Trap

to Drain (Optional)

Horizontal

Option

- Separated Combustion Heater

6" (16 cm)

Minimum

12" (31 cm)

Maximum

4"

Type

B-1

Vent

Vent Terminal

with Baffle Plate

Vent

Description Part Number Qty.

Concentric Vent Kit (150 - 250) UHVK1

Concentric Vent Box Top & Side Assembly 90504113 1

Concentric Vent Box Bottom Assembly 90504112 1

Screw #6 x 3/8 Self Drilling 91119100 14

4" Vent Terminal with Baffle Plate 90502102R 1

6" Combustion Air Terminal 90502103 1

Description Part Number Qty.

Concentric Vent Kit (300 - 400) UHVK2

Concentric Vent Box Top & Side Assembly 90504013 1

Concentric Vent Box Bottom Assembly 90504012 1

Screw #6 x 3/8 Self Drilling 91119100 14

4" Vent Terminal with Baffle Plate 90502102R 1

8" Combustion Air Terminal 90502104 1

Concentric

Vent Box

Combustion

Air Terminal

Model Vent Diameter

UHAS 150 - 400 4" (10 cm)

Model *Air Intake Diameter

UHAS 150 - 250 4" (10 cm)

UHAS 300 - 400 5" (13 cm)

Storm Collar (By Others)

(Attach with 3

sheet metal screws.)

12

Page 19

SECTION 7: AIR SUPPLY

7.1 Separated Combustion Installation

When installed as a separated combustion heater,

the air for combustion is drawn in from outside the

building. It is important to ensure that there is

adequate space around heater to provide air for the

axial air distribution fan.

7.2 Unvented Installation

It is important to ensure that there is adequate fresh

air supply at all times for both combustion and

heating requirements in accordance with local and

national codes.

WARNING: Combustion by-products contain a

chemical known to the State of California to cause

cancer and birth defects or other reproductive

harm.

7.3 Building Ventilation

Where ventilation is required, air must be taken from

an outside point where it is not likely to be

contaminated or obstructed.

SECTION 7: AIR SUPPLY

7.4 Outside Combustion Air Supply

If outside combustion air supply is required,

separated combustion model (UHAS) heaters must

be used.

IMPORTANT: If the building has a slight negative

pressure or corrosive contaminants such as

halogenated hydrocarbons are present in the air, an

outside combustion air supply to the heater is

required. Seal all combustion air pipe joints.

The air supply duct may have to be insulated to

prevent condensation on the outer surface. The

outside air terminal must not be more than 1' (31

cm) above the vent terminal.

7.4.1 Length Requirements

Follow the constraints listed on Page 8, Section 6.6.

13

Page 20

COMBAT® UHA UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL

SECTION 8: GAS PIPING

• Meter and service must be large enough to

WARNING

handle all the burners being installed plus any

other connected load. The gas pipe which feeds

the system must be large enough to supply the

required gas with a maximum pressure drop of

1/2" w.c. When gas piping is not included in the

layout drawing, contact the local gas supplier.

Fire Hazard

Fire Hazard

Connect gas supply according to Figure 9.

Connect gas supply according to Figure 9.

Gas can leak if not installed properly.

Gas can leak if not installed properly.

Failure to follow these instructions can result in death,

Failure to follow these instructions can result in death,

injury or porperty damage.

injury or property damage.

• An isolating valve and union connection should

be used and fitted into the supply adjacent to the

heater.

• A minimum 1/8" NPT plugged tapping

accessible for test connection must be installed

immediately upstream of the gas supply

connection to the heater.

It is important that the gas supply pipe and the

electrical connections do not support any of the

heater’s weight.

A gas meter is connected to the service pipe by the

gas supply company. An existing meter should be

checked, preferably by the company, to ensure that

the meter is adequate for the rate of gas supply

required.

Installation pipes must be fitted in accordance with

local and national codes. Pipes of smaller size than

the heater inlet gas connection should not be used.

• For suspended heaters, an approved metal

flexible connection between the isolating valve

and the heater may be used. To reduce

pressure loss, use one pipe size larger than

the heater gas connection.

IMPORTANT - The complete installation must be

purged and tested for gas soundness in accordance

with local and national codes.

• Do not high pressure (in excess of 1/2 psi

[14" w.c.]) test the gas piping with the burner

connected. Close manual shut-off valve

8.1 Connections

Connect the heater to the gas supply ensuring that

the final connections are as follows:

• Gas supply pipe work is run in medium or heavy

gauge tubing in compliance with local and

national codes.

during any pressure testing equal to or less

than 1/2 psi (14" w.c.). Failure to follow these

instructions can result in property damage.

Check the pipe and tubing ends for leaks before

placing heating equipment into service. When

checking for gas leaks, use a soap and water

solution; never use an open flame.

Figure 9: Gas Connection

• Hold gas nipple

securely with pipe

wrench when

attaching the flex gas

connector.

• Do not twist flexible

gas connector.

• Ensure all

joints are

gas tight.

14

Do not bend flexible

gas connector

sharply.

Gas Shut-off Valve

Union

Connection

Option A:

Stainless Steel

Flex Gas

Connector

Option B:

Medium or Heavy

Gauge Pipe

Gas Connector

Drip Leg

Cap

Page 21

SECTION 9: WIRING

WARNING

Electrical Shock Hazard

Disconnect electrical power and gas supply before

servicing.

This appliance must be connected to a properly

grounded electrical source.

Failure to follow these instructions can result in

death or electrical shock.

All heater models require constant 120 V 60 Hz 1Ø

power supply. Check heater(s) rating plate for

electrical rating for proper circuit sizing. For

servicing, a disconnect switch of proper electrical

rating should be installed in the vicinity of the heater.

All heaters are equipped with thermostat

connections suitable to power a 24 V thermostat.

Heater must be wired and electrically grounded in

accordance with local codes. In the absence of local

SECTION 9: WIRING

codes in accordance with: United States: refer to

®

National Electrical Code

ANSI/NFPA 70 - latest

revision Canada: refer to Canadian Electrical Code

CSA C22.1 Part I - latest revision.

9.1 Positioning Thermostats

A room thermostat or ROBERTS GORDON®

control should be mounted on a vibration-free wall or

column at a height of approximately 5' (1.5 m) from

the floor to measure the ambient temperature. It

should be clear of both cold drafts and the direct

path of warm air from the heater.

Avoid mounting thermostat on outside walls or in

areas directly exposed to radiant heat or sunlight.

Install wall tag in a visible location near thermostat.

9.1.1 Fan Control

The heater’s axial fan can be used during the offseason for air circulation. A low voltage thermostat

with fan control must be used.

See Page 15, Section

9.2 for thermostat connection details.

9.2 Low Voltage Thermostat with One Heater

24 Volt

Thermostat

Heating Only

R

W

24 Volt

Thermostat

with Fan Control

R

G

W

C

Electrical

Supply

Terminal

Strip

R

G

W

C

Terminal

Strip

R

G

W

C

Electrical

Supply

15

Page 22

COMBAT® UHA UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL

9.3 UHA(S) Series Internal Wiring Diagram

BLOWER

PRESSURE SWITCH

LIMIT SWITCH

(UH 300, 350,

400 ONLY)

ELECTRODE

AXIAL FAN

MANUAL RESET LIMIT SWITCH

(UH 30 - 125 ONLY)

SENSE

ORANGE

ORANGE

AXIAL FAN (UH 300, 350, 400 ONLY)

WHITE

GREEN

BLACK

WHITE

GREEN

BLUE

BLUE

LIMIT SWITCH

BLACK

BLACK

BLACK

GREEN

WHITE

ORANGE

FLAME

WHITE

GREEN

TRANSFORMER

BLUE

HOT

24 VAC

3

GROUND

ORANGE

IGNITION MODULE

ACC

BLACK

2

6

5

YELLOW

1

4

L1

L2

WHITE

BLACK

31

45

R

G

W

C

CMB BLOWER

L1

YELLOW

GREEN

BLACK

BLACK

BLACK

GAS VALVE

BROWN

R = 24 VAC TO THERMOSTAT (RED)

G = MANUAL FAN INPUT FROM THERMOSTAT (GREEN)

W= HEAT DEMAND INPUT FROM THERMOSTAT (WHITE)

C = COMMON SIDE OF TRANSFORMER

THERMOSTAT INPUT: FIELD SUPPLIED

BLACK

BLACK

NOTE:

For field wiring into service junction box, or if any of the original wire supplied with the heater

must be replaced, it must be replaced with wiring material having a temperature rating of at least 105°C

and 600 volts. For supply connections use No. 14 AWG or larger wires.

16

Page 23

9.4 UHA(S) Series Ladder Wiring Diagram

SECTION 9: WIRING

120 VAC

FLAME

SENSOR

ELECTRODE

CIRCULATION FAN

CIRCULATION FAN

COMBUSTION BLOWER

2

1

3

6

4

5

FLAME

IGNITION

MODULE

SPARK

TRANSFORMER

GAS

VALVE

PRESSURE SWITCH

LIMIT SWITCH

UH 300, 350, 400 Only

LIMIT SWITCH (UH 300, 350, 400 ONLY)

MANUAL RESET LIMIT SWITCH

(UH 30 - 125 ONLY)

THERMOSTAT CONNECTION

NOTE:

For field wiring into service junction box, or if any of the original wire supplied with the heater

must be replaced, it must be replaced with wiring material having a temperature rating of at least 105°C

and 600 volts. For supply connections use No. 14 AWG or larger wires.

17

Page 24

COMBAT® UHA UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL

9.5 Electrical Connection to the Heater

Flexible Conduit

Burner

Connect wires together

with suitable approved

wire connectors.

Green to Ground

White to L2

Black to L1

L1

L2

Ground

Black

White

Green

BX Connector

Junction Box

Note: Junction box is not provided with heater.

Conduit can also be attached directly to heater with wire junction made within the heater cabinet.

18

Page 25

SECTION 10: OPERATION AND MAINTENANCE

Installation, service, and annual inspection of the

heater must be done by a contractor qualified in the

installation and service of gas-fired heating

equipment. Read this manual carefully before

installation, operation, or service of this equipment.

All components are accessed via the door secured

by 4 sheet metal screws. Opening the door exposes

live electrical connections and hot components.

WARNING

Electrical Shock Hazard

Use extreme caution during start-up.

Controls compartment contains live electrical

connections.

SECTION 10: OPERATION AND MAINTENANCE

10.1.2 Electrical Checks

All pre-start-up checks must be carried out before

start-up the heater.

1. Check that all site wiring is connected in

accordance with the appropriate wiring diagram

on Page 16, Section 9.3.

10.1.3 Gas Supply

All aspects of the gas installation including the gas

meter must be inspected, tested for gas tightness

and purged in accordance with local and national

codes.

Ensure that the air is fully purged from the heater

inlet pipe up to the main gas valve inlet test nipple.

10.1.4 Mechanical Checks

1. Check that the fan is free to run and

delivery louvers are turned to give required

air deflection.

2. Check that the flue (and air intake for separated

combustion units) is installed in accordance

with these instructions and local regulations.

Failure to follow these instructions can result in

death or electrical shock.

10.1 Pre-Start-Up Checks

All pre-start-up checks must be carried out

before lighting the heater.

Ensure that the heater and all controls are suitable

for the gas, pressure and electrical supply to which

they are to be connected.

10.1.1 Louvers

Where fitted, the air delivery louvers need to be set

during start-up to give the required air distribution

(optional vertical louvers).

WARNING

10.2 Begin Start-Up

10.2.1 Before Operating the Heater

To ensure that all the controls are in safe working

order, operate the heater for the first time with the

isolating gas valve turned off and power supply

turned on.

1. Turn off the isolating gas valve.

2. Turn up the thermostat above room

temperature. The automatic ignition

sequence will now begin as described

on Page 20, Figure 10.

There will be no ignition of the burner and lockout

will occur, which proves the controls are operating

correctly.

Cut Hazard

Turn off gas and electrical supply before maintenance.

Fan can start automatically at any time.

Failure to follow these instructions can result in severe

injury or product damage.

19

Page 26

COMBAT® UHA UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL

½PSI IN

C

ON

OFF

Regulator

Outlet

Pressure

Gas Inlet

Inlet Pressure

Top View

End View

Figure 10: Automatic Burner Control Sequence

Burner Sequence for Ignition Control

START

Thermostat 24 V

RUN

SHUT DOWN

Flue Fan

Pressure

Switch

Ignition Spark

Start Gas Valve

Flame Signal

Axial Fan

NO

P

C

NC

*Purge time begins at pressure switch change over.

30 Sec. Purge*

ts = 10 seconds

30 Sec. Delay 90 Sec. Delay

Required Incoming Signals

Signals Output By Control

Figure 11: Gas Valve for Models UHA(S) 150 - 400

30 Sec. Post Purge

If at any stage the flame fails, the control will retry

for ignition. The control has four trials for ignition

before a one hour lockout.

Description Part Number

Gas Valve 150 - 225 NG 90032505

Gas Valve 150 - 225 LP 90032506

Gas Valve 250 - 400 NG 90032520

Gas Valve 250 - 400 LP 90032521

20

Page 27

SECTION 10: OPERATION AND MAINTENANCE

10.2.2 Start-Up the Gas Valve (All Gases)

10.2.2.1 Check Burner Gas Pressure

1. Remove the plug in the outlet (burner) pressure

test point and connect a pressure tap and a

manometer.

2. With the burner firing, measure the pressure on

the manometer. To adjust the burner pressure,

remove the regulator cover from the valve and

turn the regulator adjustment screw to set the

required burner pressure as stated in the

Technical Data Tables for the correct gas and

model

on Page 38, Section 15.3.

NOTE: If the correct burner pressure cannot be

reached, then check the inlet pressure to the valve

with the burner firing. See Technical Data Tables

on

Page 38, Section 15.3 for inlet pressure

requirement.

Do not continue to adjust the regulator if the

pressure is not changing.

If the inlet pressure is too low to allow correct burner

pressure setting, then the gas inlet pressure must be

corrected before completing the commission.

10.2.5 External Controls

External controls may include time switch, interlock

switch, room thermostat and frost thermostat.

Operate each control to ensure that they function

correctly. Set the switches (if fitted) and

thermostat(s) to the users’ requirements.

10.3 Complete the Start-Up

Ensure that all covers are fitted correctly and all test

points are properly sealed.

10.3.1 Instruction to the User

Explain the controls of the heater to the user

including how to turn it on and off, using the controls

fitted on site.

Give this manual to the user.

Ensure that the user is shown and understands the

importance of maintaining clearances to

combustibles and the user instructions

on Page 22,

Section 11 through Page 22, Section 11.5 and all

warnings defined in this manual.

Check Gas Rate

1. After burner pressure adjustment, allow the

heater to operate for at least 15 minutes and

then re-check settings. Adjust pressure setting

if necessary.

2. Check gas flow rate at gas meter.

3. Turn off heater and electrical supply.

4. Remove the manometer and refit all covers to

the valve and tighten the screw of the outlet

pressure tap.

10.2.3 Pressure Switch

The pressure switch is factory pre-set for each

model and is not adjustable.

10.2.4 Turning Off the Heater

Set the thermostat to the "OFF" position or lowest

setting and the main burner will stop.

The fan will run until it is stopped automatically by

the fan thermostat.

Do not use a disconnect switch for control of

heater. Disconnect switch will turn off the fan.

Heat exchanger could be damaged. Warranty will

not cover damage to the heat exchanger if

operated improperly. Only use the disconnect

switch for turning off heater for service or during

off-season.

21

Page 28

COMBAT® UHA UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL

SECTION 11: USER INSTRUCTIONS

11.1 User Instructions

The UHA(S) Series heaters are fully automatic and

operate from the external controls fitted on site.

11.5 Simple Troubleshooting

Some possible reasons for the heater not operating

are:

1. Gas supply not "ON".

WARNING

2. Electricity supply not "ON".

3. The time and/or temperature controls are not

"ON".

4. A limit switch may have operated. This may be

caused by an interruption of the electrical

supply, failure of the distribution fan or vent or

heat exchanger blockage.

Electrical Shock Hazard

Disconnect electrical power before servicing.

Failure to follow these instructions can result in

death or electrical shock.

If a temperature limit switch persistently trips, there

is a fault which must be investigated by a contractor

qualified in the installation and service of gas-fired

heating equipment.

11.2 Heater Operation

When the heater has been switched on by the

thermostat installed on site, the main burner will

automatically turn on.

The burner control box will control the safe ignition

of the flame.

All heaters require a constant gas and electricity

supply which must not be interrupted during the

normal operation of this heater.

11.3 Common User Controls

11.4 Lighting Instructions

11.4.1 To Turn On Heater

1. Ensure that the electrical and gas supplies to

the heater are on. Check that the on site

controls are "ON".

NOTE: The thermostat setting must be above the

ambient temperature for the heater to operate.

2. The automatic firing sequence will begin as

described

on Page 20, Figure 10. The heater

will now operate automatically under the control

of the on site controls.

11.5.1 Simple Troubleshooting (Burner Faults)

If the burner fails to ignite for any reason, it will retry

for ignition (4 trials total). After 4 unsuccessful

ignition trials, the control will put the heater into

lockout for 1 hour.

Lockout should not occur during normal operation of

the heater and indicates there is a fault condition

which must be corrected. There is an LED light on

the ignition control that flashes codes to assist in

fault correction.

See Figure 12 for LED indication

codes.

Figure 12:

LED INDICATION FAULT MODE

Slow Flash Normal Operation - No call for heat.

Fast Fl ash Normal Operation - Call for heat.

2 Flashes Ignition Lockout - No flame detected.

3 Flashes Airflow Fault - Pressure switch open or closed.

4 Flashes Temperature Limit or

5 Flashes Flame Sense Error - Gas valve not energized.

Steady On Internal Control Failure

LED Diagnostic Codes

Manual Reset Limit Switch Open

11.4.2 To Turn the Heater Off

Set the thermostat to the "OFF" position.

The burner will turn off immediately.

The fan will continue to run for 90 seconds.

To restart, turn the thermostat above room

temperature.

22

Page 29

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. DO NOT try to light any appliance.

3. DO NOT use electrical switches.

4. DO NOT use any telephone in

your building.

5. Leave the building.

6. Immediately call your local gas

supplier after leaving the building.

Follow the gas suppliers

instructions.

7. If you cannot reach your gas

supplier, call the Fire Department.

WARNING

SECTION 11: USER INSTRUCTIONS

Fire Hazard

Do not store or use petrol or other

flammable vapours and liquids in the

vicinity of this or any other appliance.

Some objects will catch fire or explode

when placed close to heater.

Failure to follow these instructions can

result in death, injury or property

damage.

23

Page 30

COMBAT® UHA UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL

SECTION 12: SERVICING

12.1 Servicing Instructions

After start-up, the heater will require maintenance to

be carried out annually. If the heater is used in a

dirty or dusty area, more frequent maintenance may

be necessary.

12.3 Fan/Motor Assembly Maintenance

The main fan bearings are permanently sealed and

do not need lubrication. Before cleaning, turn off gas

and electrical supply. Remove the fan and use a

small brush or duster to clean the fan blades from

each side. Replace fan when done.

WARNING

Cut Hazard

Turn off gas and electrical supply before maintenance.

Fan can start automatically at any time.

Failure to follow these instructions can result in severe

injury or product damage.

NOTE 1: After any maintenance or repair work,

always test fire the heater in accordance with the

start-up instructions

Page 21, Section 10.3.1 to ensure all safety systems

are in working order before leaving the heater to

operate. Minor faults may be traced by using the

troubleshooting charts

through Page 30, Section 13.5.

NOTE 2: Check all gas pipes and pipe joints to

ensure there are no cracks or gas leaks. Any cracks

in the pipes or pipe joints must be repaired.

NOTE 3: Inspect all suspended components and

hardware. Ensure that they are in good condition,

properly tightened, and corrosion free.

12.2 Burner Maintenance

1. Open the door and remove the burner compartment cover. See Page 32, Section 14.2.

2. Clean any deposits from the main burner which

may have formed in the injectors or venturi of

the burner.

3. Remove the ignition electrode and flame probe.

Check condition of ignition electrode and flame

probe. Clean off any deposits which may have

been formed, check condition of ceramic

insulators. Replace as necessary.

on Page 19, Section 10 through

on Page 27, Section 13

See Page 32, Section 14.2.

12.4 Heat Exchanger Maintenance

The heat exchanger will remain clean unless a

problem has developed with combustion. Inspect the

heat exchanger. Look for signs of overheating at the

front tubes which may indicate burner over firing or

persistently low air flows.

12.5 Gas Valve Maintenance

No regular maintenance is required on this device.

To change gas control valves,

See Page 31, Step

14.1 and Page 35, Section 14.5.

Do not repair or disassemble gas valve.

Replace faulty gas valves with genuine

®

ROBERTS GORDON

replacement parts.

12.6 Combustion Fan

The combustion fan should not require

maintenance. However, if the air pressure switch is

causing burner lockout, then remove the combustion

fan from the vent box by unscrewing the three

screws at the mounting plate. Remove the four

screws attaching the mounting plate to the fan inlet

See Page 34, Section 14.4). Ensure that the fan is

(

free to run and that the fan wheel is clean.

12.7 Venting and Air Intake Pipe

Inspect all venting and air intake pipe. Ensure that

all seams are sealed and suspension points secure.

Repair suspension points if any part of the venting

or combustion air pipe is sagging. Check to make

sure any insulation is not missing or in poor

condition. Replace as necessary. Check all venting

and air intake components to ensure they are in

good condition, gas tight and corrosion-free.

24

Page 31

SECTION 12: SERVICING

12.8 Maintenance Checklist

Installation Code and Annual Inspections: All

WARNING

installations and service of ROBERTS GORDON

equipment must be performed by a contractor

qualified in the installation and service equipment

sold and supplied by Roberts-Gordon and conform

to all requirements set forth in the ROBERTS

®

GORDON

manuals and all applicable

governmental authorities pertaining to the

Explosion Hazard

Service and annual inspection must be done by a

contractor qualified in the installation and service of

gas-fired heating equipment or your gas supplier.

installation, service and operation of the equipment.

To help facilitate optimum performance and safety,

Roberts-Gordon recommends that a qualified

contractor annually inspect your ROBERTS

Turn off gas and electrical supplies before performing

service or maintenance.

Failure to follow these instructions can result in death,

injury or property damage.

GORDON

necessary, using only replacement parts sold and

supplied by Roberts-Gordon.

®

equipment and perform service where

The Vicinity of the Heater Do not store or use flammable objects, liquids or vapors near the heater.

Immediately remove these items if they are present.

See Page 3, Section 3.

®

Vehicles and Other

Objects

Maintain the clearances to combustibles.

Do not hang anything from, or place anything on, the heater.

Make sure nothing is lodged in between the heat exchanger or in the louvers.

Immediately remove objects in violation of the clearances to combustibles.

See Page 3, Section 3.

Vent Pipe/Terminals Venting must be intact. Using a flashlight, look for obstructions, cracks on the

pipe, gaps in the sealed areas or corrosion.

The area must be free of dirt and dust.

Remove any carbon deposits or scale using a wire brush.

If the vent terminal has a screen built in, remove any dirt, dust or deposits

from the screen.

See Page 13, Section 7.

Combustion Air Intake

Pipe

Intake pipe and inlet must be intact. Look for obstructions, cracks on the pipe,

gaps in the sealed areas or corrosion.

The area must be free of dirt and dust. Clean and reinstall as required.

Heat Exchanger Make sure there are no cracks.

Gas Line and Shut-off

Valves

See Page 14, Section 8.

Make sure there is no sagging, bending or distortion.

Clean or replace as required.

Check for gas leaks. See Page 14, Section 8.

25

Page 32

COMBAT® UHA UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL

Burner Observation

Window

Combustion Fan Scroll,

Make sure it is clean and free of cracks or holes.

Clean and replace as required.

Compressed air or a vacuum cleaner may be used to clean dust and dirt.

Wheel and Motor

Inshot Burners and

Orifices

Clear of obstructions (even spider webs will cause problems).

Carefully remove any dust and debris from the burner.

Direct-Spark Igniter Replace if there are cracked ceramics, excessive carbon residue, or erosion

of the electrode.

The electrode gap should be 1/8" (3.2 mm).

Thermostat There should be no exposed wire or damage to the device or wiring.

See Page 19, Section 10.

Suspension Points Make sure the heater is hanging securely.

Look for signs of wear on the suspension materials or ceiling.

See Page 6, Figure 2.

Silicone Tubing Ensure tight, secure fit on all pressure fittings at pressure switch,

burner partition, and blower outlet.

Gas Valve Verify that cap covering pressure regulator adjustment screw is secure and

has not been tampered with.

Verify all wiring connections.

Condensate Drain

Flush drain and clear any obstructions.

(when installed)

26

Page 33

SECTION 13: TROUBLESHOOTING

13.1 General

Installation must be done by a registered installer/

contractor qualified in the installation and service of

gas-fired heating equipment or your gas supplier.

Failure to follow these instructions can result in death,

injury or property damage.

Start

SECTION 13: TROUBLESHOOTING

WARNING

Explosion Hazard

Are gas & electrical

supplies on?

Ye s

Does axial fan run

immediately upon supplying

power to heater?

No

Is ignition control showing a

"2 flashes" led code?

No

Does the combustion

fan run?

No

Ye s

Ye s

No

Turn on supplies.

Wait 10-15 minutes for limit

switch to cool. Does fan

stop running?

Replace temperature

limit switch.

Burner has locked out due

to ignition failure. Use

Troubleshooting for Automatic

Ignition Burner Systems

section to test burner.

Use Troubleshooting for

Combustion Fan section to

No

test fan.

Ye s

Fan and limit switch are

operating normally.

Ye s

Ye s

With external controls (i.e.

thermostat) on, does the

burner continue through the

heating cycle?

Ye s

Heater Operating

TROUBLESHOOT ENDS.

Has burner Locked Out?

No

Ye s

Use Troubleshooting for

Automatic Ignition Burner

Systems section to test burner.

If problems persist, contact

No

Roberts-Gordon, LLC at

www.rg-inc.com

No

The limit switch has

tripped. See Manual Reset

Limit Switch Figure.

Ensure proper air flow

clearance for axial fan.

Open louvers slightly.

Replace axial fan if it does

not operate.

Ye s

No

Replace limit switch.

27

Page 34

COMBAT® UHA UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL

13.2 Troubleshooting For Automatic Ignition Burner Systems

Start

Are gas & electrical

supplies on?

Ye s

Are external controls

(i.e. Thermostat) on?

Ye s

Is ignition control showing

a "4 flashes" led code?

No

Does flue fan run?

No

No

Ye s

No

Turn on supplies.

Turn on controls.

Press in reset button on

manual reset limit switch

Is 120 V supply at fan

connections?

Burner control faulty or wiring

connections faulty. Repair

or replace as necessary

No

WARNING

Electrical Shock Hazard

Do not touch ignition components.

Voltage from ignition components is high.

Failure to follow these instructions can

result in death or electrical shock.

Ye s

Flue fan faulty; replace

Ye s

Does air pressure switch

change over?

Ye s

Wait 30 - 40 seconds.

Does ignition spark operate?

Ye s

Does the flame light?

Ye s

Is ignition control showing

a "2 flashes" led code?

No

Heater Operating

TROUBLESHOOT ENDS.

Check for too much vent/air inlet duct. Check for blockage in

vent and combustion air circuit. Check for faulty air pressure

No

switch. Check pressure switch hoses for leaks or cracks.

Do not attempt to circumvent pressure switch circuit to

place unit in operation.See Pressure Switch section for details.

Is ignition lead okay and

No

No

Ye s

No

connected?

Is spark electrode okay?

Is the gas valve operating?

To test valve, See

Troubleshooting for Gas

Valves section.

Is the flame current at

least 1 µAmp DC when

the flame ignites?

If problems persist, contact

Roberts-Gordon, LLC at

www.rg-inc.com

Ye s

No

Ye s

Ignition control faulty;

replace.

See Ignition Control section.

Replace valve.

Trace fault in supervision

system. See

Troubleshooting

for Flame Supervision

System section.

For your safety and optimum heater performance,

use only ROBERTS GORDON

Conduct start-up procedure as shown on Page

19, Section 10.

®

replacement parts.

28

Page 35

13.3 Troubleshooting for Flame Supervision System

To measure flame current, connect a 0 - 50 μA DC meter in

series with the flame probe. If the meter reads negative

values, then reverse the test leads.

START

Connect a DC ammeter in

series with the flame probe.

SECTION 13: TROUBLESHOOTING

Is the flame present and

at least 1 µA DC flame

current?

Ye s

Is there a current flowing in the

flame probe circuit with no

flame present?

No

Does lockout occur when

there is a flame present?

No

Heater Operating

TROUBLESHOOT ENDS.

Use General

Troubleshooting section to

No

Ye s

Ye s

No

trace the fault.

Is the connecting lead

damaged? Is the flame probe

damaged or touching earthed

components?

Is inlet burner gas pressure

correct? Is live and neutral

polarity correct? Is

flame probe circuit correct?

No

Repair or replace as

necessary.

If problems persist, contact

Roberts-Gordon, LLC at

www.rg-inc.com

Repair or replace as

Ye s

Ye s

necessary.

Replace ignition control.

NOTE: Minimum flame probe current 1 μA DC. Typical flame probe current 3-5 μA DC.

29

Page 36

COMBAT® UHA UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL

13.4 Troubleshooting for Gas Valves

START

Is gas pressure at inlet of the

valve correct for gas type?

Note pressure found.

Ye s

Does gas pressure at outlet

of the valve rise when

valve turns on?

Ye s

Ye s

Does gas pressure at

outlet of valve return to zero or

lower when valve turns off?

Ye s

Valve Operating

TROUBLESHOOT ENDS.

13.5 Troubleshooting for Combustion Fan

No

No

No

No

Fault elsewhere.

Correct pressure problem.

Valve or ignition control

faulty. Replace with

one of correct type.

Valve faulty.

Replace with one of

correct type.

If problems persist, contact

Roberts-Gordon, LLC at

www.rg-inc.com

START

Does combustion fan run

automatically when there

is a call for heat?

Ye s

Does fan turn on and

off while burner is firing

continously?

No

Fan Operating

TROUBLESHOOT ENDS.

No

Ye s

No

Correct power

supply problem.

Ye s

Fan motor faulty.

Replace with correct type.

Check fan motor leads for

loose connections.

If problems persist, contact

Roberts-Gordon, LLC at

www.rg-inc.com

For your safety and optimum heater performance,

®

use only genuine ROBERTS GORDON

replacement parts.

Conduct start-up procedure as shown on Page 19, Section 10.

30

Page 37

SECTION 14: REPLACEMENT PARTS

See warnings and notes on Page 24, Section 12

before removing or replacing parts.

Burner Components

All serviceable burner parts are accessed by the

door on the side of the heater. Remove the

sheetmetal screws.

14.1 Gas Valve

Remove the gas supply pipe at the heater inlet.

SECTION 14: REPLACEMENT PARTS

½PSI IN

C

ON

Description Part Number

Gas Valve, NG (Models UHA[S] 150 - 225) 90032505

Gas Valve, LP (Models UHA[S] 150 - 225) 90032506

Gas Valve, NG (Models UHA[S] 250 - 400) 90032520

Gas Valve, LP (Models UHA[S] 250 - 400) 90032521

Follow steps in Section 14.2 and Section 14.2.1 to

remove gas valve/manifold.

Replace in reverse order. Verify that the gas flow

direction of the valve is correct. Use a minimum

amount of gas seal on the thread joint. Check that

all the joints are leak free. Reset gas valve.

See

Page 21, Section 10.2.2.

IT IS IMPORTANT THAT ONLY THE CORRECT

GAS VALVE IS USED WHEN REPLACING THESE

CONTROLS.

OFF

31

Page 38

COMBAT® UHA UNIT HEATER INSTALLATION OPERATION AND SERVICE MANUAL

Unscrew

Injectors

Manifold

14.2 Burner Compartment

The burner compartment is

a sealed compartment.

Following any work,

re-seal the compartment

with the gas pipe rubber

seal fully in place and all

screws fitted and tight.

Burner

compartment

cover

Flame probe

Viewing port

for flame probe

Remove flexible

air duct from spigot

Ignition electrode

Viewing port

for ignition electrode

Remove

access plate

Rubber Seal

Remove screws and

pull off burner cover

14.2.1

Burner Injectors

Ensure gas tight fitting of injectors.

Ensure correct alignment with burners.

Ensure all pipe joints are gas tight.

Remove manifold

Burner

venturi

MODEL

Orifice Quantity 7 8 9 10 11 12 14 14

Natural Gas (G20)

Orifice Marking 43 43 2.25 mm 2.25 mm 2.25 mm 40 40 40

RG P/N 91930043 91930043 91930225 91930225 91930225 91930040 91930040 91930040

Propane (G31)

Orifice Marking 1.35 mm 1. 35 m m 54 54 54 1. 45 mm 53 53

RG P/N 91930135 91930135 91930054 91930054 91930054 91930145 91930053 91930053

UHA[S]

150

UHA[S]

175

UHA[S]

Manifold

screws and pull

out manifold

Marking

Folded

Hem

200

UHA[S]

225

UHA[S]

250

UHA[S]

300

Burners

Injectors

Burner

Screws

UHA[S]

350

UHA[S]

400

32

Page 39

14.3 Ignition Electrode and Flame Probe

Burners

SECTION 14: REPLACEMENT PARTS

Limit