Page 1

Enclosure cooling unit

Assembly and operating instructions

3302.xxx

3302.3xx

3303.xxx

3304.xxx

3305.xxx

3328.xxx

3329.xxx

3332.xxx

3361.xxx

3366.xxx

Page 2

Contents

EN

Contents

1 Notes on documentation .................. 3

1.1 CE labelling .................................................. 3

1.2 Storing the documents................................. 3

1.3 Symbols used in these operating instructions 3

1.4 Other applicable documents ........................ 3

2 Safety notes ..................................... 3

3 Device description ............................ 4

3.1 TÜV-tested output measurement to

DIN EN 14511 .............................................. 4

3.2 Functional description .................................. 4

3.2.1 How it works ......................................................... 4

3.2.2 Control .................................................................. 5

3.2.3 Bus mode (e-Comfort controller only) .................... 5

3.2.4 Safety devices ....................................................... 5

3.2.5 Condensation ....................................................... 5

3.2.6 Filter mats ............................................................. 5

3.2.7 Door limit switch ................................................... 5

3.2.8 Additional interface X3 .......................................... 6

3.3 Proper use, foreseeable misuse ................... 6

3.4 Scope of supply........................................... 6

4 Assembly and connection ................ 6

4.1 Choosing the installation site........................ 6

4.2 Notes on assembly ...................................... 6

4.2.1 General ................................................................. 6

4.2.2 Layout of the electronic components in the

enclosure .............................................................. 7

4.3 Fitting the cooling unit.................................. 7

4.3.1 Making the cut-outs .............................................. 8

4.3.2 External mounting of the cooling unit ..................... 8

4.3.3 Partial internal mounting of the cooling unit ........... 8

4.3.4 Full internal mounting of the cooling unit ................ 9

4.4 Connecting the condensate discharge....... 10

4.5 Notes on electrical installation .................... 11

4.5.1 Connection data ................................................. 11

4.5.2 Overvoltage protection and supply line load ........ 11

4.5.3 Three-phase devices ........................................... 11

4.5.4 Door limit switch ................................................. 11

4.5.5 Notes on the flicker standard .............................. 11

4.5.6 Potential equalisation .......................................... 12

4.6 Making the electrical connection ................ 12

4.6.1 Bus connection (only when interconnecting several

units with a Comfort controller) ............................ 12

4.6.2 Connection X3 for serial interface ........................ 12

4.6.3 Mounting external transformer ............................. 12

4.6.4 Installing the power supply .................................. 13

4.7 Finalising assembly .................................... 15

4.7.1 Installing the filter media ...................................... 15

4.7.2 Fitting the cooling unit ......................................... 15

4.7.3 Setting the filter mat monitor (only with e-Comfort

controller) ............................................................ 16

6 Operation ....................................... 16

6.1 Control using the Basic controller............... 16

6.1.1 Properties ........................................................... 16

6.1.2 Operating and error display ................................. 17

6.1.3 Test mode with the Basic controller .................... 18

6.1.4 Setting the temperature ...................................... 18

6.1.5 Resetting the Basic controller .............................. 18

6.2 Control using the e-Comfort controller........ 18

6.2.1 Properties ........................................................... 19

6.2.2 Eco mode ........................................................... 19

6.2.3 Launching test mode .......................................... 19

6.2.4 General information about programming ............. 20

6.2.5 Editable parameters ............................................ 21

6.2.6 Programming overview ....................................... 22

6.2.7 Defining system messages for evaluation ............ 23

6.2.8 Setting the master/slave identifier ........................ 24

6.2.9 Evaluating system messages .............................. 24

6.2.10 Reset the e-Comfort controller ............................ 26

7 Inspection and maintenance .......... 26

7.1 Compressed air cleaning 3304.xxx,

3305.xxx .................................................... 26

7.2 Compressed air cleaning 3328.xxx,

3329.xxx, 3332.xxx .................................... 30

7.3 Installation instructions for NEMA 4X

devices ...................................................... 35

8 Storage and disposal ..................... 36

9 Technical details ............................ 36

9.1 Technical specifications.............................. 36

9.2 Performance diagrams ............................... 43

10 List of spare parts .......................... 44

11 Appendix ....................................... 47

11.1 Cut-out and hole sizes ............................... 47

11.1.1 Dimensions for external mounting ....................... 47

11.1.2 Dimensions for partial internal mounting .............. 50

11.1.3 Dimensions for full internal mounting ................... 51

11.2 Electrical wiring plan................................... 52

5 Start-up .......................................... 16

2 Rittal enclosure cooling unit

Page 3

1 Notes on documentation

1 Notes on documentation

1.1 CE labelling

Rittal GmbH & Co. KG confirms the conformity of the

cooling unit with the European Union's Machinery Directive 2006/42/EC and EMC Directive 2014/30/EC. A

corresponding declaration of conformity has been issued. This can be found at the end of this document, or

on the Rittal homepage.

1.2 Storing the documents

The assembly and operating instructions as well as all

other applicable documents are an integral part of the

product. They must be issued to everyone who works

with the unit and must always be available and on hand

for operating and maintenance personnel.

1.3 Symbols used in these operating instructions

The following symbols are used in this documentation:

Danger!

A dangerous situation in which failure to

comply with the instructions will result in

death or severe injury.

Warning!

A dangerous situation which may cause

death or serious injury if the instructions

are not followed.

Caution!

A dangerous situation which may lead to

(minor) injuries if the instructions are not

followed.

Note:

Important notices and indication of situations

which may result in material damage.

This symbol indicates an "action point" and shows that

you should perform an operation or procedure.

2 Safety notes

Please observe the following general safety notes when

assembling and operating the unit:

– Assembly, installation and servicing may only be per-

formed by properly trained specialists.

– Screw the enclosure to the floor to prevent it from tip-

ping over when the cooling unit is installed.

– Do not obstruct the air inlet and air outlet of the cooling

unit inside and outside the enclosure (see section4.2.2 "Layout of the electronic components in the

enclosure").

– To ensure problem-free opening and closing of the en-

closure door, use a ride-up door roller (refer to the accessories in the Rittal Catalogue). This raises the door

slightly and balances out the weight of the cooling unit,

to prevent buckling of the door and associated seal

problems.

– The heat loss of the components installed in the enclo-

sure must not exceed the useful cooling power of the

cooling unit.

– Cooling units with item numbers: 3303.xxx, 3361.xxx,

3304.xxx, 3305.xxx, 3328.xxx, 3329.xxx and

3332.xxx must be transported in an upright position

and protected from tipping over.

– Units with item numbers 3302.xxx and 3366.xxx must

be transported lying flat.

– Shipping braces must be used when transporting a

unit that has already been mounted (on the enclosure).

A wooden structure made from square timbers or

boards to support the cooling unit at the bottom (see

fig. 1) is suitable for this purpose. The pallet should be

big enough to prevent the enclosure and cooling unit

overturning. If the cooling unit is mounted on a door,

ensure the door is kept closed during transport.

– Use only original spare parts and accessories

– Do not make any changes to the cooling unit other

than those described in these instructions or associat-

ed instructions.

– Risk of burns! On cooling units with automatic con-

densate evaporation, the surface of the thermal ele-

ment will get very hot during operation, and will remain

so for some time afterwards.

– The mains connector of the cooling unit must only be

connected and disconnected with the system de-en-

ergised. Connect the protective device specified on

the rating plate.

EN

1.4 Other applicable documents

Assembly and operating instructions in paper and digital

format are available for the unit types described here.

We cannot accept any liability for damage associated

with failure to observe these instructions. Where applicable, the instructions for any accessories used also apply.

Rittal enclosure cooling unit 3

Page 4

EN

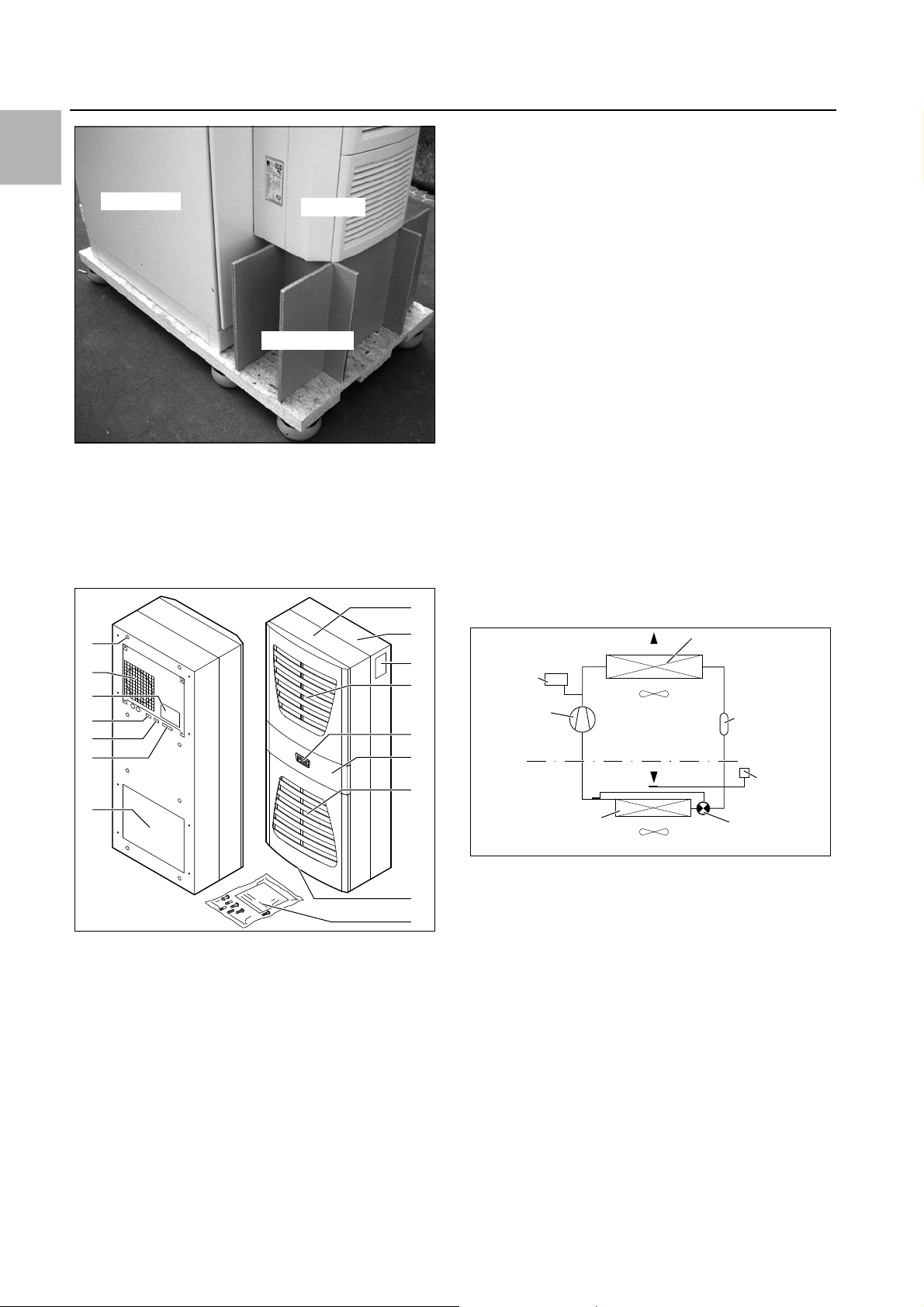

Enclosure

Support

Cooling unit

10

9

8

11

13

12

16

15

14

1

2

4

5

6

7

3

PSAH-

Pressure

switch

Condenser fan

Expansion valve (4)

Temperature

control

Filter dryer (5)

Internal circuit

Compressor (2)

External circuit

Evaporator fan

Evaporator coil (1)

Condenser (3)

3 Device description

Fig. 1: Transporting an enclosure/cooling unit combination

3 Device description

Depending on the model chosen, your cooling unit may

vary in appearance from the illustrations contained in

these instructions. However, the functions are identical

in principle.

15 Condensate discharge

16 Dispatch bag

3.1 TÜV-tested output measurement to DIN EN 14511

All TopTherm cooling units in the output range from 300

to 4000 W are tested to the latest EN 14511-1-4:201312 standard by independent test institute TÜV Nord.

This means you have peace of mind about the design of

the climate control solution and you can be sure you are

getting the performance you are paying for.

3.2 Functional description

3.2.1 How it works

The cooling unit (compression refrigeration system)

comprises four main components (see fig. 3): the evaporator (1), the refrigerant compressor (2), the condenser

(3), and the control or expansion valve (4), which are

connected by suitable pipework. This circuit is filled with

a readily boiling substance, the refrigerant. The refrigerant R134a (CH

tion Potential (ODP) is 0, making it very eco-friendly. A filter dryer (5) which is integrated into the hermetically

sealed cooling circuit provides effective protection

against moisture, acid, dirt particles, and foreign bodies

within the cooling circuit.

FCF3) is chlorine-free. Its Ozone Deple-

2

Fig. 2: Device description

Key

1 Blind rivet nut

2Evaporator fan

3 Electrical wiring plan

4 X2 master-slave connection

5 X3 optional serial interface

6 X1 terminal strip

7 Air outlet hole

8 Front half of the enclosure

9 Rear half of the enclosure

10 Louvred grille for air outlet

11 Display

12 Infill panel

13 Louvred grille for air inlet

14 Rating plate

4 Rittal enclosure cooling unit

Fig. 3: Cooling circuit

In the evaporator coil (1), the liquid refrigerant is converted to a gaseous state. The energy needed for this purpose is taken from the enclosure air in the form of heat,

which has the effect of cooling the enclosure air. In the

compressor (2), the refrigerant is heavily compressed,

so that it achieves a higher temperature inside the condenser (3) than the ambient air. This means that excess

heat may be emitted to the ambient air via the surface of

the condenser, as a result of which the temperature of

the refrigerant drops and it is converted back into liquid.

It is re-injected into the evaporator coil via a thermostatic

expansion valve (4), which causes it to cool down further, and is then once again able to absorb the energy

from the enclosure air in the evaporator coil. The whole

cycle begins again.

Page 5

3 Device description

3.2.2 Control

Rittal enclosure cooling units are fitted with a controller

for setting the functions of the cooling unit.

Depending on the design, this is either a Basic controller

(operating status display via LED) or an e-Comfort controller (display plus extended functions, see section6

"Operation").

3.2.3 Bus mode (e-Comfort controller only)

The serial unit interface X2 allows you to create a bus

connection with up to ten cooling units using the masterslave cable (shielded, four-wire cable, Model No.

3124.100). This allows you to implement the following

functions:

– Parallel unit control (the cooling units in the network

can be switched on and off simultaneously)

– Parallel door status message ("door open")

– Parallel collective fault message

Data is exchanged via the master-slave connection.

During commissioning, assign an address to each unit

that also includes the identifier "master" or "slave".

3.2.4 Safety devices

– In the cooling cycle, the cooling units (with the excep-

tion of type 3302.xxx) have a tested pressure switch to

EN 12 263 which is set to maximum PS (permissible

pressure); this operates via an automatic reset device

whenever the pressure drops again

– Temperature monitoring prevents the evaporator coil

from icing over. If there is a risk of icing, the compres-

sor switches itself off and automatically switches itself

back on again at higher temperatures

– The refrigerant compressor and the fans are equipped

with thermal winding shields to protect against excess

current and excess temperatures

– In order to allow a reduction of pressure inside the

compressor and hence a safe restart, once it has been

switched off (e.g. upon reaching the set temperature

via the door limit switch function or via de-energising),

the device will switch back on with a delay of 180 sec-

onds

– The device has floating contacts on the connection

pins (terminals 3 – 5), via which system messages

from the device may be polled, e.g. using a PLC (1 x

change-over contact Basic controller, 2 x normally

open contacts e-Comfort controller)

3.2.5 Condensation

At high levels of humidity and low temperatures inside

the enclosure, condensation may form on the evaporator coil.

The cooling units (except 3302.xxx, 3303.xxx and

3361.xxx) have automatic, electric condensate evaporation. The thermal component used for this purpose is

based on self-regulating PTC technology. Condensate

arising on the evaporator coil is collected in a tank in the

external circuit of the cooling unit, and partially evaporated via the airflow. When the water level rises, the water

enters the PTC thermal component and is evaporated

(through-flow heater principle). The water vapour

streams out of the cooling unit with the airflow from the

external fan.

The PTC thermal component is permanently connected

and has no switchpoint. It is protected against short-circuits with miniature fuses (F1.1, F1.2). If the fuse has

tripped, any condensation is drained off via the safety

overflow.

For unit types 3302.xxx, 3303.xxx and 3361.xxx, the

condensate is routed downwards out of the unit via a

drain pipe on the evaporator coil divider panel. For this

purpose, a hose must be connected to the condensate

nozzle (see section4.4 "Connecting the condensate

discharge"). External condensate evaporators are available as accessories for these unit types (refer also to the

accessories in the Rittal Catalogue).

3.2.6 Filter mats

The entire cooling unit condenser is covered with a dirtrepelling, easy-to-clean RiNano coating. In many applications, therefore, the use of filter media is unnecessary,

particularly with dry dusts.

For dry, coarse dust and lint in the ambient air, we recommend installing an additional PU foam filter mat (available as an accessory) in the cooling unit. Depending on

the incidence of dust, you will need to replace the filter

mat from time to time.

For air containing oil condensate, we recommend the

use of metal filters (also available as an accessory).

These may be cleaned with suitable detergents and reused.

Function of the filter mat monitor (with e-Comfort controller only):

Dirt on the filter mat is automatically determined by

measuring the temperature difference in the external circuit of the cooling unit. As the level of filter mat soiling increases, the temperature difference will increase. The

setpoint value of the temperature difference in the external circuit adapts automatically to the relevant operating

points in the performance diagrams. Hence there is no

need to readjust the setpoint value for different unit operating points.

3.2.7 Door limit switch

The cooling unit may be operated with a floating door

limit switch connected. The door limit switch is not included with the supply (available as an accessory, Model

No. 4127.010).

The door limit switch function causes the fans and the

compressor in the cooling unit to be switched off after

approximately 15 seconds when the enclosure door is

opened (contacts 1 and 2 closed). This prevents the formation of condensation inside the enclosure while the

enclosure door is open. In order to prevent damage to

the unit, it is equipped with an ON delay: The evaporator

fan cuts back in with a delay of approximately 15 seconds after the door has been closed, while the condens-

EN

Rittal enclosure cooling unit 5

Page 6

4 Assembly and connection

EN

er fan and compressor switch on after approximately

3minutes.

Note:

– No external voltage may be applied to the

door contacts (terminals 1 and 2).

– For cooling units with basic control, the

evaporator fan continues to run even

when the door is open.

3.2.8 Additional interface X3

Note:

The electrical signals at the interface are of

an extra-low voltage (not extra-low safety

voltages to EN 60 335).

An additional interface card may be connected to the 9pole SUB-D connector X3 in order to incorporate the

cooling unit into higher-level monitoring systems (available as an accessory, interface card Model No.

3124.200).

3.3 Proper use, foreseeable misuse

The cooling unit is only intended for cooling connected

enclosures. Any other use is not permitted.

– The unit must not be installed and operated in loca-

tions which are accessible to the general public (see

DIN EN 60335-2-40, paragraph 3.119).

– The unit is designed solely for stationary use.

The cooling unit is state of the art and built according to

recognised safety regulations. Nevertheless, improper

use can pose a threat to the life and limb of the user or

third parties, or result in possible damage to the system

and other property.

Consequently, the cooling unit must only be used properly and in a technically sound condition! Any malfunctions which impair safety should be rectified immediately.

– Use of accessories not approved by Rittal GmbH &

Co. KG.

3.4 Scope of supply

The unit is supplied in a packaging unit in a fully assembled state.

Please check the scope of supply for completeness.

Qty. Description

1 Enclosure cooling unit

1

1

1

1

4 – 10

1 Drilling template

Tab. 1: Scope of supply

Dispatch bag:

– Assembly and operating instructions

–Self-adhesive tape

– Connector X1

–Grub screws

– Nuts, washers

4 Assembly and connection

4.1 Choosing the installation site

When choosing the installation site for the enclosure,

please observe the following:

– The site for the enclosure, and hence the arrangement

of the cooling unit, must be carefully selected so as to

ensure good ventilation (clearance between units and

clearance between the unit and the wall must be at

least 200 mm in each case).

– The cooling unit must be installed and operated in a

vertical position (maximum deviation: 2°).

– The installation site must be free from excessive dirt,

aggressive ambient conditions and moisture.

– The ambient temperature must be within the limits

specified on the rating plate.

– It must be possible to fit a condensate discharge (see

section4.4 "Connecting the condensate discharge").

– The mains connection data as stated on the rating

plate of the unit must be guaranteed.

Proper use also includes the observance of the documentation provided, and compliance with the inspection

and maintenance conditions.

Rittal GmbH & Co. KG is not liable for any damage which

may result from failure to comply with the documentation provided. The same applies to failure to comply with

the valid documentation for any accessories used.

Inappropriate use may be dangerous. Examples of inappropriate include:

– Use of the cooling unit over long periods with the en-

closure open.

– Use of impermissible tools.

– Improper operation.

– Improper rectification of malfunctions.

6 Rittal enclosure cooling unit

4.2 Notes on assembly

4.2.1 General

– Check the packaging carefully for signs of damage.

Traces of oil on damaged packaging are an indication

of refrigerant loss and leakages. Any packaging damage may be the cause of a subsequent functional failure.

– The enclosure must be sealed on all sides (IP 54). In-

creased condensation will occur if the enclosure is not

airtight.

– In order to avoid excessive condensation inside the

enclosure, we recommend installing a door limit

switch (e.g. 4127.010) which deactivates the cooling

unit when the enclosure door is opened (see section3.2.7 "Door limit switch").

Page 7

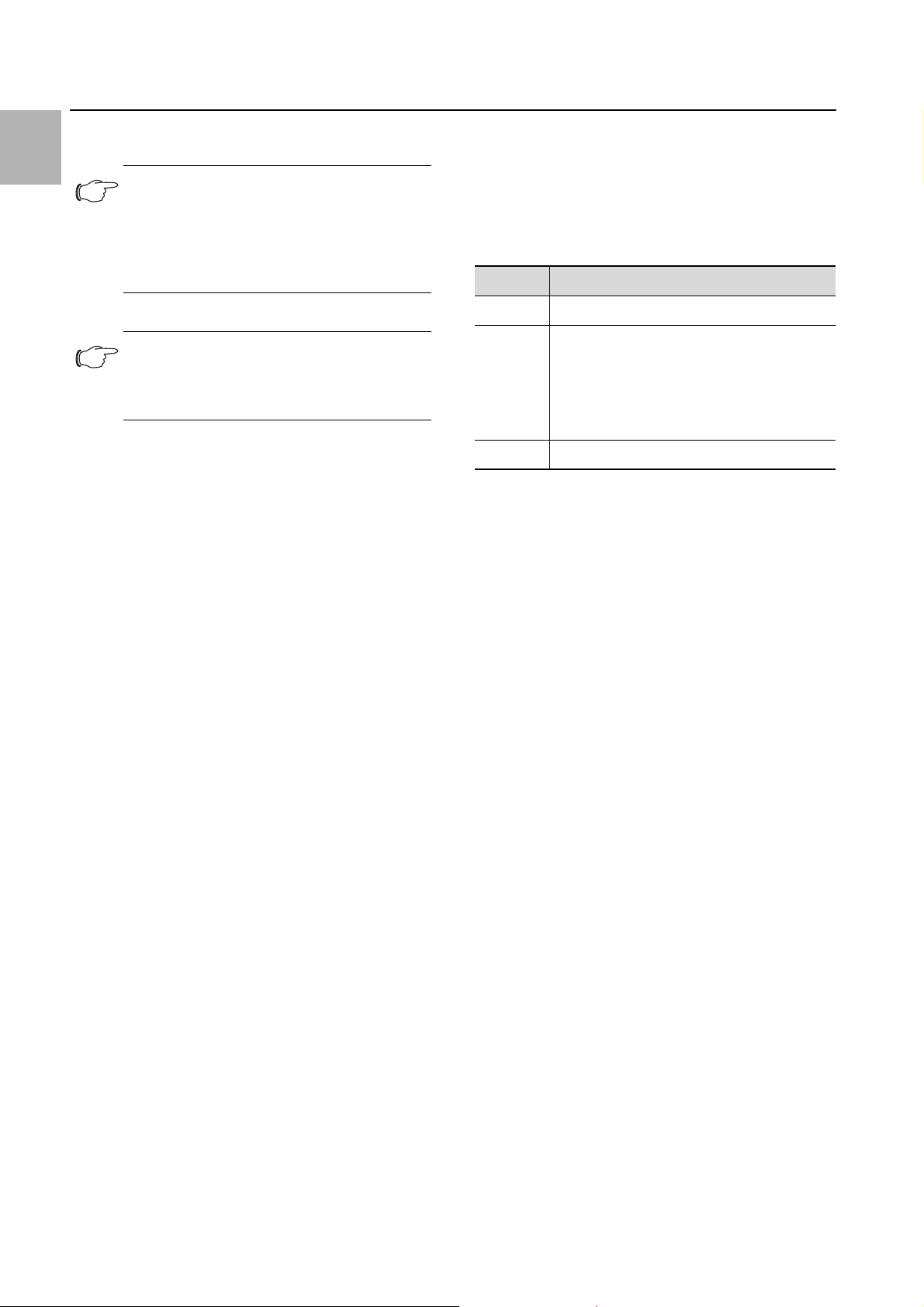

4.2.2 Layout of the electronic components in the

x

123

enclosure

Note:

Risk of condensation!

When arranging the electronic components

inside the enclosure, please ensure that the

cold airflow from the cooling unit is not directed at active components. Please also

ensure that the cold airflow is not directed at

the warm exhaust airflow from active components such as converters. This may lead

to an air short-circuit and therefore prevent

adequate climate control, or may even

cause the cooling unit’s internal safety devices to cease cooling operation.

4 Assembly and connection

EN

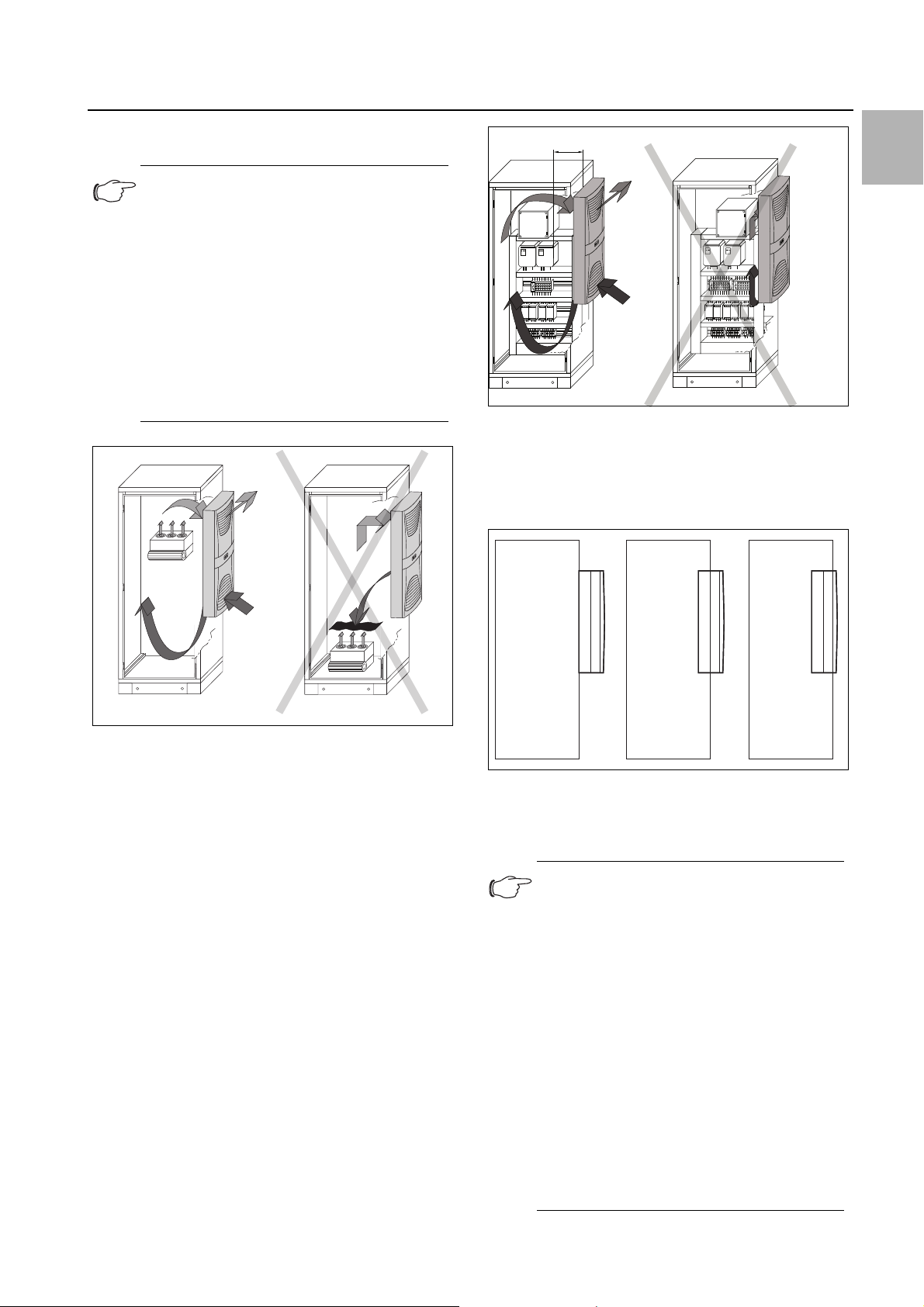

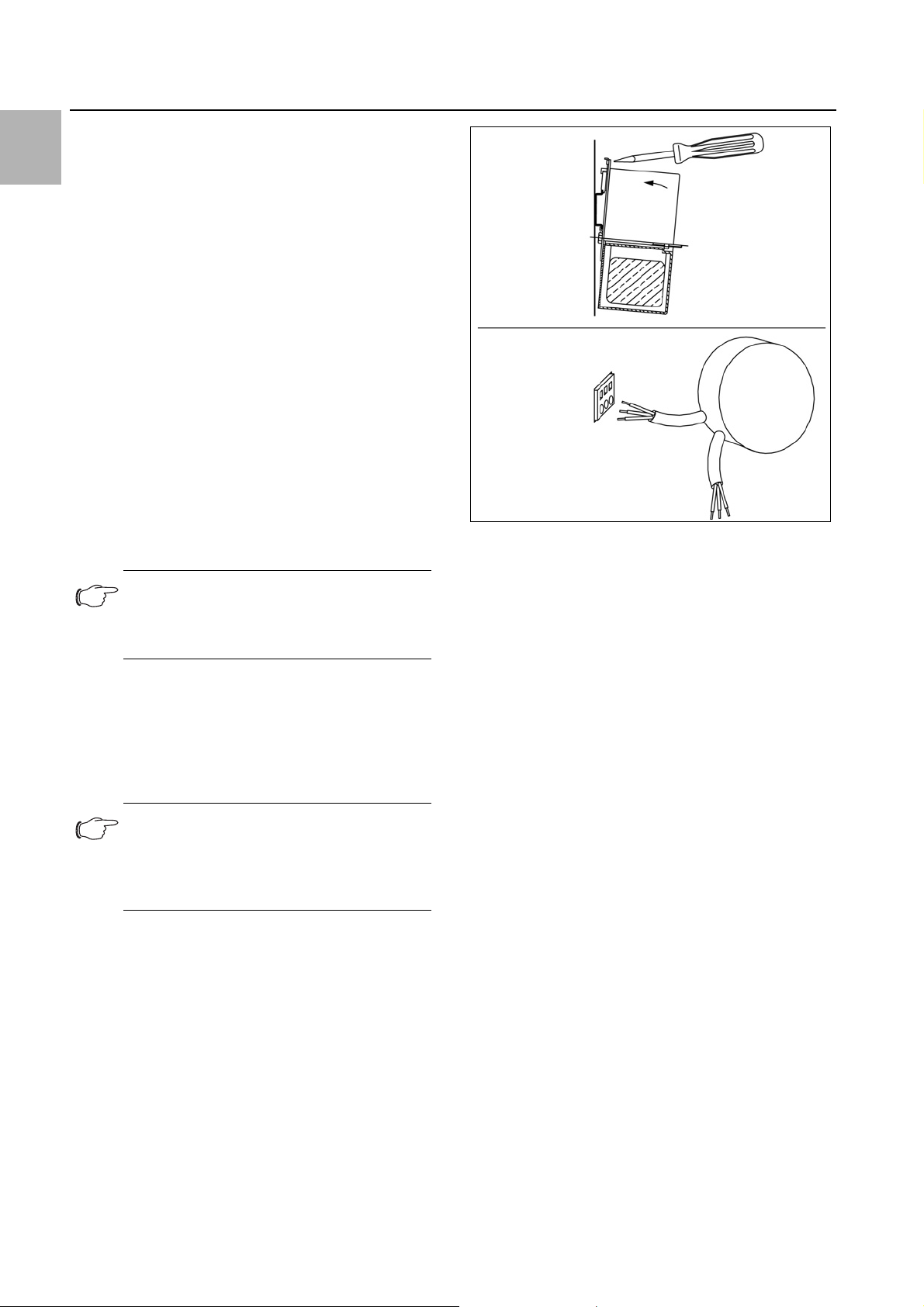

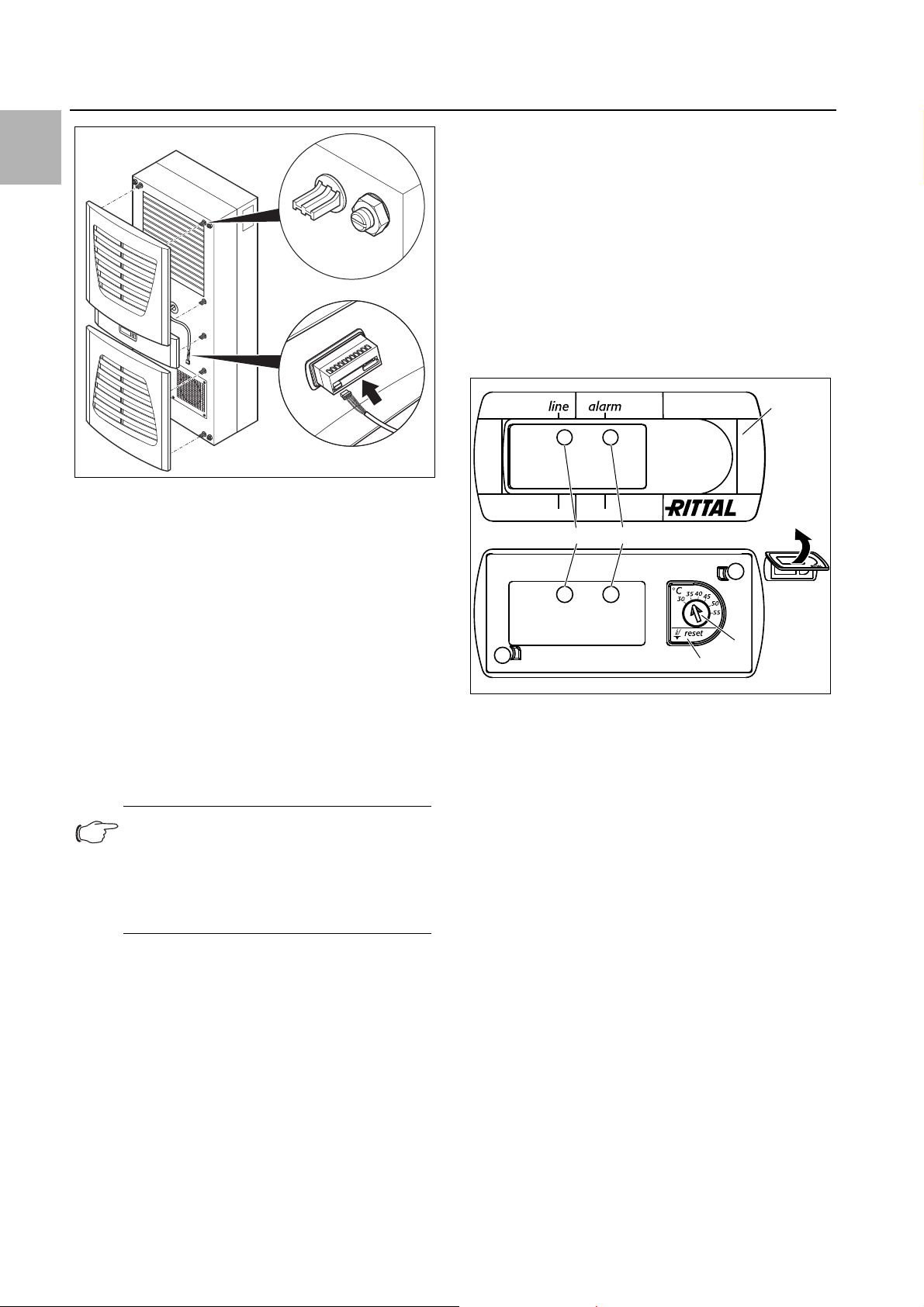

Fig. 5: Air circulation inside the enclosure

4.3 Fitting the cooling unit

The enclosure cooling unit may optionally be externally

mounted on the enclosure (1), partially internally mounted (2) or fully internally mounted (3):

Fig. 4: Never direct the cold airflow at active components

Air diversion components are available as accessories –

please refer to the Rittal Catalogue.

It is important to ensure even air circulation inside the enclosure. Under no circumstances should air inlet and

outlet openings be obstructed, otherwise the cooling

performance of the unit will be reduced. Ensure the distance "x" (see fig. 5) from components and other installed enclosures so that the required air circulation is

not obstructed and prevented.

Fig. 6: Installation method

To this end, cut the side panel or door of the enclosure

as per the drilling template included with the supply, and

drill the relevant holes.

Note:

Units of type 3302.xxx and 3366.xxx can

only be either externally mounted or fully internally mounted.

Units of type 3332.xxx can only be either externally mounted or partially internally

mounted; they cannot be mounted in lockable doors on 600/1200 wide TS enclosures.

To mount units 3328.xxx, 3329.xxx and

3332.xxx in the TS side or rear panel, we

recommend using enclosure panel fasteners 8800.071 (see Rittal Catalogue). For

high dynamic loads and mounting on the

enclosure door, we recommend using reinforced door hinges 8800.710 (see Rittal

Catalogue). Units with protection category

NEMA 4X are only suitable for external

mounting.

Rittal enclosure cooling unit 7

Page 8

EN

4 Assembly and connection

4.3.1 Making the cut-outs

Affix the supplied drilling template to the side panel or

door of the enclosure using adhesive tape.

There are dimensioning lines on the drilling template to

suit the various installation options for your cooling unit.

Using the dimension drawings (see Appendix), identify

the valid lines and dimensions for your installation type

on the drilling template.

Caution!

Carefully deburr all drilled holes and

cut-outs to prevent injuries caused by

sharp edges.

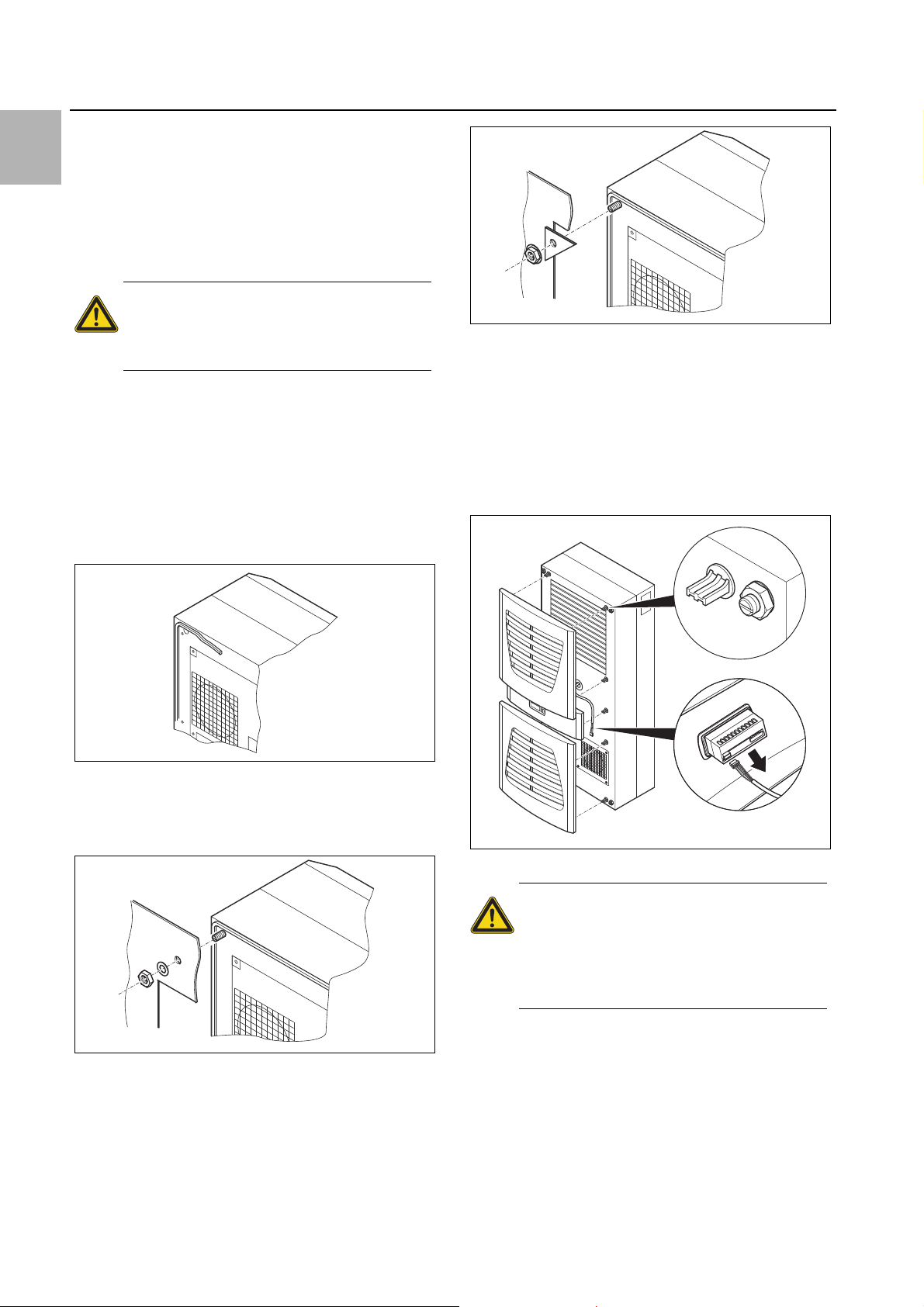

Fig. 9: Securing the cooling unit (3302.1xx only "external

mounting")

Mark, drill and deburr the holes.

Make the cut-outs including the line width as per the

drilling template.

Deburr the cut-outs.

4.3.2 External mounting of the cooling unit

Cut the supplied sealing tape to the correct length and

stick it carefully along the back of the unit so that no

gaps are left at the joints.

Fig. 7: Applying the self-adhesive tape

Screw the supplied grub screws into the blind nuts on

the rear of the unit.

Secure the unit using the supplied washers and nuts.

4.3.3 Partial internal mounting of the cooling unit

Carefully remove the louvred grille and, where applica-

ble, the infill panel, from the enclosure by pulling forwards.

Carefully disconnect the connector from the rear of the

display and gently push it inwards through the cable

gland.

Fig. 10: Removing the louvred grille & disconnecting the display

Caution!

Stability of the cooling unit is only guaranteed in its assembled state. Brace

the rear half of the enclosure to prevent

it from falling over before removing the

front half.

Loosen the four nuts on the front half of the enclosure

Fig. 8: Securing the cooling unit (all models except 3302.1xx)

and pull the enclosure forwards by approx. 5 cm.

Loosen the flat-pin connectors of the PE conductor

between the two enclosure halves.

Disconnect the fan connection.

Remove the front enclosure tray completely.

8 Rittal enclosure cooling unit

Page 9

4 Assembly and connection

EN

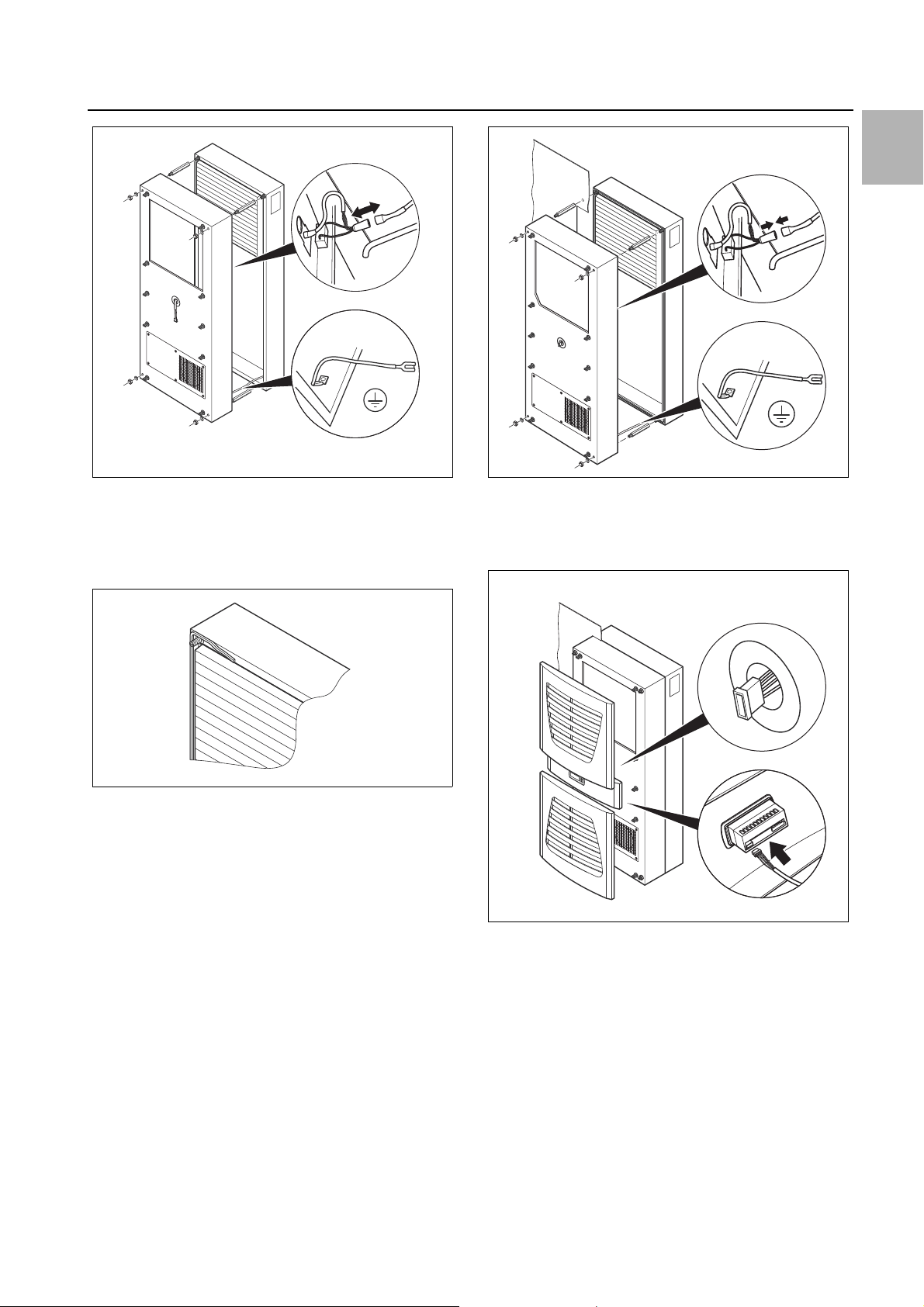

Fig. 11: Removing the cover

Remove the four spacer bolts.

Cut the supplied sealing tape to the correct length and

stick it carefully along the inside of the rear enclosure

half so that no gaps are left at the connection points.

Fig. 12: Applying the self-adhesive tape

Push the rear enclosure half into the mounting cut-out

and secure it with the four spacer bolts.

Push the display cable through the cable gland of the

front enclosure half.

Fig. 13: Securing the cooling unit

Connect the fan connector and PE conductor.

Mount the front enclosure tray using the washers and

nuts.

Fig. 14: Connecting the display connector

Carefully connect the display connector.

Push the louvred grille and, where applicable, the infill

panel, onto the enclosure.

4.3.4 Full internal mounting of the cooling unit

Carefully remove the louvred grille and the infill panel

from the enclosure by pulling forwards.

Carefully disconnect the connector from the rear of the

display.

Rittal enclosure cooling unit 9

Page 10

EN

4x

4 Assembly and connection

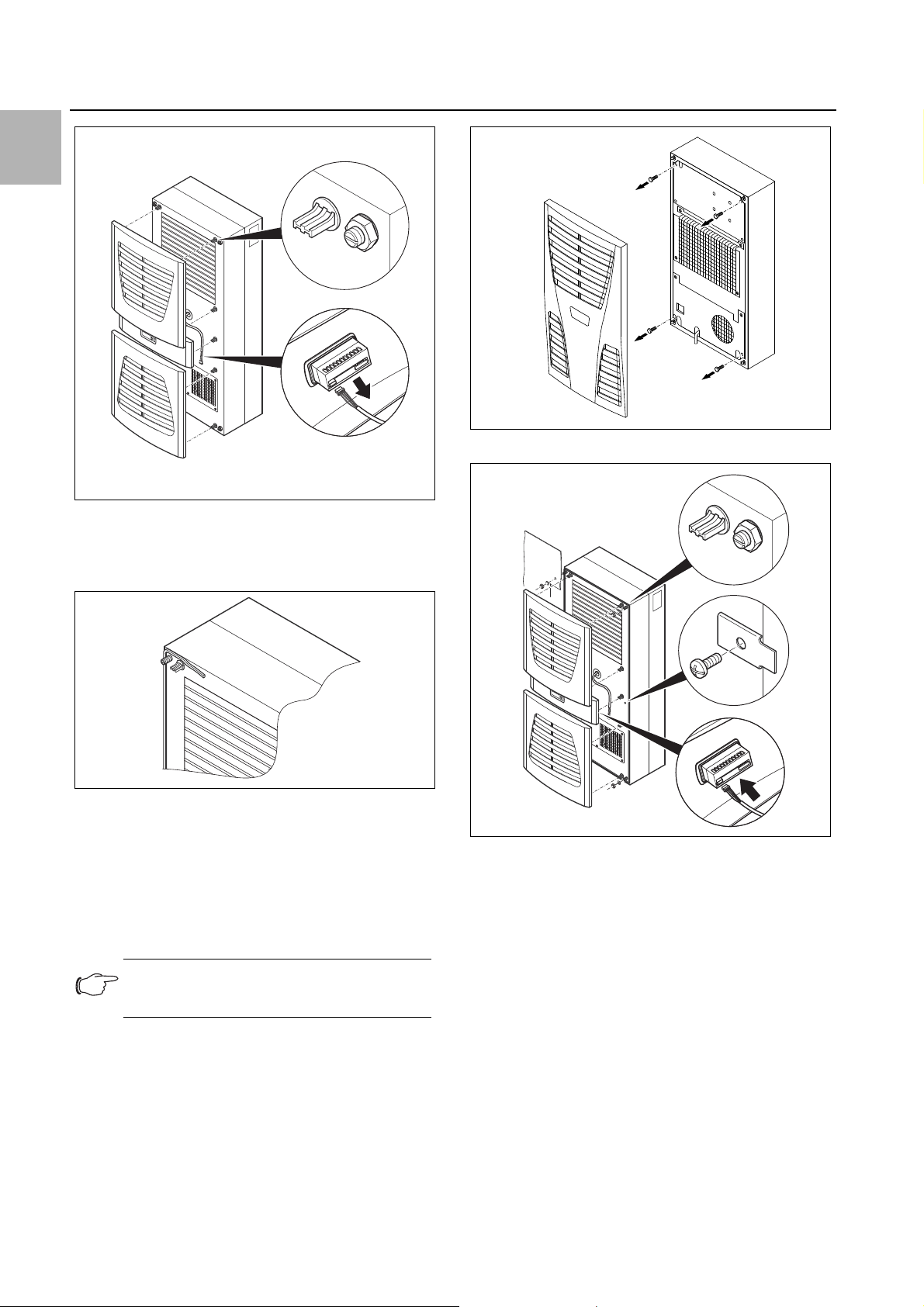

Fig. 17: 3302.xxx only: removing the four screws

Fig. 15: Removing the louvred grille & disconnecting the display

Cut the supplied sealing tape to the correct length and

stick it carefully along the front enclosure half so that

no gaps are left at the connection points.

Fig. 16: Applying the self-adhesive tape

Loosen the four nuts and washers from the front en-

closure half.

Push the unit into the mounting cut-out from the inside

of the enclosure, and secure it to the enclosure from

the outside using the washers and nuts.

Only for 3302.xxx:

Fig. 18: Securing the cooling unit

Where necessary, additionally secure the unit using

the supplied mounting plates as shown in fig. 18.

Carefully connect the display connector.

Push the louvred grille and, where applicable, the infill

panel, onto the enclosure.

Note:

The tightening torque for the nuts is 6 Nm.

4.4 Connecting the condensate discharge

A condensate discharge hose can be fitted to all types

of cooling unit (except NEMA 4X devices).

Before installing, remove the four screws as shown.

The condensate discharge

– must be laid with a suitable and constant gradient (no

siphoning)

– must be laid without kinks

– must not have a reduced cross-section if extended

The condensate hose is available as an accessory (refer

also to Accessories in the Rittal Catalogue).

10 Rittal enclosure cooling unit

Page 11

Fig. 19: Connecting the condensate discharge

Connect a suitable hose to the condensate nozzle and

secure using a hose clip.

Route the condensate hose to a drain or into the ex-

ternal condensate evaporator (refer to Accessories in

the Rittal Catalogue).

4.5 Notes on electrical installation

When performing the electrical installation, it is important

to observe all valid national and regional regulations as

well as the provisions of the responsible power supply

company. The electrical installation may only be carried

out by a qualified electrician who is responsible for compliance with the applicable standards and regulations.

4.5.1 Connection data

– The connected voltage and frequency must corre-

spond to the values stated on the rating plate

– The cooling unit must be connected to the mains via

an all-pin isolating device, which ensures at least

3 mm contact opening when switched off

– No additional temperature control may be connected

upstream of the unit at the supply end

– Install the protective device specified on the rating

plate to protect the line and equipment from short-circuits.

– The mains connection must ensure low-noise poten-

tial equalisation

4.5.2 Overvoltage protection and supply line load

– The unit does not have its own overvoltage protection.

Measures must be taken by the operator at the supply

end to ensure effective lightning and overvoltage protection. The mains voltage must not exceed a tolerance of ±10%.

– In accordance with IEC 61 000-3-11, the unit is in-

tended solely for use at sites with a continuous current-carrying capacity (incoming mains power supply)

of more than 100 A per phase and with a supply voltage of 400/230 V. If necessary, the electricity supply

company must be consulted to ensure that the continuous current-carrying capacity at the point of connection to the public grid is sufficient for connection of

such a unit.

– The fans and compressors in single- and three-phase

units are intrinsically safe (thermal winding protection).

This also applies to transformer versions, types

4 Assembly and connection

3304.510, 3305.510, 3328.510 and 3329.510, and to

special-voltage units which are likewise equipped with

a transformer.

– Install the protective device specified on the rating

plate to protect the line and equipment from short-circuits (miniature circuit-breaker with appropriate characteristic – e.g. "K" characteristic – or gG standard

type slow fuse, circuit-breaker for plant or transformer

protection). Select a suitable circuit-breaker in accordance with the information specified on the rating plate:

Set it to the minimum specified value. This will achieve

the best short-circuit protection for cables and equipment. Example: Specified setting range 6.3 – 10 A; set

to 6.3 A.

4.5.3 Three-phase devices

– The electrical connection for devices in the three-

phase version MUST be made with a clockwise rotating field

– The three-phase version of models 3304.xxx,

3305.xxx, 3328.xxx, 3329.xxx and 3332.xxx must be

connected to a TN network with star earthing via a circuit-breaker for plant protection (current setting as per

the rating plate). Three-phase units with special voltages must be protected with a circuit-breaker for

transformer protection (category AC-3) as per the rating plate.

– Units designed for three phase 400/460 V feature ad-

ditional monitoring of the rotary field or the absence of

a phase. If the rotary field is incorrect or a phase is absent, the unit will not run.

4.5.4 Door limit switch

– Each door limit switch must only be assigned to one

cooling unit.

– Several door limit switches may be connected in par-

allel to one cooling unit.

– The minimum cross-section for the connection cable

is 0.3 mm

– The line resistance to the door limit switch must not

exceed a maximum of 50 .

– The door limit switch only supports a floating connec-

tion; no external voltages.

– The contact of the door limit switch must be closed

when the door is open.

The safety extra-low voltage for the door limit switch is

provided by the internal power pack: Current approx.

30 mA DC.

Connect the door limit switch to terminals 1 and 2 of

the connector.

4.5.5 Notes on the flicker standard

The flicker limits specified in standard EN 61 000-3-3 or

-3-11 are adhered to, provided the supply impedance is

less than approx. 1.5 .

Where necessary, the unit operator should measure the

connected impedance or consult the responsible electricity supply company. If there is no way of influencing

2

for a cable length of 2 m.

EN

Rittal enclosure cooling unit 11

Page 12

EN

Mounting device

rear panel

Fastening to 35 mm

support rail

DIN EN 50 022

Mains connection for

Cooling unit

Customer-side

connection

230 V

4 Assembly and connection

the supply impedance and sensitive installed components (e.g. BUS) are subjected to interference, a line reactor or starting-current limiting device should be connected upstream of the cooling unit to restrict the startup current of the cooling unit.

4.5.6 Potential equalisation

If, for EMC reasons, the unit is to be integrated into the

customer’s existing potential equalisation system, a

conductor with a larger nominal cross-section can be

connected to the potential equalisation connection point

(attachment points) on the wall-mounted cooling units.

According to the standard, the PE conductor in the

mains connection cable is not classified as an equipotential bonding conductor.

4.6 Making the electrical connection

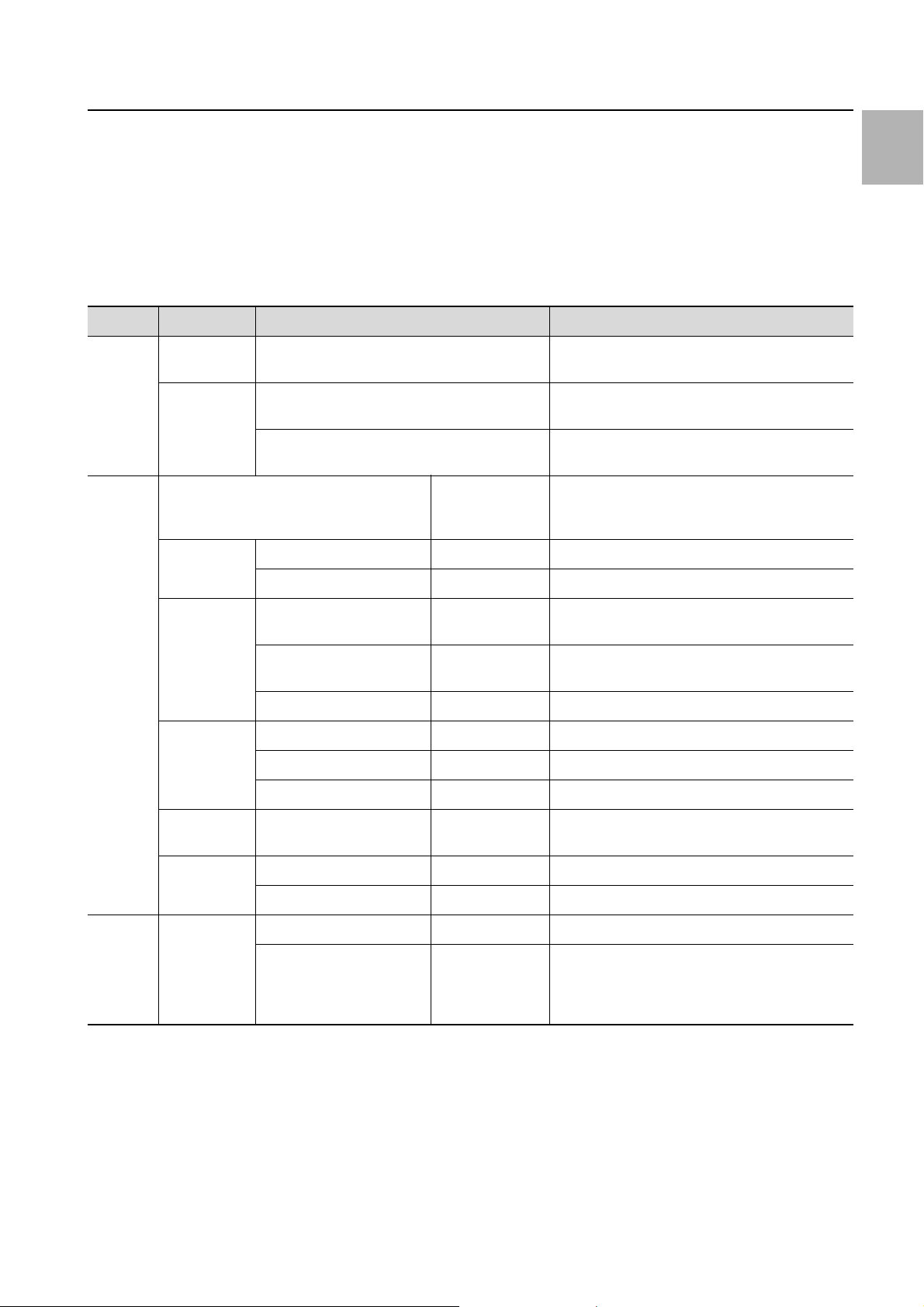

4.6.1 Bus connection (only when interconnecting several units with a Comfort controller)

When using several cooling units, the serial device interface X2 can be used to connect up to ten cooling units

with the bus cable (Model No. 3124.100).

Fig. 20: Mounting external transformer (3361.x40 only)

When interconnecting, please note the following:

– De-energise the cooling units to be connected

– Ensure proper electrical insulation

– Make sure the cables are not laid in parallel to power

– Make sure that the lines are short

4.6.2 Connection X3 for serial interface

The interface card (Model No. 3124.200) may be connected to X3. This is used to evaluate system messages

in a PLC, for remotely setting parameters and monitoring, or for integration into the facility management system.

lines

Note:

The electrical signals at the X2 interface are

of an extra-low voltage (not extra-low safety

voltages in accordance with EN 60 335-1).

Note:

With the last slave unit in the group, do not,

under any circumstances, connect the remaining socket of the Y cable 3124.100 into

interface X3 of the cooling unit!

4.6.3 Mounting external transformer

Only for 3361.x40.

12 Rittal enclosure cooling unit

Page 13

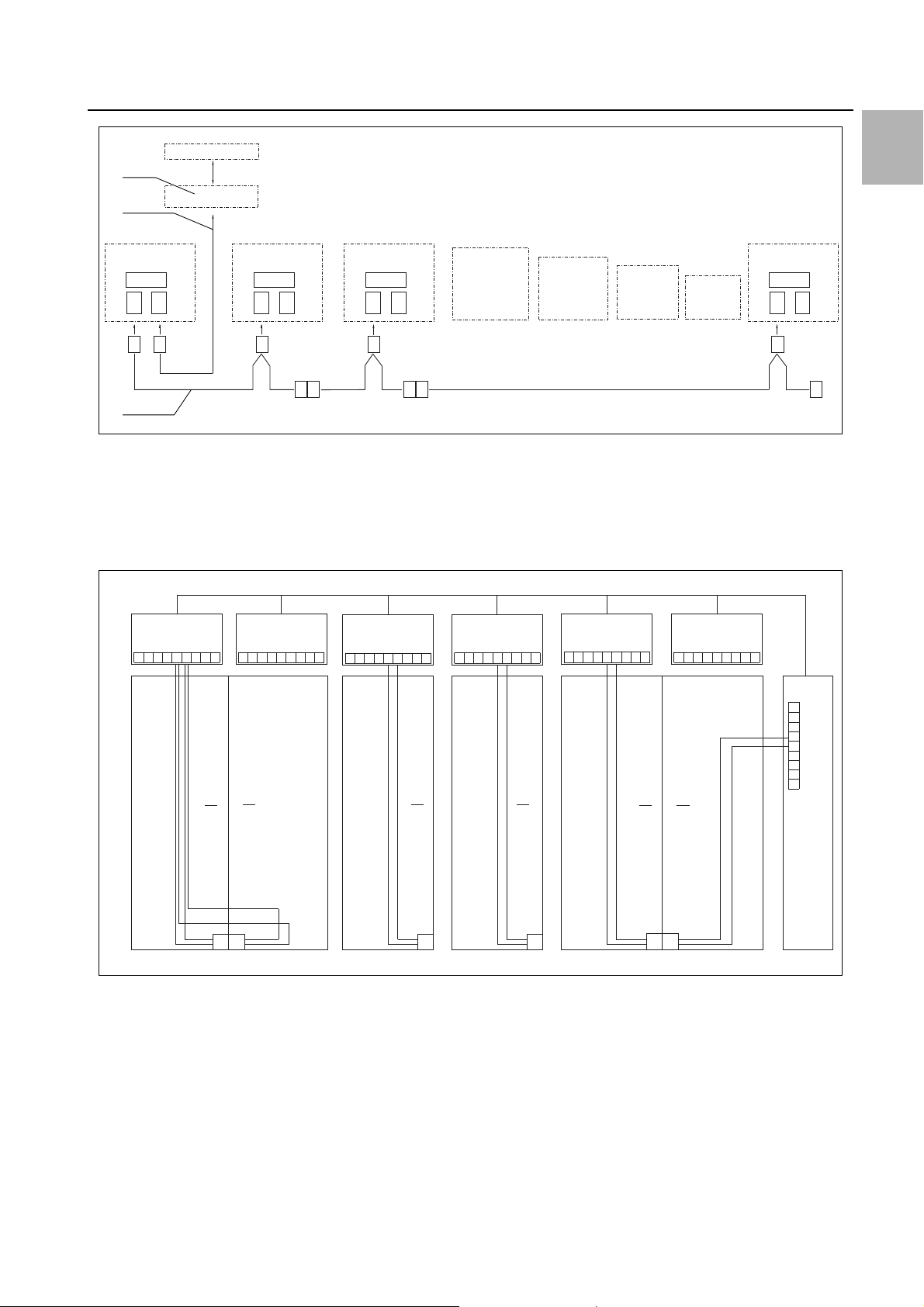

Fig. 21: Connection example: Master-slave operation

X2

CMC

I/O unit

RTT

Master

Adr.: 09

X1

X2

X3

X1

X2

X3

X1

X2

X3

X1

X2

X3

X2

X3

X2

X2

X2

X2

X2

X2

St. St. St.

Bu.

St.

Bu.

X2

Adr.: 11 Adr.: 12RTT

Slave

RTT

Slave

Adr.: 19RTT

Slave

St.

Bu.

St.

Bu.

3

2

1

X10

L1

L2

N

PE

1

2345

1

X10

X10 X10 X10 X10

X2 X2 X2 X2 X2 X2

X2

L1

PE

1

2345

L1

L2

N

PE

1

2345

L2 L3

L1

PE

1

2345

L2 L3

L1

PE

1

2345

L2 L3

L1

PE

1

2345

L2 L3

L1

L2

N

PE

1

23

4

5

X10

2

3

4

56

1

Adr.: 06 Adr.: 11 Adr.: 12 Adr.: 13 Adr.: 14 Adr.: 15

22 2 2 2

34432

Adr.: 16

Key

1 Serial interface (Model No. 3124.200)

2 Serial interface cable

3 Master-slave bus cable (Model No. 3124.100)

RTT Rittal TopTherm cooling units

X1 Supply connection/door limit switch/alarms

4 Assembly and connection

EN

X2 Master/slave connection Sub-D, 9-pole

X3 Serial interface Sub-D, 9-pole

St. Sub-D connector, 9-pole

Bu. Sub-D jack, 9-pole

Adr. Address

Fig. 22: Connection example: Door limit switch and master-slave operation

Key

1 Master cooling unit

2 Slave cooling units

3 2-door enclosure with two door limit switches

4 Enclosure with door limit switch

Rittal enclosure cooling unit 13

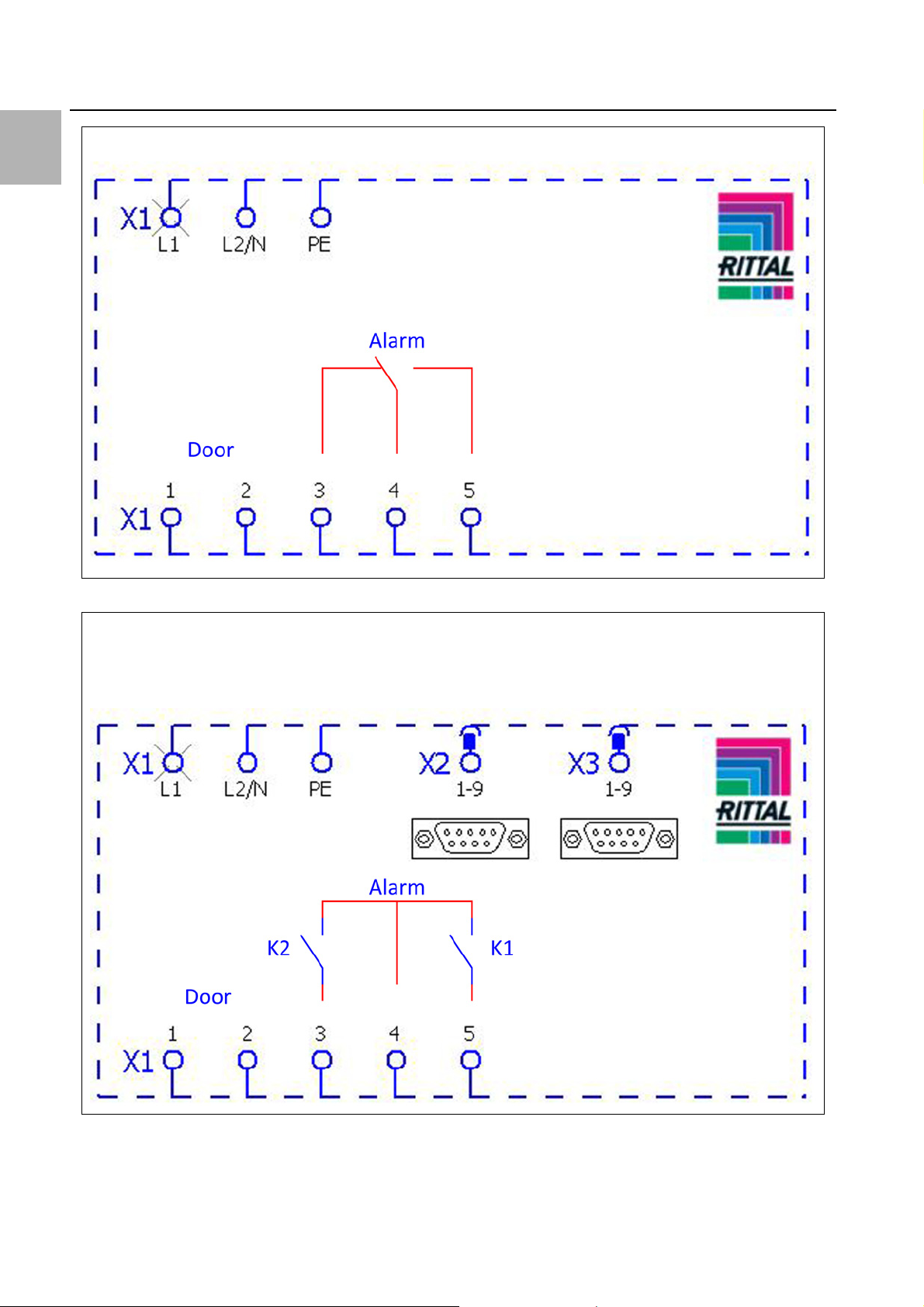

4.6.4 Installing the power supply

Complete the electrical installation by following the

wiring plan on the rear of the cooling unit (see fig. 2, for

key see page 15).

If you would like the system messages from the cool-

ing unit to be evaluated via the system message relay,

you should also connect a suitable low-voltage cable

to terminals 3 – 5.

Page 14

EN

3302.100/.110, 3302.300/.310

3303.500/.510, 3303.600/.610, 3361.500/.510, 3361.600/.610, 3361.540/.640

3304.500/.510/.504/.514/.520/.600/.610

3305.500/.510/.504/.514/.520, 3328.500/.510/.504/.514/.520, 3329.500/.510/.504/.514/.520,

3305.600/.610, 3328.600/.610, 3329.600/.610, 3366.500/.510/.600/.610

4 Assembly and connection

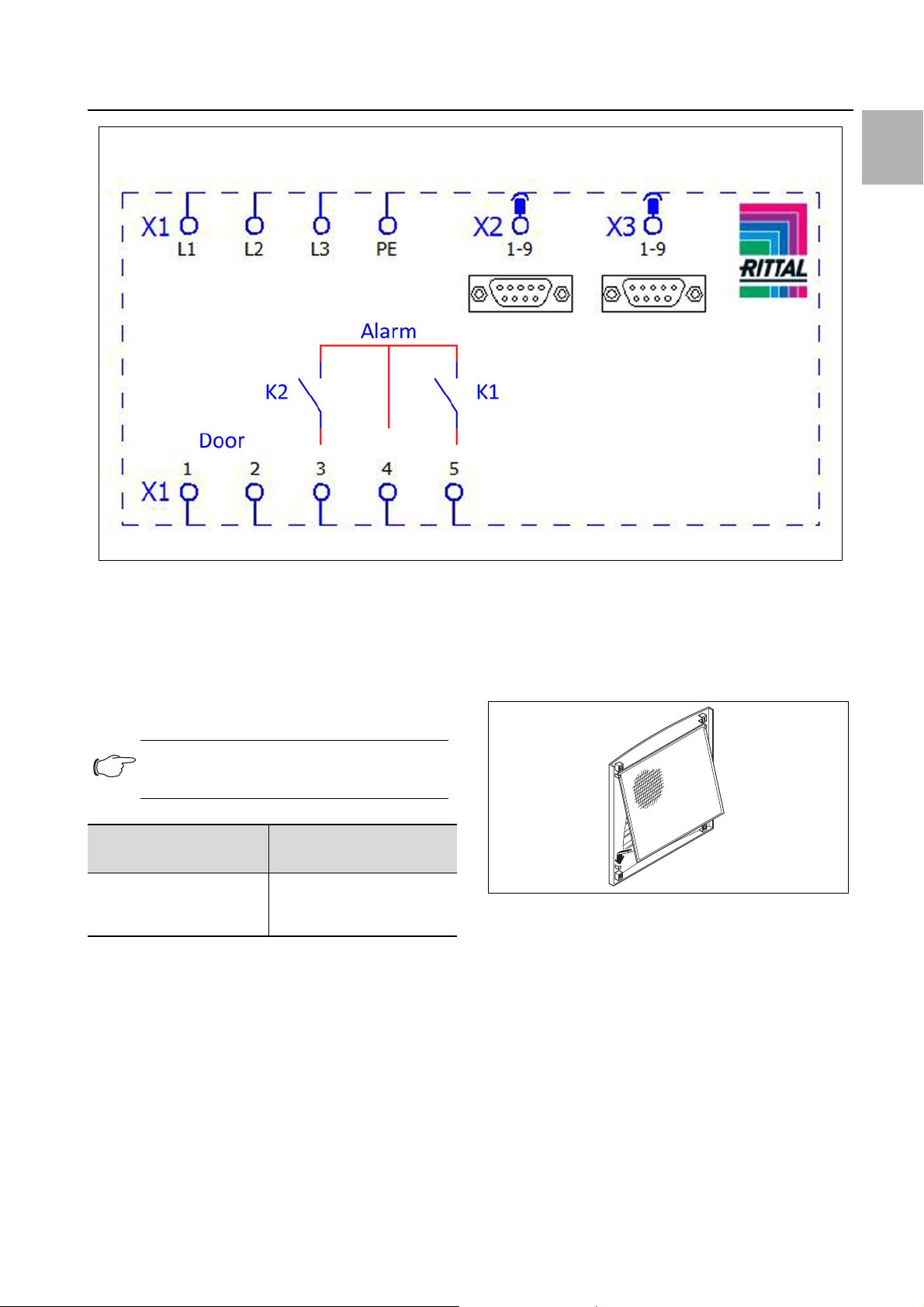

Fig. 23: Electrical wiring plan no. 1

Fig. 24: Electrical wiring plan no. 2

14 Rittal enclosure cooling unit

Page 15

4 Assembly and connection

3304.540/.544, 3305.540/.544, 3328.504/.544, 3329.504/.544

3304.640, 3305.640, 3328.640, 3329.640, 3366.540/.640, 3332.540/.640

EN

Fig. 25: Electrical wiring plan no. 3

Key

X1 Main terminal strip

X2 Master/slave connection

X3 Optional interface

K1 Relay collective fault 1

K2 Relay collective fault 2

Door Door limit switch (without door limit switch: terminal 1, 2

open)

textile plants with heavy lint contamination, lint screens

should be used (available as an optional extra).

Pull the louvred air inlet grille off the enclosure.

Insert the filter mat into the louvred grille as shown in

fig. 26 and push it back onto the enclosure.

Note:

For technical data, refer to the rating plate.

AC

cos φ = 1

I max. = 2 A

U max. = 250 V

Tab. 2: Relay contact data

4.7 Finalising assembly

4.7.1 Installing the filter media

DC

Res. Load

I min. = 100 mA

U max. = 30 V

I max. = 2 A

Fig. 26: Installing the filter mat

4.7.2 Fitting the cooling unit

For partial and full internal mounting only.

Connect the connector to the rear of the display.

Place the louvred grille onto the unit at the front, and

press it down until you hear it snap into place.

The entire cooling unit condenser is covered with a dirtrepelling, easy-to-clean RiNano coating. In many applications, therefore, the use of filter media is unnecessary,

particularly with dry dusts.

For dry, coarse dust and lint in the ambient air, we recommend installing an additional PU foam filter mat (available as an accessory) in the cooling unit. For air containing oil condensate, we recommend the use of metal filters (also available as an accessory). When used in

Rittal enclosure cooling unit 15

Page 16

EN

34

1

2

5

5 Start-up

Fig. 27: Connect the display and attach the louvred grille

4.7.3 Setting the filter mat monitor (only with e-Comfort controller)

Function of the filter mat monitor:

Dirt on the filter mat is automatically detected by meas-

uring the temperature difference in the external circuit of

the cooling unit (see section6.2.6 "Programming overview"). As the level of filter mat soiling increases, the

temperature difference will increase. The setpoint value

of the temperature difference in the external circuit

adapts automatically to the relevant operating points in

the performance diagrams. Hence there is no need to

readjust the setpoint value for different unit operating

points.

5 Start-up

Note:

The oil must be collected in the compressor

in order to ensure effective lubrication and

cooling.

Do not operate the cooling unit for at least

30 minutes after assembling the equipment.

Once all the assembly and installation work is com-

plete, switch on the power supply to the cooling unit.

The cooling unit starts running:

– With Basic controller: The green operating LED ("line")

is illuminated.

– With e-Comfort controller: The software version of the

controller first appears for approx. 2 seconds, then

"ECO" to show Eco mode is enabled. The internal en-

closure temperature will then appear in the 7-segment

display

You can now make your individual settings on the unit,

e.g. set the temperature or (with e-Comfort controller

only) assign the network identifier, etc. (refer to section6

"Operation").

6 Operation

You can operate the cooling unit using the controller on

the front of the device (fig. 2, item 11). Depending on the

model, the unit is equipped with a Basic or e-Comfort

controller.

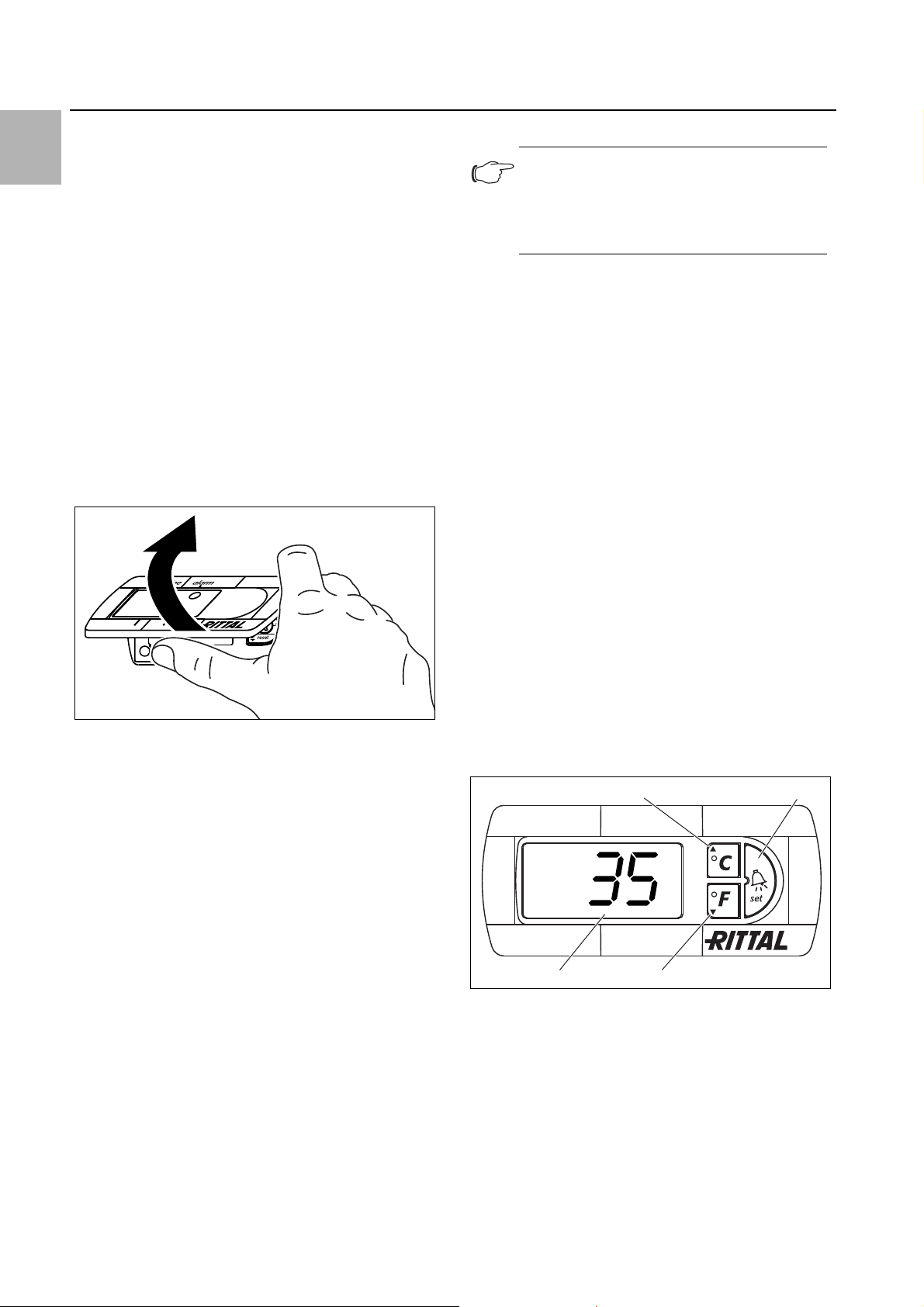

6.1 Control using the Basic controller

For Model Nos. 3302.xxx.

Fig. 28: Basic controller

Key

1 Controller trim panel

2 Temperature setter

3 LED green ("line")

4 LED red ("alarm")

5 Reset button

6.1.1 Properties

– Rated operating voltage: 115 V or 230 V

– Integral start-up delay and door limit switch function

– Protective function to prevent icing

– Monitoring of all motors (compressor, condenser fan,

evaporator fan)

– Phase monitoring for three-phase units

– Visualisation of the operating status via LED display:

– Voltage on, unit operational

– Door open (only if door limit switch installed)

– Warning of overtemperature

– High-pressure monitor has switched

– Switching hysteresis: 5 K

If the cooling unit and compressor run times are too

long < 1 minute, the switching hysteresis to protect

the cooling unit is automatically increased.

– Floating system message contact in case of overtem-

perature

16 Rittal enclosure cooling unit

Page 17

6 Operation

– Temperature setting

(setting range 30 – 55°C) via potentiometer

– Test function

– Flashing mode to indicate system messages.

See section6.1.2 "Operating and error display"

The cooling unit operates automatically, i.e. after switching on the power supply, the evaporator fan (see fig. 3)

will run continuously and permanently circulate the inter-

LED Status Cause Solution

Green

(line)

Red

(alarm)

Illuminated Power supply on,

unit operational

Flashing Only with door limit switch installed:

enclosure door open

Only with door limit switch installed:

enclosure door closed

Alarm/error/warning Number of flash

a

Implement

reset

Device reset (12) |_|_|_|_|_|_|_|_|_|_|_|*****|_|_|_|_|_|_|_|_|_|_|_|

High pressure alarm (0) |_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|

nal enclosure air. The built-in Basic controller ensures

automatic normal shut-down operation of the cooling

unit by the value of the fixed preset switching difference

of 5 K.

6.1.2 Operating and error display

The Basic controller monitors and controls the cooling

unit. It indicates the operating and error status via the

green and red LEDs (fig. 28, items 3 and 4):

–

In order to avoid condensation, close the enclosure door as quickly as possible.

Check the position of the door limit switch.

Flash interval

intervals for the

red LED

EN

Sensors Potentiometer defective or

display error

Internal temperature

sensor defective

Anti-icing sensor defective (5) |_|_|_|_|*****|_|_|_|_|*****|_|_|_|_|*****|_|_|_|_|

Overload Compressor overloaded (6) |_|_|_|_|_|*****|_|_|_|_|_|*****|_|_|_|_|_|*****

Interior fan overloaded (7) |_|_|_|_|_|_|*****|_|_|_|_|_|_|*****|_|_|_|_|_|_|

Exterior fan overloaded (8) |_|_|_|_|_|_|_|*****|_|_|_|_|_|_|_|*****

Device status/state

Warning Anti-icing alarm (2) |_|*****|_|*****|_|*****|_|*****|_|*****|_|*****|_|

Off No display No power – Check power supply

Tab. 3: Operating and error display on the Basic controller

Overload mode

(heat loss)

Overtemperature warning (1) |*****|*****|*****|*****|*****|*****|*****|*****|*****|

Rotary current phase

toring:

"LED off" = Incorrect

phase connection

moni-

(3) |_|_|*****|_|_|*****|_|_|*****|_|_|*****|_|_|*****

(4) |_|_|_|*****|_|_|_|*****|_|_|_|*****|_|_|_|*****

(9) |_|_|_|_|_|_|_|_|*****|_|_|_|_|_|_|_|_|*****

– Swap phases

Key to flash intervals

| = 500 ms (red LED on)

_ = 500 ms (red LED off)

***** = 3 s pause (red LED off)

nection diagrams under section4.6.4 "Installing the

power supply"):

– Terminal 3: NC (normally closed)

– Terminal 4: C (connection of the supply voltage to the

fault signal relay)

The overtemperature message may also be polled via an

integral floating contact on the cooling unit terminal (system message relay with changeover contact, see con-

Rittal enclosure cooling unit 17

– Terminal 5: NO (normally open)

The NC and NO definitions refer to the de-energised

state. As soon as power is applied to the cooling unit,

Page 18

6 Operation

12

4

3

EN

the system message relay picks up, so that the relay

contacts change status (contact 3 – 4 open; contact 4 –

5 closed).

This is the normal operating state of the cooling unit. As

soon as an error message occurs or the power supply is

interrupted, the relay drops out and contact 3 – 4 is

closed.

6.1.3 Test mode with the Basic controller

The Basic controller is equipped with a test function

whereby the cooling unit commences cooling operation

independently of the set temperature or door limit switch

function.

First you must remove the controller trim panel.

Switch off the mains voltage.

Remove the louvred grille or infill panel in which the

controller is installed.

Release the display lock from behind and pull it for-

wards slightly.

6.1.4 Setting the temperature

Note:

With the Basic controller, the temperature is

preset at the factory to +35°C.

In order to save energy, do not set the temperature lower than that actually necessary.

To change the temperature setting:

Take the trim panel off the controller as described in

section6.1.3 "Test mode with the Basic controller".

Set the required temperature on the temperature set-

ting device (fig. 28).

Carefully push the trim panel onto the display until you

hear it snap into place.

Push the display back into the infill panel or louvred

grille.

Re-attach the louvred grille or infill panel to the cooling

unit.

6.1.5 Resetting the Basic controller

Following a high-pressure alarm in the cooling cycle, and

once the cause has been rectified, you will need to manually reset the Basic controller:

Take the trim panel off the Basic controller as de-

scribed in section6.1.3 "Test mode with the Basic

controller".

Press the reset button (fig. 28, item 5) for at least

3seconds.

The red LED is extinguished.

Re-install the Basic controller.

Fig. 29: Releasing the Basic controller trim panel

Carefully lift the trim panel, e.g. using your thumb or a

flat screwdriver, and remove it.

You can now start test mode.

Rotate the potentiometer to the left-hand stop, then

hold the rubberised potentiometer display down while

you re-connect the mains voltage.

The cooling unit will commence operation and the green

LED will flash (I_II_I_II_. ..). Test mode is completed after

approximately 5 minutes. The unit switches off and

changes to normal operation.

Key

I = LED 500 ms on

_ = LED 500 ms off

In normal operation, the green LED is permanently illuminated.

Next, rotate the potentiometer back to the required

setpoint.

6.2 Control using the e-Comfort controller

For unit types 33xx.5xx and 33xx.6xx.

Fig. 30: e-Comfort controller

Key

1 Programming button, also display of the set temperature

unit (degrees Celsius)

2 Set button

3 Programming button, also display of the set temperature

unit (degrees Fahrenheit)

47-segment display

18 Rittal enclosure cooling unit

Page 19

6 Operation

ON

Status

internal fan

Internal

temperature

Time

Setpoint

-5°C

Setpoint

-10°C

OFF

10 min.

30 sec.

10 min.

6.2.1 Properties

– Rated operating voltage:

–115 V or

–230 V or

– 400/460 V, 3-phase, supports multiple voltages

without rewiring

– Integral start-up delay and door limit switch function

– Protective function to prevent icing

– Monitoring of all motors (compressor, condenser fan,

evaporator fan)

– Phase monitoring for three-phase units

– Master-slave function with a maximum of ten units.

One device functions as a master unit. Once the set

temperature is reached by one of the connected slave

devices or in the event of the door limit switch function,

the affected slave unit will report to the master unit that

switches all the other cooling units on or off as re-

quired.

– Switching hysteresis: adjustable from 2 – 10 K, preset

to 5 K

– Visualisation of the current internal enclosure temper-

ature and all error messages in the 7-segment display

– Using an interface card (Model No. 3124.200), the unit

may be incorporated into higher-level remote monitor-

ing systems.

The cooling unit operates automatically, i.e. after switching on the power supply, the evaporator fan (see fig. 3)

will run and circulate the internal enclosure air. The compressor and condenser fan are regulated by the e-Comfort controller. The e-Comfort controller has a 7-segment display (fig. 30, item 4). After switching on the power supply, the current software version initially appears

on this display for approx. 2 seconds together with the

symbol to show Eco mode is enabled, followed by a preset option (e.g. t10) or the temperature.

In regular operation, the display shows both the temperature (in degrees Celsius or Fahrenheit – users may

switch between the two) and any error messages.

The current internal enclosure temperature is usually displayed permanently. In the event of an error message,

this alternates with the temperature display.

The unit is programmed using buttons 1 – 3 (fig. 30). The

relevant parameters also appear in the display.

6.2.2 Eco mode

All Rittal TopTherm cooling units with e-Comfort controller from firmware 3.2 have the energy-saving eco mode,

which is enabled in the delivered state.

The eco mode is used to save energy in the heat exchanger if there is no thermal load, or there is a low thermal load in the enclosure (e. g. standby operation, no

production or weekend). During this process the evaporator fan in the internal circuit is switched off as appropriate if the actual internal enclosure temperature drops

to 10 K below the specified setpoint temperature. To ensure the internal temperature is reliably measured during

this process, the fan starts cyclically for 30 sec. every 10

minutes (see fig. 31). If the internal temperature drops to

a range 5 K below the setpoint set again, the fan switches back to continuous operation.

If required, eco mode can be disabled on the control display. For this purpose switch the parameter from 1 to 0

in the programming level (see tab.4). The fan then runs

continuously.

Fig. 31: Eco mode

6.2.3 Launching test mode

The e-Comfort controller is equipped with a test function

whereby the cooling unit commences cooling operation

independently of the set temperature or door limit switch

function.

Simultaneously press buttons 1 and 2 (fig. 30) for at

least 5 sec.

The cooling unit will commence operation. Test mode is

completed after approximately 5 minutes. The unit

switches off and changes to normal operation.

EN

Rittal enclosure cooling unit 19

Page 20

6 Operation

EN

6.2.4 General information about programming

Using buttons 1, 2 and 3 (fig. 30) you can change

24 parameters within the preset ranges (min. value,

max. value).

Tables 4 and 5 show the parameters which can be altered. fig. 32 on page 22 shows which buttons must be

pressed.

Note on switching hysteresis:

With a low hysteresis and short switching

cycles, there is a risk that cooling may not

be adequate or that only partial sections of

the enclosure are cooled. If the cooling unit

and compressor run times are too long

< 1 minute, the switching hysteresis to protect the cooling unit is automatically increased (see message "LH" in section

6.2.9 "Evaluating system messages").

Note on temperature settings:

With the e-Comfort controller, the temperature is preset at the factory to +35°C.

In order to save energy, and due to the risk

of increased condensation, do not set the

temperature lower than that actually necessary.

Press one of the programming buttons (°C) or

(°F) until the required value appears.

Press button 2 ("Set") to confirm the change.

You can now alter other parameters in the same way.

There is no need to re-enter the authorisation code "22".

To exit programming mode, press button 2 ("Set")

again for approximately 5 seconds.

"Acc" will appear in the display to indicate that the

changes have been saved. The display then switches

back to regular operation (internal enclosure temperature).

You can also program the e-Comfort controller using a

diagnosis software package (Model No. 3159.100),

which is supplied with a connection cable to the PC. The

cable connector on the rear of the e-Comfort controller

display serves as an interface.

Note on useful cooling power:

Interactive performance diagrams for calculating the useful cooling power may be

found at www.rittal.com.

In principle, the programming is identical for all editable

parameters.

To enter programming mode:

Press button 2 ("Set") for approx. 5 seconds.

The controller is now in programming mode. While in

programming mode, if you do not press any buttons for

approx. 30 seconds, the display will first flash, then the

controller will switch back to normal display mode. "Esc"

in the display indicates that any changes made have not

been saved.

Press the programming buttons (°C) or (°F) to

switch between the editable parameters (see tables 4

and 5).

Press button 2 ("Set") to select the displayed parame-

ter for editing.

The current value of this parameter is displayed.

Press one of the programming buttons (°C) or

(°F).

"Cod" will appear in the display. In order to be able to

change a value, you must enter the authorisation code

"22".

Keep the programming button (°C) held down until

"22" appears.

Press button 2 ("Set") to confirm the code.

You can now alter the parameter within the preset limits.

20 Rittal enclosure cooling unit

Page 21

6.2.5 Editable parameters

See also fig. 32 on page 32.

6 Operation

EN

Progr.

level

1 St Internal enclosure

2 Fi Filter mat monitor-

3 Ad Master-slave iden-

4 CF Switch between

5 H1 Setting for switch-

6 H2 Differential for error

Display

screen

Parameter Min.

temperature setpoint T

i

ing

tifier

°C/°F

ing difference (hysteresis)

message A2

Max.

value

20°C 55°C 35°C The internal enclosure temperature setting is

68°F 131°F 95°F

10°C 60°C 99

18°F 108°F 178

0 19 0 See section 6.2.8 "Setting the master/slave

0 1 0 The temperature display can be switched be-

2 K 10 K 5 K The cooling unit is preset in the factory to a

4°F 18°F 9°F

3 K 15 K 5 K If the internal enclosure temperature exceeds

5°F 27°F 9°F

value

Factory

setting

(= off)

(= off)

Description

preset at the factory to 35°C (95°F) and may be

altered within a range of 20 – 55°C (68 – 131°F).

To enable filter mat monitoring, the display

should be set to a minimum of 10 K (18°F)

above the temperature difference shown in programming mode "Fi"; filter mat monitoring is disabled at the factory (99 = off).

identifier".

tween °C (0) and °F (1). The LED displays the

current unit of temperature.

switching hysteresis of 5 K (9°F). This parameter

should only be changed in consultation with us.

Please contact us for advice.

the set value by more than 5 K (9°F), then error

message A2 (internal enclosure temperature too

high) appears on the display terminal. If necessary, the differential may be altered here within

the range of 3 – 15 K (5 – 27°F).

26 ECO Eco-mode opera-

tion

27 PSO Changing the au-

thorisation code

Tab. 4: Editable parameters

0 1 1 Eco mode OFF: 0 / Eco mode ON: 1

0 15 0 This parameter allows you to change the "22"

authorisation code (factory setting).

The new code results from the sum of 22 +

PSO.

Rittal enclosure cooling unit 21

Page 22

EN

= 5 sec.

= 5 sec.

6 Operation

6.2.6 Programming overview

Fig. 32: Programming overview

22 Rittal enclosure cooling unit

Page 23

6 Operation

6.2.7 Defining system messages for evaluation

System messages are shown on the display screen of

the e-Comfort controller via the displays A1 to A20 and

E0.

Progr.

level

7 A1 0 2 0 Enclosure door open

8 A2 0 2 0 Internal temperature of enclosure too high

9 A3 020 Filter monitoring

10 A4 0 2 0 Ambient temperature too high/low

11A5 020 Icing hazard

12 A6 0 2 1 PSA

13 A7 0 2 2 Evaporator coil

14A8 021 Condensate warning

15 A9 0 2 1 Condenser fan blocked or defective

16 A10 0 2 1 Evaporator fan blocked or defective

17A11 022 Compressor

Display

screen

Min.

value

Max.

value

Factory

setting

Type or location of fault

A more detailed explanation of the system messages

may be found in section 6.2.9 "Evaluating system messages".

See also fig. 32 on page 22.

H

pressure switch

EN

18A12 021 Condenser

19 A13 0 2 1 Ambient temperature sensor

20 A14 0 2 1 Icing temperature sensor

21 A15 0 2 1 Condensate warning temperature sensor

22 A16 0 2 1 Internal temperature sensor

23 A17 0 2 1 Phase monitoring

24A18 020 EPROM

25A19 020 LAN/Master-Slave

Tab. 5: System messages that can be evaluated via relays

The system messages A1 – A19 may also be evaluated

via two floating system message relays. In this way, one

of the two system message relays may be allocated to

each system message.

System message relays with normally open contact, see

wiring diagrams in section 4.6.4 "Installing the power

The RiDiag II software (available as an accessory, Model

No. 3159.100) allows you to invert the system message

relay circuit.

In the normal operating state the two relays will then

drop out. If a system message occurs, the relevant relay

will energise and the contact will close.

supply":

– Terminal 3: NO (normally open, relay 2)

– Terminal 4: C (connection of the supply voltage to the

system message relay)

Note:

This setting can only be made using the

RiDiag II software.

– Terminal 5: NO (normally open, relay 1)

Program system messages with the value

The definition NO refers to the de-energised state. As

soon as power is applied to the cooling unit, both system message relays (relay 1 and 2) energise.

This is the normal operating state of the cooling unit. As

0: System message is not sent to the system mes-

sage relay, but merely appears in the display

1: System message is evaluated by relay 1

2: System message is evaluated by relay 2

soon as a system message occurs or the power supply

is interrupted, the corresponding relay will drop out and

open the contact.

Rittal enclosure cooling unit 23

Page 24

6 Operation

Master

02

Slave

11

Slave

12

EN

6.2.8 Setting the master/slave identifier

When several cooling units are connected together

(maximum ten), one of the cooling units must be defined

as the "master" and the others as "slaves". For this purpose, assign a corresponding identifier (address) to

each cooling unit which will enable the cooling unit to be

identified in the network.

If one of the slave units reaches the set temperature or if

the door limit switch function is activated, the affected

slave unit will report to the master unit, which then deactivates all the other cooling units.

Notes:

– Only one unit may be configured as mas-

ter, and its identifier must match

the number of connected slave units.

– The slave units must have different identi-

fiers.

– The identifiers must be numbered in as-

cending order without any gaps.

On the master cooling unit (00 = factory setting), set

the number of slave units present in the network:

– 01: Master with 1 slave cooling unit

– 02: Master with 2 slave cooling units

– 03: Master with 3 slave cooling units

– 04: Master with 4 slave cooling units

– 05: Master with 5 slave cooling units

– 06: Master with 6 slave cooling units

– 07: Master with 7 slave cooling units

– 08: Master with 8 slave cooling units

– 09: Master with 9 slave cooling units

On the slave cooling unit (00 = factory setting), set its

own address:

– 11: Slave cooling unit no. 1

– 12: Slave cooling unit no. 2

– 13: Slave cooling unit no. 3

– 14: Slave cooling unit no. 4

– 15: Slave cooling unit no. 5

– 16: Slave cooling unit no. 6

– 17: Slave cooling unit no. 7

– 18: Slave cooling unit no. 8

– 19: Slave cooling unit no. 9

Fig. 33: Master/slave connection (example)

For further connection examples, see section4.6.1 "Bus

connection (only when interconnecting several units with

a Comfort controller)".

For details of how to set the identifier, see section6.2.5

"Editable parameters" or section6.2.6 "Programming

overview", parameter "Ad".

6.2.9 Evaluating system messages

In the e-Comfort controller, system messages are indicated by a number in the display.

Following the appearance of messages A03, A06 and

A07 and after rectifying their cause, you will need to reset the e-Comfort controller (see section6.2.10 "Reset

the e-Comfort controller").

Display

screen

A01 Enclosure door open Door open or door limit switch incor-

A02 Internal temperature of

A03 Filter monitoring Filter mat soiled Clean or replace;

A04 Ambient temperature

A05 Icing hazard Operational display in case of icing haz-

Tab. 6: Troubleshooting with the e-Comfort controller

System message Possible cause Measures to rectify the fault

Close door, position door limit switch cor-

enclosure too high

too high/low

rectly positioned

Cooling capacity inadequate/unit undersized Error as a consequence of

messages A03 to A17.

Ambient temperature outside permissible operating range (+10°C to +60°C)

ard.

Evaporator coil fan may be mechanically blocked, defective, or cold air outlet obstructed.

rectly, check connection if necessary

Check cooling capacity

reset the e-Comfort controller

Raise or lower the ambient temperature (e.g.

heat or ventilate the room)

Set the enclosure interior temperature to a

higher value. Check the evaporator fan;

release or exchange if necessary.

24 Rittal enclosure cooling unit

Page 25

6 Operation

Display

screen

A06 PSAH pressure switch Ambient temperature too high Lower the ambient temperature;

A07 Evaporator coil Lack of refrigerant; sensor in front of or

A08 Condensate warning Condensate discharge kinked or

System message Possible cause Measures to rectify the fault

reset the e-Comfort controller

Condenser soiled Clean the condenser;

reset the e-Comfort controller

Filter mat soiled Clean or replace;

reset the e-Comfort controller

Condenser fan defective Replace;

reset the e-Comfort controller

E-valve defective Repair by refrigeration engineer;

reset the e-Comfort controller

H

pressure switch defective Refrigeration engineer to exchange

PSA

reset the e-Comfort controller

Repair by refrigeration engineer;

behind condenser defective

blocked

Only for units with optional condensate

evaporation

reset the e-Comfort controller

Check condensate drainage;

correct any kinks or blockages in the hose

Check the evaporation unit, replace if necessary

EN

A09 Condenser fan Blocked or defective Clear the blockage; replace if necessary

A10 Evaporator fan Blocked or defective Clear the blockage; replace if necessary

A11 Compressor Compressor overloaded (internal wind-

ing protection)

Defective (check by measuring the

winding resistance)

A12 Condenser tempera-

ture sensor

A13 Ambient temperature

sensor

A14 Icing temperature sen-

sor

A15 Condensate warning

temperature sensor

A16 Internal temperature

sensor

A17 Phase monitoring For three-phase devices only:

A18 EPROM error New board installed incorrectly Software update needed (only following

Open or short-circuit Replace

Open or short-circuit Replace

Open or short-circuit Replace

Open or short-circuit Replace

Open or short-circuit Replace

Incorrect rotary field/phase absent

No action required;

Unit switches on again independently

Replace by a refrigeration engineer

Swap two phases

board installation with more recent software): Enter the programming level with

Code 22;

press button 1 and confirm with "Set" until

"Acc" appears. Next, disconnect the unit

from the mains and reconnect.

A19 LAN/Master-Slave Master and slave not connected Check setting and/or cable

Tab. 6: Troubleshooting with the e-Comfort controller

Rittal enclosure cooling unit 25

Page 26

7 Inspection and maintenance

EN

Display

screen

A20 Voltage drop Error display not shown Event is stored in the log file

E0 Display message Connection problem between the dis-

OL Overload Ambient parameters or heat loss outside the applicable limits

LH Low Heat Minimal heat loss in enclosure.

b07 Leak in the cooling cir-

rSt Reset Manual device reset required,

Tab. 6: Troubleshooting with the e-Comfort controller

6.2.10 Reset the e-Comfort controller

After the occurrence of faults A03, A06 and A07, you will

need to reset the e-Comfort controller.

Press buttons 1 () and 3 () (fig. 30) simultaneously

for 5 seconds.

The system messages disappear and the temperature

display is shown.

7 Inspection and maintenance

System message Possible cause Measures to rectify the fault

Reset: Switch power supply off, then switch

play and the controller board

Cable defective; connection loose Replace the boards

Sensor B3 and B4 swapped over Swap the sensors

cuit

see section6.2.10 "Reset the e-Comfort controller".

on again after approx. 2 sec.

Maintenance interval: 2,000 operating hours. Depending

on the level of contamination in the ambient air, the

maintenance interval may be reduced to suit the air pollution intensity.

Caution!

Risk of fire!

Never use flammable liquids for cleaning.

Warning!

The unit is live.

Switch off the power supply before

opening, and take suitable precautions

against it being accidentally switched

back on.

Caution!

Any essential repair work on the cooling circuit must only be undertaken by

a qualified refrigeration specialist.

The cooling circuit is designed in the form of a maintenance-free, hermetically sealed system. The cooling unit

is filled with the required quantity of refrigerant at the factory, checked for leaks, and subjected to a functional

test run.

The installed maintenance-free fans are mounted on ball

bearings, protected against moisture and dust, and fitted with a temperature monitor. The life expectancy is at

least 30,000 operating hours (L10, 40°C). The cooling

unit is thus largely maintenance-free. All that may be required from time to time is to clean the components of

the external air circuit using a vacuum cleaner or compressed air if they become visibly dirty. Any stubborn,

oily stains may be removed using a non-flammable detergent, such as degreaser.

Sequence of maintenance measures:

– Check the level of dirt.

– Filter soiling? Replace the filter if necessary.

– Cooling membranes soiled? Clean if necessary.

– Activate test mode; cooling function OK?

– Check noise generation of compressor and fans.

7.1 Compressed air cleaning 3304.xxx,

3305.xxx

Fig. 34: Disconnect the mains plug

26 Rittal enclosure cooling unit

Page 27

7 Inspection and maintenance

EN

Fig. 35: Remove the top louvred grille

Fig. 37: Remove the infill panel

Fig. 36: Remove the bottom louvred grille

Fig. 38: Disconnect the connector from the display (1)

Rittal enclosure cooling unit 27

Page 28

EN

7 Inspection and maintenance

Fig. 39: Disconnect the connector from the display (2)

Fig. 42: Remove the fan

Fig. 43: Disconnect the fan connectors

Fig. 40: Cooling unit without grille

Fig. 41: Remove the external circuit fan (undo four screws)

28 Rittal enclosure cooling unit

Fig. 44: Remove the cover (undo the four nuts)

Fig. 45: Slide the display cable back

Page 29

Fig. 46: Push the display cable through the cable gland

7 Inspection and maintenance

EN

Fig. 47: Remove the cover (1)

Fig. 48: Remove the cover (2)

Fig. 49: Release the earthing cable between the cover and the

chassis (1)

Fig. 50: Release the earthing cable between the cover and the

chassis (2)

Rittal enclosure cooling unit 29

Page 30

EN

7 Inspection and maintenance

7.2 Compressed air cleaning 3328.xxx,

3329.xxx, 3332.xxx

Fig. 53: Disconnect the mains plug

Fig. 51: Clean the heat exchanger coil and compressor cham-

ber using compressed air (1)

Fig. 54: Remove the top louvred grille (1)

Fig. 52: Clean the heat exchanger coil and compressor cham-

ber using compressed air (2)

30 Rittal enclosure cooling unit

Page 31

7 Inspection and maintenance

EN

Fig. 55: Remove the top louvred grille (2)

Fig. 57: Remove the bottom louvred grille (1)

Fig. 56: Remove the top louvred grille (3)

Rittal enclosure cooling unit 31

Fig. 58: Remove the bottom louvred grille (2)

Page 32

EN

7 Inspection and maintenance

Fig. 62: Slide the display cable back and push it through the ca-

ble gland (2)

Fig. 59: Take off the infill panel

Fig. 60: Disconnect the display cable

Fig. 63: Undo the four screws for the external circuit fan

Fig. 64: Remove the external circuit fan

Fig. 61: Slide the display cable back and push it through the ca-

ble gland (1)

32 Rittal enclosure cooling unit

Fig. 65: Disconnect the fan connectors (1)

Page 33

Fig. 66: Disconnect the fan connectors (2)

7 Inspection and maintenance

EN

Fig. 67: Disconnect the fan connectors (3)

Fig. 68: Disconnect the fan earthing cable (1)

Fig. 70: Undo the four screws for the cover

Fig. 69: Disconnect the fan earthing cable (2)

Rittal enclosure cooling unit 33

Fig. 71: Removing the cover

Page 34

EN

7 Inspection and maintenance

Fig. 72: Disconnect the earthing cable (1)

Fig. 74: Clean the heat exchanger coil and compressor cham-

ber using compressed air (1)

Fig. 73: Disconnect the earthing cable (2)

Fig. 75: Clean the heat exchanger coil and compressor cham-