Rio RIO09HP115V1A, RIO09HP230V1A, RIO12HP230V1B, RIO12HP115V1A, RIO18HP230V1A Installation, Service & Troubleshooting

...Page 1

DUCTLESS SYSTEM

Installation, Service & Troubleshooting

Models:

RIO09HP115V1A

RIO12HP115V1A

RIO09HP230V1A

RIO09HP230V1B

RIO12HP230V1A

RIO12HP230V1B

RIO18HP230V1A

RIO24HP230V1A

Page 2

Table of Contents

Safety Precautions & Warnings.........................................................................................................................

Model Number Identication............................................................................................................................

Physical & Electrical Data.................................................................................................................................

Product Introduction.........................................................................................................................................

Refrigeration Cycles and Components............................................................................................................

Indoor & Outdoor Components.......................................................................................................................

Basic & Protection Functions............................................................................................................................

Remote Control Operation................................................................................................................................

Refrigerant Lines, Connection, Evacuating and Charging............................................................................

Installation and Filter Maintenance.................................................................................................................

Electrical Schematics..........................................................................................................................................

3

4

5 - 7

8

9 - 13

14 - 15

16 - 21

22 - 25

26 - 29

30 -35

36 - 44

Outdoor Circuit Board........................................................................................................................................

Troubleshooting Indoor Components..............................................................................................................

Troubleshooting Outdoor Components...........................................................................................................

Fault Codes & Status Displays...........................................................................................................................

Troubleshooting Flow Charts............................................................................................................................

Disassembly of Indoor Units.............................................................................................................................

Disassembly of 9,000 & 12,000 btuh Outdoor Systems.................................................................................

Disassembly of 18,000 and 24,000 btuh Outdoor systems.............................................................................

Appendix 1 - 3 Temperature Sensor Resistance Tables..................................................................................

45

46 - 47

48 - 56

57 - 78

79 - 105

106 - 111

112 - 117

118 - 123

123 - 129

2

Page 3

Safety Precautions & Warnings

!

Installing, starting up, and servicing air conditioner can be

hazardous due to system pressure, electrical components,

and equipment location, etc. Only trained, qualied

installers and service personnel are allowed to install, startup, and service this equipment. Untrained personnel can

perform basic maintenance functions such as cleaning

coils. All other operations should be performed by trained

service personnel. When handling the equipment, observe

precautions in the manual and on tags, stickers, and labels

attached to the equipment. Follow all safety codes. Wear

safety glasses and work gloves. Keep quenching cloth and

re extinguisher nearby when brazing. Read the instructions

thoroughly and follow all warnings or cautions in literature

and attached to the unit. Consult local building codes and

current editions of national as well as local electrical codes.

Recognize the following safety information:

Warning: Incorrect handling could result in

!

personal injury or death.

Caution: Incorrect handling may result in minor

!

injury, or damage to product or property.

Warning

!

• Never install the unit in a place where a combustible

gas might leak, or it may lead to re or explosion.

• Make a proper provision against noise when the unit is

installed at a telecommunication center or hospital.

• Provide a GFIC circuit when the local or national

electric code requires it.

• Never wash the unit with water.

• Handle unit transportation with care. Use two people

when the weight exceeds the capacity for one person.

• Never touch the heat exchanger ns with bare hands,

sharp edges could cause personal injury.

• Never touch the compressor or refrigerant tubing

without proper hand protection.

• Do not operate th unit without the air lters in place.

• Should any emergency occur, stop the unit and

disconnect the electrical supply.

• Properly insulate tubing running inside the room to

prevent water damage from condensation.

!

All installation or repair work shall be performed by your

dealer or a specialized subcontractor as there is the risk of

re, electric shock, explosion or injury

Caution

Warning

!

All electrical work must be performed by a qualied,

licensed electrician according to local and national

codes as well mas the instructions provided in the

manual.

• Before installing, modifying, or servicing the

system, the main electrical disconnect must be

off. There may be more than one disconnect

switch. Lock out and tag switch with a suitable

warning label.

• Never supply power to the unit unless all wiring

and tubing are completed, reconnected and

checked.

• This system adopts highly dangerous electrical

voltage. Incorrect connections or inadequate

grounding can cause personal injury or death.

Refer to your local and national codes for proper

grounding.

• Have the unit properly grounded with all

connections tight. Loose connections can cause

overheating and a possible re hazard.

Warning

!

Warning

Pressurized Refrigerant

Personal injury could result in failure to follow this warning.

Systems contain oil and refrigerant under high pressure,

proper refrigerant handling techniques should be

completed by a qualied technician.

!

Warning

Live Electrical Components

Personal injury, property damage, or death could result in

failure to follow this warning.

Follow all electrical precautions when servicing this

system, it may be necessary to service or troubleshoot with

live electrical circuits. All work should be completed by a

qualied technician.

3

Page 4

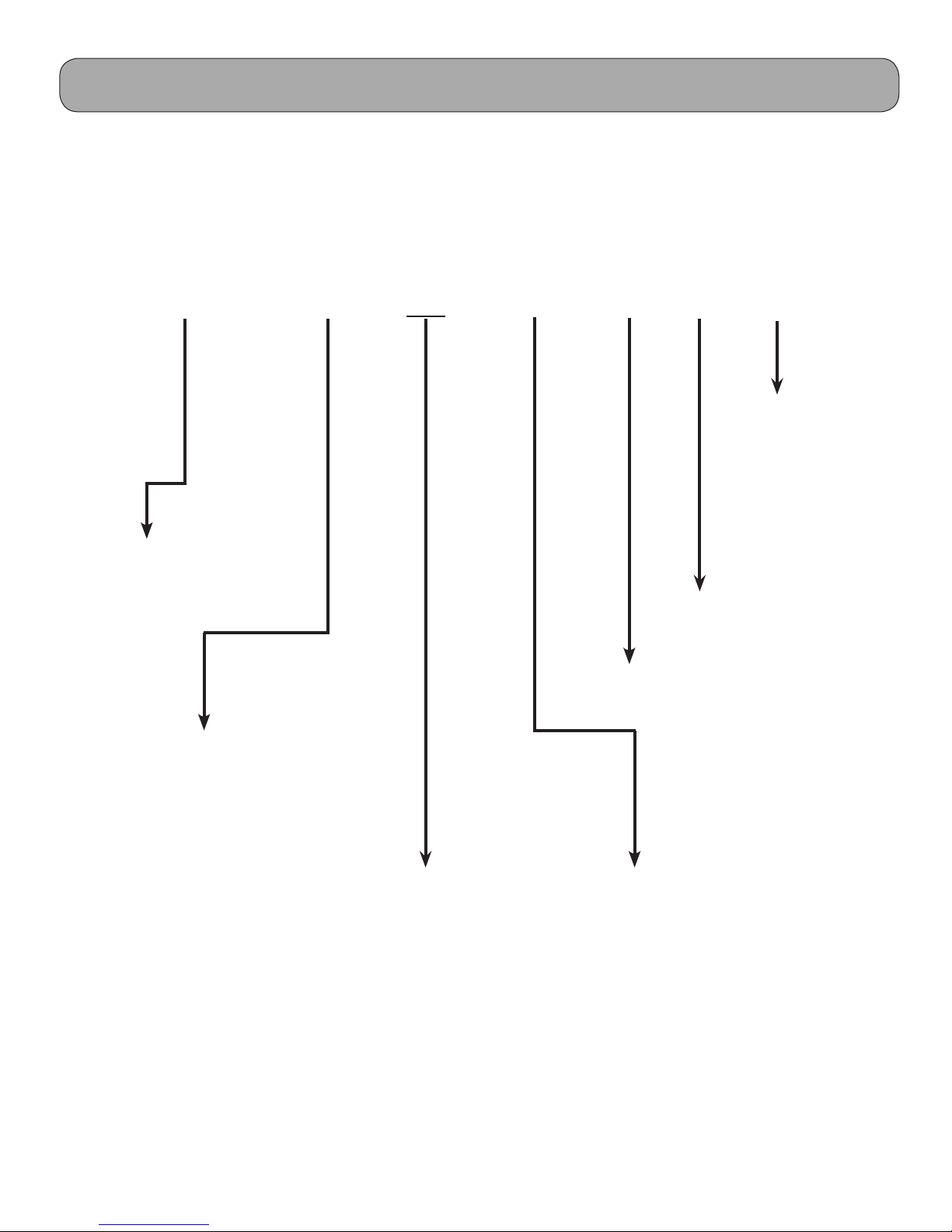

Model Number Identication

Product Catalog Number-Nomenclature

Example RIO24HP230V1AH

RIO 24 HP 230V 1 A H

S - System

O - Outdoor

H - Indoor High Wall

D - Indoor Duct

C - Indoor Cassette

F - Indoor Floor/Ceiling

RIO

NEO

TERRA

Revision Level

09 - 9,000 btuh

12 - 12,000 btuh

18 - 18,000 btuh

24 - 24,000 btuh

AC - Cooling Only

HP - Heat Pump

HC - Heat/Cool

Style/Color Designation

230V - 208/20V 60Hz 1PH

115V - 115V 60Hz 1PH

4

Page 5

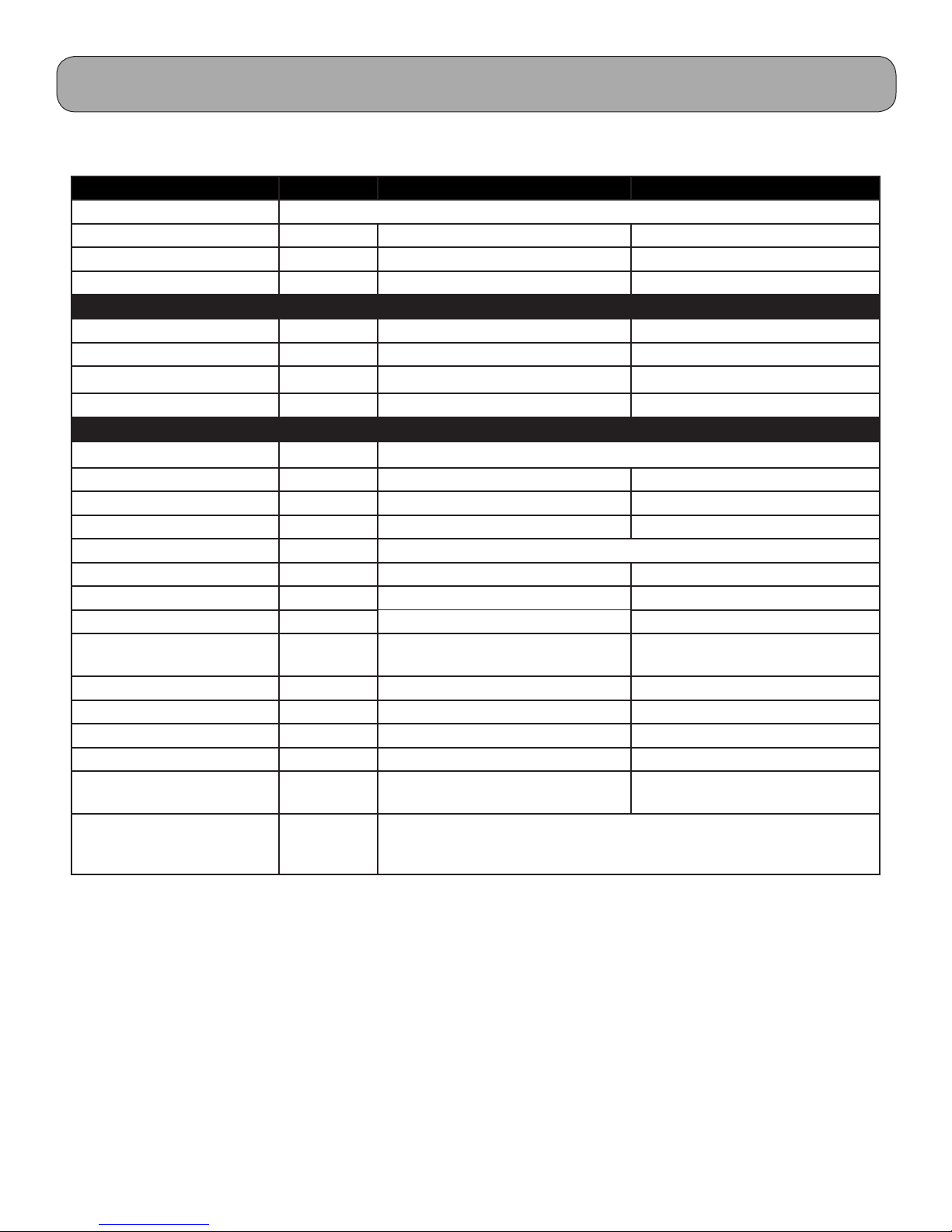

Physical & Electrical Data, cont.

Model RIO09HP115V1A RIO12HP115V1A

System Type Heat Pump

Power Supply 115v / 60Hz 115V / 60Hz

Rated Current Cooling Amps 9.0 15.0

Rated Current Heating Amps 9.5 15.5

System Performance

Cooling Cap (Min/Max) Btu/h 9,000 (3,500-11,000) 11,800 (3,300-12,500)

Heating Cap (Min/Max) Btu/h 9,800 (2,500-11,000) 13,000 (3,400-13,500)

Operating Range - Cooing deg F 64 - 113 64 - 113

Operating Range - Heating deg F 5 - 75 5 - 75

System Specications

Compressor Type DC Inverter-driven Twin Rotary

Sound Pressure - Outdoor dBA 53 55

Net/Gross Weight Indoor lbs 19/26 19/26

Net/Gross Weight Outdoor lbs 75/84 75/84

Condenser Coil Type

Refrigerant/Charge oz R410a /37.5 R410a / 41.1

Line Set Size Liq. - Suction 1/4” - 3/8” 1/4” - 3/8”

Pre-Charged Lineset Ft. Feet 25 25

Additional Refrigerant

charge/additional feet

Max. Total Piping Length Feet 66 66

Max. Elevation Feet 33 33

MCA Amps 13 15

MOCP/Breaker Size Amps 20 25

Wire Size to Outdoor Unit, #

of Wires per Local Code

Wire Size and # of

Conductors from Indoor to

Outdoor unit

oz 0.2 0.2

awg 14* 12*

14awg/4c*

*Comply with National Electric Code or Local Electric Code in selecting proper wire and circuit breaker

size. National Code or Local Code, should supersede wire sizes above.

Note: The manufacturer reserves the right to modify the design and/or change the specications without notice. Please

Note: The manufacturer reserves the right to modify the design and/or change the specications without notice. Please

refer to specic installation manual for current information.

refer to specic installation manual for current information.

5

Page 6

Physical & Electrical Data, cont.

Model RIO09HP230V1A & 1B

System Type Heat Pump

Power Supply 208-230v / 60Hz 208-230V / 60Hz

Rated Current Cooling Amps 3.9 5.4

Rated Current Heating Amps 3.4 4.7

System Performance

Cooling Cap (Min/Max) Btu/h 9,000 (3,800-11,500) 12,000 (3,300-12,500)

Heating Cap (Min/Max) Btu/h 9,000 (3,300-11,500) 12,000 (3,400-12,500)

Operating Range - Cooing deg F 5 - 109 5 - 109

Operating Range - Heating deg F 5 - 75 5 - 75

System Specications

Compressor Type DC Inverter-driven Twin Rotary

Sound Pressure - Outdoor dBA 49 52

Net/Gross Weight Indoor lb 19/25 20/27

Net/Gross Weight Outdoor lb 64/73 68/77

Condenser Coil Type

Refrigerant/Charge oz R410a / 26.1 R410a / 35.3

Line Set Size Liq. - Suction 1/4” - 3/8” 1/4” - 3/8”

Pre-Charged Lineset Ft. Feet 25 25

Additional Refrigerant

charge/additional feet

Max. Total Piping Length Feet 50 50

Max. Elevation Feet 33 33

MCA Amps 10 10

MOCP/Breaker Size Amps 15 15

Wire Size to Outdoor Unit, #

of Wires per Local Code

Wire Size and # of

Conductors from Indoor to

Outdoor unit

oz 0.2 0.2

awg 14* 14*

14awg/4c*

RIO12HP230V1A & 1B

*Comply with National Electric Code or Local Electric Code in selecting proper wire and circuit breaker

size. National Code or Local Code, should supersede wire sizes above.

Note: The manufacturer reserves the right to modify the design and/or change the specications without notice. Please

refer to specic installation manual for current information.

6

Page 7

Physical & Electrical Data, cont.

Model RIO18HP230V1A RIO24HP230V1A

System Type Heat Pump

Power Supply 208-230v / 60Hz 208-230V / 60Hz

Rated Current Cooling Amps 7.9 11.5

Rated Current Heating Amps 11.8 13.0

System Performance

Cooling Cap (Min/Max) Btu/h 18,000 (4,500-21,000) 22,000 (6,400-24,000)

Heating Cap (Min/Max) Btu/h 19,200 (4,000-23000) 24,200 (4,100-26,600)

Operating Range - Cooing deg F 5 - 109 5 - 109

Operating Range - Heating deg F 5 - 75 19 - 75

System Specications

Compressor Type DC Inverter-driven Twin Rotary

Sound Pressure - Outdoor dBA 56 53

Net/Gross Weight Indoor lb 27/35 33/44

Net/Gross Weight Outdoor lb 106 / 117 115 / 126

Condenser Coil Type

Refrigerant/Charge oz R410a / 45.9 R410a / 54.7

Line Set Size Liq. - Suction 1/4” - 1/2” 1/4” - 1/2”

Pre-Charged Lineset Ft. Feet 25 25

Additional Refrigerant

charge/additional feet

Max. Total Piping Length Feet 82 82

Max. Elevation Feet 33 33

MCA Amps 15 17

MOCP/Breaker Size Amps 25 25

Wire Size to Outdoor Unit, #

of Wires per Local Code

Wire Size and # of

Conductors from Indoor to

Outdoor unit

oz 0.2 0.2

awg 14* 14*

14awg/4c*

*Comply with National Electric Code or Local Electric Code in selecting proper wire and circuit breaker

size. National Code or Local Code, should supersede wire sizes above.

Note: The manufacturer reserves the right to modify the design and/or change the specications without notice. Please

refer to specic installation manual for current information.

7

Page 8

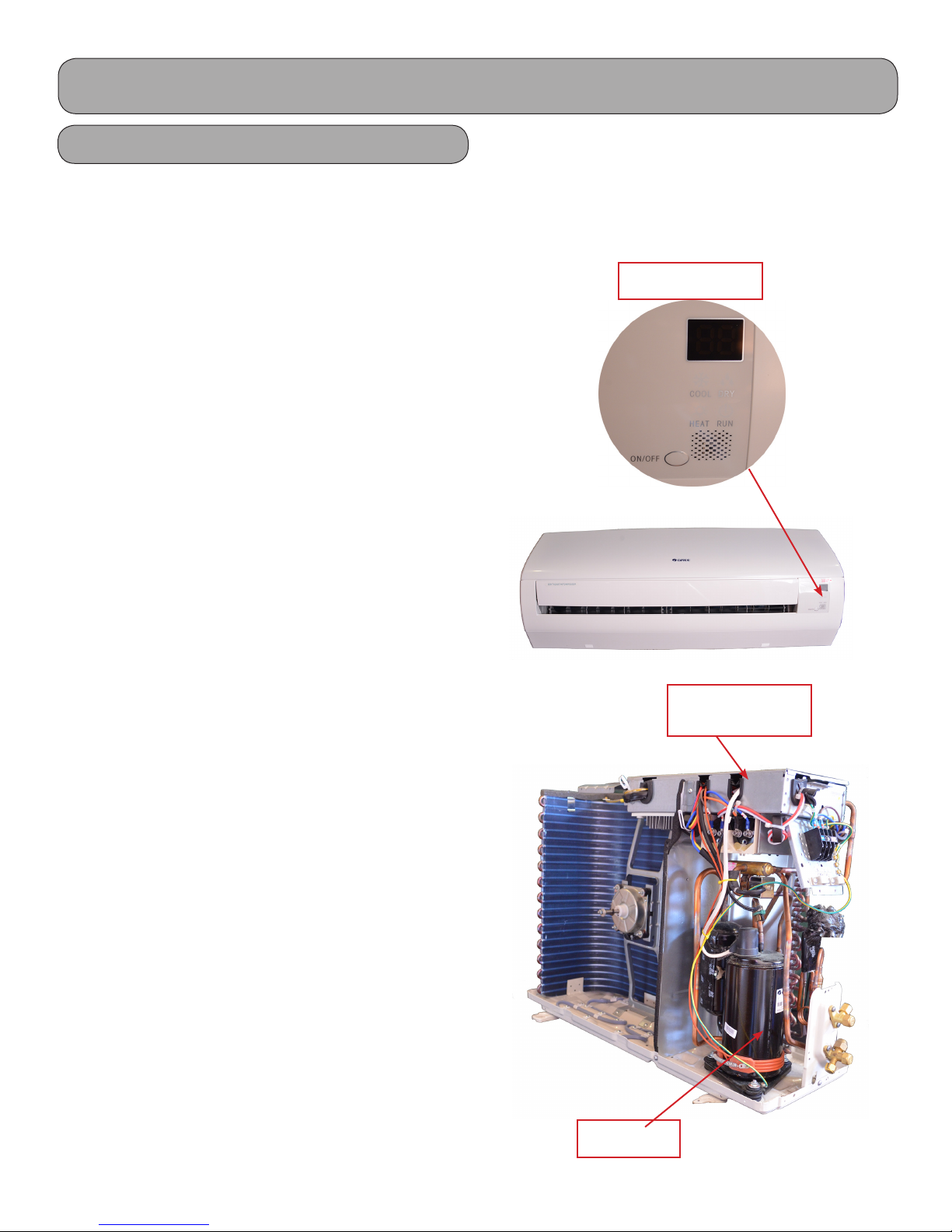

Product Introduction

System Overview

e RIO Ductless split heat pumps are single zone

units available in size from 9000 btuh to 24,000 btuh

providing heating and cooling. All comfort settings

are controlled by a remote control. e RIO unit has

many features to enhance comfort and eciency. e

operation of these features will be explained later in

this service manual.

Superior inverter technology is used to control

capacity while maintaining maximum eciency.

e RIO systems are equipped with G10 inverter

technology providing precise control over the

compressor frequency based on operating pressures

and temperatures. Should an abnormal condition

occur, the soware will adjust the compressor

frequency or shut down the system indicating the

appropriate fault.

Indoor Display

e indoor unit contains a digital display, which

will indicate the current fault. e evaporator,

swing motors, fan motors and circuit board are also

components of the indoor unit. e indoor units have

a on/o switch to bypass the remote control if lost or

batteries fail. is will be explained later in this service

manual.

e systems require R410A and are pre-charged for 25’

of lineset. Please refer to your installation manual for

additional charge for linesets longer than 25’.

e maximum allowable line li and distances vary

by model, please refer to the charts in the manual for

proper lineset applications.

e systems use a PVE oil and should require no

additional oil. All RIO units utilize an Oil Return

Mode which will return oil to the compressor should

the need arise.

Circuit Board with

G10 Technology

8

Compressor

Page 9

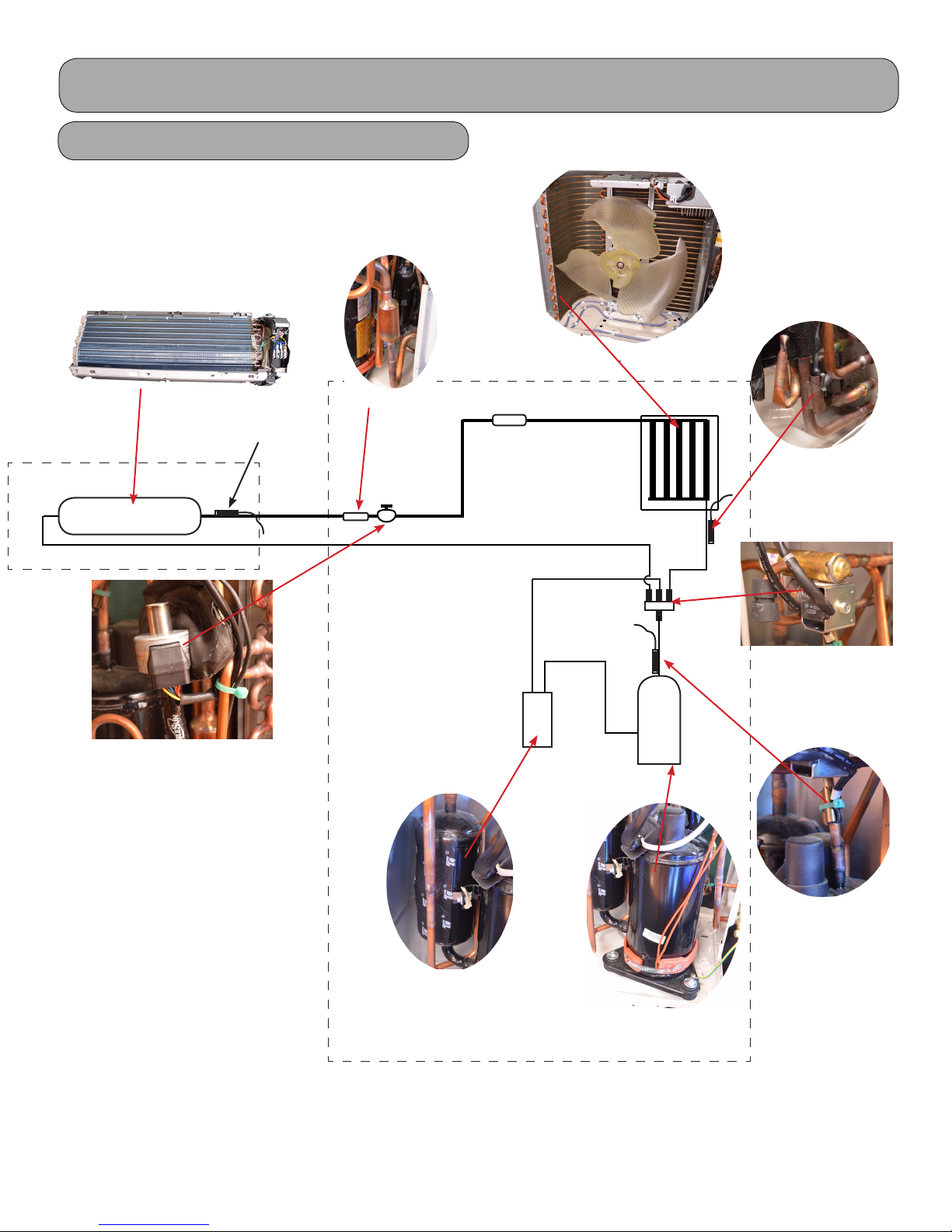

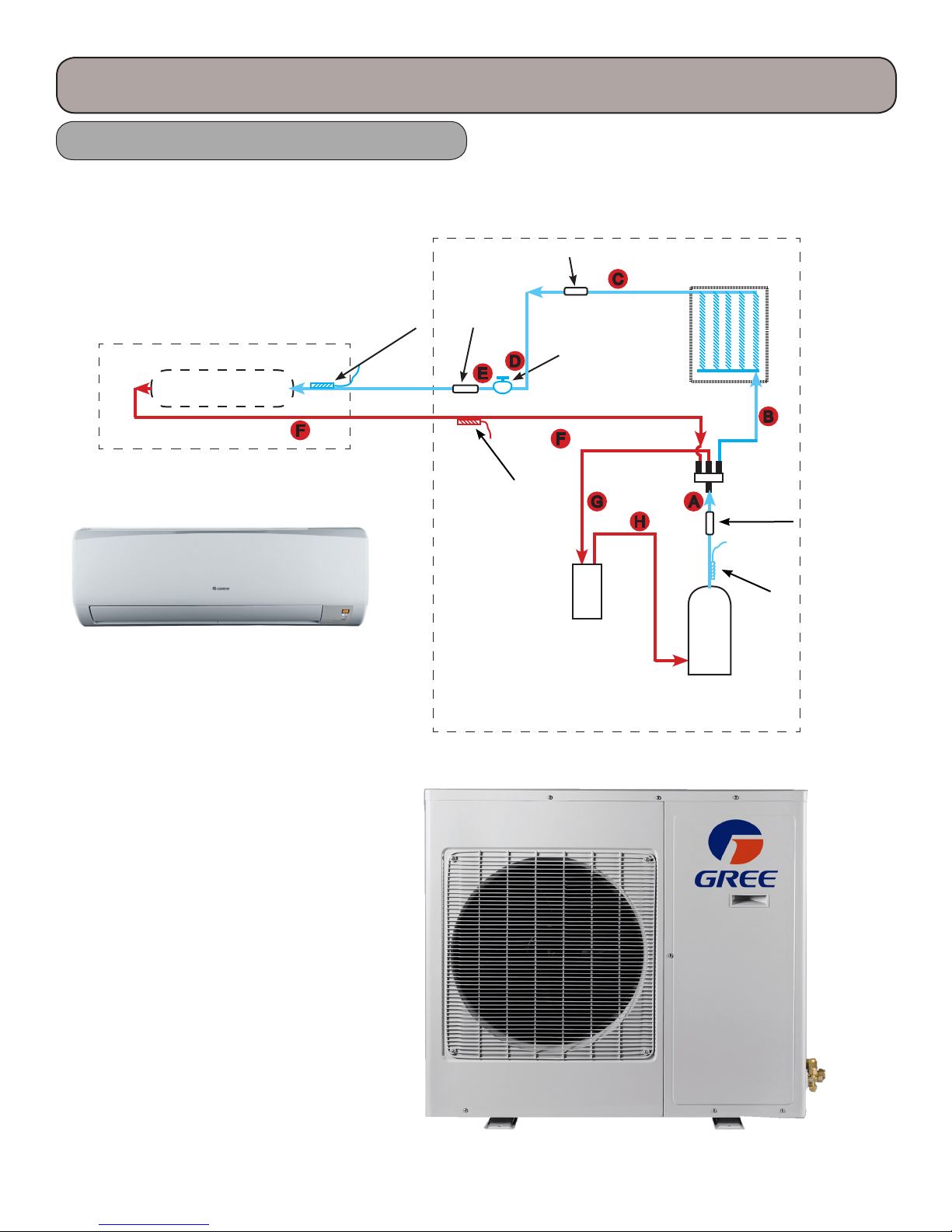

Refrigeration Cycles and Components

Refrigeration Components

Indoor Unit

Temperature

Sensor

Heat Exchanger

Strainer

Outdoor Unit

Heat

Exchanger

Temperature

Sensor

Electronic Expansion

Val ve

Accumulator

Compressor

Inverter

Compressor

4-way

Discharge Sensor

Note:

Component locations may vary depending on models.

9

Page 10

Cooling Mode

Cooling Mode

Refrigeration Cycles and Components

Outdoor Unit

Strainer

Indoor Unit

Heat Exchanger

Temperature

Sensor

Strainer

Temperature

Sensor

*Electronic

expansion

valve

Accumulator not

Exchanger

on all sizes

Heat

Compressor

Inverter

4-way

4-way

valve

valve

Discharge

Silencer

Discharge

Temperature

Sensor

10

Page 11

Refrigeration Cycles and Components

Cooling Mode

A. Hot gas is discharged from the compressor. e temperature of the gas is monitored by the Discharge

Temperature sensor and sent to the outdoor control panel.

B. e hot gas is directed through the 4-way valve, then enters the outdoor coil. e hot gas will be slightly

subcooled, however there are no pressure ports to take measurements.

C. e subcooled liquid will enter the lter to remove contaminates.

D. e subcooled liquid will enter the metering device and regulate the superheat level. e adjustment process

and compressor speed are controlled by the outdoor circuit board.

E. e refrigerant leaving the metering device will be in a low pressure/temperature saturated state. is cold

saturated refrigerant will move through the coil absorbing heat. is liquid will ash to a vapor and will be

superheated to about 10 degrees F. Since this tubing is cold, it must be insulated.

F. e superheated vapor will be returned to the outdoor unit’s 4-way valve.

G. e refrigerant will ow to the accumulator (not all models will have an accumulator) where liquid and vapor

are separated.

H. e refrigerant will ow to the compressor and complete another refrigeration cycle.

e control board will monitor the temperature and pressures and adjust the frequency of the compressor. ere

are no pressure charts to evaluate temperature or pressures.

11

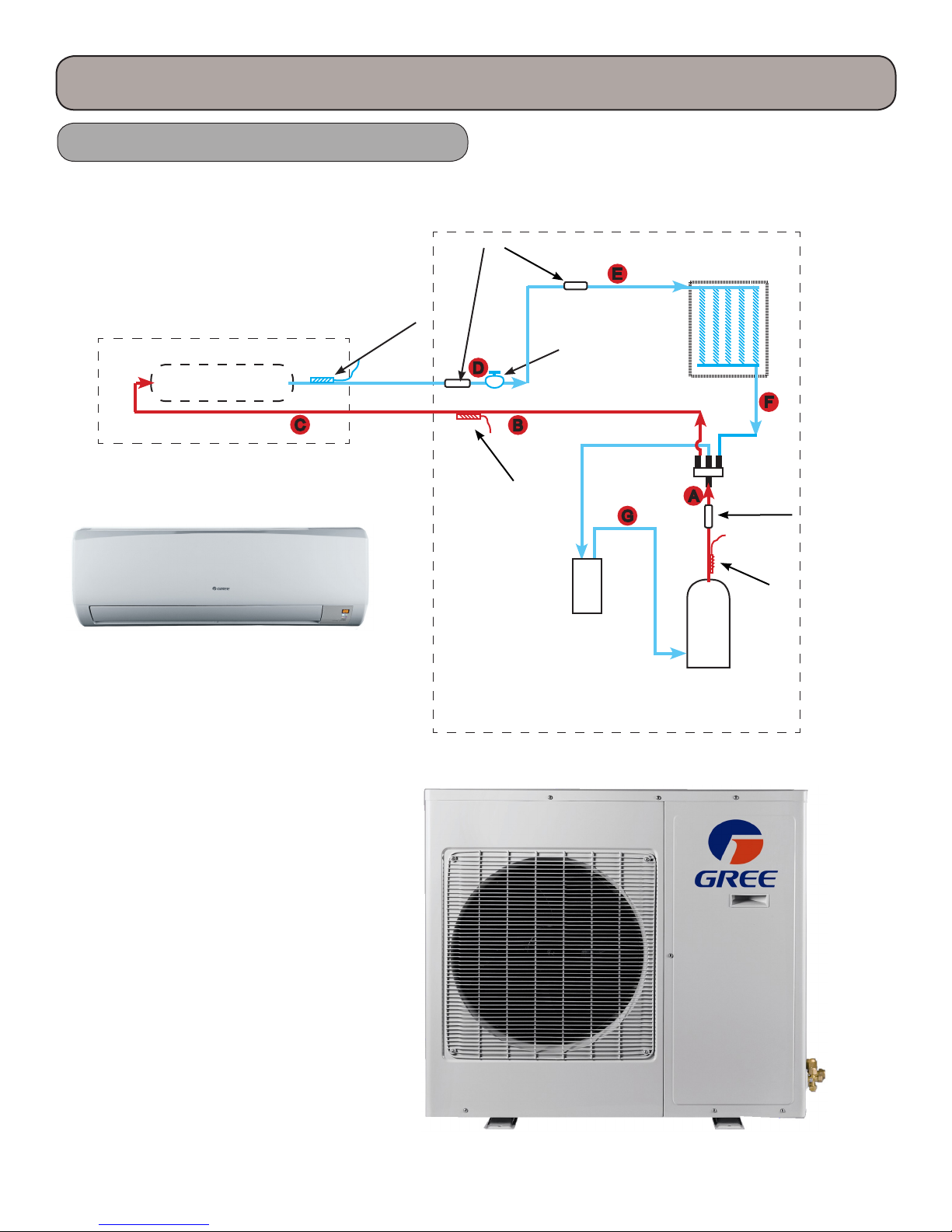

Page 12

Heating Mode

Refrigeration Cycles and Components

Outdoor Unit

Filter

Indoor Unit

Heat Exchanger

Temperature

Sensor

Temperature

Sensor

*Electronic

expansion

valve

Accumulator not

Exchanger

on all sizes

Heat

Compressor

Inverter

4-way

4-way

valve

valve

Discharge

Silencer

Discharge

Temperature

Sensor

12

Page 13

Refrigeration Cycles and Components

Heating Mode

A. Hot gas is discharged from the compressor. e temperature of the gas in monitored by the Discharge

Temperature sensor and sent to the outdoor control panel.

B. e hot gas is directed through the 4-way valve to the appropriate indoor coil making the line a hot gas line.

C. e hot gas will enter the indoor coil and condense to a saturated mix as it travel through the coil and will be

slightly subcooled.

D. e refrigerant returns to the outdoor unit through the lter, then through the metering device reducing the

refrigerant to a low pressure liquid and will maintain the proper superheat.

E. e cold refrigerant will travel through the outdoor coil (evaporator) and will pickup heat from the outdoor

air. is will cause the cold saturated refrigerant to ash to a saturated mixture which will be superheated to

10 degrees F.

F. e superheated vapor will travel through the 4-way valve to the accumulator which will prevent liquid

oodback.

G. e superheated gas will enter the compressor for another refrigeration cycle.

e control board will monitor the temperature and pressures and adjust the frequency of the compressor. ere

are no pressure charts to evaluate temperature or pressures.

13

Page 14

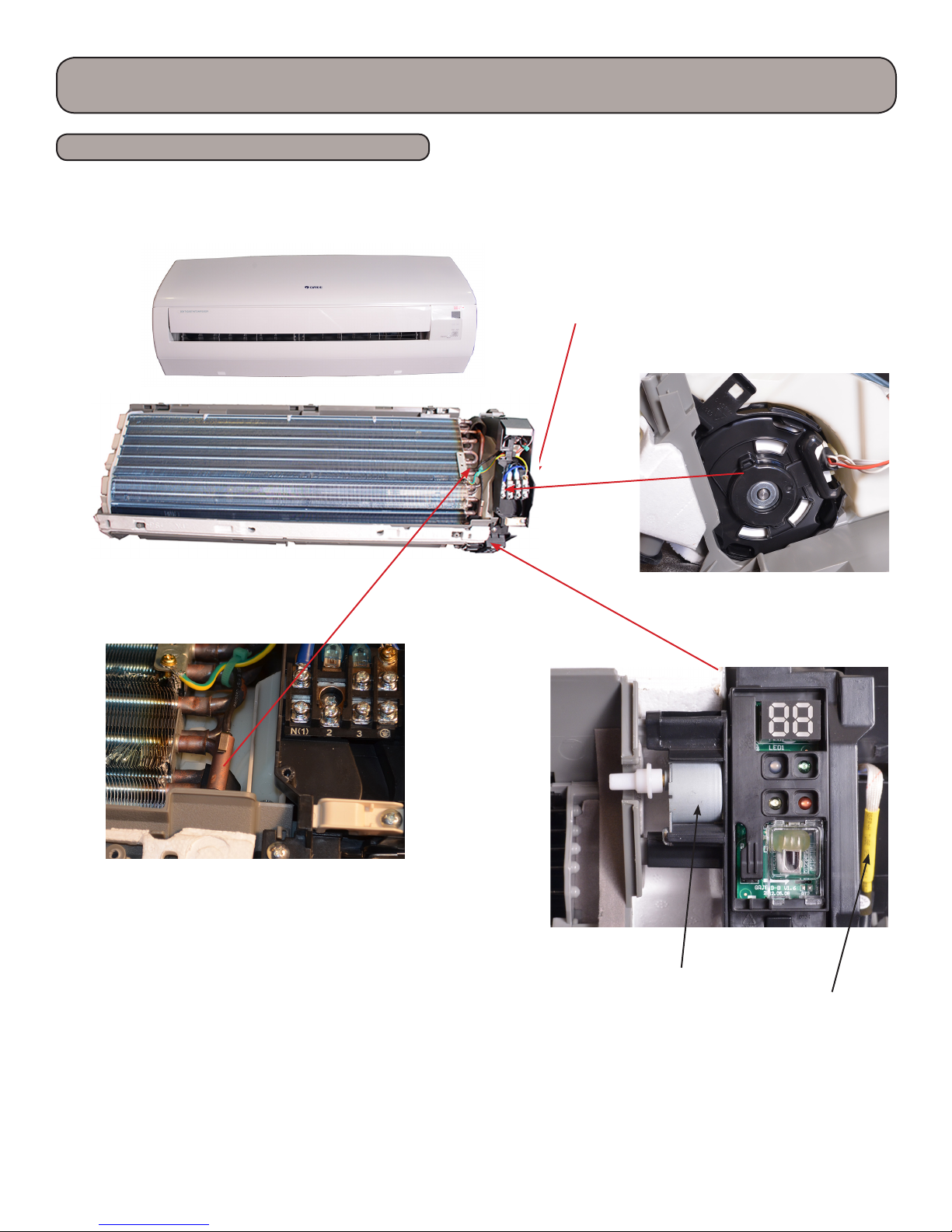

Indoor Unit Components

Indoor Unit Components

RIO 12,000 btuh model

Other RIO models may very slightly.

Indoor Circuit

Board

Indoor Tube ermistor

Fan Motor

Swing Motor

Ambient

Temperature

Sensor

Note:

Component locations may vary depending on models.

14

Page 15

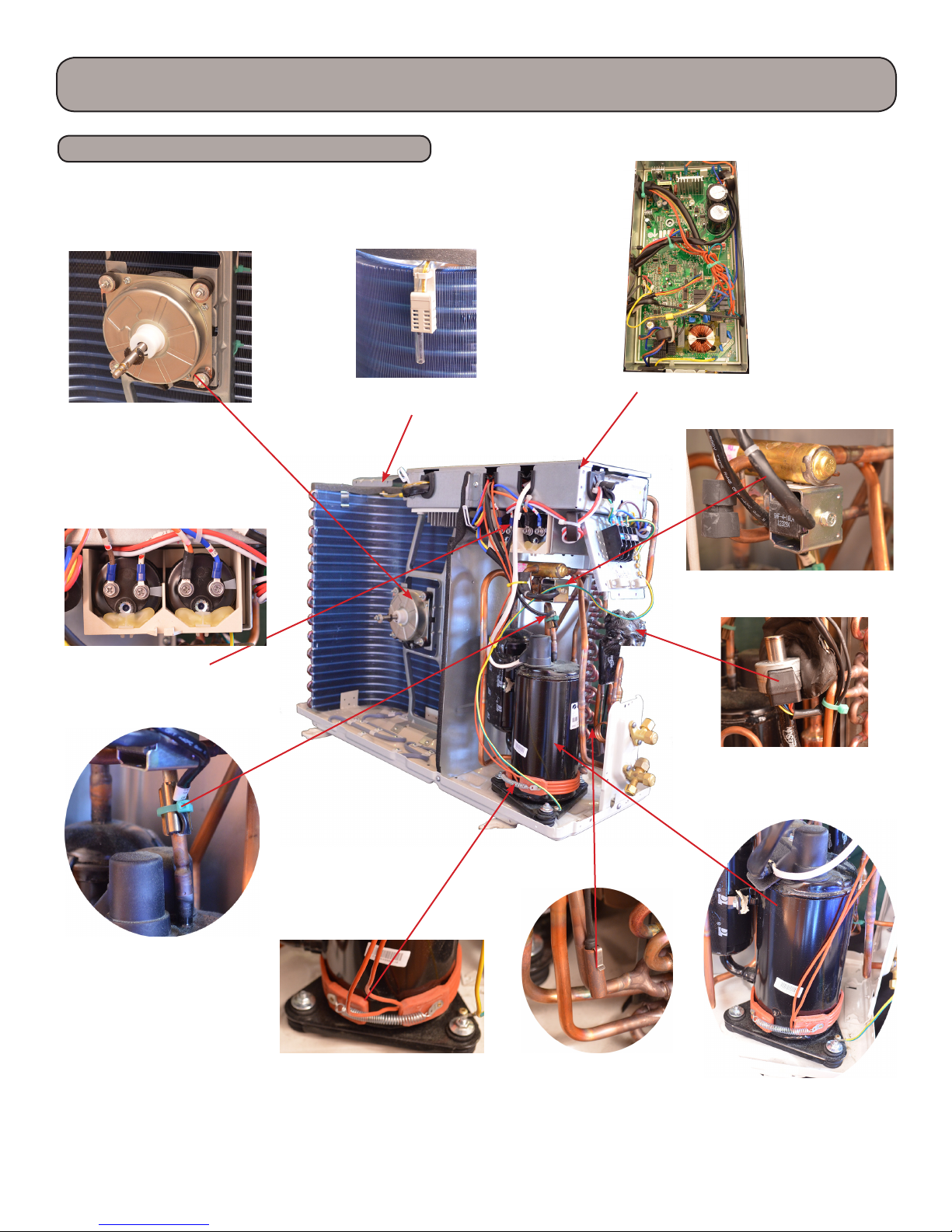

Outdoor Unit Components

Outdoor Unit Components

RIO 12,000 btuh Outdoor Unit

Other RIO models may very slightly.

Outdoor Fan

Capacitors

Outdoor Sensor, (mounted

on outside of coil)

AP1 Board

4-Way Valve

Expansion Valve

Exhaust Temp

Sensor

Crankcase Heater

Note:

Component locations may vary depending on models.

Outdoor Tube

Sensor

Compressor

15

Page 16

Basic & Protection Functions

Basic Functions

e compressor should stay o for at least 3 minutes before starting the unit. e compressor circuit has a 3 minute delay if

the compressor is de-energized during a run cycle. If the compressor starts from a de-energized cycle, there will be no time

delay. e compressor has a minimum runtime of 6 minutes regardless of room temperature.

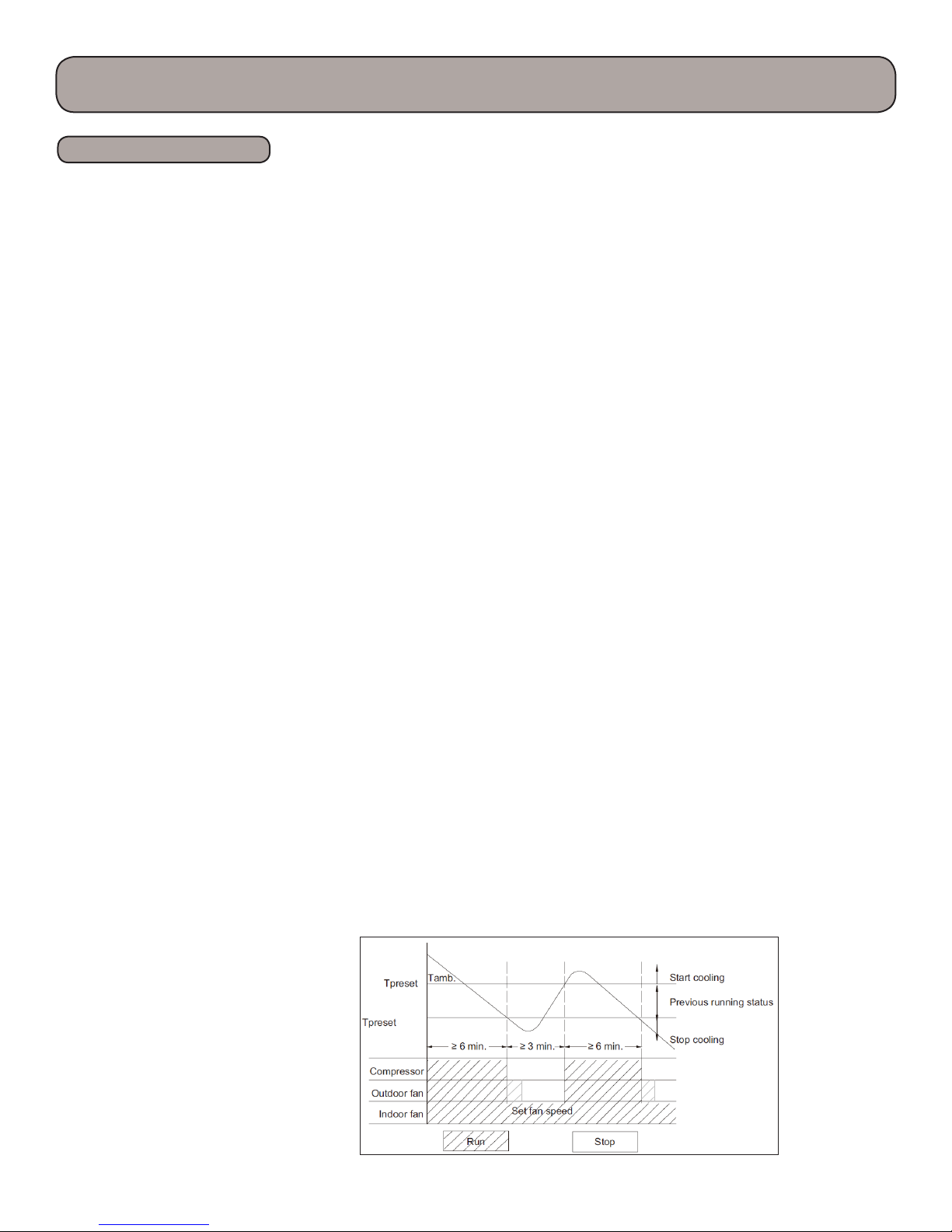

1) Cooling Mode

Cooling Process

When the indoor ambient rises 4 F above the preset temperature from a stopped state, the unit will start the cooling cycle.

e outdoor fan and compressor will start. e indoor fan will run continuously at the selected speed. e outdoor unit

will monitor the appropriate temperatures and pressure and adjust the compressor speed and the EEV as required. If the

indoor ambient is > 4 F than the preset temperature, the compressor will increase the frequency; < 4 F the compressor

will begin reducing the frequency. e EEV will be closed on indoor units with no cooling requirement. e G10

technology will control compressor speed based on indoor load and compressor amperage. When the indoor temperature

is satised, the compressor will stop, then 30 seconds later the outdoor fan will stop. When the cooling mode transfers to

heating mode, the 4-way valve will be energized aer a two minute compressor delay.

Evaporator Freeze Protection

e soware will monitor the indoor evaporator coil form freezing.

e following will occur 6 minutes aer the compressor has been operating in the cooling or dry mode:

If the evaporator temperature drops below 36 F, the compressor will operate at a reduced frequency. If the evaporator

is below 30 F for 3 minutes, the compressor will stop, 30 seconds later the outdoor fan will stop. In cooling mode, the

indoor fan and swing motor will remain on. If the evaporator temperature is >= 50 F and the compressor is o for at least

3 minutes, the compressor will resume its normal operation state.

Overcurrent Protection

e soware will monitor the compressor current to maintain it in a safety and reliable operating range.

If the total current is greater than the rating, the compressor will stop; the outdoor fan will continue to run for 30 seconds,

then stop.

2) Dry Mode

Drying Process

is feature will not take the place of a dehumidier, it is intended to dry the lter and slightly cool the air. If the indoor

ambient temperature is greater than the preset temperature, the unit will enter the cooling and drying mode, in which

case the compressor will operate and the indoor fan will run at a low speed. When the indoor ambient temperature is at or

below the preset temperature, the unit will operate in it previous running state. When the indoor ambient drops to more

than 4 F below the preset temperature the compressor will stop running, then 30 seconds later the outdoor fan will stop,

the indoor fan will run at low speed.

- 2 F

60 Sec 60 Sec

30 Sec 30 Sec

16

Page 17

Basic & Protection Functions

Basic Functions

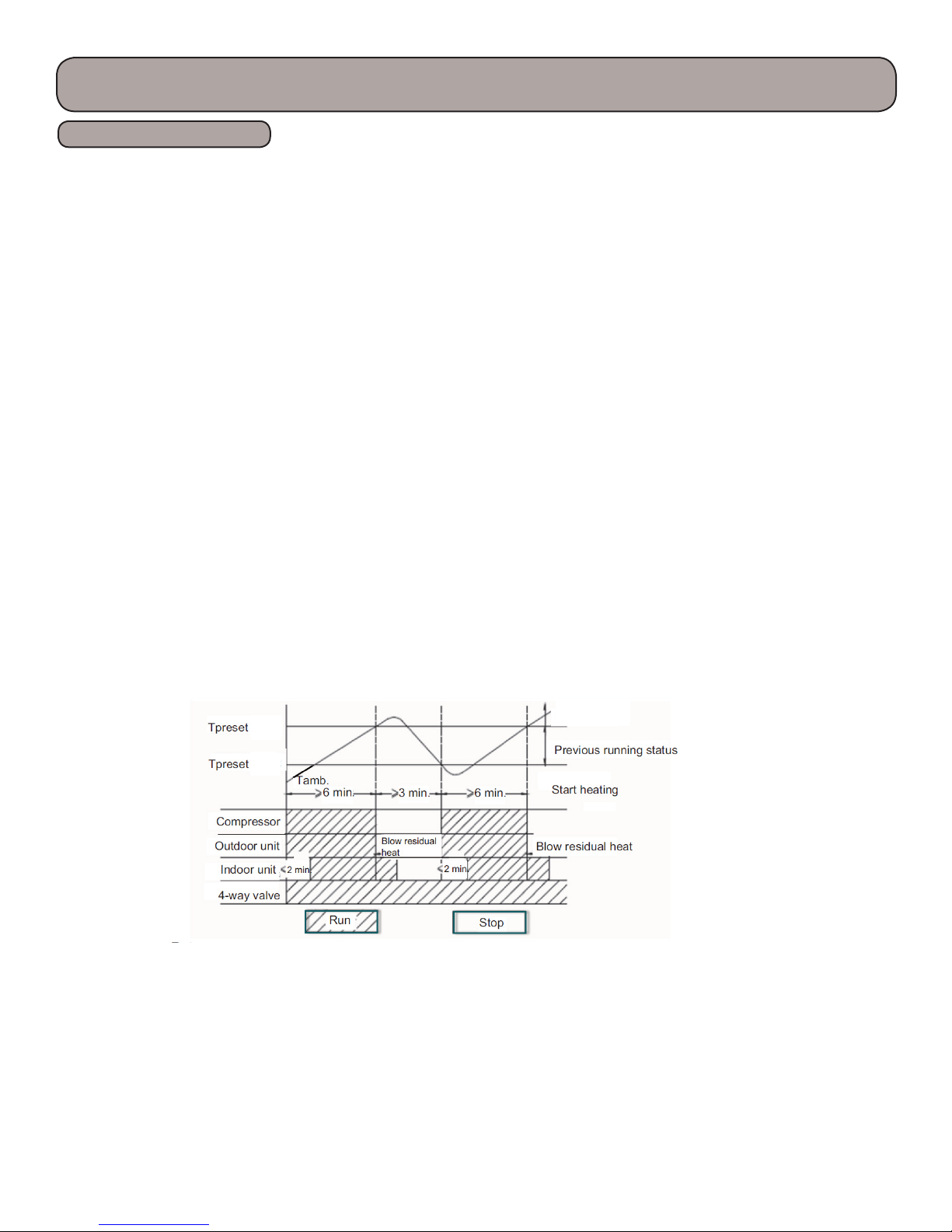

3)Heating Mode

Heating Process

When the indoor ambient drops 4 F below the preset temperature, the unit will start the heating cycle. e outdoor

fan, compressor and 4-way valve will operate. e indoor fan will operate in the “Cold Air Prevention” mode in which

the indoor fan will have a 2 minute delay aer the call for heating. e indoor evaporator coil temperature must reach

104 F before the indoor fan will start, this will prevent cold air from discharging from the indoor coil. When the indoor

evaporator coil temperature is > 104 F, the indoor fan will operate at low speed for 1 minute. With 1 minute of operation

or 2 minutes of no fan operation and the indoor evaporator coil temperature is > 108 F, the indoor fan will operate at its

preset condition.

If the indoor ambient temperature is < 9 F and > 2 F of the preset temperature, the unit will run in its original mode of

operation.

If the compressor is running and the mode is changed from heating to cooling, the compressor will stop, the 4-way valve

will be de-energized 2 minutes later, the outdoor fan will stop aer a 1 minute delay.

If the indoor ambient temperature is >= 9 F than the preset temperature, the compressor will stop and the outdoor fan will

stop aer a 30 second delay. e indoor fan will continue to operate at its preset mode.

e G10 technology will determine compressor frequency based on ambient temperatures.

+9 F

+ 2 F

Stop heating

17

Page 18

Basic & Protection Functions

Basic Functions

Defrost Process

You may force a defrost in heat mode by pressing the “+” and “-” buttons alternately three times within 5

seconds.

1) e unit will enter defrost when the following conditions are met:

A. Outdoor ambient <= 41 F

B. Compressor had accumulated more than 3 hours of operation in heating mode

C. e outdoor coil <= 32 F

Note: e compressor runtime will be cleared when the outdoor ambient is > 41 F or when the compressor has started

up aer changing to cooling or drying mode and defrost has nished. e runtime will not be cleared when the unit has

stopped aer reaching the setpoint temperature, a protection fault or changing to fan mode.

ere are 3 perimeters used in the defrost algorithms, Outdoor ambient(T

a calculated T

T

compensation

D. Aer power-up, for the rst defrost T

E. T

F. T

compensation

is calculated by the following:

tube > 36 F then T

outdoor

tube <= 36 F then T

outdoor

compensation = 32

compensation = 32

compensation = 37

F

F

F

ambient), Outdoor tube(T

outdoor

outdoor

tube) and

2) When heating has operated continuously for 45 minutes, or accumulated for 90 minutes, the unit will enter defrost

mode in 3 minutes aer meeting any of the conditions below:

A. Outdoor ambient >= 41 F and outdoor coil <= 28 F

B. 28 F <= T

C. 23 F <= T

D. 14 F <= T

ambient< 41 F, “Toutdoortube -Tcompensation ≤ 21F”

outdoor

ambient < 28 F <= Toutdoortube -Tcompensation ≤ 18F”

outdoor

ambient < 23 F , T

outdoor

outdoor

tube -T

compensation

<= (T

ambient - 37 F)

outdoor

E. Toutdoorambient < 14 F, Toutdoortube -Tcompensation <= (Toutdoorambient - 37 F)

3) During defrost, if run time for the compressor does not reach 3 minutes, the defrost cycle will not start for the next

2 hours. At that time the compressor stops operation and 30 seconds later the outdoor fan will stop. 30 seconds aer

this the 4-way reversing valves will de-energized. Following another 30 second delay, the compressor will increase its

compressor speed for defrosting. Defrosting will last for 450 seconds or until the T

tube >= 50 F, at this temperature

outdoor

the compressor will decrease it compressor speed for 30 seconds, then will stop. In another 30 seconds the 4-way valve will

energize, the 60 seconds later the compressor and outdoor fan will start. e compressor speed for defrosting will be 85hz.

During Defrost mode, a “H1” will be displayed on the indoor front panel display indicating the user selected mode has

been overridden and the system is performing a outdoor coil defrost operation.

4) Defrost Sequence:

When a defrost condition has been met, the compressor will stop, all expansions valves will open fully, the outdoor fan will

stop 40 seconds aer the compressor stops. e 4-way valve will reverse direction (cooling mode) , then the compressor

will start and enter the defrost frequency. e control, board along with ambient sensors will calculate defrost time.

5) Oil Return:

Oil return condition can be met if the unit operates at a low frequency for an extended time. e indoor display will

indicate “H1” for this condition and is a normal procedure.

18

Page 19

Basic & Protection Functions

Basic Functions

Cold Air Prevention (Heating mode with compressor running)

e system guards against discharging cold air in heating mode. It will delay the indoor fan until the evaporator coil has

warmed up to discharge warm, comfortable air into the room.

1) When the T

ambient < 75 F and the T

indoor

to run at low speed aer a 2 minute delay. is will reduce cold air upon heating startup. Within 2 minutes, if

T

tube > 104 F, the indoor fan will run at low speed. Aer 1 minute of operation, the fan will run at the preset fan

indoor

mode. Within 1 minute of low speed operation or 2 minutes of no fan operation, with the T

run at the preset mode.

tube <= 104 F with the fan in a stopped state, the indoor fan will begin

indoor

tube > 108 F, the fan will

indoor

2) If the T

ambient >= 75 F and the T

indoor

at the preset mode. Aer 1 minute of low speed operation, if the and the T

tube <= 108 F the indoor fan will run at low speed for 1 minute than run

indoor

tube > 108 F the fan will operate at its

indoor

preset mode.

Note:

e T

Overcurrent and Speed Protection (Total Current = I

ambient in 1 & 2 above refers to the unit going into the heating mode coming out of defrost.

indoor

)

total

e soware will monitor the compressor current draw and adjust the compressor speed in order to maintain the inverter and

compressor in a safety and reliable operating range.

A. If I

B. If I

C. If I

D. If I

<= 13a, an increase in frequency will be allowed

total

>= 15a, increasing the frequency is not allowed.

total

>= 17a, the compressor will decrease its frequency

total

>= 19a, the compressor will stop and the indoor fan will stop aer 30 seconds.

total

4)Fan Mode

Under this mode, the fan will run at the preset speed and the outdoor fan, compressor and 4-way valve will stop.

5)Auto Mode

Auto Mode Process

Setting the auto mode will run the unit in heat or cool automatically depending on T

1)Operating Parameters

A. If the T

B. If the T

C. When the T

ambient >= 79 F the unit will operate in cooling mode. e set temperature is 77 F.

indoor

ambient <= 72 F the unit will operate in heat mode. e set temperature is 68 F.

indoor

ambient <= 73 F and >= 77 F, the unit will operate in the previous state. If it is energized

indoor

for the rst time, it will run in Fan mode

D. In auto mode, the cooling frequency will be the same as the cooling only mode and the heating frequency will

be the same as the heating only mode.

2) Protection

A. In cooling operation, protection is the same as the cooling only mode

B. In heating operation, protection is the same as the heating only mode

C. When the indoor ambient temperature changes, the operation mode will be automatically selected. Once started

the compressor will have a 6 minute runtime.

indoor

ambient

19

Page 20

Basic & Protection Functions

Protection Functions

Common Protection Functions and Fault Displays

Coil High Temperature Protection

T

= measured temperature of outdoor coil in cooling mode, measured temperature of indoor coil in heating mode.

tube

1) Outdoor Coil High Temperature Protection - In cooling mode the soware will monitor the outdoor coil for an

abnormal high temperature condition.

A. If T

B. If T

C. If T

D. If T

2) Indoor Coil Temperature Protection - In heating mode the soware will monitor the indoor coil for an abnormal high

temperature condition.

A. If T

B. If T

C. If T

D. If T

<= 126 F, the unit will return to its original operation state

tube

>= 131 F, frequency rise is not allowed

tube

>= 136 F, the compressor will run at reduced frequency

tube

>= 144 F, the compressor will stop and the indoor fan will operate at preset speed

tube

<= 122 F, the unit will return to its original operation state

tube

>= 127 F, frequency rise is not allowed

tube

>= 133 F, the compressor will run at reduced frequency

tube

>= 140 F, the compressor will stop and the indoor fan will blow residual heat and then stop

tube

3) Compressor Discharge Temperature Protection

e soware will monitor the compressor discharge for an abnormal high temperature condition.

A. If T

B. If T

C. If T

D. If T

>= 208 F, frequency rise is not allowed

tube

>= 217 F, the compressor will run at reduced frequency

tube

>= 230 F, the compressor will stop

tube

<= 194 F and the compressor has been off for at least 3 minutes, the compressor will resume operation

tube

4) Compressor High Pressure Protection (Not available on 115v 9k & 12k models)

When the high pressure switch is detected for 6 seconds or more, the compressor will stop and can only be started by

powering o the unit. Dirty coils, refrigerant overcharge and outdoor fan problems can cause this fault.

5) Compressor Phase-lacking Protection

If one of the compressor phases are detected open before startup, the compressor will enter phase-locking protection.

e malfunction will be cleared aer 1 min, then the unit will try a restart. If an error has been detected for 6 times

continuously, the compressor will lock out and will need to have power cycled. e errors will be cleared aer the

compressor has run for 7 minutes continuously.

6) Module Protection (IPM)

Under module protection mode, the compressor will stop. When the compressor remains o for 3 minutes, the compressor

will resume operation. If the module protection occurs six times in succession, the compressor will remain o. Power will

need to be cycled to start unit. is is a thermal protection for the indoor module.

7) DC Buss Voltage Protection

e soware will monitor the DC bus voltage.

If voltage on the DC Bus is below 150 or over 420v, the compressor will stop and the outdoor fan will stop in 30 seconds.

When the voltage on the DC bus returns to normal and the compressor has been o for 3 minutes, the compressor will

resume its operation.

20

Page 21

Basic & Protection Functions

Protection Functions

8) Communication Fault

If the unit fails to receive correct signals for a 3 minutes, communication fault will occur and the whole system will stop

and a “E6” will be displayed on the front panel of the indoor unit.

21

Page 22

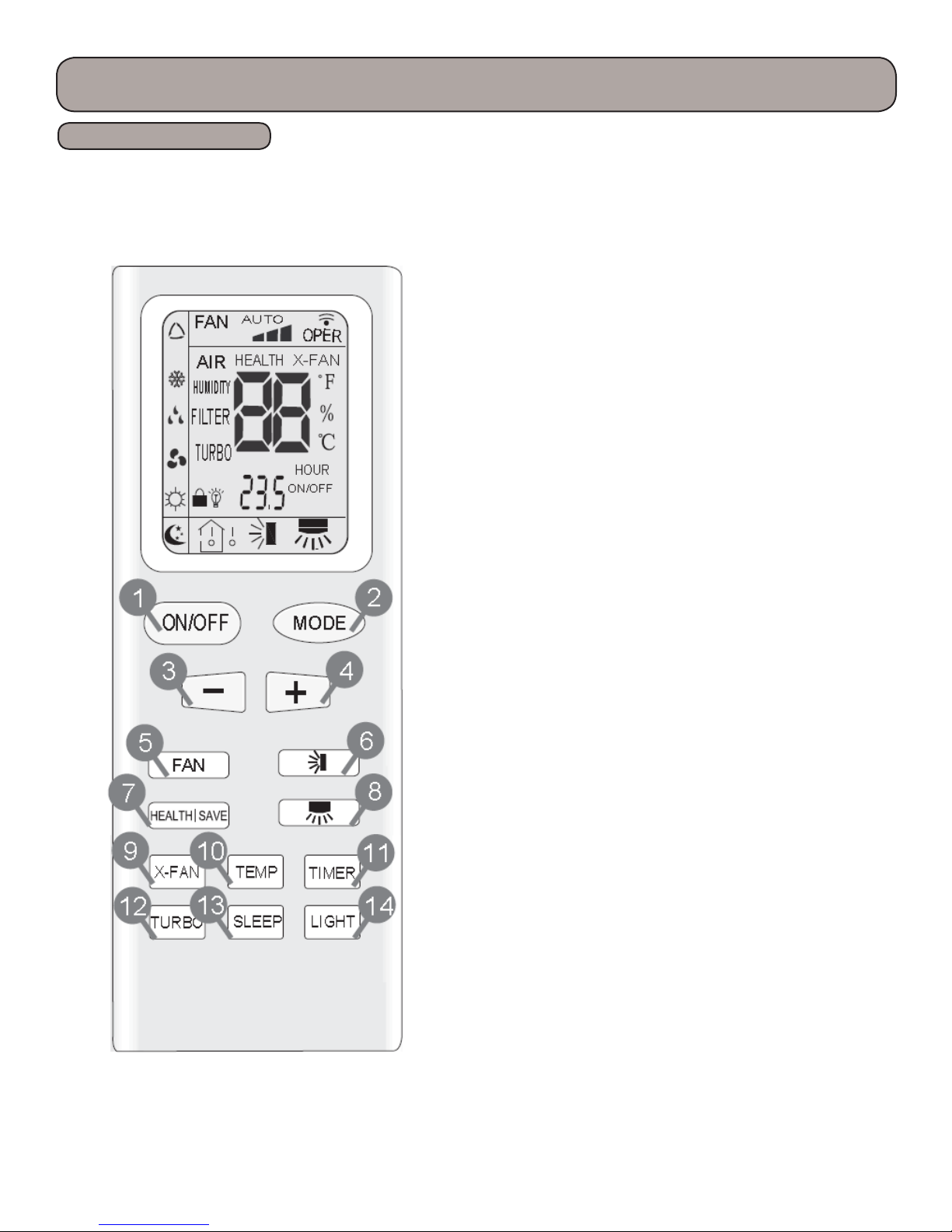

Remote Buttons

Remote Control Operation

Note:

is remote control is used in other models and some

features may or may not be available. Consult the

owners manual for specic features for your model.

ere should be no obstructions between the remote

control and the indoor unit for proper operation. Keep the

remote from direct sunlight or any source that generates

heat, keep clean and dry. Change batteries frequently.

Note:

For detailed explanation of the functions, refer to the

“Other Controls” section of this manual for your model.

Button Identication

e function and operation of each button will be

explained later in this manual under Product Functions.

1. On/O button

2. Mode, press to select desired operation

3. Decrease temperature

4. Increase temperature

5. Fan, press to select fan speed

6. Swing angle button (up & down)

7. Health/Save button, not available on all models

8. Swing angle button (le & right)

9. X-Fan button

10. Temperature Display

11. Timer Button

12. Turbo Fan Button

13. Sleep Button

14. Light Button

Press “mode” and “-” buttons to switch between

Fahrenheit & Centigrade

Press “-” & “+” to lock control

22

Page 23

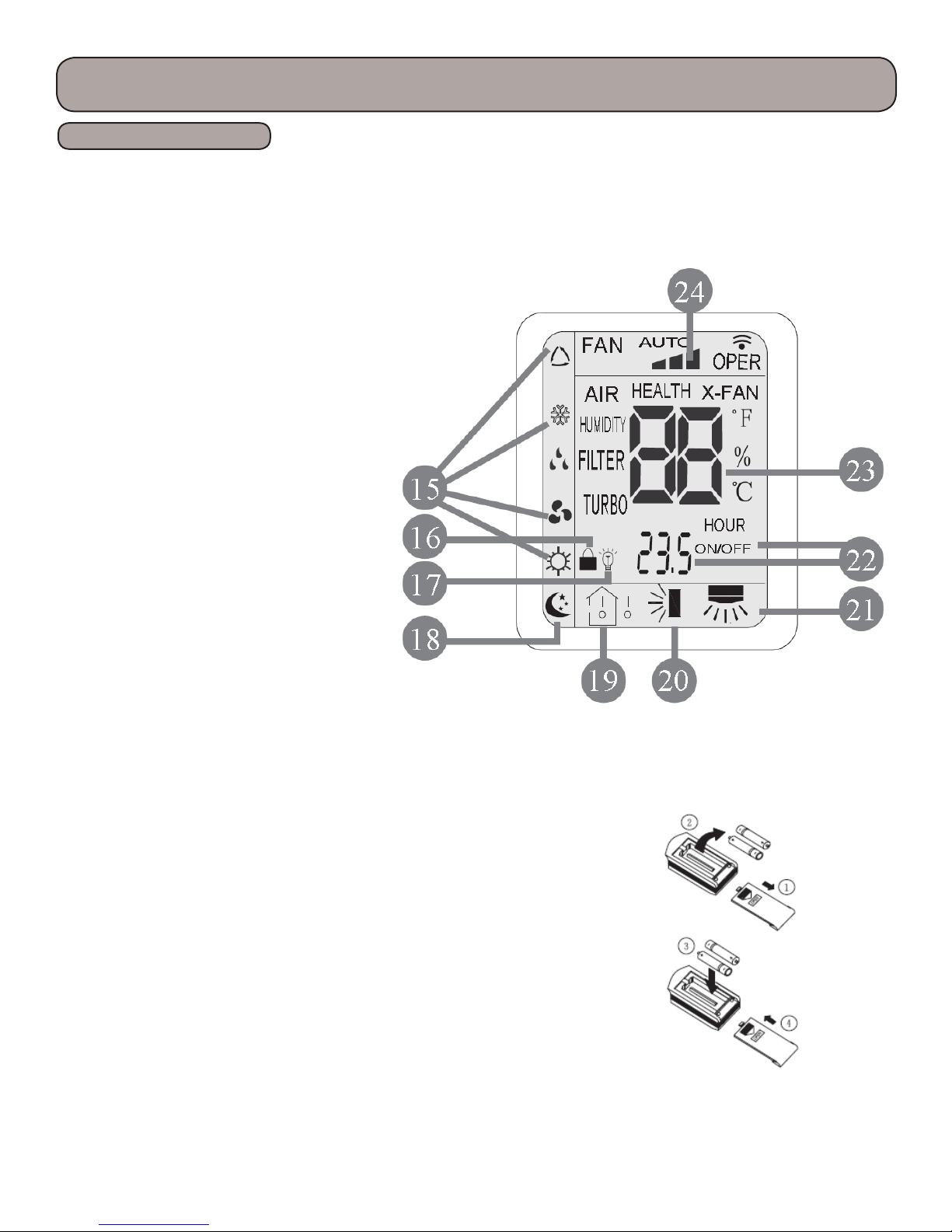

Display Icons

15. Mode icons

16. Lock icon

17. Light icon

18. Sleep icon

19. Temperature icon

20. Up & down swing icon

21. Le & right swing icon

22. Set time icon

23. Digital display

24. Fan speed icon

Remote Control Operation

Replacing Batteries:

1. Locate the battery cover on the back of the remote.

2. Slide the cover downward.

3. Make sketch of battery polarities, then replace with

two “AAA” batteries.

4. Replace cover.

23

Page 24

Product Introduction

Remote Control Functions

1)On/O

e on-o state will change with each button press.

2) Mode Setting

Each time you press this button, a mode is selected in a sequence that goes from AUTO,

COOL, DRY, FAN,and HEAT

Aer energization, AUTO mode is defaulted. In AUTO mode, the set temperature will not

be displayed on the LCD, and the unit will automatically select the suitable operation

mode in accordance with the room temperature to make indoor room comfortable.

3)”-” Button

Press this button to decrease set temperature. Hold it down for above 2 seconds to

rapidly decrease set temperature. In AUTO mode, set temperature is not adjustable.

4)”+” Button

Press this button to increase set temperature. Hold it down for above 2 seconds to

rapidly increase set temperature. In AUTO mode, set temperature is not adjustable.

5) Fan

is button is used for setting fan speed in the sequence that goes from AUTO, low, medium, high, then back to

auto.

6) Up & Down Swing

Press button to start or stop up & down swing function. e remote controller defaults to simple swing

condition. Press + button and button at the same time at unit OFF to switch between simple swing and

static swing; blinks for 2 seconds. In static swing condition, pressing

louver positions. If the unit is turned o during swing operation,the louver will stop at present position.

button, the swing angle up & down

7) Health Save

Press HEALTH part of this button to turn on or o HEALTH function.(only for some model)

Pressing SAVE this button, SE is displayed and the unit goes into SAVE operation mode. Press SAVE button

again to cancel SAVE function. During SAVE operation , the temperature and fan speed is not adjustable.

8) Le & Right Swing

Press button to start or stop le & right swing function. e remote controller defaults to a simple swing

position.

Press + button and button at the same time at unit OFF to switch between simple swing and static swing;

blinks for two seconds

In static swing position, pressing button the swing angle will change positions.

24

Page 25

Product Introduction

Remote Control Functions

9) X-Fan

Allows fan to run aer cooling cycle to dry o the coil and inhibit the growth of bacteria and mildew. Works

with “Auto” mode.

10)Temp Button

Toggles the display between set temperature, indoor temperature and outdoor temperature.

11) Timer On Button

Press TIMER button at unit ON to set TIMER OFF; HOUR OFF blinks. Press TIMER button at unite OFF to set

TIMER ON; HOUR ON blinks. In this case, pressing + or - button changes time setting. Holding down either

button rapidly changes time setting (time setting range 0.5 - 24 hours). Press TIMER button again to conrm

setting; HOUR ON/OFF stops blinking. If there is not any operation of button within 5 seconds during HOUR

ON/OFF blinking, TIMER setting will be canceled.

12) Turbo Button

Boost the cooling or heating airow, allowing the unit to reach the preset temperature in the shortest amount of

time.

13) Sleep Button

Press this button to go into the SLEEP operation mode. Press it again to cancel this

function. is function is available in COOL , HEAT (Only for models with heating

function) or DRY mode to maintain the most comfortable temperature for you.

14) Light Button

Turns the light on the indoor display on and o.

15) Combination of “+” and “-” Buttons

Press “+” and “-” buttons simultaneously to lock or unlock the keypad

16) Combination of “Mode” and “-” Buttons

Press “Mode” and “-” buttons simultaneously will switch between Fahrenheit and Centigrade.

25

Page 26

Refrigerant Lines Connection, Evacuating and Charging

Refrigerant Lines Preparation &

Connection

The refrigerant lines should be kept sealed until ready to be

connected. Follow the following steps to ensure a quality leak

proof installation:

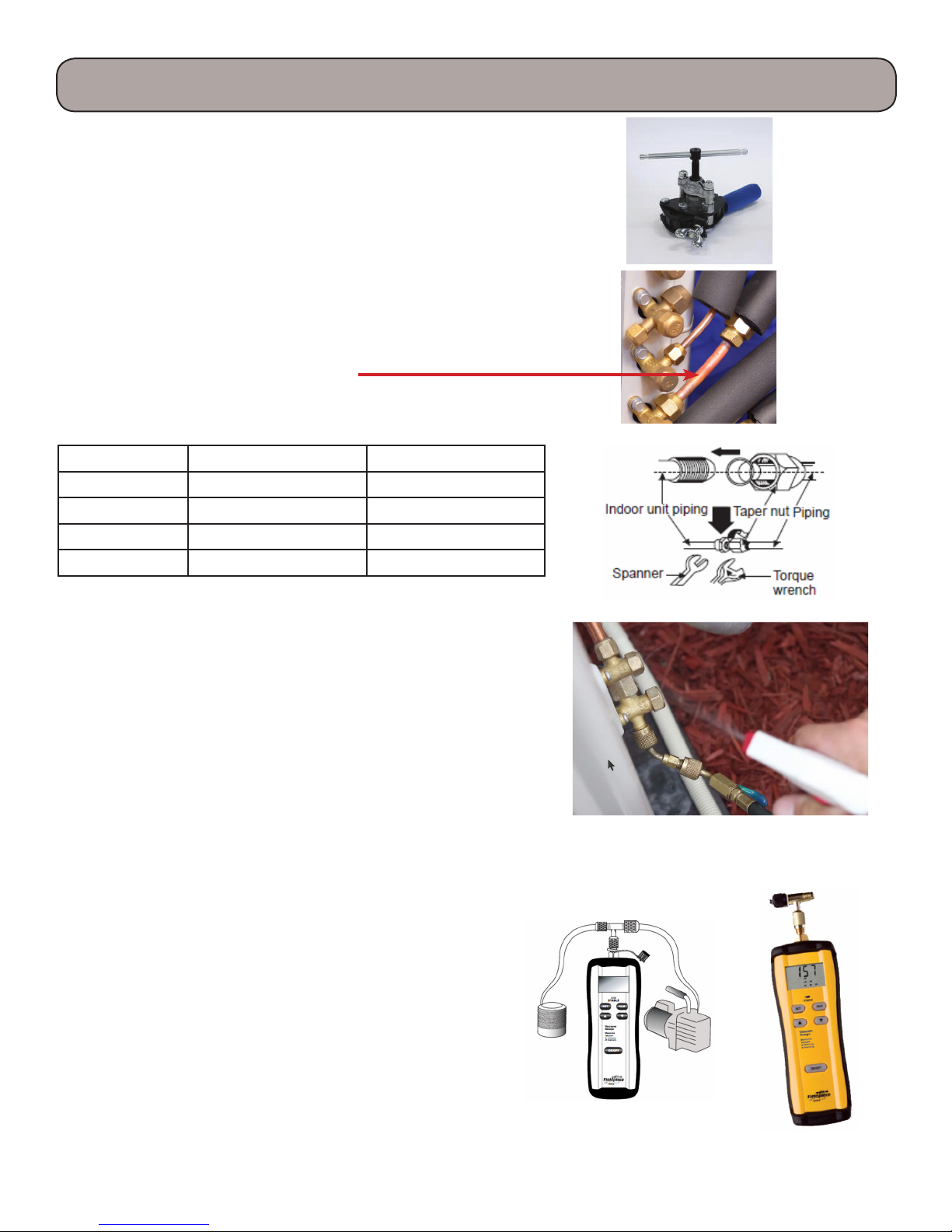

Step 1. Refrigerant Line Connection

Carefully bend and cut the tubing to prepare for aring. Use a

aring tool designed for R410a, following the recommended

manufacturer’s procedure. Tighten the are nut to the

indicated torque by using a spanner wrench and a toque

wrench. Connect the indoor unit rst, then the outdoor unit.

Use the 3/8” to 1/2” are adapter if needed.

Note:

Over tightening are nuts may damage are connections and

may cause leaks.

Tubing Size Torque (foot-pounds) Torque (inch-pounds)

1/4” 10-13 124-159

3/8” 25-31 301-372

1/2” 36-45 434-540

5/8” 50-60 602-726

Step 2. System Leak Check

Refrigerant lines should be pressurized prior to evacuating

system to check for leaks.

Use only dry nitrogen with a pressure regulator for

pressurizing unit. Pressurize with 150 psi of dry nitrogen.

Apply soap and water to check whether the joints are leaky. A

leak detector may also be used for a leakage test.

Hint:

You may want to perform leak testing and evacuation before

wiring to save time, electrical connections can be completed

while your vacuum pump is running.

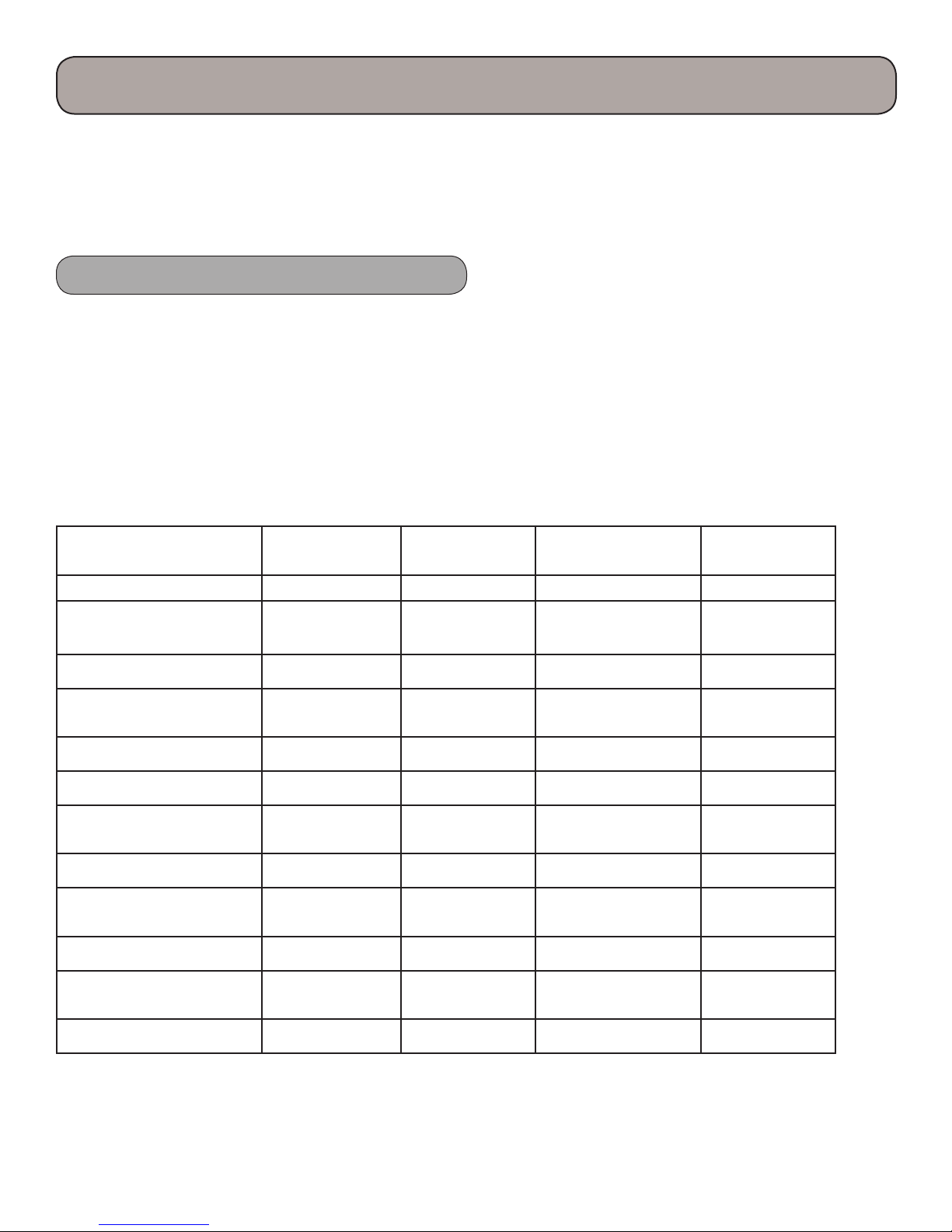

Step 3. System Evacuation

Note: The outdoor unit contains a refrigerant charge, leave

liquid and gas valves closed.

1. After no leaks have been detected, connect a vacuum

pump to the outdoor unit.

2. Connect appropriate hoses to manifold gauge, vacuum

pump and unit refrigeration connections.

3. Evacuate the system until the micron gauge reads no

higher than 350 microns.

4. Close valve to vacuum pump; if pressure does not rise

above 500 microns after one minute, the evacuation

should be complete.

5. If it does rise, check for leaks and/or evacuate longer.

6. For refrigerant lines longer than 25 feet, refer to

installation instructions chart included with the unit

installation manual for additional charge.

26

Page 27

Refrigerant Charging Procedure

Please refer to your units installation manual for proper charge. If your lineset exceeds the chart below for your

model, additional charge may be required. e charge must we weighed in with a refrigerant charging scale.

You can only add additional refrigerant to a new installation. If a low or high charge is suspected, you must

reclaim the refrigerant, then weigh in the correct amount per specications including any additional for long

linesets. It is important to check for leaks before adding refrigerant.

1. Determine addition refrigerant charge.

e RIO single zone units contain a factory charge adequate for up to a total length of refrigerant line as

indicated in the chart below. Additional refrigerant will need to be added for total lengths over the listed length.

Conrm the following chart with your installation manual for additional charge amounts:

RIO09HP115V

1A

Additional Charge 0.2 oz./. 0.2 oz./. 0.2 oz./. 0.2 oz./.

Max Length without

Additional Charge

Factory Charge

Max. Total Piping

Length

Max. Elevation

Additional Charge

Max Length without

Additional Charge

Factory Charge

Max. Total Piping

Length

Max. Elevation

25 . 25 . 25 . 25 .

35.3 oz. 35.3 oz. 26.1 oz. 35.3 oz.

49 . 66 . 50 . 50 .

33 . 33 . 33 . 33 .

RIO14HP230V1ARIO24HP230V

0.2 oz./. 0.22 oz./.

25 . 25 .

45.9 oz. 54.7 oz.

50 . 50 .

33 . 33 .

RIO12HP115V

1A

1A

RIO09HP230V

1A & 1B

RIO12HP230V

1A & 1B

27

Page 28

Refrigerant Charging Procedure

2. Leak Testing

Follow the procedures for leak testing with nitrogen

prior to adding charge on a new installation or existing

one suspected for leaks. See preceding page.

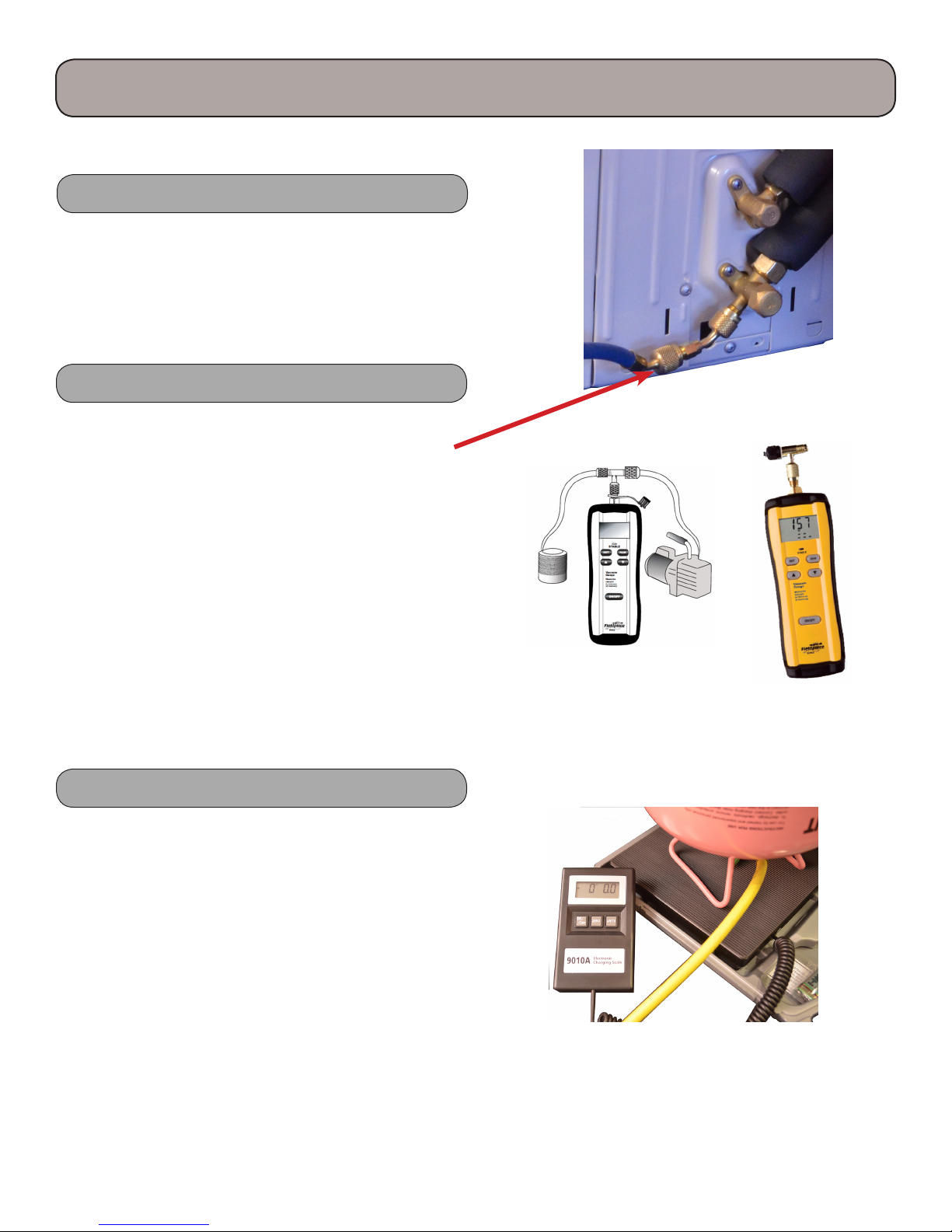

3. Attach hoses to the unit and vacuum pump

5/16” x 1/4” adapter may be required to connect hose

to port.

Check to insure that the liquid and gas valves are closed

on the unit. Close all valves on your gauge set, then

connect the vacuum pump to your gauge set. Pump

down lineset and indoor unit. is step will be repeated

for all zones.

4. Zero charging scale

Place the refrigerant tank on the charging scale. Open

the tank valve, turn on the scale, then zero the scale.

28

Page 29

Refrigerant Charging Procedure, cont.

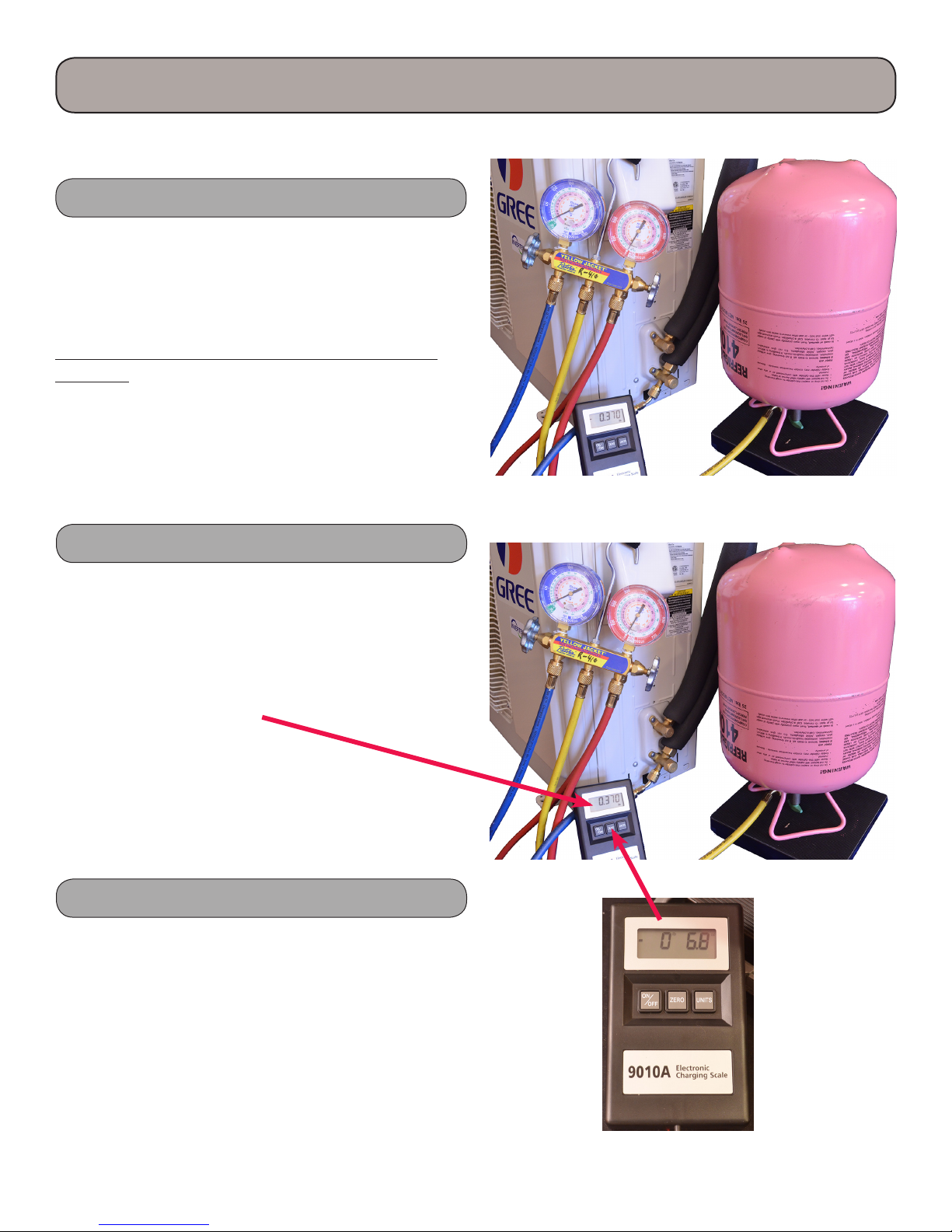

5. Begin adding additional refrigerant

Charging should be completed with the unit o (not

running) and through the liquid side with liquid

refrigerant. If there are no ports on the liquid side, use

the gas side port connection, charging with liquid.

Record the amount of additional charge for future

reference.

6. Charge to the correct weight

If the scale was zeroed with the refrigerant tank on the

scale, the amount added to the system will be a negative

amount since it was removed from the tank. Aer the

proper amount of refrigerant has been weighed in,

close the manifold valve.

7. Remove refrigerant tank

Close the tank valve, then carefully remove the hose

and adapter. Replace the charging port cap back on

the outdoor unit valves. On new installations, open all

liquid and vapor service valves.

29

Page 30

Installation

Proper installation site is vital for correct and ecient operation of the unit. Avoid the following sites where:

• Strong heat sources, vapors, ammable gas or volatile liquids are emitted.

• High-frequency electro-magnetic waves are generated by radio equipment, welders and medical equipment.

• e air is contaminated with industrial vapors and oils.

• e air contains sulfurous gas such as in hot spring zones.

• Poor air quality exists.

Indoor Unit

Outdoor Unit

e air inlet and outlet should be away from any

obstructions. Ensure the air will easily circulate through

the entire room.

1. Select a site where the condensate can be easily routed

or consider a condensate removal pump.

2. Select a place where it is out of reach of children.

3. Select a place that has adequate mounting structure,

strong enough to withstand the full weight and

vibration of the unit.

4. Be sure to leave enough space to allow access for

routine maintenance. Refer to unit installation

specications for clearances. Select a place more than

3 feet away from any TV or other electrical appliances

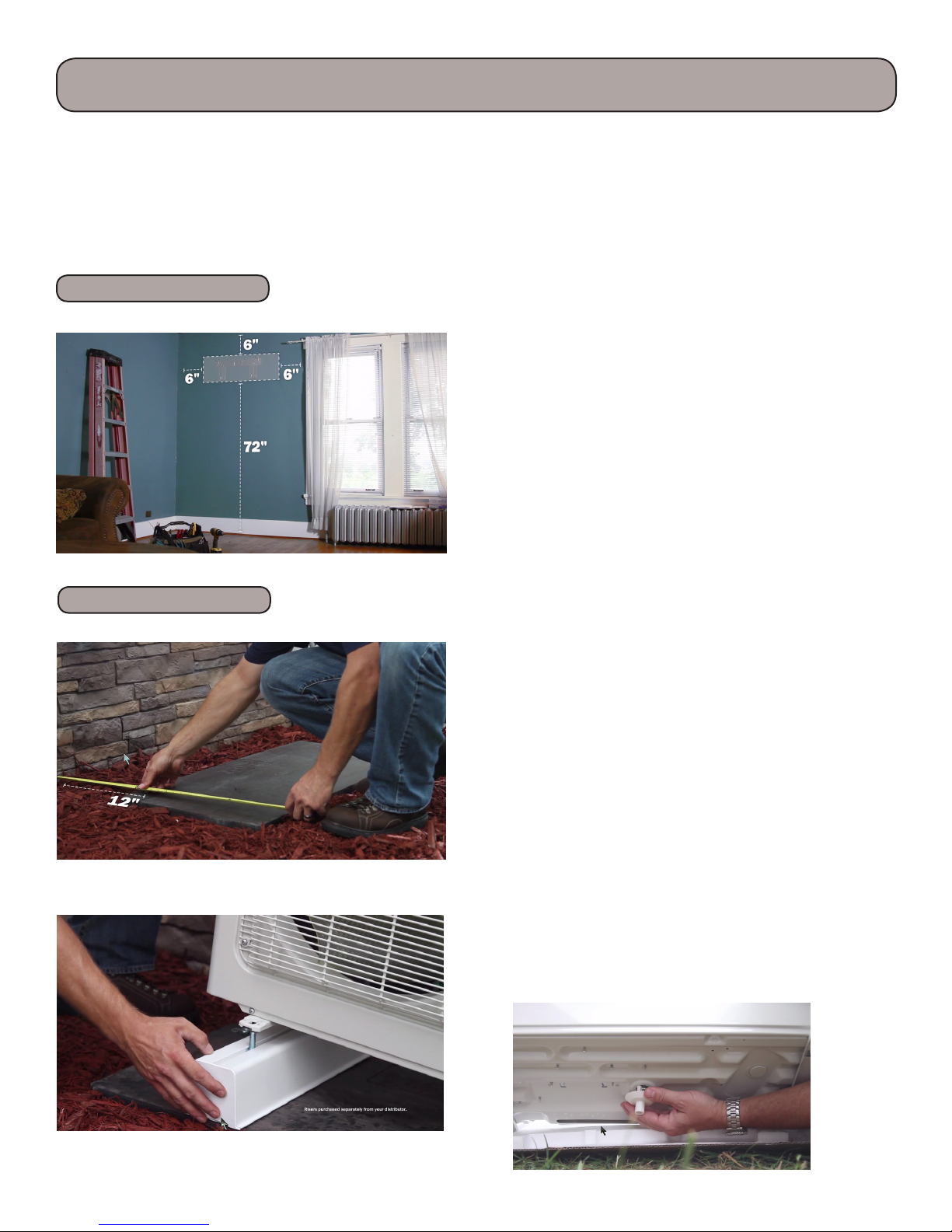

1. Select a suitable site where proper drainage will occur.

2. Select a site where there is sucient ventilation.

3. Select a site where there is no obstruction blocking the

inlet and outlet.

4. e site should be able to withstand the full weight of

the unit.

5. Try to limit expose to direct sunlight or strong winds.

6. Make sure that the outdoor unit is installed in

accordance with the installations instructions, and is

convenient for maintenance and repair.

7. Refer to your outdoor unit installation manual for

maximum lineset lengths and heights. is could be a

factor in determining outdoor location.

8. Select a place where it is out of reach of children.

9. Install Heat Pump legs to allow for proper drainage.

10. Install drain tting in bottom of outdoor unit

30

Page 31

Mounting Plate Installation

Locate and Drill Hole

Installation

1. e mounting plate should be installed horizontally

and level.

2. Measure the center of the indoor unit. Please note, that

depending on model, the center of the bracket may not

correspond with the center of the unit.

3. Attach the mounting plate on the wall with screws.

4. Be sure that the mounting plate has been attached

rmly enough to withstand approximately 132

pounds.

5. Refer to specic models for dimensional data.

1. e piping can exit the indoor unit from either side,

see pictured below.

2. Drill a 2-1/2” diameter hole at a slightly downward

angle to the outdoor side.

3. Note: e outdoor hole should be approximately 1/4”

lower than the indoor hole.

4. Insert the piping-hole sleeve into the hole to prevent

the piping and wiring from being damaged when

passing through the hole.

31

Page 32

Install Drain Hose

Install Line Set

Installation

1. Connect the drain hose to the outlet pipe of the indoor

unit using appropriate connections.

2. Insulate the condensate to prevent condensation.

3. Fasten the condensate, lineset and wring together to

prevent damage and movement. Slant the drain hose

downward for smooth drainage.

1. Install lineset and wiring from the outside through the

wall sleeve.

2. Bend the indoor lineset. Note: a tube bender will speed

up the process.

3. Carefully remove are nut from indoor coil. Listen

for holding charge from indoor unit. No charge may

indicate a leak and should be tested.

4. Use a aring tool if necessary to create the are,

connect tubing tightening to the torque listed below.

Tubing Size Torque (foot-pounds) Torque (inch-pounds)

1/4” 10-13 124-159

3/8” 25-31 301-372

1/2” 36-45 434-540

5/8” 50-60 602-726

32

Page 33

Pressure and Leak Test

Installation

1. Use only dry nitrogen with a pressure regulator for

pressurizing unit. Pressurize with 150 psi of dry

nitrogen.

2. Apply soap and water to check whether the joints are

leaky. A leak detector can also be applied for a leakage

test.

Hint: You may want to perform leak testing and evacuation

before wiring to save time, electrical connections can be

completed while your vacuum pump is running.

Evacuating the System

Note: e outdoor unit contains a refrigerant charge, leave

liquid and gas valves closed.

1. Aer no leaks have been detected, connect a vacuum

pump to the outdoor unit.

2. Connect appropriate hoses to manifold gauge, vacuum

pump and unit refrigeration connections.

3. Evacuate the system until the micron gauge reads no

higher than 350 microns.

4. Close valve to vacuum pump; if pressure does not rise

above 500 microns aer one minute, the evacuation

should be complete.

5. If it does rise, check for leaks and/or evacuate longer.

6. For refrigerant lines longer than 25 feet, refer to

installation instructions chart included with the unit

installation manual for additional charge.

33

Page 34

Connect the Outdoor Wiring

115 volt unit

shown

Installation

115 Volt unit

1. Remove the handle on the right side plate of the

outdoor unit.

2. Connect wiring from indoor unit to 1,2,3 &

ground, being careful to match color code of indoor

connections. Repeat this for each indoor unit.

3. Connect power wiring form outdoor disconnect to N,

L and ground.

4. Check all connections to tightness.

5. Reinstall the cover/handle.

Note: Follow all local electrical codes for electrical wiring.

240 Volt unit

1. Remove the handle on the right side plate of the

outdoor unit.

2. Connect wiring from indoor unit to 1,2,3 &

ground, being careful to match color code of indoor

connections. Repeat this for each indoor unit.

3. Connect power wiring form outdoor disconnect to L1,

L2 and ground.

4. Check all connections to tightness.

5. Reinstall the cover/handle.

Note: Follow all local electrical codes for electrical wiring.

34

Page 35

Filter Maintenance and Emergency Operation

Cleaning Air Filter

1. Li open the front panel as shown on the picture

2. e rst stage lter can be cleaned with a

vacuum cleaner or by washing with a mild soap

and < 113º F water.

3. e 2nd lter can be washed, use a vacuum

cleaner to clean any dust, lint, etc.

4. roughly dry lters before replacing in unit.

1st Stage Filter

Removable 2nd Stage Filter

35

Page 36

9K, 12K 115V

Symbol Color Symbol Symbol Color Symbol

WH White BN Brown

UE Ye l low BU Blue

RD Red BK Black

YEGN Yellow/Green Protective Earth

Electrical Schematics

Indoor Board

ese circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

36

Page 37

9K, 12K 115V

Symbol Parts Name Symbol Parts Name

N L Neutral Wire, 110v Live Wire WH White

4YV 4-Way Valve YE Yell o w

EKV Electric Expansion Valve RD Red

L Reactor BN Brown

COMP Compressor BU Blue

SAT Overload YEGN Yellow/Green

Electrical Schematics

Outdoor Unit

Protective Earth BK Black

ese circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

37

Page 38

9K, 12K 230V

Electrical Schematics

Indoor Board

9 & 12k

ese circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

38

Page 39

9K, 12K 230V

Outdoor Unit

Electrical Schematics

ese circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

39

Page 40

18K

Indoor Unit

Electrical Schematics

ese circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

40

Page 41

24K

Indoor Unit

Electrical Schematics

41

Page 42

24K

Indoor Unit

Electrical Schematics

42

Page 43

18K, 24K

Electrical Schematics

ese circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

43

Page 44

18K, 24K

Electrical Schematics

ese circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

44

Page 45

AP-1 Circuit Board

Compressor

Heater Band

N2 - Voltage

Terminal

4-Way Valve

Printed Circuit Boards

Compressor Wires

ermistor wires

45

Page 46

Troubleshooting Indoor Components

Indoor Fan Motor Troubleshooting

To check the condition of the indoor fan motor voltage measurements

and resistance measurements can be compared to the following charts.

Care must be taken when checking voltage measurements, all wires and

terminals must be isolated for safety. Resistance measurements must be

taken with power o and “PG” connector removed from the circuit board.

e following chart indicates approximate voltage measurements, readings may vary slightly depending on

models and should be used as a reference only. Voltages should be taken with unit running.

PG Wire Connector Low Medium High Turbo

Brown - White 130 vac 147 vac 161 vac 225 vac

Brown - Red 148 vac 184 vac 210 vac 340 vac

White - Red 123 vac 150 vac 180 vac 205 vac

e following chart indicates approximate resistance measurements, readings may vary slightly depending on

models and should be used as a reference only. Turn power o and remove connector from circuit board before

reading measurements.

PG Wire Connector Resistance (ohms)

Brown - White 97 Ω

Brown - Red 174 Ω

White - Red 78 Ω

46

Page 47

Troubleshooting Indoor Components

Step Motor Troubleshooting

To check the condition of the indoor step (swing) motor resistance measurements may be

compared to the following chart. Resistance measurements must be taken with power o and

the connector removed from the board. e following charts indicate approximate readings

and may vary with dierent models. Turn power o and remove connector from circuit board.

Connector Blue Pink Yel l ow Orange Red

Blue 397 Ω 402 Ω 400 Ω 198 Ω

Pink 400 Ω 402 Ω 198 Ω

Yell o w 402 Ω 198 Ω

Orange 198 Ω

Red

47

Page 48

Troubleshooting Outdoor Components

EEV Troubleshooting

Cooling Mode

Input

To check the operation of the EEV Valve in cooling

mode, using a digital thermometer record the

temperature of the input line and the output line

of the valve as indicated in the picture above.

With the compressor running, the input side of

the valve should have a higher reading then the

output side indicating that the valve is metering.

If the temperature readings are the same, the

valve is fully open and the valve is not metering.

Since the pressures and frequency are controlled by

the G10 technology of the outdoor circuit board,

there are no pressure checks that can be made.

Heating Mode

Output

InputOutput

To check the operation of the EEV Valve in heating

mode, using a digital thermometer record the

temperature of the input line and the output line

of the valve as indicated in the picture above.

With the compressor running, the input side of

the valve should have a higher reading then the

output side indicating that the valve is metering.

If the temperature readings are the same, the valve

is fully open and the valve is not metering. Since

the pressures and frequency are controlled by

the G10 technology of the outdoor circuit board,

there are no pressure checks that can be made.

Resistance readings of EEV valve with wire plug disconnected from circuit board. Power to unit should be o

when making resistance readings. Readings below are approximate values and may vary slightly with dierent

outdoor models.

EEV Ω Orange Red Yel lo w Black Blue

Orange 94.6 Ω 94.8 Ω 94.4 Ω 47.0 Ω

Red 94.7 Ω 94.4 Ω 47.5 Ω

Yell o w 94.6 Ω 47.7 Ω

Black 47.4 Ω

Blue

48

Page 49

Troubleshooting Outdoor Components

4-Way Valve Troubleshooting

Cooling Mode

To Accumulator

To Condenser

Suction Line

Compressor

Discharge

Checking the 4-way valve in cooling mode requires

the measurement of 4 readings. First record the

temperature of the compressor discharge tubing,

secondly record the temperature of the tubing going

to the condenser. ere should be no more than a

10 degrees dierence between the two readings.

Coil

Heating Mode

To Accumulator

To Condenser

Suction Line

Compressor

Discharge

Checking the 4-way valve in heating mode requires

the measurement of 4 readings. First record the

temperature of the compressor discharge tubing,

secondly record the temperature of the suction

line tube. ere should be no more than a 10

degrees dierence between the two readings.

Coil

e next set of readings will require recording the

temperature of the tubing going to the suction

line and the temperature of the tubing going to

the accumulator. Again, if there should be less

than 10 degrees dierence between these readings.

A temperature reading higher than 10 degrees

may indicate a leaky valve (not fully shied) or a

blockage in the valve.

4-Way valve solenoid resistance check:

Be sure all power is o to the unit. Remove the plug connecting the 4-way vale to the circuit board. Check the

resistance with an ohmmeter. e reading should indicate 1.8k Ω. If the reading is infinite, replace the solenoid

coil.

e next set of readings will require recording the

temperature of the tubing going to the condenser

coil and the temperature of the tubing going to

the accumulator. Again, if there should be less

than 10 degrees dierence between these readings.

A temperature reading higher than 10 degrees

may indicate a leaky valve (not fully shied) or a

blockage in the valve.

49

Page 50

Troubleshooting Outdoor Components

Temperature Sensor Check

Temperature

Sensor

Using a glass of ice water, place the sensor into the glass with a digital thermometer. Wait a few minutes for the

reading to stabilize. Compare the readings to the sensor tables in Appendix “A”, it the reading are not comparable,

replace the sensor. When replacing the sensor, be sure to fasten the sensor securely if it is attached to a tube.

Temp

(ºC)

0 32.0 49.02 52 125.6 4.986 104 219.2 0.898

1 33.8 46.6 53 127.4 4.802 105 221.0 0.873

2 35.6 44.31 54 129.2 4.625 106 222.8 0.848

3 37.4 42.14 55 131.0 4.456 107 224.6 0.825

4 39.2 40.09 56 132.8 4.294 108 226.4 0.802

5 41.0 38.15 57 134.6 4.139 109 228.2 0.779

6 42.8 36.32 58 136.4 3.99 110 230.0 0.758

7 44.6 34.58 59 138.2 3.848 111 231.8 0.737

8 46.4 32.94 60 140.0 3.711 112 233.6 0.717

9 48.2 31.38 61 141.8 3.579 113 235.4 0.697

Temp

(ºF)

Resistance

(k)

Temp

(ºC)

Temp

(ºF)

Resistance

(k)

Temp

(ºC)

Temp

(ºF)

Resistance

(k)

50

Page 51

Troubleshooting Outdoor Components

Compressor Windings

Red, Yellow & Blue Wires

Compressor Winding Resistance Check:

Compressor Windings

Slightly depress tab for

easy removal

Remove the compressor wires from the AP1 circuit board. e wires red to yellow, yellow to blue & red to

blue should have readings from 2 - 4 ohms. ere should be no reading from any wire to chassis ground. If the

readings between the windings dier greatly, the windings are bad. If there is a reading from any wire to the

chassis, there is leakage in the windings.

Reactor

e reactor lters out electrical noise and transient voltage spikes to the control board. ere will be a reading of

less than 1 Ω after the wires are removed. There should be no reading from either reactor terminal to ground.

51

Page 52

Troubleshooting Outdoor Components

Outdoor Fan Motor

Outdoor Motor Winding Resistance Check:

Disconnect power to the unit, all reading are made with no power and fan motor wires disconnected from

circuit board.

e chart below will indicate the approximate resistance values in ohms. is motor is a brush-less DC motor,

readings may vary slightly for dierent models. Plugging a known good motor in the board would provide a

quick troubleshooting technique.

Motor Leads Red Yell ow White

Red 75 Ω 74 Ω

Yell o w 75 Ω 74 Ω

White 74 Ω 74 Ω

52

Page 53

Troubleshooting Outdoor Components

Compressor Crankcase Heater Check

Compressor Crankcase Heater Resistance Check:

Unplug the wire connector from the circuit board. e resistance should read approximately 2.15K ohms. ere

should be no reading from either wire to ground. If readings vary from these measurements, replace the heater.

Refrigerant Temperature Sensors

ese sensors are a negative coecient thermistor that decrease in resistance as the temperature increases. e

sensors are used to monitor the temperature of the refrigerant. Please refer to the troubleshooting section for

error codes generated by a sensor fault. Temperature sensors and locations will vary depending on models.

53

Page 54

Troubleshooting Outdoor Components

Liquid Line Temperature Sensors

ese sensors are a negative coecient thermistor that decrease in resistance as the temperature increases. e

sensors are used to monitor the temperature of the refrigerant leaving the EEV to maintain a correct superheat

operation. Please refer to the troubleshooting section for error codes generated by a sensor fault. Temperature

sensors and locations will vary depending on models.

54

Page 55

Troubleshooting Outdoor Components

Exhaust Temperature Sensor

e exhaust temperature sensor monitors the refrigerant discharge temperature and will send information to the

inverter control board for system operation.

e following actions can occur:

Exhaust Temperature > 208 F - Compressor will not rise above present level

Exhaust Temperature > 217 F - Compressor will run at reduced frequency

Exhaust Temperature < 194 F - Compressor o for 3 minutes minimum, the compressor will restart

Error Code F5 will be generated if the sensor is open or shorted. Please refer to the troubleshooting section for

more detailed information.

55

Page 56

Troubleshooting Outdoor Components

Outdoor Temperature Sensor

is sensor is a negative coecient thermistor that will decrease in resistance as the temperature increases. is

sensor will monitor the temperature of the outdoor air. e reading will be used by the inverter board to adjust

frequency calculations.

Error Code F3 will be generated if the sensor is open or shorted. Please refer to the troubleshooting section for

more detailed information.

56

Page 57

Fault Displays

Troubleshooting Faults

Observe all electrical precautions during service of indoor and outdoor units. During Static service (serving nit

without power applied), wait 10 minutes before service units.

During dynamic service (servicing while unit is energized), be sure unit is properly grounded.

Troubleshooting procedure:

1. Conrmation

2. Judgment of ashing LED of Indoor/Outdoor unit

3. Check the part associated with the fault code.

Precautions:

A large capacity electrolytic capacitor is used in the outdoor unit controller (inverter). Capacitor should be

discharged before attempting to work on board. Electrical shock hazard will be present even aer unit is

disconnecte3d from power source.

Conrmation:

Conrm that the unit has proper voltage within 10% of rated value.

Observe ashing LED of indoor/outdoor unit for diagnostic information.

4 Minutes aer protection stop of motor, the malfunction error code is shown. In other situations, the

malfunction will be displayed by pressing the light button for 6 times within 4 seconds.

57

Page 58

No.

Malfuntiuon

Name

Fault Displays

9,000 and 12,000 btuh units

Display Method of Indoor Unit Display Method of Outdoor Unit

Indicator has 3 kinds of display

status and during blinking, ON

0.5ws and OFF 0.5s

Yellow

Indicator

Red

Indicator

Dual-8

Code

Display

Indicator Display (during

blinking, ON 0.5s and OFF 0.5s)

Operation

Indicator

Cool

Indicator

Heating

Indicator

A/C Status Possible Causes

Green

Indicator

1 High pressure

protection of

system

2 Antifreezing

protection

3 System block

or refrigerant

leakage

4 High discharge

temperature

protection of

compressor

E1 OFF 3s

and blink

once

E2 OFF 3S

and blink

twice

E3 OFF 3S

and blink

3 times

E4 OFF 3S

and blink

4 times

OFF

3S and

blink 3

times

OFF

3S and

blink 7

times

OFF

3S and

blink 9

times

During cooling and

drying operation, except

indoor fan operates, all

loads stop operation.

During heating

operation, the complete

unit stops.

During cooling and

drying operation,

comporessor and

outdoor fan stop while

indoor fan operates.

e Dual-8 Code

Display will show E3

until the low pressure

switch stop operation.

During cooling and

drying operation,

compressor and outdoor

fan stop while indoor

fan operates. During

heatin operation, all

loads stop

Possible reasons:

1. Refrigerant was

superabundant; 2.

Poor heat exchange

(including lth blockage

of heat exchanger

and bad radiating

environment); Ambient

temperature is too high.

1. Poor air-return in

indoor unit; 2. Fan

speed is abnormal; 3.

Evaporator is dirty

1. Low-pressure

protection; 2. Low

pressure protection

of system; 3. Low

pressure protection of

compressor

Please refer to the

malfunction analysis

(discharge protection,

overload).

5 Overcurrent

protection

E5 OFF 3S

and blink

5 times

58

OFF

3S and

blink 5

times

During cooling and

drying operation,

compressor and outdoor

fan stop while indoor

fan operates. During

heatin operation, all

loads stop

1. Supply voltage is

unstable; 2. Supply

voltage is too low and

load is too high; 3.

Evaporator is dirty.

Page 59

No.

Malfuntiuon

Name

Fault Displays

9,000 and 12,000 btuh units

Display Method of Indoor Unit Display Method of Outdoor Unit

Indicator has 3 kinds of display

status and during blinking, ON

0.5ws and OFF 0.5s

Yellow

Indicator

Red

Indicator

Dual-8

Code

Display

Indicator Display (during

blinking, ON 0.5s and OFF 0.5s)

Operation

Indicator

Cool

Indicator

Heating

Indicator

A/C Status Possible Causes

Green

Indicator

7 High

temperature

resistant

protection

8 EEPROM

malfunction

9 Limit/decrease

frequency

due to high

temperature of

module

10 Malfunction

protection of

jumper cap

11 Gathering

refrigerant

E8 OFF 3S

and blink

8 times

EE OFF

3S and

blink 15

times

EU OFF

3S and

blink 6

times

OFF

3S and

blink 6

times

C5 OFF 3S

and blink

15 times

F0 OFF 3S

and blink

1 time

OFF

3S and

blink 1

time

OFF

3S and

blink 6

times

OFF

3S and

blink 11

times

During cooling and

drying operation,

compressor and outdoor

fan stop while indoor

fan operates. During

heatin operation, all

loads stop

During cooling and

drying operation,

compressor and outdoor

fan stop while indoor

fan operates. During

heatin operation, all

loads stop

All loads operate

normally, while

operation frequency for

compressor is decreased

Wireless remote

receiver and button

are eective, but can

not dispose the related

command

When the outdoor

unit receive signal of

Gathering refrigerant,

the system will be

forced to run under

cooling mode for

gathering refrigerant

Refer to the malfunction

analysis (overload, high

temperature resistant).

Replace outdoor control

panel AP1

Discharging aer

the complete unit is

de-energized for 20

mins, check whether

the thermal grease on

IPM module of outdoor

control panel AP1 is

sucient and whether

the radiateor is inserted

tightly. If its no use,

please replace control

panel AP1.

1. No jumper cap

insert on mainboard;

2. Incorrect insert of

jumper cap; 3. Jumper

cap damaged; 4.

Abnormal detecting

circuit of mainboard.

Nominal cooling mode

59

Page 60

No.

Malfuntiuon

Name

Fault Displays

9,000 and 12,000 btuh units

Display Method of Indoor Unit Display Method of Outdoor Unit

Indicator has 3 kinds of display

status and during blinking, ON

0.5ws and OFF 0.5s

Yellow

Indicator

Red

Indicator

Dual-8

Code

Display

Indicator Display (during

blinking, ON 0.5s and OFF 0.5s)

Operation

Indicator

Cool

Indicator

Heating

Indicator

A/C Status Possible Causes

Green

Indicator

12 Indoor

ambient

temperature

sensor is open/

short circuited

13 Indoor

evaporator

temperature

sensor is open/

short circuited

14 Outdoor

ambient

temperature

sensor is open/

short circuited

15 Outdoor

condenser

temperature

sensor is open/

short circuited

F1 OFF

3S and

blink 1

time

F2 OFF

3S and

blink

twice

F3 OFF

3S and

blink 3

times

F4 OFF

3S and

blink 4

times

OFF

3S and

blink 6

times

OFF

3S and

blink 5

times

During cooling and

drying operation,

indoor unit operates

while other loads will

stop; during heating

operation, the complete

unit will stop operation

AC stops operation

once reaches the setting

temperature. Cooling,

drying: internal fan

motor stops operation

while other loads stop

operation; heating: AC

stop operation

During cooling and

drying operating,

compressor stops while

indoor fan operates;

During heating

operation, the complete

unit will stop operation

During cooling and

drying operating,

compressor stops while

indoor fan operates;

During heating

operation, the complete

unit will stop operation

1. Loosening or

bad contact of

indoor ambient

temp sensor and

mainboard terminal;

2. Components in

mainboard fell down

leads short circuit; 3.

Indoor ambient temp

sensor damaged (check

with sensor resistance

value chart); 4.

Mainboard damaged.

1. Loosening or

bad contact of

indoor evaporator

temp sensor and

mainboard terminal;

2. Components on the

mainboard fall down

leads short cirtui; 3.

Indoor evaporator temp

sensor damaged (check

temp sensor value

chart for testing) 4.

Mainboard damaged

Outdoor temperature

sensor hasn’t been

connected well is

damaged. Please check

it by referring to the

resistance table for

temperature sensor

Outdoor temperature

sensor hasn’t been

connected well or is

damaged. Please check

it by referring to the

resistance table for

temperature sensor

60

Page 61

No.

Malfuntiuon

Name

Fault Displays

9,000 and 12,000 btuh units

Display Method of Indoor Unit Display Method of Outdoor Unit

Indicator has 3 kinds of display

status and during blinking, ON

0.5ws and OFF 0.5s

Yellow

Indicator

Red

Indicator

Dual-8

Code

Display

Indicator Display (during

blinking, ON 0.5s and OFF 0.5s)

Operation

Indicator

Cool

Indicator

Heating

Indicator

A/C Status Possible Causes

Green

Indicator

16 Outdoor

discharge

temperature

sensor is open/

short circuited

17 Limit/decrease

frequency due

to overload

18 Decrease

frequency due

to overcurrent

19 Decrease

frequency due

to high air

discharge

20 Limit/decrease

frequency due

to antifreezing

21 Voltage for DC

bus-bar is too

high

F5 OFF

3S and

blink 5

times

F6 OFF

3S and

blink

6times

F8 OFF

3S and

blink

8times

F9 OFF

3S and

blink 9

times

FH OFF

3S and

blink 2

times

PH OFF

3S and

blink 11

times

OFF

3S and

blink 2

times

OFF