Page 1

• Français – 9

• Castellano – pág. 19

WARNING!

Read this Operator’s Manual

carefully before using this tool.

Failure to understand and follow the contents of this manual may result in electrical

shock,fire and/or serious personal injury.

Electric

Soldering Gun

OPERATOR’S

MANUAL

RT-175

Page 2

Ridge Tool Companyii

Model RT-175 Electric Soldering Gun

Table of Contents

Recording Form for Machine Serial Number..............................................................................................................1

General Safety Information

Work Area Safety........................................................................................................................................................2

Electrical Safety..........................................................................................................................................................2

Personal Safety ..........................................................................................................................................................2

Tool Use and Care......................................................................................................................................................2

Service........................................................................................................................................................................3

Specific Safety Information

Tool Safety..................................................................................................................................................................3

Description and Specifications

Description..................................................................................................................................................................3

Specifications..............................................................................................................................................................3

Tool Inspection..............................................................................................................................................................5

Tool and Work Area Set-Up..........................................................................................................................................5

Operating Instructions..................................................................................................................................................5

Maintenance Instructions

Carbon Tip Replacement............................................................................................................................................7

Accessories ..................................................................................................................................................................7

Tool Storage ..................................................................................................................................................................7

Service and Repair........................................................................................................................................................8

Wiring Diagram..............................................................................................................................................................8

Lifetime Warranty ........................................................................................................................................Back Cover

Page 3

Model RT-175

Electric Soldering Gun

RT-175 Electric Soldering Gun

Record Serial Number below and retain product serial number which is located on nameplate.

Serial

No.

Page 4

Ridge Tool Company2

Model RT-175 Electric Soldering Gun

General Safety Information

WARNING! Read and understand all instructions. Failure

to follow all instructions listed below may

result in electric shock, fire, and/or serious

personal injury.

SAVE THESE INSTRUCTIONS!

Work Area Safety

• Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

• Do not operate tools in explosive atmospheres,

such as in the presence of flammable liquids,

gases, or dust. Electrical switches may create sparks

which may ignite the dust or fumes.

• Keep by-standers, children, and visitors away

while operating an electric soldering gun.

Distractions can cause you to lose control.

Electrical Safety

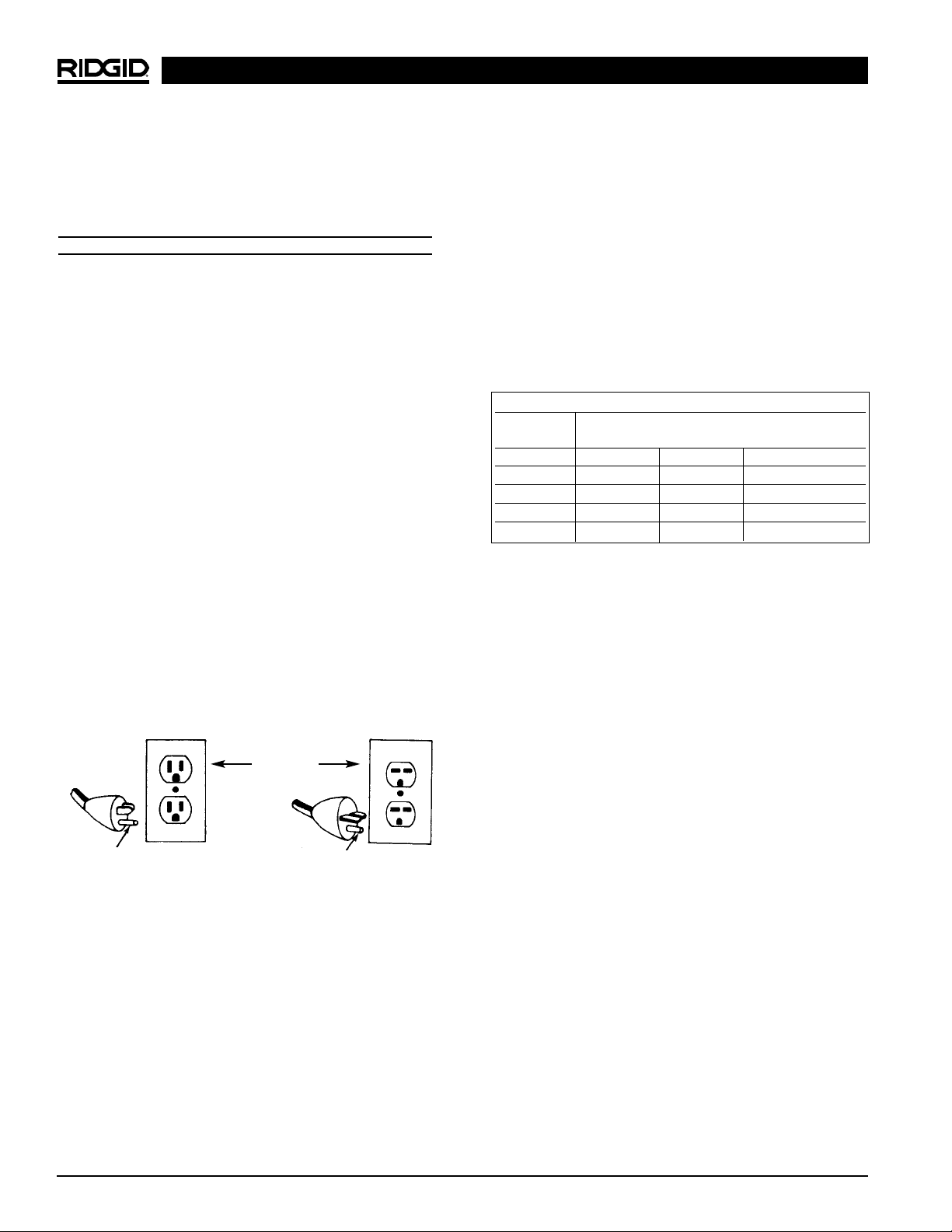

• Grounded tools must be plugged into an outlet,

properly installed and grounded in accordance

with all codes and ordinances. Never remove the

grounding prong or modify the plug in any way. Do

not use any adapter plugs. Check with a qualified electrician if you are in doubt as to whether the

outlet is properly grounded. If the tool should elec-

trically malfunction or break down, grounding provides a low resistance path to carry electricity away

from the user.

• Avoid body contact with grounded surfaces such

as pipes, radiators, ranges and refrigerators. There

is an increased risk of electrical shock if your body is

grounded.

• Do not expose power tools to rain or wet condi-

tions. Water entering a tool will increase the risk of

electrical shock.

• Do not abuse cord. Never use the cord to carry the

tools or pull the plug from an outlet. Keep cord

away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately. Damaged

cords increase the risk of electrical shock.

• When operating an electrical tool outside, use an

outdoor extension cord marked “W-A” or “W”.

These cords are rated for outdoor use and reduce the

risk of electrical shock.

• Use only three-wire extension cords which have

three-prong grounding plugs and three-pole receptacles which accept the tool’s plug. Use of other

extension cords will not ground the tool and increase

the risk of electrical shock.

• Use proper extension cords. (See Chart) Insufficient

conductor size will cause excessive voltage drop,

loss of power and overheating.

• Keep all electric connections dry and off the

ground. Do not touch plugs or tool with wet hands.

Reduces the risk of electrical shock.

Personal Safety

• Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use tool while tired or under the influence of

drugs, alcohol, or medications. A moment of inat-

tention while operating tools may result in serious

personal injury.

• Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing,

and gloves away from moving parts. Loose clothes,

jewelry, or long hair can be caught in moving parts.

• Avoid accidental starting. Be sure switch is OFF

before plugging in. Carrying tools with your finger on

the switch or plugging tools in that have the switch ON

invites accidents.

• Do not overreach. Keep proper footing and bal-

ance at all times. Proper footing and balance enables

better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protec-

tion. Dust mask, non-skid safety shoes, hard hat, or

hearing protection must be used for appropriate conditions.

Tool Use and Care

• Do not use tool if switch does not turn it ON or

Minimum Wire Gauge for Extension Cord

Nameplate

Amps

Total Length (in feet)

0 – 25 26 – 50 51 – 100

0 – 6 18 AWG 16 AWG 16 AWG

6 – 10 18 AWG 16 AWG 14 AWG

10 – 12 16 AWG 16 AWG 14 AWG

12 – 16 14 AWG 12 AWG

NOT RECOMMENDED

Grounding Prong

Cover of

grounded

outlet box

Grounding Prong

Page 5

Ridge Tool Company 3

Model RT-175 Electric Soldering Gun

OFF. Any tool that cannot be controlled with the

switch is dangerous and must be repaired.

• Store idle tools out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

• Maintain tools with care. Properly maintained tools

are less likely to cause injury.

• Check for breakage of parts and any other condition that may affect the tool’s operation. If damaged, have the tool serviced before using. Many

accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by

the manufacturer for your model. Accessories that

may be suitable for one tool may become hazardous

when used on another tool.

• Inspect tool and extension cords periodically and

replace if damaged. Damaged cords increase the risk

of electrical shock.

• Keep handles dry and clean; free from oil and

grease. Allows for better control of the tool.

• Check electrodes for wear and replace before the

threaded studs show. Prevents electrical arcing and

excessive current draw.

Service

• Tool service must be performed only by qualified

repair personnel. Service or maintenance performed

by unqualified repair personnel could result in injury.

• When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance

Section of this manual. Use of unauthorized parts or

failure to follow Maintenance Instructions may create a

risk of electrical shock or injury.

• Disconnect all power from the unit before servicing. Eliminates the risk of electrical shock and acci-

dental starting.

Specific Safety Information

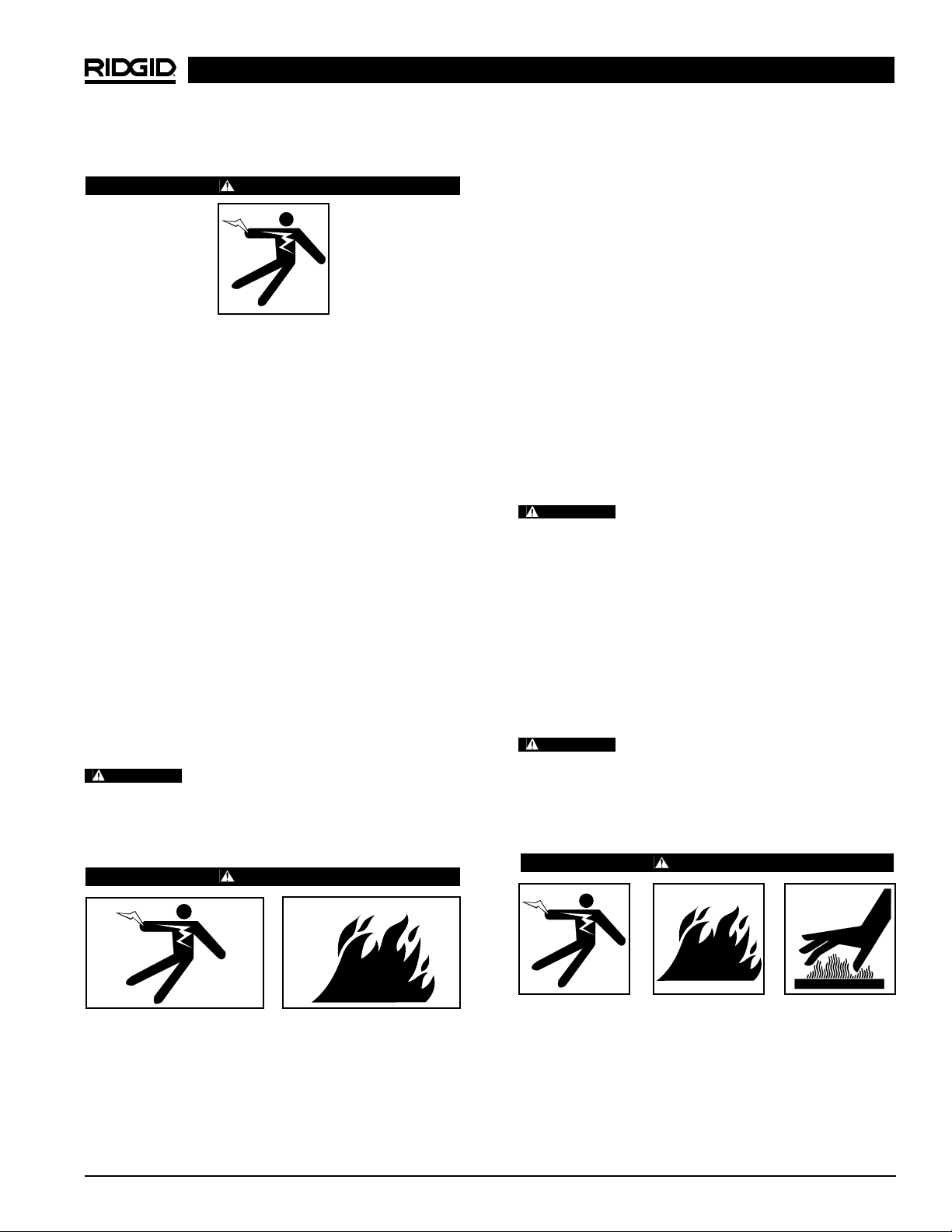

WARNING

Read this operator’s manual carefully before using

the Electric Soldering Gun. Failure to understand

and follow the contents of this manual may result

in electrical shock, fire and/or serious personal

injury.

Call the Ridge Tool Company, Technical Service Department at (800) 519-3456 if you have any questions.

Tool Safety

• Tool is made to solder copper pipe. Follow instructions on proper use. Other uses may increase the risk

of injury.

• Do not leave the unit unattended. Such preventive

measures reduce the risk of injury or fire.

• Do not touch solder gun sleeves or carbon tips.

They remain hot after use.

• Do not operate unit with the electrical box cover

removed. Exposure to internal parts increases the

risk of electrical shock.

• Use soldering sleeves and carbon tips provided

with unit. Incorrect carbon tips or sleeves may result

in overheating of the wires.

• Keep soldering sleeves away from combustible

materials or articles that can be damaged by

heat. Soldering sleeves and carbon tips remain hot

after use.

• Do not solder near combustible materials. Copper

pipe and soldering sleeves reach temperatures that

can result in fire.

• Do not store the handle in the case until the carbon

tips have cooled. They may burn the cord or solder

gun cable.

• Do not clamp or touch threaded studs or stainless

steel sleeves against pipe or fittings. Prevents elec-

trical arcing and excessive current draw that may kick

out circuit breaker.

Description, Specifications and

Standard Equipment

Description

The RT-175 Electric Soldering Gun is capable of soldering joints in copper tube up to 3″ diameter while using a

standard 110V, 15A circuit. The soldering gun will heat

copper to temperatures in excess of 750°F which allows

it to successfully melt solders used in plumbing applications – from the 50/50 solders to the 95/5 lead-free types.

Specifications

Power Input...................115 V, 15 A

Power Output ................(open circuit voltage)

Hi = 7.0 V, Low = 6.2 V

Current Draw.................13.5A @ Low Setting

15.0A @ High Setting

Page 6

Height

(A – See Figure 1).........6″

Length

(B – See Figure 1).........17″

Width

(C – See Figure 1).........11″

Duty Cycle.....................Continuous

Tube Capacity...............Up To 3″

Solder Gun

Cable Length.................136″

Power Cord Length .......98″

Weight...........................32 Lbs.

Figure 1 – Soldering Gun Case Dimensions

Model RT-175 Electric Soldering Gun

Ridge Tool Company4

B

A

C

Figure 2a – RT-175 Soldering Gun

Figure 2b – RT-175 Handles and Carbon Tips

Power Cord

Locknut

Carbon Tips

Threaded Stud

Stainless Steel

Sleeves

Solder Gun

Cable

ON/OFF Switch

Handles

Handles

Transformer

Page 7

• 15 Amp grounded electrical outlet.

• Clear path to the electrical outlet that does not

contain any sources of heat or oil, sharp edges or

moving parts that may damage electrical cord.

• Dry place for tool and operator. Do not use the

tool while standing in water.

• Flammable liquids, vapors, dust or any combustible

materials that may ignite.

2. Position RT-175 Soldering Gun near the copper tubing that is to be soldered.

3. Make sure ON/OFF switch is OFF and uncoil cable

completely from carrying case.

4. When plugging the Soldering Gun into the electrical

outlet, making sure to position the power cord along

the clear path selected earlier. If the power cord

does not reach the outlet, use an extension cord in

good condition.

To avoid electric shock and electrical fires,

never use an extension cord that is damaged or does not

meet the following requirements:

• The cord has a three-prong plug similar to shown

in Electrical Safety section.

• The cord is rated as “W” or “W-A” if being used

outdoors.

• The cord has sufficient wire thickness (14 AWG

below 25′/12 AWG 25-50′). If the wire thickness is

too small, the cord may overheat, melting the cord’s

insulation or causing nearby objects to ignite.

To reduce risk of electrical shock, keep

all electrical connections dry and off the ground. Do

not touch plug with wet hands.

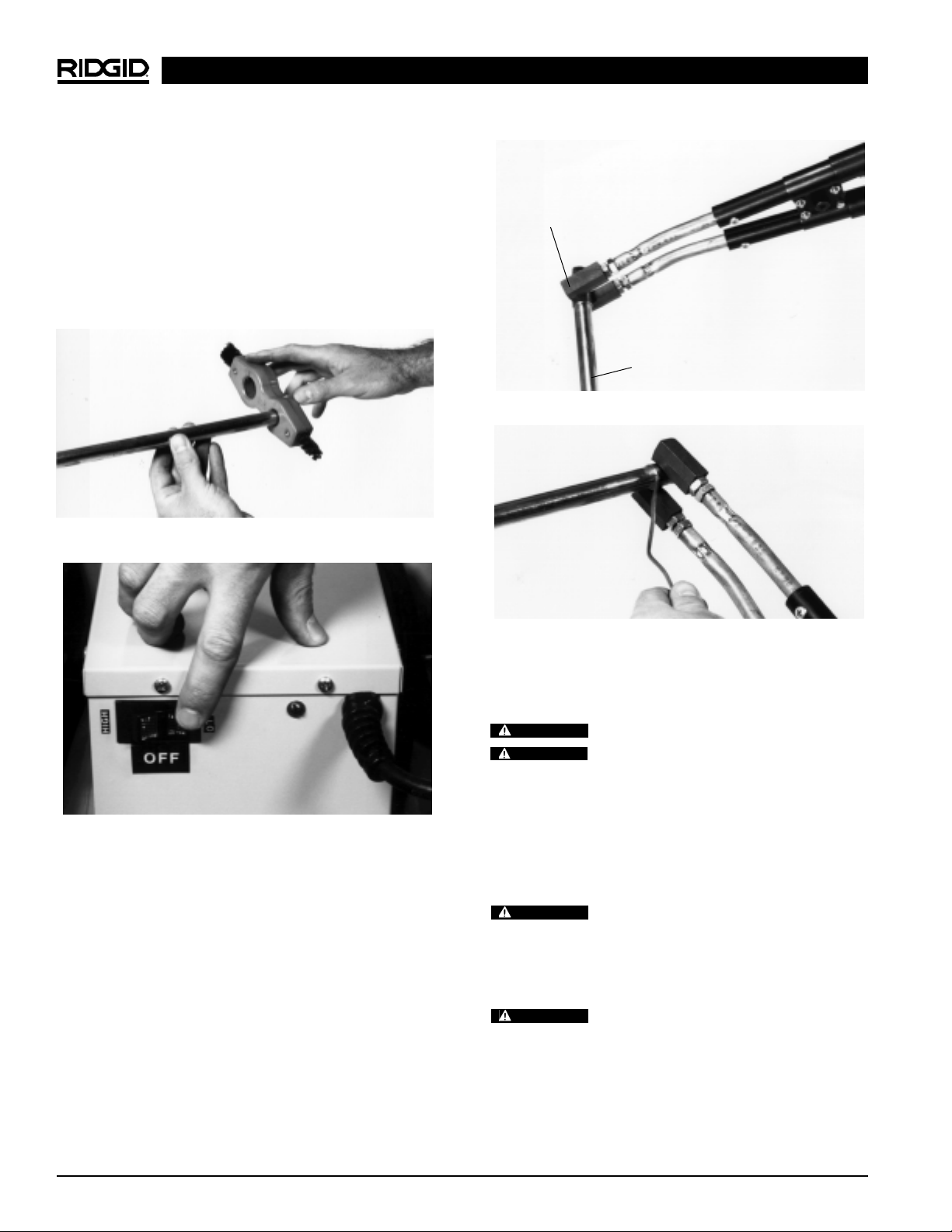

Operating Instructions

WARNING

To reduce risk of electrical shock, keep all elec-

trical connections dry and off the ground. Do not

touch plug with wet hands.

Carbon tips and sleeves become hot during use.

Avoid contact with skin as burns can result.

Keep carbon tips and sleeves away from combustible materials or articles that can be damaged by heat.

Tool Inspection

WARNING

To prevent serious injury, inspect your electric

soldering gun. The following procedures should

be followed.

1. Make sure soldering gun is unplugged and the control

switches are in the OFF position (Figure 2).

2. Inspect the power cord and plug for damage. If the

plug has been modified, is missing the grounding

prong or if the cord is damaged, do not use the tool

until the cord has been replaced.

3. Inspect the cables and carbon tips for damage (Figure

2). If cable or tips are damaged, do not use the soldering gun until they are replaced. Only use soldering

sleeves and carbon tips provided with the unit.

Incorrect sleeves or tips may result in overheating of

the wires.

4. Clean any oil, grease or dirt from handles, controls

and clamps.

5. Inspect the soldering gun for any broken or missing

parts as well as damage to the metal enclosure. If any

of these conditions are present, do not use the tool

until any problem has been repaired.

Do not operate unit with electrical box

cover removed.

Tool and Work Area Set-Up

WARNING

To prevent serious injury, proper set-up of the

tool and work area is required. The following procedures should be followed to set-up the Soldering

Gun.

1. Check work area for:

• Adequate lighting

Ridge Tool Company 5

Model RT-175 Electric Soldering Gun

WARNING

WARNING

WARNING

Page 8

Do not leave the unit unattended while in use.

1. Make sure unit is turned OFF. Plug unit into a grounded 15 amp outlet making sure to position the power

cord along the clear path selected earlier.

2. Thoroughly clean the copper tube and fitting and

apply the flux (Figure 3).

NOTE! When using the RT-175, proper soldering tech-

niques should be followed.

Figure 3 – Cleaning Copper Tube and Fittings

Figure 4 – Control Switch

3. Turn the unit ON (Figure 4). Use the following guidelines for choosing between the HIGH and LOW settings:

LOW..............................3/8″ – 11/2″ 50/50 Soldering

3

/8″ – 1/2″ 95/5 Soldering

HIGH .............................11/2″ – 3″ 50/50 Soldering

1

/2″ – 3″ 95/5 Soldering

50′ Maximum Extension Cord

NOTE! On HIGH setting, the maximum length of exten-

sion cord should be 50′!

4. Squeeze handles together to open the carbon tips to

fit of the joint. Be sure to place the carbon tips over

the joint to allow capillary effect to draw the solder into

the solder cup of the fitting (Figure 5).

Figure 5 – Positioning Carbon Tips

Figure 6 – Soldering Joint

5. Hand solder wire at fitting lip until the solder begins to

flow freely (Figure 6). When this occurs, squeeze

handles and remove solder gun.

Do not overheat fitting.

Solder gun stainless steel sleeves and

carbon tips remain hot. Do not touch. Do not lay on surfaces that may be damaged until sleeves and tips have

cooled.

6. If the joint to be soldered is in a difficult to reach

location, it is not necessary to clamp the carbon tips

around the tube. The carbon tips only have to be in

contact with the fitting (Figure 7).

Do not clamp or touch stainless steel

sleeves, threaded studs or lock nuts against the tube or

fittings. If this happens, electrical arcing or excessive current draw may occur, kicking out the circuit breaker.

7. Switch the unit OFF when not in use.

Do not store the handle in the case until

it has cooled. They can damage the power cord or solder gun cables if they are too hot.

Model RT-175 Electric Soldering Gun

Ridge Tool Company6

WARNING

WARNING

Fitting

Copper Tube

WARNING

WARNING

Page 9

Ridge Tool Company 7

Model RT-175 Electric Soldering Gun

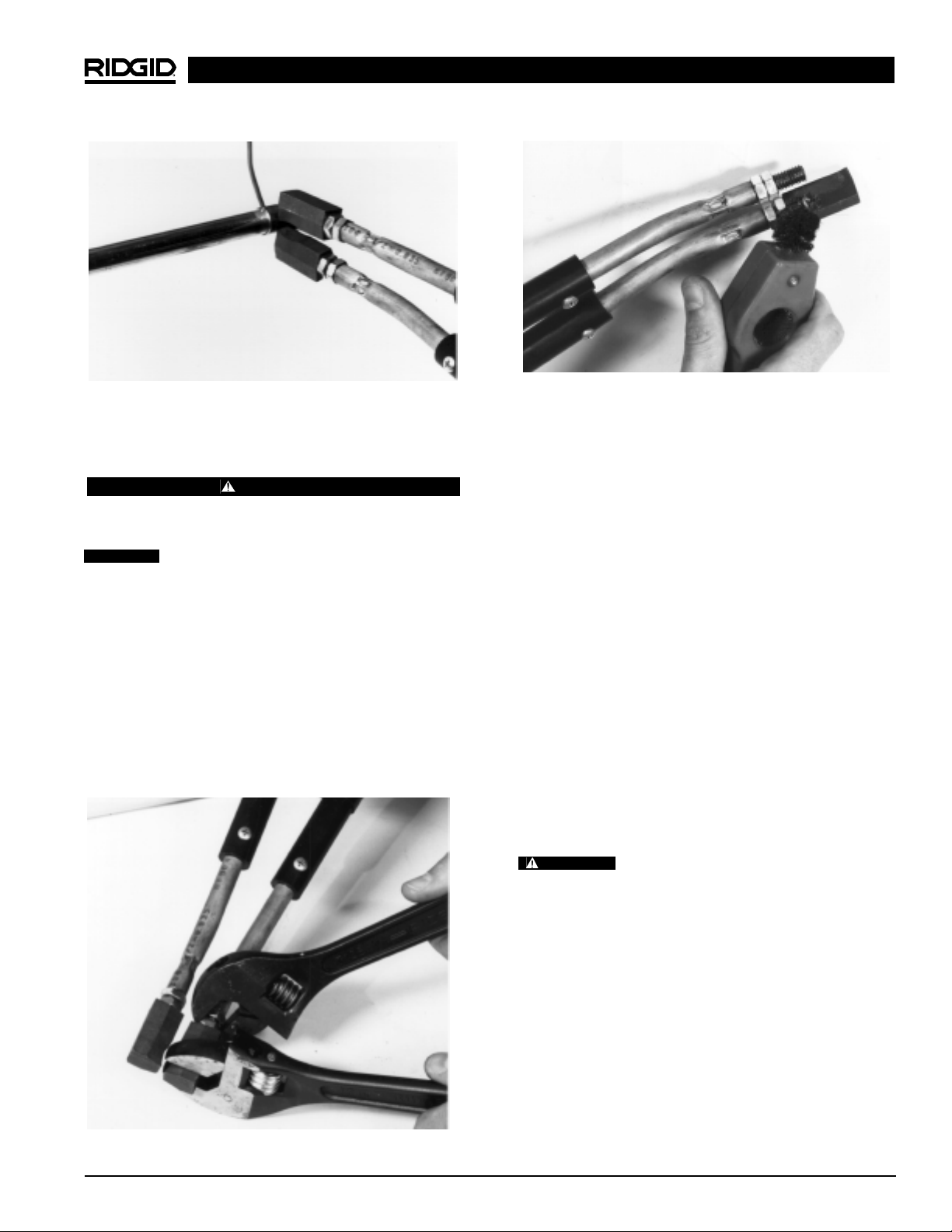

Figure 9 – Cleaning Threaded Stud

3. Clean threads of the threaded stud with a wire

brush to ensure good contact with the new carbon

tips (Figure 9). Burned threaded studs will not produce good contact and will not heat properly.

Replacement threaded studs are also available if

they are damaged.

4. Never apply torque to the insulated handles because

you can crack the plastic material.

Accessories

Only the following RIDGID products have been designed

to function with the RT-175 Electric Soldering Gun. Other

accessories suitable for use with other tools may become

hazardous when used on the RT-175. To prevent serious

injury, use only the accessories listed below.

Catalog No.

Carbon Tips 39966

Threaded Studs 39976

Tool Storage

Electrical equipment must be kept indoors

or well covered in rainy weather. Store the tool in a

locked area that is out of reach of children and people

unfamiliar with an Electric Soldering Gun. This tool can

cause serious injury in the hands of untrained users.

Figure 7 – Soldering with Carbon Tips Contacting Fitting

Maintenance

WARNING

Make sure unit is unplugged from power source

before performing maintenance or repairs.

The carbon tips are brittle. Care should be

taken when handling them. Do not over-torque and use

wrenches only when needed – otherwise, make everything “finger tight”.

Carbon Tip Replacement

The carbon tips will wear down as the RT-175 is used.

They should be inspected before each use and replaced

before the threaded studs begin to show through.

1. Unplug the RT-175.

2. Hold the lock nut and back-off the carbon tip by turning it counter-clockwise (Figure 8).

Figure 8 – Removing Carbon Tips

CAUTION

WARNING

Page 10

Ridge Tool Company8

Model RT-175 Electric Soldering Gun

Service and Repair

WARNING

Service and repair work on this tool must be performed by

qualified repair personnel. Soldering unit should be taken

to a RIDGID Independent Authorized Service Center or

returned to the factory. All repairs made by Ridge service

facilities are warranted against defects in material and

workmanship.

When servicing this tool, only identical

replacement parts should be used. Failure to follow these

steps may create a risk of electrical shock or other serious

injury.

If you have any questions regarding the service or repair

of this machine, call or write to:

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44035-6001

Tel: (800) 519-3456

E-mail: TechServices@ridgid.com

For name and address of your nearest Independent

Authorized Service Center, contact the Ridge Tool Company at (800) 519-3456 or http://www.ridgid.com

WARNING

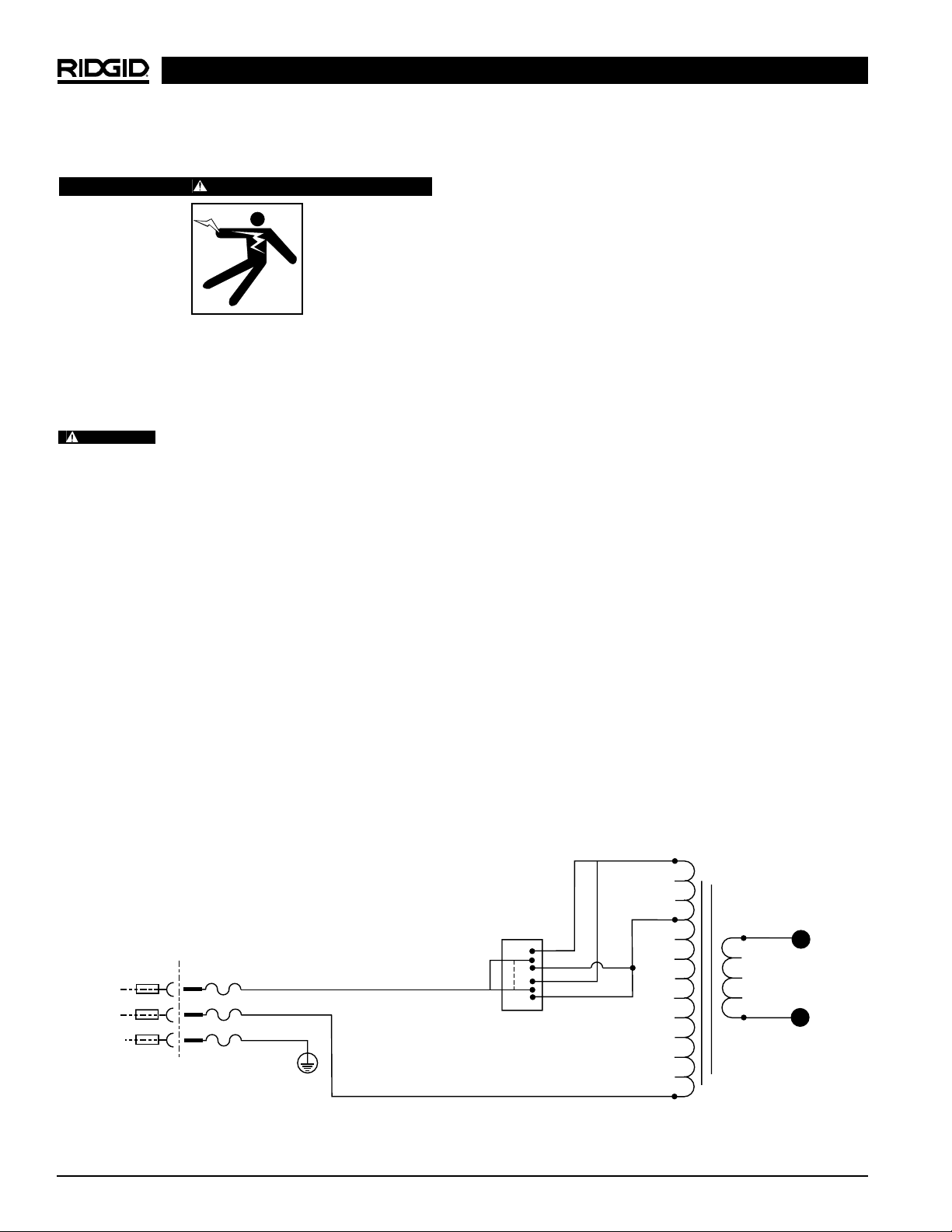

Wiring Diagram

Power

Switch

BK

WH

GN

Output

L

N

PE

115V

60Hz

15A

Page 11

Pince à souder électrique

Pince à souder électrique RT-175

Inscrivez ci-dessous le numéro de série de la plaque signalétique l’appareil pour future référence.

N° de

série :

Page 12

Ridge Tool Company10

Pince à souder électrique type RT-175

Table des matières

Fiche d’enregistrement du numéro de série de l’appareil ........................................................................................9

Consignes générales de sécurité

Sécurité du chantier..................................................................................................................................................11

Sécurité électrique....................................................................................................................................................11

Sécurité individuelle..................................................................................................................................................11

Utilisation et entretien de l’appareil ..........................................................................................................................12

Service après-vente..................................................................................................................................................12

Consignes de sécurité particulières

Sécurité de l’appareil ................................................................................................................................................12

Description et spécifications

Description................................................................................................................................................................13

Spécifications............................................................................................................................................................13

Inspection de l’appareil ..............................................................................................................................................14

Préparation de l’appareil et du chantier....................................................................................................................15

Mode d’emploi ............................................................................................................................................................15

Entretien

Remplacement des pannes au carbone ..................................................................................................................17

Accessoires ................................................................................................................................................................17

Stockage de l’appareil ................................................................................................................................................17

Service après-vente et réparations............................................................................................................................17

Schéma électrique ......................................................................................................................................................18

Garantie à vie ..........................................................................................................................................Page de garde

Page 13

Pince à souder électrique type RT-175

Ridge Tool Company 11

Consignes générales de sécurité

MISE EN GARDE ! Familiarisez-vous complètement avec

l’ensemble des instructions. Le nonrespect de ces consignes augmenterait

les risques de choc électrique, d’incendie et/ou de graves blessures corporelles.

CONSERVEZ CES INSTRUCTIONS !

Sécurité du chantier

• Maintenez le chantier propre et bien éclairé. Les

établis encombrés et le manque d’éclairage sont à

l’origine de nombreux accidents.

• N’utilisez pas d’appareils électriques en présence

de combustibles tels que les liquides, gaz ou

poussières inflammables. Les appareils électriques

produisent des étincelles capables d’enflammer les

poussières et les émanations combustibles.

• Ecartez les curieux, les enfants et les visiteurs

lorsque vous utilisez un appareil électrique. Les dis-

tractions éventuelles peuvent vous faire perdre le contrôle de l’appareil.

Sécurité électrique

• Les appareils électriques avec terre doivent être

branchés sur une prise avec terre appropriée et

installée selon les normes en vigueur. Ne jamais

tenter d’enlever la barrette de terre ou de modifier

la fiche de manière quelconque. Ne pas utiliser

d’adaptateurs de prise. En cas de doute concernant la bonne mise à la terre d’une prise électrique, consultez un électricien qualifié. En cas de

panne ou d’anomalie électrique, la mise à la terre

assure un passage de faible résistance qui éloigne le

courant électrique de l’utilisateur.

• Evitez tout contact avec des surfaces reliées à la

terre telles que tuyauteries, radiateurs, cuisinières

ou réfrigérateurs. Les risques de choc électrique

augmentent lorsque votre corps est en contact avec

une masse.

• N’exposez pas les appareils électriques à la pluie

ou aux intempéries. Toute pénétration d’eau à

l’intérieur d’un appareil électrique augmente les risques

de choc électrique.

• Ne maltraitez pas le cordon électrique de l’appareil.

Ne jamais porter l’appareil par son cordon électrique, ni tirer sur celui-ci pour débrancher

l’appareil. Gardez le cordon à l’abri des sources de

chaleur, de l’huile, des angles tranchants et des

pièces mobiles. Remplacez immédiatement tout

cordon endommagé. Les cordons endommagés

augmentent les risques de choc électrique.

• Lorsque vous utilisez l’appareil à l’extérieur,

utilisez une rallonge électrique portant la désignation “W-A” ou “W”. Ce type de rallonge est prévu

pour être utilisé à l’extérieur et réduit les risques de

choc électrique.

• N’utilisez que des rallonges électriques équipées

de fiches et de prises avec terre compatibles avec

la fiche de l’appareil. L’utilisation d’autres types de

rallonge électrique n’assurerait pas la mise à la terre

de l’appareil et augmenterait les risques de choc

électrique.

• Utilisez la section de rallonge appropriée (voir

tableau). Une section de conducteurs insuffisante

provoquerait une perte de tension excessive, un

manque de puissance et la surchauffe de l’appareil.

• Gardez toutes connexions électriques au sec et

surélevées. Ne touchez pas les fiches ou l’appareil

avec les mains mouillées. Cela limitera les risques

de choc électrique.

Sécurité individuelle

• Soyez attentif, concentrez-vous sur ce que vous

faites et faites preuve de bon sens lorsque vous

utilisez un appareil électrique. N’utilisez pas ce

type d’appareil lorsque vous êtes fatigués ou

lorsque vous prenez des médicaments, de l’alcool

ou des produits pharmaceutiques. Un instant d’inat-

tention peut entraîner de graves blessures lorsque

l’on utilise un appareil électrique.

• Habillez-vous de manière appropriée. Ne portez

pas de vêtements amples ou de bijoux. Attachez

Barrette de terre

Prise

avec

terre

Barrette de terre

Section minimale des fils conducteurs des rallonges

Ampères indiqués

sur la plaque Longueur totale (en pieds)

signalétique

0 à 25 26 à 50 51 à 100

0 à 6 18 AWG 16 AWG 16 AWG

6 à 10 18 AWG 16 AWG 14 AWG

10 à 12 16 AWG 16 AWG 14 AWG

12 à 16 14 AWG 12 AWG

Déconseillé

16 – 20 12 AWG 10 AWG Déconseillé

Page 14

Pince à souder électrique type RT-175

Ridge Tool Company12

les cheveux longs. Gardez vos cheveux, vos vêtements et vos gants à l’écart du mécanisme. Les

vêtements amples, les bijoux et les cheveux longs

peuvent s’entraver dans le mécanisme.

• Evitez les risques de démarrage accidentel.

Assurez-vous que l’interrupteur marche/arrêt est en

position OFF (arrêt) avant de brancher l’appareil. Le

fait de porter l’appareil avec un doigt sur la gâchette ou

le brancher lorsque son interrupteur est en position

de marche (ON) est une invitation aux accidents.

• Ne vous mettez pas en porte-à-faux. Maintenez

une bonne assise et un bon équilibre à tous

moments. Une bonne assise et un bon équilibre

vous permettent de mieux contrôler l’appareil en cas

d’imprévu.

• Utilisez les équipements de sécurité appropriés.

Portez systématiquement des lunettes de sécurité.

Un masque à poussière, des chaussures de sécurité,

le casque et/ou une protection auditive doivent être

portés selon les conditions d’utilisation.

Utilisation et entretien de l’appareil

• N’utilisez pas un appareil dont l’interrupteur ne

permet pas de le mettre en marche ou de l’arrêter.

Tout appareil qui ne peut pas être contrôlé par son

interrupteur est dangereux et doit être réparé.

• Rangez les appareils non utilisés hors de la portée

des enfants et des personnes non initiées. Ces

appareils sont dangereux entre les mains de personnes non initiées.

• Entretenez l’appareil soigneusement. Les outils

bien entretenus sont moins susceptibles de provoquer des accidents.

• Examinez l’appareil pour signes de mauvais

alignement ou de grippage des mécanismes ou

autres conditions qui pourraient entraver son

fonctionnement. Le cas échéant, il sera nécessaire de faire réparer l’appareil avant de vous en

servir. De nombreux accidents sont le résultat d’un

appareil mal entretenu.

• N’utilisez que les accessoires recommandés par le

fabricant pour votre appareil particulier. Des acces-

soires prévus pour un certain type d’appareil peuvent

être dangereux lorsqu’ils sont montés sur un autre.

• Examinez le cordon d’alimentation de l’appareil et

les rallonges électriques régulièrement, et remplacez tout élément endommagé. Les cordons

endommagés augmentent les risques de choc électrique.

• Gardez les poignées de l’appareil propres, sèches

et dépourvues d’huile ou de graisse. Cela vous

permettra de mieux le contrôler.

• Examinez les électrodes pour signes d’usure, et

remplacez-les avant que les goujons filetés deviennent apparents. Cela évitera les arcs électriques

ainsi qu’un appel de courant excessif.

Service après-vente

• Toutes réparations de l’appareil doivent être confiées à un réparateur qualifié. La réparation ou l’entre-

tien de l’appareil par du personnel non qualifié peut

entraîner des blessures.

• Lors de la réparation de l’appareil, utilisez exclusivement des pièces de rechange identiques à

celles d’origine. Suivez les instructions de la section “Entretien” du mode d’emploi. L’utilisation de

pièces de rechange non homologuées et le nonrespect des consignes d’entretien peut créer un risque

de choc électrique ou de blessure corporelle.

• Débranchez l’appareil avant toute intervention.

Cela éliminera les risques de choc électrique et démar-

rage accidentel.

Consignes de

sécurité particulières

MISE EN GARDE !

Lisez soigneusement ce manuel avant d’utiliser la

pince à souder électrique. Le non-respect des consignes qu’il contient pourrait s’accompagner de

choc électrique, d’incendie et/ou de grave blessures

corporelles.

Veuillez adresser toutes questions éventuelles aux services techniques de la Ridge Tool Company en composant le (800) 519-3456.

Sécurité de l’appareil

• Cet appareil est prévu pour la soudure des tuyaux

en cuivre. Respectez les consignes d’utilisation

suivantes. Toute autre utilisation pourrait augmenter

les risques d’accident.

• Ne laissez pas l’appareil sans surveillance. De

telles mesures préventives réduiront les risques d’acci-

dent et d’incendie.

• Ne touchez pas les bras ou les embouts au carbone de la pince à souder. Ils restent brûlants en fin

d’utilisation.

• N’utilisez pas l’appareil sans son couvercle de

Page 15

Pince à souder électrique type RT-175

Ridge Tool Company 13

Longueur du cordon

d’alimentation................98 po

Poids .............................32 livres

Hauteur

A (Figure 1) ...................6 po

Longueur

B (Figure 1) ...................17 po

Largeur

C (Figure 1) ..................11 po

Figure 1 – Dimensions du coffret de la pince à souder

boîtier électrique. Toute exposition aux composants

internes augmenterait les risques de choc électrique.

• Utilisez les bras et les embouts de soudure livrés

avec l’appareil. L’utilisation d’embouts au carbone ou

de bras mal adaptés risque de provoquer la surchauffe des conducteurs électriques.

• Eloignez les bras de soudure de tous matériaux

combustibles et de tout article susceptible d’être

endommagé par la chaleur. Les bras de soudure et

les embouts au carbone restent brûlants en fin d’util-

isation.

• N’effectuez pas de soudures à proximité de matériaux combustibles. Les tuyaux en cuivre et les bras

de soudure atteignent des températures suffisantes

pour commencer un incendie.

• Ne rangez pas la pince dans son coffret avant

que les embouts au carbone aient eu le temps

de refroidir. Ils risquent de brûler le cordon élec-

trique ou le câble de la pince.

• Ne laissez ni les goujons filetés ni les bras de

soudure en inox entrer en contact avec le tuyau ou

les raccords. Cela évitera les arcs électriques et un

appel de courant excessif qui pourrait faire disjoncter

le disjoncteur.

Description, spécifications et

équipements de base

Description

La pince à souder électrique type RT-175 utilise du

courant électrique standard de 110V/15A pour souder les

manchons de tuyaux en cuivre d’un diamètre maximal de

3 po. La pince à souder chauffe le cuivre à une température de plus de 750°F afin de fondre les divers types

de soudure utilisés dans la plomberie – allant des

soudures type 50/50 jusqu’aux soudures sans plomb

type 95/5.

Spécifications

Tension d’alimentation ...115V/15A

Puissance utile..............(tension à vide) élevée 7V,

basse : 6,2V

Appel de courant...........13,5A en position basse /

15,0A en position élevée

Facteur de marche........Continu

Capacité de tuyau .........Jusqu’à 3 po

Longueur du câble

de pince.........................136 po

B

A

C

Page 16

Pince à souder électrique type RT-175

Ridge Tool Company14

signes de détérioration. Si la fiche a été modifiée,

qu’elle manque de barrette de terre ou que le cordon

est endommagé, n’utilisez pas l’appareil avant d’avoir

remplacé le cordon.

3. Examinez les câbles et les embouts au carbone pour

signes de détérioration (Figure 2). Si les câbles ou les

embouts sont endommagés, n’utilisez pas la pince à

souder avant de les avoir remplacés. Utilisez exclusivement les bras de soudure et les embouts au carbone fournis avec l’appareil. L’utilisation de bras ou

d’embouts mal adaptés risque de provoquer la surchauffe des conducteurs électriques.

4. Eliminez toutes traces d’huile, de graisse et de crasse

des poignées, commandes et bras de pince.

5. Examinez la pince pour signes de composants

endommagés ou manquants, ainsi que pour signes

de détérioration de son carter métallique. Le cas

échéant, n’utilisez pas l’appareil avant d’avoir réparé

l’élément en question.

N’utilisez pas l’appareil sans son

couvercle de boîtier électrique.

Inspection de l’appareil

MISE EN GARDE !

Inspectez la pince à souder électrique de la

manière suivante afin d’éviter les accidents

graves.

1. Assurez-vous que la pince à souder est débranchée

et que son interrupteur est en position OFF (Arrêt)

(Figure 2).

2. Examinez le cordon d’alimentation et sa fiche pour

Figure 2a – Pince à souder RT-175

Cordon d’alimentation

Câble de la

pince à souder

Interrupteur

Marche/Arrêt

Poignées

Transformateur

Figure 2b – Poignées et embouts au carbone de la RT-175

Contre-écrou

Embouts au carbone

Goujon fileté

Bras de soudure

en inox

Poignées

MISE EN GARDE

Page 17

Pince à souder électrique type RT-175

Ridge Tool Company 15

Préparation de l’appareil

et du chantier

MISE EN GARDE !

Une bonne préparation de l’appareil et du chantier

permettra d’éviter les accidents graves. La préparation de la pince à souder comprend les étapes

suivantes :

1. Assurez-vous que les lieux offrent :

• Un éclairage suffisant

• Une prise de courant de 15A avec terre

• Un passage dégagé jusqu’à la prise de courant qui

ne contient pas de sources de chaleur ou d’huile,

d’objets tranchants ou de mécanismes qui pourraient endommager le cordon d’alimentation.

• Un endroit au sec pour l’appareil et son utilisateur.

N’utilisez pas cet appareil lorsque vous avez les

pieds dans l’eau.

• L’absence de liquides, de vapeurs et de poussières inflammables, voire de matériaux combustibles qui risquerait de s’enflammer.

2. Positionnez la pince à souder RT-175 à proximité

du tuyau en cuivre à souder.

3. Assurez-vous que l’interrupteur Marche/Arrêt se trouve en position OFF (arrêt), puis retirez la paire de

câbles complètement du coffret de l’appareil.

4. Avant de brancher le cordon d’alimentation de la

pince à souder, assurez-vous qu’il suit le passage

dégagé s électionné auparavant. Si le cordon n’arrive

pas jusqu’à la prise, servez-vous d’une rallonge électrique en bonne condition.

Afin d’éviter les chocs et les incendies électriques, ne jamais utiliser une rallonge électrique

endommagée ou qui ne répond pas au critères suivants :

• Fiche à trois barrettes semblable à celui indiqué à

la section “Sécurité électrique ”.

• Homologation “ W ” ou “W-A ” pour les travaux à

l’extérieur.

• Section de fils conducteurs suffisante (14 AWG

en dessous de 25 pieds ou 12 AWG de 25 à 50

pieds). Une section de fils conducteurs insuffisante

risque de provoquer la surchauffe de la rallonge et

fondre sa gaine ou provoquer un incendie.

Afin de limiter les risques de choc

électrique, maintenez toutes connexions électriques au

sec et surélevées. Ne pas toucher les fiches avec les

mains mouillées.

Mode d’emploi

MISE EN GARDE !

Afin de limiter les risques de choc électrique,

maintenez toutes connexions électriques au sec et

surélevées. Ne pas toucher les fiches avec les

mains mouillées.

Les embouts au carbone et les bras de soudure

deviennent brûlants en cours d’utilisation. Evitez

tout contact avec la peau, car cela risquerait de

provoquer des brûlures.

Eloignez les embouts au carbone et les bras de

soudure de tous matériaux combustibles et des

articles susceptibles d’être endommagés par la

chaleur.

Ne laissez pas l’appareil sans surveillance lorsqu’il

est en marche.

1. Assurez-vous que l’appareil est éteint. Branchez-le à

une prise avec terre de 15 ampères en faisant attention de faire suivre au cordon d’alimentation le passage dégagé précédemment sélectionné.

2. Nettoyez soigneusement le tuyau en cuivre et le raccord, puis appliquez le flux (Figure 3).

NOTA ! Respectez les techniques de soudage appro-

priées lors de l’utilisation de la RT-175.

Figure 3 – Nettoyage du tuyau et des raccords en cuivre

MISE EN GARDE

MISE EN GARDE

Page 18

Pince à souder électrique type RT-175

Ridge Tool Company16

Figure 6 – Soudage du raccord

5. Tenez le fil de soudure contre le rebord du raccord

jusqu’à ce que la soudure commence à couler librement (Figure 6). Appuyez alors sur les poignées afin

de retirer la pince à souder.

Ne surchauffez pas le raccord.

Les bras de soudure et les embouts

au carbone restent brûlants. Ne pas toucher. Ne posez

pas la pince sur une surface susceptible d’être endommagé avant que les bras et les embouts aient eu le

temps de refroidir.

6. Si un raccord à souder s’avère difficilement accessible, il n’est pas nécessaire que les embouts au carbone le pincent. Il est simplement nécessaire que les

embouts au carbone touchent le raccord (Figure 7).

Ne pincez pas le tuyau ou le raccord entre les bras de soudure en inox, les goujons

filetés ou les contre-écrous. Le cas échéant, il pourrait se

produire des arcs électriques ou un appel de courant

excessif qui risqueraient de faire disjoncter le disjoncteur.

7. Eteignez l’appareil lorsqu’il ne sert pas.

Ne rangez pas la pince dans le cof-

fret avant que l’appareil ait refroidi. Si elle est trop

chaude, la pince risque d’endommager le cordon d’alimentation ou ses propres câbles.

Figure 7 – Soudage avec les embouts au carbone en

contact avec le raccord

Figure 4 – Interrupteur Marche/Arrêt

3. Mettez l’appareil en marche (Figure 4). Servez-vous

des critères suivants pour sélectionner l’intensité :

LOW (basse).................Soudure 50/50 sur Ø 3/8à 11/

2

po / Soudure 95/5 sur Ø 3/8à

1

/2po

HIGH (élevée)...............Soudure 50/50 sur Ø 11/2à 3

po / Soudure 95/5 sur Ø 1/2à

3 po avec rallonge de 50

pieds maxi.

NOTA ! En position HIGH, la longueur maximale de la ral-

longe électrique utilisée doit être de 50 pieds !

4. Serrez les poignées pour ouvrir les embouts au carbone suffisamment pour envelopper le raccord.

Positionnez bien les embouts au carbone autour

du raccord afin d’assurer que l’effet de capillarité

attire la soudure à l’intérieur de la coupelle du raccord

(Figure 5).

Figure 5 – Positionnement des embouts au carbone

Raccord

Tuyau en cuivre

MISE EN GARDE

MISE EN GARDE

MISE EN GARDE

MISE EN GARDE

Page 19

Pince à souder électrique type RT-175

Ridge Tool Company 17

Entretien

MISE EN GARDE !

Débranchez l’appareil avant toute intervention.

Les embouts au carbone sont friables. Il convient de les manipuler avec précaution.

Evitez de trop les serrer et d’utiliser des clés tant que

possible – en un mot, un serrage manuel suffit.

Remplacement des embouts au carbone

Les embouts au carbone s’usent en fonction de la

fréquence d’utilisation de la RT-175. Ils doivent être

inspectés entre chaque intervention, et remplacés avant

que les goujons filetés deviennent visibles.

1. Débranchez la RT-175.

2. Immobilisez le contre-écrou, puis dévissez l’embout

au carbone en le tournant à gauche (Figure 8).

Figure 8 – Retrait des embouts au carbone

Figure 9 – Nettoyage des goujons filetés

3. Nettoyez les filets des goujons filetés à l’aide d’une

brosse métallique afin d’assurer aux nouveaux

embouts au carbone un maximum de conductivité

(Figure 9). Des goujons filetés brûlés manqueraient de

conductivité et ne chaufferaient pas correctement.

Des goujons filetés de rechange sont également

disponibles pour le remplacement de goujons d’origine endommagés.

4. Ne jamais tenir la pince par ses poignées en plastic,

car celles-ci risquent de se briser.

Accessoires

Seuls les produits RIDGID suivants sont compatibles

avec la pince à souder électrique RT-175. L’adaptation

d’accessoires prévus pour d’autres types d’appareil peut

s’avérer dangereuse en conjonction avec la RT-175.

Utilisez exclusivement les produits indiqués ci-dessous afin

d’éviter les risques d’accident grave.

Réf. Catalogue

Embouts au carbone 39966

Goujons filetés 39976

Stockage de l’appareil

Tout matériel électrique doit être

stocké à l’intérieur ou bien protégé contre les intem-

péries. Rangez l’appareil dans un local sous clé, hors de

la portée des enfants et de ceux qui ne sont pas familiers

avec les pinces à souder électriques. Cet appareil peut

provoquer de graves blessures corporelles s’il tombe

entre les mains de personnes non-initiées.

Service après-vente

et réparations

MISE EN GARDE !

L’entretien et la réparation de cet appareil doivent être

confiés exclusivement à des techniciens qualifiés.

L’appareil de soudage doit être soit confié à un réparateur indépendant agréé par RIDGE, soit renvoyé à

l’usine. Toutes réparations effectuées par les services

Ridge sont garanties contre les vices de matériaux et de

main d’œuvre.

N’utilisez que des pièces de re-

change identiques aux pièces d’origine lors de l’entretien

AVERTISSEMENT

MISE EN GARDE

MISE EN GARDE

Page 20

Pince à souder électrique type RT-175

Ridge Tool Company18

Schéma électrique

Interrupteur

N

B

T

Sortie

L

N

PE

115V

60Hz

15A

de cet appareil. Le non-respect de cette consigne augmenterait les risques de choc électrique et d’autres accidents graves.

Veuillez adresser toutes questions éventuelles concernant l’entretien ou la réparation de cet appareil à :

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44035-6001

Tel: (800) 519-3456

E-mail: TechServices@ridgid.com

Pour obtenir les coordonnés du centre de service agréé le

plus proche, veuillez contacter la Ridge Tool Company au

(800) 519-3456 ou via le site http://www.ridgid.com

Page 21

Pistola de soldar eléctrica

Modelo RT-175

Pistola de soldar eléctrica Modelo RT-175

A continuación apunte y retenga el número de serie del producto que se encuentra en la

placa de características.

No. de

Serie

Page 22

Ridge Tool Company20

Pistola de soldar eléctrica Modelo RT-175

Índice

Ficha para apuntar el Número de Serie del aparato ................................................................................................19

Información general de seguridad

Seguridad en la zona de trabajo ..............................................................................................................................21

Seguridad eléctrica ..................................................................................................................................................21

Seguridad personal ..................................................................................................................................................21

Uso y cuidado de la herramienta..............................................................................................................................22

Servicio ....................................................................................................................................................................22

Información específica de seguridad

Seguridad del aparato ..............................................................................................................................................22

Descripción y especificaciones

Descripción ..............................................................................................................................................................23

Especificaciones ......................................................................................................................................................23

Inspección del aparato ..............................................................................................................................................24

Preparación del aparato y de la zona de trabajo......................................................................................................25

Instrucciones de funcionamiento..............................................................................................................................25

Instrucciones de mantenimiento

Recambio de las puntas de carbono ........................................................................................................................27

Accesorios ..................................................................................................................................................................27

Almacenamiento del aparato ....................................................................................................................................27

Servicio y reparaciones..............................................................................................................................................28

Detección de averías ..................................................................................................................................................28

Garantía vitalicia..................................................................................................................................carátula posterior

Page 23

Pistola de soldar eléctrica Modelo RT-175

Ridge Tool Company 21

Información general de seguridad

¡

ADVERTENCIA! Lea y comprenda todas las instrucciones.

Pueden ocurrir golpes eléctricos, incendios y/u otras lesiones personales

graves si no se siguen todas las instrucciones detalladas a continuación.

¡

GUARDE ESTAS INSTRUCCIONES!

Seguridad en la zona de trabajo

• Mantenga su área de trabajo limpia y bien alumbrada. Los bancos de trabajo desordenados y las

zonas oscuras provocan accidentes.

• No haga funcionar aparatos motorizados en atmósferas explosivas, por ejemplo, en la presencia de

líquidos, gases o polvos inflamables. Los conmu-

tadores eléctricos generan chispas que pueden inflamar el polvo o los gases.

• Al hacer funcionar la pistola de soldar eléctrica,

mantenga apartados a espectadores, niños o visitantes. Las distracciones pueden hacerle perder el

control del aparato.

Seguridad eléctrica

• Las máquinas provistas de conexión a tierra deben

ser enchufadas a un tomacorriente debidamente

instalado y conectado a tierra de acuerdo con

todos los códigos y reglamentos. Jamás extraiga

del enchufe la tercera clavija que conduce a tierra

ni lo modifique de manera alguna. No use ningún

tipo de enchufe adaptador. En caso de estar en

duda referente a la conexión a tierra del tomacorriente, consulte con un electricista calificado. Si el

aparato sufre una avería eléctrica o de otro tipo, la

conexión a tierra proporciona una vía de baja resistencia para conducir la electricidad lejos del usuario.

• Evite que su cuerpo haga contacto con superficies

conectadas a tierra tales como cañerías, radiadores, cocinas o refrigeradores. Si su cuerpo

queda conectado a tierra, aumenta el riesgo de que

sufra un choque eléctrico.

• No exponga los aparatos eléctricos a la lluvia o a

condiciones mojadas. Si agua penetra en un apara-

to motorizado, aumenta el riesgo de que se produzca

un golpe eléctrico.

• No maltrate el cordón. Nunca transporte un apara-

to colgando de su cordón de suministro, ni tire del

cordón para sacar el enchufe del tomacorriente.

Mantenga el cordón lejos de fuentes de calor,

aceite, bordes cortantes o piezas movibles.

Recambie los cordones dañados de inmediato.

Los cordones en mal estado aumentan los riesgos de

que se produzca un choque eléctrico.

• Al hacer funcionar una máquina eléctrica a la

intemperie, emplee un cordón de extensión fabricado para uso exterior y rotulado “W-A” o “W”.

Estos cordones han sido diseñados para su empleo al

aire libre y reducen el riesgo de que se produzca un

choque eléctrico.

• Use solamente un cordón de extensión de tres

alambres equipado con un enchufe de tres clavijas

para conexión a tierra, y un tomacorriente de tres

polos que acoja a las tres clavijas del enchufe del

aparato. Otros alargadores no conectarán el aparato

a tierra y aumentará el riesgo de que se produzcan

choques eléctricos.

• Use cordones de extensión apropiados. (Vea la

tabla). Una dimensión insuficiente del conductor

causará una caída excesiva del voltaje, pérdida de

potencia o recalentamiento.

• Mantenga todas las conexiones eléctricas secas y

levantadas del suelo. No toque los enchufes o el

aparato con las manos mojadas. Así se evitan los

choques eléctricos.

Seguridad personal

• Manténgase alerta, preste atención a lo que está haciendo y use sentido común cuando trabaje con un

aparato motorizado. No lo use si está cansado o se

encuentra bajo la influencia de drogas, alcohol o

medicamentos. Sólo un breve descuido mientras

hace funcionar una herramienta a motor puede resultar

en lesiones personales graves.

• Vístase adecuadamente. No lleve ropa suelta ni

joyas. Amarre una cabellera larga. Mantenga su

cabello, ropa y guantes apartados de las piezas en

Clavija para la

conexión a tierra

Tapa del

enchufe conectado

a tierra

Clavija para la

conexión a tierra

Dimensión mínima de alambre para cordones de extensión

Amperios en

la placa de Longitud total (en pies)

características

0 – 25 26 – 50 51 – 100

0 – 6 18 AWG 16 AWG 16 AWG

6 – 10 18 AWG 16 AWG 14 AWG

10 – 12 16 AWG 16 AWG 14 AWG

12 – 16 14 AWG 12 AWG

NO SE RECOMIENDA

16 – 20 12 AWG 10 AWG NO SE RECOMIENDA

Page 24

Pistola de soldar eléctrica Modelo RT-175

Ridge Tool Company22

movimiento. La ropa suelta, las joyas o el pelo largo

pueden engancharse en las piezas móviles.

• Evite echar a andar el aparato sin querer. Antes de

enchufarlo, asegure que el interruptor se encuentre en la posición OFF (apagado). Enchufar má-

quinas que tienen el interruptor en la posición de

encendido o acarrearlas con el dedo en el interruptor

es una invitación a que se produzcan accidentes.

• No trate de extender su cuerpo para alcanzar algo.

Mantenga sus pies firmes en tierra y un buen equilibrio en todo momento. Al mantener el equilibrio y los

pies firmes, tendrá mejor control sobre el aparato en

situaciones inesperadas.

• Use equipo de seguridad. Siempre lleve protección para la vista. Cuando las condiciones lo requier-

an, debe usar mascarilla para el polvo, calzado de

seguridad antideslizante, casco duro o protección

para los oídos.

Uso y cuidado del aparato

• Si el interruptor de ENCENDIDO/APAGADO no

funciona, no use el aparato. Cualquier aparato que

no pueda ser controlado mediante su interruptor es

peligroso y debe ser reparado.

• Almacene los aparatos que no estén en uso fuera

del alcance de los niños y de otras personas sin

entrenamiento. Las herramientas en manos de inex-

pertos se tornan peligrosas.

• Hágale cuidadoso mantenimiento a sus herramientas. Es menos probable que las herramientas bien

mantenidas causen lesiones.

• Verifique que el aparato no tenga piezas quebradas y que no existan condiciones que puedan

afectar el funcionamiento del aparato. En el caso

de estar dañado, antes de usar el aparato, hágalo

componer. Numerosos accidentes son causados

por aparatos que no han recibido un mantenimiento

adecuado.

• Solamente use los accesorios recomendados por

el fabricante para su modelo. Los accesorios que

son los adecuados para una máquina pueden resultar

peligrosos si se acoplan a otra máquina.

• Revise el aparato y los cordones de extensión

periódicamente. Cámbielos si están averiados.

Los cordones dañados aumentan el riesgo de que

ocurran choques eléctricos.

• Mantenga los mangos limpios y secos, libres de

aceite y grasa. Esto permite un mejor control del

aparato.

• Revise los electrodos por si están desgastados y

recámbielos antes de que puedan verse las espigas roscadas. Así se evita la proyección de chispas

y tomas excesivas de corriente.

Servicio

• El servicio del aparato sólo debe ser efectuado por

personal de reparaciones calificado. El servicio o

mantenimiento practicado por personal no calificado

para efectuar reparaciones puede resultar en lesiones.

• Cuando le haga mantenimiento a una máquina,

debe usar únicamente repuestos o piezas de recambio idénticas. Siga las instrucciones en la

Sección de Mantenimiento de este manual. Pueden

producirse choques eléctricos o lesiones personales si

no se emplean piezas y partes autorizadas o si no se

siguen las instrucciones de mantenimiento.

• Desenchufe la unidad de cualquier fuente de suministro antes de hacerle servicio. Así se evitan las

descargas eléctricas y el poner en marcha el aparato

accidentalmente.

Información específica

de seguridad

ADVERTENCIA

Lea este Manual del Operario detenidamente antes

de usar la Pistola de Soldar Eléctrica. Pueden

producirse choques eléctricos, incendios y/o

graves lesiones personales si no se comprenden y

respetan todas las instrucciones de este manual.

Si tiene cualquier pregunta, llame al Departamento de

Servicio Técnico de Ridge Tool Company al (800) 519-

3456.

Seguridad del aparato

• El aparato fue diseñado para soldar tubería de

cobre. Siga las instrucciones para saber como

usarlo correctamente. Emplearlo para efectuar otro

tipo de trabajo aumenta los riesgos de lesiones.

• No deje la unidad desatendida. Cuando se la tiene

vigilada, se evitan lesiones o incendios.

• No toque las camisas ni las puntas de carbono.

Permanecen calientes después del uso.

• No haga funcionar la unidad sin la cubierta de la

caja eléctrica. Pueden producirse choques eléctri-

cos al tocar las partes internas del aparato.

• Emplee las camisas de soldar y las puntas de

carbono que vienen con la unidad. Las puntas de

Page 25

Pistola de soldar eléctrica Modelo RT-175

Ridge Tool Company 23

Altura

(A – Vea la Figura 1).....6 pulgadas

Longitud

(B – Vea la Figura 1)..............17 pulgadas

Ancho

(C – Vea la Figura 1).....11 pulgadas

Figura 1 – Dimensiones del maletín de la Pistola de Soldar

carbono o camisas incorrectas pueden recalentar los

alambres.

• Mantenga las camisas de soldar apartadas de

materiales combustibles y de artículos que pueden

dañarse con el calor. Las camisas de soldar y las

puntas de carbono permanecen calientes después

del uso.

• No efectúe soldaduras cerca de materiales combustibles. La tubería de cobre y las camisas de soldar

alcanzan altas temperaturas que pueden producir

incendio.

• No almacene el mango dentro de la caja hasta

que las puntas de carbono se hayan enfriado.

Pueden quemar el cordón o cable de la Soldadora.

• No permita que las espigas roscadas y las

camisas de acero inoxidable toquen o se sujeten

contra tuberías o contra acoplamientos (fittings).

Así se evitan las chispas eléctricas y las tomas excesivas de corriente que pueden desconectar el interruptor automático de circuito.

Descripción, especificaciones

y equipo estándar

Descripción

La Pistola de Soldar Eléctrica RT-175 es capaz de soldar

uniones en tubería de cobre de hasta 3 pulgadas de

diámetro empleando un circuito estándar de 110V y 15

amperios. La pistola de soldar calienta el cobre a temperaturas superiores a 750 *F lo que le permite fundir con

éxito los soldantes comúnmente empleados en plomería

o fontanería, es decir, desde soldantes tipo 50/50 hasta

los 95/5 sin plomo.

Especificaciones

Potencia de entrada......115 voltios, 15 amperios

Potencia de salida.........(tensión en circuito abierto)

Alta= 7,0 V; Baja= 6,2 V

Toma de corriente.........13,5 amperios en regulación

baja, 15,0 amperios en regu-

lación alta

Ciclo de trabajo .............continuo

Tubería..........................de hasta 3 pulgadas

Longitud del

cable de soldar..............136 pulgadas

Longitud del cordón

de suministro.................98 pulgadas

Peso..............................32 libras

B

A

C

Page 26

Pistola de soldar eléctrica Modelo RT-175

Ridge Tool Company24

por si están dañados. Si el enchufe ha sido modificado o no tiene su clavija de conexión a tierra, o si el

cordón está dañado, no use el aparato hasta que se

le haya cambiado el cordón.

3. Inspeccione los cables y puntas de carbono por si

están dañados (Figura 2). Si los cables o las puntas

están dañados, no use la Soldadora hasta que hayan

sido recambiados. Emplee únicamente las camisas

de soldar y las puntas de carbono provistas con la

unidad. Si no son las correctas, los alambres pueden

recalentarse.

4. Limpie el aceite, grasa o mugre de todos los mangos,

controles y pinzas.

5. Revise la Pistola de Soldar para asegurar que no le

faltan partes o tenga piezas quebradas o por si la carcasa metálica está dañada. Si detecta cualquier

defecto o avería, no use el aparato hasta que haya

sido reparado.

No haga funcionar el aparato si se le

ha sacado su cubierta de protección.

Inspección del aparato

ADVERTENCIA

Para evitar lesiones de gravedad, se requiere

revisar la Pistola de Soldar. Deben seguirse los procedimientos siguientes:

1. Asegure que la Soldadora está desenchufada y que

el interruptor se encuentra en posición OFF (apagado). (Figura 2)

2. Inspeccione el cordón de suministro y el enchufe

Figura 2a – Pistola de soldar RT-175

Cordón de suministro

Cable de

soldar

Interruptor de

ENCENDIDO/APAGADO

Mangos

Transformador

Figura 2b – Mangos y puntas de carbono de la RT-175

Tuerca de

seguridad

Puntas de carbono

Espiga roscada

Camisas de

acero inoxidable

Mangos

ADVERTENCIA

Page 27

Pistola de soldar eléctrica Modelo RT-175

Ridge Tool Company 25

Preparación del aparato y de la

zona de trabajo

ADVERTENCIA

Se requiere una adecuada preparación del aparato y de la zona de trabajo para evitar que ocurran

lesiones de gravedad. Deben seguirse los siguientes procedimientos para preparar la Soldadora:

1. Asegure que en la zona de trabajo:

• haya suficiente luz;

• exista un tomacorriente eléctrico de 15 ampe-

rios conectado a tierra;

• haya una senda directa hasta el tomacorriente,

libre de fuentes de calor, aceites, bordes afilados

o cortantes o piezas movibles que puedan dañar

el cordón eléctrico;

• haya un lugar seco para situar el aparato y al

operario. No use la máquina si se encontrará

parado sobre agua. Y,

• no hayan líquidos, vapores o gases inflamables.

2. Coloque la Pistola de Soldar RT-175 cerca de la

sección de la tubería de cobre que se soldará.

3. Asegure que la unidad se encuentra desenchufada y

apagada: interruptor en posición OFF. Desenrolle

todo el cable fuera del maletín.

4. Enchufe la Soldadora al tomacorriente ubicado al

final de la senda despejada elegida con anterioridad.

Si el cordón de la máquina no alcanza el tomacorrien-

te, use un cordón de extensión en buenas condiciones.

Para evitar choques e incendios eléc-

tricos, nunca use un cordón de extensión dañado o

que no cumpla con los siguientes requisitos:

• tener un enchufe de tres clavijas similar al que se

muestra en la sección Seguridad eléctrica.

• estar clasificado como “W” ó “W-A”, si será usado

a la intemperie.

• tener el grosor suficiente (14 AWG si mide menos

de 25 pies de largo, 12 AWG si mide entre 25 y 50

pies). Si el grosor del cable es insuficiente, el cordón puede recalentarse y derretirse su material

aislante, o prender fuego a objetos cercanos.

Para reducir el riesgo de ocasionar

choques eléctricos, mantenga todas las conexiones

eléctricas secas y levantadas del suelo. No toque el

enchufe con las manos mojadas.

Instrucciones de funcionamiento

ADVERTENCIA

Para reducir el riesgo de ocasionar choques eléctricos, mantenga todas las conexiones eléctricas

secas y levantadas del suelo. No toque el enchufe

con las manos mojadas.

Las puntas de carbono y las camisas de los terminales se calientan durante el uso. Debido a que

puede sufrir quemaduras, evite el contacto de su

piel con estas partes del aparato.

Mantenga las puntas de carbono y las camisas

apartadas de materiales combustibles o de artículos que puedan dañarse con el calor.

No se aleje de la unidad mientras esté en uso.

Vigílela.

1. Asegure que la unidad se encuentra apagada (en

OFF). Enchufe la Soldadora a un tomacorriente

conectado a tierra, de 15 amperios, y asegure que el

cordón de suministro vaya extendido por la senda

despejada elegida con anterioridad.

2. Limpie bien tanto el tubo de cobre como el acoplamiento y aplique el fundente (Figura 3).

¡

NOTA! Deben emplearse las técnicas de soldadura

apropiadas cuando se emplea la RT-175.

Figura 3 – Limpieza del tubo de cobre y el fitting de

conexión

ADVERTENCIA

ADVERTENCIA

Page 28

Pistola de soldar eléctrica Modelo RT-175

Ridge Tool Company26

Figura 5 – Soldadura

5. Coloque el alambre para soldar en el labio del fitting

hasta que el soldante fluya libremente (Figura 6).

Cuando esto ocurra, apriete los mangos y desmonte

la Pistola de soldar.

No recaliente el fitting.

Las camisas de acero inoxidable y

las puntas de carbono de la Pistola de Soldar permanecerán calientes. No las toque ni las ponga sobre

superficies que puedan quemarse o dañarse, hasta

que se hayan enfriado.

6. Si la unión que se va a soldar está en una zona

difícil de alcanzar, no es necesario colocar las puntas

de carbono alrededor del tubo. Sólo tienen que estar

en contacto con el fitting (Figura7).

No toque o abrace el tubo ni el fitting

con las camisas de acero inoxidable, las espigas

roscadas o tuercas de seguridad. Porque pueden producirse chispas eléctricas o tomas excesivas de corriente que pueden provocar la desconexión del interruptor

automático de circuito.

7. Apague la Soldadora cuando no esté en uso.

No guarde los mangos en el maletín

mientras estén calientes. Pueden danar el cordón de

suministro o los cables de soldar de la Soldadora.

Figura 7 – Soldadura con las puntas de carbono sólo en

contacto con el fitting

Figura 4 – Interruptor de encendido/apagado

3. Encienda la unidad (Figura 4). Seleccione entre las

regulaciones HIGH (alta) o LOW (baja), según las

siguientes pautas:

LOW (baja)....................3/8a 11/2pulgada Soldadura

50/50, 3/8a 1/2pulgada

Soldadura 95/5

HIGH (alta)....................11/2a 3 pulgs. Soldadura

50/50, 1/2a 3 pulgs. Soldadura

95/5 Maxima longitud del cordon de extension: 50 pies

¡

NOTA! En la regulación HIGH (alta), el cordón de exten-

sión que se emplee ¡no puede exceder los 50

pies!

4. Apriete los mangos, juntándolos, para abrir las puntas y meterlas en la unión. Asegure de colocar las

puntas de carbono sobre la unión o junta para permitir

que, mediante el efecto capilar, la soldadura se

adentre en la taza del accesorio o fitting de soldar

(Figura 5).

Figura 5 – Posición de las puntas de carbono

Accesorio o

fitting de soldar

Tubo de cobre

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

Page 29

Pistola de soldar eléctrica Modelo RT-175

Ridge Tool Company 27

Mantenimiento

ADVERTENCIA

Asegure que la unidad está desenchufada de la

fuente de suministro antes de efectuarle mantenimiento o reparaciones.

Las puntas de carbono son quebradizas. Se

deben manipular con cuidado. No las tuerza en demasía;

emplee una llave sobre ellas si es absolutamente necesario. De lo contrario, siempre apriete todo con los dedos.

Recambio de las puntas de carbono

Las puntas de carbono se desgastarán con el uso. Deben

inspeccionarse antes de cada soldadura. Recámbielas

antes que aparezcan o puedan verse las espigas

roscadas.

1. Desenchufe la RT-175.

2. Sostenga la tuerca de seguridad y retire la punta

de carbono girándola hacia la izquierda (Figura 8).

Figura 8 – Extracción de una punta de carbono

Figura 9 – Limpieza de las espigas roscadas

3. Limpie las roscas de las espigas roscadas con una

escobilla metálica para que hagan buen contacto

con las nuevas puntas de carbono (Figura 9). Las

espigas, si están quemadas, no harán un buen contacto o conexión y no calentarán como se debe.

También hay disponibles espigas roscadas en caso

de que se dañen.

4. Nunca ejerza torsión sobre los mangos recubiertos de

aislante porque puede rajarse el material de plástico.

Accesorios

Los siguientes productos RIDGID son los únicos que

pueden usarse en conjunto con la Pistola de Soldar

Eléctrica RT-175. Otros accesorios que pueden ser

apropiados para usarse con otros aparatos, pueden

resultar peligrosos al usarse con la RT-175. Para evitar

lesiones de gravedad, emplee únicamente los accesorios

que se listan a continuación:

No. en el catálogo

Puntas de carbono 39966

Espigas roscadas 39976

Almacenamiento de la máquina

Los equipos eléctricos deben guardarse dentro, bajo techo, o bien cubiertos para guarecerlos

de la lluvia. Almacene la máquina bajo llave, fuera del

alcance de los niños y personas que no conocen el

manejo de esta Pistola de Soldar. Este aparato puede

causar graves lesiones en manos de usuarios sin entrenamiento.

CUIDADO

ADVERTENCIA

Page 30

Servicio y reparaciones

ADVERTENCIA

Los trabajos de mantenimiento y reparaciones de esta

herramienta deben realizarlos técnicos calificados. La

Soldadora debe llevarse a un Servicentro Autorizado

Independiente RIDGID o devuelta a la fábrica. Todas las

reparaciones efectuadas por un servicentro RIDGID

están garantizadas contra defectos en los materiales y

de la mano de obra.

Sólo deben usarse piezas de recambio idénticas cuando se le haga servicio a esta máquina.

El incumplimiento de estas instrucciones puede crear el

riesgo de choques eléctricos y otras lesiones graves.

Si tiene cualquier pregunta relativa al mantenimiento o

reparación de esta herramienta, llame o escriba a:

Ridge Tool Company

Departamento de Servicio Técnico

400 Clark Street

Elyria, Ohio 44035-6001

Teléfono: (80 0 ) 5 19-3456

E-mail: TechServices@ridgid.com

Para información sobre el nombre y dirección del

Servicentro Autorizado Independiente más cercano, llame

a Ridge Tool Company al (800) 519-3456 o visítenos en

el sitio de internet http://www.ridgid.com

Pistola de soldar eléctrica Modelo RT-175

Ridge Tool Company28

Diagrama de cableado

Interruptor de

alimentación

NEGRO

BLANCO

VERDE

Salida

L

N

PE

115V

60Hz

15A

ADVERTENCIA

Page 31

Printed in U.S.A. 1/04 999-997-047.10

Ridge Tool Company

400 Clark Street

Elyria, Ohio 44035-6001

What is covered

RIDGID

®

tools are warranted to be free of defects in workmanship and material.

How long coverage lasts

This warranty lasts for the lifetime of the RIDGID

®

tool. Warranty coverage ends when the prod-

uct becomes unusable for reasons other than defects in workmanship or material.

How you can get service

To obtain the benefit of this warranty, deliver via prepaid transportation the complete product

to RIDGE TOOL COMPANY, Elyria, Ohio, or any authorized RIDGID

®

INDEPENDENT SERVICE

CENTER. Pipe wrenches and other hand tools should be returned to the place of purchase.

What we will do to correct problems

Warranted products will be repaired or replaced, at RIDGE TOOL’S option, and returned at no

charge; or, if after three attempts to repair or replace during the warranty period the product

is still defective, you can elect to receive a full refund of your purchase price.

What is not covered

Failures due to misuse, abuse or normal wear and tear are not covered by this warranty. RIDGE

TOOL shall not be responsible for any incidental or consequential damages.

How local law relates to the warranty

Some states do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitation or exclusion may not apply to you. This warranty gives you specific

rights, and you may also have other rights, which vary, from state to state, province to

province, or country to country.

No other express warranty applies

This FULL LIFETIME WARRANTY is the sole and exclusive warranty for RIDGID

®

products. No

employee, agent, dealer, or other person is authorized to alter this warranty or make any other

warranty on behalf of the RIDGE TOOL COMPANY.

FULL LIFETIME

Qué cubre

Las herramientas RIDGID están garantizadas contra defectos de la mano de obra y de los

materiales empleados en su fabricación.

Duración de la cobertura

Esta garantía cubre a la herramienta RIDGID durante toda su vida útil. La cobertura de la

garantía caduca cuando el producto se torna inservible por razones distintas a las de defectos

en la mano de obra o en los materiales.

Cómo obtener servicio

Para obtener los beneficios de esta garantía, envíe mediante porte pagado, la totalidad del producto a RIDGE TOOL COMPANY, en Elyria, Ohio, o a cualquier Servicentro Independiente

RIDGID. Las llaves para tubos y demás herramientas de mano deben devolverse a la tienda donde

se adquirieron.

Lo que hacemos para corregir el problema

El producto bajo garantía será reparado o reemplazado por otro, a discreción de RIDGE TOOL,

y devuelto sin costo; o, si aún resulta defectuoso después de haber sido reparado o sustituido

tres veces durante el período de su garantía, Ud. puede optar por recibir un reembolso por el valor

total de su compra.

Lo que no está cubierto