RIDGID RT-100 User Manual

Ridge Tool Co., Elyria, Ohio, U.S.A.

3/98

Printed in U.S.A. 999-998-004.10

RT-100 Mini Electric Soldering Gun

General and Specific Safety

Information

Refer to the attached RT-175 Operator’s Manual

Specifications

Power Input...................115V, 15A

Power Output

(open circuit voltage) .....4.0V

Current Draw.................12A

Duty Cycle.....................Continuous

Solder Gun

Cable Length.................72″

Power Cord Length.......84”

Weight...........................23 lbs.

RT-100 MINI ELECTRIC SOLDERING GUN

Thank-you for purchasing the RIDGID RT -100 Mini Electric Soldering Gun. It is designed to safely heat copper tube and

fittings to solder joints. The RT-100 uses resistance heating to melt the solder without the danger of using an open

flame. It is a safer, faster method of soldering copper tube.

The RT-100 can efficiently and quickly solder joints in copper tube up to 1

1

/2″ diameter while using a standard 120V,

15A circuit. The soldering gun will heat the copper to

temperatures in excess of 750°F which allows it to

melt all solders used in plumbing applications - from

the 50/50 solders to the 95/5 lead-free types.

The RT-100 has cable lengths of 72″ which lead to

the handles. The unit has a wireform welded to the

case that acts as a cord wrap for the cables and power

cord and as a handle for portability. The RT-100

is similar to Ridge Tool’s RT-175 Electric

Soldering Gun but in a smaller, more

compact design. The unit is designed

with the service plumber in mind for the

repair and renovation projects that require

soldering in tight locations and minimizing destruction

of existing structures.

This instruction sheet along with the attached Operator’s Manual for the RT-175 outline all the safety and operational

features for the RT-100 Mini Electric Soldering Gun. Listed below are the specifications and operating instructions for

the RT-100.

Dimensions

Height......................... 5″

Width..........................10″

Length........................14″

Accessories/Replacement Parts

• Carbon Tips Catalog No. 39966

• Threaded Studs Catalog No. 39976

• Leather Holster N/A

NOTE! The holster is designed to fit over the carbon

tips and stainless steel arms. It will protect the

handle cables and power cord from damage

from the tips and arms and will protect the carbon tips during transport.

Lifetime Warranty

The reputation of RIDGID®tools is the result of consistent product quality and years of pride in workmanship. Rigorous checks and controls, from raw materials

to packaged products, ensure product confidence widely accepted as the benchmark of the professional trades. RIDGID®tools are warranted to be free of defects

in workmanship or material for the life of the tool. Expendable Materials, such as pipe or drain cleaning tools, rods and cables, etc. are not covered by this warranty. Obviously, failures due to misuse, abuse, or normal wear and tear are not covered by this warranty. NO OTHER WARRANTY EXPRESS OR IMPLIED,

APPLIES, INCLUDING MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. No employee, agent, dealer, or other person is authorized to alter

this or make any other warranty on behalf of RIDGE TOOLCOMPANY. To obtain the benefit of this warranty, deliver the complete product prepaid to RIDGE TOOL

COMPANY or any RIDGID

®

AUTHORIZED SERVICE CENTER. Pipe wrenches and other hand tools should be returned to place of purchase. Warranted products will be repaired or replaced, at RIDGE TOOL'S option, at no charge and returned via prepaid transportation. This limited LIFETIME WARRANTY is the sole

and exclusive warranty for RIDGID

®

products, and the remedy of repair or replacement is the sole and exclusive remedy for any nonconformity with this warran-

ty. RIDGE TOOL shall not be responsible for damages of any sort, including incidental or consequential damages.

Ridge Tool Company/Elyria, Ohio, U.S.A.

RT-100 Mini Electric Soldering Gun Operator’s Manual

Operating Instructions

Refer to the attached RT-175 Operators Manual for

additional information.

NOTE! When using the RT-100, proper-soldering tech-

niques should continue to be followed:

1. Plug the power cord into a 115V, 15 Amp grounded receptacle.

2. Thoroughly clean the copper tube and fitting and

apply the flux.

3. Turn the unit ON.

NOTE! 26′ - 50′ EXTENSION CORD SHOULD CONSIST

OF #12 GAUGE WIRE A T AMINIMUM. (SEE SAFETY SECTION FOR PROPER SIZE CORD).

4. Squeeze handles together to open the carbon tips

to fit over the joint. Be sure to place the carbon tips

over the joint to allow capillary effect to draw the

solder into the solder cup of the fitting.

5. Hold solder wire at fitting lip until the solder begins

to flow freely. When this occurs, squeeze handles

and remove solder gun.

WARNING

Do not overheat fitting.

WARNING

Solder gun stainless steel sleeves and carbon

tips remain hot. Do not touch. Do not lay on surfaces that may be damaged until sleeves and

tips have cooled.

6. If the joint to be soldered is in a difficult to reach

location, it is not necessary to clamp the carbon

tips around the tube. The carbon tips only have to

be in contact with the fitting.

7. Do not clamp or touch stainless steel sleeves,

threaded studs, or lock nuts against the tube or fittings. If this happens, sparking or excessive current draw may occur.

8. Switch the unit OFF when not in use. After the unit

has cooled sufficiently, place the leather holster

over the tips and stainless steel arms.

Maintenance

Refer to the attached RT-175 Operator’s Manual.

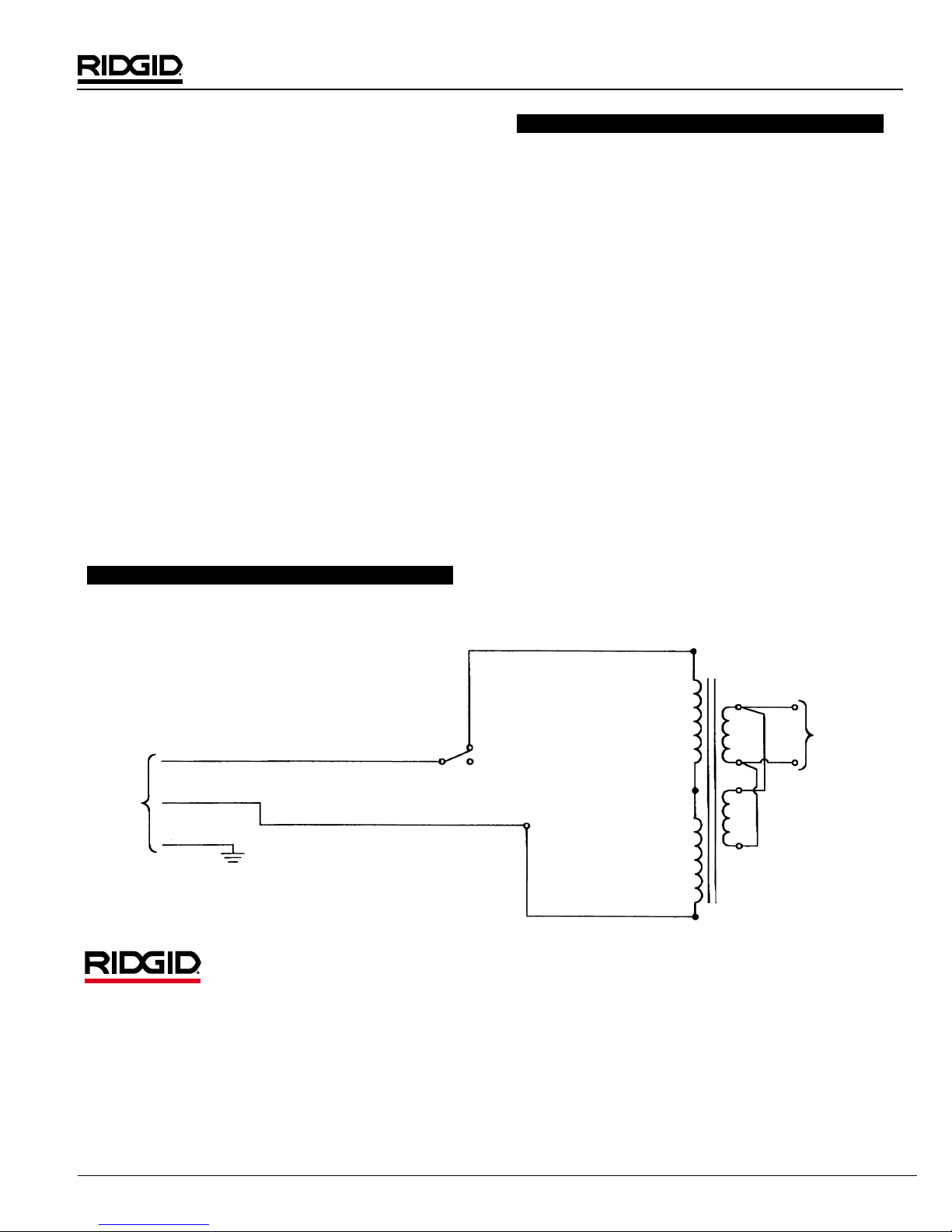

Wiring Diagram

115VAC

25-60Hz

15A

H

G

N

ON

OFF

OUTPUT

RANGE

4.0 VA C

AT CURRENT

UP TO 400A

Loading...

Loading...