Rigol DM3061, DM3062, DM3064, DM3051, DM3052 User guide

...

User’s Guide RIGOL

Publication number: UGC01106-1110

DM3000 Series Digital Multimeter

© 2007 RIGOL Technologies, Inc. All Rights Reserved

DM3061/2/4

DM3051/2/4

RIGOL

z © 2007 RIGOL Technologies, Inc. All Rights Reserved.

z RIGOL products are protected by patent law in and outside of P.R. China.

z Information in this publication replaces all previously corresponding material.

z RIGOL Technologies, Inc. reserves the right to modify or change part of or all

the specifications and pricing policies at company’s sole decision.

NOTE: RIGOL is registered trademark of RIGOL TECHNOLOGIES, INC.

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

I

RIGOL

Safety Notices

Review the following safety precautions carefully before operating the instrument

to avoid any personal injuries or damages to the instrument and any products

connected to it.

To avoid potential hazards use the instrument as specified by this user’s guide

only.

The instrument should be serviced by qualified personnel only.

To Avoid Fire or Personal Injury.

Use Proper Power Cord. Use the power cord designed for the instrument as

authorized in your country only.

Ground The Instrument. The instrument is grounded through the grounding

conductor of the power cord. To avoid electric shock the instrument grounding

conductor(s) must be grounded properly before making connections to the input

or output terminals of the instrument.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all

ratings and marks on the instrument. Follow the user’s guide for further ratings

information before making connections to the instrument.

Do Not Operate Without Covers. Do not operate the instrument with covers

or panels removed.

Use Proper Fuse. Use the fuse of the type, voltage and current ratings as

specified for the instrument.

Avoid Circuit or Wire Exposure. Do not touch exposed connections and

components when power is on.

Do Not Operate With Suspected Failures. If suspected damage occurs with

the instrument, have it inspected by qualified service personnel before further

operations.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive atmosphere.

Keep Product Surfaces Clean and Dry.

II

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

RIGOL

The disturbance test of all the models meet the limit values of A in the

standard of EN 61326: 1997+A1+A2+A3, but can’t meet the limit

values of B.

WARNING

IEC Measurement Category II. The HI and LO input terminals may be connected

to mains in IEC Category II installations for line voltages up to 300 VAC. To avoid

the danger of electric shock, do not connect the inputs to mains for line voltages

above 300 VAC.

Protection Limits: To avoid instrument damage and the risk of electric shock, do

not exceed any of the Protection Limits defined in the following section.

IEC Measurement Category II Overvoltage Protection

To protect against the danger of electric shock, the RIGOL DM3000 series

Digital Multimeter provides overvoltage protection for line-voltage mains

connections meeting both of the following conditions: The HI and LO input

terminals are connected to the mains under Measurement Category II conditions,

defined below, and The mains are limited to a maximum line voltage of 300 VAC.

IEC Measurement Category II includes electrical devices connected to mains at

an outlet on a branch circuit.

Such devices include most small appliances, test equipment, and other devices

that plug into a branch outlet or socket. The DM3000 series Digital Multimeter

may be used to make measurements with the HI and LO inputs connected to

mains in such devices, or to the branch outlet itself (up to 300 VAC). However,

the DM3000 series Digital Multimeter may not be used with its HI and LO inputs

connected to mains in permanently installed electrical devices such as the main

circuit-breaker panel, sub-panel disconnect boxes, or permanently wired motors.

Such devices and circuits are subject to overvoltage that may exceed the

protection limits of the DM3000 series Digital Multimeter.

Note: Voltages above 300 VAC may be measured only in circuits that are isolated

from mains. However, transient overvoltage are also present on circuits that are

isolated from mains. The DM3000 series Digital Multimeter is designed to safely

withstand occasional transient overvoltage up to 2500 Vpk. Do not use this

equipment to measure circuits where transient overvoltage could exceed this

level.

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

III

RIGOL

Safety Terms and Symbols

Terms in This Guide. These terms may appear in this guide:

WARNING: Warning statements identify conditions or practices that

!

could result in injury or loss of life.

CAUTION: Caution statements identify conditions or practices that

!

could result in damage to this product or other property.

CAT II (300V): IEC Measurement Category II. Inputs may be

connected to mains (up to 300 VAC) under Category II overvoltage

!

conditions.

Terms on the Product: These terms may appear on the product:

DANGER indicates an injury hazard may happen immediately.

WARNING indicates an injury hazard may not happen immediately.

CAUTION indicates that a potential damage to the instrument or other property

might occur.

Symbols on the Product: These symbols may appear on the Instrument:

Hazardous

Voltage

!

Refer to

Instructions

Protective

Earth

Terminal

Chassis

Ground

Earth

Ground

IV

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

RIGOL

General-Purpose Multimeter

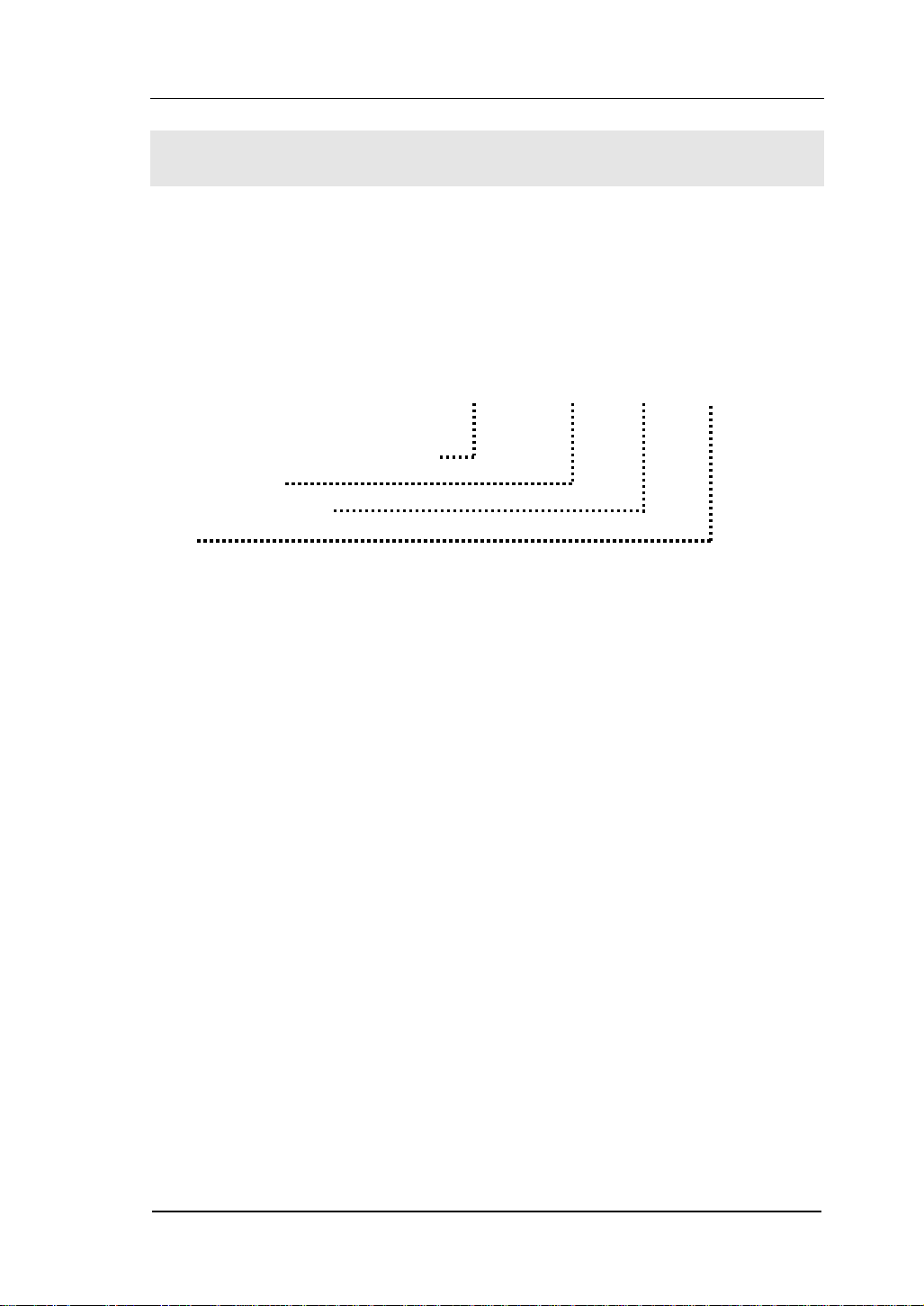

The book covers the following description and six models DM3000 Series Digital

Multimeter:

DM3061, DM3062, DM3064;

DM3051, DM3052, DM3054.

DM3000 Series Digital Multimeter naming rules:

Prefix desktop Digital Multimeter

Serial Number

6-6½, 5-5¾ digit

No.

1-Basic; 2-LAN/GPIB interface;

4-Inspection plate with the model and LAN/GPIB interface.

Application examples:

DM3061- 6½ DM3000 series, Basic type.

DM3062- 6½ DM3000 series, Basic type, equipped with LAN/GPIB module.

DM3064 - 6½ DM3000 series, Basic type, equipped with LAN/GPIB and

inspection module.

DM3051- 5¾ DM3000 series, Basic type.

DM3052- 5¾ DM3000 series, Basic type, equipped with LAN/GPIB module.

DM3054 - 5¾DM3000 series, Basic type, equipped with LAN/GPIB and

inspection module.

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

DM

30

6 1

V

RIGOL

RIGOL DM3000-Series Digital Multimeter is a equipment designed for

high-precision, multifunction, automation measurements. The series includes 6½

digits multimeter, with high-speed data acquisition, automatic measurements,

multiplexer, mathematical operations, and flexible user sensor configurations etc.

Interface includes RS-232, USB, LAN, GPIB for disk storage and print.

The DM3000 has a high-resolution monochrome LCD display system for simple

waveform display and recording. The concise and user-friendly layout of the front

panel has a keyboard, and back lighted functional buttons, embedded with

operating instructions makes the instrument more flexible, and capable. The

50kSa/s high data sampling rate allows to capture precision audio waveforms and

high speed data. It has 2Mbyte of internal memory depth while the external

memory depth is expandable as preferred. The AC voltage and current

measurement is true RMS. It supports virtual terminal display and control, and

remote network access.

With the performance and characteristics given below, you will understand how a

DM3000 can satisfy your measurement requirements.

z 50kSa/s data sampling rate can be used, such as the rapidly changing

high-precision audio waveform data. Meanwhile waveform can be displayed

on LCD Screen

z Resolving Index: > 6½ digits and 2,400,000 Count

z 24 measurement functions

DC voltage and current, AC voltage and current, two-wire and four-wire

resistance, capacitance, continuity test, diode test, frequency, cycle,

ratio measurements, sensor measurement,

and so on.

Upper limit and lower limit on threshold measurement

Arithmetic include: maximum, minimum, limit, average, dBm, dB

Data acquisition functions include : data records, inspection, automatic

measurement.

z True RMS AC voltage and current measurement

z 16-Channels inspection functional measurement and control software

(optional)

z DC voltage >10GΩ input impedance to achieve the range of 48V (±24V)

z 10 groups measuring set-up storage and unlimited setup through PC

interface

VI

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

RIGOL

z 256 x 64 pixel monochrome LCD

z I/O: RS-232, USB, LAN and GPIB

z Built-in USB Host to support USB disk and USB printer

z Simple, convenient, flexible control software: Ultralogger, Ultrasensor and

UltraDMM Supports for Microsoft® Windows 98/Me/2000/XP

Note: The chapter one, chapter two, chapter three will be described according to

6½ digits. For 5¾ digits, please refer to ‘’Chapter five: Characteristics for

DM306x’’.

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

VII

RIGOL

Content

Safety Notices ...........................................................................................II

General-Purpose Multimeter .......................................................................V

CHAPTER 1 QUICK START.....................................................................1-1

General Inspection.................................................................................. 1-2

Handle Adjustment ................................................................................. 1-3

The Front/Rear Panel and User Interface.................................................. 1-4

To Measure DC Voltage........................................................................... 1-6

To Measure AC Voltage ........................................................................... 1-8

To Measure DC Current......................................................................... 1-10

To Measure AC Current ......................................................................... 1-12

To Measure Resistance.......................................................................... 1-14

To Measure Capacitance........................................................................ 1-18

To Test Continuity ................................................................................ 1-20

To Check Diodes................................................................................... 1-22

To Measure Frequency and Period ......................................................... 1-24

To Measure Sensor ............................................................................... 1-28

To Choose Reading Resolution............................................................... 1-34

To Choose Data Digit Display................................................................. 1-35

To Choose Range Options ..................................................................... 1-36

To Control Trigger Options .................................................................... 1-38

CHAPTER 2 OPERATING YOUR MULTIMETER.......................................2-1

To Set up Measurement Parameters......................................................... 2-2

Math Functions..................................................................................... 2-12

To Set Up Triggering Parameter Function ............................................... 2-19

Store and Recall ................................................................................... 2-27

To Set Up the Utility.............................................................................. 2-32

High-Speed Data Log ............................................................................ 2-48

Multi-Route Scanning ............................................................................ 2-56

How to Use the Built-in Help System ...................................................... 2-64

CHAPTER 3 APPLICATION EXAMPLES ..................................................3-3

Example 1: Reading Statistic Functions..................................................... 3-3

Example 2: Elimination Leads Resistance Error.......................................... 3-5

Example 3: dBm Measurement ................................................................ 3-6

Example 4: dB Measurement ................................................................... 3-7

VIII

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

RIGOL

Example 5: Limit Test.............................................................................. 3-9

Example 6: Temperature Sensor ............................................................ 3-10

Example 7: Reading Hold ...................................................................... 3-15

CHAPTER 4 PROMPT MESSAGES& TROUBLESHOOTING...................... 4-1

Prompting Message................................................................................. 4-1

Troubleshooting...................................................................................... 4-3

CHAPTER 5 CHARACTERISTICS ...........................................................5-1

Characteristics for DM306x ...................................................................... 5-1

Characteristics for DM305x .................................................................... 5-11

CHAPTER 6 APPENDIX ......................................................................... 6-1

Appendix A: DM3000 Series Accessories ................................................... 6-1

Appendix B: Warranty (DM3000 Series Digital Multimeters)........................ 6-2

Appendix C: General Care and Cleaning.................................................... 6-3

Appendix D: Contact RIGOL..................................................................... 6-4

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

IX

RIGOL

Chapter 1 Quick Start

This chapter covers the following topics:

General Inspection

Handle Adjustment

The Front Panel and User Interface

To Measure DC Voltage

To Measure AC Voltage

To Measure DC Current

To Measure AC Current

To Measure Resistance

To M ea su re Ca pa ci ta nc e

To Test Continuity

To Check Diodes

To Measure Frequency and Period

To Make an Sensor measurement

To Choose Digits resolving index

To Choose Data Digit Display

To Choose Range Options

To Control Trigger Options

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

1-1

RIGOL

General Inspection

Inspect a new DM3000 Digital Multimeter with the following steps:

1. Inspect the shipping container for damage.

Keep the damaged shipping container or cushioning material until the contents of the

shipment have been checked for completeness and the instrument has been checked

mechanically and electrically.

2. Check the accessories.

Accessories supplied with the instrument are listed in "Accessories" at Appendix B of

this guide.

If the contents are incomplete or damaged, please notify the RIGOL Sales

Representative.

3. Inspect the instrument.

In case of any damage, or defect, or failure, notify the RIGOL Sales Representative.

If the shipping container is damaged, or the protective material shows signs of stress,

notify the carrier as well as your RIGOL sales office. Keep the shipping materials for

the carrier’s inspection.

RIGOL offices will arrange reparation or replacement at RIGOL’s option without

waiting for claim settlement.

1-2

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

RIGOL

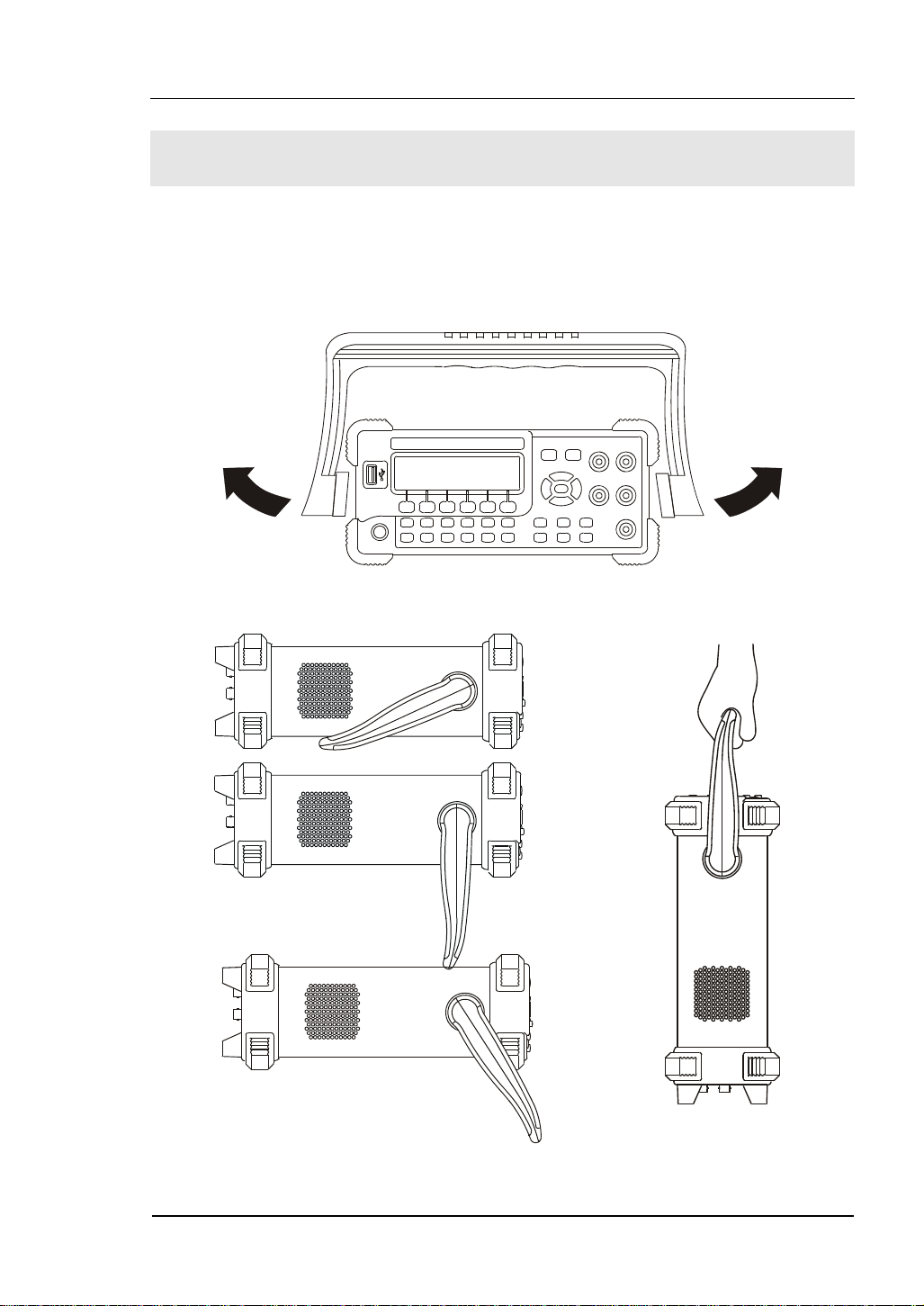

Handle Adjustment

To adjust the handle position of DM3000 Digital Multimeter, please grip the handle by

the sides and pull it outward. Then, rotate the handle to the desired position as

shown in

Figure 1- 1, Figure 1- 2.

Figure 1- 1

Figure 1- 2 Viewing Positions and Carrying Position

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

1-3

RIGOL

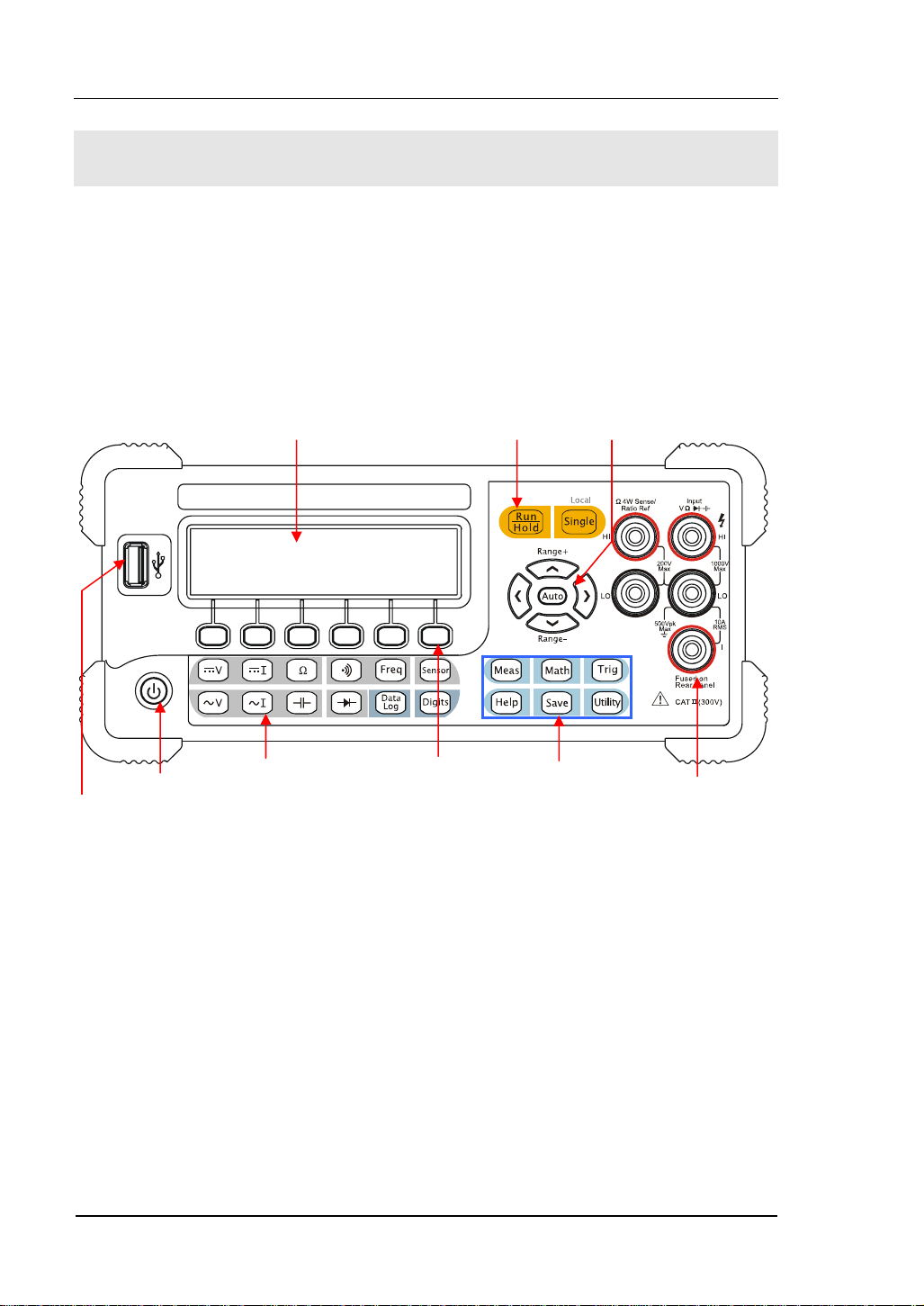

The Front/Rear Panel and User Interface

It is important to get familiar with the front panel of a new DM3000. This chapter

gives an introduction of the operation and functions of the Front Panel.

The front panel of the DM3000 is user friendly as shown below. It includes 4

Direction buttons and 12 Function keys, 6 Menu keys and 2 Control keys as shows

below:

LCD Display

Yel low Di strict :

Trigger Control Keys

Direction Keys

USB Host

1-4

On/Off

Purple District:

Measurement

Function Keys

Menu Operation

Keys

Blue Direction:

Function Selective

Keys

Figure 1- 3 The Front Panel

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

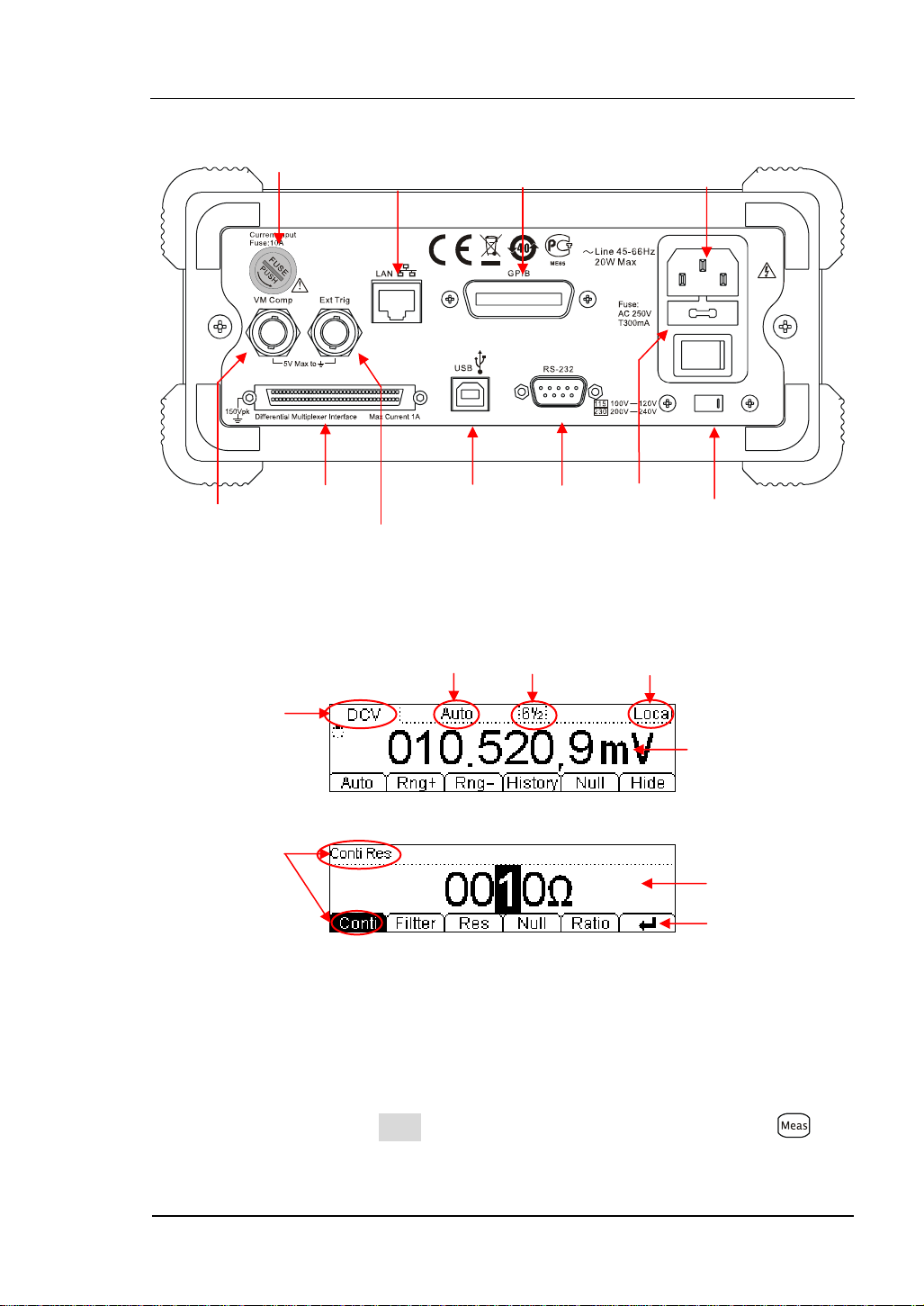

Current Input Terminal

RIGOL

play

Current Input Fuse

10/100

Ethernet

GPIB

(IEEE--488)

Power Socket

VMC

Differential

Multiplexer Interface

Ext Trigger

USB Device RS--232

Power Fuse

AC Voltage

Selector

Figure 1- 4 The Rear Panel

Range

Digits

resolving

index

Local/Remote

Operation

Current

Measurement

Measurement

Data Display

Parameters

Name

Parameters

Dis

Operation

Menu

Figure 1- 5 The Interface Explanation

How the definitions express in this book:

In this manual, the regarding keys writing expression has the same log with the keys

on the front panel. It is noteworthy that the menu operates keys, marking with the

belt shadow. For example, Conti indicates the short circuit option in menu .

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

1-5

RIGOL

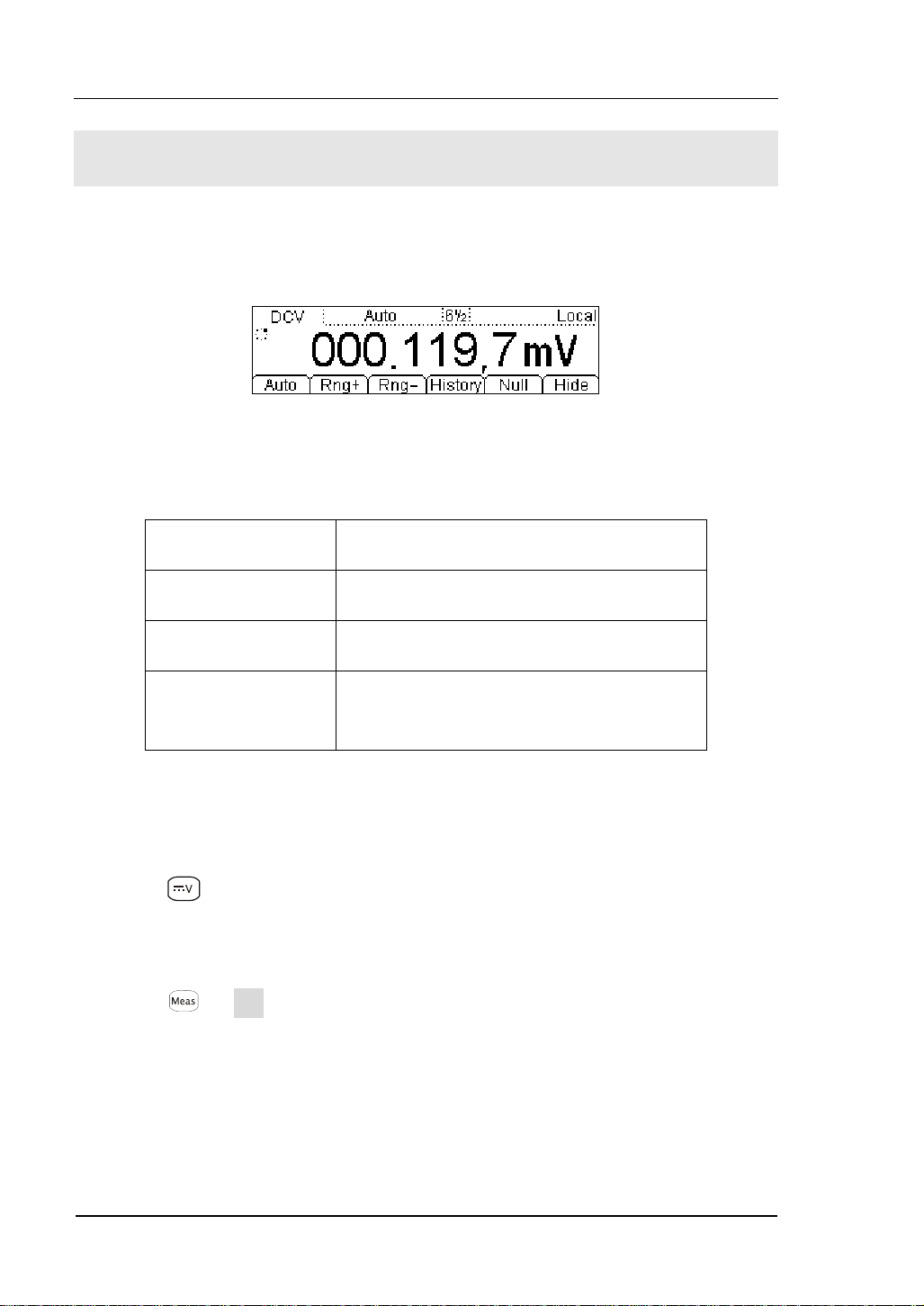

To Measure DC Voltage

The following shows the system connections and selection of measurement functions.

This practice provides a guide to get familiar with the DC Voltage measurement

technique.

Figure 1- 6 DC Voltage Measurement Data Interface

Table1- 1 DC Voltage Measurement Characteristics

Five Ranges 200mV, 2V, 20V, 200V, 1000V

Max Resolution 100nV

Input Protection 1000V on all ranges (HI Ter mi na l)

Configurable

Parameters

Range, DC impedance, Null value

Basic measurement:

1. Connect the test leads as shown in

Figure 1- 7; red test lead to the HI Terminal,

black test lead to the LO Terminal.

2. Press

to select the DC Voltage measurement function.

3. Choose the appropriate measurement range.

4. Setup the DC impedance.

Press Æ Res, to setup the DC input impedance (Default value: 10MΩ).

5. Set the Null value.

Null computing will be an option operation, it could be setup in accordance with

user demand. If user does not implement Null computing, this parameter is not

required. (To know the specific setting methods of the Null value setting, please

refer to Chapter 2 “To Set Up Measurement Parameters”, Null computing)Lead

1-6

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

RIGOL

test leads into circuit and start to measure.

DC Voltage

Figure 1- 7 DC Voltage Measurement

6. Use history function.

Press History, the menu shows as below:

Figure 1- 8 The History Data

Use the history function to review or save the data that has acquired by the current

measurement function. The data can be display “Info” (information), “List” and

“HistoG” formats.

Press Update softkey to update the History data.

Press Save softkey to save data.

Note

Select Auto range if the measurement range is uncertain to get more accurate

measurement data.

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

1-7

RIGOL

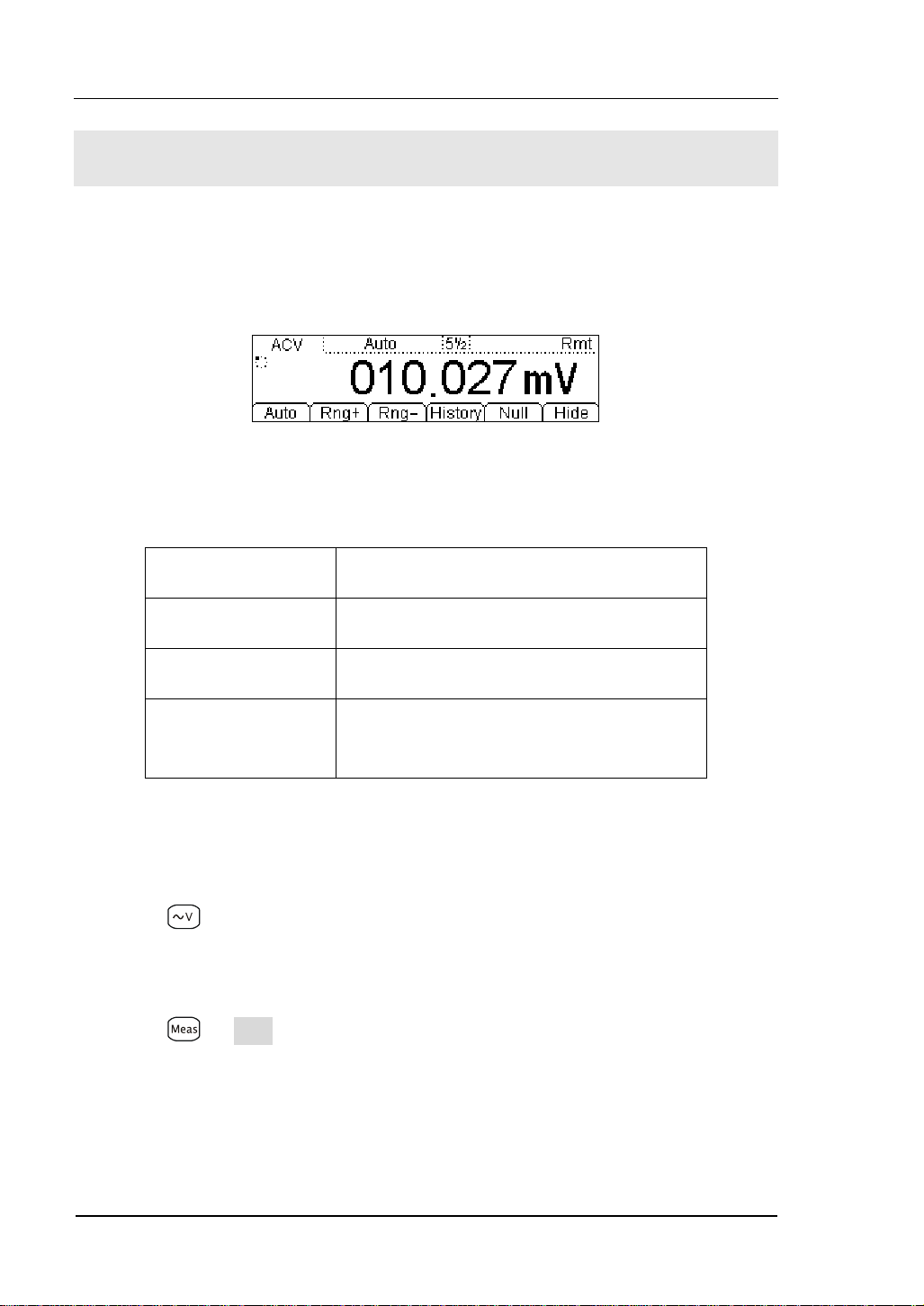

To Measure AC Voltage

The following shows the system connections and selection of measurement functions.

This practice provides a guide to get familiar with the AC Voltage measurement

technique. (The AC functions only support 5½ digits measurement.)

Figure 1- 9 AC Voltage Measurement Data Interface

Table1- 2 AC Voltage Measurement Characteristics

Five Ranges 200mV, 2V, 20V, 200V, 750V

Max Resolution 100nV

Input Protection 750VRMS on all ranges (HI Ter mi na l)

Configurable

Parameters

Range, DC impedance, Null value

Steps:

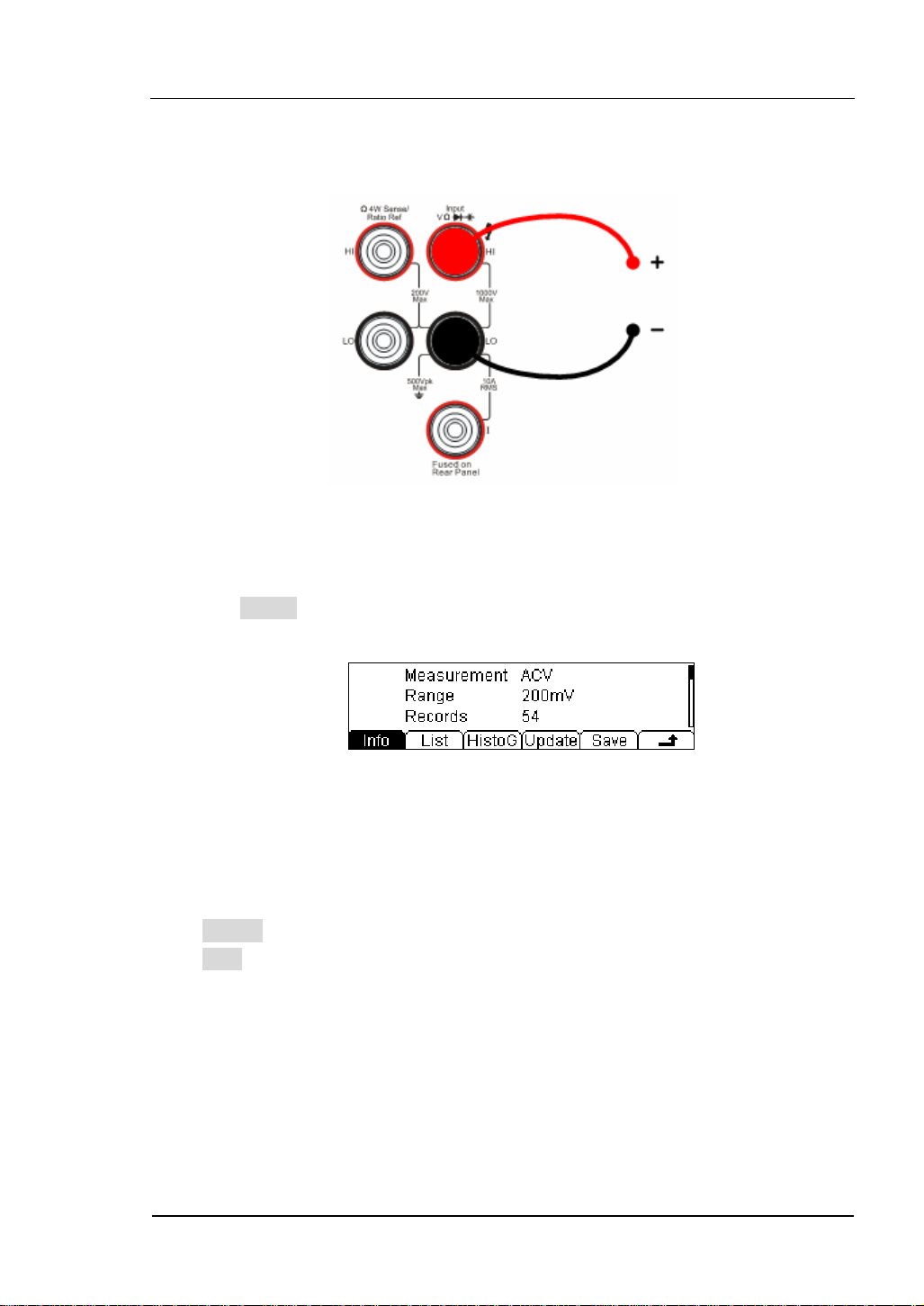

1. Connect test leads as shown in

Figure 1- 10; red test lead to the HI Terminal,

black test lead to the LO Terminal.

2. Press

to select the AC Voltage measurement function.

3. Choose the appropriate measurement range.

4. Setup the AC Filter.

Press Æ Filter, to setup the AC Filter Bandwidth (Default value: Mid).

5. Set the Null value.

Null computing will be an option operation, could be setup in accordance with

user demand. If user does not implement Null computing, this parameter is not

required, direct implementation of the next step.

1-8

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

RIGOL

(To know the specific setting methods of the Null value setting, please refer to

Chapter 2 “To Set Up Measurement Parameters”, Null computing)

6. Lead test leads into circuit and start to measure.

AC Voltage

Figure 1- 10 AC Voltage Measurement

7. Use history function.

Press History, the menu shows as below:

Figure 1- 11 The History Data

Use the history function to review or save the data that has acquired by the current

measurement function. The data can be display “Info” (information), “List” and

“HistoG” formats.

Press Update softkey to update the History data.

Press Save softkey to save data.

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

1-9

RIGOL

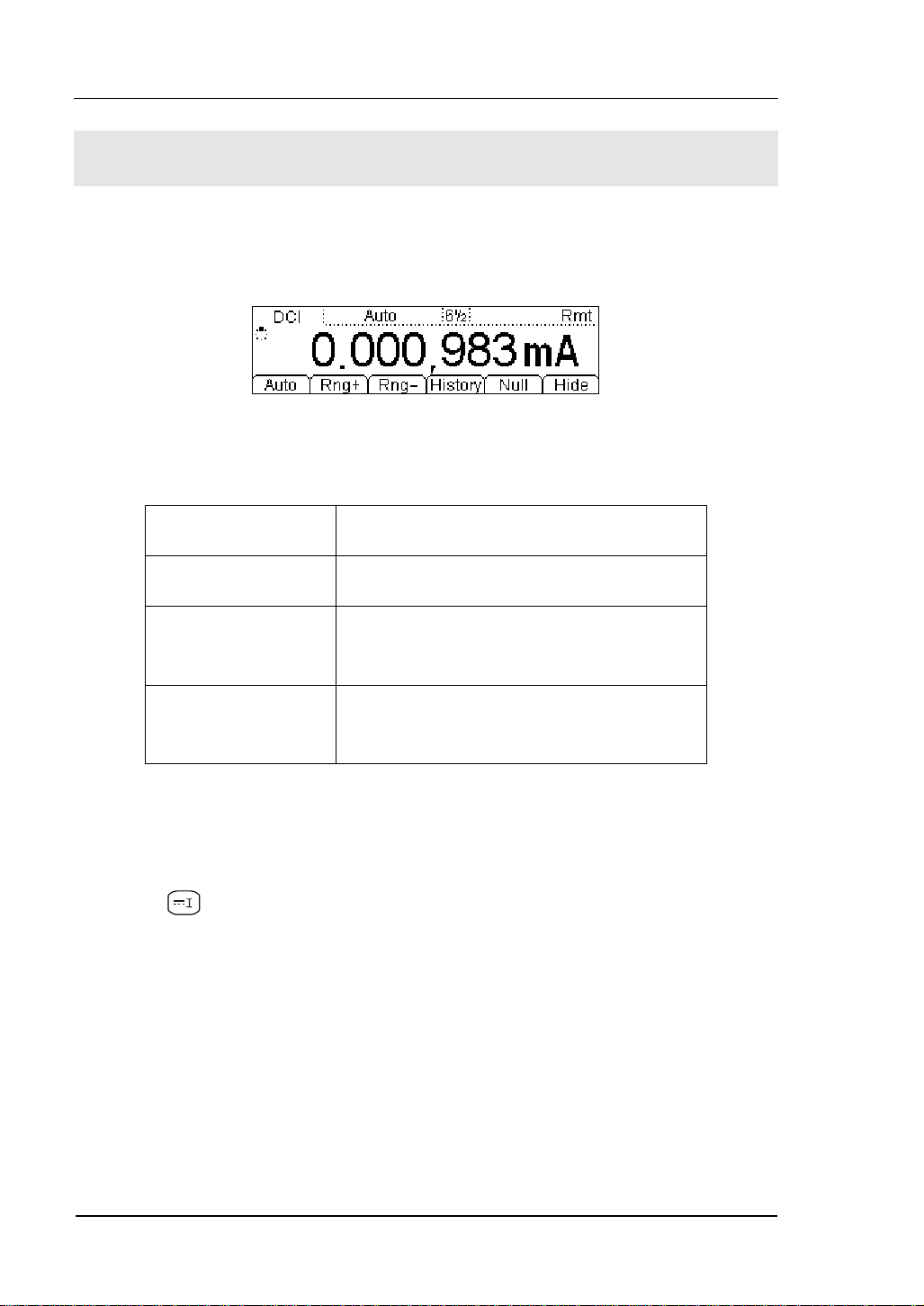

To Measure DC Current

The following shows the system connections and selection of measurement functions.

This practice provides a guide to get familiar with the DC Current measurement

technique.

Figure 1- 12 DC Current Measurement Data Interface

Table1- 3 DC Current Measurement Characteristics

Five Ranges 2mA, 20mA, 200mA, 1A, 10A

Max Resolution 10nA

Input Protection

Configurable

Parameters

10A, 250V Current Input Fuse on rear

panel

Range, Null value

Steps:

1. Connect test leads as shown in

Figure 1- 13; red test lead to the HI Terminal,

black test lead to the LO terminal.

2. Press

to select the DC Current measurement function.

3. Choose the appropriate measurement range.

4. Set the Null value.

Null computing will be an option operation, could be setup in accordance with user

demand. If user does not implement Null computing, this parameter is not required,

direct implementation of the next step.

(To know the specific setting methods of the Null value setting, please refer to

Chapter 2 “To Set Up Measurement Parameters”, Null computing)

5. Lead test leads into circuit, start to measure.

1-10

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

RIGOL

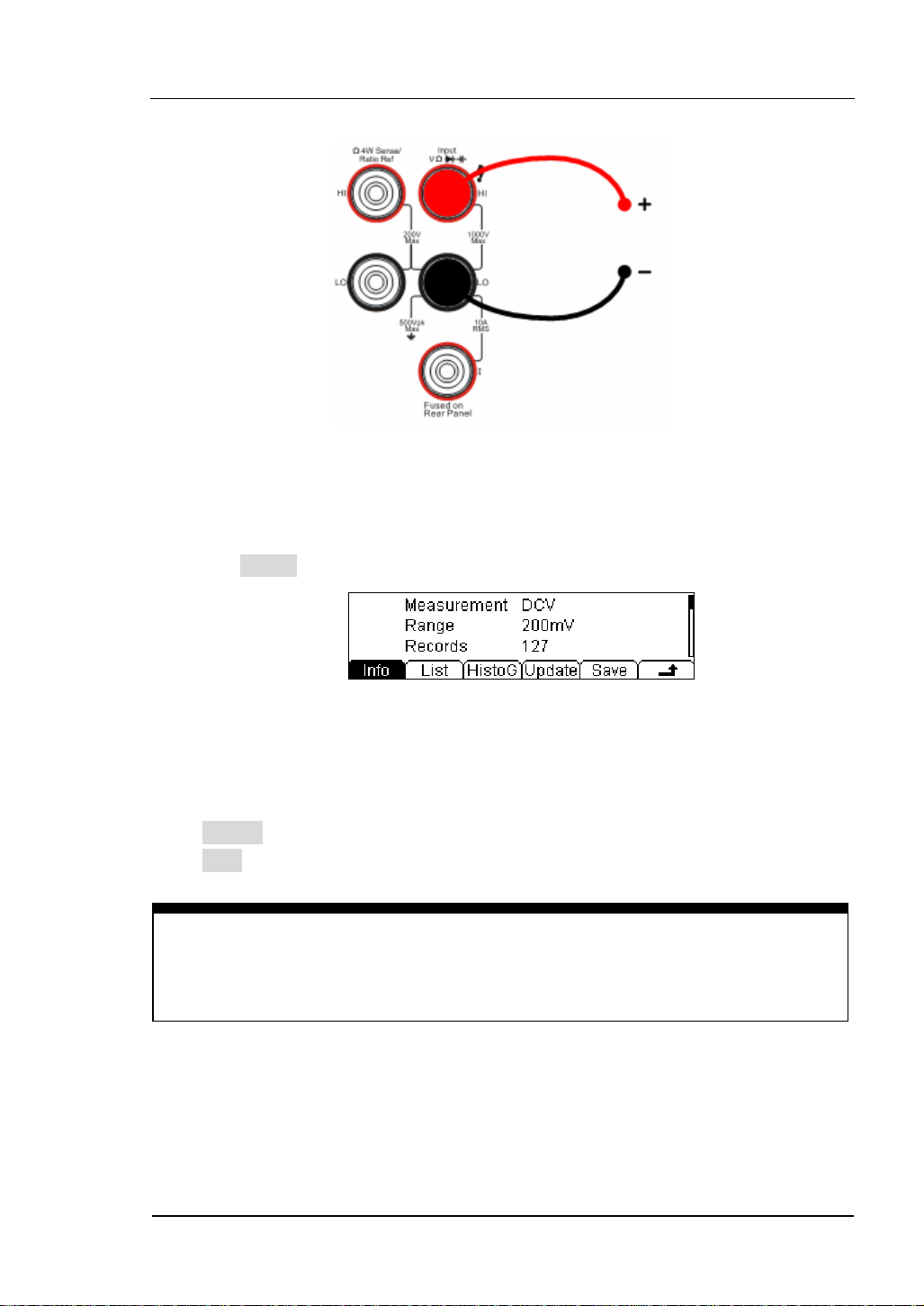

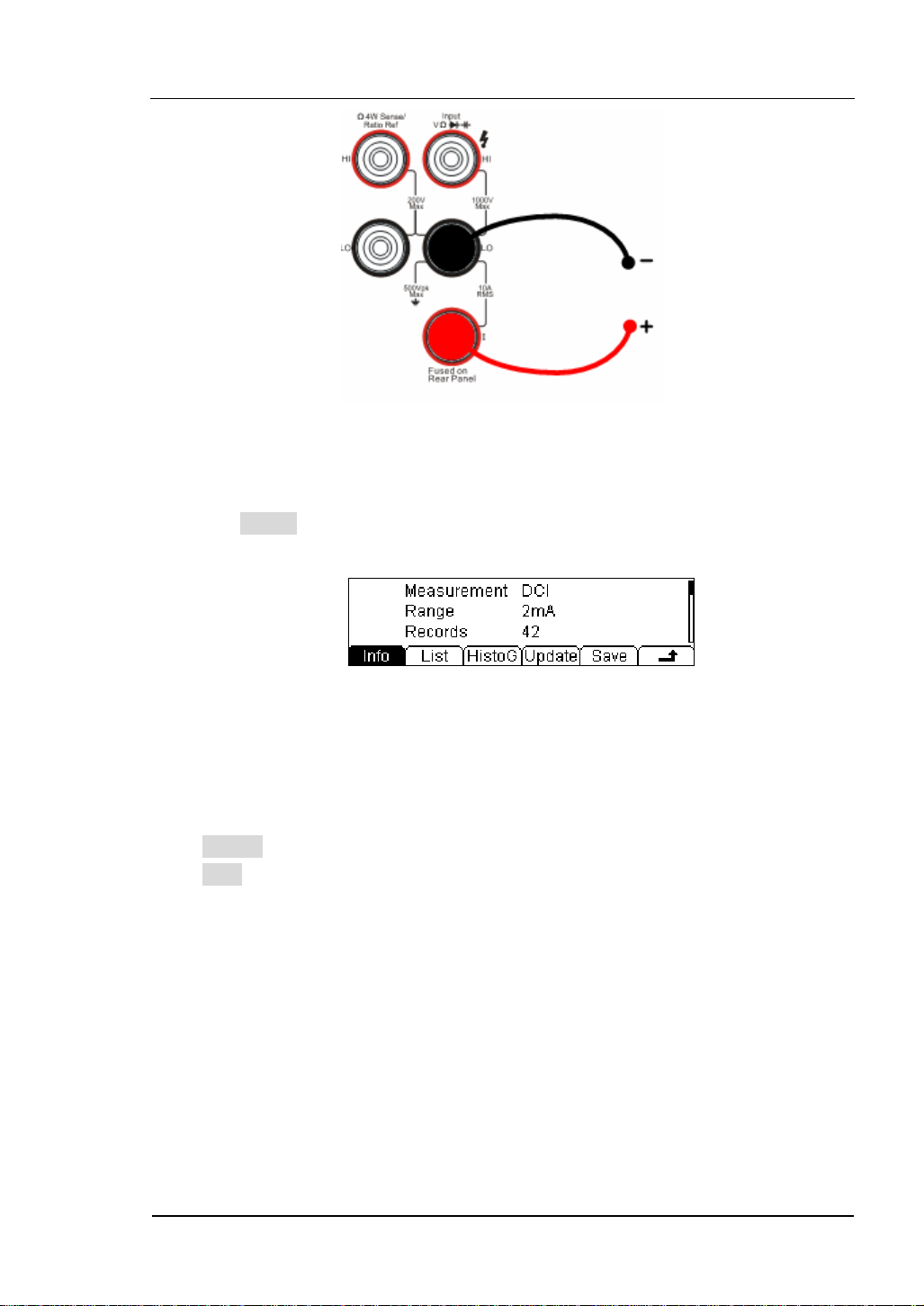

DC Current

Figure 1- 13 DC Current Measurement

6. Use history function.

Press History, the menu shows as below:

Figure 1- 14 The History Data

Use the history function to review or save the data that has acquired by the current

measurement function. The data can be display “Info” (information), “List” and

“HistoG” formats.

Press Update softkey to update the History data.

Press Save softkey to save data.

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

1-11

RIGOL

To Measure AC Current

The following shows the system connections and selection of measurement functions.

The practice provides as guide to be familiar with the AC Current measurement

technique. (The AC functions only support 5½ digits measurement.)

Figure 1- 15 AC Current Measurement Data Interface

Table1- 4 AC Current Measurement Characteristics

Five Ranges 20mA, 200mA, 1A, 10A

Max Resolution 100nA

Input Protection

Configurable

Parameters

10A, 250V Current Input Fuse on rear

panel

Range, AC Filter, Null value

Steps:

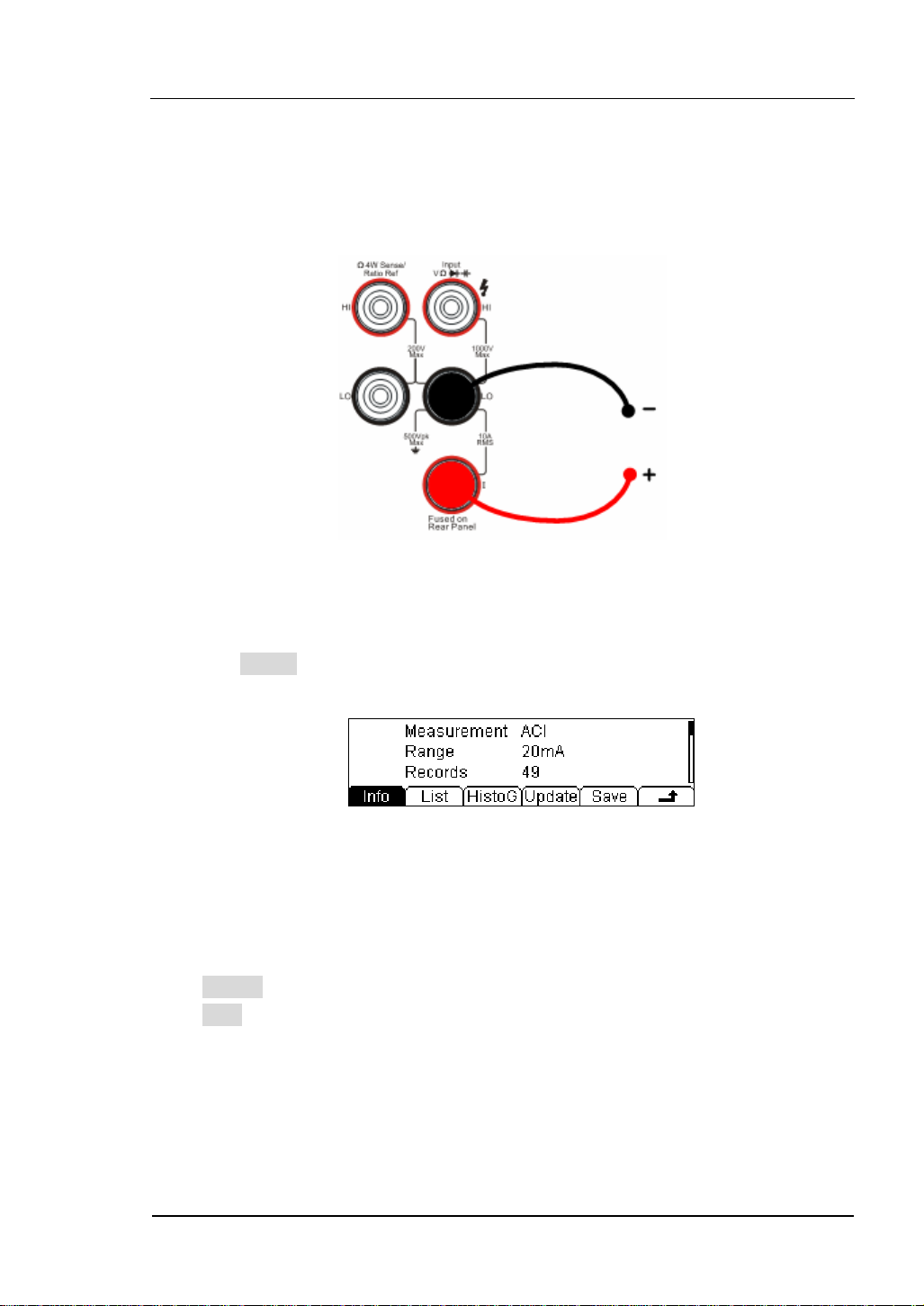

1. Connect test leads as shown in

Figure 1- 16; red test lead to the HI Terminal,

black test lead to LO Terminal.

2. Press

to select the AC Current measurement function.

3. Choose the appropriate measurement range.

4. Setup the AC Filter.

Press Æ Filter, to setup the AC Filter Bandwidth (Default value: “Mid” (Middle)).

5. Set the Null setting value.

Null computing will be an option operation, could be setup in accordance with

user

1-12

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

RIGOL

demand. If user does not implement Null computing, this parameter is not

required, direct implementation of the next step.

(To know the specific setting methods of the Null value setting, please refer to

Chapter 2 “To Set Up Measurement Parameters”, Null computing)

6. Lead test leads into circuit and start to measure.

AC Current

Figure 1- 16 AC Current Measurement

7. Use history function.

Press History, the menu shows as below:

Figure 1- 17 The History Data

Use the history function to review or save the data that has acquired by the current

measurement function. The data can be display “Info” (information), “List” and

“HistoG” formats.

Press Update softkey to update the History data.

Press Save softkey to save data.

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

1-13

RIGOL

To Measure Resistance

The following shows the system connections and selection of measurement functions.

The practice provides a guide get familiar with the Resistance measurement

technique. Resistance measurement methods include 2-Wire Resistance

Measurement and 4-Wire Resistance Measurement, and will explain

separately.

2-Wire Resistance Measurement

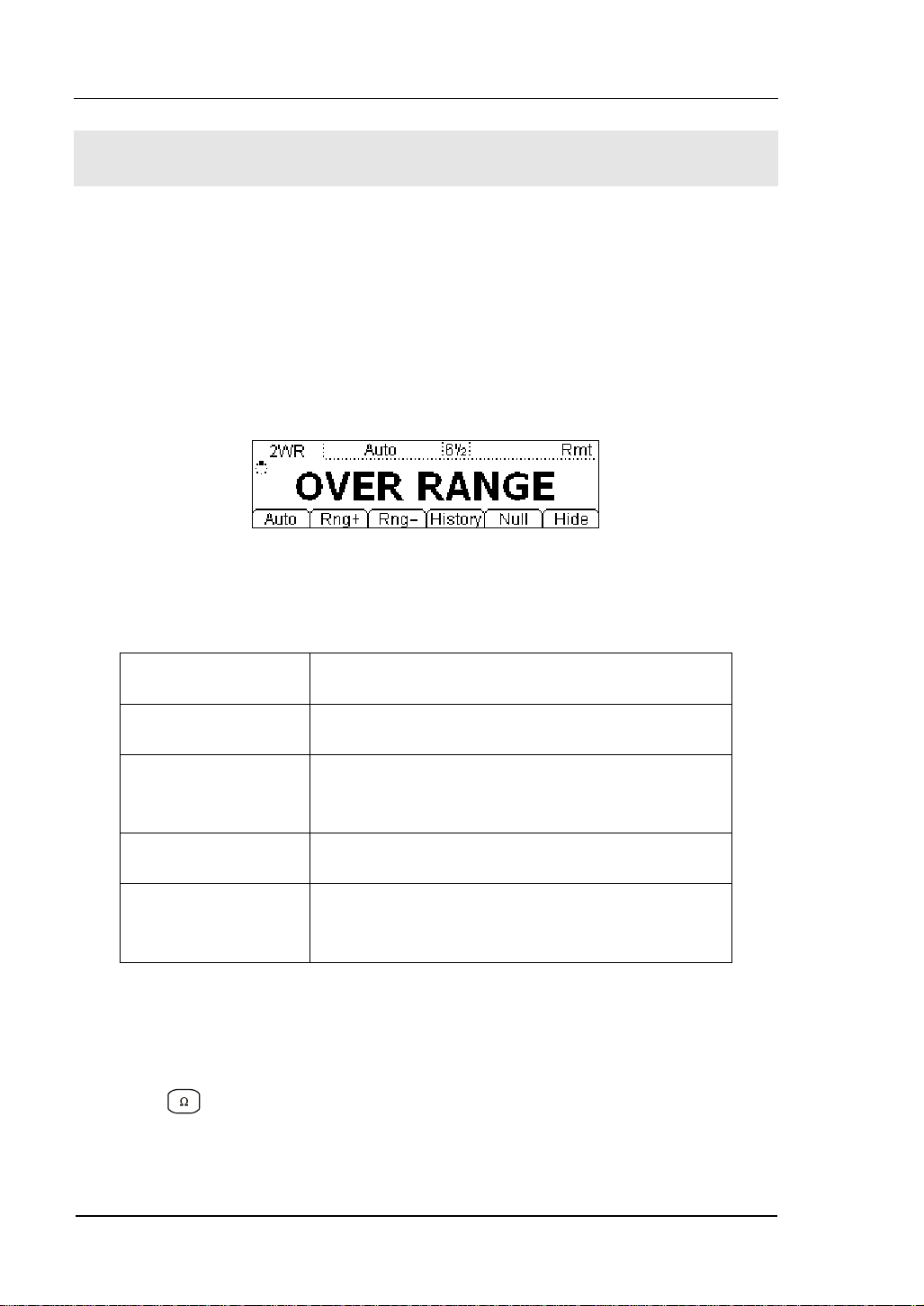

Figure 1- 18 2-Wire Resistance Measurement Interface

Table1- 5 Resistance Measurement Characteristics

Seven Ranges 200Ω, 2kΩ, 20kΩ, 200kΩ, 1MΩ, 10MΩ, 100MΩ

Max Resolution 100uΩ

Open-circuit

Voltage

Input Protection 1000V on all ranges (HI Ter mi na l)

Configurable

Parameters

Steps:

1. Connect test leads as shown in

black test lead to the LO Terminal.

2. Press

3. Choose the appropriate measurement range.

4. Set the Null value

to select the 2-Wire Resistance Measurement.

<7V

Range, Null value

Figure 1- 19; red test lead to the HI Terminal,

1-14

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

RIGOL

Null computing will be an option operation, could be setup in accordance with user

demand. If user does not implement Null computing, this parameter is not

required, direct implementation of the next step.

(To know the specific setting methods of the Null value setting, please refer to

Chapter 2 “To Set Up Measurement Parameters”, Null computing)

5. Lead test leads into circuit and start to measure.

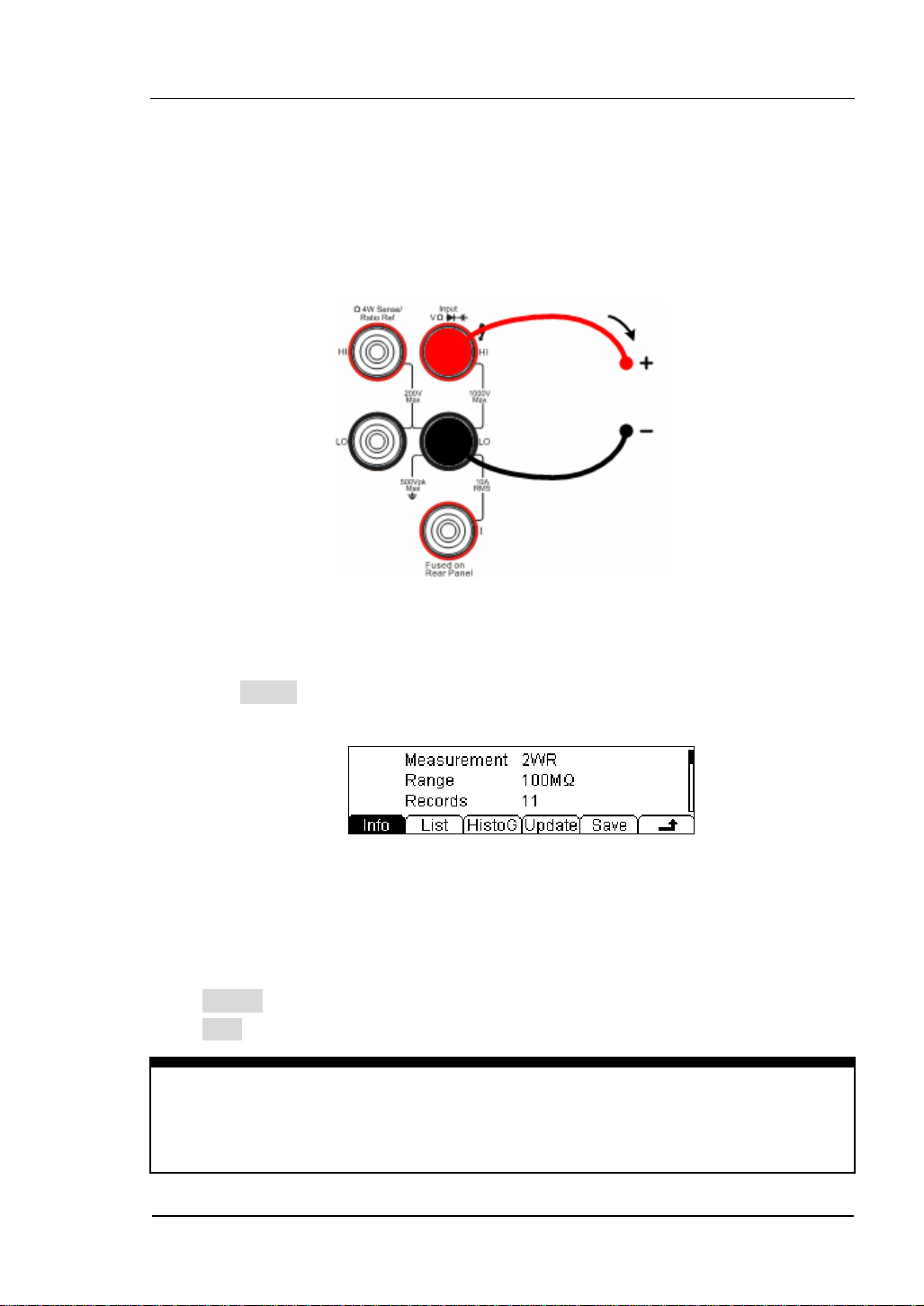

Resistance

Figure 1- 19 2-Wire Resistance Measurement

6. Use history function.

Press History, the menu shows as below:

Figure 1- 20 The History Data

Use the history function to review or save the data that has acquired by the current

measurement function. The data can be display “Info” (information), “List” and

“HistoG” formats.

Press Update softkey to update the History data.

Press Save softkey to save data.

NOTE

When measuring small value resistance, Null operation will be recommended, the

test wire impedance error could be eliminated.

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

1-15

RIGOL

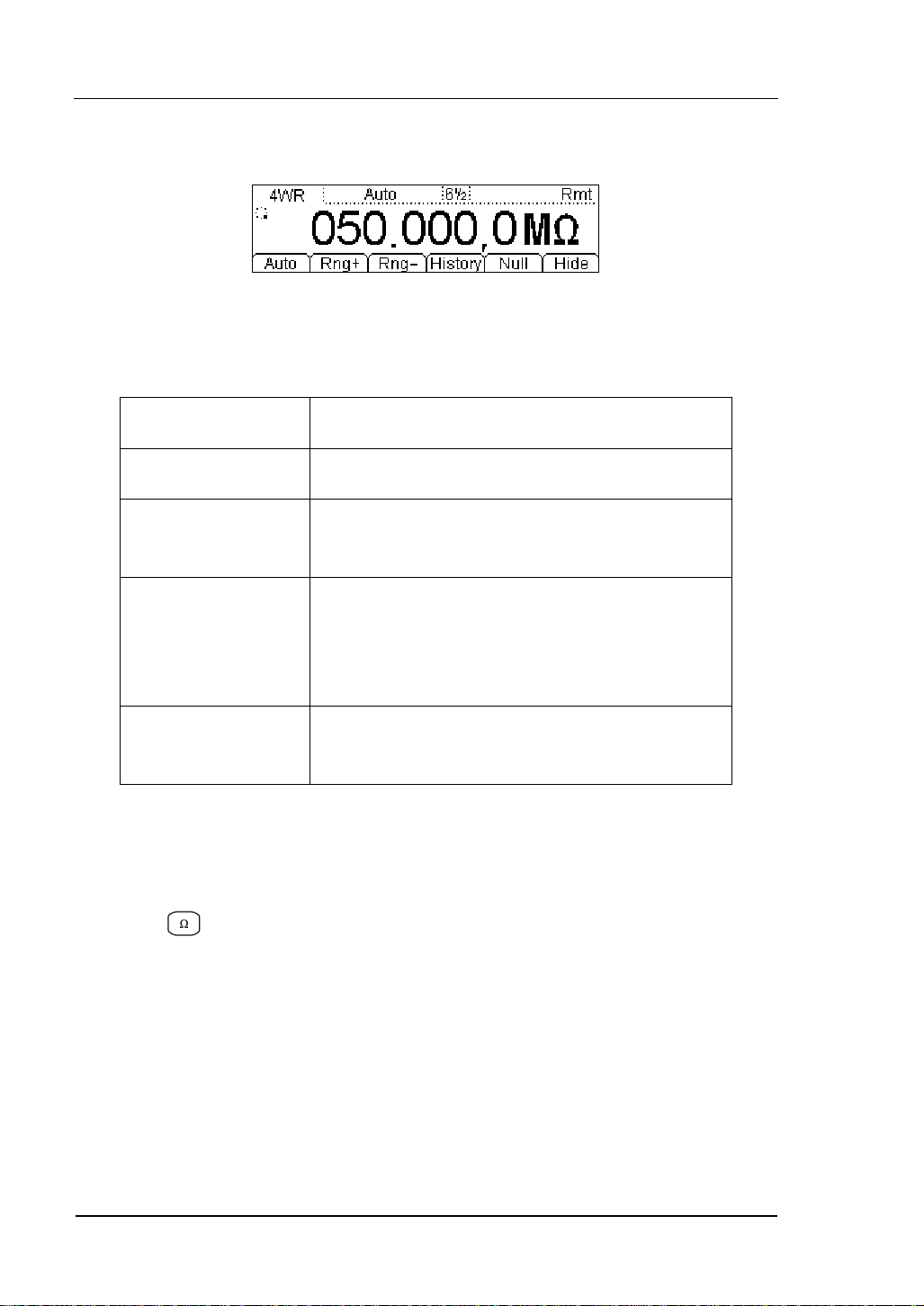

4-Wire Resistance Measurement

Figure 1- 21

Table1- 6 Resistance Measurement Characteristics

Seven Ranges 200Ω, 2kΩ, 20kΩ, 200kΩ, 1MΩ, 10MΩ, 100MΩ

Max Resolution 100uΩ

Open-circuit

Voltage

Import Protection

<7V

(1). 200V

PK

(2). 1000V on all ranges (HI

Terminal)

(3). 200V on all ranges (HI Sense, LO Sense)

Configurable

Parameters

Range, Null value

Steps:

1. Connect test leads as show in

Figure 1- 22; red test lead to the HI Terminal,

black test lead to the LO Terminal.

2. Press

twice to select the 4-Wire Resistance Measurement.

3. Choose the appropriate measurement range.

4. Set the Null setting value.

Null computing will be an optional operation, it could be setup in accordance

with users’ demand. If user does not implement Null computing, this parameter

is not required, direct implementation of the next step.

(To know the specific setting methods of the Null value setting, please refer to

Chapter 2 “To Set Up Measurement Parameters”, Null computing)

5. Lead test leads into circuit, start to measure.

1-16

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

RIGOL

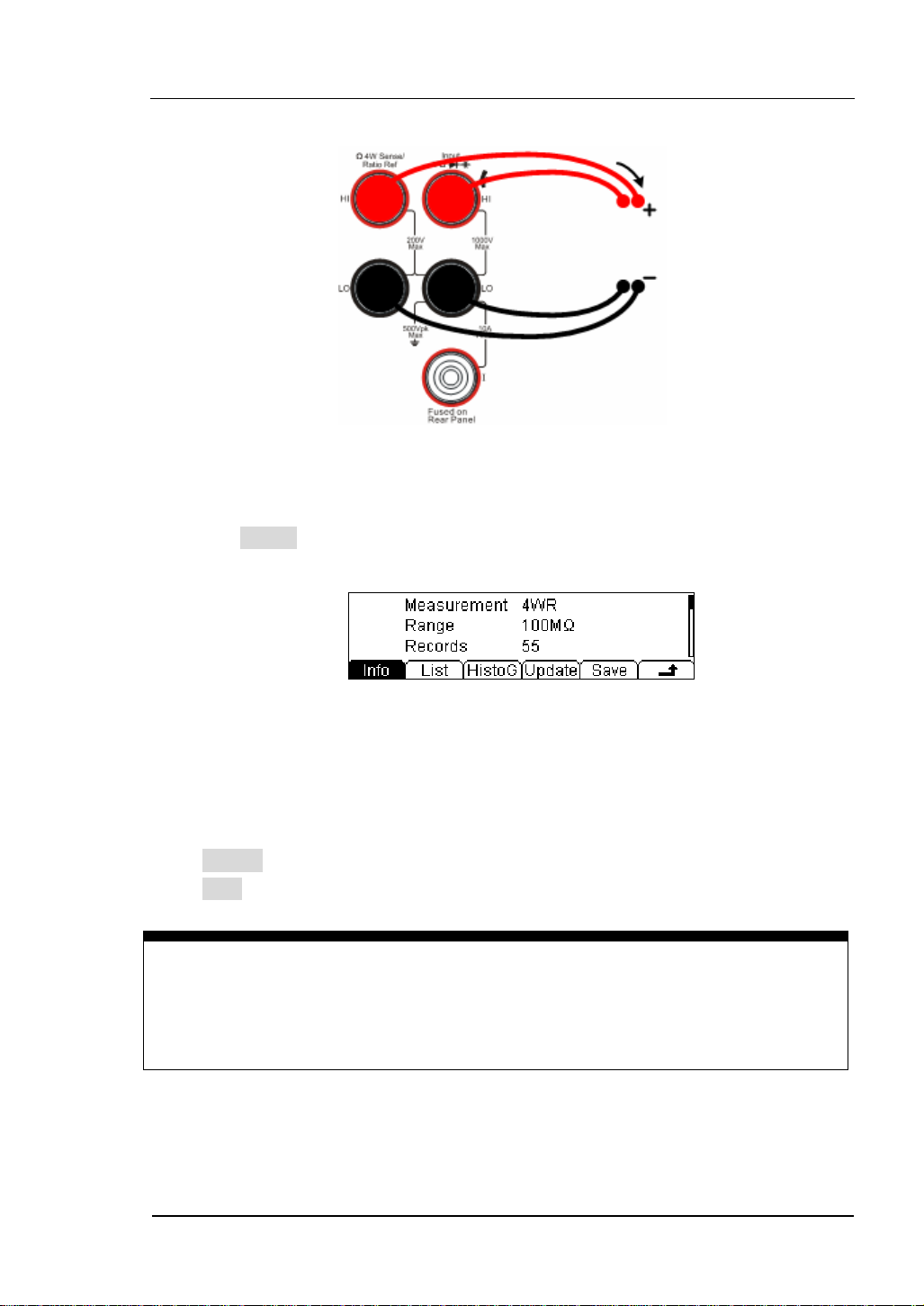

4-Wire Sense HI

Resistance

4-Wire Sense LO

Figure 1- 22 4-Wire Resistance Measurement

6. Use history function.

Press History, the menu shows as below:

Figure 1- 23 The History Data

Use the history function to review or save the data that has acquired by the current

measurement function. The data can be display “Info” (information), “List” and

“HistoG” formats.

Press Update softkey to update the History data.

Press Save softkey to save data.

NOTE

When measuring resistances,

measurement

.

avoid contacting both ends of the resistor for accurate

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

1-17

RIGOL

To Measure Capacitance

The following shows the system connections and selection of measurement functions.

The practice provides a guide to get familiar with the Capacitance measurement

technique.

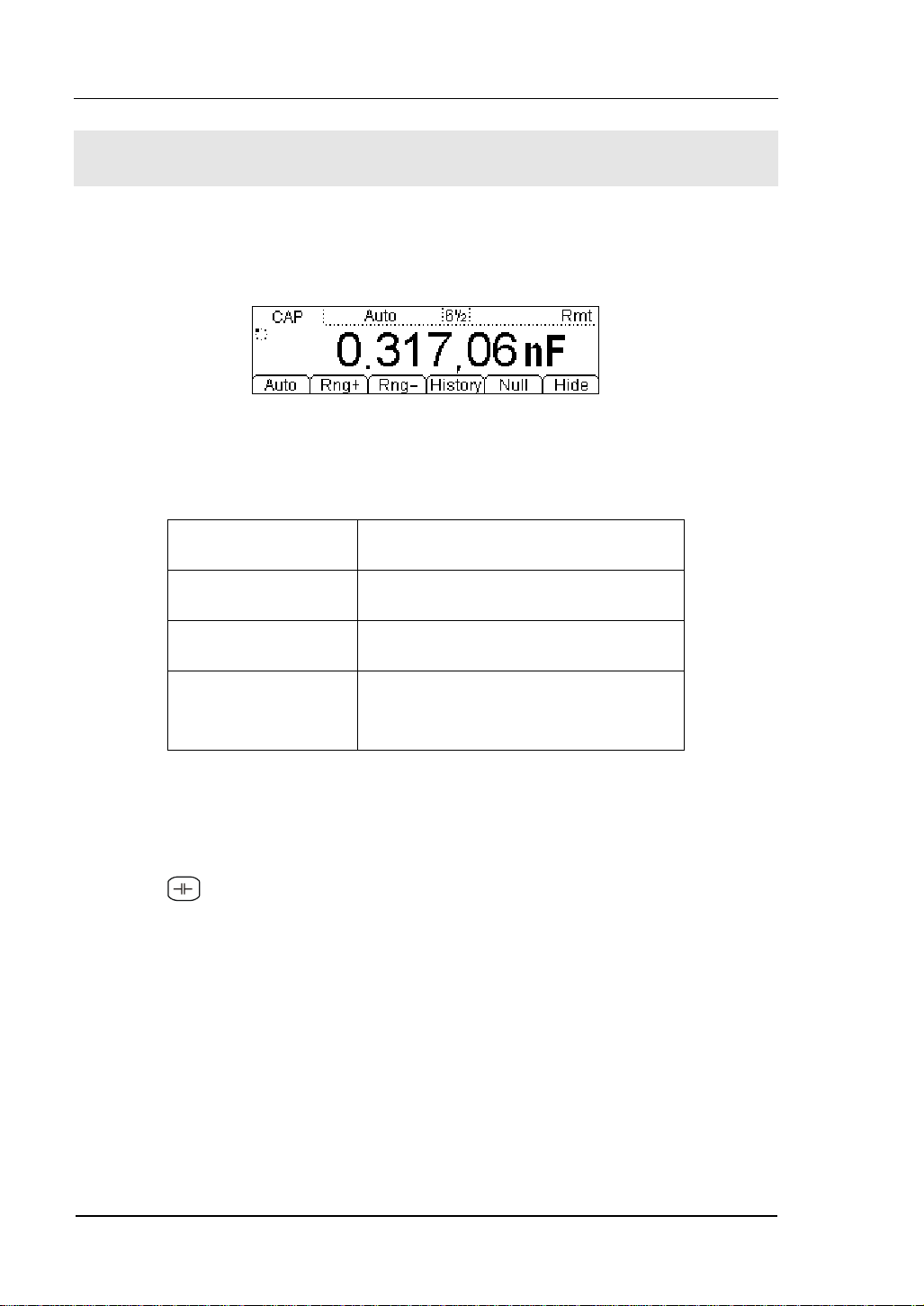

Figure 1- 24 Capacitance Measurement Data Interface

Table1- 7 Capacitance Measurement Characteristics

Six Ranges 2nF, 20nF, 200nF, 2uF, 20uF, 200uF

Max Resolution 0.1pF

Input Protection 1000V on all ranges (HI Ter mi na l)

Configurable

Parameters

Basic measurement:

1. Connect test leads as shown in

black test lead to the LO Terminal.

2. Press

3. Choose the appropriate measurement range.

4. Set the Null value.

Null computing will be an optional operation, could be setup in accordance with

userdemand. If user does not implement Null computing, this parameter is not

required, direct implementation of the next step.

(To know the specific setting methods of the Null value setting, please refer to

Chapter 2 “To Set Up Measurement Parameters”, Null computing)

5. Lead test leads into circuit, start to measure.

to select the Capacitance measurement function.

Range, Null value

Figure 1- 25; red test lead to the HI Terminal,

1-18

© 2007 RIGOL Technologies, Inc.

User’s Guide for DM3000 Series

Loading...

Loading...