RIDGID RP 330 User Manual

Pressing Tool

• Français – 13

• Castellano – pág. 27

WARNING!

Read this Operator’s Manual

carefully before using this

tool. Failure to understand

and follow the contents of

this manual may result in

electrical shock, fire and/or

serious personal injury.

RP 330 Manual

Ridge Tool Companyii

RP 330 Pressing Tool

Table of Contents

Recording Form for Machine Serial Number..............................................................................................................1

General Power Tool Safety Information

Work Area Safety........................................................................................................................................................2

Electrical Safety ..........................................................................................................................................................2

Personal Safety ..........................................................................................................................................................3

Power Tool Use and Care ..........................................................................................................................................3

Battery Tool Use and Care ........................................................................................................................................3

Service........................................................................................................................................................................3

Specific Safety Information

Pressing Tool Safety ..................................................................................................................................................4

Battery and Charger Safety ........................................................................................................................................4

Description and Specifications

Description..................................................................................................................................................................4

Specifications..............................................................................................................................................................5

Tool Inspection..............................................................................................................................................................5

Tool and Work Area Set-Up..........................................................................................................................................6

Operating Instructions

Preparing the Connection ..........................................................................................................................................7

Pressing A Fitting With Typical Scissor Jaw Set ........................................................................................................7

Pressing A Fitting With Typical Actuator and Press Ring Set ....................................................................................8

Inspecting The Pressed Connection ..........................................................................................................................9

Maintenance Instructions

Cleaning and Lubrication ..........................................................................................................................................10

Required Maintenance at RIDGID Authorized Service Center ................................................................................10

Accessories ................................................................................................................................................................10

Storage ........................................................................................................................................................................10

Service and Repair......................................................................................................................................................10

Troubleshooting..........................................................................................................................................................11

RP 330 Diagnostic Codes ..........................................................................................................................................12

Lifetime Warranty ........................................................................................................................................Back Cover

RP 330 Pressing Tool

Record Serial Number below and retain product serial number which is located on nameplate.

Serial

No.

Pressing Tool

RP 330

RP 330-B Battery Tool

RP 330-C Corded Tool

Ridge Tool Company2

RP 330 Pressing Tool

General Safety Rules

*

WARNING

Read all safety warnings and instructions. Failure to follow

the warnings and instructions may result in electric shock,

fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE!

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Work Area Safety

• Keep your work area clean and well lit. Cluttered or

dark areas invite accidents.

• Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

• Keep children and by-standers away while oper-

ating a power tool. Distractions can cause you to lose

control.

Electrical Safety

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce

risk of electric shock.

• Avoid body contact with earthed or grounded sur-

faces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electrical shock

if your body is earthed or grounded.

• Do not expose power tools to rain or wet condi-

tions. Water entering a power tool will increase the risk

of electrical shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric shock.

• If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of a GFCI reduces the

risk of electric shock.

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used to communicate important safety information. This section is provided to improve understanding of these signal words and symbols.

DANGER

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE indicates information that relates to the protection of property.

This symbol means read the operator’s manual carefully before using the equipment. The operator’s manual contains

important information on the safe and proper operation of the equipment.

This symbol means always wear safety glasses with side shields or goggles when handling or using this equipment.

This symbol indicates the risk of hands, fingers or other body parts being crushed

This is the electrical shock symbol.

NOTICE

* The text used in the General Safety Rule section of this manual is verbatim, as required, from the applicable UL/CSA 60745 standard. This section contains

general safety practices for many different types of power tools. Not every precaution applies to every tool, and some do not apply to this tool.

Ridge Tool Company 3

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol, or medication. A mo-

ment of inattention while operating power tools may

result in serious personal injury.

• Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

• Prevent unintentional starting. Ensure the switch

is in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energizing power tools that have the switch

on invites accidents.

• Remove any adjusting key or wrench before turn-

ing the power tool on. A wrench or a key left attached

to a rotating part of the power tool may result in personal injury.

• Do not overreach. Keep proper footing and bal-

ance at all times. This enables better control of the

power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewelry. Keep your hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry, or long

hair can be caught in moving parts.

• If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

Power Tool Use and Care

• Do not force power tool. Use the correct power tool

for your application. The correct power tool will do the

job better and safer at the rate for which it is designed.

• Do not use power tool if the switch does not turn it

ON and OFF. Any power tool that cannot be controlled with the switch is dangerous and must be

repaired.

• Disconnect the plug from the power source and/or

the battery pack from the power tool before making any adjustments, changing accessories, or

storing power tools. Such preventive safety mea-

sures reduce the risk of starting the power tool accidentally.

RP 330 Pressing Tool

• Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power tool or these instructions to operate the power

tool. Power tools are dangerous in the hands of

untrained users.

• Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

• Keep cutting tools sharp and clean. Properly main-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

• Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations dif-

ferent from those intended could result in a hazardous

situation.

Battery Tool Use and Care

• Recharge only with the charger specified by the

manufacturer. A charger that is suitable for one type

of battery pack may create a risk of fire when used with

another battery pack.

• Use power tools only with specifically designated

battery packs. Use of any other battery packs may

create a risk of injury and fire.

• When battery pack is not in use, keep it away

from other metal objects, like paper clips, coins,

keys, nails, screws or other small metal objects

that can make a connection from one terminal to

another. Shorting the battery terminals together may

cause burns or a fire.

• Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid contacts

eyes, additionally seek medical help. Liquid ejected

from the battery may cause irritation or burns.

Service

• Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool is

maintained.

result in extensive property damage, severe personal injury, or death.

• Charge batteries only in the appropriate battery

charger as specified in the charger manual. Other

types of batteries or non-rechargeable batteries may

burst resulting in personal injury and damage.

• Do not probe battery with conductive objects.

Shorting of battery terminals may cause sparks, burns

or electrical shock.

• Do not insert battery with cracked case into tool or

charger. Do not operate battery if it has been dropped or damaged in any way. Damaged battery

increases the risk of electrical shock.

• Do not burn batteries for any reason. Batteries

explode in fire.

• Charge batteries in temperatures above +41°F

(+5°C) and below +113°F (45°C). Store tool and

battery pack in locations where temperatures will

not exceed +104°F (40°C). Proper care will prevent

serious damage to batteries. Improper care of batteries

may result in battery leakage, electrical shock or burns.

• Do not allow anything to cover the charger while in

use. May result in fire.

• Unplug the charger when not in use. Reduces risk

of injury to children and untrained persons.

• Do not charge battery in damp or wet environ-

ment. Do not expose to rain or snow. Increases the

risk of electrical shock.

• Do not open the charger. Have repairs done only by

authorized experts.

Description, Specifications and

Standard Equipment

Description

The RP 330 Pressing Tool, when used with appropriate

jaw sets, is designed to mechanically press fittings onto

tubing to create a water-tight and permanent seal. When

the switch on the RP 330 is depressed, an internal electric motor powers a hydraulic pump which forces fluid

into the cylinder of the tool, forcing the ram forward and

applying thousands of pounds of pressing force onto

specially designed fittings. Attachments are also available

for other uses.

The entire cycle duration is approximately five (5) seconds.

Once the cycle begins to deform a fitting, it will automatically continue until completion, even if the trigger switch

is released. The LED displays on the back of the tool indi-

Specific Safety Information

WARNING

This section contains important safety information that is

specific to this tool.

Read these precautions carefully before using the RP 330

Pressing Tool to reduce the risk of electrical shock or serious personal injury.

SAVE THESE INSTRUCTIONS!

A compartment in the RP 330 carrying case is included to

keep this manual with the machine for use by the operator.

Contact the Ridge Tool Company, Technical Service Department at (800) 519-3456 or TechServices@ridgid.com

if you have any questions.

Pressing Tool Safety

• Use the RP 330 Pressing Tool only with RIDGID

Standard pressing attachments (jaw set, press

ring, actuator, etc.). Other uses or modifying the RP

330 Pressing Tool for other applications may damage

the pressing tool, damage the attachments and/or

cause personal injury.

• Keep your fingers and hands away from jaws dur-

ing press cycle. Your fingers or hands can be

crushed, fractured or amputated if they become caught

between the jaws or between these components and

any other object.

• Never attempt to repair a damaged jaw set, press

ring, actuator or other attachment. An attachment

that has been welded, ground, drilled or modified in

any manner can shatter during pressing resulting in

serious injury. Discard the entire damaged jaw set.

Replace with a new jaw set. Never replace individual

components except for damaged jaw return springs.

Please call Ridge Tool Company, Technical Services

for availability.

• Read and understand this operator’s manual, the

jaw set instructions, the fitting manufacturer’s

installation instructions and the instructions for

any other equipment used with this tool before

operating the RP 330. Failure to follow all instructions

may result in property damage and/or serious personal injury.

Battery and Charger Safety

(for RP 330-B only)

WARNING

Read the battery charger manual before using the

charger or batteries. Failure to read, understand and

follow the contents of the charger manual may

Ridge Tool Company4

RP 330 Pressing Tool

NOTE! RIDGID jaw sets are offered in two “series”

• Standard Series

• Compact Series

These jaw sets are not interchangeable. That is,

only standard series jaw sets will work with

standard series tools (RP 330, 320-E, CT-400).

Similarly, only compact series jaw sets will work

with the Compact 100-B Pressing Tool. Please

refer to the compact tool’s operator's manuals

for further information on these tools and jaws.

Selection of appropriate materials and joining

methods is the responsibility of the system designer

and/or installer. Before any installation is attempted, careful evaluation of the specific service environment, including chemical environment and service temperature, should

be completed. Consult Press Fitting System manufacturer for selection information.

Tool Inspection

WARNING

Daily before use, inspect your pressing tool and

correct any problems to reduce the risk of serious

injury from electric shock, crushing injures, attachment failure and other causes, and prevent tool

damage.

1. Make sure that the pressing tool is unplugged or the

battery is removed. If a corded tool, inspect the power

cord and plug for damage or modifications. If a battery

tool, inspect the battery for damage. If any damage or

modifications are found, do not use the tool until the

cord or battery has been properly repaired or replaced.

2. Clean any oil, grease or dirt from the equipment,

especially the handles and controls. This helps to

prevent the machine or controls from slipping from

your grip.

3. Inspect the pressing tool for any broken, worn, missing, mis-aligned or binding parts or any other condition

which may prevent safe and normal operation. Make

sure that the attachment mounting pin moves smoothly between the fully open and full closed position

and locks into each. Confirm that the switch moves

freely and does not bind or stick. If any problems

are found, do not use machine until problems have

been repaired.

cate problems such as improper temperature, open jaw

mounting pin or maintenance required.

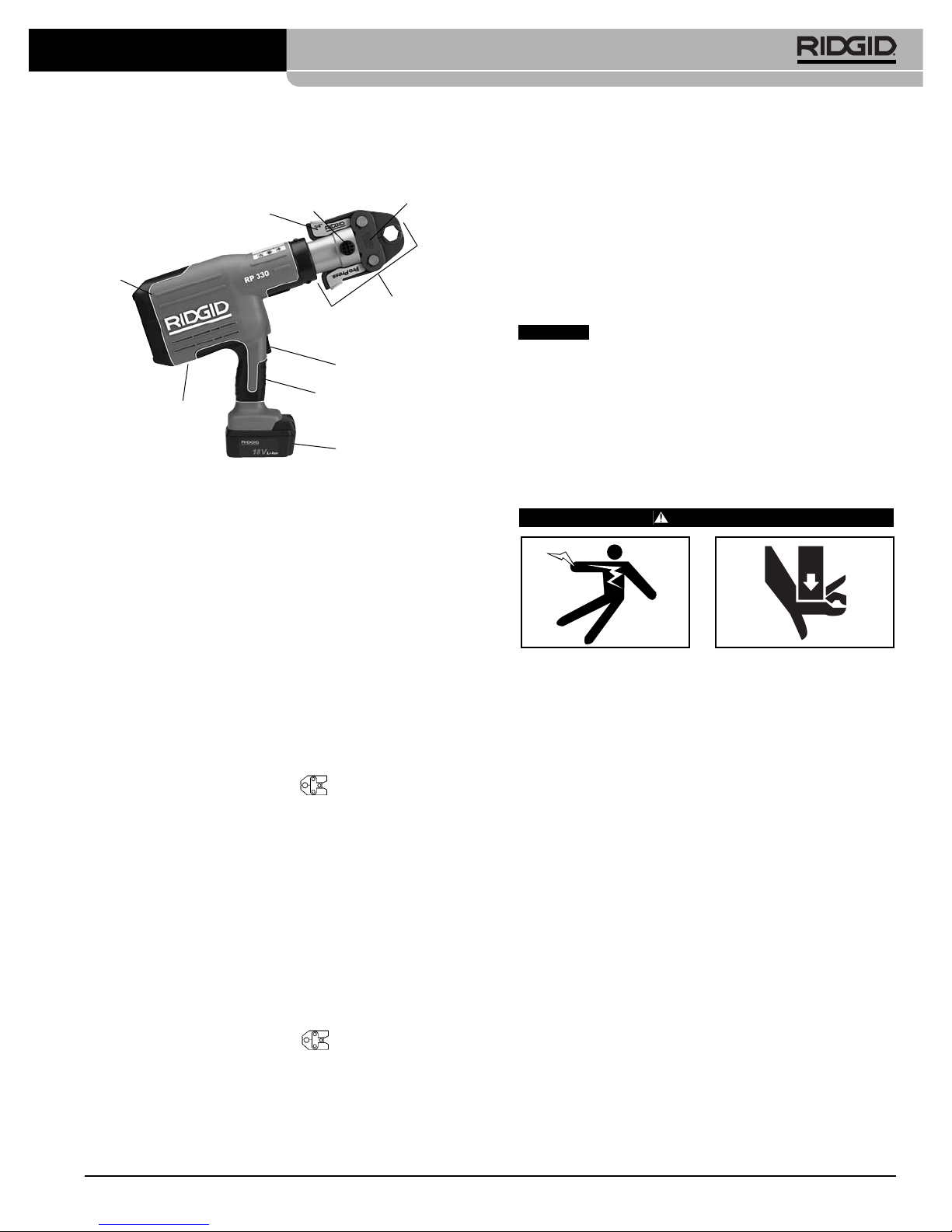

Figure 1 – RP 330 Pressing Tool and Standard Series Jaw

Set

Specifications

RP 330-C Corded Pressing Tool:

Motor

Voltage ...................120V, Single Phase AC 60 Hz

Amperage ...............5 Amp

Power .....................520 Watts

Weight........................9.00 lbs. (4.1 Kg)

Ram Force .................7,200 lbs. (32kN)

Operating Temperature

Range ...........................15° F to 122° F (-10° C to 50° C)

Duty Cycle...................1 Crimp /min.

RP 330-B Battery Pressing Tool:

Motor

Voltage ...................18V DC

Amperage ...............27.2 Amp

Power .....................490 Watts

Weight........................8.4 lbs. (3.8 Kg)

Ram Force .................7,200 lbs. (32kN)

Operating Temperature

Range ...........................15° F to 122° F (-10° C to 50° C)

Duty Cycle...................1 Crimp /min.

NOTE! The RP 330 Pressing Tool and Standard Jaw

Sets are protected under various U.S. and international patents and patent applications.

Ridge Tool Company 5

RP 330 Pressing Tool

LED Display

Panel (Rear)

Scissor Style

Jaw Set

Jaw Arm

Attachment

Mounting Pin

Battery

Tool Housing

Switch

Handle

Jaw

Sideplate

NOTICE

4. Inspect and maintain the tool attachments and battery

charger as directed in their instructions. Failure to

properly inspect and maintain attachments and chargers can result in serious injury and property damage.

5. Check that the warning label is present and firmly

attached to the tool and if required, the battery. Do not

operate the pressing tool without the warning label.

See Figure 2

for the location of the pressing tool

warning label.

Figure 3

shows the labels on the bot-

tom of the batteries.

Figure 2 – Pressing Tool Warning Label

Figure 3 – Label On Bottom Of Battery

6. With dry hands, plug the tool into a properly grounded outlet or insert a fully charged battery. Press the

ON/OFF button on the LED panel one time to turn the

press tool ON. The green, red and yellow LED on the

display panel should all blink one time on power up,

and then the green LED will remain on to indicate that

the tool is ready for use. If any other conditions exist,

use the Diagnostic Codes information on

page 12

to

determine the next step and do not use the tool until

it is working properly. With your hands and fingers

away from the tool ram, test the operation of the

switch to confirm proper operation. When used with

an attachment, once the tool sees enough load it

will lock on to insure that a complete press is made.

Once the operation has been checked, with dry

hands unplug the tool or remove the battery.

Tool and Work Area Set-Up

WARNING

Set up the pressing tool and work area according to

these procedures to reduce the risk of injury from

electric shock, fire, crushing injuries and other

causes, and prevent tool and system damage.

1. Check work area for:

• Adequate lighting.

• Flammable liquids, vapors or dust that may ignite.

If present, do not work in area until sources have

been identified and corrected. The pressing tool is

not explosion proof and can cause sparks.

• Clear, level, stable dry place for operator. Do not

use the machine while standing in water.

• Clear path to electrical outlet that does not contain

any potential sources of damage for the power

cord.

2. Inspect the work to be done and determine the correct

RIDGID tool and attachment(s) for the application.

Using an incorrect attachment for an application can

cause injury, damage the tool and make incomplete

connections. For a complete listing of RIDGID attachments available for this tool, see the Ridge Tool

Catalog on line at www.RIDGID.com or call Ridge

Tool Technical Services (800) 519-3456. Make sure

that the tool and attachment have been inspected as

directed in the instructions.

3. Evaluate the work area and determine if any barriers

are needed to keep bystanders out. Bystanders can

distract the tool operator during use.

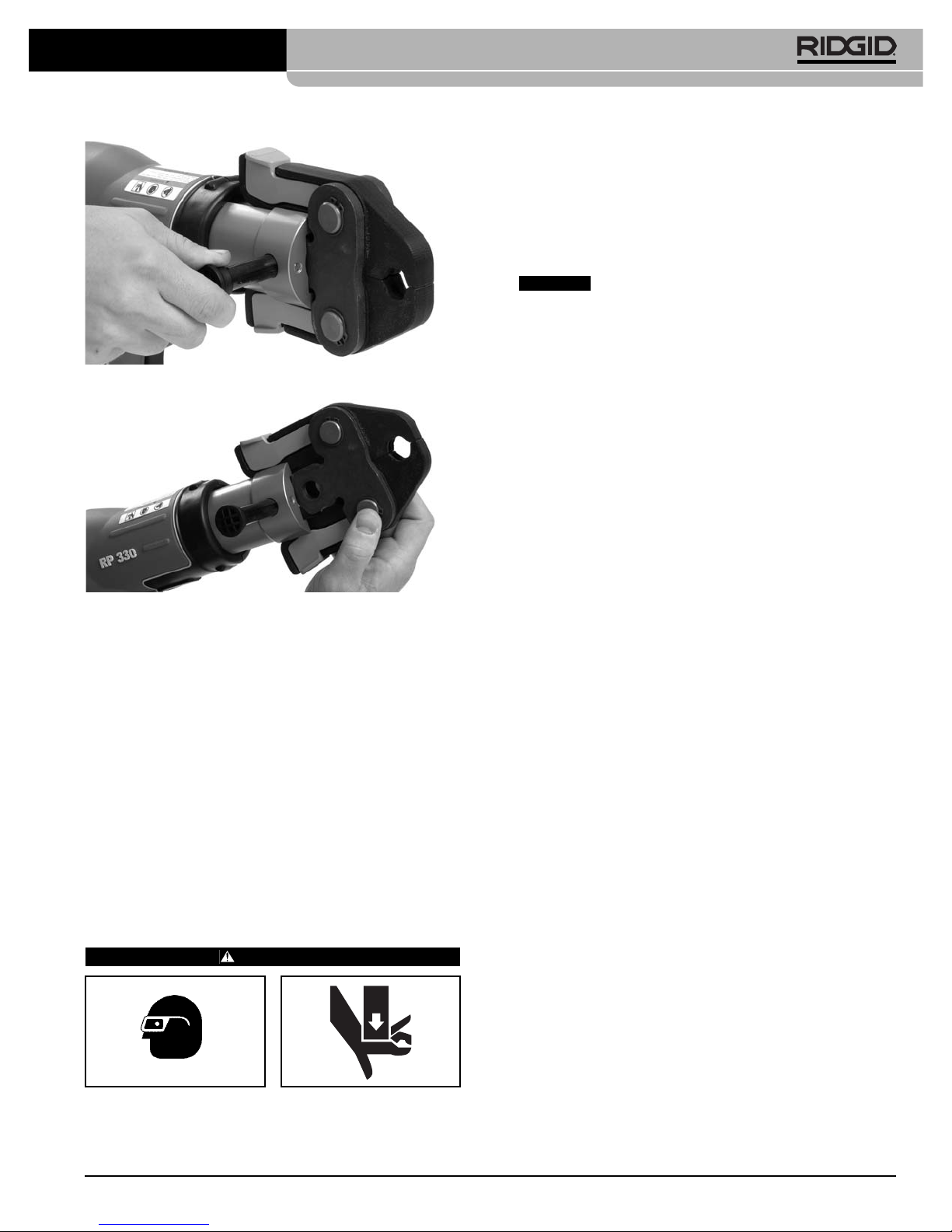

4. Confirm that the tool is unplugged or the battery is

removed and fully open the attachment mounting

pin.

See Figure 4.

If there is an attachment in the tool,

slide it out of the tool.

5. Slide the correct attachment into the pressing tool as

shown in

Figure 5

and fully close the attachment

mounting pin. The tool will not operate unless the

mounting pin is fully closed.

Ridge Tool Company6

RP 330 Pressing Tool

Ridge Tool Company 7

attachment during the press cycle. Your fingers or

hands can be crushed fractured or amputated in

the attachment or tool or between the attachment, work piece and other objects.

Follow operating instructions to reduce the risk of

injury from crushing and other causes and to prevent tool damage.

These instructions are generalized practices

for several types of press tool attachments. Always follow

the specific instructions for the pressing tool attachment

being used and the fitting manufacturers specific installation instructions. Failure to follow the specific attachment

and fitting installation instructions may result in improper

press connections that can lead to extensive property

damage.

Preparing the Connection

1. Make sure that the work area is free of bystanders

and other distractions and that the tool and work

area has been properly set up.

2. Prepare the connection according to the fitting manufacturers instructions.

Pressing A Fitting With Typical Scissor

Jaw Set

1. Make sure the RP 330 Pressing Tool has the correct

jaw set installed.

2. Connect RP 330 to proper power source. For the

RP 330-B, insert fully charged battery into the base of

the handle. For the RP 330-C plug the tool into an

appropriate outlet.

3. Depress ON/OFF button on display panel one time to

turn tool ON. All three light emitting diodes (LED’s) will

blink once. Then, the green LED should be solidly illuminated indicating the tool is ready to press.

NOTE! Tool will automatically turn off if left unused for ten

(10) minutes. To restart tool, it is necessary to

once again depress the ON/OFF button on the

top display panel.

4. Squeeze jaw arms to open the jaw set

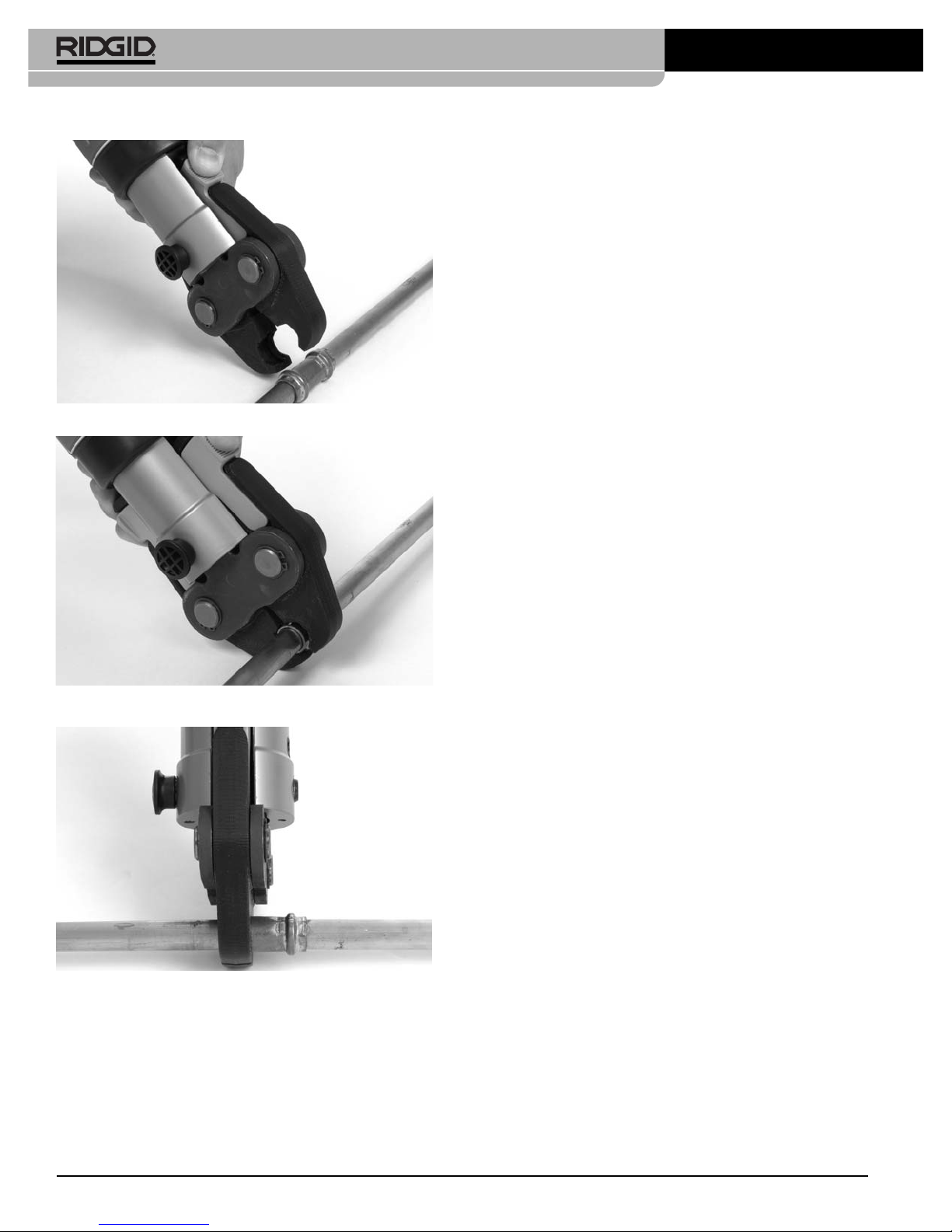

(Figure 6).

5. Place open jaws around the fitting

(Figure 7)

. Make

sure the contour of the jaw set is properly aligned with

the contour of the fitting as specified in Fitting Systems

operator's manual. Do not attempt to hang the jaw set

and tool from fitting. Tool could unexpectedly drop and

cause serious injury or death.

6. Make sure the tubing is inserted to the proper depth

in fitting, as specified in the appropriate fitting system’s

operator's manual.

Figure 4 – Fully Open Attachment Mounting Pin

Figure 5 – Slide Attachment Into Tool

6. If using a battery tool, with dry hands insert the battery

into the tool. If using a corded tool, run the cord along

the previously identified clear path, and with dry hands

plug the pressing tool in. Keep all connections dry

and off the ground. If the power cord is not long

enough, use an extension cord that:

• Is in good condition

• Is appropriately rated for the use (example – rated

for outdoor use)

• Has sufficient wire size (16 AWG for 50' or less, 14

AWG for 50' to 100'). Undersized wires can overheat, melting the insulation or causing fire or other

damage.

Operating Instructions

WARNING

Always wear eye protection to protect your eyes

against dirt and other foreign objects.

Keep your fingers and hands away from the tool

RP 330 Pressing Tool

NOTICE

Figure 6 – Opening The Scissor-Style Jaw Set

Figure 7 – Placing Scissor-Style Jaw Set Around Fitting

Figure 8 – RP 330 Tool Square To Tubing

7. Make sure the jaw set and tool are square to the tubing and depress the tool trigger switch

(Figure 8).

Keep fingers and hands away from the jaw set to

avoid crushing injuries in jaw set and between jaw set

and surrounds. The press cycle takes about five (5)

seconds. Once a press cycle begins and the rollers

contact the jaw arms, the tool will lock-on and auto-

matically complete the press cycle. Releasing the

trigger will not stop the tool once the pressing process

has begun. This assures consistent, repeatable press

joint integrity.

NOTE! If yellow LED service indicator blinks, the tool

should be sent to a RIDGID Authorized Service

Center for required maintenance. The tool will

not run if it is not maintained within 2,000 cycles

after the first blinking yellow LED.

8. Press jaw arms to open the jaw set.

9. Remove the RP 330 and jaw set from tube. Avoid

sharp edges that may have formed on the fitting

during the pressing operation.

Pressing A Fitting With Typical Actuator

And Press Ring Set

1. Make sure the RP 330 Pressing Tool has the correct

actuator installed.

2. Connect RP 330 to proper power source. For the

RP 330-B, insert fully charged battery into the base of

the handle. For the RP 330-C plug the tool into an

appropriate outlet.

3. Depress ON/OFF button on display panel one time to

turn tool ON. All three light emitting diodes (LED’s) will

blink once. Then, the green LED should be solid illuminated indicating the tool is ready to press.

NOTE! Tool will automatically turn off if left unused for

ten (10) minutes. To restart tool, it is necessary to once again depress the ON/OFF button

on the top display panel.

4. Make sure the tubing is inserted to the proper depth

in fitting, as specified in the appropriate fitting system’s

operator's manual.

5. Open the appropriate press ring and place at right

angle onto the fitting

(Figure 9).

Align ring with fitting

according to fitting system’s operator’s manual. Recheck insertion depth before completing press process.

6. Squeeze actuator arms to open the actuator assembly. Engage actuator ends into the actuator pockets in

the press ring

(Figure 10)

. Make sure actuator ends

are fully engaged in pockets. Do not attempt to hang

tool and actuator from press ring. Tool could unexpectedly drop causing serious injury or death.

7. Depress the tool trigger switch. The press cycle takes

about five (5) seconds. Once a press cycle begins and

the rollers contact the actuator arms, the tool will

lock-on and automatically complete the press cycle.

Releasing the trigger will not stop the tool once the

pressing process has begun. This assures consistent, repeatable press joint integrity. To avoid pinch

Ridge Tool Company8

RP 330 Pressing Tool

Figure 11 – Pressure Release Button

Inspecting The Pressed Connection

1. Inspect the pressed fitting. If the fitting is supplied with

a control ring and/or a control label by the fitting

manufacturer, remove it. Control rings and label are

supplied by the manufacturer to indicate that the fitting

has not yet been pressed. Removal of the control ring

and label indicates to others that the connection has

been pressed.

Look for the following:

• Excessive misalignment of the tubes. Note that a

slight amount of misalignment at the pressed connection is considered normal.

• Tubes that are not fully inserted into the fitting –

double check the insertion marks made on the

tube to see that they are still aligned with the end of

the fitting.

• Incorrect jaw or ring alignment with the fitting con-

tour, distorted or deformed fitting.

• Any other issues per the fitting manufacturer.

If any of these problems are found, then removal of

the fitting is required and a new fitting and tube will

need to be prepared and pressed in its place.

2. Test system in accordance with normal practice and

local codes.

3. See press system’s operator’s manual for specific

inspection criteria.

Maintenance Instructions

WARNING

Make sure cord is unplugged or battery is removed

from tool before performing maintenance or making

any adjustment.

point injuries, keep fingers away from actuator and

press ring during the press cycle.

Figure 9 – Installing Press Ring Onto Fitting

Figure 10 – Attaching Actuator to Press Ring

NOTE! If yellow LED service indicator blinks, the tool

should be sent to a RIDGID Authorized Service

Center for required maintenance. The tool will not

run if it is not maintained within 2,000 cycles

after the first blinking yellow LED.

8. After cycle is complete, squeeze actuator arms to

open and separate actuator from press ring. Remove

the press ring from fitting by manually grasping ring

halves and opening assembly. Avoid any sharp edges

which may have formed on fitting during pressing

operation.

The RP 330 Pressing Tool will turn off automatically if the battery is too low to successfully complete a pressed connection. This will be indicated by

blinking of the green LED. A fully charged battery should

be inserted in the tool and the pressed connection should

be repeated as indicated above. To retract the rollers

and remove the tool from the fitting if battery dies or tool

malfunctions during pressed connection, it is necessary to

press the black pressure release button on the left hand

side of the tool.

(Figure 11)

Ridge Tool Company 9

RP 330 Pressing Tool

NOTICE

Pressure Release

Button

ature within the operating range by placing it in a conditioned room for several minutes before use. This will be

indicated by a red glowing LED on the display panel.

Store the carrying case in a dry, secured,

locked area that is out of reach of children and people

unfamiliar with the RP 330 Pressing Tool. The tool is

dangerous in the hands of untrained users.

Service and Repair

WARNING

Improper service or repair can make machine

unsafe to operate.

Service and repair on this RP 330 Pressing Tool must be

performed by a RIDGID Authorized Service Center. The

tool fasteners have been marked to indicate if service has

been performed by unauthorized individuals.

For any repairs or maintenance, contact the Ridge Tool

Company, Technical Service Department at (800) 5193456 or www.RIDGID.com for nearest authorized service outlet.

If you have any questions regarding the service or repair

of this machine, call or write to:

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44035-6001

Tel: (800) 519-3456

E-mail: TechServices@ridgid.com

For name and address of your nearest Independent

Authorized Service Center, contact the Ridge Tool Company at (800) 519-3456 or http://www.RIDGID.com

Ridge Tool Company10

RP 330 Pressing Tool

RP 330 Pressing Tools

Cleaning and Lubrication

1. Daily wipe the tool clean with a clean dry cloth.

2. Inspect the attachment mounting pin and lubricate the

pin with silicone lubricant as needed.

3. Check return springs in attachments with each use.

Attachments should open and close freely with only

moderate finger effort required.

Required Maintenance at RIDGID

Authorized Service Center

After 30,000 cycles, the tool will show a blinking yellow

LED on the display panel as long as the tool is turned on

to indicate that it is time for maintenance and recalibration.

The tool will not run if it is not maintained within 2,000

more cycles after the yellow blinking LED begins.

Accessories

WARNING

Only the following tool accessories have been designed to function with the RP 330 Pressing Tools.

Other accessories suitable for use with other tools

may become hazardous when used on the RP 330.

To prevent serious injury, use only the accessories

specifically designed and recommended for use

with the RP 330, such as those listed below.

Ridge Tool Company provides Standard Pressing

attachments designed specifically for use with

RIDGID Standard Pressing tools. Only use attachments that are specifically designed to press the fitting system you are installing. For a complete listing

of RIDGID attachments available for this tool, see

the Ridge Tool Catalog on line at www.RIDGID.com

or call Ridge Tool Technical Services (800) 519-

3456.

Storage

Place the tool and jaws in its carrying case. Avoid storing

the tool, batteries or charger in extreme heat or cold.

The tool temperature sensor will not allow the tool to

turn on if oil temperature is not within the temperature

range of 15°F (-10°C) to 122°F (50°C). So it may be

necessary to allow the tool to warm or cool to a temper-

WARNING

Catalog

No. Description

27968 18V Lithium-Ion Battery Pack 2.2Ah

27958 115V Charger

27933 Carrying Case (Plastic)

RP 330 Press Tool Accessories

Ridge Tool Company 11

RP 330 Pressing Tool

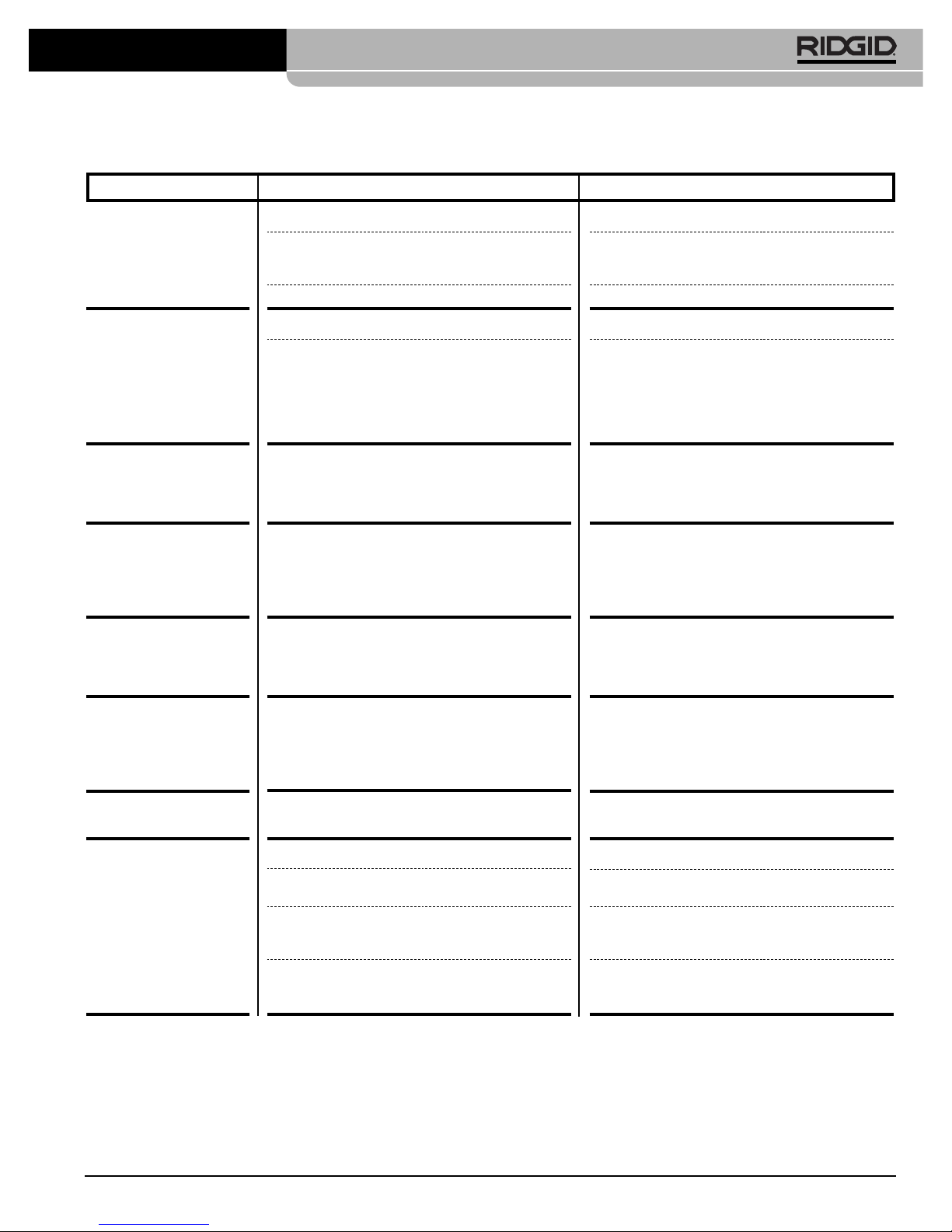

SYMPTOM POSSIBLE REASONS SOLUTION

Tool will not turn ON

when ON/OFF button on

display panel is pressed.

Tool turns OFF either

when trigger is depressed or in the middle

of a press cycle. Red

LED glows.

Yellow LED blinks

repeatedly as long as

tool is turned ON and

tool functions properly.

Yellow LED glows continuously and tool will

not begin press cycle

when trigger switch is

depressed.

Red LED blinks repeatedly and tool will not begin

press cycle when trigger

switch is depressed.

Yellow LED glows when

tool is turned ON.

Jaws are locked onto

fitting.

The pressed connections

produced are not complete.

Troubleshooting

Electric cord damaged.

Battery is completely discharged or battery has

failed or power cord not properly inserted into

outlet.

Battery not properly inserted into handle of tool.

Battery is too low.

Tool or battery is too cold or too hot.

Scheduled maintenance/recalibration is required

after 30,000 presses.

Scheduled maintenance/recalibration is mandatory after 32,000 presses. Tool is “locked” and

will not function until tool is serviced.

Accessory mounting pin not fully closed.

Tool malfunction detected.

Press was not successfully completed.

Used wrong jaw set for the tube size or material.

The tool was not square to the tube.

Jaw contour was not aligned with the fitting contour.

Tool is in need of repair.

Inspect the cord and replace if necessary.

Insert fully charged battery/recharge dead battery

or unplug and replug power cord.

Check to assure battery is fully inserted.

Insert fully charged battery/recharge dead battery.

Bring tool and battery to correct operating range

between 15°F (-10°C) to 122°F (50°C) by allowing the tool to sit in a conditioned room.

NOTE! Fitting must be repressed if tool stops

in the middle of a press cycle. Failure

to do so may result in a leaking fitting.

Contact Ridge Tool Company, Technical Service

Department at (800) 519-3456 for nearest

Authorized Service outlet.

Contact Ridge Tool Company, Technical Service

Department at (800) 519-3456 for nearest

Authorized Service outlet.

Insert accessory mounting pin to the fully closed

position.

Unplug and replug power cord or remove and reinsert fully charged battery. Be sure to repress fitting.

If LED’s continue to glow, contact Ridge Tool

Company, Technical Service Department at (800)

519-3456 for nearest Authorized Service outlet.

Push pressure release valve to remove jaws from fitting. Inspect and repress fitting.

Install the correct jaw set.

Redo the joint with new fitting and new tube.

Make sure that the tool is square to the tube.

Redo the joint with new tube and new fitting.

Make sure the jaw contour is aligned with the

fitting contour.

Contact Ridge Tool Company, Technical Service

Department at (800) 519-3456 for nearest Authorized Service outlet.

Loading...

Loading...