RKI Instruments 81-SDM03-06-HS, 81-SDM03-13-HS, 81-SDM03-13-GP, 81-SDM03-13-CO, 81-SDM03-01 User manual

...Page 1

SDM-03 Docking Station

Standalone Configuration

Operator’s Manual

Part Number: 71-0359

Revision: P1

Released: 4/7/15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Warranty

RKI Instruments, Inc. warrants gas alarm equipment sold by us to be free from

defects in materia ls and workmans hip, and perform ance for a perio d of one year from

date of shipment from RKI Instruments, Inc. Any parts found defective within that

period will be repair e d or repl ace d, at our optio n, fre e of char ge . This w arra nty do es

not apply to those items which by their nature are subject to deterioration or

consumption in normal service, and which must be cle aned, repaired, or replac ed o n

a routine basis. Examples of such items are:

Absorbent cartridges Batteries

Pump diaphragms and valves Filter elements

Fuses

Warranty is voided by abuse including mechanical damage, alteration, rough

handling, or repairs procedures not in accordance with the instruction manual. This

warranty indicates the full extent of our liability, and we are not responsible for

removal or replacement costs, local repair costs, transportation costs, or contingent

expenses incurred without our prior approval.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER

WARRANTIES AND REPRESENTATIONS, EXPRESSED OR IMPLIED, AND

ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF RKI

NSTRUMENTS, INC. INCLUDING BUT NOT LIMITED TO THE WARRANTY

I

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN

NO EVENT SHALL RKI INSTRUMENTS, INC. BE LIABLE FOR INDIRECT,

INCIDENTAL, OR CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND

CONNECTED WITH THE USE OF ITS PRODUCTS OR FAILURE OF ITS

PRODUCTS TO FUNCTION OR OPERATE PROPERLY.

This warranty covers instruments and parts sold to users only by authorized

distributors, dealers, and representatives as appointed by RKI Instruments, Inc.

We do not assume indemnification for any accident or damage caused by th e

operation of th is gas mo nitor an d our war ranty is li mited to r eplacement of par ts or our

complete goods.

Warranty

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

Table of Contents

Chapter 1: Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About the SDM-03. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

System Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Cautions & Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2: Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

AC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Single-Port AC Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4-Port AC Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

USB Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Air Filter and Sample Tubing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Instrument Cradle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Sample Fittings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

PC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 3: Preparing to Use the SDM-03. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Hardware Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Setting the Operational Parameters in Edit Mode. . . . . . . . . . . . . . . . . . . . . . . . 15

Bump Test & Calibration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Turning on the SDM-03 with an Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setting the Bump Test Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Setting the Calibration Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Connecting Calibration Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table of Contents

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

Installing the Single Module Data Viewer Software. . . . . . . . . . . . . . . . . . . . . . . 24

Chapter 4: Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Bump Testing an 03 Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Calibrating an 03 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Calibration and Bump Test Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Available Memory in the SDM-03 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Copying Calibration and Bump Test Records. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Clearing the SDM-03’s Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Bump Test and Calibration Record Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Bump Testing or Calibrating and Saving Files to a Flash Drive

Multiple Times in One Day . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Chapter 5: Single Module Data Viewer Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Launching the Single Module Data Viewer Program . . . . . . . . . . . . . . . . . . . . . 44

Data Viewing Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Using the Single Module Data Viewer Program . . . . . . . . . . . . . . . . . . . . . . . . . 45

Importing Files Into the Database. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Organizing the Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Viewing the Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Deleting Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Changing the Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Exiting the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Spare Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

CAUTION: Read and unde rst a nd this ma nual befo re u sin g the SDM -03. Also read

and understand the GP-03 and OX-03/CO-03/HS-03 Operator’s

Manuals.

Table of Contents

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

Chapter 1: Introduction

Overview

This chapter briefly describes the SDM-03 Docking Station and the Single Module

Data Viewer Program. This chapter also describes the SDM-03 Docking Station

Standalone Operation Operator’s Manual (this document). Table 1 at the end of this

chapter lists the SDM-03’s specifications.

About the SDM-03

The SDM-03 Docking Station is an advanced, reliable system that provides

calibration, bump testing, and calibration and bump test records for the 03 Series

portable gas monitors. It is de signe d to sa ve t he calibratio n a nd bu mp te st reco rds to

a USB flash drive (standalone functionality) or to be connected directly to a computer

(PC controlled funct ional ity). If calibr atio n and bump test records are sto red to a USB

flash drive while operating in the standalone configuration, the Single Module Data

Viewer Program can then be used with a Windows-based personal computer to

retrieve cal ibration and bump test data files from the USB flash drive or from the

computer’s hard drive if the files have been transferred to the hard drive from the

flash drive. If you are using the PC Controller P r ogram while operating in the PC

controlled configuration, you may retrieve instrument data, bump test, and calibrate

up to 10 instruments at once. Instrument in formation and data for each i nstrument

can be viewed directly using the PC Controller Program and can be printed from the

PC Controller Program. For instructions to use the SDM-03 with the PC Controller

Program, see the SDM-03 Docking Station PC Controlled Configuration Operator’s

Manual.

The purpose of this manual is to explain how to set up and use the SDM-03 in

Standalone configuration. It also explains how to use the Single Module Data Viewer

Program. You will learn how to:

• install and launch the Single Module Data Viewer Program

• prepare the SDM-03 for u se

• perform a bump test

• perform a calibration

• save calibration and bump test records to a USB flash drive

• view, print, and export calibr ation and bump test records

CAUTION: The 03 Series detects oxygen deficiency, elevated levels of oxygen,

combustible gases, carbo n mono xide, or hydrogen sulfi de, all of which

can be dangerous or life threatening. When using the 03 Series, you

must follow the i nstructions and warnings in the G P- 03 a nd OX- 0 3/C O03/HS-03 Operator’s Manuals to assure proper and safe operation of

the instrument and to minimize the risk of persona l injury.

Overview • 1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

CAUTION: The operator of this instr umen t is advised that if the equi pment is u sed

in a manner not specifie d in this manual, the protection pr ovided by the

equipment may be impaired.

System Requirements

To use the Single Module Data Viewer Software, your personal computer must meet

the following requirements:

• Operating System s: Windows® 7 or Windows® 8.

• Processor: IBM® compatible PC running Pentium® 2 processor or equivalent

minimum

• Memory: 3 2 MB RAM minimum

• Hard Disk Space: 32 MB minimum

• CD-RO M Drive

• Available USB port

2 • System Requirements

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

Specifications

Table 1: SDM-03 Specifications

Input Power 12 VDC

NOTE: AC Adapter with 100 - 240 VAC, 50/60 Hz,

0.6A input and 1 2 VDC, 1.2A output provided as

standard.

Environmental Conditions • For Indoor Use Only

• -10° C to 40° C, below 80% Relative Humidity, NonCondensing

Applicable Instruments • GP-03

•OX-03

•CO-03

•HS-03

Memory Capacity 64 KB

Maximum Record Size 256 bytes

Maximum Number of

Records Saved

Number of Calibration Gas

Cylinders

200

One calibration gas cylinder per bump test or

calibration

Specifications • 3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

Table 1: SDM-03 Specifications

Standard Accessories • AC Adapter

• USB Flash Drive

• Single Module Data Viewer Program

• SDM-GX Docking Station PC Controller

Program

• Inlet Air Filter

• Instruction Manual

• 10 Foot Long Exhaust Tube

• One 3 Foot Long Tube for GAS Fitting

• 10 Foot Long 3/16 Inch Tube for GAS

manifolding (used for PC Controlled

Configuration only )

• 2 T-Fittings (used for PC Controlled

Configuration only )

• Check Valve (used for PC Controlled

Configuration only )

• USB Cable, Type A to Type B

4 • Specifications

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

About this Manual

The SDM-03 Docking Station Standalone Configuration Operator’s Manual uses the

following conven tions for notes, cautions, and warnings.

NOTE: Describes additional or critical information.

CAUTION: Describes potentia l damage to equipm en t.

WARNING: Describes potential danger that can result in injury or death.

Cautions & Safety Information

• Use only polyurethane sample tubing with the SDM-03. Consult RKI

Instruments, Inc. for other materials.

• Do not subject the SDM-03 to infrared or intense light. This may cause

communication errors.

• Do not expose the SD M-03 to water.

• Do not subject th e SDM-03 to any hard impact.

About this Manual • 5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

Chapter 2: Description

To PowerJack

on SDM-03

Back Panel

Figure 1: Single-Port AC Adapter

To Power J ack

on SDM-03

Back Panels

Figure 2: 4-Port AC Adapter

Overview

This section describes the SDM-03 docking station. It is designed to be used on a

table top and cons ists of the AC ad apter , T ype A to T y pe B USB cable, air filte r , check

valve, 2 plastic T-fittings, sample tubing, instru ment crad le, back pa nel, cont rol p anel,

status LEDs, and 2 USB ports.

AC Adapter

Single-Port AC Adapter

The single-port AC ada pt er is a w all plug style ada pter w ith a 5 f oot cable. The en d of

the cable has a plug that connects to the power jack on the SDM-03’s back panel.

The AC adapter is rated 100 - 240 VAC input, 12 VDC 1.2 A output.

4-Port AC Adapter

The 4-port AC adapt er is a wa l l p lug style adapter with four 5-foot cables . The end of

each cable has a plug that connects to the power jack on the SDM-03’s back panel.

The AC adapter is rated 100 - 240 VAC input, 12 VDC 2.0 A output.

6 • Overview

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

USB Cable

Exhaust Tubing, 5/16 Inch

ID,10 feet

Particle Filter for Air Inlet

Calibration Gas Sample Tubing, 3/16

Inch ID, 3 fe et

Manifold Tubing, 3/16 Inch

ID,10 feet

Figure 4: Air Filter & Sample Tubing

A Type A to Type B USB cable is provided with the docking station. It is only for use

with the PC Controlled configuration. It is not used in the Standalone configuration.

Figure 3: USB Cable

Air Filter

A cylindrical particle filter with a short l eng th of tubi ng is s upp lied with the S DM-03 for

installation to the AIR fitting on the back panel. The filter keeps particulate

contamination out of the docking station.

Sample Tubing

Three types of sample tubes are included with the docking station. One 3 foot length

of 3/16 inch ID polyurethane tubing is provided to connect the regulator on a

calibration cylinder to the GAS fitting on the back panel. One 10 foot length of 3/16

inch ID polyurethane tubing is provided for manifolding the GAS fitti ng . Th i s t ubing is

only needed in the PC Controlled configuration of the SDM-03. In addition, a 10 foot

length of 5/16 inch ID polyurethane tubing is provided for connection to the exhaust

fitting on the back panel to allow routing of the exhaust to a location such as an open

window where the exhaust can disperse.

USB Cable • 7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

WARNING: Do not use an exhaust tube that is longer than 10 feet. The increased flow

Figure 5: Check Valve

For Exhaust

Tubing

For GAS

Tubing

Figure 6: T- Fittings

restriction caused by a longer tube may affect gas response and cause

inaccurate calibration and bump test results.

Check Valve

A check valve is included with the SDM-03 but is not needed for the Standalone

configuration. It is used for the PC Controlled configuration.

T-Fittings

Two T-fi ttings are included with the SDM-03. The larger fitting is for the exhaust

tubing. The smaller fitting is for the GAS tubing. Neither T-fitting is needed for the

Standalone configuration. They are used in the PC Controlled configuration.

8 • Check Valve

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

Instrument Cradle

Sam ple

Port

Cov er

IRPort

Instrument

Cradle

SDM-03 W ithout 03Series,

Cover Open, Top View

SDM-03 W ithout 03Series,

Cover Open, Front View

SDM-03 W ith03 Series,Cover

Closed, Top V iew

SDM-03

GP-03RKI

POWER

MODE

EDIT

ENTER

SDM-03

BUMP CAL.

COPY

03SERIESOFF

POWER

1SECON

3SECOFF

AIR

POWER

BUMP

1SECON

3SECOFF

03SERIESOFF

EDIT

ENTER

COPY

SDM-03

CAL.

Figure 7: Instrument Cradle

The instrument cradle is a recessed area on the top of the SDM-03 that is designed to

accept the 03 Series. Insert the 03 Series in the instrument cradle when you perform

a bump test or ca libration. A spring-loaded cover latches into place to secure the 0 3

Series. A sample port in the cover matches up with the 03 Series’ diffusion port and

routes air and calibration gas to the sensor during a bump test or calibration. An

infrared (IR) port at the back of the cradle lines up with the 03 Series’ IR port when it

is inserted in the cradle and is used to communicate with the 03 Series.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Instrument Cradle • 9

Page 14

Back Panel

Power Jack

Gas Fitting

Air Fitting

Back Panel US B

Port (Typ e B) ,

For Computer

Connection

Exhaust Fitting

Figure 8: Fittings and Connections

The back panel includes the power jack, sample fittings, and a USB PC connector.

Power Jack

The power jack is located in the bottom left corner of the back panel. The plug on the

end of the AC adapter cable mates to it.

Sample Fittings

Two sample fittings are located on the back of the SDM-03. The AIR fitting is in the

upper left corner and draws air into the SDM-03. The GAS fitting is to the right of the

AIR fitting and is used to connect the SDM-03 to a calibration gas cylinder. Both

fittings accept 3/16 inch ID tubing.

An exhaust fitting is located in the upper right corner. It allows routing of the

exhausted calibration gas to a convenient location. This fitting accepts 5/16 inch ID

tubing. Even though the exhau st gas can be r outed to an area to b e safely disp ersed,

the docking station should still be installed in a well ventilated a rea.

PC Connection

A type B USB connection is located beneath the exhaust fitting on the SDM-03’s back

panel. It is only used for the PC Controlled configuration and is not used in the

Standalone configuratio n.

10 • Back Panel

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

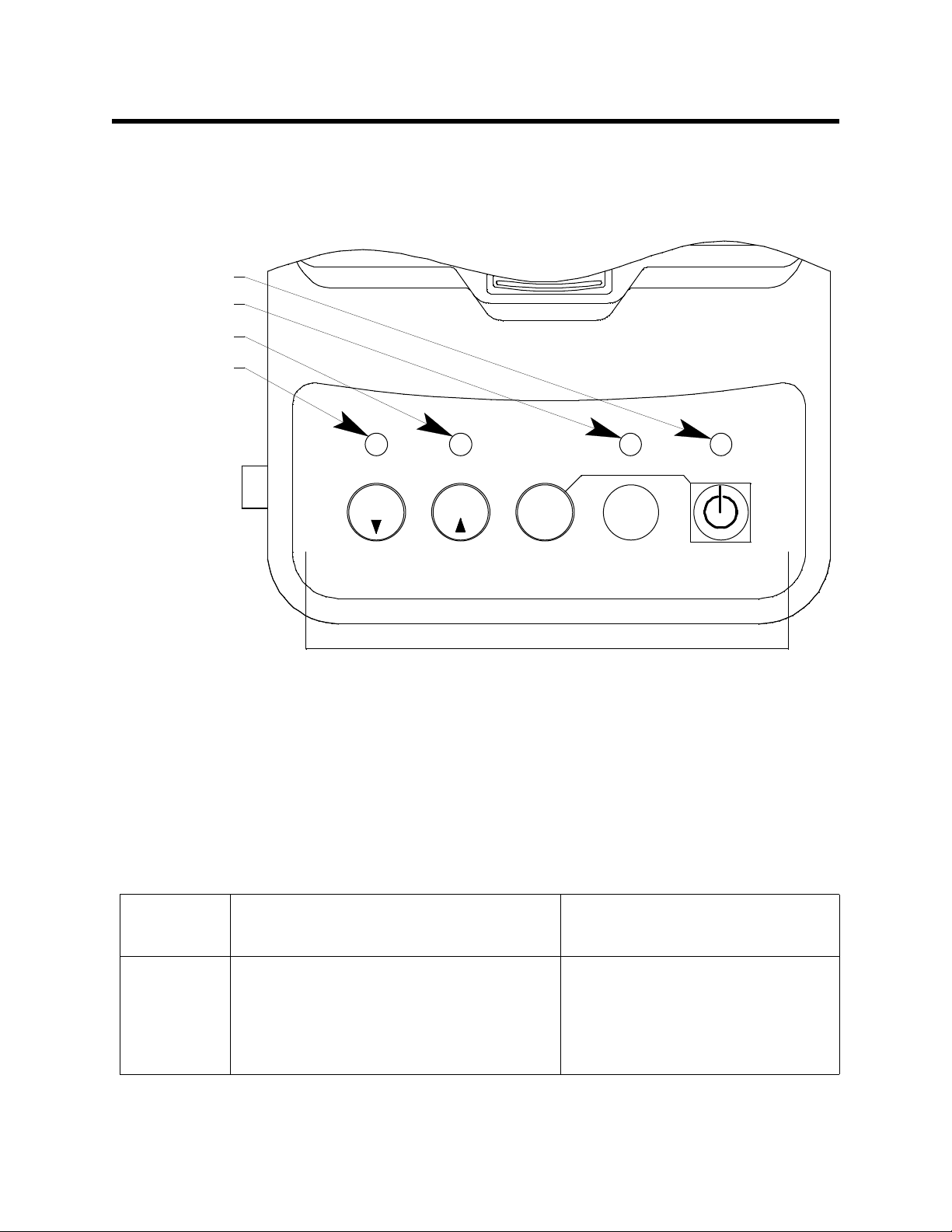

Control Panel

COPY

POWER

03 SERIES OF F

1SEC ON

3SEC OFF

BUMP CAL.

SDM-03

POWER LED

BUMP LED

COPY LED

CAL LED

Control Buttons

EDIT

ENTER

Figure 9: Control Panel

The control panel is us ed to setup and operate the docking station in the Standalone

configuration. It is located at the front of the docking station. It includes the control

buttons, the control button LEDs, and the power LED.

Five control butto ns are located on the control p anel. From lef t to right the y are BUMP

T , CAL S , EDIT ENTER, COPY, and POW ER. The BUMP T , CAL S , and COPY

control buttons each have an LE D above them that indi cates the status of th e function

controlled by that butto n. The POWER LED is l ocated above the POW ER bu tton an d

functions as a pilot LED and a system failure LED.

Table 2: Control Butto n Functions

Control

Button

Control Button Function(s)

BUMP T • Initiates a bump test

• Cancels a bump test

• Moves down a list of para m ete rs

• Decreases an ad justable

parameter

Control Button LED

Function(s)

Indicates status of a bump test

in progress

Control Pa nel • 1 1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

Table 2: Control Butto n Functions

Control

Button

Control Button Function(s)

CAL S • Initiates a calibration

• Cancels a calibration

• Clears data from docking station

memory (when used with COPY

button)

• Moves up a list of parameters

• Increases an adjustable parameter

EDIT

ENTER

• Puts docking station into various

edit modes

• Makes a displayed parameter

editable

• Escapes or cancels an operation

• Turns off connected instrument

(when used with POWER button)

COPY • Copies data to a USB flash drive.

• Clears data from docking station

memory (when used with CAL S

button)

Control Button LED

Function(s)

Indicates status of a ca l ibr ation

in progress

n/a

• Indicates amount of docking

station memory used

• Indicates status of copying

function

• Indicates the result of a copy

operation

POWER • Turns on the docking station

• Turns off the docking station

• Turns off connected instrument

(when used with EDIT ENTER

button)

n/a

12 • Control Panel

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

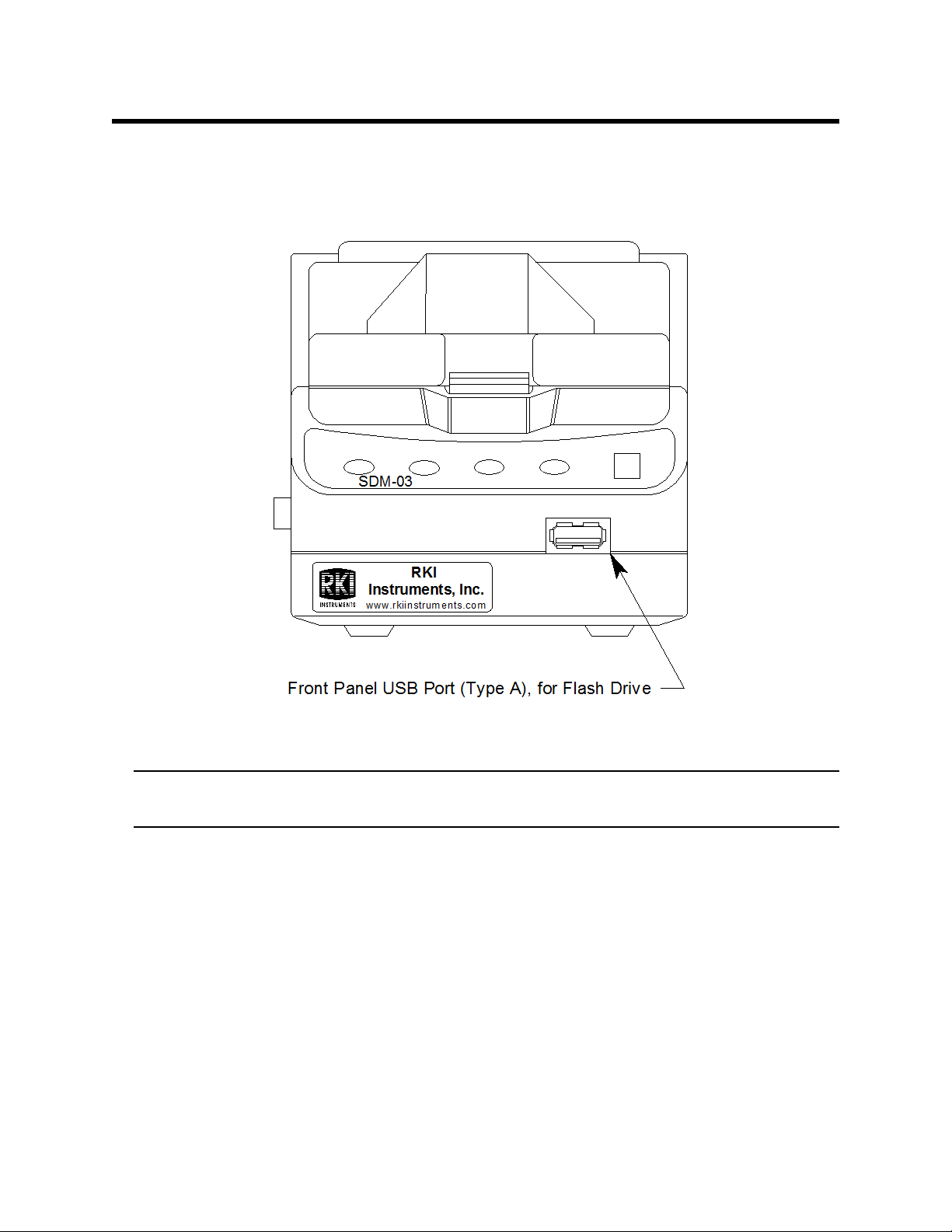

Front Panel

Figure 10: Front Panel

A type A USB port is located on the front of the docking station. This port can be used

to save calibration and bump test data to a USB flash drive. This USB port is for use

only in the Standalone configuration of the SDM-03.

NOTE: The SDM-03 does not support connection of a computer to the front

USB port, only a USB flash drive.

Front Panel • 1 3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

Chapter 3: Preparing to Use the SDM-03

Overview

There are four tasks that must be completed before you can begin to use the

SDM-03: hardware assembly, se tting or confirming the bu mp test and calibration

parameters, connecting calibration gas, and installing the Single Module Data Viewer

Software on your computer. This chapter describes how to assemble the parts that

are shipped with the SDM-03, how to set or view the bump test and calibration

parameters, and how to install the Single Module Data Viewer Software on a

Windows based personal computer.

Hardware Assembly

The hardware assembly co nsist s of connecti ng the AC ad apter, installing the a ir filter,

and connecting the sample tubing. Perform the following to complete the hardware

assembly:

1. Place the SDM-03 on a convenient table top near an AC wall socket in a well

ventilated area. A location near a window that can be opened is best so that

the exhaust c an be routed to the window.

2. Connect the AC adapter’s wall plug into a wall AC socket.

3. Insert the round plug on the end of the AC adapter’s cable into the power jack

on the back of the SDM-03.

NOTE: If you have multiple SDM-03s and are using a 4-port AC adapter, plug

each of the round plugs on the end of the AC adapter into the power

jack on the back of 4 separate SDM-03s.

4. Install the air filter so that the arrow on the filter that indicates direction of flow

is pointing towards th e AIR fitting. P ush the open en d of the flexib le tube that is

on one end of the filter onto the AIR fitting on the back of the SDM-03.

5. Install the 10 foot long 5/16 inch ID flexible tube that is included with the SDM03 onto the exhaust fitting located in the upper right corner of the back panel.

Route the tube to an are a wh ere t he exha ust can be saf ely d ispersed , su ch as

an open window.

CAUTION: The maximum recomme nded le ngth for th e exha ust tube is 10 feet. Do

not use more than 10 feet of tubing or tubing with an ID of less than

5/16 inch for the exhaust tube or the bump test and calibration

accuracy may be adversely affected. The tube that is shipped with the

SDM-03 has an ID of 5/16 inch and is 10 feet long.

6. Install the 3 foot lon g 3/16 in ch ID tube that is inc luded with th e SDM-03 on the

GAS fitting.

14 • Overview

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

Setting the Operational Parameters in Edit Mode

Once the hardware has been assembled, use Edit Mode to confirm or adjust the

bump test and calibration parameters before using the SDM-03.

The bump test paramete rs define how long fresh air and calibra tion gas are applied to

an instrument during a bump test. They also define the tolerance used in determining

whether an instrument fails or passes a bump test and whether or not a calibration

automatically takes place if a bump test fails. The calibration parameters define how

long fresh air and calibration gas are applied to an instrument during a calibration.

The bump test an d calibration parameters are saved in the SDM-03’s memory. If a

parameter is changed with one particular instrument installed in the SDM-03, the

change will be in effect for the bump test or calibration of any subsequent instruments

until the parameter is changed again.

Bump Test & Calibration Parameters

There are four bump test parameters and two calibration parameters. The two

calibration parameters, air sample time and calib ration gas sample time, are also

bump test paramet ers. The parameters are descr ibed below. Table 3 below shows

the factory settings for the bump test and calibration parameters. If you wish to use

the factory settings, then you do not n eed to make an y p arame ter adj ustme nt s. If you

wish to confirm or change the parameter settings, follow the instructions below in

“Setting the Bump Test Parameters” on page 19 or “Setting the Calibration

Parameters” on page 21.

Table 3: Bump Test & Calibration Pa rameter

Parameter

Air Sample Time AIR--IN • 15 seconds

Calibration Gas

Sample Time

Bump Test Check

Tolerance

Display

Tag

GAS--IN • 20 seconds

TOLER • ± 10%

Available

Choices

• 30 seconds

• 45 seconds

• 60 seconds

• 90 seconds

• 30 seconds

• 45 seconds

• 60 seconds

• 90 seconds

• 120 seconds

•± 20%

•± 30%

•± 40%

•± 50%

Bump Factory

Setting

15 seconds 1 5 seconds

20 seconds 6 0 seconds

50% n/a

Cal Factory

Setting

Setting the Operational Parameters in Edit Mode • 15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

Table 3: Bump Test & Calibration Pa rameter

Parameter

Automatic

Calibration

Display

Tag

AUTO--C • On

Available

Choices

•Off

Bump Factory

Setting

On n/a

Cal Factory

Setting

Air Sample Time (AIR--IN)

The air sample time can be set separately for bump testing and calibration. It is the

length of time that the SDM-03 will draw air through the AIR fitting on the back of the

docking station. Air is drawn during a bump test or calibration before an air adjust

operation and to purge calibration gas from the system aft er calibration gas has been

drawn through the GAS fitting on the back of the docking station.

NOTE: For the following parameters, the 03 Series’ setting takes precedence

over the SDM-03’s setting as long as the bump test function in the 03

Series is turned on. For exam p le , if t he SDM - 03 ’s CAL setting is set to

OFF but the 03 Series’ Calibrati on Af ter Bump Te st Failed se tting is se t

to ON, a calibration will still automatically be started after a failed bump

test. If the 03 Series’ bump test function is set to off, the 03 Series’

bump test set tings have no effect and the SDM-03’s settings are used.

Calibration Gas Sample Time (GAS--IN)

The calibration gas sample time can be set separately for bump testing and

calibration. It is the length of time that the SDM-03 will draw calibration gas through

the GAS fitting on the back of the docking station during a bump test or calibration.

Bump Test Check Tolerance (TOLER)

The bump test check t oler an ce on ly applies to bump testing. It determ ines how close

the instrument ga s reading must be to the calibration gas concentration for each

channel during a bump test in order to pass the bump test. It is defined as a

percentage of the calibration gas concentration.The amount that the instrument gas

reading differs from the calibration gas concentration must be equal to o r less than

this percentage of the calibration gas concentration. For example, if the tolerance is

set to 50%, and the %LEL calibration gas concentration is 50% LEL, then the bump

test gas reading f or th e LEL channel on the instrument m ust b e 5 0 %LEL ± 25 %LEL.

Automatic Calibration (AUTO--C)

Automatic calibration onl y appli es to bump testi ng. It can be set to on or off. If it is set

to on, then the docking station will automatically perform a cali bration if a bump test

fails.

16 • Setting the Operational Parameters in Edit Mode

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

Turning on the SDM-03 with an Instrument

CONN

CH4

50

%LEL

BATT

CHANGE

Do the following to turn on the SDM-03 and establish a connection with an

instrument:

1. Confirm that the AC adapter is connected to the SDM-03 and to an AC wall

socket.

2. Press and hold the SDM-03’s POWER button. The LEDs will turn amber.

3. When the BUMP T and CAL S LEDs turn off, release the POWER button.

4. The POW ER LE D will be bl ink ing gr een if the SDM -03 i s opera ting pr oper ly or

solid red if there is a system failure and the COPY LED will be steadily on or

off. The amount of free memory in the SDM-03 will dictate the condition of the

COPY LED (see “Available Memory in the SDM-03” on page 41).

5. Install an instrument into the instrument cradle.

6. Close and secure the SDM-03 cover over the 03 Series.

7. Press and hold the POWER MODE button on the instrument until you hear a

beep, then release it. The instrument will begin its power up sequence (see

exceptions below in st ep 8 and step 9). If a successful connection between the

instrument and the SDM-03 occurs, the home screen will appear on the

instrument display at the end of the startup sequence. The auto calibration

value for the sensor will be displayed.

NOTE: The screen shown above applies to a GP-03 instrument. If you have a

different version of the 03 Series, your screen will be slightly different.

All screens in this manual show a GP-03 instrument.

8. If the instrument’s batteries are too drained for standalone operation, the

following screen will display.

The instrument will not connect to the SDM-03 until the batteries are replaced

as described in the GP-03 or OX-03/CO-03/HS-03 Operator’s Manual and the

Find Quality Products Online at: sales@GlobalTestSupply.com

instrument is turned back on.

www.GlobalTestSupply.com

Setting the Operational Parameters in Edit Mode • 17

Page 22

9. Ther e ar e tw o exce ption s to the seq ue nce de scri b ed in step 7 above. See the

MODE

C.LIMIT

CAL

YES

C.LIMIT

CAL

AIR

C.LIMIT

CAL

NO

C.LIMIT

CAL

C.LIMIT

CAL

C.LIMIT

CAL

MODE

C.LIMIT

FAIL

YES

C.LIMIT

FAIL

C.LIMIT

FAIL

03 Series User Setup Program Opera tor’s Manual for a descript ion of the Cal.

Limit Display and Cal. Limit Check instru ment parameters.

• When Cal. Limit Display is set to On, if the unit is due for calibration and

Cal. Limit Check is set to Confirm to use (factory setting), then the

following screen sequence will occur.

The alarm LED and buzzer will pulse several times. The instrument will

then connect to the SDM-03 and display the home screen shown above in

step 7.

• When Cal. Limit Display is set to On, if the unit is due for calibration and if

Cal. Limit Check is set to Can’t use, then the following screen sequence

will occur.

The alarm LED and buzzer will pulse several times. The instrument will

then connect to the SDM-03 and display the home screen shown above in

step 7.

Find Quality Products Online at: sales@GlobalTestSupply.com

18 • Setting the Operational Parameters in Edit Mode

www.GlobalTestSupply.com

Page 23

Setting the Bump Test Parameters

CONN

CH4

50

%LEL

CAL

BUMP

AIR--IN

15

See “Bump Test & Calibration Parameters” on page 15 for a description of the bump

test parameters. Do the following to set the bump test parameters.

1. Turn on the SDM-03 with an inst rument and establish a connection between

them as described above in "Turning on the SDM-03 with an Instrumen t ". The

instrument will display the home screen .

2. Press and hold the EDIT ENTER button for 2 seconds. The instrument will

display the Edit Mode screen.

3. Press and release the BUMP T button. The instrument will display the AIR--IN

parameter screen. The BUMP T LED will turn green.

Find Quality Products Online at: sales@GlobalTestSupply.com

Setting the Operational Parameters in Edit Mode • 19

www.GlobalTestSupply.com

Page 24

4. Use the BUMP T and C AL S buttons to scroll through the d ifferent bump test

GAS--IN

20

AIR--IN

15

TOLER

50

AUTO--C

On

CH4

%LEL

50

CONN

SAVING

E

AIR--IN

15

parameters. Do n ot scr ol l past the AUTO--C para mete r until you have finished

making any desired changes.

5. To edit a parameter, press and release the EDIT ENTER button when that

parameter is displaye d. An “E” will appea r on the bo ttom of the LCD indi cating

that the parameter value can be changed. In the example below, the AIR--IN

parameter has been selected for updating.

Find Quality Products Online at: sales@GlobalTestSupply.com

20 • Setting the Operational Parameters in Edit Mode

6. Use the BUMP T and CAL S buttons to set the parameter to the desired

value, then press and release the EDIT ENTER button. The “E” to the right of

parameter name will disappear.

7. Repeat step 5 - step 6 to set any other parameters.

www.GlobalTestSupply.com

Page 25

8. When you are done setting the parameters, use the BUMP T button to scroll

SAVING

CONN

CH4

50

%LEL

CAL

BUMP

AIR--IN

15

past the AUTO--C parameter screen. The screen will indicate that the

parameter changes have bee n saved .

The instrument will return to the home screen.

Setting the Calibration Parameters

See “Bump Test & Calibration Parameters” on page 15 for a description of the

calibration parameters. Do the following to set the calibration parameters.

1. Turn on the SDM-03 with an inst rument and establish a connection between

them as described above in "Turning on the SDM-03 with an Instrumen t ". The

instrument will display the home screen .

2. Press and hold the EDIT ENTER button for 2 seconds. The instrument will

display the Edit Mode screen.

3. Press and release the CAL S button. The A IR--IN pa rameter w ill be displa yed.

It is the first of two calibration parameters that can be changed.

Find Quality Products Online at: sales@GlobalTestSupply.com

Setting the Operational Parameters in Edit Mode • 21

www.GlobalTestSupply.com

Page 26

4. Use the BUMP T and CAL S buttons to scroll through the different calibration

GAS--IN

60

AIR--IN

15

CH4

%LEL

50

CONN

SAVING

E

AIR--IN

15

SAVING

parameters. Do not scroll past the GAS--IN parameter until you have finished

making any desired changes.

5. To edit a parameter, press and release the EDIT ENTER button when that

parameter is displaye d. An “E” will appea r on the bo ttom of the LCD indi cating

that the parameter value can be changed. In the example below, the AIR--IN

parameter has been selected for updating.

6. Use the BUMP T and CAL S buttons to set the parameter to the desired

value, then press and release the EDIT ENTER button. The “E” to the right of

parameter name will disappear.

7. Repeat step 5 - step 6 to set any other parameters.

8. When you are done setting the parameters, use the BUMP T button to scroll

past the GAS--IN parameter screen. The screen will indicate that the

parameter changes have bee n saved .

Find Quality Products Online at: sales@GlobalTestSupply.com

22 • Setting the Operational Parameters in Edit Mode

www.GlobalTestSupply.com

Page 27

The instrument will return to the home screen.

Connecting Calibration Gas

The GAS fitting on the back of the docking station is designed to be used with a

calibration gas cylinder that is fitted with a demand flow regulator. The AIR fitting may

be used with a demand flow regulator and a cylinder of zero emissions air, but this is

not normally necessary since the docking station will generally be in a fresh air area.

The type of calibration gas cylinder used depends on the version of the 03 Series

being used with the calibration station. Use Table 4 below as a guide in determining

which calibration gas cylinder is appropriate fo r your system. See “Spare Parts List”

on page 55 for a list of available cylinder part numbers.

Table 4: Recommended Gas Cylinders

Typical Instrument Types

GP-03 50% LEL CH

OX-03 100% N

Recommended Calibration Gas

Cylinder

4

2

CO-03 50 ppm CO

HS-03 25.0 ppm H

S

2

To connect calibration gas to the SDM-03, do the following:

1. If the area around the docking station is not considered a fresh air area (an

area free of combustible and toxic gases and of normal oxygen content,

20.9%) install a tube not longer than 10 feet on the filter attached to the AIR

fitting on the back of the docking station and route it to a fresh air area or

connect a cylinder of zero air with a demand flow regulator to the AIR fitting.

2. Install the demand flow regulator on the calibration gas cylinder.

3. Connect the dem and flo w regulator to the GAS fitting using the 3 foo t length of

3/16 inch ID s ample tubing provided with the docking station.

Connecting Calibrat ion Gas • 2 3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

Installing the Single Module Data Viewer Software

1. Launch Windows®.

2. Exit from all applications and open windows.

3. Insert the SDM-GX Product CD into your computer’s CD-ROM drive. The CD

will automatically open revealing several folders. Open the Single Module Data

Viewer Software fold er, double click on setup.exe.

4. The Single Module Data Viewer InstallShield Wizard comes up to guide you

through installation. Click Next to proceed to the License Agreement window.

5. Read the license agreement and click the agreement acceptance selection

box, then click Next to proceed to the Customer Information window.

6. Enter a user name and organization and select if you want to install the

program for all users on the computer or just for your user account, then click

Next to proceed to the Destination Folder window.

7. The default installation fo lder (C:\Program Files\Single Modu le Data Vi ewer\) is

displayed. If you want to install the software in the default folder continue with

step 8. If you want to install the software in a different location, click Change

and choose a new installation folder now and then continue with step 8.

8. Click Next to proceed to the Ready to Ins tall the Program window.

9. Review the installation set tings. If they are OK, click Install and the installation

process will begin. If you want to change installation settings, click Back and

change them to the desired settings.

10. During software installation, the installation program may find newer versions

of Windows files on your computer than those in the Installation CD. If this

happens, the installation software will ask you if you want to keep these newer

files. Click Yes to do so.

11. Follow the on-screen instructions to complete software installation.

24 • Installing the Single Module Data Viewer Software

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

Chapter 4: Operation

Overview

When you have completed the tasks in "Chapter 3: Preparing to Use the SDM-03",

you are ready to use the SDM-03 docking station. The SDM-03 is capable of

performing bump tests and calibrations on the 03 Series. This chapter describes

procedures for usin g the dockin g stat ion t o bump test a nd calibra te instrumen ts in the

standalone configuration of the docking station. It also describes the information that

is saved in the docking station’s memory and how to save that information to a USB

flash drive for use with the Single Module Data Viewer Program.

Bump Testing an 03 Series

When a bump test is performed, the SDM-03 pe rforms a fresh air adjustment on an

03 Series and then app lies calibration gas to the instru ment. The docki ng statio n then

analyzes the response results based on criteria defined by the bump test check

tolerance parameter and determines if the instrument passed the bump test. The

bump test check tolerance is defined in “Bump Test Check Tolerance (TOLER)” on

page 16. If the automatic calibration parameter is set to ON, then the SDM-03 will

automatically perform a calibration if the bump test fails. The screens in this section

show a GP-03 but the instructions apply to all v ersions of the 03 Series.

Do the following to perform a bump test on an 03 Series:

1. Confirm that the AC Adapter is connected to the SDM-03 and to an AC wall

socket.

2. Press and hold the SDM-03’s POWER button. The LEDs will turn amber.

3. When the BUMP T and CAL S LEDs turn off, release the POWER button.

4. The POW ER LE D will be bl ink ing gr een if the SDM -03 i s opera ting pr oper ly or

solid red if there is a system failure and the COPY LED will be off or on

steadily. The amount of free me mory in the S DM-03 will dictat e the condit ion of

the COPY LED (see “Availab le Memory in the SDM-03” on page 41).

5. Install an 03 Series in the instrument cradle.

6. Close and secure the SDM-03 cover over the 03 Series.

Overview • 2 5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 30

7. Press and hold the POWER MODE button on the 03 Series until you hear a

CONN

CH4

50

%LEL

BATT

CHANGE

beep, then release it. The 03 Se ries will begin its power up sequence (see

exceptions below in st ep 8 and step 9). If a successful connection between the

instrument and the SDM-03 occurs, the home screen will appear on the

instrument display at the end of the startup sequence. The auto calibration

value will be displayed.

NOTE: The screen shown above applies to a GP-03 instrument. If you have a

different version of the 03 Series, your screen will be slightly different.

All screens in this manual show a GP-03 instrument.

8. If the instrument’s batteries are too drained for standalone operation, the

following screen will display.

The instrument will not connect to the SDM-03 until the batteries are replaced

as described in the GP-03 or OX-03/CO-03/HS-03 Operator’s Manual and the

instrument is turned back on.

Find Quality Products Online at: sales@GlobalTestSupply.com

26 • Bump Testing an 03 Seri es

www.GlobalTestSupply.com

Page 31

9. Ther e ar e tw o exce ption s to the seq ue nce de scri b ed in step 7 above. See the

MODE

C.LIMIT

CAL

YES

C.LIMIT

CAL

AIR

C.LIMIT

CAL

NO

C.LIMIT

CAL

C.LIMIT

CAL

C.LIMIT

CAL

MODE

C.LIMIT

FAIL

YES

C.LIMIT

FAIL

C.LIMIT

FAIL

03 Series User Setup Program Opera tor’s Manual for a descript ion of the Cal.

Limit Display and Cal. Limit Check instru ment parameters.

• When Cal. Limit Display is set to On, if the unit is due for calibration and

Cal. Limit Check is set to Confirm to use (factory setting), then the

following screen sequence will occur.

The alarm LED and buzzer will pulse several times. The instrument will

then connect to the SDM-03 and display the home screen shown above in

step 7.

• When Cal. Limit Display is set to On, if the unit is due for calibration and if

Cal. Limit Check is set to Can’t use, then the following screen sequence

will occur.

The alarm LED and buzzer will pulse several times. The instrument will

then connect to the SDM-03 and display the home screen shown above in

step 7.

Find Quality Products Online at: sales@GlobalTestSupply.com

10. If necessary, confirm that the bump test check tolerance is set to the desired

value. See “Setting the Bump Test Parameters” on page 19.

www.GlobalTestSupply.com

Bump Testing an 03 Series • 27

Page 32

11. Verify that the appropriate calibration gas cylinder is connected to the GAS

AIR

CH4

0

%LEL

CANC

FLOW

CH4

- - -

fitting on the back of the SDM-03. See “Connecting Calibration Gas” on

page 23 for calibration gas connection procedures.

12. Press and hold the BUMP T button until the BUMP T LED turns on (about

one second) then rel ease i t. Du ring th e bum p test, the BU MP T LED will flash

amber indicating that a bump test is in progress.

If you wish to cancel the bump test, press and hold the BUMP T button for at

least one second until CANC appears on the screen.

13. If at any point during the bump test the gas flow to the instrument becomes too

low, the bump test will be aborted and the screen will indicate a flow failure.

If a flow failure occurs, confirm all tubing connections are correct and that all

lines are cl ear.

• To return to the home screen, press and hold the EDIT ENTER button for

about 3 seconds.

• To start another bump test, press and release the BUMP T button.

• To perform a calibration, press and release the CAL S button.

14. The SDM-03 will begin the bump test by applying fresh air to the instrument for

the time defined by the AIR--IN bump test parameter.

15. The SDM-03 will perform a fresh air adjustment on the instrument.

• If the air adjustment is successful, the SDM-03 will continue as described in

step 16 below.

Find Quality Products Online at: sales@GlobalTestSupply.com

28 • Bump Testing an 03 Seri es

• If the air adjustm en t i s not succe ssful , th e S DM- 03 w ill ab or t th e b um p te st

www.GlobalTestSupply.com

Page 33

and will not apply calibration gas. If this happens, the BUMP T LED will

CH4

%LEL

35

CH4

ZERO

ZERO

F

BUMP

CH4

27

%LEL

B/C

CH4

45

%LEL

flash red indicating a failure and the following screens will alternate

indicating the fresh air reading and the failed air adjustment.

Figure 11: Failed Fresh Air Adjustment

In this case, continue with step 20.

16. The SDM-03 will apply calibration gas to the instrument for the time defined by

the GAS--IN bump test parameter.

17. The SDM-03 will analyze the re sults.

• If the bump test passes, continue with step 18.

• If the bump test fails, and AUTO--C is set to OFF, continue with step 18.

• If the bump test fails, and AUTO--C is set to ON, a calibration will

automatically begin and calibration gas will continue to flow. The CAL S

LED will begin to flash amber.

NOTE: Calibration gas will continue to be applied so that the total gas

application time is the time defined by the GAS--IN calibration

parameter. This time includes the time that the instrument was being

bump tested. If the GAS--IN calibration parameter is set to 90

seconds and the GAS--IN bump test parameter is set to 30 seconds,

the instrument will sample gas for an additional 60 seconds if the bump

test fails to bring the total exposure time to 90 seconds.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Bump Testing an 03 Series • 29

Page 34

At the end of the calibration gas application, the SDM-03 will analyze the

AIR

CH4

%LEL

50

CH4

BUMP

BUMP

P

CH4

%LEL

10

CH4

BUMP

BUMP

F

results. See “Using the Single Module Data Viewer Program” on page 45

for a description of calibration results.

18. The SDM-03 will then purge the system with fresh air for the time defined by

the AIR--IN bump test parameter.

19. After the fresh air purge is complete, the 03 Series screen will alternate

between the gas reading and the bu mp test or bump test a nd calibra tion result .

For a successful bump test, the gas reading at the end of the gas application

will be displayed. For a successful automatic calibration, the auto calibration

value will be displayed. For a failed bump test or automatic calibration, the gas

reading at the end of the gas application will be displayed. If the instrume nt

passed the bump test, the B UMP T LED will turn solid green. If the instrument

failed the bump test, the BUMP T LED will turn solid red. If the instrument

passed the automatic calibration, t he CAL S LED will turn solid green. If the

instrument failed the automatic calibration, the CAL S LED will turn solid red.

Figure 12: Screen Indication for Passed Bump Test

Figure 13: Screen Indication for Failed Bump Test, CAL OFF

Find Quality Products Online at: sales@GlobalTestSupply.com

30 • Bump Testing an 03 Seri es

www.GlobalTestSupply.com

Page 35

CH4

%LEL

47

CH4

B/C

B/C

F P

CH4

%LEL

15

CH4

B/C

B/C

F F

Figure 14: Screen Indication for Failed Bump Test and Passed

Automatic Calibration

Figure 15: Screen Indication for Failed Bump Test and Failed Calibration

20. After a successful or failed bump test,

• To perform any ot her operations:

To perform another bump test, press and hol d the BU MP T but ton unti l the

pump starts. To perform a calibration, press and hold the CAL S button

until the pump star ts. To return to the home screen, press and hold the

EDIT ENTER button until the home screen appears.

• To turn the 03 Series off:

If the bump test was successful, the instrument will shut off after 15

seconds. If the bump test failed, the instrument will shut off after 10

minutes. If buttons are presse d before th e SDM-03 tu rns off the instru ment,

it will automatically turn it off 10 minutes after the last button push.

To turn off the instrument before it is automatically turned off, press and

hold the EDIT ENTER and POWER buttons simultaneously for about one

second and then release them when the instrument turns off. To avoid

accidentally entering Edit Mode, press and hold the POWER button first,

then press and hold the EDIT ENTER button.

CAUTION: When using the 03 Series with the SDM-03, do not turn off the

instrument using the instrument power button. Use the EDIT ENTER

and POWER buttons on the SDM-03 to turn off the instrument.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Bump Testing an 03 Series • 31

Page 36

The BUMP T or BUMP T and CAL S LEDs will remain on indicating the

test results. If the same 03 Series is turned on again, the test results will

still be indicated by the BUMP T or BUMP T and CAL S LEDs and on the

03 Series screen. To clear the BUMP T or BUMP T and CAL S LEDs,

with the 03 Series on, press and hold the EDIT ENTER button for about 3

seconds until the display returns to the home screen. If a new 03 Series is

turned on and connected, the results displayed by the BUMP T or BUMP

T and CAL S LEDs will automatically be cleared.

21. The results of the bump test or bump test and calibration will be stored in the

SDM-03’s memory and wi ll be available to copy to a USB flash drive. See

“Copying Calibrati on and Bump Test Records to a USB Fla sh Drive” on

page 41 for instructions to copy the saved bump test and ca libration records to

a USB flash drive.

22. Remove the 03 Series from the SDM-03.

23. If you wish to bump test additional instruments, repeat step 5 - step 22 above

for each additional instrument.

32 • Bump Testing an 03 Seri es

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 37

Calibrating an 03 Series

CONN

CH4

50

%LEL

When a calibration is performed, the docking station performs a fresh air adjustment

on an instrument and then applies calibra tion gas to the instrument. The docking

station analyzes the calibration results and determines if the instrument passed the

calibration. The screens in this section show a GP-03 but the instructions apply to all

versions of the 03 Series.

To perform a calibration on an 03 Series:

1. Confirm that the AC adapter is connected to the SDM-03 and to an AC wall

socket.

2. Press and hold the SDM-03’s POWER button. The LEDs will turn amber.

3. When the BUMP T and CAL S LEDs turn off, release the POWER button.

4. The POW ER LE D will be bl ink ing gr een if the SDM -03 i s opera ting pr oper ly or

solid red if there is a system failure and the COPY LED will be off or on

steadily. The amount of free me mory in the S DM-03 will dictat e the condit ion of

the COPY LED (see “Availab le Memory in the SDM-03” on page 41).

5. Install an 03 Series in the instrument cradle.

6. Close and secure the SDM-03 cover over the 03 Series.

7. Press and hold the POWER MODE button on the 03 Series until you hear a

beep, then release it. The 03 Se ries will begin its power up sequence (see

exceptions below in st ep 8 and step 9). If a successful connection between the

instrument and the SDM-03 occurs, the home screen will appear on the

instrument display at the end of the startup sequence. The auto calibration

value will be displayed.

NOTE: The screen shown above applies to a GP-03 instrument. If you have a

different version of the 03 Series, your screen will be slightly different.

All screens in this manual show a GP-03 instrument.

Find Quality Products Online at: sales@GlobalTestSupply.com

Calibrating an 03 Series • 33

www.GlobalTestSupply.com

Page 38

8. If the instrument’s batteries are too drained for standalone operation, the

BATT

CHANGE

MODE

C.LIMIT

CAL

YES

C.LIMIT

CAL

AIR

C.LIMIT

CAL

NO

C.LIMIT

CAL

C.LIMIT

CAL

C.LIMIT

CAL

following screen will display.

The instrument will not connect to the SDM-03 until the batteries are replaced

as described in the GP-03 or OX-03/CO-03/HS-03 Operator’s Manual and the

instrument is turned back on.

9. Ther e ar e tw o exce ption s to the seq ue nce de scri b ed in step 7 above. See the

03 Series User Setup Program Opera tor’s Manual for a descript ion of the Cal.

Limit Display and Cal. Limit Check instru ment parameters.

• When Cal. Limit Display is set to On, if the unit is due for calibration and

Cal. Limit Check is set to Confirm to use (factory setting), then the

following screen sequence will occur.

Find Quality Products Online at: sales@GlobalTestSupply.com

The alarm LED and buzzer will pulse several times. The instrument will

then connect to the SDM-03 and display the home screen shown above in

step 7.

34 • Calibrating an 03 Series

www.GlobalTestSupply.com

Page 39

• When Cal. Limit Display is set to On, if the unit is due for calibration and if

MODE

C.LIMIT

FAIL

YES

C.LIMIT

FAIL

C.LIMIT

FAIL

AIR

CH4

0

%LEL

CANC

Cal. Limit Check is set to Can’t use, then the following screen sequence

will occur.

The alarm LED and buzzer will pulse several times. The instrument will

then connect to the SDM-03 and display the home screen shown above in

step 7.

10. Verify that the appropr iate calibration gas cylin der is connected to the GAS

fitting on the back of the SDM-03. See “Connecting Calibration Gas” on

page 23 for calibration gas connection procedures.

11. Press and hold the CAL S button until the CAL S LED tur ns on (about one

second) then release it. During the calibration, the CAL S LED will flash

amber indicating that a calibration is in progress.

If you wish to cancel the calibration, press and hold the CAL S button for at

least one second until CANC appears on the screen.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Calibrating an 03 Series • 35

Page 40

12. If at any point during the cal ibration the gas flow to the instrume nt becomes too

FLOW

CH4

- - -

CH4

%LEL

35

CH4

ZERO

ZERO

F

CAL

CH4

27

%LEL

low, the calibration will be aborted and the screen will indicate a flow failure.

If a flow failure occurs, confirm all tubing connections are correct and that all

lines are cl ear.

• To return to the home screen, press and hold the EDIT ENTER button for

about 3 seconds.

• To start another calibration, press and release the CAL S button.

• To perform a bump test, press and release the BUMP T button.

13. The SDM-03 begins the calibration by applying fresh ai r to the instrument for

the time defined by the AIR--IN calibration parameter.

14. The SDM-03 will perform a fresh air adjustment on the instrument.

• If the air adjustment is successful, the SDM-03 will continue as described in

step 15 below.

• If the sensor fails the fresh air adjustment, the SDM-03 will abort the

calibration and will not apply calibration gas. If this happens, the CAL S

LED will flash red indicating a failure and the following screens will

alternate indicating the fresh air reading and the failed air adjustment.

Figure 16: Failed Fresh Air Adjustment

In this case continue with step 18.

15. The SDM-03 will apply calibration gas to the instrument for the time defined by

the GAS--IN calibration parameter.

Find Quality Products Online at: sales@GlobalTestSupply.com

36 • Calibrating an 03 Series

www.GlobalTestSupply.com

Page 41

16. The SDM-03 will then purge the system with fresh air for the time defined by

AIR

CH4

%LEL

15

CH4

CAL

CAL

F

the AIR--IN calibration parameter.

17. After the fresh air purge is complete, the screen will alternate between the gas

reading and the calibration result. If the calibration passed, the auto calibration

value will be displayed. If the calibration failed, the gas reading at the end of

the gas applicati on will be di splayed. The cal ibration re sult is i ndicated with a P

(pass) or an F (fail). The CAL S LED will stop blinking and be steadily green if

the calibration passed or steadily red if the calibration failed.

Figure 17: Calibration Results

18. After a successful or failed calibration,

• To perform any ot her operations:

To perform a bump test, press and hold the BUMP T button until the pump

starts. To perform another calibration, press and hold the CAL S button

until the pump star ts. To return to the home screen, press and hold the

EDIT ENTER button until the home screen appears.

• To turn the 03 Series off:

If the calibration was successful, the instrument will shut off after 15

seconds. If the calibration failed, the instrument will shut off after 10

minutes. If buttons are presse d before th e SDM-03 tu rns off the instru ment,

it will automatically turn it off 10 minutes after the last button push.

To turn off the instrument before it is automatically turned off, press and

hold the EDIT ENTER and POWER buttons simultaneously for about one

second and then release them. To avoid accidentally entering Edit Mode,

press and hold the POWER button first, then press and hold the EDIT

ENTER button.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Calibrating an 03 Series • 37

Page 42

CAUTION: When using the 03 Series with the SDM-03, do not turn off the

instrument using the instrument power button. Use the EDIT ENTER

and POWER buttons on the SDM-03 to turn off the instrument.

The CAL S LED will remain on indicating the test results. If the same

03 Series is turned on again, the test results will still be indicated by the

CAL S LED and on the 03 Series screen. To clear the CAL S LED, with

the 03 Series on, press and hold the EDIT ENTER button for about 3

seconds until the display returns to the home screen. If a new 03 Series is

turned on and connected, the results displayed by the CAL S LED will

automatically be cleared.

19. The results of the calibration will be stored in the SDM-03’s memory and will be

available to copy to a USB flash drive. See “Copying Calibration and Bump

Test Records to a USB Flash Drive” on page 41 for instructions to copy the

saved bump test and calibration records to a USB flash drive.

20. Remove the 03 Series from the SDM-03.

21. If you wish to calibrate additional instruments, repeat step 5 - step 20 above

for each additional instrument.

38 • Calibrating an 03 Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 43

Troubleshooting

NOTE: This troubleshooting guide describes SDM-03 problems only. See the

GP-03 or OX-03/CO-03/HS-03 Operator’s Manual for problems you

may encounter with the instrument.

Table 5: Troubleshooting the SDM-03

Symptoms Probable Causes Recommended Action

• Fresh air

adjustment fails

• Calibration fails • The auto calibration

• The SDM-03 is not in a

fresh air environment or

the cylinder being used is

not a zero air cylinder.

• If a zero air cylinder is

used, the calibration

cylinder is out of gas.

• If a zero air cylinder is

used, the tubing from the

regulator to the AIR fitting

is not connected.

values do not match the

cylinder gas

concentrations.

• The calibration cylinder is

out of gas or is outdated.

• The calibration cylinder is

not connected to the GAS

fitting.

• The instrument is not

properly inserted in the

instrument cradle.

• The SDM-03 cover is not

closed and secured.

• The tubing from the

regulator to the GAS fitting

is not connected.

1. Confirm that the SDM-03 is in a

fresh air environment or that a

zero air cylinder is attached to

the AIR fitting.

2. If a zero air cylinder is used,

verify that it contai ns an

adequate supply of test sample.

3. If a zero air cylinder is used,

check all calibration tubing for

leaks or for any bad connections.

4. If the fail condition continues,

replace the sensor in the

instrument.

5. If the difficulti es continue, conta ct

RKI Instruments, Inc. for further

instruction.

1. Confirm that the auto calibration

values match the concentrations

listed on the gas cylinder.

2. Ver ify that t he calibra tion cylinder

contains an adequate supply of

fresh test sample.

3. Ver ify that t he calibra tion cylinder

is connected to the GAS fitting.

4. Check to make sure the

instrument is properly insert ed in

the instrument cradle.

5. Check to make sure the SDM-03

cover is closed and secured.

6. Check all calibration tubing for

leaks or for any bad connections.

7. If the fail condition continues,

replace the sensor in the

instrument.

8. If the difficulti es continue, conta ct

RKI Instruments, Inc. for further

instruction.

Troubleshooting • 39

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 44

• No IR connection

between

instrument and

SDM-03

• Control buttons do

not function

correctly for

standalone

operation

• The COPY

function does not

copy files to the

USB drive

• SDM-03 is not turned on.

• The instrument is not

correctly ins e rte d in to th e

instrument cradle.

• The SDM-03 cover is not

closed and secured.

• The IR window is dirty.

• The SDM-03 is connected

to a computer and the PC

Controller program is

running.

• The USB drive is

defective.

• The USB drive is not

inserted properly.

• The SDM-03 is connected

to a computer , the PC

Controller program is

running, and an

instrument is turned on.

1. Turn on the SDM-03. If it does

not turn on, check that the AC

adapter is plugged into an AC

socket and to the jack on the

back of the SDM-03.

2. Check to make sure the

instrument is inserted properly.

3. Check to make sure the SDM-03

cover is closed and secured.

4. Clean the IR window on the

SDM-03 and the 03 Series.

5. If the difficulti es continue, conta ct

RKI Instruments, Inc. for further

instruction.

Disconnect the USB cable from the

back of the SDM-03 if it is

connected. See the SDM-03 PC

Controlled Configuration Operat or’s

Manual for instructions to use the

SDM-03 in PC Controlled

configuration.

1. Perform a COPY operation with a

different USB drive.

2. Be sure that the USB drive is

inserted correctly.

3. Disconnect the SDM-03 from the

computer.

4. If the difficulti es continue, conta ct

RKI Instruments, Inc. for further

instruction.

40 • Troubleshooting

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 45

Calibration and Bump Test Records

The SDM-03 saves a record of each bump test and calibration performed. It is

capable of saving up to 200 such records. When a n SDM-03’ s memory become s full,

the oldest record is overwritt en when a new re cord is saved . The records saved in the

SDM-03’s memory can be saved to a USB flash drive using the USB port on the front.

Avail able Memory in the SDM-03

The COPY LED indicates how much of the SDM-03’s memory has been used. The

table below describes t he various indications.

Table 6: COPY LED Indications

COPY LED Indication Memory Used

Off None. No records are saved

Solid Green Less than 80% of th e SDM-03’s memory

has been used.

Solid Amber More than 80% of t he SDM-03’s memory

has been used.

Solid Red The docking station’s memory is full. A

newly saved record will overwrite the oldest

one.

Copying Calibration and Bump Test Records to a USB Flash Drive

The SDM-03 will only perform a copy operation if there is at least one record saved in

its memory. If there are no records saved in the docking st a tion ’ s memo ry, the COPY

LED will be off and the COPY button will not function. Do the following to copy

calibration and bump test records in the SDM-03’s memory to a USB flash drive.

NOTE: The USB port on the front of the docking station cannot be used to

connect the SDM-03 to a computer, only to save calibr ation and bump

test records to a USB flash drive.

1. Confirm that the AC Adapter is connected to the SDM-03 and to an AC wall

socket.

2. Press and hold the SDM-03’s POWER button. The LEDs will turn amber.

3. When the BUMP T and CAL S LEDs turn off, release the POWER button.

4. The COPY LED will be off or on steadily and the POWER LED will be blinking

green. The amount of free memory in the SDM-03 will dictate the condition of

the COPY LED (see "Available Memory in the SDM-03" above).

Calibration and Bump Test Records • 4 1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 46

5. Install a USB flash drive into the USB port on the front of the SDM-03. The

SDM-03 will take a few seconds to determine how much memory is available

in the flash drive.

• If the flash drive’s available memory is not enough for the contents of the

SDM-03’s memory, the COPY LE D w ill alternate between green and red.

Enough memory will have to be cleared in the flash drive to make room for

the records in the SDM-03’s memory.

• If there is eno ugh availa ble memory i n the flash drive for th e content s of the

SDM-03’s memory, the COPY LED will begin flashing in the same color

that it was before installing the flash drive.

6. Press and hold the COPY button until the COPY LED turns red, then release

it. The COPY LED will become solid red while the records in the docking

station’s mem ory are co pied to t he flash dr ive. In ad dition, if t he flash dr ive has

an LED, it will begin to blink.

7. When the COPY LED retu rns to it s origina l color and begins blin king agai n and

the flash drive’s LED (if it has one) stops blinking, t he copy operation is

complete. Remove the flash drive from the USB port.

NOTE: If you pull out the flash drive while its LED is still blinking or the COPY

LED is still solid red, the file saved in the fl ash dri ve wi th t he calibr ati on

and bump test records may be incomplete.

8. If the flash drive has not already been used with a docking station, a folder

named DAT will be created on the flash drive and a file with all the saved

calibration and bump test records will be saved to this folder.

If the flash dr ive has been used before with a docking station, the file will be

saved to the existing DAT folder.

9. The files on the flash drive can now be either transferred to a computer or kept

on the flash drive for use with the Single Module Data Viewer Software. See

"Bump Test and Calibration Record Files" belo w for a di scussion of these files

and how to use them.

Clearing the SDM-03’s Memory

Make sure that you save the bump test and calibration records in the SDM-03’s

memory to a flash drive before clea ring its memory. The docking station’s memory

can be cleared by simultaneously pressing and holding the CAL S and COPY

buttons for five seconds. After the SDM-03’s memory has been cleared, the COPY

LED will turn off indicating there are no records to be copied.

Bump Test and Calibration Record Files

Each time a copy function is performed, a file is saved to the flash drive in the DAT

folder. The file name will begin with “SDM-03” and the remainder of the file name will

depend on the seri al number of the SDM-03 used and the date of the most recent

bump test or calibration performed on the SDM-03. So it is possible to have multiple

42 • Calibration and Bump Test Records

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 47

files in the DAT folder from the SDM-03.

The files that an SDM-03 saves to a USB flash drive are structured so that they can

be imported into a database controlled by the Single Module Data Viewer Software.

See “Importing File s In to the Database” on page 46 for instructions t o a dd fi les to th e

database.

Bump Testing or Calibrating and Saving Files To a Flash Drive Multiple Times In One Day

The SDM-03 assigns file names to calibration and bump test record files based on

the day of the most recent calibration or bump test record saved in the docking

station’s memory. If bump tests or calibrations are performed, a copy operation is

performed, then additional bump tests or calibrations are performed, and another

copy operation is performed with the same flash drive all on the same day, the

existing file on the flash drive from the first copy operation will be overwritten by the

file from the second copy operation beca use its name will be the same as the new

file. In this case, no information is lost since the second file saved to the flash drive

includes all the records that were in the first file.