Page 1

Performance Verification Guide

DS1000Z-E Series

Digital Oscilloscope

Aug. 2019

RIGOL (SUZHOU) TECHNOLOGIES INC.

Page 2

Page 3

RIGOL

I

Guaranty and Declaration

Copyright

© 2019 RIGOL (SUZHOU) TECHNOLOGIES INC. All Right s Reserved.

Trademark Information

RIGOL is a registered trademark of RIGOL (SUZHOU) TECHNOLOGIES INC.

Publication Number

PVA27100-1110

Notices

RIGOL products are covered by P.R.C. and foreign patents, issued and pending.

RIGOL reserves the right to modify or change parts of or all the specifications and pricing

policies at the company’s sole decision.

Information in this publica ti on re places all previously released materials.

Information in this publication is subject to change without notice.

RIGOL shall not be liable for either incidental or consequential losses in connection with the

furnishing, use, or performance of this manual, as well as any information contained.

Any part of this document is forbidden to be copied, photocopied, or rearranged without prior

written approval of RIGOL.

Product Certification

RIGOL guarantees that this product conf orms to the national and in dustrial standards in China as well

as the ISO9001:2015 standard and the ISO14001:2015 standard. Other international standard

conforman ce ce rt ifications are in progress.

Contact Us

If you have any problem or requirement when using our products or this manual, please contact

RIGOL.

E-mail: service@rigol.com

Website: www.rigol.com

DS1000Z-E Performance Verification Guide

Page 4

RIGOL

II

Safety Requirement

General Safety Summary

Please review the following safety precautions carefully before putting the instrument into operation

so as to avoid any personal injury or damage to the instrument and any product connected to it. To

prevent potential hazards, please follow the instructio ns specified in this manual to use the instrument

properly.

Use Proper Power Cord.

Only the exclusive power cord designed for the instrument and authorized for use within the local

country could be used.

Ground the Instrument.

The instrument is grounded through the Protective Earth lead of the power cord. To avoid electric

shock, connect the earth terminal of the power cord to the Protective Ea rth terminal before connecting

any input or output terminals.

Connect the Probe Correctly.

If a probe is used, the probe ground lead must be connected to earth ground. Do not connect the

ground lead to high voltage. Improper way of connection could result in dangerous voltages being

present on t he c onne ct ors , con t rols or oth e r surf aces of the oscill oscope a nd pro bes, whi ch will cause

potential hazards for operators.

Observe All Terminal Ratings.

To avoid fire or shock hazard, observe all ratings and markers on the instrument and check your

manual for more information about ratings before connecting the instrument.

Use Proper Overvoltage Protection.

Ensure that no overvoltage (such as that caused by a bolt of lightning) can reach the product.

Otherwise, the operator might be exposed to the d anger of an electric shock.

Do Not Operate Without Co v e rs.

Do not operate the instrument with covers o r panels removed.

Do Not Insert Objects Into the Air Outlet.

Do not insert anything into the holes of the fan to avoid damaging the instrument.

Use Proper Fuse.

Please use the specified fuses.

Avoid Circuit or Wire Exposure.

Do not touch exposed junctions and components when the unit is powered on.

Do Not Operate With Suspected Failures.

If you suspect that a ny da mage may occur to the inst rument, hav e it ins pected by RIGOL authorized

personnel before further operations. Any maintenance, adjustment or replacement especially to

circuits or accessories must be performed by RIGOL authorized personnel.

Provide Adequate Ventilation.

Inadequate ventilation may cause an increase of temperature in the instrument, which would cause

damage to the instrument . So please k eep the instrument w ell ventilated an d inspect the air outlet and

the fan regularly.

DS1000Z-E Performance Verification Guide

Page 5

RIGOL

III

Do Not Operate in Wet Conditions.

To avoid short circuit insi d e the instrument or electric shock, never operate the instrument in a humid

environment.

Do Not Operate in an Explosive Atmosphere.

To avoid personal injuries or damage to the instrument, never operate the instrument in an explosive

atmosphere.

Keep Product Surfaces Clean and Dry.

To avoid dust or moisture from affecting the performance of the instrument, keep the surfaces of the

instrument clean and dry.

Prevent Ele c tr o static Impact.

Operate the instrument in an ele ctrostatic discha rge protective en vi ronment to a void dama ge indu ced

by static discharges. Always ground both the internal and external conductors of cables to release

static before making connections.

Use the Battery Properly.

Do not expose the bat tery (if av ailable) t o high tem perature or fire. Keep it out of the rea ch of children.

Improper change of a battery (lithium battery) may cause an explosion. Use the RIGOL specified

battery only.

Handle with Caution.

Please handle with care during transportation to avoid damage to keys, knobs, interfac es, and other

parts on the panels.

DS1000Z-E Performance Verification Guide

Page 6

RIGOL

IV

WARNING

Indicates a potentially hazardous s ituation or pr actic e which, if not a v oided, will result i n

serious injury or death.

CAUTION

in damage to the product or loss of important data.

DANGER

It calls attention to an operation, if not correctly performed, could

result in injury or hazard immediately.

WARNING

It calls attention to an operation, if not correctly performed, could

result in potential injury or hazard.

CAUTION

It calls attention to an operation, if not correctly performed, could

product.

Hazardous Voltage

Safety Warning

Protective Earth

Terminal

Chassis Ground

Test Ground

Safety Notices and Symbols

Safety Notic e s in this Manual:

Indicates a potentially hazardous situatio n o r p ractice which, if not avoided, could result

Safety Terms on the Product:

result in damage to the product or other devices connected to the

Safety Symbols on the Product:

DS1000Z-E Performance Verification Guide

Page 7

RIGOL

V

Document Overview

This manual is used to g uide users to correctly test the performance specifications of RIGOL

DS1000Z-E series digital o scilloscope . For the operation methods used in the test procedures, please

refer to the corresponding User’s Guide.

Main Topics of this Manual:

Chapter 1 Overview

This chapter introduces th e pre parations befo re performing the performance verification tests and the

notices.

Chapter 2 Performance Verification Test

This chapter introduces the limit, test devices required as well as the test method and procedures of

each performance specification.

Appendix Test Record Form

The appendix provides a test record form for users to record the test results and judge whether each

performance specification can meet the requirement.

Format Conventions in this Manual:

1. Key

The front panel keys are denoted by the format of "Key Name ( B o l d ) + Text Box". For example,

Utility denotes the "Utility" key.

2. Menu

The menu items are denoted by the format of "Menu Word (Bold) + Character Shading". For

example, System denotes the "System" menu item under Utility.

3. Operation Step

The next step of operat ion is denoted by an ar row "". For example, Utility System denotes

pressing Utility on the front panel and then pressing System.

4. Knob

Label Knob

HORIZONTAL SCALE

HORIZONTAL POSITION

VERTICAL SCALE

VERTICAL POSITION

TRIGGER LEVEL

DS1000Z-E Performance Verification Guide

Horizontal Scale Knob

Horizontal Position Knob

Vertical Scale Knob

Vertical Position Knob

Trigger Level Knob

Page 8

RIGOL

VI

Model

Analog Bandwidth

Number of Analog Channels

DS1202Z-E

200 MHz

2

Content Conventions in this Manual:

DS1000Z-E series digital o scilloscope in clu des the fol lowing mo dels. Unless otherwise noted, this

manual takes DS1202Z-E for example t o illustrate the performance verification test methods of

DS1000Z-E series.

DS1000Z-E Performance Verification Guide

Page 9

RIGOL Contents

VII

Contents

Guaranty and Declaration ................................................................................................ I

Safety Requirement ........................................................................................................ II

General Safety Summary ................................................................................................... II

Safety Not ices and Symbols .............................................................................................. IV

Document Overview ......................................................................................................... V

Chapter 1 Overview ................................................................................................... 1-1

Test P reparations ............................................................................................................ 1-1

Self-test .................................................................................................................. 1-1

Self-calibration ......................................................................................................... 1-1

Test Resu lt Record .......................................................................................................... 1-1

Specifications ................................................................................................................. 1-2

Chapter 2 Performance Verification Test ................................................................... 2-1

Impedance Test ............................................................................................................. 2-2

Specification ............................................................................................................ 2-2

Test Connection Diagram .......................................................................................... 2-2

Test Procedures ....................................................................................................... 2-2

Test Record Form ..................................................................................................... 2-2

DC Gain Accuracy Te s t .................................................................................................... 2-3

Specification ............................................................................................................ 2-3

Test Connection Diagram .......................................................................................... 2-3

Test Procedures ....................................................................................................... 2-3

Test Record Form ..................................................................................................... 2-4

Bandwidth Test .............................................................................................................. 2-5

Specification ............................................................................................................ 2-5

Test Connection Diagram .......................................................................................... 2-5

Test Procedures ....................................................................................................... 2-5

Test Record Form ..................................................................................................... 2-6

Bandwidth Limit Test ...................................................................................................... 2-7

Specification ............................................................................................................ 2-7

Test Connection Diagram .......................................................................................... 2-7

Test Procedures ....................................................................................................... 2-7

Test Record Form ..................................................................................................... 2-8

Time Base Accuracy Test ................................................................................................. 2-9

Specification ............................................................................................................ 2-9

Test Connection Diagram .......................................................................................... 2-9

Test Procedures ....................................................................................................... 2-9

Test Record Form ................................................................................................... 2-10

Zero Point Offset Test ................................................................................................... 2-11

Specification .......................................................................................................... 2-11

Test Connection Diagram ........................................................................................ 2-11

Test Procedures ..................................................................................................... 2-11

Test Record Form ................................................................................................... 2-12

Appendix Test Record Form ............................................................................................. 1

DS1000Z-E Performance Verification Guide

Page 10

Page 11

Chapter 1 Overview RIGOL

1-1

results in the copy so that the form can be used repeatedly.

Chapter 1 Overview

Test Preparations

The following preparations should be done before the test:

1. Self-test

2. Warm-up (make sure that the instrument has been running for at least 30 minutes)

3. Self-calibration

Self-test

When the oscilloscope is in power-on state, press the power key at the lower left corner of the front

panel to start the oscilloscope. During the start-up, the instrument pe rforms a series of self -test items.

The welcome screen is displayed after the self-test is finished.

If the oscilloscope cannot start normally, refer to "Troubleshooting" section in

to locate the problem and resolve it. Do not perform self-calibration or performance tests until the

instrument passes the self-test.

Self-calibration

Make sure that the oscilloscope has been warmed up or running for more than 30 minutes before

performing self-calibration.

1. Disconnect the connections of all the channels.

2. Press Utility Self-Cal; pr e ss Start to execute sel f-calibration.

3. The self-calibration lasts for about 30 minutes. After the self-calibration is finished, the

corresponding prompt message is displayed. At this point, please restart the instrument.

4. Press Acquire Mode and use to select "Average"; press Averages and use to set it to

16.

5. Set the probe attenuation ratio of each channel to "1X" (press CH1 (or CH2) Probe).

6. Set the vertical scale of each channel to 2 mV/div and view the o ffs e t of the waveform of e ach

channel. If the offset is greater than 0.5 div, check whether there are interference signals around

you and whether the power source is well grounded. If yes, perform self-calibration again.

DS1000Z-E User Guide

Test Result Record

Record and keep the test result of each test. In the Appe ndi x of this man ual, a test result record form

which lists all the test it ems and their corresponding performance limits as well as spaces f or us ers to

record the test results, is provided.

Tip:

It is recommended that users photocopy the test record form before each test and record the test

DS1000Z-E Performance Verification Guide

Page 12

RIGOL Chapter 1 Overview

1-2

minutes.

Specifications

The specification of each test item is provided in chapter 2. For other specifications, refer to

DS1000Z-E Data Sheet

Tip:

All the specifications are only valid when the oscilloscope has been warm ed up for more than 30

(available to download from RIGOL official website (www.rigol.com)).

DS1000Z-E Performance Verification Guide

Page 13

Chapter 2 Performance Verification Test RIGOL

2-1

Recommended

Model

DC output voltage range:

Fast edge signal rise time: ≤ 150 ps

50 Ω Impedance

Adapter

Chapter 2 Performance Verification Test

This chapter introduces the performance verification test methods and procedures of DS1000Z-E

series digital oscilloscope by taking DS1202Z-E as an example. Fluke 9500B is used in this manual for

the tests. You can also use other devices that fulfill the “Specification” in Table 2-1.

Table 2-1 Test Devices Required

Device Specification

Oscilloscope

Calibrator

Note:

1. Make sure that the oscilloscope passes the self-test and self-calibration is performed before

executing the performance verification tests.

2. Make sure that the oscilloscope has bee n warmed u p for at lea st 30 minutes before exe cuting an y

of the following tests.

3. Please reset the instrument to the factory setting before or after executing any of the following

tests.

1 MΩ: 1 mV to 200 V

50 Ω: 1 mV to 5 V

BNC (M)-BNC (F) cable --

Fluke 9500B

DS1000Z-E Performance Verification Guide

Page 14

RIGOL Chapter 2 Performance Verification Test

2-2

Input Impedance

Analog Channel

1 MΩ: 0.99 MΩ to 1.01 MΩ

Channel

Vertical Scale

Test Result

Limit

Pass/Fail

100 mV/div

500 mV/div

100 mV/div

500 mV/div

Fluke 9500B

DS1000Z-E

Impedance Test

Specification

Test Connection Di ag ram

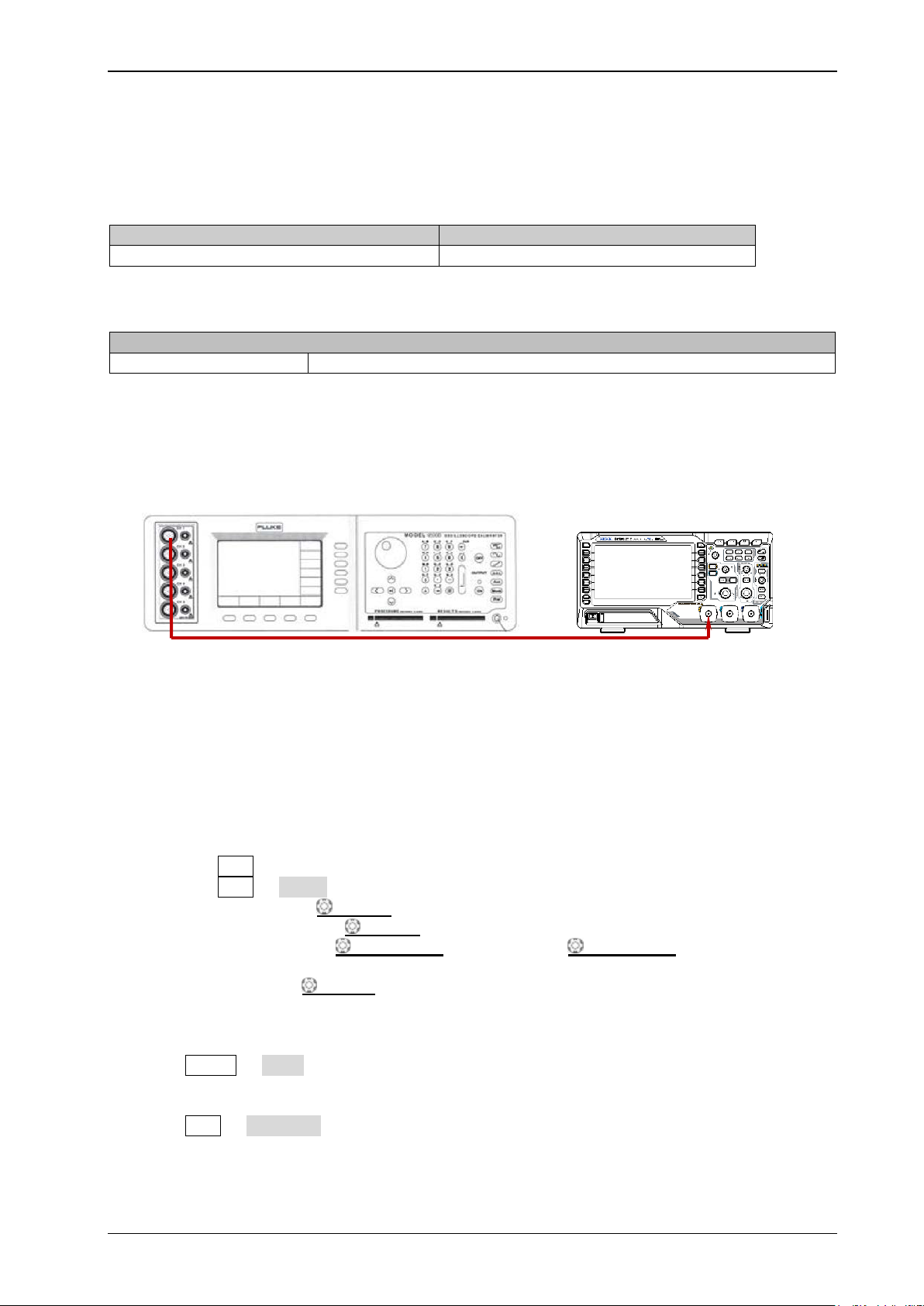

Figure 2-1 Impedance Test Connection Diagram

Test Procedures

1. Connect the active head of Fluke 9500B to CH1 of th e osci llos cope , as shown in the figure above.

2. Configure the oscilloscope:

1) Press CH1 in the vertical control area (VERTICAL) on the front panel to turn on CH1.

2) Press CH1 Probe to set the probe attenuation ratio to "1X".

3) Rotate VERTICAL SCALE to set the vertical scale of CH1 to 100 mV/div.

3. Turn on Fluke 9500B; set its impedance to 1 MΩ and select the resistance mea surement f unction .

Read and record the resistance measured.

4. Rotate VERTICAL

mV/div; read and record the resistance measured.

5. Turn off CH1. Measure the resistance of CH2 using the method above and record the

measurement results.

Test Record Form

SCALE to adjust the vertical scale of CH1 of the oscilloscope to 500

CH1

CH2

0.99 MΩ to 1.01 MΩ

DS1000Z-E Performance Verification Guide

Page 15

Chapter 2 Performance Verification Test RIGOL

2-3

DC Gain Accuracy

< 10 mV: ±4% × Full Scale

[1]

≥ 10 mV: ±3% × Full Scale

Fluke 9500B

DS1000Z-E

DC Gain Accuracy Test

Specification

Specification

[1]

Note

: Full Scale = 8 × Current Vertical Scale

[1]

Test Connection Di ag ram

Figure 2-2 DC Gain Accurac y Test Connection Diagram

Test Procedures

1. Connect the active head of Fluke 9500B to CH1 of th e osci llos cope , as shown in the figure above.

2. Turn o n Fluke 9500B and set its impedance to 1 MΩ.

3. Output a DC signal with +3 mV

4. Configure the oscilloscope:

1) Press CH1 in the vertical control area (VERTICAL) on the front panel to turn on CH1.

2) Press CH1 Probe to set the probe attenuation ratio to "1X".

3) Rotate VERTICAL SCALE to set the vertical scale to 1 mV/div.

4) Rotate HORIZONTAL SCALE to set the horizontal time base to 100 us/div.

5) Press VERTICAL POSITION to set the vertical position to 0.

6) Press Acquire Mode and use to select "Average" acquisition mode; press Averages

and use to set the number of averages t o 32.

7) Adjust the trigger level to avoid that the signals are being triggered by mistake.

5. Press MENU Vavg at the left side of the screen of the oscilloscope to turn on the average

measurement function. Read and record Vavg1.

6. Adjust Fluke 9500B to make it output a DC signal with -3 mV

7. Press MENU Vavg at the left side of the screen of the oscilloscope to turn on the average

measurement function. Read and record Vavg2.

8. Calculate the relative error of this vertic al scale: |(Vavg1 - Vavg2) - (Vout1 - Vout2)|/Full

Scale × 100%.

9. Keep the other settings of the oscilloscope unchanged:

1) Set the vertical scale to 2 mV/div, 5 mV/div, 10 mV/div, 20 mV/div, 50 mV/div, 100 mV/div,

voltage (Vout1) via Fluke 9500B.

DC

voltage (Vout2).

DC

DS1000Z-E Performance Verification Guide

Page 16

RIGOL Chapter 2 Performance Verification Test

2-4

Vertical

Test Result

Vavg1

Vavg2

Calculation Result

[1]

1 mV/div

2 mV/div

5 mV/div

10 mV/div

20 mV/div

50 mV/div

100 mV/div

200 mV/div

500 mV/div

1 V/div

2 V/div

5 V/div

10 V/div

1 mV/div

2 mV/div

5 mV/div

10 mV/div

20 mV/div

50 mV/div

100 mV/div

200 mV/div

500 mV/div

1 V/div

2 V/div

5 V/div

10 V/div

200 mV/div, 500 mV/div, 1 V/div, 2 V/div, 5 V/div and 10 V/div respectively.

2) Adjust the output voltage of Fluke 9500B to 3 × the current vertical scale and -3 × the

current vertical scale respectively.

3) Repeat steps 3 to 7 and record the test results.

4) Calculate the relative err or of eac h v erti cal scale: |(Vavg1 - Vavg2) - (Vout1 - Vout2)|/

Full Scale × 100%.

10. Turn off CH1. Test the relative error of each scale of CH2 using the method above and record the

test results.

Test Record Form

Channel

CH1

CH2

Scale

Limit Pass/Fail

≤ 4%

≤ 3%

≤ 4%

≤ 3%

[1]

Note

are 3 × the current vertical scale and -3 × the current vertical scale respectively.

: The calculation formula is |(Vavg1 - Vavg2) - (Vout1 - Vout2)|/Full Scale × 100%; w h er ein , Vout1 and Vout2

DS1000Z-E Performance Verification Guide

Page 17

Chapter 2 Performance Verification Test RIGOL

2-5

Bandwidth

Amplitude Loss

[1]

200 MHz

-3 dB, all-channel mode

Fluke 9500B

DS1000Z-E

50 Ω Impedance Adapter

Bandwidth Test

The bandwidth test verif i es the bandwidth performance of the oscilloscope by testing the amplitude

loss of the oscilloscope under test at full bandwidth.

Specification

[1]

Note

effective value at 1MHz and Vrms2 is the measurement result of amplitude effective value at full bandwidth.

Test Connection Di ag ram

: Amplitude Loss (dB) = 20 × lg (Vrms2/Vrms1); wherein, Vrms1 is the measurement result of amplitude

Figure 2-3 Bandwidth Test Connection Diagram

Test Procedures

1. Connect the active head of Fluke 9500B to CH1 of the oscill osc ope via a 50 Ω impe dan ce a dapte r,

as shown in the figure above.

2. Turn o n Fluke 9500B and set its impedance to 50 Ω.

3. Configure the oscilloscope:

1) Press CH1 in the vertical control area (VERTICAL) on the front panel to turn on CH1.

2) Press CH1 Probe to set the probe attenuation ratio to "1X".

3) Rotate HORIZONTAL SCALE to set the horizontal time base to 500 ns/div.

4) Rotate VERTICAL SCALE to set the vertical scale to 10 0 mV /div.

5) Press HORIZONTAL POSITION and VERTICAL POSITION respectively to set the

horizontal position and vertical position to 0.

6) Press TRIGGER LEVEL to set the trigger level to 0 V.

4. Output a Sine with 1 MHz frequency and 600 mVpp amplitude via Fluke 9500B.

5. Press MENU Vrms at the left side of the screen of the oscilloscope to turn on the effective

value measurement function. Read and record Vrms1.

6. Output a Sine with 200 MHz frequenc y and 600 mVpp amplitude via Fluke 9500B.

7. Rotate HORIZONTAL

8. Press MENU Vrms at the left side of the screen of the oscilloscope to turn on the effective

value measurement function. Read and record Vrms2.

SCALE to set the horizontal time base to 2 ns/div.

DS1000Z-E Performance Verification Guide

Page 18

RIGOL Chapter 2 Performance Verification Test

2-6

Test Result

Amplitude

Loss

100 mV/div

500 mV/div

100 mV/div

500 mV/div

9. Calculate the amplitude loss: Amplitude Loss (dB) = 20 × lg (Vrms2/Vrms1).

10. Keep the other settings of the oscilloscope in Step 3 unchanged and set the vertical scale to 500

mV/div.

11. Output a Sine with 1 MHz frequency and 3 Vpp ampli t ude via Fluke 9500B.

12. Repeat Step 5.

13. Output a Sine with 200 MHz frequency and 3 Vpp amplitude via Fluke 9500B.

14. Repeat Step 7-9.

15. Turn off CH1. T est CH2 using the method above and record the test results.

Test Record Form

Channel

CH1

CH2

[1]

Note

: Amplitude Loss (dB) = 20 × lg (Vrms2/Vrms1).

Vertical

Scale

Vrms1 Vrms2

[1]

Limit Pass/Fail

-3 dB to 3 dB

DS1000Z-E Performance Verification Guide

Page 19

Chapter 2 Performance Verification Test RIGOL

2-7

Input Impedance of the Oscilloscope

Available Bandwidth Limit

1 MΩ

20 MHz

Bandwidth Limit

Amplitude Loss

[1]

-3 dB, all-channel mode

DS1000Z-E

Fluke 9500B

Bandwidth Limit Test

The bandwidth limit test v erifies the 20 MHz bandwidth limit function of the os cilloscope by testin g the

amplitude loss of the oscilloscope under test at the bandwidth limit.

Table 2-2 Bandwidth Limit

Specification

[1]

Note

effective value at 1 MHz; Vrms2 is the measurement result of amplitude effective value at the bandwidth limit.

Test Connection Di ag ram

: Amplitude Loss (dB) = 20 × lg (Vrms2/Vrms1). Wherein, Vrms1 is the measurement result o f ampl itude

Figure 2-4 Bandwidth Limit Test Connection Diagram

Test Procedures

1. Connect the active head of Fluke 9500B to CH1 of the oscilloscope , as shown in the figure above.

2. Turn o n Fluke 9500B and set its impedance to 1 MΩ.

3. Configure the oscilloscope:

1) Press CH1 in the vertical control area (VERTICAL) on the front panel to turn on CH1.

2) Press CH1 Probe to set the probe attenuation ratio to "1X".

3) Rotate VERTICAL SCALE to set the vertical scale to 100 mV/div.

4) Rotate HORIZONTAL SCALE to set the horizontal time base to 500 ns/div.

5) Press HORIZONTAL POSITION and VERTICAL POSITION respectively to set the

horizontal position and vertical position to 0.

6) Press TRIGGER LEVEL to set the trigger level to 0 V.

4. Output a Sine wit h 1 MHz frequency and 600 mVpp amplitude via Fluke 9500B.

5. Press MENU Vrms at the left side of the screen of the oscilloscope to turn on the effective

value measurement function. Read and record Vrms1.

6. Press CH1 BW Limit to set the bandwidth limit to "20 M".

7. Output a Sine with 20 MHz frequency and 600 mVpp amplitude via Fluke 9500B.

DS1000Z-E Performance Verification Guide

Page 20

RIGOL Chapter 2 Performance Verification Test

2-8

Test Result

Amplitude

Loss

100 mV/div

500 mV/div

100 mV/div

500 mV/div

8. Rotate HORIZONTAL SCALE to set the horizontal time base to 50 ns/div.

9. Press MENU Vrms at the left side of the screen of the oscilloscope to turn on the effective

value measurement function. Read and record Vrms2.

10. Calculate the amplitude loss: Amplitude Loss A1 (dB) = 20 × lg (Vrms2/Vrms1) and

compare the result with the specification. At this point, the amplitude loss should be within the

specification range .

11. Keep the other settings of the oscilloscope in Step 3 unchanged and set the vertical scale to 500

mV/div.

12. Output a Sine with 1 MHz frequency and 3 Vpp amplitude via Fluk e 9500B.

13. Repeat Step 5.

14. Output a Sine with 20 MHz frequency and 3 Vpp amplitude via Fluke 9500B.

15. Repeat Step 8-10.

16. Turn off CH1. T est CH2 usi ng the met ho d above.

Test Record Form

Channel

CH1

CH2

[1]

Note

Vertical

Scale

: Amplitude Loss (dB) = 20 × lg (Vrms2/Vrms1).

Vrms1 Vrms2

[1]

Limit Pass/Fail

-3 dB to 3 dB

DS1000Z-E Performance Verification Guide

Page 21

Chapter 2 Performance Verification Test RIGOL

2-9

Time Base Accuracy

[1]

≤ ±(25 ppm + Clock Drift

[2]

×Number of years t hat the instrument h as

been used

Fluke 9500B

DS1000Z-E

Time Base Accura cy Test

Specification

Specification

[1]

Note

Note

Note

verification certificate provided when the instrument leaves factory.

: Typical.

[2]

: Clock drift is lower than or equal to ±5 ppm/year.

[3]

: For the number of years that the instrument has been used, please calculate according to the date in the

[3]

)

Test Connection Diagram

Figure 2-5 Time Base Accurac y Test Connection Diagram

Test Procedures

1. Connect the active head of Fluke 9500B to CH1 of th e osci llos cope , as shown in the figure above.

2. Turn on Fl uke 9500B and set its impedance to 1 MΩ.

3. Output a Sine with 10 MHz frequency and 1.2 Vpp amplitude via Fluke 9500B.

4. Configure the oscilloscope:

1) Press CH1 in the vertical control area (VERTICAL) on the front panel to turn on CH1.

2) Press CH1 Probe to set the probe attenuation ratio to "1X".

3) Rotate VERTICAL SCALE to set the vertical scale to 200 mV/div.

4) Press VERTICAL POSITION to set the vertical position to 0.

5) Rotate HORIZONTAL SCALE to set the horizontal time base to 10 ns/div.

6) Rotate HORIZONTAL POSITION to set the horizontal p osition to 1 ms.

5. Observe the s creen of the o scilloscope . Press Cursor Mode "Manual" to t urn on the manual

cursor function. Measure the offset (ΔT) of the middle point o f t he signal ( namely the crossing

point of the rising edge of t he current signal and the trigger level line ) relative to the screen center

using manual cursor measurement and record the measurement result.

6. Calculate the time b ase ac curacy; na mely the ratio of ΔT to the horizontal position of the

oscilloscope. For example, if the offset measured is 1 ns, the time ba se accuracy is 1 ns/1 ms=1

ppm.

7. Calculate the time b ase accuracy limit using the formula "±(25 ppm + 5 ppm/year × number of

years that the instrument has been used).

DS1000Z-E Performance Verification Guide

Page 22

RIGOL Chapter 2 Performance Verification Test

2-10

Channel

Test Result ΔT

Calculation Result

[1]

Limit

Pass/Fail

±(25 ppm + 5 ppm/year ×

instrument has been used

)

Test Record Form

CH1

[1]

Note

Note

verification certificate provided when the instrument leaves factory.

: Calculation Result = Test Result ΔT/1 ms.

[2]

: For the number of years that the instrument has been used, please calculate according to the date in the

number of years that the

[2]

DS1000Z-E Performance Verification Guide

Page 23

Chapter 2 Performance Verification Test RIGOL

2-11

Zero Point Offset

Specification

2.5 ns

Fluke 9500B

DS1000Z-E

50 Ω Impedance Adapter

Zero Point Offset Test

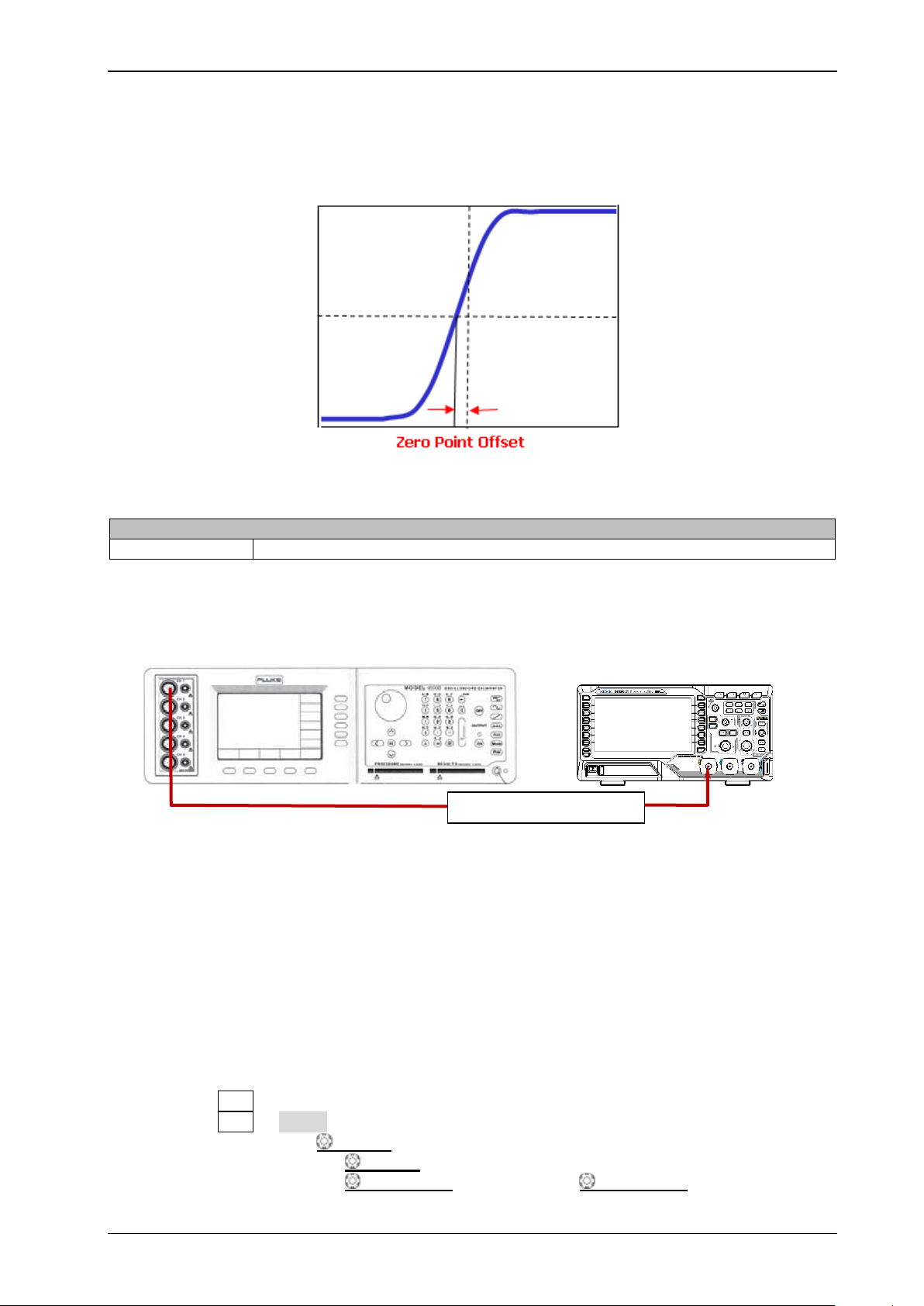

Zero point offset is defined as the offset of the crossing point of the waveform and trigger level line

relative to the trigger position, as shown in the figure below.

Specification

Test Connection Diagram

Figure 2-6 Zero Point Offset Test Connection Diagram

Test Procedures

1. Connect the active signal terminal of Fluke 9500B to CH1 of the oscilloscope via a 50 Ω impedance

adapter, as shown in the figure above.

2. Turn o n Fluke 9500B an d se t i ts impedance to 50 Ω.

3. Output a fast edge signal with 500 ps rise time and 1.2 V amplitude via Fluke 9500B.

4. Configure the oscilloscope:

1) Press CH1 in the vertical control area (VERTICAL) on the front panel to turn on CH1.

2) Press CH1 Probe to set the probe attenuation ratio to "1X".

3) Rotate VERTICAL SCALE to set the vertical scale to 20 0 mV/div.

4) Rotate HORIZONTAL SCALE to set the horizontal time base to 5 ns/div.

5) Rotate HORIZONTAL POSITION and VERTICAL POSITION respectively to

DS1000Z-E Performance Verification Guide

Page 24

RIGOL Chapter 2 Performance Verification Test

2-12

Fast Edge Signal

Amplitude

Vertical

Scale

1.2 Vpp

200 mV/div

3 Vpp

500 mV/div

1.2 Vpp

200 mV/div

3 Vpp

500 mV/div

adjust the horizontal position and vertical position properly.

6) Rotate TRIGGER

LEVEL to adjust the trigger level to the middle of the screen.

5. Observe the s creen of the o scilloscope . Press Cursor Mode "Manual" to t urn on the manual

cursor function. Measure the zero point offset using manual cursor measurement and record the

measurement result.

6. Output a fast edge signal with 500 ps rise time and 3 V amplitude via Fluke 9500B.

7. Keep the oth er settings of the oscilloscope unchanged and set the vertical scale to 500 mV/div.

8. Repeat Step 5; measure the zero point offset and record the measurement result.

9. Turn off CH1. Test CH2 according to the method above and record the test results.

Test Record Form

Channel

Test Result Limit

Pass/Fail

CH1

≤ 2.5 ns

CH2

DS1000Z-E Performance Verification Guide

Page 25

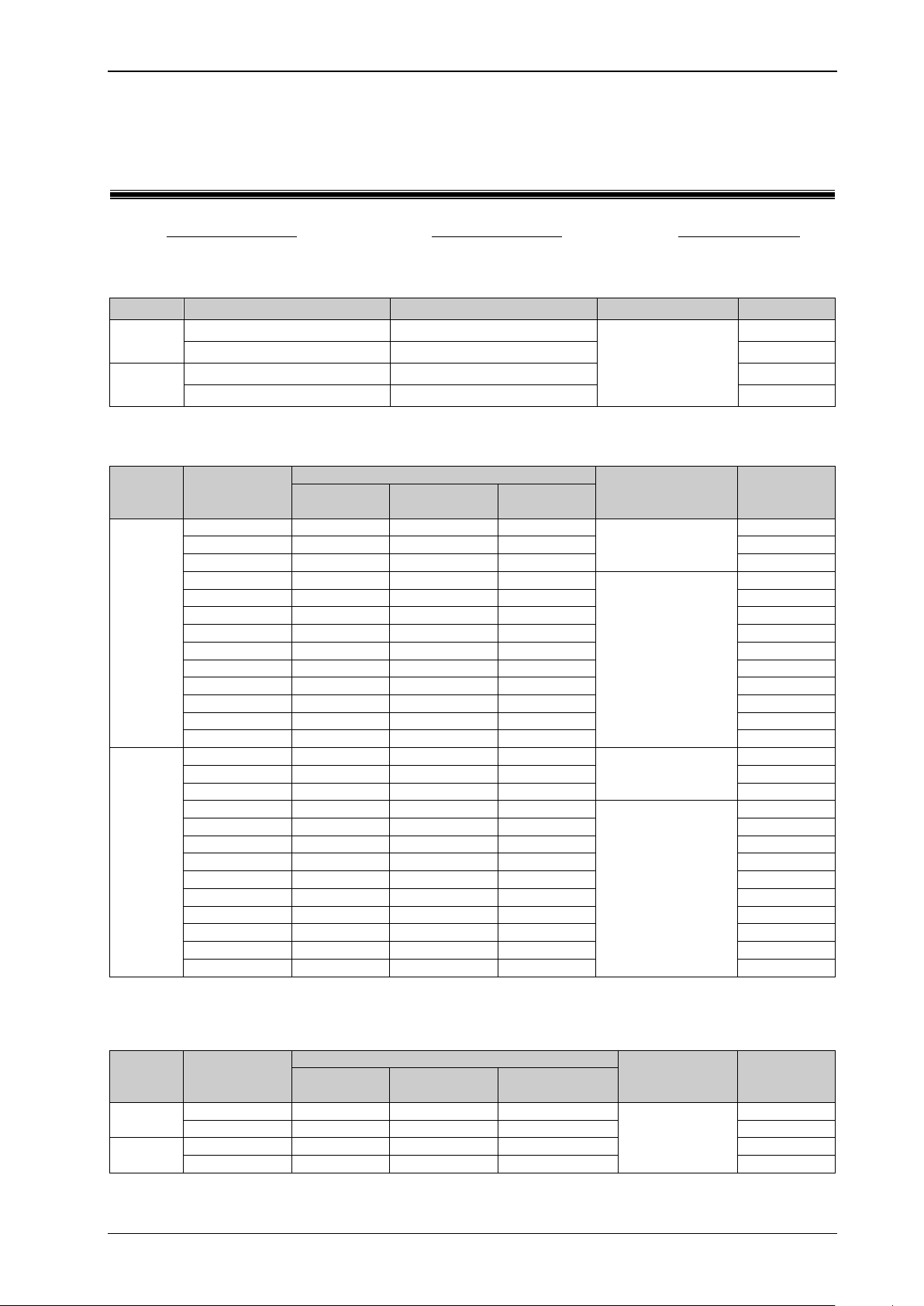

Appendix Test Record Form RIGOL

1

Model:

Tested by:

Test Date:

Channel

Vertical Scale

Test Result

Limit

Pass/Fail

Test Result

Calculation

Result

1 mV/div

2 mV/div

5 mV/div

10 mV/div

20 mV/div

50 mV/div

100 mV/div

200 mV/div

500 mV/div

1 V/div

2 V/div

5 V/div

10 V/div

1 mV/div

2 mV/div

5 mV/div

10 mV/div

20 mV/div

50 mV/div

100 mV/div

200 mV/div

500 mV/div

1 V/div

2 V/div

5 V/div

10 V/div

Test Result

Amplitude

Loss

100 mV/div

500 mV/div

100 mV/div

500 mV/div

Appendix Test Record Form

RIGOL DS1000Z-E Series Digital Oscilloscope

Performance Verification Test Record Form

Impedance Test

CH1

CH2

100 mV/div

500 mV/div

100 mV/div

500 mV/div

DC Gain Accuracy Test

Channel

CH1

Vertical

Scale

Vavg1 Vavg2

0.99 MΩ to 1.01 MΩ

[1]

Limit Pass/Fail

≤ 4%

≤ 3%

≤ 4%

CH2

[1]

Note

are 3 × the current vertical scale and -3 × the current vertical scale respectively.

: The calculation formula is |(Vavg1 - Vavg2) - (Vout1 - Vout2)|/Full Scale × 100%; wh er ei n , Vout1 and Vout2

Bandwidth Test

Channel

CH1

CH2

[1]

Note

DS1000Z-E Performance Verification Guide

: Amplitude Loss (dB) = 20 × lg (Vrms2/Vrms1).

Vertical

Scale

Vrms1 Vrms2

[1]

≤ 3%

Limit Pass/Fail

-3 dB to 3 dB

Page 26

RIGOL Appendix Test Record Form

2

Test Result

Amplitude

Loss

100 mV/div

500 mV/div

100 mV/div

500 mV/div

Calculation

Result

±(25 ppm + 5 ppm/year × number of years

that the instrument has been used

)

Fast Edge Signal

Amplitude

1.2 Vpp

200 mV/div

3 Vpp

500 mV/div

1.2 Vpp

200 mV/div

3 Vpp

500 mV/div

Bandwidth Limit Test

Channel

Vertical

Scale

Vrms1 Vrms2

CH1

CH2

[1]

Note

: Amplitude Loss (dB) = 20 × lg (Vrms2/Vrms1).

Time Base Accuracy Test

Channel Test Result ΔT

CH1

[1]

Note

Note

verification certificate provided when the instrument leaves factory.

: Calculation Result = Test Result ΔT/1 ms.

[2]

: For the number of years that the instrument has been used, please calculate according to the date in the

[1]

Zero Point Offset Test

Channel

CH1

CH2

Vertical Scale Test Result Limit

[1]

-3 dB to 3 dB

Limit Pass/Fail

[2]

Limit Pass/Fail

≤ 2.5 ns

Pass/Fail

DS1000Z-E Performance Verification Guide

Loading...

Loading...