Rigol DS1000CD, DS1000C, DS1000MD, DS1000M User guide

User Manual

Publication number DS1-060301

March 2006

RIGOL

DS1000 Series Digital Oscilloscopes

DS1000CD, DS1000C, DS1000MD, DS1000M

© Copyright RIGOL Technologies, Inc. 2006

All Rights Reserved

RIGOL

z Copyright © RIGOL TECHNOLOGIES, INC. 2006 All Rights Reserved.

z RIGOL products are protected by patent law in and outside of P.R. China.

z Information in this publication replaces that in all previously corresponding

material.

z RIGOL Technologies, Inc. reserves the right to modify or change pat of or all the

specifications and pricing policies at company’s sole decision.

NOTE: RIGOL is registered trademark of RIGOL TECHNOLOGIES, INC.

© Copyright RIGOL Technologies, Inc. 2006. I

User Manual for DS1000 Series

RIGOL

Safety Notices

Review the following safety precautions carefully before operate the instrument to

avoid any personal injury or to damage the instrument and any products connected

to it.

To avoid potential hazards use the instrument in a manner only as specified by this

user’s guide.

The instrument should be serviced by qualified personnel only.

To Avoid Fire or Personal Injury

Use proper power cord Use only the power cord designed for your oscilloscope

and authorized in your country.

Connect and Disconnect accessories properly. Do not connect or disconnect

probes or test leads while they are connected to a voltage source

Ground the instrument This oscilloscope is grounded through the protective

earthing conductor of the power cord. To avoid electric shock the grounding

conductor must be connected to earth ground. Before making connections to the

input or output terminals of the oscilloscope ensure that the instrument is properly

grounded.

Connect the probe properly. The probes’ ground terminals are at the same

voltage level with earth terminal of the instrument. Do not connect the ground

terminals to a high voltage.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and marks on the instrument. Follow the user’s manual for further ratings

information before making connections to the instrument.

Do not operate without Covers. Do not operate your oscilloscope with covers or

panels removed.

II © Copyright RIGOL Technologies, Inc. 2006.

User Manual for DS1000 Series

RIGOL

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Circuit or Wire Exposure. Do not touch exposed connections and

components when power is on.

Do not operate with suspected failures. If you suspect damage with this

product, have it inspected by qualified service personnel before further operations.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details as to the oscilloscope has proper ventilation.

Do not operate in wet/damp conditions

Do not operate in an explosive atmosphere

Keep product surfaces clean and dry

© Copyright RIGOL Technologies, Inc. 2006. III

User Manual for DS1000 Series

RIGOL

Safety Terms and Symbols

Terms in This Manual. These terms may appear in this manual:

!

!

Terms on the Product: These terms may appear on the product:

DANGER indicates an injury hazard may be immediately accessible.

WARNING indicates an injury hazard may be not immediately accessible.

CAUTION indicates that a potential damage to the instrument or other property

might occur.

Symbols on the Product: These symbols may appear on the Instrument:

WARNING: Warning statements identify conditions or practices that could

result in injury or loss of life.

CAUTION: Caution statements identify conditions or practices that could

result in damage to this product or other property.

!

Hazardous Refer to Protective Grounding

Voltage Instructions earth terminal

Terminal

of Chassis

Test

Grounding

Terminal

IV © Copyright RIGOL Technologies, Inc. 2006.

User Manual for DS1000 Series

RIGOL

General-Purpose Oscilloscopes

RIGOL DS1000-Series Digital Oscilloscopes offer exceptional waveform viewing

and measurements in a compact, lightweight package. The DS1000 series are ideal

for production test, field service, research and design and all of the applications

involving analog/digital circuits test and troubleshooting, as well as education and

training.

Each of these oscilloscopes gives you:

z Dual Channel, Bandwidth:

100MHz (DS1102CD, DS1102C, DS1102MD, DS1102M)

60MHz (DS1062CD, DS1062C, DS1062MD, DS1062M)

40MHz (DS1042CD, DS1042C, DS1042MD, DS1042M)

25MHz (DS1022CD, DS1022C, DS1022MD, DS1022M)

z Optional 16 digital channels (Mixed signal oscilloscope), each channel can be

turned on or off independently, or in a 8 bit group

z Mono/Color TFT LCD Displays at 320*234 resolution

z USB storage and printing supports, firmware upgradeable via USB connectivity

z Adjustable waveform intensity, more effective waveform viewing

z One-touch automatic setup for ease of use (AUTO)

z Saves 10 Waveforms, 10 setups, supports CSV and bitmap format

z Newly designed Delayed Scan Function, easy to give attention to both details

and overview of a waveform

z 20 Automatic measurements

z Automatic cursor tracking measurements

z Waveform recorder, record and replay dynamic waveforms

z User selectable fast offset calibration

z Built-in FFT function, Frequency Counter

z Digital filters, includes LPF,HPF,BPF,BRF

z Pass/Fail Function, optically isolated Pass/Fail output

z Add, Subtract and Multiply Mathematic Functions

z Advanced trigger types include: Edge, Video, Pulse width, Slope, Alternative,

Pattern and Duration (Mixed signal oscilloscope)

z Adjustable trigger sensitivity

© Copyright RIGOL Technologies, Inc. 2006. V

User Manual for DS1000 Series

RIGOL

z Multiple Language User Interface

z Pop-up menu makes it easy to read and easy to use

z Built-in Chinese and English help system

z Easy-to-use file system supports Chinese & English characters key-in

DS1000 Series Digital Oscilloscope accessories:

z Two 1.5 meter, 1:1 10: 1 switchable probes

z Digital test set (Mixed Signal Oscilloscope only, DS1xxxxD), include

A data line (Model: FC1868)

An active logic head (Model: LH1116)

Twenty test wire (Model: LC1150)

Twenty logic clips (Model: TC1100)

z Power cord for country of destination

z User’s Manual

z Warranty Card

VI © Copyright RIGOL Technologies, Inc. 2006.

User Manual for DS1000 Series

RIGOL

Content

Safety Notices ..................................................................................................II

General-Purpose Oscilloscopes ..........................................................................V

CHAPTER 1: GETTING STARTED..................................................................... 1-1

The Front Panel and the User Interface ....................................................... 1-2

To Inspect the Instrument .......................................................................... 1-6

To Perform a Functional Check.................................................................... 1-7

To Compensate Probes............................................................................... 1-9

To Use Digital Leads (Mixed Signal Oscilloscope) ........................................ 1-10

To Display a Signal Automatically .............................................................. 1-12

To Set Up the Vertical Window.................................................................. 1-13

To Set Up the Horizontal System............................................................... 1-15

To Trigger the Oscilloscope....................................................................... 1-17

CHAPTER 2: OPERATING YOUR OSCILLOSCOPE .............................................. 2-1

Understand the vertical system ................................................................... 2-2

Understand the Horizontal System............................................................. 2-30

Understand the Trigger System................................................................. 2-36

To Set Up the Sampling System ................................................................ 2-59

To Set Up the Display System ................................................................... 2-63

To Store and Recall Waveforms or Setups.................................................. 2-65

To Set Up the Utility ................................................................................. 2-73

To Measure Automatically......................................................................... 2-91

To measure with cursors........................................................................... 2-98

To use run control buttons.......................................................................2-105

CHAPTER 3: APPLICATION & EXAMPLES ......................................................... 3-1

Example 1: Taking Simple Measurements..................................................... 3-1

Example 2: View a signal delay caused by a circuit ....................................... 3-2

Example 3: Capture a Single-Shot Signal...................................................... 3-3

Example 4: To reduce the random noise on a signal...................................... 3-4

Example 5: Making Cursor Measurements .................................................... 3-6

Example 6: The application of the X-Y operation........................................... 3-8

Example 7: Triggering on a Video Signal .................................................... 3-10

Example 8: FFT Cursor measurement ........................................................ 3-12

© Copyright RIGOL Technologies, Inc. 2006. VII

User Manual for DS1000 Series

RIGOL

Example 9: Pass/Fail Test .......................................................................... 3-13

CHAPTER 4: PROMPT MESSAGES & TROUBLESHOOTING .................................4-1

Prompting Message ....................................................................................4-1

Troubleshooting..........................................................................................4-3

CHAPTER 5: SUPPORT & SERVICE ..................................................................5-1

CHAPTER 6: APPENDIX ..................................................................................6-1

Appendix A: Specifications ..........................................................................6-1

Apendix B: DS1000-Series Accessories .........................................................6-7

Appendix C: General Care and Cleaning .......................................................6-8

Index ................................................................................................................i

VIII © Copyright RIGOL Technologies, Inc. 2006.

User Manual for DS1000 Series

Chapter 1 : Getting Started

This chapter covers the following topics:

The front panel and user interface

To inspect the instrument

To perform a functional check

To compensate probes

To use digital leads (Mixed signal oscilloscope only)

To display a signal automatically

To set up the vertical system

To set up the horizontal system

To trigger the oscilloscope

RIGOL

© Copyright RIGOL Technologies, Inc. 2006. 1-1

User Manual for DS1000 Series

RIGOL

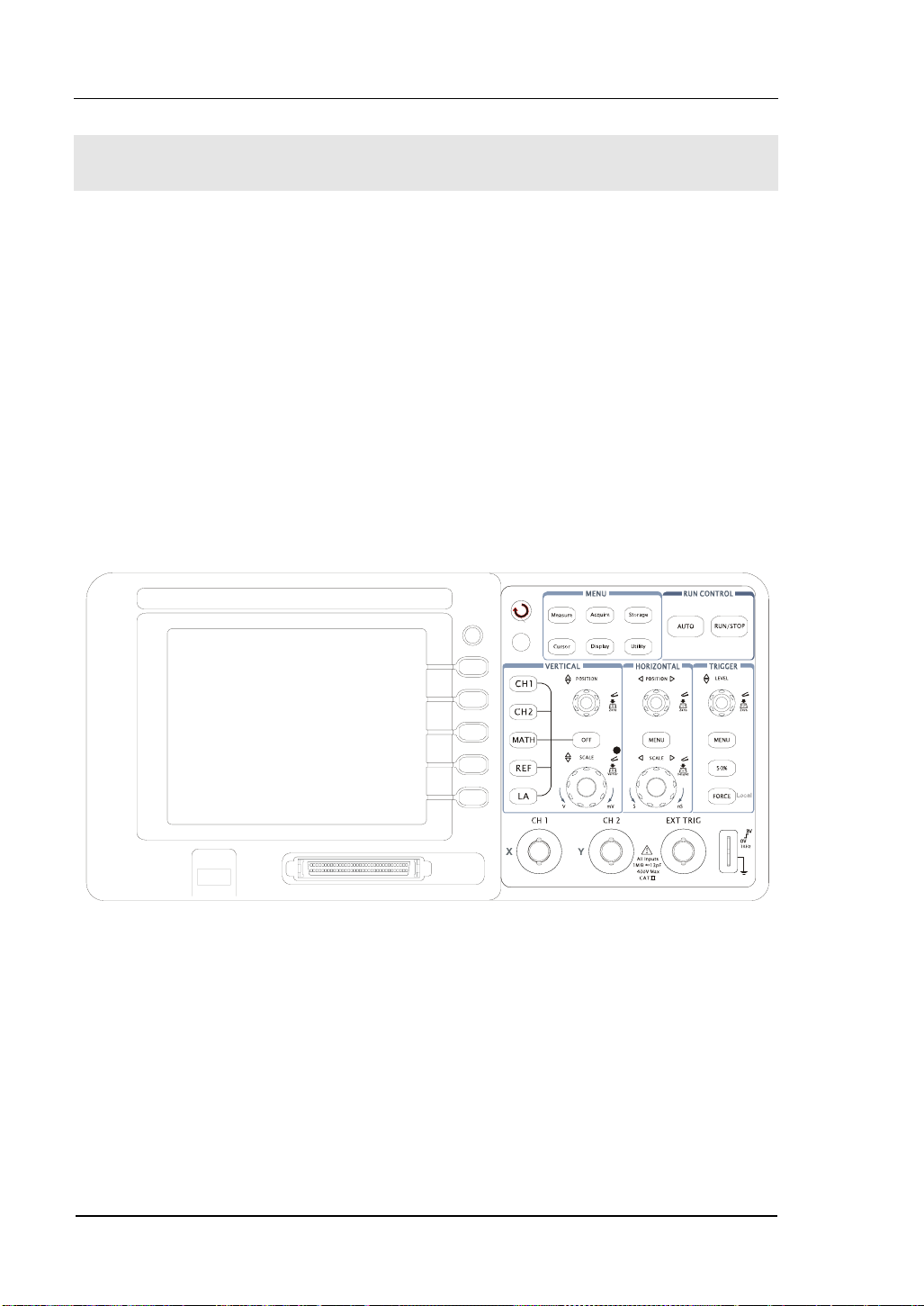

The Front Panel and the User Interface

One of the first things you will want to do with your new oscilloscope is to become

acquainted with its front panel. This chapter will help you be familiar with the layout

of the knobs and keys and how to use them. Read the chapter carefully before

further operations.

The front panel has knobs and buttons. The knobs are used most often and are

similar to the knobs on other oscilloscopes. The buttons not only let you use some of

the functions directly but also bring up soft button menus on the screen, which allow

you access to many measurement features associated with advanced functionalities,

math, and reference or run control features.

Figure1-1

DS1000-Series Oscilloscope’s Front Panel

DS1000 series oscilloscopes provide an easy-to-use user interface, the definitions of

the buttons and the knobs are as follows:

Menu buttons: Associated with Measure, Cursor, Acquire, Display, Storage, and

1-2 © Copyright RIGOL Technologies, Inc. 2006.

User Manual for DS1000 Series

RIGOL

Utility menus.

Vertical buttons: Associated with CH1, CH2, MATH, REF and LA menus, the OFF

button can set waveform or menu which currently active off.

Horizontal buttons: Associated with horizontal MENU.

Trigger buttons: Associated with trigger MENU, instant action to set 50% trigger

level and FORCE trigger.

Action buttons: Include run control buttons for AUTO and RUN/STOP.

Function buttons: Five grey buttons from top to bottom on the right to the LCD

screen, which set choices of operation in the currently active

menu.

Knobs: For the adjustment of vertical or horizontal

,

and trigger .

© Copyright RIGOL Technologies, Inc. 2006. 1-3

User Manual for DS1000 Series

RIGOL

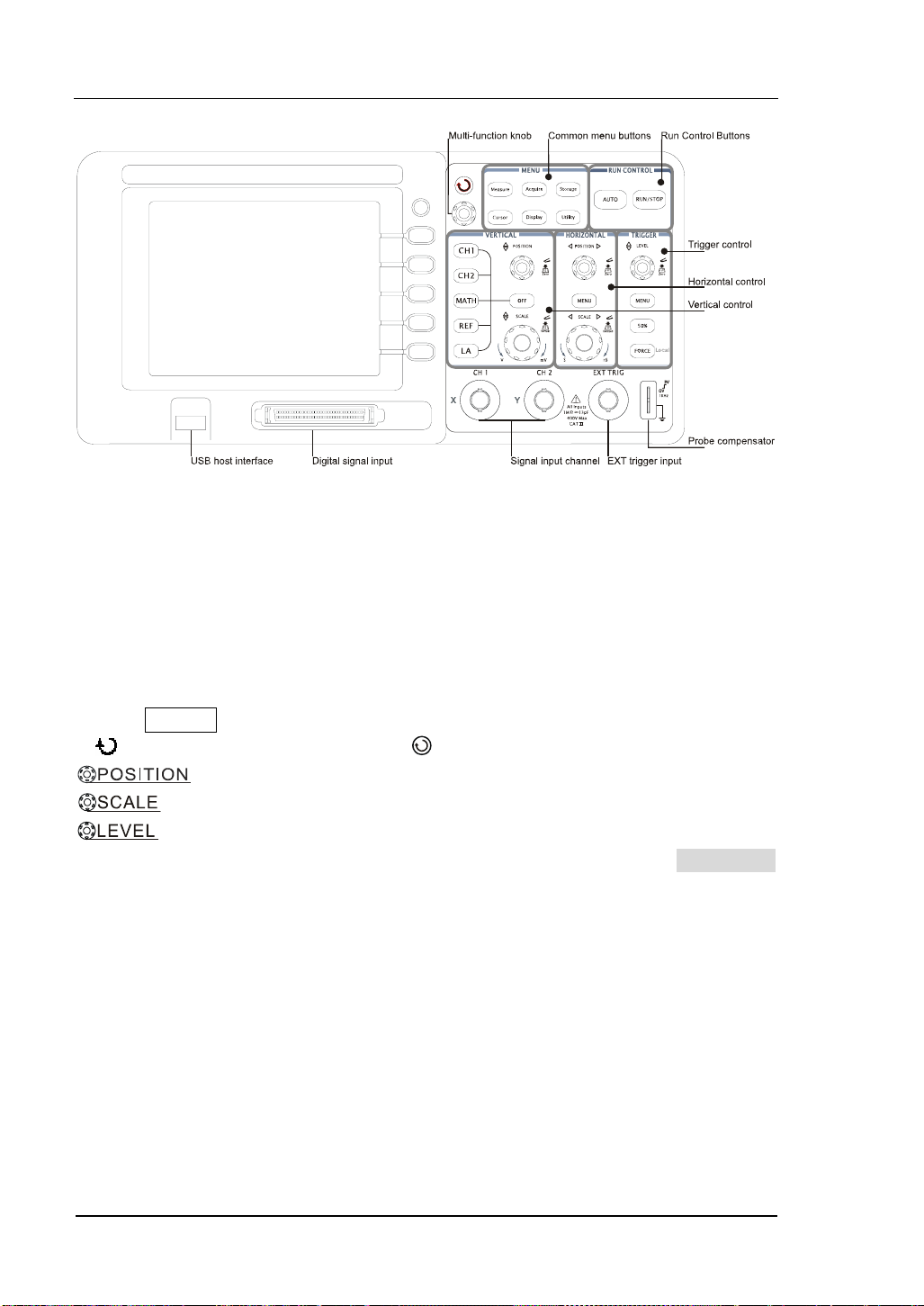

Figure 1-2

Front Panel Controls

Character definitions in this User’s Manual:

Throughout this book, character figures of buttons and knobs are the same to those

on front-panel.

A box around the name of the key denotes MENU function buttons on front-panel,

such as Measure.

( )denotes the multi-function knob .

denotes the two POSITION knobs.

denotes the two SCALE knobs.

denotes the LEVEL knob.

The name with a drop shadow denotes the menu operating key, such as WAVEFORM

soft key in STORAGE menu.

1-4 © Copyright RIGOL Technologies, Inc. 2006.

User Manual for DS1000 Series

RIGOL

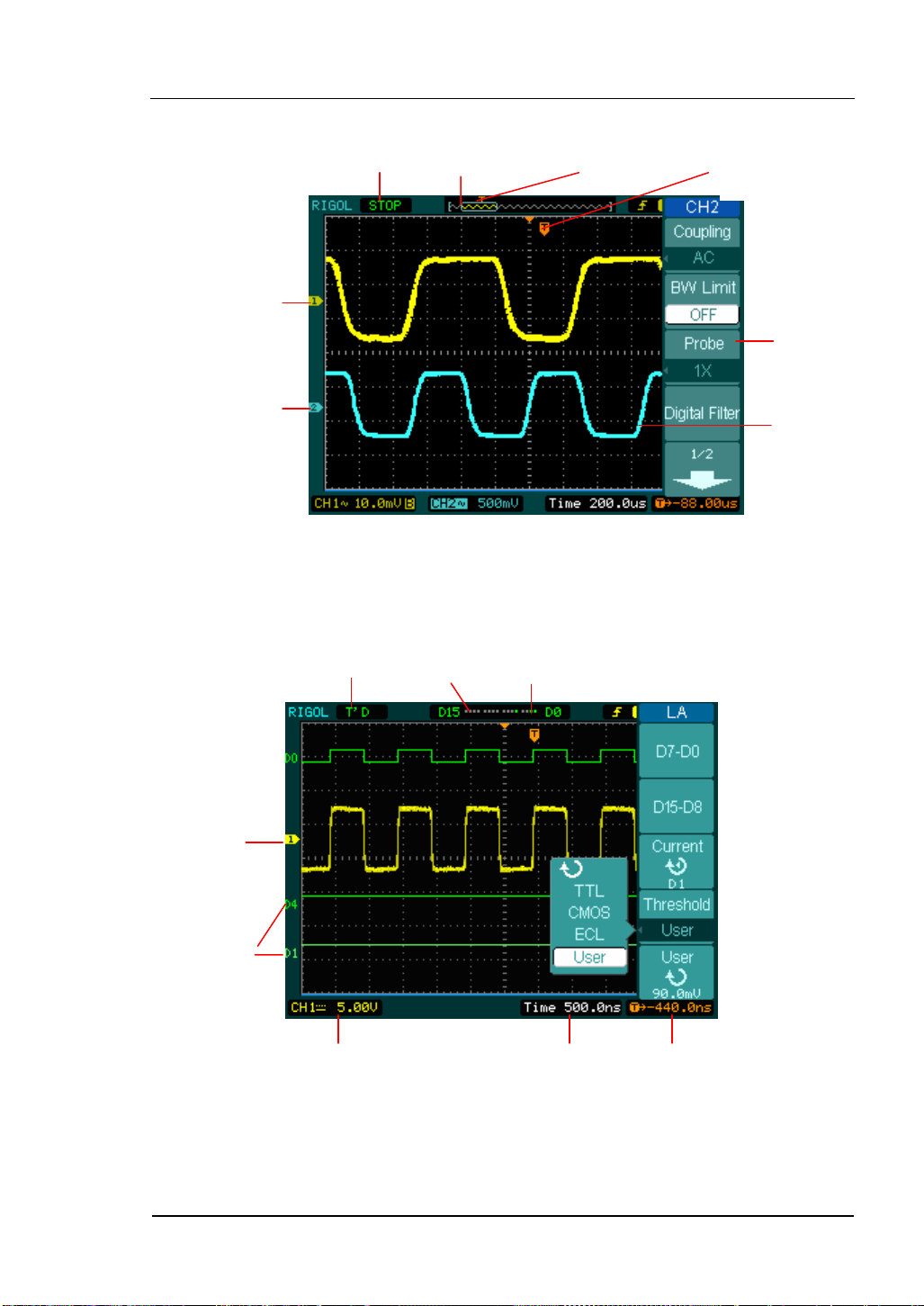

Channel 1

Channel 2

Running status

Display screen(Analog channels only)

Running status

Location of

waveform window

in memory

Figure1-3

Digital channel

turned off

Trigger point in

memory

Digital channels

turned on

Trigger point in

waveform window

Menu

Waveform

display window

Channel 1

Digital channels

Channel coupling

and vertical div.

Horizontal

time base div.

Trigger

offset

Figure 1-4

User Interface(Analog and Digital channels)

© Copyright RIGOL Technologies, Inc. 2006. 1-5

User Manual for DS1000 Series

RIGOL

To Inspect the Instrument

After you get a new DS1000 series oscilloscope, please inspect the instrument

according to the following steps:

1. Inspect the shipping container for damage.

Keep a damaged shipping container or cushioning material until the contents of

the shipment have been checked for completeness and the instrument has been

checked mechanically and electrically.

2. Check the accessories.

Accessories supplied with the instrument are listed in "Accessories" in this

manual.

If the contents are incomplete or damaged notify your RIGOL Sales

Representative.

3. Inspect the instrument.

In case any mechanical damage or defect, or if the instrument does not operate

properly or pass performance tests, notify your RIGOL Sales Representative.

If the shipping container is damaged, or the cushioning materials show signs of

stress, notify the carrier as well as your RIGOL sales office. Keep the shipping

materials for the carrier’s inspection.

RIGOL offices will arrange for repair or replacement at RIGOL’s option without

waiting for claim settlement.

1-6 © Copyright RIGOL Technologies, Inc. 2006.

User Manual for DS1000 Series

RIGOL

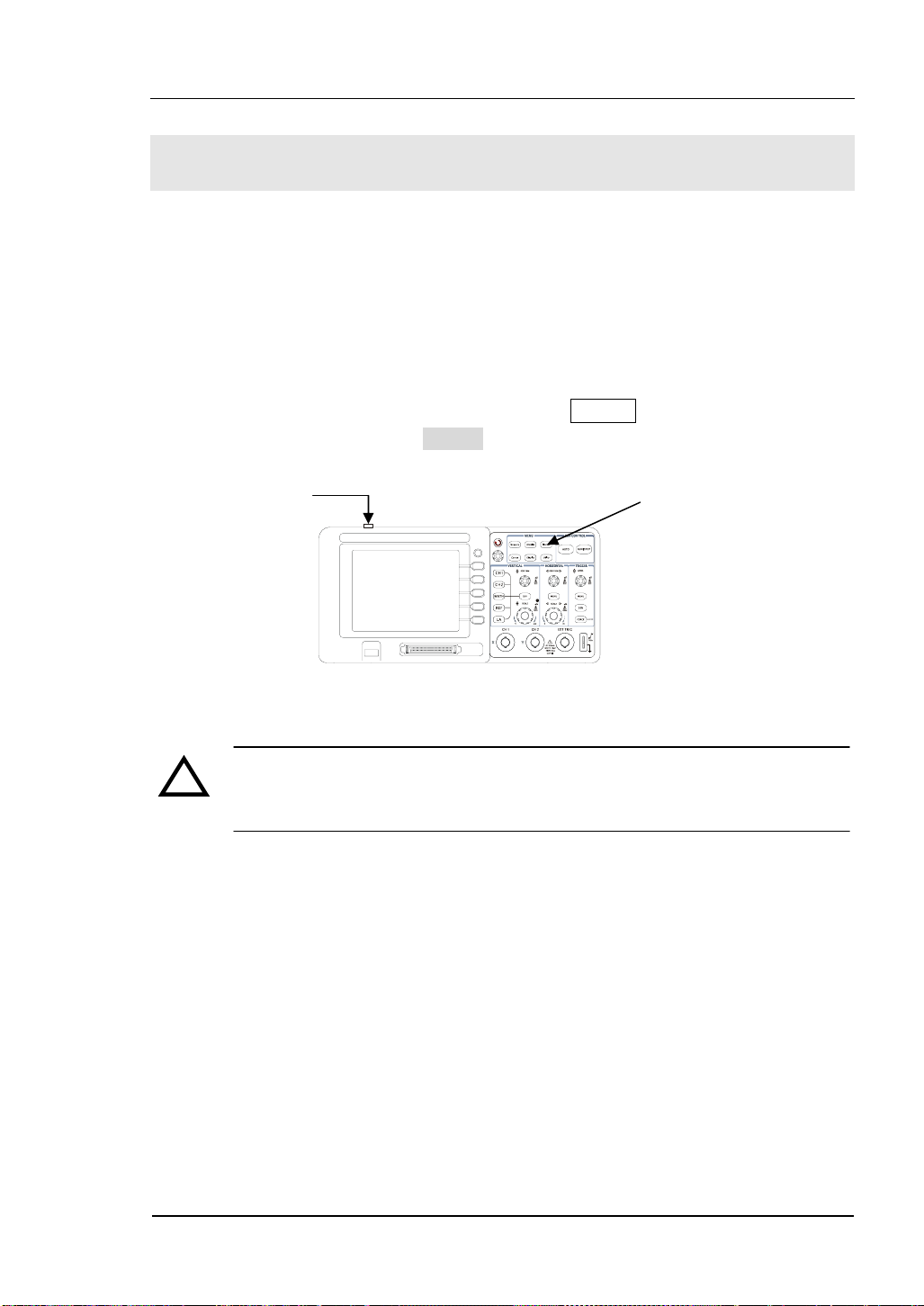

To Perform a Functional Check

Perform this quick functional check to verify that your instrument is operating

correctly.

1. Turn on the instrument.

Use only power cords designed for your oscilloscope. Use a power source that

delivers 100 to 240 VAC

the display shows the waveform window. Push the Storage

the top menu box and push the Factory menu box.

Power button

, 45Hz to 440Hz. Turn on the instruments, and wait until

RMS

button, select Storage in

Storage button

Figure 1-5

WARNNING:

!

To avoid electric shock, be sure the oscilloscope is properly grounded.

2.Input a signal to a channel of the oscilloscope

① Set the switch on the probe to 10X and connect the probe to channel 1 on the

oscilloscope. To do this, align the slot in the probe connector with the key on the

CH 1 BNC, push to connect, and twist to the right to lock the probe in place.

Attach the probe tip and ground lead to the PROBE COMP connector.

© Copyright RIGOL Technologies, Inc. 2006. 1-7

User Manual for DS1000 Series

RIGOL

Probe compensator

Figure 1-6

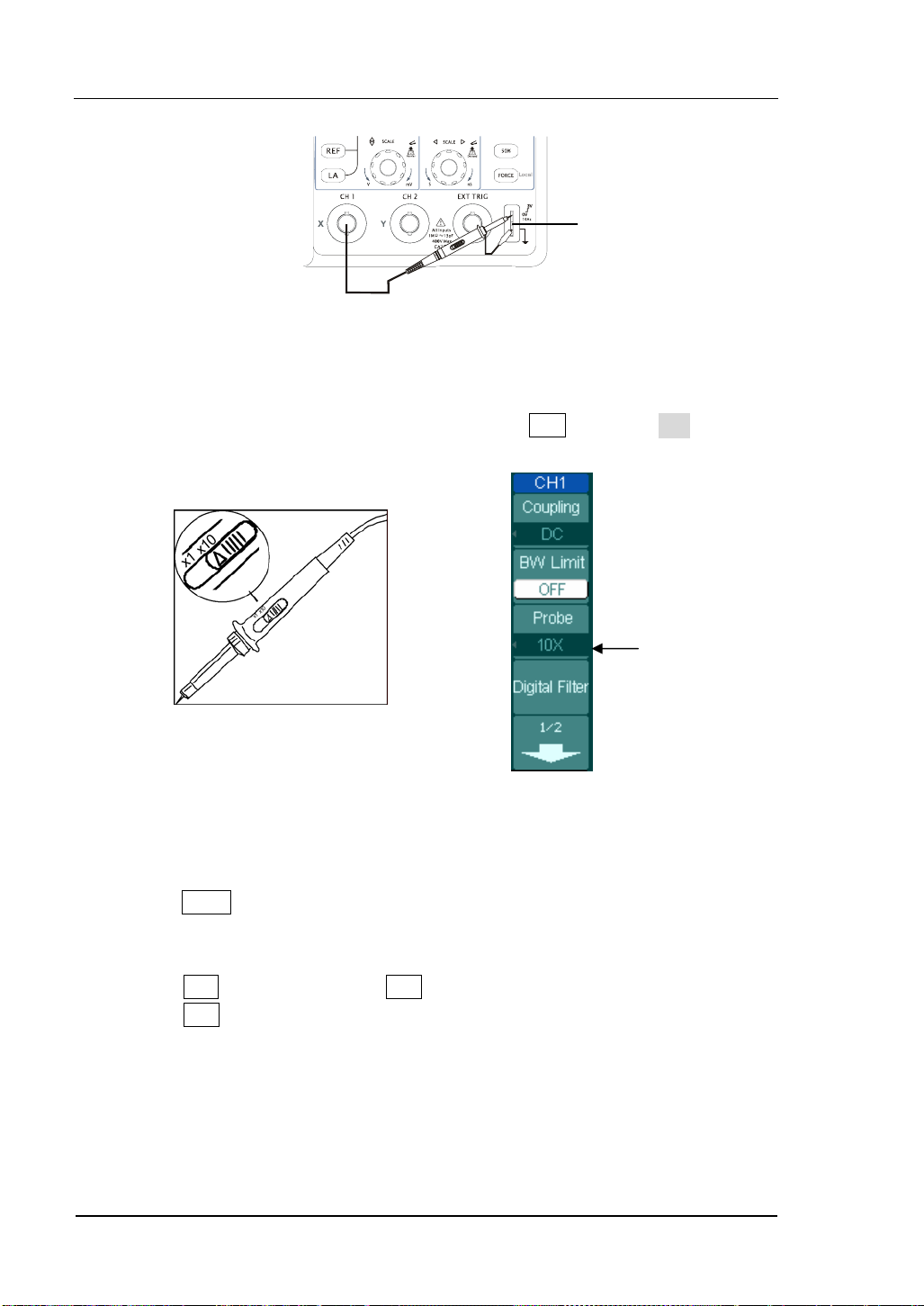

② Set the probe attenuation to 10X. To do this, push CH1→Probe→10X.

Probe scale

Figure 1-7 Figure 1-8

③ Push the AUTO button. Within a few seconds, you could see a square wave in the

display (approximately 1 kHz 3 V peak- to- peak).

④ Push the OFF button or push the CH1 button again to turn off channel 1,

push the CH2 button to turn on channel 2, repeat steps 2 and 3.

1-8 © Copyright RIGOL Technologies, Inc. 2006.

User Manual for DS1000 Series

RIGOL

To Compensate Probes

Perform this adjustment to match your probe to the input channel. This should be

done whenever you attach a probe for the first time to any input channel.

1. Set the Probe menu attenuation to 10X. Set the switch to 10X on the probe and

connect the probe to channel 1 on the oscilloscope. If you use the probe

hook-tip, ensure a proper connection by firmly inserting the tip onto the probe.

Attach the probe tip to the PROBE COMP connector and the reference lead to the

PROBE COMP Ground connector, turn on channel 1, and then press AUTO.

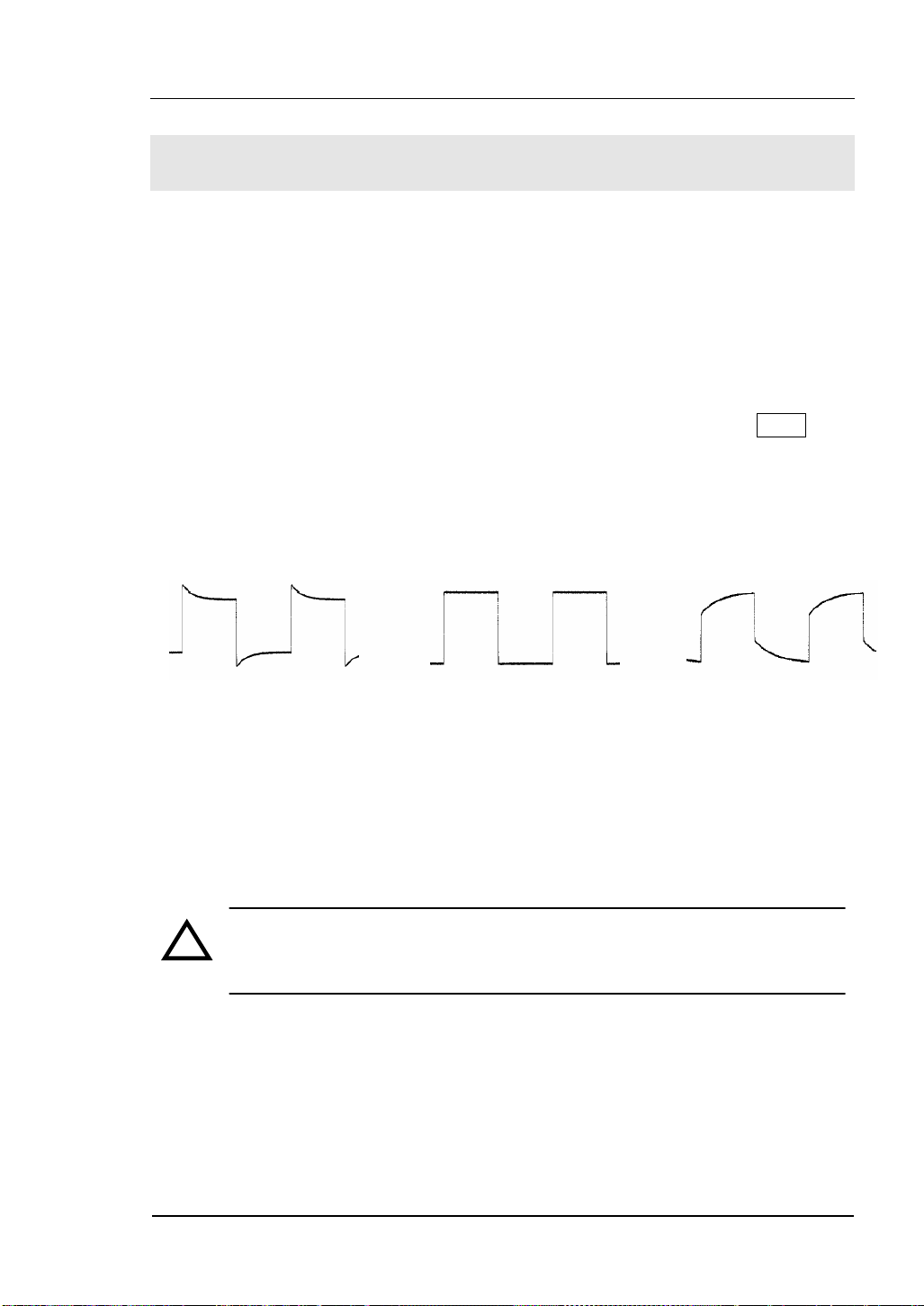

2. Check the shape of the displayed waveform.

Over compensated Correctly Compensated Under Compensated

Figure 1-9

Figure 1-9

3. If necessary, use a non-metallic tool to adjust the trimmer capacitor on the probe

for the flattest square wave possible as displayed on the oscilloscope.

4. Repeat as necessary.

WARNNING: To avoid electric shock while using the probe, be sure the

!

perfection of the insulated cable, and do not touch the metallic portions of

the probe head while it is connected with a voltage source.

© Copyright RIGOL Technologies, Inc. 2006. 1-9

User Manual for DS1000 Series

RIGOL

To Use Digital Leads (Mixed Signal Oscilloscope)

1. Switch off power supply of the Device Under Test if necessary to avoid short

circuit. Since no voltage is applied to the leads at this step, you may keep the

oscilloscope on.

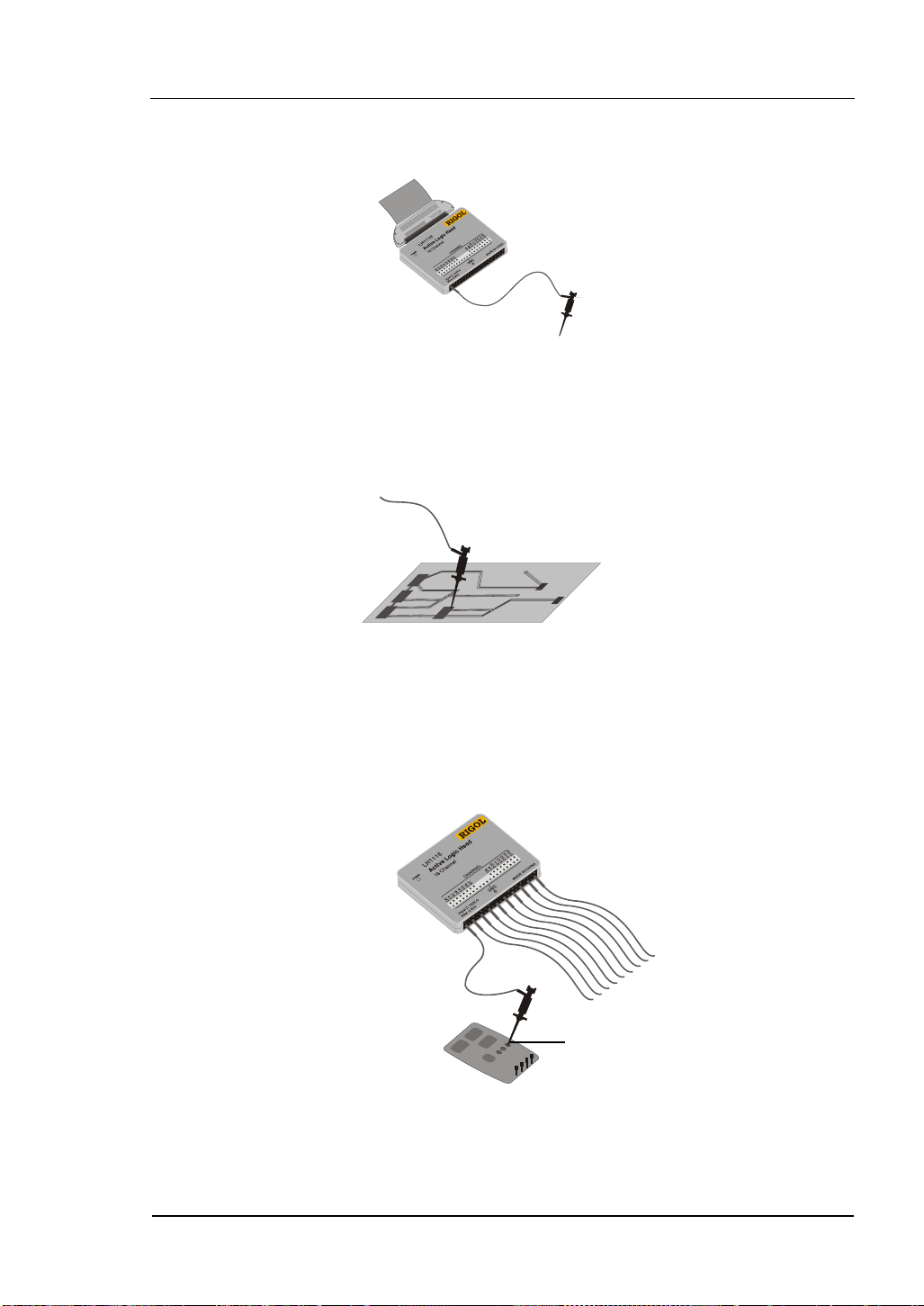

2. Connect one end of the flat cable FC1868 to the Logic Analyzer Input, connect

the other end to Logic Head LH1116. An identifier is located on each end of the

flat cable, it can only be connected in one way. It is unnecessary to switch off

power supply of your oscilloscope connect the cable.

Figure 1-10

CAUTION:Use only FC1868, LH1116, TC1100 and LC1150 made by

!

RIGOL for specified mixed signal oscilloscopes.

1-10 © Copyright RIGOL Technologies, Inc. 2006.

User Manual for DS1000 Series

3. Connect a test clip to one lead wire; make sure it’s connected well.

Test cl ip

Figure 1-11

4. Test your device with the clip.

RIGOL

Figure 1-12

5. Remember to connect Ground Channel to the DUT’s ground terminal.

GND

Figure 1-13

© Copyright RIGOL Technologies, Inc. 2006. 1-11

User Manual for DS1000 Series

RIGOL

To Display a Signal Automatically

The oscilloscope has an Auto feature that sets up the oscilloscope automatically to

display the input signal in a best fit. This Auto feature requires the input signal with a

frequency of 50 Hz or higher and a duty cycle greater than 1%.

When you press the AUTO button, the oscilloscope automatically sets up vertical,

horizontal and Trigger controls to display the input signal in the screen for view. You

may want to adjust the controls manually if necessary to get the best results.

DS1000 series are two-channel oscilloscopes with an external trigger input. In this

exercise you connect a signal to the channel 1 input.

1. Connect a signal to the oscilloscope.

2. Press AUTO.

When you press the AUTO button, the oscilloscope may change the current settings

to display the signal. It automatically adjusts the vertical and horizontal scaling, as

well as the trigger coupling, type, position, slope, level, and mode settings.

1-12 © Copyright RIGOL Technologies, Inc. 2006.

User Manual for DS1000 Series

RIGOL

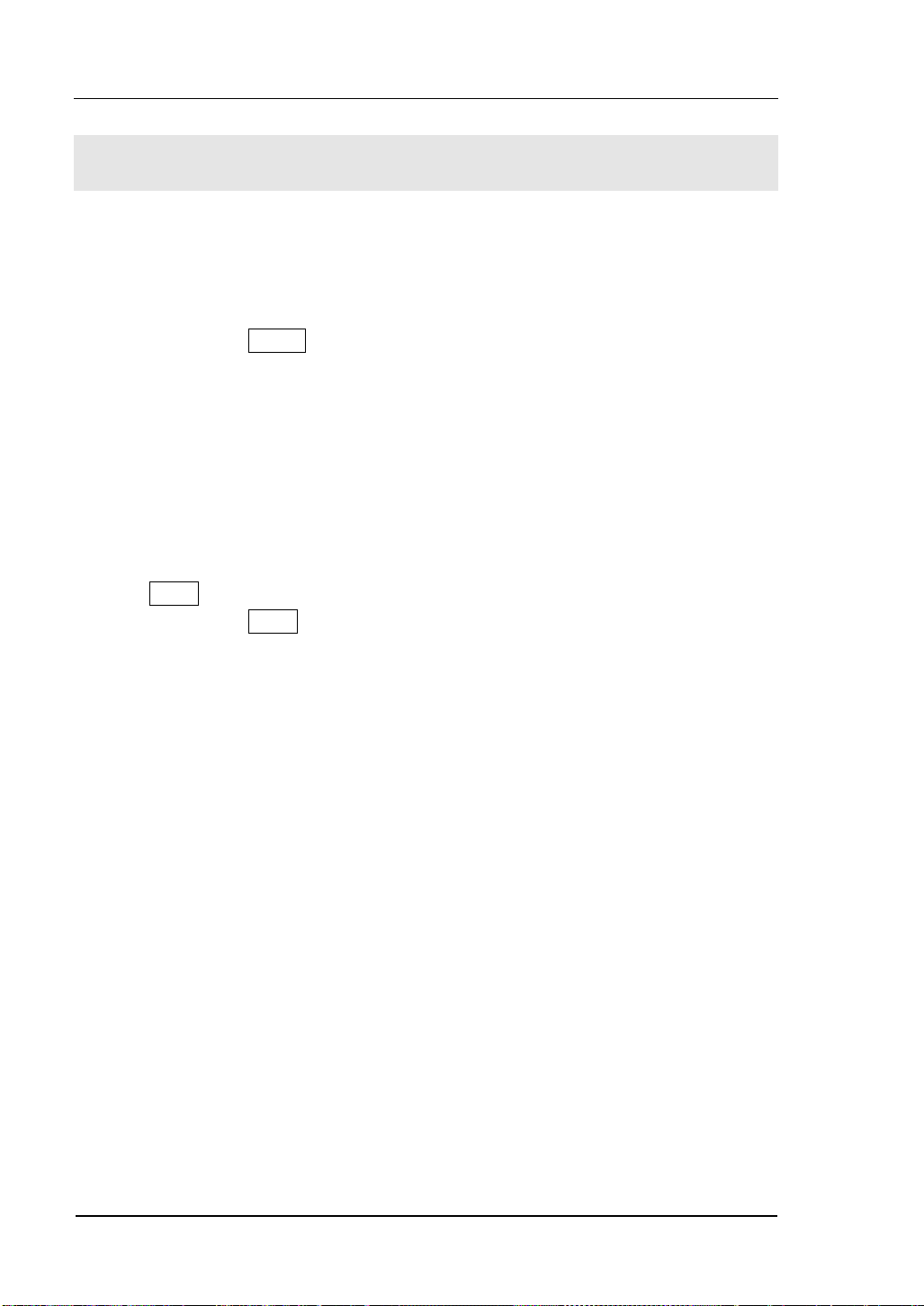

To Set Up the Vertical Window

Figure 1-14 shows the Channels, MATH, REF, Logic Analyzer and OFF buttons and

vertical , knobs. The following exercise guides you

through the vertical buttons, knobs, and status bar. It will help you be familiar with

the setting of the vertical parameters.

Figure 1-14

1. Center the signal on the display with the

knob.

The

as you turn the

knob moves the signal vertically, and it is calibrated. Notice that

knob, a voltage value is displayed for a short time

indicating how far the ground reference is located from the center of the screen. Also

notice that the ground symbol on the left side of the display moves in conjunction

with the

knob.

© Copyright RIGOL Technologies, Inc. 2006. 1-13

User Manual for DS1000 Series

RIGOL

Measurement hints

If the channel is DC coupled, you can quickly measure the DC component of

the signal by simply noting its distance from the ground symbol.

If the channel is AC coupled, the DC component of the signal is blocked,

allowing you to use greater sensitivity to display the AC component of the

signal.

Vertical offset back to 0 shortcut key

Turn the knob to change the vertical display position of

channel and press the

knob to set the vertical display position

back to 0 as a shortcut key, this is especially helpful when the trace position is

far out of the screen and want it to get back to the screen center immediately.

2. Change the vertical setup and notice that each change affects the

status bar differently.

You can quickly determine the vertical setup from the status bar in the display.

z Change the vertical sensitivity with the

knob and notice that it

causes the status bar to change.

z Press CH1.

z A soft button menu appears on the display, and the channel turns on (or remains

on if it was already turned on).

z Toggle each of the soft buttons and notice which button cause the status bar to

change. Channel 1 and 2 have a vernier soft button that allows the

knob to change the vertical step size in smaller increments. To press Volts/Div

soft button, you can change the step size into Fine or Coarse status.

z Press OFF button to turn the channel off.

Coarse/Fine Shortcut key

You can set the Coarse/Fine vertical control not only on the Volts/Div item in

the CH1 or CH2 menus, but also by simply pressing the vertical

knob.

1-14 © Copyright RIGOL Technologies, Inc. 2006.

User Manual for DS1000 Series

RIGOL

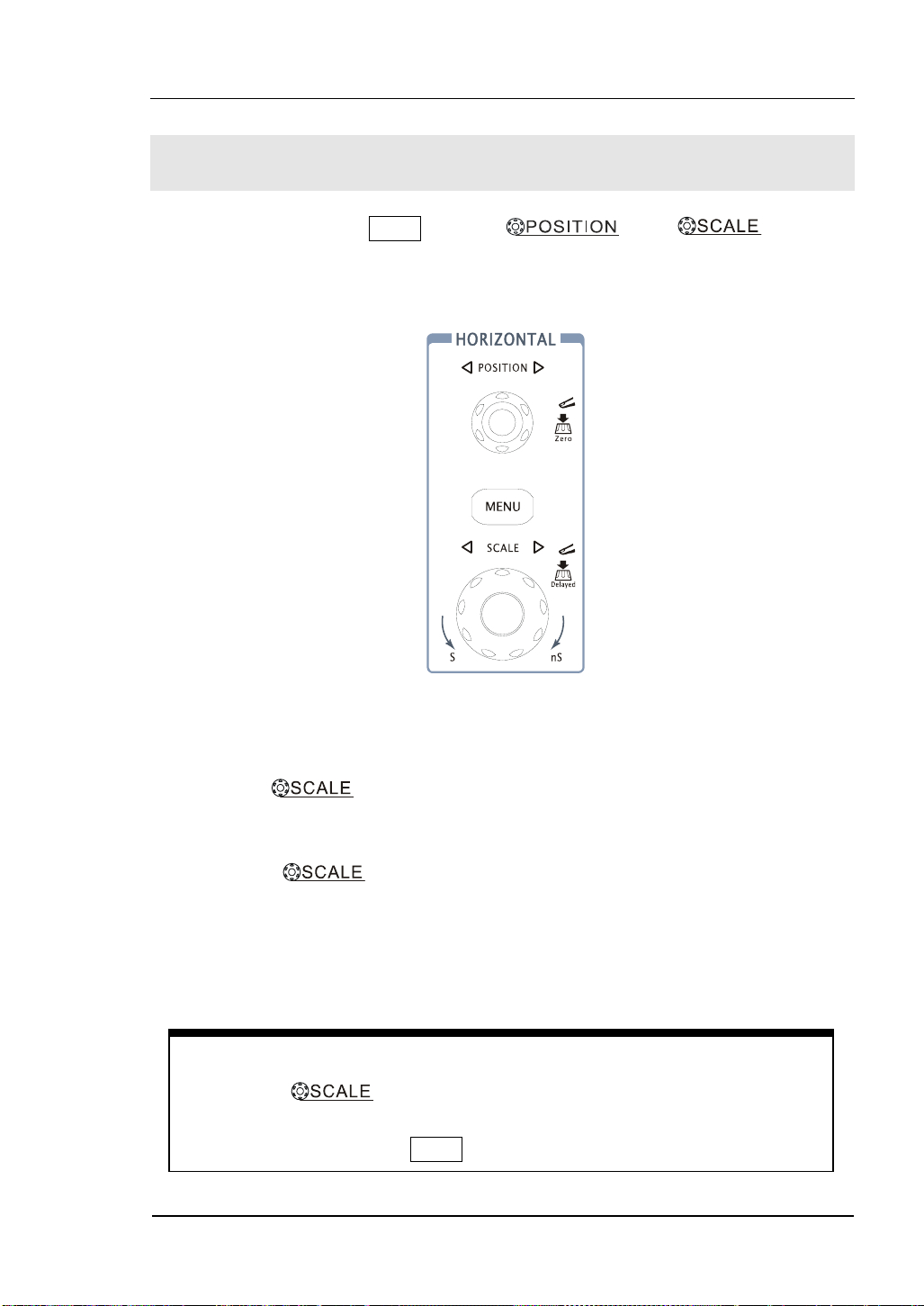

To Set Up the Horizontal System

Figure 1-15 shows the MENU button, and knobs of

horizontal system. The following exercise guides you through these buttons, knobs,

and status bar.

Figure 1-15

1. Turn the

knob and notice the change it makes to the status

bar.

The horizontal

knob changes the sweep speed in a 1-2-5 step sequence,

and the value is displayed in the status bar. The time base ranges of the DS1000

series are listed as follows. The horizontal scan speed is from 5ns/div* to 50s/div.

* NOTE: The speed of horizontal scan varies by different models.

Delayed Scan Shortcut key

To press the

knob in the horizontal control area on the front-panel

is another way to enter or exit Delayed Scan mode and it is equal to the

following menu operations, MENU→Delayed.

© Copyright RIGOL Technologies, Inc. 2006. 1-15

User Manual for DS1000 Series

RIGOL

2. The horizontal

knob moves displayed signal horizontally

on waveform window

Horizontal offset back to 0 shortcut key

Press the

knob to set the horizontal offset to 0 as a shortcut

key, this is especially helpful when the trigger point is far out of the screen and

want it to get back to the screen center immediately.

3. Press the MENU key to display the TIME menu.

In this menu, you can enter or exit the Delayed Scan mode, set the display to Y-T, X-Y

or ROLL mode, and turn the horizontal

knob to adjust trigger offset.

Horizontal position control

Trig-Offset: In this setting, the trigger position will be changed horizontally

when you turn the

knob.

1-16 © Copyright RIGOL Technologies, Inc. 2006.

User Manual for DS1000 Series

RIGOL

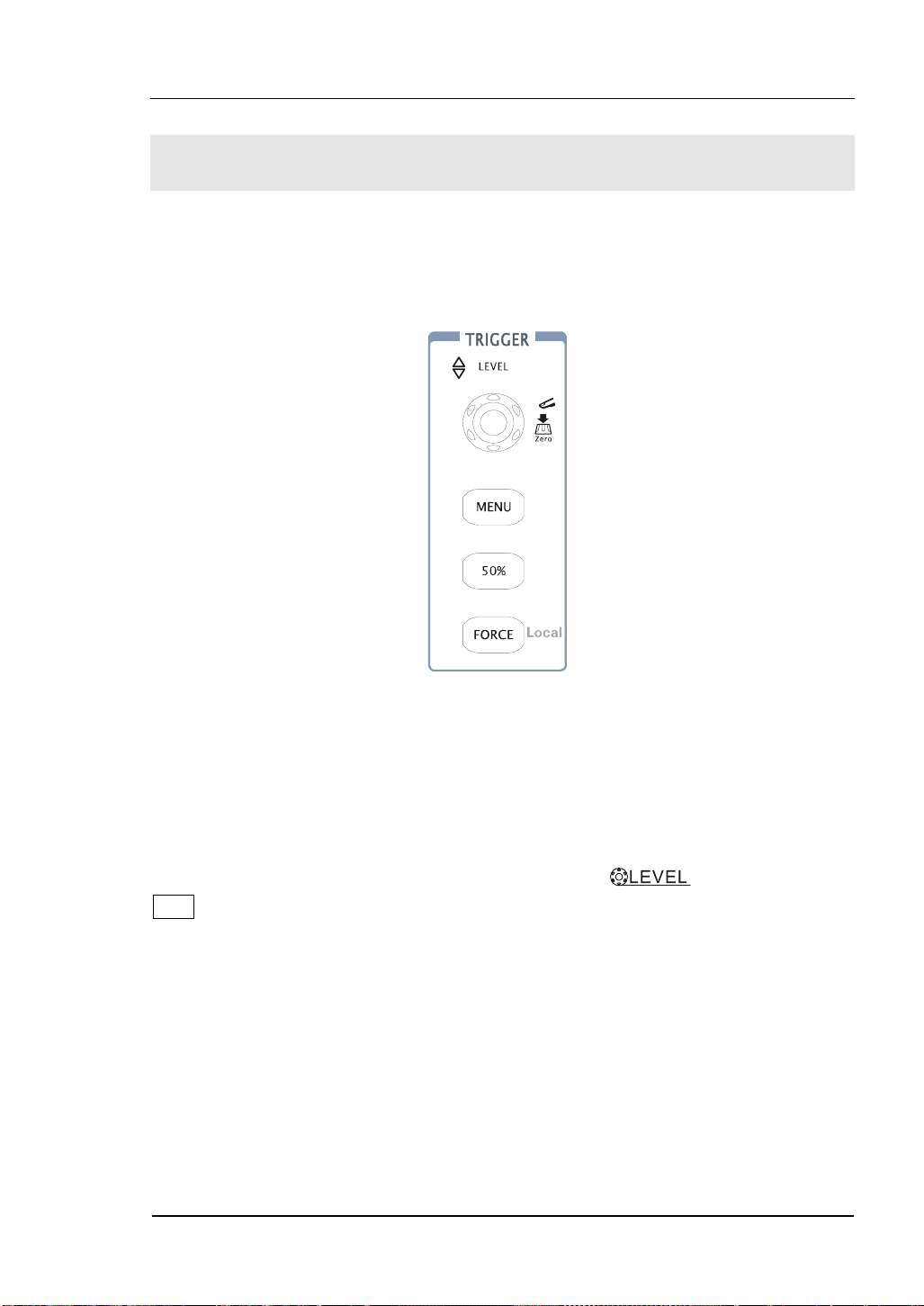

To Trigger the Oscilloscope

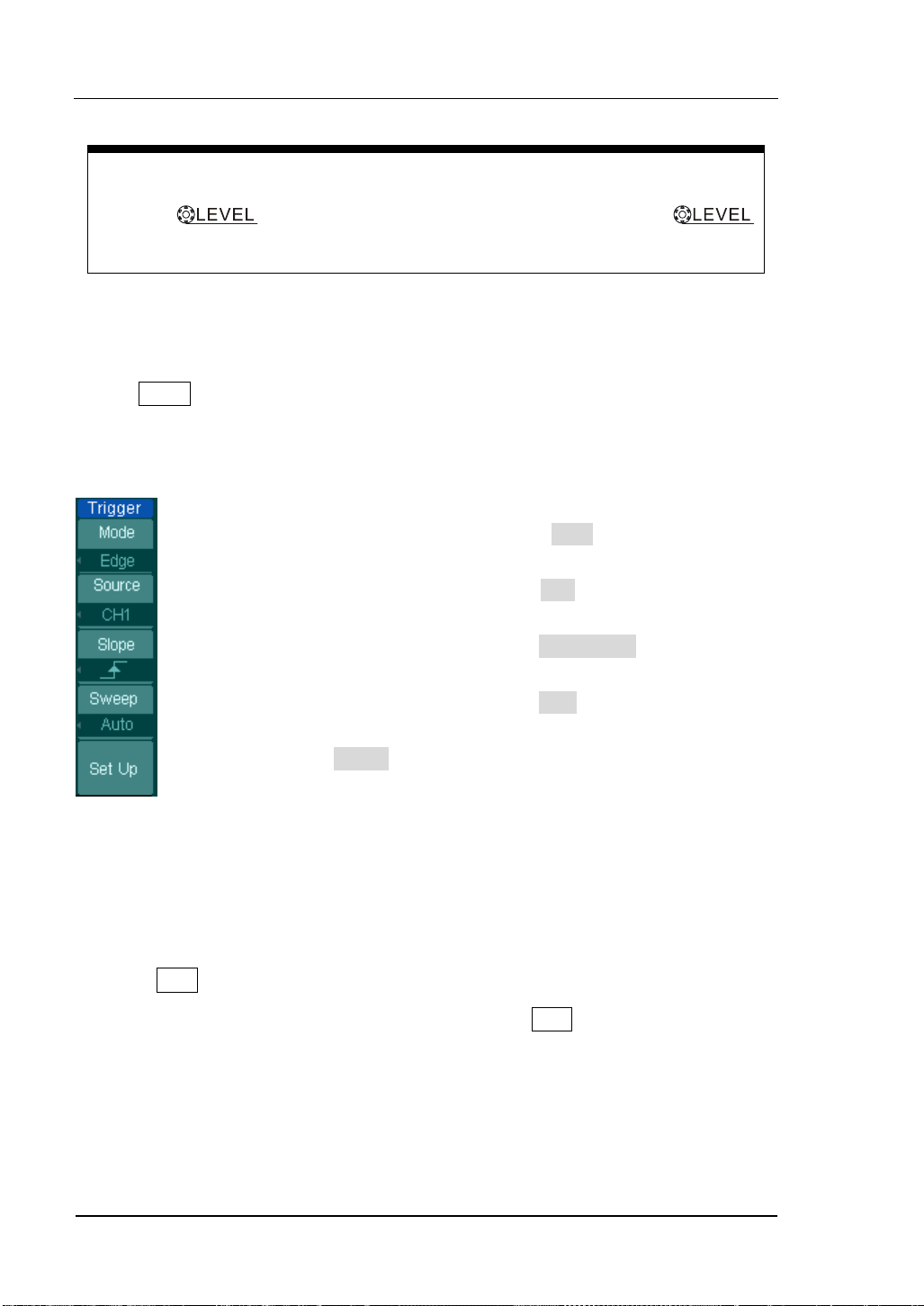

Figure 1-16 shows the trigger control area on the front panel, it has a trigger level

knob and three soft buttons. The following exercise guides you through these trigger

buttons, knobs, and status bar.

Figure 1-16

1. Turn the trigger Level knob and notice the changes it makes to the

display.

On the DS1000 series oscilloscopes, as you turn the

knob or press the

50% menu button, two things happen on the display for a short time. First, the

trigger level value is displayed at the bottom-left of the screen. If the trigger is DC

coupled, it is displayed as a voltage value. If the trigger is AC coupled or LF reject, it

is displayed as a percentage of the trigger range. Second, a line is displayed showing

the location of the trigger level (as long as AC coupling or low frequency reject are

not selected).

© Copyright RIGOL Technologies, Inc. 2006. 1-17

User Manual for DS1000 Series

RIGOL

Trigger Level to 0 Shortcut key

Turn the

knob to change trigger level value and press the

knob to set trigger level back to 0 as a shortcut key.

2. Change the trigger setup and notice these changes affect the status bar

differently.

· Press MENU button in the trigger control area.

A soft button menu appears on the display showing the trigger setting choices.

Figure 1-17 displays this trigger menu.

· Press the trigger Mode button and choose Edge.

· Press the trigger Source button to select CH1.

· Press the trigger Slope button to choose Rising Edge.

· Press the trigger Sweep button to select Auto.

· Press the trigger Set Up button to enter secondary menu.

Figure 1-17

NOTE: The trigger type, slope and source change in conjunction with the status bar

on the top-right of the screen.

3. Press 50%

This key is an action button. Every time you press the 50% button, the oscilloscope

sets the trigger level to the center of the signal.

1-18 © Copyright RIGOL Technologies, Inc. 2006.

User Manual for DS1000 Series

RIGOL

4. Press FORCE

Press this button starts an acquisition regardless of an adequate trigger signal,

usually used in “Normal” or ”Single” trigger mode. This button has no effect if the

acquisition is already stopped.

Key point:

Holdoff: A time interval before the oscilloscope response to next trigger

signal. During this holdoff period, the trigger system becomes “blind” to

trigger signals. This function helps to view complex signals such as an AM

waveform. Press Holdoff button to activate(

Holdoff time.

)knob, then turn it to adjust

© Copyright RIGOL Technologies, Inc. 2006. 1-19

User Manual for DS1000 Series

Loading...

Loading...