Page 1

Beacon 200 Gas Monitor

Operator’s Manual

Part Number: 71-0059RK

Revision: J

Released: 1/31/18

www.rkiinstruments.com

Page 2

Product Warranty

RKI Instruments, Inc. warrants gas alarm equipment sold by us to be free

from defects in materials, workmanship, and performance for a period of

one year from date of shipment from RKI Instruments, Inc. Any parts found

defective within that period will be repaired or replaced, at our option, free

of charge. This warranty does not apply to those items, which by their

nature, are subject to deterioration or consumption in normal service, and

which must be cleaned, repaired, or replaced on a routine basis. Examples

of such items are as follows:

a) Absorbent cartridges d) Batteries

b) Pump diaphragms and valves e) Filter elements

c) Fuses

Warranty is voided by abuse including mechanical damage, alteration,

rough handling, or repair procedures not in accordance with the operator’s

manual. This warranty indicates the full extent of our liability, and we are not

responsible for removal or replacement costs, local repair costs,

transportation costs, or contingent expenses incurred without our prior

approval.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER

WARRANTIES AND REPRESENTATIONS, EXPRESSED OR IMPLIED,

AND ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF

RKI INSTRUMENTS, INC. INCLUDING BUT NOT LIMITED TO, THE

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT SHALL RKI INSTRUMENTS,

INC. BE LIABLE FOR INDIRECT, INCIDENTAL, OR CONSEQUENTIAL

LOSS OR DAMAGE OF ANY KIND CONNECTED WITH THE USE OF

ITS PRODUCTS OR FAILURE OF ITS PRODUCTS TO FUNCTION OR

OPERATE PROPERLY.

This warranty covers instruments and parts sold to users by authorized

distributors, dealers, and representatives as appointed by RKI Instruments,

Inc.

We do not assume indemnification for any accident or damage caused by

the operation of this gas monitor, and our warranty is limited to the

replacement of parts or our complete goods.

ii • Product Warranty

Page 3

Table of Contents

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Beacon 200 Gas Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 2: Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

External Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Internal Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 3: Installation and Start Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Mounting the Beacon 200 Gas Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Wiring the Beacon 200 Gas Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Starting Up the Beacon 200 Gas Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chapter 4: Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Recorder Output Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Alarm Indications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Viewing & Resetting Min/Max Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Chapter 5: Channel Control and Setup Program . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Enable/Disable Channel(s) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Configure Channel Settings Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

View System Information Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table of Contents • iii

Page 4

Chapter 6: Input Setup Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Setting Up a New Channel or Changing an Existing Channel . . . . . . . . . . . . . . 41

Chapter 7: Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Calibration Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Replacing the Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

iv • Table of Contents

Page 5

Chapter 1: Introduction

Overview

This chapter briefly describes the Beacon 200 Gas Monitor. This chapter

also describes the Beacon 200 Gas Monitor Operator’s Manual (this

document). Table 1 at the end of this chapter lists the specifications for the

Beacon 200.

About the Beacon 200 Gas Monitor

The Beacon 200 is a fixed-mounted, continuous-monitoring gas detection

instrument. This gas monitor is capable of detecting gas at up to two

locations. The display screen simultaneously displays the gas readings of

the active channel or channels. Both direct connect (internal amplifier type)

detector heads and 4 - 20 mA transmitter (remote amplifier type) detector

heads may be used with the Beacon 200.

NOTE: If any of the Beacon 200’s channels have been set up for

hydrogen-specific LEL operation, that channel or channels can

only be used with a hydrogen-specific sensor. If you want to detect

a different combustible gas or use a different detector, the Beacon

200 must be sent back to RKI Instruments, Inc. for modification.

The Beacon 200 includes audible and visual alarms that warn you of

hazardous gas conditions. The alarm circuit includes two levels of gas

alarms. The fail circuit alerts you to failures in the gas detector heads or

Beacon 200.

Three instrument programs allow you to display and change channel and

calibration settings and change channel types. They are the Channel

Control & Setup Program, the Calibration Program, and the Input Setup

Program.

Overview • 5

Page 6

About this Manual

!

The Beacon 200 Gas Monitor Operator’s Manual is organized as follows:

• Chapters 1 through 6 describe components of the Beacon 200 and

procedures to install, start up, operate, and maintain the Beacon 200.

The Beacon 200 Gas Monitor Operator’s Manual uses the following

conventions for notes, cautions, and warnings.

NOTE: Describes additional or critical information.

CAUTION: Describes potential damage to equipment.

WARNING: Describes potential danger that can result in injury or

death.

I Caution: refer to accompanying documentation

~ Vac (AC voltage)

Vdc (DC voltage)

6 • About this Manual

Page 7

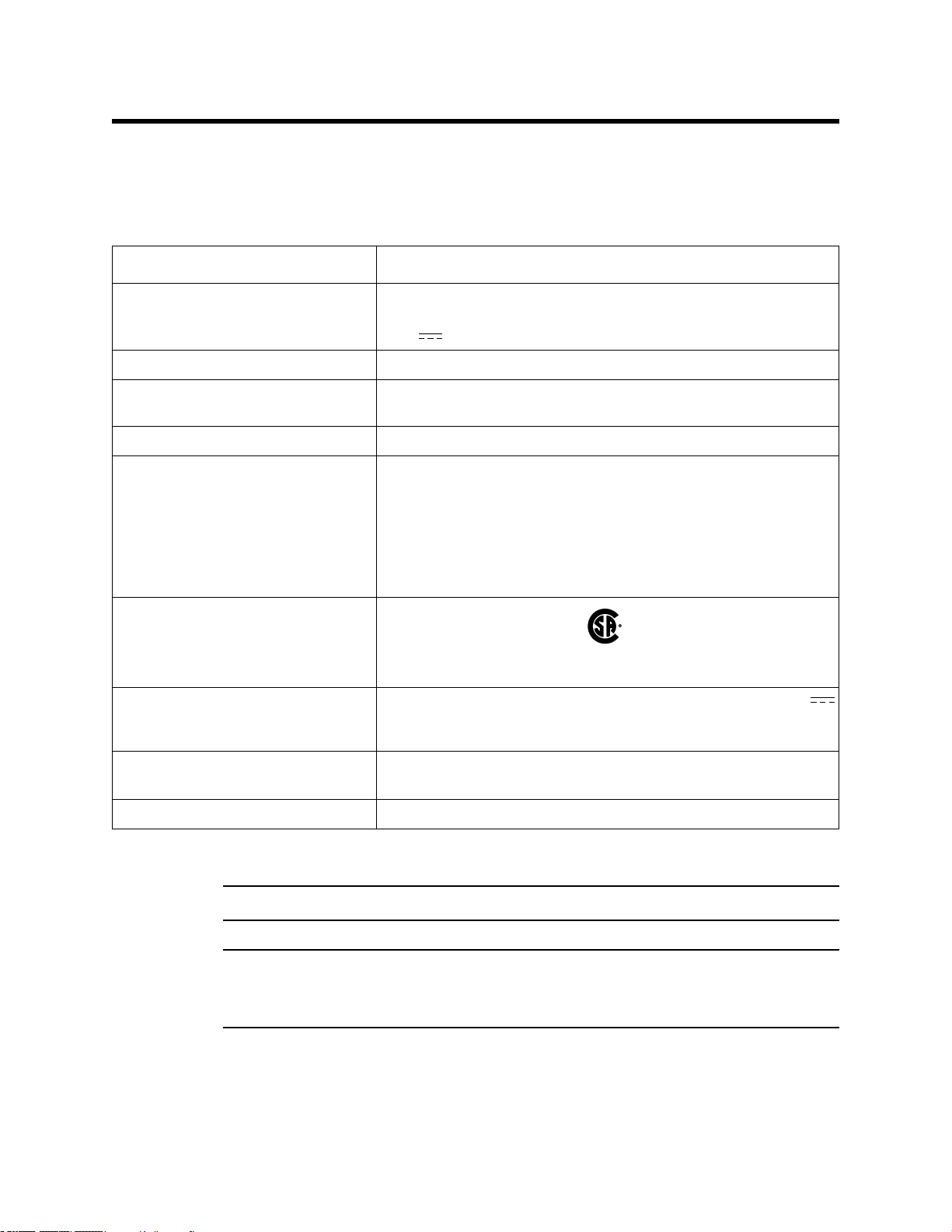

Specifications

Table 1 lists specifications for the Beacon 200 Gas Monitor.

Description Specification

Table 1: Beacon 200 Specifications

Input Power

Construction (housing) Fiberglass/polyester with lexan window (NEMA 4X)

Dimensions 10.5 in. H x 8.5 in. W x 6.25 in. D

Weight 8 lbs.

Environmental Conditions • For indoor or outdoor locations (Type 4X)

Safety/Regulatory

115/220V ~ ±10%, 50/60Hz, 0.5/0.3A

or

24 V +10% -8%, 0.6A

(267 mm H x 216 mm W x 158 mm D)

• 2000m max. altitude

• -20°C to 50°C (-4°F to 122°F) max. ambient

• Maximum humidity of 80% relative

• Mains supply voltage fluctuations not exceeding ± 10% of nominal

• DC supply voltage fluctuations not exceeding +10% -8% of nominal

• Overvoltage Category II, Pollution Degree 2

C US

186718

Relays • Relay contacts rated for 10A @ 115/220V~ resistive or 10A @ 30V

resistive

• SPDT Form C

User Controls • Reset switch

• Program buttons: ESCAPE, UP/YES, DOWN/NO, and ENTER

Standard Accessory Operator’s manual (this document)

CAUTION: Cleaning is not to be performed.

CAUTION: The operator of t his instru ment i s advised that if the equ ipment

is used in a man ner not specif ied in thi s manua l, the pr otectio n

provided by th e equipment may be impaired.

Specifications • 7

Page 8

Chapter 2: Description

Overview

This chapter describes external and internal components of the Beacon

200 Gas Monitor.

External Description

This section describes the housing and all external components of the

Beacon 200. For the purposes of this description, the housing door is

considered the front of the monitor.

Housing

The Beacon 200’s fiberglass housing is weather- and corrosion-resistant. It

is suitable for installation where general purpose equipment is in use. The

housing door is hinged on the left side and is secured by two latches on the

right side. The display screen and status lights are visible through windows

in the housing door. Four mounting feet are attached to the back of the

housing (one at each corner). The mounting feet allow you to install the

housing to a vertical surface. Three conduit hubs on the bottom of the

housing are for external wiring connections.

CAUTION: Only use the three facto ry installed condui t hubs on the bottom

of the housing for wire entry into the housing. Do not drill the

housing for any reason. See “Routing Wiring Into the Beacon

200 Housing” on page 20 for more information.

CAUTION: To avoid electrical inte rference, do not route detector head and

power wiring thro ugh the same conduit hub.

8 • Overview

Page 9

Reset Switch

The reset switch is on the bottom of the housing. It is in front of the conduit

hubs. The reset switch serves three functions:

• Resets the alarm circuits for “latched” alarms after an alarm 1 or alarm 2

condition passes.

You can set each channel for latched or self-resetting alarms in the

Channel Control & Setup Program.

• Silences the buzzer during an alarm 1 or alarm 2 condition. You cannot

silence failure alarms.

• Displays and resets the minimum and maximum gas concentration

values.

Buzzer

The buzzer is on the bottom of the housing. It is on the far right. The buzzer

sounds audible alarms to warn you of gas alarms and instrument failures.

External Description • 9

Page 10

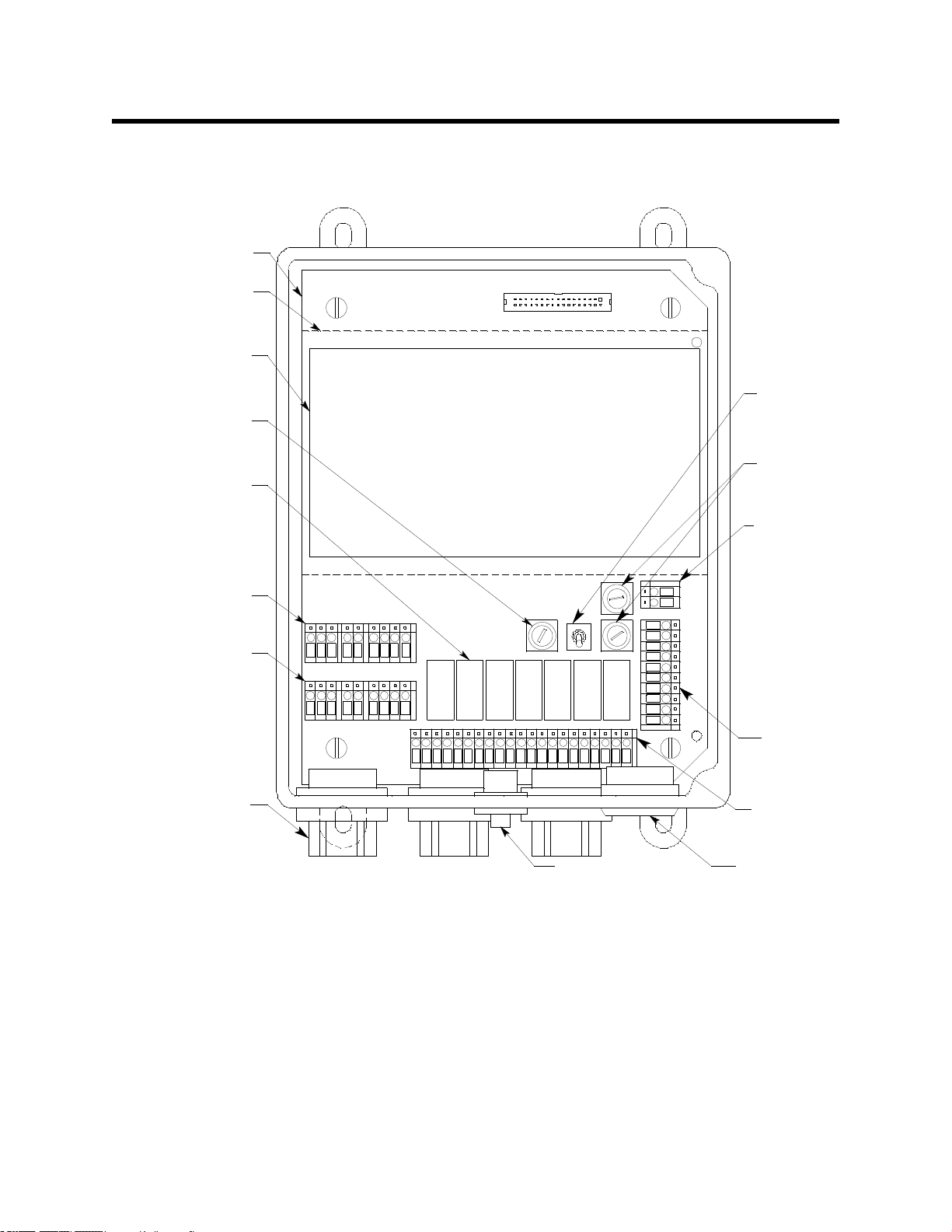

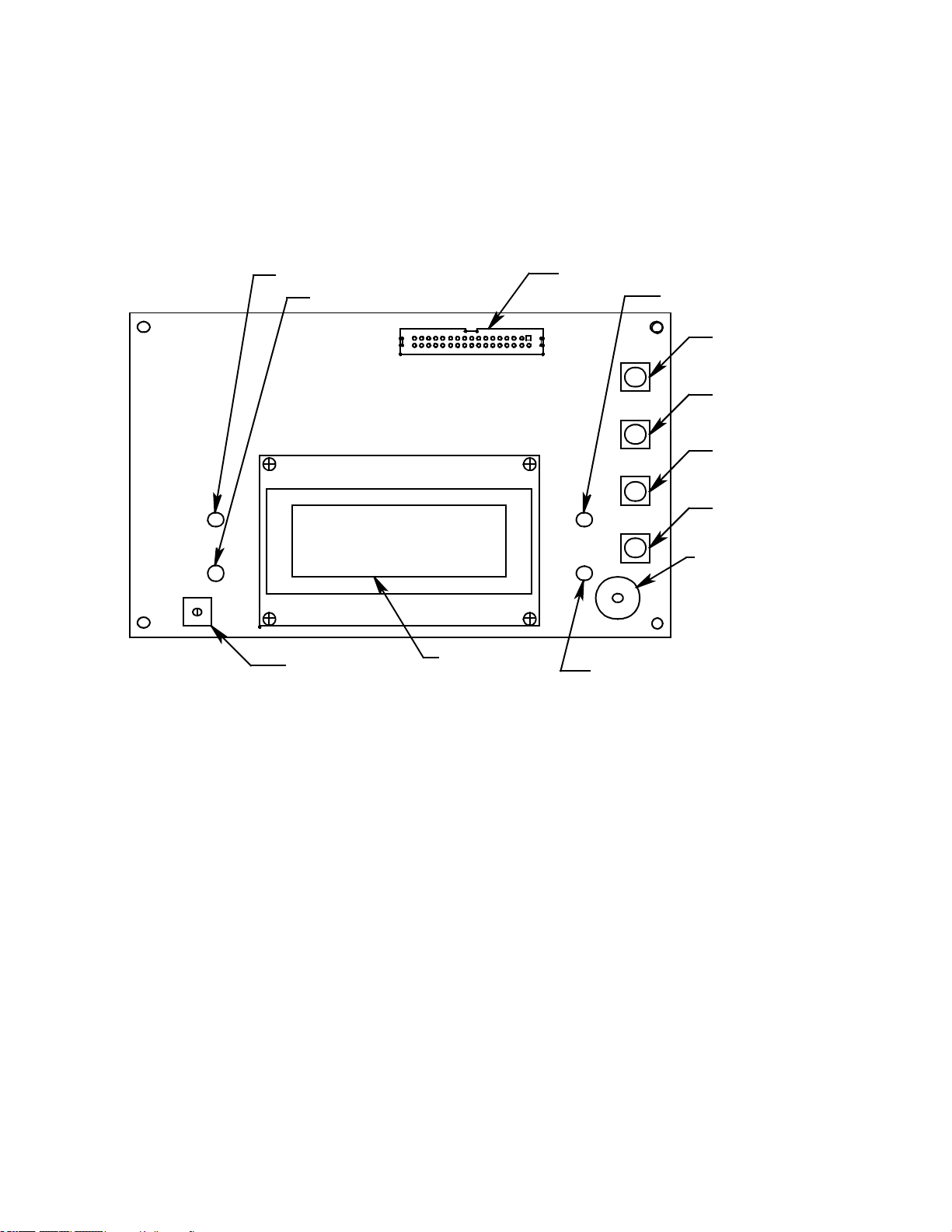

Internal Description

Power

Switch

AC Fuses

Controller

Terminal

Strip

Buzzer

Alarm

Terminal

Strip

Alarm Rel ays

(see Figure 3)

DC Fuse

Displ ay PCB

(see Figure 2)

Main PCB

Reset Switch

3/4" Conduit

Hu b , 3X

Detector/T ransm itter

Terminal Strip,

Channel 2

Detector/T ransm itter

Terminal Strip,

Channel 1

Power

Supply

AC In

Terminal

Strip

Figure 1. Beacon 200 Gas Monitor Component Location

This section describes the internal components of the Beacon 200.

Display Printed Circuit Board (PCB)

The display PCB is mounted to the power supply mounting plate which is in

turn mounted to the main PCB. The power supply mounting plate and main

PCB are described below. The display PCB includes the display, the status

lights, and the program buttons.

10 • Internal Description

Page 11

Display

ESCAPE

Button

UP/YES

Button

ENTER

Button

DOWN/NO

Button

Button Repeater

Buzzer

Display Screen

FAIL Light

PILOT Light

Display Cable Connector

J1

Display Contrast

Adjust Pot

ALARM 2 Light

ALARM 1 Light

Figure 2. Display Board Component Location

The display simultaneously indicates the channel number, current gas

reading, measuring unit, and target gas of all active channels.

The display also indicates messages, settings, and other data when you

are operating the instrument programs.

Internal Description • 11

Page 12

Status Lights

The Beacon 200 includes four status lights that indicate the current status

of the monitor. The status lights are to the left and right of the display (see

Figure 2).

• Pilot Light. The pilot light is on when the Beacon 200 is receiving

incoming power.

• Fail Light. The fail light turns on when the Beacon 200 is experiencing a

fail condition. A fail condition can be caused by a failure within the

Beacon 200 or detector head(s) wired to the Beacon 200. See Chapter

5, Maintenance, or the troubleshooting section in the applicable

detector head manual to respond to a fail condition.

• Alarm 1 Light. The alarm 1 light is on when the Beacon 200 is

experiencing an alarm 1 gas condition.

• Alarm 2 Light. The alarm 2 light is on when the Beacon 200 is

experiencing an alarm 2 gas condition.

Program Buttons

The Beacon 200 includes four program buttons that allow you to enter the

instrument programs, navigate through the programs, update instrument

and channel settings, and save changes to the program settings. When a

program button is pressed, a buzzer located on the display PCB beeps.

The program buttons are near the right edge of the display PCB (see

Figure 2).

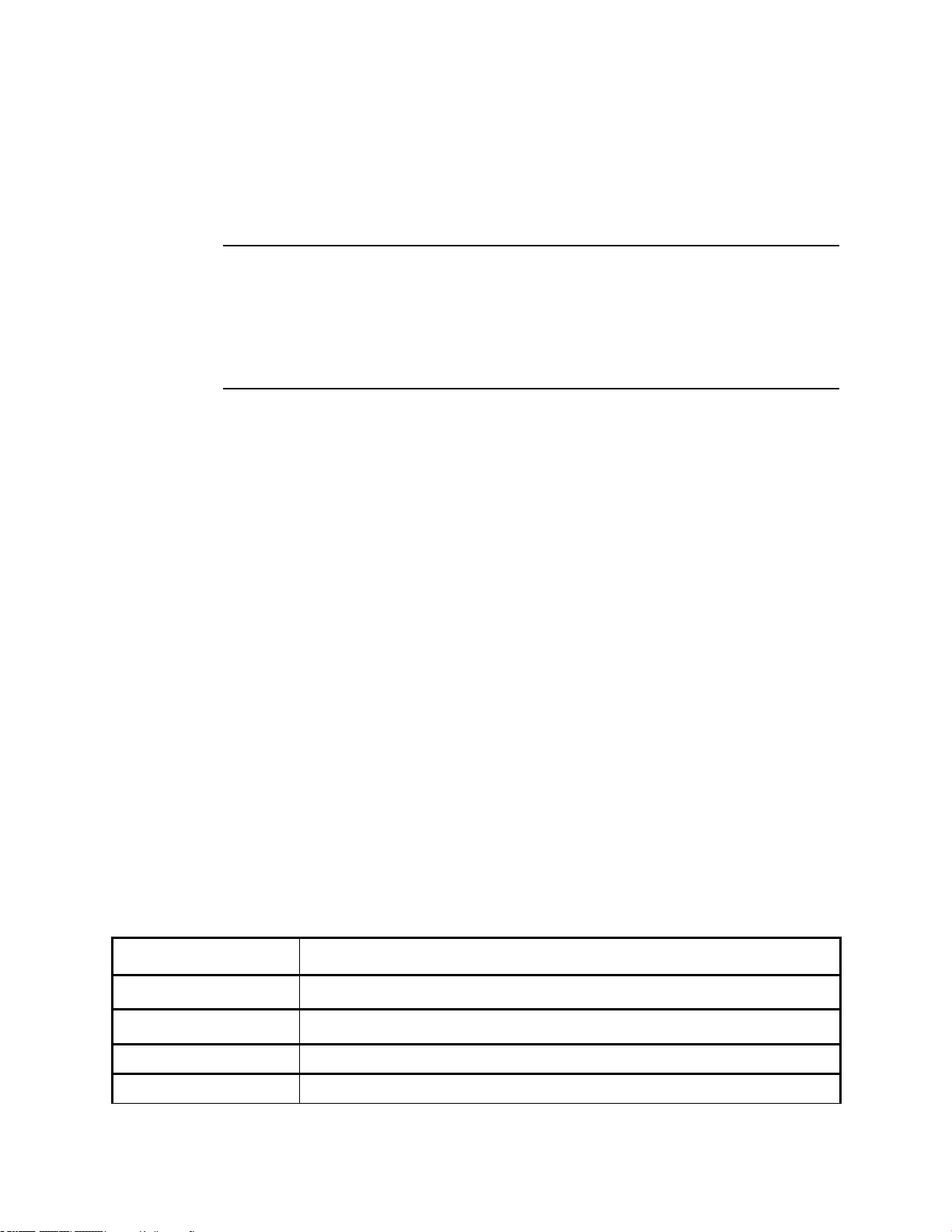

Table 2: Beacon 200 Program Button Functions

Button Function

ESCAPE • Moves backward through the program menus

• Cancels changes you make in the program menus

• Enters the Channel Control and Setup program (press with the ENTER button)

UP/YES • Accepts the displayed setting and proceeds to the next setting

• Changes the displayed setting

• Enters the Calibration program (press with the ENTER button)

DOWN/NO • Allows you to update the displayed setting

• Changes the displayed setting

ENTER • Saves changes you make in the programs

• Enters the Channel Control and Setup program (press with ESCAPE button)

• Enters the Calibration program (press with the UP/YES button)

• Enters the Input Setup Program (press while flipping power switch to ON position)

12 • Internal Description

Page 13

Main PCB

The main PCB is mounted inside the housing. The power supply mounting

plate is mounted to the main PCB with four standoffs and the display PCB

is mounted to the power supply mounting plate with four standoffs. The

main PCB includes the terminal strips, relays, fuses, and power switch.

NOTE: If any of the Beacon 200’s channels have been set up for

hydrogen-specific LEL operation, the main PCB for that channel

or channels has been modified and can only be used with a

hydrogen-specific sensor. If you want to detect a different

combustible gas or use a different detector, the Beacon 200 must

be sent back to RKI Instruments, Inc. for modification.

Terminal Strips

The Beacon 200 includes four terminal strips for external wiring

connections. See “Wiring the Beacon 200 Gas Monitor” for detailed wiring

procedures.

• Detector/Transmitter Terminal Strips. Two detector/transmitter

terminal strips are located near the bottom left corner of the main circuit

board (see Figure 1). These two 9-point terminal strips facilitate wiring

connections to the detectors or transmitters. Although each terminal

strip can accommodate several different detector head models, only

one detector head at a time may be wired per channel. The top terminal

strip is for channel 1 and the bottom terminal strip is for channel 2.

• Alarm Terminal Strip. The alarm terminal strip is located along the

bottom edge of the main circuit board (see Figure 1). This 21-point

terminal strips facilitates wiring connections to external alarm devices

(horn, strobe, etc.). Terminals are provided for individual channel as

well as common alarm relay contacts.

• Controller Terminal Strip. The 10-point controller terminal strip is near

the lower right edge of the main circuit board (see Figure 1). The

controller terminal strip facilitates various internal and external wiring

connections. Table 3 lists the function of each terminal.

Table 3: Terminal Assignments for the Controller Terminal Strip

Terminal Connects to:

BAT -

BAT +

+ CH1 OUT + connection of 4 - 20 mA output, channel 1

- CH 1 OUT - connection of 4 - 20 mA output, channel 1

- connection from 24 VDC power source

+ connection from 24 VDC power source1 (or 24 V backup battery)

1

(or 24 V backup battery)

Internal Description • 13

Page 14

Table 3: Terminal Assignments for the Controller Terminal Strip (Continued)

Terminal Connects to:

+ CH2 OUT + connection of 4 - 20 mA output, channel 2

- CH2 OUT - connection of 4 - 20 mA output, channel 2

RESET (2) Reset switch (factory-wired)

BUZ-/BUZ+ Internal buzzer (factory-wired)

1

If DC power is used as the primary power source, do not make wiring connections to the AC terminal strip.

• AC In Terminal Strip. The AC in terminal strip is a 2-point terminal strip

located above the controller terminal strip (see Figure 1). It facilitates

wiring from the AC power source. Table 4 lists the function of each

terminal.

Table 4: Terminal Assignments for the AC In Terminal Strip

Terminal Connects to:

LINE Hot wire from AC power source.

NEUT Neutral wire from AC power source.

NOTE: The AC power source’s ground wire must be connected to the

ground stud. See “Connecting the AC Power Source” on page 20

for instructions.

Relays

The Beacon 200 includes four channel relays (two per channel) and three

common relays. Both sets of relays are single-pole, double-throw (SPDT)

and are rated for 10 amps at 250 VAC (resistive).

NOTE: You can select normally energized (NE) or normally de-energized

(NDE) settings for each channel in the Channel Control and Setup

program. This section describes the default setting: normally deenergized.

The alarm 1 and alarm 2 common relays are factory-set as NDE

and the fail common relay is factory-set as NE. The alarm 1, alarm

2, and fail common relays’ NE/NDE settings are not useradjustable.

• Channel Relays. The four channel relays are above the alarm terminal

strip (see Figure 1). These relays are dedicated to specific channels

and alarm levels.

14 • Internal Description

Page 15

For example, the channel 1, alarm 1 relay energizes if channel 1

K5 K6 K7

Channel 2, Alarm 1

Channel 1, Alarm 2

Channel 1, Alarm 1

K1 K2 K3

Common Alarm 1

Common Alarm 2

Common Fail

K4

Channel 2, Alarm 2

Figure 3. Beacon 200 Channel Relay Allocation

recognizes an alarm 1 condition. Figure 3 below illustrates the

allocation of the channel relays.

NOTE: The alarm 2 channel relays may be set to operate as individual

channel fail relays. See the Configure Channel Settings section of

Chapter 5 for instructions.

• Common Relays. The three common relays, alarm 1, alarm 2, and fail,

are to the left of the controller terminal strip (see Figure 1). These relays

are common for both channels.

For example, the alarm 1 common relay energizes if either channel 1 or

channel 2 recognizes an alarm 1 condition.

Fuses

There are three fuses that are used in the Beacon 200. Two of them are AC

fuses and one of them is a DC fuse.

• AC Fuses. The two fuses located directly to the left of the controller

terminal strip are the AC fuses. They cut off the incoming AC power in

the event of a short circuit or other electrical fault which causes a high

current draw in the Beacon 200. They are housed in vertical fuse

holders and are held in the holder by a quarter turn cover. They are

labelled as F2 (top fuse) and F3 (bottom fuse) on the PCB silk-screen

and are rated to 3 A, 250 V, 1/4 x 1 1/4”, fast acting.

• DC Fuse. The fuse located to the left of the power switch is the DC

fuse. It cuts off incoming DC power in the event of a short circuit or

other electrical fault which causes a high current draw in the Beacon

200. It is also housed in a vertical fuse holder and is held in the holder

by a quarter turn cover. It is labelled as F1 on the PCB silk-screen and

is rated to 6A, 250 V, 1/4 x 1 1/4”, fast acting.

Internal Description • 15

Page 16

Power Switch

The power switch is located above the relays and in between the AC and

DC fuses (see Figure 1). The power switch turns the incoming AC power

source on and off at the Beacon 200. When the switch is up, the power

switch is on.

NOTE: The DC power input has no on/off switch and is not affected by the

position of this switch.

Power Supply

The power supply is mounted to the power supply mounting plate which is

located behind the display PCB. The power supply mounting plate is

mounted to the main PCB with four standoffs. The power supply receives

the AC input from the external power source and converts it to a DC

voltage that is usable by the Beacon 200 circuitry.

16 • Internal Description

Page 17

Chapter 3: Installation and Start Up

Overview

This chapter describes procedures to mount the Beacon 200 Gas Monitor,

make wiring connections to the monitor, and start up the monitor.

WARNING: Perform all installation and start-up procedures in a

“fresh air” environment (known to be free of combustible

gas, toxic gas, and of normal oxygen content). The

Beacon 200 is not in operation as a gas monitoring

system until the start-up procedure is complete.

Mounting the Beacon 200 Gas Monitor

WARNING: Only aut horized and properly trained personnel should

perform any mounting procedures.

Perform the following procedure to install the Beacon 200 at the mounting

site.

1. Select the mounting site. When you select the mounting site consider

the following factors:

• Is an AC or DC power source available?

• Is there enough room to open the housing door and make wiring

connections through the conduit hubs at the bottom of the housing?

• Are the display screen and status lights visible?

2. Close and latch the housing door.

3. Position the monitor on a vertical surface at eye level (4 1/2 to 5 feet

from the floor).

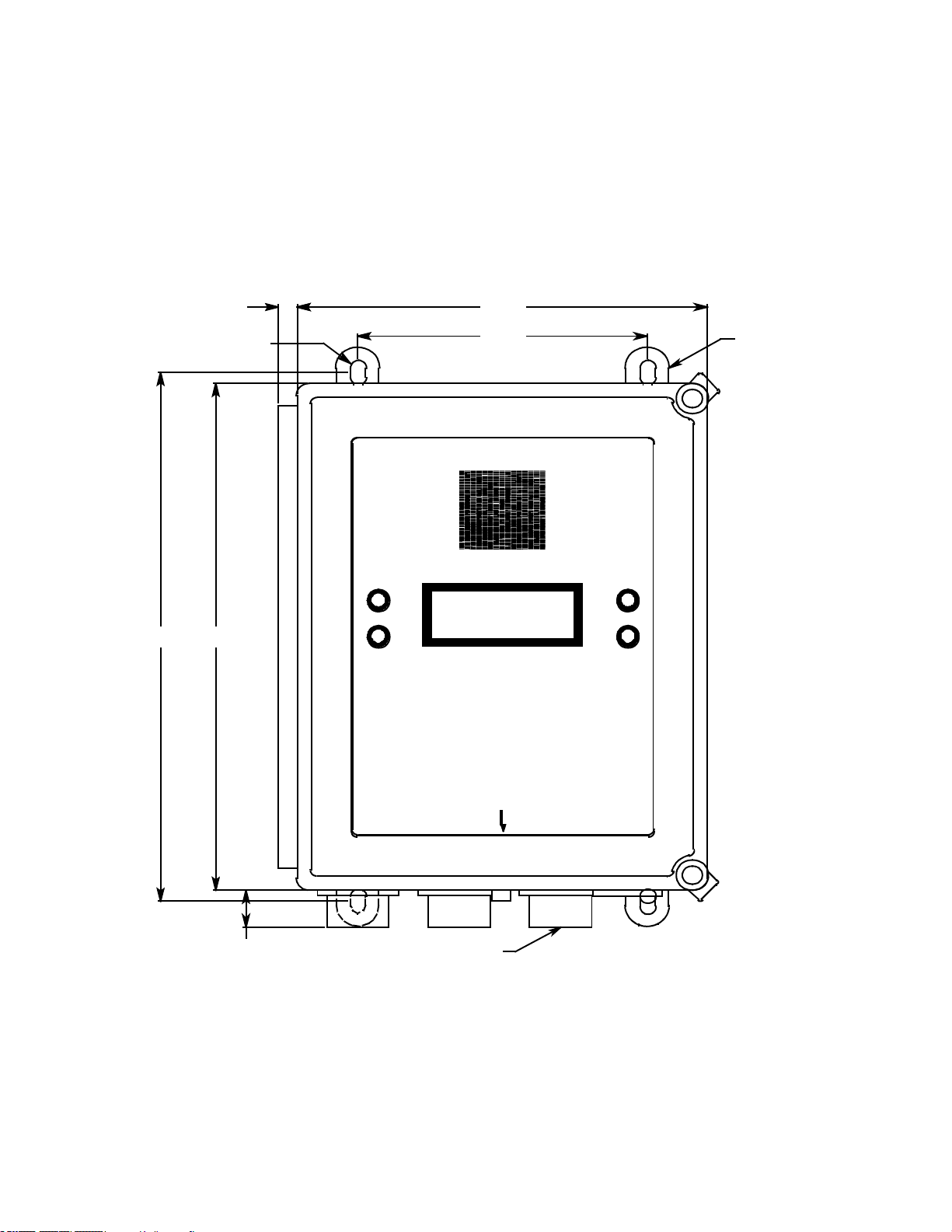

4. The Beacon 200 is shipped with the mounting feet positioned behind

the housing. Loosen the screws that secure the feet to the housing,

rotate the feet to their mounting position (as shown in Figure 4), then

tighten the screws.

Overview • 17

Page 18

5. Insert 1/4 in. or 5/16 in. screws through the slots in the mounting feet at

Mounting

Feet, 4X

Ø .38 x .50 slot, 4X

.41

6.00

8.50

ALARM 2

PILOT

FAIL

RESET

BEACON 200

GAS MONITOR

ALARM 1

10.5010.94

3/4 " Conduit Hub(3)

.80

Figure 4. Beacon 200 Gas Monitor Outline and Mounting Dimensions

each corner of the housing to secure the housing to the mounting

surface (see Figure 4).

6. Each of the door clamps has a feature for locking device installation. A

locking device that requires a tool to unlock must be installed in each

door clamp.

18 • Mounting the Beacon 200 Gas Monitor

Page 19

NO T E: A C ground

connec tion is m ade

to ground stud in

lower rig h t corn e r

of c i rcuit board.

115V/220V~

+

COM-A1 COM-FAILCOM-A2

BAT

CH2-A1CH1-A2

Reset Switch

(Fa c tory W i re d)

Buzze r

(Fa c tory W i re d)

Oxygen

Detecto r

Channel 1 Recorder

1K M axImpedance

BUZ

Green

+

White

+S

LEL

OXYG E NAMP /P REA M P

NO NC C NO NC CNO NC CNO NC C NO NC C

CHANNEL 2

+S +

LEL

OXYG E NAMP /P REA M P

Typica l Detector/Transmitter

Terminal Strip Wiring

Onl y o ne d et ector or t ransmi tterc a nbe

wired t o Ch1 orC h2 at a time. S ee d etector

head w iring d iagr am for specific wi ring.

BUZ +

RESET

RESET

CH2-A2

Typical Ala rm Re lay TerminalStrip Wiring

BAT +

AC

In Terminal Strip Wiring

CH 1

OUT

Line (H ot)

Neutral

Black

LEL Detector

Contact Rating o f 10 Amps at 115/220V~

Resistive o r 10A @ 3 0V R esistive for E ach

SetofAlarmRelayContacts.

NO NC C

RW G B

Green

FB ( 4-20 mA )

2-W ire 4-20 ma

Transm itter

+24V

3-W ire 4-20 ma

Transm itter

- DC GROUND

FB ( 4-20 mA )

RW G B

+24V

Alarm Devices

Channel 2 Recorder

1K M axImpedance

CHANNEL 1

CH 2

OUT

+

White

Red

NO NC C

Controlle r Term inal

Strip Wiring

24 V

CH1-A1

4- 20mAO ut

4- 20mAO ut

Alarm Device

Power

Figure 5. Beacon 200 Gas Monitor General External Wiring Diagram

Mounting the Beacon 200 Gas Monitor • 19

Page 20

Wiring the Beacon 200 Gas Monitor

WARNING: Only aut horized and properly trained personnel should

perform any wiring procedures.

This section describes procedures to connect the AC power source, DC

power source, external alarm(s), recorder, and detector head(s). See

Figure 5 for a general wiring diagram of all external wiring to the Beacon

200.

WARNING: Make all connections to the Beacon 200 before you plug

in or connect mains power. Before you make any wiring

adjustments, always verify that mains power to the

Beacon 200 is turned off or disconnected.

Routing Wiring Into the Beacon 200 Housing

Wiring must be brought into the housing through one of the three factoryinstalled conduit hubs on the bottom of the housing.

Do not

200 housing and routing wiring through holes not factory drilled will void the

warranty and could result in:

• Damage to internal components from the drilling process.

• Moisture damage to internal components from poorly sealed holes.

• Unpredictable Beacon 200 behavior due to EMI/RFI interference

• Possible shorting of Beacon 200 components due to wires routed

drill into the Beacon 200 housing for any reason. Drilling the Beacon

caused by wires routed across the PCBs.

across the PCBs.

Connecting the AC Power Source

NOTE: If you are using DC power as the primary power source, go to the

next section, “Connecting the DC Power Source.”

The AC In terminal strip will accept 24 - 14 AWG wire. For 115 VAC

connection, select wire that is rated to a minimum of 80°C, 0.75 A, and

150V. For 220 VAC connection, select wire that is rated to a minimum of

80°C, 0.5 A, and 250 V. When selecting wire, be sure to meet the local

electrical code.

A certified switch or circuit breaker must also be installed in the AC line. For

20 • Wiring the Beacon 200 Gas Monitor

Page 21

115 VAC connection, the switch or circuit breaker must be rated to 115

Line (H ot)

Neutral

115 V/220 V ~ ± 10%,

50/60 Hz

Disconnect D evice

AC In Terminal Strip

Figure 6. AC Power Wiring

VAC, 50/60 Hz, and 0.5 A. For 220 VAC connection, the switch or circuit

breaker must be rated to 220 VAC, 50/60 Hz, and 0.3 A.

Perform the following procedure to connect the AC power source to the

Beacon 200.

WARNING: Verify that mains power to the Beacon 200 is turned off or

disconnected before you continue with this procedure.

1. Turn off or disconnect mains power to the Beacon 200.

2. Open the housing door, then place the power switch in the OFF

position.

3. Install an appropriately rated cable bushing or conduit to the right-most

conduit hub on the bottom of the Beacon 200 housing.

CAUTION: Only use the three facto ry installed condui t hubs on the bottom

of the housing for wire entry into the housing. Do not drill the

housing for any reason. See “Routing Wiring Into the Beacon

200 Housing” on page 20 for more information.

4. Locate the 2-point AC In terminal strip (see Figure 1). The terminals

are labelled LINE and NEUT.

5. Guide the AC power cord or wires through the right-most conduit hub

on the bottom of the Beacon 200 housing.

CAUTION: Do not route power and det ector head wiring through the same

conduit hub. The p ower wiring may di sr upt th e transmission of

the detector head signal to the monitor.

6. Connect the line (hot) and neutral AC wires to the AC power terminal

strip as shown in Figure 6.

Wiring the Beacon 200 Gas Monitor • 21

Page 22

7. Connect the ground wire to the unused crimp terminal that is factory

installed at the base of the ground stud.

a. Remove all installed connections (from conduit hubs and power

supply).

b. Remove the bottom lug.

c. Crimp the ground wire to the lug.

d. Reinstall the lug.

e. Reinstall all of the other ground connections (from conduit hubs and

power supply).

WARNING: Follow this grounding procedure to maintain the CSA

classification of the Beacon 200.

Connecting the DC Power Source

WARNING: Verify that mains power to the Beacon 200 is turned off or

disconnected before you continue with this procedure.

DC power may be used as a primary power source. If DC power

(connected to the BAT terminals on the controller terminal strip) is the

primary power source, DO NOT connect AC power to the AC In terminal

strip.

A 24 VDC battery (connected to the BAT terminals on the controller

terminal strip) may also be used as a backup power source if AC power

(connected to the AC In terminal strip) is the primary power source.

The controller terminal strip will accept 24 - 14 AWG wire. Select wire that

is rated to a minimum of 80°C, 0.75 A, and 150V. When selecting wire, be

sure to meet the local electrical code.

WARNING: The BAT terminals on the controller terminal strip are

only intended for connecting a battery or a 24 VDC supply

to the Beacon 200. Do not connect any horns or strobes

to the BAT terminals on the controller terminal strip.

1. Turn off or disconnect mains power to the Beacon 200.

2. Open the housing door, then place the power switch in the OFF

position. Locate the DC power terminals on the controller terminal strip

(see Figure 1). They are labelled BAT - and BAT +

3. Install an appropriately rated cable bushing or conduit to one of the

unused conduit hubs on the bottom of the Beacon 200 housing.

22 • Wiring the Beacon 200 Gas Monitor

Page 23

CAUTION: Only use the three facto ry installed condui t hubs on the bottom

24 VDC ± 2.5 VDC

+

BAT

BAT +

Controller Terminal Strip

Figure 7. DC Power Wiring

of the housing for wire entry into the housing. Do not drill the

housing for any reason. See “Routing Wiring Into the Beacon

200 Housing” on page 20 for more information.

4. Guide a DC power cord or wires through the selected conduit hub.

CAUTION: Do not route power and det ector head wiring through the same

conduit hub. The p ower wiring may di sr upt th e transmission of

the detector head signal to the monitor.

CAUTION: When a batter y is used as backup power, the Beacon 200

trickle charges the battery. Do not use a non-rechargeable

battery as backup power. Use RKI backup battery 49-8102RK

or an appropriately rate d re cha rg ea bl e le ad acid type battery.

5. Connect the DC wires to the controller terminal strip as shown in

Figure 7.

NOTE: If a 24 VDC battery is used as a backup power source, as long as

AC power is on the Beacon 200 will keep a trickle charge on the

battery to maintain its charge. If AC power is interrupted, the

Beacon 200 will operate from the DC backup battery until the

battery voltage drops to 21.5 volts or less, or until AC power is

restored. Battery recharge time will vary depending on how much

the battery was drained.

Wiring the Beacon 200 Gas Monitor • 23

Page 24

Connecting External Alarms

The alarm terminals will accept 24 - 14 AWG wire. Select wire that is rated

to a minimum of 80°C, up to 10 A depending on the device being powered,

and up to 250V depending on the device being powered.

Perform the following procedure to connect external alarm devices to the

Beacon 200.

NOTE: The alarm terminal strip includes terminals for channel alarms

and common alarms. Channel alarms are activated by one

particular channel. Common alarms are activated by either of the

two channels.The example used in this procedure describes

connecting an external alarm device to one of the channel alarm

terminals: the channel 1, alarm 1 terminals.

WARNING: Do not connec t external alarms to the BAT terminals on

the controller terminal strip.

1. Turn off or disconnect mains power to the Beacon 200.

2. Open the housing door, then place the power switch in the OFF

position. Locate the alarm terminal strip (see Figure 1).

3. Install an appropriately rated cable bushing or conduit in an unused

conduit hub on the bottom of the Beacon 200 housing.

CAUTION: Only use the three facto ry installed condui t hubs on the bottom

of the housing for wire entry into the housing. Do not drill the

housing for any reason. See “Routing Wiring Into the Beacon

200 Housing” on page 20 for more information.

4. Guide the wiring of the external alarm device through the selected

conduit hub on the bottom of the Beacon 200 housing.

CAUTION: Do not route the external alarm wiring and detector head

wiring through the same conduit hub. The external alarm

wiring may disrupt the transmission of the detector signal to

the Beacon 200.

24 • Wiring the Beacon 200 Gas Monitor

Page 25

5. Connect the leads from the external alarm device and power to the

Beacon 200 Alarm

Terminal Strip

-(N)

+ (H)

CH1-A1

NO NC C

External Alarm

Device

External Power

Source

Figure 8. Typical External Alarm Wiring

alarm terminals as shown in Figure 8.

6. Repeat steps 3 through 5 for additional external alarm devices.

Connecting a Recorder

The recorder output terminals will accept 24 - 14 AWG wire. Select wire

that is rated to a minimum of 80°C, 0.2 A, and 150V.

Perform the following procedure to connect an analog recording device to

the Beacon 200. The output at the recorder output terminals is a 4 - 20 mA

signal that is proportional to the detection range of the applicable detector

head.

1. Turn off or disconnect mains power to the Beacon 200.

2. Open the housing door, then place the power switch in the OFF

position. Locate the recorder output terminals on the controller terminal

strip (see Figure 1).

3. Install an appropriately rated cable bushing or conduit in an unused

conduit hub on the bottom of the Beacon 200 housing.

CAUTION: Only use the three facto ry installed condui t hubs on the bottom

of the housing for wire entry into the housing. Do not drill the

housing for any reason. See “Routing Wiring Into the Beacon

200 Housing” on page 20 for more information.

4. Guide the wiring from the recording device through the selected

conduit hub on the Beacon 200.

Wiring the Beacon 200 Gas Monitor • 25

Page 26

5. Connect the wires from the recording device to the recorder output

+

CH2

OUT

+

CH1

OUT

+

Recording Device

#2, 1Kohm Max

Impedance

Recording Device

#1, 1Kohm Max

Impedance

+

Figure 9. Recorder Output Wiring

terminals as shown in Figure 9.

Connecting RKI Detector Heads

The detector/transmitter terminals will accept 24 - 14 AWG wire. Select

wire that is rated to a minimum of 80°C, 0.75 A, and 150V.

26 • Wiring the Beacon 200 Gas Monitor

Perform the following procedure to connect an RKI detector head to the

Beacon 200.

NOTE: If any of the Beacon 200’s channels have been set up for

hydrogen-specific LEL operation, that channel or channels can

only be used with a hydrogen-specific sensor. If you want to detect

a different combustible gas or use a different detector, the Beacon

200 must be sent back to RKI Instruments, Inc. for modification.

1. Turn off or disconnect mains power to the Beacon 200.

2. Open the Beacon 200 door and place the power switch in the off

position.

3. See the detector head instruction manual for instructions on how to

connect wires to the detector head.

4. Install an appropriately rated cable bushing or conduit in an unused

conduit hub on the bottom of the Beacon 200 housing.

CAUTION: Only use the three facto ry installed condui t hubs on the bottom

of the housing for wire entry into the housing. Do not drill the

housing for any reason. See “Routing Wiring Into the Beacon

200 Housing” on page 20 for more information.

Page 27

5. Route the wires in conduit or shielded cable from the detector head

through the selected conduit hub into the Beacon 200. See Table 5

below for wire size and distance guidelines.

Unshielded twisted pair cable in conduit or shielded twisted pair cable

is recommended for all the direct connect detector heads. For the LEL

detector, pair the R & B wires and the W & G wires. Shielded cable or

wires in conduit are recommended for the 2-wire and 3-wire 4 - 20 mA

transmitters.

6. Connect the wires from the detector head to the appropriate detector/

transmitter terminals. The top detector terminal strip is for channel 1

and the bottom one is for channel 2. See the detector head instruction

manual for controller terminal connections.

CAUTION: Do not route power and det ector head wiring through the same

conduit hub. The p ower wiring may di sr upt th e transmission of

the detector head’s to the Beacon 200.

Table 5: Wire Size Guidelines for RKI Detector Head Wiring

Number of

Detector Head Type

Direct Connect LEL 4 500 ft. 1,000 ft. 2,000 ft.

Direct Connect Oxygen 2 500 ft. 1,000 ft. 2,000 ft.

Direct Connect H2S 2 500 ft. 1,000 ft. 2,000 ft.

Direct Connect CO 2 500 ft. 1,000 ft. 2,000 ft.

Direct Connect Cl2 2 500 ft. 1,000 ft. 2,000 ft.

Direct Connect SO2 2 500 ft. 1,000 ft. 2,000 ft.

2-Wire 4 - 20 mA Transmitter 2 2,500 ft. 5,000 ft. 8,000 ft.

3-Wire 4 - 20 mA Transmitter 3 2,500 ft. 5,000 ft. 8,000 ft.

Wires to

Controller

Max Distance

to Controller

w/18 Gauge

Wire

Max Distance

to Controller

w/16 Gauge

Wire

Max Distance

to Controller

w/14 Gauge

Wire

Connecting User-Supplied 4 - 20 mA Transmitters

The Beacon 200 may be used with a user supplied 2-wire or 3-wire 4 - 20

mA transmitter which runs on 24 VDC. When this is done, the following

Beacon 200 parameters are normally setup at RKI Instruments: unit of

measure, item name, and full scale. For example, “PSI AIR” with a full

scale of 10 PSI.

The detector/transmitter terminals will accept 24 - 14 AWG wire. Select

wire that is rated to a minimum of 80°C, 0.75 A, and 150V.

Wiring the Beacon 200 Gas Monitor • 27

Page 28

Perform the following procedure to connect a 4 - 20 mA transmitter, which

AMP/PREAMP OXYGEN

+ + S

LEL

R W G B

2-Wire 4-20 ma

Transmitter

+ 24 VDC

FB (4-20 mA)

OXYGEN

2-Wire Connection

+ S

AMP/PREAMP

+

3-Wire 4-20 ma

Transmitter

3-Wire Connection

+ 24 VDC

FB (4-20 mA)

-

(DC GROUND)

LEL

R W G B

Figure 10. Generic 4 to 20 mA Transmitter Output Wiring

you supply, to the Beacon 200.

1. Turn off or disconnect mains power to the Beacon 200.

2. Open the Beacon 200 door and turn off the power switch.

3. See the transmitter’s instruction manual for instructions on how to

connect wires to the transmitter.

4. Install an appropriately rated cable bushing or conduit in an unused

conduit hub on the bottom of the Beacon 200 housing.

CAUTION: Only use the three facto ry installed condui t hubs on the bottom

of the housing for wire entry into the housing. Do not drill the

housing for any reason. See “Routing Wiring Into the Beacon

200 Housing” on page 20 for more information.

5. Route the wires from the transmitter through the selected conduit hub

into the Beacon 200.

6. Connect the wires from the transmitter to the appropriate detector/

transmitter terminals. The top detector terminal strip is for channel 1

and the bottom one is for channel 2. See the transmitter instruction

manual for controller terminal connections. Figure 10 below illustrates

typical transmitter wiring connections.

CAUTION: Do not route power and transmitter wiring through the same

conduit hub. The p ower wiring may di sr upt th e transmission of

the transmitter’s signal to the Beacon 200.

28 • Wiring the Beacon 200 Gas Monitor

Page 29

Starting Up the Beacon 200 Gas Monitor

WARNING: Only aut horized and properly trained personnel should

perform any startup procedures.

Perform the following procedure to place the Beacon 200 into normal

operation.

1. Complete the mounting and wiring procedures described earlier in this

chapter.

2. Complete all installation procedures described in the detector head or

user supplied 4 - 20 mA transmitter instruction manual.

3. Verify that all wiring connections are correct and secure and that the

Beacon 200’s power switch is in the OFF position.

4. Turn on or connect mains power to the Beacon 200.

5. Place the Beacon 200’s power switch in the ON position. RKI

INSTRUMENTS BEACON 200 appears on the display for a few

seconds, then WARMING UP appears for each active channel. The

warm-up period will last for one minute.

NOTE: To prevent unwanted alarms during warm up, the alarm circuits

are not active while the WARMING UP message is displayed.

6. Verify that the PILOT light is on. If the PILOT light is not on, see the

troubleshooting guide in Chapter 5, Maintenance.

7. Perform the start-up procedure for each detector head or user supplied

4 - 20 mA transmitter as described in the detector head or transmitter

instruction manual

Starting Up the Beacon 200 Gas Monitor • 29

Page 30

Chapter 4: Operation

1

2

0

20.9

%

L

E

%

CH4

Oxy

L

:

:

g

e

n

Overview

This chapter describes the Beacon 200 Gas Monitor in normal operation.

This chapter also describes the Beacon 200 in alarm 1, alarm 2, and fail

conditions and suggests response to these conditions.

Normal Operation

Normal operation is defined as follows:

• The start-up procedure is complete.

• The Beacon 200 is not indicating an alarm 1, alarm 2, or fail condition.

• The Beacon 200 is not running the Channel Control & Setup or

Calibration Programs.

During normal operation, the Beacon 200 simultaneously displays the

current gas reading, unit of measure, and target gas for each active

channel.

The PILOT light is on during normal operation indicating that the Beacon

200 is receiving incoming power.

30 • Overview

Page 31

Recorder Output Operation

The output at the recorder output terminals is a 4 - 20 mA signal for each

active channel that is proportional to the detection range of the channel. A

channel that is set as CHANNEL NOT USED or CHANNEL DISABLED in

the Channel Control & Setup Program (see Chapter 5) has an output of 0

mA.

There are several special circumstances where the recorder output will

behave as follows:

• When a channel is in WARMUP after the Beacon 200 is turned on, the

recorder output will be at 4 mA for all channel types except oxygen. For

oxygen channels, the output will be 17.4 mA while in WARMUP.

• If the Beacon 200 is being powered by a battery and is in low battery

alarm, the recorder output for each channel will be 0 mA.

• When a channel is added or a channel type changed, the display will

indicate NEEDS CALIBRATION for that channel when the Beacon 200

is first turned on and will continue to indicate this until the channel is

calibrated. In this situation, the recorder output will be 3.2 mA until the

channel is calibrated.

• If a channel goes into a fail condition, the recorder output will be 0 mA.

• If you enter any of the instrument programs, such as the Calibration

Program, the recorder output will hold at the value it was at when you

entered the program was entered until you return to normal operation.

Recorder Output Operation • 31

Page 32

Alarm Indications

This section describes the Beacon 200 in alarm 1, alarm 2, and fail

conditions and suggests response to these conditions. Table 6 below lists

the alarm indications for each condition.

NOTE: The Beacon 200 includes alarm on and alarm off delay settings for

each channel and level of gas alarm. The alarm indications

described in this section operate according to the factory set delay

settings. See the Configure Channel Settings Menu section of

Chapter 5 for all the factory settings.

Table 6: Visual and Audible Alarm Indications

Condition Cause Visual Indication(s)

Alarm 1

Alarm 2

Fail • Disconnected or misconnected

Low Battery

*

*2If DC power is used as primary or backup power source.

1

1

1

If the Beacon 200 is in both an alarm 1 and an alarm 2 condition, both alarm lights are on and the display

alternates between the gas reading and the ALARM-1 ALARM-2 messa ge.

Increasing (decreasing for O2) gas

reading at or above the alarm 1

setpoint

Increasing gas reading at or above

the alarm 2 setpoint

detector wiring

• Display reading below -10% of full

scale or lower

• Defective components

2

No AC power and DC power source

(primary or backup) less than 21.5

volts.

• ALARM 1 light is on

• Gas reading flashes and

alternates with ALARM-1

message

• ALARM 2 light is on

• Gas reading flashes and

alternates with ALARM-2

message

• FAIL light is on

• FAIL message flashes in place

of gas reading

• FAIL light is on

• SUPPLY VOLTAGE IS TOO

LOW LOW POWER

STANDBY message and actual

voltage of incoming DC power

Pulsing tone

Pulsing tone

Steady tone

None

Audible

Indication

NOTE: You can select normally energized (NE) or normally de-energized

(NDE) channel relay settings in the Channel Control & Setup

menu. The following sections describe the default setting for the

channel relays which is NDE.

Common alarm 1 and alarm 2 relays are factory-set as NDE, and

the common fail relay is factory set as NE. The common relays’

NE/NDE settings are not user-adjustable.

32 • Alarm Indications

Page 33

Alarm 1 Condition

This section describes the audible and visual indications for an alarm 1

condition and suggests response to an alarm 1 condition.

Alarm 1 Condition Indications

When the gas reading of an active channel reaches the alarm 1 setpoint,

the Beacon 200 senses an alarm 1 condition. The Beacon 200 alerts you to

an alarm 1 condition as follows:

• The ALARM 1 light turns on.

• The gas reading in alarm 1 condition flashes and alternates with the

ALARM-1 message.

• The buzzer sounds a pulsing tone.

• The common alarm 1 relay energizes.

• The applicable alarm 1 channel relay energizes.

Responding to an Alarm 1 Condition

This section suggests response to an alarm 1 condition.

1. Follow your established procedure for a low level combustible or toxic

gas condition or a decreasing oxygen content condition.

2. Oxygen alarms are self-resetting and will automatically clear when the

oxygen rises above the alarm 1 setpoint.

3. Alarms for all other gas types are latching. After the gas reading falls

below the alarm 1 setpoint, press the reset switch to reset the alarm 1

circuit. Resetting the alarm 1 circuit silences the buzzer, turns off the

ALARM 1 light, resets the channel display, and de-energizes the

common and channel alarm 1 relays.

NOTE: To silence the buzzer while in an alarm 1 condition, press the

reset switch.

You cannot de-energize the alarm 1 relays until the gas reading

falls below (above for oxygen) the alarm 1 setpoint.

Alarm Indications • 33

Page 34

Alarm 2 Condition

This section describes the audible and visual indications for an alarm 2

condition and suggests response to an alarm 2 condition.

Alarm 2 Condition Indications

When the gas reading of an active channel reaches the alarm 2 setpoint,

the Beacon 200 senses an alarm 2 condition. The Beacon 200 alerts you to

an alarm 2 condition as follows:

• The ALARM 2 light turns on.

• The gas reading in alarm 2 condition continues to flash and alternates

with the ALARM-2 messages.

• The buzzer sounds a pulsing tone.

• The common alarm 2 relay energizes.

• The applicable alarm 2 channel relay energizes.

Responding to an Alarm 2 Condition

This section suggests response to an alarm 2 condition.

1. Follow your established procedure for a high level combustible or toxic

gas condition or an increasing oxygen content condition.

2. Oxygen alarms are self-resetting and will automatically clear when the

oxygen rises above the alarm 2 setpoint.

3. Alarms for all other gas types are latching. After the gas reading falls

below the alarm 2 setpoint, press the reset switch to reset the alarm

circuit. Resetting the alarm circuit turns off the ALARM 2 light, and deenergizes the common and channel alarm 2 relays.

NOTE: To silence the buzzer while in an alarm 2 condition, press the

reset switch.

You cannot de-energize the alarm 2 relays until the gas reading

falls below the alarm 2 setpoint.

Fail Condition

This section describes the audible and visual indications for a fail condition

and suggests response to a fail condition.

Fail Condition Indications

The Beacon 200 senses a fail condition for any of the following:

• The detector head wiring to the Beacon 200 is disconnected or

34 • Alarm Indications

Page 35

incorrectly connected.

• The detector head’s detector is disconnected or incorrectly connected.

• The display reading is -10% of full scale or lower.

• The Beacon 200 or detector head is malfunctioning.

When the Beacon 200 senses a fail condition, it alerts you as follows:

• The FAIL light turns on.

• The gas reading for the failing channel is replaced by the FAIL

message.

• The buzzer sounds a steady tone.

• The common fail relay de-energizes.

NOTE: If you elected to use the channel’s alarm 2 relay as an individual

fail relay in the Channel Control & Setup menu, the relay deenergizes in a fail condition. See the Channel Control & Setup

section of Chapter 5 for a description of this setting.

Responding to a Fail Condition

This section suggests response to a fail condition.

1. Verify that the detector head wiring to the Beacon 200 is correctly and

securely connected.

2. Verify that the detector head’s detector is correctly and securely

connected.

3. See the troubleshooting guide in the detector head instruction manual.

Low Battery Condition

This section describes the audible and visual indications for a low battery

condition and suggests response to a low battery condition. This condition

only applies when DC power is used as a primary or backup power source.

NOTE: When a 24 VDC battery is used as a backup power source, the

Beacon 200 keeps the battery charged by providing a trickle

charge from the AC power source. If AC power is interrupted, the

Beacon 200 will operate from the DC backup battery until the

battery voltage drops to 21.5 volts or less, or until AC power is

restored.

Alarm Indications • 35

Page 36

Low Battery Condition Indications

The Beacon 200 senses a low battery condition when:

• AC power is disconnected, misconnected, or interrupted

AND

• the DC power source is 21.5 volts or less

When the Beacon 200 senses a low battery condition, it alerts you as

follows:

• The FAIL light turns on.

• The top display screen displays the SUPPLY VOLTAGE IS TOO LOW,

LOW POWER STANDBY message and the actual voltage of incoming

DC power.

Responding to a Low Battery Condition

This section suggests response to a low battery condition.

• If DC power is the primary power source:

1. For a temporary DC power source, disconnect primary DC power at

the Beacon 200, then connect a 24 VDC backup battery.

2. Determine and correct the cause of primary DC power loss.

When the DC power source rises above 22.0 volts, the Beacon 200

begins the warm up process.

• If DC power is the backup power source:

1. Replace or recharge the 24 VDC backup battery to resume backup

power capability.

2. Determine and correct the cause of primary AC power loss.

When backup DC or primary AC power is restored, the Beacon 200

begins the warm up process. When AC power is restored, the Beacon

200 charges the backup battery until it is fully recharged. Charge time

varies depending on the battery size and how much the battery was

depleted. Once the battery is fully charged, the Beacon 200 reverts to

a trickle charge to maintain the battery charge.

36 • Alarm Indications

Page 37

Viewing & Resetting Min/Max Readings

The reset switch may be used to view and reset the minimum and

maximum gas readings for the active channel(s).

1. While the Beacon 200 is in normal operation, press and hold the reset

switch button for 3 seconds.

2. The display will indicate MIN / MAX Display Press RESET when

done viewing . . . for 5 seconds before displaying the minimum and

maximum readings for the active channel(s). The minimum reading is

on the left and the maximum is on the right side of the display for each

channel.

3. Press and release the reset switch button to exit the min/max screen.

The display will indicate To RESET Min/MAX values Press and HOLD

RESET Button for 10 seconds and then return to normal operation.

• To return to normal operation without resetting the minimum and

maximum readings, do not press the reset switch button and allow

the unit to return to normal operation.

• To reset the minimum and maximum readings, before the unit

returns to normal operation press and hold the reset switch button

until the display indicates Min/Max Values Have Been Reset.

Release the reset switch button.The unit will then return to normal

operation.

Viewing & Resetting Min/Max Readings • 37

Page 38

Chapter 5: Channel Control and Setup Program

Overview

The Channel Control & Setup Program allows viewing of and changes to

instrument setup parameters. It is accessed using the program buttons.

The Channel Control & Setup Program includes three menus as described

in Table 7.

Table 7: Channel Control & Setup Program Menus

Menu Function

Enable/Disable Channel(s) Configures channels as enabled, disabled, or not used

Configure Channel Settings Configures alarm settings, noise filter setting, and zero

suppression setting for each channel

View System Information Displays the firmware version number and the instrument

operating voltage

To enter the Channel Control & Setup Program, simultaneously press and

hold the ESCAPE and ENTER buttons for approximately 5 seconds.

The Channel Control & Setup Program menu includes a 5-minute time-out

feature. If you do not press a button for 5 minutes, the Beacon 200

automatically returns to normal operation.

NOTE: If the Beacon 200 returns to normal operation because of a

program time-out, the active channels enter a warm-up period just

as they do when the unit is first turned on.

If you are installing a new system, the channels have been setup

at the factory for the ordered detector heads. Use the Channel

Control & Setup Program only if you want to disable or enable a

channel, delete a channel, or change channel settings. If a

channel is being added or a channel is being changed from one

type to another, contact RKI Instruments, Inc. for additional

documentation required to define the channel type.

38 • Overview

Page 39

Enable/Disable Channel(s) Menu

1. From normal operation, simultaneously press and hold the ESCAPE

and ENTER buttons for approximately 5 seconds to enter the Channel

Control & Setup Program. Release the buttons when the Control &

Setup Program Proceed? [YES] or [NO] message appears on the

display screen.

2. Press the UP/YES button to continue.

3. Press the UP/YES or DOWN/NO button until the 1) Enable/Disable

Channel(s) message appears on the display screen, then press the

ENTER button.

4. Use the UP/YES and DOWN/NO buttons to select the channel you

want to enable or disable, then press the ENTER button.

5. Press the DOWN/NO button. The CHANNEL USAGE setting displays

on the display screen.

6. Use the UP/YES and DOWN/NO buttons to display the setting you

want, then press the ENTER button to select the setting. The table

below describes the three available settings.

Table 8: Beacon 200 Channel Usage Settings

Setting Description

CHANNEL ENABLED The Beacon 200 displays gas readings and initiates gas and channel failure alarms

when appropriate.

Use this setting for normal operation when the channel has a detector head wired to

it.

CHANNEL DISABLED The Beacon 200 displays DISABLED for the channel and the channel’s alarm circuit

is not active.

Use this setting when the channel has a detector head wired to it, but gas readings

and alarms are not required for the channel (for example if the detector head requires

maintenance or is malfunctioning).

CHANNEL NOT USED The Beacon 200 leaves the channel blank on the display screen.

Use this setting when the channel does not have a detector head wired to it.

7. Press the ESCAPE button, then press the DOWN/NO button to return

to normal operation.

Enable/Disable Channel(s) Menu • 39

Page 40

Configure Channel Settings

Con f iguration for

CHANNEL 1

has nbee

completed

eSav Set t i ngs

?

[

Y

/N

]

Menu

This section describes how to view and change channel parameters for the

installed gas channels.

1. Simultaneously press and hold the ESCAPE and ENTER buttons for

approximately 5 seconds to enter the Channel Control & Setup

Program. Release the buttons when the Control & Setup Program

Proceed? [YES] or [NO] message appears on the display screen.

2. Press the UP/YES button to continue.

3. Press the UP/YES or DOWN/NO button until the 2) Configure

Channel Setting(s) message appears on the display screen, then

press the ENTER button.

4. Use the UP/YES and DOWN/NO buttons to select the channel for

which you want to set parameters, then press the ENTER button.

5. Press the UP/YES button until the parameter you want to set appears

on the display screen. The screen will display the current setting and

ask if it is OK.

Table 9 lists the parameters you can set for a channel. Table 9 also lists

the factory set value for each parameter.

NOTE: Use the ESCAPE button to go back to a previously displayed

parameter.

6. If the setting is not OK and you want to change the it, press the DOWN/

NO button. The parameter is now adjustable.

7. Use the UP/YES or DOWN/NO button to update the parameter, then

press the ENTER button to continue.

8. Repeat steps 5 through 7 to set any other channel parameters.

9. Press the UP/YES button until the following message appears on the

display screen.

40 • Configure Channel Settings Menu

Page 41

10. Press the UP/YES button to save the configuration. The screen will

then return to the Channel Control & Setup menu.

11. Press ESCAPE to return to the screen which asks Control & Setup

Program Proceed? [YES] or [NO].

12. {Press the DOWN/NO button to return to normal operation.

Table 9: Channel Setting Parameters

Parameter

(Factory-Set Value)

ALARM-1 Level

See the Beacon 200 Detector Head

Specification Sheet for the detector

head installed on this channel

ALARM-1 ON DELAY

(1 sec)

ALARM-1 OFF DELAY

(0 sec)

ALARM-1 (activation)

(DECREASING for oxygen channels,

INCREASING for all other channel

types)

ALARM-1 Relay (action)

(NORMALLY DE-ENERGIZED)

ALARM-1 Relay (reset)

(SELF RESETTING for oxygen,

LATCHING for all other channel types)

Description

The gas reading at which the Beacon 200 initiates an alarm 1 condition

for this channel.

The amount of time the Beacon 200 delays activation of the alarm 1

circuit once an alarm 1 condition is initiated.

The amount of time the Beacon 200 delays turning off the alarm 1 circuit

once an alarm 1 condition passes.

Indicates if the alarm 1 circuit is activated by gas readings INCREASING

or DECREASING to the ALARM-1 Level.

If set as NORMALLY DE-ENERGIZED, the channel’s alarm 1 relay is de-

energized in normal operation and energizes when an alarm 1 condition

is initiated.

If set as NORMALLY ENERGIZED, the channel’s alarm 1 relay is

energized in normal operation and de-energizes when an alarm 1

condition is initiated.

If set as LATCHING, you must press the RESET button to reset the

alarm 1 circuit after the alarm 1 condition passes.

If set as SELF RESETTING, the Beacon 200 automatically resets the

alarm 1 circuit after the alarm 1 condition passes.

ALARM-2 Relay (used for)

(ALARM-2 Condition)

ALARM-2 Level

See the Beacon 200 Detector Head

Specification Sheet for the detector

head installed on this channel

ALARM-2 ON DELAY

(2 min for oxygen, 1 sec for all other

channel types)

ALARM-2 OFF DELAY

(0 sec)

If set as ALARM-2 Condition, the channel’s alarm 2 relay activates

when an alarm 2 condition is initiated for the channel.

If set as FAIL Condition, the channel’s alarm 2 relay activates when a

fail condition is initiated for the channel.

The gas reading at which the Beacon 200 initiates an alarm 2 condition

for this channel.

The amount of time the Beacon 200 delays activation of the alarm 2

circuit once an alarm 2 condition is initiated.

The amount of time the Beacon 200 delays turning off the alarm 2 circuit

once an alarm 2 condition passes.

Configure Channel Settings Menu • 41

Page 42

Table 9: Channel Setting Parameters (Continued)

Parameter

(Factory-Set Value)

ALARM-2 (activation)

(INCREASING)

ALARM-2 Relay (action)

(NORMALLY DE-ENERGIZED)

ALARM-2 Relay (reset)

(SELF RESETTING for oxygen,

LATCHING for all other channel types)

NOISE FILTER

(3)

ZERO SUPPRESSION

(0.0% of the detection range in terms

of the detection units for carbon

dioxide channel types, 0.5% oxygen

for oxygen channels, 2.0% of the

detection range in terms of the

detection units for all other channel

types)

Description

Indicates if the alarm 2 circuit is activated by gas readings INCREASING

or DECREASING to the ALARM-2 Level.

If set as NORMALLY DE-ENERGIZED, the channel’s alarm 2 relay is de-

energized in normal operation and energizes when an alarm 2 condition

is initiated.

If set as NORMALLY ENERGIZED, the channel’s alarm 2 relay is

energized in normal operation and de-energizes when an alarm 2

condition is initiated.

If set as LATCHING, you must press the RESET button to reset the

alarm 2 circuit after the alarm 2 condition passes.

If set as SELF RESETTING, the Beacon 200 automatically resets the

alarm 2 circuit after the alarm 2 condition passes.

The noise filter feature helps “smooth out” jumpy or noisy signals from

the detector head. You can set the noise filter from 1 to 8.

A setting of 8 produces the greatest amount of smoothing but also

responds slowest to changes in the response reading.

A setting of 1 responds fastest to changes in the response reading but

produces the least amount of smoothing.

The zero suppression feature helps prevent “jumpy” readings near the

fresh air reading.

For example, if the zero suppression setting on a %LEL channel is 2.0%

and the full scale is 100% LEL, the Beacon 200 will display a reading of

0% LEL for gas readings from -2% LEL to 2% LEL.

View System Information Menu

The View System Information Menu consists of only one display screen

which indicates the version number of the firmware that is running the

instrument and the system voltage. The system voltage is the voltage that

is directly running the instrument’s circuitry. When the unit is running from

AC power, this voltage is normally 24.0 volts ± 0.2 volts. When the unit is

running from DC power, this voltage reading can be used as an indication

of the DC voltage powering the unit.

42 • Configure Channel Settings Menu

Page 43

Chapter 6: Input Setup Program

Overview

This chapter describes how to use the Input Setup Program to add a

channel or change the channel type of an installed channel on the Beacon

200. The Input Setup Program allows you to define the type of detector

head, the units and gas type, and the full scale for that channel.

To enter the Input Setup Program, the Beacon 200 must first be off. While

the Beacon 200 is off, press and hold the ENTER button, then turn on the

Beacon 200 with the ON/OFF switch.

The Input Setup Program menu includes a 5-minute time-out feature. If you

do not press a button for 5 minutes, the Beacon 200 automatically begins

normal operation.

NOTE: If the Beacon 200 enters normal operation because of a program

time-out, the active channels enter a warm-up period just as they

do when the unit is first turned on.

Overview • 43

Page 44

Setting Up a New Channel or Changing an Existing Channel

1. While the Beacon 200 is off, press and hold the ENTER button, then

turn on the Beacon 200 with the ON/OFF switch.

2. The Beacon 200 will beep repeatedly while you are holding down the

ENTER button and then the screen will show INPUT SETUP

PROGRAM on the top line.

3. Press the ENTER button to continue.

If you press the ESCAPE button, the unit will start-up and enter its

warm-up period.

4. Press the UP/YES or DOWN/NO button until the channel you wish to

add or change appears on the display screen, then press the ENTER

button. The detector head type screen appears.

5. The display screen indicates what type of detector head is currently

selected for that channel and asks if it is OK. Table 1 below briefly

describes each type.

Table 10: Beacon 200 Detector Head Types

Detector Head Type Description

4 - 20 mA Amp [+S(-)] A 4 - 20 mA detector head is connected to the Beacon 200

with 2 or 3 wires, depending on the detector head model,

using the AMP/PREAMP +, S, and - terminals on a detector

head terminal strip. All calibration adjustments are made at

the detector head.

PreAmp [+S] A PreAmp detector head is connected to the Beacon 200 with

2 wires using the AMP/PREAMP + and S terminals on a

detector head terminal strip. All calibration adjustments are

made at the Beacon 200.

O2 Direct [+-] An O2 Direct detector head is an oxygen detector head in

which the oxygen detector is wired to the Beacon 200 with 2

wires using the OXYGEN + and - terminals on a detector

head terminal strip. All calibration adjustments are made at

the Beacon 200.

LEL Direct [RWGB] An LEL Direct detector head is a combustible gas detector

head in which the combustible gas detector is wired to the

Beacon 200 with 4 wires using the LEL R, W, G, and B

terminals on a detector head terminal strip. All calibration

adjustments are made at the Beacon 200.

If the detector head type is not correct, press the DOWN/NO button

and continue with step 6.

44 • Setting Up a New Channel or Changing an Existing Channel

Page 45

If the detector head type is correct, press the UP/YES button to

proceed to the units and gas type screen and skip to step 7.

NOTE: See the detector head operator’s manual and the Beacon 200

Detector Head Specification sheet for the detector head to

determine the detector head type.

6. Use the UP/YES and DOWN/NO buttons to scroll through the list of

detector head types until the correct one is displayed. Press the

ENTER button to accept the type. The units and gas type screen

appears.

7. If the units and gas type are not correct, press the DOWN/NO button

and continue with step 8.

If the units and gas type are correct, press the UP/YES button to

proceed to the full scale screen and skip to step 9.

8. Use the UP/YES and DOWN/NO buttons to scroll through a list of units

and gas type choices.

NOTE: See the Beacon 200 Detector Head Specification Sheet for the

detector head to determine the correct units and gas type.

When the desired units and gas type appears, press the ENTER

button to accept the choice. The full scale screen appears.

One of the choices is User Will Specify. If the desired units and gas

type setting is not in the list, this setting will allow you to enter a 10

character units and gas type setting. With this choice displayed, press

the ENTER button and a screen will appear which allows you to input

the characters. Use the UP/YES and DOWN/NO buttons to select a

character and then press ENTER to accept it and continue with the

next character. When all characters have been entered, the full scale

screen will appear.

9. If the full scale setting is not correct, press the DOWN/NO button and

continue with step 10.

If the full scale setting is correct, press the UP/YES button to proceed

to the save screen and skip to step 11.

Setting Up a New Channel or Changing an Existing Channel • 45

Page 46

10. Use the UP/YES and DOWN/NO buttons to scroll through a list of full

scale settings.

NOTE: See the Beacon 200 Detector Head Specification Sheet for the

detector head to determine the correct full scale setting.

When the desired full scale setting appears, press the ENTER button

to accept the setting. The save screen appears.

One of the choices is User Will Specify. If the desired full scale setting

is not in the list, this setting will allow you to enter a full scale setting.

With this choice displayed, press the ENTER button and a screen will

appear which prompts you to choose how many decimal places you

want in the full scale setting. You can select up to 3 decimal places,

then press the ENTER button to proceed to the select full scale screen.

Use the UP/YES and DOWN/NO buttons to select a full scale setting,

then press ENTER to accept it. The save screen appears.

11. To save the settings, press the UP/YES button and the settings will be

saved. The display will return to the first screen of the Input Setup

Program.

If you do not want to save the settings, press the DOWN/NO button.

The display will return to the first screen of the Input Setup Program.

12. Press the ENTER button to perform additional setup or the ESCAPE

button to exit the Input Setup Program and begin the Beacon 200’s

warm-up sequence.

NOTE: Once the Beacon 200 channels are configured correctly, see the

detector head operator’s manual(s) for a complete description of

detector head installation procedures.

46 • Setting Up a New Channel or Changing an Existing Channel

Page 47

Chapter 7: Maintenance

WARNING: Only aut horized and properly trained personnel should

perform any maintenance procedures.

Overview

This chapter describes use of the Calibration Program and corrective

maintenance procedures for the Beacon 200. It includes a troubleshooting

guide for problems you may encounter with the Beacon 200. Procedures to

replace components of the Beacon 200 are at the end of this chapter.

Calibration Program

The Calibration Program is used to calibrate the Beacon 200’s active

channel(s). Since the Beacon 200 can support both direct connect (internal

amp) and 4-20 mA transmitter (remote amp) detector heads, when

calibrating the active channel(s) there are three possible detector head

combinations:

• Direct connect detector head(s) only.

If one or two direct connect detector heads are active, then all

calibration adjustments are made at the Beacon 200 after calibration

gas is applied at the detector(s).

• 4-20 mA transmitter detector head(s) only.

If one or two 4-20 mA transmitter detector heads are active, then all

calibration adjustments are made at the detector head(s) after

calibration gas is applied to the detector(s).

• A direct connect and a 4-20 mA transmitter detector head.

If one direct connect and one 4-20 mA transmitter detector head are

installed, then calibration adjustments must be made at the Beacon 200

for the direct connect detector head after applying gas to its detector,