Page 1

GAS DRYER

®

Dry-Soft

4 & 6

Operation / Installation Manual

Models: RD-400AU & RD-600AU

This appliance shall be installed in accordance with:

• Manufacturer’s Installation Instructions

• Current AS/NZS 3000, AS/NZS 3500 & AS 5601

• Local Regulations and Municipal Building Codes

This appliance must be installed, serviced and removed by an Authorised Person.

All Rinnai gas products

are A.G.A. certified.

Distributed and serviced in Australia under a Quality

System certified as complying with ISO 9001 by

SAI Global

Page 2

REGULATORY INFORMATION

This appliance must be installed, commissioned and serviced by an Authorised person in accordance

with local gas, electrical and plumbing regulations.

The installation must also comply with these instructions.

The appliances referred to in this manual have been certified by the Australian Gas Association (AGA).

The AGA Certification number is shown on the appliance dataplate.

Keep this manual in a safe place for future referenc e.

WARRANTY

WARRANTY TERMS

The benefits conferred by this warranty are in addition to all other rights and remedies in respect of the product which

you have under the Trade Practices Act and similar State or Territory Laws. Give n instal lation and a ppl ication is in

accordance with the manufacturers specifications and instructions, Rinnai gas d ryers are warranted by Rinnai for

the cost of labour and components in the event of defects arising from faulty materials and/or workmanship in

accordance with the Terms in Table 1 and Warranty Conditions and Exclusions stated in this document and any

additional conditions and exclusions stated in the Operating and/or Installation Instructions for the appliance.

Free Labour Period Free Parts Period

Domestic Use 2 Years 2 Years

Commercial Use 1 Year 1 Year

Table 1 Warranty Terms

Definition of Domestic Use

The warranty periods that are allocated under "Domestic Use" are based on the gas clothes dryer usage of a

typical family and apply only to gas dryers installed in domestic dwellings.

Definition of Commercial Use

The warranty periods that are allocated under "Commercial Use" are for gas clothes dryers installed at premises

such as commercial and industrial buildings, hotels, motels, caravan parks and sporting complexes.

WARRANTY CONDITIONS

1. Dated proof of purchase is required to be shown to the attending service person prior to the commencement

of any warranty work.

2. The gas dryer and components must be installed in accordance with the Manufacturer's Installation

Instructions, current AS 3000, AS 3500 and AS 5601, local regulations and municipal building cod es. Gas

dryers and components must only be installed, commissioned and removed by persons authorised by local

regulations to do so and serviced and repaired by Rinnai approved technicians.

3. The warranty applies only to the components supplied by Rinnai. It does not apply to compo nents supplied

by others, such as isolating valves, electrical switches, pipework, electrical cables and fuses.

4. Where the gas dryer or it's components have not been sited in accordance with the Installation Instructions

or are installed such that normal service access is difficult, a service charge may apply. At the discretion of

the attending service person, if access is deemed dangerous service will be refused. Any work required to

gain reasonable access to gas dryer components may also be chargeable at the discretion of th e attending

service person (for example, removal of cupboards, doors or walls, or the use of special equipment to move

components to floor level).

5. Where a failed component is replaced under warranty, the balance of the original appliance warranty will

remain effective. The replacement part or appliance does not carry a new warranty.

6. Rinnai reserve the right to transfer functional components from defective appliances if they are suitable.

7. Rinnai reserve the right to have the installed product returned to the factory for inspection.

WARRANTY EXCLUSIONS:

1. Accidental damage, acts of God, failure due to misuse, incorrect or unauthorized installations, attempts to

repair the appliance other than by a Rinnai approved service technician.

2. Where it is found that there is no fault with the appliance and the issue is rela ted to the in stallation or is d ue

to the failure of electric or gas supplies or a corrosive atmosphere.

RINNAI DOES NOT ACCEPT LIABILITY FOR CONSEQUENTIAL DAMAGE OR ANY

INCIDENTAL EXPENSES RESULTING FROM ANY BREACH OF THE WARRANTY.

Rinnai i Dry-Soft® RD-400/600AU Operation / Installation Manual

Page 3

OPERATION MANUAL

REGULATORY INFORMATION...................................................................................i

WARRANTY .................................................................................................................i

ABOUT YOUR DRY-SOFT GAS DRYER ...................................................................1

CONTROL PANEL NAVIGATION ................................................................................................1

OVERVIEW OF APPLIANCE ................................................................................................. .... .. 2

SAFETY INFORMATION.............................................................................................3

FEATURES AND BENEFITS ......................................................................................4

OPERATION................................................................................................................4

GENERAL INFORMATION .................................................................... ... .... ... ... ... .... ... ............... 4

FABRIC CARE AND DRYING HINTS ........................................................... ... ... ... ...................... 4

ITEMS UNSUITABLE FOR TUMBLE DRYING............................................................................ 5

CHOICE OF OPERATING MODES AND CYCLES ..................................................................... 5

DRYING PROGRAMMES ............................... .... .......................................... ... ... ... .... ... ... ... ......... 5

OPERATIONAL TIME ... ... ... .... ... ... ... .......................................... .... ......................................... ...... 5

OPERATION IN AUTOMATIC MODE.......................................................................................... 6

OPERATION IN TIMER MODE.................................................................................................... 6

CARE AND MAINTENANCE.......................................................................................7

CLEANING THE LINT FILTER..................................................................................................... 7

CLEANING THE BACK FILTER.................................................... ... ... ... ... .... ... ... ... ...................... 7

CLEANING THE AIR INLET FILTER................... ... ... ... .... ... ... ... .... ... ... ... ... .... ............................... 8

CLEANING THE HEATER BODY ................................ .... ... ... ... .... ... ... ... ...................................... 8

SAFETY DEVICES ......................................................................................................8

TROUBLE SHOOTING................................................................................................9

TROUBLE SHOOTING CHECK LIST .......................................................................................... 9

GENERAL DRYER CHARACTERISTICS..................................... ... ... ... ... .... ... ... ......................... 9

ERROR CODES......................................................................................................................... 10

SERVICE.................................................................................................................................... 10

INSTALLATION.........................................................................................................12

APPLIANCE DETAILS..............................................................................................20

CONTACT INFORMATION .......................................................................................21

Rinnai ii Dry-Soft® RD-400/600AU Operation Manual

Page 4

ABOUT YOUR DRY-SOFT GAS DRYER

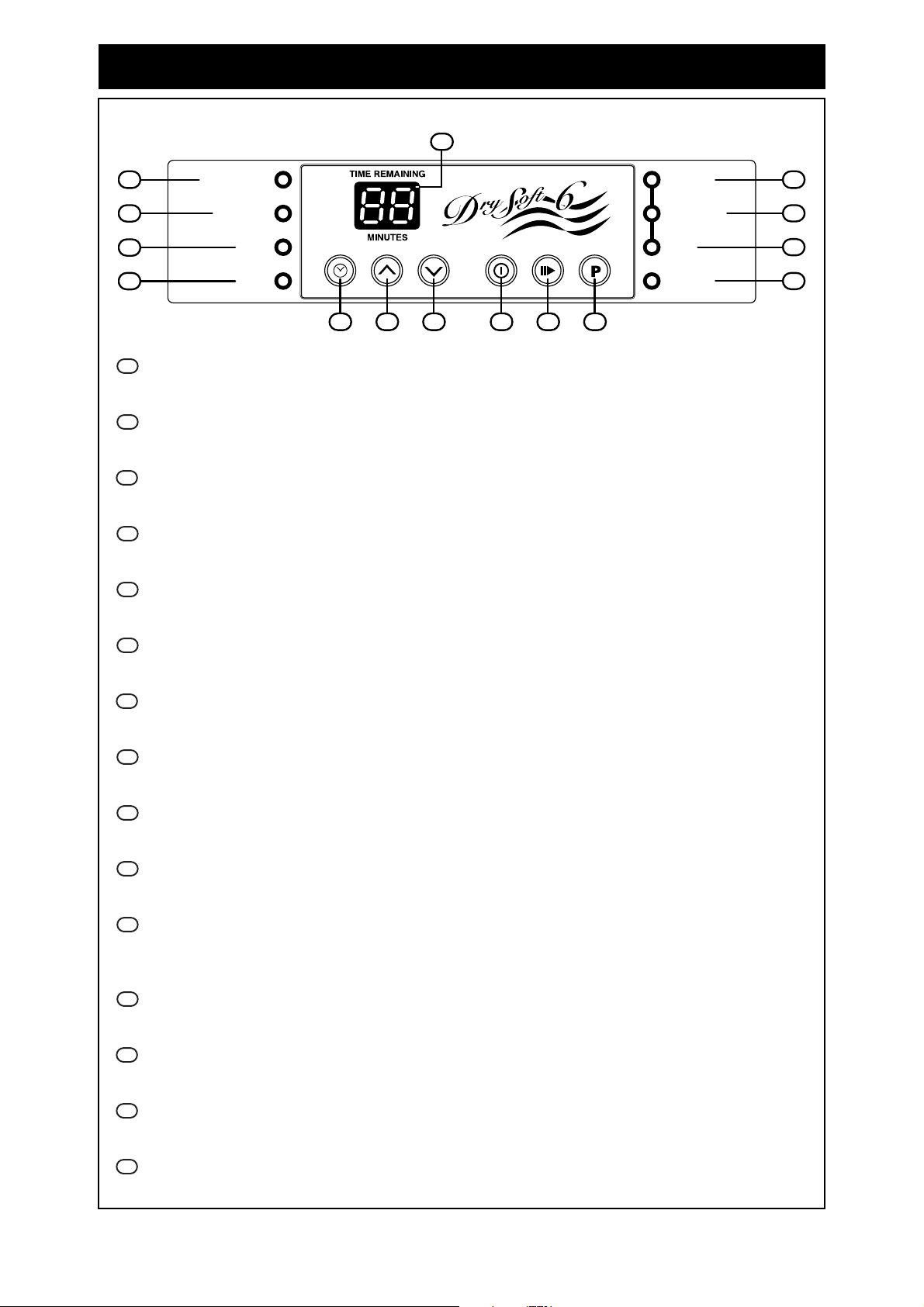

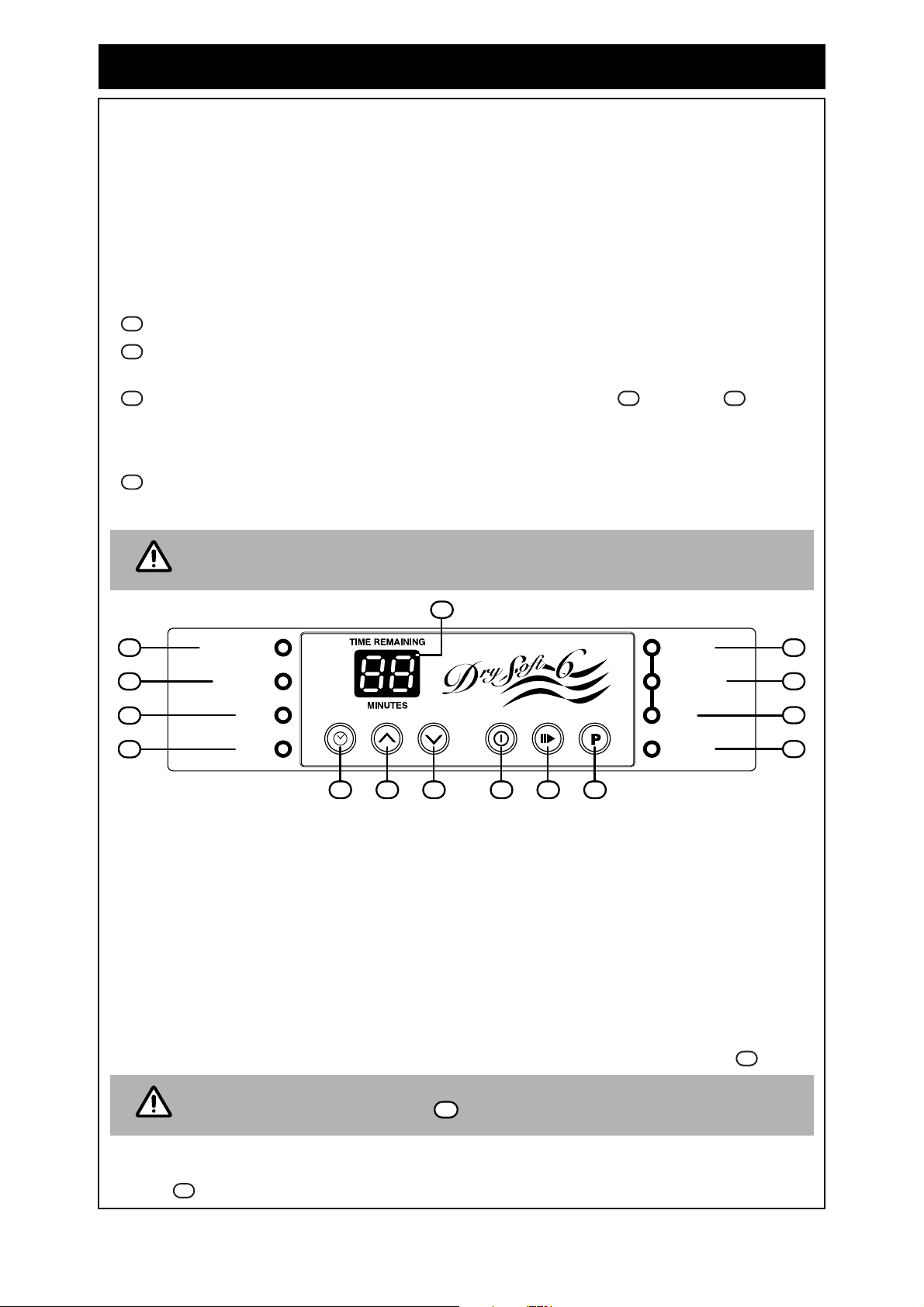

CONTROL PANEL NAVIGATION

15

14

11

12

13

ON / OFF BUTTON

1

CLEAN FILTER

OPERATING

FINISH

TIMER

5

Turn ‘ON’ and ‘OFF’ the electric power supply to the appliance.

START/PAUSE BUTTON

2

Start and pause the drying function.

PROGRAM BUTTON

3

Select the drying programme.

TIMER BUTTON

4

Select operation in Timer mode.

’UP’ BUTTON

5

Increase the drying time (operation in Timer mode only).

GENERAL

EXTRA SOFT

THICK

DELICATE

32164

7

9

8

10

‘DOWN’ BUTTON

6

Decrease the drying time (operation in Timer mode only).

GENERAL INDICATOR

7

Illuminates green when the ‘General’ drying mode has been selected.

THICK INDICATOR

8

Illuminates green when the ‘Thick’ drying mode has been selected.

EXTRA SOFT INDICATOR

9

Illuminates green when the ‘Extra Soft’ drying mode has been selected.

DELICATE INDICATOR

10

Illuminates green when the ‘Delicate’ drying mode has been selected.

OPERATION INDICATOR

11

Illuminates green when drying function has started but the gas burner is not ignited. Illuminates

red when the gas burner is ignited.

FINISH INDICATOR

12

Illuminates green when drying is completed.

TIMER INDICATOR

13

Illuminates green during operation in Timer mode.

CLEAN FILTER INDICATOR

14

Illuminates red when the filter requires cleaning.

DIGITAL DISPLAY

15

Indicates remaining drying time and error codes.

Rinnai 1 Dry-Soft® RD-400/600AU Operation Manual

Page 5

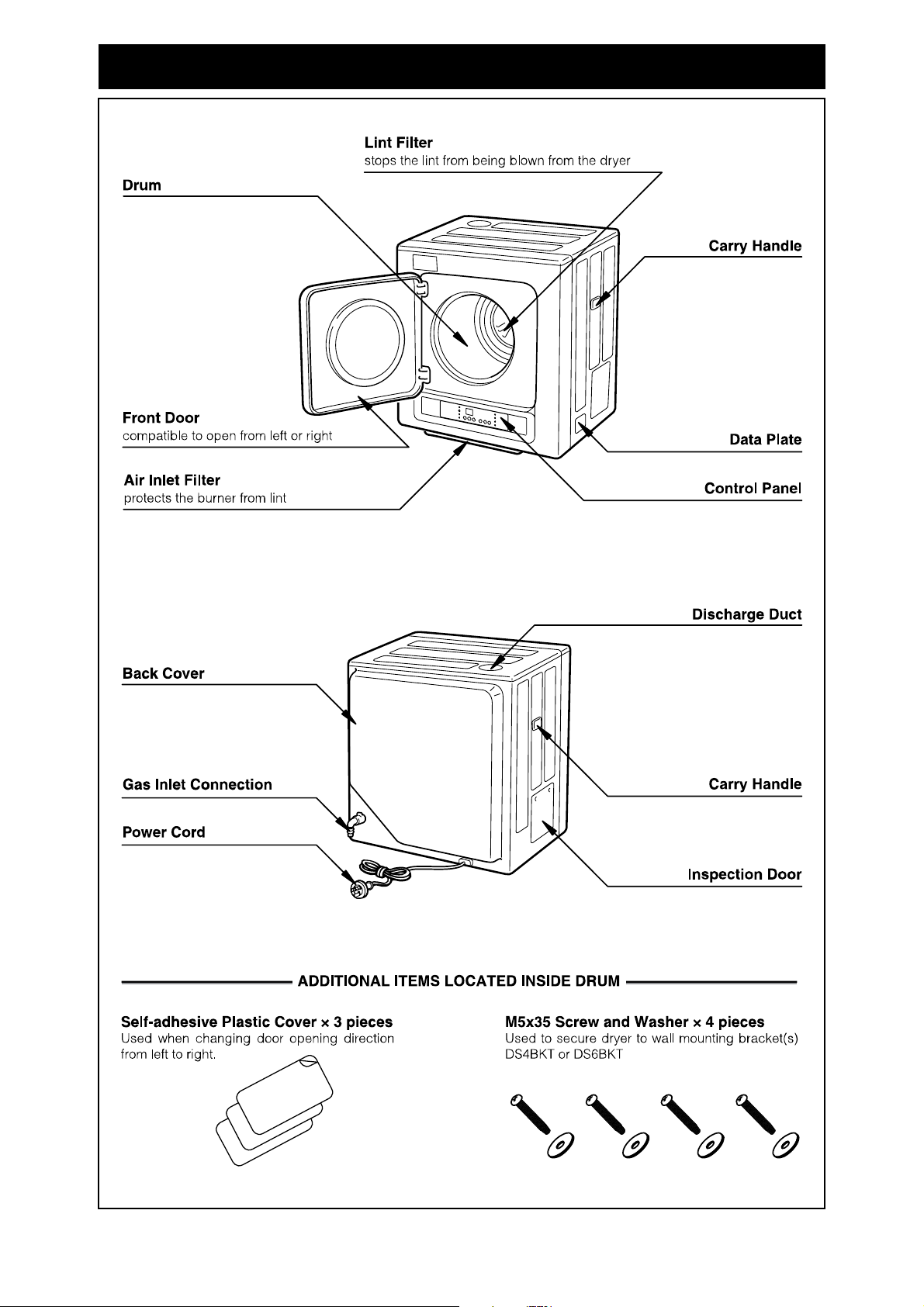

ABOUT YOUR DRY-SOFT GAS DRYER

OVERVIEW OF APPLIANCE

Rinnai 2 Dry-Soft® RD-400/600AU Operation Manual

Page 6

SAFETY INFORMATION

WARNING

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

OPERATE THIS APPLIANCE BEFORE READING THE

INSTRUCTION BOOKLET.

PLACE ARTICLES ON OR AGAINST THIS APPLIANCE.

STORE CHEMICALS OR FLAMMABLE MATERIALS,

OR SPRAY AEROSOLS NEAR THIS APPLIANCE.

OPERATE WITH PANELS, COVERS OR GUARDS

REMOVED FROM THIS APPLIANCE.

LOAD MATERIALS CONTAINING FLAMMABLE

SOLVENTS INTO THIS APPLIANCE

• Ensure all articles are removed from pockets. These include flammable items

such as matches and cigarette lighters.

• DO NOT dry clothes or materials containing foam, glue or other flammable

substances or materials.

• DO NOT use this appliance to dry off solvents, dry-cleaning fluids or other

flammable substances.

• DO NOT dry articles that have come into contact with cooking oils, petrol, dry

cleaning solvents or other flammable or explosive substances. These substances

may emit vapours or cause a chemical reaction resulting in fire or explosion.

• DO NOT operate the dryer whilst the CLEAN FILTER light is on. Any lint must be

regularly removed in accordance with these instructions.

• DO NOT open the dryer door whilst the dryer is in operation. The dryer door

should only be opened after the FINISH light illuminates.

• When the dryer cycle is finished, take care when removing laundry items. They

may still be warm or HOT.

• DO NOT use the gas clothes dryer for any purpose other than the drying of

clothes.

• Fresh air ventilation openings shall not be blocked and/or sealed.

• This appliance is not intended for use by young children or infirm persons with out

supervision. Young children should be supervised to ensure they do not play with

this appliance.

• DO NOT cover or place any articles on or against this appliance.

• DO NOT store chemicals or flammable materials or spray aerosols near this

appliance.

• DO NOT unplug the electric power cord whilst in operation.

• Ensure clothes DO NOT get stuck between the dryer door and drum. Appliance

and clothing damage may occur and an unsafe situation could result.

• DO NOT operate these appliances without the exhaust duct. These appliances

must be operated with the exhaust duct connected and terminated in accordance

with these instructions.

• If the supply cord is damaged, it must be replaced by the manufact ure r, its service

agent or similarly qualified person in order to avoid a hazard.

Rinnai 3 Dry-Soft® RD-400/600AU Operation Manual

Page 7

FEATURES AND BENEFITS

1. Quick Drying - The range of Rinnai gas clothes dryers utilise gas as the drying medium rather

than electricity. This results in a considerable reduction in drying time when compared to most

electric clothes dryers.

2.

Economical - The range of Rinnai gas clothes dryers are highly efficient. In addition, they utilise

gas rather than electricity as the drying medium. Depending on the gas type used considerable

running costs savings are possible when compared to electric clothes dryers.

Soft Clothes - Using gas as the drying medium result s in clothes tha t feel sof t er wh en compared

3.

to electric clothes dryers.

Automatic Operation - Dryer stops automatically when drying is completed. Th is eliminates the

4.

need by the user to guess how long drying might take.

5.

Time remaining indicator - Indicates the remaining time for completion of drying.

6.

Exhaust Duct - The exhaust duct vents to outside. This prevents the discharge of moist air, dust

and lint into the room containing the clothes dryer.

OPERATION

GENERAL INFORMATION

• Do not exceed the maximum drying load:

- The Maximum load for the Dry-Soft® 4 (Model RD-400AU) is 4 kg.

- The Maximum load for the Dry-Soft® 6 (Model RD-600AU) is 6 kg.

Exceeding the maximum drying load may result in uneven drying or appliance malfunction.

• Ensure clothes have been spin dried by a washing machine before placing into the gas clothes

dryer. Wet clothes may damage the dryer and will take excessively long to dry.

• Ensure washing detergents, bleaches and fabric softeners have been fully rinsed from clothes

before placing them into the gas clothes dryer. These substances may damage internal dryer

components.

• It is preferable that the space in which the gas clothes dryer is installed is well ventilated. This can

be achieved by opening a window during use.

FABRIC CARE AND DRYING HINTS

Read the fabric care label attached to most clothes to confirm if they are suitable for tumble drying

and, if so, select the drying cycle recommended by the manufacturer. In the ab sence of man ufacturer

recommendations Rinnai suggests the following:

• Use the 'GENERAL' cycle for items such as towels, shirts and underwear.

• Use the 'DELICATE' drying cycle for frayed or synthetic items (such as nylon stockings) or thin

fabrics. It is recommended that these items are placed in a laundry bag for protection during

drying.

• Use the 'THICK’ drying cycle for items such as jeans, sweatshirts or heavier winter clothes.

• If thick items are mixed with thin items, select the 'THICK' drying cycle.

• The volume of clothes in the dryer should be limited to approximately 70% of the actual drum

volume to maintain drying efficiency. If the volume of clothes exceeds 70% drying efficiency will

be reduced.

• Lint producing items (such as towels) should be dried separately to prevent the lint catching onto

other items during drying.

• For items with zippers, close the zippers and dry inside out to prevent damage to the dryer

components. The same applies to items with metallic buttons.

Rinnai 4 Dry-Soft® RD-400/600AU Operation Manual

Page 8

OPERATION

ITEMS UNSUITABLE FOR TUMBLE DRYING

• Do not tumble dry fabrics if the care label states that tumble drying is not suitable. These may

include items made from silk, wool, wool blends, leather, lace or hemp. These fabrics may shrink,

deform or fade. The same applies to items with printing or glued emblems which may fade or

separate.

• Non breathable fabrics, materials or items such as rain coats, leather, glued clothes, quilts, mats,

carpet, stuffed cushions and toys ar e unsuitable for tumble drying.

CHOICE OF OPERATING MODES AND CYCLES

Four operating modes are available as follows:

GENERAL: During the 'General' mode the gas dryer operates at full drying capacity.

7

THICK: During the 'Thick' mode the gas dryer operates for longer th an in the gen eral or delicate

8

modes.

EXTRA SOFT: This mode applies in conjunction with GENERAL or THICK modes.

9 7 8

When selected, the drying function stops intermittently. The drum sto ps rotating an d cool air is bl own

into the drying drum momentarily for 12 seconds every 4 minutes for a total cycle time of up to 120

minutes. This results in fabric that feels softer.

DELICATE: During the 'Delicate' mode the gas dryer operates at approximately half the drying

10

capacity.

i

NOTE

If the dryer door is opened during an operation cycle, the ‘Extra Soft’ function is

cancelled. There is no gas consumption during ‘Extra Soft’ operation.

15

14

11

12

13

CLEAN FILTER

OPERATING

FINISH

TIMER

5

32164

GENERAL

EXTRA SOFT

THICK

DELICATE

DRYING PROGRAMMES

Five drying programmes are available as follows:

GENERAL + EXTRA SOFT (Combines the GENERAL and EXTRA SOFT Programme modes)

GENERAL

THICK + EXTRA SOFT (Combines the THICK and EXTRA SOFT Program me mode s)

THICK

DELICATE

OPERATIONAL TIME

In automatic mode, the dryer senses the clothes volume, moisture content and drying progress

continuously. It will operate the drying function for the required amount of time for the clothes to be

dried sufficiently.The approximate remaining drying time is indicated on the digital display .

15

7

9

8

10

The remaining drying time indicated is approximate only and will be less accurate

NOTE

if the 'CLEAN FILTER' indicator is illuminated.

14

In timer mode, the user selects the duration for drying and the dryer will operate for the selected period

regardless of whether clothes are dry or not. The remaining drying time is indicated on the digital

display .

Rinnai 5 Dry-Soft® RD-400/600AU Operation Manual

15

Page 9

OPERATION

OPERATION IN AUTOMATIC MODE

1. Open the dryer door and place items selected for drying evenly into the dryer drum. Close the

dryer door and press the 'On/Off' button . The default drying programme is set to GENERAL

+ EXTRA SOFT and these mode indicators will be illuminated.

7 9

1

2. To select an alternative drying programme press the 'Programme' button until the desired

3

mode indicator illuminates. The drying programmes cycle through the following sequence:

GENERAL + EXTRA SOFT THICK+ EXTRA SOFTGENERAL THICK DELICATE

3. Press the 'Start / Pause' button . The 'OPERATING’ (Combustion) indicator will show

2

11

green, and will change to red after burner ignition which may take up to 10 seconds.

4. Drying will now commence. The approximate remaining drying time will be indicated on the digital

display . The 'OPERATING’ (Combustion) indicator may alternate between showing green

15 11

and red, however this is normal.

5. The dryer will stop when items are sufficiently dry. A tone will sound 3 times and the 'FINISH'

indicator will illuminate.

12

Before opening the dryer door, ensure the 'OPERATING’ (Combustion) indicator

shows green.

NOTE

11

If the dryer door is opened and closed dur ing op eration the dryer will go throug h a

cool down, purge and relight sequence that takes approximately 1 to 2 minut es.

OPERATION IN TIMER MODE

1. Open the dryer door and place items selected for drying evenly into the dryer drum. Close the

dryer door and press the 'On/Off' button .

2. Press the 'Timer' button , the ‘TIMER’ indicator illuminates and the default drying

programme is GENERAL and this mode indicator will be illuminated.

4

7

3. There are only two drying programmes available in “Timer’ mode, these are

GENERAL and DELICATE , press the 'Timer' button until the

7 10 4

desired programme mode indicator illuminates.

1

13

GENERAL

DELICATE

4. The default drying time in minutes is shown on the digital display . Change the drying time by

pressing the 'up' or 'down' buttons. The drying times that can be selected are

5 6

15

5,10,15,20,25,30,40,50,60,70* and 80* minutes (*Dry-Soft 6 model only).

The 'default' drying time is 20 minutes when the appliance is first c onnected t o the

NOTE

5. Press the 'Start / Pause' button , the ‘TIMER’ indicator will begin to flash to signify that a

‘Timer’ operation has begun. The 'Operating / Combustion' indicator will show green and will

electric power supply. If the appliance has operated in timer mode previously the

previous drying time selected will be shown as the default drying time.

2

13

9

change to red after burner ignition which may take up to 10 seconds.

6. Drying will now commence. The approximate remaining drying time will be indicated on the digital

display and will counted down in 5 minute increments. During operation the time may be

increased and decreased as desired by pressing the 'up' or 'down' buttons. The

'OPERA TING’ (Combustion) indicator will show green towards the end of the drying cycle, this

15

5 6

11

is normal.

7. The dryer will stop when the drying time has elapsed. A tone will sound 3 times, the ‘TIMER’

indicator will stop flashing and the 'FINISH' indicator will be illuminated.

13 12

Before opening the dryer door, ensure the 'OPERATING’ (Combustion) indicator

shows green.

NOTE

11

If the dryer door is opened and closed dur ing op eration the dryer will go throug h a

cool down, purge and relight sequence that takes approximately 1 to 2 minut es.

Rinnai 6 Dry-Soft® RD-400/600AU Operation Manual

Page 10

CARE AND MAINTENANCE

T

CLEANING THE LINT FILTER

The lint filter should be cleaned after every drying

cycle. Regular cleaning is important to maintain drying

efficiency.

The 'CLEAN FILTER' indicator illuminates when

the lint filter is too blocked and requires cleaning.

A alarm will also sound after operation stops for 5

minutes or until the dryer door is opened, whichever

comes first.

If the lint filter is not cleaned, the appliance will

eventually stop operating and an 'error' code will show

on the digital display . Refer to the Trouble

15

Shooting section on page 10 for details.

Clean the lint filter as follows:

Reach inside the drum of the dryer and remove th e

1

lint pocket/filter from the dryer by pulling on the four

finger slots of the lint pocket/filter.

Separate the lint filter from the lint pocket by pulling

2

apart as shown.

14

Remove any lint from the lint filter by using your

3

hands, a soft cloth or a soft brush as shown. If

removal of the lint proves difficult, the lint filter may

also be cleaned with the assistance of COLD water

and a soft cloth or brush.

If water is used to clean th e lint filter, then

CAUTION

4

it MUST BE thoroughly dried before it can

be re-installed.

Place the lint filter back into the lint pocket, before

attempting to push lint pocket and lint filter back

together ensure that the slotted ring of the lint filter

is forward most.

CLEANING THE BACK FILTER

The back filter is located inside the drum behind

5

the lint pocket/filter. It should be cleaned after every

drying cycle. It can usually be cleaned without

removal by using a soft cloth or brush.

Ensure dust removed from the back filter

IMPORTAN

does not remain in the drum.

If removal is required for cleaning, loosen the two

6

white plastic screws by hand or with the aid of a

phillip’s screw driver.

When re-inserting the back filter, align the holes in

7

the back filter to those in the back of the drum as

shown, insert the two white plastic screws and

hand tighten.

Rinnai 7 Dry-Soft® RD-400/600AU Operation Manual

Page 11

CARE AND MAINTENANCE

CLEANING THE AIR INLET FILTER

The air inlet filter is located at the bottom of the

8

appliance. Pull it out as shown.

Remove any dust from the air filter by using your

9

hands, a soft cloth or a soft brush as shown.

If removal of the lint proves difficult, the air filter

may also be cleaned with the assistance of COLD

water and a soft cloth or brush.

After removing dust, re-insert the air inlet filter . The

10

sides of the filter are located and guided by rails at

the bottom of the dryer body.

If water is used to clean the air filter, then it

CAUTION

MUST BE thoroughly dried before it can be

re-installed.

CLEANING THE HEATER BODY

Unplug the electrical cord before cleaning. All external parts of the appliance can be cleaned using a

soft, damp cloth and mild detergent.

DO NOT USE SOLVENTS FOR CLEANING THIS APPLIANCE.

DO NOT

SAFETY DEVICES

For your safety and peace of mind the Dry-Soft® range of gas clothes dryers are fitted with following

safety devices:

Flame failure sensing

Appliances shuts down in case of flame failure.

Drying drum overheat switch

Appliance shuts down in case the drying drum overheats. Self resetting.

Electric motor overheat switch

Appliance shuts down in case the motor overheats. Self resetting.

Drum Belt safety switch

Appliance shuts down in case of drum belt breakage.

Door Switch

Appliance cannot start unless appliance door is properly closed.

Blocked filter warning

Filter indicator lights up in case of blocked filter(s).

Electric Fuses

Protects appliance in case of electrical overload.

Rinnai 8 Dry-Soft® RD-400/600AU Operation Manual

Page 12

TROUBLE SHOOTING

TROUBLE SHOOTING CHECK LIST

Please check the following list before calling for Service. Service calls may be charged if faults are

caused by operation errors. Refer to the Warranty Conditions for more details.

If the dryer does not operate at all, check to see if the digital display is flashing with two numbers. If

yes, refer to “ERROR CODES” on page 10. If no, check the following items:

• Is the gas supply turned on?

• Is the electrical plug connected to the power supply and is the power supply switched on?

• Is electrical power available? Check supply fuses are serviceable.

• Have the 'On/Off' and 'Start Pause' buttons been presse d in accordance with these instructions?

• Is the dryer door properly closed?

• Is the digital display flashing with two numbers?

If the dryer takes too long to dry or clothing is not drying well, check the following items:

• Is the ‘CLEAN FILTER' indic ator illuminated? If yes, clean the filters in accordance with the

‘CARE AND MAINTENANCE’ instructions on page 7.

• Ensure garments have been through the washing machine spin cycle before loading into the

appliance for drying.

• Ensure garments for drying are not added during operation.

• Ensure the 'THICK' drying programme has been selected if thick garments are being dried.

GENERAL DRYER CHARACTERISTICS

The following symptoms are part of the normal opera tio n of the applian ce and do not indicate a fault:

SYMPTOMS REASON

The drum is turning even after the finishing tone

has sounded.

There is a delay after pressing the 'Start/Pause'

switch before the Operating indicator shows

red.

2

14

Dryer is operating under the 'Extra Soft'

programme.

Opening the dryer door will cancel the 'Extra

Soft' programme.

It may take some time before the burner ignites

and combustion starts.

This is a normal operational characteristic,

however if the burner does not ignite at all,

contact Rinnai.

Steam is emitted from the discharge duct

terminal.

There are some clicking noises afte r dry ing fir st

starts and after the drying cycle has finished.

The 'time remaining' shown in the digital display

has not changed for a number of minutes.

Rinnai 9 Dry-Soft® RD-400/600AU Operation Manual

High efficiency appliances tend to discharge

steam, especially on cold days. This is normal.

This is due to the expansion and contraction of

burner components with heat and is a normal

operational characteristic.

During operation in Automatic mode, the control

system continually calculates the remaining

drying time based on the rate of drying of

garments. This is a normal operational

characteristic.

Page 13

TROUBLE SHOOTING

ERROR CODES

Rinnai Dry-Soft gas clothes dryers have a self diagnostic function. If a fault occurs, a 2 digit code will

flash on the Digital Display on the control panel. This assists with diagnosing the fault and may

enable a problem to be solved without the need for attendance by service personnel. Please quote

the code displayed when arranging a service call.

Code(s) Displayed Possible Cause Remedy

05, 32, 90 Filter Blockage(s) Check and clean lint filter, back filter and air inlet filter.

11 Ignition Failure

15

Check the gas supply is turned 'on'.

Turn appliance 'off' then 'on' again.

Arrange for service if the above does not remedy the

fault.

Check the gas supply is turned on fully.

12 Flame Failure

Other - Arrange for service.

SERVICE

Rinnai recommend that this appliance be serviced every 2 years.

Any service or repair work should only be carried out by an authorised person. Rinnai Australia has a

service and spare part network in all States. Rinnai service personnel are fully trained and equipped

to provide the best service for Rinnai appliances. If your appliance needs servicing, ring the Helpline

contact numbers on the back of this manual.

Service calls for general cleaning, maintenance and wear and tear are not

NOTE

necessarily covered under the warranty. Service calls of this nature may be

chargeable.

If the power supply cord or any other component of the dryer are damaged, they

must be replaced by Rinnai or an Authorised person.

Service and repair work must be carried out by an Authorised person.

Check and clean lint filter, back filter and air inlet filter

Arrange for service if the above does not remedy the

fault.

Rinnai 10 Dry-Soft® RD-400/600AU Operation Manual

Page 14

INSTALLATION MANUAL

SPECIFICATIONS ...................................................................................................12

POSITIONING OF THE APPLIANCE ......................................................................13

GAS CONNECTION AND SUPPLY .........................................................................13

ELECTRICAL SUPPLY ............................................................................................14

APPLIANCE MOUNTING OPTIONS ........................................................................14

FLOOR MOUNTING.................. ... ... .......................................... .... ... ... ...................................... 14

BENCH OR SHELF MOUNTING............................................................................................... 14

WALL MOUNTING .................................................................................................................... 14

WALL MOUNTING BRACKET ASSEMBLY.............................................................................. 15

WALL MOUNTING BRACKET AND DRYER INSTALLATION.................................................. 15

SWAPPING DOOR FROM LEFT TO RIGHT OPENING ..........................................16

EXHAUST DUCT ......................................................................................................17

HORIZONTAL AND VERTICAL TERMINAL CLEARANCES.................................................... 17

VENTILATION REQUIREMENTS ............................................................................................. 17

EXHAUST DUCT SYSTEM COMPONENTS: ........................................................................... 18

ATTACHING THE APPLIANCE ADAPTER SPIGOT................................................................ 18

ATTACHING EXHAUST DUCT LENGTHS............................................................................... 18

ATTACHING EXHAUST DUCT VERTICAL ROOF TERMINAL................................................ 18

ATTACHING EXHAUST DUCT HORIZONTAL WALL TERMINAL........................................... 18

EXHAUST DUCT INSTALLATION OPTIONS........................................................................... 19

Rinnai 11 Dry-Soft® RD-400AU / RD-600AU Installation Manual

Page 15

INSTALLATION

SPECIFICATIONS

Description: Rinnai Gas Dryer - Dry-Soft® 4 Rinnai Gas Dryer - Dry-Soft® 6

Model: RD-400AU RD-600AU

Dimensions (mm) Height: 609, Width: 550, Depth: 490 Height: 684, Width: 650, Depth: 530

Gas Consumption 13 MJ/h 16.5 MJ/h

Gas Supply Pressure (kPa)

Weight: (Body only) 27.0 kg 32.4 kg

Standard Drying Capacity 4 kg per time 6 kg per time

Standard Drying Time 60 minutes 60 minutes

Gas Connection ½" female flared fitting ½" female flared fitting

Power Supply 240V (50 Hz) 240V (50 Hz)

Electric Consumption 260 Watts 280 Watts

Power Cord Length 1.5 metres 1.5 metres

Natural Propane Natural Propane

1.13 / 2.75 2.75 1.13 / 2.75 2.75

Drying drum overheat switch

Electric motor overheat switch

Safety Devices

Drum Belt safety switch

All dimensions in this manual are in millimetres (mm) unless otherwise stated.

NOTE

Appliance Dimensions RD-400AU

Flame failure sensing

Door Switch

Blocked filter warning

Electric Fuses

Flame failure sensing

Drying drum overheat switch

Electric motor overheat switch

Drum Belt safety switch

Door Switch

Blocked filter warning

Electric Fuses

Appliance Dimensions RD-600AU

Rinnai 12 Dry-Soft® RD-400AU / RD-600AU Installation Manual

Page 16

INSTALLATION

T

This appliance shall be installed in accordance with:

IMPORTANT

POSITIONING OF THE APPLIANCE

The main considerations when positioning the dryer are:

• Ensuring all minimum clearance requirements as shown are met.

• The location / termination of the exhaust duct system and terminal (To comply with AS 5601).

• Allowing sufficient access for ease of operation, servicing and removal of the appliance.

• Ensuring there is access to the exhaust duct connection, gas connection and air inlet filter to th e

• Ensuring there is enough ‘flex’ in the flexible gas hose when the appliance is in the installed

• Ensuring a 20mm(¤) minimum clearance be tween the exha ust duct and any comb ustible materi als.

• Ensuring that a 100mm(*) gap is provided for the opening swing of the dryer door. The dryer door

• The access door of an enclosed installation(#) must be vented with a minimum open area of

45

• Manufacturers’ Installation Instructions

• Local gas fitting regulations

• Municipal building codes

• AS 5601 Gas Installations and AS/NZS 3000 Wiring Rules

• Any other relevant Statutory Regulations

This appliance must be installed, serviced and removed by an Authorised Person.

appliance in the installed position.

position to allow for vibration which may occur during operation.

can be hinged from the left or right hand sides and therefore a gap must be provided appropriately.

250cm² (See item on page 17). A Rinnai ‘VENT’ is suitable for this purpose.

d G

55

238

20 ¤

120

120

20 ¤

150

100 *

45

TOP VIEW SIDE VIEW

440

SIDE VIEW

Enclosed Installation #

440 plus a reasonable

amount for access ~500

45

Gas connection

access hole Ø30

Chemicals or flammable materials must not be stored near the

appliance or the exhaust duct. This applies especially if the dryer is

CAUTION

positioned onto shelves or inside a cupboard.

GAS CONNECTION AND SUPPLY

The position of the gas connection is show n in “Appliance Dimensions RD-40 0AU / RD-600AU” on

page 12. The appliance is supplied with a 300mm braided flexible gas hose with a ½" female flared

fitting for connection to the consumer piping. For gas supply pressures refer to “SPECIFICATIONS”

on page 12.

The connection between the gas supply consumer piping and the flexible 300mm gas

IMPORTAN

hose flared connection must be accessible for disconnection and reconn ection when

the appliance is in the final installed position.

There must be enough 'flex' in the flexible gas hose when the dryer is installed to

allow for any vibration of the dryer that may occur during operation.

Gas pipe sizing must consider the gas input to this appliance as well as all other gas

appliances in the premises. The gas meter and regulator must be specified for the

total gas rate. Suitable sizing chart such as the one in AS 5601 should be used.

All foreign materials such as swarf must be purged from the gas supply, as they ma y

cause the gas control valve to malfunction .

Rinnai 13 Dry-Soft® RD-400AU / RD-600AU Installation Manual

Page 17

INSTALLATION

T

ELECTRICAL SUPPLY

This appliance is supplied with a 1.5 metre long power co rd with a three pin plug. Rinnai re commends

that the dryer be plugged into a dedicated 240V, 10A earthed power point.

Alternatively the appliance can be direct wired if the power supply is to be concealed.

Consult a qualified electrician if direct wiring is required as it must comp ly with the

IMPORTAN

APPLIANCE MOUNTING OPTIONS

Rinnai gas dryers may be floor, bench, shelf or wall mounted.

requirements of AS 5601, AS 3000 and any other relevant local regulations.

Floor Mounting Bench Mounting

Shelf / Cupboard

Mounting

Wall Mounting

FLOOR MOUNTING

There are no specific requirements for floor mounting of the appliance other than those that are listed

under “POSITIONING OF THE APPLIANCE” on page 13.

BENCH OR SHELF MOUNTING

Position the appliance in accordance with the requirements that are listed under “POSITIONING OF

THE APPLIANCE” on page 13.

When bench or shelf mounted, the appliance is supported by the four rubberised ‘feet’ at the base of

the appliance. These do not need to be fastened or secured to the bench or shelf. The following items

must be considered:

• The bench or shelf and it’s suppo rt(s) should be of suf f icient strength and constr uction to support the

weight of a fully loaded dryer plus the weight of any other goods it is intended to support. The loaded

weight allowances are Dry-Soft 4, 35kg and Dry-Soft 6, 45kg.

• Stability of the appliance. The bench or shelf dimension must have at least the same width and

depth as that of the appliance to provide sufficient area to support the four rubberised ‘feet’ at the

base of the appliance and allow for slight movement that may occur during operation.

WALL MOUNTING

Position the appliance in accordance with the requirements that are listed under “POSITIONING OF

THE APPLIANCE” on page 13

If the dryer is to be wall mounted, the following must be considered:

• Only the Rinnai wall mounting bracket must be used (Order codes: DS4BKT for Dry-Soft 4 and

DS6BKT for Dry-Soft 6). Alternative brackets or wall mounting options are unsuitable.

• The wall and method for fastening the wall mounting bracket to the wall must be of sufficient

strength and construction to support the weight of a fully loaded dryer. The loaded weight

allowances are Dry-Soft 4, 35kg and Dry-Soft 6, 45kg.

• The four rubberised ‘feet’ at the base of the appliance must be securely fastened to the base of the

mounting bracket using the 4 mounting screws supplied (See “WALL MOUNTING BRACKET AND

DRYER INSTALLATION” on page 15).

Rinnai 14 Dry-Soft® RD-400AU / RD-600AU Installation Manual

Page 18

INSTALLATION

WALL MOUNTING BRACKET ASSEMBLY

The wall mounting bracket is provided in kit form with the following components:

1 x Wall Fame

1 x Support Frame

4 x Hex Head Bolts and Washers

4 x Mounting Screws and Washers

Some minor assembly is required before the wall mounting bracket can be fixed to the wall.

To assemble the wall mounting bracket use the four hex head bolts and washers provided and

securely attach the support frame to the wall frame.

WALL MOUNTING BRACKET AND DRYER INSTALLATION

Attache the wall mounting bracket to a suitable wall with appropriate fixings.

Lift the dryer onto the installed wall mounting bracket taking care to locate the four securing holes of

the support frame with the four inner most holes of the appliances moulded feet.

Secure the Dryer to the frame with the four mounting screws and washers provided.

4 x Moulded Feet

4 x Moulded Feet

4 x Securing Holes

4 x Securing Holes

4 x Mounting Screws andWashers

4 x Mounting Screws andWashers

Rinnai 15 Dry-Soft® RD-400AU / RD-600AU Installation Manual

Page 19

INSTALLATION

SWAPPING DOOR FROM LEFT TO RIGHT OPENING

The dryer access door may be swapped from a left handed opening as supplied from the factory to a

right handed opening. When changing door opening direction ensure the appropriate clearances are

provided. Refer to “POSITIONING OF THE APPLIANCE” on page 13 for clearance details.

Open the dryer door fully so that it

1

locks in the open position.

Remove the two plastic tabs from

2

the appliance body to reveal the

right hand door hinge attachment

points.

Unscrew and remove the door latch

3

from the left handed position.

Apply one of the three self-adhesive

4

plastic tabs (supplied with the

appliance) over the left handed door

latch attachment point.

With the door still locked in the open

5

position remove the retaining screws

for each of the upper and lower

hinges. Remove the door with the

hinges attached by using an upward

motion to disengage the ‘T’ shaped

slots of the left handed hinge

attachment points.

After removing the door the

from the appliance the upper

NOTE

hinge will be locked into

position. However care must

be taken as the lower hinge is

only held in place by gravity.

1

4

5

180°

2

3

2

9

6

Rotate the door by 180°, ensuring

6

that the lower hinge is held in place

8

and re-attach the door to the right

hand attachment points by engaging

7

the ‘T’ shaped slots with a downward

motion. Secure both the upper and

10

11

lower hinges with a retaining screw.

Remove the plastic tab from the

7

appliance body to reveal the right

hand door latch attachment point.

Attach the door latch removed in

8

step to the above attachment

3

10

point.

180°

25mm pin

11

11

Using the remaining two self-

9

adhesive plastic tabs cover up the

left hand door hinge attachment

10

25mm pin

10

points.

Remove both the door window retaining bracket that has the 25mm pin and the door win dow

10

retaining bracket that is diagonally opposite.

Reverse the above brackets by 180° and re-attach them to the door so that the pinned bracket

11

is now in the upper most position.

9

11

Rinnai 16 Dry-Soft® RD-400AU / RD-600AU Installation Manual

Page 20

INSTALLATION

T

EXHAUST DUCT

Rinnai gas dryers must be installed with Rinnai gas dryer exhaust duct components. Two exhaust duct

kits are available, DFVKIT - vertical exhaust kit and DSHKIT horizontal exhaust duct kit. Each kit

consists of rigid aluminium pipes (can be cut to length as required) and vertical or hori zontal terminals,

stand-off brackets, rigid bends and an internal wall plate. Additional pipes and bends are available

separately if the contents of the basic kits do not meet the installations requirements.

Exhaust products from gas dryers must not be discharged into exis ting 'natural draft'

IMPORTAN

HORIZONTAL AND VERTICAL TERMINAL CLEARANCES

flue systems associated with other gas appliances. The exhaust duct(s) from multiple

Rinnai gas dryers must not be combined into a common discharge and must not be

combined with flue or exhaust duct systems from other appliances. The gas dryer is

classified as a 'fan assisted flue appliance' in AS 5601 'Gas Installations'. It must be

located so that the exhaust duct terminal exits the build ing at a suitab le point. If the

horizontal (wall) terminal is used, the location must be in accordance with Section 5

and Figure 5.3 of AS 5601. If a vertical (roof) terminal is used, the location must be in

accordance with Section 5 of AS 5601.

VENTILATION REQUIREMENTS

d

d

For enclosed installations ONLY, a minimum

d

Rinnai 17 Dry-Soft® RD-400AU / RD-600AU Installation Manual

2

250 cm

of Free Air Ventilation is required.

Page 21

INSTALLATION

g

A

A

EXHAUST DUCT SYSTEM COMPONENTS:

A

DSFSPIGOT

Appliance adapter spigot (supplied with applianc e) .

B

DSFPIPE1000

Duct pipe 1000mm and stand-off clip

(installed length 950mm, can be cut to length as required ).

C

DSVCOWL

Vertical roof terminal 1060mm and stand-off clip

(installed length to exhaust outlet 900mm).

D

DSFBEND

Pair of 45° elbows.

E

DSFPLATE

Internal wall plate.

F

DSHCOWL

Horizontal wall terminal.

G

VENT

Air vent, provides an open area of 250 cm² (x 2).

DSVKIT, Vertical Exhaust Duct Kit DSHKIT, Horizontal Exhaust Duct Kit

B C B D

DSFPIPE1000 x 2 DSVCOWL x 1 DSFPIPE1000 x 1 DSFBEND x 1

E E F

DSFPLATE x 1 DSFPLATE x 1 DSHCOWL x 1

ATTACHING THE APPLIANCE ADAPTER SPIGOT

Locate and remove the two mounting screws from either sid e of

the discharge duct, top left rear corner of the dryer.

Retrieve the appliance adapter spigot DSFSPIGOT , which is

shipped inside the drum of the dryer.

Attach the DSFSPIGOT to the discharge duct using the two

A

mounting screws removed earlier, so that the flange of the

spigot is seated flush with the top panel of the dryer.

ATTACHING EXHAUST DUCT LENGTHS

The exhaust duct components DSFPIPE1000 , and

DSFBEND , may be connected directly to the appliance

adapter spigot .

D

A

B

With the female socket end facing down, slide the selected

exhaust duct component over the DSFSPIGOT until the

female socket fully engages the spigot by 50mm.

Fit further exhaust duct components as required, maintaining

the ‘female socket end down’ orientation for the entire duct run

to the termination. Ensure that each female so cket fully engages

the male ends by 50mm.

ATTACHING EXHAUST DUCT VERTICAL ROOF TERMINAL

The DSVCOWL is fitted directly to either a DSFPIPE1000

or DSFBEND . Ensure that the female socket fully engages

C B

D

the male end by 50mm.

ATTACHING EXHAUST DUCT HORIZONTAL WALL TERMINAL

The DSHCOWL is fitted flush to the wall surface over a

35mm external wall penetration of a DSFPIPE1000 .

Secure the DSHCOWL using the 3 fixing holes provided in

F

B

F

the wall flange.

Rinnai 18 Dry-Soft® RD-400AU / RD-600AU Installation Manual

Page 22

INSTALLATION

EXHAUST DUCT INSTALLATION OPTIONS

Following are the four most common exhaust duct installation methods. The exhaust duct length can

be up to 8 metres long with a maximum of two 90° bends:

i ii iii

iv

a

C C C

c

b

e

e

B

e

b

D

e e

D

D

D

B

e

D

B

D

e

E

E

B

D

D

B

f

A

b

d

G

Direct Vertical.

i

Offset Vertical.

ii

Extended Vertical.

iii

iv

Direct or Extended Horizontal.

a

Minimum clearance 500mm to nearest part of roof.

Minimum clearance 20mm to combustible materials.

b

c

Decktite or other non lead based flashing, to be provided by installer.

d

For enclosed installations ONLY, a minimum 250cm2 of Free Air Ventilation is required.

e

The weight of the exhaust duct MUST BE supported by the stand-off supplied and NOT by the dryer.

f

A constant 2° fall to t he terminal MUST BE maintained on horizontal installations.

g

‘DSFPIPE1000’ can be cut to length as is required, provided that a clean square edge is maintained and that a minimum

penetration of 50mm remains to join other exhaust duct components.

B

B

F

g

Rinnai 19 Dry-Soft® RD-400AU / RD-600AU Installation Manual

Page 23

APPLIANCE DETAILS

For future reference please take a moment to complete the following information:

Your Retailer:

Name:

Installation Address:

Telephone No.

Date of Purchase:

Gas Dryer Model:

______________________________________________

______________________________________________

______________________________________________

______________________________________________

________ / ________ / _______________________

RD - ________________ AU

Serial Number:

______________________________________________

Rinnai 20 Dry-Soft® RD-400AU / RD-600AU Installation Manual

Page 24

CONTACT INFORMATION

Australia Pty. Ltd.

ABN 74 005 138 769

Head Office

10-11 Walker Street,

Braeside, Victoria 3195

P.O. Box 460

Tel: (03) 9271 6625

Fax: (03) 9271 6622

Rinnai has a Service and Spare Parts network with personnel who are fully trained

and equipped to give the best service on your Rinnai appliance. If your appliance

requires a service, please call our National Help Service Line. Rinnai recommends

that this appliance be serviced every 2 years.

21 Dry-Soft® RD-400/600AU TSD 05-012 Issue 1- 3/11/06

Internet: www.rinnai.com.au E-mail: enquiry@rinnai.com.au

National Help Lines

Sales & Service

Tel: 1300 555 545* Fax: 1300 555 655*

Spare Parts & Technical Info

Tel: 1300 366 388* Fax: 1300 300 141*

*Cost of a local call Higher from mobile or public phones.

BARCODE

123 45678 90123 4

U-PART Nº.

Printed in Japan YYYY.MM

Loading...

Loading...