RKI Instruments GD-70D-NH3, GD-70D-MCH4-20K, GD-70D-DEA, GD-70D-DMA, GD-70D-MR41 User manual

...Page 1

Gas Detector Head

Part Number: 71-0446

Revision: P4

Released: 4/2/21

GD-70D Series

Operating Manual

Request for the Customers

• Read and understand this operating manual before using the detector.

• You must operate the detector in accordance with the operating manual.

• Regardless of warranty period, we shall not make any compensation for accidents and damage

caused by using this product.

The compensation shall be made only under the warranty policy of products or parts

replacement.

• Because this is a safety device, daily and biannual maintenance must be performed.

• If you find abnormalities in the detector, please contact our local representative immediately.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

<Contents>

Request for the Customers ..................................................................................... 1

1 Outline of the Product .................................................................................................... 4

1-1 Preface ............................................................................................................. 4

1-2 Product Purpose ............................................................................................... 4

1-3 Definition of DANGER, WARNING, CAUTION and NOTE .............................. 5

1-4 Method of confirmation for CE marking type .................................................... 5

2 Important Notices on Safety .......................................................................................... 6

2-1 Danger Statements ........................................................................................... 6

2-2 Warning Statements ......................................................................................... 6

2-3 Caution Statements .......................................................................................... 7

3 Product Components ..................................................................................................... 8

3-1 Main Unit and Standard Accessories................................................................ 8

3-2 Outline Drawing ................................................................................................ 9

3-3 Names and Functions for Each Part................................................................. 10

3-4 Operation Diagrams ......................................................................................... 14

4 Installation ...................................................................................................................... 16

4-1 Requirements ................................................................................................... 16

4-2 Precautions for Installation Sites ...................................................................... 16

4-3 Precautions for System Designing ................................................................... 18

4-4 Proper use of alarm contact ............................................................................. 19

4-5 Installing the Detector ....................................................................................... 20

4-6 Wiring the Detector ........................................................................................... 22

4-7 Making Tubing Connections ............................................................................. 34

4-8 Disposal ............................................................................................................ 35

5 Operation ....................................................................................................................... 36

5-1 Preparation for Start-up .................................................................................... 36

5-2 Starting Up the Detector ................................................................................... 36

5-3 Turning Off the Detector ................................................................................... 38

5-4 Basic Operation ................................................................................................ 38

5-5 Modes ............................................................................................................. 39

6 Detection Mode .............................................................................................................. 41

6-1 Gas Alarm Activation ........................................................................................ 41

6-2 Fault Alarm Activation ....................................................................................... 47

6-3 External Output Operation ................................................................................ 47

6-4 Other Functions ................................................................................................ 50

6-5 About LONWORKS (LN specification) ............................................................. 53

7 Alarm Test Mode ............................................................................................................ 57

7-1 Alarm Test Mode ............................................................................................... 57

8 User Mode ..................................................................................................................... 59

8-1 User Mode ........................................................................................................ 59

9 Maintenance Mode ........................................................................................................ 65

9-1 Environmental Setting 1 "2-9" ........................................................................... 70

9-2 Alarm Value Setting "2-9" - "SET 1" .................................................................. 71

9-3 Fault Alarm Test "2-9" - "SET 4" ....................................................................... 73

9-4 Environmental Setting 2 "2-10" ......................................................................... 74

9-5 Date/Time Setting "2-10" - "SET 1" .................................................................. 79

9-6 Energized/De-Energized Contact Setting "2-10" - "SET 6" .............................. 81

9-7 ETHERNET Setting "2-10" - "SET 18" ............................................................. 83

10 Maintenance .................................................................................................................. 86

10-1 Maintenance Intervals and Items ........................................................ 86

10-2 Calibration Overview ........................................................................... 86

10-3 Calibrating with the Target Gas ........................................................... 90

10-4 Calibrating with a Surrogate Gas (Sensors with Factors) ................... 93

10-5 Calibrating with a Gas Bag (Calibrating with HCl) ............................... 99

10-6 Calibrating with a Humidifier (MOS Sensors) ...................................... 103

10-7 Calibrating a Pyrolyzer Unit ................................................................. 107

10-8 Flow Rate Adjustments ........................................................................ 11 0

10-9 Replacing Parts ................................................................................... 112

Find Quality Products Online at: sales@GlobalTestSupply.com

- 2 - GD-70D

www.GlobalTestSupply.com

Page 3

10-10 Storing the GD-70D ............................................................................. 115

11 Troubleshooting ............................................................................................................. 116

12 Product Specifications ................................................................................................... 119

12-1 Common Specifications ....................................................................... 119

12-2 Specifications for Each Model ............................................................. 119

12-3 Specifications for Each Sensor Type ................................................... 120

12-4 Full Scale and Alarm Points ................................................................. 123

13 Calibration Parts List...................................................................................................... 126

14 Replacement Parts List ................................................................................................. 129

Warranty Policy ....................................................................................................... 142

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

- 3 - GD-70D

Page 4

GD-70D

4 - 20 mA specification

Analog transmission

GD-70D-NT

NT specification

2-wire type DC power-line communication

GD-70D-EA

EA specification

Ethernet and analog transmission (4 - 20 mA)

GD-70D-LN

LN specification

LONWORKS

1

Outline of the Product

1-1 Preface

Thank you for choosing our GD-70D Series gas detector head. Please verify that the model number of the

product you purchased is included in the specifications on this manual.

This manual explains how to use the detector and its specifications. It contains information required for

using the detector properly. All users must read and understand the operating manual before using the

detector.

1-2 Product Purpose

• This is a fixed type gas detector head which detects gas leaks in semiconductor factories, etc.

• The gas detector is a safety device, not an analyzer or densitometer which performs quantitative/qualitative

analysis/measurement for gases. You must understand the features of the detector before using it, so that

you can use it properly.

• The detector detects abnormalities in the air caused by the presence of gas (or oxygen deficiency) with the

built-in gas sensor unit. The concentrations of detected gases are shown on the LCD.

• The built-in pump in the detector draws gas to perform gas detection.

• The detector has two-step gas alarm contact and fault alarm contact.

• The detector outputs the gas concentration in 4 - 20 mA or digital data.

• The communication method for each specification is as follows.

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 4 -

www.GlobalTestSupply.com

Page 5

CE Marking

1-3 Definition of DANGER, WARNING, CAUTION and NOTE

This message indicates that improper handling may cause serious damage

DANGER

WARNING

CAUTION

on life, health or assets.

This message indicates that improper handling may cause serious damage

on health or assets.

This message indicates that improper handling may cause minor damage on

health or assets.

NOTE

This message indicates advice on handling.

1-4 Method of confirmation for CE marking type

The CE marking is labeled on the detector in case of comply with CE marking. Please confirm the

instrument specification before using. Please refer to the Declaration of Conformity that is at the end of this

manual if you have CE marking type.

You can confirm instrument specification to see the CE marking as follows.

CE marking label (Back of front cover)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

- 5 - GD-70D

Page 6

Power Supply

2

Important Notices on Safety

2-1 Danger Statements

DANGER

This is not an explosion-proof device. You must not use it to detect gases exceeding the lower limit of explosion.

2-2 Warning Statements

WARNING

Before turning on the detector, always check whether the voltage is properly applied. Do not use an unstable

power supply because it may cause malfunctions.

Need of grounding circuit

Do not cut the grounding circuit or disconnect the wire from the grounding terminal.

Defects in protective functions

Before starting the detector, check the protective functions for defects. When defects are found in the protective

functions, such as protective grounding, do not start the detector.

External connection

Before connecting the detector to external equipment or an external control circuit, securely connect it to a

protective grounding circuit.

Tubing

The detector is designed to draw gases around it under normal atmospheric pressure. If excessive pressure is

applied to the sampling inlet and outlet (GAS IN, GAS OUT) of the detector, detected gases may leak from the

flow system and pose dangers. Be sure that excessive pressure is not applied to the detector when it is used.

Detected gases must be exhausted from the outlet (GAS OUT) on the bottom of the detector to a safe place

using an exhaust tube.

Handling the sensor unit

Do not disassemble the electrochemical type sensor unit (ESU) or galvanic cell type sensor unit (OSU) because

they contain electrolyte. Electrolyte may cause severe skin burns if it contacts skin and may cause blindness if it

contacts eyes. It may discolor or damage clothing. If contact occurs, rinse the area immediately with a large

quantity of water.

Zero adjustment (AIR Adjustment) in the atmosphere

When zero adjustment (AIR Adjustment for oxygen deficiency alarm) is performed in the atmosphere, check the

atmosphere for freshness before beginning the adjustment. If other gases exist, the adjustment cannot be

performed properly and the detector will not properly detect gas.

Operation in a gas

Do not operate the detector in a place where flammable/explosive gases or vapors are present. Operating the

detector in such an environment will lead to extreme dangers.

Response to a gas alarm

Issuance of a gas alarm indicates that there are extreme dangers. Take proper actions based on your judgment.

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 6 -

www.GlobalTestSupply.com

Page 7

Definition of Terms

Do not use a transceiver (walkie-talkie) near the detector.

2-3 Caution Statements

CAUTION

Radio waves from a transceiver near the detector or its cables may disrupt detector operation. When using a

transceiver, it must be used in a place where it disturbs nothing.

Do not turn the detector on less than 5 seconds after it was turned off.

Restarting the detector less than five seconds after turning it off may cause errors.

Verify that the reading on the flow rate indicator corresponds to the specified flow rate before using the

detector.

If it does not correspond to the specified flow rate, gas detection cannot be performed properly. Be sure the flow

rate is stable.

Attach the dust filter before using the detector.

Before using the detector, attach the specified filter to prevent disturbances by possible gas absorption or air

dust.

The dust filter used depends on the gas being detected. For more information on dust filters, please contact RKI.

Observe the operating restrictions to prevent condensation inside the tube.

Condensation formed inside the tube causes clogging or gas absorption, which disturbs accurate gas detection.

Thus, condensation must be avoided. In addition to the installation environment, carefully monitor the

temperature/humidity of the sampled area to prevent condensation inside the tube. In particular, when detecting

a corrosive, water-soluble gas, such as a strong acid gas, the gas is undetectable and furthermore may corrode

internal parts. Please observe the operating restrictions.

Do not use the external output of the detector to control other devices.

This is not a control device. You are not allowed to use its external output to control other devices.

Do not disassemble/modify the detector, or change the settings unless necessary.

Disassembling/modifying the detector will invalidate the guarantee of the performance. Changing the settings

without understanding the specifications may cause alarm malfunctions. Please use the detector properly in

accordance with the operating manual.

Do not forget to perform regular maintenance.

Since this is a safety device, regular maintenance must be performed to ensure its safety. Continuing to use the

detector without performing maintenance will compromise the sensitivity of the sensor, thus resulting in

inaccurate gas detection.

Find Quality Products Online at: sales@GlobalTestSupply.com

- 7 - GD-70D

www.GlobalTestSupply.com

Page 8

<Standard Accessories>

3

Product Components

3-1 Main Unit and Standard Accessories

<Main Unit>

• Operating manual

• Protective rubber cap (to be removed when using the

detector)

• Dedicated handling lever (for wiring)

• Dust filter

• Interference gas removal filter

(to be supplied with sensor units for certain gases)

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 8 -

www.GlobalTestSupply.com

Page 9

Pyrolyzer Unit

(Unit: mm)

GAS IN

GAS OUT

Sensor unit display

Operating switch

Screw for grounding earth rod

External wire hole

Connector for PLU

Power switch

<Pyrolyzer Unit (PLU-70)(Option)>

* This is needed in “pyrolyzer + electrochemical type (ESU)” and “pyrolyzer + pyrolysis-particle type

(SSU)”.

For more information on the pyrolyzer unit (PLU-70), see the separate operating manual.

3-2 Outline Drawing

M5 mounting hole

Display

Protective cover for power switch

Connector for PoE

Find Quality Products Online at: sales@GlobalTestSupply.com

- 9 - GD-70D

www.GlobalTestSupply.com

Page 10

Wall-mounted unit

Main unit

Pump unit

Sensor unit

MODE key

Lock lever

Sensor unit nameplate display window

Power lamp

First alarm lamp

Second alarm lamp

Fault lamp

Gas name display

Concentration

Unit display

Concentration

Alarm setpoint

Flow rate

indicator

Communication

Maintenance

indicator

Inhibit indicator

Pyrolyzer unit

CAUTION

the unit compromises its original performance or causes malfunctions.

3-3 Names and Functions for Each Part

The detector consists of the following units.

Each unit consists of precision parts. When a unit is detached, be careful not to drop it. Dropping

<Front Panel and Character LCD>

TEST/SET key

▲key

▼key

⑭

bar indicator

⑮

indicator

⑫

value display

⑰

indicator

⑯

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 10 -

www.GlobalTestSupply.com

⑱

⑲

⑳

connection indicator

⑬

⑪

Page 11

MODE key

Used to enter User and Maintenance Mode.

It is also used to cancel or skip in a specific mode.

TEST/SET key

Used to enter the test mode.

It is used for confirmation in a specific mode.

③

▲ key

Used to change screens or change a value (UP).

④

▼ key

Used to change screens or change a value (DOWN).

⑤

Lock lever

Lever to lock the main unit. Push it to attach or detach the main unit.

⑥

Sensor unit nameplate

display window

Window to view information on the currently installed sensor.

⑦

Power lamp (POWER)

Power lamp. Turns green when the power is on.

⑧

First alarm lamp

(ALM1)

First alarm lamp. Turns red when the first alarm is reached.

Second alarm lamp

(ALM2)

Second alarm lamp. Turns red when the second alarm is reached.

⑩

Fault lamp (FAULT)

Fault lamp. Turns yellow when an abnormality is detected in the detector.

⑪

Gas name display

Displays the gas name in chemical formula (e.g. Silane = SIH4).

Concentration value

display

Displays the gas concentration.

⑬

Unit display

Displays the unit according to the specification (ppm, ppb, vol%, %, %LEL).

Concentration bar

indicator

The detectable range (full scale = FS) is divided into 20 segments. The

increase in concentration is displayed in proportion to the full scale.

⑮

Alarm setpoint

indicator

The alarm setpoints (AL1 and AL2) are indicated on the concentration bar.

⑯

Flow rate indicator

Displays the flow rate. When the line is in the middle of the indicator, the

flow rate is normal (0.5 L/min).

⑰

Communication

indicator

For GD-70D-NT, this indicator is displayed while transmitting data with the

upper unit (TX, RX).

⑱

Maintenance indicator

Displayed while in Maintenance Mode. When this indicator is displayed, the

alarm contact is disconnected and there are no alarms.

⑲

Inhibit indicator

Displayed when the inhibition (point skip) is set.

⑳

Pyrolyzer unit

connection indicator

Displayed when the dedicated pyrolyzer unit (PLU-70) is connected.

①

②

⑨

⑫

⑭

<Main Unit>

The main unit of the GD-70D houses the sensor unit, pump unit,

and circuitry for the detector. The main unit installs to the

mounting plate’s terminal plate.

<Pump Unit>

The pump unit gets installed in the main unit. It draws sample into the detector at 0.5 L/min.

Find Quality Products Online at: sales@GlobalTestSupply.com

- 11 - GD-70D

www.GlobalTestSupply.com

Page 12

adjustment).

Mounting hole

10-point terminal plate: Connections for power supply,

signal cables and other external wires.

Locking lever: Locks the main unit to the mounting plate.

<Mounting Plate>

The mounting plate gets installed to the installation site. The main unit connects to the mounting plate

using the 10-point terminal plate.

<Sensor Unit>

A sensor unit installed in the detector is the same regardless of

the detection principle which means sensor units are

interchangeable. Each sensor unit has a different color that

corresponds to the detection principle as shown below. Handling

of the sensor unit depends on the detection principle.

CAUTION

• The sensor unit must be handled carefully to ensure quality. When the sensor unit is stored, a

dedicated warehouse and power equipment for the sensor unit are needed. In principal, the sensor

unit must not be detached from the detector when it is handled or stored.

• Be sure that the sensor unit is installed properly.

If a sensor unit is of different specification or principle than the one shipped from the manufacturer, a

message will be displayed on the detector LCD (C-02).

If this message is displayed, make sure you are using the correct sensor unit.

• After the sensor unit is replaced, always perform a gas calibration (zero adjustment and span

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 12 -

www.GlobalTestSupply.com

Page 13

Electrochemical

• Do not disassemble the sensor unit because it contains electrolyte. If contact

Pyrolysis-particle

Although the sensor unit contains radioactive materials, it is certified as a

Semiconductor

• Before using the sensor unit, it needs to be warmed up for a specified time.

Unpowered time

Suggested warm-up time

SGU-8541 (H2)

SGU (Others)

10 minutes or less

10 minutes or more

2 hours or more

1 hour or less

30 minutes or more

2 hours or more

24 hours or less

1 hour or more

4 hours or more

72 hours or less

4 hours or more

24 hours or more

10 days or less

2 days or more

2 days or more

Less than 1 month

7 days or more

7 days or more

Less than 3 months

14 days or more

14 days or more

3 months or more

1 month or more

1 month or more

Dedicated case

Dedicated case

type (ESU)

type (SSU)

occurs, rinse the area immediately with a large quantity of water.

• The sensor unit identifies the storage direction. Put the sensor unit in the

dedicated case while handling it. Do not place it on its side or upside-down.

• When a new sensor unit is installed, it must be warmed up.

Although warm-up time is different depending on the type of the installed

sensor, it is recommended that warm-up should be performed for three hours or

more. Please contact RKI for more information.

• The sensor unit must be stored in a clean, cool and

dark place away from direct sunlight. Some types of

the sensor units cannot be stored together with other

units. Please contact RKI for more information.

•

specified designing certification device, which is regarded as a device

having no influences on health. Observe the "Safety Manual" which

stipulates conditions for the certification. To dispose of the sensor unit, you

must return it to us. You do not need to take any additional actions.

• The sensor unit contains a small amount of radioactive materials. Do not

disassemble it, or dispose of it like other wastes.

• The sensor unit must be put into the dedicated case specified by us, and

stored away from direct sunlight in a clean place

where the temperature and humidity are maintained

at a normal level and where appropriate measures

are taken to prevent the sensor from being taken out

easily.

• When the sensor unit is transported out of your

factory, please use a transportation company which

can handle specified designing certification devices

(L-type packages).

• For more information, see the "Safety Manual".

type (SGU)

The sensor unit is warmed up sufficiently in our factory before it is delivered to

you. Therefore, after you receive the sensor unit, please use it as soon as

possible so that unpowered time is minimized.

• The warm-up time before using the sensor unit is related to how long the

sensor unit was unpowered.

• To store the sensor unit in an unpowered state, it must be stored under

normal temperature/humidity in a clean place away from direct sunlight.

Find Quality Products Online at: sales@GlobalTestSupply.com

- 13 - GD-70D

www.GlobalTestSupply.com

Page 14

Galvanic cell type

• Do not disassemble the sensor unit because it contains electrolyte. If contact

Sensor unit

Flow

Pump

POWER INPUT (24

VDC)

Power supply part

Gas alarm contact

Alarm contact controller

Transmitter

EA specification)

Amplifier

Controller

Display

Operating unit

4 - 20 mA specification:

(OSU)

occurs, rinse the area immediately with a large quantity of water.

• The sensor unit must be stored under normal temperature/humidity in a clean

place away from direct sunlight.

3-4 Operation Diagrams

<Electric Diagram>

(ALM1, ALM2)

Fault alarm contact

(FAULT)

* Standard setting of

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 14 -

contact activation

De-energized

(De-energized at a

normal state)

ON-ALARM

(Closed contact at

an alarm state)

(4 - 20 mA/NT/

4 - 20 mA DC transmission

NT specification: Digital

data transmission

EA specification: Ethernet

and 4-20 mA DC

transmission

LN specification: confirm to

LONWORKS

www.GlobalTestSupply.com

Controller

(CPU)

(CPU)

(POWER) (ALM1) (ALM2)

(FAULT)

LCD

(MODE) (▲) (▼) (TEST/SET)

Pump

control

circuit

sensor

Page 15

<Tubing Diagram>

Find Quality Products Online at: sales@GlobalTestSupply.com

- 15 - GD-70D

www.GlobalTestSupply.com

Page 16

working areas, carefully consider how many units to install and where to install them.

sensor unit.

4

Installation

4-1 Requirements

All users must follow the operating precautions. Ignoring the precautions may damage the detector,

resulting in inaccurate gas detection.

CAUTION

• After you receive the detector, start using the detector within the specified operation start limit of the

4-2 Precautions for installation sites

CAUTION

• This is a precision instrument. Because the detector may not provide the specified performance in

some places (environments), check the environment in the installation site, and then take

appropriate actions if necessary.

• Because the detector plays an important role for safety and disaster prevention, you must install as

many units of the detector as needed in appropriate points.

• Because gases may leak or collect in different areas depending on the types of gases and the

Do not install the detector in a place with vibrations or shocks.

The detector contains sensitive electronic parts. The detector

must be installed in a stable place without vibrations or shocks

and where it will not fall.

Do not install the detector in a place exposed to water, oil or chemicals.

Avoid installation locations where the detector is exposed to

water, oil or chemicals.

Do not install the detector in a place where the temperature drops below 0ºC or rises over 40ºC.

The operating temperatures of the detector are 0 - 40ºC. The

detector must be installed in a stable place where the operating

temperatures are maintained and do not change suddenly.

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 16 -

www.GlobalTestSupply.com

Page 17

Do not install the detector in a place exposed to direct sunlight or sudden changes in the temperature.

Avoid installation locations where the detector is exposed to

direct sunlight or radiant heat (infrared rays emitted from a hightemperature object), and where the temperature changes

suddenly. Condensation may form inside the detector, or the

detector cannot adjust to sudden changes in the temperature.

Keep the detector (and its cables) away from noise source devices.

Avoid installation locations where high-frequency/high-voltage

exist.

Do not install the detector in a place where maintenance of the detector cannot be performed or where handling the detector involves dangers.

Regular maintenance of the detector must be performed.

Do not install the detector in a place where the equipment must be stopped when maintenance is

performed, where parts of the equipment must be removed to perform maintenance, or where the detector

cannot be removed because tubes or racks prevent access to it. Do not install the detector in a place

where maintenance involves dangers, for example, near a high-voltage cable.

Do not install the detector in equipment which is not properly grounded.

Before installing the detector in equipment, the equipment must be grounded properly.

Do not install the detector in a place where other gases exist around it.

The detector must not be installed in a place where other gases exist around it.

Find Quality Products Online at: sales@GlobalTestSupply.com

- 17 - GD-70D

www.GlobalTestSupply.com

Page 18

Power supply voltage

or PoE connection (GD-70D-

EA)

Allowed time of

Up to 10 milliseconds (To

detector.)

Example of actions

Others

Do not use it with a power

frequency noise.

Example of actions

Protection against

Take appropriate measures in accordance with the importance of the facilities

Grounding

In addition to lightning, there are more sources of surge noise. To protect

devices from these noise sources, the devices must be grounded.

• An unstable power supply and noise may cause malfunctions or false alarms.

4-3 Precautions for System Designing

CAUTION

Using a stable power supply

The external output and alarm contact of the detector may be activated when the power is turned on, when

momentary blackout occurs, or when the system is being stabilized. In such cases, use a safety power

supply, or take appropriate actions on the receiving side.

The detector must be provided with the following power supply.

24 VDC ±10% (the terminal voltage of the detector)

momentary blackout

recover from a momentary

blackout longer than 10

milliseconds, restart the

supply that has a large

power load or high-

To ensure continuous operation and activation, install

a protective power supply outside the detector.

Use a line filter to avoid the noise source if

necessary.

Heat radiation designing

When it is installed in the closed instrumentation board, attach ventilation fans above and below the board.

Protecting against lightning

If cables are installed outside the factory/plant, or if internal cables are installed in the same duct as the

cables coming from outside the factory/plant, lightning will cause problems. Because lightning acts as a

large emission source while cables act as a receiving antenna, devices connected to the cables may be

damaged.

Lightning cannot be prevented. Cables installed in a metal conduit or under the ground cannot be

completely protected from a power surge caused by lightning. Although complete elimination of disasters

caused by lightning is impossible, the following protective measures can be taken.

lightning

and the environment.

• Connect the transmission signal route by using optical fiber.

• Provide protection by a lightning arrester (cable safety retainer).

(Although inductive lightning surge can be transmitted through the cable, it

is prevented by installing a lightning arrester before the field devices and

central processing equipment. For information on how to use a lightning

arrester, please contact the manufacturer.)

* The lightning arrester has a circuit to remove a surge voltage which damages field devices, so that

signals may be attenuated. Before installing a lightning arrester, verify that it works properly.

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 18 -

www.GlobalTestSupply.com

Page 19

GD-70D

SK1

SK2

Alarm

Contact

Power

Power

External relay

(low voltage relay)

* SK1, SK2: Surge absorbing parts

receiving side of the b contact.

as a CR circuit.

Coil

Load

4-4 Proper use of alarm contact

The alarm contact of the detector is used to transmit signals to activate an external buzzer, alarm lamp or

rotating lamp. Do not use the detector for controlling purpose (e.g., controlling the shutdown valve).

CAUTION

• The b contact (break contact) under de-energized state may be opened momentarily by a physical

shock, such as external force.

• When the b contact is selected for the alarm contact, take appropriate actions to prepare for a

momentary activation by adding signal delay functionality (approximately one second) to the

The specifications for the alarm contact of the detector are based on the resistive load conditions. If

inductive load is used at the alarm contact, the following errors will occur easily because counter

electromotive force is generated at the contact.

• Deposition, defective insulation or defective contact at the relay contact

• Damage of any electric parts due to high-voltage generated inside the detector

• Abnormal operations by an out-of-control CPU

CAUTION

• In principal, do not activate inductive load at the alarm contact of the detector. (In particular, never

use the inductive load to activate a fluorescent lamp or motor.)

• If inductive load is activated, relay it with an external relay (contact amplification). However, because

the coil of an external relay also involves inductive load, select a relay at a lower voltage (100 VAC or

below), and then protect the contact of the detector with an appropriate surge absorbing part, such

If load is to be activated, appropriate measures must be taken to stabilize the operation of the detector and

protect the alarm contact referring to the following information.

• Relay it with an external relay at 100 VAC or lower (contact amplification). At the same time, the surge

absorbing part, SK1, suitable for the specifications must be attached to the external relay.

• In addition, the surge absorbing part, SK2, must be attached to the loaded side of the external relay if

necessary.

• It may be recommended that the surge absorbing part be attached to the contact for certain load

conditions. It must be attached to an appropriate position by checking how the load is activated.

supply

Find Quality Products Online at: sales@GlobalTestSupply.com

- 19 - GD-70D

www.GlobalTestSupply.com

supply

Page 20

be damaged. Do not forget to remove the caps.

Leave space for the crosshatched area when installing the detector.

resonance between them. In this case, take preventive actions like reinforcing the rack or wall.

Maintenance space

Maintenance space

Maintenance space

Maintenance space

Maintenance space

Maintenance space

When

When installing usi ng 3 screws

(Unit: mm)

(300)

(90)

(300)

4-5 Installing the Detector

NOTE

To use the pyrolyzer unit (PLU-70), also refer to the individual operating manual.

CAUTION

• Before installing the detector, remove the protective rubber caps from the GAS IN and GAS OUT

fittings. If the detector is turned on while the rubber caps are still in place, the pump and sensor may

<Detector Dimensions and Maintenance Space>

installing using 2 screws

CAUTION

• Multiple detectors installed in the same location must be installed at least 5 mm apart. It is

recommended that they be 10mm apart.

• When you install more than one detector in the same location, install them in a rack or on a wall that

is not affected by vibrations.

When the detectors are installed side-by-side, if the rack or wall in which the detectors are installed

does not have enough strength, vibrations from the pumps inside the detectors can cause

The crosshatched space represents necessary maintenance space.

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 20 -

www.GlobalTestSupply.com

Page 21

Wall

Floor

Ceiling

Wall

CAUTION

• The detector must be installed in the correct orientation to ensure its performance. Install the

detector as shown on the following example. (* The detector must also remain in this orientation

during transportation.)

<Correct Installation Orientation>

<Installing the Mounting Plate>

1. Make sure power to the detector is turned off.

2. While pushing the blue lever toward the mounting plate,

push the main unit up.

3. If you cannot move the main unit, insert a larger flathead

screwdriver into the mounting plate while pushing the lever

as shown to the right. Do not rotate or move the flathead

screwdriver. Simply insert it into the mounting plate.

4. Remove the silver mounting plate from the back of the GD-70D.

Find Quality Products Online at: sales@GlobalTestSupply.com

- 21 - GD-70D

www.GlobalTestSupply.com

Page 22

For 3-wire type (common cable for

specification)

Shielded cable of CVVS, etc. (1.25 mm2) - 3-core

For 2-wire type (power and signal

specification)

Power: Cable of CVV, etc. (1.25 mm2) - 2-core

For 2-wire type DC power-line

specification)

Shielded twisted-pair cable of KPEV-S, etc. (1.25 mm2) For Ethernet (EA)

Power: Cable of CVV, etc. (1.25 mm2) - 2-core

Signal: Ethernet cable (category 5 or higher)

For PoE (EA)

Ethernet cable (category 5 or higher)

For LONWORKS output cable

Shielded twisted pair cable of KPEV-S, etc. (1.25 mm2)

1P

For contact

Cable of CVV, etc. (1.25mm2) - max. 6-core

• When stranded wires are used, prevent wires from contacting each other.

5. Attach the mounting plate to the installation surface using two or three M5 screws.

Recommended mounting screw (M5)

Length of 8 mm or more

Flat washer of φ10 mm or less (small round)

6. Leave the main unit detached from the mounting plate and continue to the wiring section.

4-6 Wiring the Detector

NOTE

To use the pyrolyzer unit (PLU-70), also refer to the separate operating manual.

CAUTION

• Be careful not to damage the internal electronic circuit when wiring. In addition, be careful to provide

appropriate strain relief when using cables for wiring.

• The power cables and signal cables must not be installed together with the motor power cables, etc.

When these cables must be installed together for unavoidable reasons, put the power cables and

signal cables in a metal conduit. The conduit must be connected to a grounding circuit.

<Recommended Cable>

power and signal) (4 - 20 mA/EA

cables separated) (4 - 20 mA/EA

Signal: Shielded cable of CVVS, etc. (1.25 mm2) - 2-core

communication system (NT

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 22 -

www.GlobalTestSupply.com

1P

・

Page 23

Dedicated

handling lever

Wiring hole

Driver slot

Conductive

part

Cage

Top handling slot

<Terminal Plate Specifications>

Specifications of terminal plate

• Rated voltage: 250 VDC

• Rated current: 16 A

Connection conditions

• Cable: 0.08 - 2.5mm2

• Bare wire length: 8 - 9 mm

• Connecting tool: Dedicated handling lever (accessory)

CAUTION

• The specified bare wire length must be observed when the wire insulation is peeled off.

• Be careful not to separate the wire strands.

Compatible bar terminal

For a bar terminal, the following items are available.

• Bar terminal (ferrule): Model 216 Series (manufactured by WAGO)

clamp/spring

• Crimping tool: Model VarioCrimp 4 (206-204) (manufactured by WAGO)

CAUTION

• A bar terminal of the specified model must be used. Using other bar terminals invalidates the

Find Quality Products Online at: sales@GlobalTestSupply.com

guarantee of the performance.

- 23 - GD-70D

www.GlobalTestSupply.com

Page 24

1 2 3 4 5 6 7 8 9

10

+

+

24 VDC

4 - 20 mA

ALM1

contact

ALM2

contact

FAULT

contact

1 2 3 4 5 6 7 8 9

10

+

+

24 VDC

LONWORKS

output

ALM1

contact

ALM2

contact

FAULT

contact

<Wiring to the Terminal Plate>

● 4 - 20 mA/NT/EA Specification

-

●LN Specification

-

-

-

NOTE

For a 3-wire type 4 - 20 mA, terminal 2 is used as common for the power supply and the 4-20 mA output.

Therefore, wiring should be connected to terminals 1, 2, and 3 only. Terminal 4 can be left open.

For the NT specification, terminals 3 and 4 are not used.

For the EA specification with PoE connection, terminals 1 and 2 are disabled.

CAUTION

• The right tools must be used.

• Only one wire can be connected to each wiring hole.

• Do not connect a wire anywhere other than a wiring hole.

1. Make sure power to the detector is turned off.

2. While pushing the blue lever toward the mounting plate,

push the main unit up.

3. If you cannot move the main unit, insert a larger flathead

screwdriver into the mounting plate while pushing the lever

as shown to the right. Do not rotate or move the flathead

screwdriver. Simply insert it into the mounting plate.

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 24 -

www.GlobalTestSupply.com

Page 25

Push the dedicated

Push the lever with your

While holding down the lever, insert the

lever is released, the wire is secured.

4. Use the handling lever included with the GD-70D or a

flathead screwdriver to make wiring connections.

5. Route the wires through the wiring opening in the bottom of

the mounting plate.

6. Insert the handling lever into the driver slot associated with

the terminal you are wiring.

7. Push the lever toward the terminal plate so the protrusion on

the lever goes into the top handling slot and opens the

wiring hole. If you are not using the handling lever, push

down into the top handling slot with a flathead screwdriver.

8. Hold the lever down while you insert a wire into the wiring

hole.

9. Release the lever. Gently pull on the inserted wire to make

sure it is connected.

10. Repeat for all other wiring connections.

finger to lower the spring

in its inside.

wire into the (round) wiring hole until it

reaches the deepest point. Once the

handling lever to

open the terminals.

Insert 1 wire per

terminal.

Find Quality Products Online at: sales@GlobalTestSupply.com

- 25 - GD-70D

www.GlobalTestSupply.com

Page 26

AL M2 FAUL T

3

4

5

6

7

8

9

10

+

-

AL M1

4-20mA

Dev i ce

Power

Dev i ce

Power

Al ar m

1

Dev i ce

Al ar m 2

Dev i ce

Fault Al arm

Dev i ce

+ 24

VDC

Control ler

or

Recording

Device

1

+

- (DC Gr ound)

4

- 20 mA

I n ( FB)

GD- 70D Terminal

Plate

DC24V

2

-

Cable Shi eld

Dev i ce

Power

Generic Controller Wiring

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 26 -

www.GlobalTestSupply.com

Page 27

FAUL T

3 4

5 6 7

8 9

10

+

-

AL M1

4-20mA

AL M2

Dev i ce

Power

Dev i ce

Power

Al ar m 1

Dev i ce

Al ar m 2

Dev i ce

Fault

Alarm

Dev i ce

Power Suppl y

1

+

- 24 VDC

+ 24

VDC

Dev i ce

Power

+

-

PLC

or DCS

Cable Shi eld

Cable

Shi eld

GD- 70D

Terminal Plat e

DC24V

2

-

PLC or DCS Wiring

Find Quality Products Online at: sales@GlobalTestSupply.com

- 27 - GD-70D

www.GlobalTestSupply.com

Page 28

FAUL T

AL M2

4-20mA

AL M1

-

+

10

9876543

Fault A l arm

Dev i ce

Al ar m 2

Dev i ce

Al ar m 1

Dev i ce

Dev i ce

Power

Dev i ce

Power

13

14

12

+

1

Dev i ce

Power

11

RM-5003

Cable Shi eld

-

2

DC24V

GD- 70D Terminal Plat e

RM-5003 Wiring

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 28 -

www.GlobalTestSupply.com

Page 29

7

6

5

4

3

FAUL T

AL M2

4-20mA

AL M1

-

+ 24

VDC

Fault

Alarm

Dev i ce

Al ar m 2

Dev i ce

Al ar m 1

Dev i ce

Dev i ce

Power

Dev i ce

Power

RJ45

Connec tor

+

10

9

8

Swit c hi ng

Hub

PC or

PLC

+

1

Power Suppl y

Dev i ce

Power

- 24 VDC

-

2

DC24V

GD- 70D Terminal

Plate

Cable Shi eld

Ethernet Wiring

Find Quality Products Online at: sales@GlobalTestSupply.com

- 29 - GD-70D

www.GlobalTestSupply.com

Page 30

9

10

+

-

AL M1

4-20mA

AL M2 FAULT

3

4 5

6 7 81

+

Dev i ce

Power

Dev i ce

Power

Al ar m 1

Dev i ce

Al ar m 2

Dev i ce

Fault Al arm

Dev i ce

PC or

PLC

Swit c hi ng Hub

(with PoE

Functi onality)

RJ45

Connec tor

GD- 70D Terminal Plate

DC24V

2

-

Dev i ce

Power

PoE Wiring

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 30 -

www.GlobalTestSupply.com

Page 31

FAUL T

AL M2

AL M1

-

Dev i ce

Power

LON

WORKS

+

10

9

8

7

6

5

4

3

Power

Suppl y

+ 24 VDC

Fault Al arm

Dev i ce

Al ar m 2

Dev i ce

Al ar m

1

Dev i ce

Dev i ce

Power

+

1

Dev i ce

Power

LON

-

24

VDC

-

2

DC24V

GD- 70D

Terminal

Plate

Cable

Shi eld

Cable Shi eld

LON Wiring

Find Quality Products Online at: sales@GlobalTestSupply.com

- 31 - GD-70D

www.GlobalTestSupply.com

Page 32

3 4

5 6

7

8 9

10

+ -

AL M14-20mA

AL M2

FAUL T

Dev i ce

Power

Al ar m 1

Dev i ce

Al ar m

2

Dev i ce

Fault Alarm

Dev i ce

1

+

Dev i ce

Power

Blocki ng Filter

(B/F)

+

-

Power Supply

(24 VDC)

DC 24V (-)

DC 24V

(+)

Upper Unit

(RM-70NT)

GD- 70D-NT Terminal Pl ate

DC24V

2

-

Cable Shi el d

+ -

Dev i ce

Power

Position the

RM-70NT Wiring (for GD-70D-NT)

NOTE

<How to Clamp Cables>

1. Insert the supplied zip tie into the hole on the mounting plate

as shown in the figure to the right.

2. Position the zip tie so that its coarse side faces the wires.

3. Tighten the zip tie to secure the wires.

When an optional cable gland is used, it must

be attached to the external wiring hole.

band so that

its coarse

side faces the

wire.

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 32 -

www.GlobalTestSupply.com

Page 33

Grounding screw (M4)

Bottom

When the main unit is fully

10mm

When reinstalling the main unit,

plate hook before pushing down.

The lock clicks.

<Grounding>

Use the grounding terminal to connect the detector to your

grounding circuit.

WARNING

• Before turning on the detector, do not forget to connect it

to a grounding circuit.

• For stable operation of the detector and safety, it must be

connected to a grounding circuit. Do not connect the

grounding wire to a gas pipe. The grounding must be

made as D type grounding (below 100 Ω of grounding

resistance).

<Attaching Main Unit to Mounting Plate>

1. Make sure power to the detector is turned off.

2. Position the main unit about 10 mm above the mounting

plate.

3. Lower the main unit toward the mounting plate. Be sure both

mounting plate hooks fit into the main unit grooves.

4. Press down on the main unit to secure it. The lock at the

bottom of the main unit clicks to fix it properly.

5. Make sure that the top center of the mounting plate is above

the main unit as viewed from front. If it is not, push the main

unit down farther.

Find Quality Products Online at: sales@GlobalTestSupply.com

- 33 - GD-70D

www.GlobalTestSupply.com

align the arrow mark on the side

of the housing with the mounting

installed on the mounting plate,

the top of the mounting plate will

protrude above the main unit.

Page 34

Ferrule

Tubi ng

Insert

Nut

4 mm x 6 mm

Teflon

Tubing

Rc 1/4

(1/ 4 PT)

Thread

Dust Fi l ter

Gas Inlet

To Sample Area

4-7 Making Tubing Connections

NOTE

To use the pyrolyzer unit (PLU-70), also refer to the individual operating manual.

1. The tube nut, ferrule, and tubing insert are shipped uninstalled and the open GAS IN and GAS OUT

fittings are plugged with protective rubber caps. Remove the rubber caps from the GAS IN and GAS

OUT fittings.

2. Install a short piece of 4 mm x 6 mm Teflon tubing to the GAS IN fitting as shown below. Be sure the

tubing insert, ferrule, and nut are installed properly.

3. Connect the dust filter to the tubing.

4. Install another piece of 4 mm x 6 mm Teflon tubing to the other end of the dust filter and route it to the

sample area.

5. Attach 4 mm x 6 mm Teflon tubing to the GAS OUT fitting and route it to a safe area. Be sure to use

the tubing insert, ferrule, and nut as shown above.

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 34 -

www.GlobalTestSupply.com

Page 35

leading to dangers. Be sure that excessive pressure is not applied to the detector during use.

• Please contact RKI for help determining an inlet tubing length.

WARNING

• The detector is designed to draw gas under normal atmospheric pressure. If excessive pressure is

applied to the GAS IN or GAS OUT fitting, detected gases may be leaked from its inside, thus

CAUTION

• Keep the inlet line as short as possible to minimize the absorption of gas by the sample tubing.

• When the humidity in the sampling point is high, condensation may be formed inside of the tube.

Make sure to avoid condensation when detecting water-soluble gases such as a strong acid gas,

because it may corrode internal parts. Also avoid looping or kinking the tubing.

4-8 Disposal

• A used sensor unit (that is not an SSU type) must be treated as hazardous waste. Follow local regulations

for disposal.

• A used SSU sensor unit must be treated as radioactive waste. Follow local regulations for disposal.

• If any liquid leaks from the electrochemical type sensor unit (ESU) or galvanic cell type sensor unit (OSU),

do not touch the liquid. If any liquid leaks while the sensor unit is installed in the detector, turn off power to

the detector and contact RKI immediately.

• The main unit must be treated as industrial waste. Follow local regulations for disposal.

WARNING

• Do not disassemble the electrochemical type sensor unit (ESU) or the galvanic cell type sensor unit

(OSU) because they contain electrolyte.

Electrolyte may cause severe skin burns if it contacts skin and may cause blindness if it contacts

eyes. Electrolyte may damage or discolor clothing. If contact occurs, rinse the area immediately with

a large quantity of water.

Find Quality Products Online at: sales@GlobalTestSupply.com

- 35 - GD-70D

www.GlobalTestSupply.com

Page 36

OFF

ON

Slide

Switch cover closed.

Switch cover open.

Power switch

5

Operation

5-1 Preparation for Start-up

Before connecting a power supply, read and understand the following precautions. Ignoring these

precautions may cause an electric shock or damage the detector.

• Connect the detector to a grounding circuit.

• Ensure the wiring is correctly connected to the external circuit.

• Ensure the main unit is properly installed on the mounting plate.

• Ensure the power supply voltage is appropriate (see Specifications).

• Alarm contacts may be activated during startup. Take steps to ensure this does not have any unwanted

effects.

• Verify that the GAS IN and GAS OUT lines are clear.

• Verify that the dust filter is installed correctly.

5-2 Starting Up the Detector

1. The power switch is protected by a cover to prevent accidental

access. Rotate the switch cover to gain access to the power

switch. (Return the switch cover to the original position once

you are done.)

2. Turn ON the power switch.

3. After the detector completes the start-up, it enters Detection

Mode.

(under cover)

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 36 -

www.GlobalTestSupply.com

Page 37

Power On

PW

A1

A2

F

LCD

Initial Clear

● ○ ○

○

──────

Gas

● ○ ○

○

15.0ppm

Detection Mode

● ○ ○

○

0.0ppm

started.

PW:POWER

F:FAULT

●

<Warm-up Sequence>

The warm-up taking approximately 25 seconds to complete.

↓

A1:ALM1

A2:ALM2

WARM UP

↓

Specifications

Display

↓

SIH4

↓

↓

SIH4

WARNING

• When Oxygen (OSU) is selected, fresh air (20.9 vol%) is

the output after the detector is started in the atmosphere.

For a specification where an alarm is triggered by the

AIR (normal oxygen concentration) output (e.g., 0 - 5

vol%), be careful of an alarm issue after the detector is

CAUTION

• Do not turn off the detector during the initial clear. The detector is reading the sensor memory during

the initial clear.

• If a new sensor unit is installed or the sensor unit is replaced after the detector is started, the sensor

unit must be warmed up for a specified period which is determined depending on the type of the

sensor unit. Suggested warm-up time for SGU type sensor units is displayed in Maintenance Mode.

During the warm-up, the alarm activation and output signals are unstable. Prepare appropriately for

false alarms.

• Because the pyrolyzer unit (PLU-70) must be warmed up for one hour, please warm it up with the

detector.

• After the warm-up is completed, verify that the reading on the flow rate indicator corresponds to the

specified flow rate, and then perform a gas calibration.

:Lamp on

○:Lamp off

Find Quality Products Online at: sales@GlobalTestSupply.com

- 37 - GD-70D

www.GlobalTestSupply.com

Page 38

"OFF" the detector.

<<Detection Mode>>

PW

A1

A2

F

LCD

● ○ ○

○

0.0ppm

<<User Mode>>

PW

A1

A2

F

LCD

● ○ ○

○

1- 1

MAINTENANCE

<<Maintenance Mode >>

PW

A1

A2

F

LCD

● ○ ○

○

2- 0

MAINTENANCE

<<Gas Alarm Test Mode>>

PW

A1

A2

F

LCD

● ○ ○

○

0.0ppm

MAINTENANCE

<<Fault Alarm Status>>

PW

A1

A2

F

LCD

● ○ ○

●

E-5

<<Gas Alarm Status>>

PW

A1

A2

F

LCD

● ● ○

○

6.0ppm

MODE

TEST

The detector is

MODE

PW:POWER

F:FAULT

●

5-3 Turning Off the Detector

To turn off the detector, open the switch cover on the bottom of the main unit, and turn "OFF" the power

switch. Then, turn off the power supply (24 VDC) to the detector.

WARNING

• When the detector is turned off, an alarm may be activated on the upper (central) system.

Before turning off the detector, the inhibit (point skip) on the upper (central) system must be

activated.

Decide whether the power can be turned off by checking the operation of the devices connected to

the external output or external contact output terminal of the detector.

• If the alarm contact is energized (option), they will activate when the detector is turned "OFF".

• If the detected gas is absorptive, the detector must be flushed thoroughly with fresh air before turning

5-4 Basic Operation

After the warmup procedure, the detector enters detection mode.

restarted after

recovering from

Fault.

SIH4

FLOW

TEST OFF

SIH4

(press and hold)

(press and hold)

A1:ALM1

A2:ALM2

GAS TEST

:Lamp on

○:Lamp off

(press and hold)

ZERO

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 38 -

www.GlobalTestSupply.com

Page 39

Mode

Item

LCD Display

Details

Detection

Mode

-

Gas concentration

Gas name

Normal state

Test Mode

User Mode

Zero Adjustment (Span

1-1 ZERO

oxygen)

Perform the zero adjustment (span adjustment for oxygen).

• Sensitivity correction ON/OFF

Flow Rate Indicator

1-3 FLOW

Show the current flow rate.

Address Display

1-4 ADDRESS

Show the address.

Detector Version Display

1-5 70D VER

Show the program version of the main unit.

Unit Version Display

1-6 UNIT VER

Show the program version of the sensor unit.

Net Version Display

1-7 NET VER

Show the program version of the communication function.

Access

this case, you must identify the causes and take appropriate actions.

Flow rate

too low

Flow rate

Normal

flow rate

WARNING

• When the detector enters each mode from Detection Mode while an alarm is activated, the alarm

contact is released.

<Detection Mode>

Flow Rate Indicator

Because the suction flow rate of the detector is automatically adjusted by the flow rate control function, the

flow rate, in principal, does not need to be controlled. As shown on the figure below, when the flow rate

does not correspond to the specified flow rate for some reasons, it is adjusted automatically.

CAUTION

• If the automatic flow rate adjustment does not work (due to clogged tube or leak), you may get a

"FLOW" message (for an unstable flow rate) or an "E-05" message (for flow rate abnormalities). In

too high

5-5 Modes

Details on each mode are provided as follows. (* Operations are slightly different depending on the

detector type or sensor unit.)

Gas Alarm

(see pg. 59)

- Gas concentration Perform the alarm test.

Adjustment for oxygen)

Setting Display 1-2 CONFIRM Show the setting of typical menus.

Maintenance Mode

(1-1 SPAN for

First alarm setpoint (AL1)

•

•

Second alarm setpoint (AL2)

•

Alarm delay time

•

Zero suppression value

•

Zero follower ON/OFF

1-8 M MODE Enter maintenance mode.

Find Quality Products Online at: sales@GlobalTestSupply.com

- 39 - GD-70D

www.GlobalTestSupply.com

Page 40

Mode

Item

LCD Display

Details

Gas Introduction Display

2-0 GAS TEST

Perform the gas introduction test.

Zero Adjustment

2-1 ZERO

Perform the zero adjustment.

Span Adjustment

2-2 SPAN

Perform the span adjustment.

Last Calibrated Date

2-3 LAST CAL

Show the last calibrated date.

Voltage)

(2-4 E VOLT)

(Show the element voltage.)

Flow Rate Setting

(adjusted to 0.5 L/min)

2-5 DEF FLOW

Set the flow sensor with the flow rate at 0.5 L/min.

Indicator

Detector Temperature

2-7 TEMP

Show the current temperature of the installation environment.

Completion Date/Time

(SGU).

Environmental Setting 1

2-9 SETTING1

Operation settings

• Fault test (F TEST)

• Pump drive level diagnosis ON/OFF setting (PUMP CK)

Pyrolyzer Data Display

2-11 P L D ATA

If a pyrolyzer unit is being used, this menu displays data for it (see

the PLU-70 operator’s manual for more description)

Fault Investigation

2-12 FA U LT

Not used

Factory Mode Switching

2-13 F MODE

Not used

Maintenance

Mode (see pg.

67)

Bias Voltage (Element

Pump Ratio/Flow Rate

Suggested Warm-up

Environmental Setting 2 2-10 SETTING2 Function settings

2-4 BIAS

2-6 FLOW Show the output and flow rate of the current pump.

2-8 WARMTIME Show the suggested warm-up completion for semiconductor type

Show the bias voltage.

• INHIBIT setting (INHIBIT)

•

Alarm value setting (ALM P)

•

Alarm delay time setting (ALM DLY)

•

Regular replacement operation (pump stop) (MAINTE)

•

Address setting (ADDRESS)

•

Date/Time setting (DAY TIME)

•

Zero suppression value setting (SUPPRESS)

•

Zero suppression system setting (SUP TYPE)

•

Alarm test time contact setting (TEST RLY)

•

Alarm test time external output setting (TEST4-20)

•

Energized/De-energized setting (RLY PTRN)

•

Alarm type setting (ALM TYP)

•

Alarm activation setting (ALM PTRN)

•

Alarm value limiter setting (AL LIMIT)

•

Fault activation setting (FLT PTRN)

•

Flow rate auto-adjustment setting (AT FLOW)

•

Zero follower ON/OFF setting (ZERO F)

•

24 hours zero follower ON/OFF setting (ZERO 24F)

•

Sensitivity correction ON/OFF setting (S ASSIST)

•

External output in maintenance mode setting (MNT OUT)

•

External output adjustment (MA 4-20)

•

Backlight setting (BK LIGHT)

•

ETHERNET setting (ETHERNET)

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 40 -

www.GlobalTestSupply.com

Page 41

6

Detection Mode

6-1 Gas Alarm Activation

A gas alarm is activated when the concentration of detected gas reaches or exceeds the alarm setpoint.

This section describes alarms assuming an auto-reset operation.

NOTE

The alarm setpoint (first alarm and second alarm) is factory set.

The alarm delay time (standard: 2 seconds) is enabled in the detector to prevent a false activation. It can

be disabled, if desired.

<Display Operation During Alarm Condition>

Gas Concentration Display

The gas concentration is displayed on the LCD. If the concentration is above the detection range (over

scale), "∩∩∩∩" is displayed on the LCD instead of the gas concentration.

Alarm Indicator Lamp (ALM1: Red), (ALM2: Red)

When the first alarm setpoint has been reached, the ALM1 LED turns red.

When the second alarm setpoint has been reached, the ALM2 LED turns red.

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 41 -

www.GlobalTestSupply.com

Page 42

<Contact Activation>

The contact is activated when the gas concentration reaches or exceeds the alarm setpoint. The contact

activation is reset automatically when the gas concentration drops below the alarm setpoint.

<Contact Activation (Auto-reset)>

In case of Auto-reset setting, the contact is activated when the gas concentration reaches or exceeds the

alarm setpoint value. The contact activation is reset automatically when the gas concentration drops below

the alarm setpoint value.

NOTE

In DETECTION MODE, select and press one of the following key to reset : “MODE”, “▲”, “▼” or

“TEST/SET”.

"Alarm Pattern (H-HH)"

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 42 -

www.GlobalTestSupply.com

Page 43

"Alarm Pattern (L-H)"

"Alarm Pattern (L-LL)"

(* oxygen deficiency alarm)

Find Quality Products Online at: sales@GlobalTestSupply.com

- 43 - GD-70D

www.GlobalTestSupply.com

Page 44

<Contact Activation (Self-latching)>

In case of Self-latching setting, the contact is activated when the gas concentration reaches or exceeds the

alarm setpoint value. The alarm indication lamp blinks during warning. It changes to a light after reset is

performed. It turns off when the gas concentration drops below the alarm set point value.

"Alarm Pattern (H-HH)"

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 44 -

www.GlobalTestSupply.com

Page 45

"Alarm Pattern (L-H)"

Find Quality Products Online at: sales@GlobalTestSupply.com

- 45 - GD-70D

www.GlobalTestSupply.com

Page 46

"Alarm Pattern (L-LL)"

<Response to Gas Alarm>

When a gas alarm is triggered, take actions in accordance with your company’s safety practices for a gas

alarm. In general, take the following actions.

1. Check the reading of the detector.

NOTE

If a gas leak is momentary or if the alarm is triggered by noise, the reading may already have dropped by

the time you get to the instrument to check it.

2. Based on your company’s safety practices, no one can be allowed to access the monitored zone to ensure

safety.

3. If the detector display is still indicating the presence of gas, close the area’s main gas valve, and then verify

that the detector’s gas concentration reading dropped.

4. While wearing protective equipment in case gas is still present, use a portable gas detector to ensure the

area is free from gas.

5. If you can determine that the leak point is free from dangers, take actions to fix the gas leak.

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 46 -

www.GlobalTestSupply.com

Page 47

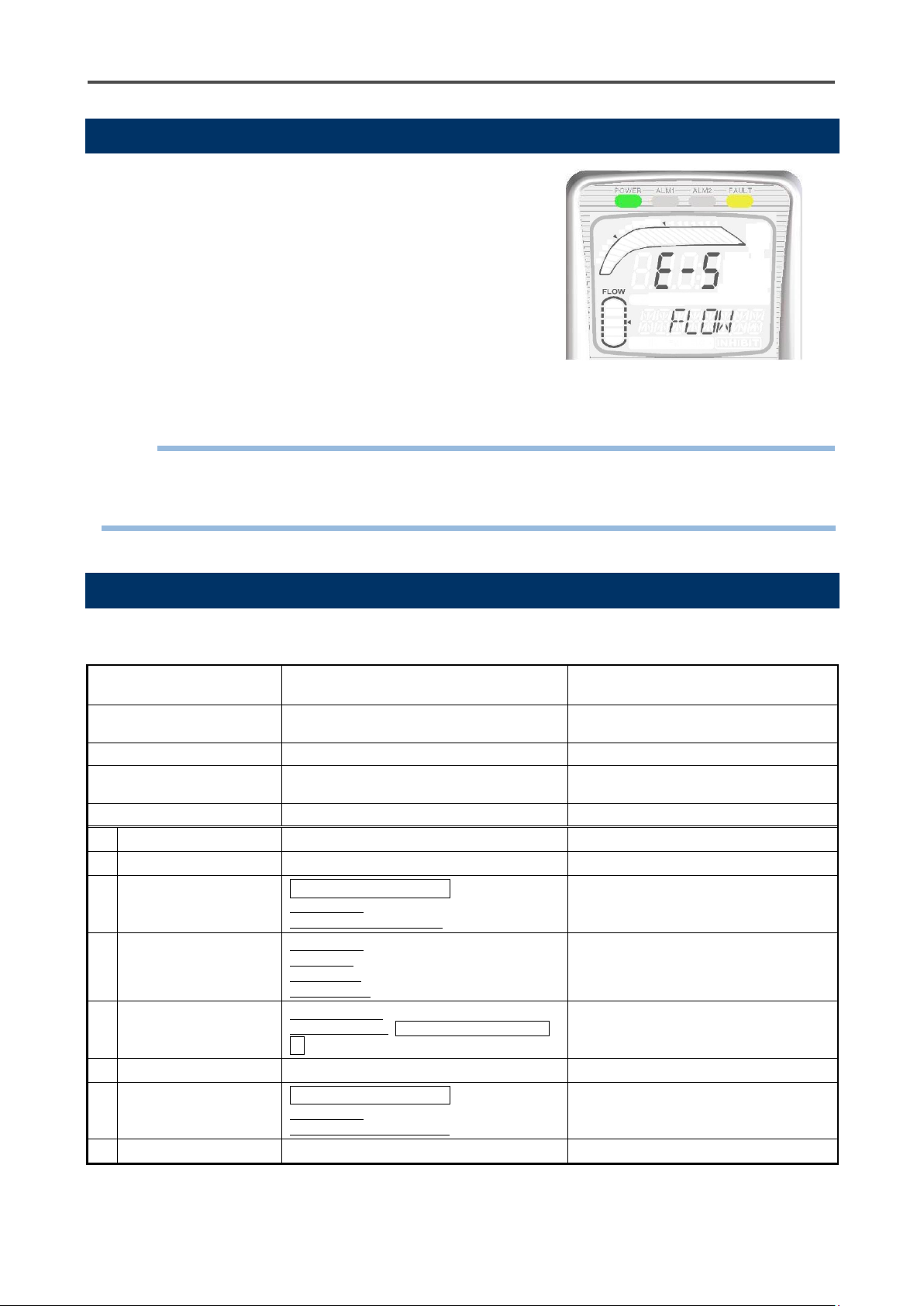

* E-5 FLOW (flow rate abnormalities)

6-2 Fault Alarm Activation

A fault alarm is triggered when the detector detects

abnormalities.

After a fault alarm is triggered, the FAULT lamp (yellow) lights up

and an error message is displayed on the LCD.

Determine the causes and take appropriate actions.

After the detector is successfully returned from the fault, it

restarts and goes through a normal warmup procedure.

If the detector has problems and is repeatedly malfunctioning,

please contact RKI immediately.

NOTE

For information on error messages and possible malfunctions, see Troubleshooting on page 116.

6-3 External Output Operation

● 4 - 20 mA/NT/EA Specification

Specifications/Condition 4 - 20 mA (for GD-70D) Power-line communication system

(for GD-70D-NT)

Signal Transmission System Electric current transmission (non-isolated) 2-wire type DC power-line communication

Transmission Path CVVS KPEV-S

Transmission Distance Below 1 km Below 300 m (depending on the system

Connection Load Resistance Below 300 Ω -

Detection Mode (No Alarm) 4 - 20 mA (concentration output) Concentration data

Detection Mode (Gas Alarm) 4 - 20 mA (concentration output) Concentration data, Alarm bits

Initial Clear

Maintenance Mode 2.5 mA setting: 2.5 mA

Alarm Test Output ON setting: 4 - 20 mA (concentration output)

Depending on the setting of

2.5 mA setting: 2.5 mA

4 mA, HOLD, 4-20 mA setting: 4 mA*

4 mA setting: 4mA*

HOLD Setting: the previous value retained

4-20 mA setting: 4 - 20 mA (concentration output)

Output OFF setting: In accordance with setting of

Fault Alarm 0.5 mA (Fixed) Fault bits

Inhibit

Power Off 0 mA Signal OFF

Depending on the setting of

2.5 mA setting: 2.5 mA

4 mA, HOLD, 4 - 20 mA setting: 4 mA*

* 17.4 mA for oxygen units

Find Quality Products Online at: sales@GlobalTestSupply.com

- 47 - GD-70D

www.GlobalTestSupply.com

system

designing conditions)

Initial bit

Concentration data, Adjustment bit

Concentration data, Adjustment bit, Test bit

Concentration data, Adjustment bit, Inhibit bit

Page 48

Specifications

LONWORKS (LN)

Signal

method

Transmission

path

Transmission

rate

Transmission

distance

Max 2700m

* When bus topology (Double ended termination ) is used.

Connection load

resistance

Maintenance output setting

Sensor unit

Details

2.5 mA

Use OSU (L-LL, L-H).

Output 2.5 mA during maintenance or inhibit.

alarm)

4 mA, HOLD, 4 - 20 mA

Specification change

When changing from a H-HH alarm pattern to

change message is confirmed.

Specification change

When changing from an L-LL or L-H alarm

“C-02” change message is confirmed.

2.5mA

4mA

20mA

22mA

Full scale

Gas concentration

External output

Zero

suppression

Detection mode

Maintenance

● LN Specification

transmission

LONWORKS

KPEV-S

78kbps

―

Example of Gas Concentration and External Output

4 - 20 mA Specification

(Maintenance output: 2.5 mA setting)

CAUTION

<<4 - 20 mA Specification>>

• The 4 - 20 mA output is already adjusted. In case of over scale, an output will not exceed 22 mA.

• Output during inhibit or warmup is based on 4 - 20 mA output setting in Maintenance Mode.

The output may drop as low as 2.5 mA during warmup for oxygen units. Understand how the

detector functions, and take actions to prepare for false alarms.

Special Cases>

<

Possibility of false alarm in the upper unit (L

(To OSU - 0 - 25 vol%)

an L-LL or L-H alarm pattern, 4 mA (equivalent

of concentration zero) is used until the “C-02”

(From OSU - 0 - 25

vol%)

pattern to a H-HH alarm pattern, 17.4 mA

(equivalent of approx. 84%FS) is used until the

Find Quality Products Online at: sales@GlobalTestSupply.com

GD-70D - 48 -

www.GlobalTestSupply.com

Page 49

GD-70D-

Power-line

system

The detector is used in a local network formed with a multi-display unit (RM-

multi-display unit.

GD-70D-

Ethernet

The detector offers functions that work in liaison with external software using

value or perform calibration and test.

GD-70D-

LONWORKS

An internationally standardized network specification for device control. It is a

flexibility.

<Communication Specifications>

NT

EA

LN

communication

70NT) as the base unit. For more information, see the operating manual of the

a standard network protocol. For details, see the separate manual for

communication function.

Web function (HTTP), mail send function (SMTP), and time synchronization

function (SNTP)

Use a Web browser of an upper-unit PC to view and change setting values

and perform calibration and test on a graphical user interface.

SMTP, when receiving a gas alarm or fault alarm from an external mail

server, can send a notification mail to a registered address.

SNTP, receiving time information from a time server, can correct the clock at

regular intervals.

Modbus slave function (Modbus/TCP)

Works as a Modbus slave and feeds back a setting value in response to a

read request or changes a setting value in response to a write request.

PLC linkage function (FINS・MC)

Sends a setting value to PLC to provide information to be processed by PLC

in a ladder program. Reading from PLC is also available to change a setting

network specification that controls and manages not only gas detectors but

also air conditioning, lighting etc. equipment by the same communication

protocol called Lon-talk.

By constructing an open system, it becomes possible to connect the system

without being bound by one manufacturer, it is possible to facilitate

procurement of parts at the time of equipment failure, and to increase design

Find Quality Products Online at: sales@GlobalTestSupply.com

- 49 - GD-70D

www.GlobalTestSupply.com

Page 50

<<Example: SiH4 0 - 15 ppm range>>

0.5ppm

SIH4

Suppression Disabled

↓

0.0ppm

SIH4

Suppression Enabled

6-4 Other Functions

<Suppression Function>

Some sensors are influenced by environmental changes (temperature, humidity, and other characteristics)