Page 1

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:19 AM Page 1

OWNER’S MANUAL

14 GALLON

SMART-PULSE VACUUM

RV34100

QUESTIONS OR COMMENTS? CONTACT US AT

www.ridgidvacs.com

In the U.S. and Canada, Call 1-800-4-RIDGID

In Mexico, Call 01-800-701-9811

WARNING:

!

To reduce the risk of injury, the user must read and understand the owner’s manual

before using this product.

Thank you for buying a RIDGID product.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Part No. SP6906 Printed in Mexico

• Español - página 21

• Français - page 41

Page 2

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:19 AM Page 2

Table of Contents

ection Page

S

Important Safety Instructions. . . . . . . . . 2

Safety Signal Words. . . . . . . . . . . . . . 2

Grounding Instructions . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking and Checking

Carton Contents . . . . . . . . . . . . . . . . . 6

Vac Assembly . . . . . . . . . . . . . . . . . . . . 7

Caddy Assembly. . . . . . . . . . . . . . . . . 8-9

Operation . . . . . . . . . . . . . . . . . . . . 10-12

Vacuuming Dry Material . . . . . . . . . . 11

Section Page

Optional Dust Collection Bags . . . . . 11

Vacuuming Liquids . . . . . . . . . . . . . . 11

Emptying the Drum . . . . . . . . . . . . . 12

Blowing Feature . . . . . . . . . . . . . . . . 12

Moving the Wet/Dry Vac. . . . . . . . . . 12

Diffuser . . . . . . . . . . . . . . . . . . . . . . . 13

Static-Dissipating Accessory Hose . 13

Maintenance. . . . . . . . . . . . . . . . . . 13-15

Repair Parts . . . . . . . . . . . . . . . . . . 16-19

Warranty . . . . . . . . . . . . . . . . . . . . . . . 20

IMPORTANT SAFETY INSTRUCTIONS

Safety is a combination of using common

sense, staying alert, and knowing how your

Vacuum cleaner (“Vac”) works.

Safety Signal Words

DANGER: Indicates a hazardous

!

situation which, if not avoided, will result

in death or serious injury.

WARNING: Indicates a hazardous

!

situation which, if not avoided, could

result in death or serious injury.

CAUTION: Indicates a hazardous

!

situation which, if not avoided, could

result in minor or moderate injury.

When using your Vac, always follow basic

safety precautions including the following:

!

WARNING

- To reduce the risk of fire, electric

shock, or injury:

• Read and understand this manual and

all labels on the Vac before operating.

• Use only as described in this manual.

• Do not leave Vac running while

unattended - you may fail to notice

important signs indicating abnormal

operation such as loss of suction,

debris exiting exhaust, or abnormal

motor noises. Immediately stop using

Vac if you notice these signs.

• Do not leave Vac when plugged in.

Unplug from outlet when not in use

and before servicing.

• Sparks inside the motor can ignite

flammable vapors or dust. To reduce

the risk of fire or explosion, do not use

near combustible liquids, gases, or

dusts, such as gasoline or other fuels,

lighter fluid, cleaners, oil-based paints,

natural gas, coal dust, magnesium

dust, grain dust, aluminum dust, or

gun powder.

• Do not vacuum anything that is burning

or smoking, such as cigarettes,

matches, or hot ashes.

• This Vac is not intended for EPA RRP

cleanup.

• Extremely small particles may pass

through the filter. Always wear

appropriate protective safety

equipment.

• To reduce the risk of inhaling toxic

vapors, do not vacuum or use near

toxic or hazardous materials.

• To reduce the risk of electric shock,

do not expose to rain or allow liquid

to enter motor compartment.

Store indoors.

• Do not allow to be used as a toy. Close

attention is necessary when used by or

near children.

• Do not use with a torn filter or without

the filter installed except when

vacuuming liquids as described in this

manual. Dry debris ingested by the

impeller may damage the motor or be

exhausted into the air.

• Turn off Vac before unplugging.

• To reduce the risk of injury from

accidental starting, unplug power cord

before changing or cleaning filters.

• Do not unplug by pulling on cord.

To unplug, grasp the plug, not the cord.

• Do not use with damaged cord, plug or

other parts. If your Vac is not working

as it should, has missing parts, has

been dropped, damaged, left outdoors,

or dropped into water, call customer

service.

2

Page 3

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:19 AM Page 3

• Do not pull or carry by cord, use cord

as handle, close a door on cord, or pull

cord around sharp edges or corners.

Do not run Vac over cord. Keep cord

way from heated surfaces.

a

• Do not handle plug, switch, or the Vac

with wet hands.

• Use only grounded extension cords that

are rated for outdoor use. Extension

cords in poor condition or too small in

wire size can pose fire and shock

hazards. To reduce the risk of these

hazards, be sure the cord is in good

condition and that liquid does not

contact the connection. Do not use an

extension cord with conductors smaller

than 16 gauge (AWG) in size. To reduce

power loss, use a 14 gauge extension

cord if 25 to 50 ft. long and 12 gauge for

50 ft. or longer.

• Do not put any object into ventilation

openings. Do not vacuum with any

ventilation openings blocked; keep free

of dust, lint, hair or anything that may

reduce air flow.

• Keep hair, loose clothing, fingers, and

all parts of body away from openings

and moving parts.

• To reduce the risk of falls, use extra

care when cleaning on stairs.

• To reduce the risk of back injury or

falls, do not lift a Vac that is heavy with

debris. Partially empty the Vac by

scooping debris to make it comfortable

to lift.

• To reduce the risk of personal injury or

damage to Vac, use only Ridgid

recommended accessories.

When using as a blower:

- Direct air discharge only at work area.

- Do not direct air at bystanders.

- Keep children away when blowing.

- Do not use blower for any job except

blowing dirt and debris.

- Do not use as a sprayer.

- Wear safety eyewear.

• To reduce the risk of eye injury, wear

safety eyewear. The operation of any

utility Vac or blower can result in

foreign objects being blown into the

eyes, which can result in severe eye

damage.

• To reduce the risk of being struck by, or

pulled down by, a rolling Vac, block the

wheels when using on any uneven or

sloped surface.

• Connect to a properly grounded outlet

only. See Grounding Instructions.

!

CAUTION:

• To reduce the risk of hearing damage,

wear ear protectors when using for

extended time or in a noisy area.

• For dusty operations, wear dust mask.

• Static shocks are common when

vacuuming fine debris such as drywall

dust or concrete dust, especially in

low-humidity conditions. To reduce the

risk of static shocks when using this

Vac, add moisture to the environment

with a humidifier. To further reduce the

possibility of static shock, this Vac can

also be used with a grounded, staticdissipating hose which can be

purchased as an optional accessory.

Observe the following warnings that

appear on the motor housing of your Vac:

WARNING: For your safety, read

!

and understand owner's manual.

Do not run unattended. Do not pick

up hot ashes, coals, toxic,

flammable, or other hazardous

materials. Do not use around

explosive liquids or vapors.

WARNING: To Reduce The Risk

!

Of Electric Shock – Do not expose

to rain. Store indoors.

!

CAUTION: To reduce the risk of

static shock, use the VT2580 staticdissipating hose.

SAVE THIS MANUAL

3

Page 4

Properly

Grounded

Outlet

Grounding

Prong

3-Prong

Plug

Make sure this is a

metal screw connected

to a known ground

Green

Grounding Lug

2-Prong Outlet

3-Prong Plug

Adapter

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:21 AM Page 4

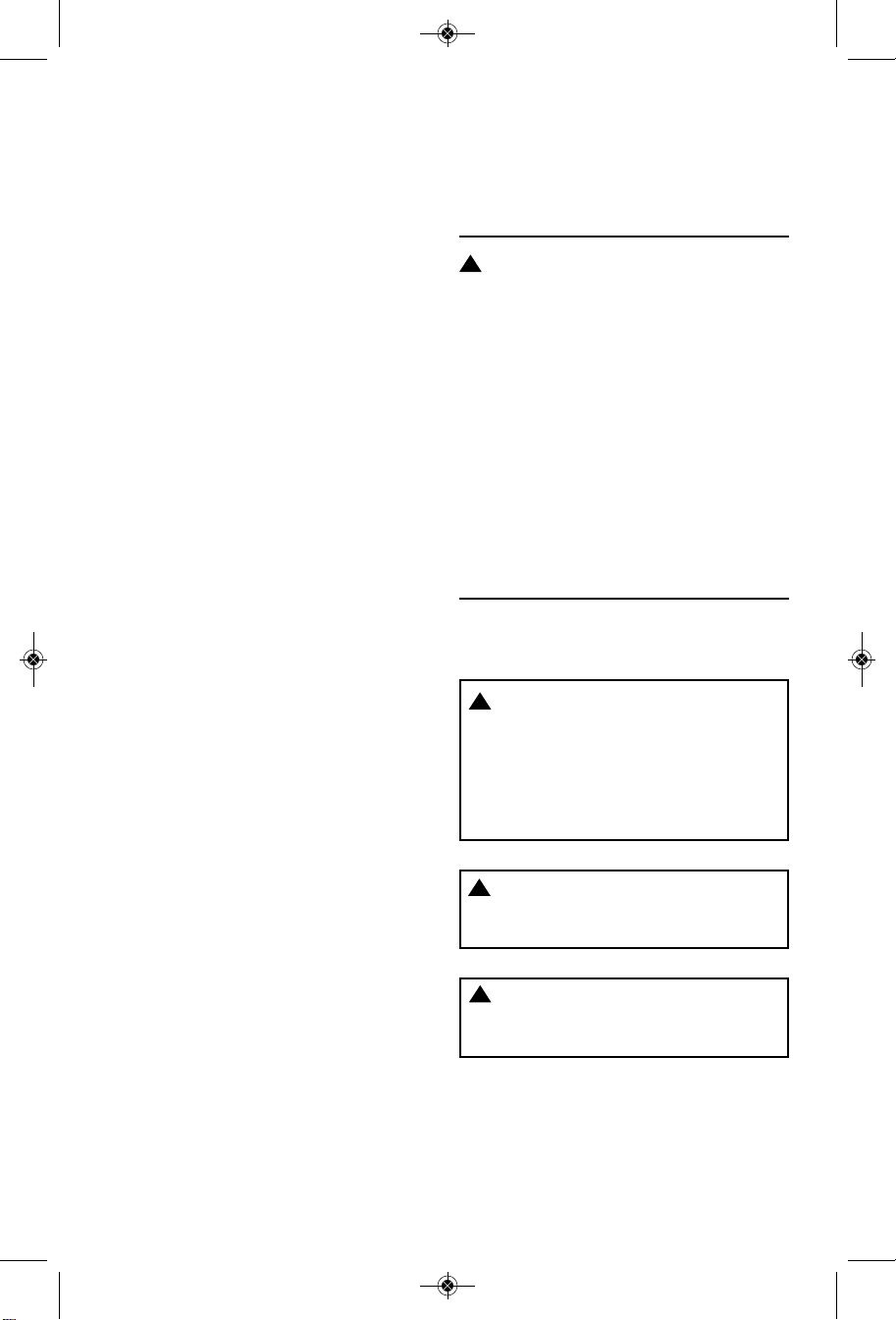

Grounding Instructions

his appliance must be grounded.

T

If it should malfunction or break down,

ground ing provides a path of least

resistance for electric current to reduce

the risk of electric shock. This appliance

is equipped with a cord having an

equipment-grounding conductor and

grounding plug. The plug must be

inserted into an appropriate outlet that is

properly installed and grounded in

accordance with all local codes and

ordinances.

!

WARNING:

Improper connection of the

equipment grounding conductor

can result in a risk of electric shock.

Check with a qualified electrician or

service person if you are in doubt

as to whether the outlet is properly

grounded. Do not modify the plug

provided with the appliance - if it

will not fit the outlet, have a proper

outlet installed by a qualified

electrician.

This vac is for use on a nominal 120-volt

circuit, and has a grounded plug that

looks like the plug shown. A temporary

adapter that looks like the adapter shown

may be used to connect this plug to a

2-pole receptacle, as shown. If a properly

grounded outlet is not available, the

temporary adapter should only be used

until a properly grounded outlet can be

installed by a qualified electrician.

The green-colored rigid ear, lug, or the

like, extending from the adapter, must be

connected to a permanent ground such

as a properly grounded outlet box cover.

Whenever the adapter is used, it must be

held in place by a metal screw.

NOTE: In Canada, the use of a

temporary adapter is not permitted by

the Canadian Electrical Code.

4

Page 5

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:19 AM Page 5

Introduction

This machine is equipped with an

automatic filter cleaning system which is

effective at minimizing filter face loading.

Throughout its operation, the control

monitors the performance level of the

Vac. When a predetermined drop in

performance occurs, the filter cleaning

cycle is initiated. Once the filters have

been cleaned, the machine returns to

monitoring mode until the next cleaning is

needed. When the cleaning cycle

becomes more frequent, or when that

cleaning cycle doesn't seem to return to

monitoring mode, it may be time to empty

the drum and / or manually clean or

replace the two filters.

ote: It is normal to hear a clicking

N

sound during the cleaning cycle.

Note: For this Vac to operate properly,

it must have two cartridge filters installed

at all times.

This Vac is rated for commercial and

household use. This Vac is supplied with

two VF3800 filters. It can be used not

only to pick up material like sawdust and

gravel but also ultra fine material like

drywall dust and concrete dust. These

types of materials are so small they

would pass through traditional filters.

An optional static-dissipating accessory

hose (VT2580) is available for pickup

operations that tend to cause static

charge buildup.

5

Page 6

A

D

B

C

E

F

M

G

I

J

K

N

L

H

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:25 AM Page 6

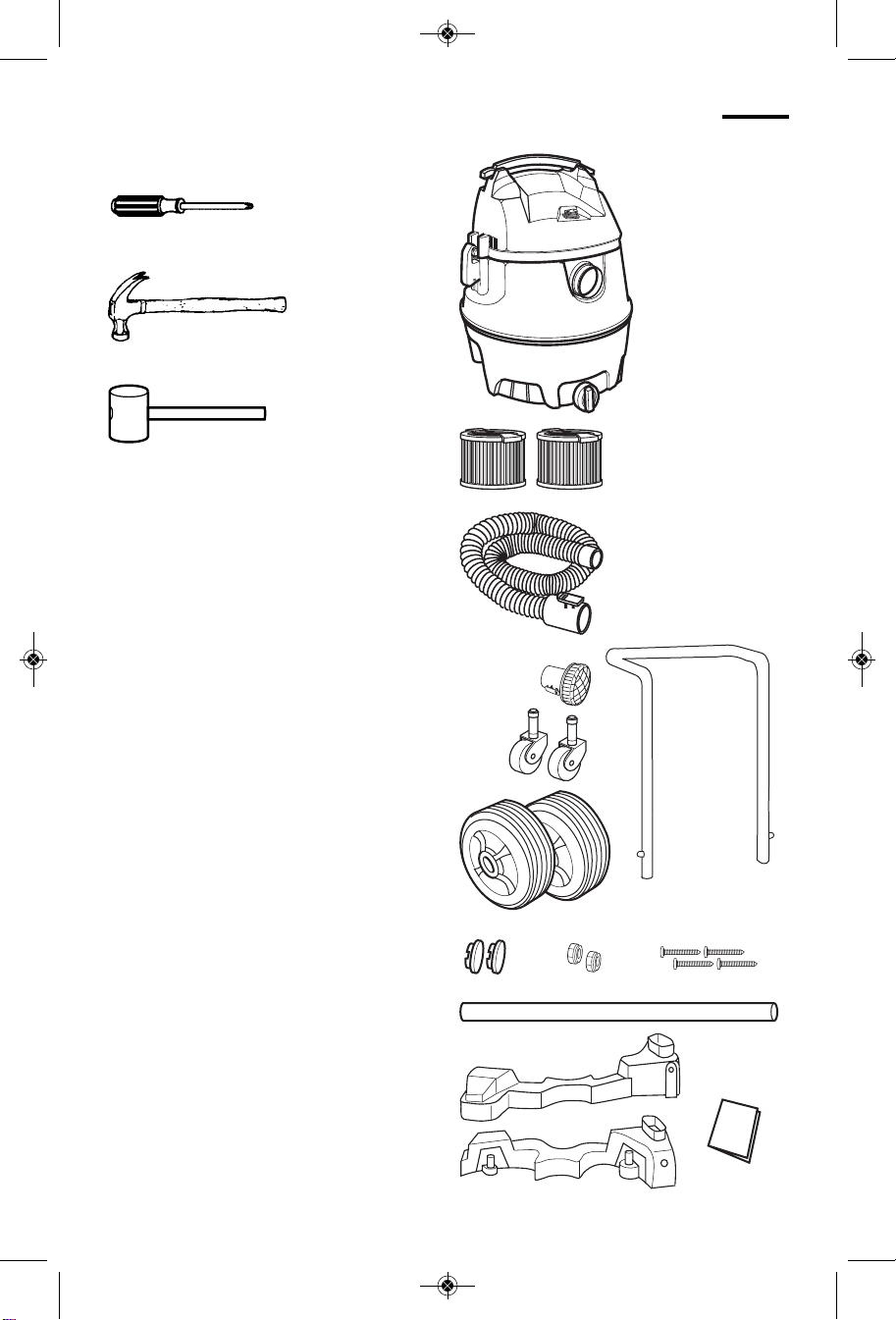

Unpacking and Checking Carton Contents

Tools Required

Phillips Screwdriver

Hammer

Mallet

Refer to the assembly sketch for

positioning of parts.

Remove contents of carton. Check each

item against the Carton Contents List.

Call 1-800-4-RIDGID (1-800-474-3443)

from the US and Canada, or E-mail us at

info@ridgid.com if any parts are damaged

or missing.

Carton Contents List

Key Description Qty

A Wet/Dry Vac Assembly ..................1

B* Filters ............................................2

C 15' ProHose ..................................1

D Muffler/Diffuser ..............................1

E 2” Casters......................................2

F 8” Wheels ......................................2

G Wheel Caps...................................2

H 1/2” Cap Nuts................................2

I #10 x 1-3/4” Screws ......................4

J Axle ...............................................1

K* Caddy, Right..................................1

L* Caddy, Left....................................1

M Metal Handle .................................1

N Owner’s Manual ............................1

* Items may come preassembled.

6

Page 7

Powerhead

Assembly

Tab (2)

Latch (2)

Release

Button

Press Then

Push or Pull

Vac Inlet

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:27 AM Page 7

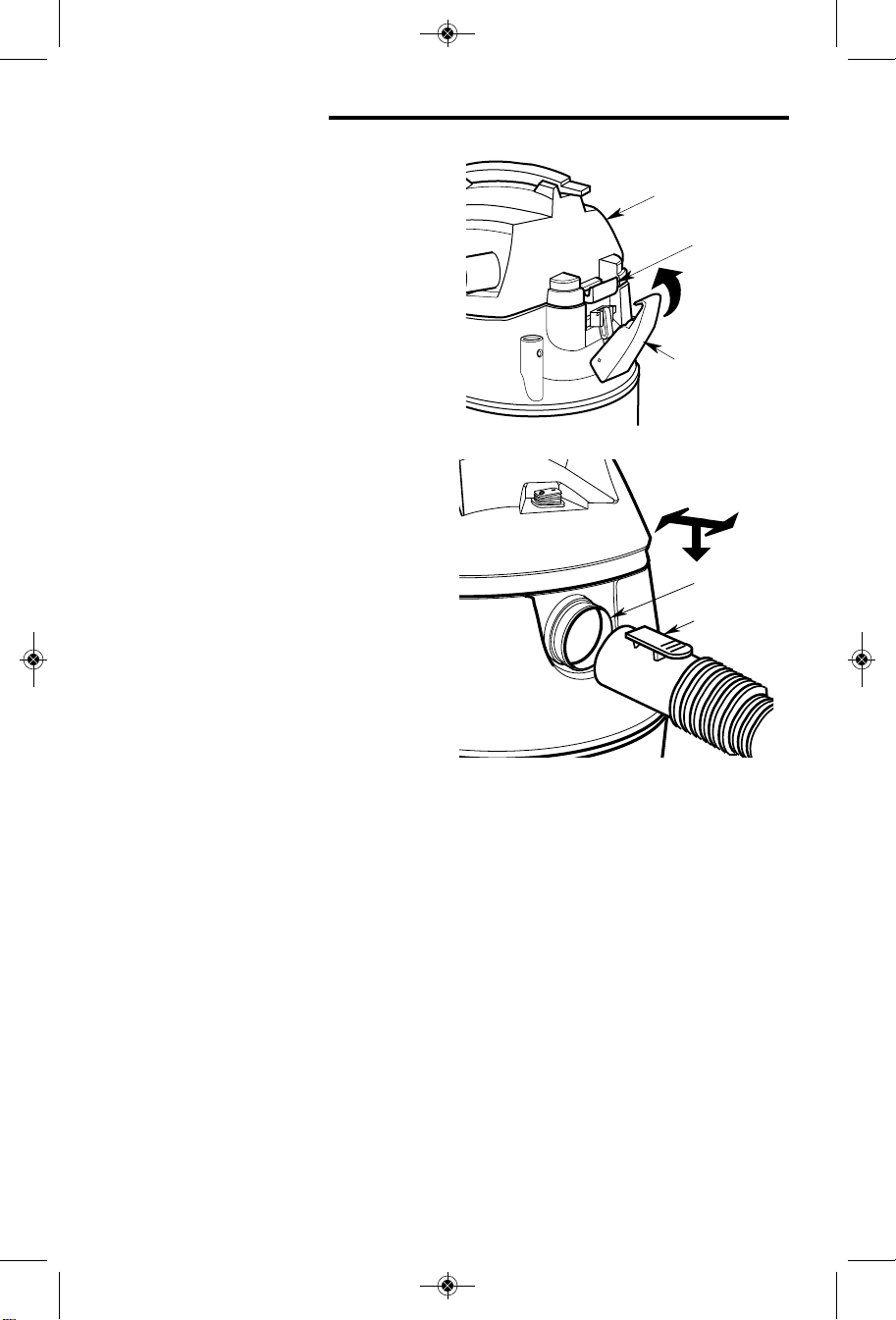

Vac Assembly

1. Position the powerhead assembly on

the drum as shown,

2. Hook the latches over the tabs on the

powerhead assembly.

3. Press the latches down until they

snap closed against the sides of the

tank.

Insert Hose

Insert the push button end of the locking

hose into the inlet of the Vac. The hose

should snap into place.

To remove the hose from the Vac, press

the release button in the hose assembly

and pull the hose out of the Vac inlet,

as shown.

7

Page 8

NOTE: Smooth side of the

wheel to the outside.

Left

Caddy

Drain

Axle

w/Wheel

Right

Caddy

Open

End

Cap

Nut

Right

Caddy

Drain

Left

Caddy

Right

Caddy

Left

Caddy

Drain

#10 x 1-3/4" Screw (4)

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:27 AM Page 8

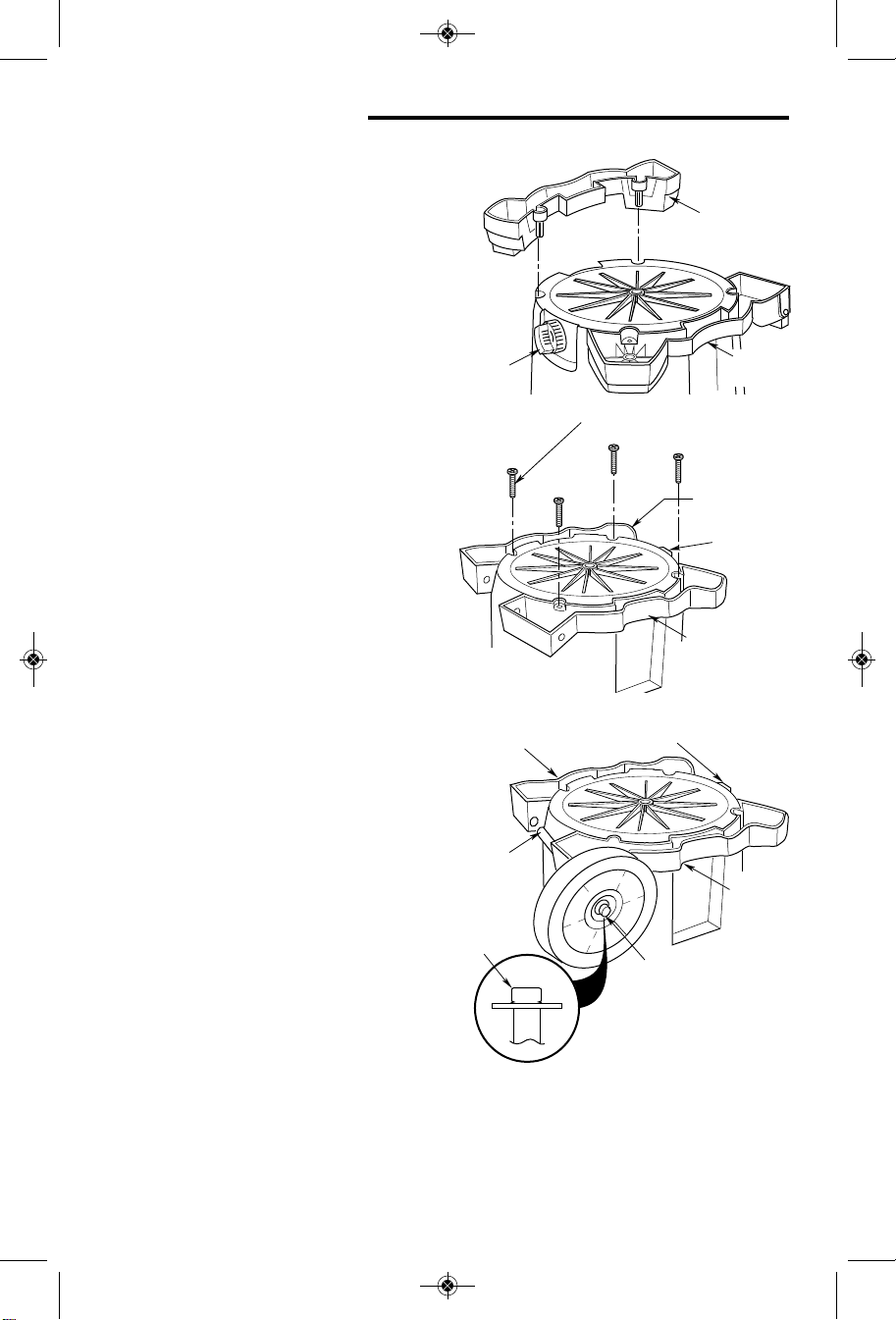

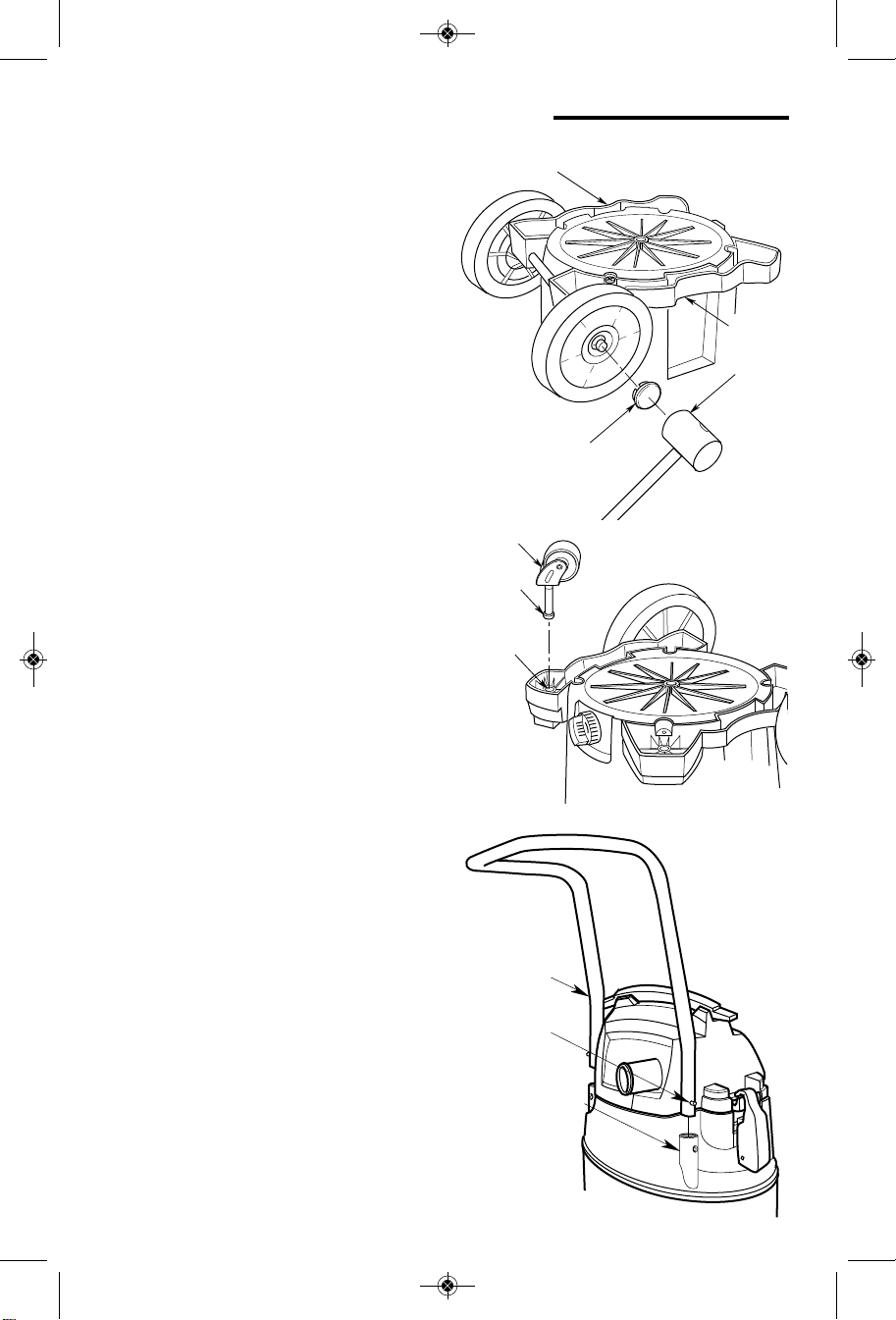

Caddy Assembly

If any parts are missing or damaged

contact Customer Service.

Do not assemble until you have all the

parts.

1. Insert left caddy and right caddy into

the bottom of drum as shown.

Light taps with a mallet or hammer

may be needed to fully seat both

caddies.

2. Install (4) #10 x 1-3/4” screws into

matching holes on both right and left

side of caddy, securing them to the

bottom of the drum. Tighten screws

until just snug. Do not over tighten as

this may tend to deform the caddies.

3. Installing Cap Nut

a. Place cap nut on end of axle.

b. Tap gently with hammer until fully

seated.

c. Place wheel on the axle with

smooth portion of wheel facing

outward.

8

Page 9

Handle

Release

Button (2)

Handle

Receptacle (2)

Mallet

Wheel

Cap

Left Caddy

Right

Caddy

Socket

Caster

Stem

Caster

Ball

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:27 AM Page 9

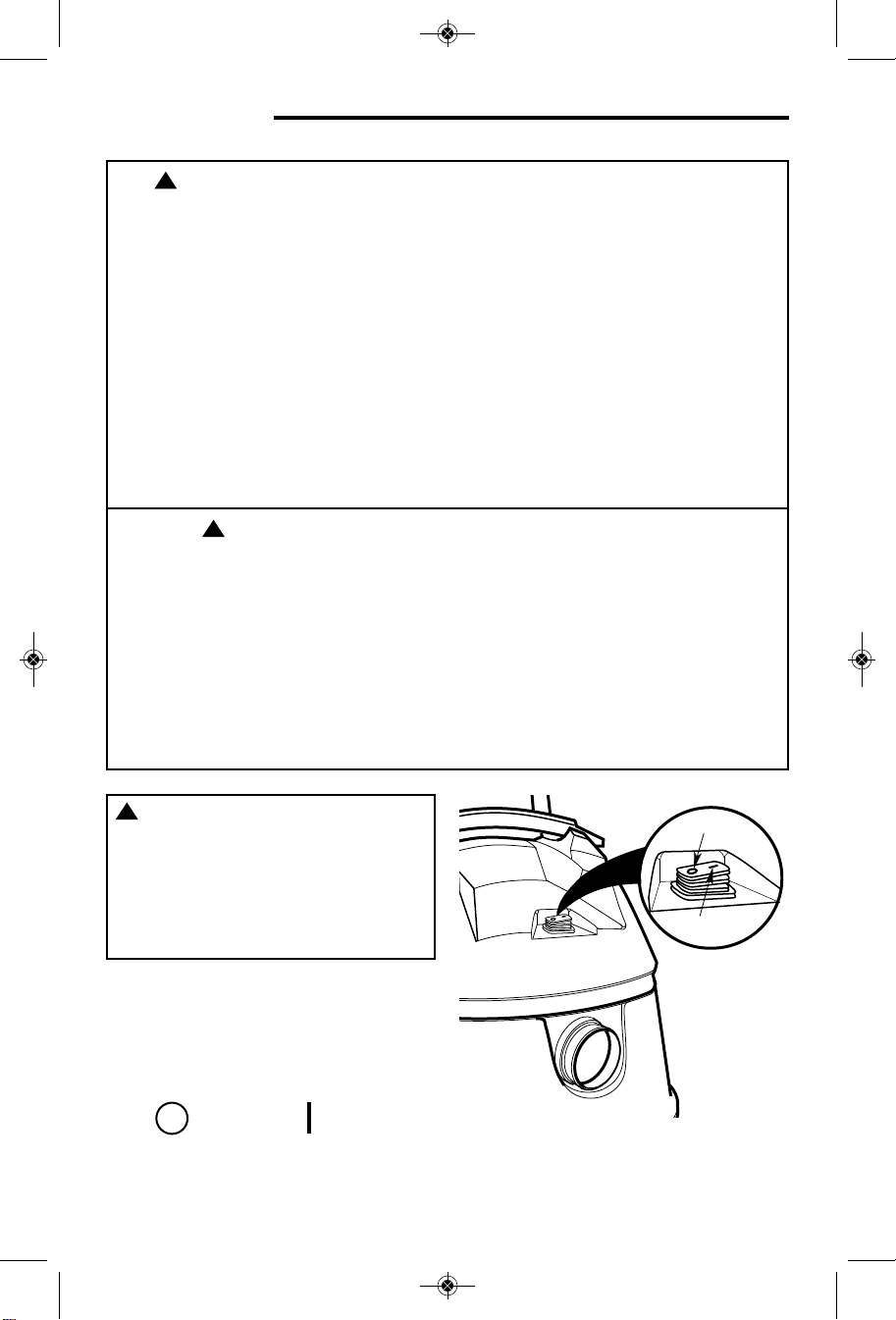

Caddy Assembly (Continued)

4. Slide open end of axle through left

caddy making sure the leg slot lines

up with the cradle hole. Slide all the

way through the right caddy. Light

taps with a mallet may be required to

fully insert axle.

5. Install second wheel onto axle with

smooth portion of wheel facing

outward.

6. Install the second cap nut. Tap gently

until cap nut is firmly seated

7. Using a rubber mallet or hammer,

gently tap the wheel cap onto the

right wheel until the wheel cap is

firmly seated onto the wheel. This is

required on both left and right sides.

8. Insert the caster stem into the socket

of the caster foot as shown. (Front

caster only).

9. Push on the caster until the ball on

Installing Handle

Press and hold release buttons while

installing handle into handle receptacles

in drum (See illustration).

NOTE: An audible snap of release

buttons indicates successful engagement

of handle.

Removing Handle

Press and hold release buttons as

shown. While firmly pushing in release

buttons, pull handle upwards to remove

(see illustration).

the caster stem is inserted all the way

into the socket. You will be able to

hear the ball snap into the socket and

the caster will swivel easily when

positioning is correct.

9

Page 10

"ON"

"OFF"

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:27 AM Page 10

Operation

!

WARNING: To reduce the risk of fire, explosion, or damage to Vac:

• Do not leave Vac running while unattended - you may fail to notice

important signs indicating abnormal operation such as loss of suction,

debris exiting the exhaust, or abnormal motor noises. Immediately stop

using Vac if you notice these signs.

• Do not leave Vac plugged in when not in use.

• Do not continue running when float has cut off suction.

• Sparks inside the motor can ignite airborne flammables. Do not operate Vac

near flammable liquids or in areas with flammable gases, vapors, or

explosive/airborne dust. Flammable liquids, gases, and vapors include:

lighter fluid, solvent-type cleaners, oil-based paints, gasoline, alcohol, and

aerosol sprays. Explosive dusts include: coal, magnesium, aluminum,

grain, and gun powder.

• Do not vacuum up explosive dusts, flammable liquids, or hot ashes.

WARNING: To reduce the risk of electric shock or injury:

!

• Do not expose to rain or allow liquid to enter motor compartment. Store

indoors.

• Do not handle the plug, switch, or Vac with wet hands.

• Unplug Vac before servicing. If your Vac is not working properly, has

missing parts, has been dropped, damaged, left outdoors, or dropped into

water, return it to an independent service center or call customer service.

• When using an extension cord, use only outdoor-rated cords that are in

good condition. Do not allow the connection to come into contact with

liquid.

!

CAUTION: To reduce the risk of

static shocks while using this Vac,

avoid using it in very dry

conditions, or use the optional

static-dissipating accessory hose,

VT2580. Always plug cord into a

properly-grounded outlet.

After you plug the power cord into the

outlet, turn the unit on by pushing the

switch from position "O" to position "l".

The symbols used on the switch actuator

are international "On & Off" symbols.

=

OFF

=

ON

10

Page 11

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:28 AM Page 11

Operation (Continued)

Vacuuming Dry Material

1. The filters must always be in correct

position to reduce the risk of leaks

and possible damage to Vac.

2. Your Vac comes with two VF3800

Filters installed. When using your Vac

to pick up very fine dust, it may be

necessary for you to empty the drum

and clean the filters periodically or

replace the filters to maintain peak

Vac performance.

NOTE: A dry filter is necessary to pick up

dry material. If you use your Vac to pick

up dust when the filter is wet, the filter will

clog quickly and be very difficult to clean.

Optional Dust Collection Bags

Note: This Vacs computer programing

only monitors for blockages in the pleated

filters. Use of the optional Dust Collection

Bag will keep the Smart-Pulse function

from sensing any blockages that occur,

leading to a premature drop in vacuum

performance.

1. The available Dust Collection Bag for

this Vac is catalog number VF3502.

2. The Dust Collection Bag is intended

for cleaning up dry debris ONLY.

3. If the debris being picked up has any

moisture, the bag will absorb the

moisture and may deteriorate very

quickly, making the bag nonfunctional.

4. If you are using your vacuum to pick

up fine dust, the Dust Collection Bag

will make cleanup easier.

Note: Dust Collection Bag MUST be

used in conjunction with a Pleated

Cartridge Filters. Do not overfill the filter

collection bags. The overfilling of these

bags may cause the weight of the

collected debris to tear these bags and/or

make it difficult to remove the bag from

the vacuum’s drum due to its physical

size.

5. Directions for Installation and

Removal of Dust Collection Bags are

printed on the bags.

Vacuuming Liquids

1. Before using your vacuum for wet

pickup, ensure the drum is empty and

free of dust or debris.

2. Remove the filters. With the filter

removed, the float mechanism

activates to prevent water from

entering the motor blower housing.

If the filters are not removed, water

could enter the motor blower housing

which could overload and damage

the motor.

3. When the liquid in the drum reaches

a predetermined level, the float

mechanisms will rise automatically to

cut off air-flow. When this happens,

turn off the Vac, unplug the power

cord, and empty the drum. You will

know that the float has risen because

the Vac airflow ceases and the motor

noise will become higher in pitch,

due to increased motor speed.

IMPORTANT: To reduce the risk of

damage to the Vac, do not run motor with

floats in raised position.

4. After using the Vac to pick up liquids,

the drum must be cleaned out,

and completely dried before use.

The filters must be re-installed before

using your machine to pick up dry

materials.

11

Page 12

Blowing

Outlet

15' Hose

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:28 AM Page 12

Operation (Continued)

Emptying the Drum

WARNING: To reduce the risk of

!

injury from accidental starting,

unplug power cord before emptying

the drum.

WARNING: To reduce the risk of

!

back injury or falls, do not lift a Vac

heavy with liquid or debris. Scoop

or drain enough contents out to

make the Vac light enough to lift

comfortably.

1. The Vac comes equipped with a drain

for ease of emptying liquids. Simply

unscrew the drain cap and lift the

opposite side slightly to empty the

drum.

2 Another option is to remove the

powerhead assembly.

3. Lay powerhead assembly aside on a

clean area while emptying drum.

4. Dump the drum’s contents into the

proper waste disposal container.

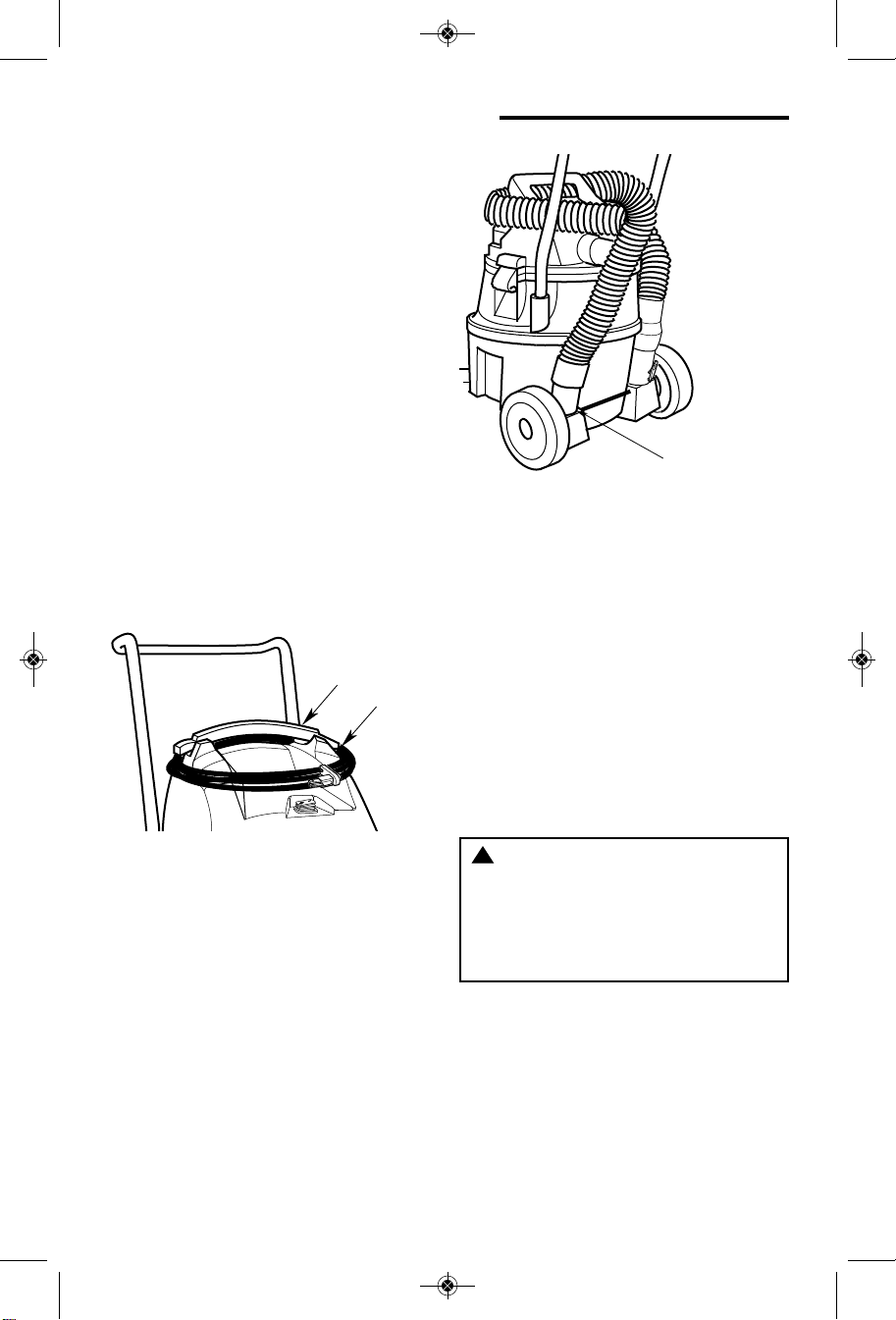

Moving the Wet/Dry Vac

Should it become necessary to pick the

Vac up to move it, the handle on the

sides of the dust drum are used to lift.

To maneuver the Vac, the push/pull

handle in the rear of the unit should be

used.

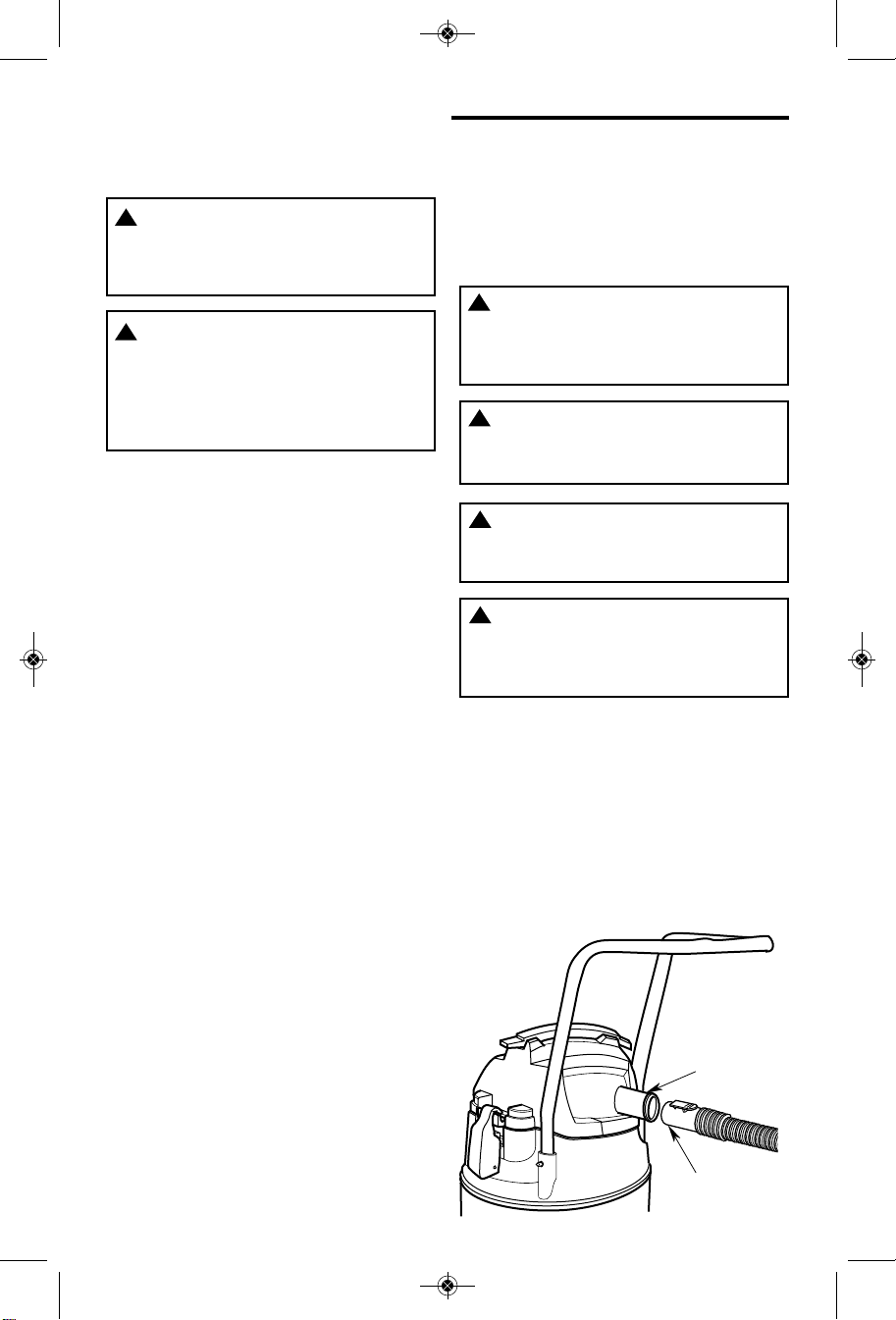

Blowing Feature

Your Vac features a blowing port. It can

blow sawdust and other debris. Follow

the steps below to use your Vac as a

blower.

!

WARNING: Always wear safety

eyewear complying with ANSI Z87.1

(or in Canada, CSA Z94.3) before

using as a blower.

!

WARNING: To reduce the risk of

injury to bystanders, keep them

clear of blowing debris.

!

CAUTION: Wear a dust mask if

blowing creates dust which might

be inhaled.

!

CAUTION: To reduce the risk of

hearing damage, wear ear protectors

when using the Vac/Blower for

extended time or in a noisy area.

1. Locate the blowing outlet of your Vac.

2. Insert the locking end of the hose into

the blowing port of the Vac. The hose

should snap into place. To remove the

hose from the Vac, press the release

button in the hose assembly and pull

the hose out of the Vac inlet.

3. Turn Vac on and you are ready to use

your Vac as a blower.

12

Page 13

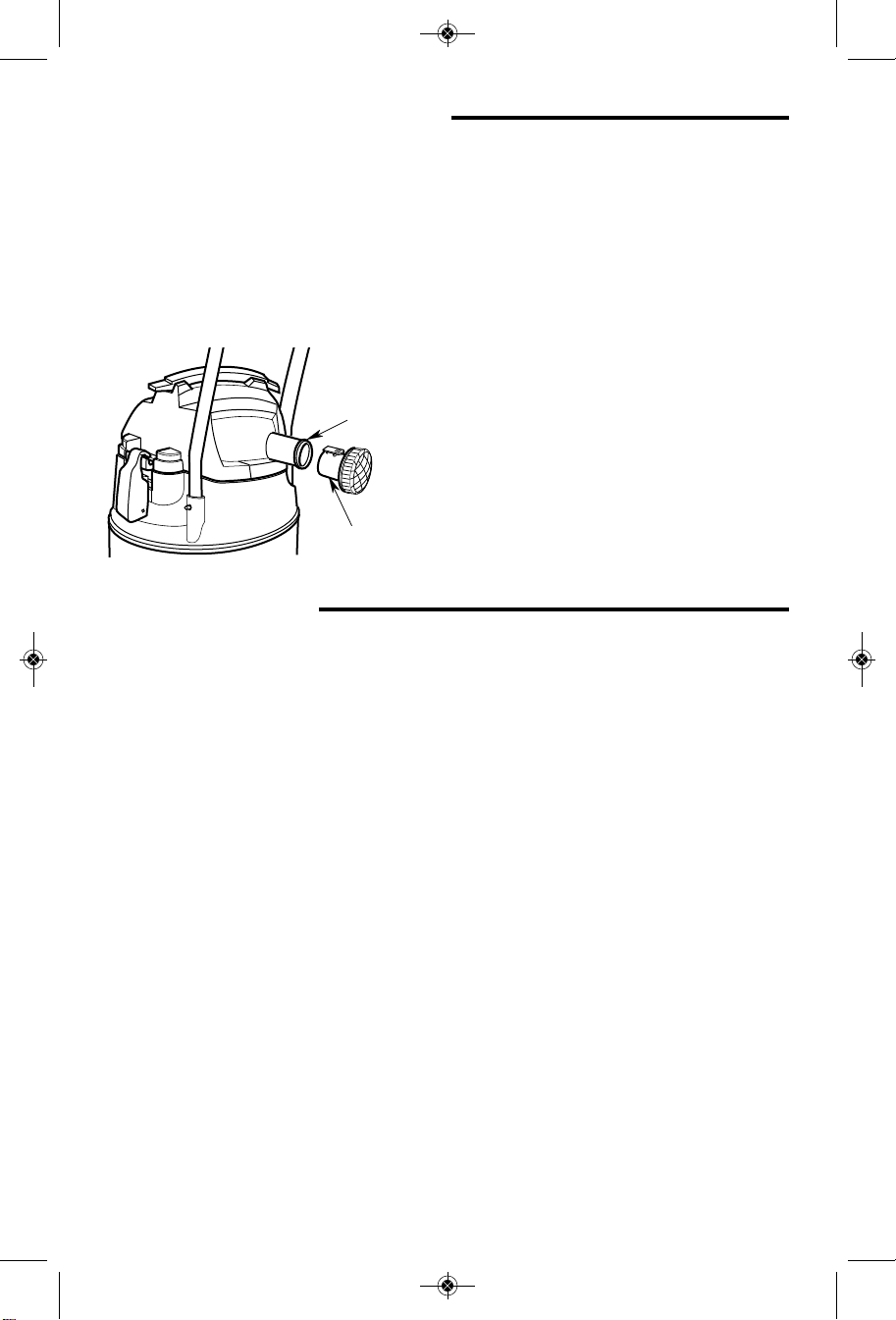

Diffuser

Blowing

Outlet

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:28 AM Page 13

Operation (Continued)

Diffuser

This Vac comes equipped with a diffuser

that can be inserted into the exhaust port

of the vacuum when it’s not being used

as a blower. This diffuser is adjustable

and can be used to change the flow and

direction of the vacuum’s exhaust away

from areas you may not want it blowing.

Static-Dissipating Accessory

Hose

An optional accessory hose, VT2580,

can be used with this Vac to reduce the

effects of static charge buildup. In dry

conditions and when vacuuming large

amounts of fine/dry dust, static charge

can build up on the hose or Vac.

The VT2580 hose will dissipate static

charge, through the ground conductor in

the cord.

Maintenance

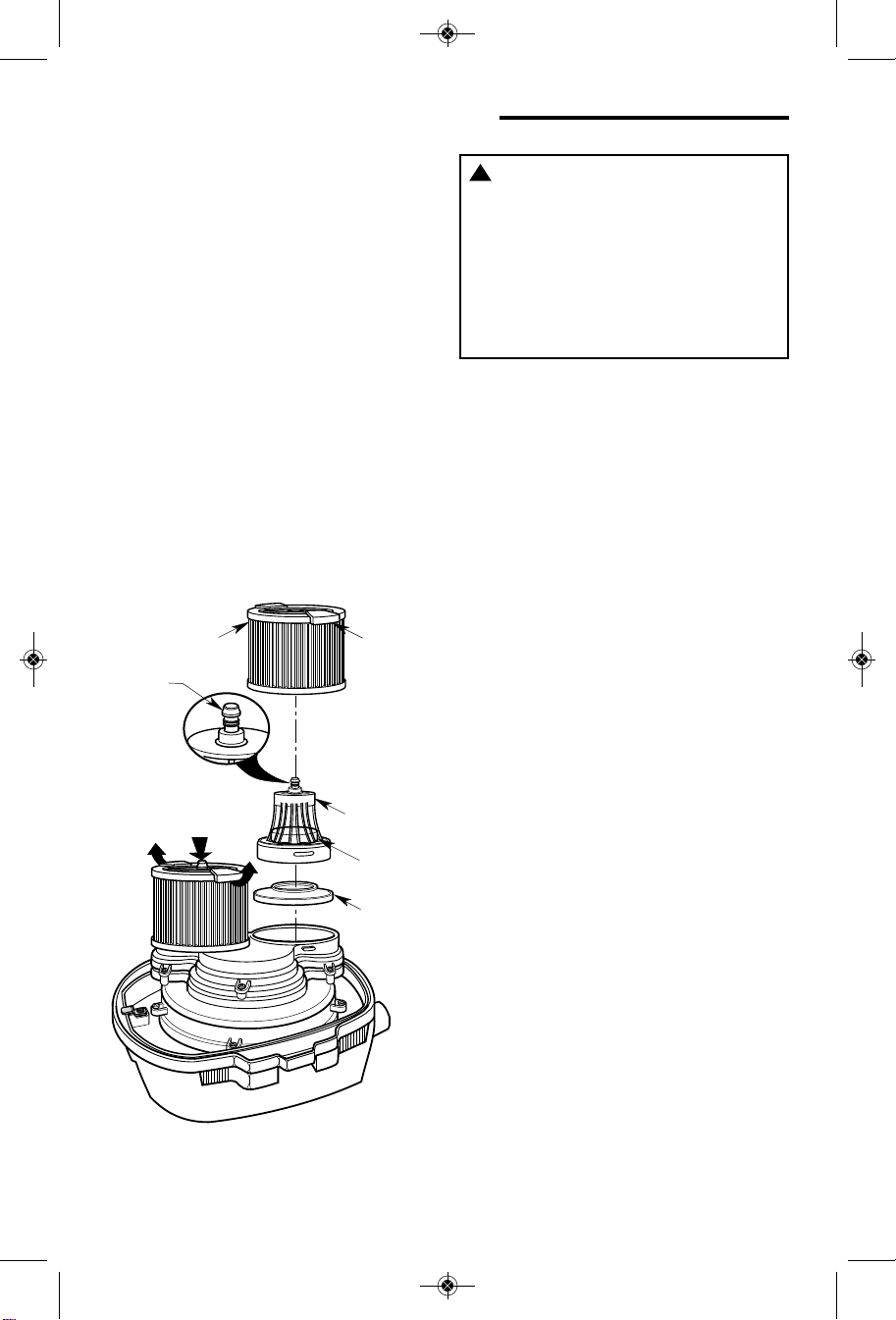

Filter Removal and Installation

This Smart-Pulse vacuum is supplied with

two of the RIDGID’s Qwik Lock™ PTFE

Filters. Replacement Filters are available

where you purchased your Vac. Ask for

the RIDGID Qwik Lock™ Filter VF3800.

NOTE: The filters are made of high

quality material designed to stop very

small particles of dust. The filters can

only be used for dry pick up. Handle the

filters carefully when removing, cleaning,

or installing them. Creases in the filter

pleats may occur from installation but will

not affect the performance of the filter.

of the Qwik Lock™ Filters

Filter Removal:

1. Hold the filter tabs of the Qwik Lock™

filter in each hand.

2. With one thumb on the Qwik Lock™

stud, which protrudes through the

integrated filter plate, lift up on the

filter tabs while pushing down on the

stud.

3. This action will cause the filter to

release from the filter cage. Slide filter

off cage. Repeat for second filter.

13

Page 14

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:28 AM Page 14

Maintenance (Continued)

Filter Installation:

1. Carefully slide the Qwik Lock™ filter

over the filter cage and press down

on the outside edge of the filter until

the rubber gasket on the bottom of

the filter seats securely around the

base of the filter cage and against

the lid.

2. Align the small center hole in the top

of the filter over the Qwik Lock™ stud

on the filter cage. Press firmly on top

of the filter near the stud to allow the

filter to snap over the ball on the end

of the stud. The filter is now

attached. Repeat for second filter.

NOTE: Failure to properly seat the

bottom gasket could result in debris

bypassing the filter.

Qwik-Lock

Filter (2)

Filter

Tab s

Stud

!

WARNING: Do not operate with

no filters or only one filter in place

unless picking up liquid. For liquid

pickup both filters should be

removed. Do not operate without

filter cages, float adapters and

floats, as they prevent liquid from

entering the impeller and damaging

the motor.

IMPORTANT: To avoid damage to the

blower wheel and motor, always reinstall

both filters before using the Vac for dry

material pick-up.

NOTE: For best cleaning results due to

accumulated dust, clean the filters in an

open area. Cleaning SHOULD be done

outdoors and not in the living quarters.

Remove filters from Vac. Gently tap filters

against the inside wall of your dust drum

and the debris will loosen and fall off.

IMPORTANT: After cleaning, check the

filters for tears or small holes. Do not use

filters with holes or tears in it. Even a

small hole can cause a lot of dust to

come out of your Vac. If damaged,

replace filters immediately.

PULL

UP

PUSH

DOWN

Filter

Cage (2)

Float (2)

Float

Adapter

(2)

Cleaning and Disinfecting

the Vac

To keep your Vac looking its best, clean

the outside with a cloth dampened with

warm water and mild soap.

To clean the drum:

1. Dump debris out.

2. Wash drum thoroughly with warm

water and mild soap.

3. Wipe out with dry cloth.

Before prolonged storage or as needed

the drum should be disinfected.

14

Page 15

Power

Cord

Pull

Handle

Hose Storage

Area

H

O

S

E

S

T

O

RA

G

E

H

O

S

E

S

T

O

R

A

G

E

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:28 AM Page 15

Maintenance (Continued)

To disinfect the drum:

1. Pour 1 gallon of water and

1 teaspoon of chlorine bleach

into the drum.

2. Let solution stand for 20 minutes,

carefully swishing every few minutes,

making sure to wet all inside surfaces

of the drum.

3. Empty drum after 20 minutes. Rinse

with water until bleach smell is gone.

Allow drum to dry completely before

sealing the motor on the drum.

Cord Maintenance

When vacuuming is complete, unplug the

cord and wrap it around the motor cover.

If the power cord is damaged, it must be

replaced by the manufacturer or their

service agent or by similarly qualified

personnel to reduce the risk of accident.

Casters and Wheels

Should your cart squeak or become hard

to roll, you should place two or three

drops of general purpose oil on each

wheel at the axle. If your casters are

noisy, you may put a drop of oil on the

roller shaft to make them quieter.

Storage

Before storing your Vac, the drum should

be emptied and cleaned. The cord should

be wrapped around the unit. The hose

may be stored by wrapping it around the

unit and plugging the open end into one

of the storage locations on the caddy

assembly. The Vac should be stored

indoors.

Frame and Handles

Your metal handle is painted to prevent

rust, however, liquids and corrosive

debris should be wiped off with a soft

cloth should they come in contact with

the handle.

!

WARNING: To assure product

SAFETY and RELIABILITY, any

other repairs and adjustments

should be performed by Authorized

Service Centers, always using

RIDGID replacement parts.

15

Page 16

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:28 AM Page 16

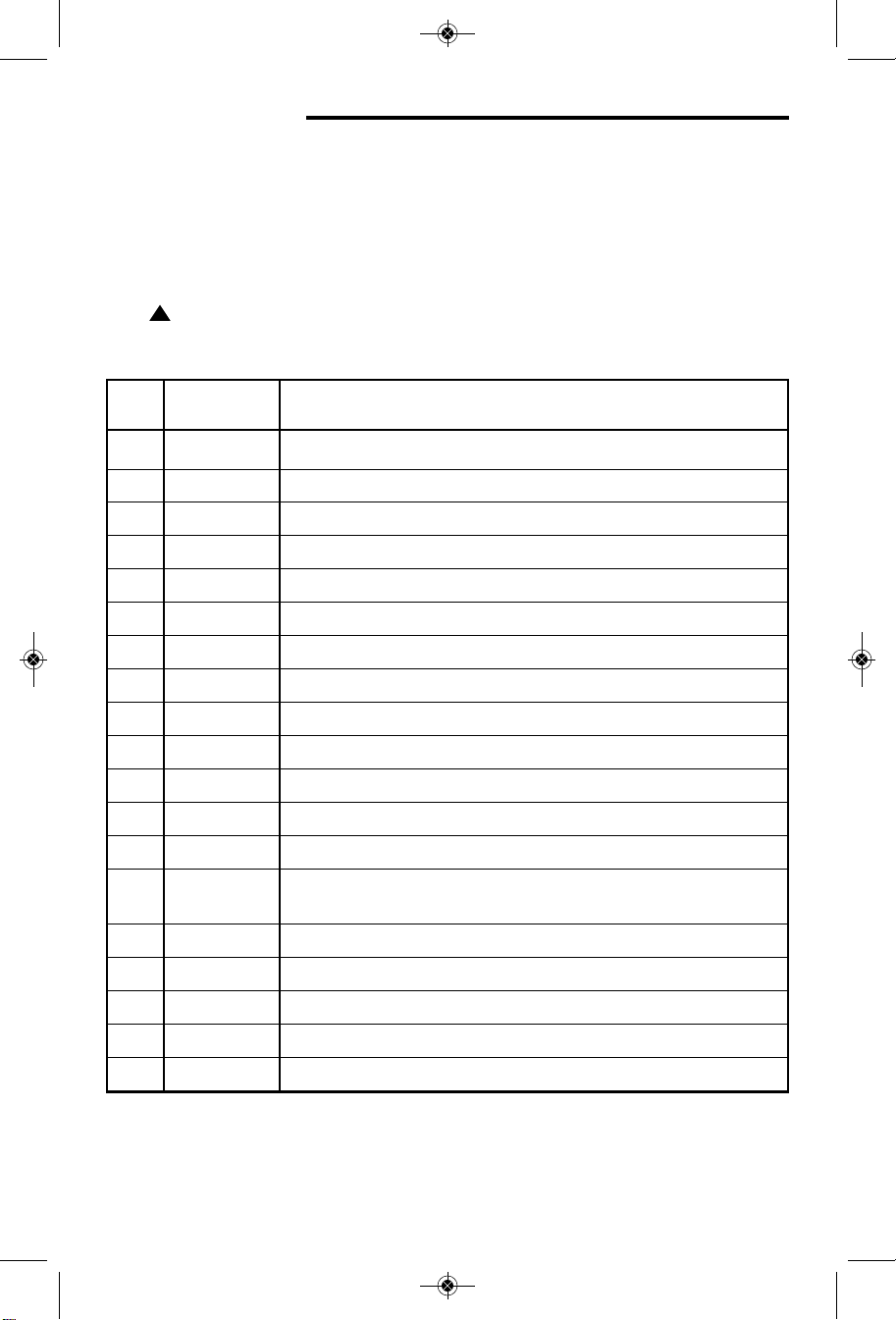

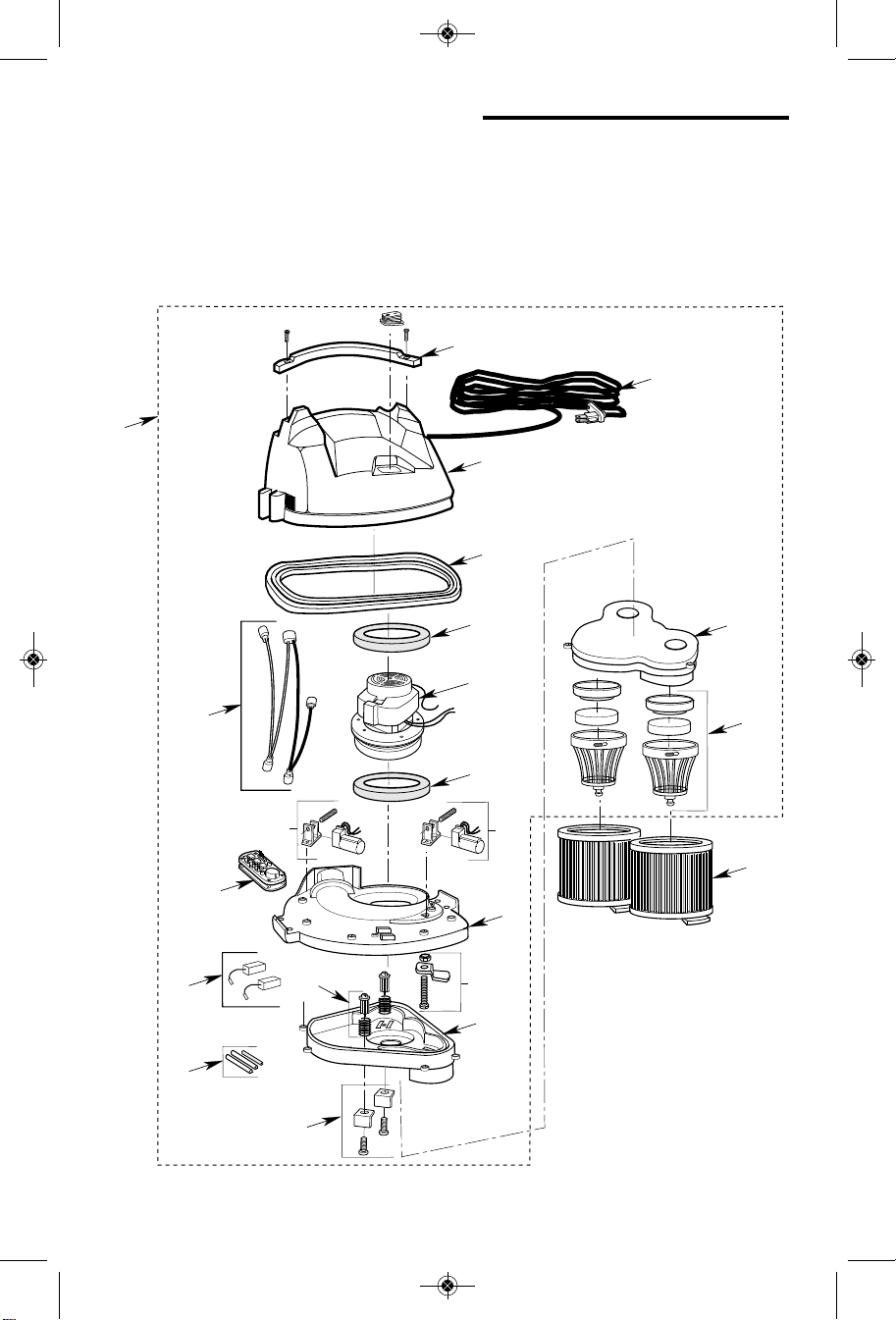

Repair Parts

14 U.S. Gallon

Smart-Pulse Vacuum

Stock Number RV3410 (Model RV34100)

RIDGID parts are available on-line at www.ridgidparts.com

Always order by Part Number - Not by Key Number

WARNING: To reduce the risk of injury from electrical shock, unplug power

!

cord before servicing the electrical parts of the Vac.

Key RV3410

No. Part No. Description

1* 510322 Powerhead Assembly (Includes Key Numbers 2 - 18)

2 831657-3 Cord Assembly

3 510321 Motor Cover Assembly

4 835195-2 Carry Handle

5 833518 Gasket For Upper Lid

6 827415 Gaskets (2 Required)

7 831567 Motor

8 510320 Wiring Harness (Power/Grounding)

9 510325 Actuator w/ Bracket (2 Required)

10 835193-2 Upper Lid

11 510318 Control Module

12 822374-8 Motor Brush Kit (1 Set)

13 835191 Lower Lid

14 510324 Valve Assembly

(Stem, Spring, Screw, Valve w/ Gasket - Includes 2 Each)

15 510319 Tubes (Set of 3)

16 510336 Grounding Spring Assembly

17 835194 Manifold

18 510332 Filter Cage Assembly (1 Filter Cage, 1 Float, 1 Float Adapter)

19 VF3800 Filters (2 Required)

* All parts are included in the Powerhead Assembly (#1) (except for the 2 Filters).

16

Page 17

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:28 AM Page 17

Repair Parts (Continued)

14 U.S. Gallon

Smart-Pulse Vacuum

Stock Number RV3410 (Model RV34100)

RIDGID parts are available on-line at www.ridgidparts.com

4

1*

3

5

2

12

15

8

11

9

14

14

6

7

6

16

13

17

18

9

19

10

17

Page 18

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:28 AM Page 18

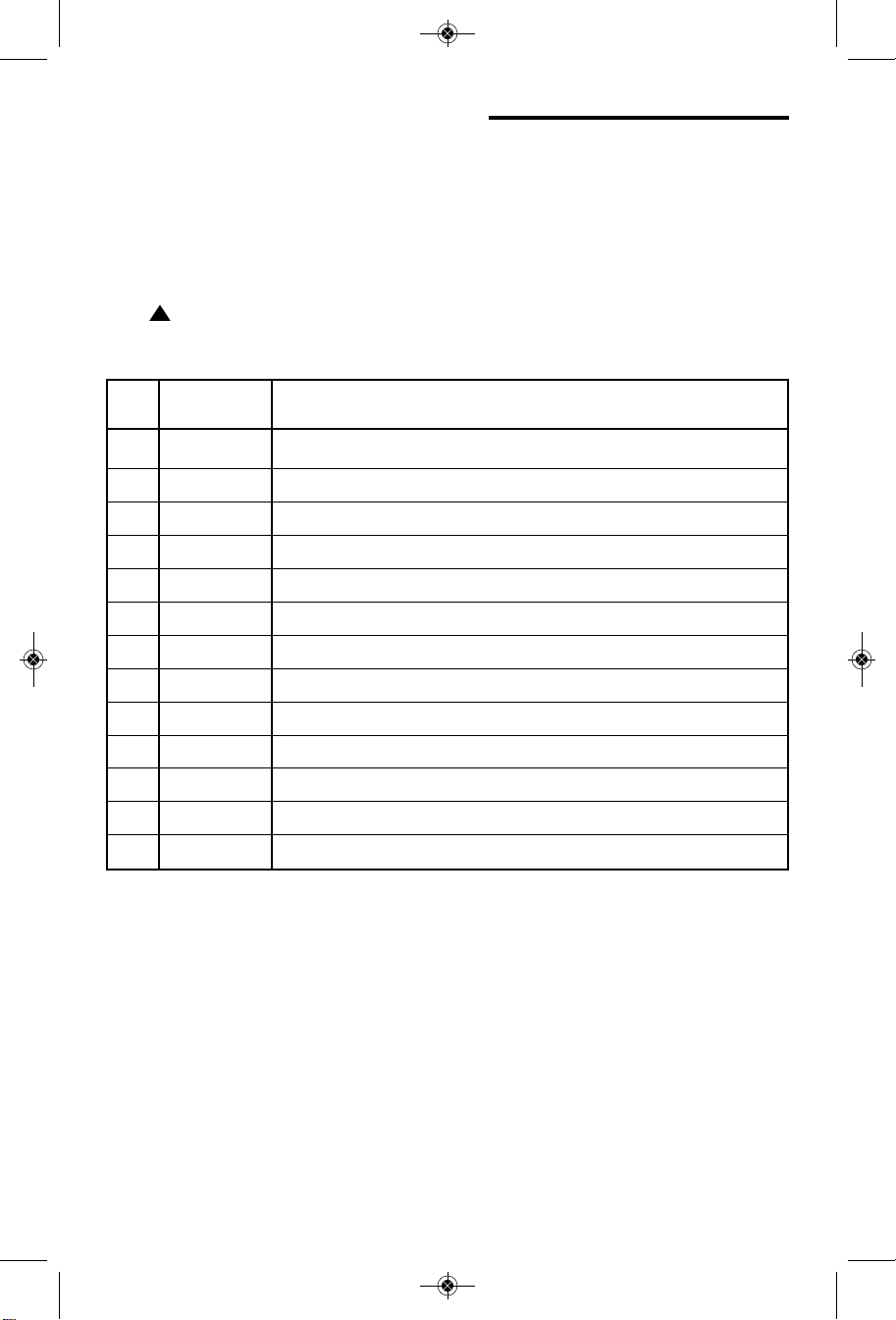

Repair Parts (Continued)

14 U.S. Gallon

Smart-Pulse Vacuum

Stock Number RV3410 (Model RV34100)

RIDGID parts are available on-line at www.ridgidparts.com

Always order by Part Number - Not by Key Number

WARNING: To reduce the risk of injury from electrical shock, unplug power

!

cord before servicing the electrical parts of the Vac.

Key RV3410

No. Part No. Description

20 830686 Drum Handle Assembly

21 510323 Drum Assembly

22 510333 Drum Latch Assembly (Complete Set)

23 832123 Casters (2 Required)

24 831337-11 15’ Hose Assembly

25 VT2580 Static-Dissipating 15’ Hose (Optional)

26 509944 Loose Parts Bag (Wheel Caps, 1/2” Cap Nuts, #10 x 1-3/4” Screws)

27 832190 8" Wheels (2 Required)

28 831024 Shaft (1)

29 830577 Left Caddy

30 830576 Right Caddy

31 830675-2 Diffuser

32 SP6906 Owner’s Manual

18

Page 19

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:28 AM Page 19

Repair Parts (Continued)

14 U.S. Gallon

Smart-Pulse Vacuum

Stock Number RV3410 (Model RV34100)

RIDGID parts are available on-line at www.ridgidparts.com

20

24

22

26

26

27

31

26

26

28

23

26

29

21

26

27

26

25

26

26

30

23

32

19

Page 20

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:28 AM Page 20

• What is covered

RIDGID®Wet/Dry Vacs are warranted to be free of defects in workmanship and material.

• How long coverage lasts

This warranty lasts for the lifetime of the RIDGID®Wet/Dry Vac.

• How to obtain service

To obtain the benefit of this warranty, deliver via prepaid transportation the complete product to

RIDGE TOOL COMPANY, Elyria, Ohio, or any authorized RIDGID® INDEPENDENT SERVICE

CENTER. Pipe wrenches and other hand tools should be returned to the place of purchase.

• What we will do to correct problems

Warranted Wet/Dry Vacs will be repaired or replaced, at Ridge Tool Company's option, and returned

at no charge; or, if after three attempts to repair or replace during the warranty period the Wet/Dry

Vac is still defective, you can elect to receive a full refund of your purchase price.

• What is not covered

Failures due to misuse, abuse or normal wear and tear are not covered by this warranty. RIDGE

TOOL COMPANY SHALL NOT BE RESPONSIBLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

• How local laws relate to the warranty

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty gives you specific rights, and you

may also have other rights which vary from state to state, province to province, or country to

country.

• No other express warranty applies

This FULL LIFETIME WARRANTY is the sole and exclusive warranty for RIDGID®Wet/Dry Vacs.

No employee, agent, dealer, or other person is authorized to alter this warranty or make any other

warranty on behalf of Ridge Tool Company.

Stock No. RV3410

Model No. RV34100

Model and serial number may be found near the blowing port. You should record both

model and serial numbers in a safe place for future use.

QUESTIONS OR COMMENTS? CONTACT US AT

www.ridgidvacs.com

In the U.S. and Canada, Call 1-800-4-RIDGID

In Mexico, Call 01-800-701-9811

Please have your Model Number and Serial Number on hand when calling.

c 2014 Emerson

Part No. SP6906 Form No. SP6906 Printed in Mexico 11/14

Page 21

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:19 AM Page 21

MANUAL DEL USUARIO

ASPIRADORA SMART-PULSE

DE 14 GALONES

RV34100

¿PREGUNTAS O COMENTARIOS? COMUNÍQUESE CON NOSOTROS EN

www.ridgidvacs.com

1-800-4-RIDGID (1-800-474-3443) desde los EE.UU. y Canadá

01-800-701-9811 desde México

ADVERTENCIA:

!

Para reducir el riesgo de lesiones, el usuario debe leer y entender el manual del operador antes

de utilizar este producto.

Gracias por comprar un producto RIDGID.

• Français - page 41

GUARDE ESTE MANUAL PARA REFERENCIA FUTURA

No. de pieza SP6906 Impreso en México

Page 22

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:19 AM Page 22

Indice

ección Página

S

Instrucciones de seguridad importantes . . . . . . . . . 22

Palabras de señal de seguridad . . . . . . . . . . . . . 22

Instrucciones de conexión a tierra . . . . . . . . . . . . 24

Introducción . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Comprobación del contenido

de la caja de cartón. . . . . . . . . . . . . . . . . . . . . . 26

Ensamblaje de la aspiradora . . . . . . . . . . . . . . . . 27

Ensamblaje del base de soporte . . . . . . . . . . . 28-29

Funcionamiento . . . . . . . . . . . . . . . . . . . . . . . . 30-32

Recogida de materiales secos

con la aspiradora . . . . . . . . . . . . . . . . . . . . . . . 31

Sección Página

Bolsas de recolección de polvo opcionales. . . . 31

Recogida de líquidos con la aspiradora . . . . . . . 31

Vaciado del tambor . . . . . . . . . . . . . . . . . . . . . . 32

Dispositivo de soplado . . . . . . . . . . . . . . . . . . . 32

Traslado de la aspiradora para mojado/seco . . 32

Difusor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Manguera accesoria disipadora

de electricidad estática . . . . . . . . . . . . . . . . . 33

Mantenimiento. . . . . . . . . . . . . . . . . . . . . . . . . 33-35

Piezas de repuesto . . . . . . . . . . . . . . . . . . . . . 36-39

Garantía. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

La seguridad es una combinación de sentido común,

permanecer alerta y saber cómo funciona la aspiradora

para mojado/seco (“la aspiradora”).

Palabras de señal de seguridad

!

PELIGRO: indica una situación peligrosa que,

si no se evita, causará la muerte o lesiones graves.

!

ADVERTENCIA: indica una situación peligrosa

que, si no se evita, podría causar la muerte o lesiones

graves.

!

PRECAUCIÓN: indica una situación peligrosa

que, si no se evita, pudiera causar lesiones leves o

moderadas

Cuando utilice la aspiradora, siga siempre las

precauciones básicas de seguridad, incluyendo

las siguientes:

!

ADVERTENCIA

– Para reducir el riesgo de incendio,

sacudidas eléctricas o lesiones:

• Lea y entienda este manual del usuario y todas las

etiquetas que están colocadas en la aspiradora para

mojado/seco antes de utilizarla.

• Utilice la aspiradora únicamente de la manera que

se describe en este manual.

• No deje la aspiradora en marcha mientras esté

desatendida. Usted podría no notar señales

importantes que indiquen un funcionamiento

anormal, tal como pérdida de succión, residuos o

líquido que salen por el escape o ruidos anormales

del motor. Deje de usar la aspiradora inmedia tamente si observa estas señales.

• No abandone la aspiradora cuando esté enchufada.

Desenchúfela del tomacorriente cuando no la esté

utilizando y antes de realizar servicio de revisión.

• Las chispas que se producen en el interior del motor

pueden incendiar los vapores inflamables o el polvo.

Para reducir el riesgo de incendio o explosión: No

use la aspiradora cerca de líquidos

o gases inflama bles o combustibles, o polvos

explosivos como gasolina u otros combustibles,

líquido encen dedor, limpiadores, pinturas a base de

aceite, gas natural, hidrógeno, polvo de carbón,

polvo de magnesio, polvo de aluminio, polvo de

granos de cereal o pólvora.

• No recoja con la aspiradora nada que esté ardiendo

o humeando, como cigarrillos, fósforos o cenizas

calientes.

• Esta aspiradora no está diseñada para realizar

limpieza conforme a la regla sobre renovación,

reparación y pintura (RRP) de la EPA.

• Es posible que las partículas sumamente pequeñas

pasen a través del filtro. Use siempre equipo

protector de seguridad adecuado.

• Para reducir el riesgo de inhalar vapores tóxicos,

no recoja con la aspiradora materiales tóxicos o

peligrosos ni la use cerca de dichos materiales.

• Para reducir el riesgo de descargas eléctricas, no

exponga la aspiradora a la lluvia ni deje que entren

líquidos en el compartimiento del motor. Guarde la

aspiradora en un lugar interior.

• No permita que la aspiradora se utilice como un

juguete. Se necesita prestar máxima atención

cuando sea utilizada por niños o cerca de éstos.

• No use la aspiradora con un filtro desgarrado o sin

tener el filtro instalado, excepto cuando recoja con

ella líquidos de la manera que se describe en este

manual. Los residuos secos absorbidos por el

impulsor podrían dañar el motor o ser expulsados

de vuelta al aire.

• Apague la aspiradora antes de desenchufarla.

• Para reducir el riesgo de lesiones debidas a un

arranque accidental, desenchufe el cordón de

energía antes de cambiar o limpiar el filtro.

• No desenchufe la aspiradora tirando del cordón.

Para desenchufarla, agarre el enchufe y no el

cordón.

• No use la aspiradora con el cordón dañado, el

enchu fe dañado u otras piezas dañadas. Si la

aspira dora no funciona como debe, le faltan piezas,

se ha caído, ha sido dañada, se ha dejado a la

intem perie o se ha caído al agua, llame a servicio

al cliente.

• No tire de la aspiradora usando el cordón ni la lleve

por el cordón, ni use el cordón como asa, ni cierre

22

Page 23

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:19 AM Page 23

una puerta sobre el cordón, ni tire del cordón alre dedor de bordes o esquinas afilados. No pase la

aspiradora en marcha sobre el cordón. Mantenga el

cordón alejado de las superficies calientes.

• No maneje el enchufe, el interruptor o la aspiradora

con las manos mojadas.

• Use sólo cordones de extensión conectados a

tierra homologados para uso a la intemperie.

Los cordones de extensión que estén en malas

condiciones o tengan un tamaño de alambre

demasiado pequeño pueden crear peligros de

incendio y descargas eléctricas. Para reducir el

riesgo de estos peligros, asegúrese de que el

cordón esté en buenas condiciones y que el líquido

no entre en contacto con la conexión. No utilice un

cordón de extensión que tenga conductores con un

diámetro menor al calibre 16 (AWG). Para reducir la

pérdida de potencia, utilice un cordón de extensión

de calibre 14 si la longitud es de 25 a 50 pies, y de

calibre 12 si la longitud es de 50 pies o más.

• No ponga ningún objeto en las aberturas de venti lación. No recoja nada con la aspiradora cuando

cualquiera de las aberturas de ventilación esté

bloqueada; mantenga dichas aberturas libres de

polvo, pelusa, pelo o cualquier cosa que pueda

reducir el flujo de aire.

• Mantenga el pelo, la ropa holgada, los dedos y

todas las partes del cuerpo alejados de las aber turas y de las piezas móviles.

• Para reducir el riesgo de caídas, tenga cuidado

adicional al limpiar en escaleras.

• Para reducir el riesgo de lesiones de espalda o

caídas, no levante una aspiradora que pese mucho

debido a que contiene líquido o residuos. Saque

parte del contenido de la aspiradora o drénela

parcialmente.

• Para reducir el riesgo de lesiones corporales o

daños a la aspiradora, utilice únicamente

accesorios recomendados por Ridgid.

• Cuando utilice la aspiradora como soplador :

- Dirija la descarga de aire solamente hacia el área

de trabajo.

- No dirija el aire hacia las personas que estén

presentes.

- Mantenga alejados a los niños durante la

operación de soplado.

- No utilice el soplador para trabajos que no sean

soplar suciedad y residuos.

- No use la aspiradora como rociador.

- Use protección ocular de seguridad.

• Para reducir el riesgo de lesiones en los ojos, use

pro tección ocular de seguridad. La utilización de

cual quier aspiradora utilitaria o soplador utilitario

puede hacer que se soplen objetos extraños hacia

los ojos, lo cual puede causar daños graves en

los ojos.

• Para reducir el riesgo de que una aspiradora rodante

le golpee o tire de usted, bloquee las ruedecillas

cuando utilice la unidad en cualquier superficie

desigual o en pendiente.

• Conecte la aspiradora solamente a un toma corriente

conectado a tierra adecuada mente. Consulte las

instrucciones de conexión a tierra.

!

PRECAUCIÓN:

• Para reducir el riesgo de daños a la audición, use

protectores de oídos cuando utilice la aspiradora

durante muchas horas seguidas o cuando la

emplee en un área ruidosa.

• Para operaciones que generan polvo, use una

máscara antipolvo.

• Las descargas de estática son comunes cuando

la humedad relativa del aire es baja. Si recoge

residuos finos con la aspiradora, se puede

depositar carga estática en la manguera o en la

aspiradora. El mejor remedio para reducir la

frecuencia de las descargas de estática en su casa

o cuando use esta aspiradora es añadir humedad

al aire con un humidificador.

Siga las siguientes advertencias que aparecen en la

caja del motor de la aspiradora.

!

ADVERTENCIA: Para su propia seguridad,

lea y entienda el manual del operador.

No tenga en marcha la aspiradora desatendida.

No recoja cenizas calientes, carbón caliente,

materiales tóxicos ni inflamables ni otros

materiales peligrosos. No use la aspiradora

alrededor de líquidos o vapores explosivos.

ADVERTENCIA: Para reducir el riesgo de

!

sacudidas eléctricas, no exponga la aspiradora

a la lluvia y almacénela en interiores.

!

PRECAUCIÓN: Para reducir el riesgo de

descargas de electricidad estática, use la

manguera disipadora de electricidad estática

VT2580.

GUARDE ESTE MANUAL

23

Page 24

Properly

Grounded

Outlet

Grounding

Prong

3-Prong

Plug

Make sure this is a

metal screw connected

to a known ground

Green

Grounding Lug

2-Prong Outlet

3-Prong Plug

Adapter

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:19 AM Page 24

Instrucciones de conexión a tierra

Este electrodoméstico se debe conectar a tierra. En

caso de mal funcionamiento o avería, la conexión a

tierra proporciona una ruta de resistencia mínima

para la corriente eléctrica con el fin de reducir el

riesgo de sacudidas eléctricas. Este electro doméstico está equipado con un cordón que tiene

un conductor de conexión a tierra del equipo y un

enchufe de conexión a tierra. El enchufe debe

introducirse en un tomacorriente apropiado que

esté instalado correctamente y conectado a tierra

adecuadamente, de acuerdo con todos los códigos

y ordenanzas locales.

!

ADVERTENCIA:

La conexión incorrecta del conductor de

conexión a tierra del equipo puede causar

un riesgo de sacudidas eléc tricas.

Consulte a un electricista calificado o a

una persona de servicio compe tente si

tiene dudas sobre si el tomacorriente está

conectado a tierra apropiadamente. No

modifique el en chufe suministrado con el

electrodoméstico. Si el enchufe no cabe

en el tomacorriente, haga que un

electricista calificado instale un

tomacorriente apropiado.

Este electrodoméstico está diseñado para utilizarse

en un circuito de 120 V nominales y tiene un

enchufe conectado a tierra que tiene un aspecto

como el del enchufe que se muestra en la

ilustración. Se puede utilizar un adaptador

temporal, que tenga un aspecto como el del

adaptador que se muestra en la ilustración, para

conectar este enchufe a un receptáculo de dos

polos, de la manera que se muestra en la ilus tración, si no se dispone de un tomacorriente

conectado a tierra apropiadamente. El adaptador

temporal debe utilizarse únicamente hasta que un

electricista calificado pueda instalar un toma corriente conectado a tierra apropiada mente.

Asegúrese de que esto sea un

tornillo metálico conectado a

una toma de tierra conocida

Tomacorriente para

2 terminales

Orejeta verde

de conexión a tierra

Adaptador

Enchufe de

3 terminales

Tomacorriente

conectado a tierra

apropiadamente

Enchufe de

3 terminales

Terminal de conexión

a tierra

La orejeta, lengüeta o pieza similar rígida de color

verde que sobresale del adaptador se debe

conectar a una toma de tierra permanente, como

por ejemplo una tapa de caja tomacorriente

conectada a tierra apropiadamente. Siempre que se

utilice el adaptador, se debe sujetar en la posición

correcta con un tornillo metálico.

NOTA: En Canadá, el uso de un adaptador temporal

no está permitido por el Código Eléctrico

Canadiense.

24

Page 25

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:19 AM Page 25

Introducción

Esta máquina está equipada con un sistema de

limpieza automática de los filtros que es efectivo

para minimizar la carga en la cara de los filtros.

Durante el funcionamiento de la aspiradora, el

control monitorea el nivel de rendimiento de la

misma. Cuando ocurre un descenso

predeterminado del rendimiento, se inicia el ciclo

de limpieza de los filtros. Una vez que los filtros

se hayan limpiado, la máquina regresará al modo

de monitoreo hasta que se necesite realizar la

próxima limpieza. Cuando el ciclo de limpieza se

vuelva más frecuente, o cuando ese ciclo de

limpieza no parezca regresar al modo de

monitoreo, puede que sea momento de vaciar el

tambor y/o limpiar o reemplazar manualmente los

dos filtros.

Nota: Es normal oír un chasquido durante el ciclo

de limpieza.

Nota: Para que esta aspiradora funcione

orrectamente, debe tener dos filtros de cartucho

c

instalados en todo momento.

Esta aspiradora tiene capacidad nominal para uso

comercial y doméstico. Esta aspiradora se

suministra con dos filtros VF3800. Se puede usar

no sólo para recoger material como aserrín y

grava, sino también para recoger material

ultrafino, como por ejemplo polvo de panel de

yeso y polvo de concreto. Estos tipos de

materiales son tan pequeños que pasarían a

través de los filtros tradicionales. Hay una

manguera accesoria disipadora de electricidad

estática (VT2580) opcional disponible para las

operaciones de recogida que tiendan a causar

una acumulación de carga estática.

25

Page 26

A

D

B

C

E

F

M

G

I

J

K

N

L

H

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:31 AM Page 26

Desempaquetado y comprobación del contenido

de la caja de cartón

Herramientas necesarias

Destornillador Phillips

Martillo

Mazo

Consulte el dibujo de ensamblaje para averiguar

el posicionamiento de las piezas.

Saque todo el contenido de la caja de cartón.

Asegúrese de que no falte ningún artículo

utilizando la lista del contenido de la caja. Llame al

1-800-4-RIDGID (1-800-474-3443) desde los

EE.UU. y Canadá o comu ní quese con nosotros por

correo electrónico a info@ridgid.com si alguna

pieza está dañada o falta.

Lista del contenido de la caja de cartón

Clave Descripción Cant.

A Ensamblaje de la aspiradora

para mojado/seco ...............................1

B* Filtros.......................................................2

C Manguera ProHose de 15 pies ................1

D Silenciador/Difusor ..................................1

E Ruedecillas de 2 pulgadas .......................2

F Ruedas de 8 pulgadas .............................2

G Tapas de rueda ........................................2

H Tuercas de tapa de 1/2 pulgada ...............2

I Tornillos de 10 x 1-3/4 ............................4

J Eje............................................................1

K* Base de soporte derecha .........................1

L* Base de soporte izquierda .......................1

M Mango metálico.......................................1

N Manual del usuario ..................................1

* Estos artículos pueden venir preensamblados.

26

Page 27

Powerhead

Assembly

Tab (2)

Latch (2)

Release

Button

Press Then

Push or Pull

Vac Inlet

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:19 AM Page 27

Ensamblaje de la aspiradora

1. Posicione el ensamblaje del cabezal del

motor sobre el tambor de la manera que se

muestra en la ilustración.

2. Enganche los pestillos sobre las lengüetas

ubicadas en el ensamblaje del cabezal del

motor.

3. Presione hacia abajo los pestillos hasta que

se cierren a presión contra los lados del

tanque.

Ensamblaje del

cabezal del motor

Lengüeta (2)

Pestillo (2)

Introduzca la manguera

Inserte en la entrada de la aspiradora el extremo

de la manguera en el cual está ubicado el botón

pulsador. La manguera debe acoplarse a presión

en su sitio.

Para quitar la manguera de la aspiradora, oprima

el botón de liberación que está en el ensam blaje

de la manguera y tire de la manguera hasta

sacarla de la entrada de la aspiradora, de la

manera que se muestra en la ilustración.

Presione y luego

empuje o jale

Entrada

de la aspiradora

Botón de

liberación

27

Page 28

NOTE: Smooth side of the

wheel to the outside.

Left

Caddy

Drain

Axle

w/Wheel

Right

Caddy

Open

End

Cap

Nut

Right

Caddy

Drain

Left

Caddy

Right

Caddy

Left

Caddy

Drain

#10 x 1-3/4" Screw (4)

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:19 AM Page 28

Ensamblaje del base de soporte

Si cualquiera de las piezas falta o está dañada,

póngase en contacto con Servicio al Cliente.

No realice el ensamblaje hasta que tenga todas las

piezas.

1. Inserte la base de soporte de almacenamiento

izquierda y la base de soporte de

almacenamiento derecha en la parte inferior

del tambor de la manera que se muestra en la

ilustración. Es posible que sea necesario dar

golpes ligeros con un mazo o un martillo para

asentar completamente ambas bases de

soporte de almacenamiento.

2. Instale (4) tornillos No. 10 x 1-3/4" en los

agujeros coincidentes ubicados tanto en el

lado derecho como en el lado izquierdo de la

base de soporte, sujetando las bases de

soporte a la parte inferior del tambor. Apriete

los tornillos sólo hasta que queden

perfectamente ajusta dos. No los apriete

excesivamente en este momento, ya que esto

podría tender a deformar las bases de soporte.

3. Instalación de la tuerca de tapa

a. Coloque la tuerca de tapa en el extremo

del eje.

b. Golpee suavemente la tuerca con un

martillo hasta que esté completamente

asentada.

c. Coloque la rueda en el eje con la parte lisa

de la rueda orientada hacia fuera.

Drenaje

Base de

soporte

izquierda

Extremo

abierto

Tuerca

de tapa

Base de

soporte derecha

Base de

soporte

izquierda

Tornillo No. 10 x 1 3/4 pulg. (4)

Base de

soporte

izquierda

Drenaje

Base de

soporte derecha

Drenaje

Base de

soporte

derecha

Eje con

rueda

NOTA: Lado liso de

la rueda hacia el exterior.

28

Page 29

Handle

Release

Button (2)

Handle

Receptacle (2)

Mallet

Wheel

Cap

Left Caddy

Right

Caddy

Socket

Caster

Stem

Caster

Ball

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:19 AM Page 29

Ensamblaje del base de soporte (continuación)

4. Deslice el extremo abierto del eje a través de

la base de soporte de almacenamiento

izquierda, asegurándose de que la ranura de

la pata se alinee con el agujero de la cuna.

Deslice completamente dicho extremo a

través de la base de soporte de

almacenamiento derecha. Es posible que se

requieran unos golpes ligeros con un mazo

para insertar completamente el eje.

5. Instale la segunda rueda en el eje con la

parte lisa de la rueda orientada hacia fuera.

6. Instale la segunda tuerca de tapa. Golpee

suavemente dicha tuerca hasta que esté

firmemente asentada.

7. Utilizando un mazo de caucho o un martillo,

golpee suavemente la tapa de la rueda sobre

la rueda derecha hasta que dicha tapa esté

firmemente asentada sobre la rueda. Es

necesario hacer esto tanto en el lado

izquierdo como en el lado derecho.

8. Inserte el vástago de la ruedecilla en el

receptáculo del pie de ruedecilla de la

manera que se muestra en la ilustración

(ruedecilla delantera solamente).

9. Empuje sobre la ruedecilla hasta que la bola

ubicada en el vástago de la ruedecilla esté

completamente insertada en el receptáculo.

Usted podrá oír cómo la bola se acopla a

presión en el receptáculo y la ruedecilla

girará fácilmente cuando su posicionamiento

sea correcto.

Base de soporte izquierda

Base de

soporte

derecha

Mazo

Tapa de

rueda

Vástago de la

ruedecilla

Bola de la

ruedecilla

Receptáculo

Instalación del asa

Oprima y mantenga oprimidos los botones de

liberación mientras instala el asa en los

receptáculos para el asa ubicados en el tambor

(vea la ilustración).

NOTA: Un chasquido audible de los botones de

liberación indica un acoplamiento exitoso del asa.

Remoción del asa

Oprima y mantenga oprimidos los botones de

libera ción, de la manera que se muestra en la

ilustración. Mientras oprime firmemente los

botones de libera ción, tire del asa hacia arriba

hasta quitarla (vea la ilustración).

Asa

Botón de

liberación (2)

Receptáculo para

el asa (2)

29

Page 30

"ON"

"OFF"

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:19 AM Page 30

Funcionamiento

ADVERTENCIA: Para reducir el riesgo de incendio, explosión o daños a la aspiradora:

!

• No deje la aspiradora en marcha mientras esté desatendida. Usted podría no notar señales

importantes que indiquen un funcionamiento anormal, tal como pérdida de succión, residuos

líquido que salen por el escape o ruidos anormales del motor. Deje de usar la aspiradora

o

inmediatamente si observa estas señales.

• No deje la aspiradora enchufada cuando no se esté utilizando.

• No continúe usando la aspiradora cuando el flotador haya cortado la succión.

• No utilice la aspiradora en áreas con gases inflamables, vapores inflamables o polvo

explosivo en el aire. Las chispas generadas dentro del motor pueden incendiar los

materiales inflamables suspendidos en el aire. Los gases inflamables y los vapores

inflamables incluyen: líquido encendedor, limpiadores tipo solvente, pinturas a base de

aceite, gasolina, alcohol o rociadores tipo aerosol. Los polvos inflamables incluyen: polvo

de carbón, polvo de magnesio, polvo de aluminio, polvo de grano de cereal o pólvora.

• No recoja con la aspiradora polvos explosivos, líquidos inflamables ni cenizas calientes.

ADVERTENCIA: Para reducir el riesgo de descargas eléctricas o lesiones:

!

• No exponga la aspiradora a la lluvia ni deje que entre líquido en el compartimiento del motor.

Almacene la aspiradora en un lugar interior.

• No maneje el enchufe, el interruptor o la aspiradora con las manos mojadas.

• No haga servicio de ajustes y reparaciones de la aspiradora mientras esté enchufada. Si la

aspiradora no está funcionando como debería, le faltan piezas, se ha caído, está dañada, se ha

dejado a la intemperie o se ha caído al agua, devuélvala a un centro de servicio independiente

o llame a servicio al cliente.

• Cuando utilice un cordón de extensión, utilice únicamente cordones con capacidad nominal para

uso a la intemperie que estén en buenas condiciones. No deje que la conexión entre en contacto

con líquido.

PRECAUCIÓN: Para reducir el riesgo de

!

descargas de electricidad estática mientras se

utilice estas aspiradora, evite utilizarla en

condiciones muy secas o utilice la manguera

accesoria disipadora de electricidad estática

VT2580 opcional. Enchufe siempre el cable de

alimentación en un tomacorriente conectado a

tierra apropiadamente.

Después de enchufar el cordón de energía en el

tomacorriente, encienda la unidad empujando

el interruptor de la posición “O” a la posición “|”.

Los símbolos utilizados en el accionador del

interruptor son los símbolos internacionales de

“encendido y apagado”.

=

APAGADO

=

ENCENDIDO

“APAGADO”

“ENCENDIDO”

30

Page 31

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:19 AM Page 31

Funcionamiento (continuación)

Recogida de materiales secos

con la aspiradora

. Los filtros deben estar siempre en la posición

1

correcta para reducir el riesgo de fugas y

posibles daños a la aspiradora.

2. La aspiradora viene con dos filtros VF3800

instalados. Al utilizar la aspiradora para

recoger polvo muy fino, será necesario que

usted vacíe el tambor y limpie el filtro a

intervalos más frecuentes para mantener un

rendimiento óptimo.

NOTA: Se necesita un filtro seco para recoger

material seco. Si utiliza la aspiradora para recoger

polvo cuando el filtro está mojado, éste se atascará

rápidamente y será muy difícil limpiarlo.

Bolsas de recolección de polvo

opcionales

Nota: La programación de computadora de esta

aspiradora sólo monitorea la aparición de

obstrucciones en los filtros plisados. El uso de la

bolsa de recolección de polvo opcional impedirá

que la función de pulsación inteligente Smart-Pulse

detecte cualquier obstrucción que ocurra, lo cual

causará una disminución prematura del

rendimiento de la aspiradora.

1. La bolsa de recolección de polvo disponible

para esta aspiradora tiene el número de

catálogo VF3502.

2. La bolsa de recolección de polvo está diseñada

para recoger residuos secos SOLAMENTE.

3. Si los residuos que se estén recogiendo tienen

algo de humedad, la bolsa absorberá dicha

humedad y es posible que se deteriore muy

rápidamente, con lo cual quedará inservible.

4. Si está usando la aspiradora para recoger

polvo fino, la bolsa de recolección de polvo

facilitará la limpieza.

Nota: La bolsa de recolección de polvo se DEBE

usar en combinación con filtros de cartucho

plisados. No llene excesivamente la bolsa de

recolección con filtro. Si se llenan excesivamente

estas bolsas, el resultado podría ser que el peso de

los residuos recogidos desgarre estas bolsas y/o

dificulte su retirada del tambor de la aspiradora

debido a su tamaño físico.

5. Las instrucciones de instalación y retirada de

las bolsas de recolección de polvo están

impresas en las bolsas.

Recogida de líquidos con la

aspiradora

1. Antes de utilizar su aspiradora para recoger

residuos mojados, asegúrese de que el tambor

esté vacío y libre de polvo o residuos.

2. Retire los filtros. Con los filtros retirados, el

mecanismo del flotador se activa para impedir

que entre agua en la carcasa del soplador del

motor. Si los filtros no se retiran, podría entrar

agua en la carcasa del soplador del motor, lo

cual podría sobrecargar y dañar el motor.

3. Cuando el líquido que se encuentre en el

tambor alcance un nivel predeterminado, el

mecanismo del flotador subirá automática mente para cortar el flujo de aire. Cuando esto

suceda, apague la aspiradora, desenchufe el

cordón de energía y vacíe el tambor. Sabrá que

el flotador ha subido porque el flujo de aire de

la aspiradora cesará y subirá el tono del ruido

del motor debido a que se producirá un

aumento de la velocidad del mismo.

IMPORTANTE: Para reducir el riesgo de daños a la

aspiradora, no tenga en marcha el motor con el

flotador en la posición elevada.

4. Después de utilizar la aspiradora para recoger

líquidos, el tambor se debe limpiar y secar

completamente antes de utilizarlo. Los filtros

se deben reinstalar antes de utilizar esta

máquina para recoger materiales secos.

31

Page 32

Blowing

Outlet

15' Hose

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:19 AM Page 32

Funcionamiento (continuación)

Vaciado del tambor

ADVERTENCIA: Para reducir el riesgo de

!

lesiones debidas a un arranque accidental,

desenchufe el cordón de energía antes de

vaciar el tambor.

ADVERTENCIA: Para reducir el riesgo de

!

que se produzcan lesiones en la espalda o

caídas, no levante la aspiradora si pesa

demasiado debido a que contiene líquido o

residuos. Saque o haga salir una cantidad

suficiente del contenido para hacer que la

aspiradora sea suficientemente liviana como

para poder levantarla cómodamente.

1. La aspiradora viene equipada con un drenaje

para facilitar su vaciado de líquidos. Simple mente desenrosque la tapa del drenaje y

levante ligera mente el lado opuesto para

vaciar el tambor.

2. Otra opción es quitar el ensamblaje del

cabezal del motor.

3. Ponga a un lado el ensamblaje del cabezal

del motor en un área limpia mientras vacía el

tambor.

4. Vierta el contenido del tambor en el

recipiente de eliminación de residuos

apropiado.

Traslado de la aspiradora para

mojado/seco

En caso de que sea necesario levantar la

aspiradora para trasladarla, las asas ubicadas en

los lados del tambor para polvo se usan para

levantar la aspiradora. Para maniobrar la aspira dora, se debe usar el asa de empuje/tracción

ubicada en la parte trasera de la unidad.

Dispositivo de soplado

La aspiradora cuenta con un orificio de soplado.

Puede soplar aserrín y otros residuos. Siga los

pasos que se indican a continuación para usar la

aspiradora como soplador.

ADVERTENCIA: Use siempre protectores ocu -

!

lares de seguridad que cumplan con la norma

ANSI Z87.1 (o en Canadá, con la norma CSA Z94.3)

antes de utilizar la aspiradora como soplador.

ADVERTENCIA: Para reducir el riesgo de

!

lesiones a las personas que estén presentes,

manténgalas alejadas de los residuos soplados.

PRECAUCIÓN: Use una máscara antipolvo si

!

el soplado genera polvo que podría ser inhalado.

PRECAUCIÓN: Para reducir el riesgo de

!

daños a la audición, use protectores de oídos

cuando utilice la aspiradora/soplador durante

muchas horas seguidas o cuando la utilice en un

área ruidosa.

1. Localice el orificio de soplado de la

aspiradora.

2. Introduzca el extremo de fijación de la

manguera con la aspiradora en el orificio de

sopla do de la aspiradora. La manguera debe

acoplarse a presión en su sitio. Para quitar la

manguera de la aspiradora, oprima el botón

de liberación ubicado en el ensamblaje de la

manguera y tire de la man guera hasta

sacarla de la entrada de la aspiradora.

3. Encienda la aspiradora y estará lista para

utilizarse como soplador.

Salida de

soplado

Manguera

de 15 pies

32

Page 33

Diffuser

Blowing

Outlet

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:19 AM Page 33

Funcionamiento (continuación)

Difusor

Esta aspiradora viene equipada con un difusor

ue se puede insertar en el orificio de salida de la

q

aspiradora cuando ésta no se esté utilizando

como soplador. Este difusor es ajustable y se

puede utilizar para cambiar el caudal de aire y la

dirección de la salida de aire de la aspiradora,

alejándola de las áreas en las que usted no quiera

que sople.

Salida de

soplado

Difusor

Manguera accesoria disipadora

de electricidad estática

Con esta aspiradora se puede usar una manguera

accesoria VT2580 opcional para reducir los

efectos de la acumulación de carga estática. En

condiciones secas y cuando se aspiren grandes

cantidades de polvo fino/seco, se puede

acumular carga estática en la manguera o la

aspiradora. La manguera VT2580 disipará la

carga estática a través del conductor de conexión

a tierra ubicado en el cable de alimentación.

Mantenimiento

Filter Remoción e instalación cuando se

Esta aspiradora Smart-Pulse se suministra con

dos filtros de PTFE Qwik Lock™ de RIDGID.

Los filtros de repuesto están disponibles en el

establecimiento donde usted compró su

aspiradora. Pida el filtro RIDGID Qwik Lock™

VF3800.

NOTA: Los filtros están hechos con material de

alta calidad diseñado para detener las partículas

de polvo muy pequeñas. Los filtros sólo se

pueden usar para recoger residuos secos. Maneje

cuidadosamente los filtros cuando los retire,

limpie o instale. Es posible que se formen

arrugas en los pliegues del filtro al realizar la

instalación, pero dichas arrugas no afectarán al

rendimiento del filtro.

utiliza el vástago Qwik Lock™

Remoción del filtro:

1. Sostenga las lengüetas del filtro Qwik Lock™ en

cada mano.

2. Con un dedo pulgar en el vástago Qwik Lock™,

que sobresale a través de la placa del filtro

integrada, levante las lengüetas del filtro a la vez

que empuja hacia abajo sobre el vástago.

3. Esta acción hará que el filtro se suelte de la jaula

del filtro. Deslice el filtro hasta retirarlo de la

jaula. Repita el procedimiento para el segundo

filtro.

33

Page 34

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:19 AM Page 34

Mantenimiento (continuación)

Instalación del filtro:

1. Deslice cuidadosamente el filtro Qwik Lock™

sobre la jaula del filtro y presione hacia abajo

sobre el borde exterior del filtro hasta que el

empaque de goma ubicado en la parte inferior

del filtro se asiente firmemente alrededor de la

base de la jaula del filtro y contra la tapa.

2. Alinee el agujero central pequeño ubicado en la

parte superior del filtro sobre el vástago Qwik

Lock™ ubicado en la jaula del filtro. Presione

firmemente sobre la parte de arriba del filtro

cerca del vástago, para permitir que el filtro se

acople a presión sobre la bola ubicada en el

extremo del vástago. Una vez hecho esto, el

filtro estará instalado. Repeat for second filter.

NOTA: Si no se asienta apropiadamente el

empaque inferior, el resultado podría ser que los

residuos pasen por alto el filtro.

Filtro Qwik-

Qwik-Lock

Filter (2)

Espárrago

Stud

JALE

HACIA

PULL

ARRIBA

UP

Lock (2)

EMPUJE

HACIA

PUSH

ABAJO

DOWN

Lengüetas

Filter

del filtro

Tab s

Jaula del

Filter

filtro (2)

Cage (2)

Flotador (2)

Float (2)

Adaptador

Float

Adapter

de flotador

(2)

(2)

ADVERTENCIA: No utilice la unidad sin

!

filtros o si sólo tiene instalado un filtro, a

menos que vaya a recoger líquidos. Para

recoger líquidos se deben retirar ambos filtros.

No utilice la aspiradora sin las jaulas de filtro,

los adaptadores de flotador y los flotadores, ya

que estas piezas impiden que entre líquido en

el impulsor y dañe el motor.

IMPORTANTE: Para evitar dañar la rueda del

soplador y el motor, reinstale siempre ambos

filtros antes de utilizar la aspiradora para recoger

materiales secos.

NOTA: Para obtener los mejores resultados de

limpieza debido al polvo acumulado, limpie los

filtros en un área abierta. La limpieza se DEBERÁ

realizar a la intemperie y no en las áreas de

vivienda.

Retire los filtros de la aspiradora. Golpee

suavemente los filtros contra la pared interior del

tambor para polvo y los residuos se soltarán y

caerán.

IMPORTANTE: Después de realizar la limpieza,

compruebe los filtros para determinar si tienen

desgarraduras o agujeros pequeños. No utilice

filtros que tengan agujeros o desgarraduras.

Incluso un pequeño agujero puede hacer que

salga una gran cantidad de polvo de la

aspiradora. Si los filtros están dañados,

reemplácelos de inmediato.

Limpieza y desinfección de

la aspiradora para mojado/seco

Para mantener el mejor aspecto posible de la

aspiradora para mojado/seco, limpie su exterior

con un paño humedecido con agua templada y

un jabón suave.

Para limpiar el tambor:

1. Vacíe de residuos el tambor.

2. Lave a fondo el tambor con agua templada y

un jabón suave.

3. Limpie el tambor con un paño seco.

Antes de un almacenamiento prolongado o según

sea necesario (por ejemplo, si se recogen aguas

residuales), se debe desinfectar el tambor.

34

Page 35

Power

Cord

Pull

Handle

Hose Storage

Area

H

O

S

E

S

T

O

RA

G

E

H

O

S

E

S

T

O

R

A

G

E

SP6906 RIDGID ESF.qxp_SP6636 12/10/14 9:19 AM Page 35

Mantenimiento (continuación)

Para desinfectar el tambor:

1. Eche 1 galón de agua y 1 cucharadita de

blan queador de cloro en el tambor.

2. Deje que la solución repose durante 20

minutos y agítela cuidadosamente cada

pocos minutos, asegurándose de mojar

todas las superficies interiores del tambor.

3. Vacíe el tambor después de 20 minutos.

Enjuá guelo con agua hasta que el olor a

blanqueador desaparezca. Deje que el

tambor se seque com ple tamente antes de

sellar el motor sobre el tambor.

Mantenimiento del cordón

Cuando se haya completado la limpieza con la

aspiradora, desenchufe el cordón y enróllelo

alrededor de la cubierta del motor. La conexión

del cordón de energía es del Tipo Y. Si el cordón

de energía está dañado, debe ser reemplazado

por el fabricante o su agente de servicio, o por