Page 1

Operation Manual

Range Hood

CXW-200-A812

CXW-200-A608

Page 2

1. Important Information 1

2. Product Overview 1

3. Packing list 2

4. Installation 3

5. Use Instruction 6

6. Maintenance and Services 7

7. Circuit Diagram 9

8. General Troubleshooting 9

.........................

................................

........................................

.........................................

...................................

..................

..................................

.....................

CONTENTS

Page 3

Improper oper ation may cause hazardous effect.

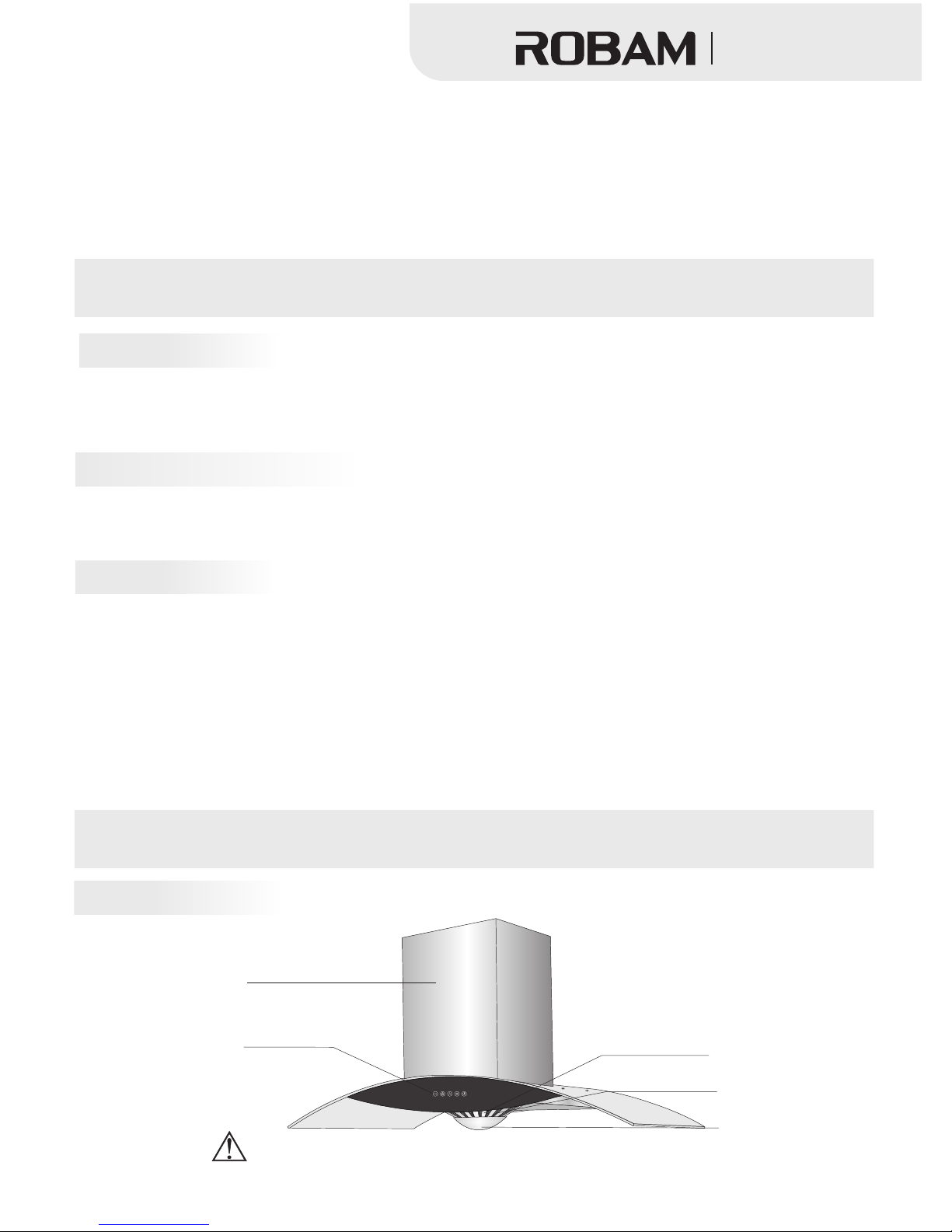

Panel

Switch

Oil mesh

Oil cup

Filter

吸油烟机

Range Hood

图1

Important Information

Dear users

Product Overview

New Package of Range Hood

Dispose Old Range Hood

Before use new range hood

Know your range hood:

1

A812

Thank for yo ur buying our range hood. Please accept our best regards. Please read this operation manual

carefully before installatio n and operation.

* The pictures in the manual for referen ce only. If picture s and actua l are discrepancy, please see actual object.

ROBAM keep s right to update structure or appearance without a dditional notice.

Please settle those packages carefully in order to protect environment.

Don’t allow children to play plastic film and package, it may cause asphyxia. Please avoid children near

package material.

If the old range hood can’t work, we suggest users to dispose them after confirming without any usage.

There are something useful material inside of old range hood, please assist us to dispose so as to

protect environment.

This range hood exhaust fume outside.

Please read this manual and all information carefully before installation and operation. Please comply

with our suggestion. If it’s necessary, please read manual for gas hob. And please keep these manual

carefully for future reference.

This manual is available for different models. So you may find different description with your own range

hood.

If range hood has obvious damage, please don’t electrify and contact operator.

Children and disability are not allowed to use range hood independently in order to avoid accident.

Page 4

A812

317

895(600 )

370

520

568

545(500 )

Note: The size ju st for reference. Size i n the brackets is s pecific to A608 hood. (Unit: mm)

Packing List

S/ C

Name

Quantity

S/ C

Name

Quantity

1

12

11

6

5

4

3

2

Range Hood

Plastic expansion tube

Manual

1 unit

4 unit

1 unit

Check Valve

1 pair

ST 4x18tapping screw

10 pieces

Φ175 (OD) aluminum exhaust pipe

13

14

ST 4x60wooden screw

4 pieces

10

Stop block for b racke t

1 unit

M6 metal expansion tube

1 pair

7

Oil cup

1 pieces

Bracket

1 piece

8

Φ175 (OD) exhaust pipe joint

9

Exhaust pipe tape

Fixed bar for exhaust pipe

1 pair

吸油烟机

Range Hood

Packing List

Size & Dimensio n

A812:895 x 520 x 545(mm)

A608:600 x 520 x 500(mm)

≤58dB

A812:25kg A608:24kg

≥90%

≤4W

204W

200W

Size(L x W x H)

Rated Main Motor Input Power

Max Lighting Po wer

Rated Whole Machine Input Power

Grease separa tion degree

Net Weight

Noise

≥220Pa

≥310Pa

≥23%

≥78%

≥98%

Normal Odor Reduction Degree

Instantaneous Odor Reduction Degree

Max Static Pres sure

Total Pressure Efficienc y

Nominal Wind Pr essure

Model

Power Supply

Air Flow Rate

Note: The toler ance between listed air flow r ate and actual da ta should be less than 10%.

CXW-200-A812

CXW-200-A608

Please check fo llowing items after opening the carton:

Technical Parameter

2

3

17m /min

220-240V~ 50H z

Page 5

吸油烟机

Range Hood

3

Installation

War ni ng

Preparation

Notice

1.2The range hood is prohibited from exhausting fume into hot flue , which is used for exhausting gas fuel or other

fuel fume.

.When installing metal expansion tube, ensure perfect match of tube diameter with hole diameter to prevent

accidental falling off from loosened expansion tube due to excessive hole expansion.

3.Please keep good ventilation in the room when range hood is working as while as and gas or other fuel combustion .

4.If flue outlet is smaller than air duct, or the air duct is too long, the absorbing will be affected.

5.This product is only used in the home daily. Don’t use it in the special environment (such as outside), or exhaust

dangerous or explosive air. Please put hood in the dry, good ventilation or safe environment before installation.

●

●

1. 2. 3 4

Ambient environment

Range hood shall be installed away from positions with too many windows or doors, which will lead to strong air

convection and thus reduce the effect of fume removal.

Tools:Installing range hood requires the following tools:

impact electric drill( with drill bit); Wrench; .Screwdriver; .Ruler

●

●Don' t conn ect electricity before ins tallation avo iding from electric shock.

●

●

●

●

●Don' t inst all range hood too high or disturbed by air. It may re duce absorbing effect.

●Please keep eno ugh space when installing kitchen cabinet s o as to maintain and repair.

●Please keep hoo d parallel when installation.

● Please keep earth well. ( It’s dangerous to connect ho od with water pipe or gas pip e, it may cause fire or

explosion).

●Pleae use appoi nted accessories to install hood or it may fall d own.

●If wire is broken, only manufa cture, appointed serv ice department or other professional e ngineers to

change it. Don't change,stretch ,press or bind wire, or it may cause wire destroyed, fire or electric

shock.

Installatio n and c ircuit setting must be done by experienced professionals . No n-professionals are not

allowed to inst all, dismantle and repair the hood.

Do not expose the h ood if your kitchen is under ren ovation, beca use construction materials, dusts, pain t,

coatings, an d emitted gases will corrode and t arnish the hood surfa ce. Therefore, it is recommended to

install it afte r the renovation is complete d.

Don' t install the hood on wood and othe r combustible walls. The wall shall be made of noncombustible

materials wit h enough strength.

The ho od may have very sharp edges. So, please wear protec tive g loves during hood installat ion, c leaning

or repair.

Please be care of e lectricity inside of wall when operator dig ging holes on the w all. It may causes fire.

Page 6

Picture 2

bracket

235mm

110mm

55mm 55mm

505 mm

65±2mm

35±2 mm

Stop blo ck

for brac ket

A812

A812

380

520

430

Picture 1

Ceiling

6

0

0

-8

0

0

mm

6

5

0

-

7

5

0

m

m

8

0

0

-9

0

0

m

m

Drawin g pan el

10mm

Ceiling

Removable panel

Removable baffle

6

0

0

-8

0

0

mm

6

5

0

-

7

5

0

m

m

8

0

0

-

9

0

0

m

m

10mm

(Picture 1 -1 installation without re movable baffle) ( Picture 1-2 intallati on with removable baffle )

Decora tiv e panel

Picture 3

wall

Instal lat ion size on t he ce iling (mm )

Size in th e bra ckets is sp eci fic to A608 hoo d.(Uni t: mm )

Range ho od

Projec tio n size

Duct hol e siz eφ20 0mm

吸油烟机

Range Hood

A812

Installation

●Install bracket

D

rill four 60-70mm-deep holes by Φ8mm drill bit at positions corresponding to the hanging plate dimension.

Force the expansion tube into the holes and fasten firmly the hanging plate by the supplied four 4×60

wooden screws. Drill a 50-55mm-deepΦ10mm hole at position 65mm high from the four holes and force the

M6 metal expansion tube into the hole.(picture 2)

Adjust the drawing panel

Pull the brackets of the panel up to an appropriate height and then pull the panel sides to find the drawing

panel. Remove the protective film, and insert it along the gap between th e decorative pan el and the housing.

Then adjust it to the pro per height .

●

4

● 650

2

3

650

Location:Reference dimension for installation of removable baffle is (mm),but subject to adjustment

according to actual situations. The installation hole(picture ) shall be centered vertically with the hood body and

kept horizontally.

Please see picture for the installation size on the ceiling.

Operator shall install range hood upright the gas hob with recommended lowest height between hood bottom

and cooktop is mm (if maximum installation distance is specified in the instruction of installation, this shall be

taken into consideration;

The installation height can be reduced according to actual situations when there is electric hob).

Mou nting h ole

of th e drawi ng

pan el

ST4 X18 sel f-tap ping

scr ews

895 (600)

520

447 .5

111

Page 7

吸油烟机

Range Hood

The hole diameter shall be cl ose to that of the exhaust pipe. Undersi zed hole will cause poo r

exhaust efficienc y, mor e nois es and lower airflow. The connection between the pipe and the ho le

or the public flue mu st be sealed tightly to ensur e that, the p ipe and the c heck val ve or public flue

is con nected securely . The blades at the check valve connection or pu blic flue connection must

be flexible.

Picture 4

Body

Check v alv e

Check v alv e con nection

ST4×18 sc rew

Check v alv e sea ls

Not e: During installation, s traighten the alumi num ex haust pipe to avoid

noi ses in semi-stretched sta te. Excess part may be cut with a w ire cutter.

Snap

Slot

●Install th e aluminum exh austing pi pe (The public flue pipe do n't need to drill ho les).

a.

b.

c.

●Connect aluminum exhaustin g pipe

Aluminum e xhaust pipe and hob facing the wind ow:

Remove one of the glasses a nd install a plywood with ve ntilation holes or punch directly on the glass.

Hob away from the window:

Install the aluminum e xhaust pipe throug h the window that is close to the hob and connected outside, or

install it by punching on the wall that is close to the hob and conn ected outside.

Drill hole thr ough the wall

Determine the location of the aluminum exhau st pipe against the wall and d raw the drilling range (i.e. a

circle slight ly larger than the pipe OD) . Use a long drill bi t to d rill through the wall. P ay attention to the wall

structure and mate rial, so as not to destroy other part s of th e wall.

Firstly, Insert the othe r pipe end to the pipe connection and stic k with tapes. Then, st raighten th e aluminum

exhaust pipe to conn ect the public flue pipe ( If no public flue pipe , p lease pull the al uminum exhasut pipe to

outdoors directly). This can be done directly when the wall hole is larger t han the pipe. Otherwise , there are

four pip e ends (OD: 14 0 , 150, 16 0 , an d 170 respect ively) to be chosen f rom according to the hole size .

Then cut the excess pa rt wi th sc issors.

Then, insert the pipe end with fixed bar to the exte rnal ring of check valve , and stick with tape. Fina lly, put

4 snaps in the 4 slots, and revolv e clockwise to fix exhasu t pipe on th e check valve.

Φ175 alu min um exhaus t pip e

Exhaus t pip e tape

Φ175 exh aus t pipe conn ect ion

Cut the ex ces s part smal ler t han the hol e

Φ180

Φ170

Φ160

Φ150

Φ140

Exhaus t pip e tape

Install aluminum exhaust pipe

Picture 5

5

●

●

Install th e hood body

Fix the ch eck valve as shown in Picture 5. Then direct the hanging holes in t he back o f hood at the hooks of

hitching foots accor ding to Picture 2, and press them together. Shake the body to check if it's hu ng securely.

After the body is m ounted, inst all the hitching fo ot stopper and gaskets to the M 6 metal expansion pipe, and then

tighten the nuts (to prevent accidental decoupling of the body under external force).

Install th e drawing panel

Aas shown in Picture 1-1, there is some gaps between the drawing pa nel and the top plate. Pu sh the panel against

the top plate and then fix it to the top plate with ST4×18 sc rews.

Don' t need to adjust a nd install drawing pane l in Pi cture 1 -2

Page 8

Use Instruction

吸油烟机

Range Hood

High

Low

Light

Power

Auto

6

Plug in and 3 tick fr om the buzzer will indicate qu alified insta llation. The hood is in standby.

●Press the light b utton to turn on the light and rep ress to turn it off.

● Press the power button, the light of “Powe r” buttonturn on, press

“High” b utton, the motor work with high speed. If press the “Low”

button,i t will work in the normal speed states.

●Afte r connect with p ower,pre ss “Power” button, the li ght of “Power”

turn o n, press “Low”, the motor works with low speed, press “High”

button again, it will change to high speed level.

●When the power icon is lit up and only the s potlight is “ON”, press

the “Power” button gently and the spotlight will be turned off directly; if

the fan is working, press the”Power” button, the power icon will flas h

and the fan will be shut down after 1min. (The fu nction of “Light”, “ High”,

“Low” and “Auto” bu tton can’t be working under delay status). If the

“Power” icon is spotlight, Press th e “ Power” button again, all functio ns

will be disable d.

● When " Po wer" icon turns on, press "Auto", the gas se nsor and

heat sensor will be turned on. During cooking status, if the gas

concentrati on or tempe rature reaches default , hood will turn on high

speed, and " High" icon will tur n on. Just press "Power" or " Auto "

to cancel gas sen sor or heat sensor function.

Auto

Light

Low High

Power

Switch Control Panel

Page 9

Note: when inst all light, just push light on th e oil mesh by hands.

●Raise it outward forcibly to remove the spotlight from

the hood. Pull out the connector to replace the spotlight.

●Insert a small fl athead screwdriver or some thing

sharp in the gap be tween the light cover and hood.

吸油烟机

Range Hood

●Use a Phillips sc rewdriver to remove the six

screws on the gla ss cover, then remove glass cov er.

●Then remove scr ews from switches to maintai n or

replace switc hes.

Notes

Light Removal

Switch Removal

7

Warning

Maintenance and Service

1.The re is a risk of fire if the appliance is not cleaned according t o the methods stated in the instructions.

2. Clea ning and maintenance must be done when the power is disconnected. Keep the electrical co mponents

(e.g. motors, switches a nd connecto rs) away from water to avoid acc idents. Don’t touch plug, electri c

components or switch es by wet hands.

3. Usually, hood body don’t nee d to disassemble. Only professional engineers can disassemble range hood.

Plug must be taken off before disassembly hoo d.

4.Don' t rinse with water to avoid accidents.

5. put ou t the fire promptly after use. Don't use the hob to bake the hood directly. Don't cook food directl y

under the hood. Otherwise, it will damage th e hood, causing accidents.

●

●Don' t use hi gh detergent , we recommend to u se

●Don' t leav e blot on the surface of hood too long time.

●Don' t clea n hood by cleaning ball, brush or other harsh too ls avoiding fro m scoring.

●Please wear glo ve when clean or maintain hood avoiding from hu rt.

●

●Don' t touc h opening bulb or closing for short time bulb avo iding from scald.

●

The hood shall be c leaned and maintained regularly dependi ng on the surroun dings, so as to keep its

cleanness & efficiency a nd extend its service life.

We recommend to: Clean the e xhaust fume collecting hood and range hood bo dy after each coo king.

In order to ensur e smooth discharge of fumes, t he filter shall be cleaned regularly . Be c areful to avoid

damage.

mild detergen t and clean it by soft wipe. Don’t t ouch

switches by det ergent .

When the oil reac hes above 2/3 of the oil cup, rota te the cup right to t oss away the oil.

Please unplug i t during long-term shutdown.

Page 10

Oil cup

Filter mesh

Filter mesh

Impeller

Cap

Air flue

Cover plate

1. Pull out the plu g;

2. Unscrew the tw o screws from the back of the deco rative panel. T hen pull decorative panel up forcibly;

3. Remove the dra wing panel from the decorative panel;

4. Use a Phillips s crewdriver to unscrew the fastening screw s on the cover to remove the cover;

5. Unscrew the fa stening screws on the retain ing ring to remov e the retaining ring;

6. Unscrew the ca p clockwise and take out the imp eller vertica lly;

7 . Remove the oil cu p and then remove the filter mes h

The installat ion and removal procedure in r everse.

(When mountin g the impeller, apply some lubricant to the shaf t hole.)

Note: Step 3 is unn ecessary if no drawing panel i s installed.

Retainer ring

Switch

Motor

Body

Glass

Decorative pa nel

Drawing panel

吸油烟机

Range Hood

heat sensor

gas sensor

A812

Gas sensor and heat sensor removal

General Plan of Body Installation and Removal

8

● Use a Philli ps screwdriver t o remove the

two scr ews on the gas sens or and heat

sensor, then rep lace it.

Page 11

The light is dama ged or poorly

connected

The body is tilt

The impeller is l oose and the

cap is not tighte ned

The power is not co nnected

properly or the re is power

failure

The power outle t is not well

grounded

Cause

No response aft er pressing any button

(e. g. t he impeller does not rotate,

light is “OFF”)

Light “OFF” after pressing the

light button

Induced curre nt on the hood body that

paralyzes han ds

No oil in the oil cup after a period of time

Abnormal sound during impeller running

FailureS/C

1

2

3

4

5

吸油烟机

Range Hood

M

General Troubleshooting

Circuit Diagram

9

Warning

1. Please unplug the

p o w e r c o r d w h e n

connecting the plug-ins

or replacing any part.

2. If the hood's power

cord is damaged, it must

be rep l aced b y o ur

maintenance staff.

3. Keep the hood

away from fire to avoid

accidents.

Warning

There sh all be adequate ventilat ion of the ro om when the range hood is used at the same time as app liances

burning gas or ot her fuels.

- Do not flambé und er the range hood.

- This appliance is no t inte nded f or use by persons (including children) with reduced physical, sensory, o r

mental capacities, or lack of experi ence and knowledge, unless they have been gi ven supervision or

instruction c oncerning use of the applian ce by a person resp onsible for their safety.

- Children shou ld be supervised to ensure tha t they do not play wi th the appliance.

- If the supply cord is damaged, it must be replaced by the manufac turer, its service agent or simi larly

qualified per sons in order to avoid a hazard.

Accessible pa rts may become hot when used wit h cooking appli ances.

The minimum d istance between the supp orting surface for the coo king vessel s on the hob an d the lowest

part of the range hood. When the range hood is located above a gas appliance, this dis tance shall be at least

65 cm. I f the instructions for in stallation for the gas hob spe cify a greater distanc e, this has to be t aken into

account.

-

-

Yellow/Green E

brown

blue

blue

blue

Yellow/Green

black

red

brown

orange

220-240V~

L

N

EL

Terminal box

Control circuit

red

yellow

gas-sensor

Operating Circuit

heat-sensor

K1

K2

K3

Page 12

Edition: A/ 2

Loading...

Loading...