RIDGID RSS-1000 Operating Instructions And Parts Manual

Model, Modèle, Modelo

S

o

Preassembled Sump System

RSS-1000

OPERATING INSTRUCTIONS

AND PARTS MANUAL

MANUEL DE PIÈCES ET

MODE D’EMPLOI

MANUAL DE INSTRUCCIONES

DE FUNCIONAMIENTO Y

PIEZAS DE REPUESTO

Système de pompe immergée

préassembleé

istema de sumidero preensamblad

Sistema de sumidero preensamblado

WARNING

READ UNDERSTAND AND

FOLLOW ALL INSTRUCTIONS

IN THIS MANUAL — DO NOT

DISCARD. Failure to understand

and follow the contents of this

manual may result in electrical

shock, fire and/or serious

personal injury.

!

AVER TISSEMENT!

LIRE, COMPRENDRE ET SUIVRE

TOUTES LES INSTRUCTIONS

DANS CE MANUEL — NE PAS

JETER. Ne pas comprendre et

ne pas suivre les contenus de ce

manuel peut avoir pour résultat

un choc électrique, de feux et/ou

de blessures personnelles graves.

¡

ADVERTENCIA!

LEA, ENTIENDA Y SIGA

TODAS LAS INSTRUCCIONES

DE ESTE MANUAL — NO LAS

DESECHE. El no entender

y no seguir el contenido de

este manual puede dar como

resultado un choque eléctrico,

incendios y/o lesiones graves.

Operating Instructions and Parts Manual

Model, Modèle, Modelo – RSS-1000 Manuel de pièces et mode d’emploi

Manual de instrucciones de funcionamiento y piezas de repuesto

Table of Contents

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

System Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

General Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Specific Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Back-up Pump Battery Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Recording Form for Pump Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Replacement Part List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

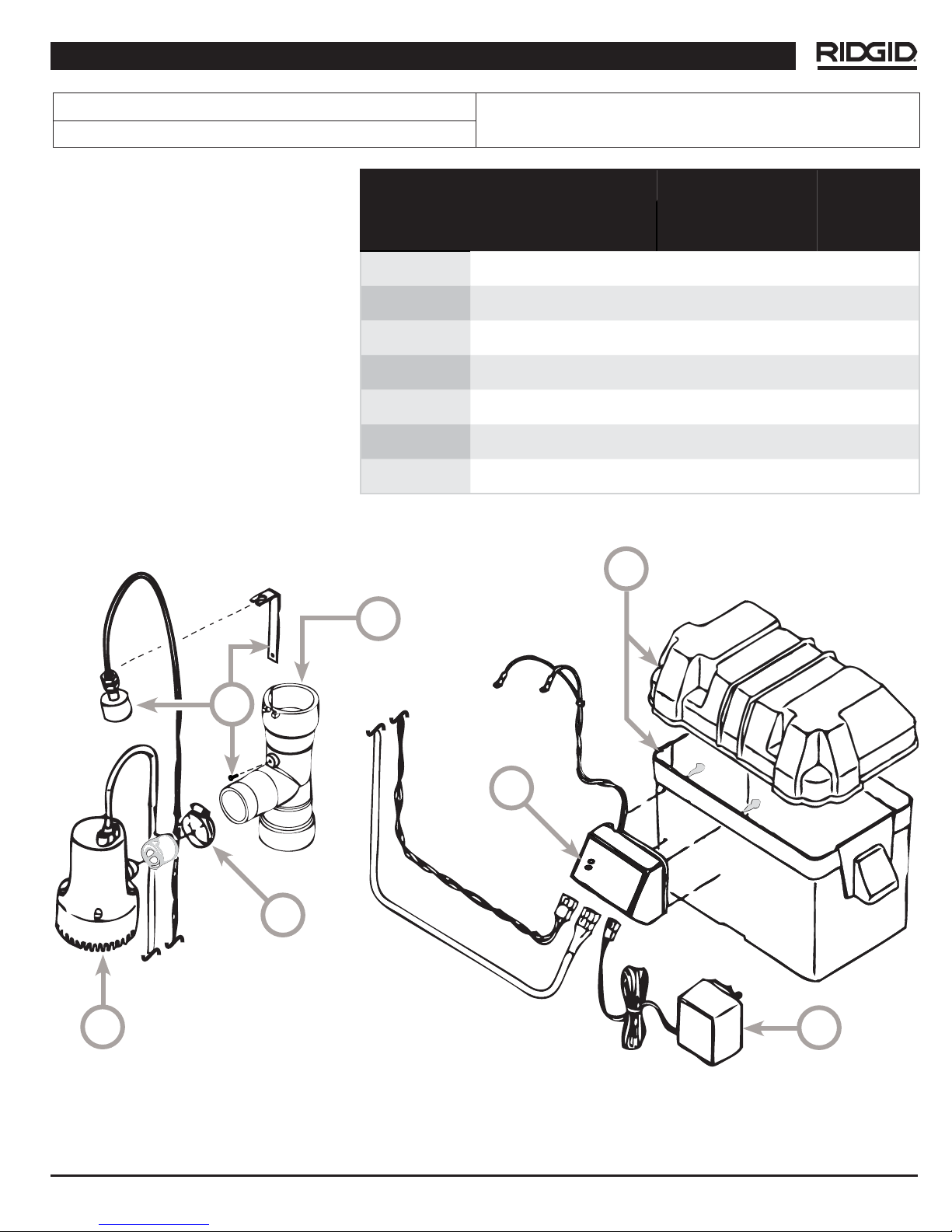

Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6, 19 - 21

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

Table des matières

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Déballage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Directives de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Spécifications de la système . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Construction de la système . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Information générale sur la sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 8

Information de sécurité spécifique. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Exigences de la batterie de la pompe de secours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation de la système . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 9

Fonctionnement de la système. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 10

Instructions d'entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Guide de dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Formulaire d’enregistrement du numéro de série de la pompe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Coordonnées . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pièces de rechange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Vue éclatée . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 - 21

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Couverture arrière

Índice

Descripción . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Desempaque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Pautas de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Especificaciones de la sistema. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Construcción de la sistema. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Información general de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 - 14

Información específica sobre seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Requisitos de la batería para la bomba de respaldo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Instalación de la sistema. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 - 15

Funcionamiento de la sistema . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Instrucciones de mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cuadro de Correción de fallas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Formulario de registro para el número de serie de la bomba . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Información de contacto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Piezas de repuesto. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Diagrama esquemático . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Notas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 - 21

Garantia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Ridge Tool Company

Contraportada

Model RSS-1000 – Operating Instructions and Parts Manual

Please read and save these instructions. This manual contains important Safety Warnings and Operating Instructions. You will need to refer to it

before attempting any application or maintenance. Always keep this manual with the unit so that it will be easily accessible. Failure to read and

follow these warnings and instructions could result in property damage, serious injury, or death.

DESCRIPTION

This pre-assembled sump system is designed for indoor

home sump applications. This system consists of a SP-1000

primary pump and a backup pump.

The primary system operates on 120-volt household electric

power. It is equipped with a 3-prong (GFCI) power cord. The

motor is dielectric oil filled and sealed for cooler running and

is designed to operate under water.

The battery operated back-up sump pump is included in the

event that the primary pump cannot function. It does not

replace the primary pump. A float switch automatically turns

on the backup sump pump when water activates the float. A

battery (not included) must be installed to operate the backup sump pump.

UNPACKING

Inspect this unit before it is used. Occasionally, products are

damaged during shipment. If the pump or components are

damaged, contact customer service at 1-877-9RIDGID.

READ & FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS — DO NOT DISCARD

SAFETY GUIDELINES

This manual contains information that is important to know

and understand. This information is provided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS. To help

recognize this information, observe the following symbols.

Danger indicates an imminently hazardous

situation which, if NOT avoided, WILL result

in death or serious injury.

Warning indicates a potentially hazardous

situation which, if NOT avoided, COULD

result in death or serious injury.

Caution indicates a potentially hazardous

situation which, if NOT avoided, MAY result

in minor or moderate injury.

Notice indicates important information, that if

NOT followed, MAY cause damage to equipment.

This is the safety alert symbol. It is used to alert you to

potential bodily injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

NOTE: indicates information that requires special attention.

SYSTEM SPECIFICATIONS

GENERAL SAFETY INFORMATION

CALIFORNIA PROPOSITION 65

This product or its power cord MAY contain

chemicals, including lead, known to the

State of California to cause cancer and birth defects or other

reproductive harm. Wash hands after handling.

WORK AREA

• Do NOT operate pump in explosive atmospheres, such as

in the presence of flammable liquids, gases, or dust. Pump

motors create sparks which MAY ignite the dust or fumes.

• Keep bystanders, children, and visitors away while installing

pump. Distractions CAN result in mistakes.

ELECTRICAL SAFETY

• This primary pump must be plugged into a properly

installed GFCI grounded outlet. Never remove the

grounding prong or modify the plug in any way. Do NOT use

any adapter plugs. Check with a qualified electrician if you

are NOT sure the outlet is grounded. If the pump should

electrically malfunction or break down, grounding provides a

low resistance path to carry electricity away from the user.

• Electrical wiring MUST be performed by a qualified electrician.

Improper wiring COULD result in fatal electrical shock.

• Do NOT abuse cord. NEVER use the cord to carry the

pump or pull the plug from an outlet. Keep cord away from

heat, oil, sharp edges, or moving parts. Replace damaged

cords immediately. Damaged cords increase the risk of

electrical shock.

• Do NOT expose battery to sparks or fl ames as an explosion

or fi re could result.

• Battery acid is corrosive. Avoid spilling on skin or clothing.

Eye protection must be worn when handling the battery.

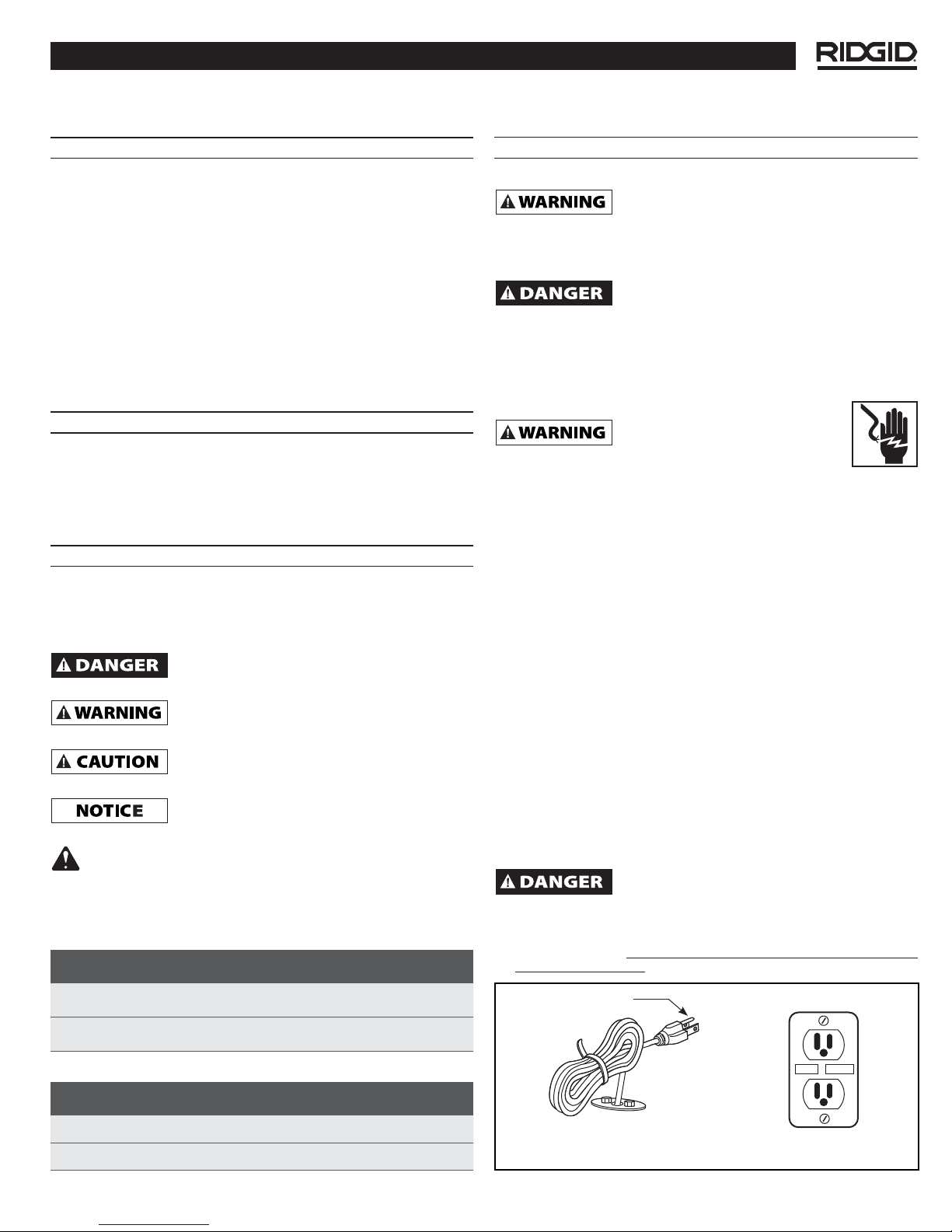

• A Ground Fault Circuit Interrupter (GFCI) is required.

• Before using, test the Ground Fault Circuit Interrupter

(GFCI) to insure it is operating correctly. A GFCI reduces

the risk of electrical shock.

• Do NOT use an extension cord. This increases the risk of

electrical shock. If necessary, install a properly grounded outlet

closer to the pump.

PERSONAL SAFETY

• If the basement has water or moisture on the fl oor, do NOT

walk on wet area until all power is turned off. If the shutoff box

is in the basement, call an electrician. Remove pump and either

repair or replace. Failure to follow this warning COULD result in

fatal electrical shock.

Power supply Requirements

Dimensions

120 V, 60 Hz, and 12 V

14-1/8 in. high x 11-1/4 in. base

SYSTEM CONSTRUCTION

Primary Pump Stainless Steel and Cast Iron

Backup Pump Thermoplastic

GROUNDING

BLADE

Figure 1

Ridge Tool Company

POWER CORD

GROUNDED OUTLET

RESET

TEST

353502-005 7/11

Model RSS-1000 – Operating Instructions and Parts Manual

GENERAL SAFETY INFORMATION (CONTINUED)

• Stay alert, watch what you are doing, and use common sense

when installing this pump. Do NOT attempt to install this

pump while tired or under the influence of drugs, alcohol or

medications. A moment of inattention MAY result in serious

personal injury.

• Dress properly. Do NOT wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry, or long hair

CAN be caught in moving parts.

• Do NOT overreach. Keep proper footing and balance at all

times. Proper footing and balance enables better control in

unexpected situations.

• Use safety equipment. Always wear eye protection. Dust

mask, non-skid safety shoes and hard hat MUST be used for

appropriate conditions.

• This pump MUST only be used to pump clear water. This pump

is NOT designed to handle effl uent, salt water, brine, laundry

discharge or any other application which MAY contain caustic

chemicals and/or foreign materials. Pump damage MAY occur

if used in these applications and WILL void warranty.

SERVICE

BACK-UP PUMP BATTERY REQUIREMENTS

1. Use only a new fully charged 12 volt deep cycle battery.

Electrolyte level must be checked and maintained in

accordance with manufacturer’s guidelines.

2. Battery sizes that will fi t into the battery box are 24C,

24VCM, 27C, 27CM and 27F.

3. Battery recharge time will be different at each installation.

Under normal conditions it will take two to four days to bring

a deep cycle battery back to full charge after it has been

discharged. If electrical power to the house is lost more than

once a week, consider keeping a spare, fully-charged battery

to replace an exhausted battery for the standby sump pump.

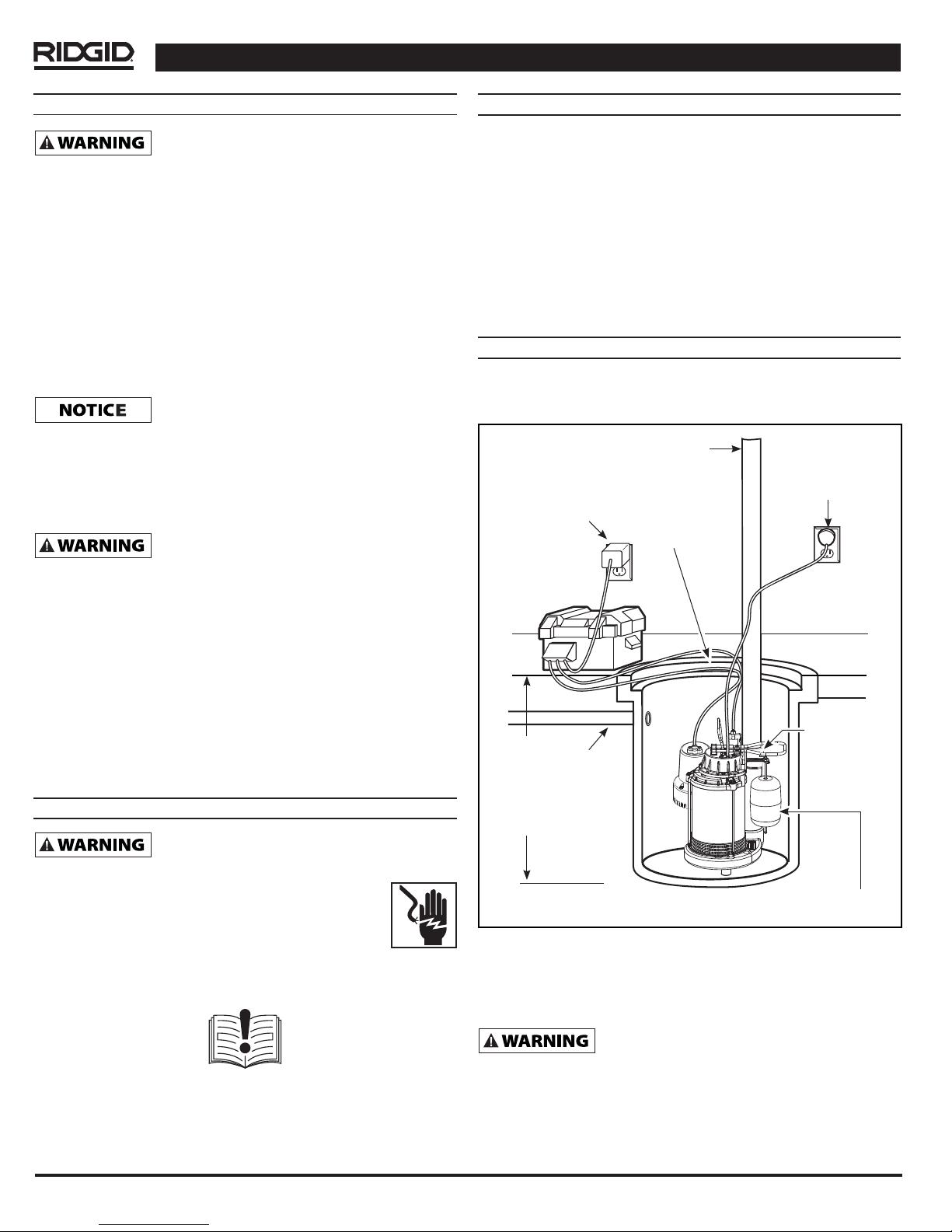

SYSTEM INSTALLATION

1. Install system in a sump pit that is 14 inches in diameter or

greater. Construct sump pit of tile, concrete, steel, or plastic.

Position primary pump switch AWAY from any inlets (Figure 2).

DISCHARGE PIPE

GROUNDED

GROUNDED

(GFCI) OUTLET

14 INCH

DIAMETER MIN.

(GFCI) OUTLET

• Disconnect power and release all pressure within the

system before servicing any component.

• Drain all liquids from system before servicing.

• Periodically inspect pump and system components,

checking for weak and/or worn hoses. Insure all

connections are secure.

• Provide a means of pressure relief in the case of an

obstructed discharge line.

• When servicing a pump, use only identical replacement

parts. Follow instructions in the Maintenance Section. Use of

unauthorized parts or failure to follow maintenance instructions

MAY create a risk of electrical shock or injury and MAY void the

warranty.

SPECIFIC SAFETY INFORMATION

• Risk of electric shock. This pump is supplied with

a grounding-type plug. To reduce risk of electric

shock be certain that it is connected only to a

properly grounded, grounding-type receptacle.

For your own safety, before assembling and

operating this unit, read this operators manual

carefully and completely. Learn the operation, application,

and potential hazards peculiar to this unit.

Call the Ridge Tool Company, Technical Service Department at

1-877-9RIDGID (1-877-974-3443) if you have any questions.

CHECK VALVE

(NOT VISIBLE)

INLET

PIPE

24 INCH MIN.

Figure 2

FLOAT SWITCH

2. The unit should be located and rest on a solid, level

foundation. Do not place pump directly on clay, earth,

gravel or sandy surface. These surfaces contain small

stones, gravel, sand, etc. that may clog or damage the

pump and cause pump failure.

Flood risk. If fl exible discharge hose is used, make

movement. Failure to secure pump could allow pump movement and

prevent pump from starting or stopping.

sure pump is secured in sump pit to prevent

3. Using PVC cement and primer, connect 1-1/4 inch or

1-1/2 inch rigid pipe to the system's discharge fi tting.

2

Ridge Tool Company

Model RSS-1000 – Operating Instructions and Parts Manual

SYSTEM INSTALLATION (CONTINUED)

Support pump and piping when assembling

and after installation. Failure to do so COULD

cause piping to break, pump to fail, etc. which COULD result in

property damage and/or personal injury.

4. Place battery in box. Attach red cable from battery box

control panel to positive battery terminal. Attach black

cable to the negative terminal. Place cover on battery box.

If cables are reversed, damage to the

control box or battery COULD result and

WILL void the warranty.

5. Place battery box within six feet of the sump and a

120 VAC separately fused outlet. The outlet must be

protected by a ground fault circuit interrupter (GFCI).

The area must also be clean, dry, and well-ventilated.

6. Plug the fl oat switch, pump, and charger into the control

box. The connections are marked on the control box.

7. Protect electrical cords from sharp objects, hot surfaces,

oil and chemicals. Avoid kinking the cord, and replace

damaged cords immediately.

8. A sump pit cover must be installed to prevent debris

from clogging or damaging the pump.

SYSTEM OPERATION

PRIMARY PUMP

For detailed operation instructions of the primary pump

for this system, please refer to the Installation manual, and

Warranty and Service parts sheet provided.

BACK-UP PUMP

Always disconnect the power source before

attempting to install, service, relocate

or maintain the pump. NEVER touch sump pump, pump

motor, water or discharge piping when pump is connected to

electrical power. NEVER handle a pump or pump motor with

wet hands or when standing on wet or damp surface or in

water. Fatal electrical shock COULD occur.

1. Test Backup Pump operation by fi lling the sump with

water while the main pump is unplugged.

2. After installation, the standby pump will start when the

water level rises above the depth that the primary pump

should start.

3. In addition, the control box has a time delay which keeps

the pump from repeated, short cycles when it shuts off.

This time delay feature will allow the pump to run 20-25

seconds after the switch reaches the off position.

4. The control box contains a multi-colored indicator light.

When AC power is present, the light will indicate the charging

state, and not refl ect actual battery voltage, particularly with

a defective battery. In order for the indicator light to provide

an accurate reading, steps “a” through “d” must be followed.

a. Unplug main AC pump and the charger-a power off

alert tone will sound for 30 seconds.

b. Lift and release the fl oat switch to activate the

standby pump.

c. When the pump stops, read the test light:

Green: Indicates battery is charged.

Yellow: Voltage is low, indicating battery is partially

charged.

Red: Battery is completely discharged or

defective.

d. Plug in charger and main AC pump.

When AC power is out, and when pump has been

running, the light will indicate battery status.

5. A chirping sound from the control box will accompany

the red light, indicating that the battery may require

attention or replacement. Voltage is only an indicator of

battery condition and may not refl ect the true condition

of the battery. See Maintenance for instruction on

assessing battery condition.

6. A single thirty-second tone will sound when power to the

system is interrupted. The unit will reset automatically

when power is restored. A three-second tone will sound

every time the pump starts.

MAINTENANCE INSTRUCTIONS

PRIMARY PUMP

For detailed maintenance instructions of the primary pump

for this system, please refer to the Installation manual, and

Warranty and Service parts sheet provided.

BACK-UP PUMP

Always disconnect the power source before

attempting to install, service, relocate or maintain

the pump. NEVER touch sump pump, pump motor, water or discharge

piping when pump is connected to electrical power. NEVER handle

a pump or pump motor with wet hands or when standing on wet or

damp surface or in water. Fatal electrical shock could occur.

1. Once a month, check battery condition.

2. Unplug the wall charger.

3. For batteries with top caps that can be removed, the

electrolyte level should be checked and fi lled to

manufacturer’s specifi cations. The charge for each cell

should be checked with a hydrometer. A specifi c gravity

of 1.265 indicates the battery is at full charge. If the

specifi c gravity of any of the cells varies more than .050,

the battery should be replaced.

NOTE: An inexpensive hydrometer can be purchased at an

automotive parts dealer.

4. Inspect the terminals and clamps for corrosion and

tightness. Clean and tighten as required.

5. Unplug the main pump and fi ll sump with water until

back up pump turns on. Repeat process two times to be

sure pump is operating normally.

6. If pump operates normally, plug charger into wall

outlet, turn on main pump. If pump fails to operate

normally, see Troubleshooting guide and correct

problem. Repeat step 5.

PART REPLACEMENT SCHEDULE

Failure to follow replacement schedule

WILL void warranty.

1. Primary Pump: Replace Float every two years. Use

RIDGID catalog #90167.

Ridge Tool Company

3

Model RSS-1000 – Operating Instructions and Parts Manual

MAINTENANCE INSTRUCTIONS (CONTINUED)

2. Back-up Pump: Replace the pump every five years. Use

RIDGID catalog #90152.

3. Back-up Pump: Replace control and charger every five

years. Use RIDGID catalog #90147 for the control and

SERVICE AND REPAIR

Service and repair work on this pump must

be performed by qualified repair personnel.

Pump should be taken to a RIDGID Independent Authorized

Service Center or returned to the factory. All repairs made

by RIDGID service facilities are warranted against defects in

material and workmanship.

90142 for the charger.

4. Back-up Pump: Replace the battery every three years.

When servicing this pump, only identical

RIDGID replacement parts should be used.

Failure to follow these steps may create a risk of flooding,

property damage, fatal electrical shock, or other serious injury.

TROUBLESHOOTING CHART – Primary Pump

For detailed troubleshooting information of the primary pump for this system, please refer to the Installation manual, and

Warranty and Service parts sheet provided.

TROUBLESHOOTING CHART – Back-up Pump

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Pump will not

run

1. Connections not secure

2. Low or defective battery

3. Float switch obstruction

4. Defective or blown fuse

1. Check all connections.

2. Check battery and replace if low or defective.

3. Make sure nothing is interfering with the operation of the

switch.

4. Check internal fuse located inside the control box. Pull the

charger from the wall outlet and remove. If the fuse is blown,

replace it with a 15 amp automotive type fuse.

Motor hums

but pump

won’t run

Pump runs

but pumps

very little or no

water

Pump cycles

too frequently

1. Defective battery

2. Obstructed impeller

1. Check valve missing or improperly

installed

2. Obstruction in discharge pipe

3. Pump not rotated 30˚

4. Pump air locked

5. Discharge pipe length and / or

height exceeds capacity of pump

6. Low or defective battery

1. Main check valve located between

the discharge of the primary pump

and the Back-up Sump Pump

tee fi tting or the Back-up Sump

Pump fl apper valve not installed or

working properly

1. Check battery and replace if low or defective.

2. Unplug pump and check to see if impeller is free to turn. If

impeller is locked, remove the 4 screws on the bottom of the

pump to release the housing around the impeller. Remove

the obstruction. Reassemble pump and reconnect.

1. Check to make sure a check valve is installed and

functioning between primary pump discharge and Standby

Sump Pump tee fi tting.

2. Check for obstruction and clear if necessary.

3. Check that pump is rotated 30˚ in tee fi tting.

4. The impeller housing has a small hole on its side. This

hole must be open for the pump to prime. With the pump

unplugged, remove the 4 screws on the bottom of the pump

to release the housing around the impeller. Clean out the

hole and replace cover.

5. If discharge is too high, a separate line may be required with

a lower discharge height.

6. Check battery and replace if low or defective.

1. Install check valve or repair as required.

4

Ridge Tool Company

Model RSS-1000 – Operating Instructions and Parts Manual

RSS-1000 — Preassembled Sump System

Serial No.

If you have any questions regarding the

service or repair of this pump, call or

write to:

RIDGID Water Systems

Attn: Customer Service Department

101 Production Drive

Harrison, Ohio 45030

csridgid@waynewatersystems.com

For name and address of your nearest

Independent Authorized Service Center,

contact the Ridge Tool Company at

http://www.RIDGID.com

For Customer Service,

call 1-877-9RIDGID.

Record Serial Number From Product Decal Below:

Reference

Number Description

1

2

3

4

5

6

7

Float Switch / Bracket Kit 31833

Tee Fitting 90132

Battery Box 90137

Charger 90142

Control Box 90147

Pump 90152

Clamp Hose 90162

RSS-1000

Cat. No.

31633

Quantity

1

1

1

1

1

1

1

1

3

2

5

7

6

Ridge Tool Company

4

5

Model RSS-1000 – Operating Instructions and Parts Manual

NOTES

6

Ridge Tool Company

Loading...

Loading...