Page 1

RIGOL

User’s Guide

DP800A Series Programmable Linear

DC Power Supply

Mar. 2013

RIGOL Technologies, Inc.

Page 2

Page 3

RIGOL

Guaranty and Declaration

Copyright

© 2012 RIGOL Technologies, Inc. All R ights Reser v ed.

Trademark Information

RIGOL is a registered trademark of RIGOL Technologies, Inc.

Publication Number

UGH03102-1110

Notices

RIGOL products are protected by patent law in and outside of P.R.C.

RIGOL reserves the right to modify or change parts of or all the specifications

and pricing policies at company’s sole decision.

Information in this publication replaces all previously corresponding material.

RIGOL shall not be liable for losses caused by either inci dental or conse quential

in connection with the fu r nis hing , use or perfo rman ce of this manual as well as

any information contained.

Any part of this document is forbidden to be copied or ph otocopied or

rearranged without prior written approval of RIGOL.

Product Certification

RIGOL guar antees this pr oduct confo rms to the national and industrial standards in

China as well as the ISO9001:2008 standard and the ISO14001:2004 standard.

Other international standard conformance certification is in progress.

Contact Us

If you have any problem or requirement when using our products, please contact

RIGOL T echnologies, Inc. or your local distributors, or visit: www.rigol.com.

DP800A User’s Guide I

Page 4

RIGOL

Safety Requirement

General Safety Summary

Please review the following safety precautions carefully before putting the

instrument into operation so as to avoid any personal injuries or damages to the

instrument and any product connecte d to it. To prevent potential haza rds, please use

the instrument only specified by this manual.

Use Proper Power Cord.

Only the power cord designed for the instrument and authorized by local country

could be used.

Ground The Instrument.

The instrument is grounded through the Protective Earth lead of the power cord. To

avoid electric shock, it is e ssential t o connect the ea rth terminal of power cord to the

Protective Earth terminal before any inputs or outputs.

Observe All Terminal Ratings.

To avoid fire or shock hazard, observe all ratings an d markers on the instrume nt and

check your manual for more information about ratings before connecting.

Replace the Fuse.

Please use fuse that matches the voltage selected at the voltage selector of the

power supply at the rear panel.

Use Proper Overvoltage Protection.

Make sure that no overvoltage (such as that caused by a thunderstorm) can reach

the product, or else the operator might expose to danger of electrical shock.

Do Not Operate Without Covers.

Do not operate the instrument with covers or panels removed.

Avoid Circuit or Wire Exposure.

Do not touch exposed junctions and components when the unit is powered.

Do Not Operate With Suspected Failures.

If you suspect damage occurs to the instrument, have it inspected by qualified

service personnel before further oper at ions. Any maintenance, adjustment or

replacement especially to circuits or accessories must be performed by RIGOL

authorized personnel.

Keep Well Ventilation.

Inadequate ventilation may cause increasing of temperature or damages to the

II DP800A User’s Guide

Page 5

RIGOL

device. So please keep well ventilated and inspect the intake and fan regularly.

Do Not Operate in Wet Conditions.

In order to av oid short circuiting t o the interi or of the device or electric shock, please

do not operate in a humid environment.

Do Not Operate in an Explosive Atmosphere.

In order to avoid damages to the device or personal injuries, it is important to

operat e the device away from an explosive atmospher e.

Keep Product Surfaces Clean and Dry.

To avoid the influence of dust and/or moisture in air, please keep the surface of

device clean and dry.

Electrostatic Prevention.

Operate in an electrostatic disc harge protective are a environme nt to avoid damages

induced by static discharges. Always ground both the internal and external

conductors of the cable to release static before connecting.

Handling Safety.

Please handle with care during transportation to avoid damages to buttons, knob

interfaces and other parts on the panels.

DP800A User’s Guide III

Page 6

RIGOL

CAUTION

WARNING

CAUTION

indicates a potential dama ge to the inst rument or ot her property mi ght

Hazardous

Safety

Protective

Chassis

Test

Safety Terms and Symbols

Terms in this Ma n ual. These terms may appear in this manual:

WARNING

Warning state ments indicate the conditions or practices that could result i n

injury or loss of life.

Caution statements indicate the c onditions or practic es that coul d result i n

damage to this product or other property.

Terms on the Product. These terms may appear on the Product:

DANGER

Symbols on the Product. These symbols may appear on the product:

indicates an injury or hazard may immediately happen.

indicates an injury or hazard may be accessible potentially.

occur.

Voltage

Warning

Earth

Terminal

Ground

Ground

IV DP800A User’s Guide

Page 7

RIGOL

To avoid damages to the instrument, do not expose them to liquids which

WARNING

General Care and Cleaning

General Care:

Do not store or leave the instrument in where the instrument will be exposed to

direct sunlight for long periods of time.

Cleaning:

Clean the instrument regularly according to its operating conditions. To clean the

exterior surface, perform the following steps:

1. Disconnect the instrument from all power sources.

2. Clean the loose dust on the outside of the ins trument with a lint - free cloth (with

a mild detergent or water). When cleaning the LCD, take care to a void sca rifying

it.

CAUTION

have cau s ticity.

To avoid injury resulting from short circuit, make sure the instrument is

completely dry before reconnecting to a power source.

DP800A User’s Guide V

Page 8

RIGOL

Environmental Consideratio ns

The following symbol indicates that this product complies with the applicable

European Union requirements according to Directives 2002 /96/EC on waste electrical

and electronic equipment (WEEE) and batteries.

Product End-of-Life Handling

The equipment may contain substances that could be harmf ul to the envi ron m ent or

human health. In order to avoid release of such substances into the environment and

harm to human health, we encourage you to recycle this product in an appropriate

system that will ensure that most of the materials are reused or recycled

appropriately. Please contact your local authorities for disposal or recycling

information.

VI DP800A User’s Guide

Page 9

RIGOL

DP800A Series Overview

DP800A series is high-performance programmable linea r DC power supply. DP800A

series which provides clear user interface, superb performance specification s,

various analysis functions as well as various communication interfaces can fulfill

versatile test requirements.

Main Features:

User-friendly Design:

3.5 inches TFT display, can display multiple parameters and states at the same

time

Support Chinese/English interfaces and input methods

Novel and exquisite industrial design and easy operation

Provide waveform display function to provide real-time and dynamic d isplay of

the output voltage/current waveform, clearly showing the output state and

tendency of the instrument in together with the digital display of the voltage,

current and power values

Provide dial display function, indicating the current output state using the dial

pointer by simulating the traditional power display mode

Provide on-line help system for easy acquisition of help information

Multiple Safety Protection:

Provide overvoltage/overcurrent protection function; users can set the

overvoltage and overcurrent parameters to realize effective protection of the

load

Provide seco nd ary over-temperature protection function to realize double

over-temperatu re protection of the s of t ware and hardware

Provide intelligent fan speed control function; judge and control the fan speed

automatically according to the working condition to effectively reduce the fan

noise

Provide fan failure check and alar m fu nction

Provide keyboard lock function to avoid misoperation

Various Functions and Superb Performance:

Multi-channel output; up to 200W total output power; the output of each

channel can be controlled independently

Superb load regulation rate and linear regulatio n r ate

Provide ultra-low output ripples an d noise

Provide timing output function and support infinite and specified number of

cycles of output

Provide output track function

Provide delay on/off output function and support infinite or specified number of

cycles of channel on/off toggle

Provide built-in digital trigger to realize digital trigger input and trigger output

functions

DP800A User’s Guide VII

Page 10

RIGOL

Provide built-in on-line analyzer to perform on-line analysis of various statistic

parameters

Provide built-in monitor to monitor the output according to the user-defined

monitor condition

Provide built-in recorder to perfor m background recor di ng of the output state

after power-on according to certain record period

Provide de di cat ed p res et key to perf o rm one-ke y reset and one-key recall of the

commonly used output voltage and current configurations

Support serial and parallel output functions

Support on-line self-test and manual calibration functions

Provide store and recall function

Support voltage and current linear programmable functions

Complete In te rface Configu rations and Flexible Control Method:

Standard configuration interfaces: USB Host, USB Device, LAN, RS232, Digital

I/O

Support to extend a GPIB interface via the USB-GPIB int e rface conve rt e r

(option)

Support USB st orage device storage

Support SCPI remote command control

Conform to LXI-C class instrument standard

Provide standard 9 pin RS232 interface with flow control function

Provide 4-wire digital I/O interface which supports the trigger input/output

function

VIII DP800A User’s Guide

Page 11

RIGOL

Tip

Document Overview

Chapter 1 Quick Start

Introduce the appearance and dimensions, front panel, rear panel, power connection ,

power-on inspection and user interface of DP800A.

Chapter 2 Front Panel Ope rations

Introduce the function and operation method of each key at the front panel of

DP800A in detail.

Chapter 3 Remote Control

Introduce how to realize the remote control of the instrument.

Chapter 4 Troubleshooting

Introduce the possible failures and their solutions when using DP800A.

Chapter 5 Specifications

List the specifications of DP800A.

Chapter 6 Appendix

Provide the accessory list, warranty information as well as service and support

information of DP800A.

Index

Provide keyword se a rch to quickly loca t e th e d e s ired information.

For the newest version of this manual, download it from www.rigol.com.

DP800A User’s Guide IX

Page 12

RIGOL

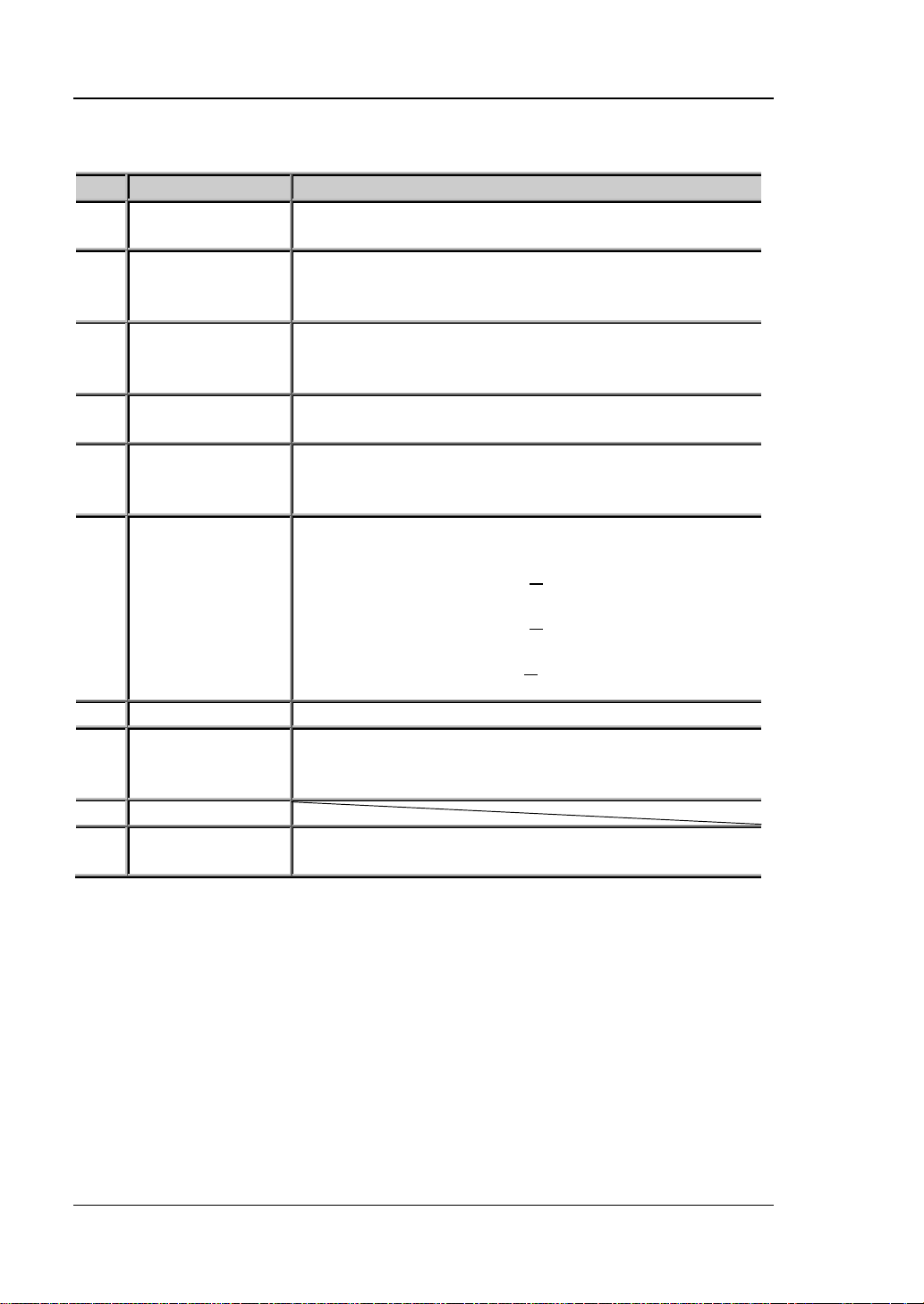

Model

Channel

Channel Output Voltage/Current

Format Conventions in this Manual

1. Button

The function key at the front panel is denoted by the format of “Button Name

(Bold) + Text Box” in the manual, for example, Utility denotes the “System

Auxiliary Function Setting” key.

2. Menu

The menu item is denoted in two modes in this manual.

(1) The menu item can be denoted by the format of “Menu Word (Bold ) +

Character Shading”, for e x ampl e , System denotes the “System” item under

Utility.

(2) The menu item can be denote by the screenshot of the menu key, for

example,

.

3. Operation Step

The next step of the operation is denoted by an arrow “” in the manual. For

example, Utility System denotes pressing Utility at the front panel and

then pressing System.

Content Conventions in this Manual

DP800A series programmable linear DC power sup pl y includes the following m odels .

In this manual, DP831A is taken as an example to illustrate the functions and

operating methods of DP800A series.

DP831A 3 8V/5A, 30V/2A, -30V/2A

DP832A 3 30V/3A, 30V/3A, 5V/3A

X DP800A User’s Guide

Page 13

RIGOL

Contents

Guaranty and Declaration ......................................................................... I

Safety Requirement ................................................................................ II

General Safety Summary ........................................................................... II

Safety Terms and Symbols ....................................................................... IV

General Care and Cleaning ........................................................................ V

Environmental Considerations ................................................................... VI

DP800A Series Overview ....................................................................... VII

Document Overview ............................................................................... IX

Chapter 1 Quick Start ......................................................................... 1-1

General Inspection ................................................................................ 1-2

Appearance and Dimensions ................................................................... 1-3

Front Panel ........................................................................................... 1-4

Rear Panel ........................................................................................... 1-11

To Connect to Power ............................................................................. 1-13

Power-on Inspection ............................................................................. 1-13

To Replace the Fuse ............................................................................. 1-14

User Interface ...................................................................................... 1-15

To Use the Built-in Help System ............................................................. 1-17

Chapter 2 Front Panel Operations ...................................................... 2-1

Constant Voltage Output ........................................................................ 2-2

Constant Current Output ........................................................................ 2-4

Track Function ...................................................................................... 2-6

Timer and Delayer ................................................................................. 2-7

To Set the Timer Parameters ............................................................ 2-8

To Enable the Timer ....................................................................... 2-16

To Set the Delayer Parameters ........................................................ 2-17

To Enable the Delayer .................................................................... 2-20

Advanced Functions .............................................................................. 2-21

Recorder ....................................................................................... 2-22

Analyzer ........................................................................................ 2-23

Monitor ......................................................................................... 2-26

Trigger .......................................................................................... 2-27

Display Setting ..................................................................................... 2-31

Brightness ..................................................................................... 2-31

Contrast ........................................................................................ 2-31

RGB Luminance ............................................................................. 2-31

Display Mo de ................................................................................. 2-32

User-defined Start-up Interface ....................................................... 2-32

Store and Recall ................................................................................... 2-34

Browser ........................................................................................ 2-35

DP800A User’s Guide XI

Page 14

RIGOL

File Type ....................................................................................... 2-35

Save ............................................................................................. 2-36

Read ............................................................................................ 2-38

Delete .......................................................................................... 2-38

Copy ............................................................................................ 2-38

Paste ............................................................................................ 2-39

Utility .................................................................................................. 2-40

I/O Configuration .......................................................................... 2-41

System Setting .............................................................................. 2-47

System Information ....................................................................... 2-48

System Language .......................................................................... 2-48

Test/Calibration ............................................................................. 2-49

Print ............................................................................................. 2-49

Preset Setting................................................................................ 2-50

Option .......................................................................................... 2-55

Chapter 3 Remote Control ................................................................. 3-1

Remote Control via USB .......................................................................... 3-2

Remote Control via LAN .......................................................................... 3-5

Remote Control via GPIB ......................................................................... 3-9

Remote Control via RS232 .................................................................... 3-11

Chapter 4 Troubleshooting ................................................................ 4-1

Chapter 5 Specifications .................................................................... 5-1

DP831A Specifications ............................................................................ 5-1

DP832A Specifications ............................................................................ 5-3

Chapter 6 Appendix ........................................................................... 6-1

Appendix A: Accessories and Options ....................................................... 6-1

Append i x B: Warranty ............................................................................. 6-2

Appendix C: Any Question or Comment? .................................................. 6-3

Index ........................................................................................................ 1

XII DP800A User’s Guide

Page 15

Chapter 1 Quick Start RIGOL

Chapter 1 Quick Start

The contents of this chapter are as follows:

General Inspection

Appearance and Dimensions

Front Panel

Rear Panel

To Connect to Power

Power-on Inspection

To Replace the Fuse

User Interface

To Use the Built-in Help System

DP800A User’s Guide 1-1

Page 16

RIGOL Chapter 1 Quick Start

General Inspection

1. Inspect the shipping container for damage

Keep the damaged shipping container or cushioning material until the contents

of the shipment have been checked for completeness and the instrument has

passed both ele ctrical and mechanical tests.

The consigner or carrier shall be liable for the damage to instrument resulting

from shipment. RIGOL woul d n ot be responsible for free maintenance/rework

or replacement of the unit.

2. Inspect the instrument

In case of any damage, or defect, or failure, notify your RIGOL sales

representative.

3. Check the accessories

Please check the accessories according to the packi ng l is t s. If t he accessories

are incomplete o r damaged, please contact your RIGOL sales representative.

1-2 DP800A User’s Guide

Page 17

Chapter 1 Quick Start RIGOL

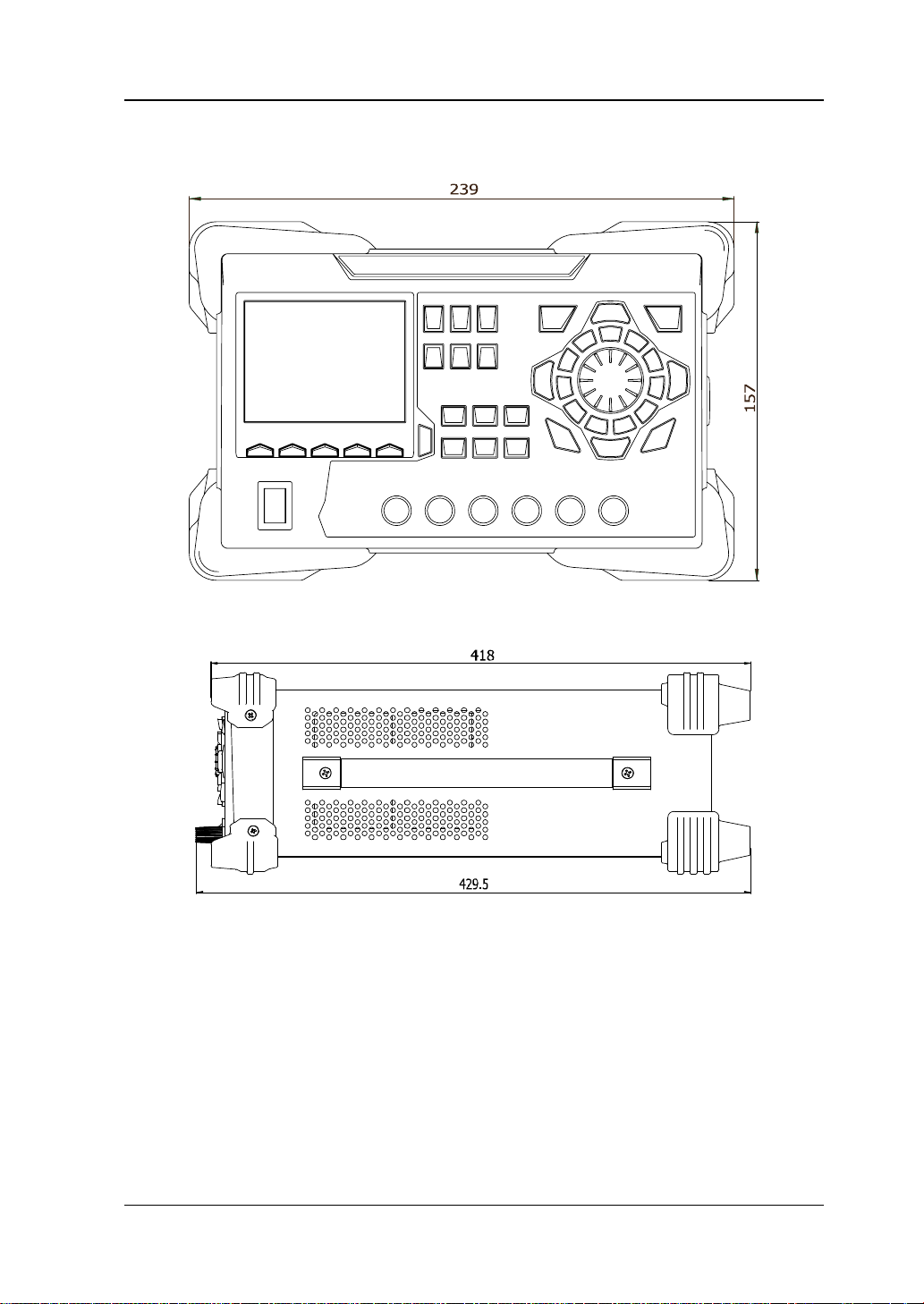

Appearance and Dimensions

Figure 1-1 Front View Unit: mm

Figure 1-2 Side View Unit: mm

DP800A User’s Guide 1-3

Page 18

RIGOL Chapter 1 Quick Start

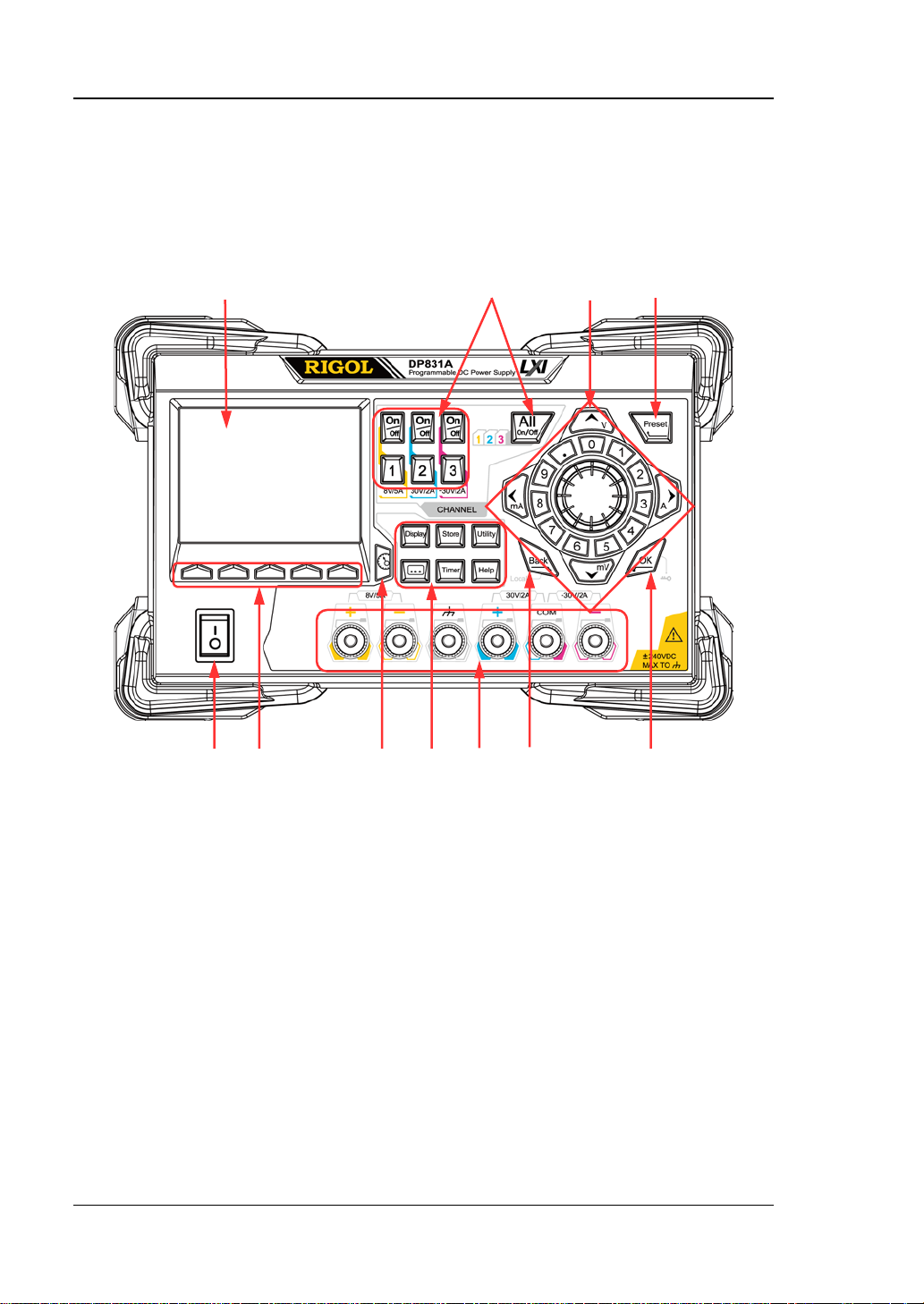

Front Panel

The front panel of DP800A is as shown in Figure 1-3. This section gives a brief

introduction of the function of each part at the front panel.

1 2 3 4

11 10 9 8 7 6 5

Figure 1-3 DP831A Front P anel

1-4 DP800A User’s Guide

Page 19

Chapter 1 Quick Start RIGOL

Press this key to select CH1 and set the parameters of this channel,

Press this key to select CH3 and set the parameters of this channel,

1. LCD

3.5 inches TFT display. It is used to display the system parameter setting,

system output state, menu items, prompt messages, etc.

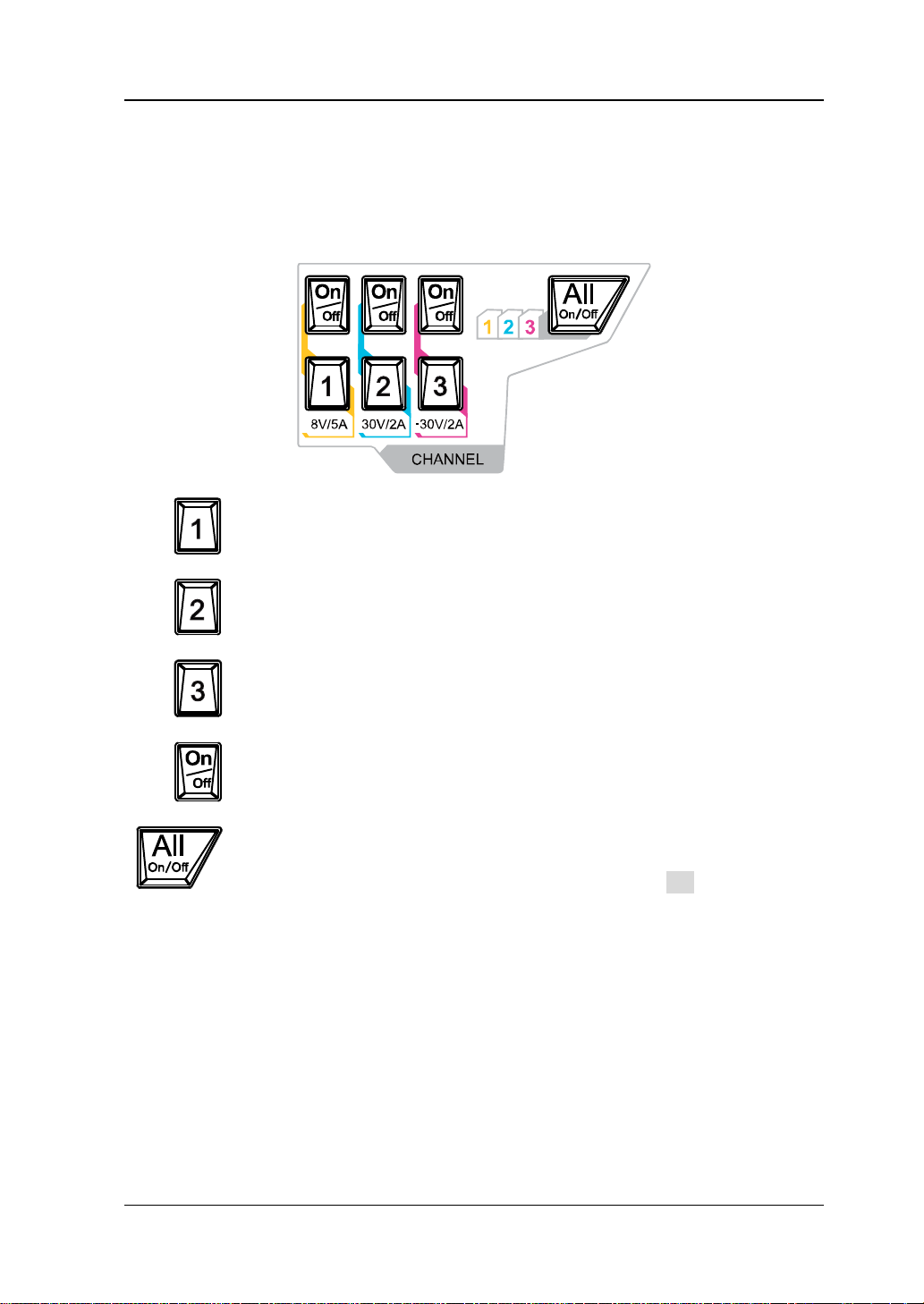

2. Channel Selection and Output Switch

such as voltage, current and overvoltage/overcurrent protection.

Press this key to select CH2 and set the parameters of this channel,

such as voltage, current and overvoltage/overcurrent protection.

such as voltage, current and overvoltage/overcurrent protection.

Press this key to enable or disable the output of the corresponding

channel.

Press this key and the prompt message asking whether to enable the

outputs of all the channels will be displayed. Press OK to enable the

outputs of all the channels. Press this key again, disa ble the outputs of

all the channels.

DP800A User’s Guide 1-5

Page 20

RIGOL Chapter 1 Quick Start

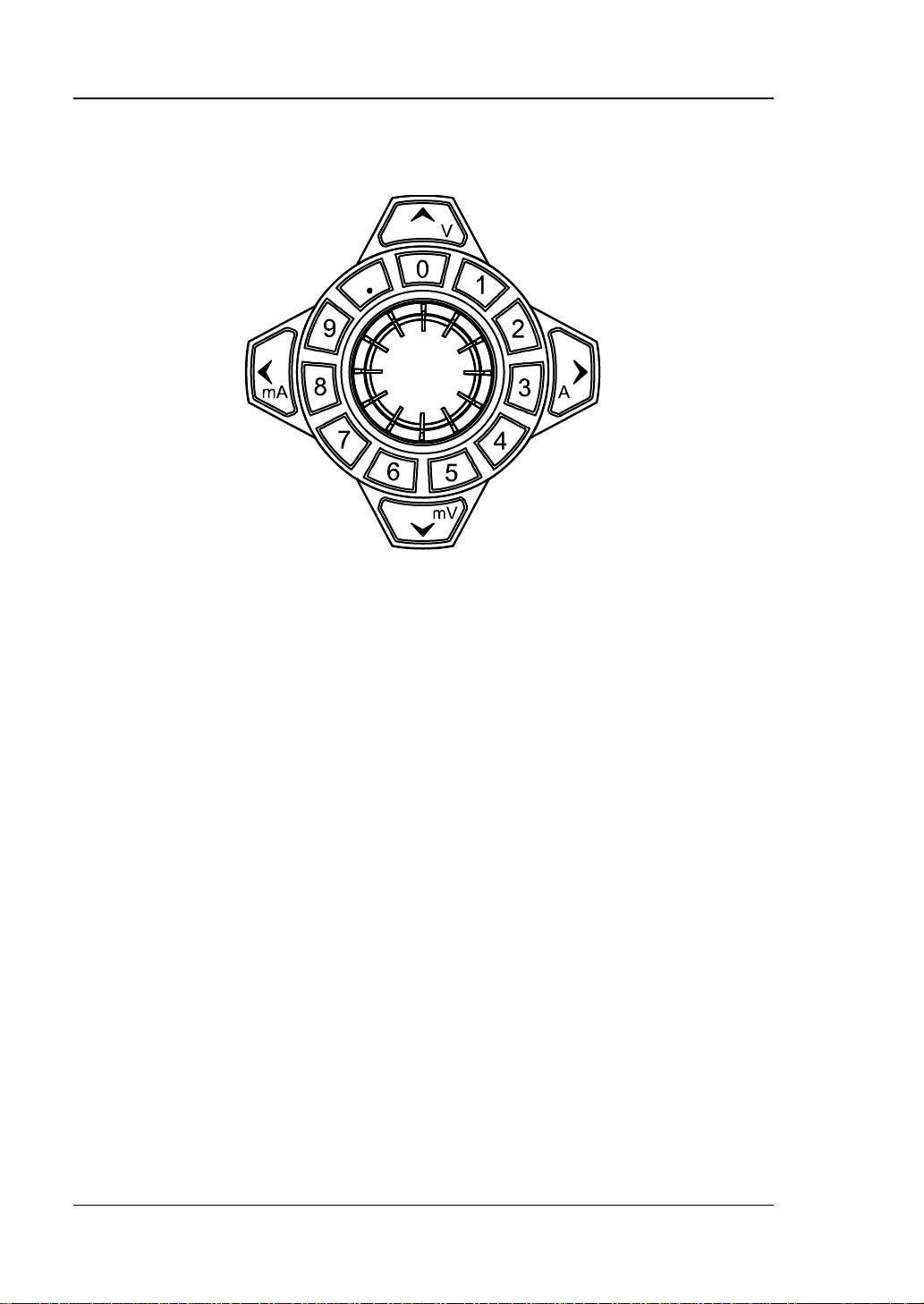

3. Parameter In p ut Area

The parameter input area is as shown in the figure below. This area includes the

direction keys (unit selection keys), numeric keyboard and knob.

(1) Direction keys and unit selection keys

Direction keys: move the cursor. When setting parameters, use the

up/down direction keys to increase or reduce the value at the cursor.

Unit selection keys: whe n usi ng the numeric keyboard to input parameters,

the keys are use d to ente r the voltage units V and mV and the cu rrent units

A and mA.

(2) Numeric Keyboard

Ring-type numeric keyboard: include numbers 0-9 and the decimal point.

Press the corresponding key to input the number.

(3) Knob

When setting parameters, rotate the knob to inc rease or decrease the valu e

of the digit at the cursor.

When browsing the settin g o bje cts (timer parameters, delayer parameters,

filename input, etc), rotate the knob to quickly move the cursor.

1-6 DP800A User’s Guide

Page 21

Chapter 1 Quick Start RIGOL

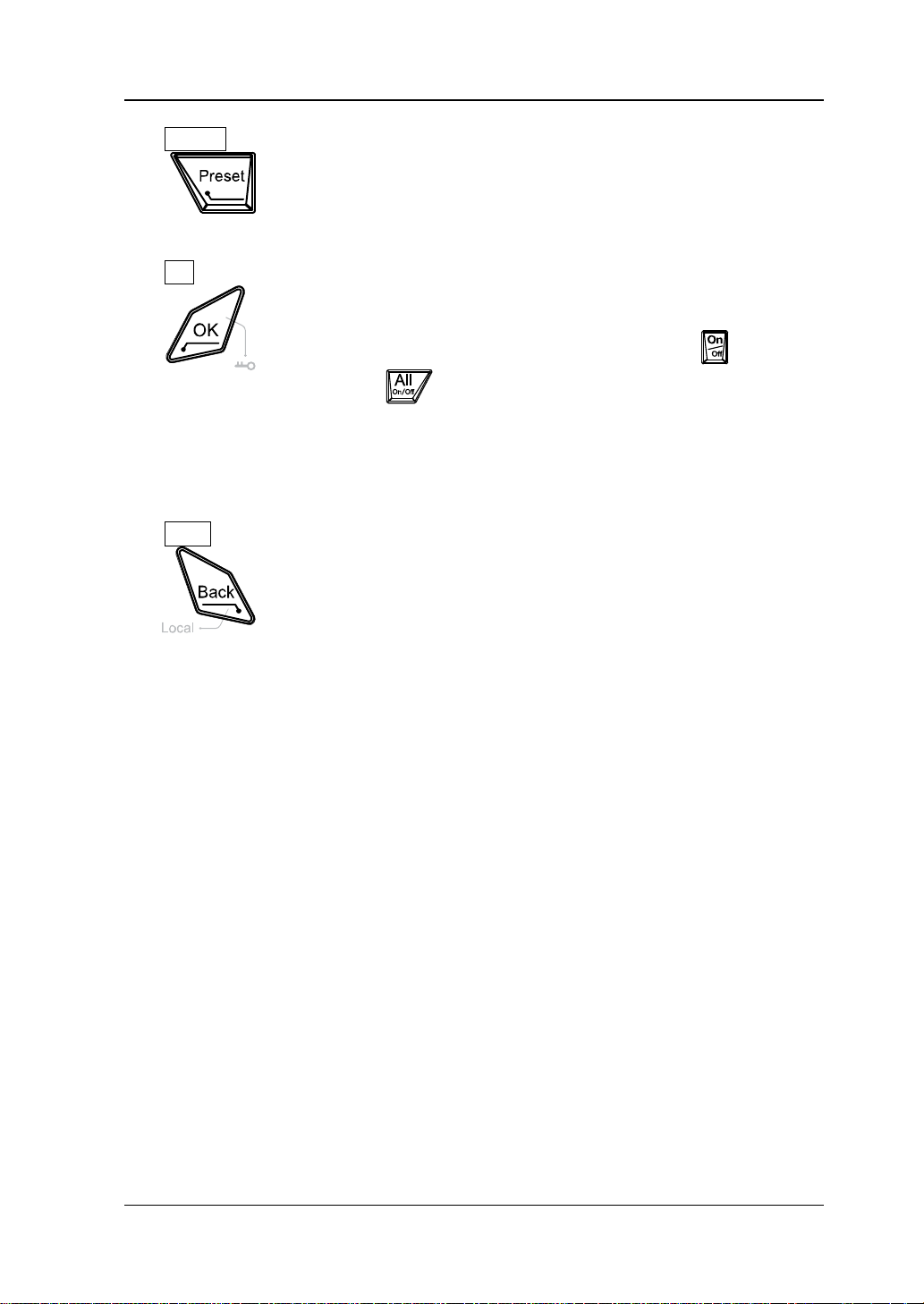

4. Preset

Restore all the settings of the instrument to default values or

recall the user-defined channel voltage/current configurations.

5. OK

Confirm the parameter setting.

Press and hold this key to lock the front panel k eys; at this point,

6. Back

the front panel keys (except the output on/off key

channel and

) are not available. Press and hold this key

of each

again to unlock the front panel keys. When the keyboard lock

password is enabled, you need to input the correct password

(2012) to unlock the front panel keys.

Delete the character currently before the cursor.

When the instrument is in remote mode, p ress this ke y to return

to local mode.

DP800A User’s Guide 1-7

Page 22

RIGOL Chapter 1 Quick Start

B

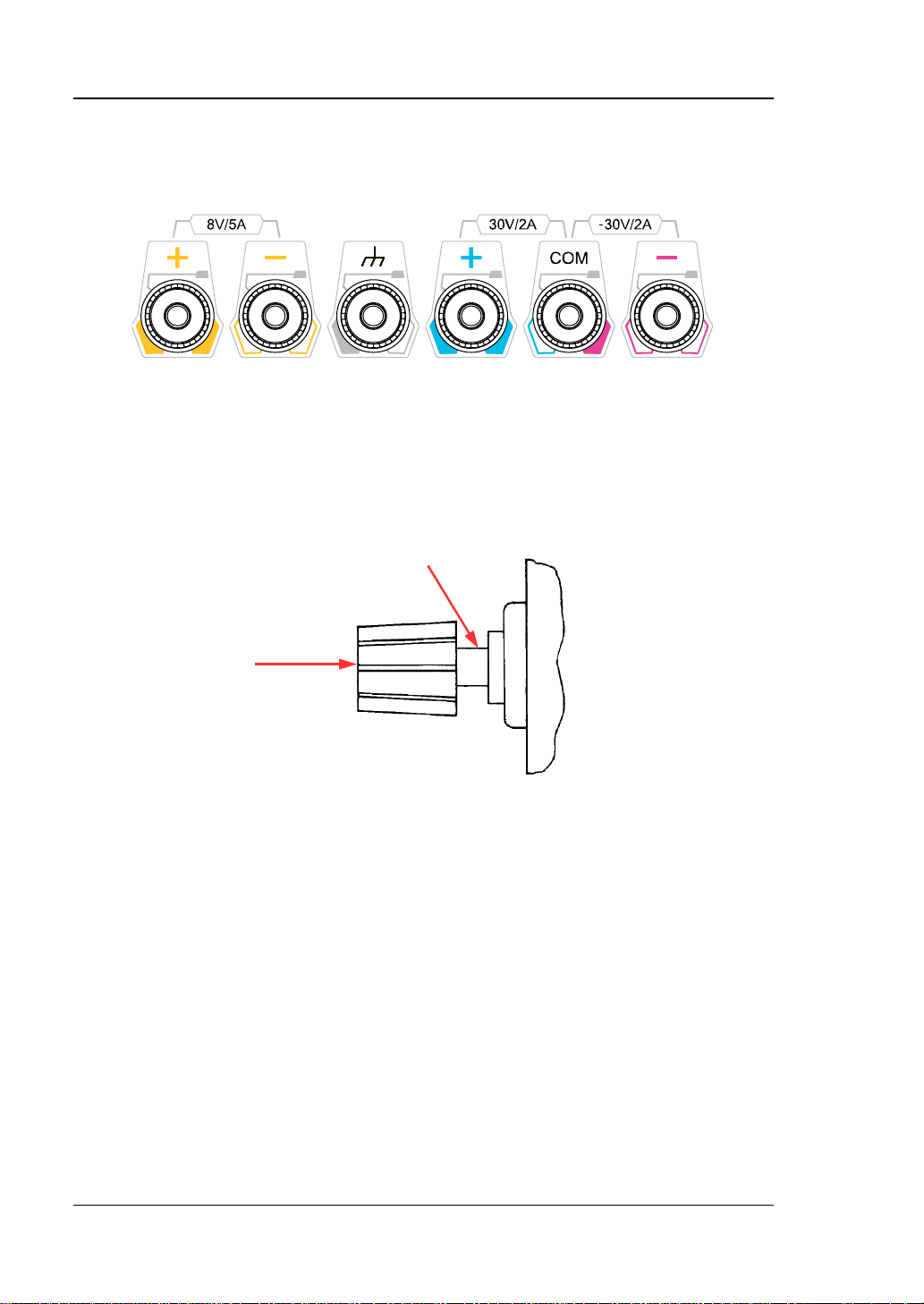

7. Output Terminals

(1) (2) (3) (4)

(1) Output the voltage and current of CH1.

(2) This terminal is connected to the instrument chassis and ground wire

(power cord ground termina l ) and is in grounded state.

(3) Output the voltage and current of CH2.

(4) Output the voltage and current of CH3.

Connection methods of the output terminal:

A

Method 1:

Connect the test lead to A of the output terminal.

Method 2:

Rotate the outer nut of the output terminal counterclockwise and connect

the test lead to B of the output terminal; then, rotate the outer nut of the

output terminal clockwise. This connection method can eliminate the error

caused by the resistance of the output terminal.

Note: Connect the positive terminal of the test lead with the (+) terminal

of the channel output and connect the negative terminal of the test lead

with the (-) terminal of the channel output.

1-8 DP800A User’s Guide

Page 23

Chapter 1 Quick Start RIGOL

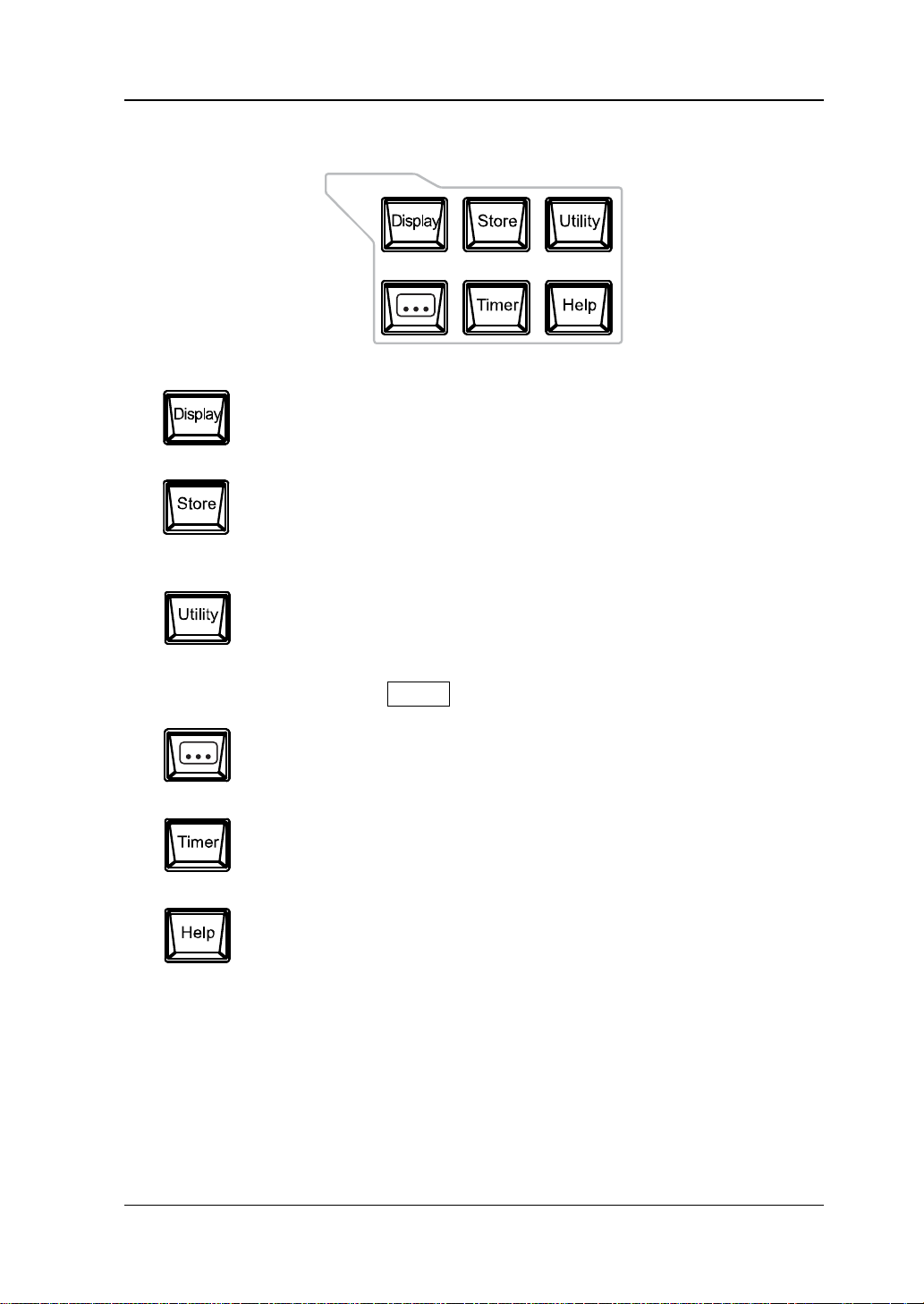

Press this key to enter the display parameter setting interface.

Press this key to enter the file store and recall interface. You can

Press this key to enter the advanced function setting interface.

8. Function Menu Area

Users can set the luminance, contrast, RGB luminance and display

mode. Besides, you can also define the start-up interface.

save, read, delete, copy and paste files. The file types available for

storage include state file, record file, timer file and delay file. The

instrument supports internal and external storage and recall.

Press this key to enter the system auxiliary function setting menu.

Users can set the remote interface parameters, system parameters

and print parameters. Besides, users can also calibrate the

instrument, view system information, define the recall

configuration of Preset and install options.

Users can set the recorder, analyzer, monitor and trigger

parameters.

Press this key to enter the timer setting interf ace. Users can set the

timer and delayer p arameters.

Press this key to open the built-in help system and press the

desired k ey t o ge t t he co rr es pon din g h el p i nf o rmation. F or detailed

introductions, refer to “To Use the Built-in Help System”.

DP800A User’s Guide 1-9

Page 24

RIGOL Chapter 1 Quick Start

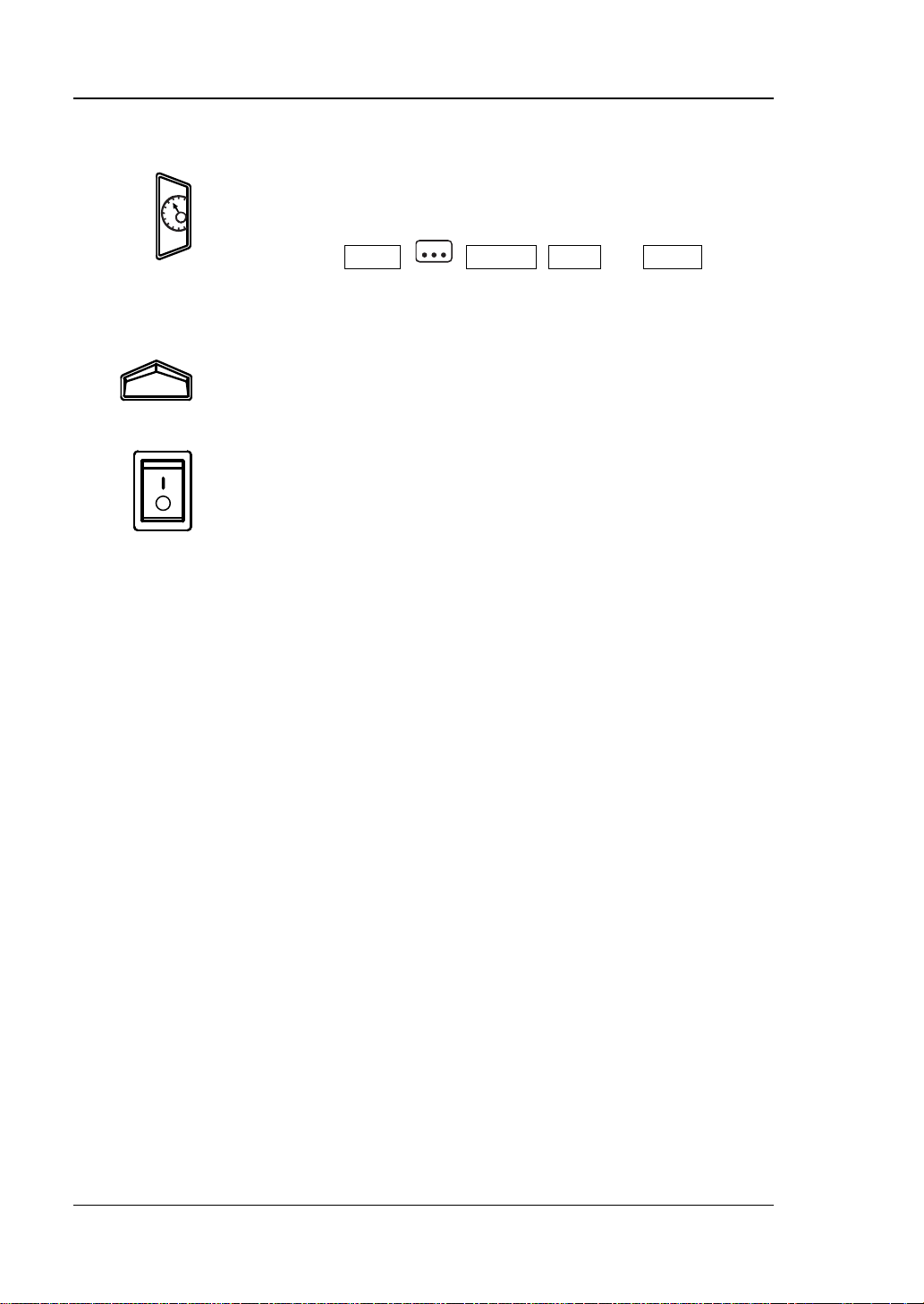

9. Display Mode Switch/Return to the Main Interface

Switch between the current display mode and dial display mode.

Besides, when the instrument is in a function interface (any

interface under Timer, , Display, Store and Utility),

press this key to exit the f unction interf ace and return to the main

interface.

10. Menu Keys

The menu keys c o rrespond to t he menus above them . P ress any

menu key to selec t the corresponding menu.

11. Power Switch Key

Turn on or off the instrument.

1-10 DP800A User’s Guide

Page 25

Chapter 1 Quick Start RIGOL

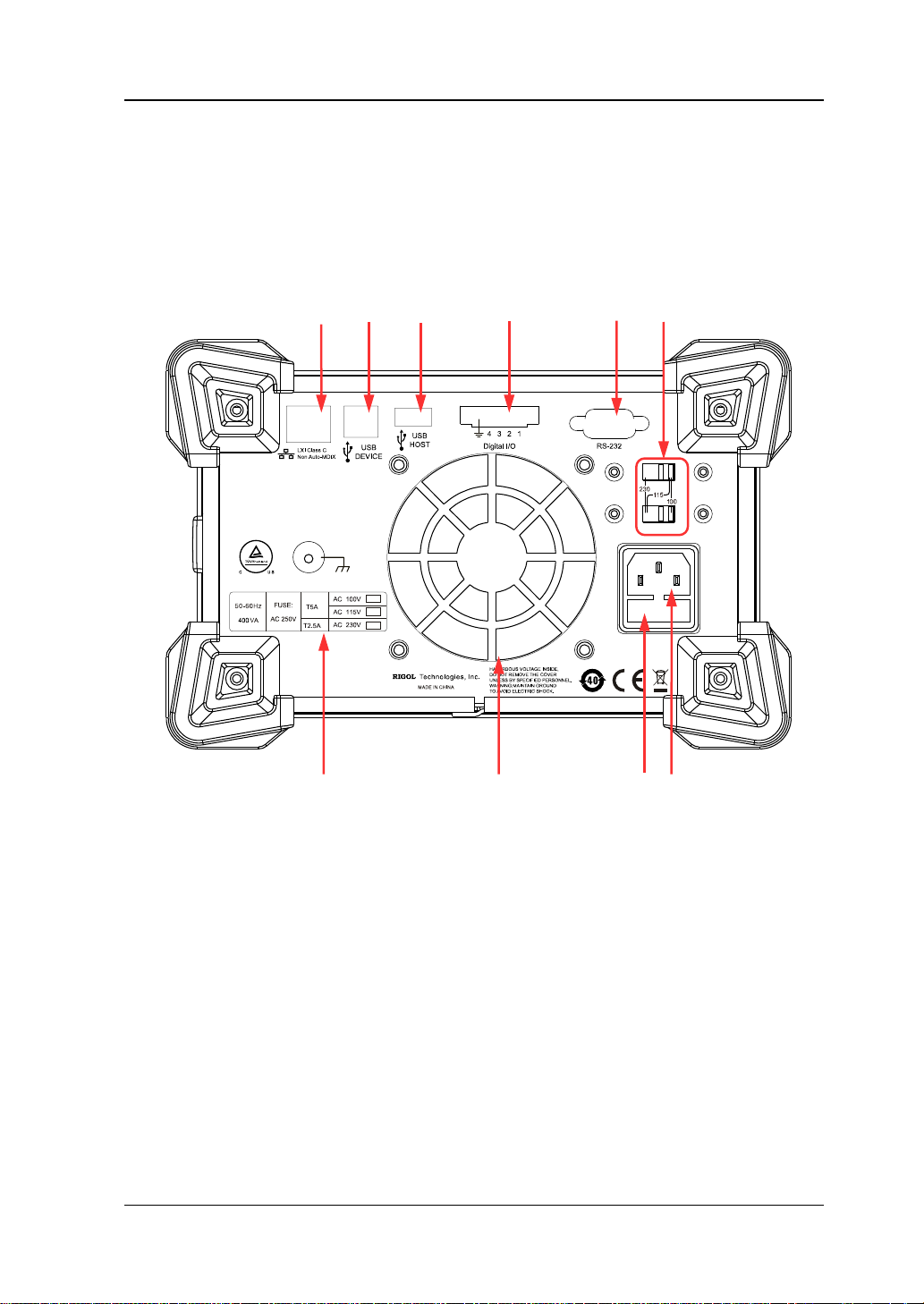

10 9 8 7

1 2 3 4 5 6

Rear Panel

The rear panel of DP800A is as shown in Figure 1-4 and the introduction of each part

is as shown in Table 1-1.

Figure 1-4 DP831A Rear Panel

DP800A User’s Guide 1-11

Page 26

RIGOL Chapter 1 Quick Start

Connect the instrument (as “slave” device) to external

For different models of instrument or when different

Table 1-1 DP831A Rear Panel Explanation

No. Name Explanation

1 LAN Interf ace

The instrument is connected to the local network to

realize remote control.

2 USB DEVICE

USB device (such as: PC) via this interface to realize

remote contr ol .

Connect the instrument (as “host” device) to external

3 USB HOST

USB device (such as: USB storage device) via this

interface.

4 Digital I/O

Digital I/O interface, used to realize the trigger input

and trigger output function.

Serial communication interface. The instrument is

5 RS232 Interface

connected to the PC via this int erface to realize remo te

control.

Select the specification of the input voltage.

DP800A supports three kinds of input voltages;

When the AC line is 100Vac+

6 Voltage Selector

selector to 100;

When the AC line is 115Vac+

selector to 115;

When the AC line is 230Vac+

set the voltage selector to 230.

7 Power Socket AC power input interface.

8 Fuse

input voltages are selected, the specifications of the

fuses are different.

9 Fan

10

Input Power

Requirement

Corresponding relations of the input AC power

frequency, voltage and the specification of the fuse.

10%, set the voltage

10%, set the voltage

10% (maximum 250VAC),

1-12 DP800A User’s Guide

Page 27

Chapter 1 Quick Start RIGOL

Tip

To Connect to Power

1. Input power requirement

DP800A series power supply can accept three kinds of AC power supplies:

50Hz–60Hz frequency; 100V, 115V and 230V voltages.

2. Check the voltage selector at the rear panel

Before connecting to power, make sure that the setting voltage of the voltage

selector at the rear panel matches the input voltage.

3. Check the fuse

When the instrument leaves factory, proper fuse is installed. Please check

whether the fuse matches the input voltage according to the “Input Power

Requirement” at the rear panel.

4. Connect the instrument power cord

Connect the instrument to AC power supply using the power cord provided in

the accessories.

WARNING

To avoid electric shock, make sure that the instrument is correctly

grounded.

Power-on Inspection

Press the power switch at the front panel, the instrument starts and executes

self-test. If the instrument passes the self-test, the welcome interface will be

displayed; otherwise, the corresponding self-test failure information (including the

top board, bottom board, fan and temperature) will be displayed.

When powering on the ins trument after powering off it, make sure that the time

interval between the two operations is greater than 5s.

DP800A User’s Guide 1-13

Page 28

RIGOL Chapter 1 Quick Start

WARNING

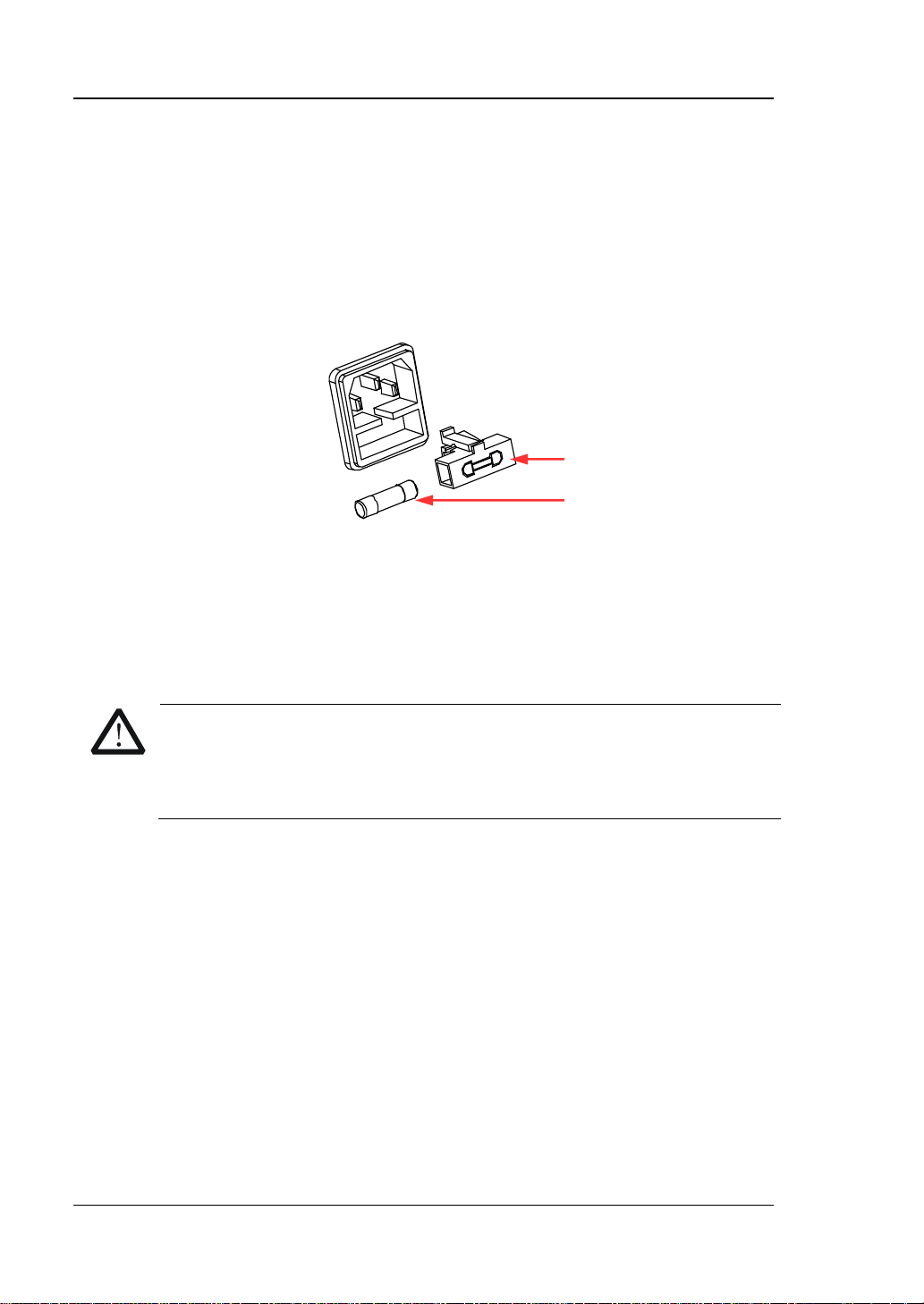

To Replace the Fuse

To replace the fuse, follow the steps below.

1. Turn off the instrument and remove the power cord.

2. Insert a small straight screwdrive r into th e slot at the pow er socke t and pri ze out

the fuse seat gently.

Fuse Seat

Fuse

3. Adjust the power voltage selector manually to select the correct voltage scale.

4. Take out the fuse and replace it with a specified fuse (for the corresponding

relations between the input voltage and fuse specification, refer to the “Input

Power R e quirement” at the rear panel).

1-14 DP800A User’s Guide

To avoid personal injuries, cut off the power supply before replacing the

fuse; to avoid electric shock or fire, select the proper power supply

specification and replace a fuse corresponding to this specification before

connecting to pow er.

Page 29

Chapter 1 Quick Start RIGOL

Tip

8 9 10 11

User Interface

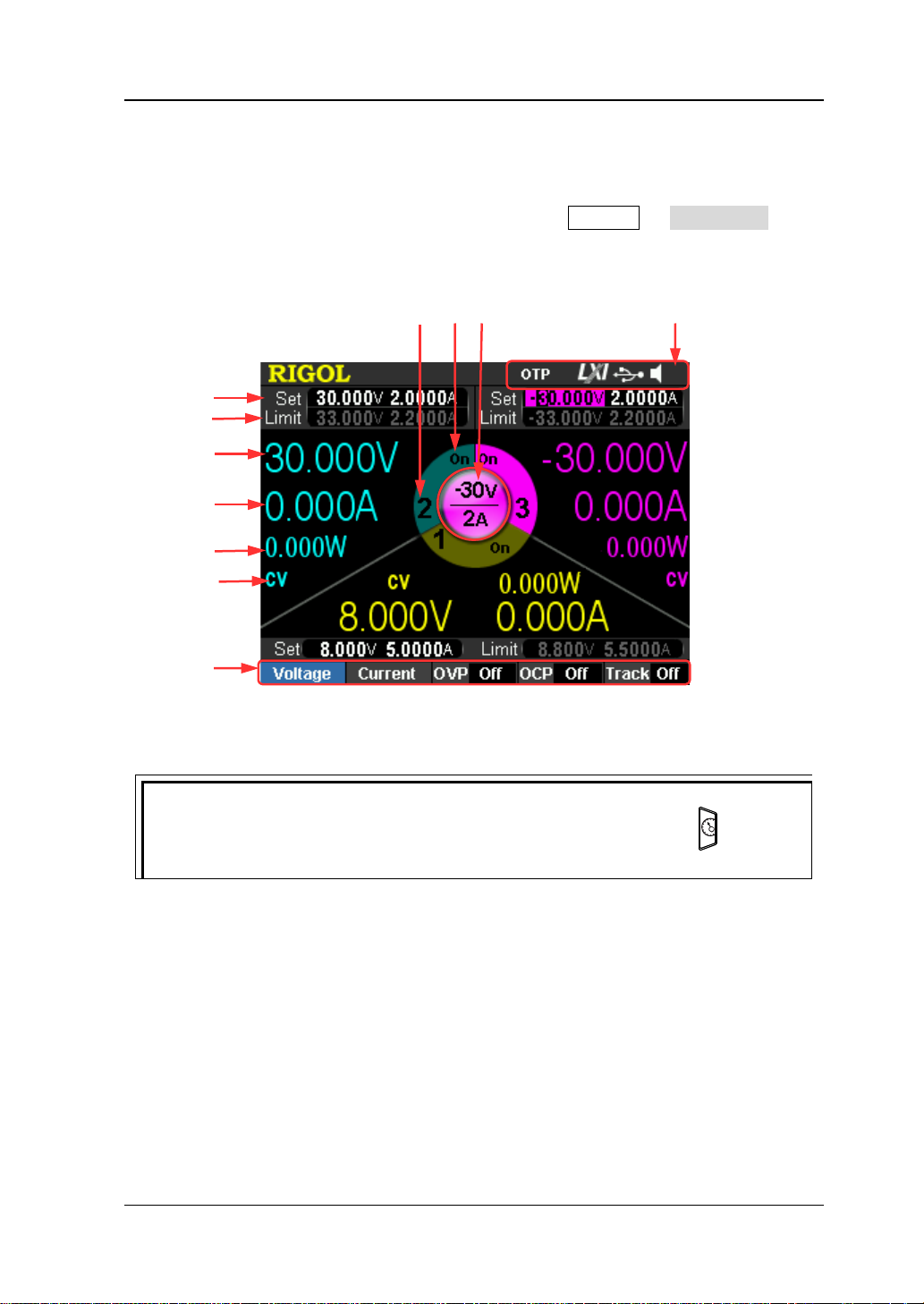

DP800A series power supply provides three kinds of display modes (normal,

waveform and dial). The default is normal and press Display Di sp Mode to s et

the display mode to “Waveform” or “Dial”. This section introduces the interface

layout under the normal display mode (as shown in

1

2

3

4

5

6

7

Figure 1-5 DP831A User Interface

Figure 1-8 and Table 1-2).

When the current display mode is “Normal” or “Waveform”, press at the

front panel to switch between the current display mode and dial display mode.

DP800A User’s Guide 1-15

Page 30

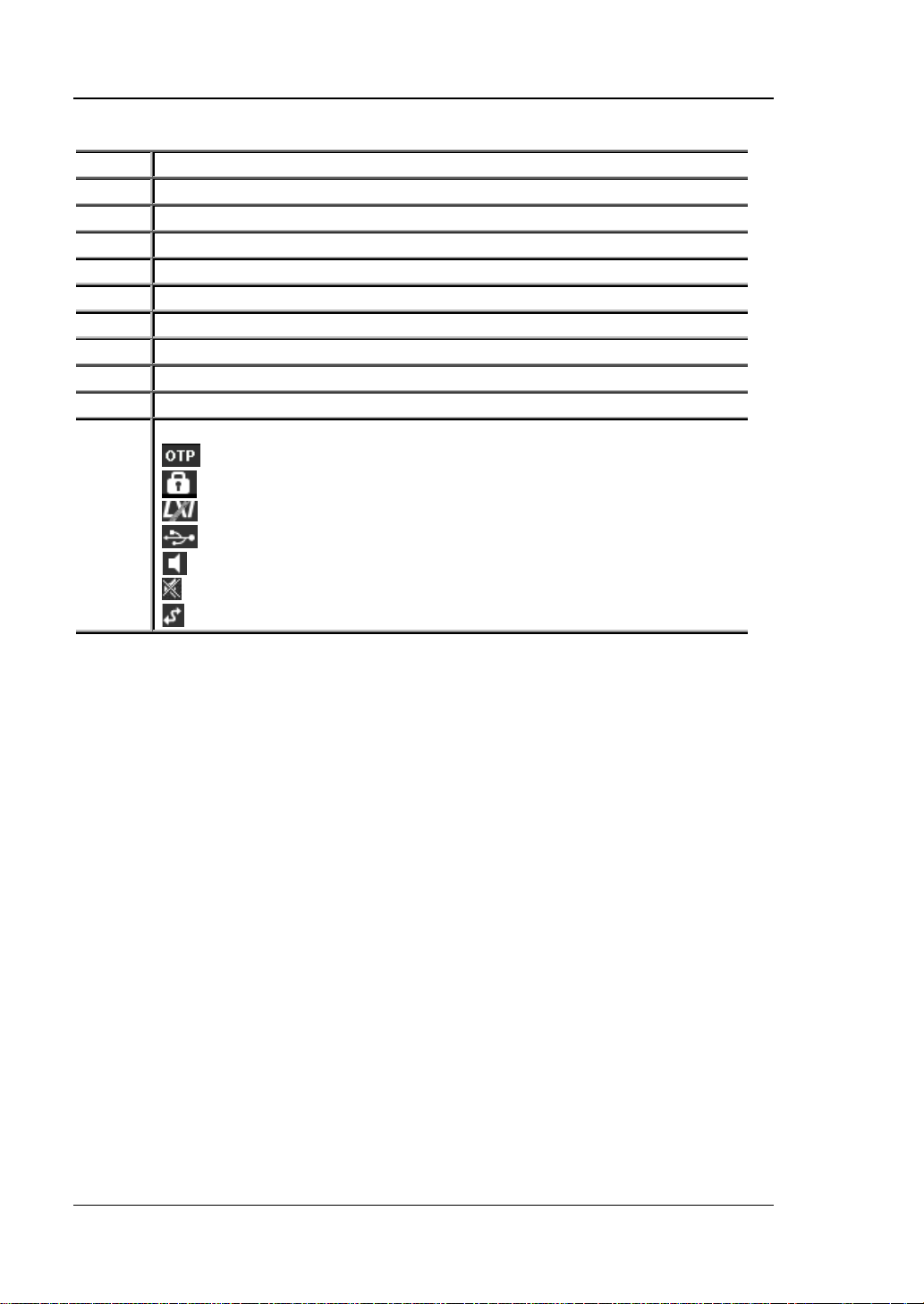

RIGOL Chapter 1 Quick Start

1

Voltage and current setting values

2

Overvoltage and overcurrent protection setting values

3

Actual output voltage

10

Channel currently selected

11

Status bar. Display the system status labels.

Table 1-2 DP831A User Interface Explanation

4 Actual output current

5 Actual output power

6 Channel output mode

7 Menu bar

8 Channel number

9 Channel output status

: over-temperature protection is enabled

: the front panel is locked.

: the network is connected.

: USB device is recognized.

: the beeper is enabled.

: the beeper is disabled.

: the instrument is in remote mode.

1-16 DP800A User’s Guide

Page 31

Chapter 1 Quick Start RIGOL

To Use the Built-in Help System

The built-in help s ystem provides help inf ormation f or any f ront panel k ey (except the

parameter input area) and menu keys for users to quickly obtain the function

prompts of the function keys or menus.

Obtain the help information of any key

Press Help to illuminate it and press the desired key to get the corresponding help

information; at the same time, the backlight of Help goes off . Press to

exit the help system.

Built-in help interface

Press Help to illuminate it and press Help again to open the built -in help interface.

Press the up/down direction keys to select the desired help topic and press View to

view the corresponding help information.

The help topics include:

1. View the last displayed message.

2. View error queue of the remote commands.

3. Get the help information of a key.

4. Storage m anagement.

5. Abbreviations list.

6. Get technical support from RIGOL.

DP800A User’s Guide 1-17

Page 32

Page 33

Chapter 2 Front Panel Operations RIGOL

Chapter 2 Front Panel Operations

The contents of this chapter are as follows:

Constant Voltage Output

Constant Current Output

Track Function

Timer and Delayer

Advanced Functions

Display Setting

Store and Recall

Utility

DP800A User’s Guide 2-1

Page 34

RIGOL Chapter 2 Front Panel Operations

Constant Voltage Output

DP800A series power supply provides three output modes: constant voltage output

(CV), constant current output (CC) and critical mode (UR). In CV mode, the output

voltage equals the volta ge set ting v alue a nd the output current is determine d by th e

load; in CC mode, the output current equals the current s etting v alue a nd the outpu t

voltage is determined by the load; UR is the critical mode between CV and CC. This

section introduces the operation method in constant v olt age outp u t m ode.

Operation Method:

1. Turn on the power switch to start the instrument.

2. Select the channel

Select the proper output channel according to the desired output voltage. Pre ss

the corresponding channel selection key; at this point, this channel, its channel

number and output state are high-lighted on the screen.

3. Set the voltage

Method 1

Press Voltage and use the left/right direction keys to move the cursor; then,

rotate the knob to set the voltage and the default unit is V.

Method 2

Press Voltage, use the numeric keyboard to input the desired voltage and press

V or mV or press the unit selection key or to select the desired

unit. Besides, you can also press OK to select the default unit V. During the

input, press Back to delete the character currently before the cursor and press

Cancel to cancel t he input.

4. Set the current

Method 1

Press Current and use the left/right direction keys to move the cursor; then,

rotate the knob to set the current and the default unit is A.

Method 2

Press Current, use the numeric k eyboard to i nput the desire d current and press

A or mA or press the unit selection key or to select the desired unit.

Besides, you can also press OK to select the default unit A. During the input,

press Back to delete the character currently before the cursor and press

Cancel to cancel t he input.

5. Set the overcurrent protection

Press OCP to set the proper overcurrent protection value. For the setting

2-2 DP800A User’s Guide

Page 35

Chapter 2 Front Panel Operations RIGOL

CAUTION

Tip

value, the power supply will swit ch to CC output mode aut omatically. At this point,

method, refer to “Set the current”. Press OCP again to enable the ove rcurrent

protection function and the output will be turned off automatically when the

actual output current is greater than the overcurrent protection value.

6. Connect the output terminals

As shown in the figure below, connect the load to the output terminals of the

corresponding channel.

CAUTION

To avoid damaging the instrument or the device connected to it, pay

attention to the polarity when connecting.

7. Turn on the output

Turn on the output of the corresponding channel and the actual output voltage,

output current, output power as well as the output mode (CV) are high-lighted

in the user interface.

Warning

To avoid electric shock, please turn on the output switch after the

output terminals are correctly connected.

When the fan stops, the channel switch can not be turned on;

otherwise, “The fan stops, stop the output!” will be displayed.

8. Check the output mode

In constant voltage output mode, the output mode displayed should be “CV”; if

“CC” is displayed, you can increase the current setting value properly and the

power supply will switch to CV mode automatically.

In CV output mode, when the load current is greater than the current setting

the output current equals the current set ting value a nd the output v oltage redu ces

proportionally.

DP800A User’s Guide 2-3

Page 36

RIGOL Chapter 2 Front Panel Operations

CAUTION

Constant Current Output

In constant current output mode, the output current equals t he cur rent setting v alue

and the output voltage is determined by the load. This section introduces the

operation method in constant current output mo de.

Operation Method:

1. Turn on the power switch to start the instrument.

2. Select the channel

Select the proper output channel accordi ng t o the desired output current. Press

the corresponding channel selection key; at this point, this channel, its channel

number and output state are high-lighted in the center of the screen.

3. Set the voltage

Press Voltage to set proper voltage according to “S et the voltage” in

“Constant Voltage Out put”.

4. Set the current

Press Current to set proper c u rrent according to “Set the current” in

“Constant Voltage Output”.

5. Set the overvoltage protection

Press OVP to set the proper over voltage protection value. For the setting

method, refer to “Set the voltage” in “Constant Voltage Output”. Press OVP

again to enable the overvoltage protection function and the output will be

turned off automatically when the actual output voltage is greater than the

overvoltage protection value.

6. Connect the output terminals

As shown in the figure below, connect the load to the output terminals of the

corresponding channel.

7. Turn on the output

2-4 DP800A User’s Guide

To avoid damaging the instrument or the device connected to it, pay

attention to the polarity when connecting.

Page 37

Chapter 2 Front Panel Operations RIGOL

Warning

CAUTION

Tip

value, the power supply will swit ch to CV output mode automati cally. At this point,

Turn on the output of the corresponding channel and the actual output voltage,

output current, output power as well as the output mode (CC) are high-lighted

in the user interface.

To avoid electric shock, please turn on the output switch after the

output terminals are correctly connected.

When the fan stops, the channel switch can not be turned on;

otherwise, “The fan stops, stop the output!” will be displayed.

8. Check the output mode

In constant current output mode, the output mode displayed should be “CC”; if

“CV” is displayed, you can increase the voltage setting value properly and the

power supply will switch to CC mode automatically.

In CC output mode, when the load voltage is greater than the voltage setting

the output voltage equals the volta ge setting v alue a nd the output current reduces

proportionally.

DP800A User’s Guide 2-5

Page 38

RIGOL Chapter 2 Front Panel Operations

Model

CH1

CH2

CH3

DP832A

Support

Support

Not support

When the track f unction is enabled, the volta ge of the t racking channe l cannot

Track Function

Some of the DP800A channels support the output track function (as shown in the

table below).

DP831A Not support Support Support

For two channels supporting the track function, when the track function of one

channel (the tracked channel) is enabled, the voltage setting value of the other

channel (the tracking channel) will change accordingly when the voltage setting

value of this channel is changed. By default, the track function is disabled and it is

usually used to provide symmetric voltage for the calculation amplifier or other

circuits.

Operation Method (Take DP831A for example):

1. Turn on the power switch to start the instrument.

2. Enable the track function

Select CH3 and press Track to enable the track fun ction. At t his point, the t rac k

status label

3. Set the voltage

Press Voltage to set proper voltage. At this point, the voltage of CH2 changes

accordingly. For example, set the voltage of CH3 to -5V and the voltage of CH2

will change to +5V automatically.

4. Disable the track function

Select CH3 and press Track to disable the track function.

is displayed in the CH2 area in the user interface.

Tip

The track function onl y tracks the voltage setting value and the actual output

voltage will not be affected.

be set.

2-6 DP800A User’s Guide

Page 39

Chapter 2 Front Panel Operations RIGOL

Tip

The timer function and delayer function are mutually exclusive. When the timer is

Timer and Delayer

DP800A provide s the timer and delayer functions.

When the timer is enabled, the instrument outputs the preset voltage and current

values (at most 2048 groups). Users can set the number of output groups of the

timer as well as the voltage, current and timing time of each group. Besides, the

instrument provides various built-in output templets and users can sel e ct and edit

the templet as well as create timer parameters based on the templet. The instrument

will output according to the parameters currently created.

When the delayer is enabled, the instrument enables or disables the output

according to the preset state and delay time (at most 2048 groups). Users can set

the number of output groups of the delayer as well as the state and delay time of

each group.

Users can store the edited timer parameters (timer file, with the suffix “*.RTF”) and

delayer parameters (delay file, with the suffix “*.RDF”) in internal or external

memory and recall them when required.

Press Timer to illuminate it. The timer and delayer setting interface is displ ayed.

1. Timer Set: To Set the Timer Parameters

2. Timer: To En able the Timer

3. Delay Set: To Set the Delayer Parameters

4. Delayer: To Enable the Delayer

enabled, Delayer is gra yed out and disabled; when the delayer is en abled, Timer

is grayed out and disabled.

DP800A User’s Guide 2-7

Page 40

RIGOL Chapter 2 Front Panel Operations

To Set the Timer Parameters

Press Timer Timer Set to enter the timer parameter setting interface as shown

in the figure below. The channel currently selected is displayed in the status bar.

Press the channel selection keys at the front panel to switch channel. This interface

provide s timer parameter preview; the horizontal axis represents time and the

vertical axis represents v oltage a nd current; users ca n view the values on t he current

page of the parameter list.

Timer Parameter Preview Channel Currently Selected Timer Parameter List

Figure 2-1 Timer Parameter Setting Interface

Number of Groups

The number of groups is defined as the number of groups of preset voltage and

current values that the power supply outputs in each cycle. Press Groups and use

the knob or numeric keyboard to input the value. The range is from 1 to 2048.

2-8 DP800A User’s Guide

Page 41

Tip

Chapter 2 Front Panel Operations RIGOL

Number of Cycles

The number of cycles is defined as the number of times that the i nstrument performs

timing output according to the preset voltage and current. Press Cycles to set the

number of cycles to “Infinite” or use the knob or numeri c keyboard to input t he value .

The range is from 1 to 99999.

The total number of groups in each timing output = the number of groups ×

the number of cycles

The power supply wil l terminate the timer function when the total number of

groups of output s is finished. At this point, the state of the power supply

depends on the setting of End State.

End State

The end state refers to the state of the instrument after it finishes outputting the

total number of gr oups of voltage an d cur rent v alues when t he num be r of cy cles is a

specif ied value. Press End State to select “Outp Off” or “Last”.

Outp Off: the instrument turns off the output automatically after finishing the

output.

Last: the instrument stops at the output state of the last group after finishing

the output.

Note: When the number of cycles is set to “Infinite”, the end state is invalid.

To Manually Edit the Timer Parameters

You can e dit the timer parameters manually . Press Parameter and use the left/right

direction keys to select the number (No.) in the timer parameter list, use the

up/down direction keys to select the voltage (Volt), current (Curr) and time ( Set) of

the current group respectively and use the numeric keyboard or direction keys and

knob to input the desired value. Use the same method to set the parameters of the

other groups.

You need to set the parameters of number 0 to number (P-1); wherein, P is the

number of output groups currently set. Only 6 groups of parameters can be

displaye d on each page of the timer parameter list an d you can press

view and set the parameters of the other groups. This interface provides timer

parameter preview; the horizontal axis represents time and the vertical axis

represents voltage and current; users can view the v alues on the current page of the

parameter list.

or to

DP800A User’s Guide 2-9

Page 42

RIGOL Chapter 2 Front Panel Operations

To Edit the Timer Parameters using Templet

The instrument provides various built-in output templets and users can select and

edit the templet as well as create timer parameters based on the templet. The

instrument will output according to the parameters currently created.

Press Timer Timer Set and press Templet to open t h e templet edit menu.

1. Select the editing object

Press Edit Obj to select “Voltage” or “current”.

Voltage: when it is selected, press Current and use the numeric keyboard

or direction keys and kn ob to set the current value. Then, sele ct the templet

and edit the templet parameters. The interface displays the voltage

preview.

Current: when it is selected, press Voltage and use the numeric keyboard

or direction keys an d knob to set the voltage v alue. Then, s elect the templet

and edit the templet parameters. The interface displays the current

preview.

2. Select the templet

Press Type to select the desired templet, including Sine, Pulse, Ramp, Stair Up,

Stair Dn, StairUpDn, Exp Rise and Exp Fall.

Sine

The Sine waveform is as shown in the figure below. The instrument

determines the Sine amplitude according to the maximum and minimum

currently set and determines the Sine pe ri od according t o the total number

of points (denoted by P) and the time interval currently set, thus

determining the Sine w av eform. When creating par ameters, the instrument

draws P values from the preset Sine waveform according to the current

time interval.

T

Pulse

The Pulse waveform is as shown in the figure below. The timer parameters

created from Pulse wavef orm only contain two points.

The first point: the amplitude (voltage or cu rrent) is determined by the high

level set; the time equals the pulse width currently set.

The second point: the amplitude (voltage or current) is determined by the

low level set; the t ime equals the period currently s et minus the pulse wi dth

currently set.

2-10 DP800A User’s Guide

Page 43

Chapter 2 Front Panel Operations RIGOL

T

t

Tip

T

t

Symmetry=t/T*100%

When Pulse is selected, if you want t o output more than 2 groups of timer

parameters, you can output the timer parameters created from the Pulse

templet repeatedly by increasing the number of cycles.

Ramp

The Ramp waveform is as shown in the figure below. The instrument

determines the amplitude of the Ramp according to the maximum and

minimum currently set, determines the period according to the total

number of points (deno t ed by P) and the time interval currently set and

determines the Ramp waveform according to the symmetry (denoted by

Sym) currently set. When creating parameters, the instrument draws

[1]

int(P*Sym)

values from the rising edge of the preset Ramp waveform at

the same time interval and draws P- int(P*Sym) values from the fa lling

edge of the preset Ramp waveform at the same time interval. The timing

time is determined by the time interval currently set.

[1]

Note

: int(P*Sym) refers to rounding P*Sym (discard the decimal part).

Stair Up

The Stair Up waveform is as shown in the figure below. The instrument

determines the Stair Up waveform accor ding to the maximum (denoted by

MAX), minimum (denoted by MIN), total number of p oints (den ote d by P,

P≥10) and time interval currently set and creates P parameters from MIN

to MAX at the step of (MAX-MIN)/(P-1). The timing time is determined

by the time interval currently set.

Stair Up

DP800A User’s Guide 2-11

Page 44

RIGOL Chapter 2 Front Panel Operations

Stair Dn

The Stair Dn waveform is as shown in the figure below. The instrument

determines the Stair Dn waveform according to the maximum (denoted by

MAX), minimum (denoted by MIN), total number of points (denoted by P)

and time interval currently set and creates P parameters from MIN to MAX

at the step of (MAX-MIN)/(P-1). The timing time is determined by the

time interval currently set.

Stair Dn

StairUpDn

The StairUpDn waveform is as shown in the figure below. The instrument

determines the StairUpDn waveform according to the maximum (denoted

by MAX), minimum (denoted by MIN), total number of points (denoted by

P) and time interval currently set and creates P parameters. When P is an

odd number, the value increase from MIN to MAX at the step of

(MAX-MIN)/int(P/2)

[1]

and then reduces to MIN at the same step.

When P is an even number, the value increases from MIN to MAX at the

step of (MAX-MIN)/int(P/2-1) and then reduces to MIN at the step of

(MAX-MIN)/int(P/2). The timing ti me is deter mined by the time inter v al

currently set.

StairUpDn

[1]

Note

: int(P/2) indicates rounding P/2.

Exp Rise

The Exp Rise waveform is as shown in the figure below. The instrument

determines the Exp Rise waveform according to the maximum (denoted by

MAX), minimum (denoted by MIN), total number of points (denoted by P)

and rise index (denoted by RiseIndex) currently set. The wavefo r m

function is (MAX-MIN)*[1-e

-i*RiseIndex/P

]; wherein, i is independent

variable and creates P groups of parameters from 0 to (P-1). The timing

time is determined by the time interval currently set.

2-12 DP800A User’s Guide

Page 45

Chapter 2 Front Panel Operations RIGOL

Note

Exp Rise

Exp Fall

The Exp Fall waveform is as shown in the figure below. The instrument

determines the Exp Fall waveform according to the maximum (denoted by

MAX), minimum (denoted by MIN), total number of points (denoted by P)

and fall index (denoted by FallIndex) currently set. The waveform function

is (MAX-MIN)*e

-i*FallIndex/P

; wherein, i is independent variable and

creates P groups of parameters from 0 to (P-1). The timing time is

determined by the time interval currently set.

Exp Fall

When the templet c urrently sele cted is Exp Rise or Exp Fall, the timer parameters

created cannot reach the maximum or minimum due to the characteristic of the

exponential function. The ran ge of the timer parameters created is related to the

rise index or fall index currently set. The larger the rise index or fall index is, the

larger the range of the tim er parameters will be, as shown in the figures below

(maximum=8, minimum=0, total number of points=100, rise index/fall index are

1, 4, 7 and 10 respectively).

DP800A User’s Guide 2-13

Page 46

RIGOL Chapter 2 Front Panel Operations

Templet

Parameter

Sine

Max Value, Min Value, Points, Interv a l, Inverted

StairUpDn

Max Value, Min Value, Points, Interval

Exp Rise

Max Value, Min Value, Points, Interval, Rise Index

3. Edit the templet parameters

After selecting the desired templet, set the templet parameters. Fo r different

templets, the parameters to be set are different as shown in Table 2-1.

Table 2-1 Templet Parameters

Pulse Hi Level, Lo Level, Width, Period, Inverted

Ramp Max Value, Min Value, Points, Interval, Symmetry, Inverted

Stair Up Max Value, Min Value, Points, Interval

Stair Dn Max Value, Min Value, Points, Interval

Exp Fall Max Value, Min Value, Points, Interval, Fall Index

Max Value

Set the maximum voltage or current of the templet currently selected. The

range is related to the channel currently selected.

Min Value

Set the minimum voltage or current of the templet currently selected. The

range is related to the channel currently selected. The minimum cannot be

greater than the maximum currently set.

Points

The total number of points refers to the number of groups of timer

parameters created using the templet currently selected. The range is from

10 to 1048.

When the total number of points ( denote d by P) and the current number of

output groups (denoted by G) are different, P groups of parameters will be

created using the templet and then, the number of output groups will

change to P automatically.

Interval

The interval refers to the time required for the instrument to output each

group of ti mer parameters created using the templet currently selected and

the range is from 1s to 99999s.

Inverted

When the templet currently selected is Sine, Pulse or Ramp, if Inverted is

enabled, the instrument will first turn the preset waveform upside do wn

and then create timer parameters.

2-14 DP800A User’s Guide

Page 47

Chapter 2 Front Panel Operations RIGOL

Hi Level

When the templet currently selected is Pulse, set the high level of the Pulse

and the range is related to the channel currently selected.

Lo Level

When the templet currently selected is Pulse, set the low level of the Pulse

and the range is related to the channel currently selected. The low level

should not be greater than the high level currently set.

Width

When the templet currently selected is Pulse, set the pulse width of the

Pulse (namely the du ratio n of high level withi n a period). The range is from

1 to (Period-1) and the unit is s econd.

Period

When the templet currently selected is Pulse, set the period of the Pulse

and the range is from 2s to 99999s.

Symmetry

When the templet currently selected is Ramp, set the symmetry of the

Ramp (namely the ratio of the dura tion of the rising edge within a period to

the whole period) and the range is from 0% to 100%.

Rise Index

When the templet currently selected is ExpRise, set the r ise index of the

ExpRise and the range is from 0 to 10.

Fall Index

When the templet currently selected is ExpFall, set the fall index of the

ExpFall and the range is from 0 to 10.

4. Create the timer parameters

After setting all the parameters, press Construct to construct th e timer

parameters. The timer parameters constructed are displayed in the timer

parameter list as shown in

Figure 2-2.

Save and Read

You can store the timer parameters edited manually or created using the templet in

internal or external memory and recall them when required.

1. Save

After editing the timer parameters, press Save to enter the store and recal l

interface, the file type is fixed at “*.rtf” and please save the file according to the

introduction in “

Store and Recall”.

DP800A User’s Guide 2-15

Page 48

RIGOL Chapter 2 Front Panel Operations

Tip

2. Read

Press Read to enter the st ore and recall int erface , the file type is fixed at “*.rtf”

and please read the desired file according to the introduction in “

Recall”. Users can edit the timer file read.

Store and

To Enable the Timer

After setting the timer parameters, pr es s Timer Timer to enable the timing

output. The timing output interface is as shown in the figure below.

Figure 2-2 Timing Output Interface

Enabling the timer will change the output value of the channel; make sur e

that the change in the output value will not affect the device connected to

the power supply be fore enabling the timer.

The timing output is valid only when both the timer and the channel output

are turned on.

When the timer is enabled, the timer parameters cannot be modified and

Delayer is grayed out and disabled.

2-16 DP800A User’s Guide

Page 49

Chapter 2 Front Panel Operations RIGOL

To Set the Delayer Parameters

Press Timer Delay Set to enter the delayer para meter setting interface as shown

in the figure below. The channel currently selected is displayed in the status bar.

Press the channel selection keys to switch channel. This interface provides delayer

parameter preview. Users can view the values on the current page of the delayer

parameter list. High level indicates turning on the output and low level indicates

turning off the output.

Delayer Parameter Preview Channel Currently Selected Delayer Parameter List

Figure 2-3 Delayer Parameter Setting Interface

Number of Groups

The number of groups ref ers to the nu mber of time s that the instrument tu rns on or

off the output according to the preset state. Press Groups and u s e th e kn ob or

direction keyboard to input the value. The range is from 1 to 2048.

Number of Cycles

The number of cycles refers to the number of times that the instrument performs

delay output according to the preset state. Press Cycles to set the number of cycles

to “Infinite” or use the knob or n umeric ke yboa rd t o in put the v alue an d the ra nge is

from 1 to 99999.

DP800A User’s Guide 2-17

Page 50

RIGOL Chapter 2 Front Panel Operations

Tip

The total number of groups in each delay output = the number of groups ×

the number of cycles

The power supply will terminate the delayer function when the total number

of groups of delays is finished. At this point, the state of the power supply

depends on the setting of End State.

End State

The end state refers to the state of the instrument when the delayer stops. Press

End State to select “Outp On”, “Outp Off” or “Last”.

Outp On: the instrument turns on the output automatically.

Outp Off: the instrument turns off the output automatically.

Last: the instrument stops at the output state of the last group.

To Edit the Delayer Parameters Manually

You can edit the dela yer parameters manually. Press Parameter and use the

left/right direction keys to s elect t he number (No.) in the delayer par ameter list, use

the up/down direction keys to select the state (State) and time (Delay) of the current

group respectively. After selecting the state (State), press OK to switch to the

desired state and after selecting the time (Delay), use the numeric keyboard or

direction keys and knob to input the desired value. Use the same method to set the

parameters of the other groups.

You need to set the parameters of number 0 to number (P-1); wherein, P is the

number of output groups currently set. Only 6 groups of parameters can be

displaye d o n ea ch page of the dela yer parameter list and you can press

to view and set the parameters of the other groups. This interfac e p rovides d e lay er

parameter preview and users can view the v alues on the cu rrent page of t he d elay er

parameter list. High level indicates turning on the output and low level indicates

turning off the output.

or

To Generate State Automatically

Press Timer Delay Set State Gen to select “0 1 Patt” or “1 0 Patt”.

0 1 Patt: the state is set to “Off” and “On” alternately.

1 0 Patt: the state is set to “On” and “Off” alternately.

2-18 DP800A User’s Guide

Page 51

Chapter 2 Front Panel Operations RIGOL

To Generate Time Auto mat ic ally

1. Select the generation method

Press Timer Delay Set Time Gen Method to select t he desir ed

generati on method.

FixTime

Users can set the durat i on of the “On” or “Off” state.

Increase

The duration is generated in monotonic increase mode.

Decline

The duration is generated in mon otoni c decline mo de.

2. On Delay/Off Delay

When the time generation method is “FixTime”, users can set the duration of the

“On” or “Off” state.

On Delay: set the duration of the “On” state and the range is from 1s to 99999s;

Off Delay: set t he dur ation of the “Off” state and the range is from 1s to 99999s.

3. Base Val and Step

When the time gener at ion method is “Increase” or “Decline”, set the base value

and step of time generation. The two fulfills the relation: time base value +

number of output groups*step ≤99999s.

Stop Condition

The instrument monitors the out put volta ge, current and power d uring dela y output.

You can set a condition and the instrument stops the delay output when state that

fulfills this condition is detected.

Press Timer Delay Set Stop Con to set the stop condition to “None”, “<

Voltage”, “> Voltage”, “< Current”, “> Current”, “< Power” or “> Power”. After

selecting the desired condition, use the numeric ke yboard or dire ction keys and knob

to input the desired value.

DP800A User’s Guide 2-19

Page 52

RIGOL Chapter 2 Front Panel Operations

Tip

Save and Read

You can save the delayer parameters edited manually or generated automatically in

internal or external memory and recall them when required.

1. Save

After finishing editing the delayer parameters, press Save to enter the store and

recall interface, the file type is fixed at “*.rdf” and please save the file according

to the introduction in “

2. Read

Press Read to enter the st ore and re call interface , the file type is fixed at “*.rdf”

and please read the desired file according to the introduction in “

Recall”. Users can edit the delay file read.

Store and Recall”.

Store and

To Enable the Delayer

After setting the delayer parameters, press Timer Delayer to enable the delay

output. The delay output interface is as shown in the figure below.

Figure 2-4 Delay Output Interface

Enabling the delayer will change the output state of the channel. Please

make sure that the change of the output state will not affect the devices

connected to the power supply before enabling the delayer.

When the delayer is enabled, the delayer parameters cannot be modified

and Timer is grayed out and disabled .

2-20 DP800A User’s Guide

Page 53

Chapter 2 Front Panel Operations RIGOL

Advanced Functions

DP800A pro vides various advanced functions, including the recorder, analyzer,

monitor and trigger. Press

1. Recorder: record the output state of each channel and store the record file.

2. Analyzer: analyze the record file saved.

3. Monitor: monitor the output of each channel and turn off the output, display

the corresponding prompt message or sound the beeper when the monitor

condition is met.

4. Trigger: the rear panel provides a digital I/O interface which supports trigger

input and trigger output.

Trigger Input: the data lines of the digital I/O interface receive external

trigger signal. The source under control (namely the output channel) turns

on the output, turns off the output or inverts the output state when the

preset trigger condition is met.

Trigger Output: the data lines of the digital I/O i nterf ace output the level o r

square signal when the output of the control source (namely the output

channel) meets the preset trigger condition.

to open the advanced function setting interface.

DP800A User’s Guide 2-21

Page 54

RIGOL Chapter 2 Front Panel Operations

Recorder

When the recorder is enabled, users can record the current state of the instrument

and if analyzer is installed, users can also analyze the file recorded.

Press Recorder to open the recorder setting interface. You can turn on or

off the recorder function, set the record period and select the store destination.

1. Switch

Press Switch to turn on or off the recorder and the default is “Off”. When the

recorder is turne d o n, the record period and destination cannot be set. The

instrument samples and records the output of each channel accord ing to the

current record period. When the recorder is turned off, the current record is

finished and the instrument prompts you to sav e t he file recorded (press OK to

save the file).

Note: During the record, make s ure that the out put of ea ch channel is enable d;

otherwise, the record data will be 0.

2. Record Period

The record period is the time interval at which the instrument samples and

records the output of each channel when the recorder is turned on. Press

Period and use the numeric keyboard or direction keys and knob to set the

record period of the recorder . The range is from 1s to 99999s and the default is

1s.

3. Destination

Before turning on the recorder, select the store destination. Press Dest to enter

the store and recall interface and the file type is fixed at “*.rof”. You can store

the file recorded in internal or external memory. After selecting the desired

destination, press Save, input the desired filename and press OK (for the

detailed operations, refer to the introduction in “

finishing the record, the instrument stores the record file with the specified

filename to the specified destination.

Store and Recall”). After

2-22 DP800A User’s Guide

Page 55

Chapter 2 Front Panel Operations RIGOL

Analyzer

The analyzer can analyze the file recorded and provides the analysis results,

including the numbe r of groups, median , mode as well as the average, VAR, range,

minimum, maximum a nd mean deviation of the volt age, current or pow er of diff erent

channel.

Press Analyzer to open the analyzer setting interface. You can open the

record file stored, set the analyzer parameters, execute the analysis and view the

analysis results.

1. Open the File

Press Open File to enter the store and recall interface, the file type is fixed at

“*.rof”, select the desired record file and press Read. At this point, the current

time and start time are 1s and the end time is the maximum record time of the

file opened.

The following operations are valid only when valid record file is opened.

2. Set the Parameters

Start Time

Press Start Time and use the knob or numeric keyboard to set the start

time of the current analysis file. The range is from 1 to the end time.

End Time

Press End Time and use the knob or numeric keyboard to set the end time

of the current analysis file. The range is from the start time to the

maximum record time of the file opened.

3. Execute the Analysis

After opening the record f ile and setting the start time and end time, press

Analyze and the instrument will start to analyze according to the current

setting.

4. View the Analysis Results

Analysis object

After executing the analysis operation, press Object to select voltage,

current, power or all and the analysis results of the object currently

selected will be displayed at the bottom of the screen. When “All” is

selected, press

the corresponding analysis results.

Display Type

After opening the record file and setting the start time and end time, the

data between the start time and end time in the record file currently

opened will be displayed in both figure and table forms on the screen. Press

or to switch the current analysis object an d view

DP800A User’s Guide 2-23

Page 56

RIGOL Chapter 2 Front Panel Operations

Disp Type continuously to switch between figure and table forms.

Figure: display the voltage, current and power of the current record file in

figure form (the voltage, current or pow e r corresponding to the current

time is displayed above the figure) and each group of measurement values

of each object are connected in linear interpolation mode, clearly showing

the variation tendency. You can press Object to switch among voltage,

current and power.

Table: display each group of voltage, current and power of the current

record file in table form.

Curr ent Time

Use the knob or numeric keyboard to quickly locate each group of data of

the current record file between the start time and end time. If the current

2-24 DP800A User’s Guide

Page 57

Chapter 2 Front Panel Operations RIGOL

display mode is figure, the interf ace will locate t he current data using cursor

line in the same color of the current analysis channel (the voltage, current

or power corresponding to the current time is displayed above the figure).

The range is from the start time to the end time.

Tip

You can switch the channel to be analyzed according to the channel number.

DP800A User’s Guide 2-25

Page 58

RIGOL Chapter 2 Front Panel Operations

Monitor

The monitor can monitor the current output state of the instrument. When the

user-defined monitor condition is met, the instrument executes the corresponding

operation according to the setting in “Stop Mode”.

Press Monitor to o pen the monitor set ting inter face. T he s tatus b ar sho w s

the channel currently sele cted. Press the channel s election ke ys at the f ront panel to

switch the channel.

Note: The instrument can monitor the output states of multiple channels

simultaneously.

1. Monitor Condition

The monitor condition can be any logic combination of the voltage, current and

power and users can also set the voltage, current and power values.

Press Condition and use the direction keys and OK to set the desired monitor

condition.

2. Voltage

Press Voltage and use the numeric keyboard or direction keys and knob to set

the voltage in the monitor condition.

3. Current

Press Current and use t he numeric key b oard or direc tion keys and knob to set

the current in the monitor condition.

4. Power

Press Power and use the numeric keyboard or direction keys and knob to set

the power in the monitor condition.

5. Stop Mode

Press Stop Mode, use the direction keys a nd OK to set the stop mode (“Output

Off”, “Warning” and “Beeper”) and multiple modes can be selected. When the

channel output state meets the monitor condition set, the instrument will turn

off the output, dis pl ay the corres ponding prompt message or sound the beeper

according to the stop mode selected.

6. Switch

Press Switch to turn on or off the monitor function.

2-26 DP800A User’s Guide

Page 59

Chapter 2 Front Panel Operations RIGOL

Trigger

The rear panel of DP800A provides a digital I/O interface (as shown below) which

supports trigger input and trigger output.

Trigger Input:

The data lines of the digital I/O interface receive external trigger signal. The

source under c ont rol (nam ely the out put channel ) turns on the output, turns off

the output or inverts the output state when the preset trigger condition is met.

Trigger Output:

The data lines of the digital I/O interface out put lev e l or squa re si gnal w hen t he

output of the control source (namely the output channel) meets the preset

trigger condition.

The 4 data lines are mutually independent and can be used as trigger input line or

trigger output line separately.

Press Trigger to open the trigger setting interface as shown in the f igure

below. Press Trig to select “In” or “Out” to switch between the trigger input and

trigger output setting interfaces and the default is trigger input.

Figure 2-5 Trigger Setting Interface

DP800A User’s Guide 2-27

Page 60

RIGOL Chapter 2 Front Panel Operations

Trigger Input

When signal th at meets the current trigger type is input on the specified data line,

the specified source under control will turn on the output, turn off the output or

toggle the output state according to the setting in output response.

Press Trigger Trig to select “In” to enter the interface as shown in

Figure 2-9.

1. Data Line

Press Data Line to select D0, D1, D2 or D3 and the data line cur rently s electe d

will be highlighted in the s creen. Use rs can set the tr igger conditions of the f ou r

data lines respectively.

2. Source under Control

Press Ctrled Src to select one or more channels as the source under control.

3. Trigger Type

Press Trig Type to select to t rigger on the risin g edge, falling e dge, high level or

low level of the input signal.

4. Output Response

Press Outp Resp to set the output response type.

Output On: when the trigger condition is met, turn on the output of the

channel currently selected as the source under control.

Output Off: when the trigger condition is met, turn off the output of the