Page 1

Beacon 110 Rig Monitor

Operator’s Manual

Part Number: 71-0 232RK

Revision: C

Released: 9/30/14

RKI Instruments, Inc.

www.rkiinstruments.com

Page 2

WARNING

Read and understand this instruction manual before operating

instrument. Improper use of the rig monitor could result in bodily

harm or death.

Periodic calibration and maintenance of the rig monitor is

essential for proper operation and correct readings. Please

calibrate and maintain this rig monitor regularly! Frequency of

calibration depends upon the type of use you have and the sensor

types. Typical calibration frequencies for most applications are

between 3 and 6 months, but can be required more often or less

often based on your usage.

Beacon 110 Rig Monitor Operator’s Manual

Page 3

Product Warranty

RKI Instruments, Inc. warrants gas alarm equipment s old by us t o be free from def ects in material s,

workmanship, and performance for a period of one year from date of shipment from RKI

Instruments, Inc. Any parts found defective within that period will be repaired or replaced, at our

option, free of charge. This warrant y does not apply to those items which by their nature are subject

to deterioration or consumption in normal service, and which must b e cleaned, repaired, o r replaced

on a routine basis. Examples of such items are:

Warranty is voided by abuse including mechanical damage, alteration, rough handling, or repair

procedures not in accordance with the operator’s manual. This warranty indicates the full extent of

our liability, and we are not responsible for removal or replacement costs, local repair costs,

transportation costs, or contingent expenses incurred without our prior approval.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER

WARRANTIES AND REPRESENTATIONS, EXPRESSED OR IMPLIED, AND

ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF RKI

INSTRUMENTS, INC. INCLUDING BUT N OT LIMITED T O, THE WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN

NO EVENT SHALL RKI INSTRUMENTS, INC. BE LIABLE FOR INDIRECT,

INCIDENTAL, OR CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND

CONNECTED WITH THE USE OF ITS PRODUCTS OR FAILURE OF ITS

PRODUCTS TO FUNCTION OR OPERATE PROPERLY.

a) Absorbent cartridges d) Batteries

b) Pump diaphragms and valves e) Filter elements

c) Fuses

This warranty covers instruments and parts sold to users by authorized distributors, dealers, and

representatives as appointed by RKI Instruments, Inc.

We do not assume indemnification for any accident or damage caused by the operation of this gas

monitor, and our warranty is limited to the replacement of parts or our complete goods.

Beacon 110 Rig Monitor Operator’s Manual

Page 4

Table of Contents

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About the Beacon 110 Rig Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 2: Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

External Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Internal Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 3: Installation & Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mounting the Beacon 110 Rig Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wiring the Beacon 110 Rig Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 4: Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Information Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4 - 20 mA Signal Output Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Viewing and Resetting Min/Max Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Alarm Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Chapter 5: Configuration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Viewing & Changing Beacon 110 Rig Monitor Parameters . . . . . . . . . . . . . . . . . . . . . . 22

Beacon 110 Rig Monitor Operator’s Manual

Page 5

Chapter 6: Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Calibration Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Calibration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Adjusting Strobe/Horn Volume. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Replacing Components of the Rig Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Trouble Shooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Appendix A: Control Button Quick Reference Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Beacon 110 Rig Monitor Operator’s Manual

Page 6

Chapter 1: Introduction

Overview

This chapter briefly describes the Beacon 1 10 R ig Monitor. This chapter also describes the Beacon

110 Rig Monitor Operator’s Manual (this document). Table 1 at the end of th is chapter lists the

specifications for the Rig Monitor.

About the Beacon 110 Rig Monitor

The Beacon 110 Rig Monitor is a fixed mount, hydrogen sulfide monitoring controller designed for

use at oil drilling sites. All user adjustable parameters may be accessed using push button switches.

A direct connect hydrogen sulfide (H

The Rig Monitor displays the current gas reading on an LCD display which is visible through a

window in the housing door. It includes audible and visual alarms that warn you of hazardous gas

conditions. The alarm circuit includes two levels of gas alarms. The fail circuit alerts you to failures

in the gas detector head or controller . The Rig Monitor pro vi des a 4 - 20 mA sig nal prop orti on al to

the target gas reading for use by a recording device. Two sets of relay contacts, one controlled by

Alarm 2 and one by the fail alarm, rated at 10 amps 115 VAC, 10 amps 220 VAC, and 10 amps 30

VDC are available for controlling devices such as lights or horns or for controlling higher rated

relays. The alarm 1 relay is factory wired to the strobe/horn.

S) detector is connected to the Beacon 110.

2

Two operating modes allow you to display and change setup and calibration settings. They are

Calibration Mode and Configuration Mode.

About this Manual

The Beacon 110 Rig Monitor Operator’s Manual uses the following conventions for notes,

cautions, and warnings.

NOTE: Describes additional or critical information.

CAUTION: Describes potential damage to equipment.

WAR NING: Describes potential danger that can result in injury or death.

1 Beacon 110 Rig Monitor Operator’s Manual

Page 7

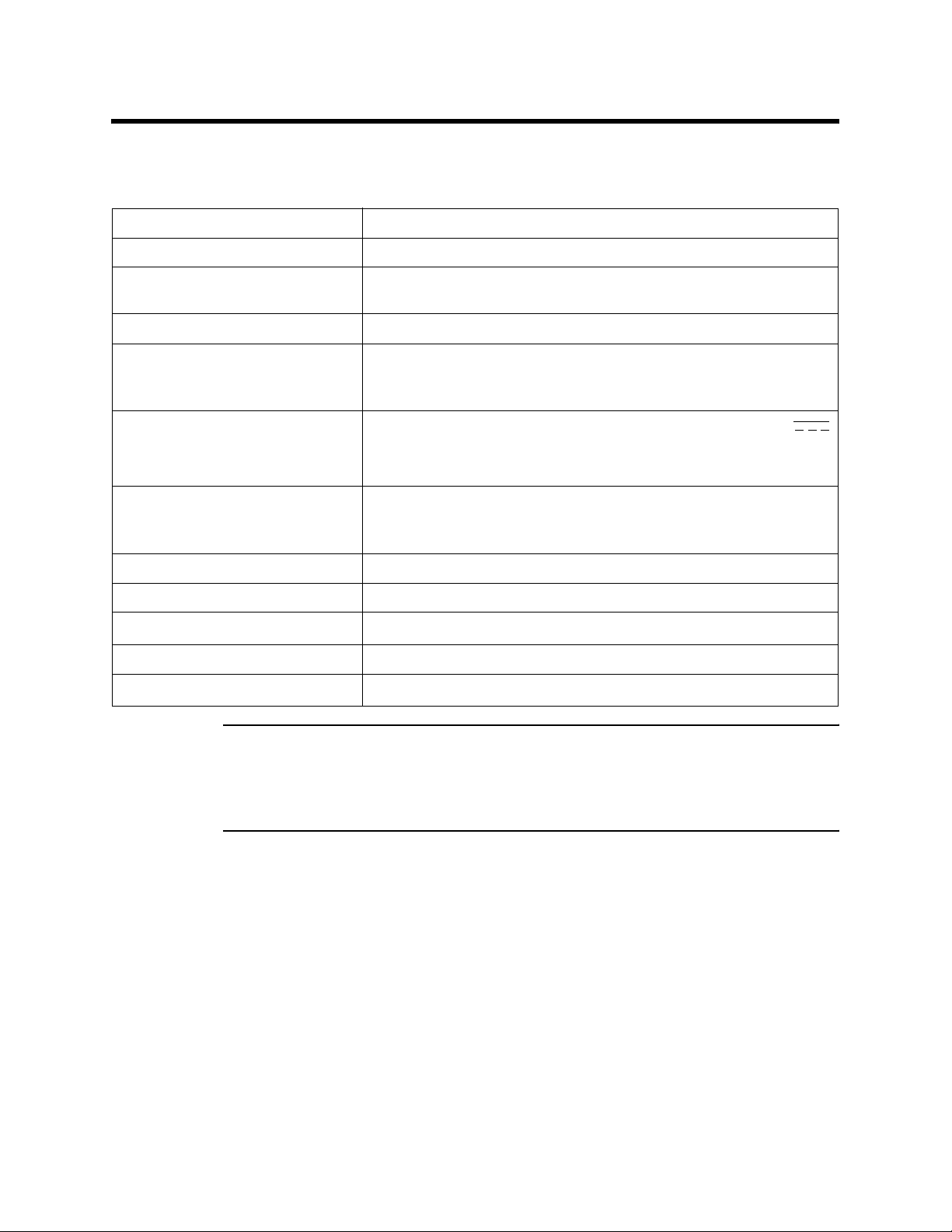

Specifications

Table 1 lists specifications for the Beacon 110 Rig Monitor.

Table 1: Beacon 110 Rig Monitor Specifications

Input Power 10.8 - 14.5 VDC, 1A VDC

Construction (housing) Fiberglass/polyester with lexan window (NEMA 4X)

Dimensions 19 in. H x 7.2 in. W x 5.6 in. D

(483 mm H x 183 mm W x 142 mm D)

Weight 13 lbs.

Environmental Conditions • For indoor or outdoor locations (Type 4X)

• -20°C to 50°C (-4°F to 122°F) ambient

• Maximum relative humidity of 80%

Relays • Relay contacts rated for 10A @ 115/220V~ resistive or 10A @ 30V

User Controls • Three push button control switches

Signal Output • 4 to 20 mA, 500 ohms impedance max

Sampling Method Diffusion

Detection Range 0 to 100 PPM (parts per million) H

Response Time 90% in 30 seconds

Accuracy ± 5% of reading or ± 2 ppm H

resistive

• SPDT Form C except for Alarm 1 relay contact (factory wired to alarm

strobe/horn)

• One ON/OFF toggle switch

• One push button reset switch

S

2

S (whichever is greater)

2

WARN ING: When using the Beacon 110 Rig Monitor, you must follow the instructions and

warnings in this manual to assure proper and safe operation of the

Beacon 110 Rig Monitor and to minimize the risk of personal injury. Be sure to

maintain and periodica lly calibr ate the Be acon 110 Rig Monitor as described in

this manual.

Beacon 110 Rig Monitor Operator’s Manual 2

Page 8

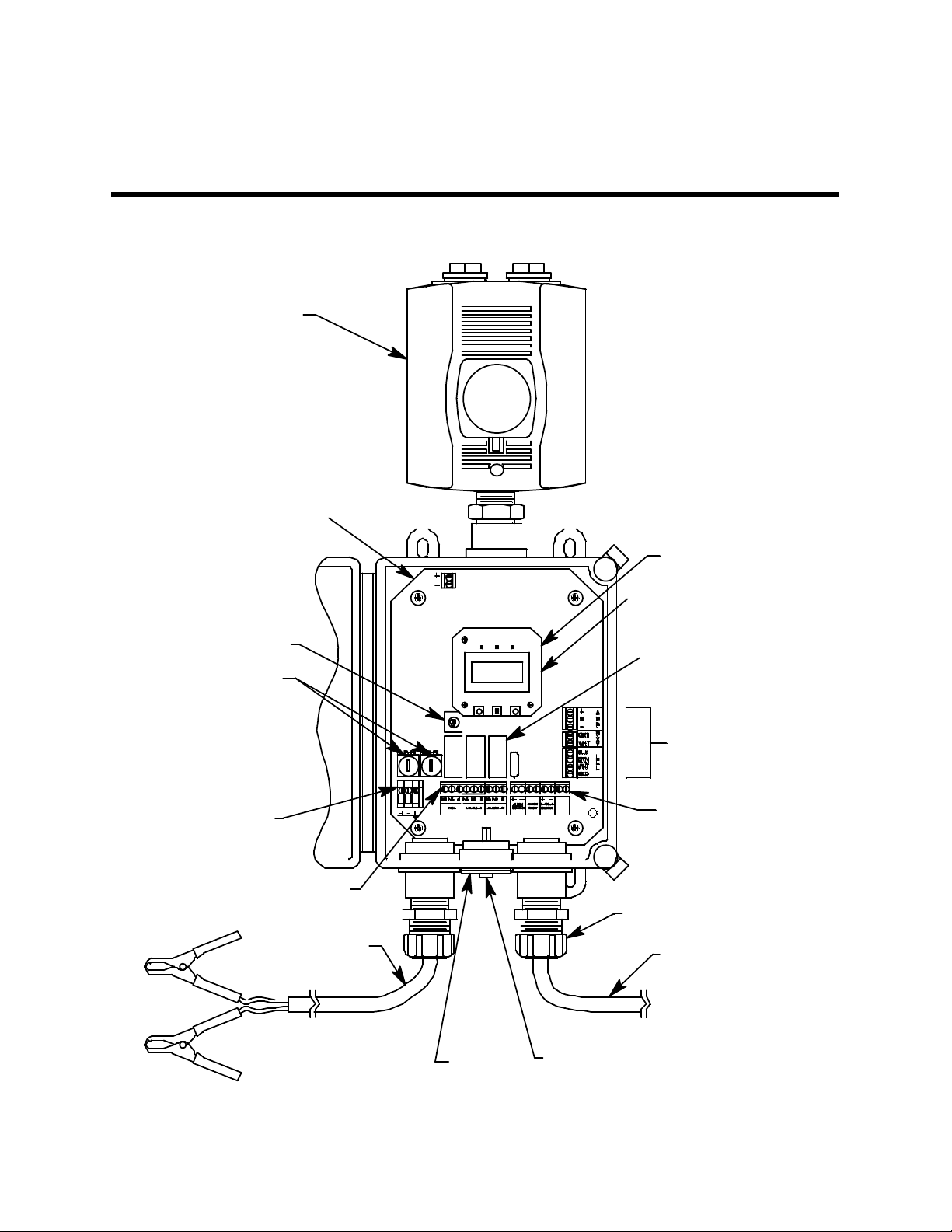

Chapter 2: Description

Overview

This chapter describes external and internal components of the Beacon 110 Rig Monitor.

HORN/STROBE

MAINPCB

POWER SWITCH

DC FUSES

DC IN

TERMINAL STRIP

ALARM TERMINALSTRIP

12VDC BATT ERY

CABLE

CONTROL PCB

POWER CONVERTER

(UNDER CONTR OL P CB)

RELAY (3X)

DETECTOR/

TRANSMITTER

TERMINAL

STRIPS

FAC TORY

12 VDC

WIRED

CONTROLLER

TERMINALSTRIP

CABLE BUSHING (2X)

DETECTOR CABLE

BUZZ ER

RESET SWITCH

(BEHIND BUZZER)

Figure 1: Beacon 110 Rig Monitor Component Location

3 Beacon 110 Rig Monitor Operator’s Manual

Page 9

External Description

This section describes th e hous ing and all external componen ts of the B eacon 110 Rig Monitor. For

the purposes of this description, the housing door is considered the front of the monitor.

Housing

The Rig Monitor’s fiberglass housing is weather- and corrosion-resistant. It is suitable for

installation where general purpose equipment is in use. The housing door is hinged on the left side

and is secured by two latches on the right side. The display screen and status lights are visible

through a window in the housing door. Four mounting feet are attached to the back of the housing

(one at each corner). The mounting feet allow installation to a ve rtical sur face. Two cable bushings

on the bottom of the housing are for wiring connections. One cable bushing is for the 12 VDC

battery connection. The other is for the direct connect H

wired.

Buzzer

The buzzer is on the bottom center of t he housing in front of the reset switch. The buzzer sounds

audible alarms to warn you of gas alarms and instrument failures.

Reset Switch

S detector connection. Both are factory

2

The reset switch is on the bottom of the housing behind the buzzer. The reset switch serves four

functions:

• You can reset the alarm circuits for “latched” alarms after an alarm 1 or alarm 2 condition

passes.

• You can silence the buzzer during an alarm 1 or an alarm 2 condition. You cannot silence a fail

condition.

• You can turn off the strobe/horn in an alarm 1 condition once the condition has passed.

• You can display and reset the minimum and maximum readings that the Rig Monitor has

experienced since the last min/max reset or startup.

Alarm Strobe/Horn

The Rig Monitor has a red alarm strobe light/horn installed on the top of the housing. The Rig

Monitor retains its NEMA 4X rating with the strobe installed. Strobe/horn operation is controlled

by the Alarm 1 relay contacts. The relay action settings can be changed in Configuration Mode.

Beacon 110 Rig Monitor Operator’s Manual 4

Page 10

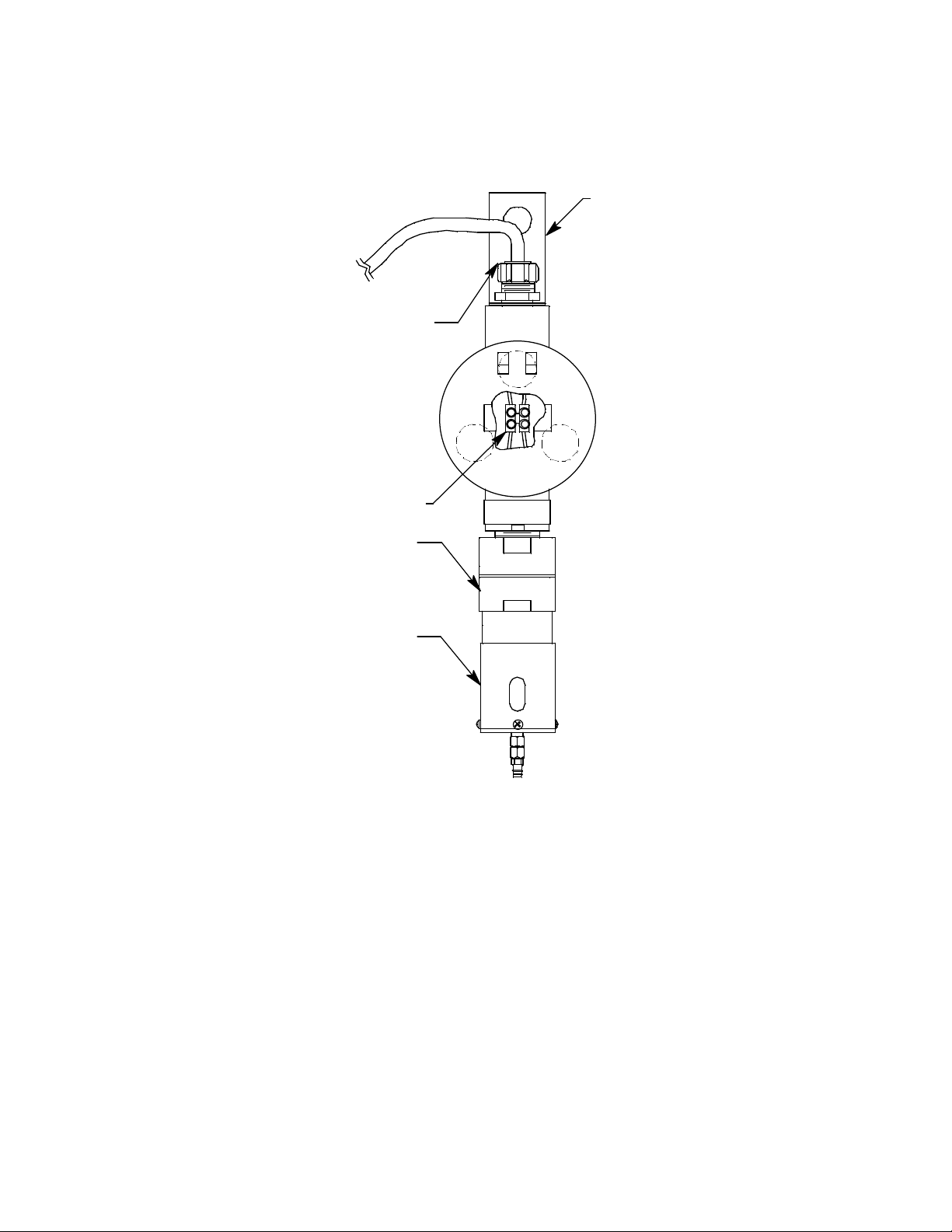

H2S Detector and Cable

The H2S detector consists of a junction box with a mounting bracket, the detector, and the

calibration cup/splash guard.

Mounting Bracket

To Beacon 110

Cable Bushing

Terminal Strip

H2S Detector

(Factory Wi red)

CalibrationCup/

Splash Guard

Figure 2: H

S Detector Component Location

2

The H2S detector is factory wired through the right cable bushing of the Beacon 110 controller an d

has a 25 foot cable for remote installation. The mounting bracket at the top of the junction box is

used to mount the junction box. The junction box protects the detector wiring connections. Three

spacers installed on the back of the junction box control the distance of the junction box from a

mounting surface and ensure that there is enough room to perform a calibration. A cover on the

front of the junction box allows access to the interior of the junction box.

The detector housing body protects the sensing componen ts w ith i n th e h ous i ng. U s e the removable

cap near the bottom of the housing to access the sensor for maintenance or replacement. The cap

protects the sensor from damage and includes a flame arrestor which contains any sparks which

may occur within the detector housing. A cap gasket seals the interface between the housing and

cap. A flame arrestor guard is permanently bonded to the cap.

The calibration cup/splash guard is screwed onto the bottom of the flame arrestor guard.

5 Beacon 110 Rig Monitor Operator’s Manual

Page 11

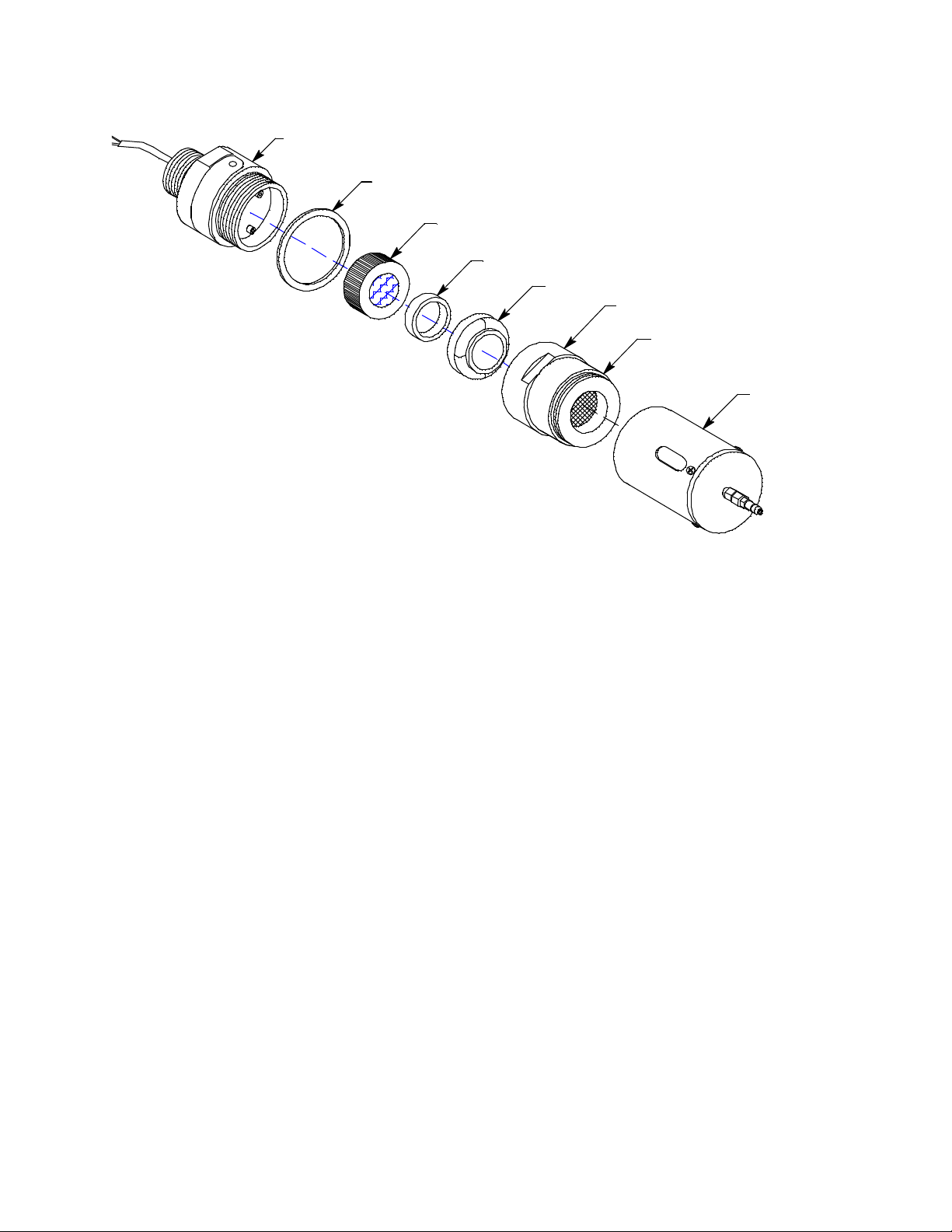

Detector Housing Body

/

Cap Gasket

H2S Pl ug - in Senso r

Spacer

Rubber Boot

Detector

Housing Cap

Flame

Arrestor

Guard

Calibration Cup

Splash Guard

Figure 3: H2S Detector Component Location

The sensor is secured within the sensor housing by four pins. Through a series of chemical and

electrical reactions, the sensor produces an electrical outp ut that corres po nds t o the det ecti on rang e

of the detector . A pre-amplifier, located between the sockets and two interconnect wires, conditions

the sensor’s signal before the signal reaches the controller. A rubber boot and spacer are installed

on the sensor face to ensure that the sensor remains plugged into the detector housing body.

12 VDC Battery Cable

A 50 foot cable with clamps for connection to a 12 VDC battery (customer supplied battery not

included) is factory-wired through the left ca ble bush ing of the Beacon 110. One end of the cable is

connected to the Beacon 110 terminal strips.

Beacon 110 Rig Monitor Operator’s Manual 6

Page 12

Internal Description

This section describes the internal components of the Beacon 110 Rig Monitor

Power Converter

The power converter is located underneath the control PCB. It takes 12 VDC voltage supplied to

the Rig Monitor and converts it to 24 VDC which is used to run the Rig Monitor.

Main Printed Circuit Board (PCB)

The main PCB is mounted inside the housing. The main PCB includes the terminal strip s, relays ,

fuses, and power switch.

Terminal Strips

The Rig Monitor includes terminal strips for field and factory wiring connections. See “Wiring the

Beacon 110 Rig Monitor” on page 13 for detailed wiring procedures.

• 12 VDC In Terminal Strip. The 12 VDC In terminal strip is a 3-point terminal strip located in

the lower left corner of the main PCB. It facilitates wiring from a 12 VDC battery with the

factory supplied battery cable. Table 2 lists the function of each terminal.

Table 2: Terminal Assignments for the DC In Terminal Strip

Terminal Connects to:

12 VDC + Positive (white) wire from 12 V battery.

12 VDC - Negative (black) wire from 12 V battery.

Earth ground, factory wired

• Alarm Terminal Strip. The 9-point alarm terminal strip is located along the bottom edge of

the main circuit board to the right of the DC In terminal strip (see Figure ). It facilitates wiring

external alarm devices (horn, strobe, etc.) to the alarm relay contacts and includes common

(C), normally closed (NC) and normally open (NO) terminals for fail, alarm 1, and alarm 2.

The factory installed s trobe/ horn i s factor y wired to the NO contact o f th e Alarm 1 relay and to

the (-) contact of the external DC terminal.

• Controller Terminal Strip. The 8-point controller terminal strip is located along the bottom

edge of the main circuit board to the right of the alarm terminal strip (see Figure ). The

controller terminal strip facilitates various internal and external wiring connections. Table 3

lists the function of each terminal.

Table 3: Terminal Assignments for the Controller Terminal Strip

Terminal Connects to:

Alarm Buzzer + & - Factory installed buzzer (factory-wired)

Alarm Reset (2) Reset switch (factory-wired)

4 - 20 mA Output + + connection of 4 - 20 mA output

4 - 20 mA Output - - connection of 4 - 20 mA output

FACTORY WIRED (TB9) (right terminal) not used

FACTORY WIRED (TB9) (left terminal) - connection from 12 VDC strobe, factory wired

7 Beacon 110 Rig Monitor Operator’s Manual

Page 13

• Detector/Transmitter Terminal Strips. Three adjacent terminal strips are located along the

right side of the main circuit board above the controller terminal strip (see Figure ). These three

terminal strips labelled LEL, Oxy , and AMP facilitate wiring connections to a detector or a 4 -

20 mA transmitter. The Beacon 110 Rig Monitor only uses the top terminal strip, labelled

AMP, for wiring to the H

S detector. The LEL and Oxy terminal strips are not used.

2

Ground Stud

The threaded ground stud is used for making connections to earth ground. It is connected through

the main PCB to the (earth) terminal on the 12 VDC In terminal strip. A kep nut on the stud

may be removed for installation of one or more lugs to make wiring connections. The detector

cable shield’s drain wire is connected to the stud.

Relays

The Rig Monitor includes three alarm relays located above the alarm terminal strip. They are from

left to right Fail, Alarm 1, and Alarm 2. The relays are form C, single-pole, double-throw (SPDT)

and rated for 10 amps at 250 VAC (resistive). The Rig Monitor uses the Alarm 1 relay to control the

factory installed strobe/horn. Only the Fail and Alarm 2 relays are available for customer use.

NOTE: You can select normally energized (N.EN) or normally de-energized (N.DE-EN)

settings for the alarm 1 and alarm 2 relays. S ee “Chapter 5: Configuration Mode” on

page 22.

The fail relay is factory set as normally energized and is not user adjustable.

DC Circuit Protection

Two DC fuses are used in the Rig Monitor. The two fuses are located on the left side of the main

PCB, above the 12 VDC power terminal strip. They cut off the incoming 12 VDC power in the

event of a short circuit or other electrical fault which causes a high curren t draw in the Rig Monitor.

They are housed in vertical fuse holders and are he ld in the holder by a qu arter turn cover. They are

labelled as F1 (left fuse) and F2 (right fuse) on the PCB silk-screen and are rated at 3 A, 250 V.

Power Switch

The power switch is located to the right o f the power s upply and above the relays ( see Figure ). The

power switch turns the incoming 12 VDC power source on and off at the Rig Monitor. When the

switch is up, the power switch is on.

Control PCB

The LCD display and control buttons are located on th e control PCB. It is installed on the main

PCB with three standoffs. The control PCB is connected to the main PCB with the display cable

which is a ribbon cable terminated with 20 position rectangular connectors on each end. The

display cable connects to the control PCB on the back of the top edge and to the main PCB directly

below the control PCB.

Beacon 110 Rig Monitor Operator’s Manual 8

Page 14

F

Alarm 1 LED

er

ail LED

F

A1 A2

Alarm 2 LED

LCD Display

Contrast

Potentiomet

UP/YES DOWN/NO

ENTER

Control Switches

Figure 4: Control PCB Component Location

LCD Display

The LCD display is located at the top of the control PCB. It indicates the current gas reading and

displays messages and parameters in the Rig Monitor’s operating modes.

Contrast Potentiometer

The contrast potentiometer is located to the right of the LCD display. It is used to adjust the contrast

of the LCD. If the background of the LCD appears so dark that the characters are not visible or if

the characters are too dim, turn the adjustment screw on the potentiometer clockwise or

counterclockwise until the desired visibility is obtained.

Control Buttons

The Rig Monitor includes three push button switches that allow you to enter the Rig Monitor’s

operating modes, navigate through the modes, update settings, and save changes to the settin gs .

The push button switches are located along the bo ttom ed ge o f th e con trol PCB (s ee Figu re 4). The

UP/YES button is on the left, the DOWN/NO button is in the middle, and the ENTER button is on

the right.

Table 4: Beacon 110 Rig Monitor Control Button Functions

Switch Function

UP/YES • Saves settings

DOWN/NO • Cancels setting changes

9 Beacon 110 Rig Monitor Operator’s Manual

• Changes the displayed setting

• Enters Calibration Mode

• Enters Configuration Mode (press with ENTER button)

• Changes the displayed setting

• Displays the Information Screen

Page 15

Table 4: Beacon 110 Rig Monitor Control Button Functions

Switch Function

ENTER • Initiates operations

• Enters Configuration Mode (press with UP/YES button)

• Accepts displayed parameters

Status LEDs

The Rig Monitor includes three active status LEDs that are located above the display (see Figure).

Two LEDs, labelled RX and TX, to the right of those described below, are not active.

• Fail LED

The fail LED turns on when the Rig Monitor is experiencing a fail condition. A fail

condition can be caused by a detector failure or low detector signal.

• Alarm 1 LED

The alarm 1 LED is on when the Rig Monitor is experiencing an alarm 1 condition.

• Alarm 2 LED

The alarm 2 LED is on when the Rig Monitor is experiencing an alarm 2 condition.

Beacon 110 Rig Monitor Operator’s Manual 10

Page 16

Chapter 3: Installation & Startup

Overview

This chapter describes procedures to mount the Beacon 110 Rig Monitor, make wiring connectio ns

to the monitor, and start up the monitor.

WAR NING: Perform all installation and start-up procedures in a “fresh air” environment

(environment known to be free of toxic gas, and of normal oxygen content). The

Beacon 110 Rig Monitor is not in operation as a gas monitoring system until the

start-up procedure is complete.

Mounting the Beacon 110 Rig Monitor

Perform the following procedure to install the instrument housing at the mounting site.

7.20

5.6

4.83

4.00 MT G

4.50"

8.0" Max

Ø .30 X .50SLOTS ( 4X) MOUNTING

1.70

ALM 1FAIL

ALM 2

8.50

10.00

Conduit

Hubs (3X)

1.47

3/4

BEACON 110

GAS MON I TOR

RESET

3.03

Door Latches

8.94 MT G

3/4 Cable

Bushings

(2X)

Figure 5: Beacon 110 Rig Monitor Outline & Mounting Dimensions

11 Beacon 110 Rig Monitor Operator’s Manual

Page 17

1. Select the mounting site. When you select the mounting site consider the following factors:

5

• Is a DC power source available?

• Is there enough room to open the housing door and make wiring connections through the

cable bushings at the bottom of the housing?

• Are the display screen and status lights on the Rig Monitor visible?

2. If necessary, close and latch the Rig Monitor housing door.

3. Position the monitor on a vertical surface at eye level (4 1/2 to 5 feet from the floor).

4. Insert 1/4 in. or 5/16 in. screws through the slots in the Rig Monitor mounting feet at each

corner of the housing to secure the housing to the mounting surface.

5. Use the mount ing bracket to hang the H

S detector at approximately breathing level.

2

To Left

Cable

Bushing

To Right

Cable

Bushing

12 VDC

Batter y

Cable

Detector

Cable

Mounting

Bracket

1.50

Ø .7

.75

14.2" Max

Figure 6: Junction Box Outline & Mounting Dimensions

6. At the monitoring site you select, hang the junction box with the detector facing down (see

Figure 6).

Beacon 110 Rig Monitor Operator’s Manual 12

Page 18

Wiring the Beacon 110 Rig Monitor

This section describes procedures to connect external alarm(s) and a recorder to the Rig Monitor.

The power, detector, and strobe/horn wiring are all factory wired as shown below.

Strobe / Horn

Beacon 110

Mai n PCB

L

N

G

24V

TB1

OUT

GND

Power

IN

Converter

Red

Black

Detector

Cable

PCB

Ground

Conduit Hubs

ALARM

ALARM

ALARM

4-2 0mA

RESET

RESET

BU ZZE R

FAIL

ALA RM 1

ALAR M 2

OUTPUT

FACTOR Y

WIRED

Terminal Block

Buzzer

Reset

Switch

Black

Red

BlackWhite

Black

White

Battery

Black

Red

TO 12

VDC

Battery

Terminals

H2S De te cto r

Cable

Figure 7: Rig Monitor Factory Wiring

13 Beacon 110 Rig Monitor Operator’s Manual

Page 19

WARNING: Make all connections to the Beacon 110 Rig Monitor before you plug in or turn

ALARM-2

ALARM-1

FAIL

Exte rn al Al ar m Dev ic e

on the DC power source. Before you make any wiring adjustments, always verify

that all power sources are not live.

Connecting DC Power

Perform the following functions to connect the Rig Monitor to DC power. One end of the battery

cable is already factory wired to the appropriate terminals at the Rig Monitor housin g. Use the ot her

end to connect a 12 VDC battery.

NOTE: Be sure to turn off the Beacon 110 Rig Monitor before connecting or disconnecting it

from the 12 VDC battery.

1. Turn off, unplug, or disconnect all incoming power to the Rig Monitor.

2. Open the housing door, then place the power switch in the OFF position.

3. Connect the red battery clamp to the (+) terminal of the 12 VDC battery.

4. Connect the black battery clamp to the (-) terminal of the 12 VDC battery.

Connecting External Alarms

Perform the following procedure to connect external alarms to the Rig Monitor’s Fail or Alarm 2

terminals. The Alarm 1 terminals are factory wired and are not available for field use.

1. Disconnect the bat tery clamps from the + and - terminals of the 12 VDC battery.

2. Open the housing door, then place the power switch in the OFF position.

3. Locate the alarm terminal strip. See Figure 1 to assist you in locating the alarm terminal strip.

4. Install an appropriately rated cable bushing i n the Rig Monitor housing. Both factory supplied

conduit hubs are used in the Rig Monitor, so you will need to drill a hole in the housing for a

conduit hub and cable bushing.

5. Guide the wiring of the external alarm through the new cable bushing.

6. Connect the leads from the external alarm to the appropriate terminals on the alarm terminal

strip as shown in Figure 8 to obtain the desired operation.

Beacon 110 Alarm

NCNO

CNO

Factory

Wired

NC C NCNO C

Terminal Strip

(+) H

(-) N

External

Source

Power

Beacon 110 Rig Monitor Operator’s Manual 14

Figure 8: Typical Alarm Device Wiring

7. Repeat steps 5 and 6 for an additional alarm device.

Page 20

Connecting Recorders

A

T

Perform the following procedure to connect an analog signal recording device to the Rig Monitor.

The output at the recorder output terminals is a 4 - 20 mA signal that is proportional to the detection

range of the H

Alarm 1 terminals are factory wired and no t available for field use.

1. Disconnect the battery clamps from the + and - terminals of the 12 VDC battery.

2. Open the housing door, and locate the recorder output terminals on the controller terminal

strip. See Figure 1 to assist you in locating the recorder output terminals. They are labelled 4 -

20 mA OUTPUT + and 4 - 20 mA OUTPUT -.

3. Place the power switch in the off position.

4. Install an appropriately rated cable bushing i n the Rig Monitor housing. Both factory supplied

conduit hubs are used in the Rig Monitor, so you will need to drill a hole in the housing for a

conduit hub and cable bushing.

5. Guide the wiring from the recording device through the new cable bushing.

6. Connect the leads from the recording device to the analog output terminal strip as shown in

Figure 9 below.

S detector head connected to the Rig Monitor’s Fail or Alarm 2 terminals. The

2

4-20 m

OUTPU

Recording Device,

500 Ohms Max

Impedance

Figure 9: Recorder Output Wiring

15 Beacon 110 Rig Monitor Operator’s Manual

Page 21

Start Up

Introducing Incoming Power

Perform the following procedure to place the Rig Monitor into normal operation.

1. Complete the mounting and wiring procedures described earlier in this chapter.

2. Verify that all wiring connections are correct and s ecure and that the Rig Monitor’s power

switch is in the OFF position.

3. If not already connected, connect the battery clamps to the + and - terminals of the 12 VDC

battery.

4. Turn on the power switch.

5. The LCD display will indicate the firmware version when the Rig Monitor is first powered up

and will then count down a one minute warm-up period before normal operation begins.

During normal operation, the display will indicate the current gas reading and target gas.

Verify that the display is indicating the current gas reading and target gas after the warm-up

period is complete and normal operation begins, for example:

H2S

0 ppm

NOTE: To prevent unwanted alarms during warm up, the alarm circuits are not active during

the warm-up period.

6. The H

S detector will begin operating once power is introduced to the Rig Monitor.

2

Beacon 110 Rig Monitor Operator’s Manual 16

Page 22

Chapter 4: Operation

Overview

This chapter describes the Beacon 110 Rig Monitor in normal operation. This chapter also

describes the Rig Monitor in alarm 1, alarm 2, and fail conditions and suggests response to these

conditions.

Normal Operation

Normal operation is defined as follows:

• The start-up procedure is complete.

• The Rig Monitor is not indicating an alarm 1, alarm 2, or fail condition.

• The Rig Monitor is not in Calibration or Configuration Mode.

During normal operation, the Rig Monitor simultaneously displays the current gas reading, unit of

measure, and target gas.

Information Screen

The Information Screen displays the Rig Monitor’s operating voltage and firmware and hardware

information. To display the Information Screen, do the following:

1. Press and hold the DOWN/NO button for 3 seconds. The Information Screen will appear.

2. Continue holding the DOWN/NO button to keep the Information Screen on the display. The

top line indicates the operating voltage that the power converter is providing to the Rig

Monitor. The second line indicates the firmware that is running, version 5.0 in this example,

and the Rig Monitor’s hard ware vers i on , vers ion 2A in this example. This information may be

useful if you need to contact the facto ry with questions about the Rig Monitor.

3. Release the DOWN/NO button when you are done viewing the Information Screen. The

display will return to the normal operation screen within a couple of seconds.

NOTE: The Information Screen is not a good indicator of battery life because the power

converter will operate as normal and have an output of 24 volts until the 12 VDC

battery dies.

H2S

0 ppm

24.2V

v5.0 2A

17 Beacon 110 Rig Monitor Operator’s Manual

Page 23

4 - 20 mA Signal Output Operation

The output at the 4 - 20 mA output terminals is a 4 - 20 mA signal that is proportional to the

detection range of the Rig Monitor. During normal operation, this signal tracks the gas

concentration on the LCD.

There are several circumstances where the signal output will not track the display reading but will

behave as follows:

• When the Rig Monitor is in its warm-up period, the signal output will be fixed at 4 mA (zero).

• If you e nter Calibration Mode or Configuration Mode, the signal output will be fixed at 3.5 mA

until the Rig Monitor returns to normal operation.

• If the Rig Monitor’s input power decreases below 10 volts so that the Rig Monitor is in a low

power alarm, the signal output is fixed below 2.4 mA until the low power alarm is cleared.

NOTE: Under typical operating conditions, there will be no low power alarm. The 12 VDC

battery that is recommended for operation will die before the power converter

recognizes a low power condition.

• If the R ig Monitor goes into a fail condition, after a 30 second delay, the signal output is fixed

below 2.4 mA until the fail alarm is cleared. During the 30 second delay, the output follows the

detector output. In the case of a downscale reading, the displayed gas reading will only go as

low as -10% of full scale but the signal output will continue to track the reading even if it’s

lower than -10% of full scale.

Viewing and Resetting Min/Max

Readings

The reset switch may be used to view and reset the minimum and maximum gas readings.

NOTE: Minimum and maximum readings are reset if the instrument is turned off.

1. While the Rig Monitor is in normal operation, press and hold the reset switch button for 5

seconds.

2. The display will indicate the minimum reading on the bottom display line and the maximum

reading on the top display line for about 3 seconds before indicating <RESET> TO CLEAR.

3. To return to normal operation without resetting the minimum and maximum readi ngs, do not

press the reset switch button and allow the unit to return to normal operation. It will return to

normal operation in about 5 seconds.

To reset the min imu m and max imu m r eadi n gs, p r ess and hol d the r es et s wit ch butt on

while the <RESET> TO CLEAR message is on the display until the dis p lay indicates

Min/MAX Is RESET. Release the reset switch button.The unit will then return to

normal operation in about 5 seconds.

Beacon 110 Rig Monitor Operator’s Manual 18

Page 24

Alarm Indications

NOTE: The Beacon 110 Rig Monitor includes alarm on and alarm of f delay settings for alarm 1

and alarm 2. The alarm indications described in this section operate according to the

factory set alarm settings. See Table 6 on page 23 for all the factory settings.

Table 5: Visual and Audible Alarm Indications

Condition Cause Visual Indication(s)

Alarm 1

1

Increasing gas reading at or above the

alarm 1 setpoint

• Alarm 1 LED is on

• Gas reading alternates with

ALARM-1 message

Audible

Indication

• Pulsing tone

• Strobe/horn

turns on

• Strobe/horn turns on

Alarm 2

1

Increasing gas reading at or above the

alarm 2 setpoint

• Alarm 2 LED is on

• Gas reading alternates with

• Pulsing tone

ALARM-2 message

Fail • Disconnected or misconnected

detector head wiring

• Display reading at -10% of full scale

or lower

• Defective components

• Fail LED is on

• FAIL mes sage replaces gas

reading

NOTE: There is a 30 second

delay on the fail indications.

Low Power Dead 12 VDC battery • Fail LED is on

• Steady tone

• None

• LowPower message

NOTE: Under typical operating conditions, there will be no low power alarm. The 12 VDC battery that is recommended for operation will die before the power converter recognizes a low power condition.

1

*

If the Beacon 110 Rig Monitor is in both an alarm 1 and an alarm 2 condition, both alarm LEDs are on

and the display alternates between the gas reading and the ALMS 1&2 message.

NOTE: You can select normally energized (N. EN) or normally de-energized (N. DE-EN)

alarm 1 and alarm 2 relay action settings in Configuration Mode. The following

sections describe the standard factory setting for these relays which is N. DE-EN.

The fail relay is set as normally energized in the firmware and is not user-adjustable.

CAUTION: Changing the relay action setting for the Alarm 1 relay in Configuration Mode will

cause the strobe/horn to be on during normal operation.

19 Beacon 110 Rig Monitor Operator’s Manual

Page 25

Alarm 1 Condition

Alarm 1 Condition Indications

When the gas reading reaches the alarm 1 setpoint, the Rig Monitor senses an alarm 1 condition.

The Rig Monitor alerts you to an alarm 1 condition as foll ows:

• The alarm 1 LED turns on.

• The gas reading alternates with the ALARM-1 message.

• The buzzer sounds a pulsing tone.

• The alarm 1 relay energizes and the strobe/horn activates.

Responding to an Alarm 1 Condition

1. Follow your establ ished procedure for a toxic gas condition.

2. The alarms are factory set as latching. After the gas reading falls below the alarm 1 setpoint,

press the reset switch to reset the alarm 1 circuit. Resetting the alarm 1 circuit silences the

buzzer, turns off the alarm 1 LED, returns the LCD to the normal operation screen, deenergizes the alarm 1 relay, and turns off the strobe/horn.

NOTE: If the reset switch is pressed while the Beacon 110 Rig Monitor is in an alarm 1

condition, the buzzer will be silenced and the alarm 1 LED will flash.

You cannot de-energize the alarm 1 relay and consequently turn off the strobe/horn

until the gas reading falls below the alarm 1 setpoint.

Alarm 2 Condition

Alarm 2 Condition Indications

When the gas reading reaches the alarm 2 setpoint, the Rig Monitor senses an alarm 2 condition.

The Rig Monitor alerts you to an alarm 2 condition as foll ows:

• The alarm 2 LED turns on.

• The gas reading alternates with the ALARM-2 message.

• The buzzer sounds a pulsing tone.

• The alarm 2 relay energizes and the strobe/horn will remain activated.

NOTE: If the Beacon 110 Rig Monitor is in both an alarm 1 and alarm 2 condition, both the

alarm 1 and alarm 2 LEDs will be on, the gas reading will alternate with the ALMS

1&2 message, and both alarm relays will energize.

Beacon 110 Rig Monitor Operator’s Manual 20

Page 26

Responding to an Alarm 2 Condition

1. Follow your establ ished procedure for a toxic gas condition.

2. The alarms are factory set as latching. After the gas reading falls below the alarm 2 setpoint,

press the reset switch to reset the alarm circuit. Resetting the alarm circuit silences the buzzer,

turns off the Alarm 2 LED, returns the LCD to the normal operation screen, and de-energizes

the alarm 2 relay.

NOTE: If the reset switch is pressed while the Rig Monitor is in an alarm 2 condition, the

buzzer will be silenced and the alarm 2 LED will flash but all other indications will

remain unchanged.

You cannot de-energize the alarm 2 relay until the gas reading falls below the alarm 2

setpoint.

Fail Condition

Fail Condition Indications

The Rig Monitor indicates a fail condition for any of the following:

• The detector head wiring is disconnected or incorrectly connected.

• The display reading is -10% of full scale or lower.

When the Rig Monitor senses a fail condition, it alerts you as follow s:

• The fail LED turns on.

• The gas reading is replaced by the FAIL message.

• The buzzer sounds a steady tone.

• The fail relay de-energizes.

NOTE: The fail alarm has a 30 second delay.

Responding to a Fail Condition

NOTE: A fail condition cannot be reset using the reset switch.

1. Verify that the detector head wiring is correctly and securely connected.

2. Verify that the replaceable plug-in sensor is properly installed.

3. If necessary set the zero reading for you r detect or head as describ ed in “Calibration Mode” on

page 25.

Low Power Condition

The 12 VDC battery that is recommended for operation of the Rig Monitor is typically dead before

the power converter recognizes a low power condition. As a result, when the Rig Monitor is used

with a 12 VDC battery, there may be no low power alarm and the unit will instead shut off once the

battery is dead.

21 Beacon 110 Rig Monitor Operator’s Manual

Page 27

Chapter 5: Configuration Mode

Overview

This chapter describes how to view and change Beacon 110 Rig Monitor parameters using

Configuration Mode. It is accessed using the program buttons.

Configuration Mode incl udes a 5-mi nute time-o ut featur e. If you do not press a cont rol but ton for 5

minutes, the Rig Monitor automatically returns to normal operation.

NOTE: If the Beacon 110 R ig Monitor returns to normal operation because of a time-out, it

enters a warm-up period just as it does when it is first turned on.

If you are installing a new Rig Monitor, it has been set up at the factory. Use

Configuration Mode only if you want to change the Rig Monitor’s setup.

Viewing & Changing Beacon 110 Rig

Monitor Parameters

1. Whil e in nor mal operation, simult aneously pr ess and h old the UP /YES and ENTER button s for

5 seconds to enter Configuration Mode. Release the buttons when the following screen

appears.

Enter

Config?

2. If you want to exit Configuration Mode, press and release the DOW N/NO button and the Rig

Monitor will return to normal operation.

If you want to continue in Configuration Mode, press and release the UP/YES button. The

target gas and the full scale will be displayed for a few seconds before the first adjustable

parameter, the alarm 1 setpoint, is displayed.

3. If you want to change the currently displayed parameter, use the UP/YES and DOWN/NO

buttons to adjust it to the desired setting, then press ENTER to continue to the next parameter.

If the currently displayed parameter is OK, press the ENTER button to proceed to the next

parameter.

Table 6 lists the Rig Monitor parameters you can set. Table 6 also lists the factory set

value for each parameter.

Beacon 110 Rig Monitor Operator’s Manual 22

Page 28

Table 6: Configuration Parameters

Parameter

(Factory Set Value)

ALARM-1

(10 ppm)

ALARM-1 (activation)

(Increase)

ALARM-1 (relay action)

(N. DE-EN)

ALARM-1 (relay reset)

(LATCH)

A1Stro be The strobe controlled by thi s para meter is not inst alled in the Rig Monitor.

A1 OnDy (alarm 1 on delay)

(1 secs)

The gas reading at which the Rig Monitor initiates an alarm 1 condition.

Indicates if the alarm 1 circuit is activated by gas readings increasing

Increase) or decreasing (Decrease) to the ALARM-1 Level.

(

• Note: Changing this parameter will affect the operation of the factory

installed strobe/horn. Do not change this parameter from the factory

setting.

If set as N. DE-EN, th e alarm 1 relay is de-ene rgized in norm al opera tion

and energizes w h en an alarm 1 condition is initiated.

If set as

de-energizes when an alarm 1 cond iti on is initia ted .

• Note: Changing this parameter will affect the operation of the factory

If set as LATCH, you must press the reset switch to reset the alarm 1 cir-

cuit after the alarm 1 condition passes.

If set as

cuit after the alarm 1 condition passes.

The amount of time the Rig Monitor delays activation of the alarm 1 circuit once an alarm 1 condition is ini tia ted .

N. EN, the alarm 1 relay i s energized in normal operation and

installed strobe/horn. Do not change this parameter from the factory

setting.

SELF-RST, the Rig Monitor autom a tically resets the alarm 1 cir-

Description

A1 OffDy (alarm 1 off delay)

(0 sec.)

ALARM-2

(50 ppm)

ALARM-2 (activation)

(Increase)

ALARM-2 (relay action)

(N. DE-EN)

ALARM-2 (relay reset)

(LATCH)

A2Stro be The strobe controlled by thi s para meter is not inst alled in the Rig Monitor.

A2 OnDy (alarm 2 on delay)

(1 secs)

A2 OffDy (alarm 2 off delay)

(0 sec.)

The amount of time the Rig Monitor delays turning off the alarm 1 circuit

once an alarm 1 condition passes. This parameter appears only if the

alarm 1 relay res e t setting is set to

The gas reading at which the Rig Monitor initiates an alarm 2 condition.

Indicates if the alarm 2 circuit is activated by gas readings increasing

Increase) or decreasing (Decrease) to the ALARM-1 Level.

(

If set as

and energizes w h en an alarm 2 condition is initiated.

If set as

de-energizes when an alarm 2 cond iti on is initia ted .

If set as

circuit after the alarm 2 condition passes.

If set as

cuit after the alarm 2 condition passes.

The amount of time the Rig Monitor delays activation of the alarm 2 circuit once an alarm 2 condition is ini tia ted .

The amount of time the Rig Monitor delays turning off the alarm 2 circuit

once an alarm 2 condition passes. This parameter appears only if the

alarm 2 relay res e t setting is set to

N. DE-EN, the alarm 2 relay is de-energized in normal opera tion

N. EN, the alarm 2 relay i s energized in normal operation and

LATCH, you must press the ENTER button to reset the alarm 2

SELF-RST, the Rig Monitor autom a tically resets the alarm 2 cir-

SELF--RST.

SELF-RST.

23 Beacon 110 Rig Monitor Operator’s Manual

Page 29

Table 6: Configuration Parameters (Continued)

ZeroSupp

(2 ppm)

FILTER

(5 secs)

CAL Time

(15 mins)

Parameter

(Factory Set Value)

4. When you have scrolled through all the adjustable parameters, SAVE IT? YES/NO appears on

the display.

5. To save the adjustments made, press and release the UP/YES button. Config Saved is

indicated on the display for a few seconds and th e Rig Monitor returns to normal operation.

Description

The zero suppression feature helps prevent “jumpy” readings near the

fresh air reading.

For example, if the zero suppression setting for the H

ppm, the Rig Monitor will display a reading of 0 ppm for gas readings

from -2 ppm to 2 ppm.

The filter feature helps “smooth out” jumpy or noisy signals from the

detector. You can set the filter from 0 seconds to 60 seconds in 5 seconds increments.

The displayed gas reading is the average reading over the previous time

period defined by the filter setting. So if the filter is set to 5 seconds, the

displayed gas reading is the average over the past 5 seconds.

The calibration tim e-out set s the am ount of time after th e last bu tton push

while in Calib ration Mode th at the Ri g Monitor wil l wait before returning to

normal operation. If the calibration time-out is set to

Rig Monitor will return t o norma l operation automa tical ly 15 minu tes af ter

the last button pu sh.

S detector is 2

2

15 mins, then the

If you do not wish to save the adjustments, press and release the DOWN/NO button. The DO

OVER? YES/NO message will display. Press and release the DOWN/NO button. The

ABORT? YES/NO message will display. Press the UP/YES button to return to normal

operation.

Beacon 110 Rig Monitor Operator’s Manual 24

Page 30

Chapter 6: Maintenance

Overview

This chapter describes how to calibrate the Beacon 110 Rig Monitor using Calibration Mode,

replace the DC fuses, and preventive maintenance procedures for the Rig Monitor. It includes a

troubleshooting guide for problems you may encounter with the Rig Monitor.

Calibration Frequency

Although there is no particular calibration frequency that is correct for all applications, a calibration

frequency of every 3 to 6 months is adequate for most Rig Monitor applications. Unless experience

in a particular application dictates otherwise, RKI Instruments, Inc. recommends a calibration

frequency of every 3 months.

If an application is not very demanding, for example detection in a clean, temperature controlled

environment where hydrogen sulfide is not normally present, and calibration adjustments are

minimal at calibration, then a calibration frequency of every 6 months may be adequate.

If an application is very demanding, for example if hydrogen sulfide is present often and in

significant concentrations or the environment is not well controlled, then more frequent calibration

than every 3 months may be necessary.

Calibration Mode

Calibration Mode is used to calibrate the Rig Monitor’s detector head. All calibration adjustments

are made at the Rig Monitor housing after calibration gas is applied to the detector.

Calibration Gas Response Memory Feature

The Rig Monitor has the capability to “remember” the detector’s response to the calibration gas

after the gas is remove d from the detector during the fresh air or span adjustment procedure. This

feature enables one person to perform calibration if the detector is mounted remotely from the Rig

Monitor. When zero air is applied to the Rig Monitor during a fresh air adjustment, the Rig Monitor

will freeze the display reading at the lowest response and the Rig Monitor will continue to display

this reading and retain it in its memory until the fresh air adjustment procedure is completed. When

calibration gas is applied to the Rig Monitor during a span adjustment, the Rig Monitor will freeze

the display reading at the highest response to the calibration gas. The calibration gas can then be

removed and the Rig Monitor will continue to display this reading and retain it in its memory until

the span adjustment procedure is completed.

25 Beacon 110 Rig Monitor Operator’s Manual

Page 31

Calibration Program Flow

Figure 10 below illustrates the general flow of the Calibration Program fo r a direct connect

detector. See the next section, “Preparing for Calibration”, for instructions to enter Calibration

Mode. In general, if a question mark, “?”, is part of the display text, use the UP/YES or DOWN/NO

button to respond. Use the UP/YES and DOWN/NO buttons to increase or decrease a displayed gas

reading when performing a span (zero for oxygen) operation, and use the ENTER button to accept

a displayed value and continue.

No

Normal Op eration

Press

UP/YES

Calibrate?

Yes/No

Yes

Fresh Air

Adjust?

Yes/No

Fresh Air Adjust

Apply Gas to

Detector

Adj ust Sp an

Setting

Yes

No

Sp an Y/ N ?

Yes

Press ENTER to

Accept Span

Setting

No

Figure 10: Direct Connect Detector Head

This section describes how to calibrate the H

S detector. It includes procedures to prepare for

2

calibration, set the zero reading, set the response reading, and return to normal operation. It

describes calibration using a calibration kit that includes a calibration cup/splash guard, calibration

gas, sample tubing, and a fixed flow regulator with an on/off knob. RKI Instruments, Inc.

recommends using a 0. 5 LPM (liters per minute) fixed fl ow regulator.

Prepari ng for Ca libration

WARNING: The Beacon 110 Rig Monitor is not an active gas monitoring device during the

calibration procedure. The 4-20 mA output signal will “freeze” at 3.5 mA and

all relays will remain in their non-alarm state while the Rig Monitor is in

Calibration Mode. The 4 - 20 mA output signal will not indi cate cur rent

readings and the relays will not resu me operating normally until the Rig

Monitor is in normal operatio n ag ain.

Beacon 110 Rig Monitor Operator’s Manual 26

Page 32

1. While in normal operation, press and hold the UP/YES button for 5 seconds to enter

Calibration Mode. Release the button when the following screen appears.

Calib?

YES/NO

2. If you want to exit Calibration Mode, press and release the DOWN/NO button. The Rig

Monitor will indicate Leaving CAL Mode and the Rig Monitor will return to normal

operation.

If you want to continue with calibration, press and release the UP/YES button. The display will

indicate the target gas and CAL Mode for a few seconds before showing FreshAir Adjust?.

Setting the Zero Reading

1. The display will indicate FreshAir Adjust? as described above in “Preparing for Calibration”.

2. If you want to skip adjusting the fresh air reading, press and release the DOWN/NO button.

The display will indicate SPAN w/Cal Gas?. Skip to Step 11.

If you want to continue with adjusting the fresh air reading, press and release the UP/YES

button. ENTER will alternate with FreshAir on the top display line and the current gas

reading will be on the bottom display line.

3. If the detector is in a fresh air environment, press and release the ENTER button. The Rig

Monitor will perform a fresh air adjustment and the display will indicate SPAN w/Cal Gas?.

Continue to the next section, Setting the Response Reading.

If you suspect the detector area is not a fresh air environment, continue with Step 4.

4. Screw the regulator into the zero air calibration cylinder.

5. Use the calibration ki t sampl e tubi ng to connect the fixed flow regulat o r to the calibrat ion cup/

splash guard.

6. Turn the regulator’s on/off knob counterclockwise to open it. The Rig Monitor will freeze the

display reading at the lowest level reached while applying zero air.

7. Allow the gas to flow for two minutes.

8. Turn the regulator’s on/off knob clockwise to close it. The Rig Monitor will continue to

display the minimum gas response on the display and retain the response level in its memory.

9. Press and release the ENTER button on the Rig Monitor controller. The Rig Monitor will

perform a fresh air adjustment and the display will indicate SPAN w/Cal Gas?.

10. If you applied zero air to the detector, unscrew the regulator from the zero air calibration

cylinder.

11. If you applied zero air to the detector, leave the sample tubing connected to the regulator and

the calibration cup/splash guard.

If you did not apply zero air to the detector, use the calibration kit sample tubing to

connect the fixed flow regulator to the calibration cup/splash gu ard.

NOTE: Depending on the size of your zero air cylinder, it is possible that you will have a

different regulator for the zero air cylinder and the H

S gas cylinder. If necessary to fit

2

the H2S calibration gas cylinder, change the regulator.

27 Beacon 110 Rig Monitor Operator’s Manual

Page 33

Setting the Response Reading

1. Screw the regulator into the calibr a tion gas cylinder.

2. If you want to skip adjusting the span setting, press and release the DOWN/NO button. The

display will indicate Leaving Cal Mode and the Beacon 110 Rig Monitor will return to normal

operation.

If you want to continue with adjusting the span setting, press and release the UP/YES button.

APPLY will alternate with SPAN Gas on the top display line and the current gas reading will

be on the bottom display line.

3. Turn the regulator’s on/off knob counterclockwise to open it.

When calibration gas is applied, the Rig Monitor will freeze the display gas reading at

the highest level reached while the gas was applied.

4. Allow gas to flow for 2 minutes.

5. Turn the regulator’s on/off knob clockwise to close it. The Rig Monitor will continue to

display the maximum gas response on the display and retain the resp onse level in its memory.

6. Adjust the gas reading up or down to match the calibration gas cylinder concentration by using

the UP/YES and DOWN/NO buttons, then press and release the ENTER button.

7. The Rig Monitor will perform a span operation. The display will indicate SPAN Gas PASS for

a few seconds, then indicate SPAN Gas SAVED before indicating Leaving CAL Mode for a

few seconds.

8. Unscrew the regulator from the cylinder and disconnect the sample tubing from the calibration

cup/splash guard hose barb.

NOTE: For convenience, leave regulator connected to the sample tubing.

Returning to Normal Operation

1. The display will now alternate between the normal operation screen and the message

REMOVE CAL GAS for 1 minute. If the calibration gas has not been removed from the

detector, remove it now to avoid unwanted alarms.

During this 1 minute period, the 4 - 20 mA output will remain fixed at 3.5 mA and the

relays will remain in their non-alarm state to avoid unwanted alarms while the

calibration gas clears from the detector. At the end of the 1 minute period, the

REMOVE CAL GAS message will stop appearing and the Rig Mo nitor will return to

normal operation.

2. Store the components of the calibration kit in a safe place.

Beacon 110 Rig Monitor Operator’s Manual 28

Page 34

Adjusting Strobe/Horn Volume

The horn volume on the strobe/horn can be adjusted by doing the following:

1. Open the housing door of the Rig Monitor, then place the power switch in the OFF position.

2. Disconnect the battery clamps from the + and - terminals of the 12 VDC battery.

3. Loosen the captive screw at the bottom front of the strobe/horn.

4. Grasp the top and bottom of the strobe/horn and push up and out in order to remove the cover.

Top

Base

Captive

Screw

Push Out

Push Up Here

Figure 11: Top Case Removal

5. Turn the cover over and locate the Audio Select switch at the top of the cover as shown in the

figure below.

5

6

4

3

2

1

AUDIO

SELECT

Audio Select Switch

CANDE LLA SELECT

Strobe Brightness Switch

(DO NOT ADJUST)

Figure 12: Strobe/Horn Cover

6. The Audio Select switch can be set at any number between 1 and 6. Numbers 1-3 all produce

an intermittent buzzing sound with 1 being the loudest and 3 being the quietest. Numbers 4-6

all produce a steady buzzing sound with 4 being the loudest and 6 being the quietest. The

factory setting is 2.

29 Beacon 110 Rig Monitor Operator’s Manual

Page 35

7. Turn the Audio Select switch so that the selection arrow is pointing to the desired number.

8. Place the cover over the base and push in and down in order to reinstall the cover. Make sure

that the cover is sealed to the base by the gasket.

9. Screw the captive screw at the bottom front of the strobe/horn back in.

Replacing Components of the Rig Monitor

This section describes how to replace the fu ses, the H2S sensor, and the en tire detector assem bly. In

most cases, it is not necessary to replace the entire detector assembly.

Replacing the Fuses

The Rig Monitor has two replaceable DC fuses.

NOTE: T o replace o ther co mpo nents of the B eacon 110 Rig Monitor, contact RKI Instruments,

Inc. for further information.

1. Open the housing door of the Rig Monitor, then place the power switch in the OFF position.

2. Disconnect the battery clamps from the + and - terminals of the 12 VDC battery.

3. Locate the vertical fuse holders above the 12 VDC In Terminal Strip. The DC fuses are

labelled F1 and F2 on the main PCB silkscreen.

4. Use a flat-blade screwdriver to rotate the applicable fuse holder 1/4 turn counterclockwise. The

fuse holder releases from the socket.

5. Remove the fuse holder from the socket, then remove the fuse from the fuse holder.

CAUTION: Verify that the replacement fuse is the same type and rating as the fuse you are

replacing. See the “Parts List” on page 36 for correct fuse.

6. Install the appropriate replacement fuse in the fuse holder, then place the fuse holder in the

socket.

7. Push the fuse holder into the socket, then turn the holder 1/4 turn clockwise to secure it in the

socket.

8. Connect the battery clamps to the + and - terminals of the 12 VDC battery.

9. Place the Rig Monitor’s power switch in the ON position, then verify that the Rig Monitor

completes its warm-up sequence and enters normal operation.

10. Close and secure the housing door.

Replacing the Plug-In H2S Sensor

CAUTION: The sensor contains electrolyte which is a dilute acid. Do not disassemble the sensor

when replacing it with a new one. If sensor electrolyte comes in contact with your

skin, wash affected area thoroughly with soap and water.

1. Turn off the Rig Monitor.

2. Disconnect the battery clamps from the + and - terminals of the 12 VDC battery.

3. Unscrew the calibration cup/splash guard from the detector housing cap.

4. Unscrew the detector housing cap from the detector housing body. Make sure not to lose the

Beacon 110 Rig Monitor Operator’s Manual 30

Page 36

cap gasket.

5. Unplug and remove the H

S sensor with the rubber boot and spacer attached.

2

6. Remove the rubber boot and spacer from the old sensor.

7. Install the spacer and rubber boot onto the replacement sensor’s face.

8. Carefully plug the replacement sensor into the four-socket pattern that is located in the detector

housing.

9. Make sure the cap gasket is in place and screw the detector housing cap back onto the detector

housing body.

10. Screw the calibration cup/splash guard back onto the detector housing cap.

11. Connect the battery clamps to the + and - terminals of the 12 VDC battery.

12. Turn on the Rig Monitor and place into normal operation.

CAUTION: Allow the replacement sensor to warm up for 5 minut es before you continue with the

next step.

13. Calibrate the replacement sensor as described in the Calibration s ection of this manual.

Replacing the H2S Detector

NOTE: In most cases, it is only necessary to replace the H2S sensor.

1. Turn off the Rig Monitor.

2. Disconnect the battery clamps from the + and - terminals of the 12 VDC battery.

3. Remove the junction box cover.

4. Disconnect the detector leads from the terminal block in the junction box. Note the position of

the color-coded leads as you remove them.

5. Unscrew the calibration cup/splash guard from the detector housing cap.

6. Unscrew the detector from the junction box hub.

7. Guide the detector leads of the replacement detector through the junction box hub then screw

the mounting threads of the detector into the hub.

8. Connect the detector leads to the terminal block the same way the old detector was wired. See

Figure 7 to verify the connections are correct.

9. Screw the calibration cup/splash guard onto the new detector’s housing cap.

10. Reinstall the junction box cover.

11. Connect the battery clamps to the + and - terminals of the 12 VDC battery.

12. Turn on the Rig Monitor and place into normal operation.

CAUTION: Allow the replacement detector to wa rm up for 5 minutes before you continue with

the next step.

13. Calibrate the replacement detector as described in the Calibration section of thi s manual.

31 Beacon 110 Rig Monitor Operator’s Manual

Page 37

Preventive Maintenance

This section describes a preventive maintenance s chedule to ensure the optimum performance of

the H

S detector. It includes daily, monthly, and quarterly procedures.

2

Daily

Verify a display reading of 0 P P M H2S at the controller. Investigate significant changes in the

display reading.

Monthly

This procedure describes a test to verify that the H2S detector responds properly to hydrogen

sulfide. It describes a test using a fixed flow regulator with an on/off knob. RKI Instruments, Inc.

recommends using a 0. 5 LPM (liters per minute) fixed fl ow regulator.

NOTE: Performing a response test on the H2S detector may cause alarms. Be sure to put the Rig

Monitor into its calibration program or disable external alarms before performing this

test.

Preparing for the response test

1. While in normal operation, press and hold the UP/YES button for 5 seconds and press the UP/

YES button again when asked if you would like to enter Calibration Mode.

2. Verify that the R ig Mon itor display reading is 0.

If the display reading is not zero, set the zero reading of the detector as described in

the Start Up section of this manual, then continue this procedure.

3. Screw the regulator into the calibra tion cylinder.

4. Use the calibration kit sample tubing to connect the regulator to the calibration cup/splash

guard.

Performing the response test

1. Turn the regulator’s on/off knob counterclockwise to open the regulator. Gas will begin to

flow.

2. Allow the gas to flow for two minutes, then verif y that the reading is within ± 20% of the

cylinder gas concentration.

NOTE: If the reading is not within ± 20% of the correct response reading, calibrate the detector

as described in the Calibration section of this manual.

3. Turn the regulator’s on/off knob clockwise to close the regulator.

4. Unscrew the regulator from the calibratio n cylinder.

5. When the Rig Monitor display readin g falls below the alarm setpoints, return it to normal

operation.

6. Store the components of the calibration kit in a safe place.

Quarterly

Calibrate the H2S detector as described in the Calibration section of this manual.

Beacon 110 Rig Monitor Operator’s Manual 32

Page 38

Troubleshooting

The troubleshooting guide describes symptoms, probable causes, and recommended action for

problems you may encounter with the Beacon 110 Rig Monitor.

Table 7: Troubleshooting the Beacon 1 10 Rig Monitor

Condition Symptom(s) Probable Causes Recommended Action

No Power • The display

backlight is off and

the display screen is

blank.

Frequent or

Suspect

Alarms

• The Rig Monitor

alerts you to

frequent or suspect

alarms while the

detector head’s

fresh air readings

remain on zero.

• The power wiring at

the Rig Monitor is

disconnected or

misconnected.

• One or both DC fuses

is blown.

• The display cable is

disconnected or

misconnected.

• The battery is dead or

at a very low vo ltage.

• The Rig Monitor is

experiencing false

readings due to R FI or

EMI.

•The H

S detector

2

head wiring is

disconnected,

misconnected, or

intermittent.

1. Verify that the wiring to the power

source is correct and secure.

2. At the Rig Monitor, verify that the

wiring to the DC terminals is correct

and secure.

3. Check the continuity of the DC fuses.

4. Verify that the display cable is

connected.

The display (ribbon) cable plugs into a

connector on the top edge of the

control PCB and on the main PCB

below the control PCB.

5. If the power difficulties continue,

contact RKI for further instruc tio n.

1. Verify that the H

S detector head

2

wiring is properly sh ielded.

2. Verify that the H

S detector head

2

wiring is correct and secure.

3. If power is routed through the Alarm 2

or Fail contacts to power a device,

confirm it is not routed through the

detector conduit hub.

4. Increase the al arm o n delay s ett ing i n

Configuration Mode.

5. If the frequent or sus p ect alarm

difficulties contin ue, cont a ct RKI for

further instruction.

Flickering

Display

• The display reading

flickers often.

• The Rig Monitor is

experiencing false

readings due to R FI or

EMI.

• The noise filter setting

is too low.

• The zero suppression

setting is too low.

• The display screen is

malfunctioning.

1. Verify that the H

wiring is properly sh ielded.

2. Verify that the H

wiring is correct and secure.

3. If power is routed through the Alarm 2

or Fail contacts to power a device,

confirm it is not routed through the

detector conduit hub.

4. Increase the filter setting in

Configuration Mode.

S detector head

2

S detector head

2

5. Increase the zero suppre ssion s etting

in Configuration Mode.

6. If the display difficulties continue,

contact RKI for further instruc tio n.

33 Beacon 110 Rig Monitor Operator’s Manual

Page 39

Table 7: Troubleshooting the Beacon 110 Rig Monitor (Continued)

Condition Symptom(s) Probable Causes Recommended Action

Buzzer Not

Working

• The buzzer does not

sound an audible

alarm during alarm

conditions.

• The buzzer sounds

weak or broken.

Reset Switch

Not Working

• The buzzer does not

silence when you

press the reset

switch.

• The alarm 1 or

alarm 2 circuit does

not reset when you

press the reset

switch after the

alarm condition

passes.

Strobe/Horn

Not Working

• The strobe/horn

does not activate

when an alarm 1

condition occurs.

Fail Condition Rig Monitor indicates a

fail condition.

• The buzzer is

disconnected or

misconnected.

• The buzzer is

malfunctioning.

• The reset switch is

disconnected or

misconnected.

• The reset switch is

malfunctioning.

• The strobe/horn is

malfunctioning.

• The strobe/horn

wiring is disconnecte d

or misconnected.

•The H

S detector

2

wiring is disconnected

or misconnected.

• The plug-in H

S

2

sensor is not properly

plugged into the

sockets in th e detector

housing body.

• The detector’s zero

reading is low enough

to cause a fail

condition.

• The detector is

malfunctioning.

1. Verify that the wiring to the

BUZZER + & - terminals of the

ALARM

Controller Terminal Strip is correct

and secure.

2. If the buzzer difficulties continue,

contact RKI for further instruc tio n.

1. Verify that the wiring to the

RESET

(2) terminals of the Alarm/

ALARM

Controller Terminal Strip is correct

and secure.

2. If the reset switch dif ficulties co ntinue,

contact RKI for further instruc tio n.

1. Verify that the strobe/horn is wired

properly to the alarm terminal strip.

The red wire goes to the + terminal

and the black wire goes to the terminal.

2. If the strobe/horn difficulties continue,

contact RKI for further instruc tio n.

1. Verify that the H

S detector wiring is

2

correct and secure.

2. Confirm that the plug-in H

S sensor is

2

installed properly.

3. Perform a zero adjustment. A full

calibration is recomme nde d.

4. If the fail condition continues, replace

the plug-in sensor as described later

in this section.

5. If the fail condition continues, contact

RKI for further instruction.

Beacon 110 Rig Monitor Operator’s Manual 34

Page 40

Table 7: Troubleshooting the Beacon 110 Rig Monitor (Continued)

Condition Symptom(s) Probable Causes Recommended Action

Slow or No

Response/

Difficult or

Unable to

Calibrate

• Detector responds

slowly or does not

respond during

response test.

• Unable to accurately

set the zero or

response reading

during calibration.

• Detector requires

frequent calibration.

Note: Under “normal”

circumstances, the

detector requires

calibration once every 3

months.

Some applications may

require a more frequent

calibration schedule.

• The cali bration cylinder

is low, out-dated, or

defective.

• The flame arrestor in

the detector housing

cap is wet or clogged

with dirt or other

particulates.

• The calibration gas is

not an appropriate

concentration.

• The detector is

malfunctioning.

1. Verify that the calibration cylinder

contains an adequate supply of a

fresh test sample.

2. Check the detector housing cap to

determine if the flame arrestor is wet

or dirty. Clean if necessary.

3. Verify that the calibration gas

concentration is appropriate for the

detector . Zero emissi on air (0 ppm

H

S) is normally used for a zero

2

adjustment if the environment is

suspect and 25 PPM H

S in nitrogen

2

is normally used for a response

adjustment.

4. If the calibration/response difficulties

continue, replace the plug-in sensor

as described later in this section.

5. If the calibration/response difficulties

continue, contact RKI for further

instruction.

35 Beacon 110 Rig Monitor Operator’s Manual

Page 41

Parts List

Table 8 lists replacement parts and accessories for the Beacon 110 Rig Monitor.

Table 8: Parts List

Part Number Description

06-1248RK-03 Sample tubing for calibration, 3 foot length

07-0033RK Detector housing cap gasket

07-0203RK Rubber retaining boot

14-2101RK Spacer between H

S sensor and rubber boot

2

18-0061RK Cable bushing

18-0107RK Conduit hub (3/4 in)

18-0400RK-01 Jun ction box with rubber spacers

43-0440RK Reset Switch

43-4165RK Fuse, 1/4” x 1 1/4”, fast acting, 3A, 250 V

51-0096RK Strobe/horn, 10-33 VDC, NEMA 4X

52-1016RK Buzzer

65-2427RK-05 H

65-2428 H