Rittal 3373.544, 3363.100, 3363.104, 3364.100, 3363.500 Assembly And Operating Instructions Manual

...Page 1

)uftWasserWÇrIetauscher

Airwater heat exchaJgers

±chaJgeurs therIiques aireau

)uchtwaterwarItewisseHaars

)uftvatteJ vÇrIevÇxHare

ScaIbiatKri di caHKre ariaacqua

IJtercaIbiadKres de caHKr aireagua

水冷式熱交換器

3363XXX

3364XXX

3373XXX

3374XXX

3375XXX

*KJtage IJstaHHatiKJs uJd BedieJuJgsaJHeituJg

AsseIbHy aJd KperatiJg iJstructiKJs

+Ktice d’eIpHKi d’iJstaHHatiKJ et de IKJtage

*KJtage eJ bedieJiJgshaJdHeidiJg

*KJtage Kch haJteriJgsaJvisJiJg

IstruViKJi di IKJtaggiK e fuJViKJaIeJ

tK

IJstrucciKJes de IKJtaFe y fuJciKJaIieJtK

取扱説明書

Page 2

Contents

EN

1 Notes on documentation. . . . . . . . . . 3

1.1 Associated documents . . . . . . . . . . . . . . . . 3

1.2 CE labelling . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Retention of documents . . . . . . . . . . . . . . . 3

1.4 Symbols used. . . . . . . . . . . . . . . . . . . . . . . . 3

2 Safety notes . . . . . . . . . . . . . . . . . . . . 3

3 Device description . . . . . . . . . . . . . . . 4

3.1 Functional description . . . . . . . . . . . . . . . . 4

3.1.1 How it works. . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1.2 Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1.3 Bus mode

(e-Comfort controller only) . . . . . . . . . . . . . . . 4

3.1.4 Safety equipment. . . . . . . . . . . . . . . . . . . . . . 5

3.1.5 Condensation. . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1.6 Leak detection

(e-Comfort controller only) . . . . . . . . . . . . . . . 5

3.1.7 Door limit switch

(e-Comfort controller only) . . . . . . . . . . . . . . . 5

3.1.8 Additional interface X3

(e-Comfort controller only) . . . . . . . . . . . . . . . 5

3.2 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3 Scope of supply . . . . . . . . . . . . . . . . . . . . . . 5

4 Assembly and connection . . . . . . . . 6

4.1 Choosing the installation site. . . . . . . . . . . 6

4.2 Assembly instructions . . . . . . . . . . . . . . . . 6

4.2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2.2 Layout of the components in the enclosure. . 6

4.3 Assembling the air/water

heat exchanger. . . . . . . . . . . . . . . . . . . . . . . 7

4.3.1 Preparing the mounting cut-out . . . . . . . . . . . 7

4.3.2 Assembling the air/water heat exchanger . . . 7

4.4 Connecting the condensate discharge . . . 9

4.5 Connecting the water connection . . . . . . . 9

4.5.1 Notes on water quality . . . . . . . . . . . . . . . . . 10

4.5.2 Preparation and maintenance of the water

in recooling systems . . . . . . . . . . . . . . . . . . 10

4.6 Notes on electrical installation . . . . . . . . . 11

4.6.1 Connection data . . . . . . . . . . . . . . . . . . . . . 11

4.6.2 Overvoltage protection

and supply line load . . . . . . . . . . . . . . . . . . 11

4.6.3 Door limit switch

(e-Comfort controller only) . . . . . . . . . . . . . . 11

4.6.4 Potential equalisation. . . . . . . . . . . . . . . . . . 11

4.6.5 Installing the power supply . . . . . . . . . . . . . 11

5 Commissioning . . . . . . . . . . . . . . . . 13

6 Operation . . . . . . . . . . . . . . . . . . . . . 13

6.1 Control using the Basic controller . . . . . 13

6.1.1 Display and system analysis. . . . . . . . . . . . 13

6.1.2 Properties . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.1.3 General programming information . . . . . . . 13

6.1.4 Operation of the Basic controller . . . . . . . . 13

6.1.5 Setting the temperature. . . . . . . . . . . . . . . . 13

6.1.6 Setting of system messages . . . . . . . . . . . . 14

6.1.7 Programming and control

of the Basic controller . . . . . . . . . . . . . . . . . 14

6.1.8 Reset of r6 and r7

(min./max. internal temperature). . . . . . . . . 14

6.1.9 System message contact (K1; floating) . . . 15

6.1.10 Programming overview of Basic controller . 15

6.2 Control using the e-Comfort controller. . 16

6.2.1 Properties . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.2.2 Launching test mode . . . . . . . . . . . . . . . . . 16

6.2.3 General programming information . . . . . . . 16

6.2.4 Eco-mode . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.2.5 Editable parameters . . . . . . . . . . . . . . . . . . 18

6.2.6 Bus connection

(only when interconnecting several units

with an e-Comfort controller). . . . . . . . . . . . 19

6.2.7 Programming overview

of e-Comfort controller . . . . . . . . . . . . . . . . 20

6.2.8 Defining system messages for evaluation . 21

6.2.9 Setting the master-slave identifier. . . . . . . . 21

6.2.10 Evaluating system messages . . . . . . . . . . . 22

7 Inspection and maintenance. . . . . . 23

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8 Emptying, storage and disposal. . . 23

9 Technical specifications . . . . . . . . . 24

10 List of spare parts . . . . . . . . . . . . . . 27

11 Further technical information . . . . . 28

11.1 Hydrological data . . . . . . . . . . . . . . . . . . . 28

11.2 Characteristic curves . . . . . . . . . . . . . . . . 29

11.2.1 Water resistance . . . . . . . . . . . . . . . . . . . . . 29

12 Appendix 1:

Cut-out and hole sizes

12.1 Dimensions for external

and internal mounting. . . . . . . . . . . . . . . . 30

. . . . . . . . . . . 30

13 Appendix 2:

Application example

Parallel connection of

4 air/water heat exchangers . . . . . . 33

2 Rittal air/water heat exchanger assembly instructions

Page 3

1 Notes on documentation

1 Notes on documentation

These assembly instructions are aimed at

– tradespersons who are familiar with assembly and

installation of the air/water heat exchanger

– trained specialists who are familiar with the

operation of the air/water heat exchanger

1.1 Associated documents

Assembly and operating instructions exist as paper

documents and/or on CD-ROM for the unit types described here and are enclosed with the equipment.

We cannot accept any liability for damage associated with failure to observe these instructions. Where

applicable, the instructions for any accessories used

also apply.

1.2 CE labelling

The declaration of conformity is supplied with the unit

as a separate document.

13ReteJtiKJ Kf dKcuIeJts

These instructions and all associated documents

constitute an integral part of the product. They must

be given to the plant operator. The operator is responsible for storage of the documents so they are

readily available when needed.

14SyIbKHs used

The bullet point indicates

an action to be performed.

2 Safety notes

Please observe the following general safety notes

when assembling and operating the unit:

– Assembly, installation and servicing may only be

performed by properly trained specialists.

– The minimum water inlet temperature of +1°C must

not be reduced at any point in the water cycle.

Otherwise there is danger of frost damage!

– Use antifreeze agents only with the manufacturer’s

consent.

– Do not obstruct the air inlet and air outlet of the

air/water heat exchanger inside the enclosure

(see also section “4.2.2 Layout of the components

in the enclosure”, page 6).

– The heat loss of the components installed in the

enclosure must not exceed the specific useful

cooling output of the air/water heat exchanger.

– Use only original spare parts and accessories.

– Do not make any changes to the air/water heat

exchanger other than those described in these

instructions or associated instructions.

– The mains connector of the air/water heat

exchanger must only be connected and

disconnected with the system de-energised.

Connect the pre-fuse specified on the rating

plate.

– Always disconnect the unit from the supply

voltage before servicing or maintenance work.

– Readily flammable objects/materials must not

be stored in the immediate vicinity of the air/water

heat exchanger.

EN

Danger!

Immediate danger to life and limb!

Caution!

Potential threat to the product

and the environment.

Note:

Useful information

and special features.

Rittal air/water heat exchanger assembly instructions 3

Page 4

3 Device description

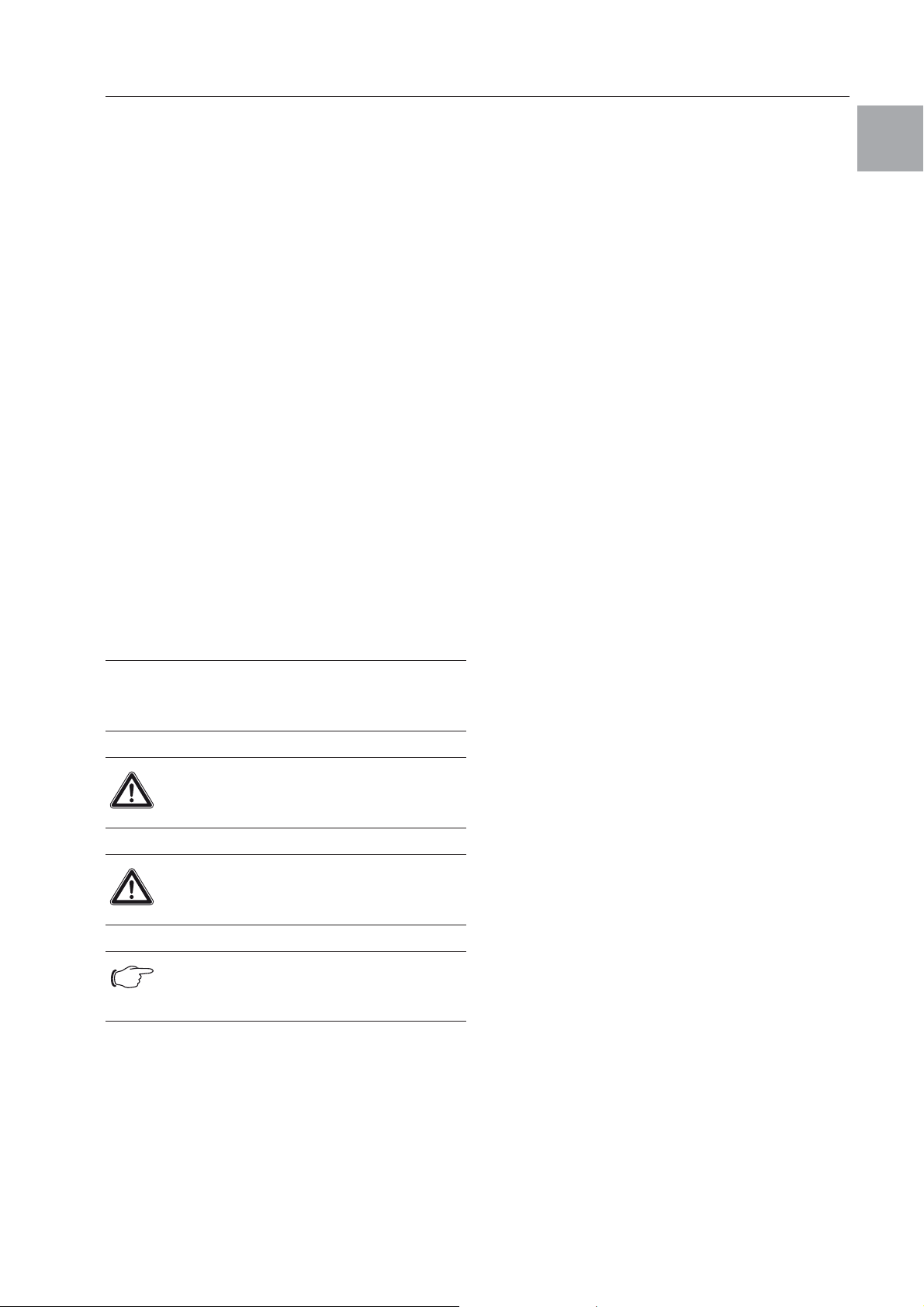

8

7

1

9 10

3

4 54 5 6

11

2

Cooling water return

Magnetic

valve (3)

Tem perature control

(4)

Cooling water inlet

Non-return

valve (5)

(for units with

e-Comfort

controller

only)

Fan (2)

Heat

exchanger

(1)

EN

3 Device description

Depending on the model chosen, your air/water

heat exchanger may vary in appearance from the

illustrations contained in these instructions.

However, the functions are identical in principle.

3.1.1 How it works

The air/water heat exchanger comprises of the following main components (cf. fig. 2): Heat exchanger

package (1), fan (2), magnetic valve (3), temperature

control (4) and non-return valve (5).

Fig. 2: Air/water heat exchanger

The heat loss of the enclosure is dissipated in

a membrane heat exchanger to the water coolant.

A fan (2) blows the internal enclosure air over the

heat exchanger (1); except for the inlet and outlet

water and the condensed water discharge, the unit

is closed to the environment. The magnetic valve (3)

controls the cooling output by changing the water

flow volume depending on the required setpoint

temperature and the water inlet temperature.

3.1.2 Control

Fig. 1: Device description

Key

1Cover

2 Display (controller)

3 X1 terminal strip (unit rear)

4 X2 master/slave connection (e-Comfort controller)

5 X3 optional serial interface (unit rear)

6 Potential equalisation

7 Rating plate

8 Cooling water inflow (underside of the unit)

9 Condensate discharge (underside of the unit)

10 Cooling water return (underside of the unit)

11 Dispatch bag

Rittal air/water heat exchangers are fitted with a

controller for setting the functions of the heat exchanger. Depending on the design, this is either

a Basic controller or an e-Comfort controller (display

plus extended functions, see chapter “6 Operation”,

page

13

).

3.1.3 Bus mode (e-Comfort controller only)

The serial unit interface X2 allows you to create a bus

connection with up to ten air/water heat exchangers

using the master/slave cable (shielded, four-wire

cable, Model No. 3124.100). This allows you to

implement the following functions:

3.1 Functional description

Air/water heat exchangers are designed and built to

dissipate heat from enclosures by cooling the air inside the enclosure and so protect the temperaturesensitive components. Air/water heat exchangers

are particularly appropriate for the temperature

range of up to +70°C where comparable units, such

as air/air heat exchangers, enclosure cooling units or

fan-and-filter units, cannot be used for system reasons to effectively and economically dissipate heat

loss. The air/water heat exchanger may be externally

– Parallel unit control

(the air/water heat exchangers in the network

can be switched on and off simultaneously)

– Parallel door status message (“door open”)

– Parallel collective fault message

Data is exchanged via the master-slave connection.

During commissioning, assign an address to each

unit that also includes the identifier “master” or

“slave”.

(See also chapter “6.2.9 Setting the master-slave

identifier”, page 21).

and internally mounted on all enclosure outer walls.

4 Rittal air/water heat exchanger assembly instructions

Page 5

3 Device description

3.1.4 Safety equipment

– To protect against overcurrent (depending on

whether an AC or EC fan is used), the fan is

equipped with thermal winding protection.

– The device has floating contacts on the connection

terminal (terminals 3 – 5), which may be used to

retrieve system messages from the device, e.g. via

PLC (1 x change-over contact Basic controller,

2 x normally open contacts e-Comfort controller).

– Air/water heat exchangers with e-Comfort control-

ler possess a leakage sensor and a condensate

warning.

3.1.5 Condensation

At high levels of humidity and low cooling water temperatures inside the enclosure, condensation may

form on the heat exchanger.

Any condensation that forms on the heat exchanger

(with high humidity and low water temperatures)

is routed to the bottom and out of the unit via a drain

opening in the heat exchanger tray. For this purpose,

a hose must be connected to the condensate nozzle

(see “4.4 Connecting the condensate discharge”,

page 9). The condensate must be able to run off

freely. The hose used for draining off condensate

must be laid free from kinks and checked for correct

drainage.

Air/water heat exchangers with e-Comfort controller

possess a leakage sensor and a condensate

warning.

Condensate hoses are available as accessories

(refer also to Accessories in the Rittal Catalogue).

3.1.6 Leak detection

(e-Comfort controller only)

If a leakage or pipe breakage occurs in the water

circuit of the air/water heat exchanger, a magnetic

valve immediately stops the cooling water supply,

the floating change-over contact is activated and the

fan switched off.

3.1.7 Door limit switch

(e-Comfort controller only)

The air/water heat exchanger may be operated with

a door limit switch connected. The door limit switch

is not included with the supply (available as an

accessory, Model No. 4127.010).

The door limit switch function causes the fan and the

magnetic valve in the air/water heat exchanger to be

switched off after approximately 15 seconds when

the enclosure door is opened (contacts 1 and 2

closed). This prevents the formation of condensation

inside the enclosure while the enclosure door is

open.

The fan will start up after about 15 seconds on

closure of the door. The connection is made at terminals 1 and 2. The extra-low voltage is supplied

by the internal power pack; the current is approx.

30 mA DC.

Note:

The door limit switches must only be

connected free from potential.

No external voltages!

3.1.8 Additional interface X3

(e-Comfort controller only)

Note:

The electrical signals at the interface

are of an extra-low voltage

(not extra-low safety voltages to EN 60 335).

An additional interface card may be connected to

the 9-pole SUB-D connector X3 in order to incorporate the air/water heat exchanger into higher-level

monitoring systems (available as an accessory,

interface card Model No. 3124.200).

3.2 Proper use

Rittal air/water heat exchangers were developed and

designed in accordance with the state of the art and

the recognised rules governing technical safety.

Nevertheless, if used improperly, they may pose a

threat to life and limb or cause damage to property.

The unit is only intended for cooling enclosures.

Any other use is deemed improper. The manufacturer will not be liable for any damages caused as

a result of improper use, or for incorrect assembly,

installation or use. All risk is borne solely by the user.

Proper usage also includes the observation of all

valid documents and compliance with the inspection

and servicing conditions.

3.3 Scope of supply

The unit is supplied in a packaging unit in a fully

assembled state. Please check the scope of supply

for completeness.

Quantity Description

1 Air/water heat exchanger

1

1

1

4

4

1

1

1

1 Drilling template

Tab. 1: Scope of supply

Dispatch bag:

– Sealing tape

– Plug-in terminal strip

– Spacer bolts including assembly parts

– Sealing bungs (not with unit types

3363.XXX/3364.XXX)

– Assembly, installation and

operating instructions

– Declaration of conformity

– Safety notes

EN

Rittal air/water heat exchanger assembly instructions 5

Page 6

4 Assembly and connection

200

4 Assembly and connection

EN

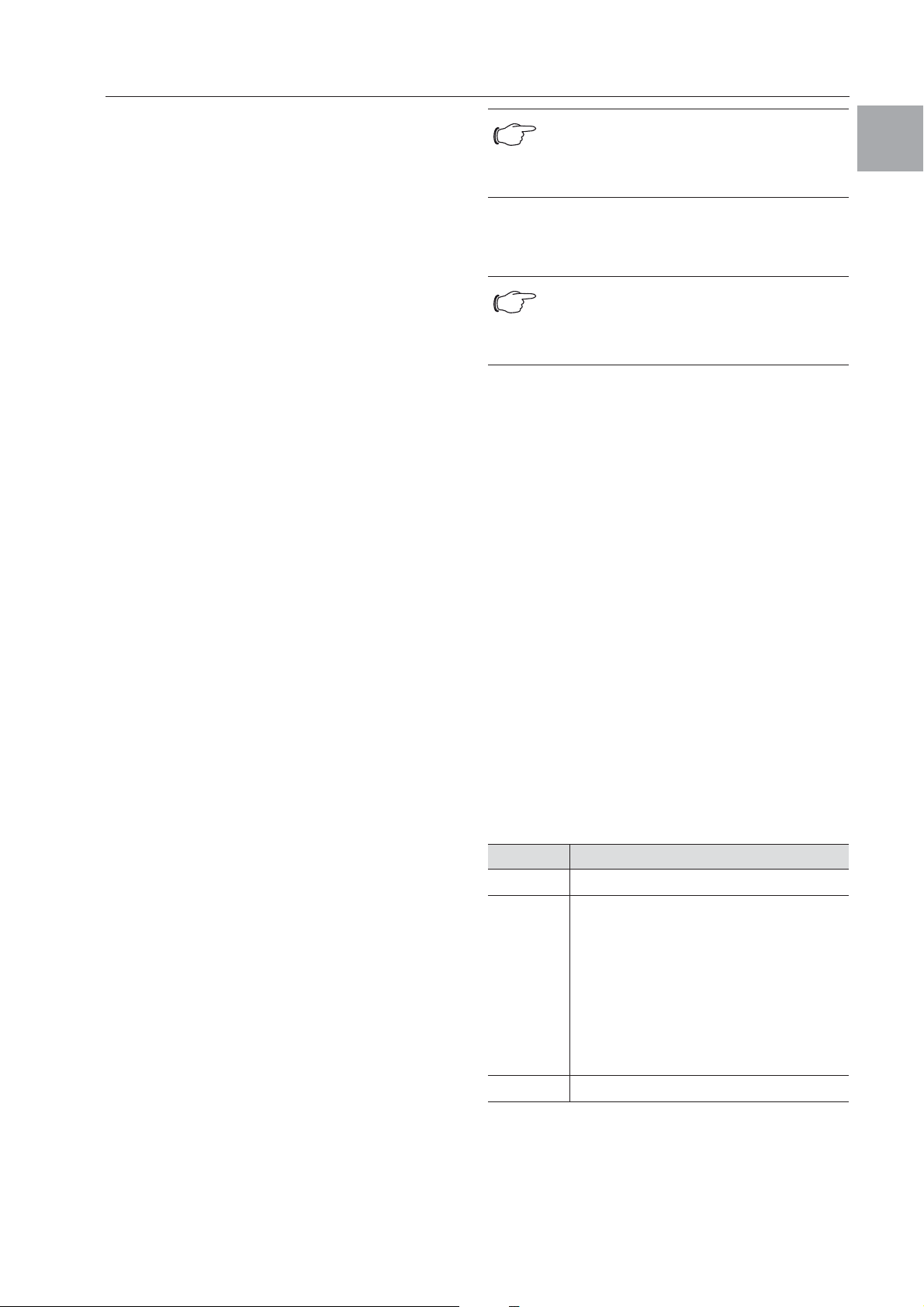

4.1 Choosing the installation site

When choosing the installation site for the enclosure,

please observe the following:

– The air/water heat exchanger must be installed

and operated in a vertical position (maximum

deviation: 2°).

– The ambient temperature must not exceed +70°C.

– It must be possible to fit a condensate discharge

(see “4.4 Connecting the condensate discharge”,

page 9).

– It must be possible to fit a cooling water supply and

return (see “4.5 Connecting the water connection”,

page 9).

– The mains connection data as stated on the rating

plate of the unit must be guaranteed.

– For ease of servicing, appropriate access to the

device must be guaranteed.

4.2 Assembly instructions

4.2.1 General

–

Check the packaging carefully for signs of damage.

Any packaging damage may be the cause of a

subsequent functional failure.

– The enclosure must be sealed on all sides (IP 54).

Increased condensation will occur if the enclosure is

not airtight.

– The air inlet and outlet must not be obstructed on the

inside of the enclosure.

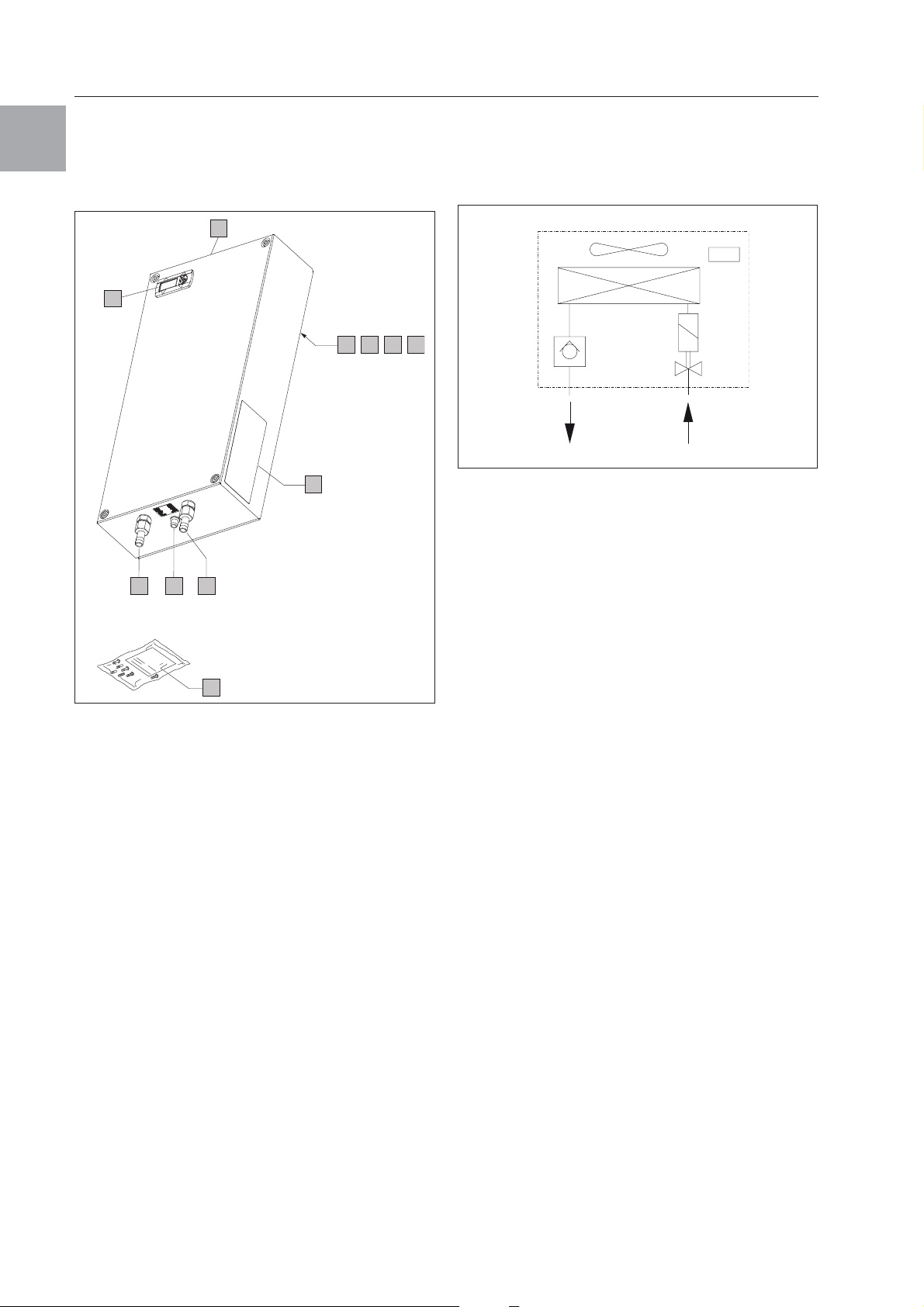

4.2.2 Layout of the components in the enclosure

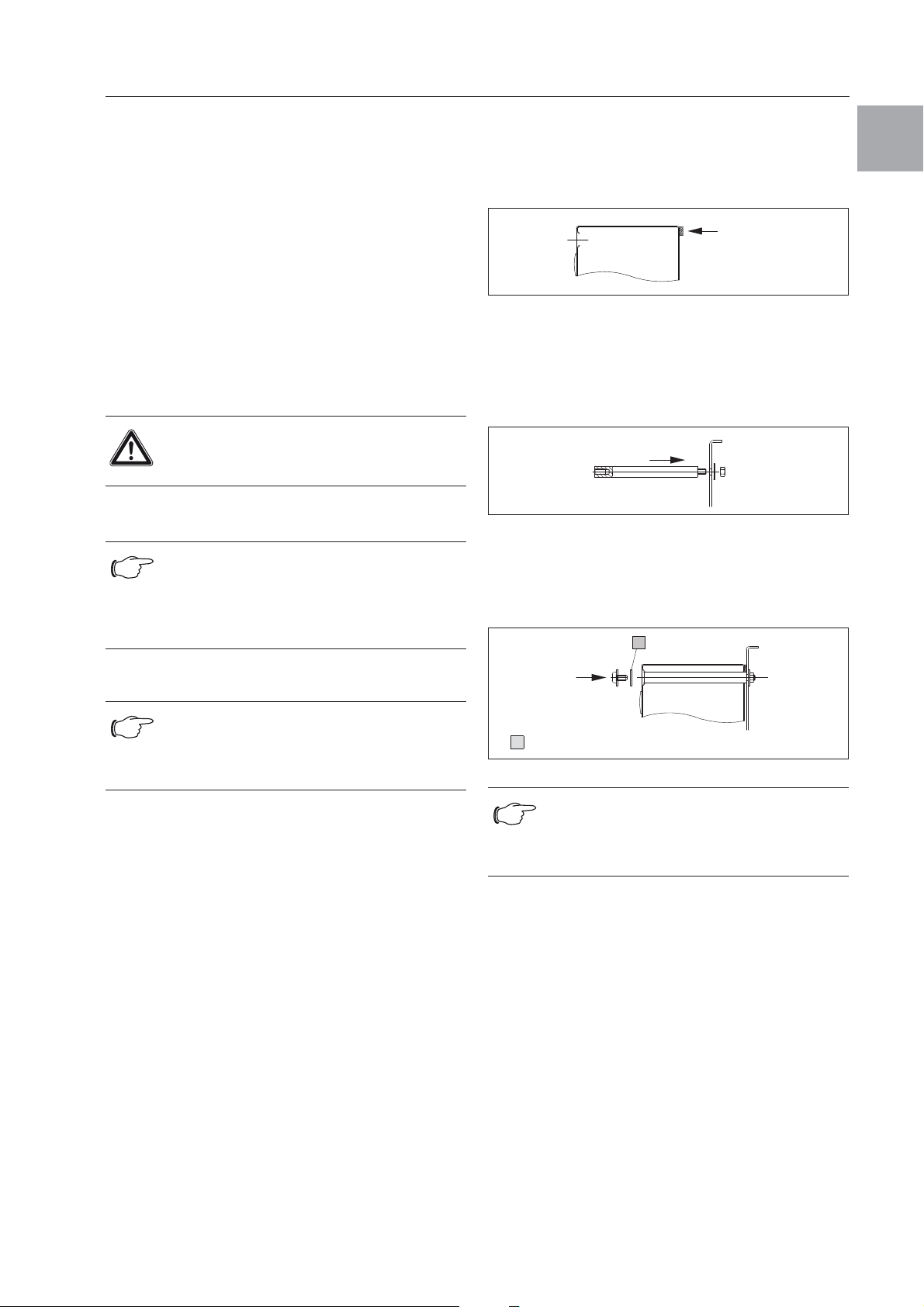

Fig. 3: Never direct the cold airflow at active components

Exercise particular caution with the airflow from the

blowers of built-in electronic components (see fig. 3).

Note:

The air/water heat exchangers should

never be fitted directly behind the mounting

plate. If it is not possible to install the unit

any other way, appropriate air baffle plates

should be used, and air inlet and outlet

openings should be provided in the mounting plate.

It is important to ensure even air circulation

inside the enclosure. Under no circumstances should air inlet and outlet openings

be obstructed, otherwise the cooling performance of the unit will be reduced. Ensure

a suitable distance from electronic components and other installed enclosures

so that the required air circulation is not

obstructed and prevented.

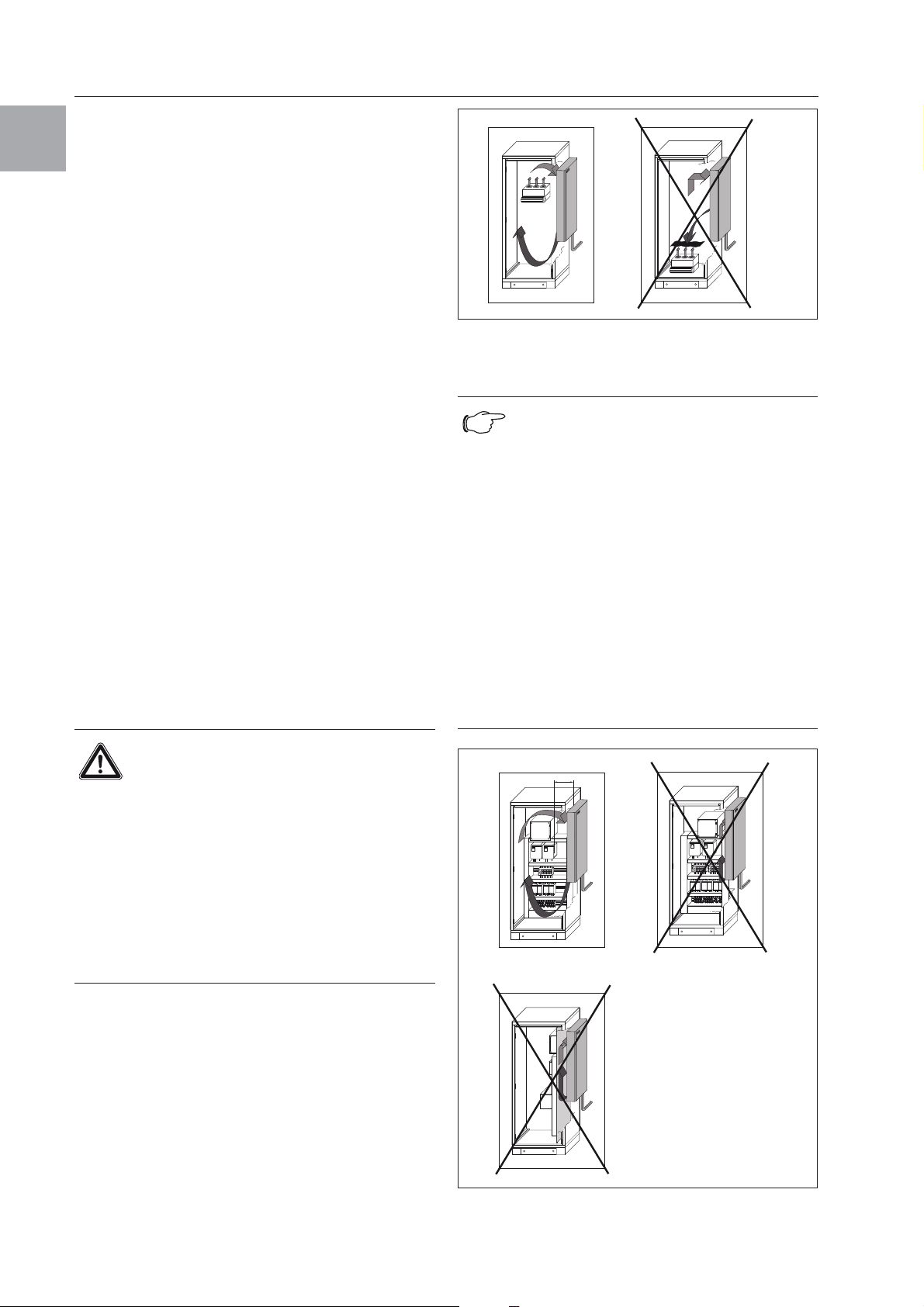

Caution! Risk of condensation!

When arranging the components inside

the enclosure, please ensure that the cold

airflow from the air/water heat exchanger

is not directed at active components.

Please also ensure that the cold airflow is

not directed at the warm exhaust airflow

from active components such as inverters.

This may lead to an air short-circuit and

therefore prevent adequate climate control, or may even cause the air/water heat

exchanger’s internal safety devices to

cease cooling operation.

Fig. 4: Targeted air routing inside the enclosure

6 Rittal air/water heat exchanger assembly instructions

Page 7

4 Assembly and connection

1

1

4.3 Assembling the

air/water heat exchanger

The air/water heat exchanger can be mounted on the

outer walls or the door of the enclosure.

For this purpose, the appropriate enclosure panel

or door must be cut out using the supplied drilling

template.

4.3.1 Preparing the mounting cut-out

Stick the supplied drilling template onto the side

panel or door of the enclosure using adhesive

tape. The heat exchanger is suitable for both external and internal mounting.

There are dimensioning lines on the drilling template

to suit the installation type for your air/water heat

exchanger.

Risk of injury!

Carefully deburr all cut-outs to prevent

injuries caused by sharp edges.

Make the cut-outs including the line width as per

the drilling template. Deburr the cut-outs.

Note:

In order to achieve a permanent seal

between the air/water heat exchanger and

the enclosure, the mounting surface should

be reinforced or supported if necessary.

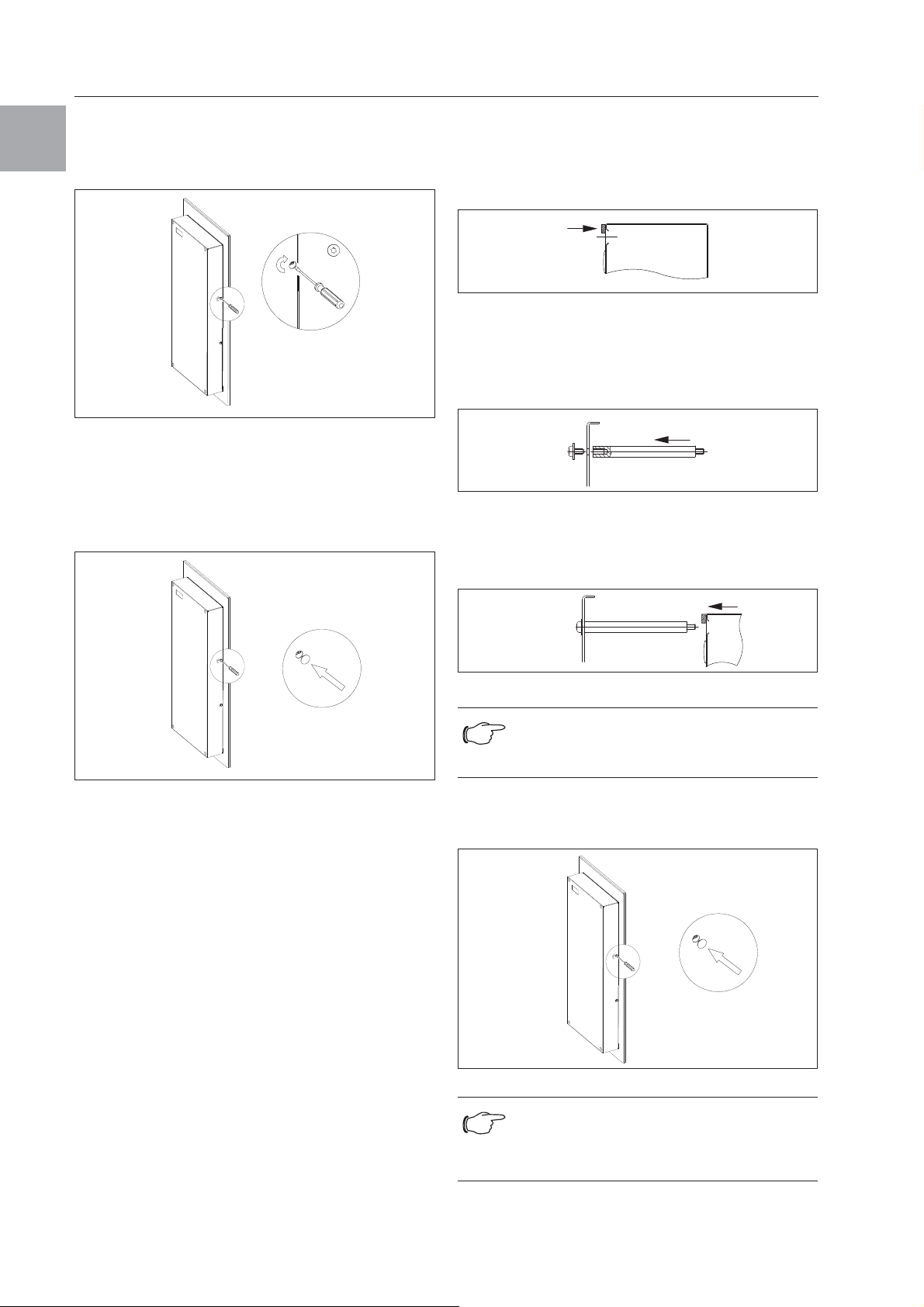

External mounting

Step 1:

Stick sealing tape to all four edges at the rear of

the device.

1.

Fig. 5: Stick sealing tape to all four edges

Step 2:

Insert the 4 spacers (external thread) into the

mounting surface through the holes, and secure

from the inside of the enclosure using the relevant

washers and nuts.

2.

Fig. 6: Insert the spacers through the holes and secure

Step 3:

Push the device over the spacers and secure with

the relevant rubber washers, washers and screws

(observe the correct assembly sequence).

3.

4x

EN

4.3.2 Assembling the air/water heat exchanger

Note:

For both types of mounting (internal and

external), use the assembly parts supplied

in the pack.

Rubber

Fig. 7: Push the device over the spacers and screw-fasten

Note:

For models 3373.XXX, 3374.XXX and

3375.XXX, steps 4 and 5 are additionally

required.

Rittal air/water heat exchanger assembly instructions 7

Page 8

4 Assembly and connection

TX30

4x

4x

4x

EN

Step 4:

Twist the side locking screws in the enclosure

cover in a clockwise direction as far as they will go,

until the sealing tape adheres securely.

4.

Fig. 8: Twist the screws in a clockwise direction as far as

they will go

Step 5:

Using the stoppers, seal the 4 openings in the

cover.

5.

Full internal mounting

Step 1:

Stick sealing tape to all four edges at the front of

the device.

1.

Fig. 10: Stick sealing tape to all four edges

Step 2:

Hold the 4 spacers (internal thread) in place on

the inside of the enclosure, and secure from the

outside using the relevant washers and screws.

2.

Fig. 11: Secure the spacers

4x

Step 3:

Push the device over the spacers and secure with

the relevant washers and nuts.

Fig. 9: Seal the openings in the cover

3.

Fig. 12: Push the device over the spacers and screw-fasten

Note:

For models 3373.XXX, 3374.XXX and

3375.XXX, step 4 is additionally required.

Step 4:

Using the stoppers, seal the 4 openings in the

cover.

4.

Fig. 13: Seal the openings in the cover

Note:

The enclosure must be sealed on all sides,

especially in the vicinity of the cable entry

8 Rittal air/water heat exchanger assembly instructions

openings and the enclosure base.

Page 9

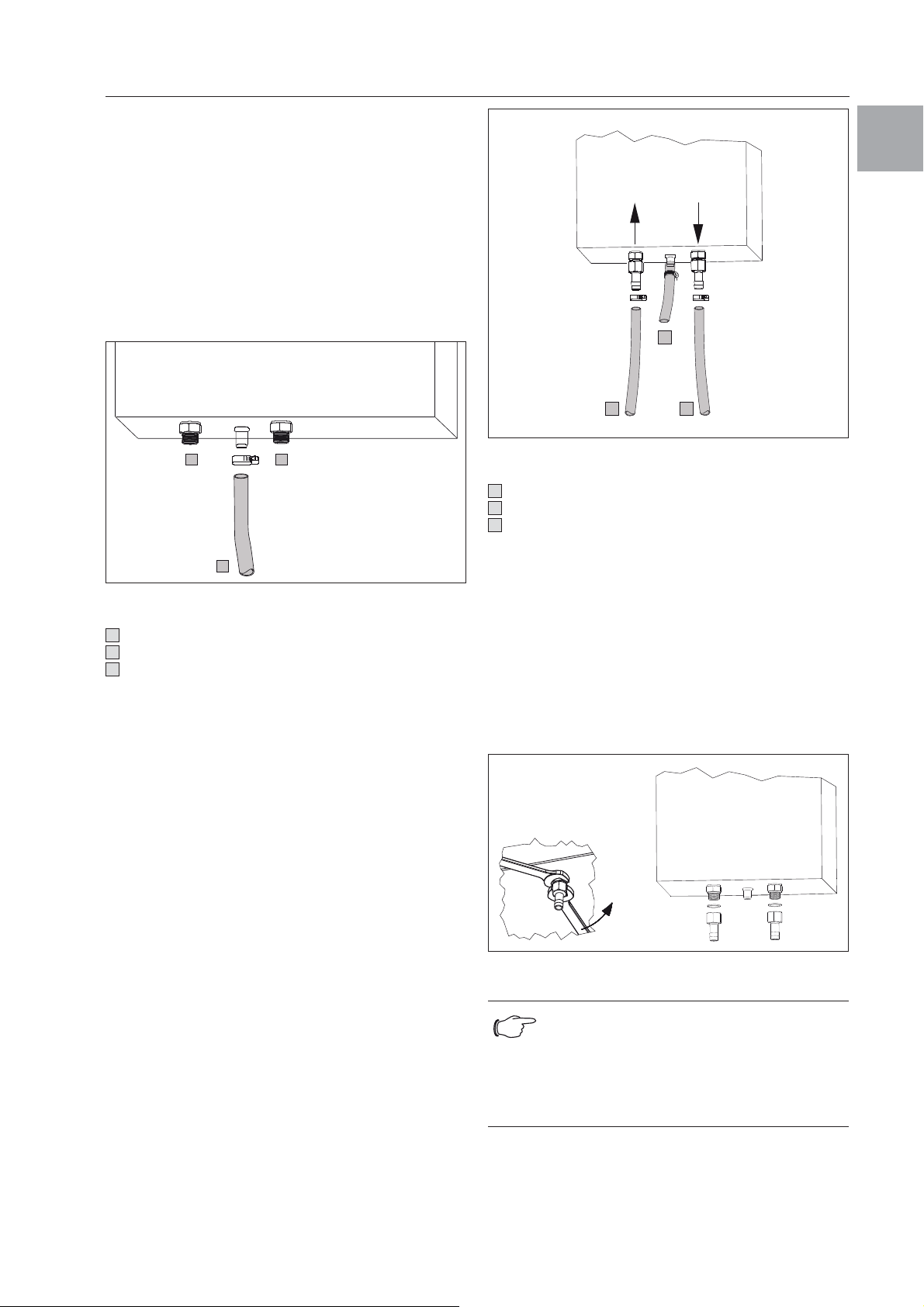

4.4 Connecting the condensate discharge

2

1

3

1

2

3

1

2

3

25 Nm

A flexible condensate discharge hose Ø 12 mm (1/2˝)

can be fitted to the air/water heat exchanger

(see fig. 14).

The condensate discharge

– must be laid with a suitable and constant gradient

(no siphoning).

– must be laid without kinks.

–

must not have a reduced cross-section if extended

The condensate hose is available as an accessory

(refer also to Accessories in the Rittal Catalogue).

4 Assembly and connection

EN

.

3

Fig. 14: Connecting the condensate discharge

Key

Cooling water connection (inlet)

Cooling water connection (return)

Condensate discharge

Connect a suitable hose to the condensate nozzle

(at the bottom of the unit) and secure it with a hose

clip (with 2 Nm torque).

Lay the condensate hose, e.g. into a drain.

To prevent the water from backing up, the hose

cross-section must not be restricted!

4.5 Connecting the water connection

There are 4 different options for connecting water to

the air/water heat exchanger.

1

Fig. 15: Connecting the cooling water inlet and return

Key

Cooling water connection (inlet)

Cooling water connection (return)

Condensate discharge

2

b) Fixed pipework with G 3/8˝ external thread

(included with the supply)

In its delivered state, fixed pipework with a G

3

/8˝

external thread may be connected to the air/water

heat exchanger for both the inlet and the return.

To this end, you will need to remove the connector

sleeve attached to the device (see fig.

The fixed pipework should be tightened with

16

).

25 Nm.

1

a)

/2˝ connector sleeve (included with the supply)

In its delivered state, a compression-proof, flexible

cooling water hose Ø 12 mm (

1

/2˝) may be connected

Fig. 16: Remove the connector sleeve

to the air/water heat exchanger for both the inlet and

the return.

The cooling water hose

– must be laid without kinks

– must not have a reduced cross-section if extended

and, if necessary, must be insulated.

Note:

When loosening the connector sleeve, it is

vital to ensure that the fitting on the device

end is fixed with an SW22 open-jawed

spanner. The connection inside the device

could develop a leak.

Rittal air/water heat exchanger assembly instructions 9

Page 10

4 Assembly and connection

EN

c) Fixed pipework with G 3/8˝ internal thread

(Model No. 3201.900)

3

The G

/8˝ internal thread adaptor, available as an

accessory, allows you to connect fixed pipework to

the air/water heat exchanger for both the inlet and

the return.

To this end, you will need to remove the connector

sleeve attached to the device (see fig. 16, page 9).

d) Fixed pipework with 1/2˝ NPT

(Model No. 3201.930)

1

The

/2˝ NPT adaptor, available as an accessory,

allows you to connect fixed pipework to the air/water

heat exchanger for both the inlet and the return.

To this end, you will need to remove the connector

sleeve attached to the device (see fig. 16, page 9).

Note:

The water circuit should be protected

from ingress of dirt or excess pressure

(maximum permitted operating pressure

10 bar)!

Note:

Observe the flow direction

and check for leaks!

The following criteria for the cooling water must be

observed:

– Water with high gypsum content is unsuitable for

cooling purposes because it has a tendency to

form boiler scale that is particularly difficult to

remove.

– The cooling water should be free from iron and

manganese, because otherwise deposits may

occur that accumulate in the pipes and block

them.

– At best, organic substances should only be

present in small quantities, because otherwise

sludge deposits and microbiological contamination may occur.

4.5.2 Preparation and maintenance of the water

in recooling systems

Depending on the type of installation to be cooled,

certain requirements are placed on the cooling water

with respect to purity. According to the level of contamination and the size and design of the recooling

systems, a suitable process is used to prepare and/

or maintain the water.

The most common types of contamination and most

frequently used techniques to eliminate them in

industrial cooling are:

Contamination

of the water

Procedure

Note:

The units do not have any separate

ventilation.

For pressure-sealed systems, install the

appropriate ventilation equipment on the

water side.

4.5.1 Notes on water quality

To ensure the reliable operation of the abovementioned units, the VBG guidelines for cooling

water must be observed (VGB-R 455 P).

The cooling water must not contain any limescale

deposits; in other words, it should have a low level of

hardness, in particular, a low level of carbonate

hardness. For recooling within the plant, the carbonate hardness should not be too high. On the other

hand, the water should not be so soft that it attacks

the materials. When recooling the cooling water, the

salt content should not be allowed to increase excessively due to the evaporation of large quantities of

water, since electrical conductivity increases as the

concentration of dissolved substances rises, and the

water thereby becomes more corrosive.

Always add the appropriate volume of fresh water.

Always remove part of the enriched water.

Mechanical

contamination

Excessive hardness Water softening

Moderate content

of mechanical

contaminants and

hardeners

Moderate content of

chemical contaminants

Biological contaminants,

slime bacteria and algae

Tab. 2: Water contaminants

Filter the water using:

– Mesh filter

–Gravel filter

– Cartridge filter

– Precoated filter

via ion exchange

Addition of stabilisers

and/or dispersing agents

to the water

Addition of passifiers

and/or inhibitors

to the water

Addition of biocides

to the water

10 Rittal air/water heat exchanger assembly instructions

Page 11

4 Assembly and connection

4.6 Notes on electrical installation

When performing the electrical installation, it is important to observe all valid national and regional regulations as well as the provisions of the responsible

power supply company. Electrical installation must

only be carried out by a qualified electrician who

is responsible for compliance with the existing

standards and regulations.

4.6.1 Connection data

– The connected voltage and frequency must cor-

respond to the values stated on the rating plate.

– The air/water heat exchanger must be connected

to the mains via an all-pin isolating device which

ensures at least 3 mm contact opening when

switched off.

– No additional temperature control may be con-

nected upstream of the unit at the supply end.

– Install the pre-fuse cited on the rating plate

(miniature circuit-breaker or gG/(gL) fuse) to

protect the cable and equipment from shortcircuits.

– The mains connection must ensure low-noise

potential equalisation.

4.6.4 Potential equalisation

Rittal recommends connecting a conductor with

a nominal cross-section of at least 6 mm

potential equalisation connection point on the air/

water heat exchanger and incorporating it into the

existing potential equalisation system.

According to the standard, the PE conductor in

the mains connection cable is not classified as an

equipotential bonding conductor.

4.6.5 Installing the power supply

Complete the electrical installation in accordance

with the wiring plan to be found on the rear of the

air/water heat exchanger.

For devices 3363.XXX and 3364.XXX in special

voltage variants, an external transformer is required (see also Rittal system accessories).

To be able to evaluate the system messages of the

air/water heat exchanger via the system message

relay, a corresponding low-voltage cable must be

connected additionally on terminals 3 – 5.

2

to the

EN

4.6.2 Overvoltage protection

and supply line load

– The unit does not have its own overvoltage protec-

tion. Measures must be taken by the operator at

the supply end to ensure effective lightning and

overvoltage protection. The mains voltage must

not exceed a tolerance of ±10%.

– The fans in single-phase units are intrinsically safe

(thermal winding protection). The same also

applies to all transformer versions and to specialvoltage units which are likewise equipped with

a transformer.

4.6.3 Door limit switch

(e-Comfort controller only)

– Each door limit switch must only be assigned to

one air/water heat exchanger.

– Several door limit switches may be connected

in parallel and operated on one air/water heat

exchanger.

– The minimum cross-section of the connection

cable is 0.3 mm

We recommend the use of a shielded cable.

– The line resistance to the door limit switch must

not exceed a maximum of 50 1.

– The door limit switch only supports a floating

connection; no external voltages.

– The contact of the door limit switch must be closed

when the door is open.

The safety extra-low voltage for the door limit switch

is provided by the internal power pack: current

approx. 30 mA DC.

Connect the door limit switch to terminals 1 and

2 of the connector.

The door limit switch is available as an accessory

(Model No. 4127.010).

Rittal air/water heat exchanger assembly instructions 11

2

for a cable length of 2 m.

Page 12

4 Assembly and connection

2

NTC_I

2

NTC_E

PE

PE

Power/G1

L N

Kx

PE

1

2

3

3

2

1

D0-E D0-I

/Y1 /M2

1

34

2

A2

A1

Mains

L1 N PE 21345

X1

M2Y1

1~

M

C2

D0-E/Kx

8 pol.

TO INTERFACE

8

S2

B1

Option T1

L1

L2

N

T1

L1 L1/N

L1 L2/N

83

PE

Term

Level

NTC_E

NTC_I

NTC_A

NTC_C

F2

Power/G1

Kx

PE

L

S1 K2 K1

1

2

3

1

2

3

1

212

3

2

1

2

33

1

N

M1

M2

M4

1

2

S

S2

1~

M2

AC

A1

A2

X2

MS1 Serial

X3

Mains

S1

L1 PE 2134

22

21

5

L2

N

X1

Y1

PE

PE

PE

PE PE

Option T1

L1

L2

N

T1

L1 L1/N

L1

L2/N

4

2

B1

C2

EN

3363.1XX, 3364.1XX,

3373.1XX, 3374.1XX, 3375.1XX

(does not apply to

3375.XXX)

Fig. 17: Electrical wiring plan no. 1

Key

A1 Power PCB (Basic 2)

A2 Display terminal

B1 Temperature sensor, internal temperature

C2 Operating capacitors

(does not apply to 3375.XXX)

Kx Collective fault relay

M2 Fan

S2 Float-actuated switch (optional)

X1 Main terminal strip (terminals 1 and 2 are free)

Y1 Magnetic valve

T1 Transformer (optional)

3363.5XX, 3364.5XX,

3373.5XX, 3374.5XX, 3375.5XX

(does not apply to 3375.XXX)

Fig. 18: Electrical wiring plan no. 2

Key

A1 Power PCB (Comfort)

A2 Temperature sensor

B1 Temperature sensor, internal temperature

Kx Relay K1 collective fault 1

Relay K2 collective fault 2

M2 Fan

C2 Operating capacitor

(does not apply to 3375.XXX)

S1 Door limit switch

(without door limit switch: terminal 1, 2 open)

S2 Float-actuated switch (closed without water)

X1 Main terminal strip

X2 Master-slave connection

X3 Serial interface (optional)

T1 Transformer (optional)

Y1 Magnetic valve

Contact data Kx (Basic controller)

AC

cos f = 1

I

max.

U

max.

Tab. 3: Contact data Kx

12 Rittal air/water heat exchanger assembly instructions

DC

Res. load

I

max.

I

min.

U

U

max.

min.

= 4 A

= 100 mA

= 200 V

= 10 V

= 4 A

= 250 V

Note:

For technical data, refer to the rating plate.

Contact data K1, K2 (e-Comfort controller)

AC

cos f = 1

= 2 A

I

max.

= 250 V

U

max.

DC

Res. load

I

= 1 A

max.

= 30 V

U

max.

Tab. 4: Contact data K1, K2

Page 13

5 Commissioning

H2 = Key K1 H4 = Key set/°F

H1 = Display terminal H3 = Key

K2

5 Commissioning

Once all the assembly and installation work is

complete, switch on the power supply to the

air/water heat exchanger.

The air/water heat exchanger starts running:

– with Basic controller: The enclosure internal

temperature is displayed.

– with e-Comfort controller: The software version

of the controller first appears for approx. 2 sec.,

then the enclosure internal temperature appears in

the 7-segment display.

You can now make your individual settings on the

unit, e.g. set the temperature or (with e-Comfort

controller only) assign the network identifier, etc.

(refer to the chapter “6 Operation”, page 13).

Note on limiting the volumetric flow

From a volumetric flow of > 400 l/h, no

significant increase in cooling output is

achieved. Appropriate measures must be

taken to regulate the flow rate, e.g. balancing valves (Model No. 3301.930/.940).

The built-in Basic controller ensures automatic

normal shut-down operation of the air/water heat

exchanger by the value of the fixed preset switching

difference of 5 K.

6.1.3 General programming information

Using buttons H2, H3 and H4 (fig. 19) you can

change 3 parameters within the preset ranges

(min. value, max. value). Tables 6 and 7 on page 14

show the parameters which can be altered.

6.1.4 Operation of the Basic controller

The display terminal “H1” consists of a 3-position

7-segment display which indicates the temperature

in °C as well as any system messages. The current

enclosure internal temperature is usually displayed

permanently. In the event of a system message, this

will alternate with the internal temperature display.

Note:

With the Basic controller, the temperature is

preset at the factory to +35°C. In order to

save energy, do not set the temperature

lower than that actually necessary.

EN

6Operation

You can operate the air/water heat exchanger using

the controller on the front of the unit (fig. 1, no. 2,

page 4).

6.1 Control using the Basic controller

For unit types 3363.1XX to 3375.1XX.

6.1.1 Display and system analysis

Fig. 19:

6.1.2 Properties

The air/water heat exchanger operates automatically, i.e. after switching on the power supply, the

fan (see fig. 2, page 4) will run continuously and

permanently circulate the internal enclosure air.

The magnetic valve controls the cooling water flow

as specified by the temperature setpoint.

Display and system analysis of the Basic controller

6.1.5 Setting the temperature

The setting of the enclosure internal temperature is

preset at the factory to 35°C. To change the value

press key H2 (▲ K

) or H3 (▼ K2) for one second un-

1

til °1 appears in the display, then confirm with the H4

“set” key.

The set value can then be altered within the preset

parameters (+20°C to +55°C) via the keys H2

(▲ K

) or H3 (▼ K2). Press the H4 “set” key for

1

5 seconds to save the new value. The current enclosure internal temperature is displayed again.

Alarm

no.

HI Internal

LO Internal

E0 Temperature

Tab. 5: Warning messages on the display

System

message

temperature

of enclosure

too high

temperature

of enclosure

too low

sensor faulty

Cause Remedy

Cooling capacity

inadequate/

unit undersized/

unit defective

Ambient temperature too low/

no heat loss in

the enclosure

Malfunction, separation or temperature sensor failure

Check

cooling

capacity/

check unit

Check unit

Check

sensor cable

and replace

if necessary

Rittal air/water heat exchanger assembly instructions 13

Page 14

6 Operation

EN

6.1.6 Setting of system messages

To change the system messages keep the H4 “set”

key pressed for 5 seconds. The controller is now in

programming mode. While in programming mode,

if you do not press any buttons for approx. 60 sec.,

the display will first flash, then the controller will

switch back to normal display mode.

6.1.7 Programming and control

of the Basic controller

See also fig. 25 on page 20.

Progr.

level

1 °1 Internal enclosure

Tab. 6: Setting the setpoint

Progr.

level

Display

screen

Display

screen

Parameters Min.

value

20 55 35 The setting of the enclosure internal temperature is

temperature

setpoint T

Parameters Min.

i

value

Max.

value

Max.

value

You can then navigate in the levels with the H2 (▲ K

or H3 (

▼ K

) keys (see tab. 4).

2

The level is selected by pressing the H4 button.

The parameters are changed with the H2 (▲ K

H3 (

▼ K

) keys. Press the H4 “set” key for 5 seconds

2

to confirm the new value.

Factory

setting

Factory

setting

Description

preset at the factory to 35°C and may be altered within a range of +20°C to +55°C. When the setpoint is

reached, the H2 (▲ K

Description

) key is lit continuously.

1

) or

1

)

1

0 Ps – – – – No function

2 H5 Software version

number

3 AH Alarm – maximum

temperature

4 AL Alarm – minimum

temperature

5 r8 Reset of r6 and r7 0 1 0 Reset of r6 and r7. Set this parameter to 1 to reset the

6 r7 Querying of the

min. internal

temperature

7 r6 Querying of the

max. internal

temperature

Tab. 7: Setting the system messages, monitoring of the min./max. enclosure internal temperature

– – – Displays the current version number of the device

software.

AL +150 50 Maximum temperature alarm (NOT in relation to the

nominal value). HI is displayed alternating with the

internal temperature. The “HI” alarm is displayed

when the internal temperature > AH.

The alarm stops when the internal temperature

< AH –2K.

–50 AH 20 Minimum temperature alarm (NOT in relation to the

nominal value). LO is displayed alternating with the

internal temperature. The “LO” alarm is displayed

when the internal temperature < AL.

The alarm stops when the internal temperature

> AL +2K.

stored maximum and minimum values of r6 and r7 to

the respective current actual value.

–50 +150 0 Stores the min. internal enclosure temperature

occurring after > 1 min.

–50 +150 0 Stores the max. internal enclosure temperature

occurring after > 1 min.

6.1.8 Reset r6 and r7

(min./max. internal temperature)

To reset the stored internal temperatures keep the

H4 “set” key pressed for 5 seconds. Navigate to level

r8 with the H2 (▲ K

14 Rittal air/water heat exchanger assembly instructions

) or H3 (▼ K2) keys. Press the

1

H4 “set” key and change the parameter from 0 to

1 using the H2 (▲ K

) or the H3 (▼ K2) keys.

1

Press the H4 “set” key for 5 seconds to confirm

resetting the values.

Page 15

6 Operation

K1

K2

K1

K2

K1 = 1 sec.

K1 = 1 sec.

K1

K2

K1

K2

K1

K2

K1

K2

K1

K2

K1

K2

= 5 sec.

= 5 sec.

K1

K2

K1

K2

6.1.9 System message contact (K1; floating)

The relay is normally closed. All assigned system

messages lead to the relay dropping out – and

likewise to loss of the control voltage. Terminal strip

X1 provides the connection. For contact data and

occupancy – see the wiring diagram in chapter

“4.6.5 Installing the power supply”, page 11.

6.1.10 Programming overview of Basic controller

SetpKiJt

ParaIeters

K1 fault signal relay

(normally open contact/change-over contact)

– Terminal 3: NC (normally closed)

– Terminal 4: C (connection of the supply voltage to

the fault signal relay)

– Terminal 5: NO (normally open)

The NC and NO definitions refer to the de-energised

state. The switching position of the terminals changes under mains voltage.

EN

Fig. 20: Programming overview of Basic controller

Rittal air/water heat exchanger assembly instructions 15

Page 16

6 Operation

12

4

3

EN

6.2 Control using the e-Comfort controller

For unit types 3363.5XX to 3375.5XX.

Fig. 21: Display and system analysis

of the e-Comfort controller

Key

1 Programming button, also display of the set

temperature unit (degrees Celsius)

2Set button

3 Programming button, also display of the set

temperature unit (degrees Fahrenheit)

4 7-segment display

6.2.1 Properties

– Door limit switch function

– Monitoring of all motors (fans)

– Master-slave function with a maximum of ten units.

One device functions as a master unit. Once the

set temperature is reached by one of the connected slave units or in the event of the door limit

switch function, the affected slave unit will report

to the master unit, which will switch all the other

air/water heat exchangers on or off as required.

– Switching hysteresis: adjustable from 2 – 10 K,

preset to 5 K.

– Visualisation of the current enclosure internal

temperature and all error messages in the 7-segment display.

The current enclosure internal temperature is usually

displayed permanently. In the event of an error message, this alternates with the temperature display.

The unit is programmed using buttons 1 – 3 (fig. 21).

The relevant parameters also appear in the display.

6.2.2 Launching test mode

The e-Comfort controller is equipped with a test

function, whereby the air/water heat exchanger

commences cooling operation independently of the

set temperature or door limit switch function.

Simultaneously press buttons 1 and 2 (fig. 21)

for at least 5 seconds.

The air/water heat exchanger starts running.

After approximately 5 minutes or upon reaching

15°C, test mode will end. The unit switches off and

changes to normal operation.

6.2.3 General programming information

Using buttons 1, 2 and 3 (fig. 21) you can change

the parameters within the preset ranges (min. value,

max. value).

Tables 8 and 9 show the parameters which can be

altered. fig. 25 on page 20 shows which buttons

must be pressed.

Note on switching hysteresis:

With a low hysteresis and short switching

cycles, there is a risk that cooling may

not be adequate or that only partial sections

of the enclosure are cooled.

Note on temperature settings:

With the e-Comfort controller, the temperature is preset at the factory to +35°C.

In order to save energy, do not set the

temperature lower than that actually

necessary.

The air/water heat exchanger operates automatically, i.e. after switching on the power supply, the

fan (see fig. 2, page 4) will run continuously and

permanently circulate the internal enclosure air.

The fan and the magnetic valve are controlled by

In principle, the programming is identical for all

editable parameters.

To enter programming mode:

Press button 2 (“set”) for approx. 5 seconds.

The controller is now in programming mode.

the e-Comfort controller.

The e-Comfort controller has a 7-segment display

(fig. 21, no. 4). After switching on the power supply,

the current software version initially appears on this

display for approx. 2 seconds. In regular operation,

the display shows both the temperature (in degrees

Celsius or Fahrenheit – users may switch between

the two) and any error messages.

16 Rittal air/water heat exchanger assembly instructions

Page 17

6 Operation

While in programming mode, if you do not press any

buttons for approx. 30 sec., the display will first flash,

then the controller will switch back to normal display

mode. The “Esc” display indicates that any changes

made have not been saved.

Press the programming buttons ▲ (°C) or ▼ (°F)

to switch back and forth between the editable

parameters (see tables 5 and 6).

Press button 2 (“set”) to select the displayed

parameter for editing.

The current value of this parameter is displayed.

Press one of the programming buttons ▲ (°C)

or

▼ (°F).

The “Cod” display will appear. In order to be able to

change a value, you must enter the authorisation

code “22”.

Keep the programming button ▲ (°C) held down

until “22” appears.

Press button 2 (“set”) to confirm the code.

You can now alter the parameter within the preset

limits.

Press one of the programming buttons ▲ (°C)

or

▼ (°F) until the required value appears.

Press button 2 (“set”) to confirm the change.

You can now alter other parameters in the same way.

There is no need to re-enter the authorisation code

“22”.

To exit programming mode, press button 2 (“set”)

again for approximately 5 seconds.

“Acc” will appear in the display to indicate that

the changes have been saved. The display then

switches back to regular operation (enclosure internal temperature).

You can also program the e-Comfort controller

using a diagnosis software package (Model No.

3159.100), the supply of which also includes

a connection cable to the PC. The cable connector

on the rear of the e-Comfort controller display serves

as an interface.

6.2.4 Eco-mode

All Rittal TopTherm heat exchangers with e-Comfort

controller from firmware 3.2 have the energy-saving

eco-mode, which is activated in the delivered state.

The eco-mode is used to save energy in the heat

exchanger if there is no thermal load, or there is a low

thermal load in the enclosure (e.g. standby operation, no production or weekend). During this process

the heat exchanger fan in the internal circuit is

switched off as appropriate if the actual enclosure

internal temperature drops to 10 K below the setpoint

temperature set. Also to reliably measure the internal temperature during this process, the fan starts

cyclically for 30 sec. every 10 minutes (see fig. 21).

If the internal temperature reaches the range 5 K

below the setpoint set again, the fan switches back

to continuous operation. If required, the eco-mode

can be deactivated via the control display. For this

purpose switch the parameter from 1 to 0 in the

programming level (see tab. 8, page 18). The fan

then runs continuously.

Time

Setpoint

–5 K

Setpoint

–10 K

ON

OFF

Internal

temperature

Internal

fan status

10 min.

Fig. 22: Diagram of eco-mode

10 min.

30 sec.

EN

Rittal air/water heat exchanger assembly instructions 17

Page 18

EN

6 Operation

6.2.5 Editable parameters

See also fig. 25 on page 20.

Progr.

level

1 St Internal enclosure

2 Mod Control mode 0 1 0 Control mode setting. The temperature control

Display

screen

Parameters Min.

value

20 55 35 The setting of the enclosure internal temperature

temperature

setpoint T

i

Max.

value

Factory

setting

Description

is preset at the factory to 35°C and may be altered

within a range of 20 – 55°C.

is made as factory setting with the magnetic

valve (0). It is, however, possible to change the

temperature control by starting and stopping

the internal fan (1); the magnetic valve then

remains permanently open. To use this control

mode, the Eco parameter must be changed from

1 (on) to 0 (off).

3 Ad Master-slave

identifier

4 CF Change-over °C/°F 0 1 0 The temperature display can be switched from

5 H1 Setting for switching

difference

(hysteresis)

6 H2 Differential for

error message A2

26 ECO Eco-mode operation 0 1 1 Eco-mode OFF: 0 / Eco-mode ON: 1

Tab. 8: Editable parameters

0 19 0 See “6.2.9 Setting the master-slave identifier”,

page 21.

°C (0) to °F (1). The corresponding LED displays

the current temperature unit.

2 10 5 The air/water heat exchanger is preset in the

factory to a switching hysteresis of 5 K. This

parameter should only be changed in consultation

with us. Please contact us for advice.

3 15 5 If the internal enclosure temperature exceeds

the set value by more than 5 K, then error

message A2 (enclosure internal temperature

too high) appears on the display terminal.

If necessary, the differential may be altered here

within the range of 3 – 15 K.

18 Rittal air/water heat exchanger assembly instructions

Page 19

6 Operation

X2

CMC

RTT

Master

Adr. : 09

X1

X2

X3

X1

X2

X3

X1

X2

X3

X1

X2

X3

X2

X3

X2

X2

X2

X2

X2

X2

St. St. St.

Bu.

St.

Bu.

X2

Adr. : 11 Adr. : 12RTT

Slave

RTT

Slave

Adr. : 19RTT

Slave

St.

Bu.

St.

Bu.

3

2

1

6.2.6 Bus connection

(only when interconnecting several units

with an e-Comfort controller)

When using several air/water heat exchangers,

the serial unit interface can be used to connect up

to ten air/water heat exchangers with the bus cable

(Model No. 3124.100).

Note:

The electrical signals at the X2 interface are

of an extra-low voltage (not extra-low safety

voltages in accordance with EN 60 335-1).

When interconnecting, please note the following:

– De-energise the air/water heat exchangers to

be connected.

– Ensure proper electrical insulation.

– Make sure the cables are not laid in parallel to

power lines.

– Make sure that the lines are short.

EN

Fig. 23: Connection example: Master-slave operation

Key

1 Serial interface

2 Serial interface cable

3 Master-slave bus cable (Model No. 3124.100)

RTT Rittal TopTherm air/water heat exchanger

X1 Supply connection/Door limit switch/Alarms

Adr.: 06 Adr.: 11 Adr.: 12 Adr.: 13 Adr.: 14 Adr.: 15

L2

L1

N

X10

Fig. 24: Connection example: Door limit switch and master-slave operation

Key

1 Master air/water heat exchanger

2 Slave air/water heat exchanger

3 2-door enclosure with two door limit switches

4 Enclosure with door limit switch

X2 Master-slave connection Sub-D, 9-pole

X3 Serial interface Sub-D, 9-pole

St. Sub-D connector, 9-pole

Bu. Sub-D jack, 9-pole

Adr. Address

X2 X2 X2 X2 X2 X2

1

1

2345

PE

1

22 2 2 2

L1PE1

L2 L3

X10

2345

2

L2

L1

1

2345

PE

N

X10 X10 X10 X10

L1PE1

L2 L3

2345

3

L1PE1

L2 L3

2345

4

56

L1PE1

L2 L3

34432

2345

X2

X10

5

4

23

1

PE

N

L2

L1

Adr.: 16

Rittal air/water heat exchanger assembly instructions 19

Page 20

EN

6 Operation

6.2.7 Programming overview of e-Comfort controller

= 5 sec.

= 5 sec.

Fig. 25: Programming overview of e-Comfort controller

20 Rittal air/water heat exchanger assembly instructions

Page 21

6 Operation

6.2.8 Defining system messages for evaluation

System messages are shown on the display screen

of the e-Comfort controller via the displays A01 to

A more detailed explanation of the system messages

may be found in section “6.2.10 Evaluating system

messages”, page 22. See also fig. 25 on page 20.

A20 and E0.

Progr.

level

7 A01 0 2 0 Enclosure door open

8 A02 0 2 0 Internal temperature of enclosure too high

9 A08 0 2 1 Condensate warning

10 A10 0 2 1 Fan blocked or defective

11 A16 0 2 1 Internal temperature sensor

12 A18 0 2 1 EPROM

13 A19 0 2 0 LAN/Master-Slave

14 A20 0 2 0 Voltage drop

Tab. 9: System messages which may be evaluated via relays

The system messages A01 – A20 may additionally

be evaluated via two floating system message

relays. In this way, one of the two system message

relays may be allocated to each system message.

System message relays with normally open contact,

see wiring diagrams at section “4.6.5 Installing the

power supply”, page 11:

– Terminal 3: NO (normally open, relay 2)

– Terminal 4: Connection of the supply voltage to the

system message relay

– Terminal 5: NO (normally open, relay 1)

Display

screen

Min.

value

Max.

value

Factory

setting

Type or location of fault

6.2.9 Setting the master-slave identifier

When several air/water heat exchangers are connected together (maximum 10), one of the air/water

heat exchangers must be defined as the “master”

and the others as “slaves”. For this purpose, assign

a corresponding identifier (address) to each air/

water heat exchanger which will enable the air/water

heat exchanger to be identified in the network.

If one of the slave units reaches the set temperature

or if the door limit switch function is activated, the

affected slave unit will report to the master unit,

which then deactivates all the other air/water heat

The definition NO refers to the de-energised state.

exchangers.

As soon as power is applied to the air/water heat

exchanger, both system message relays (relay 1

and 2) energise.

This is the normal operating state of the air/water

heat exchanger.

As soon as a system message occurs or the power

supply is interrupted, the corresponding relay will

drop out and open the contact.

Notes:

– Only one unit may be configured as

master, and its identifier must match

the number of connected slave units.

– The slave units must have different

identifiers.

– The identifiers must be numbered in

ascending order without any gaps.

Program system messages with the value

0: System message is not sent to the system

message relays, but merely appears in the

display

1: System message is evaluated by relay 1

2: System message is evaluated by relay 2

3: System message is neither sent to the system

message relay, nor does it appear in the display

(setting can only be made using RiDiag soft-

ware)

EN

Rittal air/water heat exchanger assembly instructions 21

Page 22

6 Operation

EN

On the master air/water heat exchanger

(00 = factory setting), set the number of slave units

present in the network:

01: Master with 1 slave air/water heat exchanger

02: Master with 2 slave air/water heat exchangers

03: Master with 3 slave air/water heat exchangers

04: Master with 4 slave air/water heat exchangers

05: Master with 5 slave air/water heat exchangers

06: Master with 6 slave air/water heat exchangers

07: Master with 7 slave air/water heat exchangers

08: Master with 8 slave air/water heat exchangers

09: Master with 9 slave air/water heat exchangers

Master

02

Fig. 26: Master-slave connection (example)

Slave

11

Slave

12

For details of how to set the identifier,

see “6.2.5 Editable parameters”, page 18 or

“6.2.7 Programming overview of e-Comfort

controller”, page 20, parameter “Ad”.

On the slave air/water heat exchanger

(00 = factory setting), set its own address:

11: Slave air/water heat exchanger No. 1

12: Slave air/water heat exchanger No. 2

13: Slave air/water heat exchanger No. 3

14: Slave air/water heat exchanger No. 4

15: Slave air/water heat exchanger No. 5

16: Slave air/water heat exchanger No. 6

17: Slave air/water heat exchanger No. 7

18: Slave air/water heat exchanger No. 8

19: Slave air/water heat exchanger No. 9

6.2.10 Evaluating system messages

In the e-Comfort controller, system messages are

indicated by a number in the display.

Display

screen

A01 Enclosure door open

A02

A08 Condensate warning

A10 Fan Blocked or defective Clear the blockage; replace if necessary

A16

A18 EPROM error New board installed incorrectly

A19 LAN/Master-Slave Master and slave not connected Check setting and cable

A20 Voltage drop Error display not shown Event is stored in the log file

System message Possible cause Measures to rectify the fault

Internal temperature

of enclosure too high

Internal temperature

sensor

Door open or door limit switch

incorrectly positioned

Cooling capacity inadequate/

unit undersized

Condensate discharge kinked

or blocked

Open or short-circuit Replace

Close door, position door limit switch

correctly, check connection if necessary

Check cooling capacity

Check condensate drainage;

correct any kinks or blockages in the hose

Software update needed (only following

board installation with more recent software): Enter the programming level with

Code 22; press button 1 and confirm with

“set” until “Acc” appears. Next, disconnect

the unit from the mains and reconnect.

Connection problem between the

E0 Display message

Tab. 10: Troubleshooting with the e-Comfort controller

22 Rittal air/water heat exchanger assembly instructions

display and the controller board

Cable defective; connection loose Replace the boards

Reset: Switch power supply off, then switch

on again after approx. 2 sec.

Page 23

7 Inspection and maintenance

7 Inspection and maintenance

Risk of electric shock!

The unit is live. Switch off the power

supply before opening, and take suitable

precautions against it being accidentally

switched on again.

7.1 General

The air/water heat exchanger is largely maintenance

free. The water circuit is checked at the factory for

leaks and subjected to a function trial run.

The installed maintenance-free fan is mounted on ball

bearings, protected against moisture and dust, and

fitted with a temperature monitor. The life expectancy

is at least 30,000 operating hours. If dirt is present in

the cooling water, a filter must be fitted.

Maintenance interval: 2,000 operating hours.

Caution!

Risk of fire!

Never use flammable liquids for cleaning.

Sequence of maintenance measures:

– Check the level of dirt.

– Activate test mode; cooling function OK?

– Check the noise generation of the fan.

EN

Fig. 29: Remove the cover with fan

Fig. 30: Disconnect the connector from the display

Fig. 27: Disconnect the mains plug (X1)

(Comfort version shown in figure)

Fig. 28: Remove the fastening screws for the cover with fan

8 Emptying, storage and disposal

Caution! Risk of damage!

The air/water heat exchanger

must not be subjected to temperatures

above +70°C during storage.

During storage, the air/water heat exchanger must

stand upright.

Disposal can be performed at the Rittal plant.

Please contact us for advice.

Emptying (for units with Basic controller only):

During storage and transportation below freezing

point, the air/water heat exchanger should be

drained completely in the water supply direction

using compressed air. This requires that the magnetic valve is opened.

For the e-Comfort controller, this is achieved by

simultaneously pressing the H2 (°C key) and H4

(/set key) keys for 5 seconds. The magnetic valve

is then opened for approximately 5 minutes.

Rittal air/water heat exchanger assembly instructions 23

Page 24

9 Technical specifications

EN

9 Technical specifications

– Observe the mains connection data (voltage

and frequency) as per the rating plate.

– Observe the pre-fuse as per the specifications

on the rating plate.

Fig. 31: Rating plate (Technical specifications)

Unit Model No.

Basic controller, RAL 7035 – 3363.100 3363.104 3364.100 3364.104

e-Comfort controller, RAL 7035 – 3363.500 3363.504 3364.500 3364.504

Rated voltage

Rated current A 0.18/0.18

Pre-fuse T A 4.0

Motor circuit-breaker A – – – –

Transformer circuit-breaker A – – – –

Miniature circuit-breaker or gG slow fuse (T) – 䡲 䡲 䡲 䡲

Total cooling power Pc

to DIN 3168 L35 W10 400 l/h

Power consumption Pel

to DIN 3168

Water connection –

Air throughput per fan

(unimpeded air flow)

Permissible pressure bar 1…10

Operating temperature range °C +1…+70

Setting range °C +20…+55

Noise level dB (A) 42 44

Protection category to IEC 60 529 – IP 55

Dimensions (W x H x D) mm 280 x 550 x 120

Weight kg 8 9

Volt

Hz

kW 0.5 1.0 0.95

kW 0.037/0.038

1

/2˝ hose nozzle or G 3/8˝ external thread

m3/h 290/345

230, 1~,

50/60

24 Rittal air/water heat exchanger assembly instructions

Page 25

9 Technical specifications

Unit Model No.

Basic controller, RAL 7035 – 3373.100 3373.110 3373.140 3373.104 3373.114 3373.144

e-Comfort controller, RAL 7035 – 3373.500 3373.510 3373.540 3373.504 3373.514 3373.544

EN

Rated voltage

Rated current A 0.49/0.61 0.98/1.25 0.28/0.35 0.49/0.61 0.98/1.25 0.28/0.35

Pre-fuse T A 4.0 – – 4.0 – –

Motor circuit-breaker A – – – – – –

Transformer circuit-breaker A – 3.5…5.0 3.5…5.0 – 3.5…5.0 3.5…5.0

Miniature circuit-breaker or gG slow fuse (T) – 䡲 ––䡲 ––

Total cooling power Pc

to DIN 3168 L35 W10 400 l/h kW 2.0

Power consumption P

to DIN 3168

Water connection –

Air throughput of fans

(unimpeded air flow)

Permissible pressure bar 1…10

Water inlet temperature °C +1…+30

Operating temperature range °C +1…+70

Setting range °C +20…+55

Noise level dB (A) 50

Protection category to IEC 60 529 – IP 55

Dimensions (W x H x D) mm 400 x 950 x 145

Weight kg 20 23 20 23

el

Volt

Hz

kW 0.11/0.14

3

/h 880/950

m

230, 1~,

50/60

115, 1~,

50/60

400, 2~,

50/60

1

/2˝ hose nozzle or G 3/8˝ external thread

230, 1~,

50/60

115, 1~,

50/60

400, 2~,

50/60

Unit Model No.

Basic controller, RAL 7035 – 3374.100 3374.110 3374.140 3374.104 3374.114 3374.144

e-Comfort controller, RAL 7035 – 3374.500 3374.510 3374.540 3374.504 3374.514 3374.544

Rated voltage

Rated current A 0.76/1.01 1.55/2.05 0.44/0.58 0.76/1.01 1.55/2.05 0.44/0.58

Pre-fuse T A 4.0 – – 4.0 – –

Motor circuit-breaker A – – – – – –

Transformer circuit-breaker A – 3.5…5.0 3.5…5.0 – 3.5…5.0 3.5…5.0

Miniature circuit-breaker or gG slow fuse (T) – 䡲 ––䡲 ––

Total cooling power Pc

to DIN 3168 L35 W10 400 l/h kW 3.0 2.8

Power consumption P

to DIN 3168

Water connection –

Air throughput of fans

(unimpeded air flow)

Permissible pressure bar 1…10

Water inlet temperature °C +1…+30

Operating temperature range °C +1…+70

Setting range °C +20…+55

Noise level dB (A) 60

Protection category to IEC 60 529 – IP 55

Dimensions (W x H x D) mm 400 x 950 x 145

Weight kg 23 26 23 26

el

Volt

Hz

kW 0.17/0.23

3

/h 1150/1300

m

230, 1~,

50/60

115, 1~,

50/60

400, 2~,

50/60

1

/2˝ hose nozzle or G 3/8˝ external thread

230, 1~,

50/60

115, 1~,

50/60

400, 2~,

50/60

Rittal air/water heat exchanger assembly instructions 25

Page 26

EN

9 Technical specifications

Unit Model No.

Basic controller, RAL 7035 – 3375.100 3375.110 3375.140 3375.104 3375.114 3375.144

e-Comfort controller, RAL 7035 – 3375.500 3375.510 3375.540 3375.504 3375.514 3375.544

Rated voltage

Rated current A 1.45/1.45 2.25/2.25 0.80/0.80 1.45/1.45 2.25/2.25 0.80/0.80

Pre-fuse T A 4.0 – – 4.0 – –

Motor circuit-breaker A––––––

Transformer circuit-breaker A – 3.5…5.0 3.5…5.0 – 3.5…5.0 3.5…5.0

Miniature circuit-breaker or gG slow fuse (T) – 䡲 ––䡲 ––

Total cooling power Pc

to DIN 3168 L35 W10 400 l/h kW 5 4.5

Power consumption P

to DIN 3168

Water connection –

Air throughput of fans

(unimpeded air flow)

Permissible pressure bar 1…10

Water inlet temperature °C +1…+30

Operating temperature range °C +1…+70

Setting range °C +20…+55

Noise level dB (A) 62

Protection category to IEC 60 529 – IP 55

Dimensions (W x H x D) mm 400 x 1400 x 220

Weight kg 39 42 39 42

el

Volt,

Hz

kW 0.17/0.17 0.18/0.18 0.17/0.17 0.18/0.18

3

/h 1490/1660

m

230, 1~,

50/60

115, 1~,

50/60

400, 2~,

50/60

1

/2˝ hose nozzle or G 3/8˝ external thread

450

230, 1~,

50/60

115, 1~,

50/60

400, 2~,

50/60

26 Rittal air/water heat exchanger assembly instructions

Page 27

15

55

75

40

10

71

91

33

32

73

15

55

40

91

33

32

73

75

10

71

10 List of spare parts

3363.XXX, 3364.XXX

10 List of spare parts

EN

3373.XXX, 3374.XXX, 3375.XXX

Fig. 32: Spare parts for 3363.XXX, 3364.XXX

Key

10 Fan, complete

15 Dispatch bag

32 Magnetic valve, complete

33 Non-return valve (only for 33XX.5XX)

40 Controller board

55 Display

71 Temperature probe

73 Float-actuated switch (only for 33XX.5XX)

75 Cover

91 Heat exchanger

Fig. 33: Spare parts for 3373.XXX, 3374.XXX, 3375.XXX

Note:

As well as the spare part number,

when ordering spare parts the following

information must be provided:

–Unit model

– Fabrication number

– Date of manufacture

This information may be found

on the rating plate.

Rittal air/water heat exchanger assembly instructions 27

Page 28

11 Further technical information

11 Further technical information

EN

11.1 Hydrological data

To avoid system damage and to ensure safe

operation, Rittal GmbH & Co. KG recommends

the use of system water or an additive whose

composition does not differ from that presented

in the following summary:

Hydrological data Unit

3363.100/.500/

3364.100/.500/

–

3373.100/.110/.140/.500/.510/.540

3374.100/.110/.140/.500/.510/.540

3375.100/.110/.140/.500/.510/.540

pH value 7 – 8.5 6 – 9

Calcium hardness °dH > 3 < 8 1 – 12

Free carbonic acid mg/dm38 – 15 1 – 100

Corresponding carbonic acid mg/dm38 – 15 free

Aggressive carbonic acid mg/dm3free 0 – 400

Sulphides mg/dm3free free

Oxygen mg/dm3< 10 < 10

Chloride ions mg/dm3< 50 < 200

Sulphate ions mg/dm3< 250 < 500

Nitrates and nitrites mg/dm3< 10 < 100

COD mg/dm3< 7 < 40

Ammonia mg/dm3< 5 < 20

Iron mg/dm3< 0.2 free

Manganese mg/dm3< 0.2 free

Conductivity μS/cm < 2200 < 4000

Evaporation residue mg/dm3< 500 < 2000

Potassium permanganate mg/dm3< 25 < 40

mg/dm3< 3

Suspended matter

1)

The complete absence of corrosion under experimental conditions suggests that solutions with a significantly higher salt content

and greater corrosion potential (such as seawater) can still be tolerated.

mg/dm3> 3 < 15; partial current purification recommended

mg/dm3> 15; continuous purification recommended

Model No. Model No.

3363.104/.504

3364.104/.504

3373.104/.114/.144/.504/.514/.544

3374.104/.114/.144/.504/.514/.544

3375.104/.114/.144/.504/.514/.544

1)

Tab. 11: Hydrological data

28 Rittal air/water heat exchanger assembly instructions

Page 29

150

300

600

900

1000

0

200 300 400

450

750

500

P

V

.

150

300

600

900

1000

0

200 300 400

450

750

500

P

V

.

200

400

800

1200

1000

0

200 300 400

600

1000

500

P

V

.

1000

0

200

200

400

600

800

1000

1200

300 400 500

P

V

.

.

11.2 Characteristic curves

11 Further technical information

11.2.1 Water resistance

6P: Water resistance [mbar]

.

V: Volumetric flow [l/h]

Fig. 34: Water resistance 3363.XXX

6P: Water resistance [mbar]

.

V: Volumetric flow [l/h]

Fig. 37: Water resistance 3374.XXX

700

600

EN

6P: Water resistance [mbar]

.

V: Volumetric flow [l/h]

Fig. 35: Water resistance 3364.XXX

500

P

400

300

200

100

1000

200 300 400

V

6P: Water resistance [mbar]

.

V: Volumetric flow [l/h]

Fig. 38: Water resistance 3375.XXX

500

6p: Water resistance [mbar]

Fig. 36: Water resistance 3373.XXX

Rittal air/water heat exchanger assembly instructions 29

.

V: Volumetric flow [l/h]

Page 30

12 Appendix 1: Cut-out and hole sizes

A

E

A

E

1

2

3

A

E

12 Appendix 1: Cut-out and hole sizes

EN

12.1 Dimensions for external and internal mounting

Mounting cut-out for

external mounting

250

550

256

280

1 1

520

506

Mounting cut-out for

internal mounting

20

20

49

250

91

280

550

520

15

120

120

3

25

25

100

Ø 6.5 (4x for internal

and external mounting)

1

Water connections:

3

/8˝ external thread

or G

/2˝ hose nozzle

Condensate discharge

2

1

/2˝

Fig. 39: 3363.XXX/3364.XXX

30 Rittal air/water heat exchanger assembly instructions

Page 31

12 Appendix 1: Cut-out and hole sizes

A

E

A

E

1

2

3

A

E

Mounting cut-out for

external mounting

15

920

950

400

350

250

Mounting cut-out for

internal mounting

1

20.5

15

32.5

255

350

25

40

920

950

400

250