Page 1

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 1

OPERATOR’S MANUAL

16 U.S. GALLONS/60 LITERS

PROFESSIONAL WET/DRY VAC

WD1950

FOR QUESTIONS OR INFORMATION CONTACT US AT

CALL 1-800-4-RIDGID (1-800-474-3443) OR

acs.com

.ridgid

www

!

WARNING:

To reduce the risk of injury, the user must read and understand the operator’s

manual before using this product.

Thank you for buying a RIDGID product.

v

SAVE THIS MANUAL FOR FUTURE REFERENCE

Part No. SP6567 Printed in Mexico

Page 2

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 2

Table of Contents

Section Page

Important Safety Instructions . . . . . . . . . . . . . 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unpacking and Checking

Carton Contents . . . . . . . . . . . . . . . . . . . . . 4

Removing/Installing The Metal Handle . . . . . 6

Installing Handle . . . . . . . . . . . . . . . . . . . . . 6

Lowering Handle for Storage . . . . . . . . . . . 6

Removing Handle . . . . . . . . . . . . . . . . . . . . 6

Installing Tool Holder . . . . . . . . . . . . . . . . . 6

Replacement Filter Assembly . . . . . . . . . . . . 7

Drum/Caddy Assembly . . . . . . . . . . . . . . . . . 8

Wet/Dry Vac Assembly . . . . . . . . . . . . . . . . . 9

Insert Hose . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Vacuuming Dry Materials . . . . . . . . . . . . . 10

Vacuuming Liquids . . . . . . . . . . . . . . . . . . 11

Section Page

Filter Performance Sensor . . . . . . . . . . . . 11

Emptying the Drum. . . . . . . . . . . . . . . . . . 11

Moving the Wet/Dry Vac . . . . . . . . . . . . . . 12

Blowing Feature . . . . . . . . . . . . . . . . . . . . 12

Accessory and Hose Storage . . . . . . . . . . . 12

Cord Wrap . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 13

Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cleaning & Disinfecting the Wet/Dry Vac . 14

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Casters & Wheels. . . . . . . . . . . . . . . . . . . 14

Frame & Handles . . . . . . . . . . . . . . . . . . . 14

Wet Nozzle

Filter Replacement. . . . . . . . . . . . . . . . . . . . 16

Repair Parts . . . . . . . . . . . . . . . . . . . . . . . . . 18

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

IMPORTANT SAFETY INSTRUCTIONS

Safety is a combination of common sense,

staying alert, and knowing how your

wet/dry vacuum cleaner (“Vac”) works.

Safety Signal Words

DANGER: Indicates an imminently

!

hazardous situation which, if not avoided,

will result in death or serious injury.

!

WARNING: Indicates a potentially

hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION: Indicates a potentially

!

hazardous situation which, if not avoided,

may result in minor or moderate injury.

When using your Vac, always follow basic

safety precautions including the following:

!

WARNING- To

reduce the risk of fire, electric shock,

or injury:

• Read and understand this operator’s

manual and all labels on the Wet/Dry

Vac before operating.

• Use only as described in this manual.

• Do not leave Vac running while

unattended.

ks inside the motor can ignite

Spar

•

flammable vapors or dust. To reduce

the risk of fire or explosion, do not

vacuum or use near flammable or

combustible liquids, gases, or explosive

dusts, such as gasoline or other fuels,

lighter fluid, cleaners

natural gas, hydrogen, coal dust,

magnesium dust, aluminum dust, grain

dust, or gun po

, oil-based paints

.

wder

• Do not vacuum anything that is burning

or smoking, such as cigarettes,

matches, or hot ashes.

• Do not vacuum drywall dust or cold

fireplace soot or ash with standard

filter. This is a very fine dust which may

be exhausted back into the air. Use a

fine dust filter instead.

• To reduce the risk of health hazards

from vapors or dust, do not vacuum

toxic materials.

• Do not use or store near hazardous

materials.

• To reduce the risk of electric shock, do

not expose to rain or allow liquid to

enter motor compartment. Store

indoors.

• Do not allow to be used as a toy. Close

attention is necessary when used by or

near children.

• Do not use with a torn filter or without

the filter installed except when

acuuming liquids as descr

v

ibed in the

Operation section of this manual. Dry

debris ingested by the impeller may

damage the motor or be exhausted

back into the air.

WARNING: The power cord on this

•

product contains lead, a chemical

kno

cause bir

reproductive harm.

after handling.

,

Do not lea

•

wn in the State of Calif

ects or other

th def

ve Vac plugged in. Unplug

or

Wash hands

from outlet when not in use and before

servicing.

2

nia to

Page 3

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 3

Turn off Vac before unplugging.

•

• To reduce the risk of injury from

accidental starting, unplug power cord

before changing or cleaning filter.

• Do not unplug by pulling on cord. To

unplug, grasp the plug, not the cord.

• Do not use with damaged cord, plug or

other parts. If your Vac is not working

as it should, has missing parts, has

been dropped, damaged, left outdoors,

or dropped into water, return it to an

Authorized Service Center.

• Do not pull or carry by cord, use cord

as handle, close a door on cord, or pull

cord around sharp edges or corners.

Do not run Vac over cord. Keep cord

away from heated surfaces.

• Do not handle plug, switch, or the Vac

with wet hands.

• Do not put any object into ventilation

openings. Do not vacuum with any

ventilation openings blocked; keep free

of dust, lint, hair or anything that may

reduce air flow.

• Keep hair, loose clothing, fingers, and

all parts of body away from openings

and moving parts.

• To reduce the risk of falls, use extra

care when cleaning on stairs.

• To reduce the risk of back injury or

falls, do not lift a Vac that is heavy with

liquid or debris. Partially empty the Vac

by scooping or draining liquid to make

it comfortable to lift.

• To reduce the risk of personal injury or

damage to Vac, use only Ridgid

recommended accessories.

• When using as a blower:

- Direct air discharge only at work

area.

- Do not direct air at bystanders.

- Keep children away when blowing.

- Do not use blower for any job except

blowing dirt and debris.

- Do not use as a sprayer.

Wear safety eyewear.

To reduce the risk of eye injury, wear

•

safety eyewear. The operation of any

utility Vac or blower can result in

foreign objects being blown into the

eyes, which can result in severe eye

damage.

• This Wet/Dry Vac is double-insulated,

eliminating the need for a separate

grounding system. Use only identical

replacement parts. Read the

instructions for Servicing DoubleInsulated Wet/Dry Vacs before

servicing.

• Use only extension cords that are rated

for outdoor use. Extension cords in

poor condition or that are too small in

wire size can pose fire and shock

hazards. To reduce the risk of these

hazards when using an extension cord,

be sure it is in good condition and that

the connection does not come into

contact with liquid. To keep power loss

to a minimum, use the following table

to choose the minimum wire size

extension cord.

Extension Cord Length Gauge A.W.G.

0-50 Ft. 14

50-100 Ft. 12

CAUTION:

!

• To reduce the risk of hearing damage,

wear ear protectors when using for

extended hours or using in a noisy area.

• For dusty operations, wear dust mask.

NOTE: Static shocks are common in

dry areas or when the relative humidity of

the air is low. Vacuuming fine debris with

your Vac can deposit static charge on the

hose or on the Vac. The best remedy to

reduce the frequency of static shocks in

your home or when using this Vac is to

add moisture to the air with a humidifier.

Observe the following warnings that

appear on the motor housing of your Vac:

DOUBLE INSULATED

GROUNDING NOT REQUIRED.

WHEN SERVICING USE ONLY

IDENTICAL REPLACEMENT PARTS.

ARNING:

W

!

read and under

manual. Do not run unattended.

Do not pick up hot ashes, coals,

toxic, flammable or other hazardous

materials. Do not use around

xplosive liquids or v

e

WARNING:To reduce the risk of

electric shock - do not expose to

rain - store indoors.

wn safety,

our o

For y

stand operator’s

s.

apor

SAVE THIS MANUAL

3

Page 4

C

B

H

D

E

G

F

A

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 4

Introduction

his Professional Wet/Dry Vac is intended

T

for household use. It may be used for

vacuuming wet or dry media and may be

used as a blower.

ead this operator’s manual to familiarize

R

yourself with the product features and to

understand the specific usage of your

new Vac.

Unpacking and Checking Carton Contents

Tools Required

Long Phillips Screwdriver

Refer to the assembly sketch for

positioning of parts.

Carton Contents List

Key Description Qty

A Wet/Dry Vac Assembly.................1

B Tug-A-Long Hose.........................1

C Utility Nozzle................................1

D Wet Nozzle...................................1

E Crevice Nozzle.............................1

F Car Nozzle ...................................1

G Extension Wands .........................2

H Operator’s Manual........................1

Remove contents of carton. Check each

item against the Carton Contents List.

Call 1-800-4-RIDGID (1-800-474-3443) or

E-mail us at info@ridgidvacs.com if any

parts are damaged or missing.

MalletHammer

4

Page 5

L

N

O

K

M

J

R

Q

P

S

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 5

ey Description Qty

K

Carton containing the following parts:

Storage Bag .................................1

J

K 8” Wheel .......................................2

L Metal Handle................................1

M Shaft.............................................1

N Caddy, Right.................................1

O Caddy, Left...................................1

Key Description Qty

Bag of Loose Parts -

Containing the following:

P 2” Caster ......................................2

Q 1/2” Cap Nut.................................2

R Wheel Caps .................................2

S Screw, Type AB #10 x 3/4............8

5

Page 6

Correct

Position

Storage

Position

Moving

Position

M

etal Handle in

R

eversed Position

(As Shipped)

Tote Snaps

Tote

Straps (5)

Handle

Extension

Wand

Storage

Locations

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 6

Removing/Installing the Metal Handle

Your Metal handle comes packaged in

the carton in the reverse direction. You

must pull the metal handle completely out

of vac and reinstall the handle in the

correct direction, bent area facing away

from the back of the vac, before

continuing.

Installing Handle

Press and hold release buttons while

installing handle into handle receptacles

in drum (See illustration).

NOTE: An audible snap of release

buttons indicates successful engagement

of handle.

Lowering Handle for Storage

To store Wet/Dry Vac, press and hold

release buttons while firmly sliding handle

down.

Removing Handle

Press and hold release buttons, as

shown. While firmly pushing in release

buttons, pull handle upwards to remove

(see illustration).

Installing

Install tool holder as shown with

extension wand holders facing unit.

Tool Holder

6

Page 7

Filter

Threaded Stud

Filter Cage

Slots (3)

Filter Nut

Filter Nut

Lever

Filter Plate

THIS SIDE

TOWARD LID

Filter Cage

Tabs (3)

Float

Solid End

Slots (3)

Power Head

Assembly

Filter Cage

Tabs (3)

Slots (3)

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 7

Replacement Filter Assembly

1. Carefully slide the filter over the filter

cage, sliding it over the center ring

covering the 3 slots until the filter stops

against the lid.

2. Place filter nut onto threaded stud and

tighten it down. Finger tighten only.

NOTE: Lever of filter nut should be away

from plate as shown.

IMPORTANT: Do not overtighten as this

may deform or crack the filter cage, or

filter.

NOTE: If filter cage needs to be removed,

because the float is placed in the wrong

way, use a flat blade screwdriver and

insert the blade near one of the tabs

between the filter cage and the center

ring of the lid. Pry the tab out of the slot.

Tilt the cage and lift a

way from the lid. To

replace, follow the assembly instructions

below:

!

WARNING: For your own safety,

ever connect plug to power source

n

outlet until all assembly steps are

complete and you have read and

understood the safety and operation

instructions. Do not operate vac

with any parts damaged or missing.

3. Place the float over the opening in the

center of the lid with the words "This

Side Towards Lid" laying face down

over the hole.

!

WARNING:To reduce the risk of

personal injury or damage to vac be

sure to keep hands, fingers, or any

other foreign objects out of the

center opening when assembling

the float.

4. Line up filter cage tabs with slots in the

center ring of the lid.

5. Push on the filter cage until the tabs

snap into slots for a secure fit.

7

Page 8

N

OTE: Smooth side of

t

he wheel to the outside.

Caddy

Left

Shaft

Caddy

Right

Wheel

Cap Nut

CADDY ASSEMBLY

Cap Nut

R

I

G

H

T

Raised Rib

on Back of Drum

TAP

TAP

Caddy

Wheel

1/16" Clearance

Wheel Cap

Mallet

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 8

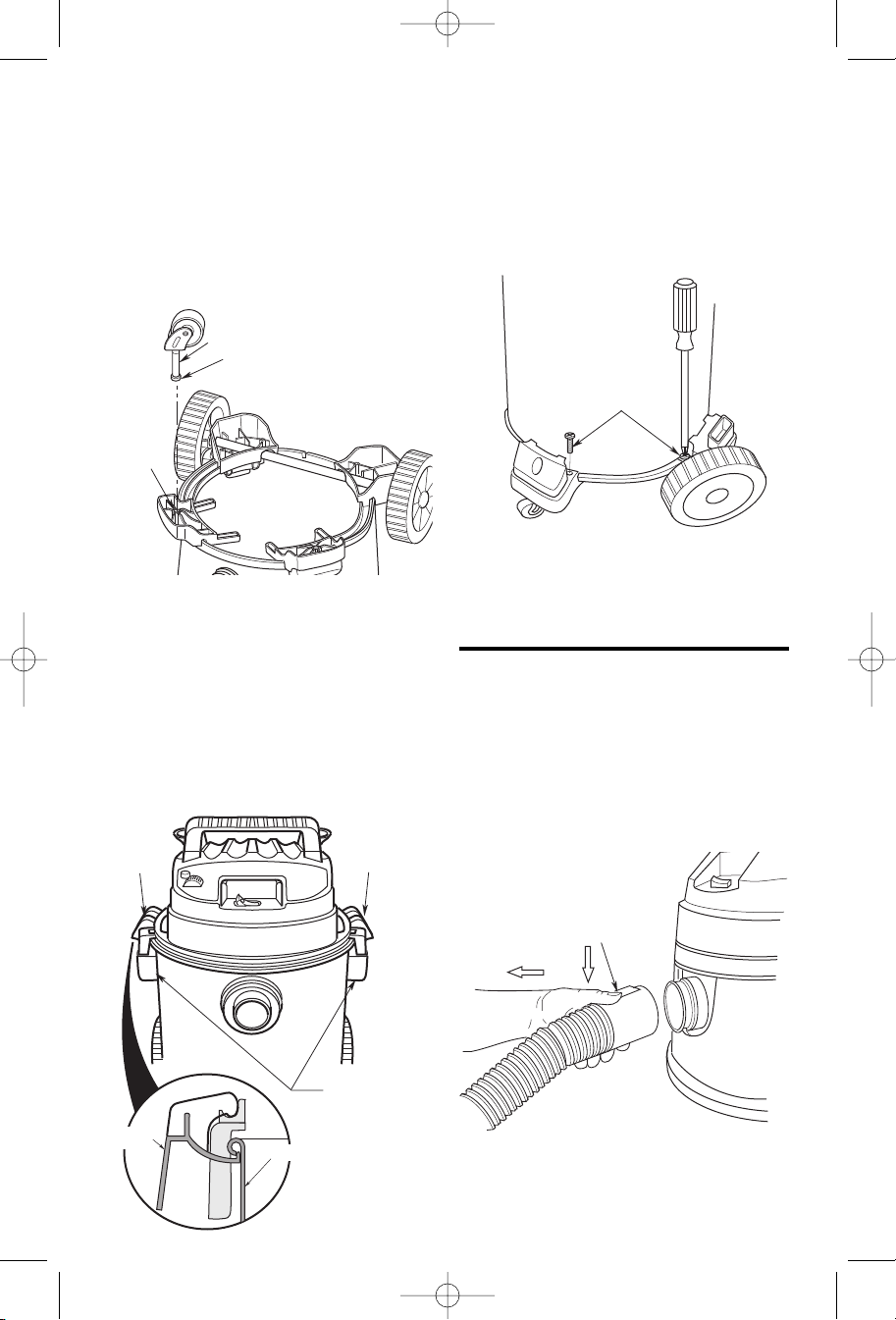

Drum/Caddy Assembly

If any parts are missing or damaged

contact Customer Service.

Do not assemble until you have all the

parts.

1. Invert drum to install caddies. Install

cap nut on one side of shaft rod. Tap

gently with rubber mallet or hammer

until fully seated. Slide open end of

shaft through the wheel (smooth side

of wheel facing outward).

2. Place wheel/shaft assembly through

caddy left and on through the caddy

right, as shown.

3. Then place the remaining wheel onto

the caddy assembly (smooth side of

wheel facing outward), and install

second cap nut.

4. Place the caddy assembly onto the

drum rim. Align inside edges of both

left and right caddies with the raised

outer ribs, located on back of the drum.

Be sure that wheels spin freely, and do

not contact the caddies. If the wheels

do touch the caddies, move caddies

inward slightly.

5. Once the caddies are aligned with the

raised ribs on back of the drum, gently

tap on rear of each caddy until firmly

seated. It is recommended to tap the

center portion of each rear caddy. After

rear portions of caddies are firmly in

place, proceed to tap into place the

front portion of each caddy until fully

seated. It is recommended to tap the

center portion of the front caddies as

shown.

6. Using a rubber mallet or hammer,

gently tap the wheel caps onto each

wheel until the wheel caps are firmly

seated onto each wheel. This is

required on both left and r

ight sides

.

8

Page 9

Latch

Drum

Latch

Handles

Drum

Drum

Latch

Release

Button

Press

and

Pull

L

E

F

T

Socket

Caster Stem

Caster Ball

#10 x 3/4"

Screw (8)

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 9

. Insert the caster stem into the socket of

7

the caster foot as shown. (Front casters

only).

8. Push on the caster until the ball on the

caster stem is inserted all the way into

the socket.You will be able to hear the

ball snap into the socket and the caster

. Rotate drum/caddy assembly upright,

9

using a long phillips screwdriver, install

(8) #10 x 3/4” screws into matching

holes on both right and left side of

caddy. Tighten screws until just snug.

Do not over tighten as this may tend to

deform the caddies.

will swivel easily when positioning is

correct.

Wet/Dry Vac Assembly

1. Position the powerhead assembly on

the drum/caddy assembly as shown

(assembled earlier).

2. Rotate both latches down and press

until you hear them snap over the

flanges on the drum.

Insert Hose

Insert the push button end of the “Tug-ALong” hose into the inlet of the vac. The

hose should snap into place. To remove

the hose from the vac, press the release

button in the hose assembly and pull the

hose out of the vac inlet, as shown.

9

Page 10

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 10

Operation

WARNING

!

To reduce the risk of fire or explosion, do not operate this vac in areas with

flammable gases, vapors or explosive dust in the air. Flammable gases or

vapors include but are not limited to; lighter fluid, solvent type cleaners, oilbase paints, gasoline, alcohol or aerosol sprays. Explosive dusts include but

are not limited to; coal, magnesium, aluminum, grain or gun powder. Do not

vacuum explosive dust, flammable or combustible liquids or hot ashes. Do

not use this vac as a sprayer. To reduce the risk of health hazards from

vapors or dusts, do not vacuum toxic materials.

WARNING:The operation of any

!

utility vac can result in foreign

objects being blown into the eyes,

which can result in severe eye

damage. Always wear safety

eyewear complying with ANSI Z87.1

(or in Canada, CSA Z94.3) before

starting operation. Safety eyewear

are available at many local retail

stores.

CAUTION:To reduce risk of

!

hearing damage, wear ear

protectors when using the vac for

extended hours or when using it in

a noisy area.

To reduce the risk of electric shock, this

appliance has a polarized plug (one blade

is wider than the other). This plug will fit

in a polarized outlet only one way. If the

plug does not fit fully in the outlet, reverse

the plug. If it still does not fit, contact a

qualified electrician to install the proper

outlet. Do not change the plug in any way.

After you plug the power cord into the

outlet, turn the unit on by pushing the

switch from position "O" to position "l". The

symbols used on the switch actuator are

international "On & Off" symbols. "O" is the

symbol for "OFF" and "l" is the symbol for

"ON".

=

OFF

Familiarize yourself with the accessories

included with the vac. Each accessory may

be used in various ways for vacuuming and

blowing debris. Here is a list of the

accessories and their uses

=

ON

.

Utility Nozzle - General purpose nozzle for

most vacuuming applications.

Wet Nozzle - Used for wet pickup on

smooth surfaces to pick up liquid and dry

the surface in one stroke.

Car Nozzle - Dry pickup nozzle for car

interiors and most upholstery cleaning.

Extension Wands - These wands can be

connected together and provides

additional length for more reach.

Hose - Provides transfer of vacuum or

blowing capability to work site. Provides

the means of attaching extension wands

and nozzles.

Crevice Tool - Use to pick up debris in

hard to reach locations.

!

WARNING:To reduce the risk of

fire or electric shock, do not run vac

unattended.

Vacuuming Dry Materials

1. The filter must always be in correct

position to reduce the risk of leaks and

possible damage to vac.

2. Your Wet/Dry Vac comes with the

VF5000 Filter installed. When using

your vac to pick up very fine dust, it will

ou to empty the

be necessary f

drum and clean the filter at more

frequent intervals to maintain peak vac

performance.

TE:

NO

dry material. If you use your vac to pick

up dust when the filter is wet, the filter will

clog quic

A dr

kly and be v

or y

y filter is necessar

y difficult to clean.

er

y to pic

k up

10

Page 11

Filter

Sensor

Reset

Button

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 11

erformance of your Wet/Dry Vac is

3. If your filter is wet but you need to use

the vac to pick up dry material, you can

quickly dry the filter by running the vac

without hose attached for about

10 minutes. The clean air rushing

through the vac will help dry the filter.

Vacuuming Liquids

1. When picking up small amounts of

liquid the filter may be left in place.

2. When picking up large amounts of

liquid we recommend that the filter be

removed. If the filter is not removed, it

will become saturated and misting may

appear in the exhaust.

3. When the liquid in the drum reaches a

predetermined level, the float

mechanism will rise automatically to cut

off air-flow.When this happens, turn off

the vac, unplug the power cord, and

empty the drum. You will know that the

float has risen because vac airflow

ceases and the motor noise will become

higher in pitch, due to increased motor

speed.

4. After using the vac to pick up liquids, the

filter must be dried to reduce the risk of

possible mildew and damage to the filter.

IMPORTANT: To reduce the risk of

damage to the vac do not run motor with

float in raised position.

Filter P

1. This Wet/Dry Vac features an innovative

2. Bars of color show the cleanliness of

3. As the filter becomes dirty, orange bars

4. All orange bars indicate that your filter is

5. Your Wet/Dry Vac operates most

erformance Sensor

device for determining when your filter

needs to be cleaned. This patent

pending design works whether the

Wet/Dry Vac is on or off.

our filter. All green bars indicate that

y

your filter is clean and ready to use.

will appear and g

disappear.

dirty and needs to be cleaned or

replaced.

efficiently and powerfully, with a clean

filter. When the filter performance

sensor shows all orange bars, the

reen bars will

p

approximately 40-55% of its original

power with a clean filter. At any point

during the increasing orange bars,

you may elect to clean the filter.

6. To set the indicator bars back to the

original full green position, press the

sensor reset button.

NOTE: Do not press the sensor reset button

while the Wet/Dry Vac is running. This may

damage the filter performance sensor.

7. Press the sensor reset button until all

green bars show. This should be done

whenever you clean or replace the filter.

Depending on how clean you get the

filter, will determine how many orange

bars show. A new filter will show all

green.

Emptying the Drum

WARNING:To reduce the risk of

!

injury from accidental starting,

unplug power cord before emptying

the drum.

1. The vac comes equipped with a drain

for easy emptying of liquids. Simply

unscrew the drain cap and lift the

opposite side slightly to empty the

drum.

2. Another option is to remove the

powerhead assembly.

3. Lay powerhead assembly aside on a

clean area while emptying drum.

4. Dump the drum contents into the

proper waste disposal container.

WARNING:To reduce the risk of

!

back injury or falls, do not lift a vac

hea

vy with liquid or debris. Scoop

or drain enough contents out to

make the v

comfortably.

11

ac light enough to lift

Page 12

Car Nozzle (Optional)

Tug-A-Long

Hose

Blowing

Port

Extension

Wand

(Optional)

Swivel

End of

Hose

Extension

Wand

Storage

Extension

Wand

Accessory Storage

Compartment

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 12

Operation (continued)

Moving the Wet/Dry Vac

hould it become necessary to pick the

S

vac up to move it, the handle on the sides

of the dust drum are used to lift. To

maneuver the vac, the metal handle in

the rear of the unit should be used.

Blowing Feature

Your vac features a blowing port. It can

blow sawdust and other debris. Follow the

steps below to use your vac as a blower.

1. Locate blowing port of your vac.

!

WARNING: Always wear safety

eyewear complying with ANSI Z87.1

(or in Canada, CSA Z94.3) before

using as a blower.

!

WARNING:To reduce the risk of

injury to bystanders, keep them

clear of blowing debris.

!

CAUTION: Wear a dust mask if

blowing creates dust which might

be inhaled.

CAUTION:To reduce the risk of

!

hearing damage wear ear protectors

when using the vac/blower for

extended hours or when using in a

noisy area.

1. Locate blowing port of your vac.

2. Insert the locking end of the tug-along

hose into the blowing port of the vac.

The hose should snap into place. To

remove the hose from the vac, press

the release button in the hose

assembly and pull the hose out of the

vac inlet.

3. (Optional) Attach extension wand to

opposite end of hose, then place the

car nozzle on the wand.

4. Turn vac on and you are ready to use

your vac as a blower.

Accessory and Storage

Your accessories may be stored in the

removable tote, or in the two locations on

the caddy r

by wrapping it around the unit and placing

each end into the two areas mar

Storage.

NOTE: Insert male end of extension

wand into the holder slee

The hose may be stored by wrapping it

around the unit and plugging the open

end into one of the storage locations on

the caddy assemb

ight/left. The hose may be stored

v

ly.

ked Hose

e as sho

wn.

12

Page 13

Push/Pull Handle

Cord Wrap

Power

Cord

Hose Storage

Area

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 13

Cord Wrap

When vacuuming is complete, unplug the

ord and wrap it around the power

c

assembly as shown. The cord should wrap

under the pull handle (above the inlet) and

around and under the cord wrap of the

motor cover.

Maintenance

Filter

!

WARNING:To reduce the risk of

injury from accidental starting,

unplug power cord before changing

or cleaning filter.

The filter is made of high quality

NOTE:

paper designed to stop very small

particles of dust. The filter can be used

for dry pick up or small amounts of liquid.

Handle the filter carefully when removing

to clean or installing it. Creases in the

filter pleats may occur from installation

but will not affect the performance of the

filter.

Filter Cleaning

Your filter should be cleaned often to

maintain peak vac performance.

Be sure to dry the filter before storing or

picking up dry debris.

IMPORTANT: After cleaning, check the

filter for tears or small holes. Do not use a

filter with holes or tears in it. Even a small

hole can cause a lot of dust to come out

of your vac. Replace it immediately.

Filter Removal

To remove the filter for cleaning or

replacement, unscre

the filter cage and lift off filter and filter

plate .

IMPORTANT: To a

w the filter n

oid damage to the

v

ut from

!

WARNING: Do not operate with

the filter cage and float removed.

The float prevents water from

entering the impeller and damaging

the motor.The cage prevents fingers

from touching the moving impeller.

blower wheel and motor, always reinstall

the filter before using the vac for dry

material pick-up.

Cleaning A Dry Filter

1. Some removal of dry debris can be

accomplished without removing the

filter from the vac. Slap your hand on

top of the lid while the vac is turned

off.

2. For best cleaning results due to

accumulated dust, clean the filter in an

open area. Cleaning SHOULD be

done outdoors and not in the living

quarters.

3. After filter removal from vac, remove

the dry debris by gently tapping filter

against the inside w

drum. The debris will loosen and fall.

4. For thorough cleaning of dry filter with

fine dust (no debr

through it as described under

"Cleaning A

13

is), run water

et Filter"

W

all of your dust

Page 14

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 14

Maintenance (continued)

Cleaning A Wet Filter

After filter is removed, run water through

the filter from a hose or spigot. Take care

that water pressure from the hose is not

strong enough to damage filter.

Installation

Refer to page 7 "Replacement Filter

Assembly" Section of this manual.

Allow the filter to dry before reinstalling

and storing the vac.

Cleaning and Disinfecting the

Wet/Dry Vac

To keep your Wet/Dry Vac looking its

best, clean the outside with a cloth

dampened with warm water and mild

soap.

To clean the drum:

1. Dump debris out.

2. Wash drum thoroughly with warm

water and mild soap.

3. Wipe out with dry cloth.

Before prolonged storage or as needed

(i.e.; waste water pick up) the drum

should be disinfected.

To disinfect the drum:

1. Pour 1 gallon of water and 1 teaspoon

chlorine bleach into the drum.

2. Let solution stand for 20 minutes,

carefully swishing every few minutes,

making sure to wet all inside surfaces

of the drum.

3. Empty drum after 20 minutes. Rinse

with water until bleach smell is gone.

Allow drum to dry completely before

sealing the motor on the drum.

Storage

Before storing your vac, the dust drum

should be emptied and cleaned. The cord

should be wrapped around the unit and

the hose should be stored as described

in this manual. Accessories should be

kept in the same area as the vac so they

can be readily available. The vac should

be stored indoors.

Casters and Wheels

Should your cart squeak or become hard

to roll, you should place two or three

drops of general purpose oil on each

wheel at the axle. If your casters are

noisy, you may put a drop of oil on the

roller shaft to make them quieter.

Frame and Handles

Your metal handle is painted to prevent

rust, however, liquids and corrosive

debris should be wiped off with a soft

cloth should they come in contact with

the handle.

WARNING:To assure product

!

SAFETY and RELIABILITY, repairs

and adjustments should be

performed by Authorized Service

Centers, always using RIDGID

replacement parts.

Wet Nozzle

To pick up liquids off a smooth surface,

use the 2-1/2 inch wet nozzle accessory

supplied with your wet/dry vac. To use this

nozzle, simply attach the nozzle to the end

of an extension wand.

Connect a second extension wand to the

first, and connect the 2-1/2 inch x 7 foot

hose to the extension wand.

Liquids may be picked up by dragging the

nozzle across the surf

will dry the surface as you vacuum.

If the rubber becomes worn, it may be

er f

flipped o

replaced. (Replacement service part

#822256). To reverse or replace the

squeegee:

14

v

ace. The squeegee

or use on the opposite side or

Page 15

Twist

Forward

Twist

Backward

Nozzle

Body

Latches

Removable

Insert

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 15

. Lay the wet nozzle on a flat surface with

1

the round inlet opening facing up and

the two latches close to you as shown.

. Using both hands, position each thumb

2

3. Press down with each thumb below the

latching tabs until you see and hear the

removable insert snap into the nozzle

body. Snap the latches over the locking

tabs into their original position.

on the removable insert, (below the

latches) and two fingers of each hand

on each latch, lift and disengage the

two latches from the tabs on the nozzle

body.

3. Gently pull the latches toward yourself

to remove the insert.

To reinstall the removable insert

correctly, follow these steps:

1. Place the removable insert on a flat

surface with the pins positioned upward

and the latches close to you as shown.

Place the rubber squeegee on the

insert, with the pins fitting through the

4. Inspect the pins of the insert to make

sure they fit through the holes of the

squeegee and fit into the matching

slots in the nozzle body.

NOTE: If the pins are out of position, hold

the nozzle assembly with both hands and

gently twist in opposite directions. The

insert pins should snap into proper

position.

matching holes in the squeegee. (Make

sure the new working edge is located

farthest from you.)

2. Using both hands, lower the nozzle

body onto the insert and squeegee with

the round opening of the nozzle closest

to you. With fingers on the far side and

thumbs holding the latches of the

removable insert, flip the nozzle over so

the latches are on the top and the

round inlet opening is f

acing away from

you. Make sure the squeegee stays on

the insert pins.

The wet nozzle assembly is ready for wet

pickup use.

15

Page 16

Microban

®

Microban

®

S

TEP UP

STEP UP

Microban

®

Microban

®

HEPA

HEPA

HEPA

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 16

Filter Replacement

Which Replacement Filter Meets Your Needs?

Filter System with

ntimicrobial product protection

a

F

ights and inhibits the growth

of mold, mildew and bacteria

t

hat can shorten filter life

Choosing a filter is as easy

as 1, 2, 3...

Standard

Filter

Filter System with

antimicrobial product protection

F

ights and inhibits the growth

of mold, mildew and bacteria

t

hat can shorten filter life

Applications VF4000 VF5000 VF6000

• Sawdust 33 3

• Wet Pick-up 33 3

• Typical Basement, 33 3

Garage or Car Dirt

• Drywall Dust 33

• Cold* Ashes

- BBQ Grill

33

- Fireplace

* DO NOT VACUUM ANYTHING THAT IS BURNING OR SMOKING, SUCH AS CIGARETTES, MATCHES OR HOT ASHES.

• Antimicrobial

Protection

• Fine Indoor Particles

- Pet Dander

- Furnace Filter

- Dryer Lint

- Upholstery

TRAPS

99.97% OF

PARTICLES

DOWN TO

.3 MICRONS

• Cement Dust

• Pollen/Allergens

MICROBAN is a registered trademark of Mircoban Products Company

MAXIMIZE VACUUM PERFORMANCE WITH A NEW FILTER

Typical Replacement Frequency is 2 Times Per Year

16

Page 17

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 17

MAXIMIZE VACUUM PERFORMANCE WITH A NEW FILTER

Typical Replacement Frequency is 2 Times Per Year

Log on to www

Enter Our $500 Home Depot Gift Card Sweepstakes.

NEW

FILTER

Keep Your

Environment

Clean!

.ridgidvacs.com to Join Our Filter Club and/or

(No Need to Join the Filter Club to Win)

DIRT

USED

FILTER

(after 8 hours

of average use)

POLLENS

WDUST

SA

DRYWALL

DUST

PET

DANDER

17

WATER/

LIQUIDS

Page 18

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 18

Repair Parts

16 Gallon Professional Wet/Dry Vac

Model Number WD19500

RIDGID parts are available on-line at www.ridgidparts.com

Always order by Part Number - Not by Key Number

Key

No. Part No. Description

1 830564 Actuator, Switch

2 813213 Switch, Toggle

3 829971-29 Motor Cover Assembly

4 830473 Filter Performance Sensor

5 509776-16 Motor Cover Assembly (Includes Keys 12 through 15)

6 829718-8 Cord Assembly

7 819260-7 Lead Assembly

8 830861 Lid Assembly (Includes Key 11)

9 830566-1 Duct Motor Exhaust

10 820563-5 Screw, Pan Head Type “AB” #10 x 1-1/4

11 830847 Lid Latch

12 818961 Spacer

13 818413 Blower Wheel

14 315534-1 Washer

15 826817 Nut, Hex Flange 5/16-18

16 829692-2 Collector Assembly

17 820563-4 Screw, Pan Head Serrated Type “AB” #10 x 3/4

18 830578-1 Tube Cover

19 820563-11 Screw, Pan Head Recessed Type “AB” #10 x 1

20 830498-2 Tube

21 823200A Float

22 823201-1 Filter Cage

23 VF5000 Filter - 2-Stage

24 73317 Filter Plate

25 73316 Filter Nut

26 VT2509 Utility Nozzle

27 VT2503 Car Nozzle

VT2510 Wet Nozzle

28

VT2502

29

30 822256 Squeegee

826356-5

31

VT2508

32

33 SP6567 Operator’s Manual

† These replacement par

†

†

†

†

†

vice

Cre

†

Hose Assemb

†

Extension, Handle

v

y be a

ts ma

T

ailab

(Includes K

ool

ly

le where y

ey 30)

ou purchased y

our vac.

18

Page 19

19

9

1

32

23

21

22

31

2

12

14

15

16

13

18

33

20

27

11

25

24

26

8

5

6

7

4

17

3

28

10

30

29

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 19

IDGID parts are available on-line at www.ridgidparts.com

R

!

WARNING

SERVICING OF DOUBLE-INSULATED WET/DRY VAC

In a double-insulated Wet/Dry Vac, two systems of insulation are provided

instead of grounding. No grounding means is provided on a double-insulated

appliance, nor should a means for grounding be added. Servicing a doubleinsulated Wet/Dry Vac requires extreme care and knowledge of the system,

and should be done only by qualified service personnel. Replacement parts

for a double-insulated Wet/Dry Vac must be identical to the parts they replace.

Your double-insulated Wet/Dry Vac is marked with the words "DOUBLE

INSULATED" and the symbol (square within a square) may also be

marked on the appliance.

To reduce the risk of injury from electrical shock, unplug power cord before

servicing the electrical parts of the Wet/Dry Vac.

19

Page 20

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 20

Repair Parts

16 Gallon Professional Wet/Dry Vac Cart

Model Number WD19500

RIDGID parts are available on-line at www.ridgidparts.com

Always order by Part Number - Not by Key Number

Key

No. Part No. Description

1 830858 Handle Assembly

2 830846 Dust Drum Assembly

3 73185 Drain Cap

4 830611 Wheel Cap

5 813836-1 Cap Nut 1/2”

6 830598 8” Wheel Assembly

(Includes Keys 4 and 5)

7 831024-1 Shaft

8 830841 Caddy, Right

9 830840 Caddy, Left

10 73102 Caster

11 830860 Tote

12 820563-4 Screw Type “AB” #10 x 3/4

13 509748-3 Bag of Loose Parts (Not Illustr

(Includes Keys 4, 5, 10, and 12)

ated)

20

Page 21

1

1

1

3

6

7

10

4

5

8

12

12

7

6

9

10

4

5

2

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 21

Repair Parts

21

Page 22

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 22

What is covered

RIDGID®tools are warranted to be free of defects in workmanship and material.

How long coverage lasts

This warranty lasts for the lifetime of the RIDGID®tool. Warranty coverage ends when the product

becomes unusable for reasons other than defects in workmanship or material.

How can you get service

To obtain the benefit of this warranty, deliver via prepaid transportation the complete product to

RIDGE TOOL COMPANY, Elyria, Ohio, or any authorized RIDGID®INDEPENDENT SERVICE

CENTER. Pipe wrenches and other hand tools should be returned to the place of purchase.

What we will do to correct problems

Warranted products will be repaired or replaced, at RIDGE TOOL’s option, and returned at no

charge; or, if after three attempts to repair or replace during the warranty period the product is still

defective, you can elect to receive a full refund of your purchase price.

What is not covered

Failures due to misuse, abuse or normal wear and tear are not covered by this warranty. RIDGE

TOOL shall not be responsible for any incidental or consequential damages.

How local law relates to the warranty

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty gives you specific rights, and you

may also have other rights, which vary, from state to state, province to province, or country to

country.

No other express warranty applies

This FULL LIFETIME WARRANTY is the sole and exclusive warranty for RIDGID®products.

No employee, agent, dealer, or other person is authorized to alter this warranty or make any other

warranty on behalf of the RIDGE TOOL COMPANY.

Stock No. WD1950

Model No. WD19500

Serial Number

Model and serial numbers may be found on the handle.You should record both model

and serial numbers in a safe place for future use.

QUESTIONS OR COMMENTS? CALL

1-800-4-RIDGID (1-800-474-3443)

www.ridgidvacs.com

Please have your Model Number and Serial Number on hand when calling.

Emerson Tool Company

c 2007 Emerson

Professional Tools

Part No. SP6567 Form No. SP6567-1 Printed in Mexico 08/07

A Division Of

Emerson Electric Co.

Page 23

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 23

MANUAL DEL OPERADOR

ASPIRADORA PARA MOJADO/SECO

PROFESIONAL

DE 16 GALONES EE.UU./ 60 LITROS

WD1950

SI TIENE PREGUNTAS O DESEA INFORMACIÓN, CONTÁCTENOS LLAMANDO AL

1-800-4-RIDGID (1-800-474-3443) O

CONECTÁNDOSE A www.ridgidvacs.com

!

ADVERTENCIA: Para reducir el riesgo de lesiones, el usuario debe leer y entender el manual del operador

Gracias por comprar un producto RIDGID.

antes de utilizar este producto.

GUARDE ESTE MANUAL PARA REFERENCIA FUTURA

No. de pieza SP6567 Impreso en México

Page 24

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 24

Indice

Sección Página

Instrucciones de seguridad importantes . . . . . . . 24

Introducción . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Desempaquetado y comprobación

del contenido de la caja de cartón . . . . . . . . . . 26

Remoción e instalación del asa metálica . . . . . . . 28

Instalación del asa . . . . . . . . . . . . . . . . . . . . . . 28

Bajada del asa para almacenar la aspiradora . . 28

Remoción del asa. . . . . . . . . . . . . . . . . . . . . . . 28

Instalación del portaherramientas . . . . . . . . . . 28

Ensamblaje de un filtro de reemplazo. . . . . . . . . . 29

Ensamblaje del tambor/base de soporte. . . . . . . . 30

Ensamblaje de la aspiradora para mojado/seco . . 31

Introduzca la manguera . . . . . . . . . . . . . . . . . 31

Funcionamiento . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Recogida de materiales secos

con la aspiradora . . . . . . . . . . . . . . . . . . . . . 32

Recogida de líquidos con la aspiradora . . . . . . 33

Sección Página

Sensor de rendimiento del filtro. . . . . . . . . . . . 33

Vaciado del tambor . . . . . . . . . . . . . . . . . . . . . 33

Traslado de la aspiradora para mojado/seco . . 34

Dispositivo de soplado. . . . . . . . . . . . . . . . . . . 34

Accesorios y almacenamiento . . . . . . . . . . . . . . . 34

Enrollado del cordón . . . . . . . . . . . . . . . . . . . . 35

Mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Filtro. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Limpieza y desinfección de la aspiradora

para mojado/seco . . . . . . . . . . . . . . . . . . . . 36

Almacenamiento. . . . . . . . . . . . . . . . . . . . . . . . 36

Ruedecillas y ruedas . . . . . . . . . . . . . . . . . . . . 36

Armazón y mangos . . . . . . . . . . . . . . . . . . . . . 36

Boquilla para mojado . . . . . . . . . . . . . . . . . . . . 36

Reemplazo del filtro . . . . . . . . . . . . . . . . . . . . . . . 38

Piezas de repuesto . . . . . . . . . . . . . . . . . . . . . . . . 40

Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

La seguridad es una combinación de sentido común,

permanecer alerta y saber cómo funciona la

aspiradora para mojado/seco (“la aspiradora”).

Palabras de señal de seguridad

!

PELIGRO: indica una situación inminentemente

peligrosa que, si no se evita, causará la muerte o

lesiones graves

!

ADVERTENCIA: indica una situación potencial-

mente peligrosa que, si no se evita, podría causar la

muerte o lesiones graves

!

PRECAUCIÓN: indica una situación potencial-

mente peligrosa que, si no se evita,

lesiones leves o moderadas.

Cuando utilice la aspiradora siga siempre las

precauciones básicas de seguridad, incluyendo las

siguientes.

!

ADVERTENCIA– Para

reducir el riesgo de incendio, sacudidas

eléctricas o lesiones:

• Lea y entienda este manual del usuario y todas las

etiquetas que están colocadas en la aspiradora para

mojado/seco antes de utilizarla.

• Utilice la aspiradora únicamente de la manera que

se describe en este manual.

• No deje la aspiradora en marcha mientras esté

desatendida.

Las chispas que se pr

•

motor pueden incendiar los vapor

el polvo. Para reducir el riesgo de incendio o

explosión: No recoja con la aspiradora líquidos o

gases inflamables o combustibles, o polvos

explosivos como gasolina u otros combustibles,

líquido encendedor

aceite, gas natural, hidrógeno, polvo de carbón,

polvo de magnesio, polvo de aluminio, polvo de

granos de cereal o pólvora, ni use la aspiradora

oducen en el interior del

, limpiador

pudiera causar

es inflamables o

es, pinturas a base de

cerca de estos materiales.

• No recoja con la aspiradora nada que esté ardiendo

o humeando, como cigarrillos, fósforos o cenizas

calientes.

• No recoja con la aspiradora polvo de panel de yeso

ni hollín frío o ceniza fría de chimenea con un filtro

estándar. Este material es un polvo muy fino que

puede ser expulsado de vuelta al aire. Utilice un

filtro para polvo fino en lugar de un filtro estándar.

• Para reducir el riesgo de que se produzcan peligros

para la salud causados por vapores o polvo, no

recoja con la aspiradora materiales tóxicos.

• No use ni almacene la aspiradora cerca de

materiales peligrosos.

• Para reducir el riesgo de descargas eléctricas, no

exponga la aspiradora a la lluvia ni deje que entren

líquidos en el compartimiento del motor. Guarde la

aspiradora en un lugar interior.

• No permita que la aspiradora se utilice como un

juguete. Se necesita prestar máxima atención

cuando sea utilizada por niños o cerca de éstos.

• No use esta aspiradora con un filtro desgarrado o si

no tiene el filtro instalado, excepto cuando recoja

líquidos de la manera que se describe en la sección

“Funcionamiento” de este manual. Los residuos

secos absorbidos por el impulsor podrían dañar el

motor o ser expulsados de vuelta al aire.

ADVERTENCIA: El cordón de energía de este pro-

•

ducto contiene plomo, una sustancia química que

según los conocimientos del estado de Califor

causa defectos de nacimiento u otros daños a la

reproducción.

manejar el producto.

No abandone la aspiradora cuando esté enchufada.

•

Desenchúfela del tomacor

utilizando y antes de realizar servicio de revisión.

Apague la aspiradora antes de desenchufarla.

•

• Para reducir el riesgo de lesiones debidas a un

arranque accidental, desenchufe el cordón de

gía antes de cambiar o limpiar el filtr

ener

Lávese las manos después de

riente cuando no la esté

24

nia

o.

Page 25

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 25

• No desenchufe la aspiradora tirando del cordón.

Para desenchufarla, agarre el enchufe y no el

cordón.

• No use la aspiradora con el cordón dañado, el

enchufe dañado u otras piezas dañadas. Si la

aspiradora no funciona como debe, le faltan piezas,

se ha caído, ha sido dañada, se ha dejado a la

intemperie o se ha caído al agua, devuélvala a un

Centro de Servicio autorizado.

• No tire de la aspiradora usando el cordón ni la lleve

por el cordón, ni use el cordón como asa, ni cierre

una puerta sobre el cordón, ni tire del cordón alrededor de bordes o esquinas afilados. No pase la

aspiradora en marcha sobre el cordón. Mantenga el

cordón alejado de las superficies calientes.

• No maneje el enchufe, el interruptor o la aspiradora

con las manos mojadas.

• No ponga ningún objeto en las aberturas de ventilación. No recoja nada con la aspiradora cuando

cualquiera de las aberturas de ventilación esté

bloqueada; mantenga dichas aberturas libres de

polvo, pelusa, pelo o cualquier cosa que pueda

reducir el flujo de aire.

• Mantenga el pelo, la ropa holgada, los dedos y

todas las partes del cuerpo alejados de las aberturas y de las piezas móviles.

• Para reducir el riesgo de caídas, tenga cuidado

adicional al limpiar en escaleras.

• Para reducir el riesgo de lesiones de espalda o

caídas, no levante una aspiradora que pese mucho

debido a que contiene líquido o residuos. Saque

parte del contenido de la aspiradora o drénela

parcialmente para hacer que sea lo suficientemente

liviana como para poder levantarla cómodamente.

• Para reducir el riesgo de lesiones corporales o

daños a la aspiradora, utilice únicamente

accesorios recomendados por Ridgid.

• Cuando utilice la aspiradora como soplador:

- Dirija la descarga de aire solamente hacia el

área de trabajo.

- No dirija el aire hacia las personas que estén

presentes.

- Mantenga alejados a los niños durante la

operación de soplado.

- No utilice el soplador para trabajos que no sean

soplar suciedad y residuos.

- No use la aspiradora como rociador.

- Use protección ocular de seguridad.

• Para reducir el riesgo de lesiones en los ojos, use

protección ocular de seguridad. La utilización de

cualquier aspiradora utilitaria o soplador utilitario

puede hacer que se soplen objetos extraños hacia

los ojos, lo cual puede causar daños graves en los

ojos.

• Esta aspiradora para mojado/seco tiene aislamiento

doble, lo cual elimina la necesidad de un sistema

independiente de conexión a tierra. Utilice

únicamente piezas de repuesto idénticas. Lea las

instrucciones de servicio de revisión de las

aspiradoras para mojado/seco con aislamiento

doble antes de realizar dicho ser

vicio.

• Utilice únicamente cordones de extensión que

tengan capacidad nominal para uso a la intemperie.

Los cordones de extensión que estén en malas

condiciones o cuyo tamaño de alambre sea

demasiado pequeño pueden conllevar peligros de

incendio y sacudidas eléctricas. Para reducir el

riesgo de estos peligros cuando utilice un cordón

de extensión, asegúrese de que el cordón esté en

buenas condiciones y de que la conexión no entre

en contacto con líquido. Para mantener la pérdida

al mínimo, utilice la tabla que aparece a continuación para seleccionar el cordón de extensión

con el tamaño de cable mínimo.

Longitud del cordón Calibre del cable

de extensión (A.W.G.)

0-50 pies 14

50-100 pies 12

!

PRECAUCIÓN:

• Para reducir el riesgo de daños a la audición, use

protectores de oídos cuando utilice la aspiradora

durante muchas horas seguidas o cuando la

emplee en un área ruidosa.

• Para operaciones que generan polvo, use una

máscara antipolvo.

NOTA: Las descargas de estática son comunes en

áreas secas o cuando la humedad relativa del aire es

baja. Si recoge residuos finos con la aspiradora, se

puede depositar carga estática en la manguera o en la

aspiradora. El mejor remedio para reducir la frecuencia

de las descargas de estática en su casa o cuando use

esta aspiradora es añadir humedad al aire con un

humidificador.

Siga las siguientes advertencias que aparecen en la

caja del motor de la aspiradora.

AISLAMIENTO DOBLE. NO SE REQUIERE

CONEXION A TIERRA.

CUANDO HAGA SERVICIO DE REVISIÓN DE

LA ASPIRADORA, UTILICE ÚNICAMENTE PIEZAS DE

REPUESTO IDÉNTICAS.

!

ADVERTENCIA: Para su propia seguridad, lea

y entienda el manual del operador. No tenga en

marcha la aspiradora desatendida. No recoja

cenizas calientes, carbón caliente, materiales

tóxicos ni inflamables ni otros materiales

peligrosos. No use la aspiradora alrededor de

líquidos o vapores explosivos

ADVERTENCIA: Para reducir el riesgo de sacudidas eléctricas, no exponga la aspiradora a la

lluvia y guárdela en interiores.

GUARDE ESTE MANUAL

25

Page 26

C

B

H

D

E

G

F

A

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 26

Introducción

Esta aspiradora para mojado/seco profesional está

diseñada para uso doméstico. Se puede utilizar para

recoger materiales mojados o secos y se puede usar

como soplador.

Lea este manual del operador para familiarizarse con

las características del producto y para entender la

utilización específica de su nueva aspiradora.

Desempaquetado y comprobación del contenido

de la caja de cartón

Herramientas necesarias

Destornillador Phillips largo

Consulte el dibujo de ensamblaje para averiguar el

posicionamiento de las piezas.

Lista del contenido de la caja de cartón

Clave Descripción Cant.

A Ensamblaje de la aspiradora

B Manguera arrastrable .............................1

C Boquilla de uso general..........................1

D Boquilla para mojado .............................1

E Boquilla rinconera ..................................

F Boquilla para auto ..................................1

G Tubos de extensión................................2

H Manual del usuario.................................1

para mojado/seco ..............................1

Saque todo el contenido de la caja de cartón.

Asegúrese de que no falte ningún artículo utilizando la lista del contenido de la caja. Llame al

1-800-4-RIDGID (1-800-474-3443) o comuníquese con nosotros por correo electrónico a

info@ridgidvacs.com si alguna pieza está dañada

o falta.

1

MazoMartillo

26

Page 27

L

N

O

K

M

J

R

Q

P

S

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 27

lave Descripción Cant.

C

Caja de cartón que contiene las piezas siguientes:

J Bolsa de almacenamiento .....................1

K Rueda de 8 pulgadas..............................2

L Mango metálico......................................1

M

Eje ..........................................................1

N Base de soporte derecha .......................1

O Base de soporte izquierda ......................1

Clave Descripción Cant.

Bolsa de piezas sueltas que contiene lo siguiente:

P Ruedecilla de 2 pulgadas .......................2

Q Tuerca de tapa de 1/2 pulgada ...............2

R Tapas de rueda ......................................2

S Tornillo de tipo AB No. 10 x 3/4.............8

27

Page 28

Correct

Position

Storage

Position

Moving

Position

Metal Handle in

Reversed Position

(As Shipped)

Tote Snaps

Tote

Straps (5)

Handle

Extension

Wand

Storage

Locations

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 28

Remoción e instalación del asa metálica

El asa metálica viene empacada en la caja de cartón

en sentido inverso. Usted debe tirar del asa

metálica hasta sacarla completamente de la

aspiradora y reinstalarla en el sentido correcto, de

modo que el área curvada quede orientada

alejándose de la parte trasera de la aspiradora,

antes de continuar.

Instalación del asa

Oprima y mantenga oprimidos los botones de

liberación mientras instala el asa en los

receptáculos para el asa ubicados en el tambor

(vea la ilustración).

NOTA: Un chasquido audible de los botones de

liberación indica un acoplamiento exitoso del asa.

Asa metálica

en posición invertida

(tal como se envía)

Bajada del asa para almacenar

la aspiradora

Para almacenar la aspiradora para mojado/seco,

oprima y mantenga oprimidos los botones de

liberación mientras desliza firmemente el asa

hacia abajo.

Remoción del asa

Oprima y mantenga oprimidos los botones de

liberación, de la manera que se muestra en la

ilustración. Mientras oprime firmemente los

botones de liberación, tire del asa hacia arriba

hasta quitarla (vea la ilustración).

Instalación del portaherramientas

Instale el portaherramientas de la manera que se

muestra en la ilustración, con los portatubos

extensores orientados hacia la unidad.

Acopladores

de la bolsa

Correas de

la bolsa (5)

Asa

Ubicaciones de

almacenamiento

de los tubos

extensores

Posición

correcta

Posición de

transporte

Posición de

almacenamiento

28

Page 29

Filter

Threaded Stud

Filter Cage

Slots (3)

Filter Nut

Filter Nut

Lever

Filter Plate

T

HIS SIDE

TOWARD LID

Filter Cage

Tabs (3)

Float

Solid End

Slots (3)

Power Head

Assembly

Filter Cage

Tabs (3)

Slots (3)

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 29

Ensamblaje de un filtro de reemplazo

1. Deslice cuidadosamente el filtro sobre la jaula

d

el filtro, deslizándolo sobre el anillo central

que cubre las 3 ranuras hasta que el filtro se

d

etenga contra la tapa.

2. Coloque la tuerca del filtro en el espárrago

roscado y apriétela hacia abajo. Apriétela

solamente con los dedos.

NOTA: La palanca de la tuerca del filtro debe

estar alejada de la placa, de la manera que se

muestra en la ilustración.

IMPORTANTE: No apriete excesivamente la

tuerca, ya que esto puede deformar o agrietar

la jaula del filtro o el filtro.

NOTA: En caso de que sea necesario quitar la

jaula del filtro debido a que el flotador esté

colocado de manera incorrecta, utilice un

destornillador de hoja plana e introduzca la hoja

cerca de una de las lengüetas entre la jaula del

filtro y el anillo central de la tapa. Haga palanca

hacia afuera en la lengüeta hasta sacarla de la

ranura. Incline la jaula y levántela para separarla

de la tapa. Para colocar de nuevo la jaula, siga

las instrucciones de ensamblaje que aparecen

más adelante.

!

ADVERTENCIA: Para su propia seguridad,

nunca conecte el enchufe al tomacorriente de la

fuente de energía hasta que haya completado

todos los pasos de ensamblaje y haya leído y

entendido las instrucciones de seguridad y

utilización. No utilice la aspiradora si alguna de

sus piezas está dañada o falta.

3. Coloque el flotador sobre la abertura ubicada

en el centro de la tapa con las palabras “This

Side Towards Lid” (Este lado hacia la tapa)

orientadas hacia abajo sobre el agujero (vea la

ilustración).

ADVERTENCIA: Para reducir el riesgo de

!

lesiones personales o daños a la aspiradora,

asegúrese de mantener las manos, los dedos o

cualquier otro objeto extraño fuera de la

abertura central cuando ensamble el flotador.

4. Alinee las lengüetas de la jaula del filtro con

las ranuras del anillo central de la tapa.

5. Empuje sobre la jaula del filtro hasta que las

lengüetas se acoplen a presión en las ranuras

para lograr un encaje seguro.

Palanca de

la tuerca

del filtro

Tuerca del filtro

Placa del filtro

Filtro

Espárrago roscado

Jaula del filtro

Ranuras (3)

Extremo macizo

29

Jaula del filtro

Lengüetas (3)

Flotador

Jaula del filtro

Lengüetas (3)

Ranuras (3)

Ensamblaje del

cabezal del motor

Ranuras (3)

Page 30

N

OTE: Smooth side of

t

he wheel to the outside.

Caddy

Left

Shaft

Caddy

Right

Wheel

Cap Nut

CADDY ASSEMBLY

Cap Nut

R

I

G

H

T

Raised Rib

on Back of Drum

TAP

TAP

Caddy

Wheel

1/16" Clearance

Wheel Cap

Mallet

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 30

Ensamblaje del tambor/base de soporte

Si cualquiera de las piezas falta o está dañada,

póngase en contacto con Servicio al Cliente.

No realice el ensamblaje hasta que tenga todas las

piezas.

1. Invierta el tambor para instalar las bases de

soporte. Instale una tuerca de tapa en un lado

de la varilla del eje. Golpee la tuerca suavemente

con un mazo de goma o un martillo hasta que

esté completamente asentada. Deslice el

extremo abierto del eje a través de la rueda (con

el lado liso de la rueda orientado hacia afuera).

2. Coloque el ensamblaje de la rueda y el eje a

través de la base de soporte izquierda y luego a

través de la base de soporte derecha, de la

manera que se muestra en la ilustración.

3. Luego, coloque la rueda restante en el

ensamblaje de las bases de soporte (con el lado

liso de la rueda orientado hacia afuera) e instale

la segunda tuerca de tapa.

4. Coloque el ensamblaje de las bases de soporte

sobre el reborde del tambor. Alinee los bordes

interiores de las bases de soporte tanto

izquierda como derecha con las nervaduras

exteriores salientes ubicadas en la parte trasera

del tambor. Asegúrese de que las ruedas giren

libremente y no entren en contacto con las

bases de soporte. Si las ruedas tocan las bases

de soporte, mueva dichas bases ligeramente

hacia adentro.

5. Una vez que las bases de soporte estén

alineadas con las nervaduras salientes ubicadas

en la par

suavemente la parte trasera de cada base de

soporte hasta que esté firmemente asentada. Se

recomienda golpear suavemente la porción

central de la parte trasera de cada base de

sopor

de las bases de soporte estén ubicadas

firmemente en su sitio, proceda a golpear

suavemente en su sitio la porción delantera de

cada base de soporte hasta que esté completamente asentada. Se recomienda golpear

suavemente la porción central de la parte delantera de cada base de soporte, de la manera que

se muestra en la ilustración.

6. Utilizando un mazo de goma o un martillo,

golpee suavemente las tapas de r

cada rueda, hasta que dichas tapas estén

firmemente asentadas en cada rueda. Se

requiere hacer esto tanto en los lados izquierdo

como derecho.

te trasera del tambor, golpee

te. Después de que las porciones traseras

ueda, una en

OTA: Lado liso de

N

a rueda hacia el exterior.

l

Tuerca

de tapa

Holgura de 1/16 pulg.

Nervadura saliente ubicada

en la parte trasera del

tambor

Rueda

Base de soporte

derecha

ENSAMBLAJE DE LAS BASES DE SOPORTE

GOLPEE

SUAVEMENTE

30

T

d

Eje

Base de soporte

izquierda

Base de soporte

Rueda

GOLPEE

SUAVEMENTE

Tapa de rueda

Mazo

uerca

e tapa

Page 31

Latch

Drum

Latch

Handles

Drum

Drum

Latch

Release

Button

Press

and

Pull

L

E

F

T

Socket

Caster Stem

Caster Ball

#10 x 3/4"

Screw (8)

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 31

7. Introduzca el vástago de la ruedecilla en el

receptáculo del pie de ruedecilla, de la manera

que se muestra en la ilustración (ruedecilla

delantera solamente).

8. Empuje sobre la ruedecilla hasta que la bola del

vástago de la ruedecilla esté introducida completamente en el receptáculo. Usted podrá oír como

la bola se acopla a presión en el receptáculo y la

ruedecilla girará fácilmente cuando el posicionamiento sea correcto.

Vástago de la ruedecilla

Bola de la ruedecilla

Receptáculo

9. Voltee el ensamblaje del tambor/base de soporte

hasta la posición vertical. Utilizando un destornillador Phillips largo, instale (8) tornillos No. 10

x 3/4 pulgadas en los agujeros correspondientes

ubicados tanto en el lado derecho como en el

l

ado izquierdo de la base de soporte. Apriete los

tornillos sólo hasta que queden perfectamente

ajustados. No los apriete excesivamente en este

momento, ya que esto podría tender a deformar

las bases de soporte.

Tornillo No. 10

x 3/4 pulg. (8)

Ensamblaje de la aspiradora para mojado/seco

1. Posicione el ensamblaje del cabezal del motor

sobre el ensamblaje del tambor/base de soporte,

de la manera que se muestra en la ilustración

(ensamblado antes).

2. Gire ambos pestillos hacia abajo y presione

hasta que los oiga acoplarse a presión sobre las

pestañas del tambor.

Pestillo

del tambor

Pestillo

del tambor

Introduzca la manguera

Introduzca el extremo con botón pulsador de la

manguera “arrastrable” en la entrada de la aspiradora. La manguera debe acoplarse a presión en su

sitio. Para quitar la manguera de la aspiradora,

oprima el botón de liberación que está en el

ensamblaje de la manguera y tire de la manguera

hasta sacarla de la entrada de la aspiradora, de la

manera que se muestra en la ilustración.

Pestillo

ambor

T

Asas

31

Oprima el

botón y

tire de la

manguera

Botón de

liberación

Page 32

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 32

Funcionamiento

!

DVERTENCIA

A

Para reducir el riesgo de incendios o explosión, no haga funcionar esta aspiradora en áreas en las que

haya gases inflamables, o vapores inflamables o polvo explosivo en el aire. Entre los gases y vapores

inflamables se incluye, pero sin limitarse a ellos, líquidos de encendedor, limpiadores a base de

disolventes, pinturas a base de aceite, gasolina, alcohol o rociadores aerosoles. Entre los polvos

explosivos se incluye, pero sin limitarse a ellos, el carbón, magnesio, aluminio, polvo de granos o

pólvora. No recoja con la aspiradora polvo explosivo, líquidos inflamables o combustibles, ni cenizas

calientes. No use esta aspiradora como rociador. A fin de reducir los peligros para la salud debidos a

vapores o polvos, no recoja con la aspiradora materiales tóxicos.

ADVERTENCIA: El funcionamiento de

!

cualquier aspiradora de uso general puede tener

como resultado que salgan proyectados hacia

los ojos objetos extraños, lo cual puede producir

daños graves en los ojos. Use siempre protectores

oculares de seguridad que cumplan con la norma

ANSI Z87.1 (o en Canadá, con la norma CSA

Z94.3) antes de comenzar la operación. Los

protectores oculares de seguridad se pueden

obtener en muchas tiendas minoristas locales.

PRECAUCION: Para reducir el riesgo de

!

daños a la audición, use protectores de oídos

al utilizar la aspiradora o durante muchas horas

seguidas o al emplearla en un área ruidosa.

Para reducir el riesgo de sacudidas eléctricas, este

aparato electrodoméstico tiene un enchufe polarizado

(una hoja es más ancha que la otra). Este enchufe

entrará en un tomacorriente polarizado solamente de

una manera. Si el enchufe no entra por completo en el

tomacorriente, déle la vuelta. Si sigue sin entrar,

póngase en contacto con un electricista competente

para instalar el tomacorriente adecuado. No haga

ningún tipo de cambio en el enchufe.

Después de enchufar el cordón de energía en el tomacorriente, encienda la unidad empujando el interruptor

de la posición “O” a la posición “|”. Los símbolos

utilizados en el accionador del interruptor son los

símbolos internacionales de “encendido y apagado”.

“O” es el símbolo de “APAGADO” y “|” es el símbolo

de “ENCENDIDO”.

=

APAGADO

Familiarícese con los accesorios que se incluyen con

la aspiradora. Cada accesorio puede usarse de diver

sas maneras para aspirar y soplar residuos. A continuación hay una lista de los accesorios y de sus

usos.

=

ENCENDIDO

Boquilla de uso general: Boquilla que se usa en la

mayoría de las aplicaciones de aspiración.

Boquilla para mojado: Se utiliza para recoger

materiales mojados en superficies lisas con el fin

de recoger líquidos y secar la superficie en una

sola pasada.

Boquilla para auto: Boquilla para recoger

materiales secos en interiores de auto y en la

mayoría de limpiezas de tapicería.

Tubos extensores: Estos tubos pueden conectarse

entre sí y proporcionan longitud adicional para tener

más alcance.

Manguera: Proporciona transferencia de capacidad de

aspiración o soplado al lugar de trabajo. Proporciona

los medios para acoplar los tubos extensores y las

boquillas.

Boquilla rinconera: Se utiliza para r

residuos en lugares difíciles de alcanzar.

!

ADVERTENCIA: Para reducir el riesgo de

incendio o sacudidas eléctricas, no deje desatendida la aspiradora mientras esté en marcha.

Recogida de materiales secos

con la aspiradora

1. El filtro debe estar siempre en la posición

correcta para reducir el riesgo de fugas y

posibles daños a la aspiradora.

2. La aspiradora para mojado/seco viene con el

filtro VF5000 instalado. Al utilizar la aspiradora

para recoger polvo muy fino, será necesario que

usted vacíe el tambor y limpie el filtro a

intervalos más frecuentes para mantener un

endimiento óptimo.

r

NOTA: Se necesita un filtro seco para recoger

-

material seco. Si utiliza la aspiradora para recoger

polvo cuando el filtr

rápidamente y será muy difícil limpiarlo.

o está mojado, éste se atascará

ecoger

32

Page 33

Filter

Sensor

Reset

Button

SP6567 16 Gallon Steel.qxd 8/15/07 1:32 PM Page 33

3. Si el filtro está mojado pero necesita usar la

aspiradora para recoger material seco, puede

secar el filtro rápidamente haciendo funcionar la

aspiradora sin tener la manguera colocada

durante unos 10 minutos. El aire limpio que

penetrará rápidamente en la aspiradora ayudará

a

secar el filtro.

Recogida de líquidos con la aspiradora

1. Al recoger pequeñas cantidades de líquido se

podrá dejar puesto el filtro.

2. Al recoger grandes cantidades de líquido

recomendamos quitar el filtro. Si no se quita el

filtro, éste se saturará y podrá aparecer niebla en

el escape.

3. Cuando el líquido que se encuentre en el tambor

alcance un nivel predeterminado, el mecanismo

del flotador subirá automáticamente para cortar

el flujo de aire. Cuando esto suceda, apague la

aspiradora, desenchufe el cordón de energía y

vacíe el tambor. Sabrá que el flotador ha subido

porque el flujo de aire de la aspiradora cesará y

subirá el tono del ruido del motor debido a que

se producirá un aumento de la velocidad del

mismo.

4. Después de usar la aspiradora para recoger

líquidos, se debe secar el filtro para reducir el

riesgo de posible moho y daños al filtro.

IMPORTANTE: Para reducir el riesgo de daños a la

aspiradora, no tenga en marcha el motor con el

flotador en la posición elevada.

Sensor de rendimiento del filtro

Esta aspiradora para mojado/seco cuenta con un

1.

innovador dispositivo para determinar cuándo es

necesario limpiar el filtro. Este diseño con

patente pendiente funciona tanto si la aspiradora

para mojado/seco está encendida como si está

apagada.

2. Unas barras de color muestran el nivel de

limpieza del filtro. Si todas las barras visibles